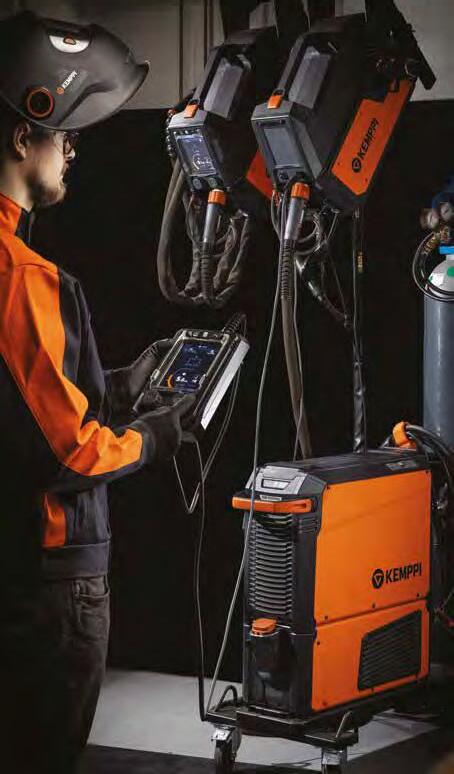

- Multi-process welder that delivers high quality welds thanks to Touch Sense Ignition

- Uses energy-efficient inverter technology

- Fast setup with Weld Assist

- Effortless operation

- Excellent welding ergonomics

- Robust and made in Finland

- Cobot and industry 4.0 ready

- Modular design for tailoring to your needs

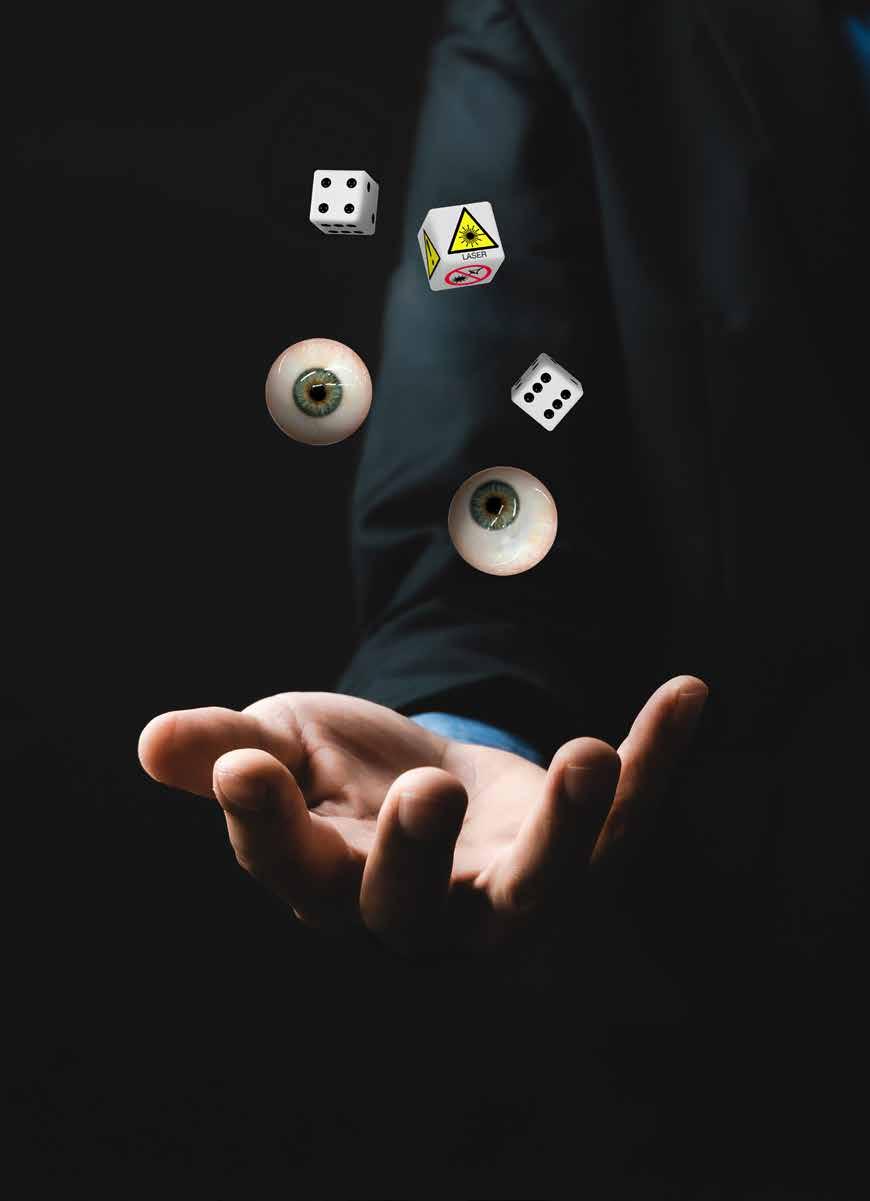

Don’t gamble with an open type laser

14 INDUSTRY 5.0

Industry’s next frontier is here. Not only overseeing robots –but collaborating with them.

24 YOUR BUSINESS

Collaboration, safety, cybersecurity, compliance and future planning – industry specialists offer their thoughts.

46 ON THE TOOLS

The tools taking Australian manufacturing into the future.

70 SUSTAINABILITY

With the right power and sustainability solutions, Australian manufacturing is charging ahead.

8 From the CEO

From the Minister

82 MEDICAL

Wearable technologies take medical solutions to a new level.

For story leads, sales enquiries or any other feedback related to AMT, contact AMTMagazine@amtil.com.au

Publisher AMT Magazine

AMTIL

Suite 10, 5 Corporate Boulevard Bayswater VIC 3153

AUSTRALIA

T 03 9800 3666

E info@amtil.com.au

W amtil.com.au

Prepress & Print

Printgraphics Australia

AMT Magazine is printed in Australia under ISO140001

Environmental Certification using FSC® Mix certified paper sourced using sustainable tree farming practices.

Copyright © Australian Manufacturing Technology (AMT). All rights reserved. AMT Magazine may not be copied or reproduced in whole or part thereof without written permission from the publisher. Contained specifications and claims are those supplied by the manufacturer (contributor).

Disclaimer

The opinions expressed within AMT Magazine from editorial staff, contributors or advertisers are not necessarily those of AMTIL. The publisher reserves the right to amend the listed editorial features published in the AMT Magazine Media Kit for content or production purposes.

AMT Magazine is dedicated to Australia’s machining, tooling and sheet-metal working industries and is published four times per year. Subscription to AMT Magazine (and other benefits) is available upon application.Contact AMTIL on 03 9800 3666 for further information.

1972AMTV25.N4OCTOBER

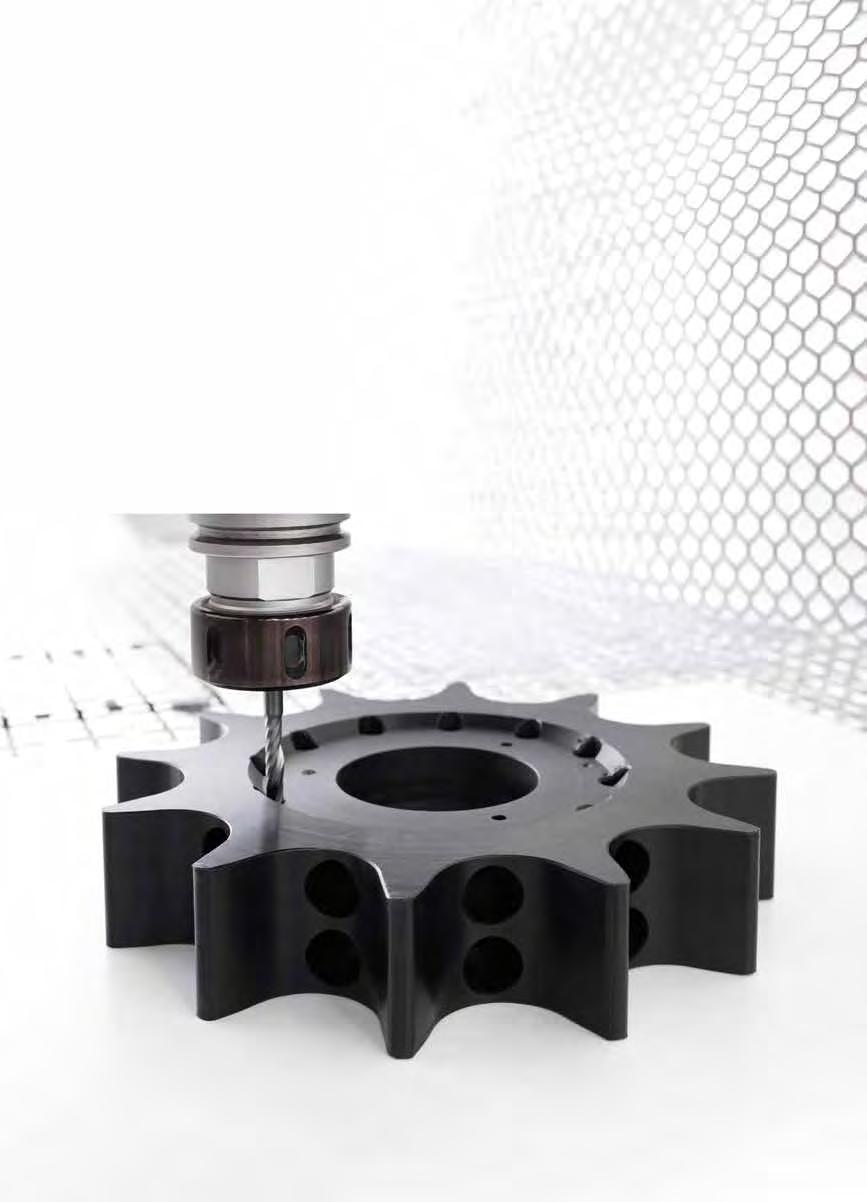

The next generation GENOS M460V-5AX and M560V-5AX, 5-axis vertical machining centers made in Japan, are specifically designed to manufacture high-precision parts and deliver impressive metal removal rates in a compact design. Its solid double-column structure, full 5-axis simultaneous control, and thermal stability performance give it the ability to easily cut a variety of materials.

