We are now ready with a new editon of NovaNews and we hope you find the articles interesting.

You will find our thoughts on the market situation, reduction of CO2 emission, products, participation at a membrane seminar i US etc.

If you have any ”stories/experiences with Novadan products” from your country that could be of interest to our other partners/ distributors, please share it with us by emailing details (and images) to hoy@novadan.dk

Or if you are anxious to know more about some topics, which you would like us to write about - again please contact hoy@novadan.dk

An increasing number of company cars have now been converted to electric vehicles (EVs), as shown in the image below. As a result, Novadan’s EV chargers are being actively used when consultants visit the premises.

by Annette Høy Marketing Manager,

by Jens Bramsen

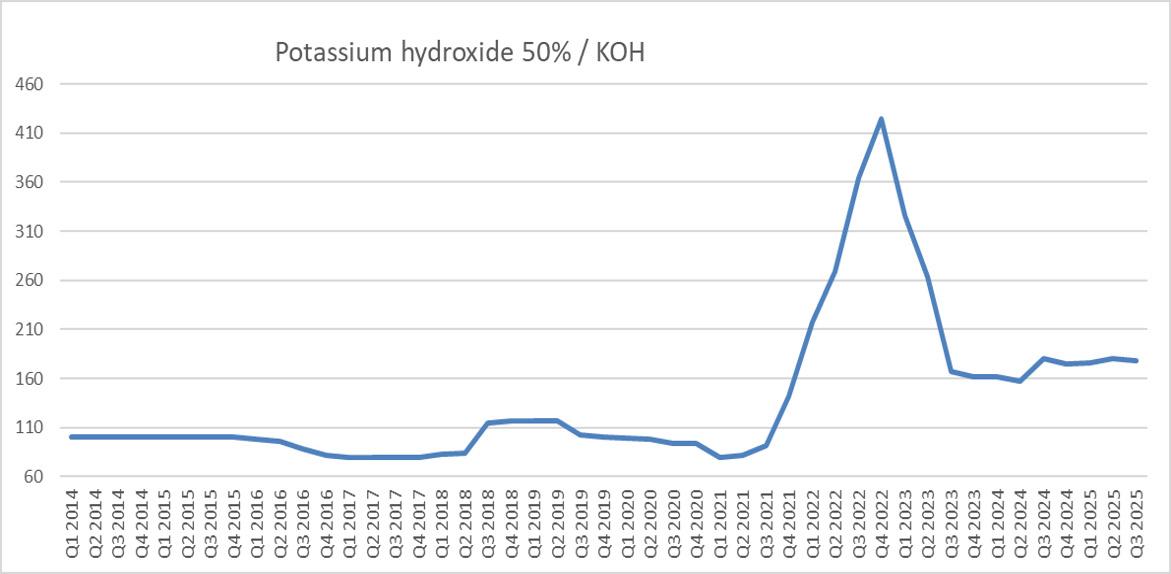

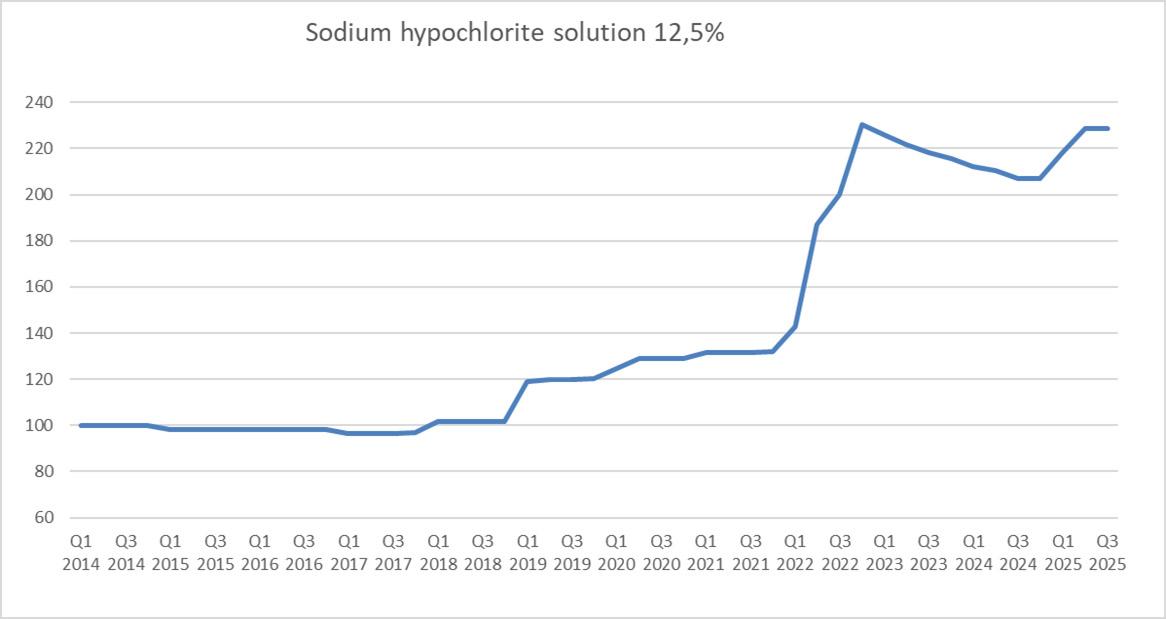

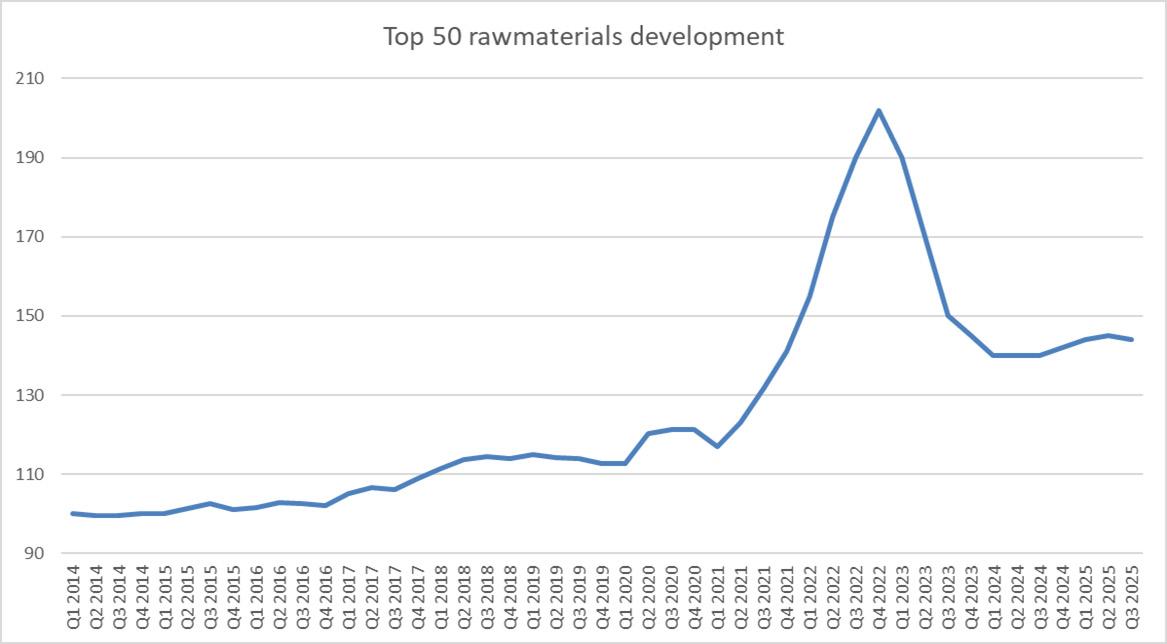

During the summer, the raw materials market has remained relatively stable in terms of both pricing and supply, following the adjustments made at the beginning of Q2. As of now, the pricing outlook for Q4 is still uncertain, but we anticipate it will be similar to Q3. Some manufacturers, however, expect energy prices to rise during the autumn and winter months — though this remains to be seen.

