SHOWISSUE

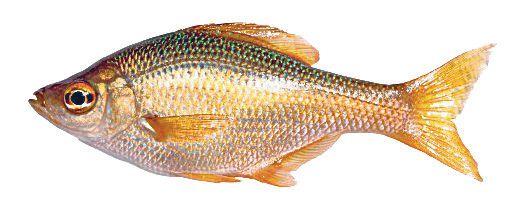

One of the world’s largest commercial aquaponics facilities under construction will eventually provide 275,000 lbs of fresh fish and 400,000 lbs of organically grown produce annually

BY TOM WALKER

One of the world’s largest commercial aquaponics facilities under construction will eventually provide 275,000 lbs of fresh fish and 400,000 lbs of organically grown produce annually

BY TOM WALKER

Tilapia in one of four 3,000-gal poly grow-out tanks, and racks of kale growing in the background

Credit: Urban Organics

ater is important for both farmers and brewmasters. So it seems fitting that two historic breweries in Saint Paul Minnesota, have been retrofitted into perhaps the largest and most advanced aquaponics operations in the country, to combine the farming of fish and vegetables.

Urban Organics (UO), a local company in St Paul, has been producing tilapia and hybrid striped bass together with high-value produce, in

the former Hamms brewery building since 2014.

“After seeing a news story featuring an urban farm in Milwaukee, Wisconsin using aquaponics as a method for indoor farming, we hatched the idea to build and operate an indoor fish and produce farm in the heart of the city,” says David Haider, one of the company’s founders.

In November, they took delivery of their first batch of Arctic charr eggs at the newly renovated Schmidt brewery, only a few blocks away. Haider will be the manager of that facility.

on page 7

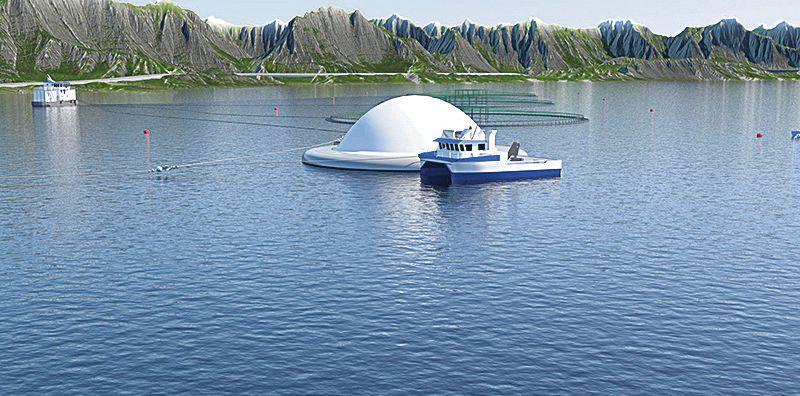

ISFA report says raising salmon in its natural habitat is still the way to go

BY RUBY GONZALEZ

s wild fish stocks are being harvested to capacity and global demand for seafood continues to grow, some sectors are espousing that land-based salmon farms are the answer. At present, most land-based farms operate for smolt production. So how economically viable is it to raise salmon on land through harvest size? And what are the implications?

The International Salmon Farmers Association (ISFA) sought to “facilitate the dialogue” with its global report released in October, The Evolution of Land-based Atlantic Salmon Farms

According to the report, it appears that the odds are stacked against land-based salmon farming.

“This report shows that farming Atlantic salmon in their natural environment — the ocean — is the responsible way to farm. Until that changes, we will do what we do best: use the marine and freshwater resources in the most efficient and considered way, in both marine and land-based systems, to help feed the world,” said ISFA president, Trond Davidsen.

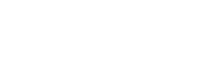

Challenges that were identified were related to energy, fish welfare, water and land use, and socio-economic realities. Pictographs effectively illustrated the significant amount of energy and natural resources it takes to raise salmon on land compared to its natural environment.

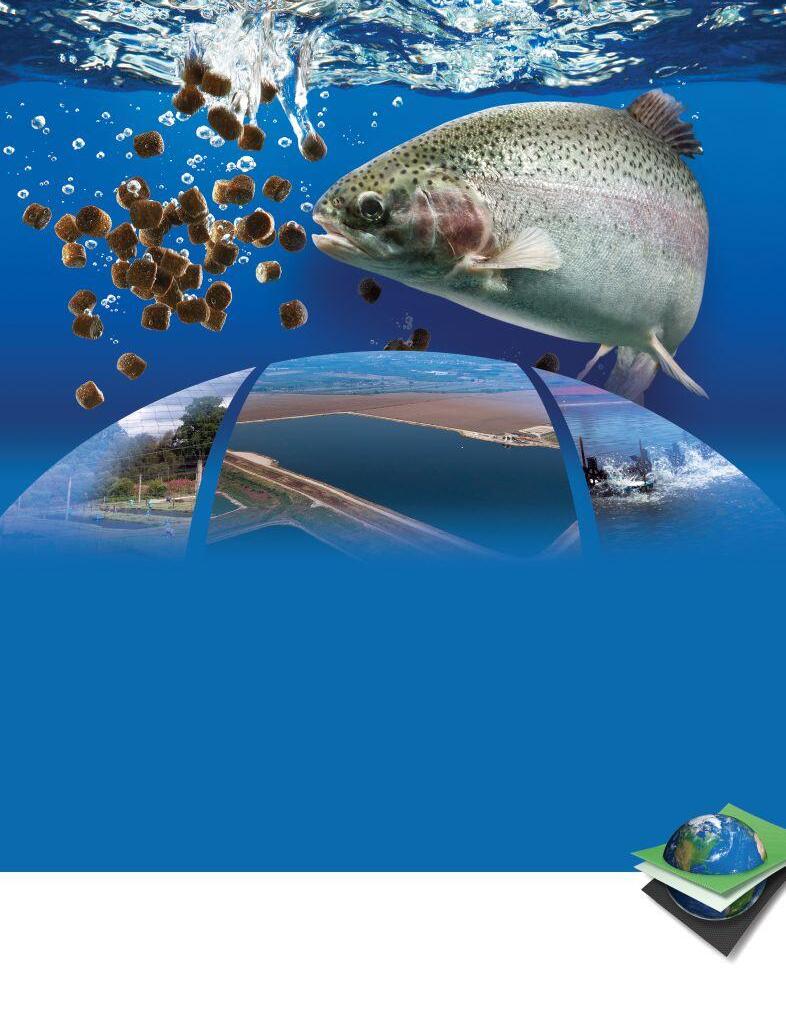

Study’s findings will benefit producers who need a set timeframe to achieve a specific fish size

BY RUBY GONZALEZ

nderstanding trout’s economic and performance traits throughout the production cycle and its impact on product efficiency is vital to a profitable operation, according to Beth Cleveland, a growth physiologist with the USDA National Center for Cool and Cold Water Aquaculture.

Cleveland presented her study, “What Size to Harvest Rainbow Trout/Steelhead in RAS?

Consider Growth Rate, Feed Conversion, Fillet Yield, Fatty Acid Deposition, and Production Efficiency,” at the 2016 Aquaculture Innovation Workshop held last August in Virginia.

She cited an interesting point about the relationship between fish growth and feed conversion throughout the grow-out process.

Credit: pixabay.com

“We see elevation rates in the food conversion ratio (FCR), which is not desirable, as the fish gets larger,” she said. It must be noted that the higher FCR, the lower the weight gain obtained from the feed. “But these increases are offset by increased product yield. And that offsets the increase in cost.”

To illustrate this, she showed a “highly simplified economic model” that factors in the different market rates for rainbow trout

on page 15

Aquaflor® is now approved for use in all freshwater-reared finfish at dose rates of up to 15 mg/kg*. I t ’s cleared for use in recirculating aquaculture systems, too.

S o whether you raise trout, tilapia, bass, c atfish or even baitfish or ornamentals, you can turn to Aquaflor for managing the toughest bac terial diseases of farm-raised fish.*

For the full stor y, call our fish-health specialist, K asha Cox, at 662.907.0692 or visit our new website at Aquaflor-USA.com.

It just keeps getting better

A Q U AF L O R ®

* In the USA, Aquaflor is approved for use at 10-15 mg/kg in freshwater-reared salmonids for the control of mor tality due to furunculosis associated with Aeromonas salmonicida and coldwater disease associated with Flavobacterium psychrophilum; in catfish for the control of mor tality due to enteric septicemia of catfish associated with Edwardsiella ictaluri; and in all freshwater-reared finfish for the control of mor tality due to columnaris disease associated with Flavobacterium columnare At 15 mg/kg, Aquaflor is also approved in freshwater-reared warmwater finfish for the control of mor tality due to streptococcal septicemia associated with Streptococcus iniae. LABEL CLAIMS NOT APPROVED IN CANADA.

CAUTION: Federal law restricts medicated feed containing this veterinary feed directive (VFD) drug to use by or on the order of a licensed veterinarian.

© 2015 Inter vet Inc., doing business as Merck Animal Health, a subsidiar y of Merck & Co Inc All rights reser ved MAH-AQF-38 ( or fenicol)

and long-line kelp structures and management in

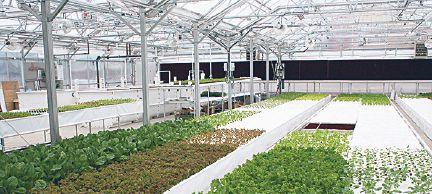

he National Sea Grant College Program is allocating $3.4 million in federal funding to support aquaculture research and outreach aimed at developing sustainable aquaculture.

