JOHNSTON DAVIDSON ARCHITECTURE

Total Precast Concrete Key Attributes to Passive House Development are:

· Manufactured in local precast facilities under controlled conditions

· The whole building envelope in one composite panel; air barrier, moisture control, insulation and the structure

· Hollowcore floor slabs allow for a much lower depth to span ratio

· Hollowcore provides the lowest GWP per m2 of concrete floor area

· Precast concrete dramatically reduces the construction schedule, site congestion, noise and environmental impacts

For more information and educational presentations check out Learn on Demand, a 24/7/365 Educational Platform. Visit: cpci-learnondemand.com/

For more information on Passive House Total Precast Concrete, visit www.cpci.ca/publications to download your free copies of the Structural Solutions Guide and the Putman Family YWCA Total Precast Concrete Case Study.

Project: The Putman Family YWCA, Hamilton, ON Architect: Kearns Mancini Architects Inc., Toronto, ON

Tracing the crucial links between architecture and Indigenous healing.

Johnston Davidson Architecture continues to score big with remarkable projects and teamwork.

The concrete industry’s resolute journey to net zero and decarbonization.

From panels to foam, insulation is helping solve environmental concerns, one cozy layer at a time.

Green building design is surpassing benchmarks with transformative strategies that are redefining the very fabric of construction.

Unveiling the latest innovations and trends reshaping the walls and ceilings industry.

Leaders in architectural woodwork ensuring wood’s future by taking on complex and innovative projects.

Exploring the rapid advancements and influential developments reshaping the audio visual industry.

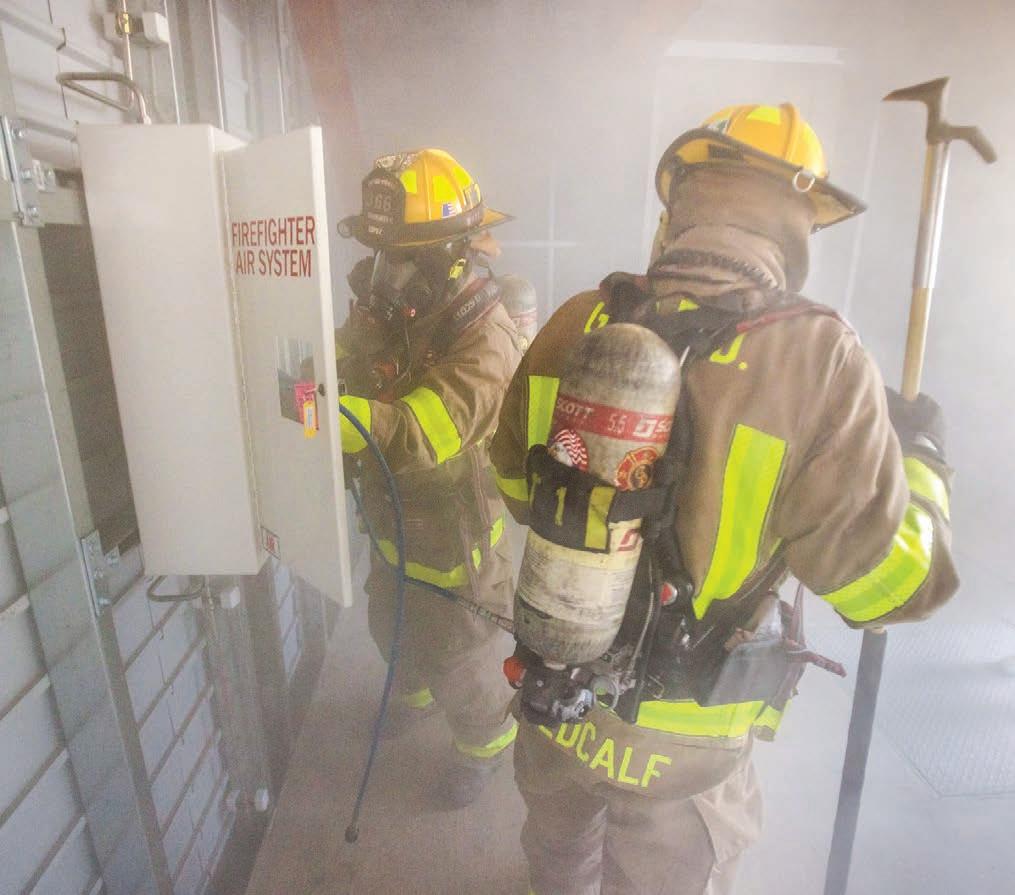

A new era in the world of fire protection systems.

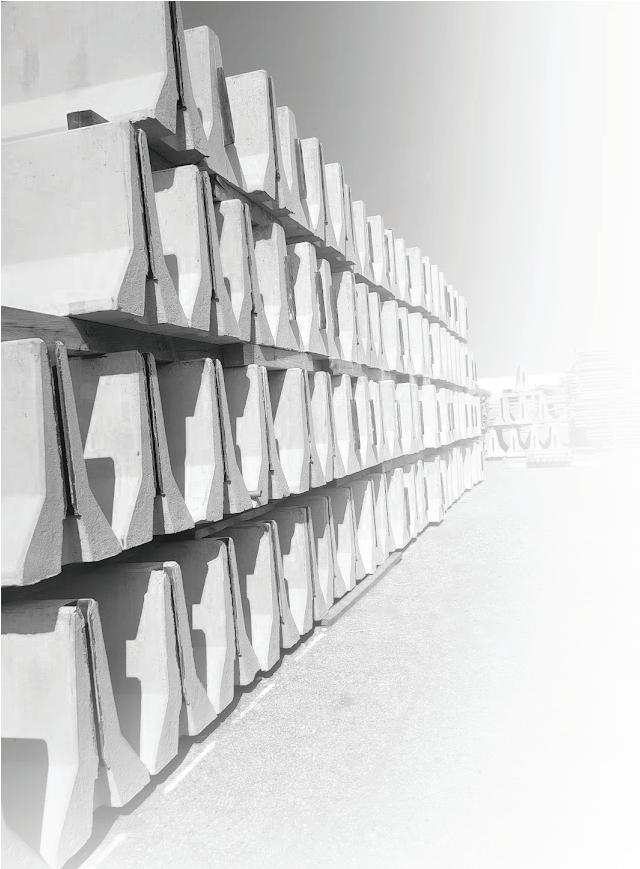

The purpose of concrete products in construction sites and their vicinity is to establish safety measures that protect workers and individuals nearby. Concrete jersey barriers, tall wall, concrete blocks, and other such products play a crucial role at minimizing ground disturbance and are an e ective way to provide footings for all types of fence.

JERSEY BARRIER HALF JERSEY BARRIER

TALL WALL HALF TALL WALL

Tracing the crucial links between architecture and Indigenous healing

he Royal Architectural Institute of Canada (RAIC) recently hosted a two-part online event to mark the 2023 National Day for Truth and Reconciliation. Collaborating with NVision Insight Group Inc., and the RAIC Truth and Reconciliation Task Force, this event served as an opportunity for architects to gain a comprehensive understanding of the historical and ongoing impact of Canada’s residential schools and to contemplate the role architects can play in the reconciliation process.

HISTORICAL CONTEXT AND NOTEWORTHY INSIGHTS

Part one of the event, held on September 26, 2023, provided a historical overview of residential schools and the Indian Act and examined the intergenerational trauma affecting Indigenous communities. An important acknowledgment was made regarding an award given by the RAIC in 1965 to the design of a residential school, as well as the presentation of an interactive map highlighting the locations of historic residential schools across Canada. Additionally, James Bird, a residential school survivor, member of the RAIC Indigenous Task Force and PhD candidate, shared his experiences and his academic pursuit of understanding architectural form through Indigenous languages.

A notable revelation emerged regarding the architectural and planning community’s role in the construction and alteration of residential schools, spanning several decades. This awareness, as evidenced by historical articles and journals from the late 19th and early 20th centuries, sheds light on the moral responsibility carried

EMPOWERING ARCHITECTURE FOR RECONCILIATION

Part two, held on September 27, 2023, shifted the focus to how architects can reconcile with the land and incorporate Indigenous values and traditions into their designs. Naomi Ratte’s (intern landscape architect and consultant with NVision Insight Group) presentation included a documentary about a residential school survivor and showcased the transformation of former school sites into places of ceremony and remembrance. Additionally, Ratte urged the federal government to develop a reconciliation framework, amending the Historic Sites and Monuments Act to include Indigenous representation. An interactive map from the National Centre for Truth and Reconciliation emphasized the significance of land in Indigenous culture and sustenance.

Throughout the event, a central theme emerged: architects must acknowledge their historical involvement in Indigenous trauma and work towards a more inclusive and empathetic future through architecture.

SHORT-TERM AND LONG-TERM IMPACTS

Over 700 members of the architectural community participated in the event, a significant milestone for the RAIC in relation to an educational opportunity regarding Indigenous values, history, and the role of design in their connection with the land.

Long-term impacts include the RAIC’s commitment to identify meaningful actions for the organization to engage in annually in furtherance of reconciliation efforts. The RAIC also plans to make these webinars available on-demand, enabling more of the architectural community having access to education about critical issues. RAIC’s dedication to engaging in reconciliation efforts remains steadfast. This is the 2nd commemoration activity the RAIC has hosted in honour of the National Day for Truth and Reconciliation. This year’s events strengthen the groundwork for architects to play an integral role in the reconciliation process. By addressing their historical involvement and reimagining the future of architecture, these professionals aim to pave the way towards a more inclusive, empathetic, and equitable built environment that honours the diverse cultures and values of Indigenous communities. A

GIOVANNA BONIFACE and LISA JIBSON

It’s A Slam Dunk

Johnston Davidson Architecture continues to score big with remarkable projects and teamwork

by ROBIN BRUNET | photography courtesy JOHNSTON DAVIDSON ARCHITECTURE

Considering she was on the University of British Columbia’s Varsity Basketball Team and a BC Summer Games’ swim champion, Kimberly Johnston, who is the principal of Vancouver-based Johnston Davidson Architecture (JDa), views project development through a sporting lens.

