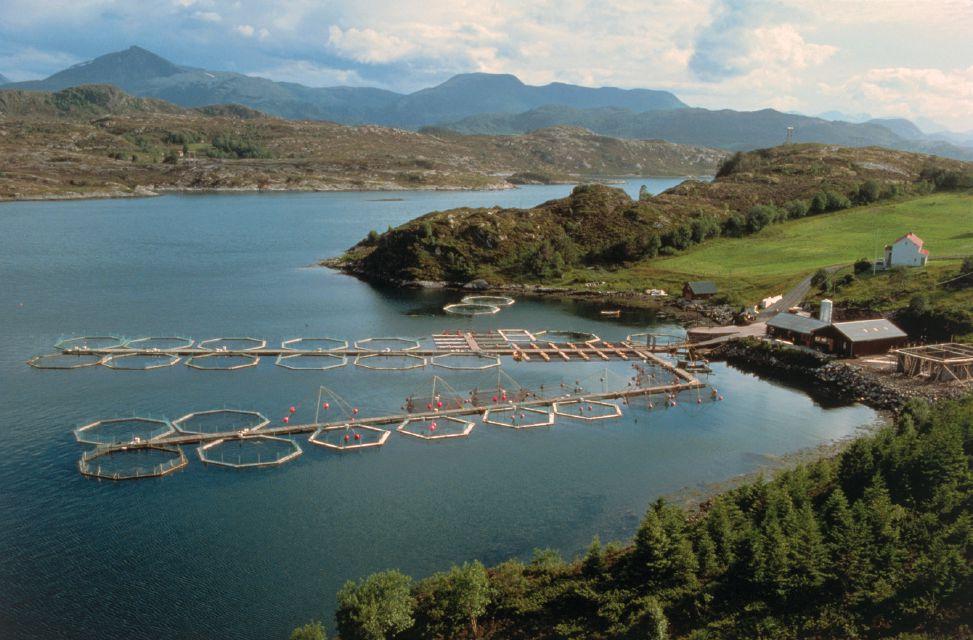

Limited number of permits issued for open-water net pens hinders commercial efforts

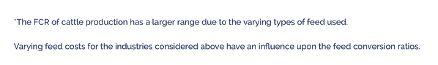

BY HEATHER WIEDENHOFT

The National Oceanic and Atmospheric Administration (NOAA) reached a milestone in May with its rst harvest of an all-female generation of mature sable sh. is is a landmark achievement as it makes the farming of this tasty, buttery sh on a commercial scale within the grasp of US sh farmers. e sh harvested weighed an average of 5.47 lbs each, for a total of 20,227 kgs (roughly 44,593 lbs).

“ at average size is akin to a 10-year-old sh in the wild,” remarked an astonished Kurt Grinnell of Jamestown S’Klallam LLC, owned by the S’Klallam tribe in Washington State and a partner

Taking ‘deadbeat’ sea urchins from the wild and fattening them in captivity opens up potential new opportunities in aquaculture From ‘deadbeat’ to delicacy

BY TOM WALKER

Taking an animal near the bottom of the benthic food chain and elevating its status to a premium sushi product, while helping to restore damaged aquatic ecosystems sounds like a win-win for Urchinomics president Brian Tsuyoshi Takeda.

“We are taking a natural resource that has very little economic value, a sea urchin with little or no marketable roe, and we are turning it into one of the most attractive seafood products on

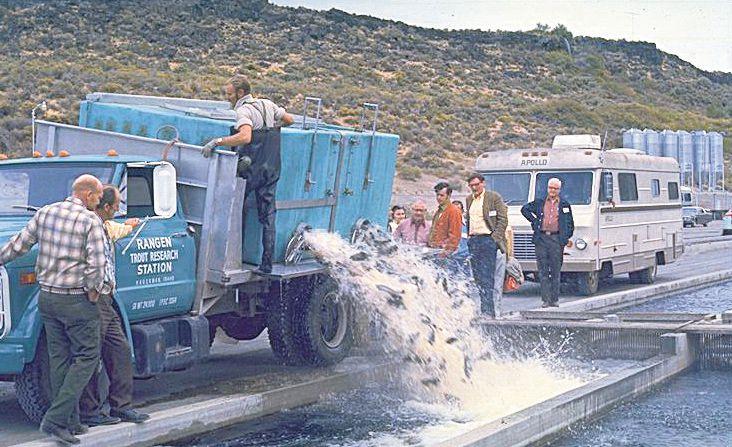

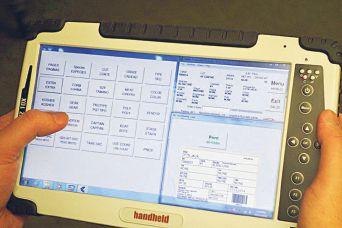

NOAA scientists Bill Fairgrieve and Adam Luckenbach hold sablefish from a trial that was completed during the first week of May 2017, when the scientists made their first harvest of mature fish raised in net pens

on the research project with NOAA. Grinnell was very happy with the harvest, with low mortality rates similar to cultured salmon species. He sees “a big yield from a small space because sable sh is a hearty species that can withstand low-oxygen conditions and large temperature changes.”

e harvest marks the culmination of e orts of researchers at NOAA’s Northwest Fisheries Science Center in Seattle who, in 2015, succeeded in producing a genetically all-female generation of sable sh (Anoplopoma mbria). Females grow faster than males and are up to 30-percent larger at 24 months in aquaculture environments. Since

continued on page 7

the planet,” says Takeda from his company base in Norway.

“I have seen one fresh whole urchin go for $10 each in Tokyo,” says Takeda. “ at’s less than 100 grams of product.” He adds that processed “roe” as it is called (actually the gonads), and known as Uni in Japan, can fetch from $80 to $400 a kilo.

Workers haul catfish out of a pond in Moorehead, Mississippi. After years of decline, the catfish farming industry in the US is rebounding

Record-high fish prices making segment attractive again

BY MATT JONES

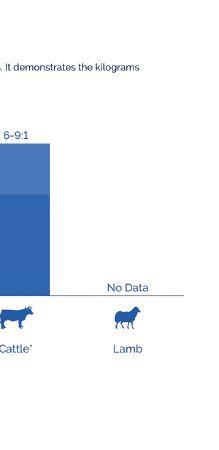

ver the past 14 years, the aquaculture industry has seen a roughly 80-percent decline in the amount of pond space dedicated to cat sh, from a peak of around 80,000 hectares in 2002 to about 25,000 hectares in 2016.

Dr Jimmy Avery, who cited the gures in his paper on the status of the US cat sh farming industry, said however that the rate of decline has slowed signi cantly in recent years and new ponds were built in 2016 due to record live cat sh prices.

Avery is with the Mississippi State University’s ad Cochran National Warmwater Aquaculture Center. He presented his paper at Aquaculture America 2017.

“If you look at the period, for example, from 2006 to 2010, you’ve got very at sh prices at about $0.77 to $0.79 per pound,”

You take pride in your operations and the health of every fish matters. Infectious Hematopoietic necrosis (IHN) is highly dangerous and unpredictable and now, more than ever, it is imperative that your fish stocks are protected. With one small dose of Apex-IHN you can help protect your fish against this deadly disease by stopping it before it starts.

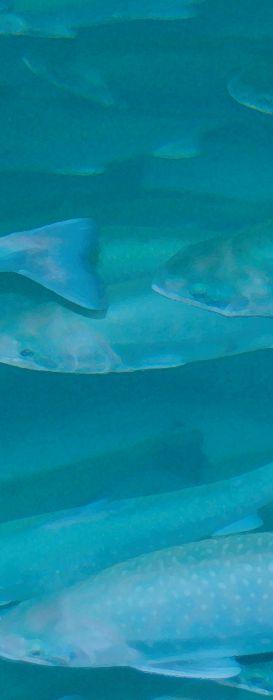

US company’s in-feed treatment approach to fight sea lice in salmon and trout has been found to provide protection against Caligus rogercresseyi most common louse species affecting salmonid farms in Chile — by an average of 35.8 weeks.

Chile was the first country to grant market approval of the Lufenuronbased treatment Imvixa, developed by Elanco. Over 50 million salmon have now been treated with Imvixa. The results show that the treatment is currently the

most effective medicinal product available in the country, said the company.

Salmon with sea lice. An in-feed treatment applied on more than 50 million salmon in Chile has been found effective against sea lice for roughly nine months

The treatment is given in feed to fish in freshwater before they are transferred to sea sites.

Studies have shown that it inhibits the formation of chitin in sea lice, which prevents the lice from developing into adults, said Elanco (ANA, Jan/Feb 2017, page 23).

UM

Project aims to identify and select species that can be successfully raised in RAS

joint-venture research project that seeks to advance aquaculture technology for high-value marine fish such as tuna and Japanese flounder (hirame) is underway at the University of Miami’s Experimental Fish Hatchery.

UM’s Rosenstiel School of Marine and Atmospheric Science and New Yorkbased Aqquua LLC are collaborating in the three-year, $1.5-million project.

“The first step towards implementing viable land-based aquaculture operations is to identify and select species that can be successfully raised in recirculating aquaculture systems (RAS),” said Charlie Siebenberg, Founder and CEO of Aqquua US. “For this reason, we have teamed up with UM Aquaculture to identify and select high-value species that can be raised at high stocking densities in such systems.”

The initiative will include upgrading existing facilities at the UM Experimental Fish Hatchery to conduct studies on reproductive physiology other requirements necessary to optimize aquaculture technologies of selected species.