TThe funding, announced in October, will support 11 aquaculture research projects and 23 projects to organize and conduct conferences and workshops to transfer aquaculture information.

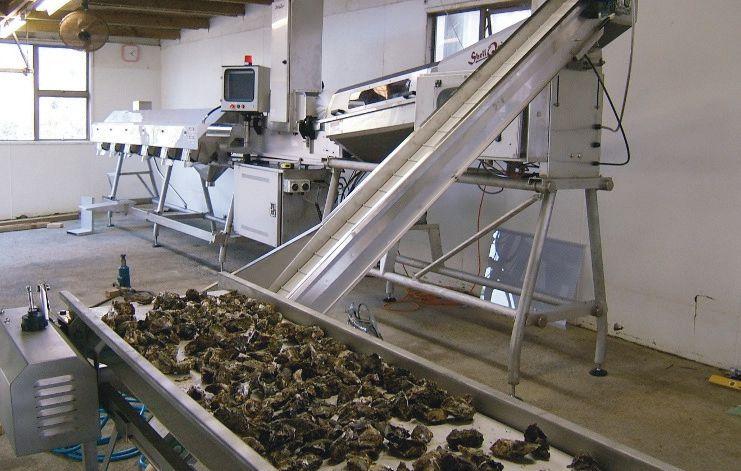

New research projects totaling $3 million in federal funds include research on managing the complex profile of biotoxins threatening the shellfish industry of lower Chesapeake Bay, integrating mussel and long-line kelp structures and management in New Hampshire, and developing technologies to expand the supply of emerging marine finfish fingerlings for commercial offshore aquaculture systems, said the announcement.

The rest of the fund will support conferences, workshops, training and technology-transfer efforts focused on advancing aquaculture knowledge, management and collaboration. Projects include strengthening the network of fishpond practitioners in Hawaii, building collaboration among the aquaculture and fishing industries in California, and training shellfish aquaculturists in Connecticut.

“An important and often overlooked area is going beyond research to integrate useable science into people’s everyday lives. The conferences and workshops funded this year will contribute to filling that gap,” said Jonathan Pennock, National Sea Grant Director.

The $3.4 million in grants is part of Sea Grant’s $9 million national aquaculture research and technologytransfer portfolio in 2016.

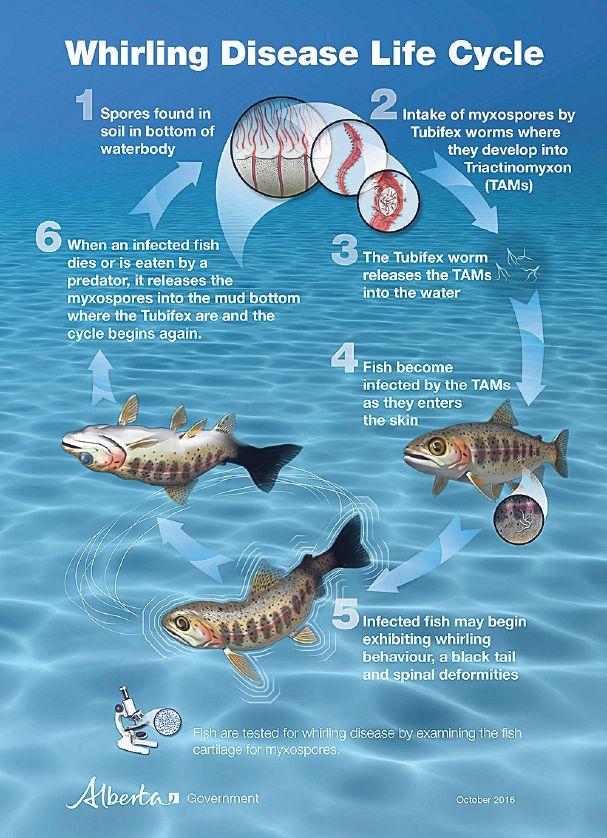

The future is uncertain for aquaculture operations in Alberta, Canada after the government ordered them quarantined after a deadly parasite affecting salmon and trout was found in Canadian waters for the first time.

The Canadian Food Inspection Agency (CFIA) confirmed the presence of whirling disease in fish in Johnson Lake in Banff National Park on August 25. This was the first case of whirling disease in Canada.

On September 6, the Alberta Environment and Parks ordered the quarantine of all commercial fish culture operations as a precaution. The province has also temporarily ceased provincial fish stocking.

The parasite, Myxobolus cerebralis, affects salmonid fish, including trout, salmon and whitefish. One of the signs of the disease caused by the parasite is a marked “whirling” swimming behavior in fish as the parasite invades cartilage and impairs the nervous system.

The quarantine is in effect until individual fish farms and hatcheries licensed for salmonids are tested and found negative for the disease. Several fish farms in the province have been tested and cleared as of December but testing of other farms continues.

One of the signs of the disease caused by the parasite is a marked “whirling” swimming behavior in fish as the parasite invades cartilage and impairs the nervous system

The Aquaculture Association of Canada (AAC) has announced it will organize the 2017 edition of Aquaculture Canada/Sea Farmers Conference and Trade Show with the Aquaculture Association of Nova Scotia.

The conference and trade show will be held at the World Trade and Convention Centre in Halifax, NS from May 27 - 31, 2017. Updates about the conference can be found in AAC’s Facebook page at www.facebook.com/AquacultureAssociationCanada.

Easy isolation options

Maximize manpower, floor space and water supply

Vertical systems can be stacked in 4-, 8-, 12- or 16-tray configurations

bill requiring West Coast finfish aquaculture to move from open-ocean fish farms to land-based containment systems has been defeated in the Canadian Parliament by 217 to 80 votes in December.

Fin Donnelly, NDP Fisheries Critic and sponsor of the bill expressed disappointment with the defeat.

Bill pushing the transfer of open ocean net pens to landbased containment systems was defeated in the Canadian Parliament

“Thousands of jobs, sensitive ecosystems, and First Nations culture depend on healthy wild salmon. I am very disappointed that Liberal and Conservative Members of Parliament joined together to defeat my bill designed to protect this important species.”

The BC Salmon Farmers Association (BCSFA) commented: “The results of the vote in parliament show the commitment the government of Canada, and the previous government, have to sustainable aquaculture in Canada.

“British Columbia’s global advantage is our ocean environment, and our members look forward to continuing to employ world best practices and farm in a responsible and sustainable manner to provide a much needed food source for Canada and the world.”

Editor Liza Mayer Tel: 778.828.6867 liza.mayer@capamara.com

Subscription Services Deirdre Chettleburgh Tel: (250) 478-3975 deirdre@capamara.com Tollfree 1-800-661-0368

Advertising Department Jeremy Thain Tel: (250) 474.3982 Fax: (250) 478-3979 Toll free in N.A. 1.877.936.2266 jeremy@capamara.com

Art Department James Lewis Tel: (709) 754-5059 Fax: (709) 754-5067 james@capamara.com

Content Manager Deirdre Chettleburgh Tel: (250) 478-3975 deirdre@capamara.com

Accounts Debbi Moyen Tel. (250)474-3935 dmoyen@capamara.com

Publisher Peter Chettleburgh Tel: (250) 478-3973 Fax: (250) 478-3979 peter@capamara.com

Regular Contributors: Quentin Dodd, Ruby Gonzalez, Erich Luening, John Nickum, Matt Jones, Tom Walker, Amanda Bibby

United States Mailing Address Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Canadian Mailing Address Aquaculture North America 4623 William Head Road, Victoria, BC, Canada, V9C 3Y7 ISSN 1922-4117 (GST# 897422788RT)

Postage paid at Vancouver, BC Aquaculture North America is published by Capamara Communications Inc.

Study focuses on salmon raised in ocean environment in British Columbia almon raised in the ocean have the lowest overall cost to the environment, says a research on consumers’ most common protein choices.

The research, prepared for the British Columbia Salmon Farmers Association (BCSFA) by Ottawa based RIAS Inc, looked at the production of salmon versus other major proteins in terms of energy use, greenhouse gas emissions, eutrophication potential, water use and land use.

Results indicate that BC farm-raised salmon is 24 percent less costly to the environment than chicken, while beef has a cost that is 500 percent greater than salmon raised in an ocean environment.

The study used a life-cycle analysis (LCA), defined by the United Nations Environmental Programme as “a tool for the systematic evaluation of the environmental aspects of a product or service system through all stages of its life cycle.”

“Health professionals agree that salmon is by far the most healthy protein choice for people to eat, this study shows it’s also the most healthy protein for our planet,” said Jeremy Dunn, BC Salmon Farmers Association Executive Director. “With world population estimated by the United Nations to grow by over two-billion by 2050, governments must consider the full environmental costs of the food we grow and eat, we have a global food supply and a global environment.”

• Farm-raised salmon ($0.59/kg) has the lowest overall environmental cost of any of the major protein options available to consumers today.

• Farm-raised salmon is 24 percent less costly to the environment than chicken ($0.73/kg) to almost 500 percent less costly than beef ($3.45/kg).

• GHG Emissions. Farm-raised salmon produce less GHG emissions than any commercially raised food animal.

• Water Use. Farm-raised salmon was found to have consistently lower water use than other types of animal farming, using only a small fraction of the water compared to other species.

• Energy Use. Over 90 percent of cumulative energy use for farm-raised salmon is from feed production. Overall, the evidence indicates that the life-cycle energy intensity for farm-raised salmon is better than beef.