• Fully equipped 5-axis simultaneous machine at an affordable price

• Double column structural design

• Ergonomic design reduces operator burden

• Automation-friendly integration

• Now with Okuma OSP-P500 Control

• 50% More Tools – Now with 48 tools for production flexibility

• Dual in machine Coil Chip Conveyors – Enhanced Chip Evacuation

• OSP Suite – Features you want with pre-loaded apps

• Massive Trunnion- Superior accuracy and machining capabilities

Machines Available Now:

Genos M560V-5AX & Genos M460V-5AX

Ex stock Melbourne*

Thermo-Friendly Concept 5-Axis Auto Tuning System SERVONAVI® *Subject to prior sale

Amidst the recent national productivity discussions, AMTIL hosted 40 organisations at the National Press Club in Canberra to have a ‘deep dive’ discission on the largest skills gap for the precision manufacturing sector: Computer Numerically Controlled (CNC) machine operators.

Officially titled the 2025 National Manufacturing Technology Skills Summit, the invitation-only gathering brought together key stakeholders from government, academia, industry associations and industry to address one very specific skills need for the current and immediate-future skills needs of the Australian manufacturing technology workforce.

While there are many areas of skills shortage in manufacturing and an inadequate number of people entering trade apprenticeships, ask anyone who works with machine tools and they’ll tell you the greatest need is CNC operators. Industry experts say it has been so for decades. AMTIL estimates that the shortage currently sits at more than 1,000 roles and to meet future needs, we will need to attract and train more than 3,000 people over the next two years.

The Summit differed from others with its specificity to a defined skill set and its collaborative approach. As there are so many areas of shortage in the sector, it is easy to be broad, but also and importantly, it’s hard to know if our work collectively is making a difference and closing skills gaps. Most machinery has moved toward being driven by computers that are programmed by highly-skilled tradespersons, often called programmers, and the machine is operated by a mix of semi-skilled (non- tradesperson) and highly-skilled (tradesperson) operators.

Australia is experiencing significant transformations in its economic and technological landscape, leading to evolving skills requirements across various sectors, manufacturing wondering what impact AI will bring and lamenting the automation that might change the playing field. And yet here we are, year after year, calling out for more CNC operators, more apprentices, more tradespeople, more…

Many Australian manufacturers, especially the smaller businesses, excel in niche production fields or act as critical suppliers within larger value chains. This diversity not only underscores the sector’s adaptability but also its importance as a source of high-skilled, high-paying jobs that span both urban and regional areas.

Skills are in shortage, but jobs are not, and we are in competition for skills not with each other but other industries. The stereotype of past manufacturing has irrevocably changed, as many don’t have a touch point to know that large production lines and commoditised manufacturing are in the decline, and instead high valueadd, small run, high tech, clean automated and digitised manufacturing is the new norm.

Over the decades, the role of manufacturing in Australia’s economy has shifted. For instance, while manufacturing once contributed approximately 11% to GDP back in 1990, its share has reduced to around 5.9% by 2024, as other sectors, notably services and mining, experienced faster growth. Traditionally, manufacturing had a larger share of the national output, but over the decades the economy has shifted increasingly toward services, health, education and other sectors.

Nonetheless, manufacturing in Australia is acknowledged as one of the country’s key industries. According to one fact file, it is the nation’s seventh largest employer, providing approximately 873,000 jobs and making up about 6.8% of all employment.

The sector is not only crucial for domestic economic activity – it also plays a major role in Australia’s international trade, generating roughly $ 117 billion in export earnings (about 11% of annual exports) and accounting for 26.9% of the nation’s total export earnings.

At the core of our discussion lies the transformative power of technology. Advances in robotics, artificial intelligence, additive manufacturing and smart sensors are reshaping every facet of production. The advent of Industry 4.0 isn’t merely about digitising existing operations; it represents a fundamental shift—a convergence of data analytics and precision machinery that creates hyper efficient, self monitoring production lines.

Importantly, the transformation does not negate or diminish our need for people and their skills! We estimate that literally hundreds of organisations around the country are working on part of this situation and skills shortages and/or are deeply concerned about it.

It is acknowledged that the attention to CNC operators is a short-term (and possibly temporary solution) and there are many medium and long-term approaches that are required. It is noted that one would expect that these semi-skilled operators, once ready for work, would naturally be eligible and attractive for pathways to apprenticeships. By developing a joint and specific strategy and work plan, we can each achieve a ‘line of sight’ to our collective impact across the sector.

Special thanks goes to the participating organisations, notably the Victorian Skills Authority, for facilitating the day’s discussion.

Keep an eye out for the Summit report, which will capture key findings and recommendations, thus forming the start of the action plan.

One of Australia’s leading high-end, high speed fiber lasers. World class componentry and build quality, whilst still offering excellent value for money. 3kW-40kW, wide range of sheet capacities and automation options available.

PBH Series CNC Pressbrakes.

Simply put, one of Australia’s favourite CNC pressbrakes. Precision manufacturing and high end components with hydraulic crowning compensation. Available from 50 ton through to 3000 ton capacities.

Combine the practicalities of a punch press for your forming needs, with the speed and accuracy of a laser for profile cutting of the same part. Tapping head and automation options available for your volume work.

6m to 12m capacity with chuck sizes from 150mm to 600mm. Small profiles through to heavy structural profiles. Bevel cutting and automation options are available to suit your requirements.

Robotic Bending Cell.

Automate your repetitive pressbrake jobs with a smart bending cell from Yawei. Robots and accessories from Kuka, Yaskawa and Estun to suit all budgets and applications. Save time and money, whilst improving efficiencies.

For maximum return and efficiencies, utilise the speed and precision of a Yawei CNC panel folder. With sheet capacities up to 3000mm and automation options available, there’s a Yawei panel folder to suit most applications.

With every Yawei machine you get the expert advice and support that only a local supplier like Applied Machinery can provide. With over 30 years’ experience, and thousands of satisfied customers across the country, we’re here for the long term. Real Service. Real Support. Real People. That’s Applied Thinking.

Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au

Medical manufacturing can help drive a successful, resilient economic future in Australia.

Australians are world-leading innovators in medical manufacturing and medical technologies. Life changing diagnostic and treatment technologies such as the cochlear implant, greyscale ultrasound imaging and cervical cancer vaccines are all products of Australian ingenuity and research capability.

In our fast-moving, competitive and disrupted global economy, resting on the laurels of world leading research alone is not an option. Future innovations in medical technology and industry can, and should, be leveraged to advance Australia’s wider economic and strategic objectives in the coming years. That means providing the right support for local researchers and developers and encouraging the commercialisation and manufacturing of these innovations at scale, here at home. Thanks to earlier Labor governments, Australia enjoys the advantage of a world-class system of Cooperative Research Centres (CRC), providing innovators the time, space and industry linkages they need to succeed. In the field of health and wellbeing, CRCs have facilitated real, meaningful change for patients. Australian CRCs accelerated the adoption of cochlear technology, pioneered breakthrough research into cardiovascular conditions and developed new treatments to improve quality of life for asthmatics.

In April, the Albanese Government announced a new CRC focussed on Additive Manufacturing (AMCRC). This CRC, built on a $270 million investment from government, private sector and universities in partnership with one another, maximises the benefits of transformative 3D printing technology. For Australia’s medical manufacturing sector, that means greater precision and efficacy in the production of medical devices, personal protective equipment, implant technologies and other therapeutic manufactures. In that respect, the AMCRC is a good example of the ambition driving the Albanese Government’s Future Made in Australia agenda. I want Australia to discover, develop, commercialise and adopt new technologies that improve our national resilience. I want to see people in regional and outer-suburban Australia engaged in good, meaningful jobs, manufacturing the tools and technologies that arise from Australian innovation. I want to see Australian medical technology and bioengineering breakthroughs leading directly to improvements in Australian living standards and quality of life.