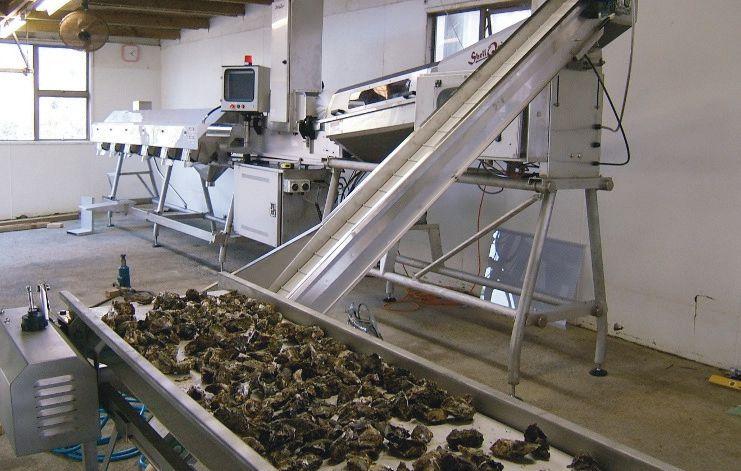

North Carolina shellfish grower sorts oysters.

Lawmakers believe that amending a federal rule that aims to protect submerged aquatic vegetation could boost the state’s aquaculture industry

Credit: Millpoint Aquaculture

orth Carolina has the potential to become the “Napa Valley of Oysters” but a federal rule that aims to protect submerged aquatic vegetation stands in the way, two state lawmakers contend.

Senators Norman Sanderson (R-Carteret) and Bill Cook (R-Beaufort) filed Senate Bill 410 (Marine Aquaculture Development Act), which seeks to allow shellfish cultivation and aquaculture activities in North Carolina waters containing submerged aquatic vegetation. The senators believe the federal rule that aims to protect submerged aquatic vegetation is too restrictive.

“This policy is more stringent than policies used in other coastal states, including the Commonwealth of Virginia,” said the senators in a statement. “Shellfish lease applications in North Carolina have been routinely denied by the Division of Marine Fisheries due to the presence of any submerged aquatic vegetation.”

They believe that amending the federal rule has tremendous potential to create new jobs in the shellfish and aquaculture industry.

“With our acres of pristine waters and a large and growing interest in cultivated oysters, the potential for the industry in the state is huge,” the senators said. “Our goal is for North Carolina to become the Napa Valley of Oysters.”

-Non-Corrosive schedule 80 PVC reactor bodies are stronger and handle higher internal pressures compared to HDPE and Polypropylene. Schedule 80 reactor bodies are seawater safe and will not corrode in harsh environments, unlike stainles ssteel

-Single end glassware access makes for easy maintenance when replacing lamps and quartz sleeves

-Thermoplastic or Fiberglass NEMA 12 Power supply enclosures with Standard HMI control package or optional HMI Pro Series control package.

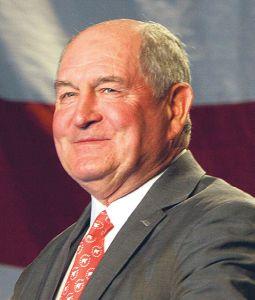

Students help tend a community garden by the Recirculating Farms Coalition. The organization is urging the new Secretary of Agriculture, Sonny Perdue (inset), to support the expansion and development of farming in the US, particularly their quest for organic certification

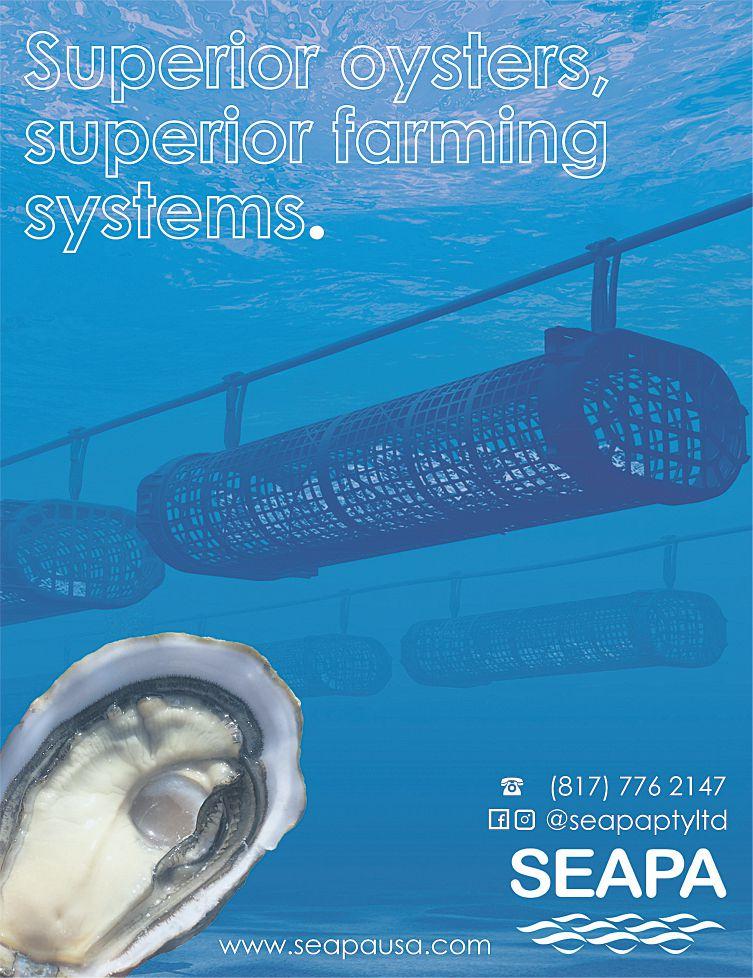

Agroup representing farmers, educators and NGOs committed to helping raise the profile of recirculating farms has asked the new US Secretary of Agriculture to support aquaponic and hydroponic farming.

Sonny Perdue was sworn in as the 31st US Secretary of Agriculture in April.

“We hope that his first accomplishments will include supporting expansion and development of farming in the United States by making sure hydroponic and aquaponic farms are able to keep their hard-earned USDA Organic certification,” said Marianne Cufone, executive director of the Recirculating Farms Coalition.

“Recirculating farms, like many hydroponic and aquaponic operations, can use less water, space and energy than most traditional in-ground and raised-bed growing methods using dirt. Many facilities already meet or can even exceed existing organic regulations. Allowing these farms to keep their USDA Organic certification would send a powerful message that the USDA values sustainability and innovation,” she added.

-Electronic ballasts matched to the performance of the specific lamp for optimal UV-C output and longest useful lamp life

-Standard Over Temperature Safety Cutoff Switch thermally protects reactor when water temperature reaches 120 Degrees F

-American made low pressure amalgam (ALH/

- AUH models) and high output (HLH/HUH models) lamps. These lamps are rated 80% efficient at the end of 12,000 hours.

Editor Liza Mayer Tel: 778.828.6867 liza.mayer@capamara.com

Advertising Sales Jeremy Thain Tel: (250) 474.3982 Fax: (250) 478-3979

Toll free in N.A. 1.877.936.2266 jthain@annexweb.com

Art Department James Lewis Tel: (709) 754-5059 james@capamara.com

Editorial Director Peter Chettleburgh Tel: (250) 478-3973 Fax: (250) 478-3979 peter@capamara.com

Regular Contributors: Quentin Dodd, Ruby Gonzalez, Erich Luening, John Nickum, Matt Jones, Tom Walker, Amanda Bibby Group Publisher - Scott Jamieson sjamieson@annexweb.com

COO – Ted Markle, tmarkle@annexweb.com

President & CEO – Mike Fredericks

UNDELIVERABLE

ADDRESSES TO: Aquaculture North America. CIRCULATION DEPT. 80 Valleybrook Dr., Toronto, ON M3B 2S9 United

alifornia-based Seafood Watch in June upgraded farmed salmon certified by the Aquaculture Stewardship Council (ASC) to “Good Alternative,” which means ASC-certified salmon is now on Seafood Watch’s list of seafood it recommends to consumers.

The updated recommendation will significantly increase the availability of sustainably farmed salmon in retail stores and restaurants, making it much easier for consumers to make an informed decision over the seafood they purchase, said Seafood Watch.

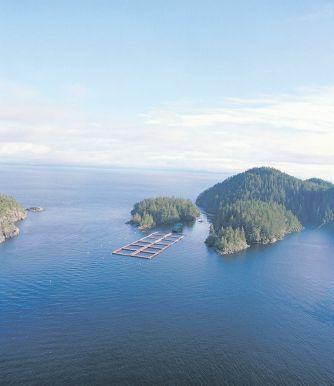

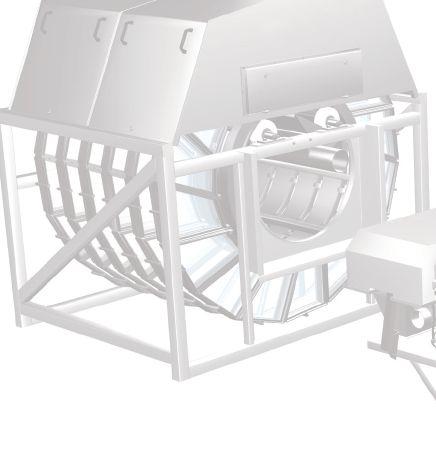

almon farming company SalMar of Norway has taken delivery of the world’s first semi-submersible offshore fish farm that’s seen as a game-changer in the aquaculture industry.

Ocean Farm 1 is designed to test out both the biological as well as the technological aspects of offshore fish farming. The 360-foot-wide structure is designed to accommodate water for farming 1.5 million fish while maintaining a death rate of less than 2 percent, according to media reports in China, where the facility was built. It has a 25-year lifespan, can resist powerful typhoons, and requires only three to seven employees to operate.