• Land Use. Overall, studies have found that production of feed for farm-raised salmon requires much less land than used in the production of most other species. Over 90

percent of land use for farm-raised salmon is from feed production.

• Eutrophication Potential. Evidence suggests that farm-raised salmon has lower potential for eutrophication (defined as the depletion of oxygen in a water body, which kills aquatic animals) than beef.

• Salmon are the most efficient of all commercially raised farm-fed animals in converting feed into a kilogram of body weight, an important metric when assessing the sustainability of a food animal production system. Farm-raised salmon have an average feed conversion ratio (FCR) of 1.2:1 compared to chicken at 1.7:1 and beef which can be as high as 9.1:1 – close to 10 times less efficient than salmon.

• BCSFA Members produced 75,000 tonnes of salmon in 2015, or about 95 percent of the total provincial harvest of farm-raised salmon.

• BC salmon farmers have 20 social and economic partnerships with coastal First Nations – and are working towards many more. 78 percent of BC’s annual harvest is covered under these agreements.

Source: BCSFA

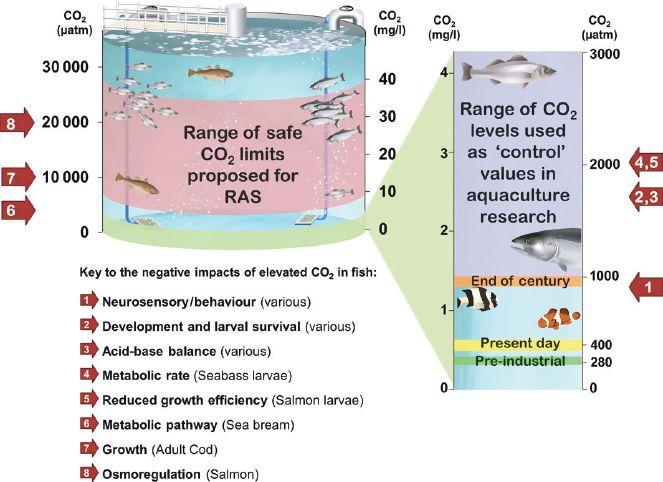

Land-based farms mimic the natural environment conditions such as flow, temperature and oxygen, necessitating high consumption of energy. To circumvent high cost of power consumption, a study suggested choosing sites with cheap power and located close to key markets. Savings in power consumption, however, will not reduce its carbon footprint.

For land-based Atlantic salmon farms to be profitable, the report suggests farmers have to raise fish at much higher densities than in marine systems. Two of the key indicators that salmon in land-based systems may not be thriving are precocious maturation and decreased or subnormal growth rates. Raising an all-female salmon population may be the solution to precocious maturation.

There is also the challenge of pathogens contaminating a land-based system. Once this happens, notes the report, it is virtually impossible to remove the pathogen unless the system is depopulated and all the biological filters are disinfected.

The report stressed the amount of water and land used to raise salmon on land. Growing 75,000 tons of salmon in a 99-percent RAS system would require 4.16 billion liters of water just to fill the tanks.

Meanwhile, it said that to move Canada’s current production to a land-based system would require 136 square kilometers of land, which could fit 28,000 Canadian football fields.

A land-based indoor salmon farm is more than three times as expensive to operate as a traditional ocean salmon farm, according to a study by the Freshwater Institute and Norwegian research organization, SINTEF. “This could ultimately have a negative effect on the sector’s contribution to the global economy as well as tax contributions in respective countries, provinces and communities,” the report said.

ISFA said it “will continue to collaborate with researchers, governments and ENGOs to understand the socio-economic and environmental realities of land-based fish farming systems, both the opportunities and limitations, to advance the technology and apply it on a case-by-case, species by-species basis as technology advances.”

Some land-based proponents acknowledged the challenges cited in the report, but wondered whether some facts and figures were skewed to exaggerate the situation.

“We all know that there are certain limitations in land-based RAS production. That said, the sea sites have a certain threshold in production capacity and, in my opinion, the large increases in production on the sea is on the wane. Therefore, I do believe that the market is ready for a limited introduction of production on land. We will therefore see some major investments in this market in the years to come,” said an industry stakeholder.

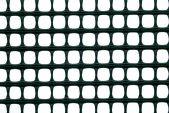

continued from cover

They are good sites, says Marc Turano, global sales manager for Pentair Aquatic Eco-Systems. The company has a unique partnership with both projects, a separate entity known as Urban Organics Pentair Group. “They source water from an aquifer below the city,” says Turano. The wells are between 350- and 400-ft deep. At 10C that’s a bit cool for the tilapia and hybrid striped bass they have been growing at the Hamms site, but it’s perfect for the salmonids they plan to raise at Schmidt.”

Turano says that the thick brewery walls help keep heating costs down, adding that the retrofits “did not present an overwhelming challenge.” Pentair supplied the RAS systems for the fish and consults with Urban Organics on the operations of the system.

“Our original Hamms site is relatively small at 8700 sq feet,” says Haider. “There are just four 3,000-gal poly tanks, but with careful planning we were able to harvest on a weekly basis.” Urban Organics started off raising tilapia, but have switched to higher value hybrid striped bass.

“What makes both of these projects different from most aquaponics systems is that each is designed to be a decoupled system,” explains Turano. “You can run the fish production system separately from the plant production system, closing a couple of valves.”

Traditional aquaponics models often operate on a ratio of 7 parts plants to 1 part fish, Turano comments. “This model we have gone with gives a more diversified cash flow. We can maximize production of fish and maximize production of plants. We are not trying to create a balanced environment to manage nutrient loads.”

The fish production side of the system is basically the RAS system that Pentair uses, Turano explains. Water from the tanks is first filtered mechanically through swirl separators to take some of the solids off the bottom. The water then goes to a mechanical drum screen filter to remove some of the larger solids and then to a bio reactor. The wastewater can then be pumped back to the tanks through UV filters, or sent over to the plants.

Turano says the project sits somewhere between a stand-alone RAS system and traditional full-loop aquaponics. “We get less waste than regular RAS, but more than traditional aquaponics,” he points out. “The waste is an added cost, but we also get more high-value fish.” They are looking at ways to reutilize the wastes.

The hybrid striped bass grow from 5 grams to a market size of 1.5 to 2 lbs in less than a year. A food conversion ratio of 1.3 to 1.5 is achieved on a diet of 40-percent protein, 10-percent fat, delivered by belt feeders. The feeders give a more continual supply of nutrients to the plants, to the fish and to the bio filter than hand feeding, Turano points out. “Frankly I’ve never see hybrids grow as fast as they were able to grow them.”

Three levels of shelves hold six-inch water trays with floating styrofoam

containers for the plants. Breweries don’t need windows, so all the light comes from LEDs and fluorescents. Basil, micro greens, kale, chard, lettuce, parsley and cilantro have all been grown depending on the needs and wants of the local market.

That’s all part of the urban farming story Haider points out. “We can produce fresh food in urban areas where there is no local source of fish and vegetables and produce year-round in regions like Minnesota, with a short growing season.”

The USDA-certified organic greens and high-value fish raised with minimal inputs in the RAS system appeal to educated consumers in the area.

Haider says there is not much aquaculture in Minnesota, mostly hatcheries for bait and stocking purposes.

“We believe the demand for commercial aquaculture will increase as we look for more sustainable systems of food production,” he says. Working closely with the Minnesota Department of Natural Resources ensured Urban Organics a smooth approval process for their commercial aquaculture license.

“Why not Saint Paul?” Haider quips. “We love our city! We live here, we are raising our family here. It’s great to contribute to the diversity of our city.”

SCHMIDT FACILITY

The Schmidt build expands on that initial success. “We were able to learn so much from the Hamms facility,” comments Turano. At 87,000 sq feet, it’s the size of 31 tennis courts combined, and will be one of the largest aquaponics systems in the world.

The larger scale allows for fluctuations in pricing and management and increases the profitability. “Small scale is one of the difficulties across the spectrum of aquaponics,” Turano says.

The tanks and filtration systems are all installed at the Schmidt facility, while they finish erecting the plant racks. “They decided to put in a small hatchery and have brought in both eggs and fry for the Arctic charr,” says Turano. “They can select how they can do it and they saw an opportunity to hatch.” There are quarantine, hatchery, and nursery tanks as well as grow-out tanks.

Haider says they moved into Arctic charr due to market demand. “We work closely with our fish processor and distributor to determine the best species to fit current markets and our farms.” He says they are also considering Atlantic salmon. Production targets are 275,000 lbs of fish and 400,000 lbs of produce a year.

Pentair is not looking to own farms long term, says Turano. “What we are hoping is that this will stimulate the growth of the model and others will replicate that.”

“The reason for Pentair’s involvement in the project is to prove the financial validity. We believe that it can be a profitable model and that is what we are trying to prove.”

The USDA-certified organic greens and high-value fish raised with minimal inputs in the RAS system appeal to educated consumers in the area.

