QUASAR CONSULTING GROUP

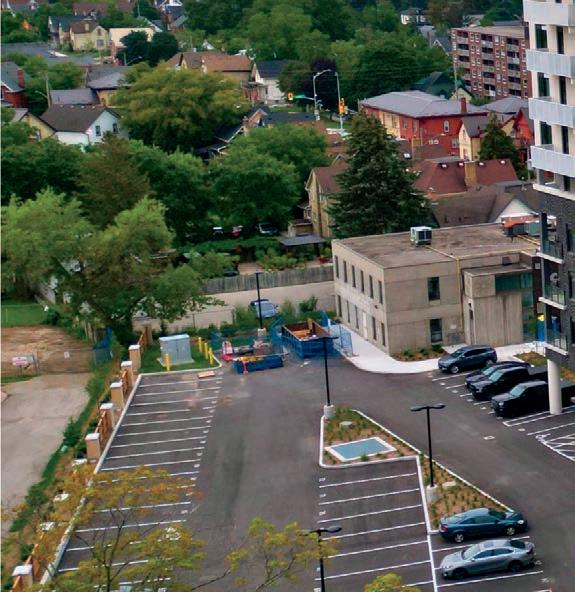

Total Precast Concrete Key Attributes to Passive House Development are:

· Manufactured in local precast facilities under controlled conditions

· The whole building envelope in one composite panel; air barrier, moisture control, insulation and the structure

· Hollowcore floor slabs allow for a much lower depth to span ratio

· Hollowcore provides the lowest GWP per m2 of concrete floor area

· Precast concrete dramatically reduces the construction schedule, site congestion, noise and environmental impacts

For more information and educational presentations check out Learn on Demand, a 24/7/365 Educational Platform. Visit: cpci-learnondemand.com/

For more information on Passive House Total Precast Concrete, visit www.cpci.ca/publications to download your free copies of the Structural Solutions Guide and the Putman Family YWCA Total Precast Concrete Case Study.

Project: The Putman Family YWCA, Hamilton, ON Architect: Kearns Mancini Architects Inc., Toronto, ON

5

RAIC PERSPECTIVE

Moving the RAIC Climate Action and Enablement Plan forward at Congress 2023.

6

THE FUTURE OF ENGINEERING

Sustainability, innovation, and empowerment: inside the world of Quasar.

11

A CLEAR VIEW TO TOMORROW

Remarkable advances reshape Canada’s curtain wall and window wall landscape.

21

SEALING IN SUCCESS

The growing demand for energy-efficient and airtight buildings sparks fascinating breakthroughs in building envelope solutions.

SOLID DEFENCE

The metal roofing and cladding industry shows resilience with larger projects and high-performance designs.

HEART OF STONE

Harnessing diversity and innovations to thrive amidst inflation hurdles in the masonry sector.

SLICE OF DESIGN HEAVEN

Exploring the hottest kitchen trends and products of 2023.

Cutting-edge technology ignites major advancements in the electrical and communications systems industry.

Blending architecture and artistry in state-of-the-art lighting.

Experts weigh in on the future of the sector amidst economic headwinds.

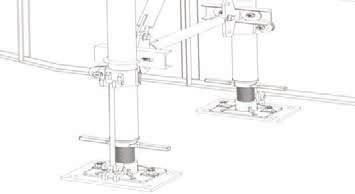

Who We Are

The Fence People Limited has been a Southern Ontario Fence Contractor since 1986. We service the Commercial, Industrial & Institutional industry.

We bring to the market a unique modular Plywood Hoarding, Covered Walkway & Overhead Gate Protection system.

Due to the modular nature of our Products We have the capability of Constructing Various structures & o er many Solutions.

Our in-house Manufacturing Allows us to respond Quickly to Customized Requirements.

•WE SUPPLY YOU WITH DESIGN & ENGINEERING

•ALL PRODUCTS & FINISHES ARE ENVIRONMENT FRIENDLY

•98% OF LUMBER COMPONENTS ARE RECYCLABLE

•WE STRICKLY WORK FROM OUR INVENTORY

SEPTEMBER 2023

VOLUME 37 | NUMBER 3

PUBLISHER

Dan Chapman

dchapman@canadawide.com

604.473.0316

EDITOR Natalie Bruckner nbruckner@canadawide.com

SENIOR

Scott Laurie slaurie@canadawide.com

McLachlan

604.299.2116

1.800.663.0518 subscriptions@canadawide.com

Moving the RAIC Climate Action and Enablement Plan forward at Congress 2023

As a human crisis, climate change urgently requires solutions that will demand collaboration across all professions, sectors of the economy, and spheres of life. This is particularly important for the building sector, which is one of Canada’s highest carbon emitters. Reducing the environmental impact of buildings is vital – but what is the role of architects and architecture in imagining and creating a climateresilient future?

The RAIC Climate Action Engagement and Enablement Plan (CAEEP) builds on a series of resolutions, strategic actions, activities, and events hosted and/or convened by the RAIC that started in October 2019, with the Resolution for Urgent and Sustained Action on Climate and Ecological Health. The resolution, developed and sponsored by the RAIC Committee on Regenerative Environments (CORE), was the RAIC Board’s commitment to develop a Climate Action Plan with a focus on education, advocacy, and practice.

This resolution paved the way for the RAIC board to establish a Climate Action Plan Steering Committee and to embed climate action in the organizations’ strategic priorities.

In 2020, 2021, and 2022, the Climate Jam and Congress on Architecture events provided opportunities for discussion on climate action and architecture, and for advancing the CAEEP. This year, Congress 2023 will be the culmination of 18 months of work by the RAIC Climate Action Engagement and Enablement Plan Steering Committee, in collaboration with working groups that have been actively engaging Canada’s architectural community in the development of the CAP.

For the first time since the Congress on Architecture was launched, this year’s event will take place in person – in Whistler, B.C. on October 2 to 3, 2023. The Congress includes three events over two days.

On October 2, World Architecture Day, the RAIC Congress on Architecture will focus on informing the development of the Climate Action Plan. Framed by a conversation on Indigenous perspectives and ecological knowledges in relation to climate action, the day will also include a look at CAEEP engagement themes to-date and close with an interprofessional discussion focused on collaboration to accelerate action. This event takes place at the Squamish – Lil’wat Cultural Centre, designed by Formline Architecture (formerly Alfred Waugh Architect) in association with contract administration architect Ratio Architecture in 2008, which showcases the culture and history of the two First Nations communities in the Whistler area.

Following this discussion, a World Architecture Day reception will be held in the evening of October 2 at the Audain Art Museum, designed by Patkau Architects and opened in 2016. Architect John Patkau and engineer Stuart Hood (Introba) will share insights on the architectural

challenges, design development, and sustainability goals of the building in the context of the demanding mechanical and environmental requirements for a museum.

Lastly, this year presents a special opportunity – an open access Low-Carbon Education Workshop, which will take place on October 3 at the Fairmont Chateau Whistler. In collaboration with the Canada Green Building Council and supported by the Government of Canada, this architect-specific workshop was developed in collaboration with the RAIC’s Low Carbon Education Advisory Group and key subject-matter experts, and is part of the Sectoral Workforce Solutions Program – a broader project to train and upskill the building design and construction workforce in low-carbon skills. The workshop is offered for free to architects, landscape architects, interns, technologists, and students, and covers the following areas:

1. Climate Change Literacy Foundations

2. Climate-Responsive Design Foundations

3. Making the Case for Change

4. Integrative Design Thinking and Regenerative Design

The aim of the RAIC’s Climate Action Engagement and Enablement Plan process has been to foster a comprehensive and inclusive dialogue for the CAEEP, because everyone has a stake in the future. The more voices we include, the better we can adapt and respond to the impact of the climate crisis.

There is still time to contribute to this process – you can join us in Whistler at Congress 2023 on October 2 to 3, and play your part in shaping a sustainable and resilient future. Registration is open until September 15, 2023. raic.org/2023-congress-architecture A

