OUR PLANET, OUR FUTURE

Players in aquaculture have the privilege and the responsibility to become stewards of the planet by making transformative changes that will impact generations to come . P. 12

TECHNOLOGY

New cage, new age Salmon grown in a semi-closed containment system tested in Norway and Canada have not required treatment for salmon aquaculture’s mortal enemy: sea lice. P. 24

SHELLFISH Glacial pace

Emerging new industry in Texas is moving slowly as permits are stuck in regulation mire. P. 30

ALTERNATIVE PROTEIN

Fishless fish

Plant-based protein producers and players in the cellular aquaculture space are eager to have a slice of the seafood market. P. 33

industry.1 The success of APEX-IHN® vaccination programs has meant that the risk of IHN is not often spoken about, and yet the potential threat of infection from wild fish remains ever present.

Don’t let IHN become the ‘elephant in the room’, keep protecting your salmon, and your profits, with APEX-IHN®

By Nestor Arellano

Next Generation Spawning

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb,

Audience Development Manager

Tel: (416) 510-5180

Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Liza Mayer lmayer@annexbusinessmedia.com

778-828-6867

Regular Contributors Ruby Gonzalez, John Nickum, Matt Jones, Lynn Fantom

Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Aquaculture North America is published six times a year by Annex Business Media. The authority for statements and claims made in Aquaculture North America is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.00+Tax Within North America: $48.00 CAD Outside North America: $62.00 CAD To subscribe visit our website at www.aquaculturenorthamerica.com

PRINTED IN CANADA ISSN 1922-4117 Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 UNITED STATES MAILING ADDRESS Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Aquaculture North America are copyright ©2021 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the Sept/Oct issue is August 3rd. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the Sept/Oct issue is August 3rd. Contact Liza Mayer at lmayer@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

FROM THE EDITOR

We’re almost there

Yay! That may sound unprofessional, but I can’t help but be excited about the signs indicating the pandemic is tapering off.

And if our past coverage at the height of the pandemic is any indication, the aquaculture industry is alright. Rather than crack under pressure, the industry stepped up to do its part to continue to provide communities with sufficient, safe, and nutritious food.

It will take time before a full picture of COVID-19’s impact on the seafood sector emerges. Global consulting firm McKinsey has warned that restaurant dining may not return to pre-crisis levels for months, or possibly even years, but when that happens we know the seafood sector is ready. Producers found new, innovative ways of doing things to usher their organization through the difficulties while keeping their employees safe.

The past several months have made us realize what’s really important; some of us are rethinking our priorities. Whereas pre-pandemic,

ADVERTISERS' INDEX

BY LIZA MAYER

earning money (and lots of it!) might have been a preoccupation for many, it’s not surprising if spending more time with loved ones has superseded that.

Like us individuals, the industry also had the opportunity during the crisis to take stock of what’s important. As our report “Beyond Resilience” on page 16, says: the crisis has presented the industry with opportunities to be better prepared in the future by shifting mindset and effecting more impactful changes. Its advances in sustainability have been instrumental in helping it weather the headwinds, it says. This issue looks at some of the progress the industry is making to make itself future-proof.

By now we’re likely starting to feel Zoom-fatigue, so let’s remain vigilant — and hopeful that soon, we’ll be able to see each other face to face in conferences once again.

TO ADVERTISE CONTACT

Jeremy Thain, associate publisher, at jthain@annexbusinessmedia.com • +1-250-474-3982

Morgen Balch, account Manager, mbalch@annexbusinessmedia.com • 416-606-6964

America’s Most Popular Seafood 2019 • National Fisheries Institute

30 YEARS IN THE MAKING.

Americans eating more seafood, trying wider range

US consumers ate 19.2 lbs of seafood per capita in 2019, up 0.2 lbs from 2018, and they tried a wider range of seafood, according to the latest data from the National Fisheries Institute (NFI).

Shrimp continues to be the most popular seafood in America with a record-high 4.7 lbs eaten per capita, unchanged from the previous year. Consumption of salmon rose by 0.54 lbs per person, keeping its spot as the second most popular seafood in the US.

It is important to keep in mind that the NFI data is pre-pandemic. But analysis of pandemic market forces by the Food Marketing Institute showed that the trends seen in 2019 continued in 2020. The industry association said Americans ate more seafood at home as food establishments shut down, boosting seafood retail sales by 28 percent to $16.5 billion in 2020 over 2019.

Leading salmon producers corroborated the trend. They reported selling record volumes of salmon in retail markets amidst the restaurant closures, helping offset some losses.

The NFI data includes both farmed and wild seafood. Consumers new to the seafood category or those who eat seafood only in food establishments “don’t have those tough beliefs on wild-caught or farm-raised,” observed an executive of a large supermarket chain.

Nutritious food purchases will benefit food banks and non-profits helping those struggling with food hardship, said the USDA

USDA buys a whopping $160M worth of local seafood

AquaBounty made its first harvest of genetically engineered Atlantic salmon in the US in June, a milestone 30 years in the making.

AquaAdvantage Salmon (AAS) was genetically modified so that it grows faster than conventional salmon. Photo shows AquaBounty processing associates Skyler Miller (left) and Jacob Clawson (right), with CEO Sylvia Wulf holding salmon from the initial harvest. AAS is approved for sale in the US, Canada and Brazil.

PHOTO: AQUABOUNTY

Food banks and the seafood industry are the clear winners in the United States Department of Agriculture’s (USDA) decision to purchase $159.4-million worth of domestic seafood in May.

The purchase marks the largest single seafood purchase in the Department’s history, according to the agency. The record purchase is in response to disruptions in the food system supply chain and the heightened food insecurity resulting from the COVID-19 pandemic. Under a domestic food procurement program policy, USDA has the authority to support prices of commodities in surplus by purchasing them in the marketplace, and distributing them domestically.

The National Fish Institute (NFI) applauded the move. “The seafood community and the 1.7 million Americans jobs along its value chain, has been hit hard by the pandemic from the men and women who work the water to processors, distributors and retailers and restaurants that offer seafood. Most of the links in that vital chain are small businesses that have struggled to survive. Help, like this, will greatly benefit recovery and help get Americans back to work,” said John Connelly, NFI president.

PHOTO: LIZA MAYER

Watchdog wants civil society to have a say in certification process

Excluding them is a threat to the legitimacy of eco-labels, it says

Aquaculture certifications should include input from civil society or risk the credibility of the eco-labels, says an environment watchdog.

While applauding the Aquaculture Stewardship Council (ASC) for being “the most inclusive and transparent eco-certification,” SeaChoice said ASC and fellow farm assurance programs – Best Aquaculture Practices (BAP) and GLOBALG.A.P – could still improve in how and when they engage with civil society stakeholders.

Not letting civil society stakeholders have their say is a threat to the legitimacy of their eco-labels, it said.

“Consumers will find these certifications’ eco-labels at their local grocery store on seafood such as farmed salmon, shrimp, basa and tilapia. Retailers often refer to these certifications as part of their sustainable seafood procurement policies.

“As a form of market-based governance, voluntary sustainability certifications rely on external parties, including civil society stakeholders, to buy into them or risk losing market support,” said the Vancouver-based group.

Kelly Roebuck, SeaChoice representative from Living Oceans, said stakeholder inclusion “also helps combat any perceptions that industry is playing the role of ‘the fox guarding the henhouse.’”

In December, ASC announced it will begin seeking input from NGOs and the community when reviewing farmers’ requests for leeway (called “variances”) on certain ASC standards, for instance on the number of sea lice acceptable per salmon.

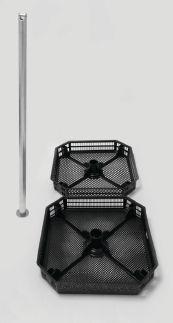

Newfoundland’s sole oyster growing operation expands

One year after the official launch of the first commercially cultivated oyster in Newfoundland and Labrador, Merasheen Oyster Farms Inc is set to grow and expand its operations.

The company, which had been producing oysters in Placentia Bay for the last few years, is adding pro duction to Notre Dame Bay.

Owner Juan Roberts, the only oyster farmer in the province, says the move is expected to result in a higher-quality product.

The shallower, warmer waters of Notre Dame Bay are likely to speed up the usual five-year growing process – resulting in a better oyster product reaching markets more quickly.

“Oysters are a higher value shellfish and we believe when things improve with restaurants and the economy and an eventual easing up on restrictions, we expect oyster sales to improve and increase. We believe that our cold clean water will give our oysters that increased flavor that will set us apart from rest of world,” said Roberts.

A non-repayable $206,400 contribution from the provincial government will assist with oyster cultivation research in Notre Dame Bay using specialized equipment, such as the floating upweller system, and dedicated oyster growth cages. The support will help the company continue its growth and development in a very competitive marketplace.