ASC-certified salmon is now on Seafood Watch’s list of seafood it recommends to consumers but SeaChoice disagrees with decision

However, SeaChoice — a coalition of Canadian environmental groups — disagrees with Seafood Watch’s decision because the ASC salmon standard, on which the upgrade was based, has allowed some “variances” when applied on certain salmon farms. For example, ASC allows British Columbia salmon farms to be certified with more than 60 times the number of lice permitted by the standard, said SeaChoice. In Chile and Norway, ASC has allowed variances in chemical and drug use on farmed salmon, such that this “far exceeds prescribed limits” in those countries, said the group.

“Allowing variances to meet the sustainability criteria undermines the salmon standard. SeaChoice does not recognize ASC-certified farmed salmon as a ‘Good Alternative’ equivalent for consumers because Seafood Watch did not review these variances in its benchmarking process,” said SeaChoice in a statement. The group is asking ASC to no longer allow requests for variances so ASC can become a true gold standard for evaluating responsible aquaculture.

“The environmental organizations behind the SeaChoice program were so bullish on the ASC standard, and the Sea Choice program itself, when our members in BC were not able to reach that standard or were not recognized by that program. Their failing to recognize the advancements and innovations in salmon farming in BC is unfortunate.”

— Jeremy Dunn, executive director, BC Salmon Farmers Association

The executive director of the BC Salmon Farmers Association (BCSFA), Jeremy Dunn, said the ASC certification is recognized as the gold standard and most robust third-party certification available for salmon farms. “In BC our members are meeting that at a rate as fast or faster than anywhere in the world. Over 15 percent of our production is certified to that standard,” he told Aquaculture North America (ANA) Dunn said close to $200 million has been invested or committed over the last three years mostly in technology and practices that increase the overall performance of BC salmon farms on many of the metrics that ASC measures on. He said many have complimented and recognized the industry for these advancements, thus it is quite “unfortunate” that SeaChoice fails to recognize them.

“The environmental organizations behind the SeaChoice program were so bullish on the ASC standard, and the SeaChoice program itself, when our members in BC were not able to reach that standard or were not recognized by that program. Their failing to recognize the advancements and innovations in salmon farming in BC is unfortunate,” he told ANA Dunn said BC salmon farmers will continue their march to sustainability and to working with organizations that are recognizing the improvements that they are making in their operations.

Seafood Watch’s decision also had its share of support from salmon farming giant Cermaq. Upgrading ASC-certified farmed salmon to “Good Alternative” is important especially in the US market, where the ASC standard is less known than in Europe, it said.

Upon arrival in Norway from Chinese shipbuilder Wuchang Shipbuilding Industry Group in the second half of the year, the offshore fish farm will be positioned in Frohavet, off the coast of Trøndelag, said SalMar in a statement.

As a full-scale pilot facility, Ocean Farm 1’s objective is to spur new technology concepts that can ensure sufficient growth whilst also ensuring environmental sustainability, said SalMar, adding that the “project could represent a new era in sustainable seafood production and is potentially adaptable worldwide.”

SalMar has reportedly ordered another five similar vessels.

Tilapia ranks fourth among Americans’ Top 10 favourite seafood but it could disappear from dinner tables if a highly contagious disease spreading among farmed and wild tilapia is not stopped in its tracks.

Although not a human health risk, the fish disease —Tilapia Lake Virus (TiLV) — has large potential impact on global food security and nutrition, said the Food and Agriculture Organization (FAO) of the United Nations, in a warning it issued on May 26.

“The outbreak should be treated with concern and countries importing tilapias should take appropriate risk-management measures — intensifying diagnostics testing, enforcing health certificates, deploying quarantine measures and developing contingency plans,” the FAO statement said.

Protests focus on industry’s expansion and new salmon-waste composting facility

rieg Seafarms’ planned expansion of operations in the Canadian province of Newfoundland and Labrador continues to draw protests from residents concerned over its potential environmental impacts. A new coalition has been formed to advocate for a more responsible expansion of the industry. At the same, a Newfoundland mayor opposes a related project, which she says will have impact her community negatively.

Our feeders deliver and pay for themselves over and over.

TILV SIGNS

First signs of the virus were discovered in the summer of 2009 in several fish farms in Israel, where massive losses of tilapia were observed, according the study, “TiLV, An Emerging New Viral Disease of Tilapia spp” by researchers Ra’anan Ariav, Natan Wajsbrot and Allan Heres.

“The existence of fish that survived the TiLV disease strongly suggests that an effective immune response against this pathogen can be mounted. This has important applications for future disease containment strategies.”

Maximize feed coverage and spread for best FCR

— Ra’anan Ariav, Natan Wajsbrot

and Allan Heres

The Newfoundland and Labrador Coalition for Aquaculture Reform (NLCAR) was formed in March by representatives from concerned organizations, including the Salmonid Council of NL, the Atlantic Salmon Federation, environmental advocacy groups, First Nations bands, and a number of scientific and academic advisors.

Reduce feed handling and labour costs

NL-CAR’s website outlines the coalition’s goals:

• freeze any further expansion of marine net pen aquaculture

Free consultation Call or email us!

• review and revise marine net pen regulations to strengthen environmental protections

Signs of the disease were “gross lesions… characterized mainly by unilateral or bilateral ocular alterations (cataracts). Other lesions, observed in diseased pondraised tilapia included skin erosions and moderate congestion of the spleen and kidney,” the researchers wrote in an abstract presented at Aquaculture America 2017 in February. They also noted that morbidity and mortality was limited only to tilapia species and hybrids (Oreochromis niloticus X O. aureus hybrid).

parasitic infection, leading to mortality rates of over 50 percent in juvenile tilapia populations. The existence of fish that survived the TiLV disease strongly suggests that an effective immune response against this pathogen can be mounted. This has important applications for future disease containment strategies,” said the researchers.

FAO said TiLV has now been reported in five countries on three continents: Colombia, Ecuador, Egypt, Israel and Thailand.

Aquaculture North America Quarter Page

“Disease outbreaks are frequently characterized by secondary bacterial and

• a reasonable transition of existing marine net pen aquaculture to closed containment systems

• require that all new salmonid aquaculture operations be closed containment only

www.iasproducts.com info@iasproducts.com +1 604.924.1844

Tilapia is among the most important fish in aquaculture, with China, the Philippines, Taiwan, Indonesia and Thailand among the leading suppliers. Tilapia culture is a small part of the aquaculture industry in North America because of their temperature-sensitivity.

— Liza Mayer

Light management for best fish growth & maturation control

• Customizable light spectrums, intensity, and sizes

• Designed for long term underwater submersion

• Manage dimming levels with SeeBrite™ L100 Light Dimmer

• Certified UL CSA & CE compliant

www.iasproducts.com info@iasproducts.com +1 604.924.1844

The coalition says government agencies have failed to protect the environment and that there is an inherent conflict of interest when regulatory agencies are responsible for both conservation and development. The coalition also wants an aquaculture advisory committee comprised of industry, government, academia, funding agencies and environmental groups be formed.

NL-CAR did not respond to a request for comment by press time.

Residents of Whitbourne have been voicing their concerns over an industrial composting facility planned for the area. Mayor Hilda Whelan has publicly pondered whether the community’s concerns were falling on deaf ears because the facility would process waste from Grieg’s planned $250-million operation in Placentia Bay, among other clients.

Whelan says that she cannot understand why the planned site for the project is so close to town when there is a no shortage of available areas further away from the community.

But Grieg NL told Aquaculture North America (ANA) that “no such arrange-

ment has been made with the proposed facility in question.” “Grieg NL has made arrangements for any future waste products with currently existing facilities in our area of operations,” the executive said.

Whelan also cited concerns over potential fires, stating that a compost fire is unlike a standard fire and that the community’s volunteer fire department has not been trained to deal with it.

Representatives for the company behind the project, Metro Environmental Services, have disregarded the Mayor’s concerns, telling CBC News that there would be no smell associated with the project and that putting out compost fires would require no special training for fire fighters.

Fire department officials agreed that no special equipment or additional firefighting training is required to extinguish Class-A piled material such as compost.

Environment Minister Eddie Joyce denied that political pressure would have any impact on whether the project is approved or not. “This will be approved or rejected on the information that’s found. This will not be done for any political expediency,” Joyce told CBC Radio — Matt Jones

continued from cover

then, scientists Adam Luckenbach and Bill Fairgrieve have been raising this generation of sablefish at facilities in Manchester, Washington (Hatchery International, Issue 5 “All Females, All the Time”).

BIG HURDLE

The scientists produce approximately 10,000 all-female juveniles each year for grow out in net pens in open water. They have the potential to produce more juveniles, a capability that’s ideal in farming an emerging aquaculture species on commercial scale. The problem, however, is the limited number of permits for net pens in open water, where these juveniles would be raised to maturity. The permits issued by the federal government are already being used to grow non-native fish species in the Puget Sound region. One company, Cook Aquaculture, owns the majority of net-pen permits and is using them to raise Atlantic salmon. NOAA is working on the permitting process for sablefish.

VALUABLE FISH

Sablefish, or black cod, has caught the public’s attention with its rich buttery flavor and healthy omega-3 fatty acids. Current wild stock numbers are unknown, but fishing is closely regulated by federal agencies. The controls on fishing have helped drive prices up. Earlier this year, prices were up roughly 11.5 percent from a year earlier — from $10 per lb at wholesale in 2015 to now $12.25 per lb — for fish 10 lbs or larger. Sablefish continues to be the highest valued finfish per pound in Alaska. The largest consumer of sablefish is Japan.

