GETTING STRATEGIC ABOUT BUILDING YOUR NETWORK

A conversation with sales experts

Ed Wallace and Mark Roberts

ALSO INSIDE

Special Section: AICC Education Catalog

Special Section: AICC Sales Compensation Report Summary

September/October 2023 Volume 27, No. 5

Digital Marketing: Web of Engagement

A PUBLICATION OF AICC, THE INDEPENDENT PACKAGING ASSOCIATION

BOXSCORE www.AICCbox.org 1 TABLE OF CONTENTS September/October 2023 • Volume 27, No. 5 BoxScore is published bimonthly by AICC, The Independent Packaging Association, PO Box 25708, Alexandria, VA 22313, USA. Rates for reprints and permissions of articles printed are available upon request. The statements and opinions expressed herein are those of the individual authors and do not necessarily represent the views of AICC. The publisher reserves the right to accept or reject any editorial or advertising matter at its discretion. The publisher is not responsible for claims made by advertisers. POSTMASTER: Send change of address to BoxScore, AICC, PO Box 25708, Alexandria, VA 22313, USA. ©2023 AICC. All rights reserved. Visit www.NOW.AICCbox.org for Member News and even more great columns. Scan the QR code to check them out! COLUMNS 3 CHAIRWOMAN’S MESSAGE 4 LEGISLATIVE REPORT 6 MEMBERS MEETING 10 ASK RALPH 14 ASK TOM 18 SELLING TODAY 22 ANDRAGOGY 24 LEADERSHIP 28 DESIGN SPACE 36 MEMBER PROFILE 64 THE ASSOCIATE ADVANTAGE 66 STRENGTH IN NUMBERS 76 THE FINAL SCORE DEPARTMENTS 5 WELCOME, NEW & RETURNING MEMBERS 31 AICC INNOVATION 70 FOUNDATION FOR PACKAGING EDUCATION 76 INTERNATIONAL CORRUGATED PACKAGING FOUNDATION 42 48 56 60 FEATURES 42 GETTING STRATEGIC ABOUT BUILDING YOUR NETWORK A conversation with sales experts Ed Wallace and Mark Roberts 48 WEB OF ENGAGEMENT Using digital marketing to increase customer connections 56 EDUCATION FOR YOUR COMPANY AND TEAMS Heading into its 50th year, AICC continues to deliver the most robust training and support for members and their employees 60 ON THE UP Sales compensation rises in 2023, says AICC survey

OFFICERS

Chairwoman: Jana Harris, Harris Packaging/American Carton, Haltom City, Texas

First Vice Chairman: Matt Davis, Packaging Express, Colorado Springs, Colorado

Vice Chairs: Gary Brewer, Package Crafters, High Point, North Carolina Finn MacDonald, Independent II, Louisville, Kentucky

Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Immediate Past Chairman: Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Chairman, Past Chairmen’s Council: Jay Carman, StandFast Packaging Group, Carol Stream, Illinois

President: Michael D’Angelo, AICC Headquarters, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

AICC Canada: Lee Gould

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Michael Drummond, Packrite, High Point, North Carolina

Midwest: Casey Shaw, Batavia Container Inc., Batavia, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos., Macedonia, Ohio

Northeast: Stuart Fenkel, McLean Packaging Pennsauken, New Jersey

AICC Canada: Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

AICC México: Sergio Menchaca, EKO Empaques de Cartón S.A. de C.V., Cortazar, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Kevin Ausburn, SMC Packaging Group

Springfield, Missouri

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Guy Ockerlund, Ox Box, Addison, Illinois

