Tech-savvy oyster farmers retool shellfish supply chain

Egg-to-market operation helps boost tilapia’s acceptance

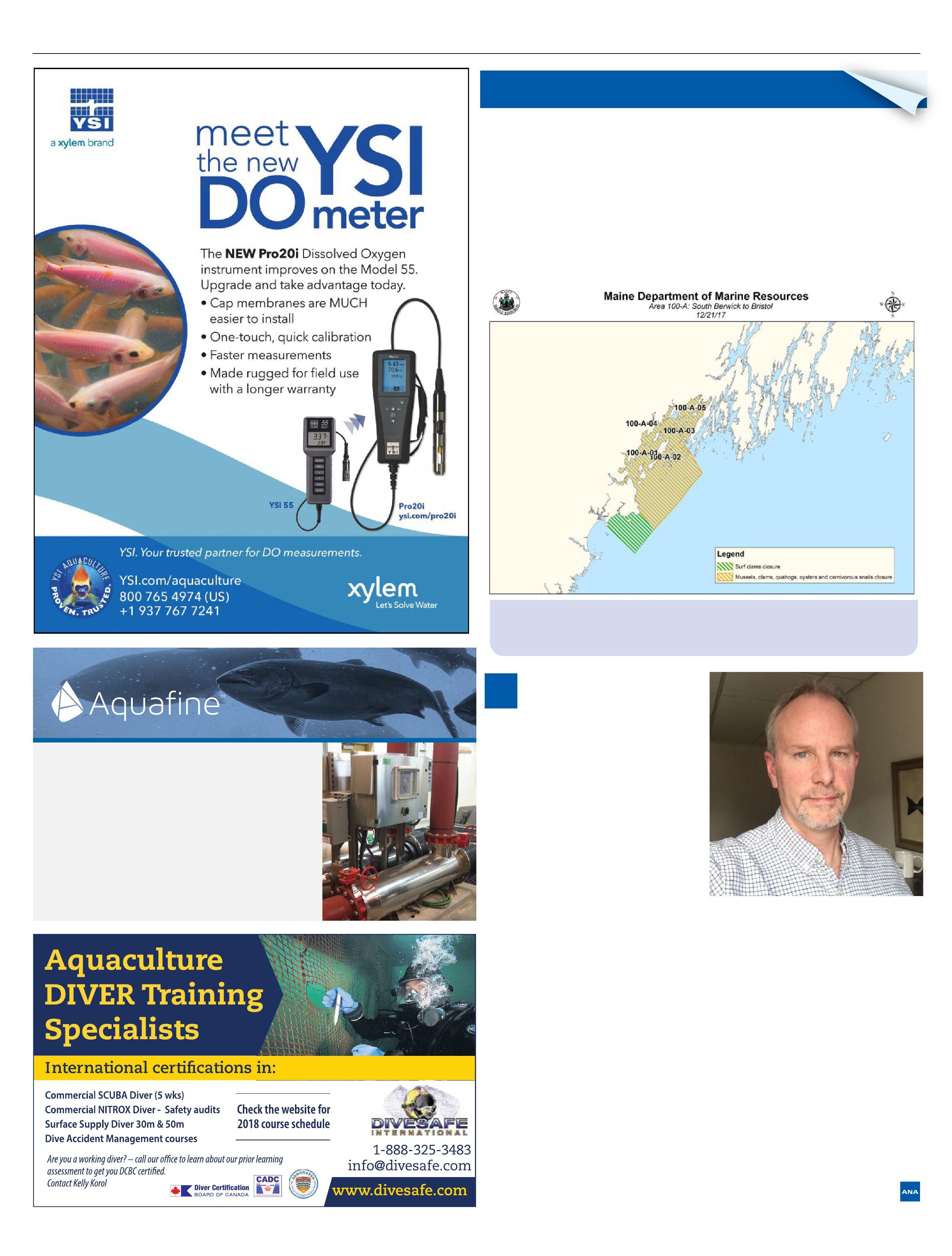

FOCUS ON SHELLFISH

Viewed by locals as “dirty trash fish,” a non-profit helps tilapia win the hearts and minds of Hawaiians

BY TREENA HEIN

BY MATT JONES

FOCUS ON SHELLFISH

ontrary to what the name may lead you to believe, there are no secret rituals or sacrifices involved in joining Real Oyster Cult.

“Our hashtag and tagline - #jointhecult – is all about joining, having fun, and is wink, wink, get in on the party,” says Sims McCormick, the creative force behind Real Oyster Cult’s unique marketing. “We’re a cult of oyster lovers, life lovers. Let’s celebrate.”

McCormick’s husband Rob Knecht spent most of his working life on the water, running a maritime school, and working as a sailing coach. When the couple launched the oyster farm in 2006, Knecht also worked with a technology company. At that company, it was interactions with technologists, developers and designers that sparked the idea to build a company that used technology to get oysters directly to consumers, shipped overnight.

“We leverage our mobile app and our website to get in front of consumers online that want to source oysters from all over North America, and we make that happen for them,” says Knecht. “Our

front-end technology really gives you access to the farmers, their story, and deeper dives if you’re really into flavour profiles, and details of the oyster and where they’re grown.”

Real Oyster Cult sells product from over 70 farms (including their own), rotating which farms are featured on a weekly basis. Some products will stay longer based on demand, but they make efforts

continued on page 7

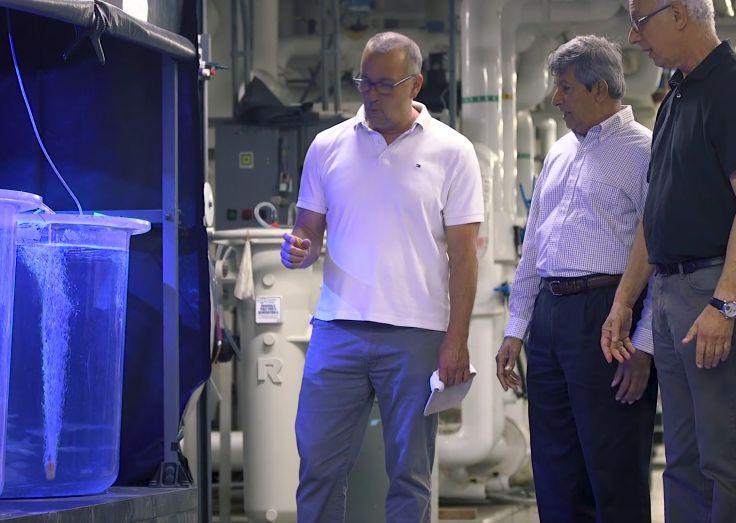

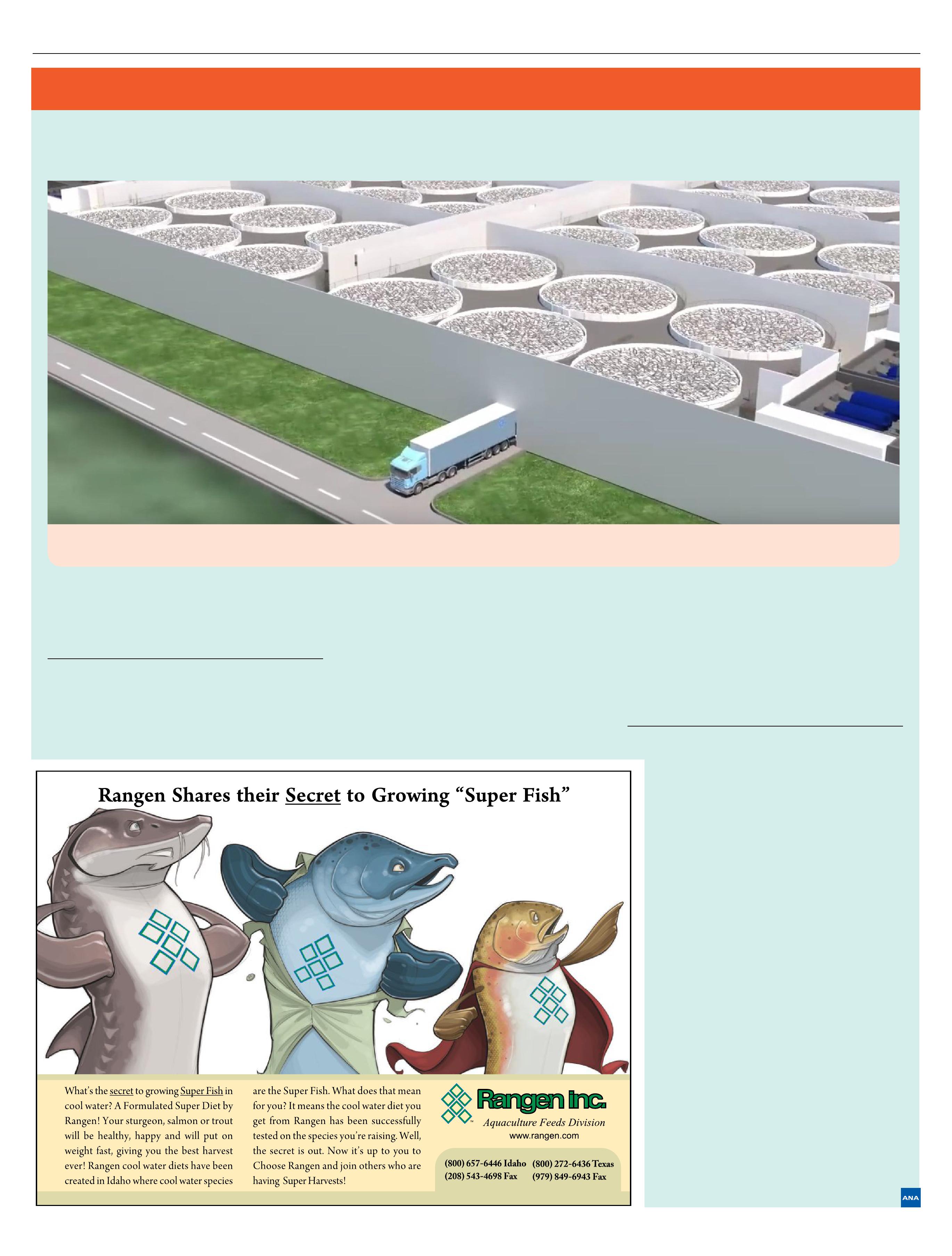

Industry cautiously optimistic about land-based aquaculture

BY LIZA MAYER

ndustry attitude about land-based aquaculture is one of cautious optimism as potential investors wait for more proof-of-concept of this nascent technology, says an analyst.

“Some find it too early to invest. There are some investors that are fairly new to the industry so they find it very hard to quantify the risk-reward adequately,” says Tone Bjorstad Hanstad, seafood equity research analyst at Norwegian investment bank DNB Markets.

Hanstad says however that she and fellow DNB analyst

Alexander Aukner are very impressed with how far the industry has come. They are confident land-based aquaculture will play

a role in satisfying the world’s demand for fish amidst dwindling wild catch and moderately growing aquaculture supply.