GROWING INTEREST

NOAA is providing a Texas-based aquaculture company, Global Blue Technologies, with about 7,000 fry (each weighing 0.5 grams on average) annually. Still in the development stage, Global Blue hopes to grow sablefish commercially in their indoor recirculating aquaculture system (RAS). Their goal is “to meet increasing consumer demand while decreasing fishing pressures on wild stock,” states their website. Black cod is the company’s first choice of species to showcase a commercially indoor-raised fish using RAS. In May, they introduced their product to chefs, university researchers, and government officials in Portland, Oregon, where it well received. The fish was tasty enough for sushi chefs to request Global Blue to harvest smaller sablefish — weighing 400-500 grams instead of 2,000 grams or larger — for the sushi/sashimi market.

The Jamestown S’Klallam tribe continues to work with NOAA and the University of Washington, with funding from Sea Grant, on how to best optimize sablefish growout Success in commercial-scale farming of sablefish means jobs and income opportunities for the tribe.

Outside the US, Golden Eagle in Canada has capitalized on the growing demand for sablefish. The company raises its own stocks in net pens off Vancouver Island. They are the only international provider of cultured sablefish so far.

EFFORTS CONTINUE

Researchers and growers are careful to note that for now, this emerging aquaculture venture is not meant to replace wild-caught sablefish, or even compete with wild stocks. Instead they see it as a way to help take pressure off the limited wild stocks and supplement market supply when fishing season is over. Luckenbach also sees the benefits of farming locally, rather than “bringing in fish from other countries where we don’t know the rearing history or treatments used on the fish.”

NOAA’s research strives to create a sustainable, non-GMO, flavorful product with maximum growth potential while limiting environmental impacts. Sablefish aquaculture ticks all the boxes for sustainability: it is a species native to the Pacific Coast; the eggs are taken from wild, parasite- and disease-free stock; and there’s little to no discharge from feeding in net pens.

A further step in this direction are Fairgrieve’s efforts to develop a diet similar to natural food sources and leaves little to no waste behind after feeding. Luckenbach is also working with the University of Maryland to produce a reproductively sterile sablefish to mitigate risks of crossbreeding with wild populations.

“In the 80s, we saw a big push for aquaculture in the US, but rising costs and other setbacks have left us no longer at the forefront of development and industry,” says Kurt Grinnell of S’Klallam Jamestown LLC, a partner on the research grant with NOAA. He sees hope for aquaculture in the advances that NOAA achieved.

NOAA’s initial harvest of an all-female sablefish at its facility in Manchester, Washington weighed an average of 5.47 lbs each, for a total of 20,227

weighed roughly 135 grams each when they were stocked

December 2015

NOAA scientist Bill Fairgrieve holds a tank-raised monosex female sablefish. Females grow faster than males and are up to 30-percent larger at 24 months in aquaculture environments

•

•

•

• Our tanks are available in many colors, shapes and sizes from 25 to 3000 gallons

• Smooth inside surfaces prevent damage to your fish

• Edge lips provide wall strength & minimize deformation

• Custom installation of optional drain fittings • FDA and UV sterilized

We also offer Vertical Storage , Horizontal, Cone bottom, and General Purpose tanks- see our website for details.

says Avery. “At the same time, feed was beginning to go from roughly $255 per tonne in 2006 to around $375 to $380 per tonne in 2010. So you’ve got increasing feed prices, relatively flat fish prices and increased competition from foreign competitors. And pretty much a sluggish economy during that time frame,” Avery tells Aquaculture North America (ANA).

After 2010, market conditions began to improve as domestic production has dropped to the point where the market was willing to pay more to make sure it was getting US product, says Avery. Catfish prices went up steadily from $0.80 per pound to $1.21 per pound in 2016 (see graph). Feed prices have dropped to $378 per tonne by 2016 from a high of $562 per tonne in 2012. Meanwhile, likely driven by previously dire market conditions — a variety of new technologies and techniques came to the forefront.

cover

producers be stronger. It doesn’t work for everybody, but it’s helped a lot of producers change the way that they were farming. Our workup is evolution – the strongest will survive and those of us who learn to adapt and tighten up some of our margins and watch everything a little bit closer –we’re able to hang around. We have been doing well for a few years to make up for some of those bad years.”

Joey Lowery, owner of Lowery Aqua Farm and former president of the Catfish Farmers of America, agrees, noting how the smart businesses that survived the difficult times changed their approach.

Catfish farmers have weathered some storms and those who have survived are here to stay, says Roger Barlow, president of The Catfish

“Whether you’re looking at increased aeration, the use of hybrid catfish, or the use of more-intensive production systems, [new technologies] have really allowed farmers to take advantage of these kinds of fish prices,” says Avery. “We can really get out there and produce more on a per-acre basis. It’s those new technologies that are really allowing people to take advantage of this upturn.”

Credit: The Catfish Institute

The president of the Catfish Farmers of America, Townsend Kyser, of the the Kyser Family Farms, noted that new technologies such as his farm’s oxygen monitoring system, have greatly improved the way they run their business.

“Those changes helped, and there have been some hybrid catfish that have been developed that seem to grow a little bit faster,” says Kyser, who was once named Catfish Farmer of the Year by the Alabama Farmers Federation. “That has helped some

“When prices are low, you need to cut your stocking back,” says Lowery. “You need to do things a lot more efficiently. It just doesn’t pay to try to raise all the fish you can when you’ve got bad economic conditions. People that saw that, and did that, I think fared better than the guys who just kept on hammering.”

A contributing factor in the industry’s upturn is the efficiency of operations in terms of the amount of space utilized. New techniques have allowed catfish farms to produce more fish from a much smaller space.

“I think the average production per acre now is around 6,000 pounds,” says Lowery. “Several years ago, it was around 3,500. That’s really significant, that we’re producing more fish on less acreage. And that’s due to some increased aeration, some split-cell, split-pond production technique.”

Roger Barlow, president of Mississippi’s The Catfish Institute, says what helped the industry further has been finding the right market and positioning the product correctly.

“We are American farmers and we’re growing American catfish for the

American consumer. We are not taking the consumer for granted,” says Barlow. “We understand it’s a challenge to maintain that loyalty that exists between the consumer and the farmer and the product that we offer.”

Kyser goes even further, noting that everyone who is still in business is now using labels that make consumers aware of the differences between their products and those imported from other areas.

“We have higher quality product, raised and grown in a much better environment, and some people are willing to pay for that,” says Kyser. “That’s the kind of people we need to be working with.”

Another recent piece of good news is the announcement that, as of September, catfish imported from Vietnam will be held to the same standards as those produced domestically. All producers we spoke to felt this was a very positive development.

“They [Vietnamese farmers] ought to be doing the equivalent of what we’re doing over here,” says Lowery. “Anything that comes into this country should meet our standards. I think people in this country take that for granted; they think that everything is inspected and everything is up to par, but that’s not the case at all. And we have a right to demand that as Americans.”

Barlow posits that as the industry continues to rebound and grow, regulatory issues will become more prevalent and will be the next challenge for the industry.

“We can really get out there and produce more on a per-acre basis. It’s those new technologies that are really allowing people to take advantage of this upturn.”

~ Dr Jimmy Avery

“There’s no question, there’s going to be more regulations as it pertains to water quality, groundwater usage,” says Barlow. “That’s coming our way fast. Too much regulation can stifle the industry, the right amount can benefit consumer confidence. A balance will have to be struck.”

Avery emphasizes that while things are going swimmingly now, catfish farmers need to remain adaptable to fluctuating market conditions.

“If production costs increase, say, by 5 to 10 percent, what kind of impact will that have in the marketplace? And if fish prices drop, or feed prices rise two years or three years out, that could certainly bring in new challenges.”

BY JOHN G. NICKUM

Adecision by the Court of Appeals for the District of Columbia in early April this year appears to have brought partial clarification to some of the long-standing arguments between American fish farmers and the US Fish and Wildlife Service (USFWS). Has it, or is there more to come? The long and complex history of the Lacey Act indicates that resolution will not come easily and Congress has shown little interest in clarifying or modifying the intent of bygone legislators.

Twenty-five year ago the Department of the Interior attorney chastised me when I suggested that the full meaning of a new regulation (not Lacey Act) would not be known until a substantial volume of case law dealing with the regulation was determined by court decisions. I laughed in response, inasmuch as I considered it to quite an honor to be called “cynical” by a “DC lawyer.”

American fish farmers and the USFWS have engaged in longstanding arguments about the full meaning of the Lacey Act on an array of matters pertaining to aquaculture. Considering the fact that the

Lacey Act was passed initially in 1900, it becomes obvious that judicial clarifications can be a very slow process.

The initial intent of Congress with respect to the Lacey Act had nothing to do with aquaculture, or even fish. The original intent of the Lacey Act was to supplement and bolster state laws for the protection of “game and birds.” Transporting illegally taken game or birds from one state or territory to another was the focus of the Act. Such illegal transport was elevated

Fish are transported for restocking.

The provisions of the Lacey Act that prosecutes violations of state laws and regulations in interstate commerce remain as powerful as ever, says columnist

Credit: Auburn University

to a federal violation, possibly a felony, if the value exceeded a prescribed amount. The Black Bass Act (1926) added similar protections for fish.

