KEARNS MANCINI ARCHITECTS

Single & Double options.

Optional roof for all-weather use.

Easy integration with any access control system.

ACCESS YOU CAN SEE / TRUST YOU CAN FEEL

45

Oak House Student Residence – University Of Toronto Toronto, Ontario 47

Bloor Collegiate Institute And ALPHA II Alternative School Toronto, Ontario 49

Centro Tower London, Ontario 53

Beaty Biodiversity Centre Addition – UBC Vancouver, B.C. 55

Verve And Symphony – UBC Vancouver, B.C. 59

Veterinary Learning Commons – University Of Calgary Calgary, Alberta 61

Canadian Food Inspection Agency (CFIA) Centre For Plant Health In B.C. North Saanich, B.C. 63

Cenovus Energy Hub Lloydminster, Saskatchewan 65

West Kelowna Fire Hall #32 West Kelowna, B.C. 67

Student Housing – University O f The Fraser Valley Abbotsford, B.C. 69

Fulmer Family Centre For Childhood Studies – Capilano University North Vancouver, B.C. 71

Queen Richmond Centre West – Phase II Toronto, Ontario

72

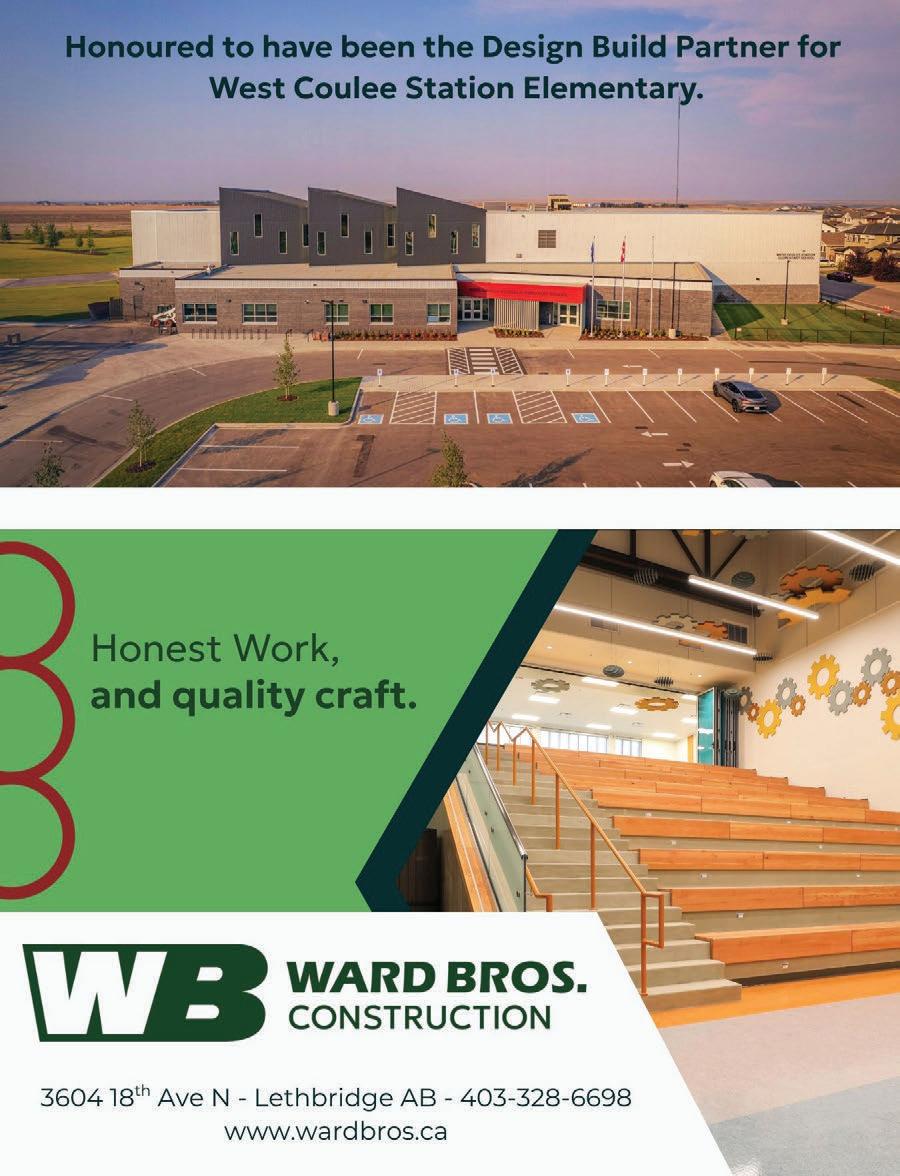

West Coulee Station Elementary School Lethbridge, Alberta 74

Kitchener Southwest Community Library Kitchener, Ontario

75

Abbotsford Recreation Centre (ARC) HeRO Project Abbotsford, B.C.

77

Quw’utsun Secondary School Duncan, B.C. 78

Calgary Soccer Centre Dome And Artificial Turf Upgrade Calgary, Alberta 81

Elementary School Langford, B.C.

83

Basin Glacial Waters – Fairmont Chateau Lake Louise Lake Louise, Alberta

39

4

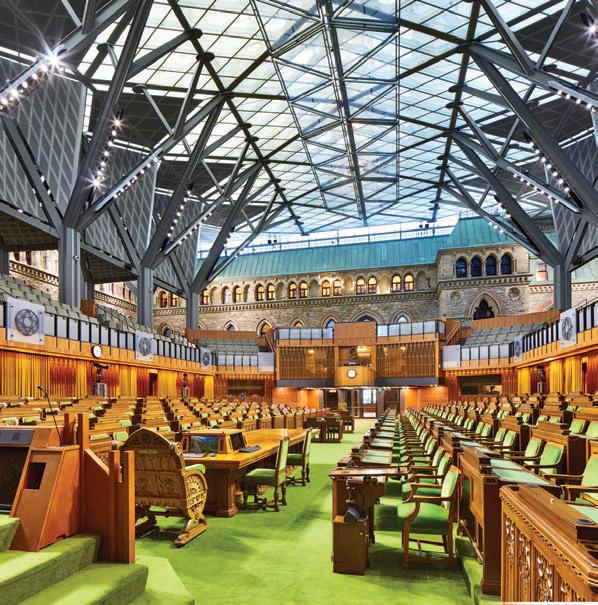

RAIC PERSPECTIVE

Reimagining architectural procurement in Canada.

6

AGENTS OF CHANGE

Kearns Mancini Architects Inc. has been designing spaces that inspire for more than four decades.

9

SLAB OF POWER

Innovations in AI and design are creating fresh opportunities across the concrete sector.

21

CANADA’S NET ZERO PLAYBOOK

Green building design is evolving rapidly as experts shape the future of Canada.

27

HOT OR NOT?

Adaptable insulation technologies deliver savings, sound control, and performance.

33

FINDING YOUR GROOVE

Architectural woodwork continues to carve out success in some unexpected places.

39

SUPPORT IN STYLE

Walls and ceilings are shaping spaces like never before.

42

OPENING DOORS TO PROTECTION

School safety and lithium-ion battery risks are among the considerations for today’s fire protection systems experts.

Reimagining architectural procurement in Canada

At the 2025 Conference on Architecture, hosted by the Royal Architectural Institute of Canada (RAIC), a session convened by the Fees and Procurement Working Group (FPWG) tackled a critical issue in the profession: the disconnect between architectural fees, procurement processes, and the actual value architects contribute to society.

Structured around six core questions, the discussion created space for delegates from across Canada to reflect on shared concerns, systemic challenges, and practical ideas for reform. What emerged was a clear imperative, to rethink how architectural services are procured and understood, and to ensure they reflect the profession’s strategic role in advancing public interest, quality of life, and long-term economic outcomes.

A PROFESSIONAL ROLE THAT SERVES THE PUBLIC GOOD

The conversation began with a reflection on public perception. Delegates emphasized that architects remain widely misunderstood, as luxury consultants or creative artisans, rather than as trained professionals delivering essential cultural, environmental, and economic benefits. Participants stressed the need to reposition architects as strategic contributors to public health, safety, sustainability, and community well-being.

There was broad support for defining architecture as a public-interest service with societal impact. Participants called for better public communication strategies, stronger narratives, and tools that allow architects to demonstrate the long-term value of design decisions, especially those made early in a project lifecycle. The RAIC’s role in equipping architects with advocacy tools and education materials was highlighted as essential.

UNDERCUTTING AND THE EROSION OF QUALITY

The issue of fee-based competition was a focal point. Delegates spoke candidly about the professional and ethical implications of undercutting, where firms lower fees beyond sustainability to secure work. While such practices may offer short-term wins, they undermine design quality, limit innovation, and place unsustainable pressure on teams.

Regional disparities in billing practices and the influence of liability insurance were also cited as contributing to inconsistent pricing and expectations. Delegates urged professional organizations to promote ethical fee practices and develop clearer standards that prioritize quality and qualifications over cost. A national architectural policy was identified as a possible mechanism for consistency and reform.

PROCUREMENT SYSTEMS IN NEED OF REFORM

When discussing procurement, the group put forward a range of strategies to improve fairness and transparency. These included the adoption of qualification-based selection (QBS), the development of standardized RFP templates, and reduced reliance on price as a primary scoring metric.

Aligning scope, deliverables, and evaluation criteria was considered vital to reducing project risk and ensuring better project outcomes.

Delegates called for the RAIC to lead efforts in advocating for these changes with public sector clients and to provide tools and training to support architectural firms in pursuing equitable procurement opportunities.