Listening

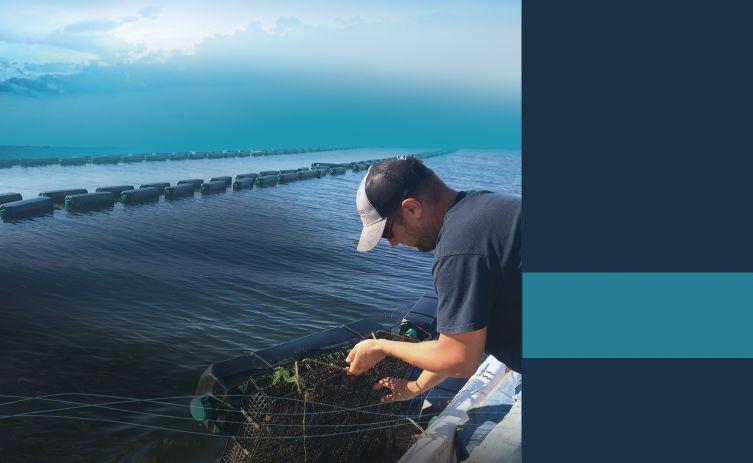

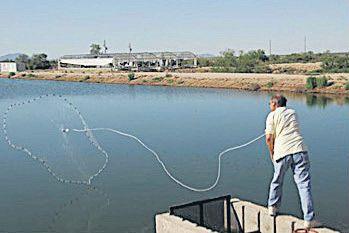

Dr Jeffrey Hill checks a minnow trap on a fish farm in Florida as part of a research on escapes of non-native species from aquaculture operations in the state

Study shows high BMP compliance and low levels of escapes for non-natives

By Matt Jones

ne of the most contentious issues surrounding aquaculture operations across the continent is the escape of non-native fish species and their potential impacts on native species and the environment. As such, researchers from the University of Florida’s Institute of Food and Agricultural Sciences conducted a study looking at the incidence of non-native escapes and Best Management Practices (BMP) compliance, which has shown very positive results for the industry in the state.

In-Situ Ad – Aquaculture North America

Size: 6.84” x 5” print: 4-color / CMYK

“One of the criticisms of aquaculture in regards to nonnative species and sustainability is escape of non-natives into the environment,” says Dr Jeffrey Hill, University of

SCD# 16INST206 / Date: November 2016

Florida professor, extension specialist, and one of the coauthors of the papers and extension publications generated by the study. Hill says the study was highly recommended for funding by the aquaculture industry in the state, particularly the tropical fish aquaculture sector, which comprises the majority of non-native farmed species in Florida.

“Politically, at times, it’s definitely an issue,” says John Skidmore, president of the Florida Tropical Fish Farms Association and owner and operator of Golden Pond Tropicals Inc. “It comes up here and there. There are some non-native established fish here that were a result of the farming industry, but most of those have been established for quite a while. The vast majority of the tropical fish that

With the SMARTROLL™ Handheld System, you can easily check the water quality of your aquaculture ponds. Measure pH, ORP, salinity, optical dissolved oxygen, and more.

• Instantly see results on your Android™ or iOS™ mobile device –just plug in the probe, launch the app, and go.

• Email or log data to your smartphone.

• Save time monitoring large facilities.

• Lower costs with durable sensors, cables, and battery pack. Learn more at

we produce cannot survive free, so even if they get out into local waters they get wiped out.”

Under the Florida Department of Agriculture and Consumer Services, aquaculture operates under mandatory, outcome-based BMP. They are non-prescriptive, however, they contain provisions for many aspects of the operations including effluent, aquatic animal health and non-native species containment, among other aspects.

“One of our applied research channels is helping this idea of preventing escapement, evaluating best management practices, getting more information on those and helping producers comply with those regulations.”

The process of Hill’s work involved a review of BMP in the state, and then accompanying Department of Agriculture officials on their twice-yearly BMP inspections and touring 23 different fish farms in central Florida and scoring BMP compliance independently of the inspectors so scores could be compared after the fact. They also sampled from those facilities every month to determine if

“We were collecting literally from the effluent on the fish farms, and we had a sampling scheme that worked our way downstream through the ditches, which are typical in this part of the state to the more natural streams and wetlands, and then on to the larger systems.”

The results of the study were very positive to both aquaculture producers and the BMP, finding high rates of compliance by fish farmers. Non-compliance issues were generally very minor and easily corrected.

“There were cases of fish off-site, where some fish were escaping in small numbers,” says Hill. “That was pretty much one of the big findings – the rate of escapement is relatively small in number and the compliance was high. We did find some things that were related to reducing those problems of escape or non-compliance – having a detention pond or retention system helps immensely. We had a couple of facilities that did not discharge off-site at all and they had zero BMP compliance issues. Even those who discharged through a detention pond, there were very,

Skidmore says that the type of fish raised is a big reason for the low numbers of non-native species downstream from aquaculture operations – the majority of tropical fish raised in Florida aquaculture operations are completely

Hill’s co-authored papers published in scientific journals and within Florida’s own land grant system contain a number of recommendations for aquaculture producers in the state to reduce the number of fish who escape from their operations.

Though the tips were intended for the Florida aquaculture industry, many are applicable to operations around the world.

Aquaculture producers should make efforts to understand the process of escape and to determine the most likely points of escape in their facility. Producers should regularly inspect barriers and check effluents leaving the farm for the presence of cultured fish. Attention should be paid to any practices that may increase the chance of escapement, such as pumping. Where practical, detention and retention ponds should help.

Producers should also identify structural and operational strategies to maintain compliance with escape provisions that are in effect in their own jurisdictions. And most importantly, producers should take quick action to correct any escape issues which do occur.

incapable of surviving the more aggressive predators that lurk in the waters. Escaped non-native species were found primarily near effluent, with numbers dropping dramatically as researchers moved further away from the farms.

“Mosquitofish (Gambusia affinis) are a pretty vicious consumer of anything that escapes,” says Skidmore. “They attack by numbers. First, they’ll eat the eyeballs out and make the fish blind and then will just start pecking at them.”

Skidmore’s Golden Pond Tropicals was one of many farms included in the study. He says many fish farms were eager to participate in the study to help separate fact from fiction as it relates to these issues, but also to improve their own processes if necessary.

“We may have learned something that we could use to make our BMP even better,” says Skidmore. “If it wasn’t working, then we needed to do something about it. But for the most part, we found that it was working. Looking at a problem scientifically, we were able to get away from the noise that’s out there that’s not based on any science, that’s just based on supposition.”

Hill says that another indicator of the success of BMP in Florida is how they did not discover any escapes of conditional species which are regulated at a higher level than many of the tropical fish.

“We view it as a risk-based approach,” says Hill. “What are the risks of these species? Based on our research, we would say [tropical fish escapes] are not a major environmental issue. Obviously, you keep up with regulations, and we do risk assessments and do work on other species to make sure we don’t get those in the environment. In research, we didn’t find any escape of conditional species. So from the facilities that had a higher level of containment required because of the type of fish they had, we found no escapement of those types of fish form those facilities.”

quaculture feed producer Cargill released a new shrimp feed product called iQuatic in October for acoustic feeding systems.

Using acoustics to study behavior in marine life has been part of oceanographic research for decades, but using acoustics to control feeding behavior in aquaculture is relatively nascent.

Using microphones and sensors, automatic feed dispensers are able to detect when shrimp are eating. Understanding the natural eating patterns of shrimp results in improved efficiency. Because the shrimp make better use of the nutrients delivered, they grow faster and produce less waste, the company asserted, improving feed conversion ratio and better water quality. This allows for a more environmentally sustainable operation with healthier and larger shrimp, it added.

“Giving shrimp food during their natural feeding patterns makes a huge impact on productivity, but the nutritional and functional design of the feed itself has to be right,” explained Adel El-Mowafi, Cargill global technology director for aquaculture, in the announcement. “Otherwise key nutrients can dissolve. Cargill is now able to give shrimp farmers the precise pellet qualities needed to help ensure productivity gains.”

iQuatic feed field trials have resulted in improved feed conversion ratios as much as 15 to 20 percent, the company claimed.

— Erich Luening

he small town of Souris in Prince Edward Island, Canada is now home to a private aquaculture research facility. After several years of preparation, the Center for Aquaculture Technologies Canada (CATC) research facility held its grand opening in December to celebrate achieving a Canadian Food Inspection Agency certification for Level-3 containment of aquatic pathogens. The new facility is a $6-million renovation on a disused lobster processing plant. The center is a subsidiary of San Diego-based Center for Aquaculture Technologies.

Debbie Plouffe, vice president of research for CATC, says the new center began to take shape in 2012. Inspired by their research experiences, they saw a need for a Canadian facility that could do research for industry.

“When you want to work with aquatic animal pathogens, it’s highly regulated as you might imagine, and there’s not a lot of facilities in which it’s easy for private companies to go and have highquality research conducted,” says Plouffe. “Certainly, there are lots of opportunities to work with academic researchers, various institutions across the country,

and government labs, but those don’t necessarily operate on the sorts of timelines that technicians need to adhere to when you’re developing a new product. We saw a need, did some market research and decided that we needed to build a facility like that, where people could come and have research conducted for them by highquality scientists with a lot of expertise in the area of aquatic animals and aquaculture.”

With a very supportive PEI government behind them, Plouffe says they found both the area of Souris, and the former Ocean Choice Inc lobster processing plant to be ideal locations. A deciding factor was the plant’s access to freshwater and seawater on site. Once finalized, CATC invested $6 million

into renovating the facility, the majority of that on equipment required to obtain their Level-3 animal pathogen containment certification.

“In the containment zone, we’ve got 12 different challenge rooms that are available with all different tank sizes ranging from 40 liters up to 1,500 liters that we can move in and out,” says Plouffe. “We really tried to design the space to be as flexible as possible to meet as many needs of industry as possible. On the nutrition side, we’ve got four separate tank systems with varying tank sizes – 56 four-liter tanks up to 32 800-liter tanks. There’s a lot of different possibilities depending on what species you’re working with and what types of studies that they want to conduct.”