One notable development is the expected impact on Nitric Acid prices in Q4. A Nordic manufacturer has announced the discontinuation of Nitric Acid sales, reallocating production capacity to increase fertilizer output. This decision will affect the overall market for Nitric Acid and the products that rely on it as a key raw material.

Stable supply of raw materials: The market is currently functioning normally with no major disruptions.

Inflation rates across markets remain elevated (~3–6%), including wage increases. This trend is expected to continue into 2026.

The construction and automotive sectors in Europe are experiencing a downturn, leading to reduced production. As a result, chemical prices are under pressure due to falling demand, and some manufacturers are opting to halt production and carry out maintenance projects.

Compared to previous years, the energy challenge in Europe is more manageable. Many manufacturers have introduced energy surcharges on raw materials, adjusting prices according to market regulations.

Trade conflicts within and outside Europe continue to create uncertainty. The full impact of increased tariffs on raw material supply has yet to be realized.

Several European countries have implemented new taxes and fees aimed at reducing the use of packaging materials, particularly plastics. These measures are expected to have a lasting impact on the market.

In June 2025 my colleague Jimmi Schmidt and I participated in the Membrane Technology Forum in Minneapolis. A wide range of membrane professionals attend the Forum each year to listen to interesting presentations, visit the different booths and to network with others from the membrane business.

The attendees are membrane manufacturers, OEM’s, suppliers of ingredients, chemicals or instruments, teachers and professors from different universities and institutes, and finally producers using membrane technology.

The presentations could be educational, information regarding new or improved products, case studies or a combination of them all. This years topics were about new membranes from Zwitterco, improved membranes from Alfa Laval and Dupont, case study about using AI to improve membrane lifetime and a whole section regarding CIP where all the participating detergent suppliers had the opportunity to present something educational or new and innovative.