Recalling her earlier years, she says, “It was a thrill to score, but what I really loved was the teamwork that led to getting the shot. I loved the sensation of passing the ball in an open space, knowing a colleague would catch it.”

This innate appreciation for teamwork informs JDa as Johnston and senior associates John Botelho and Edward Craig guide a company that was founded in 1976 by Johnston’s father, Douglas Johnston, alongside Ian Davidson. It also explains why they are so passionate about working in the Integrated Project Delivery (IPD) realm – to the point where it has become JDa’s specialty.

The friendly and engaging Johnston says, “One of the many things dad taught me was to always work with others to find different solutions – and that’s the essence of IPD.”

Some of JDa’s more notable successes include West Kelowna City Hall and Library; Squamish Fire Hall No. 2; and the recently completed Pitt Meadows Fire Hall, a 26,000-square-foot, mass timber building that contains a dedicated emergency operations centre.

JDa’s focus on protective services is noteworthy, especially at a time when many architects feel compelled to diversify to ensure a steady stream of work.

“We’ve designed over 75 firehalls in B.C., Alberta, and even Prince Edward Island,” Johnston says. “My dad and Mr. Davidson first ventured into this niche with Vancouver Fire Hall No. 12, and the specialty work snowballed from there.”

Craig, who was initially sceptical about the IPD process (“It seemed too Kumbaya to me”), adds, “We’re perpetually busy. The need for protective services is growing as populations increase, existing neighbourhoods expand, and new ones are being built.”

Doug Johnston and Ian Davidson built JDa from the ground up, initially as a two-man team, with the goal of capturing the essence of life in the built form. Also, while they weren’t interested in the “starchitect” mentality, they believed in the value that architects brought to the table and always fought to be heard.

Boundary Bay Fire Hall, Delta, B.C.

Abdul Ladha Science Student Centre, Vancouver, B.C.

Although friends assumed Johnston’s daughter would make sport her profession, she found the lure of architecture irresistible. “I studied art history at UBC and was fascinated with how life was represented on canvas and other mediums,” she says. “I loved watching dad work in the office – so following in his footsteps seemed natural. He impacted my brother as well, who is an industrial designer.”

Following her father’s passing in 2010, Johnston vowed to maintain JDa’s values; but, realizing the benefits of the IPD process and the growing need for protective services, she focused increasingly on those facets of business. Currently some of their IPD projects consist of working innovatively with the City of Burnaby on fire halls 4 and 8 and well as Fire Hall No. 2 for the District of Squamish, which is designed to accommodate housing above it at anytime.

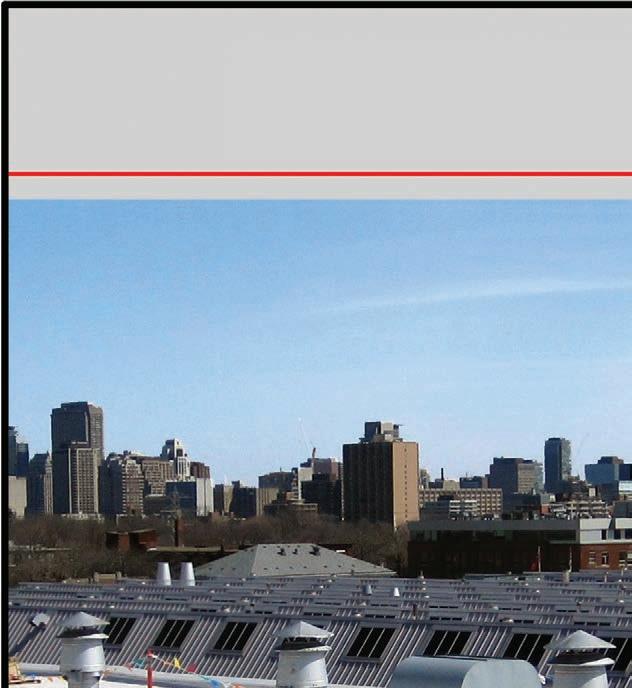

Johnston also ensured that JDa gained expertise in co-location facilities that mix municipal services with affordable housing and/or other civic operations. The result was designing Vancouver Fire Hall No.5 and housing complex (the first of its kind in Canada), a LEED Gold project in which sustainable and energy efficient design strategies are combined with the specific programmatic needs of the Vancouver Fire Rescue Services and the YWCA. The 21,000-square-foot fire hall includes three apparatus bays and supporting spaces, and the 36,000 square feet of housing includes 31 suites, amenity rooms, and communal rooftop outdoor spaces.

Evolving JDa in this manner invites two key questions: doesn’t working predominantly on municipal/public projects limit one’s creative abilities? And isn’t Johnston, like an actor gaining fame for a specific role, worried about being typecast?

Botelho addresses the former issue. “Working in the public realm has given us lots of creative leeway because we’re relied upon to develop a vision – as opposed to some clients in the private sector who try to impose ideas that aren’t feasible.”

Johnston adds good-naturedly, “I’ve been known to ask some people, ‘Why buy a dog if you’re going to bark yourself?’”

As for being typecast, she says, “Our portfolio is diversified – it even includes over 50 acute care and non-acute health-care projects, university buildings, police stations, city halls, and childcare facilities – but I don’t mind being pigeonholed. It reminds me of an instance when a project manager told us condescendingly, ‘Oh, you’re just suburban architects.’ And I replied, ‘If you mean we’re approachable and like working with people, I can live with that.’”

As JDa’s principals and staff prepare for a busy workload in 2024, Johnston exudes the confidence of presiding over a company that is well-positioned for future opportunities. “We’re in a good place,” she says, smiling as JDa’s canine mascot, Louie, wanders through the office. “The IPD teams we’ve worked with have been fantastic and exciting projects are coming down the pipe.

“About the only thing we’re wary of is expansion: we never want to grow to the point where it would compromise the collaborative approach to work. When I throw the ball into the open air, I always want to know it will be caught by a colleague.” A

Sechelt Justice Building, Sechelt, B.C.

North Shore Hospice, North Vancouver, B.C.

Vancouver Fire Hall No.5, Vancouver, B.C.

Pitt Meadows Fire Hall, Pitt Meadows, B.C.

Nanoose Bay Fire Hall, Nanoose Bay, B.C.

PHOTOGRAPHY

*(CPCQA) CERTIFICATION PROGRAM BY PROCESS OFFERS KEY BENEFITS TO ARCHITECTS, CONTRACTORS, ENGINEERS, GOVERNMENT AUTHORITIES AND OWNERS.

Project: Champagne Quarry Park, Calgary, AB Architect: Gibbs Gage Architects

Mixing It Up

The concrete industry’s resolute journey to net zero and decarbonization

by ROBIN BRUNET

As 2023 draws to a close, the talk within cement and concrete manufacturing circles is all about net-zero and ways to achieve it, with cement companies and concrete associations moving forward to secure a more prominent footing.

That includes the Canadian Precast Prestressed Concrete Institute (CPCI), which in 2023 launched the 2030/2050 Net-zero Roadmap Initiative, a detailed guide for a decarbonized precast concrete industry by 2050. “Five industry working groups were established to develop the initiative, which includes how to execute reductions through facility design improvements, optimization, and acceleration of precast concrete construction, and more,” says CPCI managing director Brian Hall, adding that the initiative will be published before year-end. Also, the CPCI worked with the Global Cement and Concrete Association (GCCA) on a web-based Environmental Product Declaration (EPD) tool that allows members to prepare EPDs (self-declarations) of clinker, cement, aggregates, concrete, and precast elements, and contains new precast concrete LCI data, which a third-party verifier can use

to authenticate and become official public EPDs. “Since the GCCA EPD tool has been pre-verified by an approved EPD International verifier, the overall verification cost of EPDs generated by the GCCA tool decreases significantly,” Hall says. The tool was launched in October.

Heidelberg Materials prides itself in leading the decarbonization of the cement industry, thanks to seven major carbon capture projects around the world. One of these projects – the first full-scale carbon capture and storage facility in the cement industry – is taking shape in Edmonton in partnership with the Government of Canada; when it becomes operational in 2026, this new facility will capture more than one million tonnes of CO2).

The Edmonton plant will treat all emissions of flue gas from the kilns. Additionally, the heat and power plant that runs the facility will have its own carbon capture, resulting in the achievement of netzero carbon emissions without the use of offsets.

Many other initiatives contribute to Heidelberg Materials’ decarbonisation push. “Our EvoBuild brand of low carbon concrete is available in a variety of ranges [Bronze, Silver, Gold, and Zero], takes specific targets and budgets into account, and helps ensure there is a sustainable solution to every

Putman Family YWCA, Hamilton, ON

Total Precast Panel construction on the Putman Family YWCA, Hamilton, ON.

The first full-scale carbon capture and storage facility, Edmonton, AB.

Strong, innovative, sustainable

EvoBuildTM is the evolution of sustainable building materials designed to meet today’s sustainability targets.

With knowledgeable experts, science-backed data and sustainable product formulations, we’re able to work alongside you, offering unparalleled service from concept to completion.

EvoBuild™ Low Carbon Concrete is part of Heidelberg Materials’ Evolve™ Family of Products. Learn how these revolutionary products can help your project be part of a greener tomorrow.

heidelbergmaterials.ca

Material to build our future.

project,” says Shane Mulligan, Heidelberg Materials’ sustainability and technical marketing manager. “EvoBuild is focused on working with different stakeholders along the project value chain to highlight the opportunities that exist with lower carbon concrete.”

Heidelberg Materials is also involved in load assurance whereby sensors are mounted within the drums of ready mix trucks as well as on rebar in concrete pour jobsites; these sensors gather information on exactly how the substance performs as it is poured and cures. “This allows operators to make adjustments and reduce waste as well as improve batches before they leave the plant,” Mulligan says.

