1.Background

ThebackgroundofKFC

2. Problem Statement

IdentifythecurrentproblemofKFCoperationas

3. Strategic Capacity Management

helpsKFCtoforecastdemandandensurethatithasthe rightamountofcapacitytomeetthatdemand.This includesensuringthatKFChasenoughstaff,equipment,

KFCcanuseprocessanalysistomonitortheperformanceofits kitchenoperationsandensurethattheyarealignedwithits strategiccapacitygoals.

KFCusewaitinganalysistomonitortheperformanceofitskitchen operationsandensurethattheyarealignedwithitsstrategiccapacity goals. KFCcusewaitinganalysistotracktheaveragewaittimefor customers.Thisinformationthenbeusedtomakeadjustmentstothe kitchenprocessasneeded.

Theoverallsummaryandreccomendation

This section contains of :

Company history

Company strategy

Mission & Value

SWOT analysis KFC

KFC supply chain

Problem statement

KentuckyFriedChicken(KFC)isagloballyrenownedfast-foodre wasfoundedbyColonelHarlandSanders,whobegansellingfried Corbin,Kentucky,USA,duringtheGreatDepression.Overtheyear mostrecognizablefast-foodchainsintheworld.

smallr chisebusiness.

omingahousehold

KFC'smaingoalistoprovidethe tastiestfriedchickenusingtheir secretrecipeanduniqueherbs andspices.

KFCfocusesonmakingsurethey serveyouquicklyandthatyou alwaysgetthesamegreattaste everytimeyouvisit,nomatter whereyouare.

They'reopeningmoreKFCrestaurantsall overtheworld,adaptingtheirfoodto matchlocalflavors,andthey'realso tryingtobemoreeco-friendlyandgive backtocommunities.

KFC'smissionistoservegreattasting,high-qualityfriedchickento

satisfytheircustomers'cravings,ensuringajoyfulandfulfillingdining experienceeverytime.

KFCiscommittedtodeliveringtop-notch,deliciousfood madewiththefinestingredientsandcookedtoperfection.

MakingcustomershappyisatthecoreofwhatKFCdoes. Theystrivetoprovideexcellentserviceanddelightfulmeals.

Honesty,ethics,andtransparencyarefundamentaltoKFC'soperations,both withinthecompanyandinitsrelationshipswithcustomersandpartners.

Strongbrandidentityrenownedforiconicfriedchicken andsecretblendof11herbsandspices.

Wideglobalpresencewithavastnetworkoffranchised andcompany-ownedrestaurants.

Menuinnovation,offeringdiversechickenoptionsand adaptingtolocaltastes.

Expandingintonewmarkets

Developingnewmenuitems

Improvingcustomerservice

Reducingtheenvironmentalimpactofoperations

Unhealthyfoodoptions

Longwaittimesinsomerestaurants

Negativeperceptionofanimalwelfarepractices

Perceivedhealthconcernsrelatedtothefriedandfastfoodimage

Competitionfromotherfastfoodrestaurants

Risingfoodcosts

Healthconcerns

Economicrecession

Sourcing

Processing

Distribution

KFCsourcesitsingredientsfromavarietyofsuppliersaroundthe world.Someofthekeyingredientsincludechicken,potatoes,flour,and spices.

KeyPlayers

Poultrysuppliers,potato farmers,flourmillers,spice companies

KFC'singredientsareprocessedatavarietyoffacilities,including chickenprocessingplants,potatoprocessingplants,andflourmills.

Poultryprocessors,potato processors,flourmillers

KFC'singredientsaredistributedtoitsrestaurantsthroughanetworkof distributioncenters.

Third-partylogistics providers

Warehousing KFC'singredientsarestoredinwarehousesatitsrestaurants. KFCemployees

Preparation

KFC'singredientsarepreparedintomealsatitsrestaurants. KFCemployees

Serving KFCmealsareservedtocustomersatitsrestaurants. KFCemployees

KFC'sComboPackagemenuisapopularchoiceforcustomers,butthedemandforthismenu expectedtoincreasesignificantlyoverthenextthreeyears(YoYincrease10%).Combopacka chicken+rice+drinks.Thepriceperpackageis$2.5.

ThisisputtingastrainonKFC'skitchenoperations,andthecompanyisfacinganumberofcha including:

Bottleneckinthekitchenprocess:ThecurrentkitchenprocessforpreparingtheComboPackageisnot efficientenoughtomeettheexpectedincreaseindemand Thisisleadingtolongwaittimesfor

apacitytomeetthe osoinawaythatdoesnot

Helps KFC to forecast demand and ensure that it has the right amount of capacity to meet that demand. This includes ensuring that KFC has enough staff and equipment

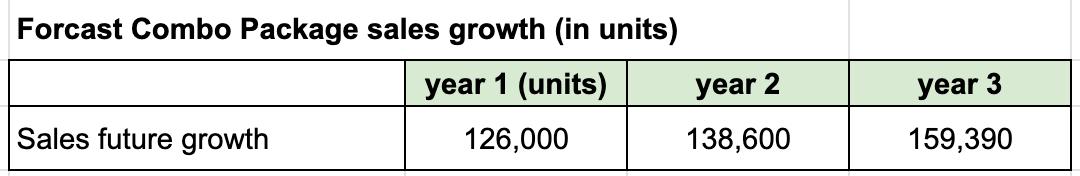

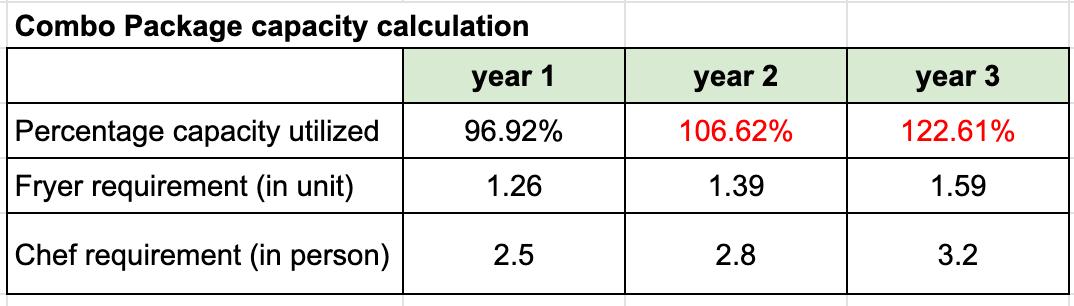

Determining capacity requirement for increasing demand in the next 3 years

Calculating value of decisions tree to know which one the most valuable decisions

KFChavemenu:Combopackage(chicken,rice,drink).Managementwouldliketodetermine yearlyequipmentandlaborrequirementsforitspackingoperationforthenextthreeyears.

KFCneedstodetermineifithasenoughcapacitytomeetfuturedemand.Thecompany currentlyhasacapacityof130,000Combopackagesperyear,andsalesareexpectedtogrow

boPackage.We e/year

To answer Capacity requirement for the next 3 years :

First, need Forecasting to Predict Sales for Kombo Package KFC with growth 10% YoY

Then, Calculate Equipment and Labor Requirements

WithCapacitylimitAssumption130,000peryear

2chefneededtoprepareCombopackage

1fryercanpackageeacharound100,000Combopackageperyear.

Thesalesisincreasingyear1-3,andthere willbeovercapacityinyear2&3.Sowe needtoaddextralabourandfryertomeet thedemand

Basedontheprojectedsalesgrowth,KFCwillhaveacapacityshortfallinyear2andyear3.Toaddressthisshortfall,KFC

canconsiderhiringmorekitchenstaffandpurchasingadditionalfryers

Basedontheprojectedcapacitycalculation,therewillbeovercapacityinyear2&3.Totackletheissue,thereare3strategy toconsider:Addnewchef,buynewfryer,andaddnewcashier.

KFC,iscurrentlyatapivotalcrossroadsastheownerdeliberatesonhowtomanagetheanticipatedgrowthoverthenext3years.

TheThreeOptionscostassumption:

AddingNewChef

Cost:$43,000

ExpectedOutcome:

StrongGrowth:AnnualReturnsof$150,000

WeakGrowth:AnnualReturnsof$110,000

AddingNewFryer:

CostofImplementation:$15,000

ExpectedOutcome:

StrongGrowth:AnnualReturnsof$90,000

WeakGrowth:AnnualReturnsof$60,000

Addnewcashier:

Cost:$25.000

ExpectedOutcome:

StrongGrowth:AnnualReturnsof$120,000

WeakGrowth:AnnualReturnsof$105,000

ProbabilityofStrongGrowthduetoincreasedpopulationfromthenewelectronicsfirm:55%~0.55

ProbabilityofWeakGrowth:45%~0.45

Operatingcostsforalloptionsareequal.

Waitingformorethanoneyearcouldleadtocompetitionmovingin,makingexpansioninfeasible.

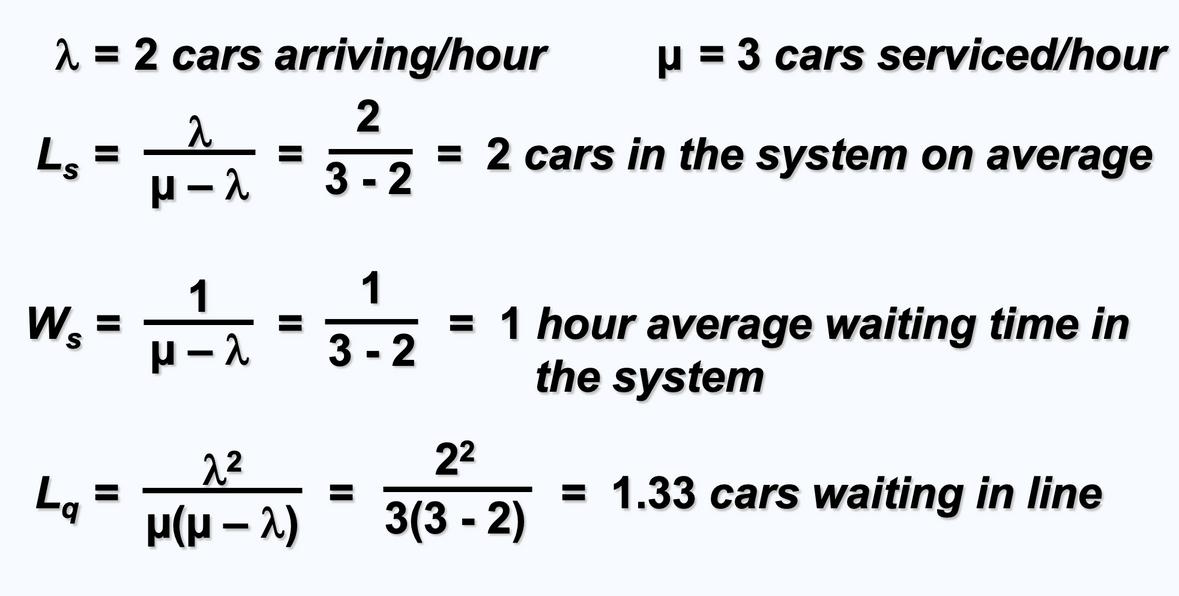

1. 2. 3.Fromtheassumptionof3options,wedeterminethedatatothetable.Andcalculatevalue$for3yearsofeachoptions. theobjectiveofcalculatingthevalueofadecisiontreeforaddingachef,addinganewfryer,oraddingacashieristo determinewhichoptionwouldhavethegreatestpositiveimpactonthecompany 'sprofitability

Revenue-Addchef=$410,000

Revenue-addchef=$290,000

Revenue-Addnewfryer=$255,000

Revenue-Addnewfryer=$165,000

Revenue-AddCashier=$335,000

Revenue-AddCashier=$290,000

Wehave3optionstoaccomodatesalesgrowthfor3years:Addnewchef,addnewfryer,addnewcashier

Addingachefisthemostlikelyoptiontoleadtoasignificantincreaseinrevenue,withanexpectedvalueof $356,000.Thisisthehighestexpectedvalueofthethreeoptionsthatleadtobestoptionforfuture.