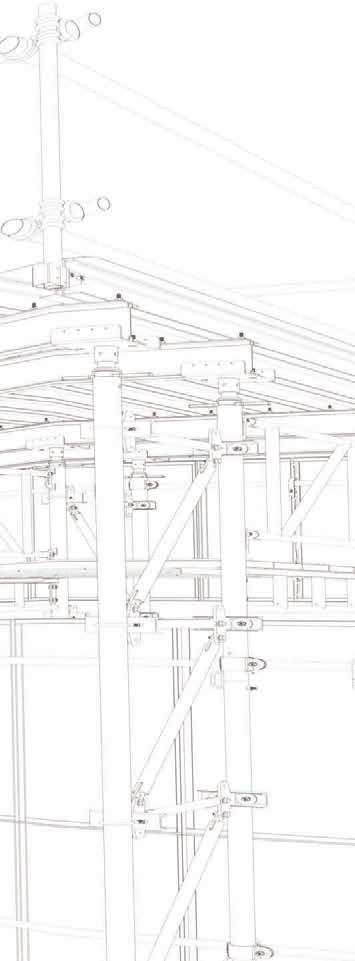

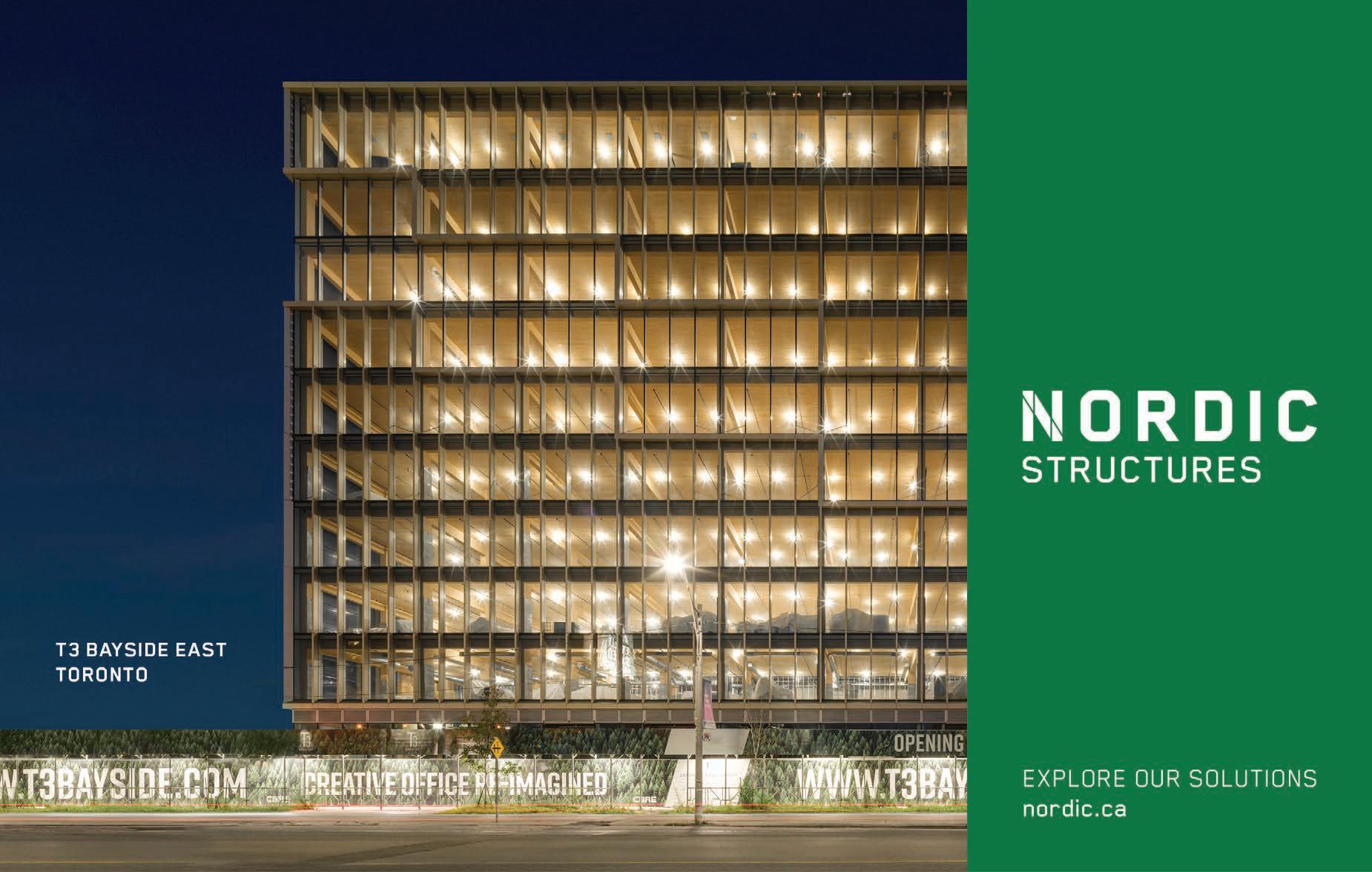

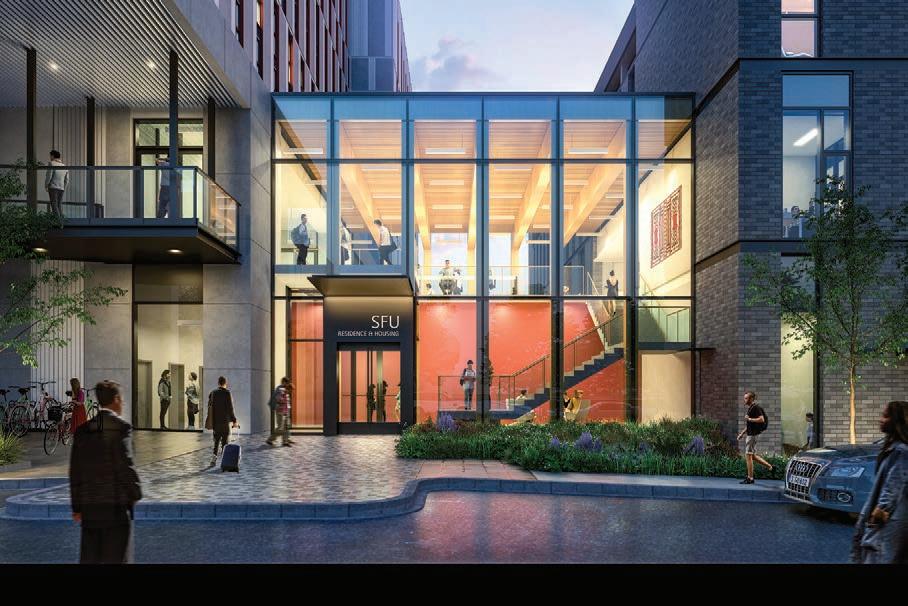

The Future Of Engineering

Sustainability, innovation, and empowerment: inside the world of Quasar

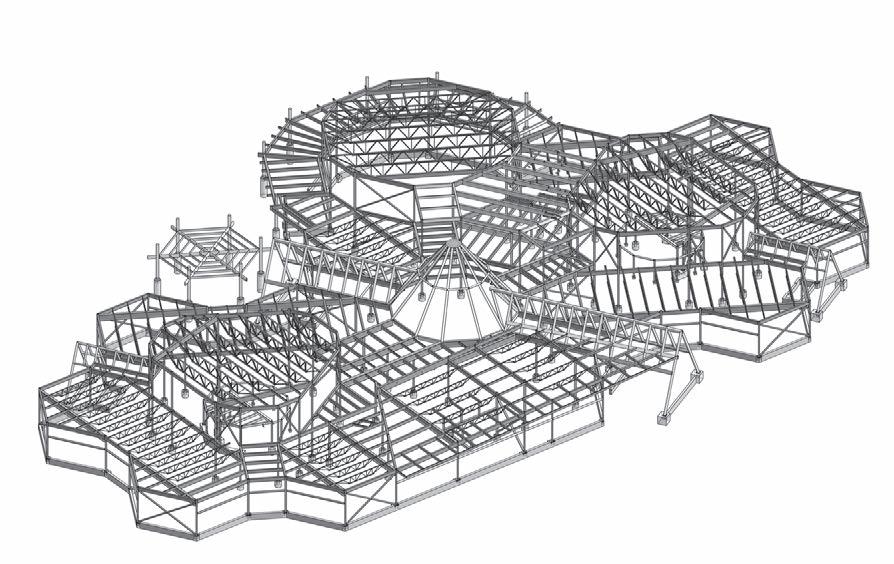

by NATALIE BRUCKNER | photography & renderings provided by QUASAR CONSULTING GROUP

In the ever-evolving world of engineering consultancy, Quasar Consulting Group (Quasar) shines as a beacon of innovation and excellence. Since its inception in 2018, this visionary firm has had a passion for revolutionizing the construction industry, captivating the hearts of professionals across Canada. With a passion for people, a drive for pushing boundaries, and an unwavering commitment to delivering exceptional results, Quasar is helping transform the landscape of engineering consultancy.

Quasar’s journey started less than a decade ago, as Kenan Huskovic, Quasar’s CEO explains: “On March 12, 2018, through an acquisition from Racon – a mechanical and electrical engineering firm founded in 1993 – Quasar Consulting Group [Quasar] opened its doors. The vision at the time was very simple and stands firm today: to introduce a new type of consulting engineering company to the market that is led by a collection of experienced, recognized industry professionals who share one common vision. We provide uncompromising quality; unmatched service to our employees, clients, and industry partners; and accountability to both staff and clients, all built on a foundation of strong external and internal relationships. This is reflected in our name, which is an acronym for quality, service, accountability, and relationships.”

Over the next couple of years, the company grew relatively quickly and moved into the Woodbridge office in the Summer of 2019. “We grew from 15 people in March 2018 to approximately 60 in early 2020. We opened an office in Ottawa in the fall of 2019, which is now 15 people strong and growing,” says Huskovic.

Quasar’s ascent continued with the acquisitions of Pratus Group in 2021 and Induspec in 2023. Huskovic explains: “Pratus Group – Quasar’s dedicated team of sustainability, building performance, ESG, and commissioning professionals – has driven our designs toward a more sustainable future.” In 2021, Quasar opened its Vancouver office, in 2022 they established their presence in Calgary, and in 2023 they established strong local presence in Northern Ontario through an acquisition of Induspec. Shortly thereafter they opened the North Bay office and also established presence in Montreal.

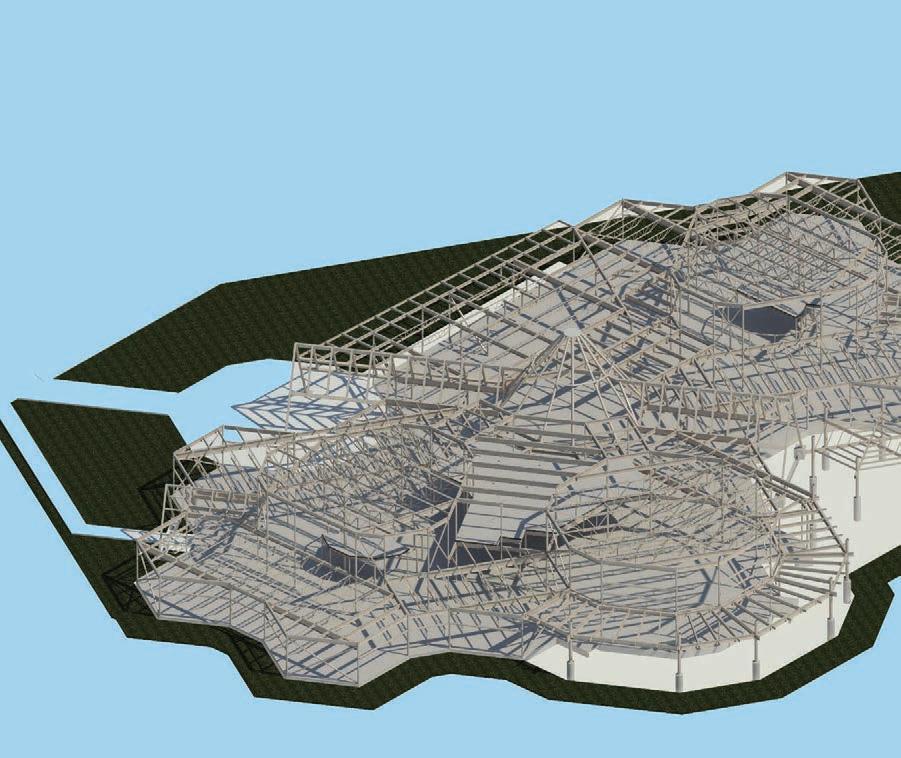

As the industry continues to undergo rapid transformation, Quasar remains at the forefront, embracing change as an opportunity for growth. The company takes pride in introducing ground-breaking products like the Citizen Care Pod, a COVID-19 smart screening and testing initiative. Huskovic states, “This innovative solution revolutionizes screening and testing, prioritizing public health and safety.” The Intelligent Structural Panel (ISP) is another marvel, streamlining construction while enhancing building performance and sustainability.