Rob Cumming, head of sustainability and public affairs at Lafarge Canada Ltd., reports that his company continues to enjoy success with its ECOPact brand, the world’s broadest range of low-carbon concrete offering up to 90 percent lower CO2 emissions compared to standard (CEM I) concrete, and with no compromise in performance. The range includes a basic 30 percent carbon reduction solution; ECOPact Prime (over 50 percent reduction); and all the way to ECOPact Zero (total carbon neutrality).

However, Cumming stresses the Pact aspect of ECOPact when discussing Lafarge’s future initiatives. “Pact suggests working relationships, and

that’s what we’re fostering with our customers,” he says. “Increasingly, they are discovering that by consulting with us they can achieve significant reductions in carbon intensity at no or minimal costs. We provide specific solutions – exactly the right concrete properties required for any given job –while assuring they achieve desired performance.”

ECOPact comes with third party-certified quantifiable data that confirms the reduced carbon, calculating improvements based on CO2 values from all of Lafarge’s raw material procurement, transportation, and production.

Cumming adds that such services are becoming vital and cites the Toronto Green Building standard as a regulatory body whose newest mandate requires builders to offset all embodied carbon in construction projects in that jurisdiction. “We’ll continue to see more advancements on these fronts, hence our continued focus on ECOPact.”

But not everyone in the concrete realm was exclusively focused on decarbonisation in 2023. Kingston-based Anchor Concrete Products Limited’s ongoing mission, which it advanced this year by working to secure licensing agreements with developers globally, is unique: CEO Jeff Bradfield wants to spearhead a paradigm shift in the way homes are built – and help solve the chronic housing shortage not only in Canada but also in the U.S., Brazil, Africa, and many other parts of the globe.

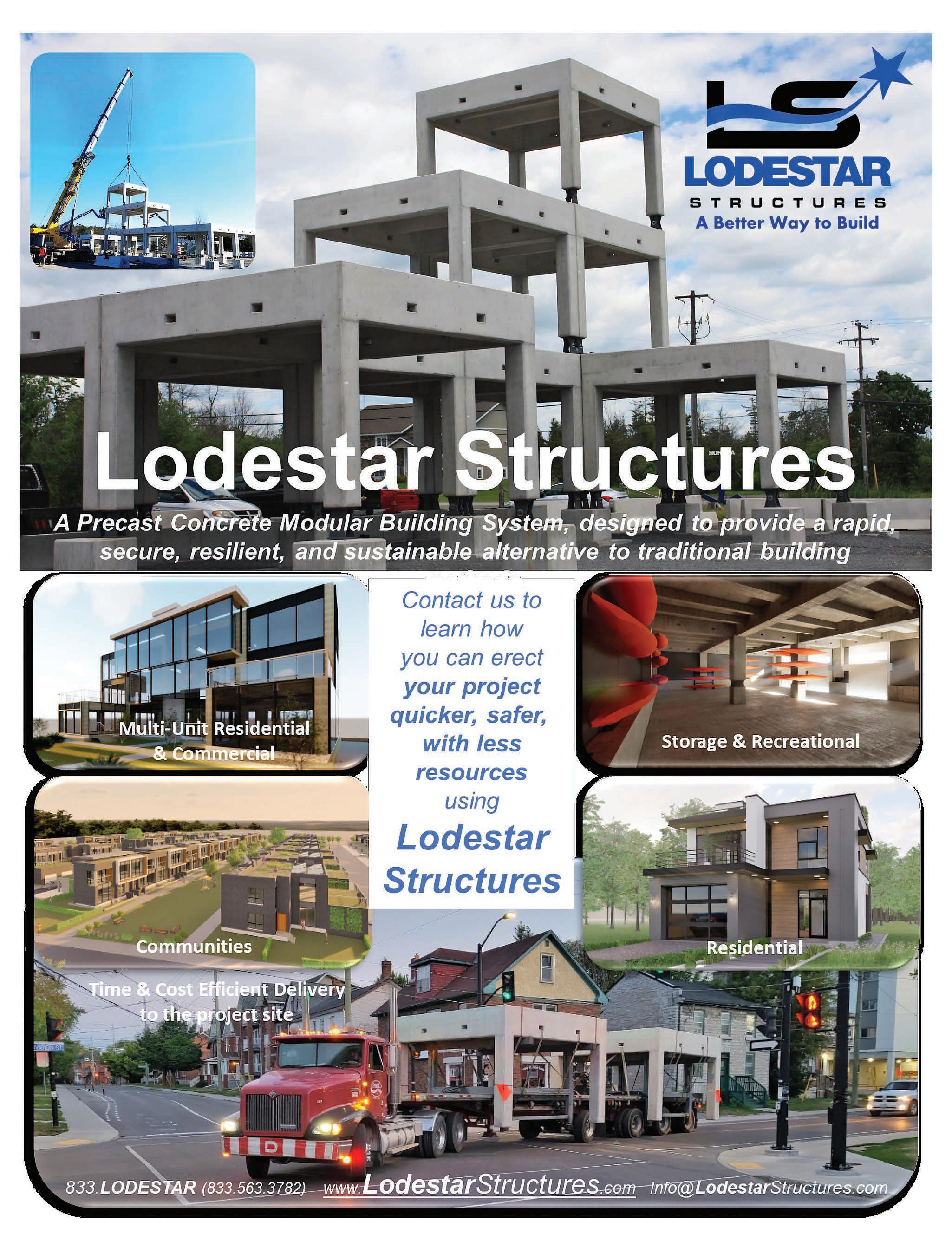

He intends to do so thanks to having introduced (in 2021) a modular building system under the name of Lodestar Structures Inc. This building system combines the resilience of precast concrete

Sensors mounted within the drums of ready mix trucks gather information on exactly how the substance performs as it is poured.

with the efficiency of modular building technology, allowing the primary infrastructure of a home (as well as commercial structures and even mid-rises) to be completed in a fraction of the traditional building time with far less tooling required – and at a cost on par with traditional construction, even though Lodestar buildings are said to be able to achieve a lifespan of several hundred years.

Darrell Searles, president of the Lodestar division, says, “By licensing precast concrete or ready-mix plants near areas where Lodestar structures are required, we supply the moulds and technology required to make structures to build, or re-build entire communities. Each Lodestar structure provides up to a 436-square-foot building footprint consisting of commercial rated support columns and integrated surface slab, and when connected horizontally or vertically they expand the footprint to accommodate up to seven storeys tall and unlimited width and length.”

In the Kingston region over 200 Lodestar projects are at various stages of conceptualization and execution, and major developers and contractors have expressed interest in the system. Inquiries have come from as far away as France, United Arab Emirates, and West Africa.

“Our small Kingston facility of less than 80 people can produce and install up to 6,000 square feet of product – the equivalent of three homes – per day,” Bradfield adds. With the addition of recently released Lodestar Precast Architectural Wall Panels, structures can now be erected and enclosed at a spectacular pace (providing a fire

rating of between 90 minutes and two hours).

To test the efficiency of the construction process, Anchor constructed a Lodestar tiny home combining a Lodestar Base Module, a Lodestar Structural Building Module, and enclosing the structure using Lodestar Precast Wall Panels, a process that took less than a day to complete.

“Licensing will be the key to achieving our mission both in Canada and abroad: any community that has a ready mix or precast plant can have safe, comfortable, and sustainable Lodestar homes, and the sustainability benefits are obvious,” adds Searles.

EXPRESS REBAR

Completion of the Lodestar tiny home.

Lodestar Precast Wall Panels.

Lodestar Base and Structural Building Module.

Diamond Polished Concrete. A Strong & Beautiful Concrete Flooring Solution

Diamond Polished Concrete is a unique, advanced flooring system that brings out the natural beauty of concrete, helps reduce maintenance costs and enhances the natural durability of concrete surfaces. The Tri-Con Diamond Polish System employs an innovative 7-step grinding and polishing process that utilizes progressively finer diamond grinding heads. This system also uses the most advanced penetrating sealer technology.

Tri-Con Concrete Finishing is an industry leader with more than 30 years experience in the concrete industry. We are a one-stop supplier capable of pouring new floors to exact specifications as well as restoring existing concrete surfaces with endless versatility. We guarantee that we deliver on time, on budget and on spec every time.

ASK ABOUT OUR I.C.I. JOINT FREE CONCRETE FLOORS

Business at Stubbe’s (which includes Stubbe’s Precast, Redi-Mix and Cement) was “better than expected” in 2023 according to managing director Jason Stubbe, with an increase in the commercial warehousing sector and recently in seniors housing. “Plus, we have seen an increase of requests for our Whispercrete sound barrier products and recently completed a 13-metre-tall wall for AIM in Hamilton. Our precast stair and elevator cores for buildings that aren’t total precast have gained popularity as well – they really help cut construction time, save money, and allow for a superior quality and finish in the cores.”

The Whispercrete noise wall systems can be designed using either a single-sided absorptive finish or a double-sided reflective (concrete) finish, depending on the acoustic requirements of the site. As for Stubbe’s Modular Stair shafts, they have the capability to install stairs and elevators up to nine floors in advance. Other building systems, such as steel, CIP, CLT, or any other type of construction material, can then proceed at their own pace. This solution can greatly decrease the overall build time by giving all trades access to all floors as soon as construction begins on each floor.

John Carson, executive director at Altus Group (a collaboration of 14 North American precasters), has this to say about the precast market in 2023 and moving forward: “Business in U.S. and Canada remains robust. Data centre work is still very strong, and government/municipal projects spurred by spending and legislations support geographical needs such as water and education.”

Carson adds that while resilient, the precast industry is still dealing with familiar challenges. “On time delivery and project complexity is paramount, while labour supply remains a critical concern. Schedule slides and slowdowns are occurring as developers and contractors continue to try and cope with significant material cost increases, higher fuel, labour and insurance costs fuelled by rising interest rates, and increasing hurdles to achieve go-aheads.”

