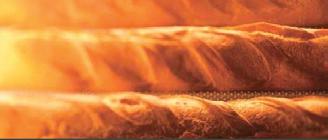

It’s the perfect mix of protein and pride. Ask your supplier for flour made from 100-per-cent western Canadian wheat.

It’s the perfect mix of protein and pride. Ask your supplier for flour made from 100-per-cent western Canadian wheat.

Iwill tell you a few secrets about your new editor. I have been lured from my office in the middle of the day by the mere promise of a cupcake. I have baked a batch of peanut butter cookies only to eat the entire lot in a day. Beyond a sweet tooth, I have a hobbyist’s fascination with dough, the mysteriously rising foundation of the freshly baked bread smell I like to keep around on cold winter days. Needless to say, my palate is rather pleased with my new role as editor of Bakers Journal. Generally, I love to be in the kitchen and in earlier years earned my keep in restaurants, at the front and back of the house.

As the editor of .Bakers I am hoping to build on my experience in the foodservice industry at the helm of Canadian Pizza magazine since 2008, with the goal of better serving both readerships. This publication celebrated its 70th birthday in 2010, no small accomplishment in the dog-eat-dog world of magazines. It is through continual innovation and dedication to truly serving the needs of the readership that a magazine earns such longevity. As I step into Brian Hartz’s shoes (no small feat), I hope to carry on his fantastic work, exemplified by the Canadian Business Press silver award Bakers won last year for best issue. There is a great fit between Canadian Pizza and Bakers Journal, where my learning more about one industry will do well to serve the other.

}This publication celebrated its 70th birthday in 2010 … It is through continual innovation and dedication to truly serving the needs of the readership that a magazine earns such longevity.

The baking industry is worth $3.2 billion in Canada, notes the Baking Association of Canada (BAC) website. It is amazing how unique the products made under this multibilliondollar umbrella are. This edition features bakeries from across Canada, reminding of us of the diversity and success that is experienced nationwide. Our industry is made up of about 2,300 businesses ranging from independent shops to in-store grocery bakeries and regional and national wholesalers. Of these, 41 per cent are in Ontario; 26 per cent are located in Quebec; 14 per cent are found in British Columbia; six per cent in Alberta; three per cent in Manitoba; two per cent in Saskatchewan; two per cent in Nova Scotia; two per cent in New Brunswick; 0.9 per cent in Newfoundland and Labrador; 0.5 per cent in Prince Edward Island; 0.1 per cent in Yukon Territory; one bakery was located in Nunavut; and zero were found in the Northwest Territories.

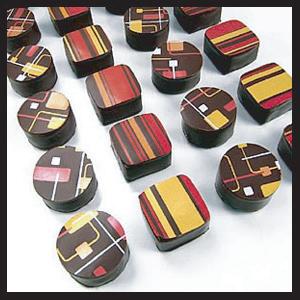

No matter which end of the compass a baker finds himself or herself on, certain trends bind the industry coast to coast. Sodium reduction, trans fats and healthier products in general will continue to dominate headlines. Consumers will carry on searching for natural ingredients and simplicity in their food choices. However, I bet they will also continue to be delighted with artistry and dessert will still be a dish meant to thrill. For this sweet tooth, it is still a dish that nearly always follows up dinner, and the more elaborate, the better.

Now that I have told you a little about myself, there is something I would like you to share with me. If you could solve just one problem in your business, what would it be? What solution do you want to find in Bakers Journal when you flip open the next edition? What would you like to see more or less of? E-mail me at laiken@annexweb.com or call me at 416-522-1595 to share your thoughts. I look forward to getting to know you. / BJ

JUly 2010 | Vol. 70, no. 7

Editor | laura Aiken editor@bakersjournal.com 416-522-1595 1-888-599-2228 ext. 250

tEchnical

Editor | John mcColl, puratos Canada jmccoll@puratos.com

national advErtising ManagEr | Stephanie Jewell sjewell@annexweb.com 705-826-2254 1-888-599-2228 ext. 268

salEs assistant | barb Comer bcomer@annexweb.com 519-429-5176 1-888-599-2228 ext. 235

Production artist | brooke Shaw grouP PublishEr | martin mcAnulty mmcanulty@annexweb.com

PrEsidEnt | mike Fredericks mfredericks@annexweb.com

Mailing address P.o box 530, 105 donly dr. s., simcoe, on n3Y 4n5

Publication Mail agrEEMEnt no. 40065710. rEturn undElivErablE canadian addrEssEs to: circulation dEPartMEnt, P.o box 530, siMcoE, on n3Y 4n5 e-mail: lmorrison@annexweb.com

ISSn 0005-4097

Published ten times per year (Jan/Feb, Mar, apr, May, Jun, Jul, aug/sept, oct, nov, dec) by annex Publishing & Printing inc.

SUbSCrIpTIon rATeS canada — 1 Year $ 30.00 (with gst $31.50 #867172652rt0001, with hst/ Qst $33.90) usa — 1 Year $ 45.00 usd best pricing is available online at www. bakersjournal.com

Send your subscription request to: bakers Journal P.o box 530, simcoe, on n3Y 4n5 tel: 1-866-790-6070 ext. 206 Fax: 1-877-624-1940

E-mail: lmorrison@annexweb.com

occasionally, bakers Journal will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. if you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. opinions expressed in this magazine are not necessarily those of the editor or the publisher. no liability is assumed for errors or omissions. all advertising is subject to the publisher’s approval. such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

no part of the editorial content of this publication may be reprinted without the publisher’s written permission.

© 2010 annex Publishing & Printing inc. all rights reserved. Printed in canada.

And family, friends and celebration-friendly

At Redpath Sugar, we craft sugar for all Canadians. That’s why our sugar is suitable for vegans.

Because the things that bring us together are the most important things of all.

briefly | Spiroflow buys rival Dynamet | L.V. Lomas completes HACCP certification | Fortin named to Lallemand sales role | FOR MORE news in the baking world, check out our website, www.bakersjournal.com

TORONTO – Peter Jacobs, Lesaffre and Red Star Yeast Corp.’s regional sales manager for Eastern Canada, has obtained Certified Master Baker (CMB) status from the Retail Bakers of America (RBA), becoming only the fifth Canadian to achieve this level of accreditation from the RBA.

To qualify for CMB status, a baker must pass a written test and a practical test; possess Certified Baker (CB) designation plus at least four additional years of full-time retail/commercial baking experience; obtain Serv-Safe or equivalent food safety certification; and demonstrate that he or she has spent 30 or more hours in

professional development courses, seminars or workshops focusing on bakery management and production.

“Your accomplishment is significant,” RBA education programs manager Howard Cook wrote in a letter to Jacobs. “The CMB is a symbol of your love of baking and dedication to high professional standards.”

Prior to joining Lesaffre in 2007, Jacobs spent five years with BakeMark Canada as national director of technical sales and training. He has been a fixture in Canada’s baking industry since immigrating to Canada from Germany in 1990, serving as

MONTREAL – Lallemand has named Caroline Fortin sales manager for the Quebec and Atlantic region of the company’s North American baking division.

Fortin is based in Montreal, providing market sales representation to one of the organization’s top Canadian markets. With an outstanding track record of success in the baking industry, she also competed in an international baking competition as part of Team Canada in 2004.

With in-depth industry knowledge, baking experience and key customer contacts, Fortin will be responsible for the development and execution of the company’s strategic baking sales efforts across all channels in Quebec and the Atlantic provinces.

Fortin holds a baking degree from the Institut de tourisme et d’Hotelerie du Quebec and she is a third-generation baker. She has worked in the baking industry since 1996. Since coming to Lallemand in 2005, she has been a test baker and a technical sales representative for the Quebec region.

OTTAWA – Health Canada has issued a ruling that will allow plant sterols to be added to foods.

Health Canada’s confirmation will clear the way for manufacturers in Canada to add plant sterols to a variety of foods and beverages up to approved levels.

Plant sterols, also known as phytosterols, occur naturally in plants and have been shown to be effective in blocking cholesterol absorption in the body, which may help lower cholesterol. Today, nearly 40 per cent of Canadian adults have high blood cholesterol levels, according to the Heart and Stroke Foundation.

Archer Daniels Midland Co. (ADM) introduced CardioAid plant sterols in the 1990s, and today offers the commercial product line globally in powder and water-dispersible forms.

Health Canada has confirmed that plant sterols may be added to the following foods: mayonnaise, margarine, calorie-reduced margarine, yogurt and yogurt drinks, vegetable and fruit juices, salad dressing and unstandardized salad dressings and spreads. ADM is available to assist customers seeking to expand the use of CardioAid plant sterols to additional categories.

an instructor at George Brown College in 2000-01; owning his own bakery, Heavenly Sweets, in Newmarket, Ont., from 1992 to 1995; and also working for the likes of Puratos and Fiera Foods.

“I am proud and happy to call the baking industry my industry of choice for 34 years now,” Jacobs told bakers Journal.

“I call Toronto my home, love Canada as a country and I am a proud to say I am Canadian – well, with a German twist and a funny accent when I speak French.”

Jacobs added that Lesaffre and Red Star Yeast supported him “100 per cent in acquiring this honourable certification.”

Jacobs can be reached at peter.jacobs@ lsaf.com or 1-416-315-9587.