Quasar has its finger on the pulse of the industry, anticipating and embracing the changes that lie ahead. “We see the desire for new products and systems rising to meet the needs of our clients and communities – including prefabricated, modular, and volumetric construction and highly smart buildings. We also know that Canada has aggressive net zero targets to reduce greenhouse gas emissions, and the building industry holds in their hands a great amount of opportunity to make change,” says Huskovic.

While Quasar has been involved in numerous standout projects, Lakeridge Gardens accelerated long-term care, which was awarded Best Project, Health Care in the ENR 2022 Global Best Projects Awards, is one that demonstrates Quasar’s ability to adapt and pivot. “What is unique about this project is the accelerated schedule for completion of 18 months from the start of design procurement to construction completion. The aggressive schedule was enabled by the extensive use of modular components prefabricated off-site and delivered for final assembly,” Huskovic explains.

Other projects that showcase the company’s versatility include Toronto General Hospital’s ground-breaking Organ Regeneration Laboratory, the Toronto Zoo Conservation Campus, the Ministry of Education’s new Rapid Build Pilot Program, and Toronto Police Service’s Division 41 – the service’s first facility designed in compliance with the Zero Carbon Building standard, with solar panels and a large green roof.

A visit to any of Quasar’s offices offers a glimpse into their vibrant and collaborative culture. While each office has its unique characteristics, they all share the “Quasar vibe” of openness, camaraderie, and social interaction. “We use our offices to enhance our collaboration, training, and to build relationships both internally and externally – it’s important that we feel comfortable with each other, similar to a work family. Everyone is welcome at any office, no matter the location,” says Huskovic.

When it comes to the future of engineering consultancy and the industry as a whole, the team at Quasar is most excited about the industry’s evolving mindset. “We are excited to see our clients and partners think outside the box when it comes to tackling change in our industry, climate or otherwise, through new processes and technology,” explains Huskovic.

The team is proud to be part of this movement, working hand-in-hand with visionary teams and industry partners who are committed to driving positive change. By collaborating with like-minded individuals and organizations, Quasar believes they can create a better quality of life for communities and contribute to a more sustainable and resilient future.

“We are seeing a shift away from ‘capital-only’ thinking. By working with teams and industry partners who are trying to move the needle by embracing change, we are providing solutions that are holistically more beneficial for the client, their users, and the communities they support. A key example of this is the small, but impactful inclusion of touch-free technology in the residential sector. While it has an impact on design and construction cost, these features have shown to result in a building with increased wellness scores, greater user comfort, and a higher client end-value,” says Huskovic.

Quasar Consulting Group has emerged as a trailblazer in the engineering consultancy field, redefining the boundaries of what is possible. “We are people-first and know that we can continue to drive change in our sphere of influence that creates a better quality of life for our communities,” concludes Huskovic. A

“ We are people-first and know that we can continue to drive change in our sphere of influence that creates a better quality of life for our communities.”

Kenan

RENDERING COURTESY WZMH ARCHITECTS

Huskovic

The Saint, 89 Church Street, Toronto, ON

Organ Regeneration Laboratory, TGH, Toronto, ON

Toronto Police Service 41 Division, Scarborough, ON

Lakeridge Gardens, Ajax, ON

WEST COAST CONTEMPORARY LINE

A custom home build is quite often the single largest investment in one’s life. This is a tremendous responsibility to entrust to the construction community.

Understanding this concept and exceeding customers’ expectations are what Westeck strives for and is at the core of the Westeck culture.

BIG PRODUCTS FOR ALL SIZES EMBRACE THE PATIO EXPERIENCE INDOOR/ OUTDOOR LIVING VANCOUVER 1480 Kootenay St, 1‑877‑606‑1166 CHILLIWACK 8104 Evans Rd 1‑877‑606‑1166

westeckwindows.com sales@westeckwindows.com

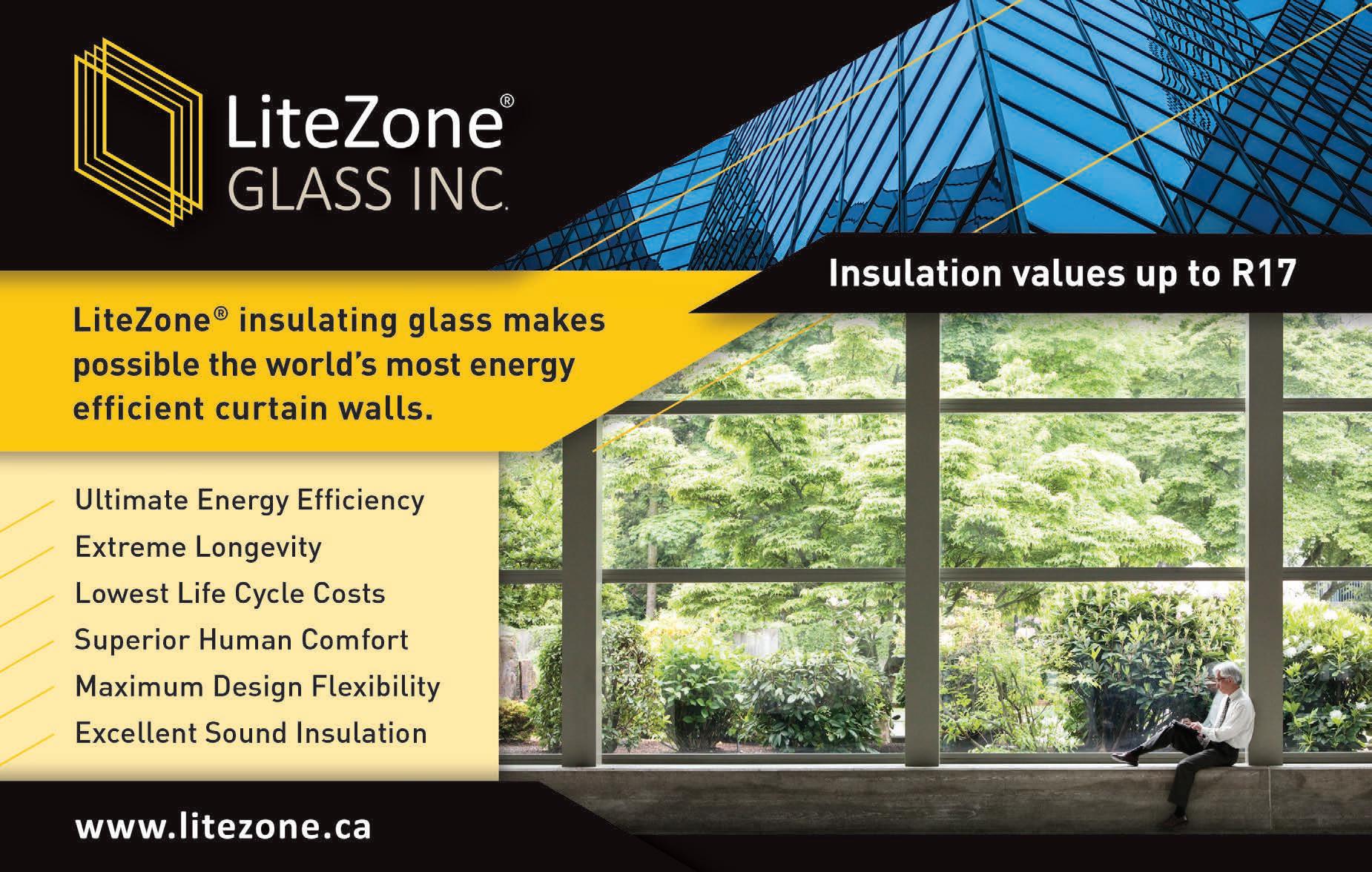

A Clear View To Tomorrow

Remarkable advances reshape Canada’s curtain wall and window wall landscape

by NATALIE BRUCKNER

As Canada’s curtain wall and window wall industry evolves to meet the changing needs of the built environment, remarkable advancements and transformative shifts are reshaping the landscape. Fuelled by emerging technologies, sustainability objectives, and a quest for enhanced performance, this industry is paving the way for innovative solutions. We delve into the cutting-edge developments and gain valuable insights from industry experts, shedding light on the exciting transformations taking place in Canada’s curtain wall and window wall sector.

EMERGING TRENDS

Michael Bousfield, technical director at Cascadia Windows & Doors, has observed a fascinating trend of late: an increasing demand from designers for incorporating opaque elements into window framing systems instead of the actual building. This shift allows designers to strategically incorporate decorative opaque cladding components without disrupting the overall fenestration system covering the entire building.

In the past, building designs have tolerated structural projections that cause thermal bridging. For instance, horizontal concrete eyebrows at multiple floor levels, which were once common, are now considered insulative nightmares. To create depth in the outer skin of buildings without protruding structures, Bousfield says designers seek to integrate depth into exterior elements.