VALUE, NOT JUST COST: A NEW NARRATIVE

Delegates consistently returned to the need for a paradigm shift, from treating architecture as a cost to seeing it as an investment. Welldesigned buildings and infrastructure reduce operating costs, manage risk, improve health outcomes, and build community resilience. Framing architectural services this way can helps foster long-term partnerships and strengthen public trust.

Delegates recommended the use of clear, phased service breakdowns to improve client understanding and to avoid the misperception of design fees as arbitrary. The session also surfaced confusion about the RAIC Fee Guide and its varied use across jurisdictions. Addressing this inconsistency through clearer communication and regional engagement was identified as a critical step.

INNOVATIVE MODELS AND GLOBAL EXAMPLES

Participants explored emerging models that could support more robust and responsive approaches to fees and service delivery. Examples included international tools like the RIBA fee calculator, outcome-based contracts such as post-occupancy evaluations, and new fee structures based on project complexity or community engagement needs.

Delegates also noted the potential for technology to support fee transparency and service differentiation. Areas such as digital design review, lifecycle analysis, and participatory planning were identified as possible avenues for expanding services and creating new value propositions.

UNIFIED ADVOCACY FOR A STRONGER FUTURE

The final theme of the session focused on advocacy. Delegates encouraged the development of multi-format campaigns, including videos, award programs, and thought leadership content, that communicate the value of architecture to diverse audiences. Employer branding, client education, and coalition-building with engineers, planners, and contractors were also seen as crucial to amplifying the message.

A strong recommendation was for the RAIC to provide member firms with advocacy and communications toolkits tailored to different audiences: clients, decision-makers, and the public. These tools would help firms articulate the link between fees, scope, and outcomes in a way that resonates beyond the profession.

ONGOING WORK AND NEXT STEPS

This session was a catalyst, not an endpoint. Delegates urged the RAIC and its working group to maintain momentum through concrete initiatives: developing a national construction cost calculator, reviewing the current RFP processes, updating the RAIC Fee Guide, and continuing this dialogue at the 2026 Conference on Architecture. By taking up these calls to action, Canada’s architecture community can ensure that architectural services are not only fairly compensated, but also properly understood as critical investments in sustainable, resilient, and inclusive communities.

Agents Of Change

Kearns Mancini Architects Inc. has been designing spaces that inspire for more than four decades

by

NATALIE BRUCKNER

| photography + rendering courtesy KEARNS MANCINI ARCHITECTS INC.

The year was 1984. Canada’s economy was thriving, and Toronto was on the cusp of a five-year real estate boom. In a loft at the corner of Widmer and Richmond streets in Toronto, two young designers, Jonathan Kearns and Anthony Mancini, began shaping an idea. What started as sketches and late-night conversations would grow into one of the most innovative and environmentally-conscious design firms, with influence extending far beyond the province and onto the global stage. This was the birth of Kearns Mancini Architects Inc. (KMAI).

From the beginning, both founders were motivated by a desire to bring intelligent, positive change to the environments and lives of individuals and their communities through thoughtful, but not iconoclastic architecture. “We were inspired by some of the great change experiments of 20th-century modernism, such as the Bauhaus and Brasilia, but we were particularly interested in how these grand design experiments trickle down and are used to improve everyday life in homes and in cities, as they did in our favourites, Rio de Janeiro and São Paulo,” explains Mancini.

“We were always up for a challenge,” adds Kearns. “We undertook projects in architecture, urban design, heritage conservation, landscape architecture, and interior design, not only in Canada but also in Ireland, the UK, and Brazil.”

Every detail mattered. Every calculation, every material choice, every structural decision reflected their pursuit of technical perfection – a pursuit that would evolve into groundbreaking work in low-energy and low-carbon design.

Early on, a Postmodern emphasis on history and placemaking informed the collective design approach, but the founders preferred to keep their design vocabulary modernist and forward-looking, always respecting the finest lessons of their urban and architectural legacy. Over time, this focus grew into a

UTIAS Microsatellite Science and Technology Centre

CAMH at Queen Street West Phase 1B

philosophy of architecture as a form of cultural engineering. It was an approach that activated their collective imagination and, in later years, evolved into a vision of architecture as a holistically designed engine for sustainable living within cultural ecosystems.

“Our very early embrace of the science and technology-focused Passive House Standard drove our design focus toward finding the perfect balance between sustainable performance and cultural expression,” says Kearns.

It was this fearless pursuit of challenging projects that led them to reimagine 43 acres of Belfast’s port lands, now known as the Titanic Quarter; to redesign the world’s oldest mental hospital, St. Patrick’s in Dublin; and to found the consortium that won the commission for the new CAMH at Queen Street West in Toronto.

KMAI’s portfolio is truly rich and varied. Take The Corleck adaptive renovation that is currently under construction. Building on their experience with landmark cultural projects such as the Fort York Visitor Centre and the award-winning Ireland Park, KMAI is transforming the former Canada Malting Company administrative building on Eireann Quay into The Corleck, a 9,600-square-foot, two-and-a-half-storey, six-level cultural arts and community hub celebrating Irish-Canadian connections.

Then there’s the award-winning Passive House MURB, YWCA Hamilton, that was completed in 2021. Similar to KMAI’s high-performance residential projects such as Meadowbrook Passive House development and Bay Cannon Hamilton, the YWCA Hamilton is one of Canada’s first mid-rise multi-residential Passive House developments, setting a bold new standard for sustainable, affordable housing. The project delivers a healthy, comfortable living environment while tackling climate and housing challenges head-on. “The fusion of creative architecture and science-based Passive House is our greatest challenge,” says Kearns.

Other incredibly notable projects that demonstrate the breadth and ambition of KMAI’s work include the UTIAS Microsatellite Science and Technology Centre that was completed in 2012 and combined a world-class research facility with bold, expressive architectural form, reflecting the firm’s ability to balance technical complexity with visual impact. That same year, the CAMH redevelopment, master plan phases 1A and 1B, demonstrated KMAI’s ongoing commitment to advancing mental health care through thoughtfully designed spaces.

While biophilic design may have only recently hit the headlines, back in 2020 the firm completed the nature-inspired Endymion Guesthouse in the bucolic landscape of Black Creek, Prince Edward County, Ontario, bringing a serene, environmentally sensitive vision to residential design. This year, the

BMO Fischer Hallman sustainable branch raised the bar for sustainable design in financial institutions. Designed with CLT to Passive House Classic and Zero Carbon standards, the building operates at net zero energy.

So, who exactly are the talented minds behind such groundbreaking projects? It’s a collaboration of energetic individuals nurtured by a culture rooted in learning, mentorship, curiosity, and shared design exploration. “We balance imagination with pragmatism, approaching construction and cost thoughtfully while pursuing innovative design. We value inclusivity, encourage diverse perspectives, and celebrate milestones together, from design reviews to office traditions that keep our team connected. We are very supportive of each other and feel like a family – one that loves to throw a good party,” explains Kearns. And a “family” that is known for asking a lot of questions!

“Our approach is one where we are driven to truly understand and define the soul of each project and never rest until we have found the ideal solution,” says Mancini. “A solution that allows the end-users of the building to naturally become a part of their new space while being liberated by it.”

And with so much achieved already in four decades, what can we expect from KMAI in the future? “We are excited by the opportunity to shape a sustainable future through Net Zero, Passive House, and innovative and artistic architectural solutions. The challenges of climate change and affordability inspire us to push the boundaries of design, research, and technology in service of healthier, more resilient communities,” says Kearns. A