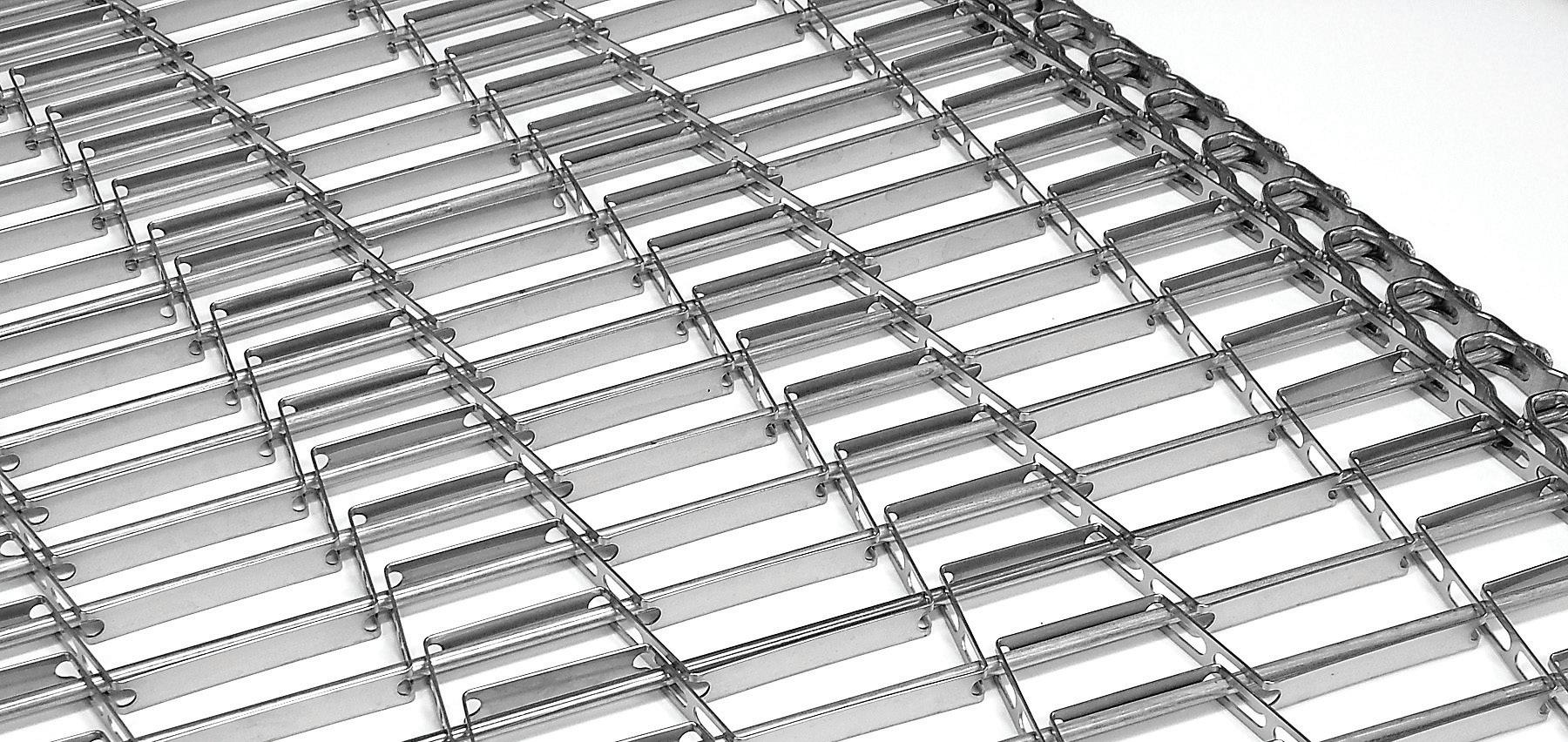

Dynamet’s chain drag conveyor.

CHARLOTTE, N.C.

– Spiroflow Systems, a maker of bulk materials handling equipment, has acquired Dynamet, a Michigan-based manufacturer of bulk materials handling equipment with more than three decades of experience in the industry.

Dynamet designs and manufactures a full range of powder-handling equipment, including tubular drag chain conveyors, flexible screw conveyors, bulk bag unloaders, manual dump bag stations and pneumatic tilt tables for a variety of industries including food, chemical, pharmaceutical, packaging and plastics.

With its acquisition of Dynamet, Spiroflow Systems expands its equipment and experience scope and now offers one of the largest selections of powder-handling equipment in the industry.

By J EFF M OWATT

From conversation pieces to name recognition, here are five greetings that can help you boost sales to walk-in customers

Quick, what’s the typical greeting used most often by 60 per cent of retail stores? You’re right if you guessed, “Can I help you?” The visitor’s usual response, “No thanks, just looking.” The problem is the walk-in customer is never “just looking.” They came into the premises because at some level they perceived a need. This greeting only reminds visitors that they’re not here to buy. Lousy selling strategy.

The way you and your front line employees greet walk-in customers has a huge effect on your bottom line. Here are some tips to ensure that you and your employees greet customers in a way that makes them want to buy and keep coming back.

1. Show that you recognize them.

}greeting have seen sales increase by 16 per cent. While Gerber claims to have no idea why this works so well, I think it’s because this greeting reminds the customer that they’ve been at your business before, so it’s a familiar place. Familiar means safe. Safe means trust. And trust means buy.

“If saying, ‘Hi, have you been here before?’ can increase sales by 16 per cent, then it’s certainly worth a test.”

With this greeting the employee can also add, “Welcome back; we appreciate your coming to see us again.” That provides that all-important recognition. They can ask the customer about what they bought on their last visit and how they like it. That provides the opportunity to provide positive reinforcement and/or clear up any concerns.

If this is the visitor’s first visit, then the employee has a great excuse to show them around, identify needs and point out specials. At any rate, if saying, “Hi, have

Customers return to secure, friendly environments. Show that you recognize them, and they’ll want to come back.

If you deal with customers, the two most important words are not, please or thank you, but are your customers’ first and last names. Take the restaurant I patronized in Greece, for example. As I walk in with my friends, he shouts, “Jeff, you’re back! Welcome!” He smiles at the rest of my party and says, “I see you’ve brought your friends, excellent! We’ll clear one of our best tables for you!” At this point I don’t care what the food tastes like – this guy gets my business.

If you don’t remember the customer’s name, you need to at least let them know that you recognize them and are happy to see them. So an effective greeting would be, “Well, Hello! It’s nice to see you again.”

Customers return to secure, friendly environments. Show that you recognize them, and they’ll want to come back.

2. Ask if they’ve been in before.

One of the best money making greetings is, “Hi, have you been here before?”

Michael Gerber, author of the best seller, The E-myth, says that his clients who have switch from, “Can I help you?” to this

you been here before?” can increase sales by 16 per cent, then it’s certainly worth a test.

3. Ask about the weather

I realize the weather is an often-used topic, but it’s disarming, and gets the customer talking about something where they can be the expert. The critical step that’s often missed is you need to respond to the customer’s comments. That shows that you’re listening – not just techniquing them. Once you’ve addressed their comments, you can then transition from the weather to identifying their needs. Example: “Well, at least you’re in from out of the wind now. What brings you in aside from the cold weather?”

4. Compliment appropriately. Be careful with this one. If you do it wrong, you be construed as being a phony and will lose the most important thing you need to sell – trust. So don’t offer a general compliment such as, “Don’t you look good today.” Instead make sure your compliment is relevant and specific. If you work in a clothing store you might say, “That scarf is terrific; its autumn colours are

perfect with your colouring.”

5. Use a conversation piece.

Interesting artwork, a talking parrot, or anything you place near your entrance that draws comment is great. It gets the customer talking, questioning and interested.

Timing is everything.

More important than what you say, is the fact that the visitor is acknowledged –not necessarily served – the moment they enter. One study revealed that 68 per cent of customers who leave do so because they feel like no one cares that they’re there. Picture entering an establishment waiting to be served. Then use your watch to count off 30 seconds. You realize that even half a minute is too long to wait.

One of my seminar participants, a bakery owner, ensured a fast greeting if the employees were working in the back room by installing a doorbell that rings as the visitor enters. They call out, “Hi there, I’ll be right out!” and they keep the business. Simple and smart.

1. A stare – like employees are watching to see if you’re going to steal something.

2. The daze – they pretend they’re so busy they can’t see you.

3. (As you enter a restaurant) “Just one?”

4. “Can I help you?”

5. “Next!”

6. A canned phony sounding speech. / BJ

This article is based on the critically acclaimed book Becoming a Service Icon in 90 Minutes a Month, by customer service strategist and professional speaker Jeff Mowatt. To obtain your own copy of his book or to inquire about engaging Jeff for your team, visit www. jeffmowatt.com or call 1-800-566-9288).

Whatever your formulation needs, choose from the AB Mauri Fleischmann’s family of yeast and bakery ingredients—and tap into the industry experience and proven critical thinking of our talented team.

W e’re committed to a relationship-oriented partnership—serving as your total resource for process optimization and custom formula solutions.

By M ICHELLE B RISEBOIS

Freshness, support for area producers and environmental effects are key messages in promoting your products to ‘locavores’

In 2007, the Oxford English Dictionary dubbed “locavore” its word of the year. This term describes a style of food consumption centred on products hailing from a local source.

That same year, two journalists living in Vancouver – Alisa Smith and J. B. MacKinnon published a book about their efforts to eat only foods grown within a 100-mile radius of their home for an entire year. The 100-Mile Diet: A Year of Local Eating chronicled their trials and tribulations as they navigated their menu planning. One of the first surprises they encountered was the realization that pastas and breads were mainly made from wheat grown in parts of Western Canada, far outside their 100-mile radius.

}As Smith and MacKinnon point out on their website, “It took us seven months to find a rogue local farmer who actually grows wheat.”

sale at a supermarket chain. Foods grown and made “close to home” can be bred to focus on taste rather than withstanding the abuse of shipping or industrial harvesting.

So shine the light on other ingredients besides wheat flour. Your pies can feature fruit picked fresh off of the vine. According to the Ontario Fruit and Vegetable Association, the average distance food travels from farm to plate is 1,500 miles. During this delay between harvest and consumption, sugars turn to starches, plant cells shrink and produce loses its vitality. You likely know all of this as a baker, but it’s important that you let your customers know not only when a product came out of your oven but also how fresh the ingredients are. Look for provincially focused organizations that have wellestablished brands you can tap into. “Saskatchewan Made” and “A Taste of Nova Scotia” are two such examples.

Make sure you talk up the sense of place on your shelf signage, packaging and other communications efforts. If you can name the farmers who grow or produce your ingredients, that’s even better.