The Albanese Labor Government is using all of the levers at our disposal to help make that ambitious agenda a reality. Public investments under the Industry Growth Program (IGP), for example, are helping worthy recipients to advance and commercialise their innovations, crowding in the private sector capital that the advanced medical technology sector needs. More than 300 small and medium enterprises working in the medical science field have received zero-cost advisory services under the IGP, and 10 enterprises have received grants to accelerate the commercialisation and adoption of their innovations. For example, Incisive Technologies received $2.1 million to develop a dental ‘paint’ that can prevent or detect common oral diseases. EMVision received a $5 million grant for a ‘First Responder’ portable brain scanner that can

provide rapid diagnosis of traumatic brain injuries and strokes. If successful, Australians will benefit from these medical advancements and the manufacturing and service jobs that come with them. And if these projects don’t succeed as intended, our innovation ecosystem learns valuable lessons that help drive successful research and innovation forward. In our first term, the Albanese Government established the $15 billion National Reconstruction Fund, which will lead public investment in areas of critical importance to Australia’s domestic industrial and economic capabilities. Medical Science manufacturing is listed as one of the Fund’s seven priority areas for investment. This sends clear signals to private investors that Australia wants to enhance its own industrial capabilities in medical manufacturing and biotechnology. Australia’s economic success over the next few decades will depend on its ability to drive cutting-edge innovations all the way through the R&D pipeline from discovery to commercialisation, and good manufacturing jobs, at scale. Australian researchers are rightly renowned worldwide for their biomedical expertise. The Albanese Government’s policy strategy is designed to translate Australia’s medical research into Australian medical technology and biotechnology manufacturing in the interests of Australian researchers, firms, patients and communities.

SENATOR HON TIM AYRES Minister for Industry and Innovation and Minister for Science

Promising and challenging signs for Australian manufacturing amid an overall economic and productivity downturn, a new report reveals

A new report from the Australian Industry Group (AIGroup) says, “Metals and machinery and equipment grew strongly since the pandemic but have seen some of this growth ease in 2024 with more difficult economic conditions.”

According to the Manufacturing in Australia: Performance and Outlook Report 2025, produced by the AIGroup in July, manufacturer margins have been improving over the last decade in Australia, to return to near the all-industry level, “reflecting the consolidation toward more competitive subindustries.”

The report says that manufacturing is the only industrial sector to see a material improvement in business margins, with others still near long-term levels. It said post-pandemic growth saw manufacturer margins improve from 10% to 12% and now exceed the all-industry rate for the first time since 2007.

Investment levels in Australian manufacturing have also improved, with the report showing levels rose significantly following the pandemic, but growth levelled off in 2024.

“Industrial capex levels leaped following the pandemic, as businesses invested to meet growing demand from economic recovery and disrupted supply chains,” the report says.

“Manufacturing investment levels in 2023 were 55% higher than in 2019. Allied industrial sectors saw a similar degree of uplift. “As conditions deteriorated in 2024, manufacturing investment eased back by around 10%... however, capex levels remain structurally higher than the years before the pandemic.”

There was challenging news too, with the report noting four factors that have combined to put pressure on the manufacturing industry –productivity difficulties, skills shortages, trade risks and energy costs.

Australia’s manufacturing sector has taken a hit, contracting 2.6% over the last year after two years of growth following the COVID-19 pandemic. The report says overall productivity in manufacturing was 1% lower in 2023-24 than it was ten years prior – with labour productivity falling 3.7% over the same period, with a major fall during the pandemic.

This makes manufacturing one of only four industries –alongside construction, utilities and arts & recreation – to record productivity declines over the past decade, at a time when the nation’s overall productivity rose 4.7%.

AIGroup head of research and economics Jeffrey Wilson wrote in a research note that this was exacerbating the skills shortages, lowering the ability of employers to increase wages and reducing the financial resources available for employers to invest in research and development.

“It weakens our international competitiveness at the very time when trade disputes are putting our manufacturers under extra competitive pressure,” says Wilson.

Shortages of skilled labour mean 45% of advertised job vacancies go unfulfilled, the report says, with greater shortages remaining in technical and trades roles (61%) and professional roles (51%).

Further to this is a rise of manufacturer input prices by 37.5% in the five years since the end of the COVID-19 pandemic, due in part to rising gas prices. This outpaced the growth of consumer (22.2%) and Australian industrial (20%) input prices, with Australian manufacturers paying 48% more for gas today than they were in 2019, due to price linkages with the export LNG sector.

Wilson says that as metals manufacturers cannot substitute gas for a lower cost electricity supply, surging energy costs must be borne on a balance sheet.

“This means prices are largely set in global markets, and rapid cost increases can be difficult to pass on,” he wrote.

The report noted that manufacturing is Australia’s most R&D “intensive industry, but how can rates be maintained while conditions are weak?”

AIGroup says manufacturing also spends more on R&D investment than any other sector, with spending exceeding $5 billion in 2021-22, and 4.2% of value-add reinvested.

This high rate of reinvestment reflects a sense of competition with imports at home and challengers abroad, driving innovation among Australian companies.

Nonetheless, Wilson says there is a clear and pressing need to get manufacturing activity back on track.

“Manufacturers will struggle to make the investments needed to raise productivity while their balance sheets are weakened by high energy prices, and they cannot recruit the technical specialists required for technology projects,” he says.

“With recession conditions already in play and the risks of the trade war looming, now is the time to urgently address these issues confronting our manufacturing sector.”

R&D Investment will be key for the future of Australian manufacturing.

The full report, Manufacturing in Australia: Performance and Outlook Report 2025, is available at go.aigroup.com.au/manufacturing.

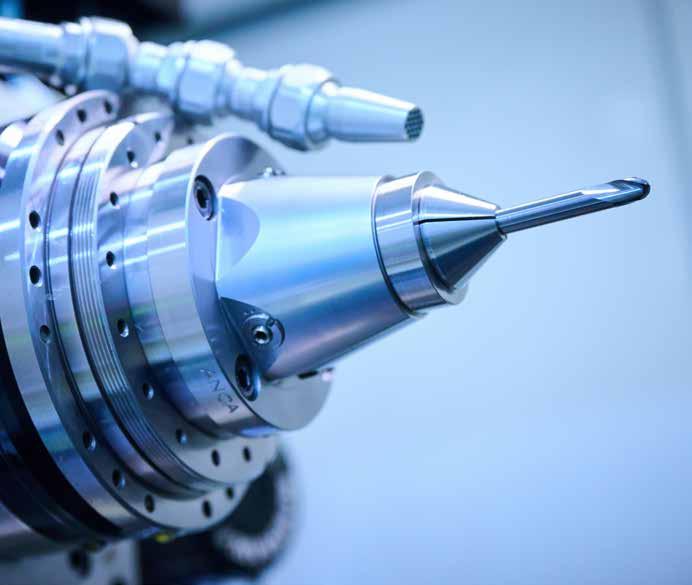

Don’t slow down. Machine it faster.

Discover the power of high feed milling with square inserts. Higher material removal rates, reduce cycle times, and longer tool life.

Outperforming traditional systems.

The High Feed SP system performs 6 different operations: face, slot, plunge, and side milling, ramping, and helical interpolation. Perfect for roughing operations and tough materials like titanium and stainless steel.

Not only fast but strong too.

Nothing to worry about anymore. The square inserts are hard to break and they just work, even on smaller machines. secotools.com

INDUSTRY 5.0

Industry’s next frontier is here. Not only overseeing robots – but collaborating with them.

16 State of Play – Industry 5.0 is the human upgrade – so what happens next, with collaborative robots?

18 Revolutionising Industrial Repair – Developed within the CSIRO, a new technology is quietly transforming how industries approach the repair and maintenance of critical metal components.

20 Scaling Smart – Key considerations for startups on the path to manufacturing success from Bradley Trewin, Head of Sales, Marketing and Key Account Programs from Bosch Australia Manufacturing Solutions

22 Getting Network Fundamentals Right – Ankur Jain, Director Infrastructure Solutions (AMEA) for BT International discusses creating the infrastructure foundations businesses need for a scalable future.

23 Go Go Gadget Arms – T ips for developing in-house robotic welding skills within your manufacturing business from Orion Automation Systems technical director Jeff Fordham.

Industry 5.0 is the human upgrade – so what happens next, with collaborative robots?

Industry 4.0 – the integration of digital technologies into all aspects of industry – has been well established for some time now. But now researchers are looking at ways of using robots with a much older, more unpredictable technology. The human being.

At the heart of the human-centric approach of Industry 5.0 is collaborative robotics, or “cobotics” – which are designed to work safely alongside human workers, and currently for sale and working at sites across Australia.

Australian Cobotics Centre (ACC) associate director for research training Glenda Caldwell says there’s “a big shift” for researchers to consider. “Industry 4.0 is very much about how industry develops and uses more advanced technologies in their processes,” Caldwell says..

“So the focus of Industry 4.0 is the technology itself, whereas Industry 5.0 is looking at, well, what are the complex problems that we face… and how do we use those technologies in different industry sectors to address those problems?”