Mike Schaefer, Tavens Packaging & Display Solutions, Bedford Heights, Ohio

Ben DeSollar, Sumter Packaging, Sumter, South Carolina

Jack Fiterman, Liberty Diversifies, Minneapolis, Minnesota

EMERGING LEADER DELEGATES

Lauren Frisch, Wasatch Container, North Salt Lake, Utah

John McQueary, CST Systems, Atlanta, Georgia

Jordan Dawson, Harris Packaging, Haltom City, Texas

ASSOCIATE MEMBER DIRECTORS

Chairman: Greg Jones, SUN Automation Group, Glen Arm, Maryland

Vice Chairman: Tim Connell, A.G. Stacker Inc Weyers Cave, Virginia

Secretary: John Burgess, Pamarco/Absolute, Roselle Park, New Jersey

Director: Jeff Dietz, Kolbus America Inc., Cleveland, Ohio

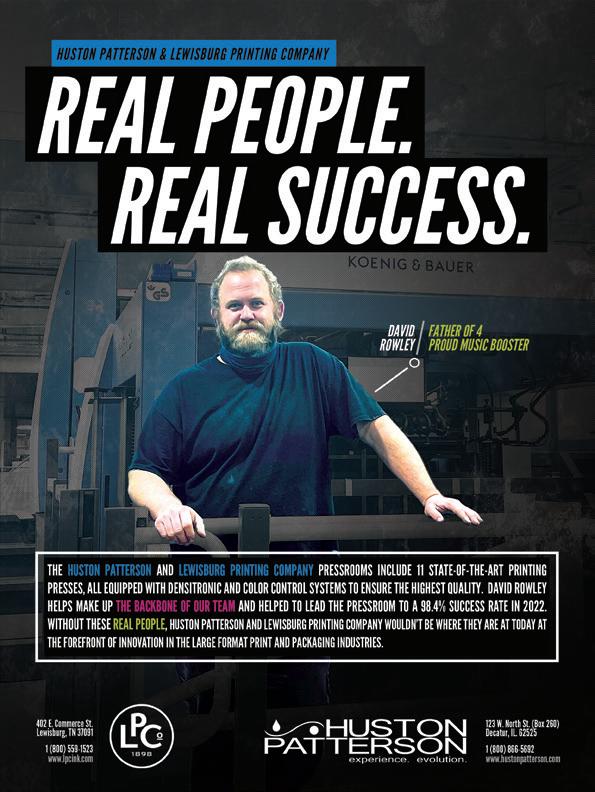

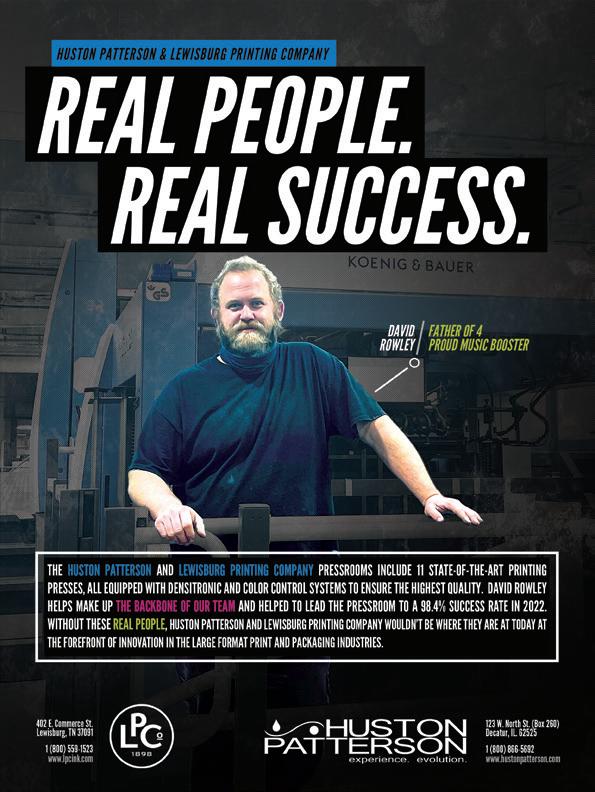

Immediate Past Chairman, Associate Members: Joseph Morelli, Huston Patterson Printers/Lewisburg Printing Co., Decatur, Illinois

ADVISORS TO THE CHAIRMAN

Al Hoodwin, Michigan City Paper Box, Michigan City, Indiana

Gene Marino, Akers Packaging Service Group, Chicago, Illinois

Greg Jones, SUN Automation, Glen Arm, Maryland

PUBLICATION STAFF

Publisher: Michael D’Angelo, mdangelo@AICCbox.org

Editor: Virginia Humphrey, vhumphrey@AICCbox.org

ABOUT AICC

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President: Serena L. Spiezio

Senior Director of Content Strategy: Craig Lauer

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Frankie Singleton

SUBMIT EDITORIAL IDEAS, NEWS, & LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Cindy Huber, Director of Conventions & Meetings

Chelsea May, Education and Training Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore, Membership Services Manager