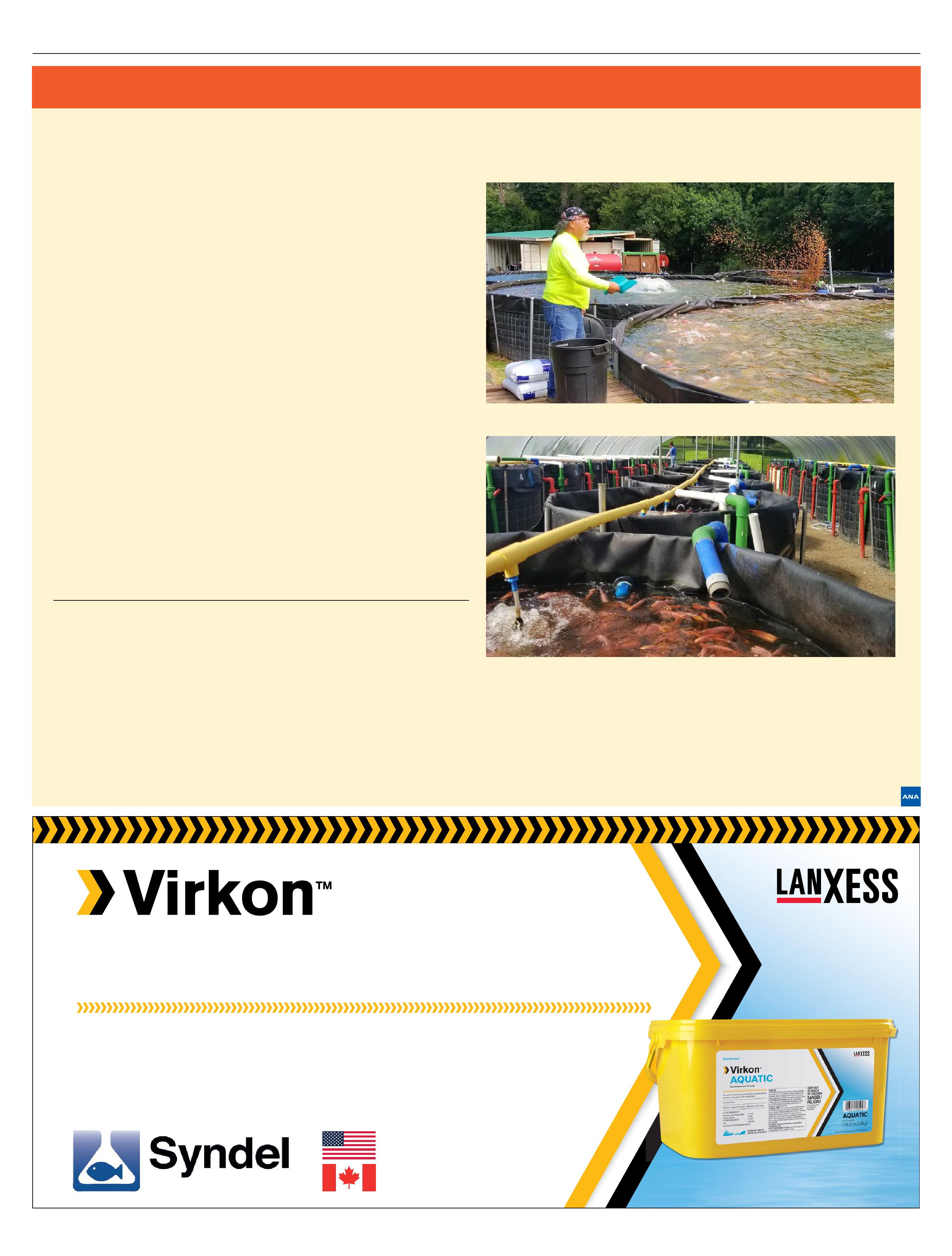

here has been no stopping the success and progress of Kohala Mountain Fish Company (KMFC) in Kapaau, Hawaii since operation began in late 2014. The operation is situated on, and jointly owned by, the Kohala Institute. The not-for-profit institute promotes connection to traditional Hawaiian lands and their sustainable use, with the goal of creating a better world.

Before KMFC got going, tilapia farming in the state was extremely limited, notes KMFC General Manager/Head Biologist John Oliva. “Tilapia in Hawaii did not have a very good reputation,” he explains. “It was viewed as a dirty trash fish… It has taken some work by KMFC and others like Denise Yamaguchi from the Hawaii Food and Wine festival to win hearts and minds here. Our products have received much praise in the marketplace for their presentation, flavor and fat content, allowing us to get a higher market price from the target customer base.” Currently, Kohala supplies whole fresh fish to distributors in Oahu and to restaurants as far away as New York.

ECO-FRIENDLY

In harmony with the values of the Kohala Institute, the operation is designed to be as environmentally friendly as possible. Tilapia was chosen as best for integrating with all the sustainable aspects

on page 10

Genomic tool detects early signs of fish diseases

Ascientist at Fisheries Oceans Canada (DFO) has developed a diagnostic tool that could be used to rapidly diagnose early signs of infectious disease in fish.

Scientists currently rely on techniques that generally detected disease once clinical signs have developed or once the fish is dead.

The viral disease diagnostic panel that DFO scientist Kristi MillerSaunders developed uses the activity of the genes to determine whether salmon are suffering from a viral disease.

“Any organism at any point in time will carry in their bodies an array of pathogens including viruses that exist in background levels but not necessarily causing disease. Disease occurs when they start causing damage to the host cells.

A technician shows a microfluidics dynamic array, which can assess 96 gene assays against 96 samples at a time. The technology allows scientists to simultaneously assess the presence and abundance of dozens of infectious agents and the activation of host immunity, specifically in this application, biomarkers from the viral disease diagnostic panel. In the background is a Fluidigm BioMark HD quantitative PCR machine used in genomic applications

velopment because if a wild salmon gets diseased they will be very vulnerable to being eaten by a predator or to dropping out of the water column,” said Miller-Saunders.

The technology could differentiate healthy fish — both those carrying or not carrying known viruses — from those in an active disease state, and can be implemented as part of routine screening.

“We were interested in developing a tool that could detect early stages of disease de-

“The molecular viral disease diagnostic panel we developed is capable of recognizing the development of diseases caused by an arraay of salmon viruses, differentiating individuals that may simply carry virus(es) from those in a disease state, and differentiating viral from bacterial diseases, all using a non-destructive gill clip,” Miller-Saunders told Aquaculture North America (ANA)

She said the implementation also led to the discovery of eight new viruses in BC salmon, obtained through sequencing tissues from fish testing positive for viral disease but for which no known virus was detected. The discovery not only provides a strong validation of the approach, but also demonstrating its high utility towards rapidly identifying viral causation of emerging diseases, she added.

In salmon farming, detecting diseases in the early stages would enable farmers to implement biosecurity measures and help stop the spread of diseases. These may include minimizing handling of the fish or limiting any kind of transfer of fish between different areas in the farm, she said. As the tool does not require destructive sampling of fish, it could easily be incorporated into routine screening, for instance, during sea lice treatments.

Moreover, the tool could be highly valuable in quickly determining the likelihood of viral causation of emerging diseases.

The tool’s development is part of the Canadian government’s ongoing Strategic Salmon Health Initiative, a collaboration between DFO, the Pacific Salmon Foundation and Genome British Columbia.

— Liza Mayer

Four biggest aquaculture trends in 2018

The industry’s reduced use of antibiotics is one of the four biggest trends coming to aquaculture in 2018, says feed developer

Aquaculture feed additive developer

Bentoli Inc identified the four biggest trends coming to aquaculture in 2018 and beyond.

The four trends are: reduction in the use of antibiotics; continued industry growth; focus on sustainability; and the evolution of aquaculture systems and equipment.

“Aquaculture producers faced intense pressure in 2017 for their overuse of antimicrobials. With the World Health Organization labeling antimicrobial resistance a major threat to worldwide health, the discussion of antibiotic use will take center stage in 2018,” says the Texas-based company. “Many organizations are already calling for restrictions on the use of antibiotics and—in some cases—proposals have been presented to completely halt the use of antibiotics.”

Bentoli says all indications show con-

tinued growth for the aquaculture industry over the next decade. It noted that global aquaculture has grown at an impressive rate of 5.8 percent annually since 2005. The new year will usher in a year filled with more growth and more change for aquaculture when it comes to aquaculture systems and equipment. “In an industry that’s experiencing massive development, aquaculture shows great promise despite exhibiting signs of growing pains,” it says. Finally, the company sees the quest for sustainability to remain in focus. Discussion of sustainability will be surrounded by issues of environmental degradation, impact of farmed species on wild gene pools, and feed. “Feed systems have changed to meet the growing demand for higher inclusion of nutrients in aquaculture diets,” it added.

Editor Liza Mayer

Tel: 778.828.6867 lmayer@annexweb.com

Advertising Manager Jeremy Thain Tel: (250) 474.3982 Fax: (250) 478-3979 Toll free in N.A. 1.877.936.2266 jthain@annexweb.com

Media Designer Alison Keba akeba@annexweb.com

Circulation Manager Barb Adelt Tel: 416-442-5600 ext. 3546 badelt@annexbusinessmedia.com Editorial

Chettleburgh

(250) 478-3973 Fax: (250) 478-3979 peter@capamara.com

Regular Contributors: Quentin Dodd, Ruby Gonzalez, Erich Luening, John Nickum, Matt Jones, Tom Walker

Group Publisher - Scott Jamieson sjamieson@annexbusinessmedia.com

COO – Ted Markle tmarkle@annexbusinessmedia.com

President & CEO – Mike Fredericks

Washington county feels impact of immigration crackdown

ICE detentions put Pacific County shellfish industry at risk

BY MATT JONES

On the campaign trail, much of President Donald Trump’s rhetoric around immigration focused on the need to remove what he called “bad hombres” – illegal immigrants who are dangerous criminals and should be removed from American soil. However, as US Immigration and Customs Enforcement (ICE) officers have pursued their mandate over the past year, their efforts appear to have targeted all illegal immigrants, not just those who pose a threat to the community. Pacific County in Washington State, in particular, has seen significant ICE detentions, putting the county’s shellfish farming industry at risk. Dr Kim Patten, Washington State University Extension horticulturist, says businesses find it tough to find skilled labour that will replace workers who have been detained by ICE or who have gone into hiding pre-emptively.

“It has had a huge impact on the natural resource industries that utilize that labour force – the cranberry industry, the crabbing industry and the shellfish industry. Not having workers impacts everything from to driving barges, harvesting, to maintaining facilities,” says Patten, who is also a board member of the Ocean Beach School District. He says it has been difficult to find replacements. “It’s been a huge challenge because many of the workers have been there more than 20 years and it’s hard to replace someone with that knowledge.”

The increase in ICE activity has primarily impacted smaller companies in the area. Larger companies tend to use contract labour through companies that would guarantee the paperwork of their employees. However, smaller operations generally cannot afford to utilize such services.

“Those have definitely been targeted proportionally more,” says Patten. “I’m not sure of the methods they go about doing that. It might be records of who might have gotten a DWI (driving while intoxicated) 10 or 20 years ago and going from there. Also, a lot of people who are picked up just happened to be there when ICE agents were looking for someone else.”

The issue has compounded the industry’s difficulty in attracting workers. Often, illegal immigrants are the only workforce who will stick with this type of manual labour.

“You can look in the newspaper and you can see labour wanted for this and that,” says Patten. “People get hired and they last a day and that’s that. You can’t legitimately say there’s a workforce out there that has the skillset. It’s hard work shucking oysters, for example, or digging clams. As a clam digger, for example, you work at night, rain or shine, or at three in the morning in the pouring rain. “It’s small industries that use this type of skill set that are more susceptible.”

As a member of the school board, Patten has also

noted that the school has lost many students of Hispanic origin, who are either no longer going to school out of fear, or have simply left for areas with less of an ICE presence.

Patten says he is impressed by the community response – in some cases after an ICE detention, members of the community have volunteered and held fundraisers to raise bail money, which could range between $5,000 and $20,000.

“That shows you, if they’re really the ‘bad hombres,’ the community wouldn’t be doing that,” says Patten. “That shows you the true nature of the character of the people who are being picked up.”

In spite of these efforts, however, there is a sense of helplessness in the community with regards to the issue. Even if the sheriff or the county commissioners or the governor or the state attorney general are sympathetic to the issue, there is little they can do to address it.

“They can rattle a sabre, but it doesn’t have any impact,” says Patten. “If we are targeted, as a small county, we can’t do anything about it. No matter how high you go, you can talk to our federal senators, and they’re well aware of it, but there’s little they can do.”

Patten says that one cannot yet put a dollar value on the amount of lost productivity these labour gaps will cause. But as industries move into the busy season where, for example, oyster farms would require shuckers, the financial impacts will become more pronounced. However, the impact on the individual businesses will be immediate.

“I know many small family-owned operations that are really hurting,” says Patten. “It hits right away. We’re not going to farm what we used to because we can’t harvest as many oysters, or I have to quit my other job so I can spend more time farming because my farm manager got picked up. They’re a great resource and it’s a tragic circumstance for them and for employers.”

Members of the Willapa-Grays Harbor Oyster Growers Association would not provide comment for this article due to frustrations at having been named in previous media coverage of the issue when they thought they would be kept anonymous.

Requests for comment from ICE were not returned by press time.

Not in my backyard

A New York county’s aquaculture lease program faces legal challenge from a yacht club over oyster farms in Gardiners Bay off Amagansett.

The Devon Yacht Club, which has 326 member families, claims the aquaculture lease board did not consider its user group, the recreational boaters of Devon, before it granted leases in July.

The club cited in its complaint vested property rights, historical access, and navigability, among other issues. It said roughly 120 acres “are in the heart of the area used for Devon’s members and the kids it teaches at sailing camp,” reported The East Hampton Star.

It filed a lawsuit in State Supreme Court against officials in Suffolk County, New York and agencies and leaseholders under the county’s aquaculture lease program.

It is seeking to bar the holders of leases for bottomland near the club from undertaking or continuing any action related to oyster farming at lease sites granted by the county’s aquaculture lease board in July, or

engaging in any other activity that would interfere with sailing on Gardiner’s Bay, said the report.

The parcels are leased for private, commercial shellfish cultivation. The county’s director of sustainability, Dorian Dale, said the aquaculture lease program “holds great promise in terms of improved water quality and revival of a shellfish industry that once provided considerable economic benefits, not to mention very tasty appetizers,” during public meetings held last fall.