Thismeansthatthereisa55%chancethataddingachefwillleadtoanincreaseinrevenueof$410,000anda 45%chancethatitwillleadtoweakgrowthof$290.000.Theexpectedvalueof$356,000issumofstrong& weakgrowthaftermultiplyby%probability

Thedecisiontreeshowsthataddingachefisthemostlikelyoptiontoleadtoasignificantincreaseinrevenue, witha55%chanceofincreasingrevenueby$410,000.Addinganewfryeristhesecondmostlikelyoptionto leadtoasignificantincreaseinrevenue,witha55%chanceofincreasingrevenueby$255.000.

KFC can use strategic capacity management to forecast demand and ensure that it has enough staff and equipment on hand to meet customer demand. Steps involved in strategic capacity management :

Forecast demand. KFC demand for next 3 years increased 10% YoY

Assess current capacity. = KFC in year 2 & 3 will going to be over capacity

Develop plans to address capacity gaps. = To tackle the issues, we will choose add new chef for year 1-3

Improve profitability can help to reduce costs and increase revenue.

Improve customer satisfaction

By ensuring that the company has the capacity to meet customer demand

Gain a competitive advantage can help companies to gain a competitive advantage over their rivals.

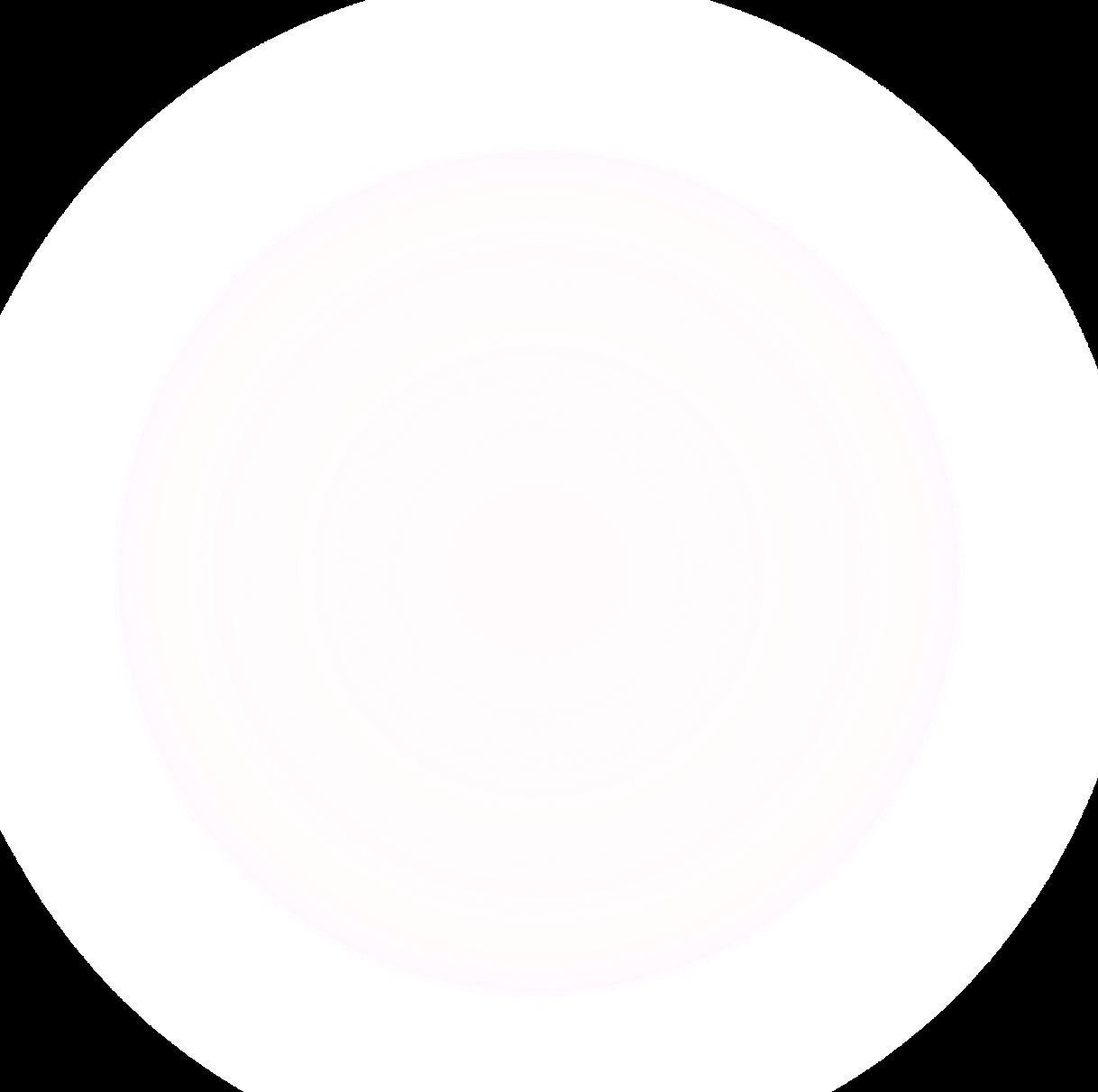

TheobjectiveofprocessanalysisforKFCistoidentifyand improvetheefficiencyandeffectivenessofitsbusiness processes.Wedeterminetheprocessofkitchenformaking 1kombopackagechicken.Herearethecontent:

Theflowchartprocess+stepsofactivities

Throughput

BalancingbottlenecksfromChefAtoChefBbyadding

newfryerandnewchef

ProductProcessMatrix

Break-evendemandforinvestmentnewfryerandnew chef

Executed by 2 chef

Executed by 1 person food preparator

Executed by 1 cashier

Theobjectiveoftheprocessistotakeanorderfromacustomeranddeliverthefriedchicken tothe customerquickly.Theproccessexecutedby2chef,1foodpreparator,1cashier.Thecurrent processtook 33.5minutesfor12kombopackage.Theflowchartcanbeusedtoanalyzetheperformanceofthe orderingandfulfillmentprocessandtoidentifypotentialbottlenecks.

Aftervisualizetheflowchart,wedeterminethestepofactivities.Itshowsthecycletimeofeachactivities,starttimeandfinish,theworker whoresponsibletothetask.Weknowthattheoveralltimetofinishtheprocessis33.5minutes,andthetotalchickenfrom1batchis1dozen ~12pcsKombopackage(chicken,rice,drink)

9

Thisshowsinformationaboutcycletime,totalproduction.Wecalculatethetotalproductionfor8hours(1daywork).

1 Accepting order in

2 take the chicken from refrigerator and cooling

3 Put the chicken into the fryer & set temperature

4 Frying the chicken

5 Remove the chicken from the fryer

6 Put the chicken + rice into the packaging

7 Check the

8 Prepare drink by cashier

9

refrigerator = 3 dozen/5 min

Chef B

- 1 fryer = 1 dozen/15 min

Chef B

Food preparator

Food preparator

FirstBatchintotaltimeweneed=33.5minutes~1dozen

Cycletime2ndbatchandsoon=16minutes(putchickenintofryerandfryingthechicken)

8hours=480minutes

Sointotal#dozenwecanmake=(480-33.5)/16min+1dozen=29dozenchicken

**thefirstbatchneedtopreheatthechickenand2ndbatch=justaddadditional16minutes

How much of time for Chef A and Chef B to fill each orders?

WewanttoknoweachCheftaketimepereachorder,anditshowsthatinbalancetimework

take

ChefAneedtimetoacceptingorder(2min)+takeoutfromrefrigerator(2.5min)=4.5minutes

ChefBneedtimetoputchickenintothefryer(1min) +removethechickenfromthefryer(3min)= 3minutes

We relized that there’s bottleneck (inbalance) from take chicken from refrigerator to put the chicken into fryer. Below show the closeup bottleneck process :

Current layout

Takethechickenfrom refrigerator

Cycletime:

Putthechickenintothefryer andFriedthechicken

Cycletime:

Raw Chicken cooked fried chicken (WIP)

ChefA=40dozen/hour have3refrigerators=3 dozenchicken 3dozen/4.5minutes

1chef=20dozen/hour

have1fryer=1dozen chicken

1dozen/3minutes

ChefA

3Refrigerators 1Fryer

There’s inbalance process from refrigerator to fryer

Capacity=1chef/3dozen/4.5minutes

ChefB

Capacity=1chef/dozen/3minutes

Inbalanceprocessfrom3refrigeratorto1fryer,alsothere’sinbalancecapacityfromChefA(40dozen/hour)toChefB(20dozen/hour)

How to balance the process from refrigerator to fryer?

If we add 1 fryer, the capacity will balance

CapacityofChefAandChefBarenotbalanceiftherejust1fryer,butifweadd1morefryertotheprocess,thecapacityofChefA andChefBwillBalance.ChefBcapacityincreasedduetothejobdescthatcorrespondswiththenumberofthefryer(Putthe chickenintothefryer&settemperature,revomethechicken)

Before

3dozen/4.5minutes

Rateperhours=40dozen/hour

ChefB

ChefA +

1dozen/3minutes

Rateperhours=20dozen/hour

If we add 1 fryer

After

ChefA

3dozen/4.5minutes

Rateperhours=40dozen/hour

ChefB

2dozen/3minutes

Rateperhours=40dozen/hour

Ifweadd1fryerthecapacityproductionfromChefAtoChefBwillbalance.ChefAwillproduce40dozenchicken/hour,andafter addingnewfryertheChefBwillproduce40dozenchicken/hourtoo

If we add 1 new Chef, the capacity will balance

CapacityofChefAandChefBinadayarenotbalance.Ifwehire1newchef,thecapacityperdaywillbalance.ChefCwillhelpChefBtofriedthe chicken.thetotalcapacity/dayofChefA=320;ChefB+ChefC=320(balance)

Takethechickenfrom refrigerator

Putthechickenintothe frierandFriedthe chicken

Cycletime: 1chef=20dozen/hour

Raw Chicken cooked fried chicken (WIP)

Cycletime:

ChefA=40dozen/hour 1hour/40dozen

Takechickenfromrefrigerator=

Produce40dozen/hourx8hourworkindayx1chef=320capacity/day

Fryingthechicken=

Produce20dozen/hourx8hourworkindayx2chef=320capacity/day

Thecapacitiesareroughlyequals

Currentsituation:

totaldozenthatchefAproduceinamonth=320x12=3.840dozen

totaldozenthatchefBproduceinamonth=160x12=1920dozen

totaldozenthatchefCproduceinamonth =1600x12=1920dozen

Sothetotalof3chefs=7680capacity

Ifweadd1chef,thetotalproductionwillincrease100%

Add new 1 Chef C

Putthechickenintothe frierandFriedthe chicken

Cycletime: 1chef=20dozen/hour 1/2hour=40dozen

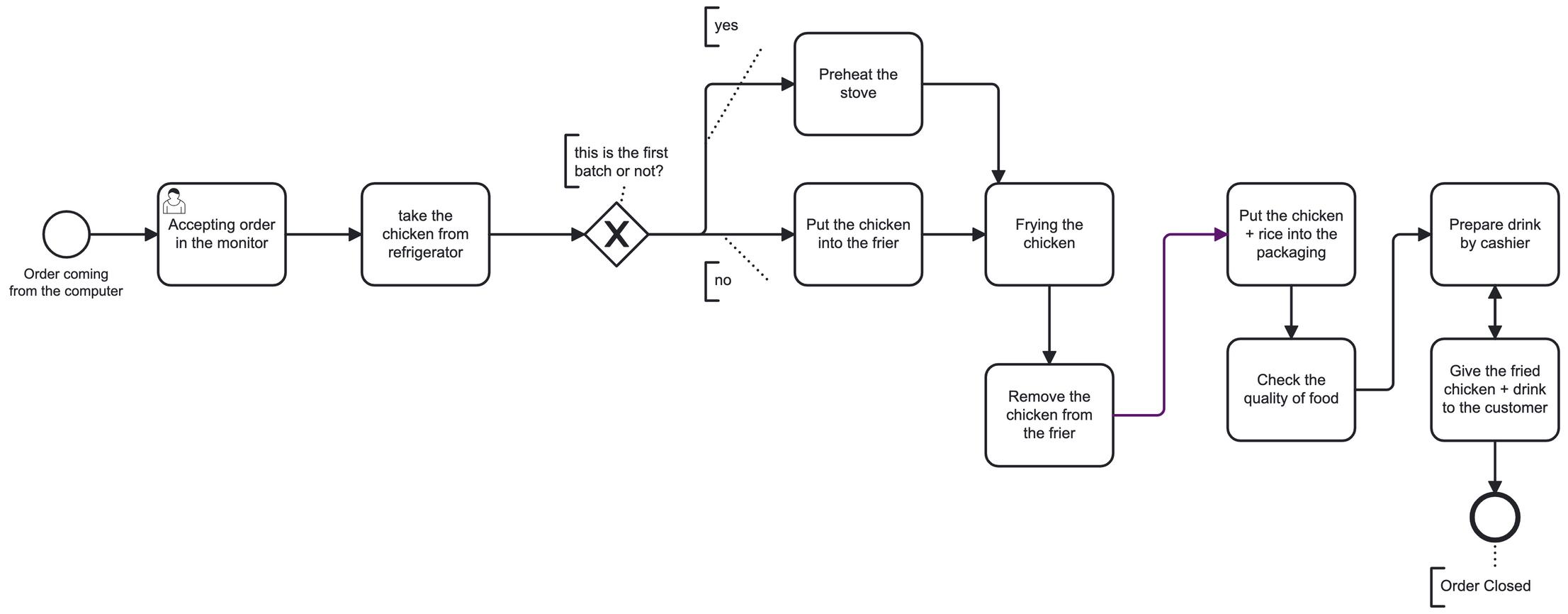

Chef A Chef BTheproduct-processmatrix,alsoknownastheoperations processmatrix,helpsinunderstandingtherelationshipbetween thetypeofproductbeingproducedandthetypeofproduction processused.

InthecaseofKFC,afast-foodrestaurant,themostsuitable representationontheproduct-processmatrixwouldbethe "AssemblyLine"approach.

KFCoperatesusinganassemblylineapproach,characterizedby acontinuousflowofstandardizedfooditemsbeingprepared, cooked,andassembledinasequentialorder.

Explanation:

Differentcomponentsofameal(chicken,drink,friesetc.)arepreparedatdifferentstations,eachspecializinginaspecifictask (frying,grilling,etc.).

Theitemsmovedowntheline,andeachstationaddsspecificelementstotheorder,suchasfryingchicken,preparingsidedishes, andassemblingthefinalmeal.

Thisapproachallowsforahighvolumeofstandardizedproductstobeproducedefficientlyandquicklytomeetcustomerdemand.

The"AssemblyLine"approachisthemostsuitableforKFCgiventhestandardizednatureoftheirmenuitemsandthehighdemand forfastfood.Itensuresefficiency,consistency,andspeedindeliveringtheirsignatureproductstocustomers.

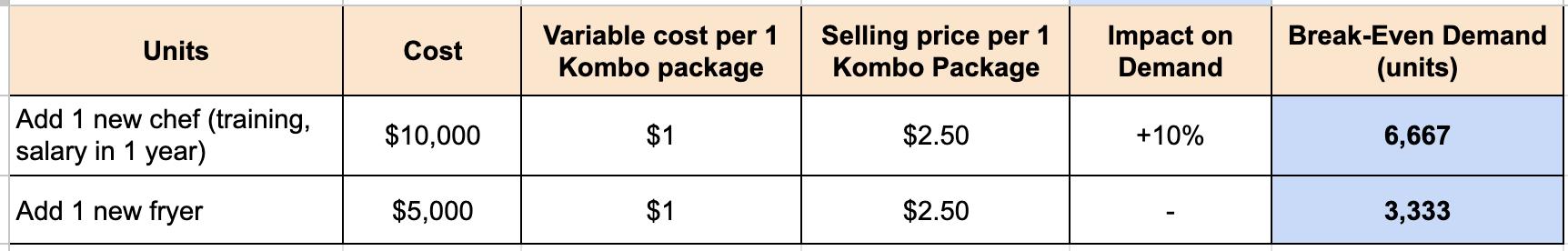

Afterwecalculatecapacityafterweadd1newchefand1newfryer.WewanttoknowaboutBreak-evendemand oftheseinvestment.Theobjectiveisto determinetheminimumnumberofunitsthatmustbesoldinordertocoverallcostsandmakenoprofitorloss.ThisinformationcanbeusedtohelpKFCmake decisionsaboutpricing,marketing,andproduction.

Tocreateabreak-evendemandassumptionfortheoptionofKFCaddnewchefandaddnewfryerweneedtomakesomeassumptionsaboutthefixedand variablecostsassociatedwitheachoption.

Basedontheassumptionsabove,thebreak-evendemandforKFCtoadd1newchefis6.667unitsperyear,whilethebreak-evendemandforKFCto add1newfryeris3.333unitsperyear.Thismeansthataddinganewchefismoreexpensivethanaddinganewfryer.But,thebenefitsofaddingachef outweighthebenefitsofaddingafryer.AchefcanhelpKFCtoincreasedemand(chefcanpreparevarietyoffoodandcanalsocookfooditemsto order),improvecustomersatisfaction,andincreaseflexibility(achefcancreatenewmenuitems,preparefoodforspecialeventsetc)

Identifying and eliminating bottlenecks. Bottlenecks are the steps in the process that take the longest. By identifying and eliminating bottlenecks, KFC can reduce the cycle time and improve throughput.

Thetotalprocess1stbatchrequired33.5minutes

Throughput=29dozenchicken/8hour~ 348pcsKomboPackagein8hour

There’sbottleneckfromtakechickenfromrefrigeratortoputintothefryer.Tobalancetheprocess,weneedtoadd1

chefandadd1fryer,thetotalcapacity/daywillincrease100%

theproduct-processmatrixofKFCwouldbethe"AssemblyLine"

FromtheBreakevendemand.add1newchef=BEP6.667unitsperyear.add1newfryer=BEP3.333unitsperyear.Add chefismoreexpensive,butthedemandwillincreaseduetoproductivityincrease,improvesatisficationandhelpnew jobdesk.

HerearesomespecificexamplesofhowKFCcanuseprocessanalysistoimproveitsbusiness:

Reducethetimeittakestofulfillcustomerordersbyaddingnewchef

Improvethequalityoffood.Thiscanbedonebyimplementingaqualitycontrolprocessthatensuresthatallfoodis preparedtothesamehighstandards.

Reducefoodwaste.Thiscanbedonebyimprovingtheaccuracyofinventoryforecastsandbyusingfreshingredients.

Improvecustomersatisfaction.Thiscanbedonebyprovidingbettercustomerserviceandbyimprovingthequalityof food.

KFCusewaitinganalysistomonitortheperformanceofitskitchen operationsandensurethattheyarealignedwithitsstrategiccapacity goals. KFCcusewaitinganalysistotracktheaveragewaittimefor customers.Thisinformationthenbeusedtomakeadjustmentstothe kitchenprocessasneeded.

ThroughprocessanalysisatKFC,we'vedeterminedthattheadditionof1chef effectivelybalancesthedailymenuproductioncapacityandtime.

Inourwaitinglineanalysis,weaimtoquantifytheeffectsofthecurrentsituation(no addchef)versusthenewscenario(with1extrachef) intermsofcustomerwaiting timesandorderprocessingattherestaurant.

howfoodordersflowthroughthekitchen,Averagewaitingtimeforcustomers, Averagequeuelength,Probabilityofacustomerhavingtowaitinline.

Inthissectionyou’llfind:

1.

CalculatingWaitingLinecurrentsituation

2.

CalculationWaitingLineafteradd1newchef

3.

Comparingcurrentvsnewscenario

4.