The Corleck

Endymion Guesthouse 3100 Meadowbrook Lane

Fort York Visitor Centre

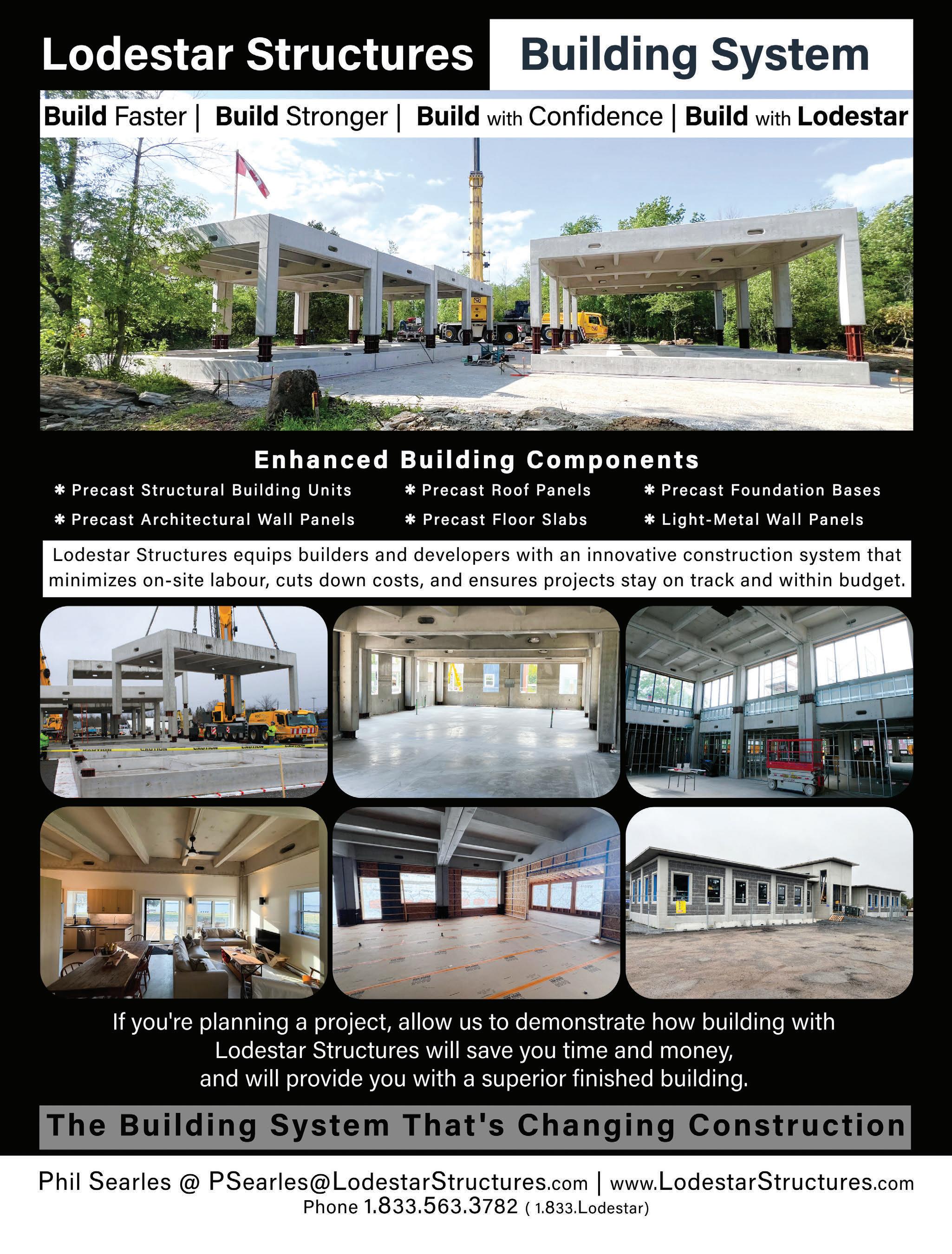

Build Smarter. Build Faster.

Build with Prefab Precast Concrete.

In response to Canada’s housing crisis, prefab precast concrete provides a powerful solution. It is faster, durable, and cost-effective, as each component is made in a controlled environment. Prefab precast concrete offers superior quality, making it a resilient and sustainable approach to addressing Canada's mid to high–rise housing shortage.

Find out more about the benefits of using prefab precast concrete for your next project.

Let’s build fast, affordable housing together!

For more information, visit: www.cpci.ca/publications or scan the QR Code.

Charis

Village, Lacombe, AB |

Owner: Charis Village Housing

S ociety

|

Architect:

OCA Architects

SLAB of POWER

Innovations in AI and design are creating fresh opportunities across the concrete sector

by ROBIN BRUNET

The end of 2025 finds concrete advocates and manufacturers in a familiar spot: in a market of robust demand, and striving as always to advance concrete’s reputation as a sustainable building material.

Arguably the most vigorous advocate of precast/prestressed concrete is Brian Hall, managing director of the Canadian Precast Prestressed Concrete Institute (CPCI), who is effusive in explaining precast concrete’s sustainable benefits.

“Due to the inherent high-performance qualities of precast concrete, buildings that perform better and last longer can naturally help reduce the longterm impact on climate change. While all long-term operational benefits are significant, it is also important to address the effects of climate change in the short term,” says Hall. “The goals of the precast concrete industry include reducing greenhouse gas emissions by lowering carbon emissions during production, decreasing the amount of Portland cement used in concrete mixes, and increasing strength and durability while using less material.”

Hall goes on to note that, “An ongoing innovation is the use of supplementary cementitious materials [SCMs] that can reduce the amount of Portland cement in concrete. Recycled by-products such as fly ash, slag cement, and silica fume are commonly used to decrease cement content, while also enhancing the strength and durability of the precast concrete. Since the publication of our first industry-average EPD [environmental product declaration] in 2015, the Canadian precast industry has

seen a 22 percent reduction in our embodied carbon across our main product categories, as documented through CPCI’s three rounds of EPDs.”

Hall adds that precast concrete’s durability and resiliency give it a service life of 100 years or more.

“No other building material matches precast concrete in terms of resiliency, sustainability, blast

resistance, storm resistance, inherent fire resistance, and overall durability,” he says. “The precast concrete industry continues to explore innovative new technologies to increase production efficiency and reduce embodied carbon and greenhouse gas emissions.”

Amrize Building Materials, which was announced as the name of Holcim’s North American business sector in February 2025, is one of many examples of a company whose collaborative capabilities advance concrete as a sustainable material. A major example is its recent partnership with U.S. technology company Meta.

Together, the two companies created a first-of-its kind AI-optimized concrete mix for surface use that was 43 percent faster in early strength and 35 percent less carbon-intensive – all at similar cost.

Essentially, Meta, with the University of Illinois, used concrete ingredients from Amrize to generate, mix, and test recipes in a lab, the data of which (mix meets strength and other performance parameters) was used to train an AI model developed by Meta. This project moved from theory into practice when Amrize then became the main concrete supplier for Meta’s new data centre in Rosemount, Minnesota – data centres in general require excellent finish quality of the concrete for the installation, operation, and maintenance of mission-critical servers.

Jaime Hill, president of Amrize, says, “Partnering with Meta and using AI to develop an innovative concrete mix that meets the unique needs of data centres is just the beginning. Using AI, we can optimize our specialized concrete formulations for data centre requirements, from performance needs like

Poured concrete floor at Meta’s new data centre.

Precast panels with pre-installed windows, Odea, Montréal, QC.

strength and durability to thermal regulation and energy efficiency. We look forward to continuing this exciting work with Meta to scale up the adoption of advanced tailored concrete mixes.”

Providing new housing in huge volumes across North America is a social challenge that has inspired at least two concrete companies to develop innovative solutions. The first comes from Lodestar Structures, which was launched into the Canadian construction industry by Anchor Concrete Products in 2020, immediately receiving multiple industry awards and earning international recognition. In 2021, Lodestar Structures introduced a global licensing program, expanding access to Lodestar Structures to companies around the world. Today, Lodestar is actively engaged in various stages of planning and contract negotiations with teams in more than 60 countries.

Phillip Searles, director of global sales and business development, says, “Essentially, with Lodestar, we created a solution for communities to have immediate access to high-quality, locally manufactured building components, allowing them to rapidly erect structures where they can confidently live, learn, work, and play.

“Our manufacturing program is scalable to address demand growth and can be deployed in remote communities as efficiently as in urban regions. A major advantage of Lodestar is that the components used in the manufacturing process can be sourced locally, and the skill level required to manufacture or install the modules isn’t extreme,

allowing teams to competitively deploy Lodestar Structures without the requirement for highly skilled individuals, and without the need for major equipment investment.”

Lodestar consists of precast foundation base units, precast structural building units, and precast panels used for perimeter cladding. Components are manufactured offsite and delivered to the construction site ready for immediate installation; they are designed to provide unlimited building designs and layout options. The construction process reduces superstructure framing schedules by as much as 90

percent and overall construction time by up to 50 percent, allowing builders to concentrate on enclosing the structures and completing interior works.

Searles describes business in 2025 as “fantastic,” and while Anchor continues to ship products across Canada, he is most excited that Lodestar has established license agreements in three countries and will add another six countries in 2026. “We’re in discussions with potential licensees in over 60 countries, including Africa, South America, Mexico, and Australia,” he says. “The potential for growth is phenomenal and limitless.”

Lodestar consists of precast foundation base units, precast structural building units, and precast panels used for perimeter cladding.

THE SMARTER WAY TO MULTI-FAMILY

Accelerate your multi-family development with Stubbe’s Total Precast solutions; one system, one source, total efficiency.

Our Total Precast package combines structure, cladding, and hollowcore floors into a single, coordinated system for faster construction, higher quality, and fewer onsite delays.

Built in CPCI-certified facilities, Stubbe’s delivers precision, durability, and speed. Helping you build smarter and finish sooner.

MILE AND CREEK

In a similar vein, FastTrack by Stubbe’s is an ingenious modular precast system that enables developers to deliver buildings faster and at a competitive price. “We’ve driven the cost of residential projects by 20 percent, or in one case down to $225 per square foot, and we’re not done making adjustments that will lower costs even further,” says Jason Stubbe, managing director at Ontario-based Stubbe’s.

FastTrack modules, which meet the criteria required by the CMHC, are comprised of standardized precast pieces that include floors, ceiling, walls, and exterior building envelope (with windows and patio doors) all in one enclosed unit. Interior finishes are still built out traditionally, but by integrating the design, manufacturing, and installation processes off-site, construction time and on-site labour requirements are significantly reduced.

And while the parameters of the modules can’t be adjusted, they can be combined to achieve a huge variety of layouts. “And we deliver quickly,” Stubbe says. “If a customer needs a 50-unit building, we can give them a working plan within 10 days.” Indeed, a five-storey, 50-unit rental building from Livwell Development in Niagara Falls was completed less than one year after breaking ground, six months ahead of the anticipated completion schedule.

More importantly, from an end-user’s perspective, all of the projects built with the FastTrack system exhibit the quality and aesthetic appeal of high-end condos. “We’re coming off our busiest year ever, and the New Year is very promising,” Stubbe says. “We have the capacity to build 3,000

Diamond Polished Concrete.