Serious disagreements between the USFWS and American fish farmers started to develop in the 1970s as commercial production of channel catfish and several species of bait fish expanded rapidly. Enactment of the Endangered Species Act and amendments to the Lacey Act introduced additional factors, but nothing in the legislation or the accompanying “report language” suggested that Congress was terribly concerned about the potential effects of non-indigenous species and/ or injurious species on endangered species, or native species in general. However, the belief-driven philosophies of environmentalists within the USFWS promoted a culture in which nonindigenous and/or injurious wildlife were matters of great concern and had to be tightly controlled.

The USFWS and environmental colleagues attempted to promote a “clean list versus dirty list” approach to injurious wildlife law in the early 1970s. The proposed regulations would have barred importation of any wildlife or fish not listed as approved (aka, the clean list). Congress, due largely to opposition from the pet industry, aquarium enthusiasts, and fish hobbyists, rejected the “clean list” approach; preferring to list only those species deemed to be “injurious.” The question of whether or not injurious wildlife already present in the United States were to be banned from interstate commerce or transport was not addressed. The absence of Congressional clarification left the door open for actions and interpretations that would impose the tightest controls possible.

When I arrived in the Washington, DC offices of the USFWS in 1985, the arguments were starting to simmer. My appointment as National Aquaculture Coordinator for the USFWS (and the Department of the Interior) in 1989 was driven in part by the USFWS Director John Turner’s desire to “Help Aquaculture Grow” by placing a scientist with aquaculture background in a liaison position. An “Aquaculture Summit” attended by fish farmers, fishery scientists and government officials provided lists of

priorities for research and management strategies. The summit also confirmed the need to resolve issues related to the Lacey Act, the Migratory Bird Treaty Acts and government services, such as fish health inspections.

Even as progress on these issues was developing, the belief-driven attitudes of environmental managers dealing with non-indigenous species, endangered species, and the potential effects of rearing animals in captivity was becoming evermore established in divisions other than the Division of Fish Hatcheries. Outright hostility to aquaculture was displayed occasionally. In my opinion, decisions based on personal beliefs, not evidencesupported science became more common. Given their mindsets that interpreted the Lacey Act as providing the USFWS with authority to regulate interstate movement of fish based on their injurious wildlife status was reasonable to these individuals. In their minds it was a logical extension of the Lacey Act. I resorted to keeping a copy of The Evolution of National Wildlife Law on my desk, so as to document my disagreements with them.

Although the decision by the Court of Appeals for the District of Columbia in April clearly limits the authority of the USFWS to regulate the interstate movement of animals deemed injurious by the USFWS, individual states retain the authority to ban species that the states consider injurious.

Although the decision by the Court of Appeals for the District of Columbia in April clearly limits the authority of the USFWS to regulate the interstate movement of animals deemed injurious by the USFWS, individual states retain the authority to ban species that the states consider injurious. The provisions of the Lacey Act that prosecutes violations of state laws and regulations in interstate commerce remain as powerful as ever. If a fish farmer in state “A” ships into state “B” a fish banned by state “B” for whatever reason, including classification as injurious, that farmer can be arrested and prosecuted under the Lacey Act.

The basic purposes of the Lacey Act to supplement and bolster state laws and regulations are not affected by the Court of Appeals decision. The intent of Congress stated in 1960 reaffirmed its position that interstate commerce of species listed as “injurious” was not regulated under the Lacey Act. The injurious species provisions of the Lacey Act apply only to foreign species. However, based on my experiences, I will be surprised if there is not further litigation over definitions of “foreign species” that are already present in the United States.

‘Being realistic about fish production numbers’ is key to marketing success

erry Brooks, president of Golden Eagle Aquaculture of Agassiz, British Columbia, says he has the formula to fine-tune coho farming in land-based closed containment systems. “We can do this all day long and provided we don’t outstrip the demand we will be fine,” says Brooks, who got directly involved in the company two years after Golden Eagle acquired the operations from Swift Aquaculture in 2014.

Brooks knows whereof he speaks. Under his management, Golden Eagle’s sister company — Golden Eagle Sablefish on Salt Spring Island, BC — thrived. Today, marketing and fish production at both companies are stable, the key, he said, is “being realistic about fish production numbers.”

‘We think we understand what the reasonable market expectations are. We know what we need to do to make this work.’

- Terry Brooks, president of Golden Eagle Aquaculture

The use of land-based tanks in salmon farming is technology that some, particularly environmentalists, favor over net pens in open water.

“Everybody has their own take on net pens,” Brooks says. “Some people want RAS to replace net pens. Some people think it’s the be all and end all and others think it can’t be done,” says Brooks. “I think where we are is we are beyond the research part of it. We think we understand what the reasonable market expectations are. We know what we need to do to make this work.”

“But our particular theory for our recirculation system is that it is a niche market and providing you don’t over produce, it can be a very nice market of supplying highquality fresh fish at a reasonable price. We know fresh is best.”

“There is always going to be a market for good quality fresh salmon,” Brooks says. “That is our goal here at this facility — to produce a good quality salmon and produce it for 12 months.”

Brooks believes one of the advantages of the farm’s location is the water quality. “The farm is on the north shore of the Fraser River, up against the Coast Mountains. A shallow well produces ample 8-14C water. The alkalinity is good, and we don’t have to filter it, but as with any RAS system we do add oxygen.”

“We are running our RAS system at about 80- to 90-percent recirculation,” Brooks says. “An Aquacare micro-bead biofilter system filters the water and a couple of local dairy farmers take the wet solids to fertilize their fields.”

“We are sourcing 5-gram fry from Target Marine,” says Brooks. “This is coho stock that they have been breeding for 20 years”.

Golden Eagle has two or three intakes a year. The fry are quarantined in a separate heated building, before being

Coho from Golden Eagle Aquaculture. ‘We are definitely on the higher end of the salmon product. We’re within the $3.75- $4.50 (C$5-6) per lb range at wholesale,’ says Terry Brooks

transferred to six 280m3 growout tanks, which are outside under unheated fabric domes. Total production is currently 120 tonnes a year.

The company uses a combination of Ewos and Taplow (local BC company) feeds. “We are using a very standard formula based on years of Pacific salmon research, so it’s pretty much a done deal,” says Brooks. “We do things a little bit differently because it’s a recirculation system.” He says that they work closely with Taplow, in particular, to continually develop their feed. “We use small low-tech automatic feeders.”

“Feed conversion ratios are pretty solid at 1.25 to 1.3,” Brooks says. “We have a customized conditioning method 10 days prior to harvest. The coho pigment up very well.”

Brooks says the fish are graded once at around 50 grams. It takes 16 months to reach a target harvest weight of 5 lbs. Fish are harvested every 10 days and then it’s off to a custom processor in Vancouver. The fish are distributed as both whole and fillets by Willowfield Enterprises, a Surrey, BC specialty food distributor that carries Ocean Wise-certified fish.

RETAIL MARKET

“We are doing retail right now,” says Brooks. “The fish are distributed, always fresh, between BC and Alberta. We

Tanks containing coho for grow-out. ‘Our particular theory for our recirculation system is that it is a niche market and providing you don’t over produce, it can be a very nice market of supplying high-quality fresh fish at a reasonable price,’ says Terry Brooks

don’t ship to the US. We are trying to source customers for this project as close to the farm as possible.”

“We are definitely on the higher end of the salmon product,” says Brooks. “We’re within the $3.75- $4.50 (C$5-6) per lb range at wholesale.”

“We have worked from the market backwards for two years now,” Brooks explains. “We have lots of customer feedback. We know the product is doable, so now the job is to find out what is going to be the overall tonnage we can put into an area without having send the fish too far away.”

“We are looking at expanding, but again, not to exceed the market capability [to absorb our production],” says Brooks. “I think $5-6 is sustainable. I could tell you that I’d love to get $8-9 a pound. There are certain markets that will let us do that, but they are so small that it wouldn’t be prudent to budget on that.”

– Tom Walker

Urchinomics is currently partnering to test ranching techniques to fatten the roe of wild-caught sea urchins, using a specially formulated feed and a proprietary tray system, at several Canadian locations.

It all began in Japan, after the 2011 tsunami. The tsunami washed away predator species such as crabs and starfish and within two years the urchin population increased about seven-fold, Takeda explains. “They ate the entire kelp bed that is the foundation of the coastal fishery,” he says. “No cover for fish to spawn and hide means no fish, and the ecosystem collapses. One of the most important fishery regions in Japan went from super productive to dead.”

Observers note that these so-called “urchin barrens” are occurring more frequently not only in post-tsunami Japan but also across the globe when the predator/prey balance is out of whack. “It seems to be a combination of overfishing, pollution and climate change,” notes Takeda.

If unchecked, urchins will over graze an area, destroying the kelp and eating themselves out of house and home, but the hardy creatures don’t die says Takeda. They keep their size, but remain in a dormant state. If something shows up they eat it, which will prevent the kelp from coming back and then they return to being dormant. But the roe that is the edible part of the urchin shrinks away. “Fishermen don’t want them and even the predators don’t eat them,” says Takeda. “They seem to know that they are empty.”

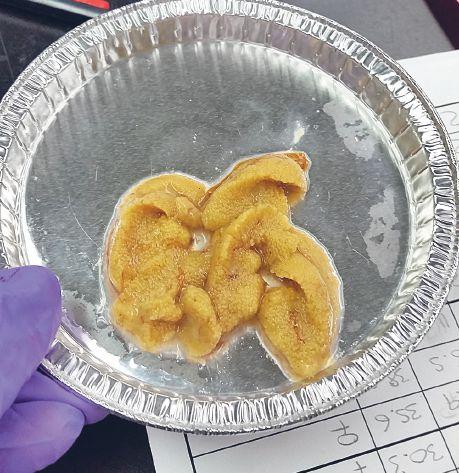

Gonads from a green sea urchin. Also called ‘processed roe’ and Uni in Japan, gonads can fetch from $80 to $400 a kilo

“We are taking an overly abundant resource that is hindering the growth of other stocks and turning it into something that tastes good and sells.”