Conclusion

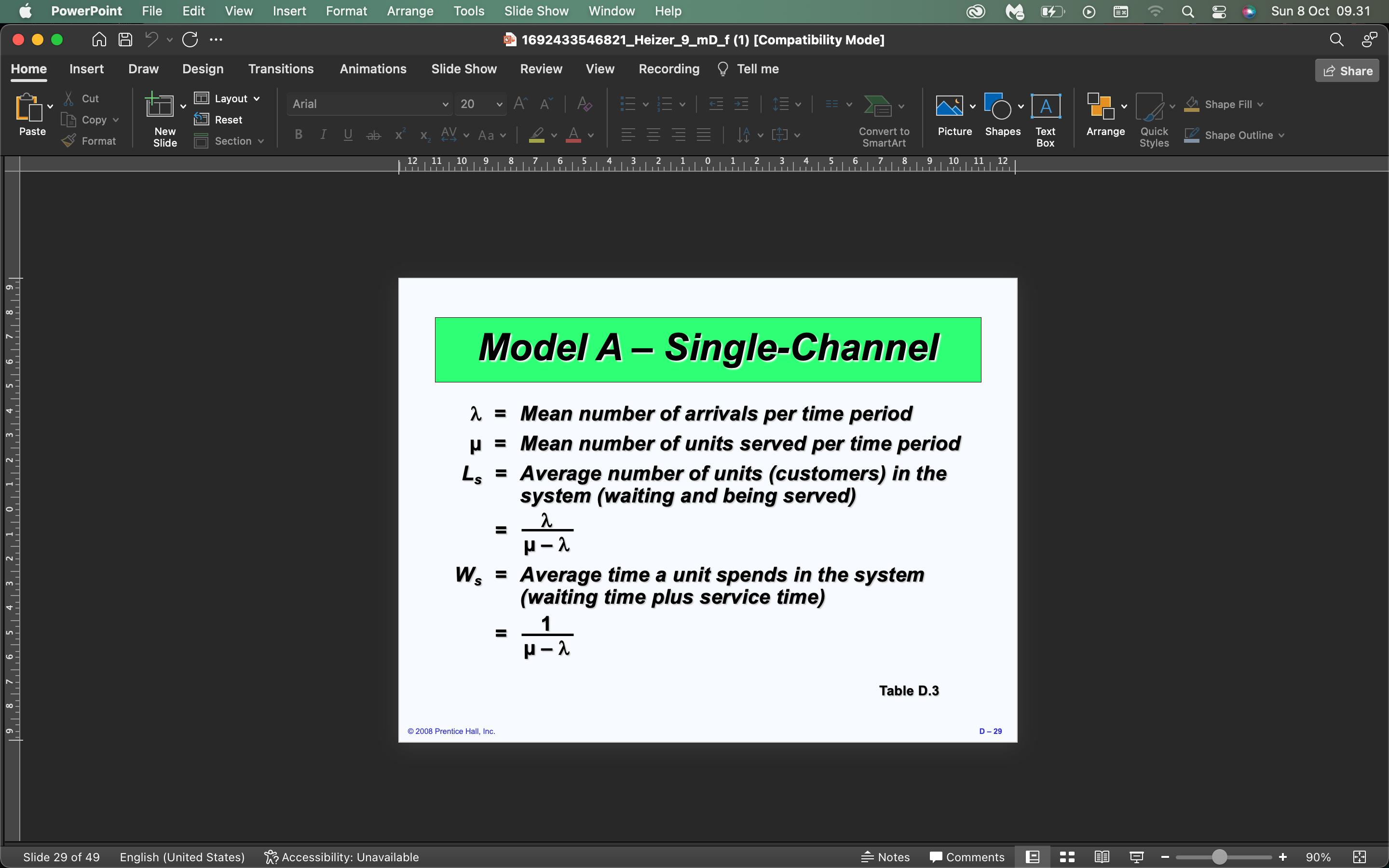

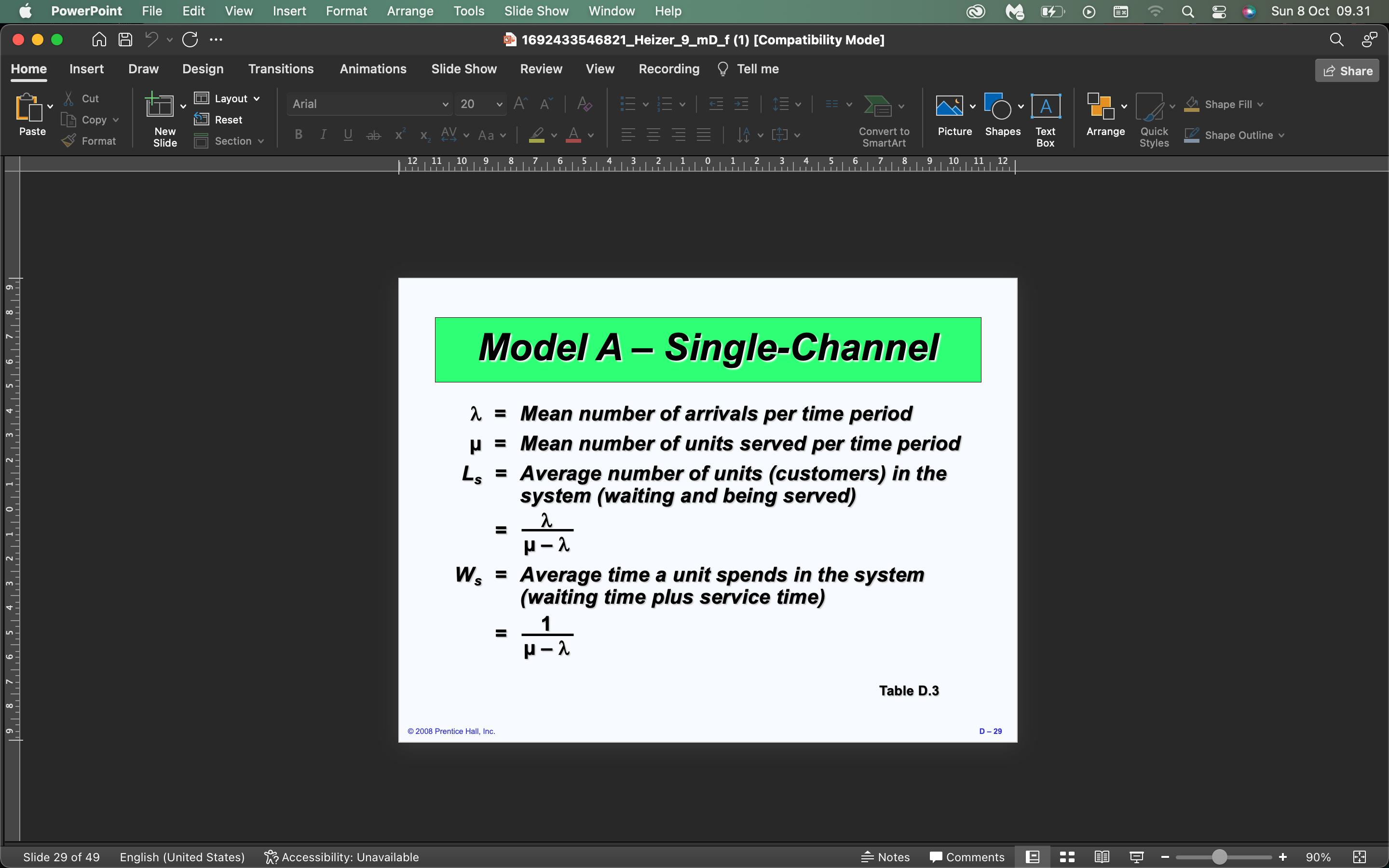

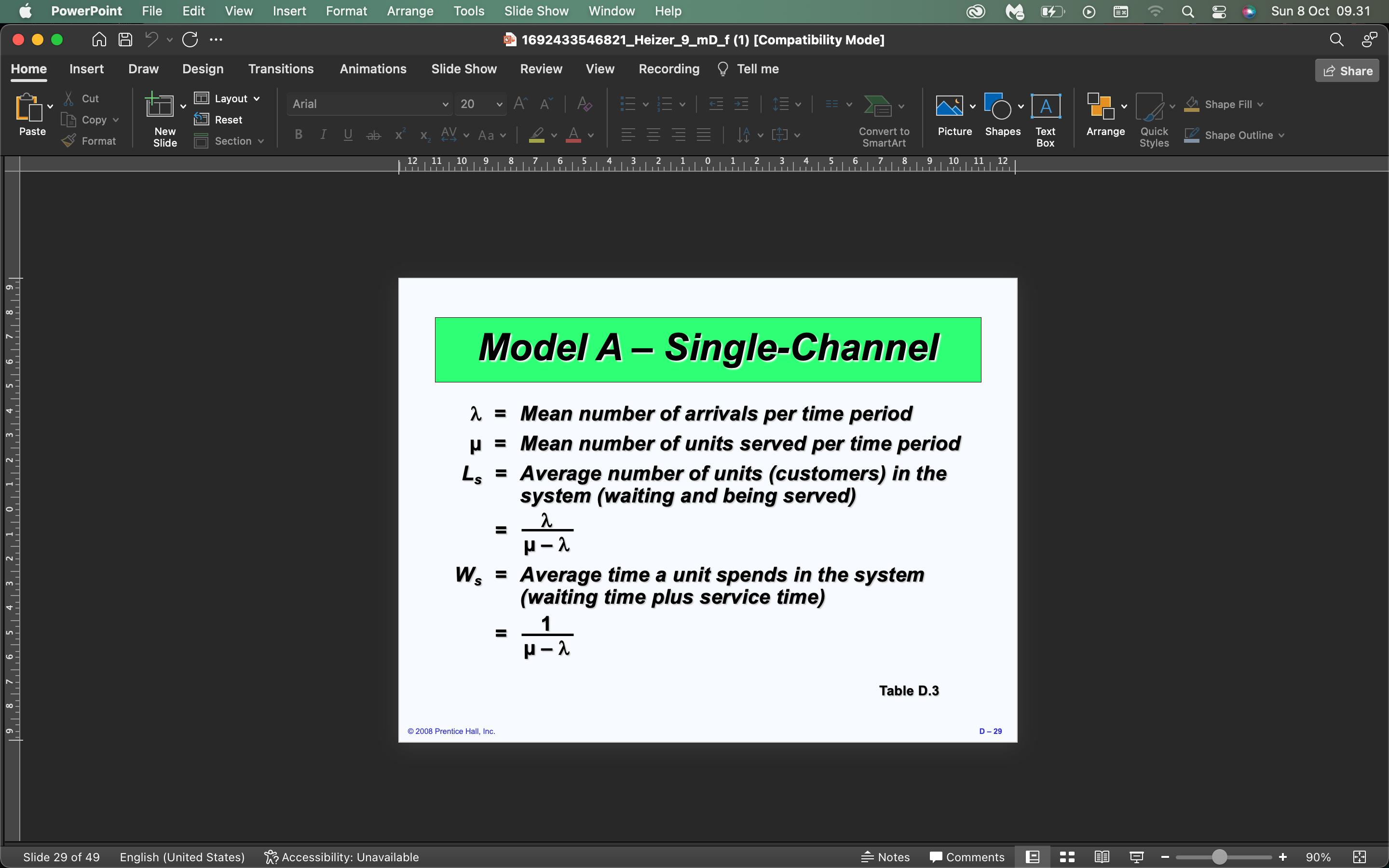

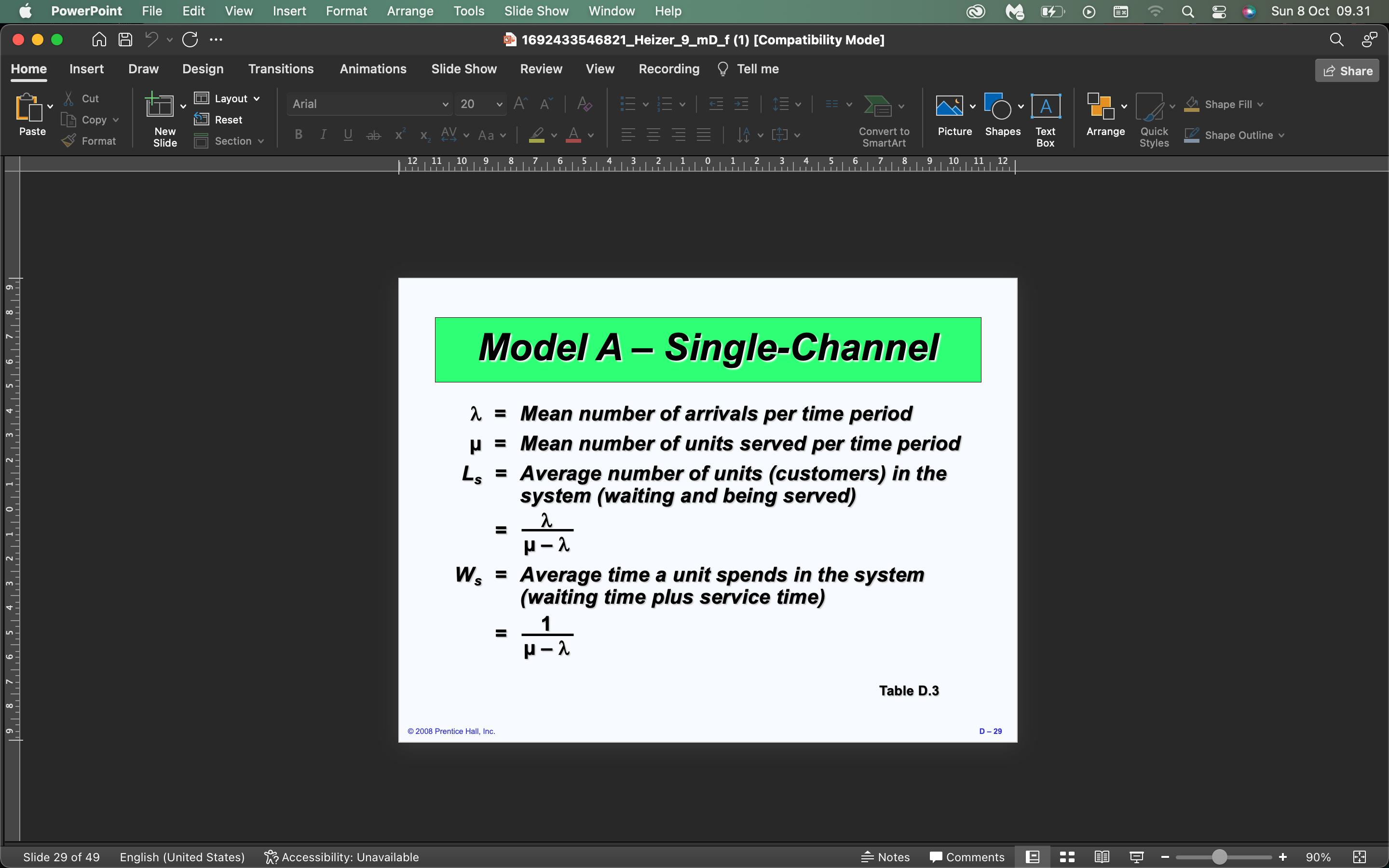

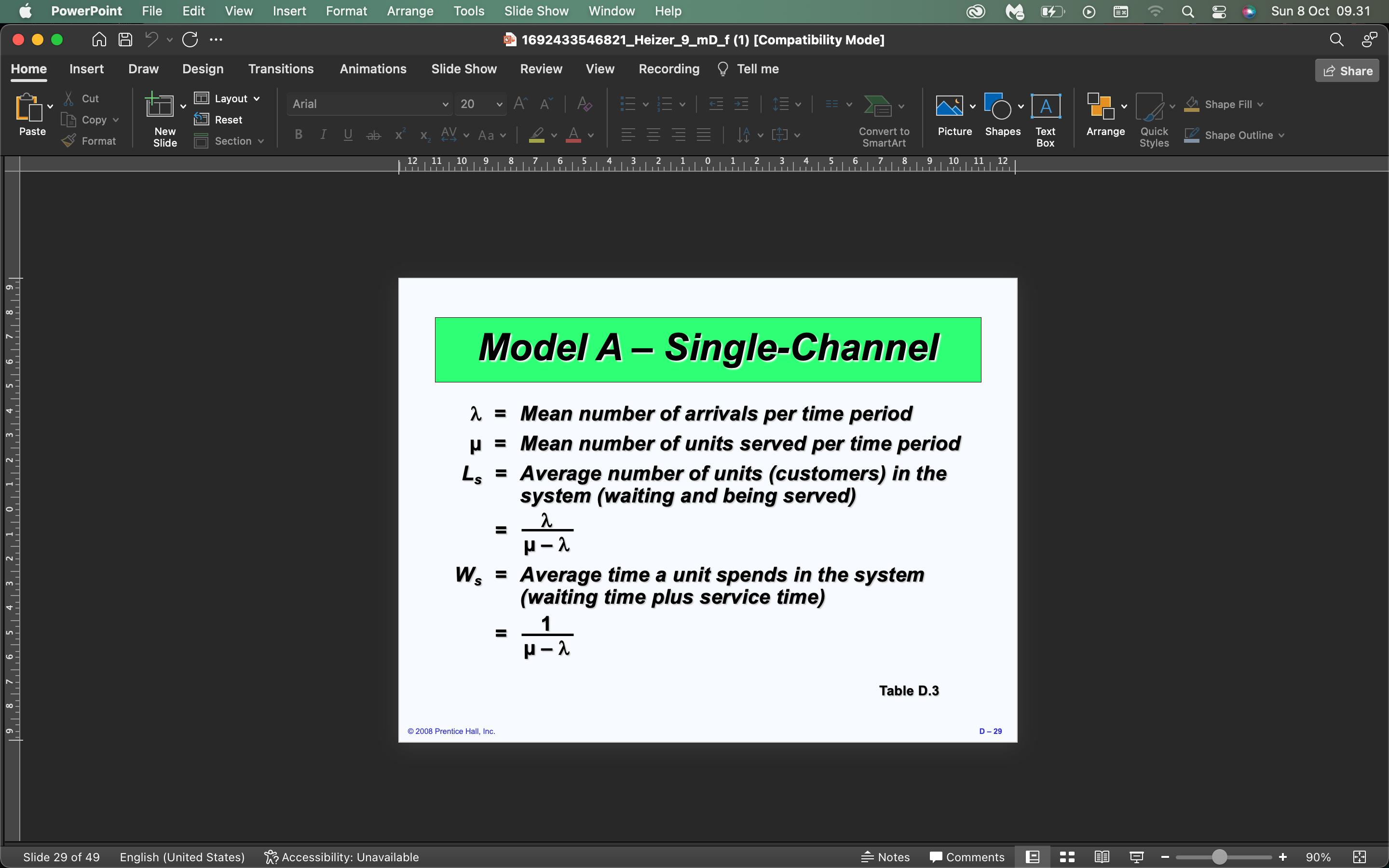

Waitinglineanalysisisamathematicaltechniqueusedtoanalyzeandmodelqueuingsystems.Itcanbeusedtounderstandhow customersflowthroughasystem,identifybottlenecks,andimprovetheefficiencyofthesystem.

InthecontextofKFCkitchenproduction,waitinglineanalysiscanbeusedtounderstandhowfoodordersflowthroughthekitchen, identifywherebottlenecksoccur,andimprovetheefficiencyofthekitchenoperation.