It could be argued that sustainability and other green initiatives contribute to the long list of challenges, and Carson notes that “precast producers are doing their part to implement viable practices and technologies in order to deliver realistic, carbon footprint-lowering product solutions like CarbonCast wall panels and precast walls with composite design – both of which can reduce the amount of concrete in a panel. Energy efficiency via mass walls and insulated sandwich panels are delivering performance on this front, in the face of ever-increasing building code regulations and standards.”

In fact, CarbonCast panels with carbon fibre grid reinforcing and integrated insulation can reduce concrete use by 30 percent or more compared to solid panels, and the thermal efficiency of the panels results in higher R-values than other technologies, which reduces operational carbon.

Along with brisk business in the concrete sector comes the inevitable expansion of manufacturing infrastructure. Cresswell Industries, a Peikko Group Corporation manufacturing partner, is investing in a large-scale Deltabeam slim floor structure facility

in Montreal. One of many benefits of this facility is that Peikko’s products will be delivered more quickly to the market.

Manufacturing in the new factory is expected to commence early in the new year; between 100 and 150 Deltabeam Composite Beams are expected to be produced weekly. Deltabeam Slim Floor allows for lower floor-to-floor heights and maximizes the number of floors in a building, and in some cases additional floors can be gained while maintaining the same building height. The composite action between steel and concrete allows Deltabeam to easily span over 30 feet between columns, and since the system is often utilized to support prestressed hollowcore slabs, the spans perpendicular to the beam can exceed 40 feet.

Deltabeam installation at Amica North Oakville, Oakville, ON.

In the additives and admixtures realm, Kryton International continues to provide robust waterproofing and corrosion resistance solutions thanks to its proprietary Krystol crystalline technology. One of the more recent examples of Kryton products being used to solve water ingress problems is the mixed-use condo tower project The Heights on Austin in Coquitlam, B.C. Doug Adam, Kryton’s technical services technician, notes that water ingress from a subterranean river caused significant cracking from the fourth to sixth levels of the east tower’s parkade, the result of not being treated with the high-performing crystalline admixture. Also, steel rails used in conjunction with rebar had been placed with insufficient cover, further contributing to cracks at regular spacing.

The solution was a full-on concrete leak repair system consisting of a rapid setting hydraulic cement, a crystalline grout with advanced fibre

technology and shrinkage-controlling additives, and a surface-applied crystalline slurry treatment. Adam points out that all of these materials were capable of working in synergy with the crystalline waterproofing admixture that had been used in the first three levels of the parkade. A combination of grout and injection repairs were also undertaken, with the entire process taking about six months to complete. The cast-in-place structural walls were left looking pristine and free of any residual water.

Finally, it has been a busy year as usual at Euclid Canada, dealing with complex administrative tasks as well as providing the construction market with a wide range of concrete-strengthening admixtures. National business development manager Brian Salazar explains, “We’ve spent a great amount of time and effort obtaining our EPD certification; as we speak in September our fibre additives produced in our Georgia plant have received designation, and we’re aiming for the additives made in our Canadian plants to follow suit next year.”

It wouldn’t be hyperbolic to describe the paperwork and auditing necessary for the certification as onerous, but the reason for pursuing such a complex process is simple: more and more developers are requiring EPD certified products to be used in a wide range of projects in order to secure LEED points. Whether good or meddlesome, certifications such as EPD have become a business necessity: if a company decides to postpone being designated, sales could be lost.

With Euclid products such as PSI Fiberstrand and Tuf-Strand SF, EPD assures users that the company’s

fibre reinforcement products for concrete do not contain any hazardous substances according to the Resource Conservation and Recovery Act, and do not release dangerous substances to the environment, including indoor air emissions, gamma or ionizing radiation, or chemicals released into the air or leached to water and soil.

For the record, PSI Fiberstrand fibres are synthetic monofilament and fibrillated polypropylene microfibres for concrete, mortar, and grout specifically designed for plastic shrinkage crack control and secondary reinforcing applications for slabs and pre-cast concrete. Tuf-Strand SF is a patented polypropylene and polyethylene synthetic macrofibre for composite steel deck construction and is used for replacement of limited structural steel in pre-cast, slabs on ground, pavements and shotcrete applications. A

The Definitive Concrete Waterproofing & Watertightening Checklists

Application of Tuf-Strand SF for composite steel deck construction.

Completion of a full-on concrete leak repair, The Heights on Austin, Coquitlam, B.C.

Panel

R-5 XP INSUL-SHEATHING PANELS ARE NOW GREY, BUT GREENER THAN EVER

R-5 XP Insul-Sheathing panels are now available with DuPont’s new reduced global warming potential Styrofoam™ Brand XPS formulation. This means that our already eco-friendly panels are now greener than ever — and still provide the same benefits that have made them so popular:

• No additional bracing required

• Integrated air barrier

• Lightweight and easy to install

To make them easy to identify, they are now grey instead of blue. That way, when you see our new GREY panels, you will know instantly that you are looking at a GREENER product.

All-Natural Wood Fibre Panel The Leslieville Laneway house is a project in the Toronto area. This discovery home is built for climate change.

It Features superior woodfibre insulation combined with energy-e cient HVAC and grey water recycling. The innovative design creates e cient spaces for more occupants, resulting in a reduced carbon footprint building. The project is targeting LEED Platinum.

SINCE 1905

A Barbini Design Build (barbini.ca) construction, developed with the assistance of Clearsphere Consulting for Skye Mainstreet Properties Ltd bpcan.com

Beyond The Layers

As with so many other sectors in the construction realm, companies specialising in the manufacture and provision of insulation products in 2023 continued to focus on environmental concerns and the effort to decarbonize – while improving the efficacy of the products themselves.

Matthieu Danis, product manager for wood fibre at Building Products of Canada Corp., says, “We’ve seen a lot of natural disasters such as droughts and heat spells combined with forest fires. As people become increasingly aware of the changes in weather caused by global warming, so is their concern to consume more responsibly, mostly in sectors that have such a big impact on the carbon footprint as construction. For this reason, there is more talk and demand for products with lower embodied carbon and/or with better life cycles.

“Fortunately, wood fibre insulation panels check the box on most, if not all these aspects. The wood content used to manufacture these panels comes from recycled sources, making it a good choice for builders wanting to offer a reduced carbon build. Secondly, the wood used is also a huge contributor since the trees they come from have already contributed significantly in reducing CO2 emissions and converting this into oxygen. These panels are literally the perfect product from a carbon footprint point of view.”

Danis points out that while the European market is ahead of North America in terms of incorporating wood fibre insulation into buildings, some products are gradually making their way into North America via LEED and passive house developments. “European manufacturers are using a dry process that results in thicker wood fibre panels in both mats and thick tongue-and-groove decking panels,” he explains. “These products can be used in more applications than the current panel form, since they are using these mats in wall cavities [like fibreglass or mineral insulation batts] and thicker roofing panels as insulated roof decking. These thicker panels are also used as continuous insulation on exterior walls. Although demand for these products is still marginal, due mostly to public perception and different installation techniques, there is enough interest for European companies to invest with North American partners to manufacture these products locally.”

BP’s wood fibre panel manufacturing process is unique, with panels offering higher strength and lower density: a lighter product with a higher insulation value (R-3 per inch). BP wood fibre panels are offered in natural formats ranging from 7⁄ 16 inch to 1 ⁄2 inch in thickness in both four feet by eight feet and four feet by nine feet dimensions. They can help reduce a building’s carbon footprint, partly due to their ease of recycling. “Although we don’t currently offer the thicker wood fibre panels, it’s possible to install these natural panels using a staggered joint installation, further improving the continuous insulation effectiveness by reducing the ingress of cold air in the wall stud and or cavity,” says Danis. To help reduce a building’s carbon footprint by limiting the poured foundation thickness, BP also offers hybrid or laminated panels: wood fibre panels laminated to low GHG extruded polystyrene that provides higher insulation values (R-5 per inch). “Our R-5 XP panel is a half-inch wood fibre panel laminated to a 0.71-inch XPS for a total thickness of 1 3⁄ 16 inches, providing both structural resistance and superior insulation. This leaves plenty of space even for brick veneer siding on an eight-inch poured foundation wall,” Danis says. “Not only does this panel provide superior air barrier properties, but because we are only using 0.71 inches of XPS, the assembled panel also offers a vapour permeance rating of 2, allowing any trapped moisture or humidity from escaping the wall cavity and further reducing chances of mold/mildew development in the wall structure.”

From panels to foam, insulation is helping solve environmental concerns, one cozy layer at a time

by ROBIN BRUNET

But wood is hardly the only substance that contributes to superior insulation properties. The Canadian Precast Prestressed Concrete Institute (CPCI) continues to promote certain concrete products as a superior insulation solution, specifically precast double wythe insulated panels. These panels consist of two reinforced or prestressed concrete wythes with a continuous layer of rigid insulation sandwiched between them. The type and thickness of insulation vary with the RSI value required for each project.

From a developer’s perspective, these panels also contribute to design and construction efficiency. They are mass-produced in standard widths on long line casting beds and can be made with attractive sculptured exterior surfaces,

Building Products of Canada’s wood fibre insulation panels are manufactured from recycled sources.

The finished product.

DISCOVER YOUR DARK SIDE.

INTRODUCING THERMAFIBER RAINBARRIER DARK

Welcome to the dark side of continuous insulation — where designs are quicker, easier and a whole lot more aesthetically pleasing.

RainBarrier ® Dark™, our newest CI portfolio offering, provides the same exceptional moisture mitigation with a brand-new darker facing — letting you design with a dark side.

including thin brick, form liners, and coloured stains on interior faces. Moreover, they can be erected at a rate of up to 120 linear metres per day on concrete or steel frame buildings. Notable clients of CPCI members who have taken advantage of double wythe systems include Amazon, Canadian Tire, AMC Theatres, and Walmart (the latter of which relied on precast concrete insulated Thermowall System panels from Central Precast to enclose a new 40,000-square-foot store in Kanata, Ottawa in just four weeks).