Netting Protection

Investment

bank says prudent expansion and the efforts addressing biological challenges are behind modest forecast

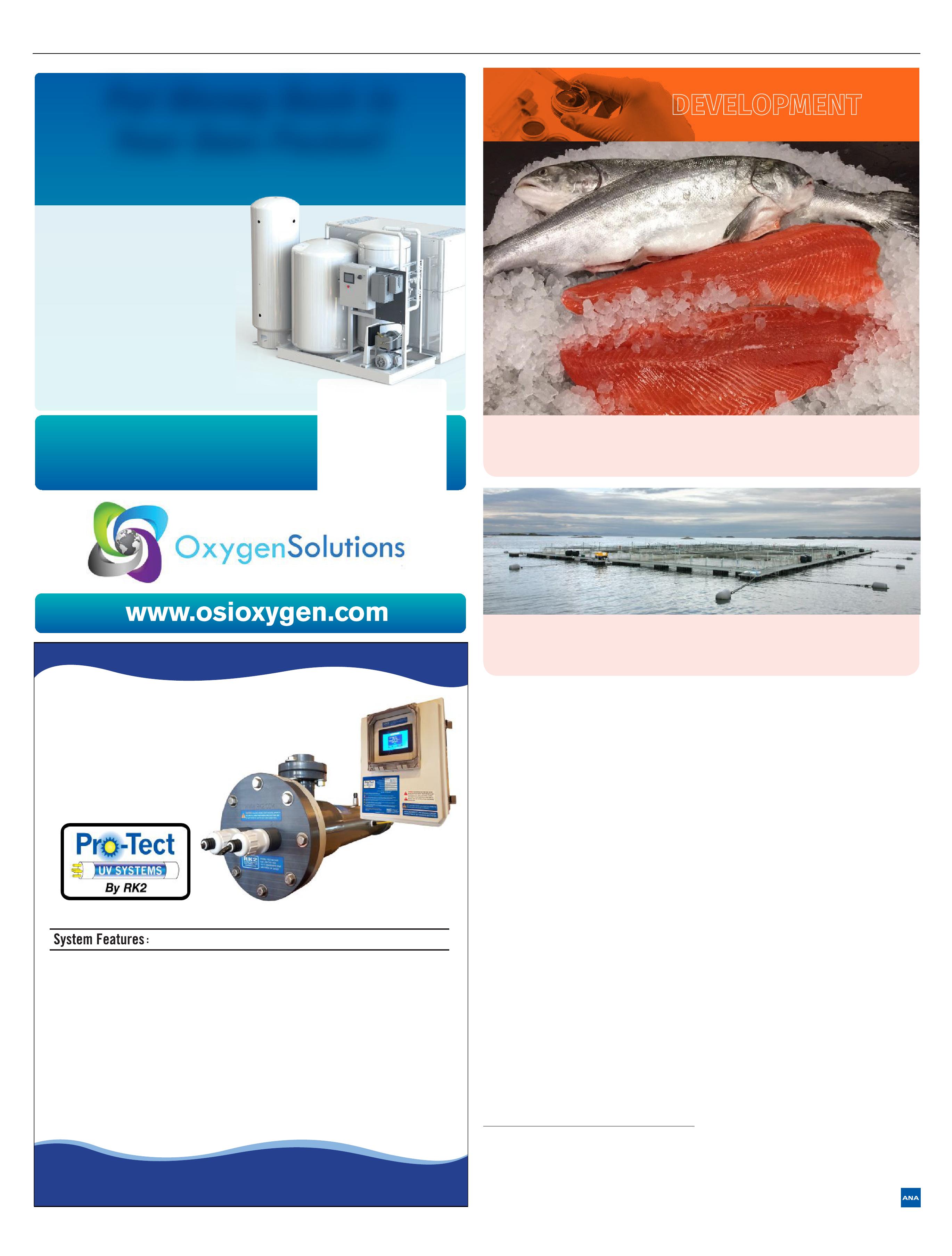

Global harvest volumes for farmed salmon will see moderate growth this year, with supply from traditional and non-conventional sources including land-based salmon farming contributing to that growth, according to an equity research analyst.

In 2016, global harvest volumes fell 7 percent due to biological challenges in the main salmon farming regions — Norway and Chile — which faced sea lice and algal bloom problems, respectively, said Tone Bjorstad Hanstad, analyst at Norwegian investment bank DNB Markets.

“Farmers are testing out new solutions to these biological challenges and, from what we are both hearing and seeing, these are showing good results now. This is one of the reasons for our expectations for some growth in 2018,” she said.

Handstad said the moderate-growth expectation is also due to the continued reluctance of governments in allowing too much growth.

Salmon net pens in Norway. Norwegian investment bank DNB Markets says prudent expansion and the efforts addressing biological challenges are behind modest forecast

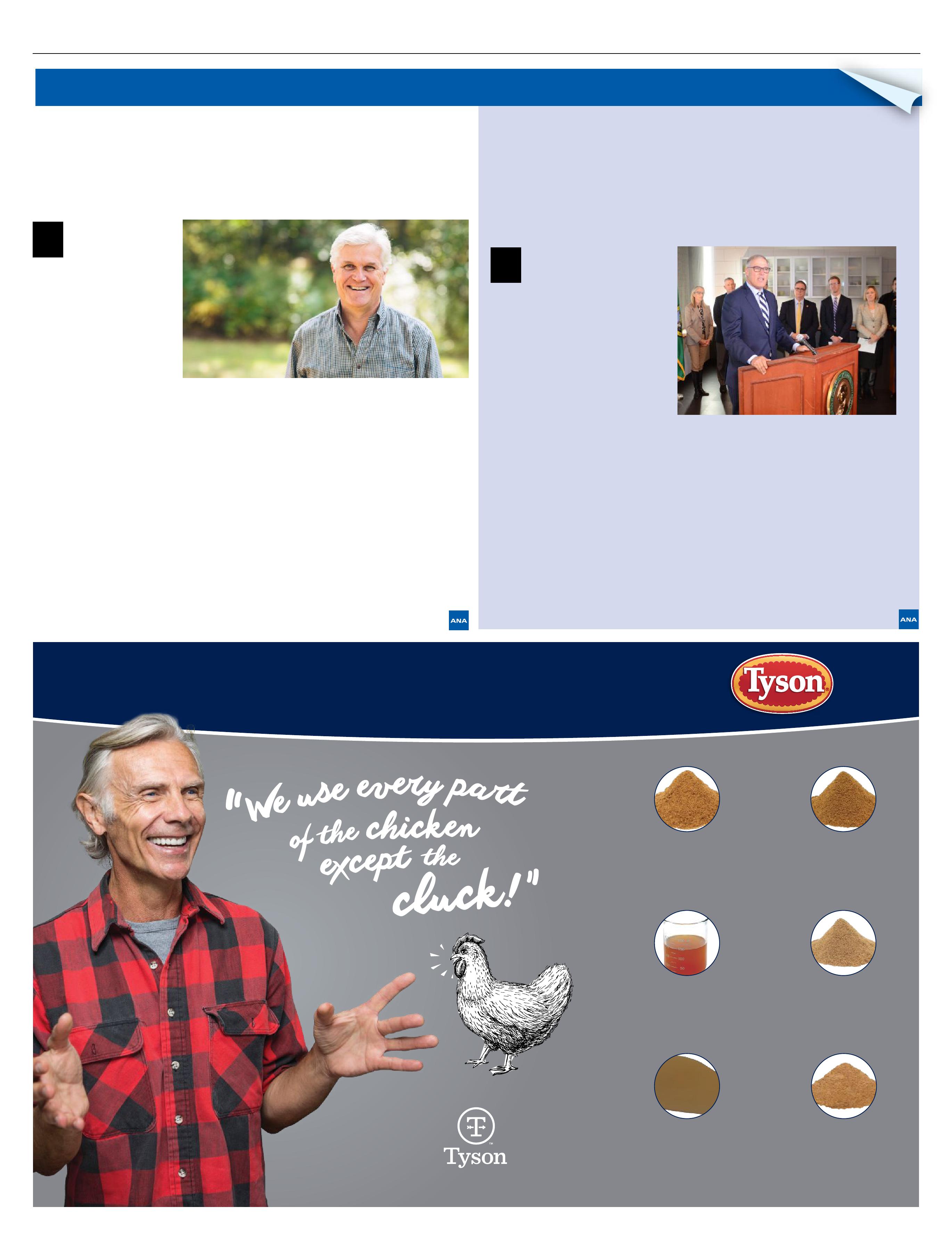

Washington State has cancelled Cooke Aquaculture’s lease at the site where net pens holding farmed Atlantic salmon collapsed last summer.

The termination comes after a state investigation found the net pen collapse could have been prevented. The company’s failure to adequately clean its nets directly contributed to the net-pen failure at the facility in August, investigation showed.

Speaking about Norway’s experience, “they’re reluctant because of the challenges that we have experienced and also due to the impact on biolife, especially on wild salmon,” she said. Sea lice problems dragged down Norway’s production volumes by 5 percent in 2016.

She described Chile as “facing a new dawn” following 2016’s dismal harvest. An algal bloom dragged down production by 20 percent that year.

“Chile is known for its volatile past with different types of biological challenges, and this has been followed by years with uncontrolled growth,” noted Handstad. “We believe in a rebound in the next years. This is due to the new regulations that are put in place, which we believe will create a more sustainable and controlled growth going forward.”

Norway and Chile account for 75 percent of global farmed salmon supply.

— Liza Mayer

Cooke was fined $332,000 for the incident. The company criticized the investigation conducted by the state’s Ecology, Fish & Wildlife, and Natural Resources departments as “incomplete and inaccurate” and “conducted by investigators with limited experience in aquaculture or net-pen operations.”

Tech-savvy oyster farmers retool shellfish supply chain

continued from cover

to highlight a new farmer at least once a week through their newsletter and their platform.

Solving the technological and logistic challenges with this model is what Knecht calls their ”secret sauce.”

“We’ve solved some of those issues with technology,” says Knecht. “We not only have our front end technology, but our backend tech helps smooth that process out. Some of them are custom and proprietary, and others are technologies that you can get; whether it’s Slack technology [a cloud-based suite of collaboration tools] or another third party that we implement into our system.”

While Real Oyster Cult has sold oysters to chefs on a limited level, the majority of the clientele is B2C — end consumers who love oyster lovers and adventurous foodies. Knecht says they are riding the wave of Plated, Blue Apron and other ready-to-cook meal kits, which opened a window into people’s buying habits. They have shipped to all 48 continental states and their most popular markets currently include Texas, Ohio, Illinois, Florida, Colorado and Pennsylvania.

Real Oyster Cult’s operation relies on technology, from their proprietary logistic tech to this gel temperature sensor used in their packaging

However, freshness is important, particularly as it comes to shellfish. As always, Real Oyster Cult answers the challenge with technology.

“We use a little gel temp sensor in our package, which provides a level of security on temperature so that the consumer knows that they’ve stayed under about 50 degrees for the whole trip to their door,” says Knecht.

CULTIVATING A COMMUNITY

While the business certainly sees booms around holidays, where customers may want oysters for celebrations and events, they also have a monthly cult membership which sends 20, 40 or 60 oysters every month. The cult membership features oysters hand curated by Knecht and McCormick.

“We’re picking some very special oysters based on what’s highly in season and what’s tasting phenomenally,” says Knecht. “They’re going to be at their peak flavours and they’re going to be the best of the best. And we also try to pick what’s not readily available everywhere, oysters you may not find at any restaurant — ones that are only locally sourced, for instance. We like to give our cult members something special.”

The cult theme may be whimsical, but it also refers to a real community and culture which McCormick and Knecht attempt to cultivate. They interact directly with their customers through a variety of platforms. McCormick notes that their Facebook page is currently blowing up with excitement over Glacier Point oysters from Halibut Cove, Alaska.

“They obviously have a really nice community of supporters around them that were able to share the story and comment on it,” says McCormick. “The oysters are truly glacier-fed. Theirs is a great story – husband and wife team, raising oysters, mussels and kids in remote Alaska. We got a chance to tell their story across our platform and on social media last week and the response was tremendous. That’s really what we’re all about, trying to spread the love – give our customers direct access to the farmers and regions that grow oysters and giving the farmers a platform to shine.”

AWARD-WINNING

In November, Real Oyster Cult were one of the eight finalists awarded a cash prize at Fish 2.0’s 2017 Innovation Forum. Fish 2.0’s release says the winners were selected for ”simplifying supply chains while increasing income for fishers and farmers, bringing to market creative approaches to aquaculture production and traceability, and getting consumers excited about seafood.”

“We had a great experience there, met a lot of great people,” says Knecht. “Getting to meet folks and hearing about their challenges and different things they were working through at start-up. It was very refreshing. We still keep in touch with the folks that we’ve met through that. Trying to help each other out and network, even on a global scale, is what’s neat about the program, for sure.”