Asinglechannel-singlephasewaitinglinesystemisaqueuingsystemwherethereisonlyoneserver(thekitchen)andonephaseof service(preparingthefood).

Themodelcanbeusedtocalculatethefollowingmetrics:

Theaveragewaitingtimeforcustomers

Theaveragequeuelength

Theprobabilityofacustomerhavingtowaitinline

Theprobabilityofacustomerhavingtowaitlongerthanacertainamountoftime

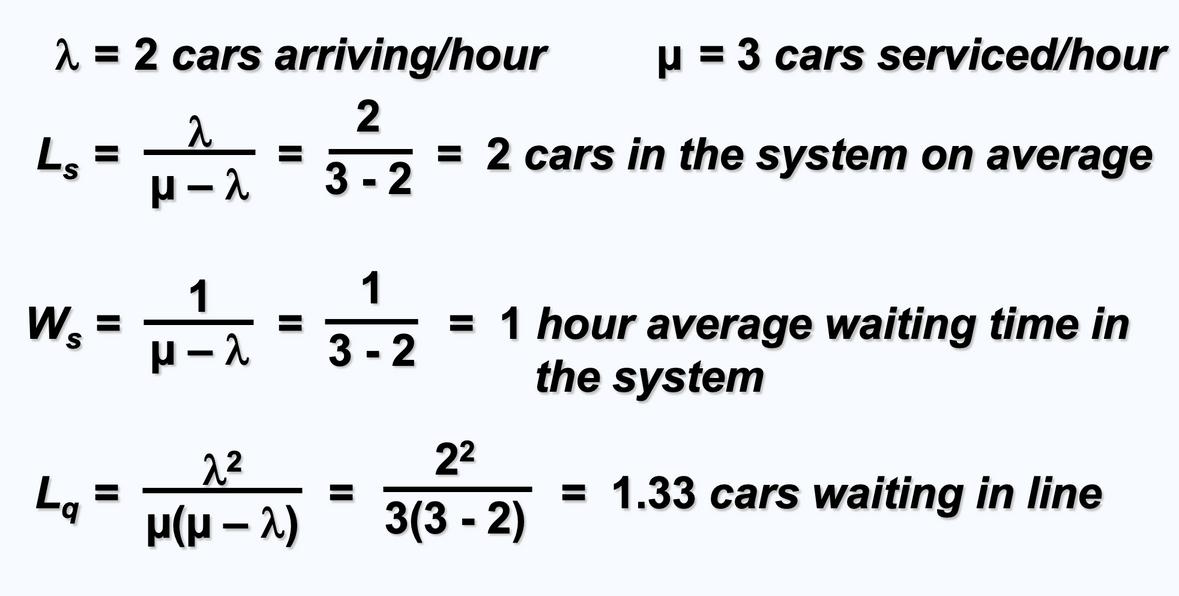

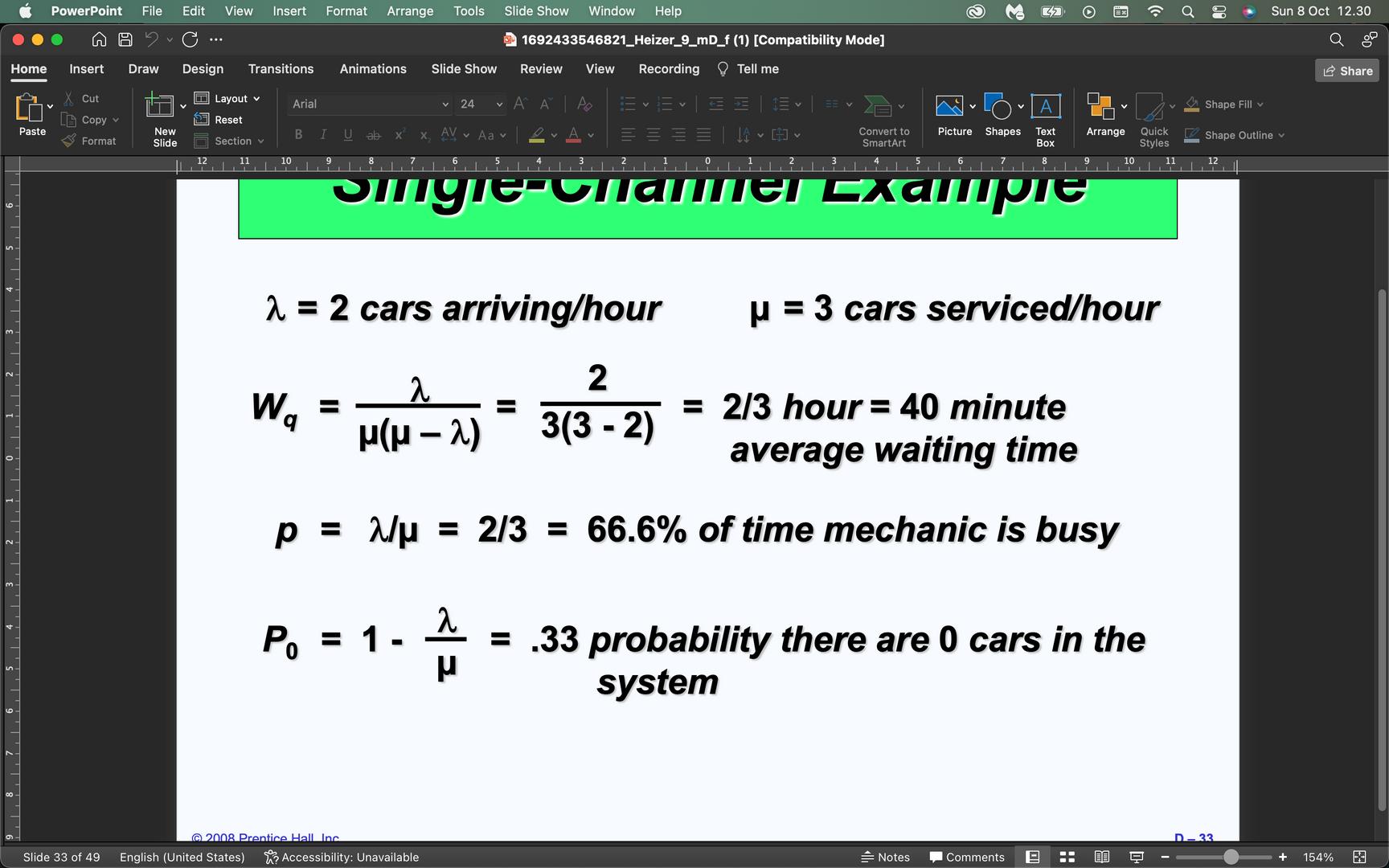

Question:HowcanKFCimprovetheefficiencyofitskitchenoperationsandreducethewaitingtimeforcustomers?calculate

Averagewaitingtimeforcustomers,Averagequeuelength, Probabilityofacustomerhavingtowaitinline