A Strong & Beautiful Concrete Flooring Solution

Diamond Polished Concrete is a unique, advanced flooring system that brings out the natural beauty of concrete, helps reduce maintenance costs and enhances the natural durability of concrete surfaces. The Tri-Con Diamond Polish System employs an innovative 7-step grinding and polishing process that utilizes progressively finer diamond grinding heads. This system also uses the most advanced penetrating sealer technology.

Tri-Con Concrete Finishing is an industry leader with more than 30 years experience in the concrete industry. We are a one-stop supplier capable of pouring new floors to exact specifications as well as restoring existing concrete surfaces with endless versatility. We guarantee that we deliver on time, on budget and on spec every time.

FastTrack modular precast system utilised on The Drummond, Niagara, ON.

PRODUCTS

• Black, Stainless & Epoxy Coated

Rebar • Threaded Rebar

• Welded

Wire Mesh • Reinforcing Steel

Accessories • Plain Round Bars

• Post Tensioning Systems

• Mechanical Couplers

SERVICES

• Consultation

• Budgeting

• Estimating

• Detailing

• Fabrication

• Installation

units annually, and given the need for quality residences and other infrastructure at a lower cost, we see demand booming.”

Since its founding 22 years ago, AltusGroup continues to spearhead precast concrete innovation, its main achievement being CarbonCast Enclosure Systems

that use advanced carbon fibre technology to improve precast concrete by integrating ultra-strong, noncorrosive C-Grid into the panels during fabrication.

CarbonCast High Performance Insulated Wall Panels use C-GRID as a shear connector between the inner and outer wythes of concrete, delivering

a panel with full composite action and continuous insulation; and CarbonCast Insulated Architectural Cladding is one of the only exterior architectural precast wall panels with continuous insulation to meet ASHRAE requirements (it also weighs up to 40 percent less than conventional precast wall panels).

Licensing CarbonCast has enabled this system to be used internationally, and in February, Belgian precast manufacturer C-concrete became the latest producing member of AltusGroup. “C-concrete’s experience with walls, façade panels, insulated sandwich panels, and brick veneer panels will enable it to integrate CarbonCast technology into existing enclosure platforms to produce highly sustainable, low-carbon footprint sandwich panel wall assemblies to satisfy European market needs,” says Katherine Klosowski-Blatz, AltusGroup’s executive director.

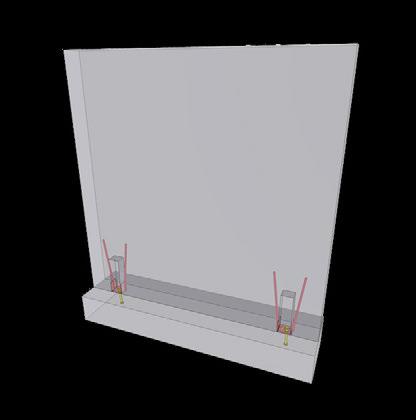

As for products that aid concrete’s performance and resiliency, Peikko Group Corporation is renowned globally for its slim floor structures and connection technology for precast and cast-in-place construction, thus aiding the ongoing goal to build faster, safer, and more sustainably.

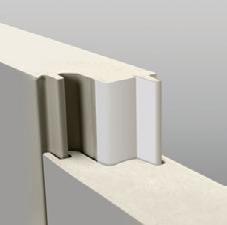

Sumo Flex is the latest product from Peikko to benefit concrete, specifically precast wall panels. Sumo Flex Bolted Wall Panel Base Connections provide a fast and efficient alternative to traditional embed and welded items for connecting precast concrete wall panels to foundations. By eliminating on-site welding, Sumo Flex significantly reduces labour time and also eliminates the need for costly fire watch supervision.

Nova Scotia Community College’s Ivany Campus student residence built with CarbonCast High Performance Insulated Wall Panels.

Strong, innovative, sustainable.

EvoBuildTM is the evolution of sustainable building materials designed to meet today’s sustainability targets.

With knowledgeable experts, science-backed data and sustainable product formulations, we’re able to work alongside you, offering unparalleled service from concept to completion.

EvoBuild™ Low Carbon Concrete is part of Heidelberg Materials’ Evolve™ Family of Products. Learn how these revolutionary products can help your project be part of a greener tomorrow.

Sumo Flex is designed for use with three-quarter-inch post-installed anchors and features two bolt holes for enhanced flexibility during installation. The components are optimized using finite element analysis and manufactured from ASTM Grade 50 plates and Grade 60 reinforcement bars.

The connection accommodates a six-degree bolt angle and achieves a tension capacity of 10 kips. Sumo Flex is ideal for applications where speed, flexibility, and code-compliant performance are required without the complications of welded field connections.

Also aiding concrete’s performance is Kryton International Inc., whose integral concrete waterproofing and durability solutions are used globally. Ironically, Kryton most recently achieved growth not by expanding, but by contracting: in July, CEO Kari Yuers explained that a decision to narrow Kryton’s product line from 150 to just 12 – focusing on integral concrete waterproofing with its awardwinning Krystol technology – sparked a new era of focused growth for the Vancouver-based company thanks to being able to streamline resources, double down on innovation, and ultimately accelerate global expansion.

As far as Yuers is concerned, this comes at an opportune time: for example, Yuers believes

outdated or untreated concrete is no longer acceptable in mission-critical infrastructure such as data centres, where even minor slab weaknesses or hairline cracks can lead to $1 million-per-hour outages.

Yuers also recently cited Krystol products as ideal solutions for America’s wastewater and stormwater systems, which in August received failing grades from the American Business Times: “Our admixtures are ideal for water infrastructure projects because they waterproof and abrasion-proof the concrete, ensuring a lifespan of around 100 years that not only secures the drinking water or sewage system of major population centres, but yields significant ROI for taxpayers and utilities who won’t have to keep paying for costly maintenance efforts.” A

BUILDING THE FUTURE

Foundation concrete pour of the 43-storey campus tower at UBC Okanagan.

PRECAST CONCRETE QUALITY ASSURANCE!

THE CPCQA CERTIFICATION PROGRAM

The Canadian Precast Concrete Quality Assurance (CPCQA) Certification Program prequalifies precast concrete manufacturers who fabricate structural, architectural and specialty precast concrete products, including concrete pipe and underground utility and drainage products.

Manufacturers adhere to the CPCQA certification program requirements, and to the applicable requirements of the CSA, PCI, ASTM, and Provincial Standards.

THE CPCQA CERTIFICATION PROGRAM OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Endorsed by the Canadian Concrete Pipe and Precast Association (CCPPA) www.ccppa.ca and the Canadian Precast/Prestressed Concrete Institute (CPCI) www.cpci.ca

For more information, scan the QR Code or visit www.precastcertification.ca

Project: Champagne Quarry Park, Calgary, AB

Architect: Gibbs Gage Architects

CPCQA

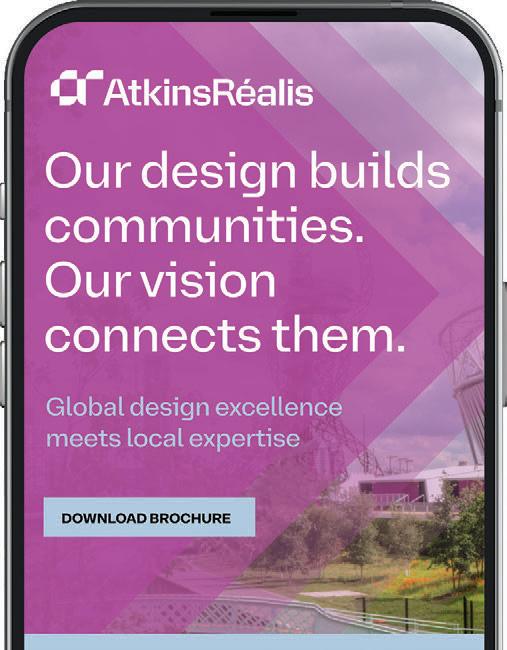

Connecting communities through purposeful architecture

Performance. Sustainability. Connectivity.

Scan the QR code to explore our vision for Canada

AtkinsRéalis Architecture & Design Canada Inc.

Green building design in Canada has continued to gain momentum this year, with advances in sustainable materials, low-carbon construction techniques, and operational efficiency reshaping the way projects are conceived and executed. Across architecture, engineering, and construction, the focus on energy performance and transparency reflects an industry increasingly committed to environmental responsibility, regardless of economic pressures or the regulatory landscape.

Among the most significant and potentially historic developments of 2025 in Canada (and one that hopes to fill a critical gap in the infrastructure and construction ecosystem) was the appointment of Hellen Christodoulou (former executive vice-president of Corbec) as president and CEO of the Canadian Galvanizing Institute. CGI-IGC is dedicated to supporting the promotion of durable, low-carbon solutions that contribute to Canada’s Net Zero goals.

“The reason I am taking this role is because during my journey at Corbec, I realized that if I want to advance greening standards, environmental product declarations, and improvements in corrosion protection – which are part of the operational side of infrastructure construction – we need alignment,” she says.

Christodoulou’s goal is to establish a Canadian framework that brings designers, galvanizers, procurement teams, government, and researchers onto the same page. “Currently, Canadian standards do not exist, and the industry has had to rely on U.S. standards that are ridiculously outdated. We will work with the Canadian Standards Association, national research bodies, and larger fabricators to gather needs and put everything together. It is a big ask, but the needle will move. This is Canada first,” she adds.

PARTNERING FOR SUCCESS

Other big news for this year is the number of partnering opportunities. Partnership has long been recognized as the most effective path to excellence in green building design. SMS Engineering, Number TEN Architectural Group, and Crosier Kilgour have embraced this approach to deliver some of Winnipeg’s most iconic sustainable projects.