Farmers’ markets have been catering to the locavore movement for years. Now it’s time for your bakery to capture those customers.

and it can have significant ramifications.

This raises an interesting dilemma for the baking industry. If flour, the cornerstone of most baked goods, must travel great distances to get to bakeries for processing, is capitalizing on the “eat local” movement even possible for our industry?

The answer is “yes” because it’s not only about the food miles attached to an item. It seems that how one defines “local” is a very subjective and personal decision, and thus food makers can take many angles to target this trend. A Foodland Ontario study in 2009 revealed that freshness of food is the primary driver for consumers when choosing a locally produced option. Support for local producers comes in second with positive environmental effects coming in third.

The bakery industry is naturally linked to the notion that baked goods made onsite and served that day are fresher than those processed en masse and frozen for eventual

It’s comforting to be able to see who’s producing your food. Consumers like that link to the local producers – it gives them an emotional connection to their plates.

Terroir is a wine term that means the taste of the grapes gives one a “sense of place” – a sense of the soil, the wind, rain and sun. Some people believe that consuming locally grown foods that have been exposed to the elements and pollens of your area may actually have some kind of inoculating effect against allergies. Make sure you talk up the sense of place on your shelf signage, packaging and other communications efforts. If you can name the farmers who grow or produce your ingredients, that’s even better.

Many consumers see buying locally as a way of reducing their carbon footprint. Food miles are a measure of the distance travelled from farm to fork. This is one measure of the environmental effects of one’s meal choices

A 2007 article published in the Clearwater Times in British Columbia and the Peterborough Examiner in Ontario claims the average number of food miles for one kilogram of chocolate is 8,598 kilometres or 1.3 kilograms of greenhouse gas emissions. The 100-Mile Diet cites an example in which local salmon are sent far away to be deboned and then returned to the source for packaging and sale. The authors refer to this as “swimming upstream” to look beyond the surface in terms of defining what’s local. They ask whether the fresh eggs they get from a chicken are negatively affected by the great distance between the grain and the chicken that ate it.

If your baked goods are made on premises, you’ve already eliminated many food miles compared to a similar chain store product that has required more energy to package, freeze and transport. Why not take a stab at calculating the food miles of your bakery products? The website www.fallsbrookcentre.ca has a great calculator that allows you to easily estimate a product’s food miles.

Setting a standard by which to categorize foods that are “local” is too difficult because there are too many ways to define it. On the upside, this gives us flexibility to tell our product stories in ways that truly address those issues that are important to our customers. It’s fresh, it’s good stewardship and, ultimately, it allows us to craft a message that truly “hits home.” / BJ

Michelle Brisebois is a marketing professional with experience in the food, pharmaceutical and financial services industries. She specializes in helping companies grow their brands and can be reached at briseboismichelle@sympatico.ca.

On a quiet Tuesday afternoon in May, Puratos Canada hosted a 1st of a kind event; the Toronto International Bakery Symposium at the famed Old Mill Inn in Toronto. The historic inn wPas host to bakers, Ppatissiers and chocolatiers from PCanada for a half dPay event followed bPy a unique bread and wine tasting and a scrumptious dinner.

The event consistedP of public speakersP from Belgium, theP US and Canada who Pshared their views Pon a host of ideas to boost sales in the bakery industry. The topics and speakers were as follows –

Frederik Lievens, wPho is a food enginPeer and Director oPf the business uniPt Bread Improvers aPt the Puratos Group (Belgium), bPelieved that over tPhe last 150 years tPraditional baking hPas been lost in thPe industrialized world. He gave a very interesting presentation on the ‘Revival of Bread’.

Diane Chiasson, PrePsident of Chiasson PConsultants Inc., isP a certified merchaPndising expert whoP talked about measurPes that could be tPaken to be successfPul in the ever chanPging retail merchaPndising environment.

Dr. Phillip Lee Wing, who is a Food Scientist and President of the Food Development Group, discussed Health and Wellness trends in the food industry.

As the sessions concluded, guests were led to the Guildhall for a very interesting one of a kind concept –bread and wine pairing. This session was conducted by Peter Blakeman, Professor of Culinary Arts from Niagara CollegPe, as well as DavidP Deblauwe, from PurPatos US. The pairinPg consisted of tasPting sourdough breads fProm around the worPld that were pairePd with different wPines. Who would’ve tPhought one could pair brePad and wine?

When asked what wasP the impetus for cPonducting such an Pevent, Benoit KeppePnne, General ManagPer for the Canadian opPeration, had this Pto say – “We realized that it has been a challenging few years for the baking industry and Puratos, as a major player, thought of ways to assist the industry by providing a meeting ground for professiwonals to conduct mewaningful exchanges win a forum where rewtail merchandisingw, health and wellness trendsw, the revival of bwread and bread andw wine tasting sessiwons were exchanged”w.

Overall, it was a very exciting event for us all and we look forward to the 2011 TIBS.

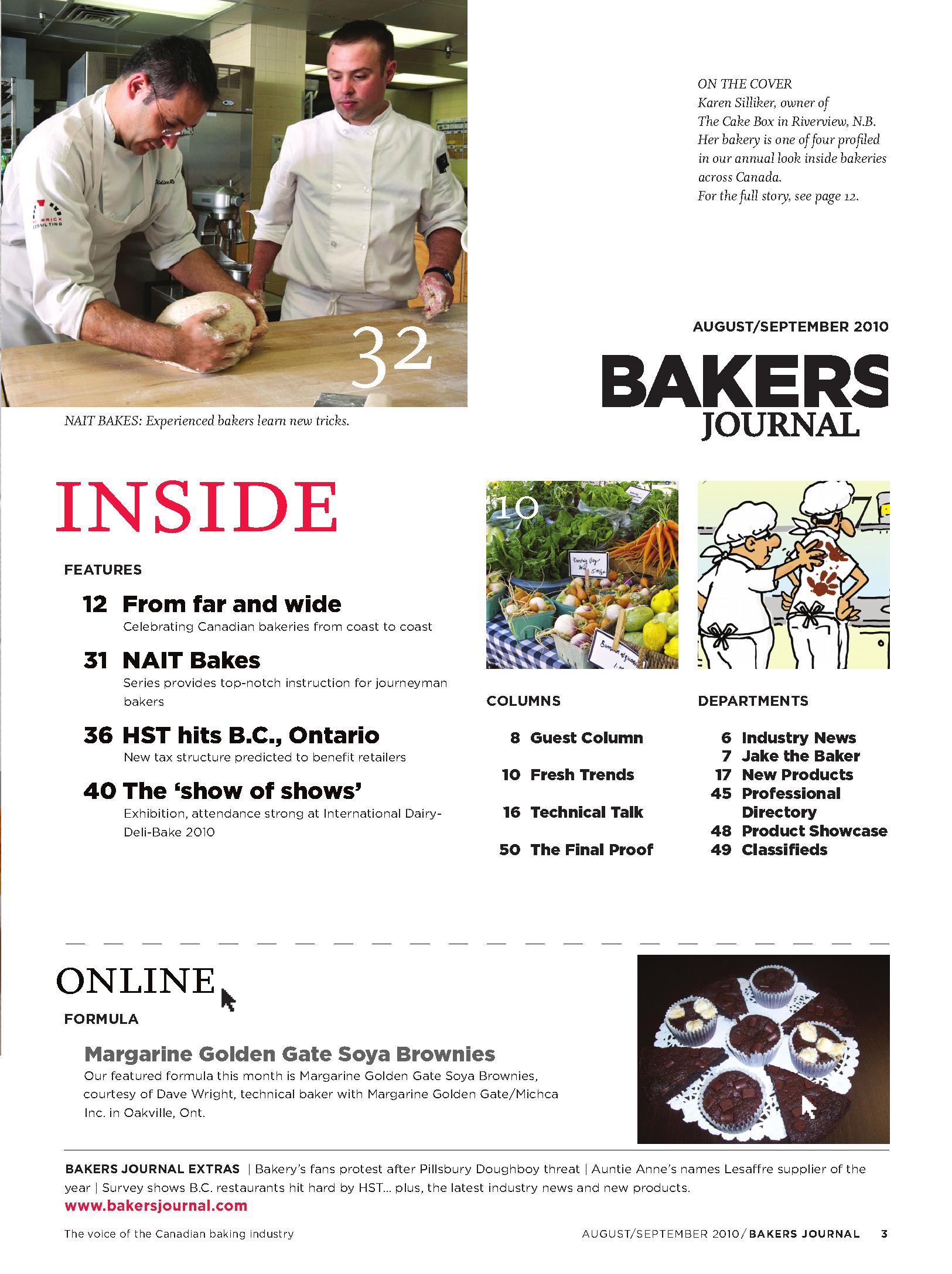

Bakers Journal presents our annual look inside Canadian bakeries from coast to coast

By WENDy HELFENBAuM

J

acques Landry is an accidental pastry chef, thanks to a sprinkling of serendipity.

During the late 1970s, Landry’s father found out through his accountant that Montreal’s famed Pâtisserie Duc de Lorraine was for sale.

“He thought it would be a great business for my two brothers and me, so we decided to give it a go,” recalls Landry, who studied at the Quebec Tourism and Hotel Institute and at the Lenôtre Culinary and Pastry School near Paris.

Founded in 1952 by renowned French pastry chef Jean Adam, the award-winning bakeshop, located near Mount Royal, was named for the owner’s birthplace near the Lorraine region of France.

When Landry and his brothers Sylvain and Alain took over the business, they worked from Adam’s original recipes. “For 58 years, almost everything has been made the same way, with real butter,” notes Landry. “We use real liqueurs in our pastries, and everything is sold the day it’s made.”

}A quarter of the bakeshop’s 28 employees have been there for three decades. Landry’s brother Sylvain handles chocolatier duties, and makes ice creams and sorbets. Alain left the business 15 years ago.

The industry is evolving; you have to keep traditions while adapting and being innovative at the same time. Our customers want lighter, healthier versions of our pastries.

pies, specialty cheeses and fresh breads.