Providing businesses such as Merasheen Oyster Farms with the tools they need to compete and succeed in global markets is important to the Government of Newfoundland and Labrador. Increased export activity helps create jobs and economic

The shallower, warmer waters of Notre Dame Bay in Newfoundland will result in better oysters, says Juan Roberts (inset), owner of the only oyster farming operation in the province

PHOTOS: MERASHEEN OYSTER FARMS

benefits for all Newfoundlanders and Labradorians, it said.

While oyster aquaculture is a very small part of the aquaculture industry in the province, the industry at large contributed $961 million in total economic activity to Newfoundland in 2018; $395 million in GDP; $204 million in wages; and more than 3,500 person years of employment, according to latest data from Statistics Canada.

“Through proper development, there is potential for oysters to be a significant commercial product in our province, one that could grow our economy for years to come,” said the Minister of Industry, Energy and Technology, Andrew Parsons.

“The unique growing conditions in Placentia Bay create an oyster with a distinct flavor that is appreciated throughout North America. The expansion of Merasheen Oyster Farms in to Notre Dame Bay will lead to increased economic opportunities for Newfoundlanders and Labradorians and allow for increased product exposure to overseas markets,” said the Minister of Fisheries, Forestry and Agriculture, Derrick Bragg.

NEWS AND NOTES

Maine farmers unite to quash proposed ‘reform’ bill

Members of the Maine community who make a living in its waters put forward a powerful case against an aquaculture bill in the state that prompted even the bill’s sponsor to vote against it.

LD 1146, sponsored by Rep. Robert W. Alley Sr. (D-Beals), would have restricted the size of aquaculture leases and further tightened the state’s stringent regulatory framework.

But on April 20, seafood farmers of all sizes and members of the lobstering community made their case heard before the Marine Resources Committee, attesting to the grave impact the bill will have on coastal livelihoods.

“Current law already prohibits the Maine Department of Marine Resources from issuing a lease to a farmer if it does not comply with a series of criteria designed to protect the environment, prevent conflicts with other user groups, prevent interference with navigation, and prevent obstruction of riparian landowners’ access to the water,” said Sebastian Belle, executive director of the Maine Aquaculture Association.

The proposal includes the repeal of the Natural Resources Protection Act, which

would have added a “visual impact” criterion to the lease application requirements. It would also have repealed site development exemptions for any leases larger than five acres, limit leases to 50 acres and restrict owners from holding more than 10 leases or a total of more than 100 acres.

“The site development law was developed for Land Development. For example, if somebody wants to come into an area and put a supermarket in or wants to put a housing

development in and it’s over five acres, they are required to do what’s called an alternate sites analysis, which means they basically have to go and look at a couple of other areas and tell the Dept of Environmental Protection why the development shouldn’t occur in another area,” explained Belle.

“In the case of aquaculture, what that would mean is that we would have to go from one site to another anytime somebody objected to the alternate site. We would have to find other sites, which means you’d end up in this endless Nimby loop.”

Belle described the outcome of the virtual committee hearing as a victory for aquaculture and a testament to the strength and unity among members of Maine’s working waterfront community.

As for Alley deciding to vote against his own bill, Belle commented, “Rep. Alley’s motivations were very sincere. He was responding to constituents’ concerns and interests, but I don’t think he understood how diverse and how large the aquaculture sector is and how closely it’s linked to Maine’s traditional working Waterfront (culture).”

Rep. Alley’s office did not return our request for comment.

NEWS AND NOTES

PEI shellfish farmers get help to find workers

Misconception that aquaculture offers only seasonal jobs discourages people from applying, suggests an industry executive

Prince Edward Island’s aquaculture industry is thriving and eager to hire, but it struggles to find workers.

Its farmed mussel industry yields 50 million lbs annually, representing 80 percent of mussel production in Canada. Jobs range from working aboard a boat, physically farming the sea, to quality assurance and research in a lab.

But misconception as to what jobs are available may be discouraging people from applying, suggested Denna Keating of the PEI Aquaculture Alliance.

She believes some issues with recruitment stem from a lack of understanding that full-time, year-round employment is available alongside seasonal work.

With the industry’s dire need to fill vacancies, it has become apparent that good old-fashioned “We’re Hiring” signs and word of mouth, which most employers have been relying on, won’t cut it.

“We need to look beyond our traditional pools of labour and expand how we’re advertising jobs. We also need to look at why some employees leave the industry and what we can do to make them want to stay,” says Keating.

In May, the Alliance hired a consultant to help develop a workforce strategy.

Some of the goals would be to explore group benefits in order to enhance employers’ capacity to offer incentives; share recruitment best practices; increase training and certification opportunities for employees; and create pilot projects to tackle some of the issues identified by employees as barriers to working in the industry, such as transportation and hours of work. The Alliance is also in the process of forming a Workforce Steering Committee, for which it is looking for partners and interested industry participants.

Cold-water coastal shellfish aquaculture is one of the key sectors that will benefit from the labor-force development program underway in

Program aims to combat labor shortage in Maine

A labor-force development program is underway in Maine to help combat aquaculture labor shortage.

A $500,000 grant from the USDA will fund the program, which will be jointly implemented by the Maine Aquaculture Innovation Center and the Washington County Community in Calais.

The goal is to come up with a curriculum that will result to a new generation of world-class, data- and tech-savvy aquaculturists in four key aquaculture sub-sectors: land-based recirculating aquaculture; marine fin-fish aquaculture; cold-water coastal shellfish aquaculture; and marine macroalgae aquaculture.

Salmon virus study biased and questionable, says industry

Asks authors to publish a correction in science publication

BY LIZA MAYER

The British Columbia farmed salmon industry has questioned the credibility of a local study that points to aquaculture as the source of piscine orthoreovirus (PRV) transmission to wild salmon, adding that it is yet another publication that expresses “a clear bias against salmon farming.”

The study “Aquaculture mediates global transmission of a viral pathogen to wild salmon” was conducted by Gideon Mordecai, a researcher at the University of British Columbia, and the Strategic Salmon Health Initiative (SSHI) – a partnership of Fisheries and Oceans Canada (DFO), Genome BC and the Pacific Salmon Foundation.

In a statement, the British Columbia Salmon Farmers Association (BCSFA) challenged the following claims in the study:

1

Farmed salmon industry’s development brought the PRV virus from Europe to BC

This claim is based upon the authors’ determination that the PRV virus in the NE Pacific diverged from the virus in the Atlantic Ocean between 1981-1997. This timing is consistent with the arrival of Atlantic salmon egg imports from Europe for salmon farms in the NE Pacific, said the authors.

The BCSFA says this conclusion is flawed because PRV has been found, via by PCR analysis, in a wild-source steelhead trout in BC in 1977.

But Mordecai et al. dismissed the 1977 test results, stating that it has not been verified by genetic sequencing. They also did not acknowledge the results of a test on the same 1977 sample conducted in May 2020 by DFO researchers, which confirmed it is positive for PRV.

“We recommend that the authors submit a correction to Science Advances that would be appended to the online version of the study. This correction should consider the impact of the presence of PRV in the 1977 sample on their estimates of the arrival of PRV in the NE Pacific.”

2 Evidence strongly supports Atlantic salmon aquaculture as a source of infection in wild Pacific salmon

The study found that the closer wild salmon are to the fish farms, the higher the PRV

The voice of the BC farmed salmon industry noted the shortcomings of the Mordecai-led study

infection rates. But the authors admitted that they did not take into account other factors that might influence the virus’ prevalence, such as different environmental conditions or differences in host condition between regions.

Salmon farmers therefore ask: How could the authors arrive at their conclusion without accounting for these important factors?

It further said that the three studies that the authors cited to support their conclusions are flawed: One of them was found to be erroneous and later corrected, making the original conclusions of the Mordecai study invalid, says the BCSFA. And one of them studied farm-to-farm transmission (rather than farmed-to-wild), while the third was unable to establish a clear line of transmission from farmed to wild salmon.

“In an effort to bolster their own questionable conclusion, the authors of the Science Advances study thus appear to have adopted rather lax citation standards,” says the BCSFA.

“Furthermore, any study considering the transmission dynamics between farmed and wild salmon should recognize that all young farmed Atlantic salmon entering the marine

environment have been verified PRV-free. In other words, farmed Atlantic salmon do not introduce PRV to the marine environment. Rather, they acquire it during their ocean residency.”

3PRV is now an important infectious agent in critically endangered wild Pacific salmon populations, fueled by aquacultural transmission

In making the above statement, Mordecai et al. fail to recognize two things, says the BCSFA: firstly, that BC farmed salmon are healthy; and secondly, that detection of the virus in fish does not equate to disease.

“Evidence presented from fish farm data through DFO reporting indicates that ‘mortality events’ are overwhelmingly (nearly 100 percent in 2019) due to environmental and mechanical/handling incidents rather than infectious disease; and about 80 percent of ‘fish health events’ – where disease is known to be a factor – were due to the prevalence of three infectious diseases historically common and managed in populations of BC farmraised salmon.