Canada’s Net Zero Playbook

Green building design is evolving rapidly as experts shape the future of Canada

by NATALIE BRUCKNER

One example is the University of Winnipeg Axworthy Health and RecPlex, which officially opened in 2014. This 160,000-square-foot, three-storey facility achieved LEED Gold and Power Smart status with Manitoba Hydro, and houses a regulation-size indoor soccer field, 10,000-square-foot wellness centre, parkade, and classrooms.

Energy efficiency and user flexibility guided every decision. As the first building in Manitoba to use 100 percent LED lighting, it features advanced lighting controls across three zones and five brightness levels. Mechanical systems emphasize sustainability and adaptability, while high-efficiency condensing boilers feed a distributed fan coil system for zone-specific temperature control across offices, gyms, meeting rooms, and multipurpose areas (including those used for smudging). Ventilation includes a reverse-flow energy recovery unit and an economizer cycle that draws on outdoor air for cooling in colder months. Through collaboration, the Axworthy Health and RecPlex stands as a major recreational and wellness expansion for the downtown campus, showcasing how sustainable design can shape healthier, more connected communities.

Another great partnership is that between Architek Group of Companies and LACF and the launch of the Sustainable Urban Development Grant to be offered as a Research Grant over the course of the next five years.

Vancouver House

University of Winnipeg Axworthy Health & RecPlex

Architek is committed to advancing sustainable practices in the built environment through innovative solutions in green roofs, living walls, green façades, and water conservation technologies. This grant supports pioneering research in sustainable landscapes for urban settings, focusing on design solutions that address challenges related to urban green roofs, green walls, and water management in Ontario.

“For over two decades, we’ve worked to make biophilic design a necessity, not a luxury,” says Letitia Silk, national director of business development and growth. “This grant will uncover bold, research-driven solutions, showing how green roofs, water management, and living architecture can shape resilient, human-focused cities.”

WHAT’S TRENDING

According to Iain MacFadyen, sustainability strategist, one of the biggest trends the Parkin team has seen this year is cost pressure, with sustainability often being viewed as a line item cut.

On the positive side, this has given Parkin the chance to guide clients toward value-driven, evidence-based strategies. “We are also seeing green building evolve beyond energy efficiency alone. The focus has expanded to holistic sustainability, including carbon neutrality, resilience to climate change, and the integration of biophilic design. In health-care architecture, this translates into healthier indoor environments, reduced operational costs, and facilities that support patient wellbeing,” says architect Kayla Murrell.

Architect Paloma Szpaizer highlights the Cowichan District Hospital replacement project as a showcase. Fully electric, it has achieved LEED Gold and the CAGBC Zero Carbon Building Design Standard. “The project included a multidisciplinary team, with the client aligned on strict energy and carbon targets. Alliance Project Delivery allowed strategies to be tracked and refined throughout the design stages and communication between parties improved. Innovations include high-performance heat recovery systems using 100 percent outdoor air, a photovoltaic panel system supplying two percent of total energy through a non-invasive roof installation, extensive daylighting analysis for patient comfort, and a concrete mix with reduced cement volume and GWP.”

At Diamond Schmitt Architects, the predominant trends in green building design this year have centred on embodied carbon reduction and net-zero energy projects, with these areas now dominating their current portfolio of projects.

“Academic, library, and federal projects are really pushing the envelope,” explains Lisa Prime, director of sustainability. “In the last couple of years, we achieved zero-carbon design certification on several projects, including Guelph Central Library, the first stand-alone library in Canada to achieve Canada Green Building Council’s Zero Carbon Building – Design Standard, Humber Cultural Hub, and Ādisōke – the new Ottawa Public Library – Library and Archives Canada joint facility.”

With respect to material innovation, Prime highlights the exploration of solar-integrated façades, as exemplified in projects such as Manitou a bi Bii daziigae at RRC Polytech, Innovation Village at Fanshawe College, and the Toronto Paramedic Services Multi-function Station 02. “There is also a growing adoption of low-embodied-carbon materials, including low-carbon concrete,” she adds. “Stronger policy frameworks and increased market availability have prompted clients to request these materials more, enabling us to integrate them more frequently – an important factor for achieving zero-carbon projects.”

Although economic pressures and evolving regulatory contexts pose challenges, Prime says that steady progress remains essential. Diamond Schmitt has developed a comprehensive benchmarking database encompassing all its projects to systematically track embodied and operational carbon, health, social sustainability, and resilience metrics. “This enables us to measure outcomes, generate insights, and demonstrate leadership both internally and across the broader architectural and construction industry,” Prime explains.

ADAPTING TO A NEW NORMAL

In regions increasingly affected by extreme heat and wildfires, there’s an understanding that green building design must extend beyond efficiency to encompass climate resilience. Introba, one of the world’s largest building engineering and consulting firms, has been instrumental in guiding municipalities and Indigenous communities in B.C. to understand and respond to heat risk. Through detailed climate risk and vulnerability assessments, coupled with mapping of social and environmental data, Introba emphasizes the importance of connecting technical analysis with lived experience. Community stories illuminate how heat impacts daily life, shaping strategies that are both data-driven and human-centered.

Robin Hawker, associate principal for climate resilience, notes that interactive tools such as GIS-based story maps enable residents to visualize areas of vulnerability and understand the reasoning behind targeted interventions. This process strengthens trust and supports meaningful engagement. Introba is also evaluating existing public buildings for upgrades that would allow them to operate as resilient cooling shelters. Incorporating passive cooling, backup power, and flexible design ensures these spaces can provide comfort and safety year-round.

Cowichan District Hospital

Manitou a bi Bii daziigae at RRC Polytech

Innovation Village at Fanshawe College

CHANGING THE RULES

Experts at global engineering and professional services consulting firm WSP say there is good news for low-carbon grid capacity. Recent developments include streamlined permitting through new legislation such as B.C.’s Bill 14 and Ontario’s Bill 40, a growing number of large-scale wind and solar projects with significant First Nations equity ownership in Alberta, B.C., and New Brunswick, and Nova Scotia’s approval of the $60-billion Wind West Atlantic Energy project.

“We expect to see growing attention in 2026 on the scalability and cost of lowcarbon hydrogen and small modular reactors, supported by Ontario’s Hydrogen Innovation Fund,” says Veronica Owens, interim market leader, energy and sustainability, property and buildings at WSP in Canada.

In defence, Owens notes a rapid increase in spending, with a $9-billion budget for the 2025 to 2026 fiscal year (less than two percent of GDP), and a commitment of five percent of GDP by 2035. “Defence buildings, new or existing, need to meet net-zero carbon, low-embodied carbon and 100 percent clean electricity targets. We expect to see more building-integrated renewables and low-carbon district energy systems on defence campuses. What to watch: lowcarbon fuel development for submarines, aircraft, and ships,” she says.

On design co-ordination, Owens says there’s good news on the horizon with the adoption of building information modelling (BIM) level of detail 300 and beyond to 4D, 5D, and 6D to reduce rework, improve quality, and support compressed schedules. As 2026 approaches, she says the convergence of BIM, digital twins, and AI automation, along with the effects on early optioneering and alternative procurement models, are also trends to watch.

On the topic of regulations, FortisBC continues to support the development of high-efficiency homes and buildings to help lower overall emissions and support B.C.’s climate goals.

Two recent projects in the B.C. Interior highlight how building to higher levels of the BC Energy Step Code can be achieved across different building types and regions, with support from FortisBC’s rebate program for commercial new construction.

In Castlegar, the Chamber of Commerce’s new Confluence of Tourism and Economic Development building has become a model for sustainability. The Passive House-certified, all-electric facility prioritized engineered wood panel walls and roof systems with exceptional insulation, combined with airtight construction, to significantly cut heat loss and eliminate drafts.

Meanwhile, in Kelowna, Okanagan College’s new student housing project was built to Step 4 of the BC Energy Step Code. The design integrates highefficiency dual-fuel heating and cooling systems, balancing electricity and gas use to optimize performance. This hybrid approach reduces overall energy demand while lowering associated emissions, offering a practical pathway for larger institutional projects.

THIRD PARTY TESTING

Green building design is about so much more than the obvious. It’s about striving to exceed standards through third-party testing. This year, Innotech announced the successful testing and certification of its products to meet the stringent requirements of the North American Fenestration Standard (NAFS) AW Class – the highest performance class under NAFS.

This major milestone validates that select Innotech window and door systems have undergone rigorous third-party laboratory testing to meet and exceed the demanding criteria of the AW Class, also known as the Architectural Class, as defined by AAMA/WDMA/CSA 101/I.S.2/A440 (NAFS), consequently further verifying their suitability for high-performance multifamily and commercial buildings.

info@niacoat.com

Confluence of Tourism and Economic Development

“This achievement reflects our ongoing commitment to engineering and manufacturing high-performance fenestration solutions for the most demanding applications,” says Troy Imbery, president of Innotech Windows + Doors. “Our AW Class certified products offer developers and building professionals the confidence that our systems can withstand the harshest environmental conditions while delivering superior energy efficiency and long-term durability.”

MASS TIMBER

For Glotman Simpson, it has been a milestone year in sustainability, marked by contributions to mass timber projects that continue to expand the possibilities of the material.