In response to this, Cascadia is actively exploring innovative approaches to design cladding attachment components that can be held by window frames, going beyond the conventional practice of holding glass or metal within the frame. While there isn’t currently an off-the-shelf system available, Cascadia can design a bespoke system tailored to each project’s requirements. However, Bousfield envisions the possibility of a standardized kit of parts becoming available from the factory in the very near future.

In other news, Cascadia has been actively involved in several noteworthy projects of late. One of these projects is The Courtenay, located in the British Properties at the base of Cypress Mountain in West Vancouver. This particular development showcases a groundbreaking achievement: the world’s first fibreglass window wall.

Another remarkable project Cascadia has been part of is Pacific Point II, situated on Homer Street in Vancouver. This undertaking is a unique rehabilitation project, setting new standards in terms of scale and approach. “For Pacific Point we were tasked with

The Courtenay, West Vancouver, B.C.

Pacific Point II, Vancouver, B.C.

Windows + Doors for Passive House Projects

Innotech Windows + Doors is a Canadian manufacturer of high-performance windows and doors. The Defender 88PH+ System combines decades of fenestration knowledge to deliver a robust window and door system that is not only Passive House Institute certified, but that also delivers the air, water and structural performance required for highly sustainable housing developments.

Ask us about the Defender 88PH+ XI: the first Passive House Institute (PHI) cold climate certified window system manufactured in North America!

innotech-windows.com

EVOLVE IN VANCOUVER, BC

Passive House Multi-Family Project by ZGF Architects and Peak Construction.

replacing failed aluminum windows with a system that eliminated the requirement for the scope of the rehabilitation to include mechanical system upgrades. The difference is very subtle, aesthetically, but thermally blew the new requirements out the water,” Bousfield says.

INNOVATION AND PERFORMANCE

Innotech Windows + Doors has stepped up to meet the booming demand for high-performance building products and achieved a North American fenestration industry milestone.

Recently the company introduced its highest performing window to date, the Defender 88PH+ XI, which is the first Passive House Institute cold climate certified window manufactured in North America.

“The Defender 88PH+ XI is the cumulative result of continuous improvements learned over two decades of engineering, manufacturing, and installing windows and doors in thousands of projects throughout North America,” says Troy Imbery, president of Innotech Windows + Doors. “We’re very excited to offer our clients a range of window and door systems that not only exceed the requirements of the BC Building Code, but that also meet the rigorous voluntary performance standards of Passive House.”

Achieving high levels of energy performance in buildings such as those required under the BC Energy Step Code requires a high skillset from all building professionals. The Certified Passive House Tradesperson (CPHT) course is offered by Passive House Canada and the British Columbia Institute of Technology throughout the year, both in person

and virtually. The CPHT designation offers tradespeople and other building professionals, including several employees at Innotech Windows + Doors, the skillset required to achieve a net-zero energy future

– now less than a decade away. “As a manufacturer of building products, it’s our responsibility to push the boundaries of performance,” says Imbery. “Our health and the health of our planet depends on it.”

The Future is Fiberglass

•

•

•

INDUSTRY CHANGES

Over the past 12 months, the window wall and curtain wall industry has continued to witness significant changes, particularly in the areas of product delivery and quality. Jim Lebedovich, president at Phoenix Glass says the impact of COVID-19 has led to inflation, resulting in higher costs for lesser service and longer delivery times. He explains that supply chain materials are now predominantly made to order, emphasizing the need for efficient production and delivery processes.

Although Lebedovich says there hasn’t been any groundbreaking new products in the market that he has witnessed, “energy requirements remain a crucial consideration in glazing and wall systems design. Existing products continue to help owners meet stringent targets in this regard.”

Phoenix Glass has been actively involved in various noteworthy projects of late. “We recently completed works at The Post, which had all sorts of different scopes. We also completed some hybrid curtain wall/wall panel systems for Mondivan and Focal and we have some nice high-performance unitized projects coming up – The Luxe and 360 West 2nd,” says Lebedovich.

Looking ahead, Lebedovich is enthusiastic about integrating curtain wall and wall panel assemblies to meet evolving energy requirements. “We are wellprepared and eager to contribute to the future of the industry in this regard,” he says.

GLASS TECHNOLOGY

The team at Noram Glass has seen some notable trends over the past 12 months, one of which is the use of electrochromic glass, which continues to be implemented in current projects. This innovative glass technology allows for dynamic control of sunlight and glare, enhancing energy efficiency and occupant comfort. Another emerging trend, according to Jess Redlarski at Noram, is the introduction of photovoltaic glass, which is expected to be utilized in the company’s future projects. This type of glass incorporates solar cells to generate renewable energy, while maintaining the transparency and aesthetics of the building envelope.

The company has seen some exciting changes of late as it continues to experience growth and expands its involvement in challenging and sophisticated architectural designs. This signifies Noram’s commitment to pushing boundaries and delivering innovative solutions in the industry.

Noram has also been engaged in some remarkable projects recently. One notable project is The Cooperators Head Office, where Halio’s electrochromic glass has been incorporated. This advanced glass technology provides occupants with control over the amount of daylight and privacy, creating a comfortable working environment. Additionally,

The Post, Vancouver, B.C.

Mondivan, Vancouver, B.C.

Noram has been working on Crosstown, a residential tower featuring a fully unitized curtain wall that combines vision glass and porcelain panels. This design integration adds aesthetic appeal and enhances the building’s overall performance.

RESEARCH AND DEVELOPMENT

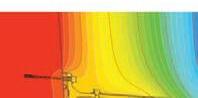

With extreme events and disasters becoming more common, RJC Engineers is once again taking the lead to find solutions to protect buildings and as such has been participating in seismic testing of the Natural Hazards Engineering Research Infrastructure (NHERI) TallWood project, currently underway in San Diego, California.

The project, funded by the National Science Foundation, aims to study the earthquake resilience of mass timber buildings by simulating large earthquakes on a 10-storey mass timber structure. RJC’s role in the project is to analyze the impact of seismic events on window integrity, as windows play a crucial role in a building’s energy efficiency and safety.

“The project testing is attempting to detect the point at which window seals fail when subject to lateral building movements. Lateral, or sideways movements of a building can occur in both wind and seismic conditions. Window damage can be hidden and expensive to repair, and unseen breaches can cause larger impacts in energy efficiency and building durability if gone unnoticed,” says Dennis Gam, principal, RJC Engineers.

The findings will be invaluable, especially considering new code requirements are coming to B.C. this fall that will require buildings with high importance and post-disaster occupancies to remain

undamaged for large (but not severe) earthquakes.

“This implies a higher level of structural performance for other aspects of a building, including its enclosure. Our work attempts to quantify this risk and to inform how much repair cost can be affected by damage to window seals,” explains Terry Bergen, managing principal, RJC Engineers.

RJC’s involvement in the research will help inform sustainable building design decisions and reduce the carbon impact of the construction industry. The findings will contribute to the development of seismic

design methodologies and inform the creation of more sustainable and resilient buildings.

“The interaction of structure with building enclosure and functional components of a building is an under-researched area. Although the industry can create building structures that survive earthquakes, what needs to continue to be researched is how to make the building survive while also being occupiable and functional. What form this research takes is to be determined, but more full-scale testing is planned for the future,” says Gam. A

Seismic testing at the Natural Hazards Engineering Research Infrastructure (NHERI) TallWood project, San Diego, CA.

*(CPCQA) CERTIFICATION PROGRAM BY PROCESS OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Project: Champagne Quarry Park, Calgary, AB Architect: Gibbs Gage Architects

Sealing In Success

The

growing demand for energy-efficient and airtight buildings sparks fascinating breakthroughs in building envelope solutions

by ROBIN BRUNET

With everything from energy costs to the net zero push affecting the way buildings are constructed, it’s not surprising that some basic concepts driving the green movement have become rote, without much consideration to their meaning. And as far as Jeff Ker, senior technical advisor at Engineered Assemblies (EA), is concerned, one example is the chronically overused term ‘sustainability,’ especially as it applies to building façade envelopes.

EA supplies world-class facade materials backed by leading expertise in RearVentilated Rain Screen (RVRS) sub-structure assemblies. Of late, Ker has been talking with the architectural community to break down what sustainability actually means in his line of work. “First, it means a building must consume less energy to function,” he says. “Then, sustainability applies to materials used –which incidentally must be installed properly. And finally, it means the building has to last and be serviceable.”

Architects have reportedly responded strongly to Ker’s discussions, which pertain to something EA has been promoting of late: its Certified Series, which has been developed in response to the need for transparency, due diligence, and proper installation execution of a correctly detailed RVRS.

EA created the Series in the hope that it will become an industry standard, offering a superior program of delivery and ensuring that all RVRS system installations are conducted properly and that the façade manufacturers’ warranty requirements will be met. This is accomplished by EA uniting the architect, the general contractor, and the subcontractor under a common methodology and “with a software platform to monitor and report on the execution of a proven RVRS design in real time,” according to Ker.

Ker says, “I’ll be continuing my talks because we regard the façade envelope as possibly the most important building component as it is the primary passive environmental control system. As more architects are trying to adopt National Building Code CSA S478 standards, we hope the use of our Certified Series will make the process easier to achieve.”

Holcim is a global leader in sustainable building solutions and respected for providing a full range of roofing systems. Jasmeet Deol, senior manager, product marketing for Holcim Building Envelope, reports that “overall in the commercial roofing space, material lead times and availability of raw materials are returning to normal levels. But labour shortages are still an issue, so we strive to provide roofing solutions that help contractors and building owners save time.”

Deol cites the Elevate SA (formerly Firestone SA) product category, a singleply self-adhering membrane roofing system specially designed to allow contractors to install more squares every season and do it up to four times faster. There’s no need to spread or spray adhesive during installation, plus Elevate SA membranes are free of VOCs. “This is not only a great advantage to crews because it improves the installation experience for contractors, but it also benefits owners because businesses can stay open and occupied while the roofing system is being installed,” Deol says.

Installation of the Elevate SA single-ply self-adhering membrane roofing system.