“Given that there have been no major die-offs, or significantly high numbers of uncontrollable fish health events on farms, it does not stand to reason that BC farmed salmon are spreading highly infectious and harmful diseases to wild populations.”

The association also cited studies that have indicated the PRV isolate found in BC does not cause disease in wild or farmed salmon in the Pacific. It also says Heart and Skeletal Muscle Inflammation – the disease associated with PRV elsewhere – has not been diagnosed by licenced veterinarians caring for fish in British Columbia.

The BCSFA says the Mordecai-led study “highlights yet again the long-standing concerns of the BC salmon farming industry regarding the bias and credibility of research supported by the SSHI.” It cited instances where research supported or conducted by SSHI needed to be corrected or declared invalid because of flawed evidence.

SSHI is funded largely by the DFO to study the distribution and impact of potential disease agents in BC Pacific salmon. SSHI scientists have so far only identified viruses currently carried by BC’s wild and farmed salmon; they have yet to study if these are actually threatening wild or farmed fish.

Because its work remains unfinished, it has failed to contribute “to a greater understanding of the factors actually impacting the health of BC’s wild salmon populations” but instead “simply succeeded in generating alarm and uncertainty,” said the association.

KEN’S CORNER BY DR

KENNETH CAIN

Sorting through the noise in the farmed-versus-wild debate

Activists overlook the role of commercial harvesting in decimating wild fish populations and the role of aquaculture in restoring them, says columnist

Iam often asked to explain the issues regarding hatchery or farmed fish and the concerns over how they may impact wild salmon populations in the Pacific Northwest. The public is largely unaware of the complexities; many believe what they hear from the media. Wild, hatchery, and farmed fish issues are multi-facetted and there is seldom a clear and concise answer regarding how each impacts the other.

How did we get here?

What do we mean by “wild” salmon? When First Nation and native American people inhabited the coastal areas, they saw salmon as sacred and took what they needed for subsistence and ceremony. The oceans, rivers, and streams that were essential for salmon to survive were not impacted by human activity. When settlers arrived along the west coast from California up to Alaska, the abundance of salmon allowed excess exploitation of this resource. Overfishing during the 1800s began to wipe out what earlier seemed like an endless supply of wild fish and set in motion the shift from wild fish. This was compounded by habitat destruction through mining, logging, and hydropower, which to this day impact rivers and natal streams that salmon and steelhead rely upon to complete their life cycles. Now, we live in a much different world and most of us have lost the concept of what “wild” means, and in much of this region truly “wild” populations of salmon are rare.

What are the issues?

Salmon and steelhead populations are managed for many purposes, including sport fishing, commercial fishing, tribal harvest, and even recovery of endangered and threatened species. Hatchery-reared fish are primarily used as tools to enhance fisheries or address conservation goals. This has led to controversy and not everyone agrees that hatchery fish are a benefit or should play a role in fisheries management. Beyond this, net pen farming of Atlantic salmon along the Pacific coast is viewed as another threat to wild fish, and anti-salmon farming groups have had their influence on government policy regarding salmon farms. A clear example is the recent termination of salmon farming in

the Discovery Islands in British Columbia. Whether farming fish for consumption or restoration purposes, someone is likely to have an opinion about how wild fish are affected. The concerns often center around arguments that farmed fish will dilute wild genetics, transfer disease, compete for habitat, or escape into the wild and establish invasive populations — concerns that have followed net pen farming of salmon for years.

For the most part, scientific studies do not support the claims made by the anti-salmon farming groups regarding these risks nor the idea that farmed fish will lead to the extinction of wild fish along the coast (see related repot on previous page). However, we know for a fact that wild salmon are impacted by habitat change and overfishing.

Opponents of aquaculture fail to acknowledge that given the anthropogenic changes that have occurred, it is likely that only remnant populations of salmon would exist without hatchery mitigation. There may be exceptions in some systems, but the bottom line is that as long as we manage for substantial harvest of salmon and steelhead, there will be a need for hatcheries to produce them. In fact, even in

Alaska where finfish aquaculture is banned, there is a private program that releases billions of hatchery salmon annually to directly support the commercial fishery in the state.

Are there solutions?

Common sense would tell you that rebuilding fish populations along the coast would require us to limit overfishing and commercial harvest of wild salmon and steelhead. Salmon farming increases the supply of salmon to the market and augments reduced harvest from the wild. Clearly, this is not a popular subject for some groups, and it is easier to blame salmon farms and call for their removal. And instead of calling for restrictions on commercial fisheries harvests, wild salmon marketers even capitalized on the farmed-versus-wild debate by re-branding their product as a “luxury” compared with readily available farmed salmon. So, instead of using aquaculture as the means to solve wild fish problems, we have made it the scapegoat and blamed aquaculture for a problem caused by a multitude of factors that began over a century ago.

In the absence of the pristine environment that existed in the 18th century, we cannot expect wild salmon to persist at numbers anywhere near what they were. Given the myriad of issues and the unwillingness to change how we manage harvest fisheries for salmon and steelhead, the best option remains to utilize hatchery fish as tools to support fisheries managers and produce farmed salmon as sustainably as possible.

Aquaculture needs science-based solutions – reflections from Our Planet, Our Future

Our role as stewards of the industry gives us the opportunity and the privilege to make transformative changes that will impact generations to come, writes Cermaq

CEO Geir Molvik

The unique Nobel Prize Summit Our Planet, Our Future in April was a breathtaking event to everyone engaged in sustainable development.

Breathtaking in two ways – firstly because the need for fundamental changes from our current path was made so clear, and secondly because examples from the past as well as from today demonstrate that science is an efficient tool to find solutions to manage changes. The collective approach and rapid development of COVID-19 vaccines being the most recent example.

In Cermaq, we have founded leadership initiatives and engaged broadly in sustainable development in the salmon industry (Global Salmon Initiative), the seafood industry (Seafood Business for Ocean Stewardship), and the ocean industries (UN Global Compact Action Platform for Sustainable Ocean Business). Science is the at the core of our operations as well as our engagement in transitioning the food system where seafood will play a larger role.

Threat from temperature rise must trigger action

We are on a path that has taken us to 1.2°C warming so far — the warmest temperature on Earth since we left the last ice age some 20,000 years ago, and which will take us to >3°C warming in 80 years.

In aquaculture we must both adapt to changes related to low oxygen levels in the ocean, algae blooms, storms and rising ocean temperatures, and also contribute to mitigate climate change, analysing our carbon footprint, setting science-based targets and implementing changes.

Seafood is a climate winner – but the industry must improve Seafood having a lower carbon footprint than land-based animal production is well recognised by global policymakers such as the High-Level Panel for a Sustainable Ocean Economy. But this is not enough; we must continue reducing our footprint by small adaptations every day as well as through transformative changes.

Digitalization will play a key role, not only in aquaculture, but across industries and

society in general, and this technology connects industries that historically have been very different. The potential for precision in operations, from analyses of large amount of data and the use of sensors, is starting to unfold. In Cermaq, the development of iFarm, individualized farming with facial recognition, is one example of improving operations while reducing the environmental footprint and increasing animal welfare. The digitalisation of operations can also be used for real-time automated reporting to authorities, reducing workload for companies and improving efficiency.

Fish supports public and planetary health

Far too often fish is seen as a resource only and sustainable production focus on the footprint of production without looking at the impact of consumption. No food production comes without a footprint. The health impact of what you eat is recognised, health authorities recommend increasing seafood consumption worldwide. But the two aspects of health and sustainability are not well connected.

In 2021, major global summits will generate political and societal momentum for action on climate, biodiversity, food systems, desertification, and the ocean. Aquaculture intends to increase this connection; the relatively small footprint compared to the large

health benefits of seafood consumption. That must be recognized when we are transforming our food systems.

Sustainable, healthy protein is needed

The summit addressed many more aspects than the climate and environment, e.g., social conditions, population growth and migration. According to the Nobel Prize Laurates Call for Action, the urban population will increase by about 1.3 million every week until 2050. This growth will increase pressure on agricultural land. Our growth potential for protein production lies in the ocean.

Fish feed requires some agricultural land, but far less than the farming of land-animals. We must use our arable land effectively and hence fish feed is a better growth option. In Cermaq, we are proud of the employment our operations represent in multiple communities, and not at least the ripple effects from our operations resulting in robust and viable communities. Ocean stewardship is not enough, enhancing social capital — building trust within societies and between societies is needed for planetary stewardship.

Balancing for a holistic solution

Time is running out. 193 nations have adopted the Sustainable Development Goals. We are in the decade of action towards 2030. The industries are critical for our common success, says Marcia McNutt, President of the National Academy of Sciences of the United States. “While policies that are adopted by government can be important in motivating the right behaviour, unless industry embraces this as part of their core values, we’re not going to have any success.”

Cermaq’s call to action to politicians is to make brave policies and decisions, to recognise that all activities come with a footprint, to balance the alternatives and prioritize those which in total provides the best solution.

In the end, we all want a bright future for our children and grandchildren – Our planet, Our future.