Taryn Pyle, Director of Training, Education & Professional Development

Alyce Ryan, Marketing Manager

Steve Young, Ambassador-at-Large

ADVERTISING

Taryn Pyle 703-535-1391 • tpyle@AICCbox.org

Patrick Moore 703-535-1394 • pmoore@AICCbox.org

AICC

PO Box 25708

Alexandria, VA 22313

Phone 703-836-2422

Toll-free 877-836-2422

Fax 703-836-2795

www.AICCbox.org

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

A Year of Memories and More

Wow, how a year can fly by! It seems like yesterday that Gene Marino passed me the gavel in San Antonio. It has been such an honor to be AICC’s chairwoman. My husband, Zachary, and I enjoyed the opportunity to travel on behalf of AICC and see what many of you are up to in your regions. We made our fair share of trips and made some new friends along the way. We had a lot of fun and got some work done. Our experiences and trips were all memorable, but here are some of the highlights.

The first trip as chair was to speak at the AICC México Annual Meeting and Trade Fair in Guadalajara. It was a great time and turnout. If you have not attended an AICC México meeting, I highly recommend it, and if you do not speak Spanish, they have translators.

Next up, we took a trip to South Carolina for the first fundraising event for the Foundation for Packaging Education. It was a wonderful time networking and getting a little golf in when the weather permitted. The foundation was established a few years back by AICC, and its mission is to fund the continuation of ongoing education for individuals employed in our industry. The foundation’s next fundraiser will be in July 2024 in Napa, California, so make sure you join us.

Another memorable event was in December. Zachary and I made it to the annual International Corrugated Packaging Foundation (ICPF) Holiday Weekend in New York City. ICPF welcomed its new president, Caitlin Salaverria, and I am so excited about the direction she will be taking this foundation. She and the ICPF board are committed to investing more heavily in education and focusing on two-year colleges, trade schools, high schools, and even middle schools. You can learn more about this effort at www.icpfbox.org. I am excited to say that AICC, ICPF, and the Foundation for Packaging Education are more synergized now than ever, and I see good things ahead with packaging education. Better Minds, Better Boxes!

AICC’s Spring Meeting in Miami also made the cut. We had an outstanding turnout at Trump Doral and raised money for the Foundation for Packaging Education at the 9th Annual Independents’ Cup Charity Golf Tournament. What a successful meeting!

Last but not least, I made it to Colorado Springs for the Emerging Leaders (ELs) First Vice Chair Workshop. I am so proud of these young adults and how eager they are to learn from us and each other. If you have any young talent whom you see being a future leader, consider enrolling them in this program. We have three ELs from our company who are active, and they love it.

So, after an amazing whirlwind year, I say thank you for allowing me to represent AICC, thank you to the staff for making it easy, and thank you for the memories! I now have the pleasure of turning over the chairmanship to the very capable Matt Davis of Packaging Express. Congratulations, Matt!

Cheers!

Jana Harris CEO and Co-owner, Harris Packaging and American Carton Co. AICC Chairwoman

BOXSCORE www.AICCbox.org 3 Chairwoman’s Message

In Full Transparency, You Heard It Here First

BY ERIC ELGIN

In this issue of BoxScore, we present “Everything You’ve Always Wanted to Know About the Corporate Transparency Act (CTA).” What’s this? You haven’t heard about the CTA and the reporting requirements it will impose beginning January 1? If not, you’re in good company. But AICC, through its network of allied small-business organizations in Washington, D.C., can now bring you up to speed on what to expect.

We start our primer by going to the source of all things legal—lawyers. In a recent article in the ABA Journal , the American Bar Association says, “At its core, the CTA is a mechanism to deal with issues related to ‘dirty money’—i.e., guarding against money laundering, terrorism financing, and other forms of illegal financing—as well as the general lack of beneficial owner (i.e., ‘true owner’) information with respect to many domestic entity structures. ... The CTA was born of the view that the availability of beneficial ownership information is a crucial tool in the fight against tax evasion, money laundering, corruption, terrorist financing, and other financial crimes.”

The “high crimes and misdemeanors” against which the CTA is targeted are hardly the stuff of our businesses’ day-today accounting challenges. (Just ask your accounts receivable manager.) Yet, it is precisely the small-business community that will bear the brunt of what the CTA and its enforcement arm, the Financial Crimes Enforcement Network (FinCEN), will require. Says Brian Reardon, CEO of the S Corporation Association, “Starting next year, millions of small-business owners will get a letter from a federal agency they never heard of telling them they need to comply with a law nobody’s

told them about. Most, like reasonable people, will probably think the notice is a scam and throw it away.”