— Brian Tsuyoshi Takeda president, Urchinomics

incentive for fishers to remove these deadbeat zombie urchins,” says Takeda “The trials in Japan were fantastic, almost too good, we thought we should probably do this again. And that was when the Mitsubishi Corporation came on board and partnered with us.”

“We have this catch-and-feed technology that we developed in Norway and we wondered if it might work in the Japanese situation,” Takeda says. “The plan was to catch, feed and fatten up the roe in these urchins and after 10-12 weeks sell them as a premium seafood product.”

“We wanted to create an economic

Urchinomics is currently working with Fisheries and Oceans Canada (DFO) at the Pacific Biological Station in Nanaimo, the DFO in Saint Andrews New Brunswick, the Memorial University in Newfoundland, and Merinov in Quebec.

“We have signed partnership agreements that include information sharing,” Takeda points out. “Cooperation and cross pollination of information is very important to the company.”

Over the last 20 years, Nofima — the Norwegian Institute of Food, Fisheries and

• 0,2g to 1000g

• Easy setup and use

• Compact Units

• Pipeline or flatbed counting

Stacks of urchin trays on John Lindsay’s boat. Urchinomics devised a proprietary tray system for sea urchin ranching

Sea urchin feed from Nofima holds its form in the water for between 7-14 days without dissolving, a quality important for urchins, which take a long time to eat

Dr Chris Pearce, research scientist at the DFO Pacific Biological Station in Nanaimo, on Vancouver Island, British Columbia, says the practice of enhancing urchin gonad yield shows promise but a lot of work needs to be done to determine its economic viability on a commercial scale.

Pearce has had a lot of experience working on gonad enhancement in urchins using commercial diets. He even developed a feed on his own.

“I was first approached by John Lindsay, a BC urchin fisherman and member of the Pacific Urchin Harvesters Association. He came to me to talk about taking low-roe-yield adults from the wild and impounding and feeding them,” says Pearce. “I knew the Norwegians have been using special trays and feeds for gonad enhancement and I eventually connected with Brian Takeda at Urchinomics.”

Pearce has just completed a 12-week gonad enhancement trial in partnership with Lindsay and Urchinomics. The company supplied the trays and the feed in-kind for the project.

“We used both green and red urchins Strongylocentrotus droebachiensis and Strongylocentrotus franciscanus that Lindsay collected from the wild,” says Pearce. They were housed in the trays supplied by Urchinomics and fed either a Nofima diet or a control diet of bull kelp. “The results of the trial showed that the prepared diet increased gonad yield much more than the kelp after the animals spawned part way through the trial.”

Pearce says in previous work with prepared diets, he started with animals as low as 3- to 5-percent roe yield and

within 12 weeks has been able to get that up to 20- to 25-percent yield.

“Research on this practice of enhancing gonads has been around for decades, but there has not been much work on a commercial scale,” Pearce points out.

“We can certainly bulk them up with these prepared diets. Some of the latest formulations are showing we can get the right color and flavor although there is still some work to be done there,” says Pearce. “The containment systems work well, but can you make money at this?”

The Norwegian trays have been developed specifically for urchin gonad enhancement and are more expensive than say, an oyster tray. There is a mesh bottom that supports the animals, with a mesh size small enough to hold the pelleted fed, but large enough for the feces to drop through. The feces and unused food collect on the solid lid of the tray below.

“There are labour costs involved with lifting up the stacks of five or 10 trays to the surface, cleaning and disposing of the waste material appropriately and then feeding every tray, restacking them and placing them back in the water,” Pearce points out. “There is a lot to be worked out.”

“We are considering research to put in a commercial site and look at this on a much grander scale,” says Pearce. “I think it can work biologically. We really need to prove it on an economic basis by considering tray cost, feed costs, labor, boat costs and market value. And we want to look at the environmental impacts as well.”

Aquaculture — has developed a unique feed that holds its form in the water for between 7-14 days without dissolving, explains Takeda. “Urchins, unlike fish, take a long time to eat so the feed has to keep its form and not dissolve,” he says. “The feed does contain some fish meal, sourced from sustainable off cuts.”

Although urchins eat mostly kelp, they are not herbivores, Takeda points out.

“We have secured the global rights to the feed technology as well as the rights to the Norwegian sea-based farming technology and some land-based technologies,” says Takeda.

FARMING TECHNOLOGY

“Anyone who has oyster farming infrastructure has 98 percent of what they need to be able to do urchin farming with our specifically designed cages,” says Takeda. “We are trying to deliver all the pieces that you need to be able to do this farming. We take responsibility for the entire value chain from start to finish at our operating sites.”

“We bring not only the production technology, but also the seafood distributors from Japan and China that are ready to sign long-term contracts for production because they want to secure supply,” Takeda adds.

“A sea-based solution will probably be the most cost-effective, but we are also developing land-based systems for colder climates or less optimum sites,” says Takeda. “The prototype we hope to launch in a few months will be designed for both for flow-through and recirculation.”

Takeda says the pilots they are running suggest that the economics make a lot of sense. “If we factor in the ecological impact we provide and the social benefit we provide through jobs, the total bottom line looks very promising,” he says.

“There is not an aquaculture that I know of that adds that amount of value in just 10-12 weeks,” says Takeda. “We are taking an overly abundant resource that is hindering the growth of other stocks and turning it into something that tastes good and sells.”

Globally Trusted UV Experience

Proven bio-security; over 35 years, 380 installations, more than 740 million gallons per day

Lifetime Disinfection Performance Guarantee

Aquafine Genuine parts program provides this peace of mind

Long-term Industry Commitment

Collaboratively advancing UV research in aquaculture

aquafineuv.com

“Anyone who has oyster farming infrastructure has 98 percent of what they need to be able to do urchin farming with our specifically designed cages.”

Above and Below

l UV resistant plastic l Easy to fabricate l Rolls, sheets and tubes custom cut-to-size in 24 hours

Studies performed at the Oceanic Institute (2001) indicate “poultry meal can replace fish meal at an inclusion level of 45% in shrimp diets without loss of growth.”

We o er:

• Extensive technical support with access to juveniles and seed

• Academic partnerships with the University of Maine

• Entrepreneurial training & business counseling

• RAS and ow-thru culture facilities from 50-1000 sq meters

• State-of-the-art culture systems

• Business support facilities and networking opportunities

We provide entrepreneurs and business startups professional support and excellent facilities to develop their aquaculture ideas.

Research performed at the University of Missouri (2009) showed poultry by-product meal can completely replace fish meal in the diets of largemouth bass and rainbow trout without affecting weight gain while reducing the cost of dietary protein by 60%

• Assistance in grant writing and identifying funding opportunities

• Plus exceptionally high quality sources of water!

For more information, contact: Chris Davis, Maine Aquaculture Innovation Center 193 Clarks Cove Road, Walpole, ME 04573 Phone: (207) 832-1075, cdavis@midcoast.com

Massachusetts-based biotech company KnipBio has unveiled a sh feed derived from microbes instead of wild-caught sh or agricultural crops.

e new product, named KnipBio Meal (KBM), is derived from the company’s development of a range of single cell proteins, all drawn from non-food feedstocks.

them to move KBM towards commercial production.

“ e key appeal of this development is that we can take a low-value item, say by-

KBM makes use of the bacteria Methylobacterium extorquens, a common bacterium cultured by the conversion of methanol through fermentation. But instead of beer as end product, the fermentation produces a bacterium that the company says is composed of “protein and amino acids very similar to the protein found in wild sh.”

uses fermentation process to produce a variety of protein meals that can be milled into

KnipBio has already released test results showing that a diet consisting of between 30 and 100 percent of the pelleted bacterium would be a suitable feed for farmed sh and shrimp.

To nd out if sh fed with KnipBio passes consumer tastes, the company and its collaborator, Kampachi Farms, conducted a taste test involving samples of yellowtail (Seriola rivoliana) shashimi.

e yellowtail were fed a diet containing up to 7.5 percent of the KnipBio meal. e trial was conducted at the Food Innovation Center at Oregon State University.

Larry Feinberg, CEO of KnipBio, said the results indicated that testers were “statistically unable to discern any di erence between KBM-fed samples and a control shmeal-fed sample.” Further tests are planned across a wider range of species.

e next big challenge for Knipbio is to nd a development partner to enable

products from ethanol production, and use that as the base on which to grow the new protein,” Catherine Pujol-Baxley, Knipbio’s vice president for research & development, told Aquaculture North America (ANA).

“Having started the company four years ago, and the R&D work (behind KBM) two years ago, we’re now at the point where we have the bacteria ready for scaling up to commercial production.

“ e science is already great, being based on work which started 20 years ago. We know how to grow it and maintain it. What we’re looking now, is to nd a partner who will help us to scale up and take it to the marketplace.”

Working with Knipbio in the project are the New England Aquarium, the University of Massachusetts at Boston, Roger Williams University and the USDA Agriculture Research Service.

— Colin Ley

BY TREENA HEIN

mong other cutting-edge presentations at the Aquaculture America conference in San Antonio, Texas in February, one focused on how success with commercial aquaponics can be achieved. With interest in these types of ventures growing, but the success rate not exactly stellar, the topic was certainly timely.