Geir Molvik is CEO of Cermaq, one of the leading global salmon producers.

Geir is deeply engaged in the global agenda and the role of seafood. He parlayed this passion into salmon aquaculture, where he held various roles in farming operations and feed production in Norway, Canada and Tasmania. Geir is also a board member of Regal Springs, the world’s largest integrated tilapia producer.

Shellfish grower signs environmental stewardship deal

California-based Hog Island Oyster Co has signed deal with the Marin Agricultural Land Trust (MALT) that will preserve the natural character of its 250-acre farmland in Marin County, where it processes and packs its harvests.

Such deals, called conservation easements, are a way for the private sector to address the problem of disappearing natural habitats due to, for instance, industrial development.

MALT’s mission as a land trust is to protect Marin County’s unique landscape and the food it generates through agricultural conservation easements. The deal with Hog Island marks its first deal with an aquaculture landowner.

The deal permanently protects the farmland, called Leali Ranch, from industrial development. However, it allows for mariculture support infrastructure such as oyster holding tanks and solar-powered water-cooling systems; and provides for a residence in the 10 acres closest to Hog Island’s bayside facility.

Hog Island staff with harvest on boat. The oyster grower has signed a deal that will preserve and steward its farmland in perpetuity PHOTO: BRENNA SCHLAGENHAUF

“Hog Island’s Leali Ranch has tremendous agricultural, environmental and historical significance, and we share the owners’ desire to preserve and steward this beautiful land in perpetuity,” said Thane Kreiner, CEO of MALT. “Through this agricultural conservation easement, MALT permanently protects Leali Ranch and enables Hog Island Oyster Co to further invest in innovative circular production practices.”

There are financial benefits for landowners in granting an easement. In Hog Island’s case, it received $1.1 million from MALT, which it said will help it weather the “devastating drop” in business due to the COVID-19 restaurant shutdowns.

Waste not, want not

Scaling up to a more sustainable aquaculture with industrial symbiosis

BY NESTOR ARELLANO

We’ve all learned about it in our elementary science classes. Different organisms living together in a particular habitat. Each living thing with their own role, dependent on one another so that all could survive and thrive in this symbiotic relationship.

Aquaculture is just one of recent areas where this principle is being adopted in a form known today as industrial symbiosis.

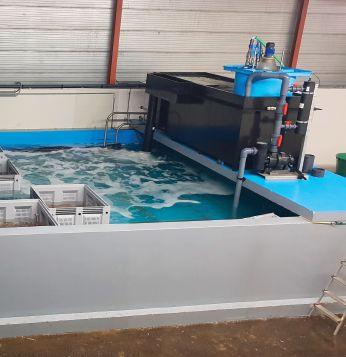

Picture a gigantic recirculating aquaculture system (RAS) facility producing tens of thousands of salmon per year. Nearby is a smolt facility. Its next-door neighbour is a fish-feed manufacturing plant. Down the road are a fish processing plant and a renewable energy plant.

A walk in the industrial symbiosis park

Such is the millieu that Quality Salmon envisions and is investing in. Its massive $2.4-billion project in Sotenäs, Sweden

will create what’s touted as “a true circular industry” in land-based salmon farming. The facility will sit on 140-hectare leased land, hailed as the largest land-based salmon farm in terms of and area (Atlantic Salmon in Miami is 65 hectares) and produce 100,000 tons of salmon per year.

The RAS facility and the other tenants in industrial park – called the Sotenäs Symbioscentrum (Sotenäs Symbiosis Centre) – will benefit from each other by sharing resources and energy.

The network includes an algae production plant, and a system for recycling plastic waste from the sea, a feed factory, salmon farm, slaughterhouse, processing facility, and facilities for water purification and management of residual products.

A key part of the network is an anaerobic digestion (biogas) plant. The plant will transform fish waste into energy for heat and electricity to be used by other tenants.

The municipality of Sotenäs is leasing the

Traceability and documentation throughout the value chain are a constant at Quality Salmon Industrial Park in Sotenäs, Sweden

PHOTOS:SALMON /© ALEXANDER RATHS / ADOBE STOCK; BARCODE/ © DLYASTOKIV / ADOBE STOCK

land to the network tenants. In return, the venture is expected to produce 2,000 new jobs in the municipality. The network will also benefit the fishing community of Sotenäs by way of improved use of sea-based resources and a reduction of environmental impacts.

Beyond raising salmon

They’re creating a circular economy, according to Roy W. Høiås, CEO of global advisory firm Lighthouse Finance, the owner of Quality Salmon.

Circular economy, also called circularity, is an economic system which focuses on eliminating waste. It employs principles of reusing, sharing, and recycling to create a closed-loop system that cuts waste, pollution, and carbon emissions.

“This is more than just producing salmon,” says Høiås. “This industrial park will include all the functions involved in completing the value chain…it’s about maximizing the value for the client.”

Proximity cuts down the need for transportation, helping bring down carbon emissions, but the closer integration of process and the exchange of data from the players also ensures that production of goods by each player is kept to the quantity and quality needed.

The result is lower cost of production, less wastage, a smaller CO2 footprint, zero emissions into the sea, and the opportunity to put a “green label” on the final product.

How to feed a feed factory sustainably

In the United States, French biotechnology company InnovaFeed SAS is building an insect protein factory in Decatur, Ill. The factory will replicate the industrial symbiosis model implemented in the company’s two other factories in France.

‘This is more than just producing salmon… it’s about maximizing the value for the client,’ says Roy Høiås, CEO, global advisory firm Lighthouse Finance, which owns Quality Salmon

‘Industrial symbiosis is in essence a circular production model on an industrial scale,’ says Clement Ray, cofounder and president of InnovaFeed

InnovaFeed is partnering with US-based global food giant ADM to build one of the world’s largest insect protein factories. ADM will provide InnovaFeed with corn byproduct and energy.

When completed, the US plant will produce 60,000 tons of protein derived from black soldier fly larvae per year to feed scores of aquaculture operations in North America. The plant will also produce 20,000 tons of insect oil which is used as a soy alternative for poultry feed, and 400,000 of fly feces for fertilizer.

“… In total, the industrial symbiosis model developed by InnovaFeed allows us to reduce our carbon footprint by 80 percent compared to a standard model with no symbiotic relations. This represents 57kt of CO2 saved per year,” says Clement Ray, co-founder and president of InnovaFeed.

Part of the value proposition of InnovaFeed is that is brings to the market, insect-based

CIRCULAR ECONOMY

Industrial symbiosis focuses on eliminating waste and maximizing use of resources

feed products that come with the best environmental performance.

“This model takes the form of a co-localization of InnovaFeed’s facilities with industrial players able to provide it with agricultural by-products to feed its larvae, waste energy to power the plants and existing infrastructure,” according to Ray.

For instance, the company’s plant in Nesle, France is adjacent to the Tereos starch manufacturer.

InnovaFeed’s flies produce feces that are used as fertilizer for the wheat that the starch manufacturer needs.

Fly larvae feed on wheat by-products produced by the starch company.

The starch factory is connected to the insect protein plant via pipeline. The pipeline cuts CO2 emissions and the need to use energy to dry the byproduct and transport it by truck to the plant.

The insect protein plant is also connected

to the Kogeban biomas plant that produces renewable energy.

With the use of a hydro condenser, InnovaFeed is able to capture the waste energy which would otherwise have been expelled to the atmosphere. This recaptured waste energy, provides for 60 percent of the protein plant’s energy needs.

According to Ray, many aquaculture operations around the world employ strategies that have “similar in ethos” to industrial symbiosis. Some examples of these can be found in aquaponics and the growing of finfish, shellfish and marine plants together. The practice of integrated multi-trophic aquaculture (IMTA) employs a concept from nature where in a food chain, one species feed on the waste generated by another.

“Industrial symbiosis is in essence a circular production model on an industrial scale – with multiple integrated players within a very small geographic range,” says Ray.

The current crisis can open up opportunities for change not just in rules and practices but also in values, suggests a panelist

BEYOND RESILIENCE: How the seafood industry can transform and effect change in post-pandemic world

BY ARSENIA KING

The current pandemic presents the seafood industry with opportunities to shift mindset and effect change that will have broader, deeper, and more inclusive global impact as it prepares for similar turmoil in the future.

At the Seafood Expo North America Reconnect virtual conference early this year, a panel of experts in resiliency and transformation research shared insights on how the seafood industry and its partners can address issues that negatively impact the sector, including COVID-19, supply chain disruptions, climate change and systemic inequity perpetuated by global supply chains.

The panel, which included Eduard Müller, president of the University for International Cooperation in Costa Rica; Peter Olson, researcher from the Stockholm Resilience Centre; and Steve Waddell, co-lead of The Bounce Beyond, said tackling these issues requires understanding how change happens and designing appropriate response to them.