Looking forward, they hope that the networking opportunities that Fish 2.0 offers will help them as they develop their next steps forward – expanding into international markets, and, domestically, moving into a direct chef/ pop-up model. But in the meantime, they are happy to grow their cult.

“We’ve had such a great response from people who said, ‘I never would have gotten any kind of live seafood shipped to my door. And I’ve never shucked an oyster before, but I did this, and I watched your video on how to shuck, and taught my daughter and had an amazing experience,’” says McCormick. “That is just so much fun for us. We converted them.”

Top Gun competition now open to aquaculture startups

A business accelerator program is set to accept applicants from aquaculture companies for the first time. The Maine Centre for Entrepreneur (MCE) Top Gun program is a 15-week entrepreneurial boot camp, designed to support Maine entrepreneurship and to help companies grow. This spring will see aquaculturefocused sessions in Brunswick, Maine.

“We never themed Top Gun around any particular industry, but we decided this year that we would launch a Top Gun cohort that was specifically themed around aquaculture,” says MCE Executive Director Tom Rainey.

John Pavan, program coordinator and subject matter expert for the program, says the aquaculture program was developed in partnership with the Gulf of Maine Research Institute. Pavan is currently helping to secure participants and industry experts that will give presentations.

“I want to ensure a good cross section of participants,” says Pavan. “The participants learn from one another, so we’re trying to

make sure they represent as many parts of the industry as possible. The goal is not to grow a handful of companies, but to grow an industry.”

The Top Gun program ends with a pitch-off competition, where the two finalists come to an annual showcase event in May or June to compete for the cash prize of $25,000. In addition, the Gulf of Maine Research Institute has also promised to give a $5,000 prize to each of the top two finalists from the aquaculture sector. The institute is also offering a $200 scholarship to each company that participates to help offset the $500 Top Gun entry fee.

— Matt Jones

Anti-salmon farming bill advances

Washington State Governor, Senate support bill

Abill calling for a ban on salmon farms in Washington State has received support from Gov. Jay Inslee and the state Senate.

The bill passed the senate by a vote of 35-12, reported the Seattle Times. If approved by the House, Atlantic salmon net-pen farming in Washington will end after current leases expire by 2025.

The salmon escape incident at a Cooke Aquaculture farm in the state invited intense scrutiny on the industry and intensified calls to ban salmon farming. Protestors are concerned over the perceived effects of foreign fish on wild Pacific salmon native to the area.

A state investigation found Cooke Aquaculture was negligent in operating its net pen. “Cooke absolutely could have – and should have – prevented this incident,” the investigation said.

Inslee called such farming “a risk that is intolerable.” “This risk is simply too great,” Inslee said. “It is no longer acceptable to the people of the state of Washington to expose our waters to the threat of Atlantic salmon net pens.”

Joel Richardson, Vice President Public Relations at Cooke Aquaculture, told Aquaculture North America (ANA): “While disappointed in this direction, our familyowned company and our local employees are committed to working with legislators and regulators to continue operating our Washington fish farming sites sustainably.”

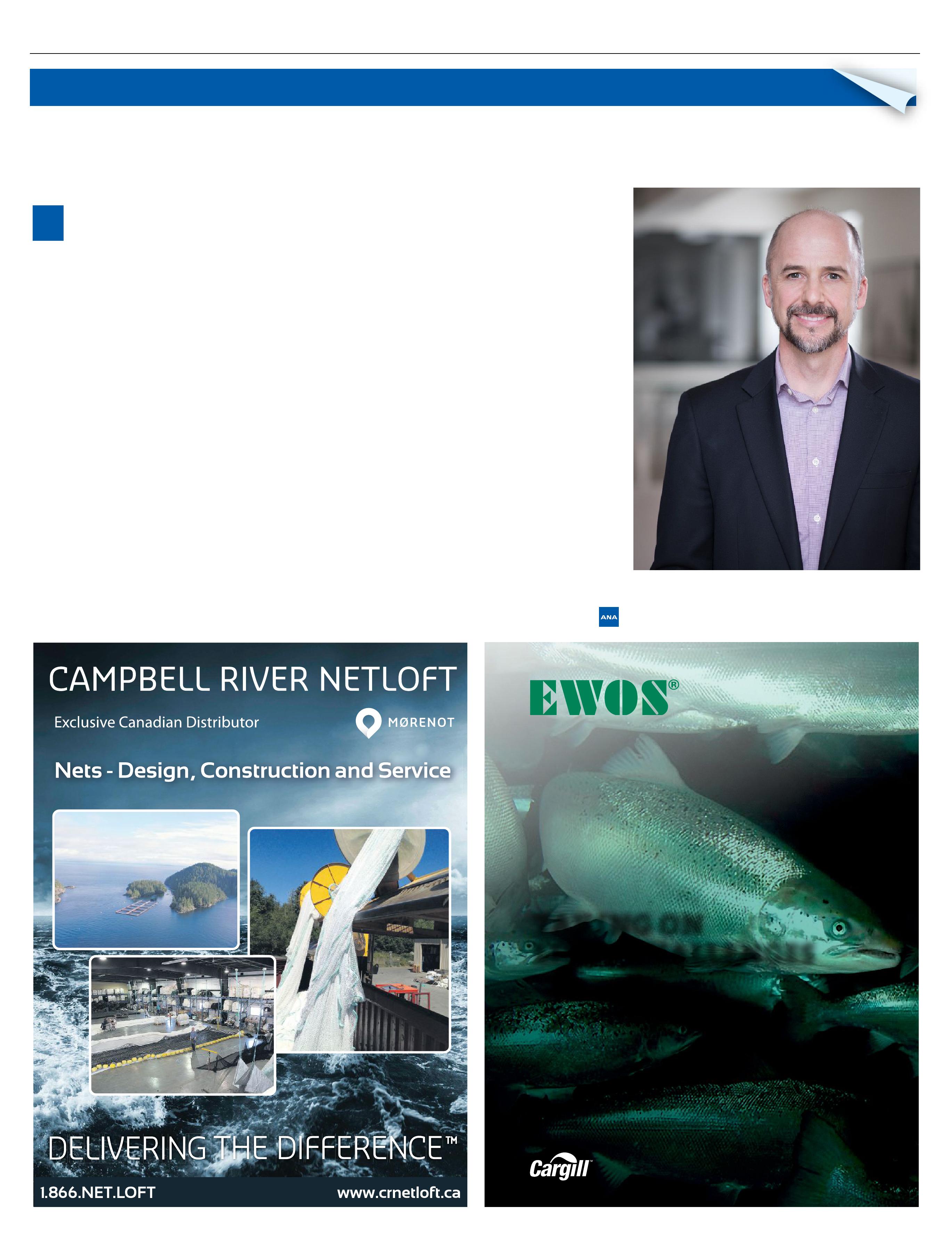

Support for Canadian aquaculture is strong, says CAIA head

‘Community support for aquaculture is strong but one weakness will stem industry growth.’

Support for the aquaculture industry in Canada is strong despite “vociferous” resistance from a small number of opponents, according to the new executive director of the Canadian Aquaculture Industry Alliance (CAIA).

“From research we did in the fall we know that the support for aquaculture in Canada, even in British Columbia, is actually very high,” says Tim Kennedy, who was appointed in April last year.

“The small number of very strong, vociferous opponents in BC has a very large voice but they are an extreme case. Generally across the country the support for, and interest in, our sector is strong.”

“There are regressive environmental organizations that are still stuck in the 1980’s and 90’s that are not looking at the bigger picture here,” he adds. “If they are constantly threatening to try to get governments to shut down our sector, they are working against the environment.”

He says there’s much more positive messaging about aquaculture’s potential as a sustainable mode of food production from a number of large international conservation organizations such as Nature Conservancy International.

“If we had a constructive process dialogue, with some smart environmental groups that were really dedicated to seeing true improvement, not dedicated to shutting down our sector, we could really progress much faster to a real solution to the global seafood challenge,” he says.

Images of the twisted and torn Cooke salmon pens in Washington State last fall had an effect on the Canadian farmed salmon industry. “It was a US incident, but there is no question it sparked a lot of activism on the west coast

and the federal government has felt a lot of heat due to that,” says Kennedy. “We are performing at a very high level on the west coast.

Salmon escaping from pens is not new, but he says “new people in the government don’t have any history on the files so they will say, ‘oh my gosh the sky is falling’.”

Kennedy says he spends “a fair bit” of time trying to address the facts of aquaculture as much as possible with Members of Parliament.

As a national association, CAIA’s role is to represent all seafood farmers at the Canadian Federal government level on policy, and to take the lead in international communications, Kennedy explains.

Aquaculture is present in all 10 provinces and the Yukon Territory. Its biggest challenge is the lack of a department at the federal level that champions the industry,” says Kennedy. “We need a Canadian Aquaculture Act and a department that takes a lead.”

What Canada has is the DFO (Fisheries and Oceans Canada), which has the mandate to conserve and manage Canada’s fisheries and safeguard its waters, Kennedy points out. “Other nations, like Norway for example, has a very strong growth and support component.”

He believes lack of support at the federal level will stem aquaculture’s growth. “We cannot grow this sector and compete effectively unless we have clarity around the responsibility of the federal government,” Kennedy says. “DFO has said ‘we will take aquaculture’, but they have never said ‘we will adopt a new mandate that allows us to support the aquaculture industry in Canada’.”

It’s time for DFO to fish or cut bait,” he quips, “We are not moving forward effectively.”

Egg-to-market operation helps boost tilapia’s acceptance

continued from cover

of the Kohala operations, in addition to being the most easily acquired and easyto-rear fish, with a fast growth rate and great market versatility. Water for the fish is sourced from a spring inside nearby Kohala Mountain and after flowing through the fish farm, it’s filtered through water cress tanks and settling ponds before moving into various gardens and macadamia nut orchards. Fish farm sludge is composted with processing waste and Institute green waste to fertilize cattle pastures.

KMFC uses a batch harvesting method and a stocking density of 60 kg/m3, with egg-to-harvest timelines of six to nine months. The hatchery has 10 recirculating 600-gal round broodstock holding tanks, three 1,000-gal spawning tanks, 12 McDonald upwelling hatching jars and 24 self-contained 150-gal fry-rearing tanks. The nursery consists of 36 1,000-gal round tanks on three recirculating systems. Grow-out occurs in 47 30,000-gal round tanks, operating as completely flowthrough to completely recirculated.

No antibiotics or other substances are used to farm the fish, and the feed is all “certified sustainable” from Ewos. Oliva’s relationship with Ewos began over a decade ago when he was the manager of a salmon hatchery in Alaska. There he found Ewos outperformed other feeds and he formed a great relationship with the Ewos feed rep. He says all the Ewos feeds have been useful at KMFC, but especially the #00 micro diet. “[It] has reduced mortalities in our swim-up fry (first feeding) by about 50 percent over the #0 feed and…a doubling in growth rate.”

It’s in KMFC’s feed trials in the grow-out phase, however, where Oliva says Ewos’ knowledge in fish nutrition and feed manufacturing has been particularly valuable. KMFC’s fish are red tilapia, and in Oliva’s words, “we wanted something that would make their color pop. We had Ewos add some astaxanthin to the feeds, which has the additional benefit of providing antioxidants to the diet. The fish responded beautifully with color and vigor.” A colour change in the flesh (desired by some customers) is achieved through longer feed duration and higher amounts of astaxanthin. KMFC’s latest trial involves feed higher in protein and fat to produce fish that really smoke well, and initial results look promising, Oliva says.

FARM-TO-MARKET

It was critical from the start for KMFC to be an integrated operation — from egg to processing — because Hawaii has strict importation rules, Oliva adds. This arrangement also circumvents the increasing threat of tilapia lake virus (TiLV) reaching the islands. Having a processing facility is “necessary to be able to sell and market the amount of tilapia we are producing and will be producing,” says Oliva. “We have 1 million lbs of fish ready now and we hope to have at least moved 3 million lbs through the system by years’ end. With the completion of our fish processing facility slated for March, we will be looking to bring our satellite co-op farms on board. We provide the technical and biological expertise, the seed stock and feed to the farmers, so we will be able to control the quality and consistency.”

In addition, KMFC will expand its hatchery and nursery, and add 40 more grow-out tanks. The firm will start shipping its production to mainland wholesale distributors and also start producing whole frozen fish and fillets (including a very

frozen fillet for the USDA farm-to-school program). “We even have interest in our product from buyers in South Korea,” Oliva reports. Over his nearly 30 years in aquaculture, Oliva has seen consumer attitudes fluctuate, and notes that the times where consumer perception is down were usually a result of unsubstantiated rumors started by a person or group with an agenda. When a fish farmer or the industry in general can address legitimate concerns with scientific truth however, he notes public attitudes become positive. Oliva believes the future is bright for aquaculture as the need for healthy, sustainable protein grows.