Rear-Ventilated Rain Screen (RVRS) sub-structure assembly.

FOCAL ON THIRD

Additionally, thanks to Secure Bond Technology, both RubberGard EPDM SA and UltraPly TPO SA can be installed in temperatures as low as minus seven degrees celcius.

Deol adds, “Our work in Canada, focusing on end of life roof recycling and landfill diversion, continues in collaboration with Geocycle Canada where we co-process roofing products in the production of cement. While that has proven successful, we continue to explore other landfill diversion opportunities as well.”

Brian Hall, managing director at the Canadian Precast/Prestressed Concrete Institute (CPCI), reports that in collaboration with RDH Building Science, CPCI has completed a comprehensive report on the air permeance testing of fullscale precast concrete wall assemblies following ASTM E2357. “The test results showed that single-wythe precast and double-wythe insulated precast concrete wall assemblies with properly installed two-stage joints meet and exceed the air barrier system requirements of the National Building Code of Canada,” he says. “The second phase of this testing program that focused on testing the precast wall assemblies for moisture leakage, following ASTM E331, has also been recently completed.”

Hall also credits Malcolm Hachborn, president of M. E. Hachborn Engineering, for recently introducing a new lighter, more energy-efficient and higher-performing cladding precast concrete system called DreamWall. “DreamWall panels are engineered and configured for use in exterior and interior façades,” he says. “If a client desires a high-performance prefabricated wall panel system that is remarkably lightweight, thermally efficient, versatile, durable, and aesthetically pleasing, DreamWall is an outstanding choice.”

Matthieu Danis, product manager, wood fibre at Building Products Canada, says, “Energy efficiency is certainly getting more attention than ever. Although this is more easily said than done, one thing that is certain is that most people understand the importance and value of continuous insulation in the increased performance and energy efficiency of a house. There is also pressure to use higher R-value continuous insulation in the very near future, as building codes are being reviewed and renewed.”

BP offers a complete line of wood fibre-based insulation panels under the Insul-Sheathing brand. All the panels offered in this category use a soft wood fibre panel that is either 7⁄ 16 inch or 1 ⁄2-inch thick. BP’s manufacturing process is unique because it manufactures a high resistance panel with an insulation value of R-3 per inch. Using wood fibre panels that are laminated to synthetic insulation panels results in a panel that is both structural, suitable for most buildings that fall under Part 9 of the National Building Code, and has a much lower upfront embodied carbon due to the use of recycled wood fibres.

All Insul-Sheathing panels provide superior protection of the exterior shell by offering continuous insulation and reducing thermal bridging at framing members.

Sound Solutions provides architects and contractors with an extensive line of product options for both interior and exterior applications from the best North American and European manufacturers. The company also provides extensive design, drafting and modelling capabilities, including comprehensive custom manufacturing when required.

Andrew Rogers, principal at Sound Solutions, reports that he has witnessed “an exponential increase in the use of extruded terracotta for rainscreen cladding, which is very encouraging because in Europe there are no end of roofs made of terracotta that are hundreds of years old. It’s a particularly sustainable material.”

Rogers is also heartened that the increase of terracotta usage is happening at a time when developers are more cost conscious than ever. “They obviously realise that with this material you can create expensive systems, but you can also develop affordable solutions,” he says. “About four years ago we clad the entire Etobicoke General Hospital in terracotta, and the tiles were under $10 per square foot.

“Typically, we’ve done several projects a year using terracotta, but this year we’re supplying the material on about seven projects, and next year we’ll double that figure. In Canada overall there have been 40 completed projects over the past 15 years, and this number will double in the next two years.”

Joe Baz, product manager for Flynn Canada Ltd. (part of The Flynn Group), says, “With the need for more energy efficient and airtight buildings, Flynn set out to develop a high performing modular wall system. We wanted to utilize the framing of our unitized curtain wall as it is very airtight and watertight but thought of an innovative approach to insulate the outside of the aluminum framing with an insulated metal panel to minimize thermal bridging and maximize performance. This drastically improves the performance to a degree that an effective R value of greater than 40 can be achieved, which is unheard of in this industry.”

Speedwall is a factory-assembled modular exterior wall system that delivers quality and performance levels far beyond what is possible with on-site construction. Built on an aluminum chassis based on Flynn’s 6450 unitized curtain wall system, Speedwall modules are completely self-framed, sealed, and insulated in Flynn’s manufacturing facility, with all windows, doors, and exterior cladding pre-installed. Larger modules mean fewer interfaces between elements, which combined with factory QA and QC equals superior air tightness.

Baz calls the usage of Speedwall “future proofing” because where previous energy codes evaluated the system efficiency of building envelope components in isolation, emerging requirements take more comprehensive thermal bridging calculations into account. The sheer number of interfaces between window and wall components in traditional building envelope construction, coupled with their installation and quality control in the construction site environment – often by multiple trades – renders the final product challenged to meet the incoming codes. But Speedwall delivers the performance required for net-zero energy performance standards.

Etobicoke General Hospital, Etobicoke, ON

Extruded terracotta cladding, Seneca College, North York, ON.

Insul-Sheathing wood fibre-based insulation panels.

From a construction point of view, Speedwall, which will soon be used on the exterior of the new TELUS Ocean building in Victoria – with the components arranged in strips with an architectural sawtooth effect – can enclose an eightstorey building in as little as a month, depending on its design.

Greenstone Building Products also provides a prefab solution. The ICE Panel is an energy-efficient structural insulated building envelope panel for residential and commercial construction. They are made with expanded polystyrene (EPS) insulation and galvanized steel stud structural frames.

“We believe in innovation and continuous improvement, and that technology is the solution to the climate challenges we currently face,” says Tilda Fortier, business manager for Greenstone Building Products. “There is no other panelized assembly like ours and we will continue to develop our technologies to improve our offering.”

The ICE Panels have impressive transverse and compression bearing capabilities, and the unique manufacturing process and connection details completely eliminate thermal bridging, which results in one of the most energy-efficient panelized systems sold today.

“As building performance codes are adopted across the country, we are excited to be able to offer a practical and proven solution to achieve any building performance target,” says Fortier. “Panelized construction and Building Information Modelling [BIM] are relatively new to the building industry, which has a reputation for being slower to innovate and adopt new technologies. And while it does require some forward planning, the benefit to our process is that you can catch errors that might normally not be seen until everything is delivered to the site”.

Douglas Brady, chief strategy officer at Huntsman Building Solutions (HBS), notes that his company is constantly striving to improve the environmental attributes and efficiency of its blowing agents that form air barriers. For example, its popular closed-cell spray foam product, Heatlok Soya HFO, leverages the new HFO (hydrofluoroolefin) blowing agent which was considered a significant step up from the earlier HFC agent, resistant to the most extreme wind loads on the tallest buildings. It is the most environmentally conscious blowing agent produced to date, with a zero ozone depletion potential (ODP) and a global warming potential (GWP) below 1.

But now Huntsman Building Solutions has returned to what Brady describes as “our spray foam roots” with Heatlok Soya HP, the latest addition to HBS closed-cell product portfolio, which was released during summer in Canada. This high-performance insulation solution has improved environmental qualities and achieves a long-term R value higher than 2.0 making it one of the best R values of any HFO product on the market. “We found that HFC blowing agents distributed insulating molecules into the atmosphere and over a five-year period saw a reduction in R values to 1.5-1.9,” Brady says. “The HFO agent has a very weak molecule that does not linger in the atmosphere, plus the R value is maintained.”

In 2023, ongoing advances are being made in the aesthetic appeal of envelopes. Ontario Panelization offers extensive experience in pre-panelized and field-applied exterior wall systems, with finishes that include the Ceramitex Sintered Ceramic Façade system, Alcotex Aluminum Composite Panels, Aluminum Plate, Phenolic Resin Panels, and other products.

Recently, Ontario Panelization gained recognition for an unusual project: on behalf of the Havergal College Upper School it manufactured 11,354 square feet of copper cladding made of 16-ounce copper pans with two-inch single-lock standing seams, which added a textural pattern to the facade. The pan profiles included a sprung edge to help allow for expansion and contraction of the copper during varying weather conditions.

Over the decades, admixtures have played an increasingly important role in improving the integrity of building envelopes, as well as repairing faults. “The idea of basements essentially being tanks is relatively new and is the result of more and more cities prohibiting the drainage of water into storm systems,” says Kevin Yuers, VP product development at Kryton International.

Kryton famously enabled basements to become watertight via application of its Krystol Internal Membrane (KIM), a hydrophilic crystalline admixture that lowers the permeability of concrete and is used instead of surface applied waterproofing membranes. KIM’s Krystol technology chemically reacts with water and un-hydrated cement particles to form insoluble needle-shaped crystals that fill capillary pores and micro-cracks in the concrete, permanently blocking the pathways for water and waterborne contaminants.

Recent projects of note relying on KIM are Concord Gardens from Concord Pacific, the residential estates of which “are built well into the water table, which in Richmond is typically right at ground surface level,” according to Yuers; the high-rise Capstan Village from Pinnacle, also in Richmond, and Concord developments beside Calgary’s Bow River. “Concord recently advertised that its basements were waterproofed with the same technology our company used on the Site C Dam, which was very complimentary,” Yuers says.

Yuers goes on to note that while Kryton doesn’t get heavily involved in building envelopes above grade, “We still offer Hydrostop, a high-performance penetrating sealer used by itself to protect concrete, brick, mortar, and masonry from the damaging effects of water intrusion.” Hydrostop contains a unique blend of silane and siloxane compounds that chemically react with silicates below the surface of the substrate to form an insoluble, waterrepellent barrier.

Finally, Brian Salazar, national business development manager with Euclid Canada, reports that on the repair side of building envelope business his company “is supplying repair products for a lot of residential and commercial buildings as well as admixtures for new precast buildings in Ontario.”

One product in particular is EucoRepair V100, a single component, fast setting, very low shrinkage mortar for trowel applied vertical and overhead concrete repair. EucoRepair V100 contains microfibre, unique additives, and a specialty cementitious blend to optimize the physical properties that fight cracking. The result is a concrete repair material with exceptional engineering properties.