The letter we’ll receive will tell us that starting January 1, 2024, all newly formed corporations, LLCs, and other covered entities must report the personal information of their “beneficial owners” to FinCEN. On January 1, 2025, all covered entities with less than $5 million in revenue and 20 employees will have to do the same. The information to be provided for beneficial owners includes name, address, Social Security number, and photos. Noncompliance can result in fines of up to $500 a day or two years’ imprisonment.

Now you know about the CTA. There is a bright side to this dark story, however. The National Small Business Association has filed a lawsuit against it,

NSBA v. Yellen, which argues that the CTA is unconstitutional. Given recent landmark decisions by the U.S. Supreme Court and its subsidiaries, we can hope that reasoned judges will see this law for what it is: an unconstitutional invasion of privacy.

Let your U.S. representatives and U.S. senators know how you feel about this law and its potential effects on your business. Go to www.house.gov or www.senate.gov to find your congressional representatives. Or call the U.S. Capitol switchboard at 202-224-3121.

Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com

BOXSCORE September/October 2023 4 Legislative Report

SAICA PACK U.S., LLC

BRIAN GREENBUSH

Sales Manager

2995 McBride Ct. Hamilton, OH 45011 513-399-5602

www.saica.com

PACIFICOLOR LLC

KENNETH BROOKS

Vice President of Business Development

1547 W. 2290 South Woods Cross, UT 84087 801-294-4455

www.pacificolor.com

EOS AMERICA CORP.

JEFFERY ROTH

North America Sales Manager

450 7th Ave., Suite 1501 New York, NY 10123 614-824-9558

www.eos-corrugated.com

DS SMITH – NORTH AMERICA

CHERYL HOLLIDAY

Marketing Director

600 Peachtree St. NE, Suite 4200 Atlanta, GA 30308 470-645-1320

www.dssmith.com

DIAMONDBACK CORRUGATED CONTAINER

JOHN BRADLEY JR. Managing Partner 4302 Profit Dr. San Antonio, TX 78219 210-807-7296

www.diamondbackbox.com

ADVANCED EQUIPMENT SALES

JEFFREY DIETTERICH

President 535 Hagey Rd. Souderton, PA 18964 215-723-7200

www.advancedequipmentsales.com

CHAMPION CONTAINER CORP.

ANNA RIZZO

General Manager 1455 N. Michael Dr. Wood Dale, IL 60191 630-530-1990

www.champion-container.com

Welcome, New & Returning Members BOXSCORE www.AICCbox.org 5

Welcome AICC’s New Members!

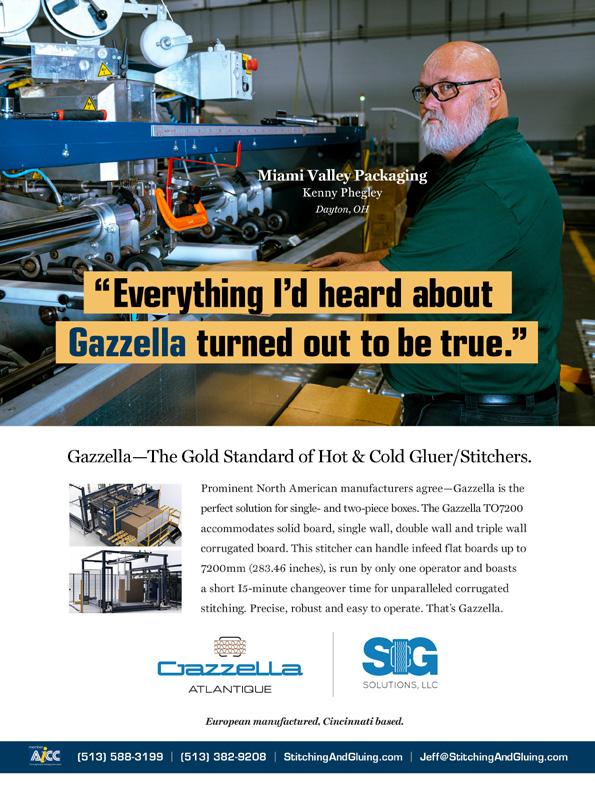

2023 Southeast Summit: Mill Tour Brings 60 Members Together

Over 60 attendees participated in the 2023 AICC Southeast Summit in July in Kingsport, Tennessee, touring Domtar’s mill, playing in the annual golf tournament, and strengthening their industry relationships.