With more than 200 different cakes, pies and pastries, and 25 kinds of Christmas logs, Landry has more than one favourite.

“Our Patate Grand-Marnier is very special: it’s an almond-flavoured mini-cake soaked in Grand-Marnier, rolled in almond paste and cocoa. Our Côte-desNeiges is a light-tasting cheese mousse topped with fresh raspberries.”

The bakeshop also offers gourmet gift baskets, ready-made platters and boxed lunches for hospitals and universities, adds Landry, as well as foie gras, caviar, meat

But Duc de Lorraine’s croissants, consistently named “Best in Montreal” year after year, remain the star item. “Our Viennoiseries sell as much as all our pastries and cakes combined,” Landry says.

Landry takes pride in maintaining the original equipment he inherited from Adam.

“The Austrian machine that rolls out our croissant dough dates back to 1967, and still works incredibly well,” he says. “We’ve also used the same Hobart oven for more than 30 years.”

Landry has updated his bakeshop while maintaining its storied history. In 1993, the brothers added a 40-seat salon de thé (tea room).

“The industry is evolving; you have to

keep traditions while adapting and being innovative at the same time,” he explains. “We still grind the almonds to make our praline bases – which is very rare in the industry – but we’ve modified some of the old recipes. Our customers want lighter, healthier versions of our pastries. Our mousses are less in demand today. We’re still making buttercream, but it’s less rich, less sweet.”

When you’re a Montreal landmark, there’s no need for splashy print ads or Facebook campaigns.

“Our marketing is mostly word of mouth,” explains Landry. “We have clients that have been coming here every week for 40 years. Some come every day. We open the doors, and they’re waiting to come in for their café/croissant breakfast. Clients from Boston and New York take boxes of our pastries home on the plane.”

Landry is as passionate about his craft today as the day he took over Duc de Lorraine.

“I just love it,” he says. “People have asked us to open a place in New York, and in Toronto. We once opened a franchise in a nearby shopping centre, but people told us things didn’t taste the same. The water was different; not having the same oven changed everything. We’re better off having one location and taking care of everything really well.”

Wendy Helfenbaum is a Montreal writer and television producer. Visit her at www. taketwoproductions.ca.

As this issue was going to press, Bakers Journal learned that Patisserie Duc de Lorraine had been sold to Elio Pagliarulo, former owner of Pâtisserie Pagel in Laval, Que. However, the Landry family remains involved in the operation of the business. – Ed.

By NORDAHL FLAkSTAD

– Spend some time in France and you might return to Canada wanting to set up a Parisian-style patisserie. But Japan seems an unlikely source of similar inspiration. Yet while teaching English for four years in Tokyo, Giselle Courteau and Garner Beggs were inspired to return to Edmonton and open their French masterpiece, the Duchess Bake Shop.

Finding inspiration in Japan isn’t as strange as it seems. Patisseries are popular in the Japanese capital, with recognized French brands such as Ladurée having set up shop. French pastry chefs give courses in Tokyo and Courteau signed up for one. Although the Edmonton native didn’t have

Giselle Courteau, a co-owner of the Parisianstyle Duchess Bake Shop, works the counter at the Edmonton bakery.

formal bakery training, she already had worked in bakery production and sales in Victoria and Vancouver.

Just three months after returning from Japan in April 2009, space had been leased northwest of Edmonton’s downtown core. On Oct. 2, the Duchess doors opened onto a décor that successfully blends the gilded finery of a traditional patisserie with a clean, contemporary look.

“We wanted to take something from the French tradition and combine it with a bit that was modern,” explains Courteau.

Patrons can walk away with their order or linger over a coffee while sampling from some 30 regularly featured products – including croissants, éclairs and the house speciality: macarons consisting of filling placed between almond-flour meringue cookies. To complement what may seem exotic to Edmontonians, Duchess’ pie selection offers more familiar fare.

All products are baked from scratch, using natural ingredients and no artificial preservatives or stabilizers. Duchess is also particular about ingredient sourcing – for example, butter comes from New Zealand, almond flour from California and Valrhona chocolate from France.

Courteau believes Edmonton was ready for Duchess. For example, the oncestrange macarons now have gained North American exposure through appearances

That’s been our philosophy for over 150 years.

It’s why, beyond superior yeasts and ingredients, we also offer customers the advantages of industry-leading technical support. Our knowledgeable technical team of skilled master bakers and baking scientists, all who have extensive experience in commercial baking and are recognized leaders in their fields, are dedicated to helping our customers succeed.

Through our innovative Baking Center in Milwaukee, we offer support and leadership to the baking industry. Staying up-to-date on new baking techniques and specificities in every country. Developing knowledge and expertise. Introducing innovations, and, just as importantly, sharing it all among our customers to further the creation of new products and advancements in their baking processes.

Strong relationships and support have always been the formula for success.

www.lesaffreyeastcorp.com www.redstaryeast.net

By D R . J OHN

Complex and unique among ingredients, proteins play essential roles in formulating quality baked goods.

Three major groups of compounds play a pivotal role in the function and existence of all living things. These are carbohydrates, fats or oils, and proteins. Of all these, the most important and complex are the proteins.

Proteins are made of building blocks, including amino acids, which are arranged in a sequence to form the of protein types that exist in nature. Plants using nitrogen and other simple compounds and the sunlight as an energy source synthesize these amino acids. Animals are unable to synthesize amino acids and therefore rely on plants for such a supply to build up their own proteins.

adding it to foods or ingredients we can elevate their protein content.

In 2008 in China, melamine in dairy products caused the deaths of six people and made thousands ill. Thus, manufacturers of certain foods have to adhere to mandatory levels of protein content, resulting in adulteration attempts. To combat the adulteration of foods with melamine, China has recently lowered the required minimum levels of protein in such foods.

Proteins from different sources have different nutritional values, determined by the combination of the amino acid composition.

Proteins play an important role as functional ingredients. They provide structure and texture, viscosity, foaming and water binding, colour and flavour, many other roles. Proteins such as egg albumin traditionally have been important in the production of cakes and other baked goods.

Because of the high cost of such ingredients, much research has been done to find

Proteins can reduce the effect of staling.

}Proteins are mainly composed of carbon (50-55 per cent), oxygen (20-23 per cent) and nitrogen (12-19 per cent). Of these, nitrogen is the most important.

Although quite often wheat and flour are sold on the basis of their protein content, a high amount of protein does not necessarily mean that their quality is high as well.

Normal analysis of food products and ingredients relies on the amount of the nitrogen for the determination of the protein content. As a basic rule, the nitrogen content of a food can be multiplied by 6.25 to determine the protein content of that food. However, this can only produce an approximate number because the 6.25 factor is based on an average nitrogen content of 16 per cent and the nitrogen content of proteins varies from 12 to 19 per cent.

In some cases, other factors can be used if the nitrogen content of the specific protein is well established. For example, in the case of wheat, the accurate factor for whole kernel is 5.83, for bran it’s 6.31, and for the endosperm (flour) it’s 5.7. For convenience, however, the factors of 6.25 and 5.7 are normally used.

Because we determine the protein content of foods indirectly based on the amount of nitrogen content, this leads to occasional food adulteration issues. The food industry’s recent problems with melamine adulteration emphasizes this inadequacy. Melamine contains high nitrogen, and by

cheaper alternatives. Indeed, protein isolates and concentrates from soy and whey, as well as other plant sources, have been introduced as substitutes for the role that egg albumin plays in baked goods. These ingredients have enjoyed limited success, as substantial reformulation efforts are required to remove or reduce the egg albumin.

Proteins are complex and unique, and their functionality is often attributed to their complexity. Their structure and configuration in many cases plays a role in their function in biological and food systems. For example, enzymes are proteins and it is their structural configuration that determines their ability to attach themselves to substrates on which they act as catalysts. Enzymes are widely used in the food industry and recently have been found to be very important tools for the baking industry. They are used to improve wheat flour performance, reduce the effect of staling, and replace or reduce other unfriendly chemicals used in baking.

In the baking industry, many sources of protein, are used as functional ingredients. However, the most functional as they are

applied to baking are the natural proteins that form the gluten. Two major proteins are found in wheat flour that, when combined with water and energy (mixing), will develop the gluten matrix and form the dough. They are gliadin and glutenin, and when developed into gluten they are responsible for gas retention in the dough and the characteristics of bread and related products as we know them.

For this reason, these proteins were recognized as early as the 16th century as playing a role in the quality of the wheat flour. In the past hundred years, many researchers have contributed to the elucidation of the role of these proteins in wheat flour functionality. In turn, this research provided the basis of the process of industrial production of bread and other baked goods.

The functionality of wheat proteins varies from variety to variety, and crop to crop. Although quite often wheat and flour are sold on the basis of their protein content, a high amount of protein does not necessarily mean that their quality is high as well. Flour manufacturers often resort to other tests to determine the quality of the protein before it is sold to the industry.

Proteins play a very important role as biological agents in living things but also as components of foods. Incorporating proteins into food products fulfils two major purposes: as nutrition enhancement and as functional ingredients, allowing us to process and produce valuable food products. / BJ

Dr. John Michaelides is Guelph Food Technology Institute’s director of research and technology. For more information, or fee-for-service help with product or process development needs, please contact GFTC at 519-821-1246 or gftc@gftc.ca.

From Satin Ice’s new fondant colours to the S+S Varicon range of metal detectors, Bakers Journal keeps you “in the know.” FOR MORE on new products for the baking industry, check out our website, www.bakersjournal.com.

Satin Fine Foods has taken a cue from its loyal Satin Ice users who were looking to save time. A new line of soft, beautiful pastel colours eliminates the added step of mixing and kneading your own. Also new: a bright,

Ashworth Flexlite conveyor belts

Ashworth Bros. Inc.’s new Omni-Pro FlexLite belt for conveying pans and trays has been tested to withstand tensions of 400 pounds for 100,000 cycles. The design utilizes a very open 1.5- by 3-inch flat wire overlay and is manufactured with the Omni-Pro link and zero tension buttonless welds. Omni-Pro FlexLite has an open surface area of 90 per cent in a straight run and 87 per cent in spiral or turn-curve applications. The result is a lightweight belt with increased carrying capacity that cools/freezes foods faster by improving air circulation and is easy to clean. Visit www.ashworth.com or call 1-800-682-4594.