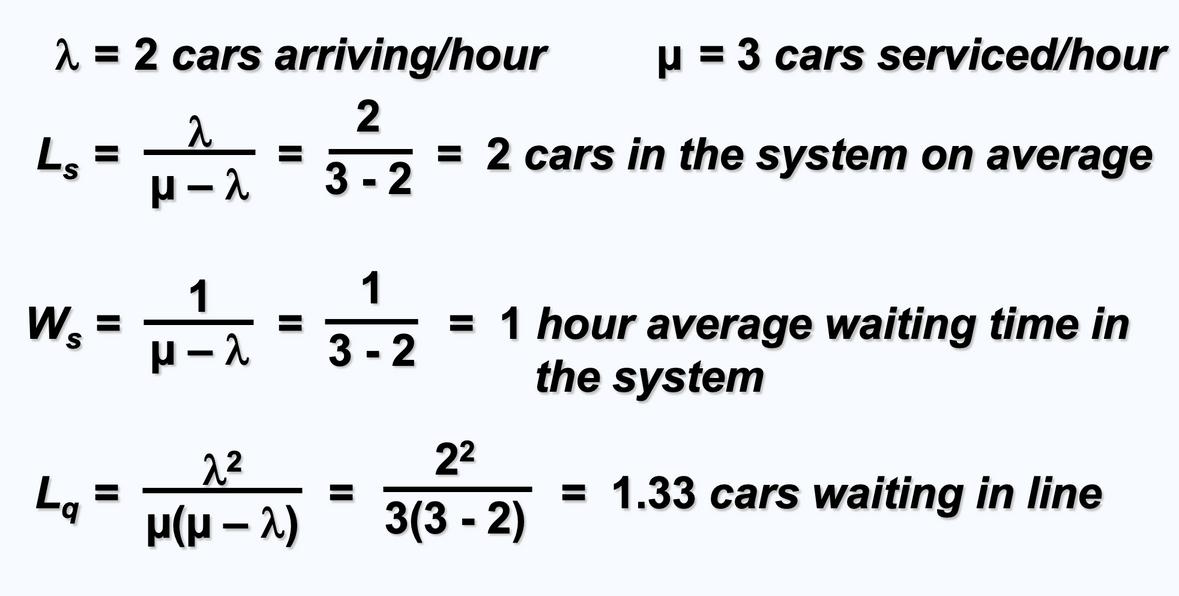

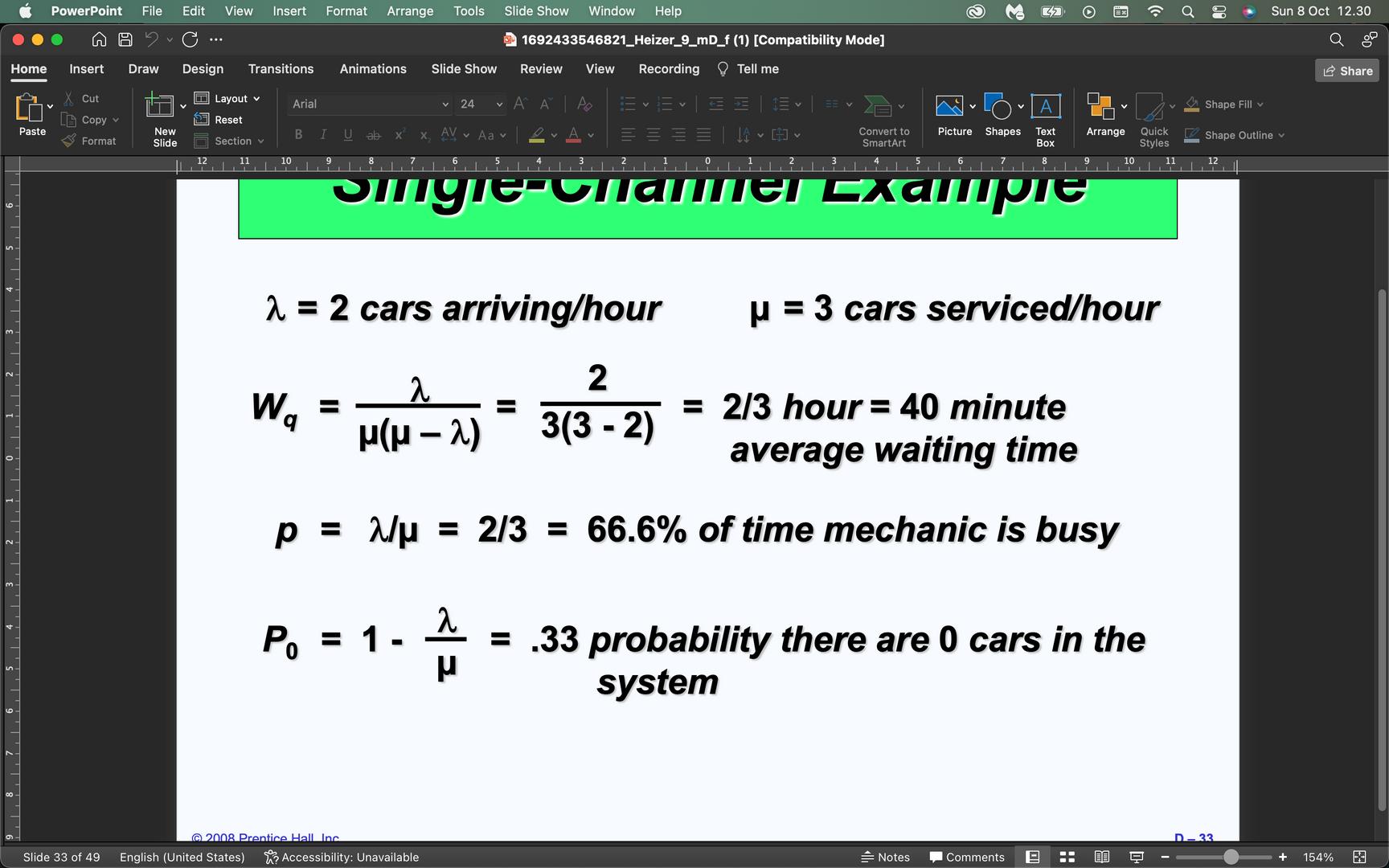

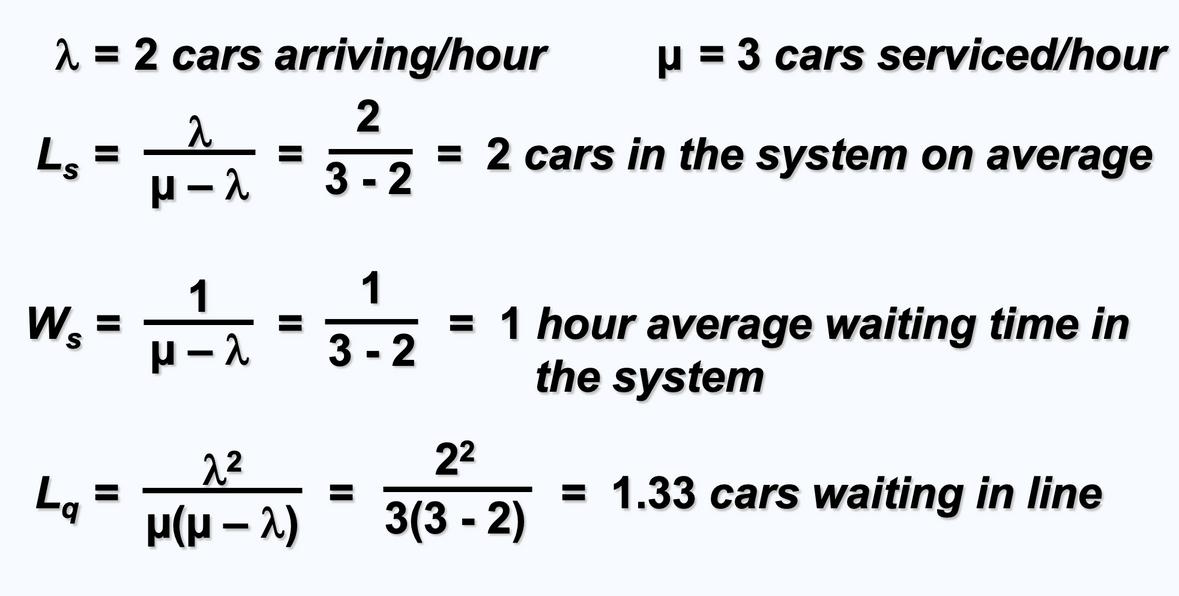

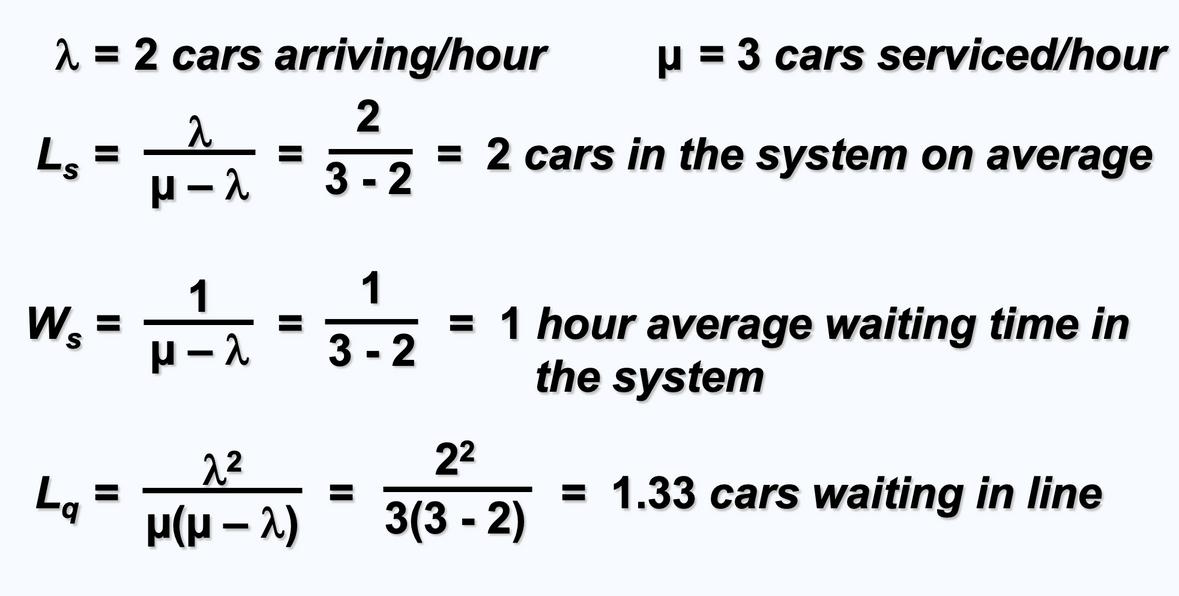

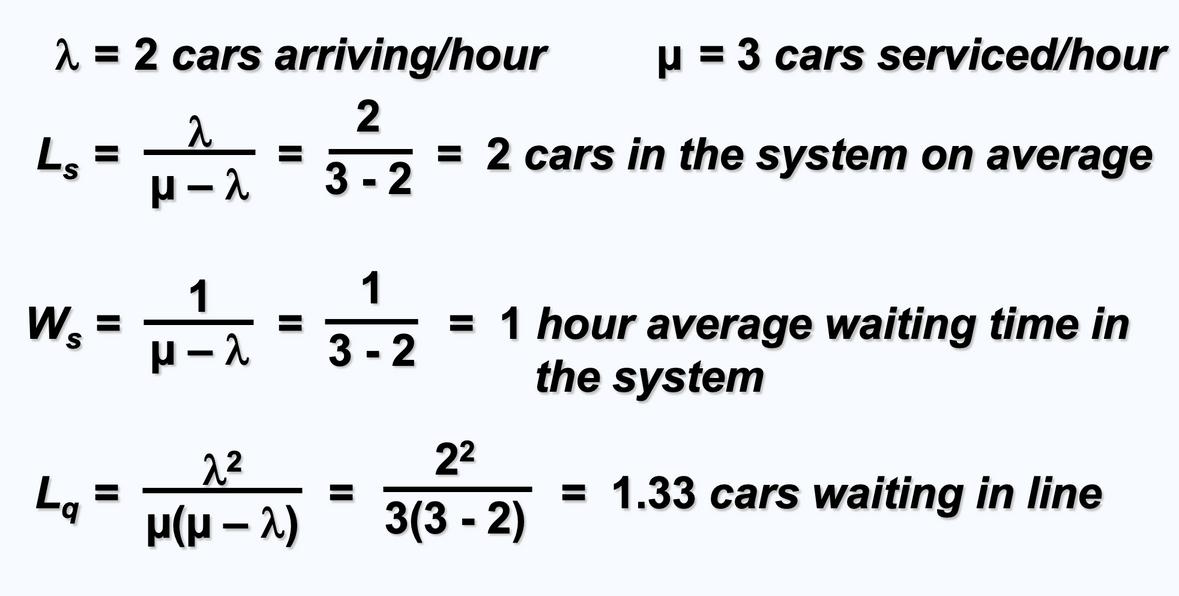

Assumptioncurrent(2chef)

Thearrivalrateofcustomersis30customersperhour.