Salazar says, “Cracking is the most frequent cause of concrete repair failure, but EucoRepair V100 is a great solution for high rise facias and any exposed areas where rebar is showing.” This product provides resistance to drying shrinkage, while microfibre provides three-dimensional reinforcement and increased tensile strength. It is also polymer modified for strong adhesion, improved elasticity, and resistance to creep.

Also from Euclid Canada is EucoRepair SCC, a pourable and pumpable selfconsolidating concrete repair mortar that can be placed from 2.5 centimetres up to full depth without extending with aggregate. Salazar says, “It quickly spread into place, filling formwork and encapsulating reinforcement without the need for mechanical consolidation such as vibration.” A

Speedwall modular exterior wall system specified for the TELUS Ocean building, Victoria, B.C.

Krystol Internal Membrane in use at Concord Gardens, Richmond, B.C.

Sustainable

Meet

Approaches

to Abrasion and Erosion Resistance

Use

Reduce

Postpones

SOLID DEFENCE

The

metal roofing and cladding industry shows resilience with larger projects and high-performance designs

by ROBIN BRUNET

The more things change, the more they stay the same: that is the case with the metal roofing and cladding market in 2023, and it’s a good thing inasmuch as the elements characterizing the sector over the past number of years – strong sales growth, strong variety of product, and the growing appreciation of high performance and sustainable design – are evident today.

With regard to the concealed fastener metal roof market, Doug Wells, RoofStar Technical Advisor at the Roofing Contractors Association of British Columbia (RCABC), recently examined his association’s database with the expectation that guarantees issued on metal roofing were increasing. “We looked at two blocks: 2017 to 2020 and 2020 to 2023,” he says. “Interestingly, we had the exact same number of projects in each block. But there was a 40 percent increase in squares – a square is a 10-foot by 10-foot area – between the two time frames, meaning that while we don’t have more projects today,

we do have bigger projects.” RCABC offers the only third-party comprehensive metal roof guarantee in the industry.

One of those projects is the newly named Rosemary Brown Arena (formerly the South Burnaby Ice Arena), designed by hcma and consisting of 87,000 square feet of space, two full NHL-size ice sheets, and a complex metal roof (with exposed mass timber beams) of various planes and geometries.

Wells goes on to note that, “We’ve also been working with Studio One Architecture on numerous schools. A school in Surrey is replacing a barrel skylight with a metal panel roof that will have a seven-foot elevation and a 14-foot radius engineered by Rimkus Consulting; and Ladner Leisure Centre is getting a replacement roof designed by FaulknerBrowns Architects, all installed by active RCABC members.”

Wells says, “There was no market slowdown during the COVID lockdowns and there is every possibility of growth in the foreseeable future thanks to the desire for metal roofs to provide longer

life cycles in schools and other government institutions, warehouses, and civic arenas.”

The metal cladding sector is no less robust.

Sobotec, North America’s largest fabricator of metal composites and one of the largest manufacturers of engineered panel systems, recently provided full window wall and integrated aluminum plate panel façade along with other areas of field-installed aluminum plate panels and siding for the 30-storey McMaster University Graduate Student Residence, which is scheduled to open this September.

The building is designed to meet LEED Gold standards and contributes to the ongoing revitalization of downtown Hamilton, with Diamond Schmitt Architects using metal to create a unique lightcatching textural treatment (each vertical strip of cladding is composed of two projected right angled triangle segments that meet on a diagonal line, either creating shadows or reflections, and giving the building a twisting appearance).

Also nearing completion is Transit City 4 and 5 by CentreCourt and SmartCentres, for which Sobotec

Cascadia Metals’ pre-painted PVDF (polyvinylidene fluoride) steel roofing.

has provided about 25,000 square feet of Aluminum Plate Panels (SL-2000P) along with 10,000 square feet of Stainless Steel Plate panels and 10,000 square feet of Siding. Diamond Schmitt created unique spiral designs and metal panel borders for the 45 and 50-storey edifices, part of the multi-tower Vaughan Metropolitan Centre development.

Sean Lepper, VP and general manager at Behlen Industries, echoes the sentiment of his colleagues by noting that, “Business is still strong despite rampant inflation, with metal roofs and cladding being specified for industrial, commercial, recreational, and many other types of projects.

“The biggest challenge overall, and the biggest change in how things are done in this sector, is the ‘new’ energy code, first introduced in 2020, and now coming into effect. Essentially it increases the amount of insulation required for new builds, and that’s driving a lot of thought into how to create wall and roof cavity expansions.”

Lepper goes on to note that “fortunately steel buildings are highly adaptable” and can accommodate this expansion of space “in a cost-effective

manner, in most cases. What it requires is a combination of research and development and testing, in order to ensure that the space created to add more insulation is structurally stable. It also requires some thought with regards to the actual construction process, as added insulation could require a substantial increase in labour for larger-scale projects.”

However, Lepper says there is opportunity to explore insulated metal panels as an option with Behlen, with the potential to offset some additional costs such as the cost of increased labour needs overall: “At Behlen we’re enjoying great success in serving

our various markets, and we’re confident we’ll be able to meet all of the new code requirements.”

Of course, metal cladding providers have become well known for their insulated metal panel products that go a long way in boosting a building’s energy efficiency. The insulated metal panels and facades available from Kingspan cover a wide range of needs, from projects requiring bold architectural expressions to those large in scale. An example of the latter is the Aspire Food cricket farm and processing centre in London, Ontario, the largest facility of its kind in the world at 165,000 square feet. This project required constant temperatures for insect breeding and storage, and Kingspan’s KS Shadowline interior panels, which deliver the highest R-values on the market and are specifically engineered for controlled environments, were sourced. Also, Optimo panels integrated seamlessly

Waywayseecappo First Nation Food Mart, Waywayseecappo, MB

Aspire Food cricket farm, London, ON

EXPERIENCE THE NUCOR ADVANTAGE

As the construction industry has grown more sophisticated, so has the versatility of custom metal building systems. By adopting advanced tools, practices and products, Nucor Buildings Group actively evolves to meet industry demands. Metal building systems are flexible by design and can be tailored to fit the needs of any market, offering the ability to incorporate energy-efficient products like insulated metal panels and advanced insulation systems alongside architectural elements such as stone and glass.

Whether your building is architecturally complex or value engineered, from a 1-million square foot mega project to a small specialty building, we work together with our Authorized Builder Network to offer products and solutions that bring our customers’ dreams to life.

with the KS Shadowline panel joints, providing the airtightness necessary to ensure a steady temperature and a flawless transition between different areas of the processing centre (it also allowed for colourful accents in the exterior design).

In terms of sheer visual appeal, the three-storey addition to Mandeville High School in Louisiana is a prime example of the ability of Kingspan’s Designwall Insulated Metal Panels to create a bold look with custom colours, while integrating into translucent glazing (the Designwall 2000 architectural panels used for the project not only enhance creative freedom, with horizontal and vertical application capability, they also provide maximum thermal efficiency while creating a double barrier against air and water penetration).

North Carolina-based Nucor Corporation bills itself as “North America’s most sustainable steel and steel products company,” and as such it continues to pursue carbon reduction goals (it already has a carbon intensity less than one-third of today’s steel mill average globally), and it continues to make advancements in steel products, the latest of which, Elcyon, is the world’s first sustainable steel plate for offshore wind projects (it has a recycled content in excess of 90 percent and is produced with ¹⁄5 the global blast furnace average for greenhouse gas emissions).

With regard to Nucor Corporation’s heavy involvement in building construction, Adam Scott, senior district sales manager at Nucor Buildings Group, says, “While we’re known for contributing to large-scale projects with large amounts of metal roofing and cladding, we love to fit in smaller projects too. One of our more fortunate strategies in recent years was to acquire two valued insulated metal panel legacy brands, CENTRIA and Metl-Span, which provide a full range of products to service high-end architectural applications in the cold storage and warehousing realms. Specifically, this enabled us to serve the quickly growing non-residential insulated metal panel category.”

Scott says that a new elevated roof insulation system, R-Boost, “is being used in a variety of projects, and the feedback we’re getting is that it is very easy to install. Equally important, this is a high R value solution to projects that must meet stringent energy efficiency codes.”

R-Boost’s unique patent-pending design features a bridge between an initial and secondary layer of blanket insulation, doubling the insulation capacity and meeting energy codes throughout North America. With the Nucor CFR roof panel, R-Boost can realize U-factors as low as 0.026, which in the US meets the requirements of IECC 2018 (Climate Zones 1-8) and ASHRAE 90.1-2016 (Climate Zones 1-8). Moreover, it is designed to work with Nucor Buildings Group’s SS360 roof system. Both the CFR and SS360 panels are well known for their performance, strength, and weather tightness. Nucor CFR and SS360 panels have been tested and approved by Factory Mutual and Underwriters Laboratories for wind uplift as well as hail and fire resistance, and when used in combination with R-Boost, this system provides the highest potential for total building system cost savings (plus, on average, R-Boost installation costs are considerably lower than that of competing systems).

Companies specializing in metal products and components continue to evolve in 2023. Cascadia Metals, the premium metal distributor of coil and sheet products, announced earlier this year that it is now manufacturing a new line of products at its Tubular Division in Brandon. All told, Cascadia’s output in addition to coil and sheet metal includes HSS tubing, merchant bar, rebar, expanded metal, wide flange beam, galvanized fence pipe, and UL/FM rated sprinkler pipe. But Cascadia’s pre-painted PVDF (polyvinylidene fluoride) steel products are of special interest to architects. Available in coil and flat sheet, these products are galvanized and 55 percent aluminum-zinc alloy coated substrates and come in a variety of popular colours, fully supported by industry competitive warranties.