In recent years, the insulation spray foam sector has undergone a seismic change driven by a heightened focus on environmental integrity. Notably, one company recently unveiled the latest eco-friendly closed cell spray foam that delivers the highest R value in the industry.

Huntsman Building Solutions worked closely with spray foam contractors to develop and offer the new Heatlok Soya HP, which has the best R-value of any HFO product on the market with an LTTR value at 50mm of 2.06 RSI (R 11.68).

Recognized for its ease of adhesion and superior insulation value, Heatlok Soya HP leverages Honeywell’s latest Solstice Liquid Blowing Agent, a hydrofluoroolefin agent said to be the most environmentally conscious produced to date. It boasts zero ozone-depletion potential and a global warming potential of less than one.

Doug Brady, chief strategy officer for Huntsman Building Solutions, notes that it took about nine months of development and demos to arrive at Heatlok Soya HP, but the efforts were well worth it. “We launched in September and already it has been very well received by test users in different parts of Canada,” he says. “I’m excited by the product’s potential. It helps contractors by being a more efficient spray, and its proper application results in better building energy efficiency.”

Heatlok Soya HP is an all-in-one product: insulation, air barrier, vapour barrier, and rain screen. Up to eight inches of this spray foam insulation (which has a total of 20 percent recycled plastic and renewable soya oil) can be applied in a single day, boasting a high compressive strength of 37psi. Heatlok Soya HP can be used for a variety of applications: roofs, walls, and sub-slabs. It is ideal for cathedral roofs where ventilation may be challenging, and it also minimizes the penetration of other pollutants, allergens, and airborne irritants, thus contributing to improved indoor air quality and increasing the comfort of a home while considerably reducing heating and cooling costs.

The Canadian Urethane Foam Contractors Association (CUFCA) continues to advocate on several fronts, one being the advantage of unventilated (or conditioned) attic assemblies for residences. “A study we conducted with the University of Waterloo demonstrated a variety of benefits when insulation in homes is changed from the ceiling to along the roofline, one of them being resistance to high winds – because essentially the foam insulation used glues the entire roof assembly together,” says CUFCA executive director Andrew Cole.

Plus, such assemblies mean that if ductwork, air handlers, and sprinklers are located in the attic space, there’s no need to worry about the thermal penalties associated with duct leakage, the moisture penalties associated with induced negative pressures, the durability issues associated with locating equipment in hostile environments, or the freezing pipe issues associated with sprinklers.

Precast Double Wythe Insulated Panels with pre-installed windows.

CUFCA is also well known in the construction industry for warning about radon gas accumulation in basements (the second leading cause of lung cancer in Canada), and it was the first organization in Canada to test a radon control system with a two pound closed cell medium density spray foam. “Radon continues to be a hazard, but now CUFCA Certified Contractors can create a gas-proof basement using our tested and ULC evaluated foam system Grizzly Gold HFO by CUSE,” Cole says.

The Grizzly Gold HFO can be a single application process that provides an all-in-one solution of air barrier, moisture barrier, soil gas barrier, plus a high R-value thermal barrier. Once installed, the SPF forms a single monolithic sheet upon which construction crews can walk and use wheelbarrows without any damage to the underlying radon and vapour barrier spray foam. This far exceeds the performance of mechanically sealed sheet or tile alternatives.

As always, insulation is playing a huge role as advanced construction standards continue to become more highly sought in Canada. The Rockwool Group is the world’s leading manufacturer of stone wool insulation, in demand globally in residential, commercial, and industrial projects, and in Canada the new University of Victoria Student Housing and Dining project is a case study of how stone wool can be used to achieve the highest degree of performance standards.

That’s because the 333,681-square-foot, mixed-used complex was built to Passive House standards and intended to achieve rigorous energy targets. The project incorporates eight inches of Cavityrock continuous exterior insulation into the exterior wall system to serve a number of important functions. Primarily, the stone wool meets the need for high insulation levels, which passively work to maintain consistent temperatures inside the building, providing occupants with reliable thermal comfort, while reducing demand on energyreliant mechanical systems.

Stone wool also served to address long-term resilience and durability, particularly as the buildings will need to withstand extreme weather events. Also, because stone wool insulation is vapour permeable and allows any moisture to dry to the outside, it will help keep the wall system dry, mitigating any potential moisture-related issues over the life of the building.

Additionally, stone wool insulation also satisfied the requirement for a fire-rated wall assembly where an exterior canopy was incorporated to create a covered loading area on one of the buildings.

Finally, Johns Manville manufactures premium-quality insulation, commercial roofing and fibres and nonwovens for commercial, industrial, and residential applications. Recently, the company expanded its industrial insulation portfolio with a product that addresses corrosion under insulation (CUI).

Johns Manville Cross-Flo Jacketing is an innovation for ambient and hot systems, designed to help mitigate the potential for CUI. It has an embossed pattern engineered to promote cross-directional flow, providing a path for unwanted liquid to reach the low point of a system and exit the jacketing through a weep hole or drainage port more rapidly.

In addition to numerous technical benefits, Cross-Flo Jacketing has a distinctive aesthetic appearance and comes standard with a three-millimetre-thick polyfilm moisture barrier, heat laminated to the interior surface to provide additional protection against corrosion. A

Grizzly Gold HFO closed cell medium density spray foam.

We’re finding

energy in unlikely places

Like biogas captured from cow manure to create Renewable Natural Gas1 (RNG). It’s a low-carbon energy2 that can be used in homes and businesses across the province—and we’re adding more to our supply every year.

Our natural gas delivery system can provide RNG to buildings and developments to reduce greenhouse gas emissions. This means buildings can meet strict emissions guidelines without expensive upgrades or retrofits.

Find out more about RNG at fortisbc.com/rngbuild

with us @fortisbc

Greening The Blueprint

Green building design is surpassing benchmarks with transformative strategies that are redefining the very fabric of construction

by NATALIE BRUCKNER

In the ever-evolving landscape of Canadian architecture, the momentum of green building design surges forward at an accelerated pace. As our understanding of environmental challenges evolves, so too does the urgency to innovate within the architectural sphere. It’s no longer about just following rules; it’s about learning to quickly adapt to the changing environment.

Municipalities, regions, and provinces across Canada are fast-tracking the implementation of green building measures, surpassing original 2030 benchmarks, according to Terry Bergen, managing principal at RJC Engineers. They are achieving this by promptly implementing codes and standards that address operational and embodied carbon concerns. Two core strategies underpin these efforts: reducing operational carbon and minimizing embodied carbon.

Bergen adds that design elements such as building shape, form, and use significantly impact both operational and embodied carbon, too. “A building with simple form and few structural transfers will have a more effective thermal envelope and less embodied carbon than a building with complicated form and several setbacks,” Bergen explains.

In green building design, HRV/ERV systems also play a pivotal role in optimizing energy efficiency. “Limiting the design loads the HRV/ERV has to manage is critical,” says Bergen. “This involves thoughtful, integrated design – starting with a highperformance envelope and minimizing unintended gains or losses, while tightening the air barrier to minimize leakage and allow mechanical systems to be designed to known parameters.

“Suite-to-suite or building compartmentalization also becomes a key consideration for design teams. When the exterior envelope is designed and built to exacting standards, interior inequities can become apparent if not accounted for.”

With regard to the energy demand, Bergen says that designing a fully electrified building with capacity for EVs is a challenge designs teams can easily overcome, however, it can require significant electrical supply that may require significant capital cost outside of the building itself. “One of the strategies here again is to limit the loads by designed high-performance, low intensity buildings. Society has a better understanding of the critical importance of reducing the intensity of our buildings, and the importance of reducing this impact to the

greatest extent possible. At RJC we are excited and passionate to help our communities tackle this challenge, for all buildings new and existing.”

MONUMENTAL SHIFTS

According to Lindsay Oster, principal architect at Prairie Architects Inc., green building design is currently experiencing a significant shift in focus, with embodied carbon emerging as a central concern. Oster highlights this growing emphasis on embodied carbon as a pivotal aspect of contemporary design discourse. While operational carbon has long been the primary focus in sustainable architecture, the projection that the global building stock will double in size by mid-century underscores the need to address the carbon footprint of materials and construction processes.

Oster and her team have embarked on a journey to scrutinize the materials and products they specify in their designs, utilizing lifecycle analysis software to gain a more comprehensive understanding of sustainability. This approach goes beyond the immediate environmental impact of a building’s operations and considers the broader implications leading to the climate emergency. “It’s been eye-opening. Using lifecycle analysis software has provided us with a more fulsome picture of what is truly sustainable when taking into account larger consideration of the factors leading to the climate emergency.

The challenges facing the industry are formidable, but Oster sees a path forward. “We really need quite a radical market transformation when it comes to tackling embodied carbon. The more we can educate, innovate, and advocate as architects, the more we can move the dial when it comes to decarbonization,” Oster says.

The team at Diamond Schmitt Architects (DSAI) has also witnessed a monumental shift in the green building design industry, transcending the status of niche specialization to become the overarching imperative of every construction endeavour. This transformation is driven by a collective commitment from industry stakeholders, including fabricators, contractors, clients, and policymakers. Amy Norris, OAA at DSAI says sustainability discussions now permeate every facet of the process, with particular emphasis on energy efficiency and embodied carbon. The advent of planning standards mandating sustainable designs looms large on the horizon, uniting all hands in the mission to create greener structures.

DSAI is at the forefront of this revolution, boasting a portfolio of groundbreaking projects. “In particular, public projects with ambitious targets for operational and embodied carbon are challenging our team to develop innovative solutions for building types that are traditionally very energyintensive: research facilities such as the Atlantic Science Enterprise Centre [ASEC)] in Moncton, NB, and the new City of Toronto Paramedic Services Multifunction Paramedic Station, all of which are targeting Net Zero Carbon,” explains Norris.