Presenters at the session were the team behind Greener Scenes Aquaponics (GSA) in Brazil, Indiana, who outlined their exciting journey from small proofof-concept to commercial success. GSA was established in 2012 by chief operations officer Mathew Pollom. In 2013 and 2014, respectively, he brought on board chief production officer Brandon Hall and chief financial officer Dan DeBard. CEO Zachariah Chambers joined in mid-2015 and, by the fall of that year, the team started building the facility at the city’s historic Telephone Building.

While the team did an excellent job in estimating costs, they did not anticipate construction delays. “Building and rampup took about nine months longer than anticipated, resulting in money out the door with no revenue coming in,” Chambers recalls. “To keep things on track, we advise being 100-percent sure your build-out meets all codes and requirements and all pertinent parties are properly introduced to the project. Still, anticipate delays.”

One particularly large snag reared its head during electrical system installation. Two of the three required approvals went swimmingly, but a delay on the third put GSA about four weeks behind schedule. Chambers adds, “Things we did ourselves took much longer than anticipated, whereas contracted work with external experts was pretty much on time, so understand that unless you are an expert in construction, your schedule will slip if you choose to do it yourself.”

The GSA business plan stipulated that the greens side would be established first. (Among others, Aqua Greens in Toronto is also following this model.) “It’s a nobrainer,” Chambers explains. “Lettuce has a very quick turn-around and it’s profitable. By July, when we have more plants growing, the entire business will be self-sustaining just based on income from the greens.” Sales of their salad mix greens — oakleaf, arugula, kale, Swiss chard and spinach — began in April to the firm’s sole customer, Baesler’s Market, in Terre Haute. GSA ships about 10 lbs to Baesler’s every second day as it ramps up production and, by around the end of 2017, it will reach Phase II with a maximum of about 100 lbs every second day. Expansion to the second floor, a rooftop greenhouse, and/or a second site may someday be in the cards.

And the fish? They’ll go to market sometime in 2018. “We currently have the tilapia in 27 IBC tanks, and we plan to have up to 5,000 in the system,” Chambers says. “We had to start with economical tank options. Right now, they are providing our nutrient load and when we’re ready, we’ll look at selling to grocery stores and restaurants, along with non-food markets such as pond maintenance fish.”

While some aquaponics ventures have each component of the business –fish and plants – being operated to maximize each one’s profit by giving plants fertilizer if needed, or by getting rid of excess fish wastewater through composting or field application, GSA operates holistically to achieve a balanced nutrient load. Chambers says they want to keep the system simple and consume everything that’s being produced.

Additional revenue streams were never a part of the core GSA business plan and still aren’t today. “We wanted to be conservative and achieve financial sustainability just from greens production,” Chambers explains. “However, additional revenue is coming from consulting, tours, and from sales of home aquaculture kits and components sourced primarily from Hydrofarm.” This echoes findings in the study “Commercial Aquaponics Production and Profitability” published in the January 2015 issue of the journal Aquaculture –that operations that sell equipment, offer consulting/educational services or integrate agritourism are the most profitable.

Organic certification is listed as a big success factor for some aquaponics operations – not just for the premium price that organic fish and greens can bring, but also to secure demand. For GSA however, it’s not worth the effort. “For our market, locally-grown trumps organic, and people will buy Indiana-grown food over shippedin organic vegetables,” Chambers says. “We are part of a hub of many Indiana-grown vegetable operations and we are very glad GSA greens are among the large number of locally-grown items that Baesler’s Market carries.”

Cost savings during greens build-out and production come from the use of induction lights, which are less expensive upfront than LED but have equivalent efficiency and nearly equal growing results, says Chambers. GSA has 36 of them, each one set up on a track with a small electric motor moving it back and forth over its designated plant bed. “We reduce the number of fixtures from four per bed to one, and we just have to run them a little longer,” says Chambers. “We also have our

insect pest control ‘automated’ and done naturally through the release of a large number of lady bugs, green lace wings, praying mantises and so on.”

GSA has also reaped start-up cost savings by having only Pollam and Hall draw salaries (from full-time positions). Chambers, a professor of mechanical engineering at Rose-Hulman Institute of Technology, and DeBard, a retired accountant, have not yet taken pay, but will do so sometime in the future.

Lastly, Chambers advises that all aquaponics ventures involve a team with core expertise in fish, plants, operations, finance and marketing –ideally with expertise overlap – and with

a performance-driven and dedicated mindset. “The light is always at the end of the tunnel but the tunnel just keeps getting longer as you hit challenges and obstacles,” he says. “And when that obstacle does present itself, you need to have a team, the team that doesn’t give up and digs down and makes it happen. Starting a business is hard, especially when it requires infrastructure and multiple levels of expertise. Aquaponics takes all of the challenges of hydroponics and aquaculture and elevates the difficulty. GSA has made it through the darkest parts of the tunnel and we are now in production!”

orth Star Agriculture (NSA) of Whitehorse in Canada’s Yukon territory has partnered with NutraPonics of Alberta to build a vertical aquaponics facility later this year. The facility will be built in Carcross, home to the Carcross/ Tagish First Nation, who has pledged to become 51-percent owner.

The Canadian Northern Economic Development Agency (CanNor) announced in May an investment of roughly $55,000 (C$75,000) to support the project.

NSA CEO Sonny Gray says it will cost millions to build the facility, which will annually produce 200 tonnes of tilapia and over 200,000 kg of assorted greens and vegetables. “The focus for the hydroponics is to have fresh greens and vegetables available yearround for Yukon residents as what we have access to in the winter here is usually terrible or non-existent,” Gray tells Aquaculture North America (ANA)

Construction of Yukon’s first vertical aquaponics farm begins this fall. People behind the project are (front L-R): Tami Grantham of CTFN (Carcross/Tagish First Nation), Sonny Gray, CEO North Star Agriculture, Jillian MacIsaac and Krisandra Reid, both from CanNor. (Back L-R) Tanner Stewart, CEO Nutraponics, Joel Gaetz, CFO North Star Agriculture, Travis Armour, Strategy North Consulting and Andy Carville, Chief of the CTFN

“The fish is for export. We will be selling them to Washington or California via Alaska. Fish raised in a clean way are in great demand. Consumers don’t want to eat the fish from Indonesia and other parts of Asia that is farmed in lakes containing pesticide residues and other contaminants.” Gray is preparing to secure letters of intent from at least one US fish buyer.

Tilapia was chosen because it is a proven aquaculture success that can be raised at high stocking densities and because they thrive at the same temperature (20°C) that the greens need.

The venture, not yet named, has received an exemption from the Yukon government’s current ban on fish farming. Gray says the Yukon Department of the Environment has

been very supportive, and is working to create aquaponics regulations and to secure an agreement from the federal government to allow tilapia to be raised in the territory. While the venture will use electricity from the grid, Gray says there are plans to look into solar and wind. About 20 employees will be needed for greens and fish production, including ongoing care, harvest, processing, flash freezing, packaging and shipping.

— Treena Hein

Tilapia farmer Regal Springs donated 48,000 servings of tilapia to SeaShare in Honor of National Volunteer Week in April.

SeaShare is a nonprofit organization dedicated to helping the seafood industry contribute to hungerrelief efforts in the United States.

Regal Springs has been a supporter of SeaShare since December 2015, having donated over 140,000 servings of healthy tilapia to the organization.

Regal Springs made its latest donation of tilapia during National Volunteer Week, an annual celebration to promote and show appreciation for volunteerism

“We are thrilled to work with Regal Springs again,” said Jim Harmon, executive director of SeaShare, “and so grateful for this generous donation. With their continued support, we are able to provide thousands of people with nutrientrich, high-quality fish that they might not have access to otherwise.”

Asalmon farmer says it has begun feeding its Pacific salmon (Oncorhynchus kisutch or coho) with AlgaPrime DHA, a whole algae feed ingredient, and has achieved “unprecedented sustainability” as a result.

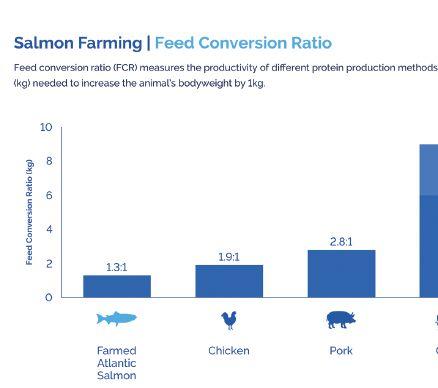

The farmer, Ventisqueros of Chile, used the Forage Fish Dependency Ratio (FFDR) metric to define sustainability. FFDR describes how many kilograms of wild fish are needed to produce one kilo of farmed fish. The current industry average FFDR is about 1.3 kg, but Ventisqueros’ Silverside Premium Pacific Salmon fed with AlgaPrime DHA results to an industry-low FFDR of 0.5 kg, the company says.

AlgaPrime DHA, made by TerraVia and Bunge in Brazil, is deemed more sustainable because it reduces the aquaculture industry’s dependence on fish oils for feed. Terra Via Global Sustainability Director Jill Kaufmann Johnson last year described the manufacturing process to Aquaculture North America (ANA): “What we do is that sugar [sugarcane feedstock] is crushed at the mill and it is fed to the algae in very large fermentation tanks – like eight stories high.

“The algae grow plump with oil, as algae is the original oil producer, that’s what it

naturally does. We remove them from the tank and then they are dried – it’s like a powder. The oil is still encapsulated in the algae. We are making the DHA product in a matter of days.” The innovation represents a step change to current industry solutions and offers consistent supply and quality to customers.

CEO of Ventisqueros, José Luis Vial, said by achieving an FFDR of 0.5 kg, the company has become the first “net fish producers” in the salmon farming industry.