Rory Roberts, director of sustainability at Glotman Simpson, says, “At Kalesnikoff’s Head Office in Castlegar, the emphasis was on precision – concealed fire-rated connections, long-span glulam beams, and prefabricated wall systems – all detailed to showcase the material’s strength and clarity. The result is not just an office, but a living demonstration for Canada’s largest mass timber producer. At North Shore Neighbourhood House Phase 2, those lessons were applied at a larger scale, into high-rise construction. By pairing a concrete core with prefabricated CLT panels, we developed a hybrid system that meets seismic and fire requirements at 18 storeys, while supporting affordable housing and critical community services. Together, these projects illustrate the breadth of what mass timber can achieve – from finely crafted workplaces to large-scale, mixed-use housing – and underscore the role of engineering in making these possibilities real.”

Beyond mass timber, Roberts points out that sustainability gains often come from planning early, particularly when it comes to embodied carbon.

“Structural efficiency is one of the most effective ways to reduce embodied carbon. Starting in schematic design, when decisions carry the greatest influence, creates opportunities to explore innovative structural strategies, including mass timber. Increasingly, clients are engaging with us at this stage, knowing that the additional effort upfront leads to meaningful carbon savings, cost efficiencies, and stronger long-term outcomes for both projects and the environment.” A

Structural details of the Kalesnikoff Head Office mass timber project.

Timbre & Harmony in Vancouver, BC Passive House A ordable Housing Ryder Architecture & Etro Construction

Hot Or Not?

Adaptable insulation technologies deliver savings, sound control, and performance

by ROBIN BRUNET

Acombination of traditional materials and new formulations continues to characterize insulation development in North America, to satisfy ever-stricter energy regulatory bodies as well as end users who more than ever need to lower their energy costs.

Concrete products remain an effective insulation solution for a variety of buildings. Brian Hall, managing director of the Canadian Precast Prestressed Concrete Institute (CPCI), explains, “Double wythe insulated precast wall panels offer all the benefits of traditional precast, such as durability, acoustic absorption, and quick installation, along with the added advantage of being a comprehensive, all-in-one building enclosure system. These panels are suitable for a variety of applications, including mid- and highrise residential buildings, office towers, data centres, schools, gymnasiums, and industrial facilities.”

Hall says the most common types of insulation used in precast concrete are rigid foam boards, “particularly Expanded Polystyrene [EPS], Extruded Polystyrene [XPS], and Polyisocyanurate [Polyiso], which are sandwiched between two concrete wythes to form an insulated panel. Other options may include Graphite Polystyrene [GPS] for enhanced thermal performance. The choice of insulation depends on factors such as cost, R-value, density, and moisture resistance requirements specific to each project.”

Hall reports that his institute is collaborating with RDH Building Science to update the CPCI Architectural Precast Concrete Walls Best Practice Guide, scheduled for publication in late 2025.

Saint-Gobain Canada, through its CertainTeed brand, introduced two new insulation products across Canada in June 2025: Lanaé Sustainable Insulation and the Lanaé Noise Reducer range.

Manufactured at CertainTeed’s insulation facilities in Redcliff, Alberta, and in Ottawa, Lanaé insulation represents a leap forward in sustainable building practices. It is formulated with a bio-based binder that is formaldehyde-free and intended to reduce environmental impact while maintaining superior thermal performance and acoustic comfort.

Key benefits include up to 82 percent recycled content and a bio-sourced renewable binder; reduced dust, odourless installation, and improved handling, recovery, and rigidity. The formulation without formaldehyde demonstrates Lanaé’s commitment to the comfort and well-being of Canadian households, while enhancing energy efficiency.

CertainTeed Lanaé Sustainable Insulation is an easy-to-install, cost-effective solution to help save energy in residential and commercial new construction, as well as for renovating or retrofitting existing buildings. In addition to its thermal properties, this insulation also provides excellent acoustical performance. It is made of glass fibre that consists of rapidly renewable content, a high percentage of recycled glass, and a plant-based binder – no dyes or unnecessary fire retardants added. It is designed for use in standard wood stud and steel frame assemblies.

CertainTeed Lanaé NoiseReducer Sound Attenuation Batts are designed for use in residential and commercial wall and ceiling assemblies. These sound-absorbing batts fill the void between interior standard studs, and break the path of sound

Installation of CertainTeed Lanaé Sustainable Insulation.

Harvestview Apartments, Tillsonburg, ON, constructed with precast Double Wythe Insulated Panels.

Where SUSTAINABILITY meets SUPERIORITY.

High performance

Bio-based building materials

PERFECT COMBINATION

BP’s R-1.5 exterior sheathing panel provides structural strength, noise reduction, superior water vapour permeance at 37 perms, and a remarkably low carbon footprint, at a value based pricing. R-1.5 Continuous superior water vapour permeance – a perfect combination for our canadian climate.

DISCOVER BP’S WOOD FIBRE INSUL-SHEATHING PANELS

Recycled wood fibre sourced from post industrial and post consumer origin

REDUCE MATERIAL and LABOR COSTS

BP’s Excel exterior sheathing panel provides R-1.5 of continuous insulation while providing superior structural strength, weather resistive and air barrier properties ensuring that your walls remain warm and dry, mitigating moisture entrapment in the wall cavity.

PERFORMANCE and STRENGTH

BP’s R-5 XP exterior sheathing panel provides R-5 of continuous insulation using Dupont’s low GHG STYROFOAM™ Extruded Polystyrene, laminated to a ½" high performance wood fiber panel. The overall panel assembly provides a water vapour permeance rating of 2 perms, ensuring an optimal performance of your overall building envelope.

for added privacy and quiet. They provide excellent acoustical performance to reduce sound transmission between adjoining rooms; plus, they are lightweight and flexible – easy to conform to irregular surfaces – and resist mould and mildew.

Maxime Duzyk, senior global director, building science and engineering at Huntsman Building Solutions, reports that his company’s D-Max wall assembly is “always gaining in popularity, with many more projects all across Quebec province.” Those projects include the multi-residential Complexe 2L at Mirabel; multiple locations of Maison des Aînes (affordable senior housing); the luxury rental condos of Project Le Miner in Granby;

LUX rental condos in Montreal; and in Ontario, Everhome Markham condominiums.

Duzyk says the appeal of D-Max is simple: “General contractors appreciate the cost and time savings of the assembly, while architects appreciate the simplicity of details, adaptability, durability, and the quality of the building envelope.”

The D-Max wall assembly allows the installation of spray foam insulation from the interior of the building, while managing the thermal bridging of the studs and the structure. Spraying can be conducted regardless of temperature or wind, less machinery means less rental cost, and sequencing of work is simpler and easier to manage due to fewer

workers required. Plus, overspraying is avoided, as is the requirement to install an interior furring (in comparison with a wool-insulated cavity where the electricity cannot run through the stud cavity).

Duzyk says he fully expects D-Max to be used in an increasing number of construction projects in the New Year, “because it’s recognized as the easiest path to meeting new energy efficiency requirements. New residential and commercial energy studies demonstrate D-Max’s energy and cost savings as well as the environmental benefits of spray foam versus traditional wall assemblies.”

Other companies are equally ambitious in providing wall assemblies with superior insulating

provided a level of fire protection suitable for use in non-combustible construction, and using a two-inch layer of mineral wool to encapsulate Sopra-ISO V maximized

Roofing is a prime focus of attention for developers seeking energy efficiency and lower heating bills. Amrize Building Envelope manufactures roofing solutions through its Elevate brand, which provides commercial roofing products for industrial and commercial projects. The company offers a broad range of roofing solutions, including components such as membranes, insulation, and

“Elevate Isogard is unique because the thermal performance is up to 40 percent better than major competitors. The increased R-value per inch means better thermal performance from the same roofing systems using the same amount of insulation compared to leading competitive products on the market today. Building owners may realize in HVAC savings due to the added value that Isogard brings,” says Jasmeet Deol, senior manager, product marketing at

Elevate Isogard polyiso insulation is the first product on the market that meets both ASTM C1289 required and recommended thermal performance values. And its superior performance in colder mean temperatures makes it is a good solution for roofing projects across Canada.

In addition to standard insulation products, such as Isogard GL and CG, the Elevate Isogard portfolio also includes specialty insulation products such as Isogard HG panels that help protect against accidental punctures, hail, and winds up to 160 kmph. Isogard HD Composite provides a factory-laminated cover board directly to Elevate standard Isogard polyisocyanurate insulation, creating a high-performing, energy-efficient insulation board, while helping to save installers time and labour due to not having to adhere another layer. Meanwhile, Isogard Tapered Insulation provides an effective and economical solution when a substrate’s slope will not permit efficient drainage.

Greenstone Building Products of Brandon, Manitoba, distinguishes itself with Insulated Composite Envelope (ICE) panels, a product engineered to combine two well-known building materials: EPS and galvanized steel. This combination creates a much lighter and stronger building envelope, and the manufacturing process, on top of connection details, eliminates thermal bridging.

ICE panels have been used in retail spaces across Canada, but arguably they are ideal for multi-unit residences in which the envelope is vital in maintaining a high efficiency value across every living unit. An additional benefit of ICE panels is their versatility: they can be used for roofing applications, below-grade, and for floor systems (in the latter case, a subfloor placed on top of 5.5-inch ICE panels results in a floor equally as warm as one with in-floor heating, but without the cost).

Finally, a new and unique insulation for unusual applications was recently released by Johns Manville: the Insul-Shield Black is a fibreglass insulation board with a black core intended for use in theatres, music studios, and dark amusement park rides, because the black core reduces the potential for the yellow fibreglass colour to show through. It’s an ideal backdrop behind theatre screens (it eliminates back scatter into the viewing area), and it also provides excellent sound control.