The panel kicked off with sharing of results from the Global Seafood Market Strategy Evaluation jointly undertaken by grant-making organizations The David and Lucile Packard Foundation and the Walton Family Foundation which sought to understand the progress the global sustainable seafood movement has made over the past two decades.

The report suggested that progress by the movement has been instrumental in helping the seafood industry weather the headwinds caused by the COVID-19 pandemic.

However, the report also noted that

industry intervention on things like buyer commitments, pre-competitive collaborations, certifications and ratings, and social responsibility are “not enough.”

“We saw that our impact is really too small to match the global scale of the challenges. We had to question whether we are achieving what we needed to achieve if we were to serve as resource for our businesses, our planet, and the people who depend on seafood for their livelihood,” said Teresa Ish, senior program officer, Environmental Program, Walton Family Foundation.

Affirming that individual companies and nations alone cannot address these challenges, Steve Waddell, who is involved in Global Sustainable Seafood Transformations Working Group, emphasized the importance of transformation, which he said requires a shift in thinking about seafood as a “discrete activity” to understand the broader concern for the industry’s social and environmental impact.

“When we talk about the seafood industry and system, there was a recognition that its success is dependent upon a complexity of environmental social and market factor,” Waddell said.

Waddell maintained that transformation requires broader involvement of communities, regulators, and interest groups. He also emphasized the importance of collecting data to guide the industry in its desired environmental and social outcomes as well as applying “systems thinking” to better understand the connections between individual actions and diverse relationships.

Peter Olsson agreed with Waddell’s suggestion on the need to ensure a voice and

representation of small-scale stakeholders and marginalized groups if the seafood sector were to take on transformation issues and aspire to be a true sustainability forerunner.

Olsson said a lot of the transformation initiatives nowadays are more about changing rules and practices than changing deeper values, but the current crisis can open up opportunities for change. “We need specific capacities to seize those opportunities. The pandemic has shown the importance of understanding the role of crisis in societal change. Crisis can trigger the mobilization of networks of people who want to develop alternatives that will have an impact at scale,” Olsson said.

Eduard Müller expressed the need for immediate action. “The big question is: Will we be able to act on time? What will we tell our kids?

“Our problem is our structure and science are reductionist. We cannot solve complex problems unless we adopt a holistic way of thinking. Many people do not really realize that biodiversity loss, which includes marine biodiversity, is probably going to be the biggest issue that gets us out of our safe operating space. Agriculture is responsible for 80 percent of global changes,” said Müller.

Müller said lack knowledge is not the issue. “Every year we produce more knowledge, more data than previous history. We have just forgotten to turn it into wisdom, think what this knowledge can provide us and how to bring it into decision making.

Müller left the audience with a challenge: “So the question is: Are we going to just watch and see how this new normal goes, or are we going to act?”

SUSTAINABILITY

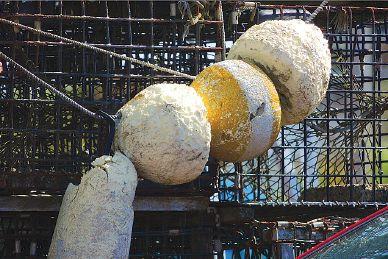

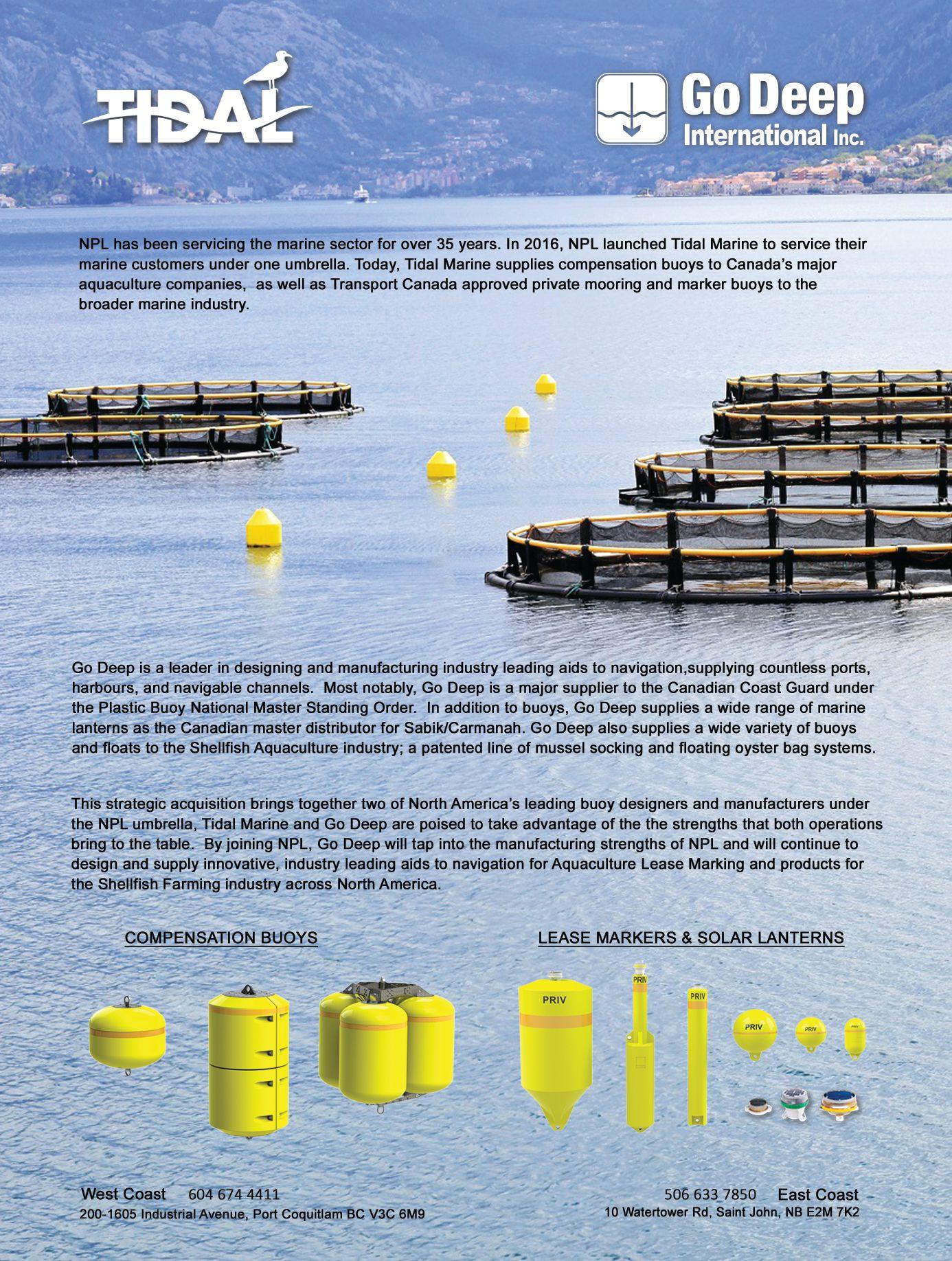

PEI aquaculture ditching styrofoam buoys

Anew pilot project in Prince Edward Island, Canada will replace styrofoam buoys used in the aquaculture industry with an environmentally friendly version, with financial help from the provincial government.

Styrofoam comprises 28 percent of the visible ocean debris per a United Nations study, and it is one of the biggest components of marine debris from the shellfish aquaculture sector.

The PEI initiative will work with identified stakeholders in the aquaculture industry to remove approximately 40,000 buoys made of polystyrene (popularly known as styrofoam) and replace them with buoys made of more durable and environment friendly materials.

“We are very pleased to collaborate with the aquaculture industry on this project to help fund an innovative, cost-saving product that also benefits our waterways and the surrounding ecosystem,” said Fisheries and Communities Minister Jamie Fox, in announcing the Expanded Polystyrene Replacement initiative.

“Our hope is that this program will continue to grow so we can eventually replace

the millions of polystyrene buoys that exist in our waterways.”

Delivered by the PEI Aquaculture Alliance, the program requires a minimum replacement of one polystyrene buoy for every new buoy. The Alliance covers 50 percent of the costs of the replacements as well as the fees associated with disposing the old buoys.

“The PEI Aquaculture Alliance is extremely grateful this this provincial initiative, which

“We are very pleased to collaborate with the aquaculture industry on this project to help fund an innovative, cost saving product that also benefits our waterways and the surrounding ecosystem.”

will accelerate the replacement of existing polystyrene flotations with newer more environmentally friendly alternatives,” said PEI Aquaculture Alliance Executive Director Peter Warris.

“All island aquaculture operations are committed to minimizing shoreline waste, and these new buoys will assist in that as they are more durable and less likely to breakup.”

The Department of Fisheries and Communities will work with Island Waste Management Corp to ensure the proper collection, storage, and disposal of buoys for the project.

OYSTER GRADING

OFFSHORE FARMING:

It’s all about economics

Fish farming further out into the open ocean has great potential but how economically and efficiently it can be done will be the deciding factor for its growth, say experts BY

LIZA MAYER

Farming fish in cages located anywhere from 2km to 25 km from the shore, known as open ocean aquaculture, accounted for 29 million metric tonnes or one-third of aquaculture production in 2016, according to the latest figures available from the Food and Agriculture Organization (FAO).