Averagenumberofunitswaitinginthequeue

=4customers

Theservicerateofthekitchenis45ordersperhour.

Thenumberofcustomersinthesystemis30

Theaveragewaitingtimeforcustomersinsystem

Averagetimeaunitspendsinthesystem

= = hour

=2customersinthesystemonaverage =4minutesaverage waitingtimeinsystem

waitingtimeinthesystem

Averagetimeaunitspendswaitinginthequeue

hour

=2.67minutesaverage waitingtime

Utilizationfactorforthesystem

30/45=67%thekitchenarebusy

Probabilityof0unitsinthesystem

=0.33probabilitythereare0customersin thesystem

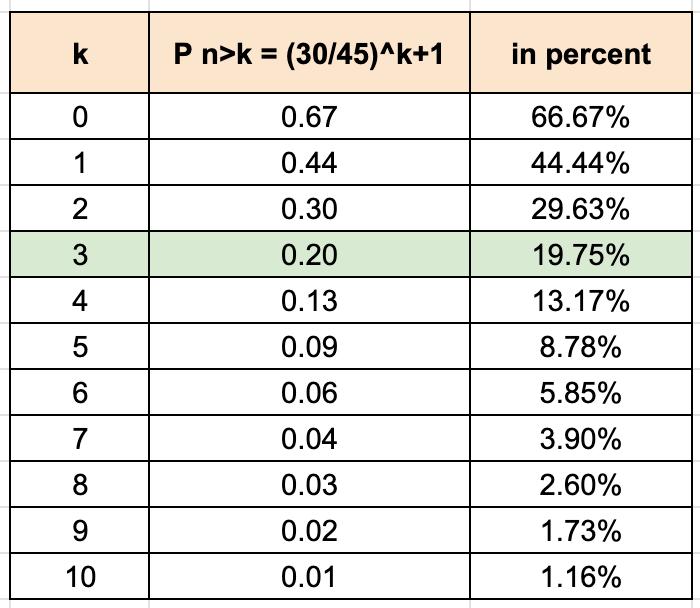

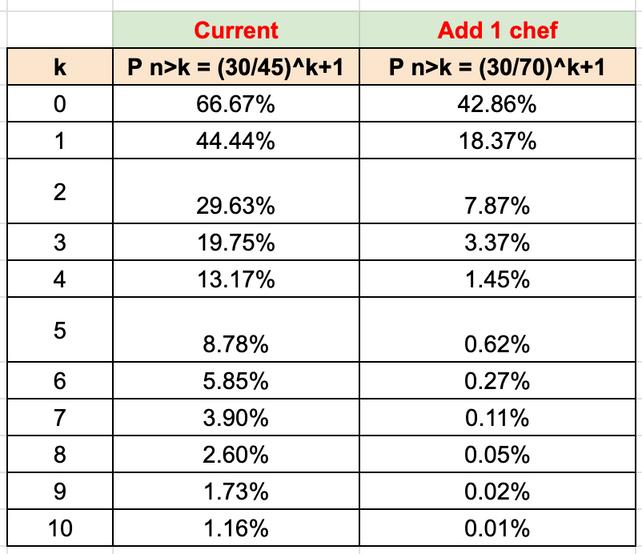

Afterthat,wecalculateprobabilitykcustomersinthesystemtogetfoodfromthekitchen

Assumptioncurrent

Thearrivalrateofcustomersis 30customersperhour.

Theservicerateofthekitchenis 45ordersperhour.

Thenumberofcustomersin thesystemis30

Probabilityofmorethan0unitsinthesystem,wherenis

thenumberofunitsinthesystem

Impliesthatthereisa 19.75%chancethatmore than3customersarein thesystem

Wesawthattheprobabilityof0customerwaitnginfrontis66%,andprobability3customerwaitinqueuesystemis19.75%

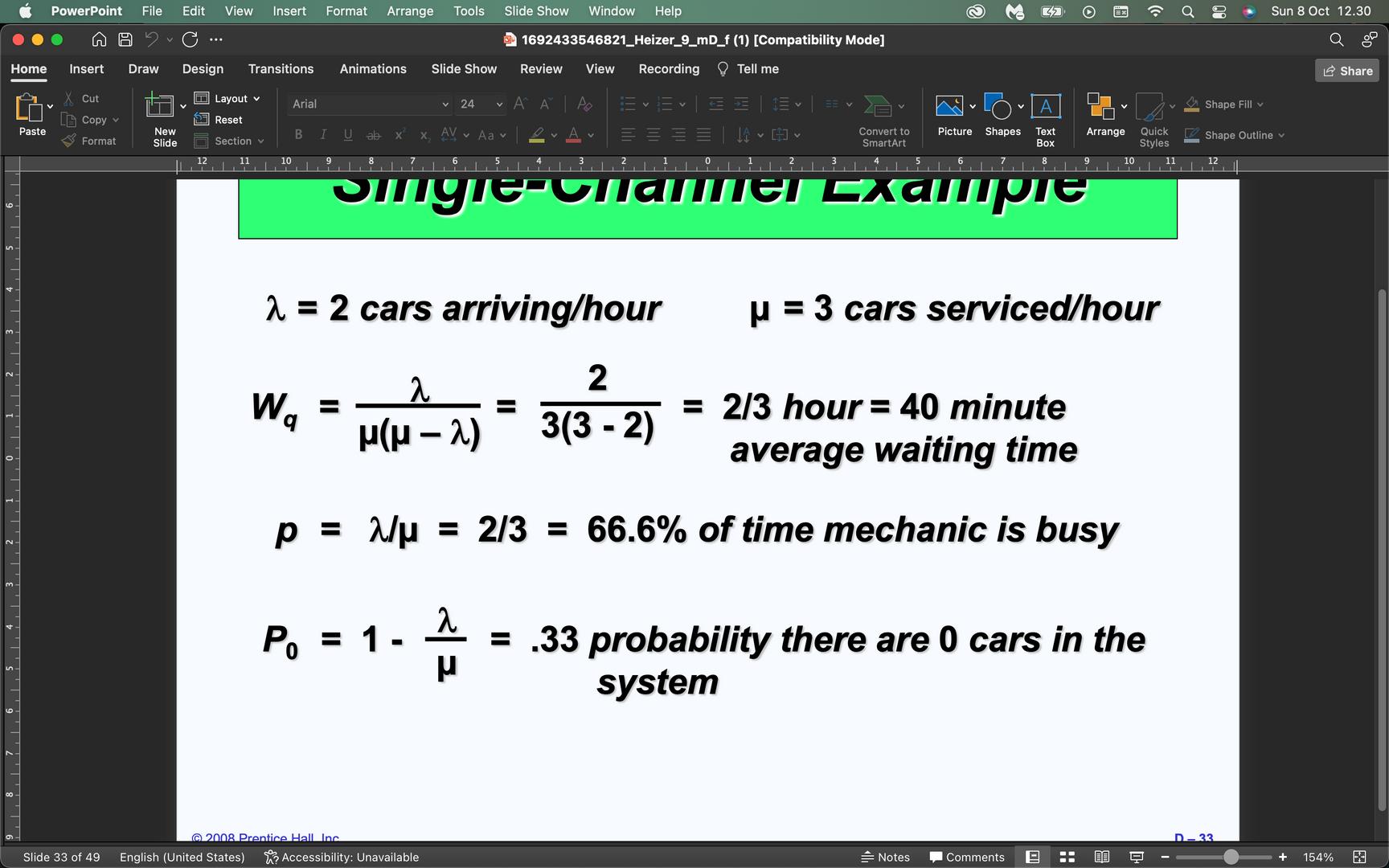

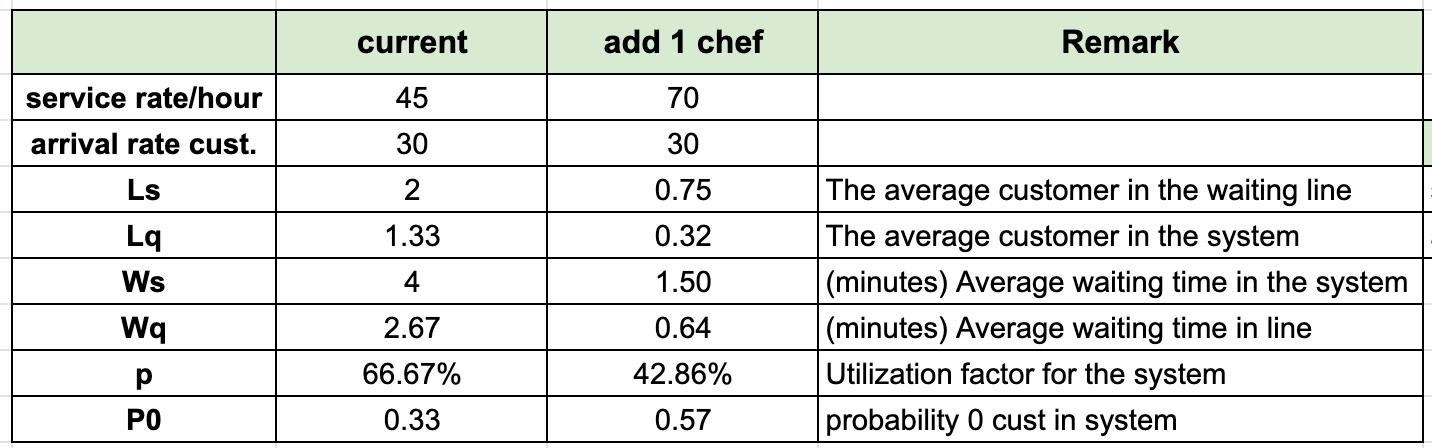

Afterwecalculatethecurrentsituation,weneedtoknowaboutwaitinganalysissaferweadd1newchef,thedifferencein servicerate=70ordersperhour(increase55%)