Inline Plastics Corp., a Connecticut-based maker of rigid plastic food containers, continues to improve the environmental and sustainability benefits of its container line. Having previously converted its entire line of packaging to polyethylene terephthalate (PET), the most recycled plastic in the world, Inline’s PET material is now produced using a unique proprietary method. This process achieves such high-energy efficiencies that the material now has a carbon footprint as low as competing materials containing 50 per cent post-consumer recycled content from water and soda bottles. Visit www. inlineplastics.com.

electric orange. All the new colours feature Satin’s preferred signature vanilla flavour. For more information, including tutorial videos by some of the industry’s finest cake decorators and sugar artists, visit www. satinfinefoods.com.

• Assist in Product Development & Implementation of Custom Formulations

• Provide Practical Hands-On support to your existing R&D Team

• Extensive Knowledge in the Application and Trans Clean TM Usage of Icing and Glazing Machinery and Equipment.

• Support with the Transition from Product

• Development to Plant Trials, and finally into Full Production.

• Guidance and Direction to your Research and Development Team.

• Zero “Trans” Icings

• No Sugar Added / Low Fat Icings

• Organic Icings

• Coatings for Nutrition Bars and Meal Replacement Bars

• Nutritional Analysis

• Clean Labels

Our team consists of consultants, whose combined expertise is paramount to over one hundred years of knowledge and experience in the industry! Offering you, our clients, the quality and expertise you demand, you can rest assured that when you call on Paragon Glaze Consultants, you are obtaining assistance from top experts in the fields of Lab Technology, Product Development, Pharmaceutical Expertise and Food Microbiology to name but a few.

www.paragonglaze.com

and mentions on TV shows and movies, making Canadian customers eager to see what all the fuss is about.

Duchess doesn’t sell breads, partly because Edmonton already has several quality bread bakeries. Courteau admits bread production would have required higher initial investment in larger ovens, mixers and other equipment – leaving less to spend on crafting the patisserie’s ambiance.

The quick acceptance of Duchess surprises Courteau and Beggs. Success originates with superior products but also with the effects of positive reviews by Internet bloggers and Facebook users. That led to local entertainment guides and mainstream media checking out this piece of Parisian pastry heaven located on 124th Street, near several commercial art galleries and specialty food and wine outlets.

Duchess draws an eclectic clientele, including a trendy younger set from throughout Edmonton as well as customers dropping by from nearby neighbourhoods. Opening on weekends

(while closing Mondays and Tuesdays) has enhanced Duchess’ reputation as a dessert destination.

The enthusiastic response means Duchess now has more than a dozen part- and full-time staffers, including well-known local pastry chef and instructor Jake Pelletier.

“We’ve already outgrown our space,” Courteau says.

This means that in addition to replacing the shop’s current small (overworked) Baxter oven, her wish list includes expanding into adjacent premises. Given the strong reception so far in Edmonton, that shouldn’t take long.

By BRIAN HARTz

Thesedays it’s hard enough for a family-run bakery to survive one generation, let alone three.

Easier access to, and cheaper, education and travel lead children to careers that didn’t exist in the 1950s and ’60s in places their parents might never

have heard of.

That’s not the case with Dutch Bakery in Victoria, B.C. A mainstay near the busy downtown corner of Fort and Douglas streets since 1955, it was founded by Kees and Mable Schaddelee – immigrants from the Netherlands – along with their two oldest sons Arie and Jack.

Eventually, after finishing school, the two younger sons – Kees Jr. and Maarten – came to work at the family business, which is actually part bakery and part diner/café, offering a full breakfast and lunch menu in addition to a large assortment of pastries, chocolates and cakes. All four sons’ wives – Anke, Donna, Bonita and Nadine – were hired on at Dutch Bakery as well.

Eight grandchildren have worked at the bakery; four of them – Lavonne, Jack Jr., Brook and Michelle – are currently on staff. Jack Jr. is one of the lead bakers and has been at the bakery for 28 years. His colleagues in the kitchen, Gerry Hambley and Roberto Pivetta, have been plying their trade there for 30 years and 19 years, respectively.

Although Kees Schaddelee Sr. passed away in 2007 at age 97, the bakery retains the décor and furnishings of his heyday nearly half a century ago, including a soda fountain. Beyond the front area with its cash register, waiting area and pastry and chocolate display cases, there is a dining room with small tables and booths, complemented by a long counter with swivel stools running along almost the entire west side. Small pastries cases are attached to the counter at eye level for maximum temptati.on, while up above . the wall is covered with black-and-white photos of Dutch Bakery taken during its formative years, confirming the business’s charming resistance to change.

ty Pro duc ts c an i mpro v e pro duc t qu ali t y, per form anc e, nut rit i on al val ue an d pro fi t m argi ns Whe t he r yo u a re bu y in g B ase Ingredi e nt s, i m prov i ng y ou r pro du ct 's val u e p ro po si ti o n or tw eak in g margi ns, tru st De al e rs I ngredi e nt s to d e l i ve r r es ul ts

Butte r Bu ds

Butter, cre am an d ch ee se nat ural dai r y c once nt rate s r edu c e f at w h il e enhanc i ng f l avo ur c harac te ri st ic s a t a lower t o tal co st. Im pro v e y o ur p rodu c t per form anc e – nat ural l y

Cit r i-f i

Ci t ri- fi offe rs e xc ept i on al val ue an d pe r fo rman c e b y im pro vi n g mo i stu re m anage m en t, r e duc i ng f ats a nd c alo ri e s w hi l e enh anc i ng tast e an d te xt ure It 's a w in ni ng f o rm ul a fo r y ou an d y ou r co ns um e rs – nat ural l y

P rod uct of th e Un i t ed S ta t es

The booths and tables are cramped by today’s standards, no reservations are taken, and, unless you’re sitting by yourself at the counter, expect to have company if no other tables are available.

That’s by design, says Bonita Schaddelee, who helps run the business most days but says she’s “easing into retirement.” She says Dutch Bakery has historically been a meeting place for many social clubs and groups, and that the business strives to foster a sense of togetherness and community by seating solo customers at partially occupied tables.

A perfect example of this occurred on the day Bakers Journal visited. It was just before noon and Dutch

was in

The combined sourcing resources and technical expertise of Quadra and René Rivet make us a leading specialized supplier of ingredients in Canada.

Providing baking solutions with a complete line of Nutritional & Functional Ingredients:

• Alginates

• Caramel Colours

• Chocolate

• Dried Fruits

• Egg Powders

• Flax and Fish Oils

• Gluten Free Ingredients

• Hydrocolloids

• Inulin & Oligofructose

• Low Sodium Leavening Solutions

• Natural Fruit Inclusions

• Nutritional Dairy Ingredients & Flavours

• Starches & Proteins

• Specialty Phosphates

• Wellmune® Immune Functional Ingredients

• Yeast

Quadra toll free: 1 800 665 6553

René Rivet toll free: 1 800 465 9241

please refer to our websites www.quadrachemicals.com www.renerivet.com

midst of its late morning rush. The lunch crowd was starting to trickle in and the place was filling up fast. I was lucky enough to run into the now-retired Arie Schaddelee, one of the sons who helped start the business, and his wife, Anka, who had stopped by for brunch.

While Bonita attended to the swell of customers, I took at seat at Arie and Anka’s table to ask them a few questions about

Call our Canadian Distributors to request our catalog:

BakeMark of Canada

3202 - 9th Street S.E. Calgary, Alberta T2G 3C3 (800) 663-CAKE (604) 303-1700

Cake Top Inc.

151 Carling View Drive, Unit 2 Etobicoke, Ontario M9W 5S4 (800) 584-9883 (416) 798-1777

Catalog Sales Division (800) 428-4413

L & M Bakers Supply Co. 2501 Steeles Ave.W., Unit 1 Downsview, Ontario M3J 2P1 (800) 465-7361 (416) 665-3005

Nicholson Equipment Ltd. 3975 Kitchener Street Burnaby, B.C.V5C 3L9 (800) 668-3722 (604) 291-1901

Nicholson Equipment Ltd. 11640 - 147th St. Edmonton, AB T5M 1W2 (800) 661-9026 (780) 451-6262

Traynor's Bakery Wholesale

191 Victoria Ave.S., Hamilton, Ontario L8N 3C8 (800) 263-9239 (905) 522-2730

Vincent S.Varietes Ltd.

433 Rue Saint Paul LeGardeur, Quebec J5Z 4C7 (800) 263-1687 (450) 585-1687

Vixit Products Ltd.

290 Henri Bourassa Ouest Montreal, Quebec H3L 1N7 (800) 463-8782 (514) 337-0814

the bakery. Another woman was at the table and I apologized to her for interrupting her time with her friends.

“It’s OK, I don’t even know them,” she said.

She’d been seated with the Schaddelees because all the other tables, booths and stools were full, she explained.

In the back, Jack Jr. proudly confirmed that Dutch Bakery’s products are as stuck in the past as its décor.

“All the recipes came with Kees from Holland,” he said, pointing out a thick book he referred to as the business’s “baking Bible.”

“Not much has changed since then. Everything is made from scratch with no preservatives.”

In a nod to modern trends, Dutch Bakery has done some tinkering with recipes to accommodate customers who want sugar- and gluten-free products.

“It’s not like the old days when you could just make a whole pile of product and expect it to sell,” said Jack Jr. However, nearly two million of the bakery’s most famous pastry, the Vanilla Slice, have been sold and consumed over the years. That amounts to almost 800 per week – and that’s just one product.