Insul-Shield Black is fire resistant and comes in thicknesses of one to three inches and in two-by-four feet or four-by-eight feet sized boards for easy installation. A

FINDING YOUR GROOVE

Architectural woodwork continues to carve out success in some unexpected places

by ROBIN BRUNET

Architectural woodwork is the sector best suited to make any building interior really shine, however, changing market conditions, high inflation, and many other factors also make it especially prone to slowdowns. Yet, in recent years, woodworking shops, manufacturers, and distributors have been especially busy on a wide range of projects – and in one notable case, a change in business model has allowed a network of established woodworkers to experience new heights of success.

Ciaran Adams, owner at Oake & Rowan Millwork Design Ltd. of Cobble Hill, B.C., presides over a small, five-year-old firm that recycles 75 percent of its waste and uses only LEED and FSC-certified domestic wood in its cabinet cores.

Usually, firms that employ a handful of people are the most prone to market fluctuations, but Adams reports that “the market is healthy for commercial work, and we’re adept at taking on specialty projects. We have just completed an architectural firm’s office renovation in Victoria on one end of the scale, and previous to that, we finished supplying and installing all of the millwork for the Nanaimo General Hospital, which was a far more substantial undertaking.”

Adams is not averse to taking on residential projects: “We’re happy to be of service to one of our regular clients, especially if the work offers a rewarding challenge for our team. But the market is always changing. For example, earlier this year we prepared for two residential projects four months apart, which would have worked out well, but then, and beyond our control, the projects became only two weeks apart, and this was extremely difficult for a fivemember team to schedule.”

Still, the overall volume of work is robust, and Adams reports that, “In some cases, we’re taking over cabinetry construction in the commercial realm from a man well known in woodworking circles and who now acts as a general contractor for such projects. Thanks to him, we’re currently engaged in a job worth at least $1 million in high-level millwork.”

Adams adds, “These kinds of opportunities happen all the time, and smaller players such as my company can greatly benefit from them. But it takes a knowledgeable general manager to make these projects a success.”

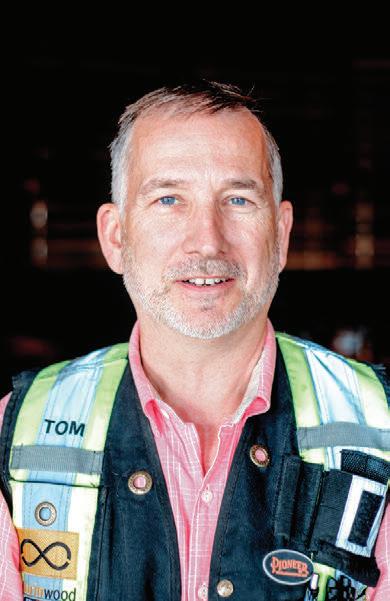

The manager Adams refers to is Tom Morin, president of Morinwood, who has worked in architectural millwork for more than 20 years. During the COVID slowdown, Morin reimagined his business model by shifting from a single manufacturing plant to a network of trusted partner shops, including Oake & Rowan.

“It’s been a huge differentiator for us,” Morin says. “In commercial construction, manufacturers struggle to keep a steady workflow. Plants have fixed

capacity, but project schedules are unpredictable, so there’s either too much or too little work. That’s no longer our problem. Now we focus on our customers instead of the shop schedule. With a network of 30 certified partners, capacity is never a limitation.”

He points to the Cowichan District Hospital replacement project in Duncan as an example. “It’s a major project that would normally exceed the bonding capacity of a single firm. By engaging multiple specialty manufacturers, we can scale as needed while maintaining tight quality control.” Morinwood’s team is supplying cabinets, counters, labs, acoustic finishes, and other millwork for the hospital, with on-site work continuing through next year. All production meets ISO 9001 standards.

Alongside this collaborative production model, Morinwood is leading the integration of AI tools into the design-assist process. The company first used artificial intelligence to analyze architectural drawings during pre-construction – automatically identifying and quantifying millwork to accelerate budgeting and co-ordination.

“Our goal was to give design teams and contractors faster, more reliable cost feedback from the earliest stages,” says Morin. “That’s where real value is created, in helping projects stay on budget before the first board is cut.”

Those early successes inspired Morin to found TakeoffBOT.ai, a constructiontech startup developing AI that converts drawings directly into data. The technology has been refined on projects such as Cowichan Secondary School and Cowichan District Hospital, helping design teams collaborate faster and prevent late-stage rework. A commercial launch is planned before year-end, bridging the gap between design intent, fabrication, and cost certainty.

Morinwood also recently began work on the Royal BC Museum Collection and Research Building, a mass-timber facility that will house the museum’s collections and archives. “It’s the most elegant warehouse ever built,” Morin says. “The B.C. fir wall panelling will make wood-lovers drool.

Morinwood provided millwork for the Cowichan Secondary School in Duncan, B.C.

Even though the multi-residence market is considered too volatile by some, Tim Benson, president of Benson Cabinetry & Millwork Ltd., sees it as the company’s core strength. “Business is really good,” Benson says. “We’re extremely busy. We’ve expanded our shifts and now run from 6 a.m. to 11 p.m.”

Celebrating its 50th anniversary next year, Benson Cabinetry & Millwork has built its reputation on precision-crafted cabinetry and millwork for multiresidential developments. “While there’s been a considerable decline in condo sales, we’re fortunate to have strong partners in the industry and have secured a robust order book that will carry us through 2026 and into 2027 at the same operating pace,” Benson explains. With a team of more than 100, it’s common for Benson to be engaged on a single project for more than 12 months.

During slower market cycles, Benson says the company pivots strategically. “We feel it aggressively, but we’ve developed initiatives to mitigate the sting, such as shifting to hotel and institutional work. We also expand our geographic reach beyond Vancouver Island and Greater Vancouver into the Okanagan and Whistler regions.”

For now, down cycles are not a concern. Benson Cabinetry & Millwork is currently delivering cabinetry and millwork for several high-profile projects, including Band by Townline & QuadReal, Botanica by Qualex-Landmark & Marcon, PKWY T3 by Axiom & Bosa, and Cascades by Chard & Ledcor, among many others across B.C.

The wood building industry is experiencing significant growth, with companies like Sansin driving innovation with the development of environmentally-friendly wood protection. Sansin has researched and developed waterborne wood coating solutions for 40 years, offering alternatives to traditional wood coatings.

One 2025 project of note was a private home in Michigan lake country that recently won the Wood Design & Building Sansin Award. The home, designed by Wheeler Kearns Architects, features exposed glulam from Sansin partner Western Archrib and weathered grey Accoya siding inside and out that harmonizes with the surrounding forest. KP-12 UVW provided the clear natural wood tone desired for this project, and the ENS Optimum Clear topcoat enhanced durability and protection.

Closer to home, a vacation residence by custom home builder Smith Timber Works, located on a small lake in the Cariboo Region of B.C., used Sansin throughout the interior and exterior of the building. The siding features SDF Roasted Almond, the timbers are finished in SDF Natural Cedar, and the tongue-and-groove boards shine with ENS Optimum Clear. Even the stairs are treated with SDF in a custom colour. Smith Timber Works uses Sansin on their wood projects as they offer beauty and durability, whilst being a sustainable coating solution.

Another notable B.C. project for Sansin in 2025 was the təməsew̓txʷ Aquatic and Community centre in New Westminster, Canada’s first completed Zero Carbon Building – Design certified aquatic centre. Wood features prominently throughout the design, and all the CLT and glulam elements are protected and beautified with a comprehensive system of Sansin coatings, including KP-12 and Precision Coat KP-30 (formerly Precision Coat SDF) in Sansin’s 2025 Colour of the Year, Ivory 21. The wood creates a warm and natural environment that stands in contrast to typically sterile aquatic environments. Sansin’s KP-12 and Precision Coat KP-30 allow wood to breathe during the absorption and release of humidity from the aquatic environment.

Other product suppliers associated with the woodworking sector are focused on either augmenting wood or replicating it, and Denise Barcia, marketing director at NewTechWood Canada, reports that two new brands were launched

in late September at the IDS Vancouver design show. “The first is freske: designdriven surfaces for modern commercial spaces,” Barcia says. “We have five wall panel collections, including flexible stone, lightweight panels, marble replica, and textured surfaces.”

The second brand is Aluxe, which Barcia describes as “non-combustible fluted exterior siding made with thick-gauge aluminum but with an ultra-realistic wood touch finish, ideal for large-scale projects.” Aluxe’s finish captures the warmth, grain, and texture of real timber.

Benson provided precision-crafted cabinetry and millwork for Timber House by Aragon.

Freske wall panels in marble replica.

Aluxe non-combustible fluted exterior siding.

Vacation residence by custom home builder Smith Timber Works.

Sansin Precision Coat™. High performance wood protection for mass timber structures.

PC WoodForce has a 20-year history of performance. As a newly certified Euroclass D s1, d0, fire retardant coating, PC WoodForce can be used as a topcoat for ASTM E84 “Class A” treated timber. PC WoodForce will provide added value and beauty as it weathers naturally, making long term maintenance easy. Warrantied for up to 20 years, Precision Coat factory finishes deliver the color, transparency and performance that architects, engineers and builders can count on.

Contact us about our specification program so we can help you achieve the perfect finish and protection, every time.