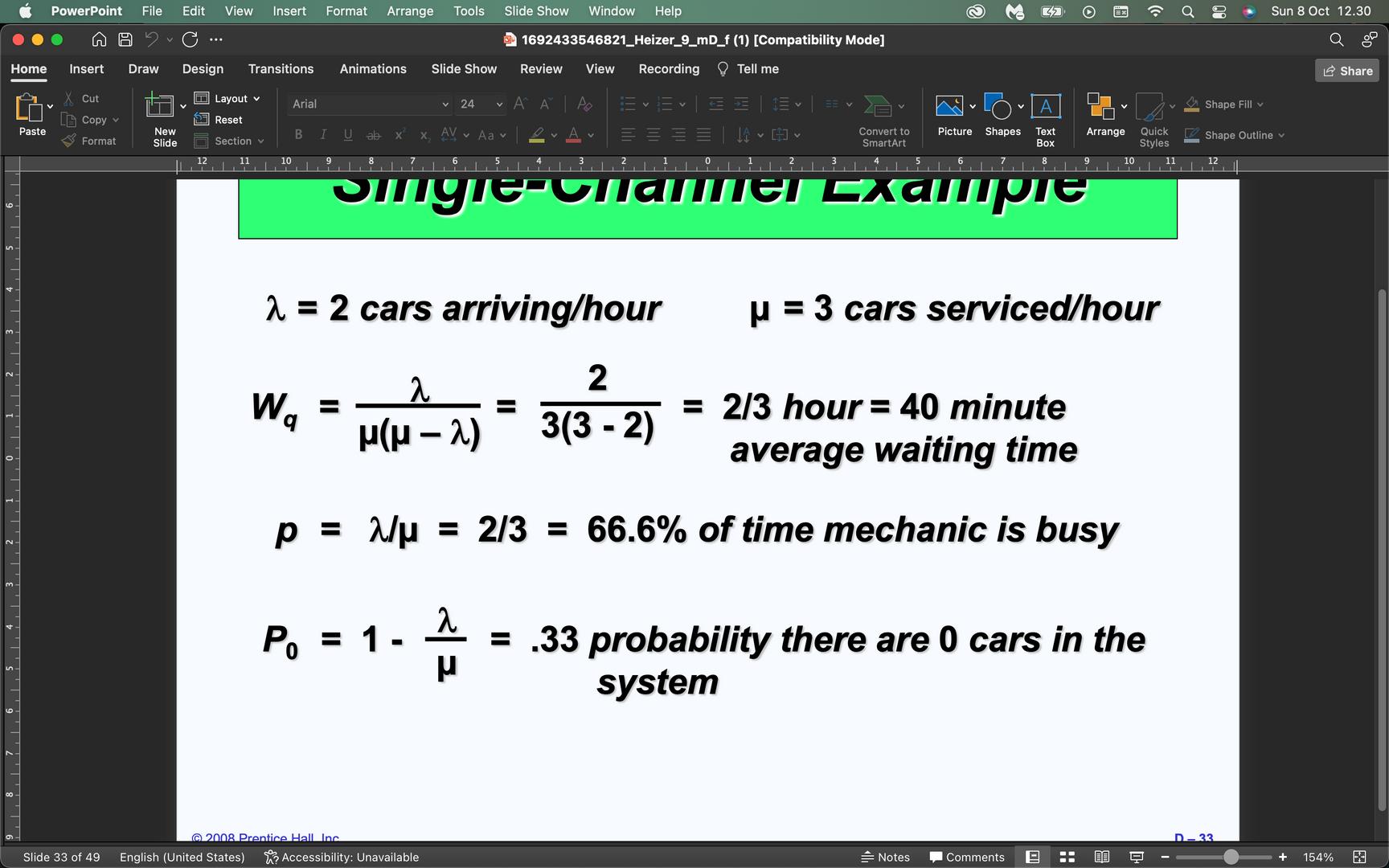

AssumptionNewscenario(3chef)

Thearrivalrateofcustomersis30customersperhour.

Theservicerateofthekitchenis70ordersperhour.

Averagenumberofunitswaitinginthequeue

=0.32~0customers

Thenumberofcustomersinthesystemis30

Theaveragewaitingtimeforcustomersinsystem

=1customersinthesystemonaverage

Averagetimeaunitspendsinthesystem

= hour

Averagetimeaunitspendswaitinginthequeue

waitingtimeinthesystem =

=1.5minutesaverage waitingtimeinsystem

=0.64minutesaverage waitingtime

Utilizationfactorforthesystem

30/70=43%thekitchenarebusy

Probabilityof0unitsinthesystem

=0.57probabilitythereare0customersin thesystem

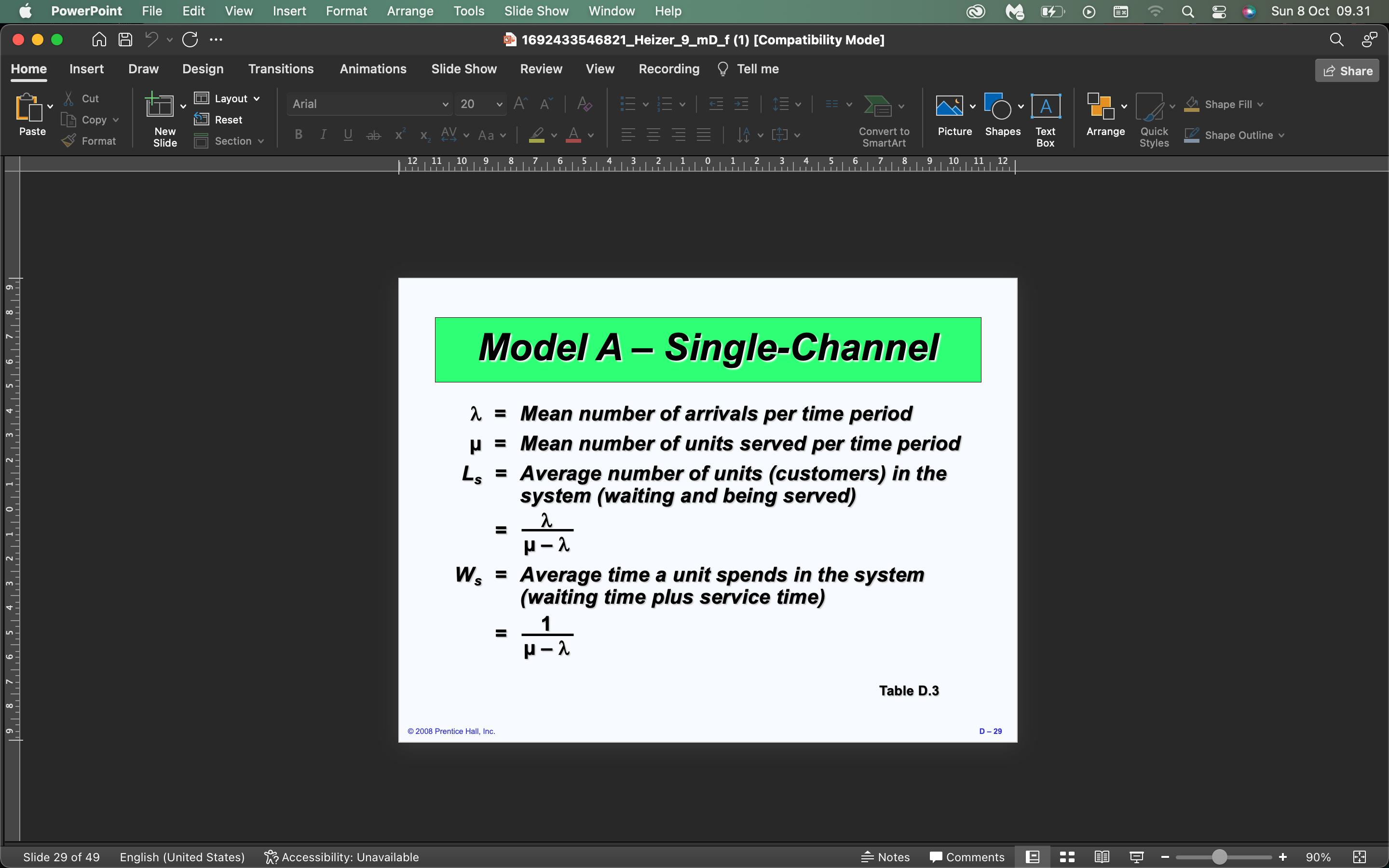

Thisisthetablesummaryofcomparisonbetweencurrentvsadd1chef.Ifweadd1chef,there’spositiveimpactthat

Averagewaitingtimeinsystemdecreased(from4minutesto1.5min)->sothatthecustomercanimmediatelygetafood.

Theaveragecustomerinwaitinglineisdecreasedfrom2to1costomer,thisispositiveimpactsotheCustomersaremore likelytobesatisfiedwiththeirexperienceandKFC'sbrandimagewouldbeenhancedasabusinessthatisknownforhaving shortwaittimes.

Probabilityofmorethan0unitsinthesystem,wherenisthe numberofunitsinthesystem

To improve the efficiency of the kitchen and reduce the waiting time for customers, Here are the things they can do :

Changing thewaythatfoodordersareprepared,suchaspreparingKombopackage(Chicken,rice,drink)inadvance becauseitisfavoritemenu

Implementingaqueuingsystemthatgivesprioritytocustomerswhohaveorderedmorecomplexortime-consumingmenus

Theimpactofadd1newchef:Averagewaitingtimeinsystemdecreased(4minutesto1.5min),averagecustomerinwaitingline isdecreasedfrom2to1cust.

In1day(8hours),KFCcanreduce487minutesofcustomerwaitingtimeinlineperday

Customers are satisfied with their experience if they don't have to wait a long time in line.

Customers who are satisfied with their experience are more likely to return and make repeat purchases

Employees are more likely to be happy and productive if they are not constantly rushed and stressed

Business that is known for having short wait times.

KFC'sComboPackagemenuis expectedtoincrease significantlyoverthenextthree years(YoYincrease10%),the impacttoconsiderare:

Capacitymanagementto meetdemand

Bottleneckinthekitchen processanalysis

Waitingtimeimpactto accomodatedemand

Themanagementhasoptionto hirenewcheforbuynewfryer tofulfillthedemand.

Wedeterminetheprocessofkitchenfor making1Combopackagechicken.

Afterweknowthedemandof ComboPacakgewillincrease, First,wemakeflowchartandstepof activitiesfromordercamein-fryingthe chicken-packaging-orderclose

then,weanalysisthesales growthfornext3years (increased10%YoY)

KFCinyear2&3willgoingto beovercapacity(106%and 122%utilizationrate)

Totackletheissue,thereare3 strategiestoconsider:Add newchef,buynewfryer,and addnewcashier.

Then,Wecalculatethedecision treetoknowthehighestvalue ofeachoption

Theconclusionis:Addinga chefisisthehighestexpected value,withanexpectedvalue of$356,000.Thisofthethree optionsthatleadtobestoption forfuture.

Thetotalprocess1stbatchrequired33.5 minutes

Throughput=348KomboPackage/8 hour~10.440pcs/month

Thevalue=$26.100/month

There’sbottleneckprocessfromtake chickenfromrefrigeratortoputintothe fryer.Tobalancetheprocess,weneedto add1chefandadd1fryer,thetotal capacity/daywillincrease100%

TheBEPforadd1newchef6.667unitsper year.add1newfryer=BEP3.333unitsper year(Addchefismoreexpensive,butthe demandwillincreaseduetoproductivity increase)

Wechoosetoaddnewcheftobalancing theprocess,Reducethecustomertime, improvequalityoffood

ThroughprocessanalysisatKFC, we 'vedeterminedthattheaddition of1chefeffectivelybalancesthe production.Then,Weanalyze waitinglineofcurrentsituationvs newscenario(+1chef)intermsof customerwaitingtimesandorder processingattherestaurant.

Theimpactofadd1newchef: Averagewaitingtimeinsystem decreased(4minutesto1.5min), averagecustomerinwaitinglineis decreasedfrom2to1cust.

In1day(8hours),KFCcanreduce 487minutesofcustomerwaiting timeinlineperday thisispositiveimpactsothe

Customersaremorelikelytobe satisfiedwiththeirexperienceand KFC'sbrandimagewouldbe enhancedasabusinessthatis knownforhavingshortwaittimes.