Plouffe says the value of the company is that it offers services in a variety of different areas of aquaculture. Fish Contract Services, the group she leads, covers fish nutrition and fish health, doing tank studies to evaluate new feed

ingredients, new feed additives and new fish health products such as vaccines or anti-microbial treatments. CATC’s Lab Services department houses their experts in genetics, genomics and collective breeding. The facility is also capable of supporting both cold and warm water fish.

“The nice thing for our clients is having all that capability in house really makes life easy for them,” says Plouffe. “They don’t have to look for several different research or academic institutions, they can get it all done in one place, which helps them achieve their goals and bring new products to the marketplace faster.”

The CATC had been operating in PEI for roughly one year prior to the official launch in December. In that time, they added 15 employees and expect the workforce to grow to 30 or 35 by the end of 2017.

— Matt Jones

BY ERICH LUENING

everal hatcheries that fell in the path of Hurricane Matthew, which struck a number of southern states in the United States last October, have sustained damages, say government fish and wildlife officials.

The costs of the damages have yet to be determined as officials take stock of the mess the storm left in its wake in the southern states of Florida and South Carolina.

“I can tell you that the following hatcheries sustained damage; Welaka in Florida, and Bear’s Bluff and Orangeburg in South Carolina,” Chief of Public Affairs US Fish and Wildlife Service Gavin Shire told Aquaculture North America (ANA). “At this time, I don’t have figures on the cost of damages.”

The southeastern United States was hit hard by Hurricane Matthew in October as it moved very close to the coasts of Florida, Georgia, South Carolina and North Carolina. It made one US landfall southeast of McClellanville, South Carolina as a Category 1 hurricane with 75-mph winds.

One of the first to get hit was the Welaka National Fish Hatchery. Originally operated by the State of Florida, it was transferred to the US Fish and Wildlife Service in 1938. Ponds are operated at two locations. Those ponds at headquarters near the aquarium are called the Welaka Unit, and a second group of ponds about three miles south of the headquarters is called the Beecher Unit.

“We are a little bit further inland,” assistant hatchery manager Tony Brady said. “Some signs were destroyed and there was some leaking in ceiling lights and windows. We had a few trees down. There was a good amount of wind; the power went out and the generators ran out of fuel. But

it’s a good thing the water continued to flow through the hatchery with no problem.”

Further north in the state of South Carolina, two hatcheries had more significant damage.

One of these is Bears Bluff National Fish Hatchery, which comprises of 31 acres bordering the North Edisto River south of Charleston, South Carolina. Facilities include nine recirculated intensive culture systems; three recirculated egg incubation/larval rearing systems; numerous holding and intensive rearing tanks; and six salt and freshwater ponds.

The Bears Bluff hatchery works to restore and manage interjurisdictional coastal and riverine fishes, such as the American shad, anadromous sturgeon, and red drum. The hatchery is also responsible for the recovery of species listed under the Endangered Species Act, such as the shortnose sturgeon and candidate species such as the Atlantic sturgeon.

Hurricane Matthew had its way with the hatchery campus and some of the ponds, say staff.

“We have a generator on site that kept the lights on when we lost power,” said Gena Long, fisheries biologist at Bear’s Bluff. “We did have 25 to 30 trees down on the property, but no structural damage. The most significant impact was the high water from estuaries; a lot of saltwater mixed with one of our freshwater ponds. Now it’s totally brackish.”

But all was not lost, Long said.

“We had our scheduled harvest in our red drum ponds and, surprisingly, it was a very successful harvest, better than we thought,” she added.

The Orangeburg National Fish Hatchery produces a variety of warm-water freshwater fish, including striped bass, redbreast sunfish, American shad and lake sturgeon.

“We had over 40 trees that were uprooted by high winds,” said Byron Hamilton, Orangeburg National Fish Hatchery manager. “One of the trees fell on one of our quarters and caused significant roof damage. That is the bulk of the damage we received from the hurricane.”

A Fish & Wildlife Special Operation Response Team (SORT) came out to remove the trees that were hazardous to staff and visitors, he added. None of our ponds and fish facilities were affected.

our grants totaling $1.2 million have been awarded to research projects aimed at supporting the development of environmentally and economically sustainable aquaculture in the United States.

The US Department of Agriculture’s (USDA) National Institute of Food and Agriculture (NIFA) awarded the grants to researchers in Alabama, Michigan, New York and Virginia November.

The projects funded include research conducted by scientists at Michigan State University, who will identify strains of a common bacteria that threaten farmed rainbow trout as a step toward improved disease prevention and control. Virginia Tech researchers will work with commercial farmers to compare profitability of both pond and recirculating-water commercial business models. An Auburn University project will evaluate and optimize the economics, fish and plant biology and food safety aspects of a highyield aquaponics system that utilizes fish waste to generate additional revenue. The Research Foundation of the State University of New York, Stony Brook will use molecular genetics techniques to identify disease-resistant clam germlines, to help improve commercial shellfish stocks.

“In 2015, Americans spent $96 billion on seafood, but only a small portion of that was produced by US aquaculture,” said NIFA Director Sonny Ramaswamy. “To meet the growing demand for this healthy source of protein, NIFA investments are helping enhance US aquaculture production to promote both economic opportunities and a safe, reliable domestic seafood source.”

Since 2009, USDA has invested $19 billion in research. The investment has resulted in 883 patent applications filed, 405 patents issued and 1,151 new inventions covering a wide range of topics and discoveries, said the agency.

Cargill is developing a new type of canola oil that could give the aquaculture industry a more sustainable way to raise fish rich in EPA/DHA Omega-3 fatty acids.

The plant-based source of the nutrients, developed in collaboration with BASF, could provide an alternative to using fish oil in aquaculture feed and could ease pressure on wild fish populations that currently supply much of that oil, said the company.

Canola flower. Cargill is developing canola oil as an alternative to fish oil used in aquaculture feed

In feeding trials it conducted with salmon in Chile, Cargill said it was able to completely replace fish oil in feed rations with oil from EPA/DHA canola.

Right now, raising fish rich in Omega-3s means supplementing their feed with fish oil. This new canola, which is genetically engineered to make long chain Omega-3 fatty acids, will offer a more sustainable alternative as it eases pressure on finite marine resources. Testing and regulatory approval for both the canola and the EPA/DHA enhanced canola oil is underway. The EPA/DHA enhanced canola oil is expected to reach the market sometime after 2020.

“As a fish feed producer, we need to reduce our dependency on marine resources,” Einar Wathne, president of Cargill Aqua Nutrition. “This new canola can create tremendous opportunities across the global food and feed markets, and we believe it is critical for the growth of aquaculture.”

Producing high quality fish in freshwater requires a great deal of time, care and consideration. Widespread and often undetected presence of Bacterial Kidney Disease (BKD) poses a threat to your investment. Chronic and long-lasting, BKD infection commonly leads to higher background mortality and lower performance. Renogen® is a vaccine specifically designed to aid in the prevention of BKD and reduce the need for later treatment, leading to healthier fish at a lower production cost.

oxygen

ponds, lakes, and during transport. Their proven dependability results in better production, reduced loss, and improved growth rate for your fish.

Marine Harvest ASA has been nominated to purchase the assets of Canadian salmon farmer Gray Aqua Group from receivership, a move that will see the Norwegianbased company further broaden its farming footprint in Canada.

The acquisition price on a cash and debt-free basis is $11.2m (C$15 million). Marine Harvest said its plans include building an organization capable of producing 15,000-20,000 metric tons gutted weight equivalent of salmon per annum

Gray Aqua Group is based in New Brunswick, on the east coast of Canada. “The acquisition is important from a strategic point of view, as it further broadens Marine Harvest’s global farming footprint in a country where we are already present on the West Coast,” said Marine Harvest.

A Marine Harvest Canada staff member at work. The company says the acquisition will further broaden its footprint in the country

“The market for salmon in North-East America continues to develop very favorably, and the acquisition represents as such a compelling value proposition,” it added.

The assets purchased include one hatchery and two farming licenses in New Brunswick, seven farming licenses in Newfoundland, and one processing plant in Newfoundland.

Currently, no fish has been stocked in the above-mentioned licenses. In addition, the company has applied for 17 farming licenses in Newfoundland, which are yet to be approved.

Marine Harvest said it is looking forward to engaging with the relevant authorities to secure additional farming locations, as well as to establish new jobs in the local communities.

Marine Harvest will shortly start to detail a production plan and investment framework for the east coast of Canada.

opens up new marketing opportunities for North American fish feed producers

North American producers of alternative fish feeds could look forward to new opportunities in European markets, with the EU countries’ endorsement of the European Commission’s proposal to allow insect feed in the aquaculture industry.

The vote took place in December, following a discussion on the proposal in a meeting of the biological safety of the food chain section of the EU standing committee on plants, animals, food and feed.

North American producers of alternative fish feeds could look forward to new opportunities in European markets Credit: diginomica.com

The text is expected to be formally adopted during the Spring of 2017. This means that insect proteins will be authorized for use in fish feed beginning July 2017, according to the International Platform of Insects for Food and Feed (IPIFF).

“We are particularly pleased with the move made by EU institutions: the opening of this legislation is in our view a major milestone towards the development of the European insect production sector,” said IPIFF President Antoine Hubert, as quoted by Agripress

“In the long run, these changes should contribute to alleviate European dependency on protein imports, whilst securing a promising source of protein for EU farmers & customers,” concluded the IPIFF Chair.