“Now we understand we’ve got these technologies, but how do we use them beyond just to produce more stuff? How do we increase human wellbeing, climate, planetary wellbeing?”

CSIRO Robotic Manufacturing Team senior research scientist

Peter King says regular industrial robots are almost like power tools – “just it’s so much more efficient and productive to use than hand tools.”

Whereas a cobot is designed with some awareness, whether it’s in sensors, cameras or programming, to be safe to move or work alongside people. At the ACC, Dr Caldwell oversees researchers who investigate how humans and robots might work together. “We spend a lot of our time understanding what the person needs to do… We really want to understand what the person is doing in that task or in that environment, and then working with them to identify the best way to introduce a cobot into their workflow and, you know, getting their input and understanding," she says.

Advanced manufacturing manager for Weld Australia Cornelius van Niekerk says that the cobots currently on the market are equipped with sensors that can be adjusted to stop before coming into contact with a human.

“So, you don’t need the safety cages, you don’t need all the screens that you have with an industrial robot and all the warning labels as well. But there’s still safety aspects to it –you still need to be aware of the fact that you have a moving machine part near you.”

At Weld Australia, van Niekerk helps build connections between technology suppliers and industry experts through cobot road shows, giving him a front-row seat to observe how industry is responding to the arrival of cobots in the market, and what they’re hoping it might achieve.

"The two big ones our member base typically bring up when I ask them about their biggest challenges are skill shortages and productivity problems," he says.

"Most of them say to me, 'Cornelius, if we could double our welding workforce, our number of welders, that would actually solve—we would start running at capacity.'" And the promise

Cornelius van Niekerk says cobots aren’t heading to work on roof beams, yet.

of cobots for welding applications is a profound one, he adds. “Most of the members say to us that they get about one to two hours of actual arc-on time in an eight hour working day, which is the average – but it’s shockingly low,” he says. This low utilisation occurs because skilled welders spend most of their time on ancillary tasks—joint preparation, materials handling, warehousing and setup work rather than the highvalue welding itself. Cobots offer a solution that addresses both productivity and workforce concerns without the fear factor associated with traditional automation.

"A big fear is that these things will replace the welders in the workforce," van Niekerk acknowledges. "Cobots kind of address that fear because they're so collaborative, whereas an industrial robot, you put it in a cage with all the safety that goes with it—it has no idea it's working with a human.

That said, the collaborative nature of cobots means they still require skilled operators. "It still takes a skilled welder to program that robot," van Niekerk explains. "It can take the repetitive, fatiguing jobs off of a welder's hands to free up that welder to do more skilled work." King agrees, saying the cobot can complement the work of an existing welder.

“Ideally what you want to do is, once you’ve done your initial assessment of exactly what needs to be repaired, is to then set the robot to go about doing that mind numbingly difficult sort of work… Sometimes it’s done under conditions where you don’t want to have a human doing that sort of work.”

This human-centric approach extends beyond individual workstations to encompass entire organisational systems.

The ACC research that Caldwell oversees focuses on what she terms "socio-technical systems" that consider human factors, design factors, and extended reality (XR) applications.

"We're looking at the human factors—how do humans and robots work together, what are the emotional and psychological aspects, how do we design better interfaces and programming methods," she explains.

As an Australian Research Council supported organisation, Caldwell and the ACC researchers have worked with medical device manufacturers, metal fabricators and construction material producers, while van Niekerk has facilitated implementations across welding and fabrication workshops.

Van Niekerk says cobots right now can be programmed to perform very basic welding – making them suited for straightforward, simple and highly repetitive jobs where they are moved into place. “Some people walk away saying automation is actually not for us at all, because it still takes some time to set the cobot up. You still have to move it into place point by point, so it could take a significant amount of time.”

Australia's manufacturing sector presents a few challenges for the adoption of cobots and Industry 5.0 more broadly, compared to overseas markets.

Unlike mass production environments, Australian manufacturing is characterised by "mass customisation rather than mass production," Caldwell says.

"We're not manufacturing huge assembly lines of cars. Most of our manufacturing is smaller production runs, and that's where these collaborative robots can provide a lot of benefit."

Van Niekerk says the fabricators that visit his workshops are looking to secure a return on their investments.

He says the economic case for cobots depends on the application, the duration and complexity of the tasks planned.

"The general rule is, you can rent a cobot, but if you have a job that's going to run for more than 18 months to two years, then you're moving into the space where it becomes more economical to buy a cobot," he says.

But the successful implementation of Industry 5.0 requires a strategic approach, Caldwell says – adding that she aims to show that there will be some value in giving cobots a try.

“They’re not going to solve every problem,” she says.

“I think it's a slow, incremental introduction—you introduce them to do one specific thing, and once there's trust and understanding and confidence around what it can do there, then gradually the complexity can increase.”

Developed within the CSIRO, a new technology is transforming how industries approach the repair and maintenance of critical metal components.

The CSIRO’s Continuous3D project is giving robots the “brains and eyes” they need to make industrial repairs more efficient –while also addressing the sector’s shortage of skilled labour. Like many advanced economies, Australia faces a looming shortage of skilled tradespeople.

CSIRO Robot Manufacturing Team senior research scientist

Peter King says he understands Australia needs 70,000 welders by the year 2030.

“Whereas in the past, we had these people, now the younger generation is more interested in other professions. That leaves us with the problem of keeping critical infrastructure running and manufacturing things,” he says.

Continuous3D was born out of the need to make working with industrial robots easier and more productive, King explains.

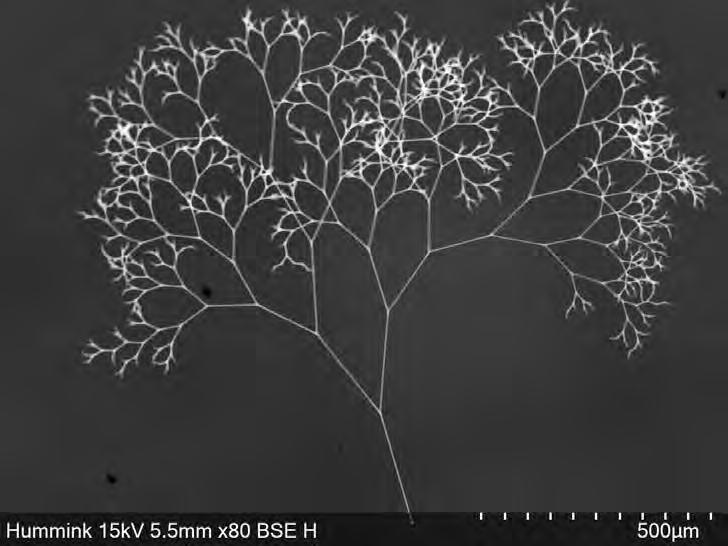

“The first part of a project typically involves a lot of robot programming, and that can often be quite a headache,” he says. “Often you want to get down to actually doing the task, but the first thing you’ve got to do is spend a bunch of time with the robot offline.” The Continuous3D system changes this paradigm by equipping industrial robots with advanced sensors – such as laser scanners – and intelligent software.

“We gave the robot brains, as in the software, and we gave it eyes, which is the sensor,” says King. “A robot equipped with those two things is able to understand the work it has in front of it and act.”

“It’s a relatively small sensor – it might weigh a few kilos or so, and it’s very robust. It’s attached to the robot arm and there’s a connection to a computer there as well. So, the robot controller, the computer controlling the robot, is connected to a PC running our software.”

This means that instead of painstakingly programming robots for each new repair job, measuring the work piece and even creating CAD files, operators can rely on Continuous3D’s software to automatically generate the necessary tool paths. The robot scans the component, identifies areas that need repair, and creates a plan to rebuild the surface – often in minutes rather than hours.

One of the key breakthroughs of Continuous3D is its ability to handle complex geometries. Traditional 3D printing and repair systems are often limited to flat surfaces, but industrial robots offer six degrees of freedom – allowing them to move and operate in far more complex ways. “With printing, you are often printing onto a flat surface, and that comes down to the design of the 3D printer,” King says.

“What you can do with the robot is you actually have six degrees of freedom, allowing the robot arm to move in different orientations and to grow material in different directions. That’s incredibly useful and flexible, but you need to have the maths to be able to produce the tool path. That’s what we’ve done.”

The result is a system that can repair curved surfaces, complex castings and other challenging shapes – opening new possibilities for in-situ repairs and large-format additive manufacturing.

Dr Peter King in one of CSIRO’s robotic additive manufacturing laboratories with a 3D printed titanium component.

The potential applications for Continuous3D are vast, King says, with mining and aircraft maintenance two focus areas at present. “Right now, we often work with robots that have, say, payload capacities of 20 to 60 kilograms… the kinds of robots that handle metal spray equipment, manipulating welding torches or laser cladding heads,” he says.

“Now in in the future, we imagine that you could be using mobile robots. So instead of taking components offline and shutting down a line… you could bring the robot with the tool to the point of need, so that it actually does the repair on site where the equipment is wearing down – on a mine site, on board a ship or in dry dock.”