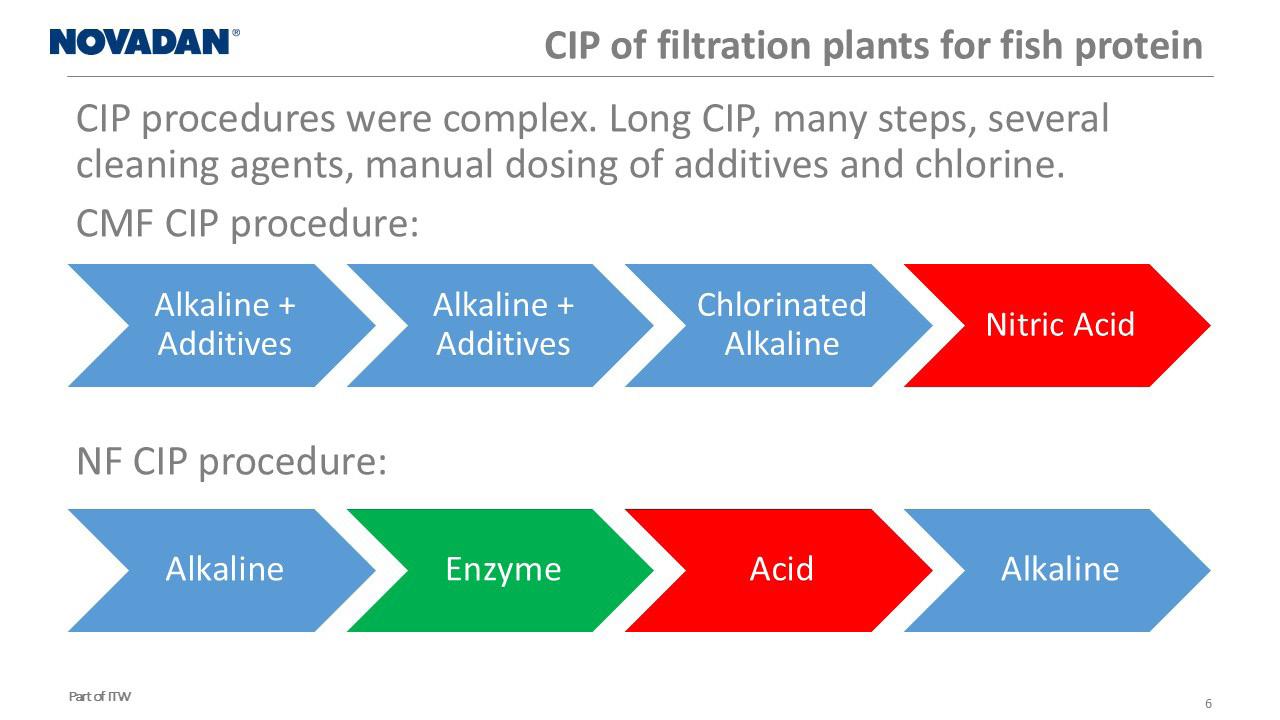

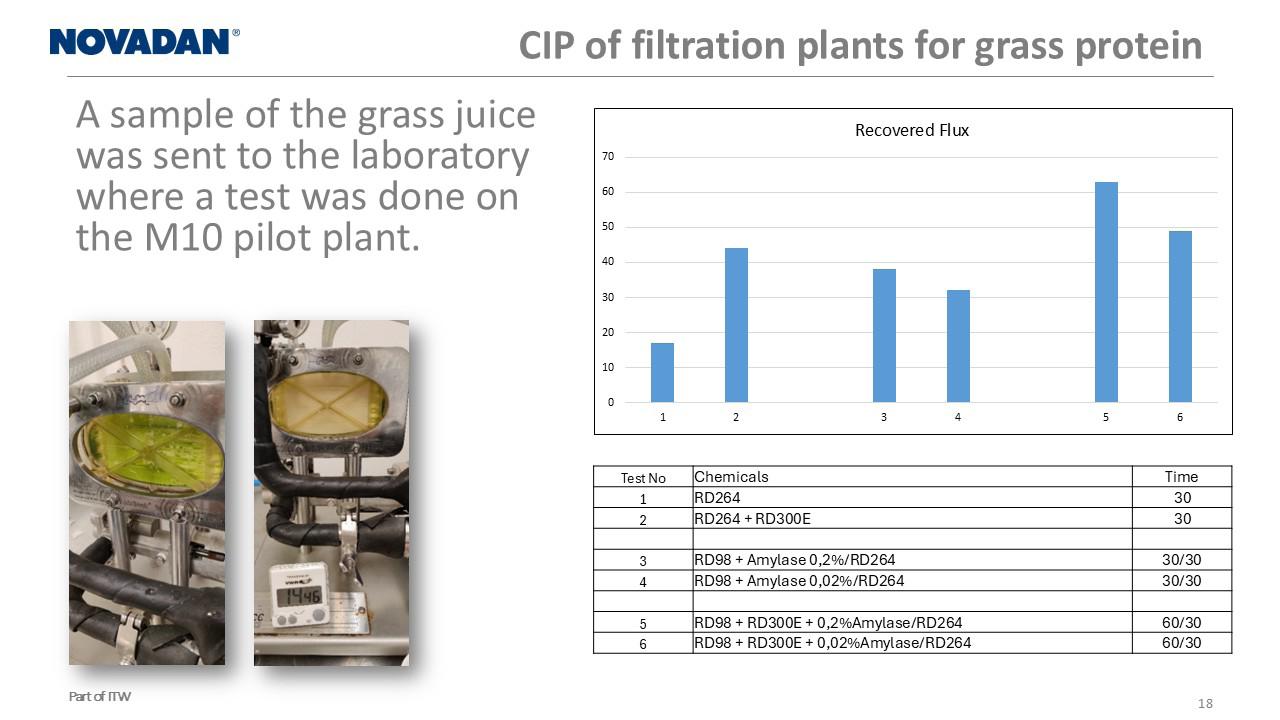

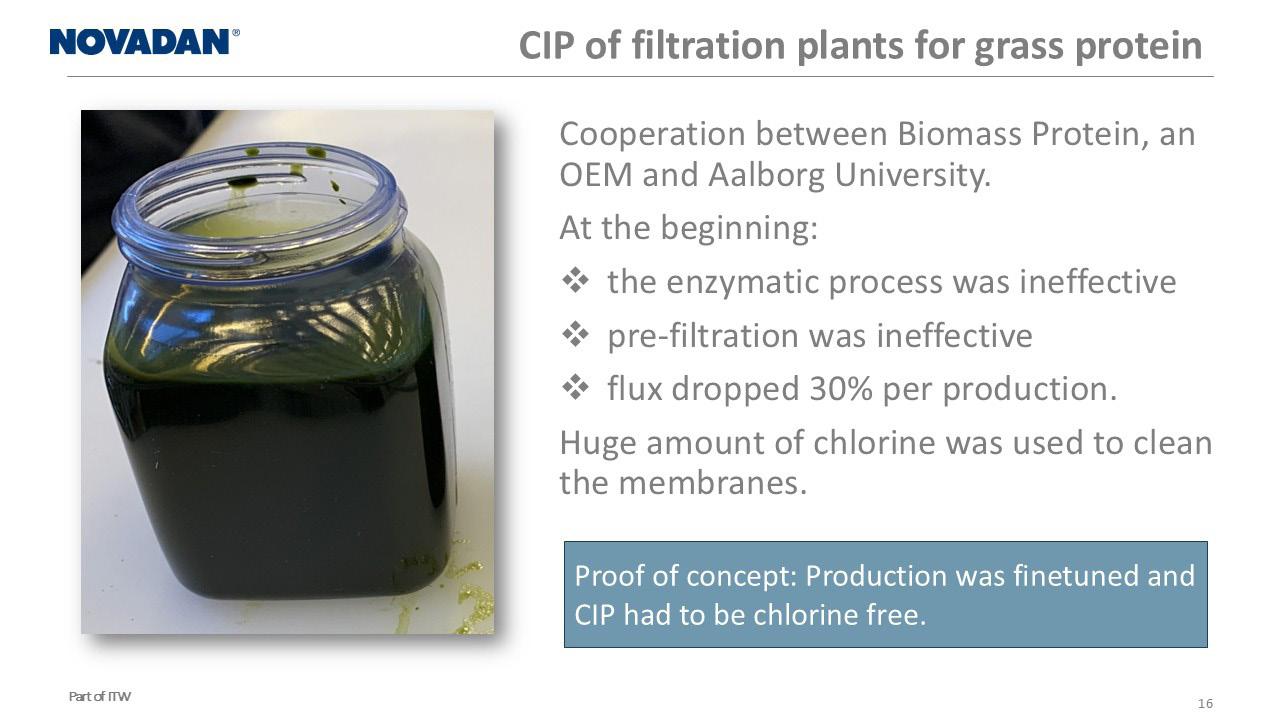

The Novadan presentation was about CIP after “new products”. We presented 3 cases with different products. First, we had a case about cleaning the membranes after fractionating and concentrating hydrolyzed fish protein. How we screened and tested different detergents to find a solution. Secondly a case about cleaning after fractionation of hydrolyzed grass protein.