AICC members, including several first-time summit attendees, saw Domtar’s venerable, now modernized Kingsport Mill. Originally opened in 1916, the mill is a downtown landmark on the Holston River. Through extensive renovation, Domtar converted the facility into the company’s first 100% recycled containerboard facility. It is expected the mill will produce and market about 600,000 tons of recycled linerboard and corrugated medium annually, making it the second-largest recycled containerboard machine in North America. Domtar sells its output to independents.

Attendees received a tour that began with the historical aspects of the mill and progressed through the renovations and upgrades that

have made the mill a showcase of the most modern papermaking technology. The mill utilizes 50,000 tons of recycling residuals and other

BOXSCORE September/October 2023 6

Members Meeting

AICC Southeast Summit attendees were treated to a tour of Domtar’s Kingsport Mill in Tennessee.

This year’s AICC Southeast Summit golf tournament was held at the Cattails at the MeadowView Golf Course at the MeadowView Marriott Resort.

Photos courtesy of AICC.

CARE® Pads & Brushes

Solvent & UV Based Cleaning Products

CARE® Pads & Brushes

Solvent & UV Based Cleaning Products

Members Meeting

byproducts that otherwise would enter landfills.

“AICC appreciates Domtar opening the facility for our members,” says

AICC President Michael D’Angelo. “It is impressive to see one of the widest, fastest paper machines in the world creating 100% recycled product.

It is the cleanest paper mill that I have ever visited.”

The summit golf tournament was held on the Cattails golf course at the MeadowView Marriott Resort, one of the top public golf courses in Tennessee. The winning team included Gregg Diethorn, Longreach International; Greg Jones, SUN Automation Group; James Moncure, J.M. Fry; and Chris Neighbors, Cumberland Container.

AICC thanks platinum sponsor Domtar, along with other event sponsors Haire Group, A.G. Stacker, Bobst, SUN Automation Group, Independent Corrugator, American Corrugated Machine, Independent Paperboard Marketing, Baysek Machines, EAM Mosca, and TranSouth Logistics.

Join us for the 39th Annual West Coast Golf Tournament on October 17 at the Strawberry Farms Golf Club in Irvine, California. Learn more at www.AICCbox.org/calendar.

For more information about AICC summits, contact Laura Mihalick, senior meeting manager, at 703-836-2422 or lmihalick@AICCbox.org.

BOXSCORE September/October 2023 8

Troy Wilson, Domtar Kingsport Mill manager, leads AICC members by incoming mill furnish.

Tourgoers take in the majesty of Domtar’s Kingsport Mill.

Some Corrugated and Containerboard History: Part One

BY RALPH YOUNG

More than 10 years ago, we published a trilogy of the last 50–70 years of our industry. As AICC is getting ready to celebrate its 50th anniversary at the Spring Meeting in April in Palm Desert, California, we wanted to remind everyone where we came from. Our incoming chairman, Matt Davis, recently said, “We need to embrace and honor the past.” Remember the independent advantage. So, for those of you who are new to this industry, we submit this legacy for you. For those of us who are veterans, a few memories:

Our industry has a rich history of single entrepreneurs, families, and partners taking risks in very local venues. The beginnings were not corporations; they were very fragmented and very independent. It might have been as simple as a straw farmer seeking a higher return on his crop (an early fiber source for medium), rather than just a feed for cattle. And he would partner with papermakers and box manufacturers that were moving out of wooden crates into corrugated “packaging.” It was only over many years that larger and more geographically focused companies came to acquire the local and regional business operations.

St. Regis

On August 1, 1984, Champion International Corp. and St. Regis Corp. announced jointly that they had signed a definitive agreement to merge the two big paper companies in a deal valued at $1.7 billion in cash

and stock. The merger would create the nation’s biggest paper producer in terms of sales, far outstripping GeorgiaPacific Corp., the then-current leader. It would also challenge International Paper Co. for the top spot in the industry in terms of pulp and paper tonnage produced.