PVDF is a highly non-reactive and pure thermoplastic fluoropolymer used in a variety of applications where the highest purity, strength, and resistance

Nucor CFR roof panels, Aerocentre 2, Edmonton, AB.

to solvents, acids, bases, and heat are required. As an added bonus, PVDF has the ability to selfextinguish and generates little smoke in the event of a fire. Designers typically specify PVDF not only to achieve colour vibrancy but also because of the added benefits of flexibility, durability, and low maintenance that only steel can provide.

The metal roofing panels from PAC-CLAD Petersen, a Carlisle company, are coated in PAC-CLAD PVDF coating, applied to both steel and aluminum and originally developed for use in abrasive environments. The PAC-CLAD architectural panels for metal roofing systems are produced in factory-formed lengths of up to 55 feet and have PAC-CLAD Kynar 500 finishes available in 45 colours.

An example of how PAC-CLAD products can contribute to projects requiring a classic appearance is the Coastal Georgia resort hotel on Jekyll Island off the Georgia coast. The hotel’s design featured plenty of outdoor eating and drinking spaces sheltered under spacious overhangs, but these overhangs face the elements all year and required some attention when it came to materials selection. Architects with Ontario-based Chamberlain Group opted for flush aluminum panels installed to look like an old-school clapboard ceiling.

To source those panels, the architects, along with installers Thorne Metal Systems, relied on PAC-CLAD Flush panels for the building’s soffit and overhanging outdoor ceilings. Fabricated from .032- and .040-gauge aluminum, all the panels were finished in Stone White to emphasize the project’s clean, crisp lines.

Finally, Longboard Architectural Products has established itself as a reputable manufacturer of high-quality cladding and soffits for the past 15 years. With a commitment to excellence, the company oversees the entire manufacturing process in-house, from extrusion to powder coating and finishing.

Offering three distinct cladding and soffit systems, Longboard prioritizes ease of installation, sustainability, and superior craftsmanship. All its exterior products and systems are powder coated with AAMA 2604/2605 certified powder, guaranteeing resilience against external elements such as corrosion and UV rays. The systems are available in 12-foot or 24-foot lengths, equipped with a quick screen clip for convenient installation, and offer perforated plank/ panel options and a range of trim choices, including Traditional, Precision, and Craftsman styles.

Longboard’s product lineup also includes a rainscreen system, which is gaining popularity throughout North America. These wall assemblies feature drained and back-ventilated (DBV) rainscreen cladding, effectively managing water and moisture while simultaneously preventing radiant heat gain. Furthermore, they accommodate continuous exterior insulation, improving thermal performance, and contribute to better Indoor Environmental Quality (IEQ).

For those seeking enhanced thermal performance, Longboard’s cladding attachment system, Hitch, stands out. Compatible with any of the aforementioned systems, Hitch offers a thermally broken and intermittent structural approach. Hitch utilizes thermally efficient materials and robust clips, resulting in reduced material requirements, improved thermal efficiency, and significant labour savings. Achieving thermal efficiency levels of up to 94 percent, Hitch can attain effective R-values that surpass R-60, making it an ideal choice for those prioritizing energy efficiency. A

Cascadia Metals’ pre-painted PVDF steel cladding.

PLAYING TOGETHER TO GIVE SUPPORT FOR BC’S KIDS

BC Children’s H osp i tal Foundation would like to thank t he following sponsors and all participants of the 28th A nnual Building for Kids Charity G olf Clas s ic which took place on T hu r sday July 20, 2023.

This sold out event hosted 144 golfers from across the construction and development industry in BC , for a fun filled day at Beach Grove in Tsawwassen, BC.

This year’s tournament successfully raised $472,000, adding to the tournament’s cumulative total of $4.1 million to date. Funds raised will help us enhance the physical space of the Heart Centre to create a more comfortable and healing environment for patients and their families.

For a full list of supporters and to learn more about the event please contact golf committee chair Gavin Yee GYee@ventanaconstruction.com or visit bcchf.ca/bfk

TOURNAMENT SPONSORS

Heart Of Stone

Harnessing diversity and innovations to thrive amidst inflation hurdles in the masonry sector

by ROBIN BRUNET

Even though masonry is arguably more vulnerable to inflation than other building materials – one example being brick, whose popularity is at least partly driven by developers willing to pay a premium for the product – the category remains resilient in 2023.

For example, Basalite Concrete Products gives developers a huge range of options in building design, not just in terms of diversity of products (ground face, smooth, and split face concrete blocks are part of a masonry range that includes brick, deck blocks, and wall caps) but also advice to contractors and architects regarding everything from suitable admixtures to customized mix designs.

As for innovation, new for 2023 from Endicott are Invisi-Lug clay pavers, whose recessed lugs provide a host of benefits including proper joint spacing to eliminate chipping, as well as the creation of crisp, square edges. The design also eliminates the need for plastic spacers (which on large projects can be a notable expense) and speeds up installation times, with accurate spacing of joins easily achieved.

As with all Endicott products, Invisi-Lug comes in a variety of vibrant colours – including ironspots – that other materials can’t mimic. Equally important is the product’s high durability and incredibly high compressive strength.

Gerald Martin, technical representative at Mutual Materials, echoes the sentiments of many colleagues in the masonry trade by stating, ”Yes, prices overall are going up in the back end, but demand remains strong. Business for us is brisk in 2023, which reflects a healthy economy.”

Accompanying this is something most masonry providers relish: consumer trends that keep manufacturers busy. “With bricks, we’re seeing a growing number of projects in which three blended colours have been specified, something that has been commonplace down south in Seattle and Portland for some time now,” Martin says. “One such current project is the Burnaby Alliance Church, whose architect we worked with to determine the right colours: Seattle Cream, Limestone, and Desert White. The Church is also providing the opportunity for another design trend: the creation of a brick screen wall on one side of the building that allows light to spill into the parkade area.

“Our brick products have also been sourced for the Richmond Centre revitalization, another project in which the architects went with blended brick colours. The same applies to a Kingsway condo development project currently under construction.”

Martin points out that one reason the market for brick continues to grow is that “pockets of cities are being revived and reimagined, and nothing beats brick for imparting warmth and elegance. We’ve also gotten an order for the new Bridge Studios on Lake City Way in Burnaby, a prime example of an ‘industrial’ facility that incorporated brick to reflect a modern design.” Bridge Studios-Lake City will have over one-million-square-feet total floor area, including 21 sound stages, 330,000 square feet of support space, and 150,000 square feet of production office space.

Several years ago, General Shale, the North American subsidiary of Wienerberger (the world’s leading supplier of building materials and infrastructure solutions) acquired Meridian Brick. Today, the rebranded Canada Brick continues to deliver the tremendous product quality that the company was known for since the 1950s, with Red River, General Shale, Columbus, and other products constantly being specified for a wide variety of projects.

Canada Brick recently unveiled new residential brick colours: Hazelton (warm off-white with delicate distressing), Dakota (which exhibits a unique, vertical striated detail reminiscent of watercolours), and Steel City (variable grey with a soft mottled finish, perfect for natural wood or black accents).

King Klinker Thin Brick from I-XL Building Products.

Brickwork detail, Burnaby Alliance Church, Burnaby, B.C.

WHAT’S YOUR Colour Narrative?

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

This line is in addition to the new architectural brick colours Creekside, Shadow Ridge, and Spring Hill (each coming in matt and velour finishes that lend a modern elegance to commercial and residential projects) as well as the new White Ash brick featuring an iron spot finish to impart an old-world character. Each of these Architectural Series products is available in Metric Modular, Imperial Modular, Quebec, Ontario, CSR, MAX, Metric Norman, Engineer Norma, and Metric Jumbo sizes.

Canada Brick is another company that is sourced to supply multiple shades of brick to bring projects to vibrant life, an example being the renovation of SaintNoël Chabanel School in Montreal that used three different shades of brown brick to create a spectacular diamond pattern wrapping around the exterior walls, further enhanced with colourful glazed brick insets. The pattern also serves as a target for ball games.

Joe Black, director of sales, Western Canada at I-XL Building Products, reports that in his company’s specialty as a wall material provider, “we’re enjoying expansion and growth. Projects are calling for multiple exterior building materials and have required building supply companies to become more diverse. Therefore, I-XL Building Products has expanded beyond masonry into metal cladding via MAC Metal Architectural, to compete for more wall share.”

That said, Black acknowledges the various trends in the masonry market. “With both manufactured and natural stone, larger format profiles are being specified in blacks, dark greys, and whites. Interior thin brick is really a growing trend, whether inside a home or in restaurants and retail stores, and we’re seeing a lot of rumbled /loft style/old world brick. For both residential and commercial applications, white brick and black brick with a manganese metallic sheen are very popular.”

Just as I-XL diversified into metal cladding, beyond its already existing clay brick product lines (Hebron Brick, Interstate Brick, and Endicott Brick) it also fortified its commitment to providing masonry products by becoming a distributor for King Klinker Thin Brick products throughout Western Canada.

As always, the best masonry manufacturers thrive by listening to feedback. “We get product ideas by listening to our customers, and we’re always coming up with innovative colours and sizes,” says Bradley Belden, president of The Belden

Hebron Americana Rumbled

Eldorado Chalk Dust

Brick Company in Canton, Ohio. “Overall, Canadians have been more likely than Americans to try new styles and push us to innovate, so it’s no surprise that in 2023 we continue to enjoy great relationships with our distributors in the north and strong demand for our product, even though high interest rates threaten to slow the residential market.”

Emerging from Belden’s five production plants yearly are up to 180 million bricks ranging in size and type from face, thin, oversize, and structural to special shapes, moulded, and more. “We’re small but mighty and aided greatly by a robust research and development process,” Belden says. “We’ve also dipped our toes in the coatings market with ceramic based coatings; we also automated one of our plants so we could dry our bricks prior to firing them in a kiln, in order to coat them and achieve a better, more resilient bond.”

As Belden discusses trends (“we’re working on multi-colours on the same brick, but that product offering is still in the future”), he stresses the importance of developers appreciating the strong thermal performance of brick walls. “We’ve done a lot of work with organizations such as the National Brick Research Center [NBRC] and proven that brick walls carry heat into the night and coolness into hot days,” he says.