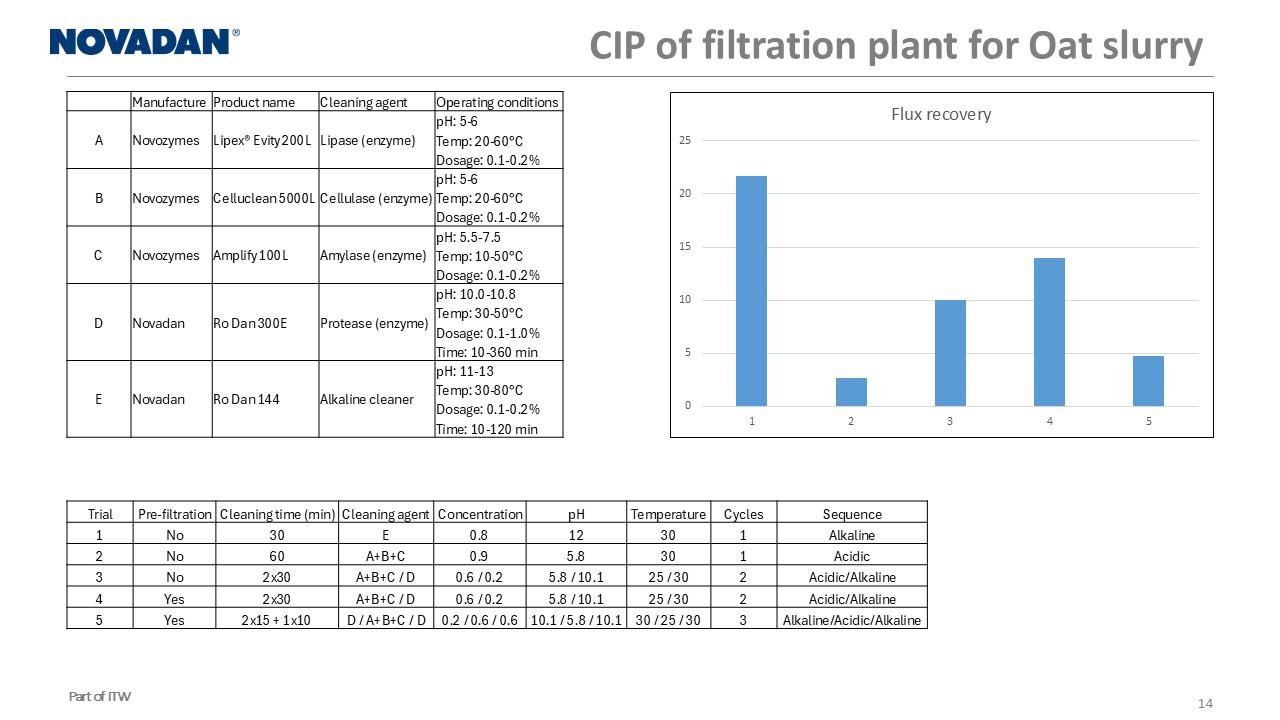

In this case the Novadan R&D had to evolve a new enzyme detergent which now have been implemented with great success. The final case was a corporation between Aalborg University and Novadan trying to clean membranes replacing the decanter in oat drink process. This turned out to be a difficult task due to the amount of sediment fouling the membranes. Different enzymes and procedures were tested. We learned a lot, but the project was terminated before we found the solution for this issue. Production only runs minutes not hours, so the project replacing the decanter with a membrane plant is, for now, dead.

We got nice feedback on the presentation and a lot of questions was asked to begin different dialogues.

For many years, phenolphthalein has been used as an indicator when determining the alkali content in a solution.

However, phenolphthalein has now been classified as harmful to reproduction, and we will therefore be replacing it.

Instead, we will start using cresolphthalein as the indicator. The new indicator has a more blue-violet color but otherwise functions in the same way.

There will be no changes to titration curves or factors.

We are already using cresolphthalein in Production and in the LAB, and will have it replaced at consultants and customers as soon as practically possible.

We have therefore encouraged all consultants who uses phenolphthalein to stop by the LAB to have the indicator replaced, and also to take some with them for customers.

by Frank Sode Chemist

Our product information and titration guides will be updated continuously, but you may still see the name phenolphthalein for some time to come.

Jeppe Framnes Flye Service Technician

My name is Jeppe Framnes Flye. I live in Aars with my wife Bettina and our 2 children. For the past 6 years, I have worked in the food industry as a service technician.

I am looking forward to new exciting tasks together with Novadan.

Click on the image of our newest CSR report below to read about Novadan’s sustainability efforts, achievements, and plans.

This is the fourth CSR report published by Novadan.

The future EU requirements for sustainability reporting is changing and CSRD and VSME are terms that all SMEs and larger companies will have to know about.

This will also have impact on how Novadan will be reporting in the futuremore about that in coming NovaNews.

by Annette Høy Marketing Manager

by Annette Høy Marketing Manager,

Do you follow Novadan on LinkedIn? If not, we kindly encourage you to do so. But why?

Yes, we admit that we would love to have many followers - however, we can only gain followers if we share relevant content on LinkedIn.

And that’s exactly what we aim to do. We see this platform as an opportunity to share relevant and informative content that is of interest to our followers.

Give it a try? All feedback is welcome.