St. Joe

The St. Joe paper mill at the corporate headquarters in Florida was most profitable in the 1960s, with products being marketed directly to independents, trade partners, and company-owned box plants. However, an extended period of downtime (nine months) due to market conditions in 1996 signaled the beginning of the end for the mill. After nearly 60 years, St. Joe decided to get out of the paper business. The mill was sold in 1996 to Florida Coast Paper for $390 million and was able to operate and produce paper until another decline of the containerboard market. The mill closed August 16, 1998, and did not reopen. The mill was gone by 2003.

In November 1995, St. Joe announced a deal to sell 16 box plants and its pulp and paper mill for $390 million, taking a big step to divest its noncore assets. Box USA, owned by Four M Corp. of Valhalla, New York, the largest privately held corrugated boxmaker in the nation at that time, acquired the East Coast box plants. It also bought the pulp and paper mill in Port St. Joe, Florida, in a joint venture with Stone Container Corp. of Chicago. After the sales, St. Joe Paper

was left with 1 million acres of forest land and property in Florida, among other assets.

Gaylord

Gaylord Container was a byproduct of the hostile takeover of Crown Zellerbach by Sir James Goldsmith in July 1985, which resulted in the breakup of the San Francisco-based forest products corporation in May 1986. The more profitable manufacturing assets (fine paper mills) were sold to James River Corp. of Richmond, Virginia—which became Fort James in 1997 and was acquired by GeorgiaPacific in 2000. The less profitable container division (brown paper) became Gaylord Container and, after a brief period as a limited partnership, was sold in November 1986 for $260 million to a group of Midwest investors, led by Warren Hayford and Marvin Pomerantz. They headed MidAmerica Packaging, a single kraft paper mill in Pine Bluff, Arkansas, acquired from Weyerhaeuser in December 1985 for $28 million. Soon after the acquisition of the former Crown Zellerbach assets, the headquarters of Gaylord Container were moved from California to Illinois.

The company was originally named after the gaylord container, a bulk-size corrugated box by a company of the same name, based in Gaylord, Michigan. The company was acquired by Crown Zellerbach in 1955, which renamed its brown paper operations to Gaylord Container Division.

BOXSCORE September/October 2023 10

Ask Ralph

4 trends are reshaping the future of the corrugated industry. PrintEnomics.com Download the eBook

Ask Ralph

In 2002, Inland acquired Gaylord Container Corp.

Container Corp. of America Container Corp. of America (CCA) was founded in 1926. In 1968, CCA merged with Montgomery Ward & Co. Inc. in a move that was largely intended to thwart takeover bids against either company. MARCOR maintained separate management for the operations of each company but had a joint board of directors. In 1986, Mobil Corp., which had bought MARCOR in the early 1970s, sold the CCA company to Jefferson Smurfit Corp., which merged with Stone Container Corp. in 1998 to become part of Smurfit-Stone Container Corp. CCA was a wholly owned subsidiary of Smurfit-Stone Container Corp.

Wabash/Weston Paper

Also added in 1998 by International Paper was Weston Paper and Manufacturing Co., acquired through a stock deal valued at $232 million. Based in Terre Haute, Indiana, Weston operated 11 corrugated container plants in the South and Midwest, including a medium mill at its headquarters.

Mead

MeadWestvaco was formed in January 2002 as the result of a merger between the Mead Corp. of Dayton, Ohio, and Westvaco (originally Piedmont Pulp and Paper Co. and then West Virginia Pulp and Paper Co.). In 2005, the papers business unit—including both Mead and Westvaco paper mills—was sold to investment firm Cerberus Capital Management for about $2.3 billion. The new company is called NewPage Corp.

In 2008, MeadWestvaco sold its Charleston, South Carolina, kraft paper mill to Kapstone Paper and Packaging and its Stevenson, Alabama, medium mill to Smurfit-Stone, which became RockTenn.

Box USA

In April 2004, International Paper announced it had agreed to acquire Box USA Holdings Inc., one of America’s leading corrugated packaging companies.

MacMillan Bloedel

In June 1999, Weyerhaeuser announced its intention to buy MacMillan Bloedel Ltd. of Canada for stock valued at about $2.45 billion. The merger made Weyerhaeuser, which at that time was already the world’s largest producer of softwood lumber and market pulp, a leader in packaging as well.