Looking forward, DSAI envisions a future marked by heightened collaboration and knowledge sharing. “Generating a sufficiently swift response to the climate crisis requires knowledge development and sharing above and beyond what we have experienced to date. This is true both within the design profession and between design, consultant, and construction teams. It is imperative that we learn from each other and find better ways to organize and communicate the best solutions to the considerable challenges ahead,” says Norris.

FOCUS ON WELL-BEING

Taraah Den Boer, associate at Parkin, says she has also seen some remarkable developments over the past year that reflect a growing commitment to green building design. One notable achievement is the WELL Accreditation earned by the South Niagara Health project, signifying a substantial leap in health-focused health-care building design.

“Another noteworthy project is the New Surrey Hospital, which emphasizes a reduction in the carbon footprint by utilizing wood structures in public areas. Both of these projects in B.C. prioritize the ‘Wood First’ approach to mitigate the carbon footprint,” Den Boer explains.

The West Lincoln Memorial Hospital, another example of Parkin’s commitment to green building design, incorporates advanced features like electrochromic glazing and photovoltaic panels. This design not only prioritizes staff wellness and efficiency but also effectively reduces the building’s carbon footprint, establishing new standards in health-care architecture.

Den Boer acknowledges persistent challenges in the sector, such as supply chain issues and budget constraints for infection-resistant materials and suggests that early alignment of the project team and advocacy for sustainable, infection-resistant

products are the solutions. “Addressing this issue involves ensuring that the entire project team is aligned with key sustainable elements, even in the early stages of project delivery. When manufacturers understand our demand for healthier materials meeting infection control standards and testing requirements, we can utilize products that were previously only available in the European market, known for their inherent sustainability,” Den Boer notes.

ENERGY SAVINGS

Undeniably, green building design has emerged as a potent tool in Canada, revolutionizing energy consumption patterns. Stuart Hood, VP Institutional at Introba, underscores the vital role of green building principles in reducing energy demand and stabilizing energy usage profiles

Hood explains that minimizing the size of the HVAC heat pumps through Passive House design with super insulation and including solar shading in the design make a dramatic difference. “By super insulating the building, the building structure becomes a thermal battery,” he says. “In other words, during times of peak demand heating and cooling, production by the heat pumps can be switched off and the building can coast through these times for many hours or even days without changing temperature. Think of it like a thermos flask keeping your coffee hot for hours compared to a porcelain coffee cup cooling off in 20 minutes.”

All Introba’s Passive House work showcases these technologies, however Hood cites one great example in particular: Vienna House, a near

zero-emissions rental apartment community in East Vancouver that is about to start construction. Vienna House will showcase innovative materials and processes designed to deliver high energy performance with low greenhouse gas emissions. These include prefabricated wall, floor, and ceiling components constructed off-site from renewable materials, building information modelling that will create a “digital twin” of the proposed building, which will in turn allow the project team to optimize all components and systems, and an integrated design process that brings all the partners together at regular intervals to maximize efficiencies and collaboratively solve project challenges as they emerge.

All of these approaches, working together, aim to make Vienna House a potential template for other affordable housing projects across Vancouver, the province, and beyond.

PERFORMANCE GOALS

The past 12 months have welcomed a number of notable trends and innovations, and Greenstone Building Products has remained at the forefront of these developments. Among them is the advancement of panelized construction and Building Information Modelling (BIM). “As energy performance codes are being implemented nationwide, we are thrilled to provide a practical and tested method for achieving any building performance goal,” states Tilda Fortier, business manager at Greenstone. “Although it does require some proactive planning, our process offers the advantage of identifying

errors that would typically go unnoticed until everything is already delivered to the job site.”

One remarkable application of Greenstone’s ICE Panels can be seen in collaboration with Arctic Modular Homes, a company specializing in energyefficient housing for Canada’s northern regions. By incorporating ICE Panels into their modular designs, they achieved the impressive feat of closing in homes within just 10 days.

Another special project in 2023 saw Greenstone ship five eight-plexes and six 12-plexes (a total of 112 residential units) to ICE Panel Partner, NCC Development Ltd., to contribute to the Nunavut 3000 Building Program. Igluliuqatigiingniq Nunavut 3000 is committed to delivering 3,000 new units across the housing continuum in Nunavut by 2030. “ICE Panel construction will assist NCC to meet the energy efficiency requirements of the program, while increasing construction speed in locations with limited building seasons,” explains Fortier.

HOLISTIC SOLUTION

In the past year, FortisBC has made significant strides in its deep energy retrofit program, focusing on transforming existing buildings to align with B.C.’s provincial climate action goals. These efforts encompass various regions, including four multi-unit residential buildings and 20 single-family homes in the Lower Mainland, Vancouver Island, Okanagan, and Kootenays. These initiatives go beyond conventional methods, adopting a holistic approach. By taking a holistic approach that prioritizes the building envelope, these retrofits aim to enhance

Proudly contributing to a more sustainable approach to building in the prairies.

WEST COAST CONTEMPORARY LINE

A custom home build is quite often the single largest investment in one’s life. This is a tremendous responsibility to entrust to the construction community.

Understanding this concept and exceeding customers’ expectations are what Westeck strives for and is at the core of the Westeck culture.

BIG PRODUCTS FOR ALL SIZES EMBRACE THE PATIO EXPERIENCE INDOOR/ OUTDOOR LIVING VANCOUVER 1480 Kootenay St, 1‑877‑606‑1166 CHILLIWACK 8104 Evans Rd 1‑877‑606‑1166

westeckwindows.com sales@westeckwindows.com

insulation, replace windows with more efficient models, and increase airtightness. Simultaneously, they upgrade mechanical systems, employing innovative solutions like gas heat pumps and dual-fuel hybrid systems. Such comprehensive upgrades aim to reduce emissions in buildings by over 50 percent, while improving living conditions for residents.

Looking ahead to 2024, FortisBC plans to continue these transformative efforts, lowering energy use and encouraging the integration of Renewable Natural Gas (RNG) to meet the reduced heating needs. This approach not only minimizes emissions but also lowers operational costs, charting a path towards net-zero for buildings where converting to electricity is not feasible.

Currently, construction is underway for all projects, with the goal of completion by the end of 2024. Once finished, FortisBC will monitor and evaluate the energy use of each retrofitted home and building for a year, share the learnings and use the information to develop the next generations of energy efficiency programs. For example, in Vancouver, incorporating gas heat pumps, improving the building envelope, and upgrading windows could potentially achieve a remarkable 77 percent reduction in emissions, demonstrating the program’s positive impact on greening up buildings in B.C.

ONGOING EDUCATION

Williams Engineering, renowned for its forwardthinking approach, continues to lead in green building design by prioritizing continuous education and staying informed. Earlier this year, the team engaged in a pivotal lunch-and-learn session

focusing on the Practice of Regenerative Design in the Buildings Industry. This enlightening session, presented by Genan Hamad, a Ph.D. student and sustainability intern through the University of Alberta’s Adaptation Resilience Training (ART) program, delved into the critical aspects of regenerative design.

The ART Program, aimed at preparing Alberta for the impacts of climate change, provided invaluable insights. Williams Engineering’s participation showcased their commitment to proactive climate risk management. The presentation addressed diverse topics, ranging from how regenerative design can effectively counteract climate challenges to the specific roles and responsibilities associated with it. This newfound knowledge empowers Williams Engineering to seamlessly integrate regenerative design concepts into their infrastructure projects, reinforcing their position as pioneers in sustainable and resilient building practices.

TAKING ACTION, TODAY

Over the past 12 months, the Canada Green Building Council (CAGBC) has witnessed a significant shift towards heightened attention on carbon reduction and retrofitting existing structures. In fact, CAGBC has certified 26 projects under the Zero Carbon Building –Performance standard and 23 under the Zero Carbon Building – Design standard. Notably, the design community is taking a central role in advancing lowcarbon approaches in new constructions and finding innovative solutions for retrofitting existing buildings.

To foster industry growth, this fall CAGBC and its partners are launching the pioneering Low Carbon

Training Program. Funded in part by the Government of Canada’s Sectoral Workforce Solutions Program, this first-of-its-kind initiative aims to prepare professionals for work on efficient and low-carbon buildings, a crucial step in meeting the increasing demand for green structures. Concurrently, establishing a Canadian low-carbon supply chain is seen as vital, prompting collaboration with the University of Toronto on carbon capture research and the launch of a Sustainable Materials accelerator.

“To achieve zero carbon buildings and retrofits, architects and general contractors need access to a robust supply of innovative and low-carbon materials. Many Canadian companies offer new low-carbon solutions designers can implement – from reused and recycled construction materials to products that capture carbon dioxide through their production. However, companies – especially small and mediumsized manufacturers - can struggle with documenting the benefits of their products. CAGBC is working to level the playing field for these companies and secure the support they need to compete in the Canadian and U.S. markets,” says Mark Hutchinson, VP of green building programs and innovation at CAGBC.