Testing with fixed temperature conditions conducted by the NBRC confirms that heat takes two to three times as long to go through a brick wall assembly than it does others. The brick wall’s heat storage capacity is twice the storage capacity of the brick alone. An NBRC test with varying temperature conditions proves that brick walls reduce heat energy movement by 60 percent over the closest competing wall assembly.

Additionally, a brick veneer wall assembly combined with continuous insulation is especially beneficial in cooler climates. Increasing the size of the air space allows continuous insulation to supplement the insulation between the studs, and the NBRC has found that a minor increase in the width of the foundation wall will permit including continuous insulation with no change to the building’s interior space or the exterior appearance. A

Custom Blend of Ashberry, Black Diamond, and Sienna Blend Velour brickwork, René-Guénette Elementary School Montreal, QC.

Commodore Clear Velour brickwork, Element AI offices, Montreal, QC.

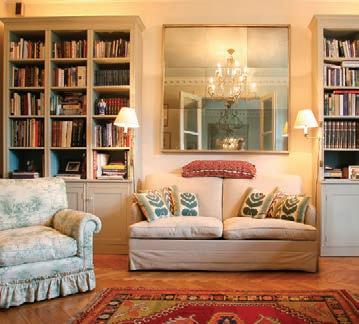

Kitchen product manufacturers and suppliers are once again changing the way designers and consumers approach finishing what is arguably the centre of all homes. From imported stone to state-of-the-art technology, the options are boundless.

COUNTERTOPS

Caesarstone Canada unveiled its multi-material portfolio in 2023, with porcelain and stone being added to its current offerings of Quartz and Outdoor Quartz. The expanded portfolio of more than 100 colours tastefully combines the company’s innovative technology with its powerful design passion, empowering consumers to design with freedom. “This is a pivotal moment for Caesarstone,” says Ken Williams, president and CEO of Caesarstone The Americas. “We wanted to make it easy for people to design their dream spaces by offering our multimaterial surface solutions all in one place. Across the world, people choose Caesarstone because we bring joy and freedom to the design process.”

For the new Porcelain range, Caesarstone utilizes its technological expertise and design leadership to capture the visual qualities of a wide range of material types: from natural marble to the industrial aspects of concrete and metal. “The heightened veining, palpable textures, and dynamic patterns of the Porcelain collections are available in a highly curated range of 22,” Williams explains.

A Slice Of Design Heaven

Exploring the hottest kitchen trends and products of 2023

by LAURIE JONES

“Caesarstone’s Porcelain range is extremely hard material that will stay as strong as the day you have it installed.”

The Living Impressions Collection by Formica Canada offers designers a line-up of organic patterns, modern marbles, and a wide selection of 14 new sophisticated surfaces for elevated interiors. Following leading design trends, Formica’s new Residential Collection includes Light and White, Rustic Luxury, and New Classic. “Our homes have become so much more than just living space,” says Christelle Locat-Rainville, marketing director at Formica Canada. “Homeowners are craving simple, minimal spaces that bring them peace and calm, but they also don’t want their homes to feel austere. We’re seeing them seek out materials with natural textures like patina that feel clean while making a statement. And perhaps most importantly, these surfaces need to be maintenance-free and stand up to the rigours of everyday life and multipurpose use.”

The new 180fx by Formica Canada is a revolutionary surface line that offers true-to-scale granite, stone, and woodgrain patterns with visual drama. Options include: White Alabaster, Manhattan Marble, Mediterranean Marble, Woodland Marble, and Marbled Gray.

The Formica Laminate designs offer surfaces that reflect natural materials such as wood and metal, while being durable, cost effective, and easy to install. Selections include the Patine Series, Patine Concrete, Patine Bronze, Burnished Coin, and Burnished Iron.

Laminam North America has launched its innovative Diamond Series that infuses light into the surface for a unique effect. The collection is comprised of two new colours, Calacatta Black and Cristallo Gold. Calacatta Black – available in Bocciardato and Polished Starlit surface finishes – captures the elegance of black marble, while incorporating a warm twist with subtle hints of beige. Cristallo Gold – also offered in Polished Starlit and Caress finishes – has a soft aesthetic and veins of beige, amber, and gold, emulating natural crystal patterns on a milky surface.

“Like all Laminam porcelain surfaces, Calacatta Black and Cristallo Gold do not absorb liquids or odours and are stain resistant, making them a popular choice for high-traffic interior areas and outdoor spaces,” says Philip Eeles, president of Laminam North America. “Additionally, the highperforming surfaces have antibacterial properties that prevent the growth of bacteria, making them a safe and hygienic choice for use in kitchens and bathrooms.” Laminam slabs are the first in the world to have obtained the Solid Surfacing for Food Zone certification for contact with food from the American National Standard for Food Equipment.

The Exotic Collection from Vicostone has introduced luxurious and regal surfaces that will make any kitchen come alive. The Tyrol design, inspired by natural Quartzite stone and sea cliffs, features multiple shades of white and dark grey veins. “These jumbo slabs are 130-inch by 65-inch and are available in thicknesses of ³⁄4-inch or 1 ¹⁄4-inch with a polished finish,” says Alicia Meeker, A&D account manager.

Formica in Calacatta Marble.

The new Porcelain range from Caesarstone in Smokestone.

System.

Everything. Except ordinary .

Until recently, the very idea of reducing a drawer side to 8 millimetres and, above all, making industrial production commercially viable would have been unthinkable. The new slim drawer system not only offers the only 8-millimetre one-piece steel drawer side in the world – Vionaro V8 is also the first pure-metal drawer side with no plastic elements. All parts are made of steel and joined using cutting-edge laser welding technology. That produces maximum stability plus longevity and ensures an almost 100 per cent recycling rate.

Vionaro V8 Slim Drawer

Vionaro V8 Slim Drawer System

Vicostone products are stain and heat resistant, with only mild soap and warm water required for clean-up. “Application options are only limited to your imagination, with many clients choosing to use quartz on their backsplash or shower surrounds, for a seamless and grout free option on vertical surfaces, as well as horizontal,” says Meeker. “Vicostone is proud to have many environmental certifications, such as NSF, Greenguard Gold, Declare, as well as a 15-year limited warranty.”

Exotic Stone Ltd. has been working with designers and suppliers to create outdoor living kitchens and JD Singh, owner, says the company can accommodate stone counters for any budget. “We get requests for all types of outdoor projects, from a simple barbecue surround to working counters to full, state-of-the-art chef kitchens. We have also done firepit projects.”

Singh explains while the colour choices vary, most often people are looking for dark tones that are less affected by weather. “We use the Dekton counters that are simple to install so we work with cabinet designers to get a perfect fit for customers.”

CABINETRY

Grass Canada Inc. recently introduced a state-ofthe-art drawer system – the Vionaro V8. “The V8, a revolutionary new drawer box system, is a wood drawer box substitute that is the thinnest double wall drawer box system on the market,” says George Pavlov, regional sales manager, Ontario. “This innovation means the system reduces the footprint that the drawer box occupies in the cabinet. The V8 drawer

system is only eight millimetres, compared to previous drawers, which would have been up to 1.25 inches away from the inside of the cabinet. The compact aspect maximizes the internal volume of the cabinet, and creates more storage in the actual drawer.”

With the constantly decreasing footprint in multi-unit homes, saving every millimetre means extra room and this makes a difference. “With an increase of 20 percent, that’s a lot of space and over the length of a kitchen, this gives the homeowners extra room for books, spices, or other items,” he says. The V8 comes in five heights and is available in three colours.

Sean Gerolimatos, director of research and development at Schluter Systems North America, notes that countertop trends have moved towards large thin tile format, eliminating the traditional grouted look. To accommodate this new fashion, Schluter offers the Kerdi-Board, an extruded foam board with a polystyrene core. “Our Kerdi-Board for kitchen countertops is either one-and-a-half or twoinches thick, and are easy to cut,” he explains. “This creates a waterproof, flat, ready-to-tile substrate, which saves a lot of time during installation.”

Gerolimatos adds that using their profiles with the larger tiles creates a smooth transition for the front of the countertop as well as the transition to the backsplash. “This also enables installations similar to undermount sinks using stone countertops, but the same result can be done with tile.”

Another Schluter product that is enhancing kitchen designs are stylish metal shelves. “These are either stainless steel or powder coated aluminum

Vionaro V8 drawer system from Grass Canada Inc.

Stylish metal shelves from Schluter Systems North America.

Dare to Accelerate Change

BUILDEX

shelves that have little tabs on the outside, enabling installation on a backsplash, right in the grout joints,” he says. “This addition to a design can be done at the planning stage, as well as a later add-on. They can also be used in shower designs.”

Blum Canada Ltd. launched the Legrabox system that allows for personalization of metal drawers and pull-outs. With slim .5-inch drawer sides, extra space gained inside the drawer can be used in all types of furniture. “The customizable design of Legrabox supports the latest living trends and opens up a wide range of design possibilities,” says Lucy Traetto, marketing representative. “The load carrying capacity of Legrabox is 40 and 70 kilograms, which is easily accommodated thanks to the smooth-running action of the runner systems.” Fitted with the Blumotion S cabinet profile, Legrabox features low opening forces, a synchronised feather-light glide, and gives you the flexibility to implement three different motion technologies.

Traetto adds that the high fronts of Legrabox are becoming a popular design element. “Our special front fixing bracket guarantees maximum stability when opening and closing drawers and pull-outs.” Legrabox pure and Legrabox free offer a selection of matt colours and a premium look in anti-fingerprint stainless steel. In addition to Legrabox pure with matt and metal finishes, the Legrabox free design version allows you to use glass or customized

20 years, but their latest product – the Piano line –adds a new level of sophistication to their projects. “This is a product we’ve used for a while in higher end applications, but now with the escalating cost of real estate, many people are renting,” explains Jason Coroy, president. “This allows developers to install a durable, maintenance-free option. Handleless cabinets are practical, easy to clean, and create a streamlined, cohesive interior scheme.”