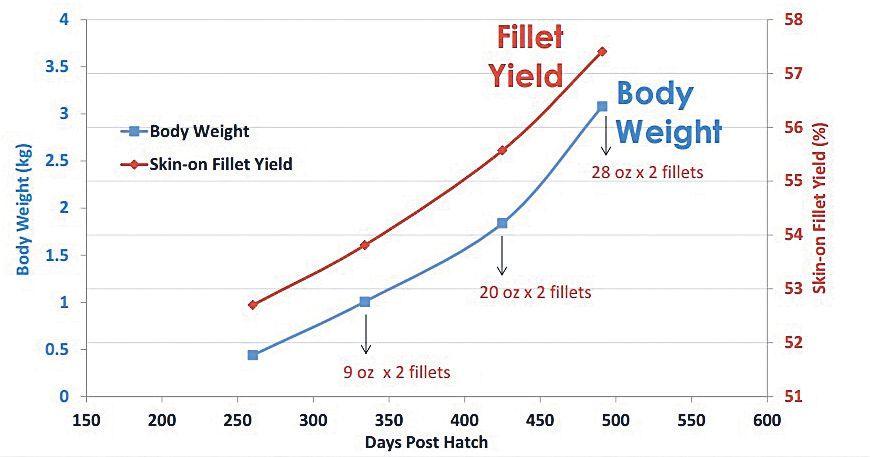

and steelhead, differences in the types and yield of the products. Rainbow trout had a harvest size of 500 g, and steelhead, 1 kg and 3 kg. The three each had a 1,000-ton volume harvest.

The 1-kg steelhead had a fillet yield of 53.8 percent and the 3 kg, 57.4 percent. Not surprisingly, the revenue from the latter turned out higher. Another advantage it had was that because it was larger, it commanded a better price.

Despite having the largest volume of product, because of its 58 to 68 percent butterfly fillet yield, the 500-g rainbow trout posted the lowest revenue because its price per pound was much lower.

Propping revenues, however, is “not as simple as scaling up production.”

The critical factors to consider are changes in growth rate, reductions in FCR with age, changes in product yield and product quality.

Rainbow trout is usually sold as a butterfly, skin-on fillet. Cleveland said 50 percent of the output is grown by Clear Springs in Idaho, which supplies national restaurant chains like Cracker Barrel and Red Lobster. “This leaves smaller producers and new producers to find different markets, mostly local supermarkets or the local whitetablecloth restaurants.”

Per anecdotal report, she said steelheads are sold as part of the commodity market, thus enjoying a higher demand. The downside is that the price fluctuates; it follows the price of the Atlantic salmon.

“Steelhead is often produced with a large, skin-on beautiful fillet. It is a lot like salmon. That’s probably why it follows the trend of the salmon market,” she said.

While steelhead is priced about 10-percent lower than salmon, when raised in RAS, it posts a rapid growth trajectory. It could be harvested at 3 kg after 17 months. It takes salmon about 21.5 months to reach that weight. “There is much earlier increase in growth performance in the steelhead and get them to the market faster,” she said.

The rainbow trout and steelhead were studied in the Freshwater Institute’s RAS tanks. Throughout the study, the selected harvest weights were 500 grams, and 1, 2 and 3 kg.

Growth and feed conversion are directly proportional throughout the production cycle.

Compared to the period between 500-g to 1-kg body weight, FCR posted a “dramatic increase” between the 1- and 2-kg. “This will certainly affect the amount of feed purchase.”

The basis for increased FCR are feed intake, digestible energy, metabolizable energy and net energy.

FCR is all about how energy is transferred and how it adds to growth formation. “Sometimes, it doesn’t even have the chance to get into the fish. This passes out as fecal matter,” she said, referring for food intake. “The difference between energy consumed and energy that’s available for use is the digestible energy. Energy is also lost through excretion whether in the form of urine or through the gills. Energy is also heat. Heat is given off. Heat is energy. So, energy is lost,” she summed up.

“Most of the energy is lost through maintenance. This is the amount of energy required just to maintain biomass of the fish. A larger fish requires more energy. This also includes voluntary activities like swimming, and thermal regulation. Whatever is left over after energy is allocated to all these essential processes, is what’s left over for growth,” she said. OPTIMUM FEEDING SATIATION

Cleveland explained that maximizing the amount of energy the fish consumes can improve FCR. This includes increase in nutrient and energy density of the pellet.

“Fish are slightly different from mammals in that if the mammals consume a very energy–dense diet, they correct that by reducing food consumption,” she said. Thus, pellet size must be optimized to fish size.

Feed must be formulated according to palatability and ingredients that increase amount of digestible energy. Cleveland said ingredients that are not very digestible contribute to diarrhea and, eventually, loss of nutrients through fecal matter.

Understanding nutrients demand is also important. Citing protein-to–fat-to-carbo ratio, she said, “Too much fat will contribute to visceral fats and reduction in fillet yield. Too many carbo can lead to fatty liver syndrome.”

When it comes to feeding regime, there are two options: the low-dose, high-frequency approach and highdose, low-frequency approach.

The study revealed a new way at looking at fish feeding satiation.

While most of the previous studies were completed by feeding fish to satiation, Cleveland and her team had observed that optimum feeding satiation doesn’t occur at 100 percent of satiation but at 75 percent. Specific growth rate, however, is achieved at 100 percent of satiation.

Table shows a dramatic increase in the skin-on fillet yield. The fillet yield more than doubles when fish is grown from 1 kg to 2 kg

She said these facts will be help producers who need a set timeframe to achieve a specific fish size.

“For example, if a fish needs to get at 3 kg at a specific time, it is more beneficial to feed a fish to a small level of moderate feed restriction during this time because this will result in improved feeding procedure,” she said. This is a better approach compared to feeding the fish through satiation, reaching market weight too early and then feeding maintenance ration through the remainder of the period.

Four percent less feed was consumed in this method, saving the producer $50,000 in feed cost.

Ultimately, the harvest size depends on what the consumers want.

The small rainbow trout butterfly fillet is usually served pan-friend and enjoyed for its light, delicate texture. The larger steelhead has firm meat and resembles salmon. For increased appreciation of the different sizes that the fish can offer, she suggested that producers could provide recipe cards or other educational materials to make sure the consumers understand what they are getting.

This article was based on the video and PDF presentation uploaded by the Conservation Fund’s Freshwater Institute on its website.

BY ERICH LUENING

It’s been known for centuries that animals consumed by humans undergo a certain amount of stress before they get to the dining table, lowering meat quality and processing efficiencies.

The use of sedatives before and after harvest to achieve a “rested harvest” has proven to lessen stress effects, but the US Federal Drug Administration (FDA) has limited such drugs for use in animals raised for human consumption. A recent study found that using electricity may offer a nonchemical means to sedate farmed fish while in pre-harvest stages.

The study, by biologists at the Southern Illinois University at Carbondale, compared both the effects of drug (chemosedative) and electricity (electrosedative) on the rested harvest conditions of rainbow trout.

Although the authors concluded that rested harvest did show reduced pre-harvest stressors in the tested trout — with electricity appearing to improve some aspects of product quality — they encourage other researchers to further look into rested harvest for fish using both electrosedative and chemosedative techniques to develop adequate protocols for fish farmers.

“One of the most important factors to consider, really from the beginning, is how the technique or technology might feasibly be implemented by a farm,” research team leader Jesse Trushenski, who now works at the Idaho Department Fish and Game as the fish pathologist supervisor, told Aquaculture North America (ANA). “We had quite a few discussions about how the things we were testing at an experimental scale could be adapted and scaled up to match commercial conditions. There’s a certain element of ‘if you build it, they will come’ in that if the technique/technology is absolutely perfect and offers clear advantages, the industry can always adapt to use it.”

Currently, the only commercially available FDAapproved fish sedative is a tricaine methanesulfonate product, Tricaine-S, which has to be used 21 days before human consumption. The fish anesthetic is regularly used in hatcheries, labs, and aquariums to immobilize fish for marking or transport and to suppress sensory systems during invasive procedures. The drug is provisionally approved for use in fish in Canada, the United Kingdom, and the United States.

Harvesting and slaughtering methods usually involve some degree of handling and crowding, which tend to increase plasma cortisol, glucose, and lactate levels in fish, and could remain elevated for hours or days. Slaughter methods tend to exacerbate these stresses, the authors said.

For instance, rainbow trout are often slaughtered by dewatering (asphyxia; also referred to as “air shock”), and hypoxia is known to induce stress responses in this species, according to the authors of the study.