But, whether because of health or economic concerns, “people have cut back a bit,” Jack Jr. added. “So we check the front to see what’s selling and what’s not. But for the most part we have a pretty set schedule.”

Dutch Bakery’s reputation has made it an icon in Victoria, and word-of-mouth reviews have spread to the U.S., so much so that customers from Washington State make the trip to get pastries and cakes for weddings. It has also been featured in the Lonely Planet series of travel guides, further burnishing its status as a must-visit location for sweet treats in the capital of British Columbia.

Despite the acclaim, Bonita didn’t seem to think much would change at Dutch Bakery in the 21st century, including their business mode.l.

“We’re all self-taught – and it’s all on-the-job training,” Bonita said. “People still come in here to visit with the Schaddelee family.”

Something tells us they won’t be going anywhere.

ST. FRANCIS, Wis. – Wixon Inc., a leading food and flavour products manufacturer, has named Ed Becerra vice-president of operations. Becerra is responsible for all aspects of manufacturing including safety, quality, cost-effective manufacturing, and management of production personnel.

“My major role is to continue Wixon’s commitment to world-class performance by achieving excellent results in all areas

KANSAS CITY, Mo. – Multivac, Inc., a leading global supplier of packaging solutions for food, medical, consumer and industrial products, announced new roles and responsibilities for three of its food division managers.

and ensuring all our resources are utilized to their full potential,” he said. “This is in keeping with Wixon’s total commitment to quality and of not only meeting customers’ expectations but exceeding them.”

Becerra plans a comprehensive gap analysis of the entire system. Utilizing gap analysis methodology enables a company to compare its actual performance with its potential performance. “We will be

Mark Wilhelm is now eastern division sales manager, Gregg Poffenbarger is western division sales manager and Bill

Williams takes over as compact packaging systems and tray sealers product manager.

Wilhelm steps into his new position after serving as Multivac’s tray sealer product manager for the past nine years. He will now manage all regional sales managers in Multivac’s food division in the eastern half of the United States. Poffenbarger, formerly a regional sales manager

defining elements that need improvement and taking corrective action where needed,” he said.

Becerra is a seasoned veteran in leading companies to industry standards and best practices. He has more than 25 years of manufacturing and management experience at companies such as Exxon Chemical, CHR Hansen and Associated British Foods.

in Multivac’s southwest territory, takes on management responsibility for all Multivac food division regional sales managers in the western half of the United States, including Alaska and Hawaii.

Bill Williams has served as Multivac’s product manager for compact packaging systems for the past eight years. His product portfolio will now include Multivac’s complete line of automatic and semi-automatic tray sealers.

With offerings in more than 10 categories including caramels, fruit fillings, sauces, icing and glaze, we manufacture some of the food industry’s most innovative “behind-the-scenes” products for the manufacturing, food service and in-store bakery sectors. With one of the industry’s widest ranges of packaging options including flexible pouches, drums, totes, pails and more, we leverage our knowledge and technology to help our customers push the boundaries of food.

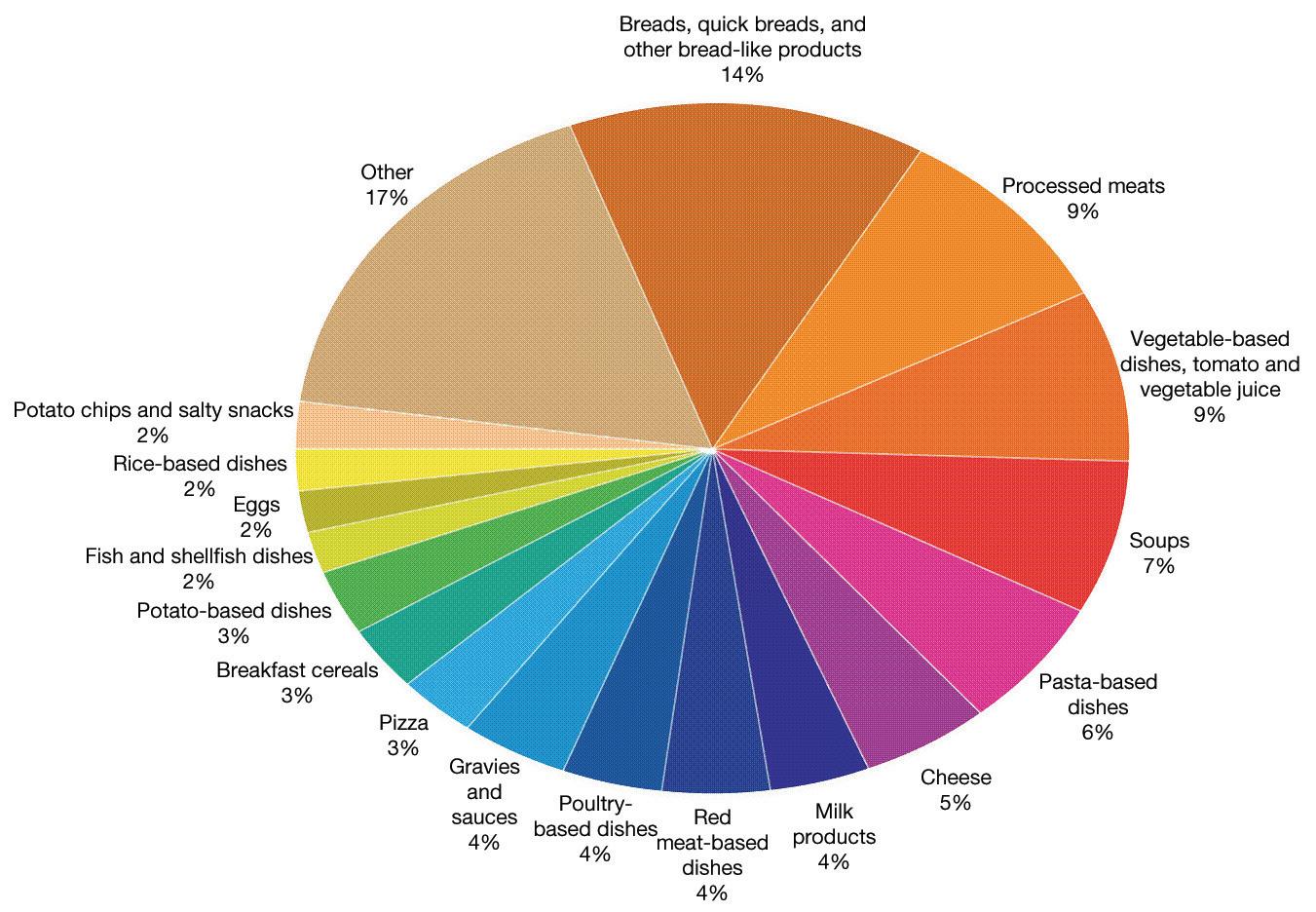

The Multi-Stakeholder Working Group on Sodium Reduction issued its report on July 29, 2010 to aggressively pursue sodium reduction in Canada. The Working Group, of which BAC President & CEO Paul Hetherington is a member, was formed in 2007 to develop a strategy to reduce the daily average intake of sodium from 3,400 mg to 2,300 mg by 2016 in order to address growing health concerns related to excess sodium consumption. The Working Group’s full report on sodium reduction is available at

English: http://www.hc-sc.gc.ca/fn-an/nutrition/ sodium/strateg/index-eng.php

French: http://www.hc-sc.gc.ca/fn-an/nutrition/ sodium/strateg/index-fra.php

The plan is a three-pronged, multi-staged approach, which includes government-supported consumer education and awareness building; government-supported research into viable alternatives; and a voluntary reduction of sodium levels in processed foods and foods sold in food service establishments.

Processed foods are estimated to contribute more than 75% of sodium in the diet and the voluntary reduction efforts will focus on a wide variety of foods. The voluntary reduction targets were not part of the release of the Sodium Working Group’s final report, as Health Canada is still in consultations with numerous industry groups including BAC. The final targets are expected in early 2011.

Baking Association of Canada supports the leadership of the Multi-Stakeholder Working Group on Sodium Reduction’s voluntary three-pronged, multi-staged approach to reducing sodium in Canadians’ diets. BAC is committed to supporting an average daily recommended intake of 2,300 mg of sodium and the voluntary reduction of sodium levels in processed foods and foods sold in food service establishments. Indeed, BAC members have already made progress as an industry and are highly engaged in the complex process of reformulation of bread and other recipes to lower sodium levels.

In order to be successful, the report states clearly that all three prongs of the strategy, education, research, and a reduction of sodium in processed foods need to be implemented in tandem. Salt is essential in the chemistry of baking so research will play an important role in

(Source:

developing product reformulations and determining alternatives. Other basic ingredients such as baking powder also add sodium to the baking process. Changing consumer behaviour and researching alternatives to sodium will require dedication and consistent efforts by government, health professionals and the food industry.

In addition, the report acknowledges that reducing sodium is a complex undertaking for several reasons, including its unique taste, functional properties and health safety benefits. Salt has an essential role in baking as it allows dough of yeast bread to rise and strengthens the gluten in flour. Sodium also assists in enhancing flavour and controls the growth of bacteria, an important role in food safety. Researching alternatives to salt and recreating product formulations is a key focus to reducing sodium in baked goods, but will require time and significant effort given the essential role salt plays in baking.

The following are a listing of the Sodium Working Group recommendations and excerpts of selected excerpts for some but not all recommendations. For full detail on all recommendations refer to the Sodium Working Group report.

In developing its recommendations, the SWG’s Food Supply Sub-Committee was guided by the criteria that the approach should be voluntary, significant (with respect to the reduction in sodium content in foods and in sodium intakes of Canadians), gradual, realistic, feasible, measurable, time-delimited and sustainable. Sodium reduction targets for foods for achieving the interim sodium intake goal with a specific plan to measure progress towards those targets over time. In consultation with the food industry, Health Canada is working on establishing Canadian sodium reduction targets for foods, with the aim of achieving the interim sodium intake goal of 2,300 mg per person per day by the year 2016. These targets apply to all foods in each category, whether sold to consumers, for further manufacturing or for use by food service operations.

recoMMendation 1-1: the Working group recommends that Health canada continue to work with the food industry to establish voluntary sodium reduction targets by food category.