Citing the FAO data, policymakers behind the 2019 paper “The Future of Food from the Sea” say this type of aquaculture could produce six times as much with policy reforms.

Also known as offshore aquaculture, its advocates see a greater role for it as overall aquaculture growth is expected to slow down from 4.6 percent in 2017-2018 to 2.3 percent

CUSTOM AQUATIC FEED SOLUTIONS ARE WAITING

Surround Yourself with Unparalleled Resources for Extrusion and Drying Systems

Do you know what aquatic feed you need to produce – but unsure of the next steps? Wenger will put unsurpassed technology and process expertise to work, developing flexible solutions specific to your operation. We expertly evaluate and guide the development and processing applications for floating, sinking, shrimp and micro aquatic feeds. Every one of our systems is customized, serving you best by going beyond a standardized approach.

Let us help you solve production challenges now. Email us at info@wenger.com today.

the world’s first offshore

over the period 2019-2030. FAO says the reduced availability of water and suitable production locations in coastal areas, the ever tightening environmental regulations, and outbreaks of aquatic animal diseases related to intensive production practices are among the factors behind the projected reduction in growth rate.

The open ocean can pitch in because the greater depths and stronger currents make it an ideal environment for farmed fish, say experts.

“Offshore, in my view, is the right direction,” said Daniel Benetti, professor and director of Aquaculture at the University of Miami-Rosenstiel School of Marine and Atmospheric Science, a panelist at The Future of the Blue Revolution virtual conference hosted by Intrafish this past spring.

“But it is a big investment. It is a big commitment in terms of money and time. We’re talking about long-term projects here; it cannot be short term going to five years. This is five to 10 years at the very least. We’re looking at tens of millions of dollars. It is not for the faint-hearted.”

Fish farmers and offshore farming technology specialists say nothing is more urgent than making operations efficient so that it becomes profitable.

The recent arrival of data-driven technologies in aquaculture, such as machine leaning and artificial intelligence, are significantly improving the sector’s economic viability

CAGE CULTURE

‘US laws and regulations and permitting processes are impossibly difficult. Investors recognize this but they will not stop; they will be moving abroad and they will be doing what it takes to do it.’

– Daniel Benetti, Professor and Director of Aquaculture, University of Miami

because they “smarten up” automated processes developed over the past 20 years.

For offshore farming innovator Innovasea, the priority is to achieve efficiency in feed because it accounts for at least 50 percent of the operating costs of a farm, whether in coastal areas or offshore. Among the many data-driven tools the company uses detects fish satiation, helping reduce feed waste and optimize feeding opportunities.

“I think that the biggest lever to pull is feed. Feeding optimization is critical to sustainability and profitability. It’s all about economics,” said Langley Gace, senior VP of business development at Innovasea, which has installed over a hundred open-ocean systems in 25 countries.

“A small tweak in the positive direction of the economic FCR (feed conversion ratio) can have dramatic effects on reducing the cost of operations. In fact, reducing the FCR by 10 percent on a 3,000-tonne farm can yield a cost-reduction of over a million dollars annually,” Gace said.

But “we really have not had the opportunity to drive that FCR down and make the profitability,” he acknowledged. However, he is confident that “dramatic improvements” will be seen over the next couple of years as investment in smart technology comes to fruition.

The cost and man-hours necessary to maintain the infrastructure further out at sea, to say nothing of the risks to divers, would make the use of robots such as autonomous underwater vehicles the holy grail, he added. But given that there are still imitations in autonomous tech, the use of robots to reduce diver time and minimize fish-human interactions would be more realistic than replacing humans at this point, he said.

Regulatory challenges

For Henrik Hannus, VP of floating wind and aquaculture at Aker Solutions, regulations –more specifically uncertainty over regulations –are the main challenge in offshore aquaculture.

In the United States, unclear regulations, multi-agency permitting and resistance from environmental activists have stalled the development of offshore aquaculture.

Hawaii-headquartered Ocean Era is slated to become the first commercial-scale finfish farm in US offshore waters. However, it has been delayed yet again after its permits were put on hold early this year as environmentalists urged for a further review. The company,

formerly known as Kampachi Farms, plans to produce 88,000 lbs of Almaco jack annually in the Gulf of Mexico.

Meanwhile the first and only offshore shellfish farm permitted in US federal waters, Catalina Sea Ranch, has filed for bankruptcy protection in early 2020 amidst a number of allegations of wrongdoing. It has been alleged that it ignored permit requirements from the California Coastal Commission and the US Army Corps of Engineers, that it did not perform required inspections, and that it failed to repair equipment, reported the publication calmatters.org. The farm, sited roughly 10 km (6 miles) off Huntington Beach, CA was also hobbled by a wrongful death lawsuit.

Legislative efforts to advance offshore aquaculture have faced delays as well. The bipartisan AQUAA Act has not made any headway since it was introduced to lawmakers for consideration last year.

Executive Order 13921 signed by former President Donald Trump in May 2020 to promote American seafood competitiveness and economic growth faces the risk of being overturned after animal-rights group PETA and “Seaspiracy” documentary producer Kip Andersen jointly urged US President Joe Biden this past May to repeal the EO.

NOAA Fisheries, which under EO 13921 was named as the lead agency for identifying “aquaculture opportunity areas” in US offshore waters, has found via public consultation that resistance is focused on finfish aquaculture. Water quality and impact on marine mammals were the main concerns, said the agency (see related report on p. 26).

CAGE CULTURE

“US laws and regulations and permitting processes are impossibly difficult. Investors recognize this but they will not stop; they will be moving abroad and they will be doing what it takes to do it,” said Benetti of the University of Miami. Benetti agrees that the economics of offshore farming will be the deciding factor in offshore aquaculture’s advancement.

In Canada, offshore farming was among four salmon production systems evaluated in the 2019 report called “State of Salmon Aquaculture Technologies.” The Department of Fisheries and Oceans (DFO) report concluded that offshore farming technologies would require

“We believe it is important to work closely with the traditional suppliers to the aquaculture industry.”

– Henrik Hanus, VP, Aker

Solutions

five to 10 years of review to assess their readiness for commercial development in British Columbia, the nation’s salmon farming capital. DFO, the agency responsible for regulating aquaculture, says it is watching developments across the border.

“The inventory and identification of regulatory development initiatives and tools for offshore aquaculture in the US will provide the opportunity for Canada to examine the US framework and enable future alignment of Canada’s framework for offshore aquaculture to that of the US,” the agency said on its website.

Gace sees nations with friendlier regulations as having the opportunity to lead this sector.

“It’s a seminal moment for those folks to lay the groundwork for a sort of a fair, safe, reasonably paced permitting process and also to identify the economic potentials,” said Gace, adding that there’s considerable interest from Central America, the Caribbean and the Middle East.

In Norway, efforts are underway to build commercial-scale offshore farming operations. The country hosts the world’s first offshore salmon farm, Ocean Farm 1, operated by SalMar’s fish farming subsidiary SalMar Ocean AS.

The farm started operations in November 2017 and completed its second production cycle in 2020. SalMar plans to expand offshore operations by building additional facilities. It has already applied for a permit for such facility to be established at a site in the Norwegian Sea“further out in the open ocean than any other fish farm currently in operation,” it said in its 2020 Annual Report.

It plans to build an “even better and more cost-effective” Ocean , based on lessons learned from the US$120-million Ocean

. SalMar has made those leanings available publicly so that the entire aquaculture industry could benefit from them.

Hannus says Aker Solutions has the opportunity to play role in facilitating environmentally sustainable salmon farming further out into the open sea by leveraging its expertise and capabilities from the oil and gas sector. The company signed a deal in December to build two large offshore fish farming facilities for Norway Royal Salmon’s Arctic Offshore Farming project.

Such partnership is not surprising given that both sectors operate in the depths of the sea, subject to the same harsh environments. In California, decommissioned offshore oil and gas platforms at the Santa Barbara Channel are being eyed as potential sites for aquaculture projects.

It takes a village Hannus acknowledged, as did SalMar, that inter-disciplinary partnerships are required for the sector to succeed. Shoreside infrastructure such as hatcheries and nurseries will be crucial in supporting the sector’s development.

For example, keeping fish longer in land-based hatcheries and the nurseries will result to more hardy fish that would withstand the offshore environment better.