Because of stress, hyperactivity, and their consequences, the ease and efficiency of processing (filleting), fillet quality, and shelf life are all negatively affected. Pre-rigor filleting results in the highest filleting yields, but stressful harvest and slaughter conditions can accelerate the timeline of rigor development. Pre-slaughter stress and hyperactivity can also cause external mechanical damage (e.g., scale loss,

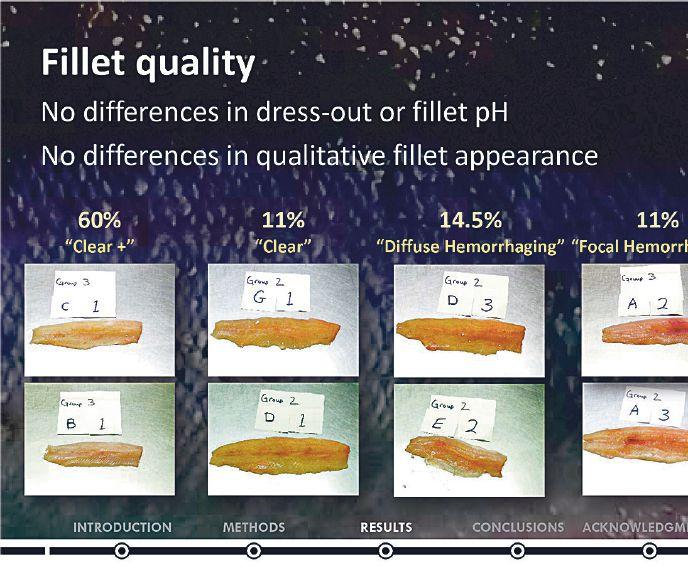

Representative images and frequency of categorical scores assigned to fillets of Rainbow Trout subjected to the rested harvest treatments and stress challenge associated with trial 1 (overall frequency, pooled across treatments). Treatments were not observed to vary with respect to appearance scoring frequency.

bruising, lacerations) as well as internal injuries, according to the study.

Trushenski’s approach was to simulate harvest and slaughter of rainbow trout that typically occur at large commercial farms and processors, and to test possible rested harvest protocols in this context.

The advantages of electrosedation are that it requires no expensive toxicology testing to prove that sedated fish are safe to eat, has no withdrawal period, poses no concerns regarding chemical disposal, offers faster induction times, and is easy to use.

Her team found that direct current (DC) electricity effectively sedates fish and may be an appropriate alternative to chemosedation for rested harvest. Based on the principles of electrophysics, the strength and size of an electric field in water is highly controllable, allowing delivery of electricity to selected areas of a water body or, in the case of aquaculture, to selected holding systems or areas within holding systems.

Sedation of fish encountering the electrical field is generally quick but is dependent, in part, on the fish’s conductivity, the electrical resistance of its skin and body and its size and surface area. The advantages of electrosedation are that it requires no expensive toxicology testing to prove that sedated fish are safe to eat, has no withdrawal period, poses no concerns regarding chemical disposal, offers faster induction times, and is easy to use. Unlike chemosedation, however, there is the possibility of physical trauma as a result of exposure to DC electricity, depending on the fish, waveform, and environmental conditions, the study found.

Now Trushenski looks to other researchers to continue the observations she and her team made.

“Our team probably won’t be doing more of this work, simply because the principal investigator (me) has changed jobs and the students involved are all moving on to other careers,” she explained. “That said, I don’t think the interest in rested harvest has diminished, so I hope other researchers are able to learn from what we have reported and take this research forward.”

Ewos is a world leader in the research, development and manufacture of feed and nutrition to the international aquaculture community.

BY JOHN G. NICKUM

t is difficult to foresee what aquaculturists can expect after President-elect Donald Trump takes office, but based on his rhetoric during the campaign, or on what various pundits have suggested as actions he might propose, some changes appear to be in the cards. Changes pertaining to environmental regulation, food safety laws, international trade, interstate commerce regulations, the Lacey Act, Endangered Species Act, and the EPA could be some of them.

That said, I think it is safe to predict that Mr Trump will not identify aquaculture as a specific area that will require major changes during his administration. He can be expected to focus on economic and political issues. Perhaps regulations affecting aquaculture will be priority targets. Within conservation and resource management matters, I expect him to give much more attention to environmental regulations and terrestrial wildlife, than to fisheries issues. Perhaps he will follow a path similar to that of Shell Chemical/Petroleum 40 years ago, when Shell determined that aquaculture had a great future, but was not as financially rewarding as petro-chemicals. Potential for maximum profits outweighed the societal

benefits of aquaculture. The Trump administration can be expected to focus on big economic matters, not small fish.

Mr Trump has never voiced a strong interest in fisheries issues in general and has not been known to comment specifically on aquaculture issues. Although seafood importations are major components in our international trade deficits, they seldom receive much attention in political discussions. Despite the probable absence of direct actions affecting aquaculture, I suggest that aquaculture will be affected by initiatives taken in other areas, such as changes in environmental regulations, tax reforms, food quality standards for imports, and international trade agreements. Some changes in environmental law and international trade may have profound effects on American aquaculture.

Given the extreme amount of hyperbole and acrimony generated during the presidential campaigns; and since, as well; I must review some basic facts about American government. Most importantly, we must remember that a President’s powers are quite limited. The President has a “bully pulpit”, but not much else. However, the President, his Cabinet members, and civil servants in administrative positions, have considerable flexibility in how laws and regulations are implemented. Ultimately, court decisions may determine whether or not laws and regulations are being implemented in accordance with Congressional intent and our Constitution. Until

court decisions are rendered, the interpretations of Executive Branch officials determine implementation. As one official told me when I worked in Washington, DC, “Until my interpretation of the regulation is beaten through litigation and a court decision, this is how it’s going to be.” That can be good, or bad… sometimes, very bad.

Here’s a quick review of the structure of American government. Our government consists of three branches: the Executive Branch (the President, administrators, and civil servants); the Legislative Branch (Congress); and the Judiciary (the Supreme Court and other Federal Courts). Each branch is limited by a series of checks and balances; therefore, all branches must agree before major actions can be taken. It is highly doubtful that President Trump will take Executive Actions that affect aquaculture directly. It’s also doubtful that he will ask Congress to enact new laws pertaining directly to aquaculture; but, individual Members of Congress could propose new legislation. Court decisions certainly could affect aquaculture, but I am not aware of any pending decisions related to aquaculture. Actions to modify implementation of existing laws are the most probable source of interest and concern for American aquaculturists. The Secretary of Agriculture, the Secretary of the Interior, and the Secretary of Commerce will oversee the policies and action of those three Departments. The priorities and actions of the Secretary of Agriculture will probably have the greatest effects on aquaculture research and services, but mariculture activities and regulations fall under the Department of Commerce. Commerce has been relatively friendly to aquaculture in recent years, and can be expected to continue as a positive force. The Department of the Interior has become pretty much a regulatory entity for aquaculture in recent years. Members of Congress from States with active, relatively large, aquaculture programs, such as, Mississippi, Arkansas, Louisiana, Texas, Florida and Idaho will be able to exert influence on the implementation guidelines of the Departments designated for leadership by the National Aquaculture Act, but major legislative actions are doubtful. Among American aquaculturists there is almost universal hatred for specific portions of the Lacey Act. When the Lacey Act was enacted in 1900, the primary purpose was to control market hunting and poaching. Aquaculture was not even mentioned. Provisions in the Lacey Act were designed to prevent hunters from escaping arrest for violations of State regulations by carrying their illegally taken animals to a neighboring State. Transporting game that had been taken in violation of State regulations across State lines to avoid arrest and prosecution is a Federal felony rather than a simple misdemeanor. Fish farmers have been prosecuted under the Lacey Act for hauling legally owned fish grown on their own farms. It has been nearly impossible for fish farmers to track the variations in State-to-State regulations governing non-native fish and/or fish disease agents.

In addition to identifying the interests of the Secretaries for Agriculture, Commerce, and the Interior, aquaculturists need to track the appointments of new leaders for the Food & Drug Administration, the Environmental Protection Agency, the US Army Corps of Engineers, the National Marine Fisheries Service (note change in agency name), and the US Fish and Wildlife Service. The priorities of these new leaders will determine whether or not their goal is to “help aquaculture grow”, or to exert increasing pressure on everyday activities in the name of protecting wild, free-ranging aquatic wildlife.

Fish farmers often state, “Aquaculture is Agriculture”, but State and Federal resource management agencies counter this argument by claiming, “Fish are Wildlife.” Which interpretation is preferred by the Trump administration is yet to be determined.

Today’s modern aquaculture farmer needs a partner that is able to help with the scope and variety of challenges they face every day. That is why Pentair AES has assembled a team of experts with diverse backgrounds in aquaculture, biological and technological engineering that is grounded in decades of research and commercial industry application experience. We help our customers run successful operations by providing the design expertise they need, a responsive service team and the largest selection of equipment and supplies in the industry. Trust in a team that’s here to help you—ASK US!

BY MATT JONES

The demographics and purchasing behaviour of seafood consumers present a host of challenges and opportunities, says Matt Lally, Manager, Analytics and Insight for Nielsen Perishables, a consultancy firm on fresh seafood for the marketplace.

Speaking at the Canadian Aquaculture Industry Alliance’s Annual General Meeting in November, Lally noted that sales of seafood, viewed collectively rather than in various formats such as canned, frozen and fresh, has seen a growth of only 1.5 percent annually. “Fresh, specifically, performs a little bit higher and has continued to perform over the last five years at a higher growth rate [than canned and frozen]. But there’s still a large room for improvement and a lot of opportunity for fresh seafood to continue to outpace the growth that it has experienced.”

He said there is much that can be learned from analyzing the consumer. Lally’s analysis starts by understanding who the consumer is. Fresh seafood only reaches about 55 percent of American households, leaving a lot of room for growth, he said. However, examining the 55 percent who purchase seafood, only one-third of those households make up 80 percent of the sales, which means there is a further opportunity to drive those who did purchase seafood to purchase more.

“We looked at it from an ethnicity perspective and we looked at it from a generation perspective,” says Lally. “As we expected, the multicultural households over-spent in their share of sales within fresh seafood. Similarly, as we’ve known, the older generations overspent in their share of fresh seafood. What that immediately shows us is that multicultural households, which is a growing group within the American household, present that natural opportunity because they’re already engaged in the food and there’s rapid growth in the number of multicultural households. And on the other hand, there’s a real opportunity to reach the younger generations who, right now, are not as actively engaged with fresh seafood.”