Health Canada and the food industry should jointly lead the implementation of this recommendation.

The draft targets for a first group of foods have been published, with final targets to be published along with those for a second group of fohods planned for rehlease early in 201h1. The rate at which targets will be reached will vary by food category, but should occur by 201h6. Milestones willh be established to hensure that progress towards meeting the targets by 2016 is maintained.

recoMMendation 1-2: the Working group recommends that Health canada, in collaboration with the provinces and territories, continue to work with the restaurant and food service industries to establish voluntary sodium reduction targets for meals and menu items sold in restaurants and food services establishments.

Health Canada, in collaboration with the Provinces and Territories, and the restaurant and food service industries should lead the implementation of this recommendation. In order to benefit all Canadians, targets for meals and menu items sold in restaurant and food service establishments should be consistent across the country.

recoMMendation 1-3: the Working group recommends that manufacturers lower the sodium content of their products to meet the voluntary targets and go beyond them over time to the lowest level possible, taking into consideration microbial food safety, quality and consumer acceptance.

In some cases, it will be necessary to find alternatives to salt or other sodium-containing ingredients due to microbial food safety or functionality reasons. However, it would be beneficial when formulating commercially prepared foods to first reduce the use of salt. Since it has been shown that, over time, the palate will condition itself to less salty tasting foods, salt alternatives should only be used when salt replacement is absolutely necessary.

recoMMendation 1-4: the Working group recommends that a mechanism be established on Health canada’s sodium website that would allow individual companies to commit to the sodium reduction strategy. Putting in place such a mechanism would allow companies to indicate their awareness of and commitment to meeting the sodium reduction targets for new and existing products in their portfolios. It is also a key component of the structured voluntary program of sodium reduction in foods. Specific terms and conditions would need to be agreed to in order to have a company’s name on the site. Each company’s progress towards meeting the targets in a meaningful way would need to be updated on a regular basis to maintain its online commitment.

recoMMendation 1-5: the Working group recommends that the food and drug regulations be amended to ensure that the serving sizes used in the nutrition facts table (nft) are as uniform as possible to facilitate the comparison of sodium levels in similar foods. Nutrition Facts table (NFT) requirements were put in place as a labelling tool to allow consumers to easily compare the nutrient value of foods and to make informed purchasing decisions. When the serving sizes for similar products are not exactly or approximately the same, comparisons of the relative sodium contribution of foods is difficult.

recoMMendation 1-6: the Working group recommends that the food and drug regulations be amended to change the basis of the daily Value (dV) for sodium in the nutrition facts table (nft) from 2,400 mg to 1,500 mg to reflect the adequate intake (ai) level. For many nutrients in the NFT, the DV is based on the target daily intake that individuals should meet or exceed. Having the DV for sodium based on a reference standard of 2,400 mg, which is closer to the UL than the AI for sodium, promotes undesirably high intakes of sodium from a public health perspective. Ultimately, it is desirable for Canadians to be consuming sodium levels at or around the AI. It is therefore the opinion of the SWG that the basis of the sodium DV in the NFT should be that of the AI and not the UL.

recoMMendation 1-7: the Working group recommends that Health canada improve the current nutrition labelling system in canada to facilitate consumer understanding and use, particularly as it relates to sodium. Recognizing the increasing call for improvements to the current nutrition labelling system in Canada, Health Canada should review current regulations governing labelling requirements. The goal of the review would be to improve the current system to enhance consumers’ ability to read, interpret and use nutrition information effectively in order to make choices that support healthy eating.

recoMMendation 1-8: the Working group recommends that the food and drug regulations and applicable provincial regulations be amended to require the on-site disclosure of nutrition information in a consistent and readily accessible manner for standardized menu items

prepared and assembled on-site at restaurants and food services establishments, where feasible (i.e., in establishments with a high degree of standardization).

Feasibility of on-site disclosure of nutrition information should be determined by the extent to which standardized menu items are available across multiple restaurant or food service outlets of the same chain. Standardization means using a common supply chain (i.e., the same supplier), and the same standardized ingredients and recipes across all establishments of a given chain.

recoMMendation 1-9: the Working group recommends that the federal government, along with the provincial and territorial governments, where necessary, review the food additive approval process and modernize the standards of identity for foods while maintaining microbial food safety.

It is recognized that the overall reduction of sodium in the food supply is desirable in order to achieve a meaningful reduction in the dietary sodium intake of Canadians. At the same time, it is not always possible simply to remove the salt or other sodium containing food additives because of the role they are playing in specific foods, particularly in relation to microbial food safety, food preservation, texture and flavour. In some of these cases, the salt and/or other sodium containing compounds that are removed must be replaced by other ingredients or food additives that will fulfill the same function. In order to ensure that this can occur in the food industry in a timely manner, certain regulatory changes may be needed to facilitate innovation. There is a need to streamline the current regulatory review process for food additives without compromising the rigour of the safety assessment, as well as to modernize the standards of identity for the use of ingredients to replace sodium, particularly when required for microbial food safety purposes.

recoMMendation 1-10: the Working group recommends that the federal government, together with provincial and territorial governments, develop more consistent sodium guidelines and procurement policies for use by food service operations in publicly-funded institutions such as schools, daycares, hospitals, care facilities, correctional institutions and for the armed forces.

Health Canada, working with provincial/territorial governments, should lead the implementation of this recommendation.

Government policy encompasses promoting healthy eating to the general population. This should be reflected in guidelines developed for food services in publicly funded institutions to ensure that their consumers are provided with a nutritious diet-particularly since consumers in these settings often do not have direct control over their food choices.

The recommendations of the Sodium Reduction Strategy for Canada concerning awareness and education are intended to:

z inform and educate Canadians about sodium and the

health consequences linked to high levels of sodium intake

z influence consumers to reduce sodium intake

z increase consumer demand for lower sodium products

The key messages to support implementation of the sodium reduction strategy will need to reflect the following important points:

z Individuals in Canada are consuming too much sodium – in many cases, more than double the recommended amount.

{ Adults should aim for 1,500 mg of sodium or less each day and should not exceed 2,300 mg per day. These numbers are lower for children.

{ Canadians consume, on average, 3,400 mg of sodium daily from all sources.

{ Most Canadians recognize that the population’s salt intake is too high but wrongly believe that they themselves consume a healthy amount.

z High sodium intake increases blood pressure which is the leading preventable risk factor for death.

{ High blood pressure is the major cause of cardiovascular disease and a risk factor for stroke and kidney disease.

{ There is evidence to suggest that a diet high in sodium is a risk factor for osteoporosis, stomach cancer and asthma.

{ According to the World Health Organization, interventions to reduce population-wide salt intake have been shown repeatedly to be highly cost-effective.

z Three quarters of the sodium Canadians consume comes from sodium added to food during processing.

{ Most of the sodium consumed by Canadians comes from pre-packaged, ready-to-eat foods, rather than from salt added at the table or in home cooking. Restaurant foods also generally contain high amounts of sodium.

{ In some cases consumers will notice a change in taste in foods that have been reduced in sodium; consumers need to be made aware that taste adapts quickly to these lower levels of sodium and they need to be encouraged to not add salt back to their foods.

{ Messaging should also address salt added in food preparation and added at the table.

z The Nutrition Facts table can help consumers choose products that are lower in sodium.

{ There is great variation in the levels of sodium among products, so the % Daily Value or mg of sodium and serving size information in the Nutrition Facts table should be used to compare products and choose the ones with less sodium.

{ Ask for the sodium content of foods when eating out in restaurants, cafeterias and when taking meals home.

Eating more vegetables, fruit and whole grains contributes to better health.

Eating Well with Canada’s Food Guide provides guidance to make healthy food choices and to help reduce sodium intake.

recoMMendation 2-1: the Working group recommends that education programs be developed and

adapted for intermediaries working in the various sectors of the food industry (manufacturing, distributing and food service) to inform them about sodium and the sodium reduction strategy for canada.

recoMMendation 2-2: the Working group recommends that education programs be developed to reach key intermediaries in the health, media, education and government sectors to inform them about sodium and the sodium reduction strategy for canada.

recoMMendation 2-3: the Working group recommends that the federal government lead the development and implementation of a social marketing campaign on sodium. this campaign should be aligned with efforts of the food industry to reformulate their products.

recoMMendation 2-4: the Working group recommends that governmental and non-governmental funding bodies develop cohesive and coordinated funding mechanisms to enhance community-based activities that will support the sodium reduction strategy.

recoMMendation 2-5: the Working group recommends that federal, provincial and territorial governments continue to explore options to reduce the exposure of children to marketing for foods that are high in sodium.

recoMMendation 2-6: the Working group recommends that, in the context of a broad education campaign on sodium, a strategy be developed to help consumers understand the current nutrition facts table (nft). it should be understood that changes to the nft will be made in the future and a comprehensive strategy will be needed to support the revised nft.

recoMMendation 2-7: the Working group recommends that the federal government review and update canada’s food guide to increase the prominence and effectiveness of advice regarding sodium and calories.

The Sodium Research Sub-Committee of the SWG was mandated to identify knowledge gaps and to establish research priorities that would engage partners and the community in generating key data to support the Sodium Reduction Strategy for Canada. In conducting its work, the Research Sub-Committee also recognized the need to explore appropriate benchmarks and indicators for measuring progress on the Sodium Reduction Strategy, in conjunction with the Monitoring and Evaluation Sub-Committee.