The Continuous3D system is designed to be flexible, retrofitting onto existing industrial robot arms. The sensors are robust, capable of operating in dusty, hot, and otherwise challenging environments. The system can handle components ranging from large mining buckets to small, intricate engine parts.

of the Continuous3D Team participating in CSIRO’s ON Accelerate Program in 2024.

King adds that Continuous3D doesn’t aim to replace human workers, but to augment their capabilities. “If you are doing welding manually, there are plenty of studies as to how long the welding torch is actually on. For humans, it’s less than 20% of the time,” King explains.

“If you are doing that robotically, you can get potentially five times improvement in efficiency. Now you still have the human there, supervising a robot or perhaps supervising many robots.” This shift allows skilled workers to focus on higherlevel tasks—such as quality control and decision-making –while robots handle the repetitive, physically demanding, and sometimes dangerous work.

Continuous3D is already in use across several CSIRO labs and is being trialled with industry partners in mining and aerospace. “We are currently working with a number of companies,” King says. “One example is doing metal spray repair onto complex shaped castings used in aircraft engines. We also have components that have been coated using our technology out for evaluation in the mining industry.”

King adds that Continuous3D is not a cloud-based solution, meaning it could offer some peace of mind for industries concerned about data security and industrial reliability.

“If you've got a heavy capacity robot moving around and operating high energy processes, the last thing you want is for it to stop just because the internet cut out,” he says.

“In terms of data security, the software is designed in a way that the data never leaves the user's site.”

The team is actively seeking new collaborators and sees potential for the technology to expand beyond metals to polymers, composites, and even concrete. “Nowadays you can print almost anything,” King says. “If you can stick it on a robot, we’ll take a look at it.”

As manufacturing faces the twin challenges of labour shortages and increasing complexity, technologies like Continuous3D offer a glimpse into the future – where humans and robots work side by side, combining the best of both worlds to keep industry moving forward.

For more information about Continuous3D and opportunities for collaboration, visit the CSIRO website or contact the project team directly.

Key considerations for startups on the path to manufacturing success from Bosch Australia Manufacturing Solutions head of sales, marketing and key account programs Bradley Trewin

For many startups, the journey from a brilliant product idea to a market-ready, scalable solution can be fraught with challenges. While innovation sparks the initial concept, navigating the complexities of manufacturing and scaling up requires a strategic approach. For startups looking to de-risk their automation journey and achieve sustainable growth, here are a few insights the team at Bosch Australia Manufacturing Solutions has picked up along the way.

1. Understand your market and be prepared to pivot: The startup landscape is dynamic and market demands can shift rapidly. It is vital to deeply understand your target market and be agile enough to pivot when necessary. Many startups experience a pivot – whether it's a market strategy pivot or a hardware design pivot. The key is to make these critical adjustments before significant scaling efforts begin, as once you've scaled, it's already too late. Early feedback and quick decision-making are paramount to avoid costly missteps.

2. Design for Manufacture and Assembly (DFMA) –Early engagement is key:

Often, product design proceeds without sufficient consideration for how it will be manufactured at scale. This can lead to significant rework, delays and increased costs down the line. BAMS stresses the importance of early engagement with manufacturing partners during the design phase. Design is subservient to manufacturing, not the other way around. Bringing in external expertise from material vendors, subcontractors and automation partners can provide invaluable feedback, ensuring your design is optimised for efficient and cost-effective production.

bodd, an Australian Software as a Service (SaaS) company specialising in 3D body scanning technologies, faced the challenge of not having manufacturing facilities or hardware expertise despite developing early-stage prototypes. To commercialise their scanners and scale globally while keeping its manufacturing 'Made in Australia', bodd partnered with BAMS, which provided crucial support in validating designs, prototyping, testing and overcoming hardware and engineering challenges, including IP roadblocks and highspeed data communication.

3. Start with a Minimum Viable Product (MVP) with variants and an upgrade roadmap:

The temptation to perfect a product before launch can delay market entry and burn through resources. Instead, focus on developing a Minimum Viable Product (MVP). This allows for faster deployment, quicker returns on investment and crucial real-world learning that can inform future iterations. A critical aspect of this stage is the "design freeze." While designers always find improvements, at some point the design must be finalised to allow manufacturing to proceed. Prioritising that design freeze is essential to move the project forward efficiently.

4. Scale and automate when and where appropriate:

Scaling does not always mean immediate, full automation. The decision to automate should be strategic, considering factors like product volume, variability and the need to avoid downtime from changeovers.

RayGen, a Victorian startup, spent 12 years developing its innovative solar technology, initially proving its concept with a largely manual setup at its Mildura site. This manual approach was appropriate for the early development phase. However, manual operations became unviable as RayGen transitioned to scaling up – now producing 150 fields that require 41,000 heliostats, 330,000 mirrors and millions of components.

RayGen approached BAMS seeking a production line that could produce a 5x5 metre array of mirrors in just three minutes, operate 24/7 in remote locations and be deployable, packable and re-deployable to new sites. This strategic decision to move from manual to highly automated manufacturing, with BAMS's support, exemplifies the principle to "scale and automate when and where appropriate," driven by the significant increase in projected volume, complexity and unique operational requirements.

5. Collaborate with the right partners to concentrate on your core business:

For startups, resources are often limited, and focus is everything. Identify your core value proposition – what truly differentiates your product or service – and dedicate your primary efforts there. Do not get distracted with the hardware aspect if your core business is software, for example. Therefore, collaborating with experienced partners is critical at every step of the journey, as no startup can do it all alone. Leveraging partners who specialise in the numerous facets of the manufacturing ecosystem allows you to outsource complexities, enabling you to focus on that core business proposition and where you add value.

By thoughtfully considering these key principles, startups can significantly enhance their chances of moving from an innovative idea to scaled, successful manufacturing, ultimately de-risking their automation journey.

BRADLEY TREWIN Head of Sales, Marketing and Key Account Programs at Bosch

Australia Manufacturing Solutions

RJS Tech Group advanced Australian manufacturing and engineering businesses, united by innovation, precision, and certification excellence.

• PPTools – High-precision custom tooling (ISO-certified)

• NanoTech – World-class surface coatings and PVD technology

• Rogers Industries – Australian-made plastic injection moulding & aluminium die casting

• Whitelaw Engineering Machinery – Premium European lathes and milling machines

• MetalTech – Industrial metal 3D printing specialists

• Wood Tech – National supplier of CNC and woodworking equipment

• PPE Tech – ISO-certified, TGA-listed P2 face masks made in Australia

Certified quality, local capability, and industry-leading solutions.

www.rjstechgroup.com.au

ISO 9001ISO 13485

Registered Australian Made

CMI Certified TT10061

AS/AZS 1716:2012

ARTG 352290

BT International Infrastructure Solutions (AMEA) director Ankur Jain discusses building the infrastructure foundations businesses need for a scalable future.

Generative Artificial Intelligence (GenAI), automation and machine learning are driving generational change, reshaping the future of business and society as we know it. However, for these capabilities to accelerate innovation at an organisational level, Australian enterprises must first overcome a critical hurdle: getting their network fundamentals right to fully embrace the future. The growing importance of digital revenue underscores Australian businesses’ importance in getting their Network-as-a-Service (NaaS) fundamentals right. The trouble for enterprises is knowing where to start.

The lack of a widely adopted industry definition for NaaS creates confusion. In many ways, it is customer-specific, and the NaaS your company requires is unique and evolving, just like your business. It’s like having a virtual toolbox that allows you to adapt the network to suit your needs in real time, whereas it could take weeks with previous technologies. This enables you, as a business, to modernise traditional networks into highly scalable cloud-centric solutions and flexible architectures that adapt quickly to different organisational needs. Instead of patching together legacy networks, a NaaS platform simplifies the secure and reliable interconnection of employees, customers, suppliers and operational devices to applications and digital services — including AI — that are hosted across multiple clouds. Ultimately, this provides flexibility and scalability to meet the evolving needs of your business and the market.

Fundamentals that matter

To realise the full potential of digital revenue, companies must first solidify foundational elements like seamless third-party connectivity, automation and scalable architecture. Without this, organisations face unpredictable costs, slow application performance (especially for AI and cloud services) and vendor lock-in. Investing in a robust NaaS platform allows you to spin services up or down based on demand. This ‘build once, scale many’ approach ensures you meet today's GenAI workloads while remaining ready for tomorrow’s innovations. Failing to get these basics right often means costly technology sprawl, fragmented visibility and endless forklift upgrades - a future resource drain.

The insatiable demands of GenAI GenAI’s appetite for data is unrelenting. Large language models (LLMs) ingest vast volumes from edge sites, data centres, cloud and third-party sources, all with optimal latency. This distribution necessitates a network that balances low latency (processing at the edge) with high-speed and secure transport to LLMs in the cloud. Industry uses of GenAI also rely heavily on large data lakes where the LLM acts as a reasoning layer. The outcome here is to enhance or personalise the information generated by the underlying LLM with more relevant and up-to-date information from the data lake. Traditional legacy infrastructure with long lead times and manual configurations simply can’t keep up with these demands. This is hindering GenAI adoption and blocking enterprise transformation; as adoption rates of this technology accelerate, your network will quickly become incapable of meeting demands.

