Leading provider of cathodic protection solutions with over 40 years of experience.

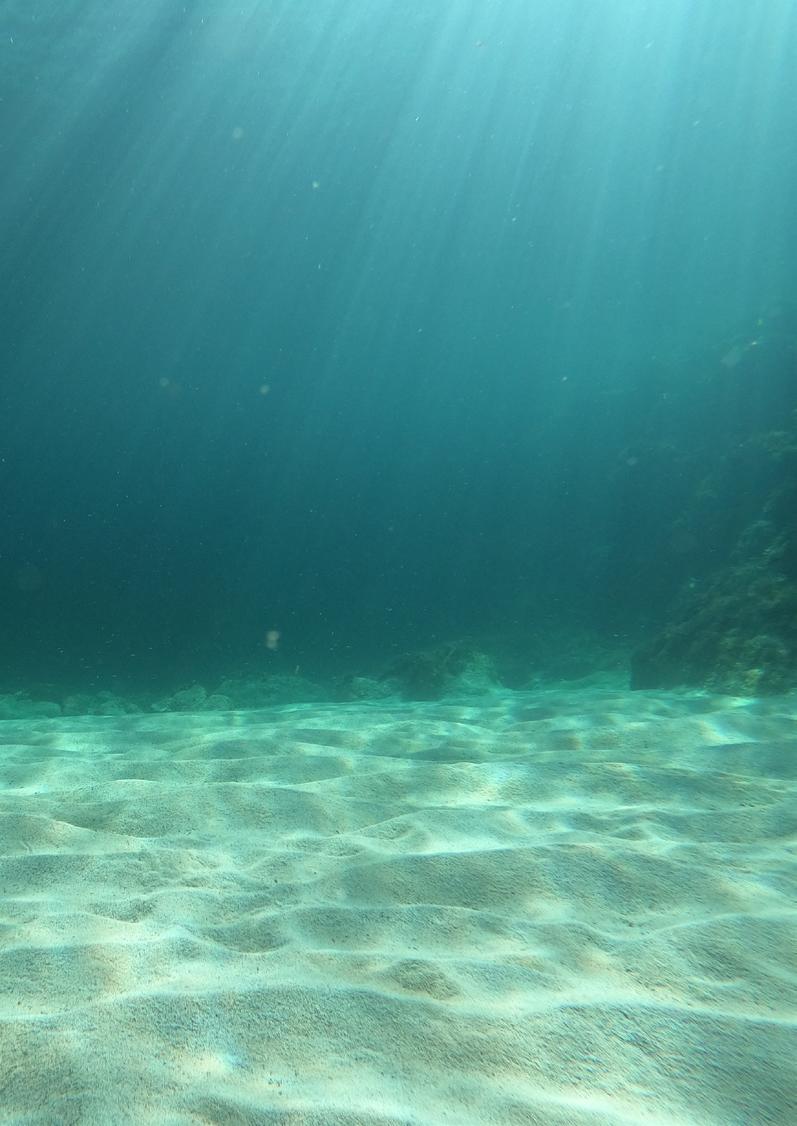

Corrosion remains one of the most persistent challenges in infrastructure, quietly compromising the strength, safety, and longevity of vital assets. From pipelines and offshore platforms to bridges and wind turbines, structures are constantly exposed to environmental forces that cause gradual, often unseen, deterioration.

If left unmanaged, corrosion can lead to critical performance failures, environmental damage, and significant financial consequences. That’s why proactive corrosion control is essential to maintain operational reliability and extend asset life.

Cathodic protection (CP) is a cornerstone in the global fight against corrosion. Trusted across industries for its reliability and effectiveness, CP acts as a protective barrier—shielding metal structures from corrosive forces. By utilising sacrificial anodes or impressed current systems, CP actively redirects electrochemical activity, preventing corrosion from taking hold on key infrastructure components.

We specialise in delivering high-quality cathodic protection solutions tailored to meet the unique needs of your infrastructure. With an unwavering commitment to Health, Safety, Environment, and Quality (HSEQ) and operational excellence, we provide comprehensive solutions designed to enhance the longevity and integrity of your assets in even the most challenging environments.

With more than 40 years of worldwide experience in cathodic protection, our team has been the backbone of our continued success. We take pride not only in our technical proficiency but also in the core values that define us - integrity, reliability, and a strong commitment to our customers.

Partner with us to protect the future of your infrastructure, leveraging the power of cathodic protection and the expertise that has defined Stork’s reputation for decades.

We take pride in our ability to support a variety of top-tier clients by providing trusted solutions globally.

As the industry partner of choice, we deliver unique packages that combine technical excellence and knowledge-based engineering, with practical field-based experience.

• Consultation, FEED (front end engineering design) and supply of CP systems

• Installation and commissioning management

• Maritime dry-dock integrity checks

• ICCP system healthcare

• CP survey and evaluation/auditing of existing systems

• Interference, evaluation and mitigation studies

• Comprehensive data analysis, management and continuous monitoring

• Corrosion root cause investigation and simulation studies

• Long-term simulation of gathered data

• CP life-extension and retrofit systems

THE INDUSTRIES WE SERVE OFFSHORE WIND

OFFSHORE/ONSHORE PIPELINES

CATHODIC PROTECTION SYSTEMS & DESIGN

Stork provides comprehensive cathodic protection engineering solutions for both marine and land-based applications.