Three domains of research questions were identified:

z Health aspects of sodium, including:

{ exposure to sodium in childhood or in utero as a predisposing factor for hypertension and cardiovascular diseases

{ the vulnerability of at-risk populations to the effects of sodium – for example, Aboriginal people, people of South

Asian and African origin, infants, children and the elderly

{ the influence of sodium reduction in the population, including long-term benefits and risks other than cardiovascular endpoints, such as asthma, osteoporosis, gastrointestinal cancers, etc.

z Food science aspects of sodium, including:

{ the role of sodium in microbial food safety

{ limits to lowering sodium in food while maintaining the functional aspects for which sodium is added

{ role of sodium in taste physiology

{ alternatives to sodium, considering safety and functionality, and including technological innovations and alternative food processing strategies

z Knowledge-to-action aspects of sodium, including:

{ the impact of regulation and policy, including questions such as how package labelling affects food choices and an examination of “natural experiments,” based on policy approaches used in different countries

{ the effectiveness of taking action, including understanding the barriers to going from knowledge to action with respect to sodium, differences according to segments within the general population and implications for developing enabling tools

recoMMendation 3-1: the Working group recommends that the federal government provides increased resources to the granting councils and the relevant sciencebased departments and agencies to develop and implement mechanisms to build capacities, target research funding and improve research collaborations amongst academic, government and industry sectors, and enhance these partnerships to advance sodium reduction-related research.

recoMMendation 3-2: the Working group recommends that the federal government empower the granting councils and relevant partners to develop and implement a program of research funding to address knowledge gaps in basic understanding of sodium physiology to inform both policy and practice.

recoMMendation 3-3: the Working group recommends that the federal government empower the granting councils, relevant departments and agencies, and the food industry to work together to better understand the minimum levels of sodium attainable in foods without sacrificing the specific functional aspects of salt in foods, with an emphasis on microbial food safety and food technology issues.

recoMMendation 3-4: the Working group recommends that the federal government, relevant health non-governmental organizations (ngos) and other stakeholders fund population and public health policy and program research.

recoMMendation 3-5: the Working group recommends that the federal government provide adequate resources to the granting councils and interested stakeholders to develop and implement a research initiative to investigate sodium reduction in the context of healthy eating patterns.

Phil Robinson - Membership, Dawn Foods

Dr. Phillip Lee Wing - Member-At-Large, The Food

Development Group

•

Ira Day - Member-At-Large, Prosperity Foods

• Wholesale Ltd

Dan Peroff - Committee Member, Olympic

recoMMendation 4-1: the Working group recommends development of a comprehensive sodium monitoring and evaluation plan.

recoMMendation 4-2: the Working group recommends monitoring the sodium intake of canadians.

Progress towards reaching the overall sodium intake interim goal of 2,300 mg per day by 2016 should be monitored regularly and reported at provincial/territorial and national levels. The monitoring of sodium intake by Canadians should use the gold standard of a 24-hour urine analysis with creatinine, to assess the completeness of the collections.

recoMMendation 4-3: the Working group recommends monitoring the foods canadians consume using a national dietary intake survey similar to the canadian community Health survey (ccHs) 2.2.

This monitoring is important to determine if there is a change in the food consumption pattern of Canadians and, in particular, if there is a shift in the consumption of foods that are generally high in sodium to those that are generally lower in sodium.

Each and every year we kick off the year with a sold out and very successful social with the Annual Night at the Races held at Woodbine Racetrack, members enjoy a fabulous dinner and wager a few dollars on the ponies. Tom Nowak our Social Chair once again executed a well planned and organized our spring 4-Man Scramble Golf Tournament. This event is sold out every year yet Tom finds a way to squeeze a few more in year after year. Our fall golf classic held in September at Glen Eagles Golf Club allows players to play their own ball while also submitting a team score. Thanks as well to Dan Peroff for the many years he has organized this tournament. Funds generated from both golf tourCnaments will supportC the chapters many initiatives including financial awards for academic achievement in the field of baking at many Ontario based community colleges.

recoMMendation 4-4: the Working group recommends monitoring and evaluating the progress for each of the program components of the sodium reduction

This program carries top of the line news on what’s happening in the industry with governments, services, BAC activities, etc. The E-Bulletin is ONLY available to BAC Member companies a’nd their employees.’

Don’t miss out on receiving time sensitive news - if you’re not currently receiving the E-Bulletinplease email info@baking.ca to be added.

strategy for canada – specifically, the food supply, awareness and education, and research.

Activities for each component should be monitored by tracking the progress made on achieving outputs, short term outcomes and intermediate outcomes. For example, for the consumer awareness and education component, the reach and success of the education campaign would be monitored.

Nealanders while competing in a Triathlon event in Northern Ontario. A great friend to many and a true industry professional who volunteered for many years on the former Bakery Production Club of OCntario (BPCO) beforeC it joined forces nationally with thCe Baking AssociatiCon of Canada. I had Cthe pleasure of working with Matt on many industry initiatives while volunteering and was motivated by his excellent work ethic and fresh perspective. Matt always had a genuinely friendly smile and made everyone feel welcome. Matt you will be missed.

In closing I would like to especially thank Dieter Claassen for keeping our finances in order and the entire executive for their well thought out contributions at every meeting toward the betterment of our industry. The Baking Association of Canada

In addition, progress towards reaching the sodium reduction milestones for foods should be monitored. A coordinated monitoring plan to measure sodium in the food supply needs to be developed, using data available from food label reviews combined with market share information, results of Health Canada’s Total Diet Study and targeted analyses of food products. Health Canada should specifically monitor the sodium in food products in collaboration with the food industry. Additional data sources to monitor changes in the sodium content of the food supply would be identified as needed.

The level of funding to support priority research projects identified in the research plan also needs to be monitored.

– Ontario Chapter would like to thank Paul Hetherington, BAC President, Rosemary Dexter & Gillian Blakey for their assistance with chapter activities and all those industry professionals who attended this year’s activities, we look forward to your support in 2010.

recoMMendation 4-5: the Working group recommends monitoring long-term health outcomes, including blood pressure, morbidity and mortality from cardiovascular disease (acute myocardial infarction, stroke and heart failure, etc) and other sodium-related diseases (such as stomach cancer), as well as monitoring cost savings to the health system.

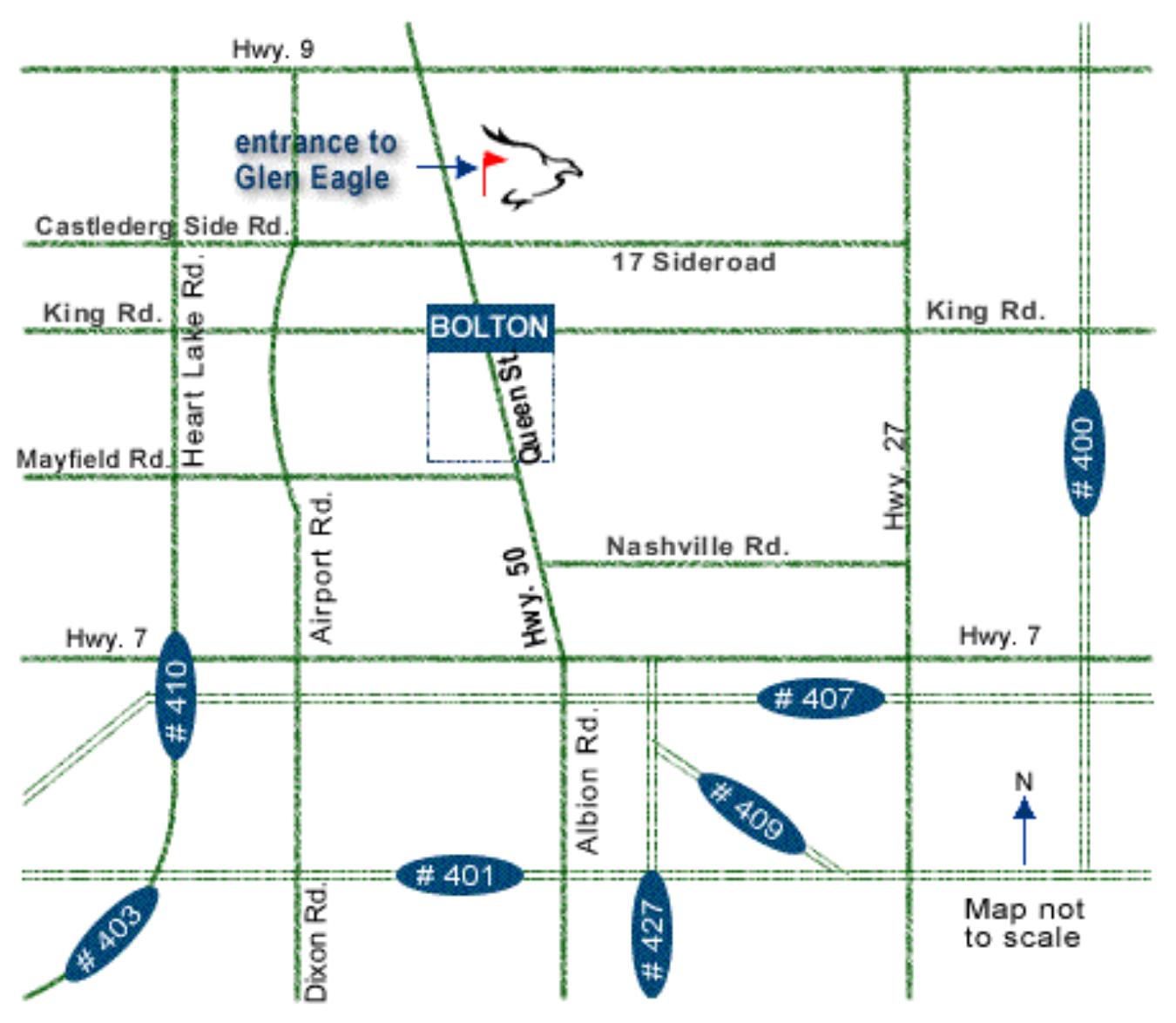

BAKING ASSOCIATION OF CANADA

ANNUAL FALL GOLF TOURNAMENT

Tuesday, September 21, 2010

GLEN EAGLE GOLF CLUB

BOLTON, ONTARIO

SHOT GUN START! TEE OFF TIME AT 10:00 AM SHARP