Embracing flexibility: pay-as-you-use

Just as hyperscalers offer pay-as-you-go compute, modern networks must also deliver commercial flexibility. Companies should review their fixed, multi-year contracts that necessitate over-provisioning. With multi-cloud adoption, organisations also encounter ‘bill shock’ from unexpected egress fees when transferring data from hyperscalers. NaaS platforms that simplify multi-cloud connectivity with usage-based autoscaling are the way forward. You only pay for what you consume while maintaining enterprise-grade security and global reach.

Overcoming complexity with automation and API-first design

Concealing the intricate orchestration of network components and presenting it as a straightforward ‘click to deploy’ solution is essential for simplifying and expediting infrastructure outcomes. To be genuinely future-proof, a NaaS platform must provide 100% automated capabilities – from bandwidth adjustments to dynamic network and service policies, driven by real-time telemetry, which eliminates manual intervention and ensures a swift response from IT to evolving business needs. Similarly, an API-first architecture, instead of API as an add-on, ensures that network services integrate seamlessly into DevNetOps workflows. This gives organisations digital control over their connectivity fabric, and thus the ability to leverage a NaaS platform to deliver a step change in their user experience.

From foundations to frontier

Getting the fundamentals right, which means defining clear service objectives, investing in a flexible platform, and adopting pay-as-you-use models, sets the stage for NaaS to become a true enabler of digital and AI transformation in your business. As GenAI accelerates innovation across industries, networks that deliver low latency, automated scalability and financial predictability will be the differentiators between those organisations that merely adapt and those that lead. By solidifying these building blocks today, businesses can confidently scale to meet the demands of tomorrow.

ANKUR JAIN Director, Infrastructure Solutions (AMEA) at BT International

Tips for developing in-house robotic welding skills within your manufacturing business, from Orion Automation Systems technical director Jeff Fordham.

For your initial robotic welding system to provide the optimal return on investment, your personnel need good inhouse programming skills to quickly adapt to new products and changing production requirements. With good training, your personnel will quickly become competent and confident programmers and learn from experienced systems integrators how to efficiently program the robot welding system – and develop in-house product jigging techniques.

At Orion Automation, we are often asked "What skills do we need in our personnel to program the robot welding system?". The answer is no different to learning any new skill - they need to be "keen to learn". Of course, it helps if they understand good welding practice. We have found that apprentices in their early fabrication years make excellent students because of their familiarity with the intuitive programming technology. They are also eager to further develop their skills with the new generation of automatic robot programming software and advanced searching techniques often required in Australia's high product mix environment.

So, for your first robot welding system, let’s focus on automating the welding of your small to medium fabrications in a single station robot welding cell. The cell simplicity of a single station system minimises investment and maximises technology, while providing the tools to automate a significant proportion of your welding needs. All of this while providing the training platform for your personnel to learn how to program robot welding systems, manufacture in house production jigs and bring your welding into automatic production.

It should take about three days of training on site to upskill your personnel to be confident robot welding system programmers for small to medium products.

And the cost? To set up a dedicated fully integrated robot welding system cell within guarding to Australian standards – including jig table and "Ready to weld", with only product jigs required to start production should cost about $150,000 + GST. Of course, additional assets are required when progressing to the more flexible robot welding systems that can position larger and more complex fabrications, and which can locate fabrications that might vary in position or in individual component dimensions.

Ensuring the fabrication is oriented to the optimal welding position requires integrated additional external axes to move the product into position prior to, and during, welding. These external axes will extend the reach of the robot and orientate the fabrication during welding. Searching technologies that locate the position of the fabrications through standard touch sensing techniques or seam location by laser sensors are well established.

Establishing a system that can orient the fabrications with a dual axes positioner, within guarding to Australian standards, including a jig table, "Ready to weld" and advanced touch sensing controls and programming - with only product jigs required to start production – will cost about $230,000 plus GST and take an additional two days to train personnel. With your inhouse programming and production capabilities progressing to robotically welding small through to mid size

complex fabrications, the goal of automating the welding of your larger fabrications such as construction, mining, chassis and other large fabrications can be achieved.

Your personnel can now use their programming skills to weld larger fabrications in dedicated robot welding systems, with these standard track systems extending robot reach by tens of metres and the multi axis positioners extending payload ratings by tonnes. With your personnel confident they know how to successfully program various robot welding systems to sub assembly stages, you can transition to confidently program your large fabrications.

To ensure that these larger robot welding systems are fully utilised, the operators are upskilled to program the robot welding systems "offline", meaning that they are incorporating the 3D models of your fabrications into a computer simulation to fully program the robot welding system. Using the current generation of automatic robot programming software to further reduce programming time and complexity is an exciting development that is a true gamechanger for the robot welding industry. The cost to establish facilities to robotically weld large fabrications such as vehicle and truck chassis and heavy construction equipment is as follows:

For a dedicated fully integrated multi station robot welding Track system cell with the ability to orientate the fabrications with high payload positioners, within guarding to Australian standards. including master jigs and "Ready to weld", including advanced touch sensing controls, offline and automatic robot programming will cost about $900,000 plus GST. Training on site to develop your personnel to add Offline and Automatic Robot Programming to confidently program large fabrications will take about four days. This training is normally conducted at the time of the full factory acceptance testing of the system prior to shipping.

With experience in robotic welding systems in Australian, New Zealand, Japanese and American factories since 1987, we are available to assist you in the correct path to successfully incorporate robot welding systems within your fabrication business.

safety, cybersecurity, compliance and future planning –industry specialists offer their thoughts.

26 Collaboration and Transformation – How working together helps manufacturers make the right changes for their businesses.

28 In the Green – Applications for part of a $500 million funding pool for future green iron manufacturing open this October.

28 New Path – ATSE calls for overhaul of diesel incentives to drive industrial decarbonisation

29 Industrial Heart – New city partnership aims to fast-track emerging manufacturers, strengthen supply chains and boost Australia’s sovereign industrial capability.

30 T iming is Everything – From installing new machinery to investigating a close all, knowing when to conduct a risk assessment can make all the difference, Machine Safety Australia Senior Safety Automation Engineer Sergej Patkovic says.

34 Manufacturing campaign debuts – Industry stakeholders urged to share campaign assets as Manufacturing Industry Skills Alliance seeks to drive engagement.

36 Manufacturing Leads in Gender Balance – More women are working more hours in manufacturing, and careers are also getting longer, according to new research.

37 Safe and Sound – Elmo Software’s chief operating officer James Haslam looks at how smarter systems can turn safety into a competitive advantage.

38 Changing the Outcome – GuardWare Australia general manager of business development Richard Matthewman says even if you suffer a cybersecurity breach, losing CAD files and other secure files isn’t inevitable.

39 Turning Investments into Reality – Mattingly partner Anthony Hengel looks at the business case for new equipment and what decisions could guide your next upgrade.

40 Staying Audit-Ready – Consistent, thorough records management helps companies keep tabs on employee training and skills management without the chaos, OneCard founder and chief executive Kareena Waters says.

41 Getting your paperwork in order – It pays to optimise your processes and practices before expanding or bringing an external investor on board, says ECI Solutions vice president APAC manufacturing division Andrew Mamonitis.

42 Industry Optimisation in a Volatile Market – SYSPRO head of services for the Asia Pacific James Robinson discusses how balancing stock levels can help companies weather trade tariff challenges.

43 Balance Sheet: People, Planet and Industry – Integrating the priorities of people and planet has become not just an ethical imperative, but a strategic necessity for industry says AR & Associates creative director Ella Averill-Russell.

44 Keeping Compliance on Track – OneAdvanced head of people management solutions Damien Durston looks at ways to meet labour obligations in 24/7 shift-based supply chains.

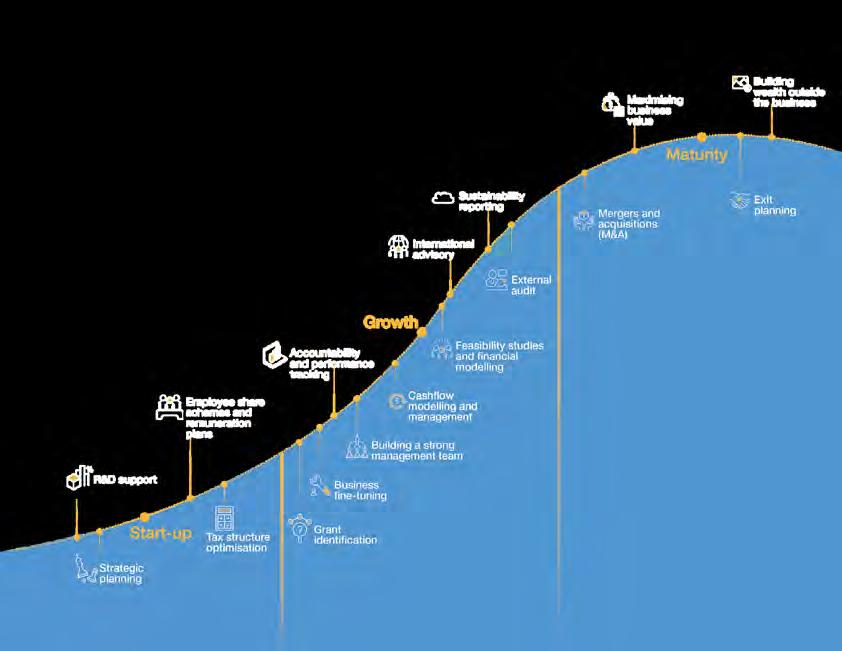

45 Third Party – How an offsite Virtual CFO can help give your manufacturing operations a strategic edge, with William Buck principal Jeremy Raniti and senior manager Karly Whitehead.