AQUATIC

• EPA registered broad spectrum disinfectant and virucide*

• Maximum 10 minute contact time

• For use in cleaning and disinfecting environmental surfaces associated with aquaculture

Pellet-based vaccine against VNN in the offing

Proprietary vaccine technology a potential game changer

ABaltimore, Maryland startup has come up with a novel way of battling Viral Nervous Necrosis (VNN), a disease that affects over 40 aquaculture species worldwide.

Dr Ken Malone, CEO of startup VakSea Inc, says the aquaculture industry’s big problem has not been the absence of effective vaccine, rather, it is in the way those vaccines are delivered.

“Current methods of delivering vaccines to fish involves injecting fish with vaccine one by one, which is expensive, labor intensive, and stressful to the fish,” says Malone.

VakSea grows the vaccine inside insect larvae, grinds up the larvae, mixes it into fish feed, then feeds it directly to the fish. When the fish eats the feed, they become immune to the disease.

The startup’s proprietary vaccine technology was developed at the University of Maryland Baltimore County in the lab of Dr Vik Vakharia beginning in 2014. VakSea filed a provisional patent application in 2016. It is now developing a pellet-based vaccine aimed at protecting European seabass juveniles from VNN and hopes to get it to market over the next 12 to 18 months.

Organic

Correction

VNN “damages the central nervous system in susceptible fish species and typically affect younger stages of fish (larvae, fry, fingerlings), although older, market-size fish can be affected as well, with losses ranging from 15–100 percent,” according to University of Florida-IFAS Extension researcher Roy P. E. Yanong, in his paper Viral Nervous Necrosis (Betanodavirus) Infections in Fish.

“Infected larvae and juvenile stages often show abnormal swimming behaviour, including vertical positioning and spinning; flexing of the body,” he wrote.

Species susceptible to VNN include red drum, cobia, sea bass, barramundi, gilthead seabream, Pacific bluefin tuna, various grouper species, various flatfish species including halibut and Japanese flounder, and tilapia.

Malone is confident of the potential of VakSea’s proprietary vaccine technology in other species. “We’ve proven it out on the nervous necrosis virus and we know it’s going to work on a large number of species and a large number of other diseases,” he says.

Today’s modern aquaculture farmer needs a partner that is able to help with the scope and variety of challenges they face every day. That is why Pentair has assembled a team of experts with diverse backgrounds in aquaculture, biological and technological engineering that is grounded in decades of research and commercial industry application experience. We help our customers run successful operations by providing the design expertise they need, a responsive service team and the largest selection of equipment and supplies in the industry. Trust in a team that’s here to help you—ASK US!

Incorrect information was provided for a profile on Creative Salmon that appeared on page 10 of the Jan/Feb 2018 issue of Aquaculture North America. The company stopped using antibiotics for market fish in 2001, not 2011.

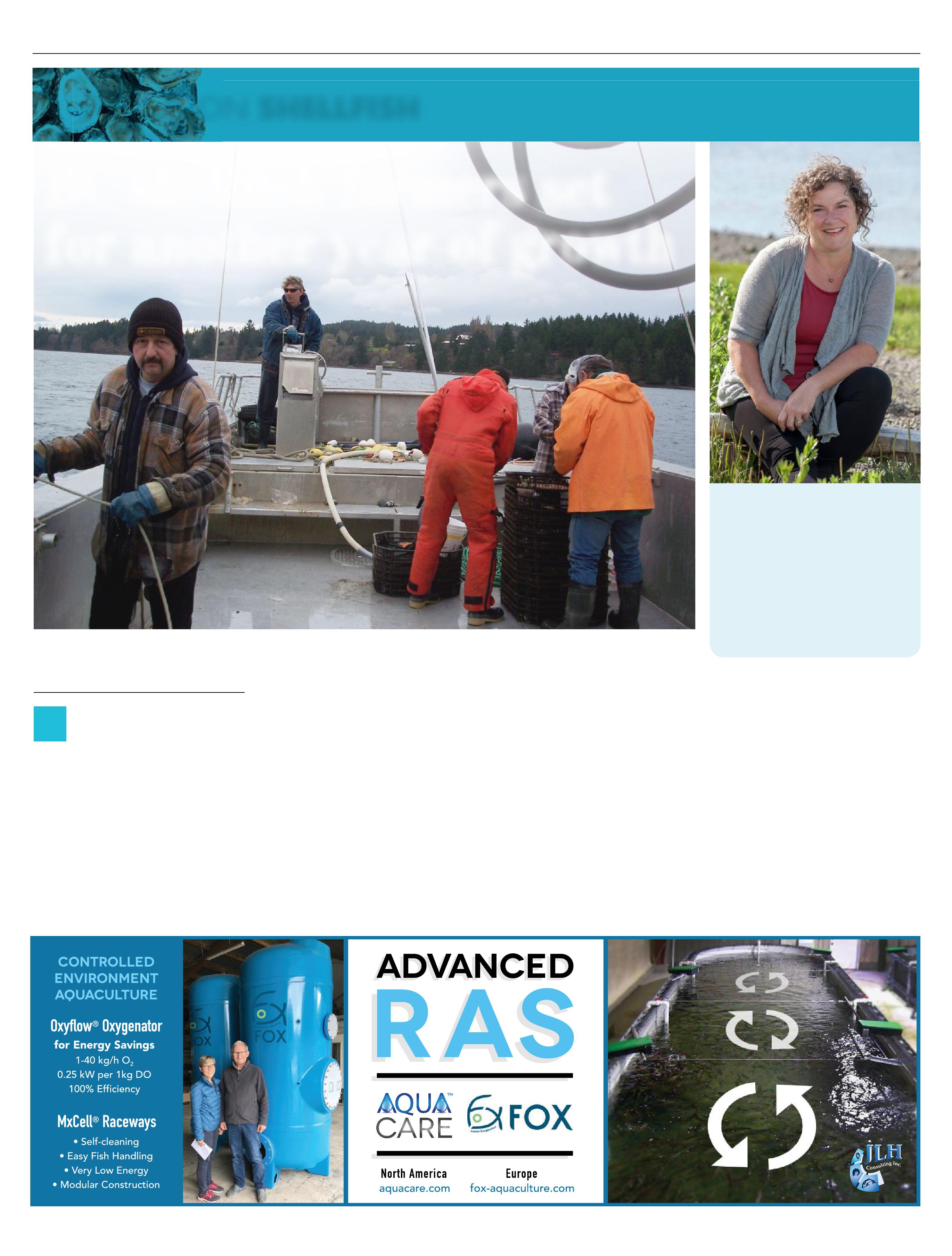

BC shellfish farmers set for another year of growth

FOCUS ON SHELLFISH FOCUS ON SHELLFISH FOCUS ON SHELLFISH

2017

successful despite challenges, says BCSGA

BY MATT JONES

Shellfish famers in British Columbia faced an interesting problem in 2017: there was more demand than they could supply.

“All production was spoken for, no farmer had any problem selling his shellfish. The biggest problem was producing enough to meet the demand,” says Darlene Winterburn, executive director of the BC Shellfish Growers Association (BCSGA).

Behind the industry’s struggle to meet demand is the regulatory process for assigning, modifying or expanding tenures for shellfish farms. The lengthy process limits industry expansion and it is

a challenge that the association continues to work towards a resolution.

“The government came up with a new harmonized form this year, we’ll see how that works out,” says Winterburn.

“We’re hopeful that it will be a positive change. We’re working with the government on addressing problems because we are limited in our ability to expand production. It also raises issues around the level of security that people have when investing in infrastructure to increase their production. But everybody is working together.”

2017 began with a significant challenge as the winter season saw an outbreak of norovirus. The British Columbia Medical Journal eventually

attributed that outbreak to sewagerelated contamination spread by ocean currents. Winterburn says the association worked with all levels of government to address the issue. A working group including the BCSGA, government and other stakeholders modified the Canadian Shellfish Sanitation Program to include site response measures, including temporary shellfish closures. The program is run by the Canadian Food Inspection Agency.

“With that, there has been a broader awareness of the importance of clean water to produce healthy animals, which are critical to a healthy people and a healthy planet,” says Winterburn. “Safety of our products is a top priority and, as

LEFT: Innovative and hardworking individuals help BC’s shellfish industry thrive

an industry, we do everything we can to ensure that.”

The installation of a “Burke-oLator” water-quality monitoring device in Baynes Sound was another positive development for the industry. The device collects real-time ocean acidification data, enabling shellfish farmers to make informed decisions on when to grow larvae, when to set juvenile oysters out into the field, or when to draw the thousands of gallons of seawater they need to fill their tanks, for instance. The project is a joint effort between BCSGA and the Vancouver Island University. Live feed of data is open to the general public.

“This is going to provide really strong foundational data that pertains to environmental intelligence in Baynes

FOCUS ON SHELLFISH

FOCUS ON SHELLFISH

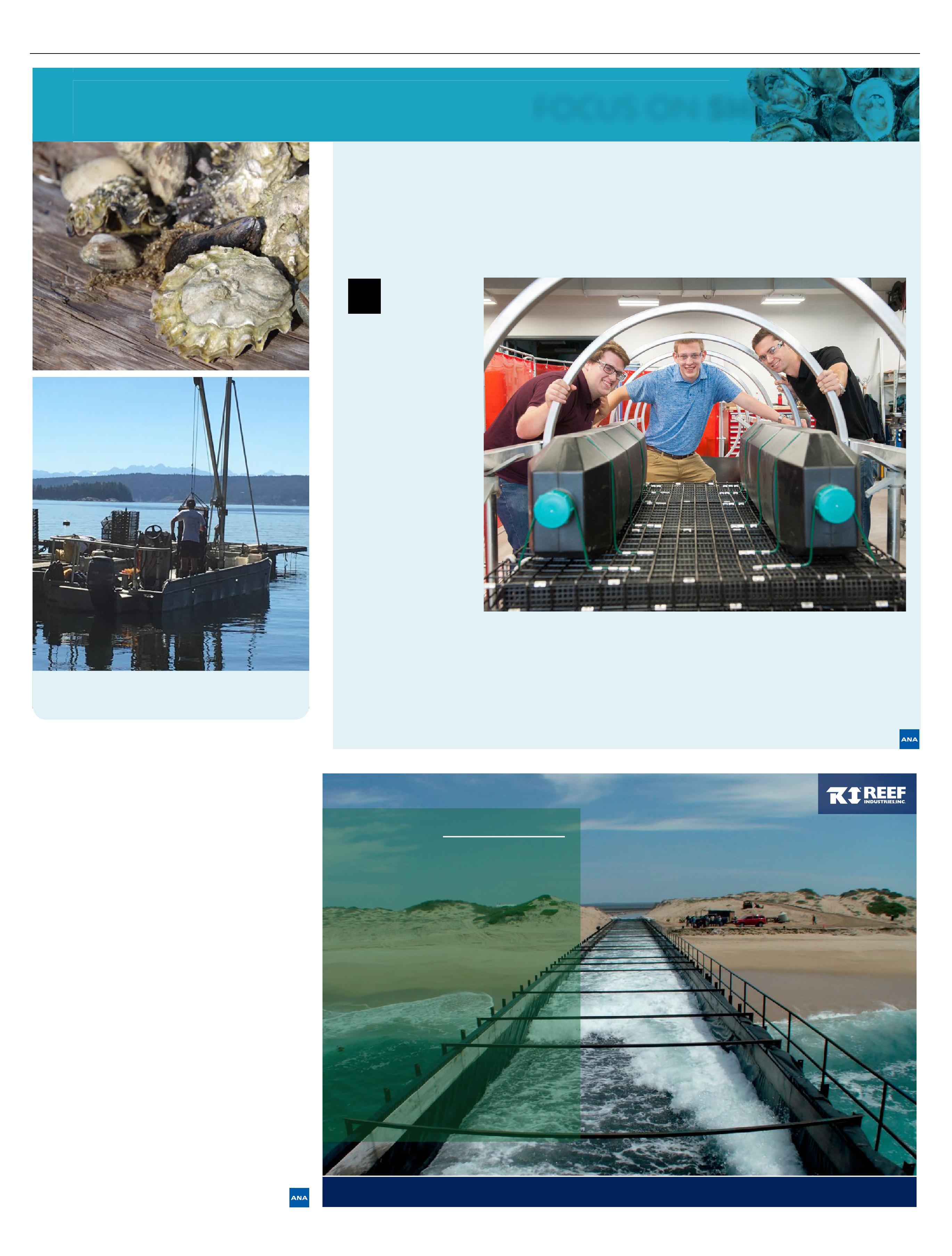

Three engineering students in Prince Edward Island, Canada have invented a tool that could make one laborintensive task in shellfish farming a thing of the past.