“We believe it is important to work closely with the traditional suppliers to the aquaculture industry, as well as aligning typical marine and offshore suppliers with decades of experience from exposed waters and developing a competitive national network of suppliers and contractors for the future aquaculture industry,”

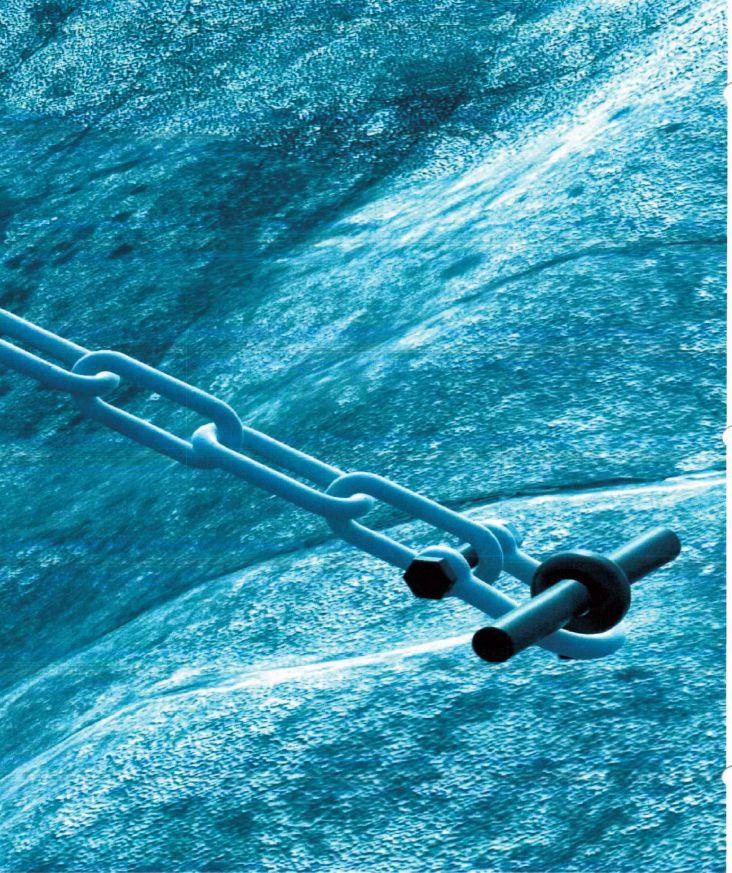

AKVA group Flying Net Cleaner 8 V2.0 The One-Stop Shop for Net Cleaning Solutions

The Flying Net Cleaner is more then just a net cleaning solution, it supports an optimal environment for feeding and fish performance

“The AKVA FNC8 is the best performing net cleaner we have ever purchased. It performs really well cleaning the nets from the get-go- keeping the growth from reoccurring for a longer period of time. The cameras are very high quality and we use them as a net inspection, reducing dive time”

- Donald McIntyre

AKVA group is a leading supplier of aquaculture technology, promoting well known brand names such as: Wavemaster, Polarcirkel, Fishtalk and Akvasmart. With offices located in British Columbia, Newfoundland, and New Brunswick, AKVA group North America can deliver from coast to coast.

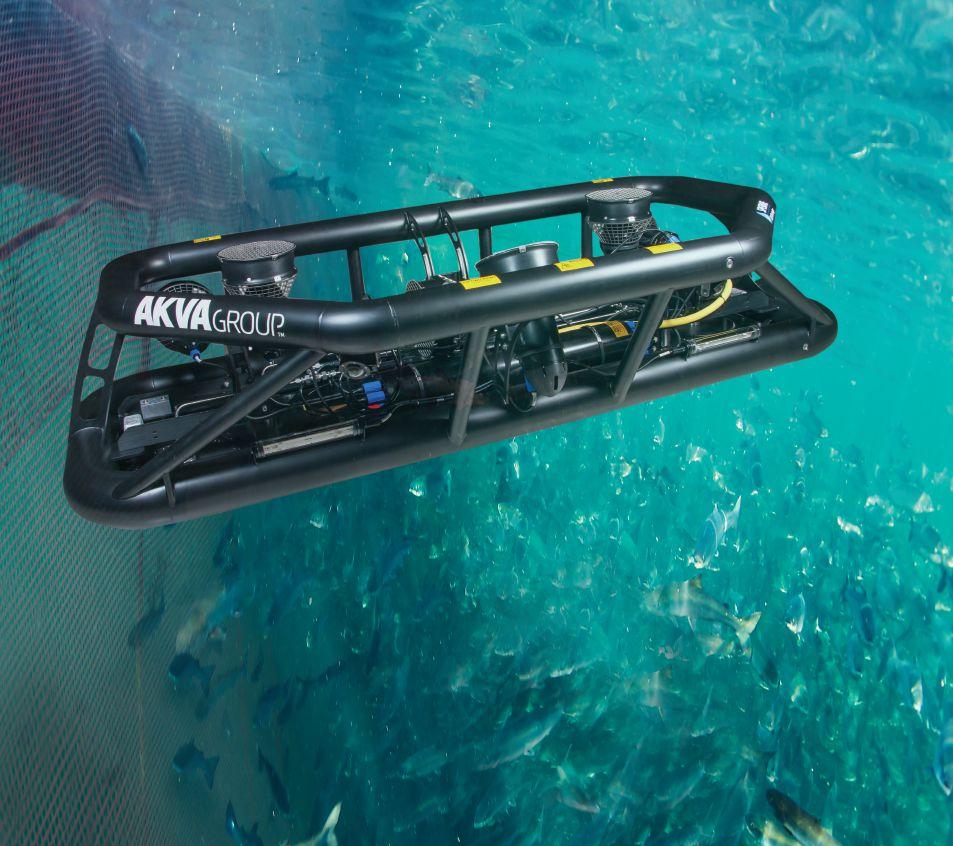

BIG PLANS for innovative salmon venture proposed for Maine

American Aquafarms to invest $250 million in world’s largest full-cycle facility based on floating cages

BY LYNN FANTOM

Unlike many management teams who trial technology new to them on a smaller scale, American Aquafarms is starting out big. The Norway-based entity, founded in late 2019, is making its first foray into salmon farming with a floating semi-closed containment system that itself was first marketed at commercial scale in 2019.

If approved in Maine, it will be the first deployment of Ecomerden’s “eco-cage” in the US and, experts believe, the first such semi-closed system in the country. The goal is to produce 30,000 metric tons of Atlantic salmon by 2024.

The venture comes at a time of robust exploration of semi- and closed-containment technologies. “We see a clear new direction politically worldwide, in both Canada and Norway, where the governments are starting to demand using other systems to make sure that we can increase production and, at the same time, take care of the environment,” says American Aquafarms chief executive Mikael Rønes.

Another pioneering aspect of the young company’s plan is to raise salmon to harvest size in the “eco-cages,” a benchmark Cermaq Canada is now testing. “The primary use [in Norway] is to produce a smolt and post-smolt,” notes Eirik Jors, American Aquafarms vice president.

The company is applying for two lease sites

of 60.3 acres each in Maine’s Frenchman Bay. Each mooring system will tether 15 pens, along with a barge for power generation, feed, waste, and monitoring technologies.

It remains to be seen whether or not this is all too much for a busy harbor between two sites of Maine’s historic Acadia National Park. The company filed its pre-application with the Maine Department of Marine Resources on March 3 and has a “very comprehensive and very rigorous” process ahead if it gets a green light to proceed, according to Sebastian Belle, executive director of the Maine Aquaculture Association (MAA).

“Things may take time, but we are here for the long run,” Rønes says. “We do not have external investors we need to answer to on why things are slowing down or moving faster.”

American Aquafarms is co-owned by Rønes’ investment company Global AS and Amar Group, which is led by aquaculture heavy-hitter Bjorn Apeland.

Rønes, who grew up in Norway surrounded by aquaculture, pursued an early career in finance. In 2008, he was convicted of defrauding investors and sentenced to four years in prison. Later, he saw the potential of cod as a species for aquaculture and, in 2017, founded a company now known as Norcod. He exited in 2019, and Norcod went public in 2020.

Rønes sees himself as an entrepreneur who has defied those who tell him things can’t be done. “I’ve gone against the wind,” he says.

American Aquafarms plans to invest about $250 million in the end-to-end operation that includes both hatchery and processing operations on an 11-acre site. It is envisioned as the world’s largest full-cycle facility based on semi-closed floating cages. Rønes says the scale is driven by the goal to keep the facility humming 52 weeks a year.

That volume is a step in satisfying the appetites of American salmon lovers. Within a 24-hour truck drive, Maine farmers can reach 130 million consumers, notes MAA’s Belle. Because of its quality, Maine seafood typically fetches prices 10 to 20 percent higher in the marketplace, he adds.

For American Aquafarms, Frenchman Bay in Maine met criteria for water temperature, depth, and shelter from harsh weather. That is of particular concern as Atlantic coastal storms, known as nor’easters, increase in intensity due to climate change. In fact, engineers say that the main challenge of a floating closed containment structure is to obtain a calm environment suitable for fish farming during high energy conditions.

Ecomerden touts its cage as “able to withstand a long wave resonance period…on more exposed sites.” Such equipment standards, as well as operational produces (no sure if you meant to have produces here), will be part of the containment management plan American Aquafarms must submit to Maine regulators as it vies for permits.