“That is why CAGBC recommends that the federal government create a grant program to support companies seeking Environmental Product Declarations for the products designers need for zero carbon buildings and energy efficient retrofits. Our southern neighbour is investing $250 million USD in this issue through the Inflation Reduction Act, and Canada cannot afford to be on the sidelines,” adds Hutchinson. A

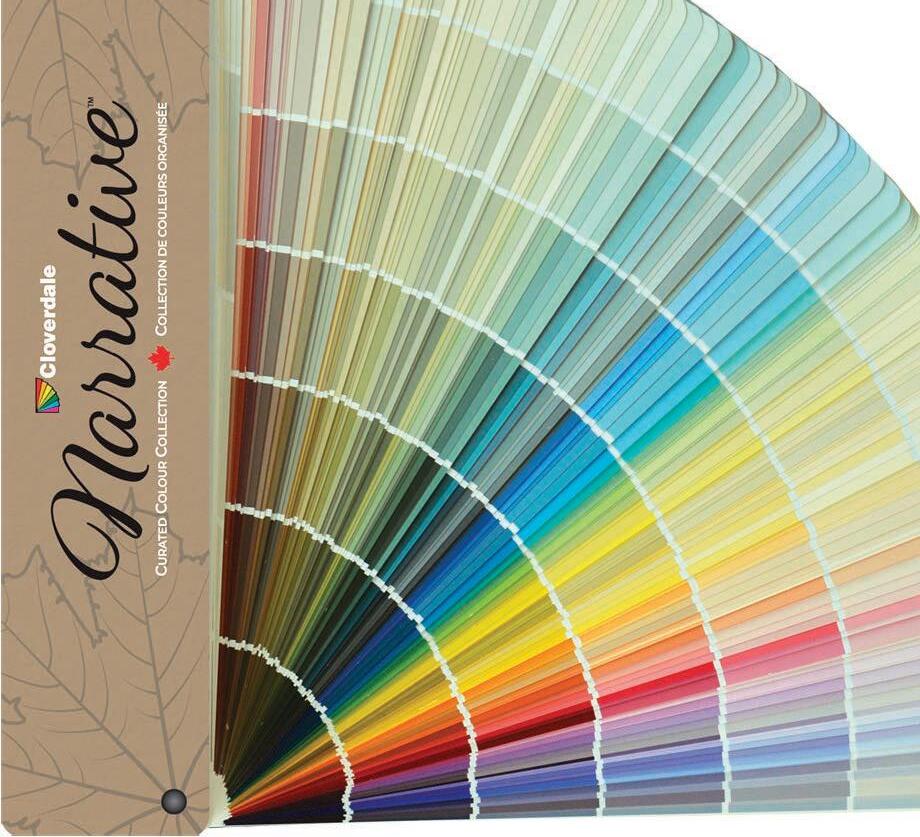

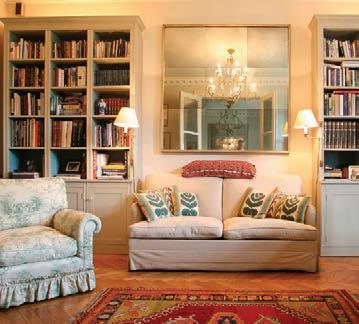

WHAT’S YOUR Colour Narrative?

Urban or Rustic?

Neutral or Colourful?

Modern or Classic?

Find your Colour Narrative in our fullspectrum palette that captures more of the widely specified paint colours from across Canada, determined by our Customers and Colour Experts.

Ceiling The Deal

Unveiling the latest innovations and trends reshaping the walls and ceilings industry

by LAURIE JONES

The rapidly advancing technology landscape has revolutionized the walls and ceilings industry, offering a plethora of stunning options. Precision laser-cut designs are now delivering awardwinning results, while the use of feather-light materials is transforming interiors into jaw-dropping spaces that exceed the benchmarks set by previous installations.

From acoustic fabric panels and acoustic wood panels to blinds and other architectural décor items, Wallworks Acoustic Architectural Products Inc. offers state-of-the-art, head-turning products that create wow factors and acoustic solutions suitable for any type of business or facility.

Procédés Chénel International is one of the many unique specialties carried by Wallworks. Chénel paper creates light and clever applications for both temporary and long-term installations. Some of the more whimsical creations are undeniably avant-garde. Whether employed for banners, dropped lighting features, partition walls, or instant ceilings, Chénel paper exudes a sense of professionalism and sophistication. In its essence, paper proves exceptional for printable concepts, making it suitable for use in schools, museums, or public displays. Portable and sustainable, these products can be used in simple or highly complex and enduring installations.

One of the most unique aspects of the Chénel line is that, despite being made up of paper, the finished product is remarkably stable, as explained by Lyle Fuller, general manager. “It is CAN ULC tested, and suitable for a wide range of draped commercial applications. It consists of different types and weights of anti-static fire tested kraft layer or honeycomb paper and comes in a significant range of standard colours, as well as an expansive custom pallet. In addition, Chénel’s ingenious systems can be set up in minutes to create consulting areas, offices, or private workspaces. Soil resistant and fireproof, whether used whole or in strips, Chénel can be attached to both wall and ceiling designs and plays well with lighting elements,” says Fuller.

Another equally unique product offered by Wallworks is Braug. Crafted with Swiss-made precision using the latest in digital technology, these custom-cut graphic panels yield high-quality finished results. These panels can be used for artistic interiors or spectacular exterior applications, or even integrated as part of an acoustic or lighting system. “Their use of laser technology allows for maximum flexibility in the cutting, providing a level of detail and colour range capable of matching the exact vision of the designer,” says Fuller. “The shape of the panel can also replicate historic patterns and recreate complex and accurate detail.” They can be used against exterior windows or to form entry cladding or railings. When combined with natural lighting, they cast their custom patterns on ceilings and on walls.

At PC350, the company has added a new choice to its Elite Glass Wall Solutions that features designs for enhancing the potential of natural light, acoustic performance, and individual well-being. The collection offers a range of options, including single glass, double glass, and now, curved glass wall solutions. “Our interchangeable product lines offer customizable applications that can radically transform space management, providing endless possibilities,” says Katie Lind, VP of sales and marketing.

Lind explains that the Single Glazed Walls are compatible with any door or standalone and are customizable and transformative. Both the Single and Double Glazed Walls can be integrated seamlessly with most configurations,

including finished and unfinished walls. “All our walls have a panel height capability of up to 12 feet, with a diverse range of profile options available in various heights and thicknesses for base, vertical, and ceiling conditions. Both the Curved Single and Double Glazed Walls offer a radius range from 20 inches to an unlimited maximum, providing the flexibility to achieve elegant and precise curved configurations.”

Whether opting for Single or Double walls, both seamlessly integrate with swing and sliding door options, offering flexible access to working areas.

The Double Glazed Walls have the added benefit of speech privacy and exceptional acoustical performance. “Your confidential discussions remain securely contained within a space that radiates style,” says Lind. The installation process is seamlessly managed by the dedicated teams at PC350, who proactively oversee every stage of construction to ensure timely installation without any delays.

Partition Systems Ltd. (PSL) based in Edmonton, Alberta, has been crafting Demountable Wall Systems for more than 50 years. Each system features varying wall thicknesses, performance ratings, and aesthetic capabilities. Proudly made in Canada, PSL products are manufactured, supplied, and installed using one single installation subtrade. This streamlines the process and eliminates

Braug custom-cut graphic panels.

Double Glazed Curved Walls.

Executive Demountable Wall.

the need for co-ordination among multiple subtrades on the job site. This efficient method not only simplifies the process but also reduces stress for clients. Steve Nasholm, national director of sales, architectural walls and dealers, explains: “Because our systems are customized and prefabricated, they are delivered to the site and installed as one clean package.”

PSL offers a diverse range of products and among them are three demountable wall selections that can work in any office environment: the Executive Demountable Wall, the Corporate Demountable Wall, and the Corporate Low Glazing. The design options for these panel systems are vast, with finishes in laminate, wall fabric, glass, back-painted glass, or even TV screens mounted in the wall sections. According to Nasholm, the choice of demountable walls significantly influences the acoustical performance of the system. “Our Executive Demountable Wall, with four-and-a-quarter-inch wall thickness, provides the highest level of acoustics [up to STC51], while the Corporate Demountable Wall has a two-and-a-quarter-inch wall thickness. The Corporate Low Glazing also hits that low profile look that clients and architects really strive for. All of our products are made from 100 percent reusable materials, which can ultimately contribute to LEED credits.” Each of the demountable walls can be integrated seamlessly with other selections for a true mix-and-match design option.

Nasholm adds that all solid wall sections can be pre-wired in a more modular configuration to meet clients’ electrical and data requirements. The CSAcertified wiring systems, coupled with removable panelling, result in lower costs compared to traditional electrical installations, and save time during office setup. “The key here is the ability to install construction with Partition Systems and have the ability to reconfigure and reuse these wall systems on future design.”

Sound Solutions – Architectural Products, distributors of innovative interior and exterior architectural products, now offers the Bendheim interior glass cladding system. “These are fully engineered products, including the Turnkey Fusion Light Wall system, and the Turnkey system for Back-Lit Glass Walls and Ceilings,” says Ed Makarchuk, principal.

Building on the success of Bendheim’s Turnkey Glass Wall system, the Fusion system offers a completely integrated solution for backlighting. Turnkey Fusion now provides a completely integrated solution for backlighting, with Bendheim’s new Fusion LED panels built right into the system. The Fusion LEDs, along with Bendheim’s innovative LE’Diffusion Safety Glass, are specifically engineered for even dispersion of LED light.

The Turnkey System for Back-Lit Glass Walls and Ceilings boasts an ultra slim design, measuring approximately 1.65 inches deep. “This fast, user-friendly illuminated interior glass cladding is easy to install and maintain,” says Makarchuk. The system features fully reversible mechanical connections, eliminating the need for adhesives or glass drilling. “These panels can be replaced without damaging the walls, offering easy access to systems behind the glass.”

Installed in notable locations such as the Kostali Chicago/The Gwen Hotel and the Extra Butter store in Queens, N.Y., the system for Back-Lit Glass walls can be seen in a variety of industries.