The invention flips oyster cages mechanically, which shellfish farmers currently do manually. The floating shellfish cages need to be flipped often to expose parasites like barnacles, algae and mussels to sunlight in order to kill them.

“Currently the cages are all flipped manually, usually by two or three guys and (the cages) weigh about 200 or 300 lbs,” one of the students, Dylan MacIssac, told The Chronicle Herald. “They also work right up until the ice forms. They’re basically doing 200-lbs dead lifts for 10 to 12 hours a day.”

The students have since formed a company, called Island AquaTech, to further develop their invention.

non-equity funding with $20,000 from Springboard Atlantic and $25,000 from Innovation PEI’s Ignition Fund. The co-founders plan to use the funds to help produce their prototype, says the report.

Sound and it’s going to be key for all sorts of science,” says Winterburn. “It’s going to be quite invaluable as we’re looking at global issues as well as industryspecific issues.”

Another challenge that the association is addressing is debris from shellfish farms that strong winds cast out into the ocean. As earlier reported in Aquaculture North America, BCSGA led a “Turn It In Week” over the summer, where the association and partners set up large bins in strategic locations around the province, enabling farmers to easily dispose disused equipment and other refuse from their farms. BCSGA also collaborated with Fisheries and Oceans Canada (DFO) to organize a beach clean up on Denman Island and other beaches in the area.

“We still have some work to do, but the vast majority of our farmers are quite responsible,” says Winterburn. “While they’re out doing their business, whether they’re on the farm or travelling back and forth, debris is an issue. They’ll stop and pick it up, they want to make sure that their beach is in a good state of care. As an association, we encourage our members to be good neighbours.”

Other issues that the industry faced in 2017 included feed availability, high cost of equipment and the need for more research on production. The association is addressing these through collaborations with the Hakai Institue and the Vancouver Island University.

“People are being really proactive to expand our capacity and to work through some of our issues,” says Winterburn. “We have no problem selling the product we have – there’s a shortage of product. What we need are ways to enhance our production and to do that we need to overcome these challenges. If we’re able to jump those hurdles, the potential is limitless.”

To date, the young company has raised $55,000 in

FOCUS ON SHELLFISH

Small but beautiful

ON SHELLFISH

BY TOM WALKER

Like many kids on the east coast of Vancouver Island in the ‘60s and the ‘70s Keith Reid grew up messing around with boats and the sea. “I worked for an oyster farmer in the summer,” recalls Reid. “I apprenticed as a wooden boat builder and worked at that for about 10 years and then I was a commercial fisherman during the 1980s.”

“My dad had a small oyster lease here in Deep Bay, but it was something I tried to stay away from,” Reid chuckles. “I knew, from summers as a kid, how much hard work it was. “

But the wild catch was dwindling and there were too many boats in the fleet. “They would do crazy things like have a two-hour opening (for fisheries),” says Reid. He started to look for something else to do in the winter to balance out his fishing season and help support his family. “My dad was just ranching his oyster lease, he didn’t produce a lot of product. But the more I looked, the more I saw the incredible potential. The environment in Baynes Sound is so ideal for growing oysters,” says Reid.

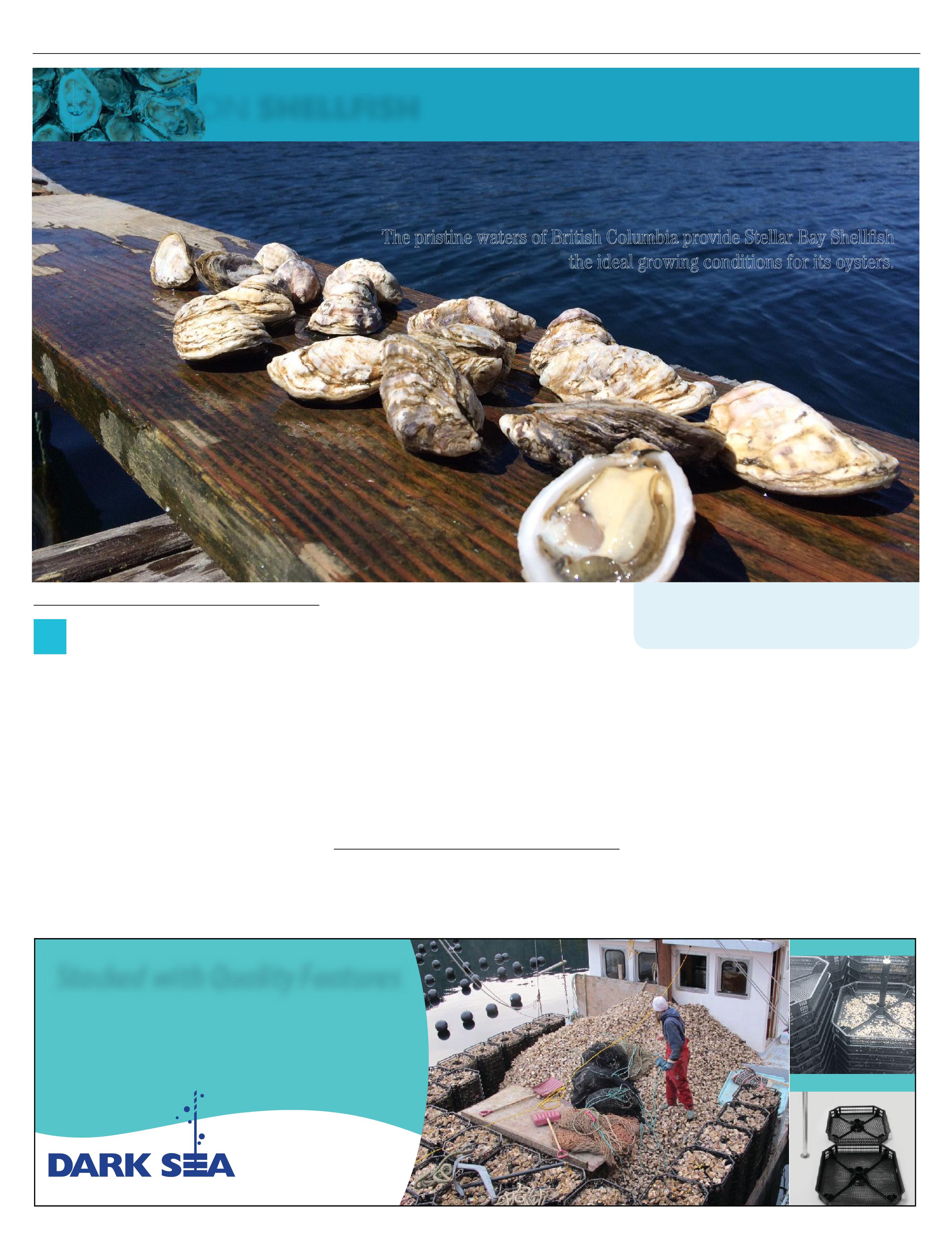

Baynes Sound is a narrow protected channel between

Vancouver Island and Denman Island in British Columbia. Some 25 miles long and between one and two miles wide, it produces 50 percent of the cultured shellfish in BC. Deep Bay is tucked inside a peninsula that juts into the sound.

Tapping into that potential, Reid started Stellar Bay Shellfish, now one of the largest half-shell producers in BC and indeed all of Canada. “I started my oyster education in 1991,” Reid says. “I asked my dad if he’d sell me his lease and he gave it to me. For the first couple of years I worked the oysters and the salmon boat together but by 1993, I went full time into oyster farming.”

That original 30-acre lease of his father’s has been expanded to 130 acres. Roughly 98 percent of the oysters have been moved off the beach out into deep water and Reid has built a stable of customers across North America and Asia for his specialty, Kusshi oyster.

EGG TO MARKET

“Kusshi” – Japanese word for “precious” – starts as a Japanese oyster seed (Crassostrea gigas) that is carefully managed in deepwater trays. “It’s proprietary,” says

A labor-intensive proprietary process over the course of 18-24 months results to these

Reid, “but I can tell you we screen and sort a lot and we use custom-built equipment to tumble the oysters. The result is a cocktail-size product after 18-24 months of grow-out.”

It’s a lot more labor-intensive than other growout systems, Reid admits. And there’s a lot of work to manage the inventory. “I need to be sure that I have enough product in November to last me through the winter to the start of growing season in April.” He currently tracks stock in 80,000 trays, but expects to nearly double that this spring, bringing another 50,000 to 60,000 trays into production.

Seed supply is a perennial problem for oyster growers on the Canadian west coast. “We don’t have enough production capacity here right now. We have several hatcheries that are expanding and I buy some product from every one of them to spread out the risk,” he says.

He plans to buy 60 million seeds this year. “I couldn’t risk the chance that one or two growers might run into

FOCUS ON SHELLFISH

a problem and couldn’t deliver.” For that same reason Reid says he wouldn’t build or rely on a hatchery of his own.

He says he is buying about 50 percent of his seeds from Chile. “I have been working with a company down there to select some of the broodstock traits that I want for the Kusshi oysters.”

A group of hand-picked distributors deliver product locally, to the east coasts of Canada and the US and down the US west coast. About 80 percent is exported, with the US market accounting for the majority of that, while Asia accounts for about 5 percent. “We are slowly working to develop markets in Asia for our increasing production,” Reid says.

His processing plant is styled after a Boca Raton Florida mansion, featuring a 20-foot fountain in front. Although Stellar Bay ships out all of its oysters to seafood distributors, Reid’s vision during the building’s construction was to offer an “attractive place” for people to come and buy oysters. There are no tired flatbed trucks rusting in the yard, nor dilapidated boats pulled up on the shore.

“We have worked really hard to build social license along the coast,” he says. “At one time there was a petition out there to get oyster farms pulled out of the water. Now, I am the largest employer in the area.

“When I go to a meeting about a new development in the region, I don’t have to sing about water quality, I have other people championing that for me.”

BC AT A STANDSTILL

But while he has built a successful business, Reid is not optimistic about the growth of the oyster industry in BC. He describes it as “paralyzed.” “You can’t get a lease, you can’t get a permit to expand a lease, or to change a management plan, or to add a new species. You submit an application, it goes into the system and just sits there.” Some leases are only renewed for one year and that’s not enough security to take to the bank when

Founder Keith Reid says seed supply is a perennial problem for oyster growers on the Canadian west coast. ‘I buy some product from every one of these suppliers to spread out the risk,’ he says

one needs financing, he adds.

The problem, he says, is the process of First Nations consultation and a lack of agreement between the provincial and federal governments. One level of government will say there has been enough consultation but the other will disagree.

“They say that the First Nations do not have a veto, but it has certainly stopped the industry from moving,” he says.

As with salmon farms in BC, the dispute is about the rights of First Nations to decide what goes on in their traditional territories.

“That’s something the governments have to work out,” says Reid. “And until they do, we are at a standstill.”