In January, IFFO — the international non-profit organization that represents and promotes the fishmeal, fish oil and wider marine ingredients industry worldwide — cautioned that the use of FFDR as a measure of sustainability should not be not be examined in isolation. Rather, it said FFDR should be regarded as part of an overall package of information relating to aquaculture sustainability.

Chilean salmon farmer Ventisqueros, a boutique salmon producer in north Patagonia, said it will start harvesting Pacific salmon (Oncorhynchus kisutch or coho) fed with AlgaPrime DHA in October.

Prior to feeding their fish with the algae-based feed made by TerraVia and Bunge, Ventisqueros used standard formulas from different feed producers, whose main ingredients included fishmeal, fish oil and vegetable protein, said Guillermo Staudt, commercial manager of Ventisqueros.

Staudt noted the fish fed with the new formula are growing well. “We see no deviations in any productive parameter versus what we expected. The use of AlgaPrime DHA allows us to reduce the amount of fish oil and consequently have a lower FFDR (forage fish dependency ratio),” Staudt told ANA

He said that the company’s efforts are focused on the US market, where the product, to be sold under the brand Silverside Premium Pacific Salmon, will be sold at a premium. “Algae-fed fish addresses consumer demand for responsibly sourced seafood. This is an important topic for consumers today and many are willing to support products like the one we are offering, even if there is a difference in price. Nevertheless, we believe we must remain at competitive and affordable level,” he said.

Ventisqueros is the first company to feed coho with AlgaPrime DHA.

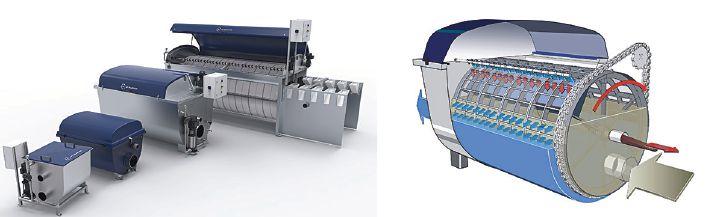

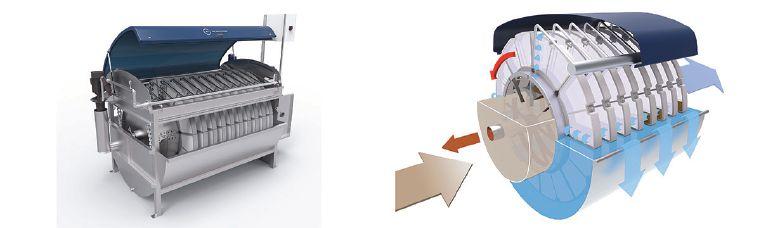

Pranger is proud to be the U.S. distributor of Hydrotech™ microscreen filters for the aquaculture industry. Hydrotech has been leading the market in microscreening technologies for over 30 years, providing filters for removing particles from liquid flows - a process critical to the aquaculture industry.

Today’s modern aquaculture farmer needs a partner that is able to help with the scope and variety of challenges they face every day. That is why Pentair AES has assembled a team of experts with diverse backgrounds in aquaculture, biological and technological engineering that is grounded in decades of research and commercial industry application experience. We help our customers run successful operations by providing the design expertise they need, a responsive service team and the largest selection of equipment and supplies in the industry. Trust in a team that’s here to help you—ASK US!

Alaskan shellfish and marine plant farmers have access to capital

laska’s goal to grow its fledgling mariculture industry from $1 million currently to $1billion over the next 30 years is getting some help with the passing of two bills that will expand existing frameworks to better manage the industry.

The Alaska House of Representatives in May passed Bill 76, which would amend the Alaska Mariculture Revolving Loan Fund to include eligibility for shellfish hatcheries. HB 128 would allow non-profits to pursue enhancement and restoration projects with oversight by the Alaska Department of Fish and Game. Representative Dan Ortiz (I-Ketchikan) sponsored both bills.

These bills would help increase and diversify Alaska’s fishery portfolio to help realize the $1 billion potential of commercial shellfish production.

“I hope to support the continued growth of local industry, and help Alaska remain competitive with China, Russia, and Canada, all of whom have invested significant resources in mariculture infrastructure,” said Ortiz in a statement. “We can do this by ensuring Alaskan shellfish and marine plant farmers have access to capital to jumpstart the year-round, in-state seed supply they need.”

By expanding the purview of an existing revolving loan fund, HB 76 provides the financial infrastructure to develop a stable supply of seed for resident aquatic plants and other shellfish at no additional cost to Alaskans. Today, Alaska shellfish farms do not have a regular, in-state source of seed for aquatic plants and other shellfish.

HB 128 allows qualified non-profits to pursue enhancement and/or restoration projects involving shellfish species, including red and blue king crab, sea cucumber, abalone, geoduck and razor clams.

arine Harvest has introduced a new technological innovation for their fish products on the European market.

Called “Keep-it,” the smart labels are attached on the product directly after the fresh fish is cut and packed. Throughout the cold chain, Keep-it will track the actual temperature impact on the fish product in real time, thus enabling a more dynamic and precise shelf life than traditional date stamping.

The innovation is a first for the company and for the industry. “The technology will revolutionize and redefine the way the industry will define shelf life by making it much easier to secure freshness, food quality and reduce food waste,” Marine Harvest said.

The project has been launched in Europe and is in its early stages. The company is planning to introduce their products with Keep-it indicators in 10 European markets by 2019. While the technology is not yet being introduced in the US market, it may be something that will be explored in the American market in the future, a source from the company told Aquaculture North America (ANA)

Packaged salmon with a ‘Keep-it’ indicator

California-based boitech firm Calysta Inc said it has raised $40 million in extra capital to advance the commercial scale manufacturing of its FeedKind protein, a new fish-feed ingredient that is touted to reduce aquaculture’s use of fishmeal.

Mitsui & Co Ltd of Tokyo, Japan, and Temasek, a Singapore-based investment firm, are new investors in the company. Current investors include Cargill, the Municipal Employee Retirement System (MERS) of Michigan, Walden Riverwood Ventures, Aqua-Spark and Pangaea Ventures.

Calysta expects the facility, located in Memphis, Tennessee, to be completed by the end 2018. Commercial production of the FeedKind protein is expected to begin in 2019.

arine Harvest Canada (MHC), British Columbia’s largest salmon aquaculture company, has awarded a multi-million-dollar contract to a local company that designs and builds aquaculture infrastructure.

Campbell River-based Poseidon Ocean Systems — dealing on behalf of manufacturer Hvalpsund Net — will construct eighty-seven 120-metre diameter high-density polyethylene circular fish pens for Marine Harvest. The first orders for 29 pens were immediately placed by MHC and will be built on Vancouver Island.

“The HD 500 Extreme pens are a wider and more stable platform than existing pens in use at Marine Harvest Canada, and are particularly well-suited to dual-net predator-exclusion programs,”

says Matt Clarke, President of Poseidon Ocean Systems. “In addition, the pens were supplied with alternative supplementary flotation that allowed us to eliminate the use of polystyrene foam inside the float pipes, which is a nice environmental benefit.”

Marine Harvest says the new cages are one part of a multi-million-dollar investment to further improve its farming operations, which has also recently included feed and monitoring systems and staff accommodations.

“It’s great to see local businesses on Vancouver Island with the ability to supply these vital services to our company,” says Marine Harvest’s Production Director, Dougie Hunter.

The world’s largest retailer has added a Norwegian salmon product to its wide range of offerings in 485 stores in the US midwest.

Citing consumers’ more discerning attitudes towards food, retail giant Wal-Mart says pre-portioned and seasoned Norwegian salmon fillets, under the brand Salmon Man Salmon Portions, caters to their preferences.

The product is now available in Wal-Mart stores in Michigan, Ohio and Indiana, where there is a large Scandinavian population and an appetite for authentic Scandinavian salmon, the retailer says.

The Salmon Man sources it premium salmon from Platina Seafood, which raises salmon in ocean farms in Norway.

Wal-Mart has launched pre-portioned and seasoned Norwegian salmon fillets in 485 stores in US midwest, which has a large Scandinavian population

cientists have managed to successfully breed blue cod for the first time, opening up new potential opportunities in aquaculture.

Behind the milestone are the Seafood Technologies team at Plant & Food Research’s new fish hatchery in Nelson, New Zealand, and Ngāi Tahu Seafood Ltd.

For the first time, they have managed to breed and grow blue cod to fingerlings. “New Zealand can now consider potential opportunities for this desirable table fish, such as intensive aquaculture grow out or supplementing local populations under pressure from fishing,” Plant & Food Research said in a statement.

Chief Executive of Ngāi Tahu Seafood, Joseph Thomas, says the outcomes of the programme could have real commercial and guardianship benefit for the seafood industry.

Around 2,000 hatchlings have been raised, most of which are now around 5 to 7cm long. Their parents were wild blue cod from the Marlborough Sounds

“By enhancing our understanding of blue cod breeding we may be able to identify ways to replenish and strengthen our fishing stocks, which will have a positive impact on customary, recreational and commercial availability. It will help us sustain the health of our fisheries,” said Thomas.

Limited supply and strong demand in China for the rubbery creature make it a good candidate for aquaculture

BY TOM WALKER

esponding to strong market demand for sea cucumbers in China, Alaska- and Washingtonbased researchers are developing hatchery and grow-out techniques for the indigenous giant red sea cucumber (Parastichopus californicus).

“Californicus has similar characteristics to the highly prized Japanese spiky sea cucumber Apostichopus japonicas,” says Andy Suhrbier, senior biologist with the Pacific Shellfish Institute (PSI). “While populations have declined in certain areas along the West Coast, the market remains intact.”