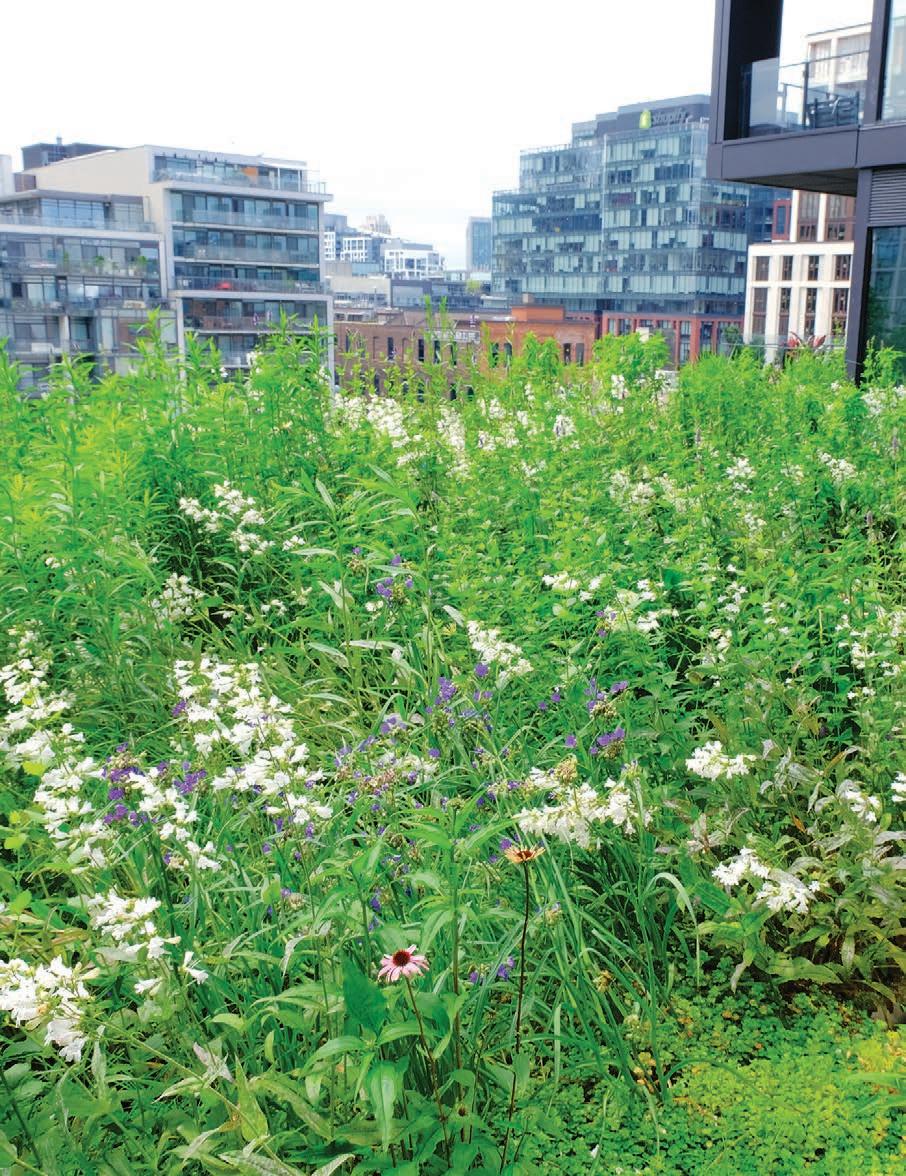

LIVING WALLS

In the quest for a greener and more sustainable future, companies like New Earth Solutions are at the forefront of pioneering environmental technologies. This forward-thinking company has been making waves in the living wall industry by advancing biofilter technology and making it accessible for all types of buildings and businesses. With a mission to transform urban landscapes and

indoor environments, New Earth Solutions is redefining the way people interact with nature in their daily lives.

“At the heart of this innovation is our advanced biofilter technology,” says Sean Ludchen, president of sales. “These living walls are not just visually stunning; they are also efficient air purifiers. The design of New Earth Solutions’ system is unique in that it optimizes a plants natural air-purifying capabilities, allowing them to remove harmful pollutants and toxins from the environment.”

He explains that the key is the system is hydroponic and thereby exposes the root zone of the plant – where the air purifying processes actually take place – to the contaminated air flow. “This design significantly enhances the natural air purifying ability of a plant and greatly improves the indoor air quality, promoting healthier spaces,” he says.

Ludchen notes that what sets New Earth Solutions apart is its commitment to accessibility. “We’ve developed scalable solutions that can be tailored to fit any space, from sprawling corporate offices to small local shops. Our modular system integrates the most advanced living wall technology available, making it easy to install and maintain.”

New Earth Solutions is fervently dedicated to sustainability. Their biofilter technology not only benefits the health of the indoor environment but also contributes to increasing energy efficiency within the building. Additionally, New Earth Solutions can assist businesses in achieving LEED and WELL certifications. By incorporating New Earth Solutions’ biofilter living walls, projects can earn valuable points toward certification while reaping the benefits of improved air quality and reduced energy expenses.

Drawing on years of experience, the GinkgoWalls team designs and installs living walls and facades tailored to each client’s aesthetic and functional requirements. Ginkgo Sustainability offers living walls that are completely mobile, ones affixed to walls that are hand-watered, plus others that are fully automated built-in systems.

GinkgoWalls provides a comprehensive range of services, including assistance with feasibility studies, vertical garden assessments and recommendations, plant information, and LEED credit guidance.

Ensuring the longevity and vitality of a living wall necessitates ongoing care. “Regular plant maintenance, such as pruning, fertilizing, or plant replacement, is imperative to sustain the wall’s health and prevent issues like plant deterioration or overgrowth. Maintenance visits are crucial for monitoring the wall system, assessing water, light, and temperature levels. GinkgoWalls offers maintenance services that not only preserve the living wall’s health but also contribute to the overall success of the wall project, aligning with its aesthetic and functional objectives,” emphasizes Sandy Dos Santos, Living Walls Maintenance Supervisor. The team not only tends to the plants but also conducts systematic checks to ensure the seamless functioning of the entire system. Dos Santos explains: “Without regular maintenance visits, unnoticed issues could lead to system failure, posing risks not only to the plants but also to potential property damage. Addressing these concerns proactively during routine maintenance proves more cost-effective in the long run.” A

GinkoWalls living wall installation.

Turnkey Fusion Light Wall system.

Carving Out Success For 2024

We’re busy in 2023 and there’s more to come in 2024. That’s the sentiment of people in the architectural woodworking sector as the year draws to a close.

Kelly Glanzer, manager at Top40 Woodworks in Kamloops, says, “Life is busy and gratefully so are we: thanks to our wonderful clients, 2023 is completely sold out, 2024 is almost sold out, and we are booking into 2025. This year we’ve been producing a lot of work for hospitality, multi-family, retail, daycare, pharmacy, and office projects for Canada as well as into the U.S.”

Part of Top40’s success is also due to ongoing selfimprovement. “We are always trying to improve our LEAN manufacturing efficiencies with the philosophy ‘What gets measured gets managed,’” Glanzer says. “We have already re-organized many of our internal systems for efficiency and workflow. Expansion plans in the New Year include adding another high-capacity CNC and edge bander with an advanced gluing system for improved quality.

“Plus, over the last year we have rolled out a new web-based, data driven ERP system that gives us amazing forecasting, scheduling, manufacturing, and project management tools with communication between us beyond what we have ever had previously. Being web based it also allows us to employ much needed remote workers and attract quality talent.”

Tom Morin, president of Victoria, B.C.-based Morinwood, reports that “2023 was a solid year and we continue to be busy. That’s due partly to the fact that we’re not involved in residential construction, so the interest rate surge hasn’t affected the institutional market.”

Leaders in architectural woodwork ensuring wood’s future by taking on complex and innovative projects

by ROBIN BRUNET

It’s a far cry from just a few years ago, when the pandemic lockdowns caused huge increases in material and labour prices. As Morinwood heads into the New Year, Morin says material costs have stabilized, “and we’re well equipped to pay even unskilled labour better than Victoria’s living wage of $25 per hour –with skilled labour making between $40 and $50 per hour. If this is the new normal people kept insisting would result from the pandemic, I hope it continues. Tradespeople deserve to make a healthy wage.”

Morin’s company is known for its collaboration on the most challenging projects (the Vancouver Convention Centre and the BC Children’s Hospital are prominent in its extensive portfolio of completed projects), with a preference for design-build, P3, design assist, or IPD delivery methods. It orchestrates interior finishes on institutional projects, and its scope includes architectural millwork, systems furniture, acoustic panelling, wall protection, and specialties.

In the past Morin has commented that when one visits a new elementary school “it’s built like a university building in terms of the level of finishes,” and as such he is enthusiastic about having recently begun work on the new Cowichan Secondary School. “It’s a project whose design incorporates a lot of First Nations themes, and we’re able to use locally harvested wood to build a warm and welcoming environment for the students. My team is so proud to be part of a project that will be the heart of the community for decades to come.”

Morin is also gearing up for a New Year start on the Cowichan District Hospital replacement project, which he describes as “massive in size that will require wood to impart an inviting rather than an institutional ambiance. One highlight of this project will be a beautiful atrium whose design calls for extensive wood use.”

While such projects will keep Morin’s firm busy “for at least the next several years,” there’s no escaping the challenge that has dogged the woodworking sector for many years now: attracting newcomers to the industry. “The irony that we have a skills crisis and yet zero wood shops in high schools is not lost on us,” he says. “The expertise required to work with wood is increasingly rare, which keeps us in demand, but I worry about the future.

“But as always, we’re trying our best to rectify the situation. For the two Cowichan projects we’ll be hiring kids between 18 and 25 and investing in their training in the hopes that they will have long careers in construction.”

Training new talent has become a priority for many millworking companies. Executive Millwork Inc. is committed to a continuous improvement culture that

Indigenous meeting circle.

encompasses technology, skill development, product quality, and planning processes. This has resulted in the successful completion of a host of unique projects, among them The Ampersand in Calgary, which features dramatic and unique architectural millworking throughout its 57,000 square feet of space.

All of Executive Millwork’s employees participate in trade related and other selected business skills training. In addition, Executive Millwork actively participates in the provincial cabinetmaker apprenticeship program. Its key personnel are involved in the Calgary Construction Association and the local and national Architectural Woodwork Manufacturers Association of Canada (AWMAC).