FOCUS ON SHELLFISH

Oyster farmers find strength in numbers

FOCUS ON SHELLFISH

BY MATT JONES

TFOCUS ON SHELLFISH

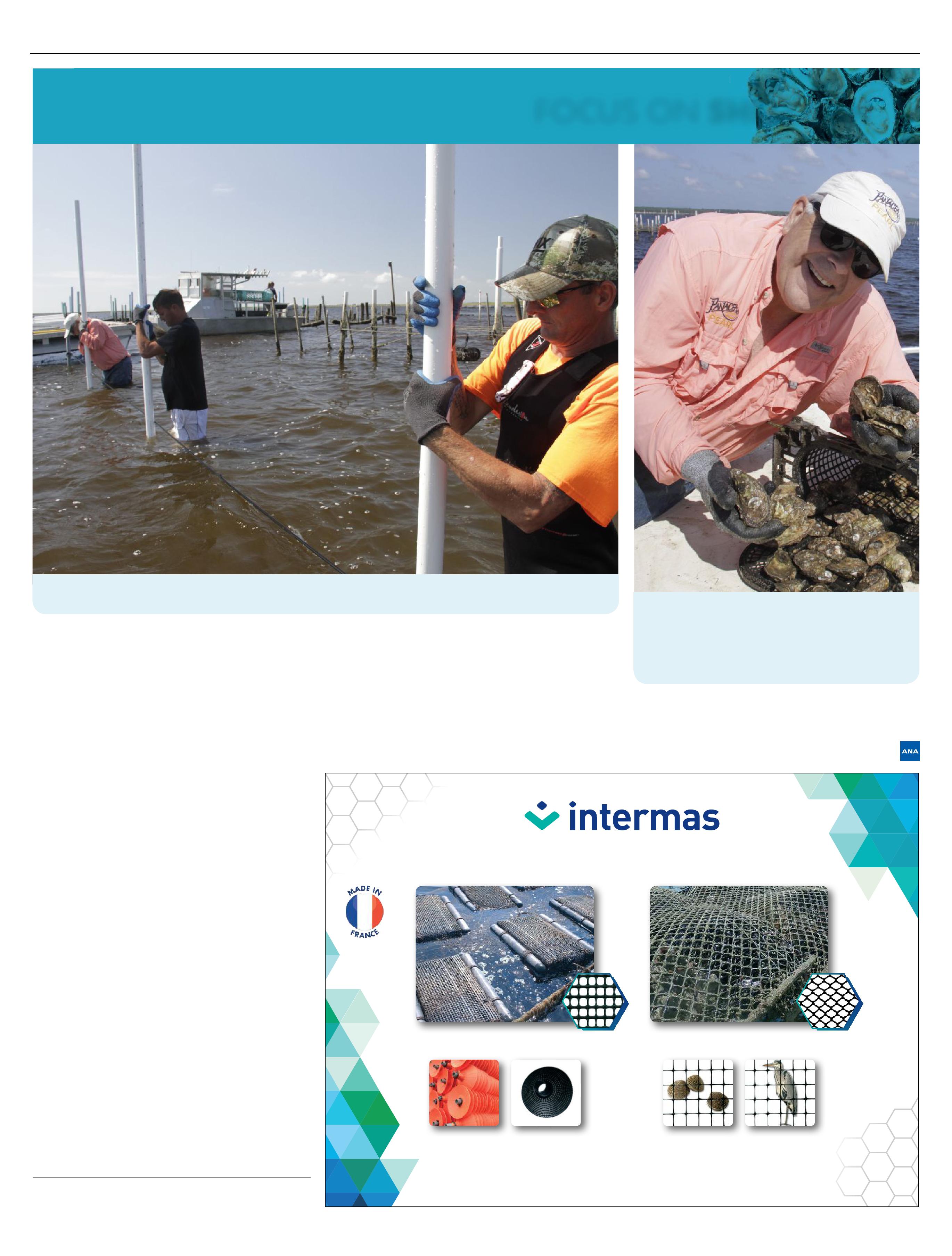

he Panacea Oyster Co-op is a collaborative enterprise borne out of a desire to strengthen and revitalize oyster farming in Florida’s Apalachee Bay and other parts of the estuary. By bringing together individual farmers to work towards a common goal, the co-op has brought its members collective benefits. Its efforts are paying off, for the co-op has been championed by US sustainable seafood investment forum, Fish 2.0.

The co-op was formed two years ago by a group of classmates at the Wakulla Environmental Institute’s Oyster Aquaculture program. While working on separate aquaculture operations, an Australian equipment supplier suggested that they consider forming a cooperative. It didn’t take much convincing; the group voted Rob Olin as CEO and, later, as chairman of the board.

“We just cobbled a team of very diverse but incredibly talented professionals together for the business side,” says Olin. “I think we’ve attained our goal, which is to provide our members with everything they need — support in terms of accounting, legal, finance, operations, and advertising and marketing. So all they have to worry about is growing the perfect oyster. We now have a pretty substantial juggernaut.”

A FOR-PROFIT CO-OP

The co-op provides seed, ongoing training, technology and a guaranteed place to sell their product, at a guaranteed price. They also help them make effective business plans.

A key difference with many co-ops, Olin notes, is Panacea’s for-profit nature. “We have to have investors to

build the infrastructure we needed. We have to have enough money to buy the marina to house everything. We had to have an actual structure for a USDA loan, so in that way we’re different.”

As CEO and chairman, Olin is the decision-maker for a lot of day-to-day issues, however, larger questions regarding operations or philosophical changes are made with the 30 members of the co-op. The rancher members and the board of directors both meet once a month, in additional to an annual shareholders’ meeting.

“We’ve been able to enhance the rancher’s performance by way of the financial allowance and economies of scale that we bring to the table,” says Olin. “This is brand new. And like anything you do that’s brand new, it’s like walking into a hotel room when the lights are off. You stumble around and you find your way and you start to get a rhythm, then you start to elevate your performance, and from that elevation you move on to perfect performance. We’ve been able to cover so much ground as a team that we could never have gotten done as any one individual.”

The co-op also benefits from their location, next to Florida’s Spring Creek, the largest freshwater spring in the world. The pure spring water flows through and mixes with the saltwater, making up North America’s most diverse estuary. Olin says this allows for algae to thrive, which feeds the oysters and allows them to grow more quickly. The location also has two tides per

FOCUS ON SHELLFISH

FOCUS ON SHELLFISH

day, which keeps nutrients moving in and out.

“When you’ve got oysters that rely on filtering more than 50 gallons of water per day, giving them the mega nutrients that our waters do, that allows them to grow faster than anywhere else on the planet.”

The farming operations are centered around the Apalachee Bay, which is part of the same estuary as the Apalachicola Bay. Farmers in the Apalachicola Bay harvested as much as 100 million oysters per year five years ago, but this has gone down to less than five million now. Olin hopes Panacea’s efforts to resurrect the oyster industry in Apalachee Bay will inspire farmers in the Apalachicola Bay.

“We’re putting the money, capital and effort back into building the infrastructure into Apalachee Bay,” says Olin. “Hopefully folks in Apalachicola Bay will see the magic that happens from this reintroduction of oysters – a totally different way to harvest and they’ll embrace it and start doing it over in their own bay and bring back that incredible potential that they once had.”

Panacea Oyster Co-op was one of the winners of the recent Fish 2.0 competition. The co-op’s ability to organize people and motivate them to commit to a shared endeavour has been a key factor behind its win, says Olin. Part of the appeal for many in the oyster farming industry is the independence and freedom it allows, but the co-op has convinced its members to give up some of that freedom for the greater good.

“It’s kind of like the old west,” says Olin. “You’ve got a bunch of independent water cowboys and cowgirls. They can make their own agenda for the day because they can adjust to the tide, wind, temperature and current. They don’t especially like to be collaborators or joiners. But here, because the old ways—commercial fishing and commercial oyster harvesting—were gone forever, they saw hope in this new technology, this new way of doing things. And they committed, even though it went totally against their natural instincts and they’re building something much bigger than themselves.”

VISION

The goal of the co-op is to establish their model as a

prototype that can be adapted in different areas, either as satellite operations, or the co-op can provide its services as mentors and consultants. The important thing is to help the industry get firmly established.

Oysters are the ideal panacea not only to help supply the world’s growing need for food but also to keep the waters healthy, says Olin. “Oysters are essential for the survival of 3,000 aquatic species. They’re the original filters in the aquarium. Take the filters out, the aquarium dies. Put the filters back, the aquarium comes back to

‘They committed, even though it went totally against their natural instincts and they’re building something much bigger than themselves,’ says Panacea Oyster Co-op CEO and chairman Rob Olin on co-op members

life. The best thing we can do is put filters back in the aquarium. The best way to do that is through aquaculture. The best way to make sure coastal communities see it is through this collective collaboration of a co-op.”

FOCUS ON SHELLFISH

Connecticut shellfish sales on upswing

FOCUS ON SHELLFISH

Industry sales have increased 100 percent between 2007 and 2015

FOCUS ON SHELLFISH

Areport from the University of Connecticut shows that the state’s shellfish industry has grown drastically, with all indications showing that trend will continue. Sales between 2007 and 2015 increased by nearly 100 percent, to a value of nearly $30 million in 2015. Connecticut Sea Grant, meanwhile, is conducting a more comprehensive study into the state’s industry, which will be completed by October this year.

Every five years, the University of Connecticut conducts an economic assessment of the entire agriculture industry, taking raw harvest data and estimating the multiplier effects on the economy. It also looks at direct

sales, jobs and how that revenue plays out in the local and state economy.

“There’s been a gradual increase in oyster production,” says Tessa Getchis, aquaculture extension specialist and educator with the Connecticut Sea Grant and UConn

Extension Program. “We had a disease event in the late ’90s that wiped out most of our oysters. We saw a slow recovery at first and now a more rapid recovery.”

Getchis says increased diversification of operations and techniques have helped strengthen the industry. While a large portion of the industry continues to harvest seed from natural, public oyster beds, some use the remote setting technique of oyster seed production when natural seed supplies are not available consistently.

The state has also seen the industry diversify into container culture, where producers utilize flip bags or cages rather than traditional beds. These tend to be smaller operations, but still important to the growth and health of the industry.

“A volume of shellfish is still coming out of those natural beds, but the diversification is coming from these smaller operations that are located near shore and are using different types of gear to grow oysters,” says Getchis. “We’ve had a lot of interest in that, and it is poised to scale up.”

Connecticut Sea Grant’s study into the industry is tied to the Connecticut Shellfish Initiative, which aims to grow all of the shellfish sectors in the state. Getchis says that they are collecting information about jobs, harvesting areas, types of gear used and other information to create a baseline to inform the growth of the industry.

“It’s a plan that was developed by interested parties, a public process and an evolving process,” says Getchis. “Things that were important a year ago when we created the plan may not be as important now or may have already been addressed. There are new challenges that arise and new opportunities. It’s a living document and we’re working on the implementation of the plan.”

– Matt Jones

FOCUS ON SHELLFISH

West Coast oyster tech comes east

Findings of three-year on-farm demonstration study entice Eastern seaboard oyster farms to begin adapting flip-bag technology

SEAPA baskets loaded with oysters ready to be deployed on longlines in Virginia. When installed and maintained properly, flip bags are proven to produce oysters with significantly deeper cups, heavier shell and more meat compared to rack and bag, bottom cage and floating bag culture oysters, says study

BY TREENA HEIN

Oyster aquaculture in the United States has rapidly expanded in the past 20 years, and oyster cup shape, as well as taste, is critical to the consumer. Deeper cups are preferred because they suggest a higher volume of meat.

Cup shape can be manipulated through handling practices – the more an oyster is handled, the more new linear shell growth gets broken off, leading to the formation of a deeper cup. Some oyster farmers use a method of breaking off new growth by placing oysters in a “tumbling” device once in a while. A more convenient alternative is the relatively new “flip-bag” system, a conventional plastic mesh bag designed to rotate with the rise and fall of the tide, tumbling the oysters automatically.

While the flip bag method has been a big success on the West Coast, it has yet to make a big impact with growers on the East Coast. A small research project at Rogers Williams University in Rhode Island a few years ago showed that flip bags resulted in oysters of excellent quality, so the technology was further studied in a research project from 2014 to 2017 as part of a bigger plan to develop a Northeast Aquaculture

Research Farm Network (NARF-Net) through on-farm demonstration projects.

The use of NARF-Net “provided an excellent opportunity to evaluate the efficacy of using tide-tumbled flip bags to produce superior grade oysters on New England farms,” states the final study report, released in July 2017.

The study evaluated three styles of flip bags (Seapa, BST and ADPI bags) in terms of the grade and meat quality of the eastern oyster (Crassostrea virginica) compared to traditional rack and bag and floating culture systems.

The research team found that the flip bag system produces an oyster with higher meat content than a conventionally farmed oyster. “The application of flip bag culture yields a slower-growing but higher grade oyster, compared to traditional culture methods, with a large volume of edible tissue, which may lend itself to a higher market value,” states the final report. It cautions, however, that “careful consideration of site selection and space utilization is critical in successful application of the flip bag system.”

As of July 2017, the researchers were aware of two East Coast oyster farms (that had participated in the study) using the flip-bag system “with numerous more farms considering it.”

FOCUS ON SHELLFISH

‘Tide to table’ and other trends gaining momentum

FOCUS ON SHELLFISH

FOCUS ON SHELLFISH

The Executive Director of the Pacific Coast Shellfish Growers Association, Margaret Barrette, shares with Aquaculture North America (ANA) trends she sees strengthening in the shellfish industry.

TIDE-TO-TABLE DINING

Margaret Barrette, Executive Director of the Pacific Coast Shellfish Growers Association (PCSGA), has seen a major change in the shellfish sector over the past eight to 10 years as clamor for “tide to table” dining experience among consumers grew. “The oyster bar experience and being able to sample a variety of oysters from different locations is becoming extremely popular,” she says, adding that the trend has boosted half-shell sales.

Indeed, several oyster companies have moved into the restaurant market and are able to control production from farm to plate. Washington’s Taylor Shellfish has four restaurants in Washington State and one in Vancouver BC, while Hog Island has led the industry in California for several years with three off-site oyster bars. “It really gives companies direct control over the quality of product that is delivered to the consumer,” says Barrette. “I think we will see more of it, although it certainly requires a different skill set than farming.”

CO-CULTIVATION OF SPECIES

The adoption of IMTA techniques by the industry is one trend that could strengthen. IMTA is a process of combining the culture of a fed species (i.e. salmon) with other, extractive species such as shellfish and seaweed, or invertebrates such as sea cucumbers. In the shellfish industry, Barrette sees the co-cultivation of species such as oysters and kelp as being an important direction.