How working together helps manufacturers to make the right changes for their businesses.

There’s no shortage of innovators in Australian manufacturing – but industry collaboration is the key to driving those innovations forward. That was the consensus of a panel discussion held at Bosch Australia Manufacturing Solutions’ (BAMS) campus in Clayton, Melbourne.

Held in commemoration of the company’s 70 years of manufacturing innovation in Australia, the company brought together business leaders for a panel discussion: “The Ecosystem of Success: Fostering Innovation and Collaboration for Australian Global Competitiveness.”

Among them was David McLaughlin, the co-founder of bodd – a full body 3D scanner machine that captures rich biometric data across the entire human body, with applications in health and wellness. The company originally planned to use the scanner for 3D printing life-size replicas of individuals for custom clothing.

“That was an idea we had. It was an example of a willingness to try, put it into market, test it, and then basically say ‘You know what? This is not the product. The product is actually our scanner.’”

Once the company reached that conclusion, bodd turned to BAMS to manufacture, distribute and provide in-field technical support for all its hardware units, helping to scale the product into Australian and global markets.

Speaking on the panel, McLaughlin said securing an “ecosystem of support” early on had been important for the company’s success.

“For us as an early-stage company or a startup, it’s impossible to do it all, so you really need to lean on experts in their domain partnerships. You need as much support as you possibly can to make it and survive.”

“Having the support network, whether it’s for export marketing or R&D funding... all those elements play a big role in helping companies take a little bit more of a risk and starting to think globally,” he said.

“From day one in our business, we said this has to be a global business, because the runway in Australia is not big enough. If you’re thinking globally, all of a sudden, those things start to become economical, because the market size is just so significant.”

It was a statement echoed by BAMS head of sales Bradley Trewin, who noted the importance of partnerships.

“When I look at the people I have dealt with over the years, the ones that have tried to do it all themselves haven’t been able to be successful because fundamentally, they haven’t understood the importance of having consistent partnership.”

AMTIL CEO Lorraine Maxwell said that while collaboration between companies was important, it was industry organisations that kept the industry together.

“So, you can organise your connections within that, or you can look to the network or the coordinators that are there to help businesses grow and connect,” she said.

A dedication to innovation was also important, she added, regardless of the size of the company involved.

The manufacturing line Bosch Australia Manufacturing Solutions produced for RayGen.

“It is the companies who are looking to change, to horizon scan, and respond to what’s going on in the world, as well as how to adapt and evolve their technology, that will be successful in the future,” she said.

“I think that some of the biggest opportunities for us to move the dialogue in the future will be not only about embracing new technologies and implementing them but also making sure that we’ve got it right in terms of processes and people.”

Digital transformation

Panellists also broadly agreed that digitalisation and the adoption of advanced technologies such as AI, digital twins and even data-driven automation are becoming nonnegotiable for future competitiveness. Bosch Rexroth business development manager Igor Kabakov explained how his company is integrating technical advancement with products to enable advanced manufacturing. “It’s a modular system, which helps manufacturers start small and expand over time without having any larger scale platforms and upfront capacity,” he said.

RayGen product development manager Derek Scott shared how his company uses new technologies to run its solar energy farms and storage solutions. “We have a digital twin, but it’s coupled into what we call a techno economic model, because electricity prices are dynamic, and you need to be predicting what's happening in the future to electricity prices,” he said.

The company also uses data tracking to check on the lifecycle of their solar modules, providing valuable feedback for continuous improvement.

“Tracing product all the way from built materials through construction or fabrication in its life, and then even where it goes at the end is all tracked through that. That kind of feedback loop is critical for us.”

Trewin advised companies to start their digital transformation journeys by focusing on solving specific problems, proving a return on the investment and then getting a buy-in to scale up, rather than attempting to overhaul everything at once.

“You’ve got to understand what your problem is, what it is you’re trying to solve,” he said.

Scott added to this in saying there’s a balancing act to be respected in getting the product right before trying to scale up production.

“You can’t completely finish your product and then hand it over to manufacturing, because there are probably manufacturing efficiencies you can achieve by doing it collaboratively,” he said.

Instead, RayGen’s approach with one heliostat product was to engage Bosch before it was fully finalised, allowing for iterative improvements and smoother scaling.

“We could learn a lot, we could improve, we could make a robust product. Then we engaged Bosch, not when we were completely finished, but when it was getting there, when they knew what product we were trying to make, but there was still time to make minor tooling changes and that sort of thing to make the manufacturing easier,” he said.

“So, finding that balance around when to scale automation that kind of locks you in and makes changes more difficult, but your product has to be mature enough… if you've gone too far, then you've lost some opportunities to build an efficient product.”

For McLaughlin, creating a support framework to encourage and celebrate businesses that are taking risks is important for the future of Australian innovation.

“We've spent the last 10 years telling all the kids they need to go and be software developers, and AI has basically come along and said, actually, don't worry about that, we’ve got this,” he said.

“But I think the skills that are going to be really valuable are those skills that blend software with the physical.

So, mechatronics, systems, level design…

“What AI and new software technologies cannot do is they cannot come up with new problems and the solutions to those new problems. So, we need to teach people. We need to teach people skills on how to be critical thinkers.”

Scott highlighted the importance of maintaining a “critical mass” of manufacturing capability and expertise in Australia, warning that losing this base could have l ong-term consequences for the sector’s resilience and innovation capacity.

“Having a critical mass of that capability here, whether it's machine shops, fabrication, automation specialists, and that sort of thing, is critical for us to be able to go and have a range of other businesses to support what we're doing, as a start,” he said.

“So, making sure that we have this critical mass and it continues to be encouraged, is critical, because there is a bit of a risk that you start to lose capability and snowball… there’s got to be that availability.”

Applications for part of a $500 million funding pool for future green iron manufacturing open this October.

Australian companies aiming to produce iron in a more sustainable manner are invited to apply for grants from the National Development Stream of Australia’s $1 billion Green Iron Investment Fund.

While up to $500 million of that fund has been dedicated to supporting changes to the Whyalla Steelworks, another $500 million will be available to support early mover green iron projects and help overcome the initial hurdle of capital investment. To be eligible for the grant, projects must aim to develop a commercial scale green iron facility, be focussed on capital works and located in Australia. Only entities with an ABN and which are registered for GST can apply.

Industry Minister Tim Ayres says the grant funding will support early mover projects ready to start commercial scale production of green iron by 2031.

“Green iron is a major opportunity to grow Australia’s iron ore industry and build a new industrial sector,” he says. “This $500 million investment lays the foundation for a multibillion-dollar industry and thousands of good, secure jobs.”

Applications open on October 28 and close on 16 January 2026.

ATSE calls for overhaul of diesel incentives to drive industrial decarbonisation.

Australia must urgently reduce its reliance on diesel in heavy industries, according to a new report from the Australian Academy of Technological Sciences and Engineering (ATSE).

Released in partnership with Fortescue, the report warns that mining, road freight, agriculture, fisheries and forestry cannot meet emissions targets without a shift away from diesel fuel – and that current policies are holding back progress.

ATSE chief executive Kylie Walker says reforming tax and policy settings was essential to enable industry to embrace clean fuel technologies. “There is an urgent need to decarbonise Australia’s most emissions-intensive sectors,” she says.

“By encouraging the application of mature clean fuel technologies, investing in fast-tracking clean tech in development, reducing the cost of green alternatives and increasing the cost of diesel in a targeted and balanced way, Australia can achieve its industrial decarbonisation.”

The report makes five key recommendations, starting with an independent review of financial incentives that support diesel. It singles out the Fuel Tax Credits Scheme (FTCS), which subsidises diesel use and shields operators from the true cost of fossil fuel consumption. According to ATSE, this creates a structural barrier to investment in low-emissions alternatives and undermines national decarbonisation goals.

The Academy also calls for reforms to Australia’s emissions reduction mechanisms, such as carbon pricing or adjustments to the Safeguard Mechanism to account for diesel’s full environmental impact. Other measures include a coordinated Future Diesel Strategy, new infrastructure to enable

clean energy uptake, and targeted R&D investment to bring emerging technologies to market. ATSE Fellow, Fortescue Board Member and former CSIRO chief executive Larry Marshall says the current policy mix discourages innovation.