With extensive expertise in galvanic anode and impressed current systems, we offer tailored solutions that empower industries to tackle corrosion effectively. As a trusted partner, Stork supports clients throughout the entire process, ensuring long-term asset protection and performance.

Our services include:

• Site Survey and Data Gathering

• Design and Engineering

• Installation and Commissioning

• Troubleshooting and System Optimisation

• Routine Specialised Testing and Monitoring Services

• Interference Evaluation and Mitigation Studies

• Comprehensive Data Analysis, Management, and Continuous Monitoring

• CP Life Extension Studies

FROM INITIAL ASSESSMENTS TO ONGOING SYSTEM OPTIMISATION, STORK IS COMMITTED TO DELIVERING INNOVATIVE, RELIABLE, AND COST-EFFECTIVE CATHODIC PROTECTION SOLUTIONS.

DETAILED DESIGN & ENGINEERING

• Review of requirements and site surveys

• Detailed designs tailored to our client’s requirements

• Installation management

• System commissioning and handover

MONITORING & MAINTENANCE

• Routine and specialised testing and monitoring

• Troubleshooting and system optimisation

• System health checks and maintenance

• Data management and reporting

• Simulation studies and consultancy

LIFE EXTENSION & RETROFIT

• Life extension assessments

• Simulation and modelling

• Retrofit design and implementation

• Maintenance and monitoring programs

• System upgrades with the latest innovative solutions

In the ever-evolving landscape of infrastructure management, ensuring the integrity and longevity of critical assets is paramount. Cathodic protection survey plays a pivotal role in this endeavour, serving as a vital tool to assess, diagnose and address corrosion threats.

With an excess of over 70,000km of pipelines and thousands of structures surveyed globally, we’ve delivered industry leading reliability and provided actionable insights empowering our clients to mitigate risks, extend their asset’s lifespan and ensure operational reliability, all while achieving regulatory compliance.

SUBSEA CP SURVEY SYSTEM (SubCAPSS)

• Continuous measurement of CP potential, field gradient and current density

• Detect active coating damage

• Calculate anode current output and remaining life predictions

• Does not require continuous contact with the pipeline

• Proven equipment reliability and robust design

• CP and FG value can be displayed real time on video overlay

• Temperature & resistivity measurements

• Measurement of pipeline CP potential

• Allows for rapid rate of survey

• Generally adopted for CP inspections of shallow water pipeline shore approaches, where vessels and work class ROV cannot operate

• Measurement of asset CP potential

• Commonly used for ports and harbours, vessels and monopiles

• The CP diver probe is designed to allow a diver to make quick, convenient Cathodic Protection (CP) measurements of underwater structures

• Compact, rugged designed tool for use with any diver survey on pipelines, harbours ships or oil and gas platforms

CLOSE INTERVAL PROXIMITY SURVEY (CIPS)

• Above ground, nonintrusive survey

• Accurately determine the effectiveness of a cathodic protection system along the entire buried or immersed pipeline route

• Both ‘On’ and ‘Instant Off’ potentials recorded

• Pipe to soil potentials are measured at nominal 1-2m intervals

• Comparison with static, potential/ time plots indicates if stray current is present

DIRECT CURRENT VOLTAGE GRADIENT (DCVG)

• Above ground, nonintrusive survey

• Provides an accurate detection of coating defects by means of measuring voltage gradients within the soil

• Can be used to estimate the size of a coating defect

REMOTE MONITORING SYSTEMS

• Remote monitoring systems are designed to allow continuous monitoring of CP systems.

• Real time data captured remotely

• Data analysis and automated digital reporting

• Increased asset integrity and lifetime due to outages being detected earlier

SOIL RESISTIVITY TESTING

• Assess the corrosiveness of the soil

• Measurement recorded in the field

• Essential parameter for CP design calculations

Type of facility: offshore wind farm

Industry: offshore renewable energy

Site location: North Sea

Safety: no incidents occurred

Efficiencies: the scope was delivered on time and In budget

Our cathodic protection and corrosion surveys provide critical data to help understand the effectiveness of the asset’s cathodic protection system. This determines if corrosion is fully arrested. In turn CP provides asset owners with assurance on the long term health of their assets. Stork ’s experts were contracted to perform a cathodic protection dip/drop cell survey at an offshore wind farm based in the North Sea.

Stork efficiently mobilised highly competent personnel to site, despite challenging sea and weather conditions, successfully surveyed 19 monopiles.

The final report, which was put through a stringent two-stage verification process by our data analysis and report writing team, to ensure accuracy and reliability, was delivered to the client within only a few days.

Work was completed to the highest standards and within the client’s expected time frame and budget.

By carrying out this cathodic protection survey it was confirmed that all monopiles were well protected against external corrosion.

Being proactive and flexible throughout the planning of the project, enabled us to support and manage the requirements and challenges faced with operations during the ongoing Covid-19 pandemic.

As a partner of choice, Stork is now supporting further cathodic protection survey requirements at the same offshore wind farm.