In addition to environmental conditions, Maine’s heritage as a working waterfront attracted the Norwegian investors. Aquaculture is a key industry in Maine’s 10-year economic development plan, notes David Farmer, spokesperson for American Aquafarms. Although robotics will bring operational efficiencies, about 90 jobs sea-side are anticipated, with even more in processing.

But those jobs may not offset the concerns about “industrialized” aquaculture among environmentally and tourism-minded Mainers. When the first commercial-size Ecomerden cage was installed in Norway in 2019, one observer said it resembled “a spacecraft from one of the Star Wars movies, hanging on steel wires.” Maine’s tolerance for an interplanetary invasion

CAGE CULTURE

DESIGNING WAYS

The innovative design of American Aquafarms will wrestle down some of the toughest challenges facing sea farming.

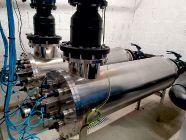

The semi-closed pen structure tackles sea lice. A floating ring of rigid aluminum holds a circular sack made of a high-strength polymer, which extends in a cone to a depth of 36 meters. The pen’s water supply is drawn from below, where fewer sea lice exist.

Water flow via four pipes in different positions creates a circular current and refreshes the sack every 80 minutes. Seasonally, the intake can be adjusted to different depths to help control the water temperature inside the pen, providing a more stable environment for the fish. Because the pen is closed, oxygen must be continuously added, but this gives operators more control.

Prolonged high temperatures and low oxygen have caused mass mortalities in open fish pens in the recent past.

The closed membrane is designed to withstand 28 tons of force per square meter. Such strength protects against breaks by predators and related fish escapes. A secondary nylon net inside the polymer membrane adds redundancy.

of 30 such cages among its quaint lobster boats and kayaking tourists remains an open issue.

Every project of any size in Maine has to overcome the “uncertainty of something new,” adds Farmer, who is based in Maine.

“Is the visual impact of multi-story cruise ships coming in and out of Frenchman Bay any worse than the lights from fish pens? But we are familiar with the cruise ships,” he says. “I would just posit that if we tried today to build a lighthouse in the state of Maine, we could not do it.”

Biofouling, the cause of a 2017 open net pen collapse in Washington State, will be addressed by a robot that moves around the cage rim with a submerged brushing system. It scrubs the net inside and out from top to bottom, 24/7. A remotely operated vehicle will clean the outside of the pens and the mooring systems periodically.

All of this occurs under the watchful eye of the land-based control facility, where operators will control feeding, regulate oxygen, inspect pens, and monitor fish behavior. The system can collect about 90 percent of fish waste, a major environmental concern. It is pumped to a central main line connected to the barge. There, a sludge treatment system developed by Blue Ocean Technology will use recycled heat to dry it down to 45 percent “virtually odorless” solids. This process cuts energy costs and carbon emissions, while making it easier to transport sludge back to the land-based facility. American Aquafarms will soon decide which byproducts to pursue, such as production of biogas or pyrolysis oil.

David Kiemele: On Leadership, Expertise, and the Scientific Method

Reflections as Cermaq wraps up first phase of semi-closed containment test in BC

BY LYNN FANTOM

After launching Canada’s first trial of a semi-closed containment system (SCCS) last fall, Cermaq is now announcing positive initial results. The news follows successful tests in Norway, beginning in 2017, with Certus, a system that prevents the transfer of lice from wild salmon to farmed populations, among other benefits. But the Canadian team, under the leadership of David Kiemele, plans to go one step further: to grow a cohort to harvest size for the first time.

ANA asked managing director Kiemele for his perspective at this important juncture.

You have a rigorous learning agenda.Will you describe it?

David Kiemele: So, we initially stocked the cage back in November, with a plan to take a group of fish out of that pen at around 700 grams and then another group out at 1.5 kilos, and transfer them to traditional ocean cages located next to the semi-closed cage. The final group stays in until harvest weight.

We successfully moved the first group of those fish out at 700 grams last month (in April) and they’re now growing in traditional ocean cages. It’s exciting to see how they’ll perform (in the open cages) and how the remaining two cohorts in the SCCS perform with a third of the population now out.

This technology has performed well in Norway. Now you are testing it again in Pacific waters. Why?

DK: I work for a company that allows innovation to take place. And it fosters a global network of experts. But it’s not only learning how to use the technology efficiently. It’s also learning to use it in harmony with your legislative jurisdictional requirements.

The new system, known as Certus during promising tests begun in 2017 in Norway, features an impenetrable barrier between the open ocean and the inside of the pen. It is the first of its kind in Canada

For example, here in Canada, the cage that’s deployed at the Millar Channel farm site is engineered to hold more fish through the whole harvest than we’re currently planning to grow this cycle. And that is directly related to a “proof of concept” that our regulators require before we increase densities. Which I think is a smart idea.

So, how’s it going?

DK: It’s like driving a sports car, you have a person who can drive it really well and knows how to handle it…And you have someone who’s never driven a car before and they’re handed the same car. The performance around that track is going to vary greatly, right? So, to use the analogy, we’re getting our laps in right now. But I must say we are very pleased with the results to date.

Can you share some performance metrics?

DK: At the time of the movement of the fish into the ocean cages last month, we’d seen that the fish in the SCCS are growing about 25 percent faster than in neighboring ocean cages. We have not had to treat or manage the fish in the semi-closed cage to date for lice, where neighboring cages on the same site have required one treatment. And the growth has

also spurred a lower feed conversion rate, which is, again, a positive sign that the fish are happy in the cage and performing well.

What challenges do you see going forward?

DK: So, we’ve been talking about our experience during winter months. The real benefits we’re hoping to see with SCCS will really shine through in the summer as the environment starts to change on the west coast of Vancouver Island.

Spring and summer mean increased incidence of harmful plankton or jellyfish. The intake pipes of the SCCS have been designed to be lowered to a depth of 23-24 meters, based on year-over-year water samples from that site before the cage arrived.

— is I reflect a lot about what I’ve been through, what I’ve seen work, what I’ve seen not work. I do my own analytical exercise in my head. You can really only undertake that if you’ve been through certain experiences, right?

I’ll be at home on a Saturday night watching a hockey game. All of a sudden something will pop into my head pertaining to the business. And I’m like, “This is a good idea.”

It happens all the time. You’ll find that a lot if you talk to salmon farmers. They’re very

passionate about what they do. You’re raising an animal, providing food for people.

What are the factors of success today?

DK: We talk a lot about the fish. Innovation. Technology. Political challenges. But, at the end of the day, I could get a new farm tomorrow with the best feed barges, the best cages, the best fish. And if the people aren’t there, then the results aren’t going to reflect those advances.

We have profiled our water column and the deeper you go for the majority of the time, the lower the risk. The plankton, the jellyfish we see usually occur in the top 15 meters of water. And, so, we dropped the pipes below to avoid bringing them into the SCCS. And, so far, it appears to be working.

How does your background with traditional net pen cages help you farm with this new technology?

DK: I’ve been doing this now for 21 years. I’d like to think that what I’ve done — and continue to do — is learn something new every day.

Farming fish in the ocean is never the same. No day is like the last. And really how I approach opportunities — and challenges

as the first two opportunity areas for open ocean aquaculture in the US

US search for ‘aquaculture opportunity areas’ advances

NOAA Fisheries has named Southern California and the Gulf of Mexico as the first regions suitable for commercial aquaculture in the United States under the agency’s mandate to identify “aquaculture opportunity areas” (AOAs) per former Pres Donald Trump’s Executive Order on Promoting American Seafood Competitiveness in May 2020.

Input from stakeholders guided the agency in the selection of regions in federal waters, defined as located 46 km (25 nautical miles) from the shore and with depths of 10 to 150 meters. This means coastal areas, where salmon aquaculture is happening for instance, are not part of the selection pool.

Further investigation is underway to determine which particular areas within the two regions identified are suitable for aquaculture. The “triple bottom line” of environmental, economic, and social sustainability further guide NOAA in the selection process.

It may take at least another two years, NOAA said, before the specific areas within the first two AOAs are identified because they will have to undergo a lengthy environmental impact assessment.

The good news is that seafood farmers looking to set up operations within AOAs means background information on what other resources exist in that area and what the potential impact of aquaculture operations may be, are already in one place to help in the permitting process.

“If they opt to set up farming operations outside an AOA, all that information would have to be pulled together,” said Christy Beard, policy analyst at NOAA Fisheries, said in a webinar in May.

“AOAs are about finding the best locations. There are no restrictions on the types of operations or who can set up,” she added.

Meanwhile, feedback from stakeholders showed “opposition focused on finfish aquaculture,” with issues raised centering on water quality ad impact on marine mammals, said Beard.

In terms of regions, Alaska showed support for AOAs for shellfish and seaweed aquaculture, while coastal Washington opposed AOAs. The Northeast, where stakeholders cited conflicts with the lobster industry, also opposed them. “Florida is the only place where we have overlap in where we should go next,” she said.