“Heavy industry wants to transition to cleaner fuels, but the current policy settings make it harder than it should be,” he says. “Right now, the Fuel Tax Credit Scheme effectively subsidises burning diesel, while companies that invest in clean alternatives face higher costs. That imbalance holds back innovation and locks in emissions.”

Marshall says government and industry must work together to accelerate the transition. “If we want Australia to become a clean energy superpower – if we want a Future Made in Australia – then we need a system that rewards smarter, cleaner choices,” he says.

“Emerging clean technologies need the right mix of policy, incentives and investment to make Australia’s green and gold vision a reality.” The report stresses that a one-size-fits-all approach will not work. While electrification offers solutions in some areas, ATSE highlights the need for a wider range of clean fuels and technologies to support industries that depend on high-density, portable energy sources.

A comprehensive techno-economic assessment of these options is needed to chart realistic decarbonisation pathways. Walker says the transition would be complex but achievable with the right mix of policies and investment. “We have the technology; we can do it if we get the settings right,” she says.

New city partnership aims to fast-track emerging manufacturers, strengthen supply chains and boost Australia’s sovereign industrial capability.

Australia’s advanced manufacturing sector is the focus of a new partnership between the National Reconstruction Fund (NRF), the Bradfield Development Authority (BDA), and the Advanced Manufacturing Readiness Facility (AMRF).

Bradfield, the new city taking shape alongside Western Sydney International Airport, will host an innovation cluster designed to connect firms with the facilities and capabilities they need to scale.

The partnership will create a pipeline of referrals between the NRF and AMRF, ensuring businesses can access support for both capital investment and technical readiness.

The groups aim to help emerging manufacturing firms grow by providing coordinated support across the entire supply chain — from research and design through to production, distribution and sales.

For manufacturers, this means streamlined access to investment, technical expertise and industry networks.

With New South Wales contributing nearly a third of the nation’s manufacturing output — and accounting for 37 per cent of the proposals currently before the NRF — the state is positioned to play a central role in strengthening sovereign capability.

Federal Industry and Science Minister Tim Ayres says the partnership would directly support the creation of highly skilled manufacturing jobs and a stronger industrial base.

“With AMRF’s technical expertise guiding NRF investment decisions, this partnership will help build out Australia’s industrial capability and deliver a Future Made in Australia,” he says. NSW Planning Minister Paul Scully notes Bradfield’s role as a hub for advanced industries, noting that businesses across the country are already engaged with the AMRF.

NSW Industry and Trade Minister Anoulack Chanthivong says aligning state and national initiatives would boost the innovation ecosystem and help manufacturers better prepare for private capital investment. “The AMRF will offer technical advice and assistance to ensure businesses better prepare themselves to attract private capital,” he says.

“Partnering with NRF will help grow and develop the state’s innovation ecosystem and industry even further.”

“Alongside the existing agreements the AMRF has with 11 NSW and ACT universities, this will support the entire manufacturing supply chain from R&D through to full scale commercialisation,” he says.

From installing new machinery to investigating a close call, knowing when to perform a risk assessment can make all the difference, Machine Safety Australia senior safety automation engineer Sergej Patkovic says.

Imagine this scenario: Your team installs a new collaborative robot application on the production line to automate what was once a manual task and introduce collaborative interaction with workers. Because the system does not rely on physical distance barriers such as perimeter guarding, it promises flexibility, space savings and productivity gains. The robot has been designed to operate under a power and force limiting (PFL) safety function, but no risk assessment was carried out to identify the contact scenarios, nor has validation been performed using a pressure and/or force measuring device. As a result, when the robot moves into action, its force and power output exceed the biomechanical limits set out in ISO 10218-2:2025, putting operators at risk of injury. It’s a stark reminder that a thorough risk assessment might have flagged that hazard and prompted better safeguards.

Risk assessments are a cornerstone of workplace safety. They involve finding potential hazards, evaluating how serious and likely those hazards are to have a negative outcome, and then fixing them before harm is done. Australian standards and safety codes make it clear that risk assessment isn’t a one-and-done task, it’s an ongoing process through the life of any equipment or process. In fact, the Australian Standard AS/NZS 4024.1201 (Safety of Machinery) emphasises considering safety throughout a machine’s life cycle – from transport and installation to commissioning, use, and eventual decommissioning. It stresses that only when hazards have been identified can steps be taken to eliminate them or to reduce risks, advising designers (and by extension, employers and engineers) to identify all tasks and operations associated with a machine. In simpler terms: you need to anticipate danger at every stage if you want to keep people safe. So, when exactly should a risk assessment be carried out in a manufacturing context? The short answer: both regularly and whenever something changes that could affect safety. Below, we break down some of the key triggers for conducting a risk assessment.

Key triggers for risk assessments in manufacturing Manufacturing is dynamic. New products, new machines, and new processes are part of the game. Recognising the situations that call for a fresh risk assessment can prevent accidents and keep you compliant. Work Health and Safety authorities across Australia consistently point to a few critical moments when you should hit pause and reassess the risks:

• When introducing new equipment or processes: Every time you bring in a new machine, install a piece of plant or even use a new substance or material in production, it’s time for a risk assessment. The WorkSafe Victoria Compliance Code: Plant explains that if a known safe way to control a well-understood hazard exists, you might implement that immediately. But if you’re unsure how to control a risk associated with a new item of plant, a formal risk assessment is the way to figure it out. This is because a risk assessment will reveal what could go wrong and how severe it could be. Essentially, new things equal new risks, until proven otherwise.

• When modifying or upgrading equipment or procedures: If you change an existing machine or process, even slightly, you should reassess the risks. This includes physical modifications to machinery (adding new tooling, altering guards, software upgrades) as well as changes in how work is done (new production methods or workflow changes). A fresh risk assessment will ensure these modified conditions remain safe.

• When work practices or the environment change: Changes in work schedules, procedures, or even the workplace environment should trigger a risk review. WorkSafe Tasmania advises doing a new assessment when you are “changing work practices, procedures or the work environment”. Perhaps you’ve introduced shift work at night, or moved a machine from a spacious area to a cramped corner, these scenario changes can introduce fatigue or ergonomic hazards, respectively, that warrant a fresh look. Even a change in environmental conditions (like ventilation, temperature, or noise levels) can increase risks. The goal is to catch any new hazard that creeps in through change.

• After any accident, incident, or near miss: A serious incident or a near miss is a flashing red light that something in your risk control system might be inadequate. Investigating the event should include a risk assessment to prevent it from happening again. WorkSafe Victoria urges employers to look at near misses as a cue to improve safety before a tragedy occurs. One real-life case: a Victorian plastics manufacturer had a worker suffer severe burns while cleaning a plastic granulator machine. The subsequent investigation found it was “reasonably practicable for the company to undertake a risk assessment of the granulator” to devise a safer cleaning method. Near misses and incidents provide hard evidence that a hazard wasn’t fully controlled, they absolutely justify doing a fresh risk assessment.

• Periodically or when new information emerges: Even if nothing major has changed and no incidents have occurred, it’s wise to conduct periodic risk assessments as a proactive measure. Machinery wears out, staff come and go, and industry knowledge evolves. Regular safety audits or risk reviews (say, annually or at an interval appropriate to your level of risk) can catch issues that develop slowly over time. WorkSafe Tasmania highlights that risk assessments should be done regularly as well as when a specific change occurs. Likewise, the SafeWork NSW Code of Practice: Managing Risks of Plant notes that control measures must be reviewed (in effect, re-assessed) if a new or relevant hazard or risk is identified or if consultation with workers indicates a problem. Regular reviews also help ensure compliance with any updated laws or standards. Think of it as preventative maintenance for your safety system.

Conducting risk assessments at the right moments isn’t just about ticking a compliance box, it has real benefits for legal peace of mind, the wellbeing of workers and even your bottom line.

• Legal compliance and duty of care: Under Australian law (whether Victoria’s Occupational Health and Safety Act 2004 or the model Work Health and Safety Act adopted in NSW and other states), employers or people conducting a business or undertaking (PCBUs) have a duty to ensure a safe work environment so far as is reasonably practicable. Performing timely risk assessments is a practical way to meet this duty by identifying hazards and controlling risks before they harm someone. While the law doesn’t always say the words “thou shalt do a risk assessment” for every scenario, it effectively requires it by insisting that risks be proactively managed.

• Safety of workers (and others): The most important reason to do a risk assessment is, of course, to prevent injuries and save lives. It’s about making sure everyone goes home in one piece. By systematically examining what could go wrong, whether it’s a worker’s hand getting caught in machinery, exposure to hazardous chemicals, or a forklift collision, and then implementing controls (like guarding, training, safe work procedures, PPE), you drastically reduce the chance of harm. Many near misses and injuries in manufacturing can be traced back to hazards that were either not spotted in time or not properly understood. Risk assessments bring those issues into the open. They also help evaluate how serious a risk is, which existing controls are or aren’t working, and what action is needed. This clarity can literally be life-saving.

Continued next page

• Productivity and business continuity: Safety and productivity in manufacturing are two sides of the same coin. It might seem like stopping to do risk assessments could slow down projects or production, but in practice it prevents far more costly downtime in the long run.