Zoomers Beach Hotel | Castricum, Netherlands Photographer: Courtesy of Leegwater

HARDWARE FOR WOOD

Richelieu Hardware is a major go-to and one-stop source for specialty wood hardware products, and new offerings have been released in categories ranging from kitchen to decorative hardware. Modern-style pull knobs continue to be in high demand and provide a pleasing contrast when matched with wood surfaces, and an example of the sublime design aesthetic Richelieu provides is the new 1743 Modern Metal Pull, an elegant cupped aluminum pull featuring a smooth finish for a striking modern look. Designed for surface-mount applications, this is the perfect product to impart contemporary refinement.

Rustic barn doors continue to be a desired feature of new residences and renovations, and Richelieu has no less than 10 such systems covering both classic and modern appearances. One example is the new Cavalier Barn Door wall mount sliding door system with visible black “U” horseshoe shape flat bar steel straps and two trolleys for doors weighing up to 100 kilograms. Three choices of standard flat bar upper track sets are available, with wall mounts and fastener lag bolts for wood wall construction.

Meanwhile, at Häfele, the new Häfele Lighting sub-brand represents the company’s commitment to developing the highest quality and easiest to install lighting options available to customers, whether it’s incorporating lighting into cabinetry, furniture, backlighting for walls and ceiling coves, textiles, and more.

Häfele has also invested in developing adaptive lighting solutions that go into cabinetry and is designed to enhance mood, support natural circadian rhythms, and provide a fully customizable, health-conscious lighting experience. As for new products, Häfele’s Universal Drawer Light Bar provides customizable, energy-efficient illumination for drawers in kitchens, bathrooms, and closets; it features a push-button switch for adjusting colour temperature and optimal lighting with both downward and front-facing output. It also features an integrated sensor that automatically turns the light on and off, and the system includes dimming functionality. A

PREMIUM MODERN MATTE PANELLING

Behind its sophisticated ultra-matte surface, Zenit 3.0 delivers outstanding technical performance. Available in a palette of 15 curated colours, it’s as resilient as it is refined. Silky to the touch, it’s anti-fingerprint, antibacterial, stain-resistant, and rigorously scratch-tested. This is the panel designed to elevate projects of every scale.

TALK TO

specs@richelieu.com 1-800-619-5446

Cavalier Barn Door wall mount sliding door system.

AI IS A LEVER: HOW TOM MORIN KEEPS CRAFT IN THE DRIVER’S SEAT

From robotics to TakeoffBOT.ai, the Morinwood founder proves the smartest tech keeps the craftsman in control.

Productivity has long been construction’s toughest challenge. Too often, the push for efficiency comes at the expense of craft. Tom Morin, president of Morinwood and co-founder of TakeoffBOT.ai, has built a career at the seam between hand and machine— between judgment and automation.

Over two decades, Morinwood has delivered architectural millwork for some of British Columbia’s most complex institutional projects—from the Cowichan District Hospital to the UBC Faculty of Pharmacology and BC Women’s & Children’s Hospital. Each reinforces a simple truth: the earlier skilled tradespeople contribute their expertise, the better the outcome.

“Craft is the desire to do a job well for its own sake,” Morin says. “Tradespeople have an overwhelming instinct to build great things.”

Where Precision Meets Judgment

Morin’s curiosity about automation sharpened during the Vancouver Convention Centre Expansion, where his team built a robotic cell for a repetitive, precision task. “Everyone wanted to give it human traits—we named her Victoria—but it was a one-trick pony,” he says. “Still, it worked through the night and did a job nobody wanted to do—with amazing consistency.”

AI as a Force Multiplier

Morin sees AI not as a replacement for craftsmanship but as a force multiplier for human capability. That thinking led to TakeoffBOT.ai, an AI-powered estimating platform for the millwork trade and beyond. “It’s not a self-driving car,” he laughs. “It’s power steering for your brain. You’re still at the wheel—just with less strain. Estimating shouldn’t be about counting; it’s about knowing what counts.”

That aligns with human-centered AI pioneer Ben Shneiderman’s principle: “superhuman performance, but human control.” Machines accelerate analysis; humans retain final judgment. For Morin, progress in construction isn’t automation for its own sake—it’s augmentation that protects human agency, improves clarity, and elevates craftsmanship.

Craftsmanship in the Age of AI

“Construction will benefit most when we use AI to compensate for—not compound—our cognitive design flaws,” Morin says. “AI should amplify human insight, not automate it away.” He envisions a future where digital tools and design intelligence align earlier—budgets hold, coordination improves, and the trades’ practical wisdom shapes projects from the start.

The community hall at Cowichan Hospital takes shape. AI systems helped track data over Morinwood’s 5-year project duration.

Victoria the robot toils during the assembly of the Vancouver Convention Centre’s iconic wall panels.

Tom Morin

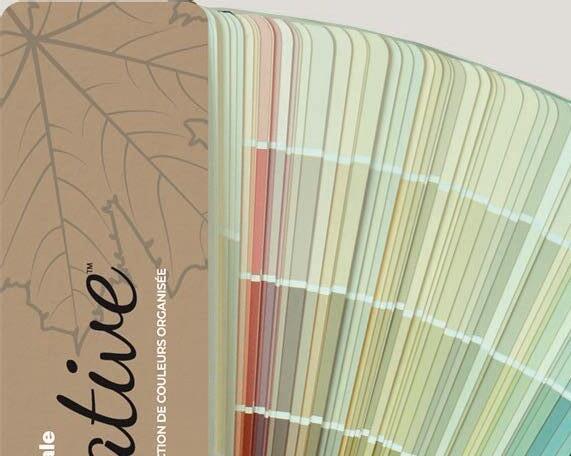

WHAT’S YOUR Colour Narrative?

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

Support In Style

Walls and ceilings are shaping spaces like never before

by LAURIE JONES

From sleek finishes to durable builds, wall and ceiling manufacturers are responding to diverse needs with products designed for every type of installation.

This industry-wide push for innovation is evident at Calgary-based Wallworks Acoustic Architectural Products, where keeping pace with shifting design trends is both exciting and challenging. Among its standout offerings are P.E.T. ceiling options. Custom moldings and designs once topped the list of specialty requests, but as they become more common, Wallworks has forged new paths in creativity that are resonating with clients and sparking unique finishes that stand out.

“We’re installing coffered look ceilings and more for a range of clients, from schools to executive bank offices,” says Lyle Fuller, general manager. “It is all about the finishes, and that can be a simple paint colour match, or a laser print image that can create the look of wood, wood beams, metal, or many other materials, allowing something that may look like a steel, brass, or gold finish ceiling to be fully acoustic. Given that the standard P.E.T. felt look is now becoming commonplace in the market, some leaders in design are utilizing the latest exceptionallooking custom fabric coverings over the P.E.T. to provide more texture, more combinations, and renewed interest, which can also blend in corporate branding, multi-faceted finishes, and more.”

Made from recycled plastic pop bottles, P.E.T. products are sourced globally and imported to cutting, finishing, and distribution facilities in Canada and the U.S. Wallworks partners with several companies that specialize in laser printing and painting to achieve exceptional finishes. “The results really are unique,” says Fuller. “The creativity of designers and architects continues to set the tone.”

Canadian, family-owned True North Floors and Walls (a division of CDS Distribution) specializes in premium wall cladding products designed for health-care environments, including hospitals, laboratories, and kitchens. The company also serves commercial food and beverage outlets, as well as

commercial kitchens. “Some of our most recent projects include the Surrey Memorial Hospital and Cancer Centre, the South Niagara Hospital, the North York General Hospital in Toronto, and the West Lincoln Memorial Hospital in Hamilton,” says Derek Motley, owner and president.

Available in more than 50 colours, with custom options, the panels come in two standard sizes: four by 10 feet or four by eight feet. “One important feature of the product is that the seams are heat-welded to make it impervious to water and ensure no bacteria or anything else can build up underneath. The panels can also be heated and bent around corners to eliminate trim pieces that can be an area for mould buildup,” says Motley. The panels are also suitable as ceiling tiles, with the same thermoforming and heat-welded seam capabilities.

Motley adds that over the last five years, the company has invested heavily in testing to ensure all health and safety concerns are addressed for architects and builders.

DESIGN VERSATILITY

Richelieu has introduced a new collection of grooved decorative panels designed to elevate interiors with elegance, warmth, and functionality. Ideal for hospitality settings such as hotels, conference rooms, and lounges, as well as residential spaces including bedrooms, living rooms, and family areas, these panels add a refined, contemporary touch to any environment.

Grooved decorative panels in black oak from Richelieu.

P.E.T. acoustic felt cloud baffles from Wallworks.

Available in three colours with a Kalmate felt backing, the panels combine sleek design with remarkable versatility. They can cover an entire wall for a bold statement or be applied as wainscoting for subtle visual interest. Beyond their aesthetic appeal, the panels also deliver practical benefits. The polyester felt base enhances acoustic comfort by reducing noise, while the MDF core with wood veneer ensures durability and a sophisticated finish.

For those seeking modern simplicity, Richelieu also offers two-inch decorative slatted wall panels. Their clean lines and streamlined design instantly refresh interiors, creating a stylish, contemporary look. Quick to install, they allow professionals and homeowners alike to transform spaces with minimal effort and maximum impact.

The collection also features the Kalmate Acoustic Grooved Tile 6-Piece Kit, available in Light Oak and Walnut. Designed for flexibility, the tiles can be arranged to suit a variety of layouts, giving designers and end-users creative freedom. Like the full panels, the tiles combine acoustic performance with visual appeal, making them well-suited to projects that demand both form and function.