“There’s a huge opportunity in fresh seafood because it stands to have the greatest gain from the Americans’ increased focus on health.”

~ Matt Lally, Manager, Analytics and Insight, Nielsen Perishables

Lally is quick to caution that the industry cannot simply rely on the growth of multicultural households and the influx of younger generations of multicultural consumers because while they are still engaged in purchasing fresh seafood, it is nowhere near the level of their parents.

Non-Hispanic white households on the other hand, show more of a desire for convenient options; they tend to spend more on frozen seafood or prepared seafood alternatives, such as deli sushi.

Recent increased consumer interest in healthy eating will also benefit the industry, Lally notes.

“There’s a huge opportunity in fresh seafood because it stands to have the greatest gain from the Americans’ increased focus on health,” says Lally. “After the economy, that’s the number one American concern right now, and most Americans feel they can manage their health through their diets. Given the high amount of nutrients, natural vitamins and enrichments from seafood, there is a big opportunity through messaging, education and communication to really increase consumer engagement.”

US retailer Sam’s Club offers consumers opportunities to sample seafood meal kits at its stores. Meal kits are a growing area in retail and a great way to introduce a variety of seafood to consumers, says consultant

The key challenge will be reaching consumers who may not be interested in purchasing seafood products. Lally cites the importance giving consumers the opportunity to try seafood through convenient product offerings that appeal to younger households, or incorporating more seafood into the deli area of retailers. Products such as seafood soups, salads, entrees and deli sushi are all growing between 9 and 20 percent annually in sales, which give households an opportunity to try seafood products with limited risk from a monetary perspective.

“One growing area that we’re really talking about is meal kits,” says Lally. “That’s something that is increasingly growing in popularity and one of the benefits of meal kits is it offers customers the opportunity to try new products in portioned sizes as well as having instruction on how to prepare the product. That’s a great way to expose consumers to different varieties. For instance, while tilapia may be something that more consumers are comfortable with, and it’s an easier product to prepare, exposing consumers to different species of fish, or even getting into some of the crustaceans, through meal kits will be a great way for consumers to try them. There has to be a level of comfort in the knowledge and preparation of the product.”

The key to changing those behaviours and getting consumers to expand their seafood choices will be in truly reaching consumers and making an impact on them. Lally says that while he believes a lot of Americans know that dieticians and nutritionists recommend eating two portions of seafood a week, in reality many Americans fall significantly short of that. The seafood industry must find a way to, not only get their messaging out through marketing, but to help consumers feel comfortable and educated with the products.

“Sustainability is such a buzzword in the industry right now,” says Lally. “But there’s a lot of confusion and often even contradictory sources of information on fresh seafood. Finding a consistent and cohesive message around that is going to be really critical, and with that is finding consistency in the perception of seafood. Customers just don’t know what information to trust. There really need to be either government or industry leadership to elevate seafood as a whole.”

Americans ate 15.5 pounds of seafood per capita, up nearly a full pound (0.9 lb) from 2014, data from the National Fisheries Institute (NFI) show.

The increase is reflected in multiple species across the NFI’s annual Top 10 list, with shrimp maintaining its top rank as most popular among Americans.

This is the third consecutive year that seafood consumption increased in the US, and nutrition experts are celebrating the trend, said NFI.

Shoppers at Seattle’s Pike Place Market. US per capita consumption of seafood has jumped third year in a row, NFI reports

“Three years’ worth of increase in seafood consumption is good news from a public health perspective,” said Rima Kleiner, MS, RD, registered dietitian at NFI and Dish on Fish blogger. “The fact that we see a variation in expansion and contraction across the top ten species, coupled with overall growth, is actually very positive. The nutrition community recommends that Americans eat a variety of seafood and this type of distribution reflects that message.”

Three of the top ten species saw an increase in consumption — salmon, pangasius and crab; two maintained their volume — catfish and perennial list leader shrimp.

Globally Trusted UV Experience

Proven bio-security; over 35 years, 380 installations, more than 740 million gallons per day

Lifetime Disinfection Performance Guarantee

Aquafine Genuine parts program provides this peace of mind

Long-term Industry Commitment

Collaboratively advancing UV research in aquaculture aquafineuv.com

THE WAY WATER WAS INTENDED:

Achieve a balanced aquatic ecosystem with water movement and proper aeration. Clean, healthy water is crucial to raising high quality fish.

The Aquarian Aquaculture Aerator works to bring about increased productivity and fish quality, while saving energy and money. Backed by outstanding customer service, Air-O-Lator eco-friendly aerators are easy to install and maintain.

www.airolator.com 800-821-3177

Contest encourages innovation of alternative ingredients for aquafeeds and reduced pressure on fi sheries

The quest for a fish-free feed for the aquaculture industry is making strides through the “F3 Fish-Free Challenge,” which as of November has attracted a range of multinational companies as contestants.

The F3 Fish-Free Challenge aims to help catalyze the development and sale of costcompetitive, viable aquafeeds free of fishmeal and fish oils.

At the Aquaculture 2016 conference in Las Vegas in February last year, USDA Research Nutritionist Dr Rick Barrows told Aquaculture North America (ANA) that there are fish-meal-free and/or fish-oil-free diets available but they are “challenging” as an alternative protein source because while they are effective, they are also expensive. “It can be done, but expensive right now. It is difficult to commercialize it,” Barrows said.

aquafeed business. If none of the contestants have met the 100,000 MT target by Sept. 15, 2017, the prize will go to the company closest to the target.

Contestants range from companies with their own mills and farms with multinational sales and hundreds of employees to start-up farms and ingredient companies with just a dozen employees. Farms and ingredient suppliers partnered with feedmills to form larger teams. Companies submitted feeds for a range of seafood including shrimp, tilapia and trout.

Under the F3 Challenge, the first company to produce and sell 100,000 metric tons (MT) of aquafeed that does not contain marine animal meal or oil will be awarded a prize in excess of $200,000 to support their fish-free aquafeed business. If none of the contestants have met the 100,000 MT target by September 15, 2017, the prize will go to the company closest to the target.

Team Diets

Submitted

AgriProtein (Gibraltar), Abagold (South Africa) Rainbow Trout Guangdong Evergreen Feed Industry Co. (China) Tilapia, Carp, Dace Htoo Thit Co. (Myanmar), Biomin (Austria) Tilapia/Carp JAPFA Feeds (Singapore/Indonesia) Tilapia Oryza Organics (Pakistan) Tilapia (x2) Ridley (Australia), Sureerath Prawns (Thailand) Shrimp TomAlgae (Belgium) Shrimp TwoXSea (U.S. California), Star Milling Co. (U.S. California), Alltech (U.S. Kentucky), TerraVia (U.S. California) Trout

The Monterey Bay Aquarium, New England Aquarium, University of Arizona and World Bank are sponsoring the F3 Challenge, with additional donations to support the administrative costs of running the prize.

Teams are expected to report their first quarterly sales figures in January 2017. The F3 Challenge team is optimistic that the 100,000 MT target, which would represent a major milestone in validating the market viability of fish-free feeds, will be met.

Eight registered teams have submitted a specimen of feed that they want to qualify for the contest, which are currently being analyzed to ensure they are free of fishmeal and fish oils, said the organizers. Contestants range from companies with their own mills and farms with multinational sales and hundreds of employees to start-up farms and ingredient companies with just a dozen employees.

The contest arose out of discussions first held at the 2015 World Aquaculture Society meeting in Busan, Korea, between Fitzsimmons and several environmental non-profit organizations, and demonstrates how industry and environmental groups can come together to achieve the common goal of developing cost-effective substitutes.

An intent of the contest is to ensure that the feeds are at least as nutritious for the farmed-raised seafood being fed and that the final seafood produced is just as nutritious for consumers

Companies submitted feeds for a range of seafood including shrimp, tilapia and trout.

The Monterey Bay Aquarium, New England Aquarium, University of Arizona and World Bank are sponsoring the F3 Challenge, with additional donations to support the administrative costs of running the prize.

“Eventually we would like to see that fishmeal free seafood would be considered as sustainable and good for the environment as grass-fed beef or free-range poultry,” said Fitzsimmons.

The contest arose out of discussions first held at the 2015 World Aquaculture Society meeting in Busan, Korea, between University of Arizona Professor Kevin Fitzsimmons, the former president of the World Aquaculture Society and lead spokesperson for the F3 Challenge, and several environmental non-profit organizations.

Teams are expected to report their first quarterly sales figures in Jan. 2017 The F3 Challenge team is optimistic that the 100,000 MT target, which would represent a major milestone in validating the market viability of fish-free feeds, will be met.

# # #

Tanks for your every need!

• Our tanks are available in many colors, shapes and sizes from 25 to 3000 gallons

• Smooth inside surfaces prevent damage to your fish

• Edge lips provide wall strength & minimize deformation

• Custom installation of optional drain fittings • FDA and UV sterilized

We also offer Vertical Storage , Horizontal, Cone bottom, and General Purpose tanks- see our website for details.

Aquaculture Without Frontiers (AwF) has formalized working relationships among three AwF-affiliated groups in the US, Australia and Mexico to ensure consistency in the charity’s operations globally.

The new executive group is called the ‘Aquaculture without Frontiers International Council’.