SCAN THE QR CODE OR CLICK HERE TO FOLLOW!

https://www.linkedin.com/company/itw-novadan-aps/?viewAsMember=true

by Jimmi Schmidt

At a customer site where cheese moulds made from food-grade plastic are cleaned, Novadan had previously used the product Cip Box LP which contains phosphoric acid. This product proved to be highly effective in emulsifying cheese particles and providing the necessary release effect, allowing the cheese to be easily removed from the moulds.

However, local authorities have mandated the phasing out of phosphoric acid in waste water. Based on that request, the need for developing an alternative without phosphoric acid arose -but with the same benefial properties.

Novadan’s development department initiated thorough research by reviewing solutions used by colleagues both domestically and internationally. Based on this, we developed at test product that was trialed at the customer’s facility. The technical team at Novadan was present at the dairy every day for two weeks to monitor the washing results and ensure the product performed as expected. This process provided great reassurance to the customer.

The test product performed as desired but a minor adjustment was needed - a specific substance had to be slightly increased to achieve optimal performance. From development and adjustments to stability testing and practical trials at the customer’s site, the entire process took six weeks.

The result was the new CIP Box CA product which is based on citric acid. It meets the customer’s requirements for effective washing and release-performance - while also complying with environmental regulations for phosphorus-free wastewater.

At the recently held sales seminar, the sales team, Quality, Development and Reg., and Marketing visited Mosevang Mælk (Hejrskov).

They are one of our large and very professional customers in the milk producing segment. They buy products for cleaning milking systems, Nova Calforce, Nova Hoof Hygiene, and Nova Sani.

On the next page you can see some facts about the company and about the production of milk.

• Milking takes place in a 60-stall external rotary milking carousel.

• All cows are milked three times a day.

• This means milking occurs for approximately 23 hours per day.

• There are three work shifts.

• The remaining hour is used for three cleaning sessions.

• Current production is approximately 14,000 kg of milk per cow per year.

• This results in around 39,200 tons of milk per year, which equals approximately 107 tons per day.

Mosevang Mælk ApS is a Danish dairy producer located near the village of Føvling, close to Holsted. The company is owned by Torben Vejrup Pedersen and Brian Lykkebo Nielsen, who founded the company in 2009. The business employs approximately 40 people.

2,800 (+) milk-producing dairy cows Including calves and young stock = approx. 6,000

by Jens Ole Jensen

Novadan collaborates with one of our key accounts, TekniClean -one of Denmark’s largest cleaning companies. TekniClean provides cleaning services at major food producers such as Danish Crown, Tican, and Danpo, and is responsible for cleaning approximately 40 food production facilities across the country, each with its own delivery location.

Together, we identified an opportunity to reduce CO₂ emissions by optimizing purchasing behavior. Previously, each site placed orders either weekly or biweekly, resulting in frequent deliveries and consequently high transport-related CO₂ emissions.

• We applied a straightforward method by collecting monthly purchasing data from each location over a six-month period.

• This data enabled us to determine what an optimal monthly order pattern should look like for each site..

• TekniClean has shifted its order frequency from weekly to monthly,

• resulting in a 50–75% reduction in the number of deliveries.

• Reduction in transportation-related CO₂ emissions

• Novadan contributes by using less plastic foil and reducing the number of pallets in circulation.

• Reduced transportation costs

• Enhanced effeciency in inventory management and planning

• Number of annual deliveries reduced from 1,500 to appr. 480!

• This initiative demonstrates how a simple change in purchasing behavior can positively impact both the environment and the economy. It serves as a clear example of how collaboration with customers can lead to practical, sustainable solutions.

by Annette Høy Marketing Manager,

Each year, Novadan’s Sales, Marketing, Quality, Registration, and Development teams gather for a two-day seminar.

The purpose of the event is to share insights and updates on topics such as sales performance and strategy, sustainability and future opportunities, new tools, legislation, and brainstorming activities.

As part of the seminar, we always visit one of our customers — this time, Hejrskov Mælk (read more in this newsletter). These visits offer valuable firsthand insight into who we develop our products and solutions for.

The seminar also includes team-building activities and plenty of opportunities to enjoy good company with colleagues.