OFFSHORE FARMING

She also sees offshore farming strengthening. Catalina Sea Ranch is the first offshore shellfish farm permitted in United States federal waters.

INNOVATIVE PARTNERSHIPS

“I’m really interested to watch the innovative partnerships that several harbor districts are initiating,” says Barrette. She is referring to ventures and programs that a number of ports in the United States have initiated in recent years aimed at advancing aquaculture.

For instance, the Humboldt Bay Harbour District in California plans to go through the permitting process for aquaculture plots and then lease the “pre-permitted” property to farmers with the goal of encouraging future aquaculture production in the Bay.

“Permitting is a huge issue for our members as people are still reluctant to allow this use of the land,” says Barrette. “It’s a long, complicated and costly process.”

The Port of San Diego champions water-dependent businesses such as aquaculture

FOCUS ON SHELLFISH

Shellfish

aquaculture on the US Pacific Coast

Shellfish farming is an industry worth more than $177 million for the five member states that make up the Pacific Coast Shellfish Growers Association (PCSGA) — Alaska, Hawaii, Washington, Oregon and California.

Founded in 1930, the PCSGA has a mandate to work on behalf of members on a broad spectrum of issues, including environmental protection, shellfish safety, regulations, technology and marketing. The members farm various shellfish, including oyster, clam, mussel and geoduck.

But as early as 1905, a group of shellfish growers have organized themselves to rally around common issues,” says PSGA executive director Margaret Barrette. “Early on, our industry was plagued by a lot of water quality issues caused by timber processing and growers stood up in unison and said we have to stop this.”

The Olympia oyster all but disappeared from the Pacific Northwest in the early 1900s and importing Pacific or Japanese (Crassostrea gigas) seed from Japan became the backbone of the industry. The Pacific oyster grows well along the US pacific coast but natural sets were not a reliable way to ensure production.

When consistent hatchery techniques were developed in the ’70s the Pacific oyster became the farmed mollusk of choice. Oysters are grown in the four states excluding Hawaii (which has a strong oyster hatchery sector), followed by clams (except in Oregon). Mussels are grown in Washington, Alaska and California, while Alaska and Washington raise geoduck, and there are abalone producers in California and Hawaii. Barrette says that abalone and kelp are the new species of interest.

Washington State is the largest producer of hatchery-reared and farmed shellfish in the US, with more than 300 farms accounting for 25 percent of the total domestic production by weight and an annual farmgate value exceeding $108 million, according to the Pacific Shellfish Institute (PSI). In terms of economic impact, the sector generated $185 million of economic impact yearly and created 2,700 jobs as of 2013.

In California, total economic impact of the shellfish industry was estimated to exceed $23 million, and support 280 jobs. There was inadequate information about Oregon, but industry experts put the value at between $10-20 million.

and has established the Aquaculture and Blue Tech Program in 2016 to support them. Portland, Maine Redevelopment meanwhile has launched a plan that seeks to transform the municipal pier into incubator for aquaculture enterprises.

“You wouldn’t think of a port as getting into the shellfish business but they have so much infrastructure already in place,” says Barrette, “Its really exciting.”

SECTOR CHALLENGES

Aside from trends, Barrette also discussed some of the sector’s challenges. She said there’s a need to encourage people who will spend $3.50 for an oyster in a restaurant to buy more shellfish at the seafood counter. “How much education is getting to the home consumer?” she wondered.

Growers are meanwhile concerned about the future availability of labour, particularly immigrants who are known for “showing up on time and staying on the job,” she said.

“We have the potential to grow shellfish aquaculture particularly in Washington,” Barrette says. “It’s a balance to cater to the needs of people who swear they love the coast line but have a sense of entitlement and the value that growers contribute to the local economy.”

FOCUS ON SHELLFISH

Mook Sea Farm pursues multiple avenues to success

FOCUS ON SHELLFISH

Maine company focuses on oyster seed, the half-shell market and R&D

BY MATT JONES

BFOCUS ON SHELLFISH

ill Mook had been interested in marine science his entire life, a passion that led him to oceanography courses and eventually teaching marine and earth science in the Virgin Islands and Connecticut. He was in the process of pursuing a graduate degree in oceanography when, in his words, he got sidetracked by aquaculture. What started as a labour job to put food on the table while studying soon led to the creation of Mook Sea Farms in 1985 on the Damariscotta River in Midcoast Maine. The multifaceted operation produces up to 100 million juvenile oysters and cultivates oysters for the half-shell market.

“I started out with literally a half an acre of land that I leased on the Upper Damariscotta River and built my first hatchery there,” says Mook. “A couple of years later, it was 1988 or so, I purchased the land we’re on now, which is maybe one lot removed from where that first hatchery was, and I built the business that we have here now.”

In the early days of the business, they produced and sold seed of almost every commercially available bivalve other than mussels, but in the early 2000s Mook decided to stop producing everything except American oysters and he became an oyster seed supplier as well.

OPPORTUNITY TO ACQUIRE THE FOLLOWING:

• MARINE SITES = 277 HECTARES (684 ACRES)

• LICENCED TO PRODUCE OYSTERS, MUSSELS, MARINE PLANTS

• ONSITE INFRASTRUCTURE: LINES, ANCHORS

• LAND BASE WITH NEW WHARF

• PROVEN SITES

INTERESTED PARTIES PLEASE CONTACT: BRIAN ROGERS 902.497.5898

brian.rogers@ns.sympatico.ca

Mook sees a lot of room for growth for the oyster half-shell market in the United States and that optimism has been the driver behind the company’s continued expansion.

“This has led us to increase our seed sales because we feel there’s still going to be a number of years where demand for good quality half-shell oysters will exceed supply,” says Mook. “We also have increased quite dramatically our market oyster production. We sell winter seed from North Carolina to Maine. Our market oysters are basically all wholesale, to three or four different wholesale companies, and those oysters go all over the country.”

Mook Sea Farm uses OysterGro cages, which utilize floats that suspend six bags of oysters below the water’s surface. The cages are manipulated seasonally as necessary, flipped up during the growing season so the oyster can be air-dried and then sunk during the winter to prevent ice damage.

R & D

One of the most important and unique facets of Mook Sea Farm’s work is their commitment to research and development.

“A lot of people will say that in operating a hatchery, there’s a lot of art involved, kind of the green thumb thing,” says Mook. “I’ve always felt that wasn’t true. This is a biological science. Part of our business model is to really attack biological problems head on. That’s not necessarily cheap, but what it does is it increases your dependability as you go. That’s something that’s led us to really making a commitment to R&D.”

The company has a variety of proprietary and nonproprietary R&D projects. One proprietary system is a way of growing microalgae using fermentation technology. The company grows 99.5 percent of their microalgae using sugar as fuel to run cultures. They maintain a clean room under sterile conditions, producing microalgae continuously.

“If you think of the hatchery as the engine that drives our business, which it is, the microalgae are the fuel that runs our engines,” says Mook.

Another R &D effort is to find ways to reduce or even eliminate harmful vibrio bacteria. The company recently built a facility that’s now home to these efforts. It will have four in-ground tanks with roughly 26,000-gallon capacities which they will keep at an

optimum temperature – warm enough that the oysters are still metabolically active, but cold enough so that the vibrio reproduction rates are dramatically decreased. Researchers will look at the possible relationship between oyster feeding and vibrio, as some preliminary work indicates that feeding them could make purging vibrio more effective.

Further research efforts will be directed at developing a post-harvest process to further ensure the safety of the product, which could potentially be licensed out to other operators. The company is also working on research related to climate change issues.

The new facility is a 9,000-square-foot multi-purpose building, which will include an Oyster Inventory Room that will enable them remain open even during rainfall. They will isolate oysters from the Damariscotta River and hold them in highly filtered water which will still be irradiated before going in the tank. Microalgae production will also be moved to the new facility. Mook is excited about the industry’s future and he hopes that his company and their research will play a part in it. “The market growth that I’ve observed over the last decade or so, it’s really being driven by a younger demographic people in their 20s, 30s and 40s. There seems to be a parallel between market growth and the growth of the whole food movement. People want to know where their food is grown, that it’s natively grown. Our oyster’s story is consistent with that,” he says.

Since the early 2000s, Mook Sea Farm has focused on growing Eastern oysters (Crassostrea virginica)

RESEARCH & DEVELOPMENT

New year brings laser focus on sustainability

BY LOU CORPUZ

From tiny inland farms to sprawling net pens, fish farmers around the world are under renewed pressure to embrace more sustainable practices to safeguard an increasingly fragile environment.

2017 was a hectic year for the industry, especially following the collapse, in August, of a net pen in Washington State, which allowed more than 160,000 adult Atlantic salmon to escape into the Puget Sound. The incident invited new scrutiny on the industry and intensified concerns over the effects of foreign fish on wild Pacific salmon native to the area.

At the time, many in the industry argued that the spill involved an outdated salmon-farming structure and suggested that having newer equipment in place could have averted the disaster.

Hallvard Muri, CEO of the Norwegian Akva Group, agrees that using the latest technology is crucial. At a seafood summit in Victoria, British Columbia, last year, he traced how Norway’s introduction in 2012 of new standards for the design and operation of floating fish farms led to the widespread adoption of new equipment and technology and a dramatic decline in fish escapes.

“Since NYTEK regulations were implemented, there’s been a dramatic impact on escapes in Norway – it’s down to virtually zero,” Muri told Aquaculture North America (ANA) in a phone interview.

NORWAY’S SYSTEMS APPROACH

But Muri also insists having the latest technology isn’t enough in itself: a concerted effort by government, technology providers, fish farming companies, educators and researchers is necessary to promote growth at sustainable levels.

In addition to NYTEK, the Norwegian government opened 45 new salmon farming licenses, the so-called “green licenses” which gave farmers the opportunity to expand production if they adopted new solutions that reduced sea lice and prevented escapes. A growth management system modelled on the colours of traffic lights was implemented in October 2017—green meant areas where growth could take place, yellow indicated areas to watch, and red was for areas that should reduce production.

“Aquaculture is a sustainable industry when done right, and the technology exists to mitigate escapes and other risk factors,” said Muri. “But it’s important to remember that it’s not necessarily about having new, breakthrough technology. You should make sure that technology is used the right way, that things are being kept up to speed, and that equipment is being used before things happen.”

LOOKING INLAND

Heightened ecological concerns have boosted interest in inland systems as a greener alternative to net pen aquaculture. (See Industry cautiously optimistic about landbased aquaculture on page 1.)

But the reality is there is a limit to growth in land-based fish farming, says Don Read, president of sockeye salmon supplier Willowfield Enterprises, based in Langley, BC. With inland fish farms, escapes aren’t a problem and wastes and nutrients aren’t discharged into the ocean. But it takes a lot of energy to pump water through these farms, and high land costs means there’s a limit to expansion.

Fish farming at large is a capital-intensive business,

Tighter production controls, new feed sources address some of industry’s key challenges

•

•

•

•

•

•

80 reactor bodies are seawater safe and will not corrode in harsh environments, unlike stainless steel

- Single end glassware access makes for easy maintenance when replacing lamps and quartz sleeves

- Thermoplastic or Fiberglass NEMA 12 Power supply enclosures with Standard HMI control package or optional HMI Pro Series control package.

RESEARCH & DEVELOPMENT

- Electronic ballasts matched to the performance of the specific lamp for optimal UV-C output and longest useful lamp life

- Standard Over Temperature Safety Cutoff Switch thermally protects reactor when water temperature reaches 120 Degrees F

- American made low pressure amalgam (ALH/AUH models) and high output (HLH/HUH models) lamps are rated 80% efficient at the end of 12,000 hours

Read said. “You have higher production costs and you need significant capital to make it a feasible business, so I think it’s going to remain a niche industry at least for the foreseeable future,” he said. He noted that many producers that were active 20 years ago have either closed shop or aren’t growing salmon anymore.

Willowfield first caught attention in 2013 as the first commercial land-based producer of sockeye salmon and for its non-polluting design—spring water flows into sockeye tanks and then on to trout ponds stocked with native plants that absorb fish waste and ammonia. The solids from the trout ponds and holding pond are used as plant fertilizer.

Read is planning to expand his sockeye operation to 250 to 500 metric tons a year. The company has partnered with Golden Eagle Aquaculture on a land-based coho salmon facility in Agassiz, BC that grows around 200 metric tons of salmon each year.

Read believes farmed fish has a future if it’s marketed right. “As producers, we need to educate more consumers to appreciate farmed fish, which has the advantage of being harvested close to source but may be somewhat more expensive than other fish,” he said.

THE FEED FACTOR

Another environmental concern in aquaculture is that small “forage” fish are being depleted in the oceans to feed the farmed fish. About a third of all the fish harvested worldwide are processed into fish

meal and fish oil—most of which is used to feed other fish, according to the National Oceanic and Atmospheric Administration.