Union Camp

In 1999, Union Camp Corp. was acquired by International Paper. At the time, it was referred to as a merger, but it was actually a takeover. The Union Camp chairman at that time, W. Craig McClelland, had actually sold another company, Hammermill Paper Co., to International Paper in the mid-1980s, when he was also in charge of that company. He finally retired from International Paper’s board of directors in late 2006.

Continental Can

In 1976, Continental Can Co. changed its name to Continental Group, a conglomerate with operations in many countries, but it kept Continental Can as its packaging unit within Continental Group. In 1987, the remnants of Continental Can became part of the United States Can Co. (a subsidiary of Inter-American Packaging). Continental Group was dismantled in 1991, and early that year, Continental Can Co. was ordered to pay out $415 million to some 3,700 former employees and members of the United Steel Workers of America, when the courts found that the company had attempted to defraud the employees

of pensions during the late 1970s. The rights to the Continental Can Co. name and logo were sold in 1991 and renamed Viatech Continental Can Co. Inc. in October 1992. In June 1998, Suiza Foods Corp. completed its acquisition of Continental Can. In July 1999, Suiza sold all of Continental Can’s U.S. packaging operations in partial exchange for a minority interest in the purchaser, Consolidated Container Co. As of 2000, the only remaining business of Continental Can was Dixie Union, a small flexible film business based in Kempten, Germany.

Champion International

In 2000, Champion International was bought by International Paper. Champion had operated since the late 19th century in the United States and other countries.

Next Issue

In the next two issues, we will cover Owens-Illinois, Great Northern Nekoosa, Crown Zellerbach, Southern Container, Longview Fibre, Boise Cascade, Hinde and Dauch, Inland, U.S. Corrugated, CeCorr, St. Laurent, Westvaco, Horner Waldorf, and Chesapeake.

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@AICCbox.org

Sources: Personal knowledge from employment, media articles over 40 years, Corrugated Shipping Container: An Engineering Approach, annual reports, 10Ks, industry technical committees, interviews, personal relationships, and Wikipedia.

BOXSCORE September/October 2023 12

Unbox faster turnarounds

Make the move to digital – and unbox your business with the flexibility to accommodate fast turns, versioning requests, last minute edits, and changing buying decisions.

With the new EFITM Nozomi 14000 LED digital press for corrugated packaging and POS, you can reduce process steps from weeks and days to hours and minutes. And personalize runs from one to infinity at higher margins and with lower costs – all in a single pass.

Let’s build your brilliant future. Together. Scan to learn how corrugated converters and packaging printers are opening up new ways to say, “Yes!”

©

ALL

| WWW.EFI.COM

2023 ELECTRONICS FOR IMAGING, INC.

RIGHTS RESERVED.

Pay for Performance in 2023

BY TOM WEBER

My intention below is to recap my recent three-part webinar series with what I have seen progressing in the packaging industry from a market compensation perspective. There have been many changes occurring into mid- and late 2023, as well as many planned for 2024 and beyond.

The biggest change is considering the labor market and how fast or slow salaries are moving in the market across different geographical areas, industries, and job levels. A key to understanding your company pay positions is ensuring you have relevant survey data to benchmark positions and assess how much inflation and other economic factors impact the market.

Pay for performance is expected to be a significant approach for pay differentiation in late 2023 and 2024. The big question is, how does the employer ensure they are spending their merit increase dollars the right way?

One effective method of merit dollar allocation is a traditional merit pay chart. Merit pay charts consider an employee’s performance rating and pay within their salary range. The merit pay charts intend to ensure the highest increases are awarded to employees with the best performance who are also paid low in the salary range. As employees reach midrange, assuming they are meeting performance expectations, increases will trend with the budget. For employees high in the salary range or near the top, pay slows down, and increases tend to trend at or below budget as those employees are likely already paid above market.

The table at right is a sample merit chart based on three performance ratings. This is the expected distribution that will drive how much above or below the intended budget increase can be allocated to each

cell. In the example table, the budget was anchored at Meets Expectations for employees in the bottom third of their range. Higher performance will allow for a salary increase allocation above the 4% budget. All other positions will result in a salary increase below budget. Below are some examples of how this chart is implemented:

• Sally Smith is a financial analyst performing at an Exceeds Expectation level. She is currently paid at the minimum of her salary range. As a result, Smith’s manager can allocate a 6.5% increase.

• John Snow is a purchasing manager who has been with the company for 15 years. He is meeting expectations but is paid almost at the top of his salary range. Snow would be eligible for a 3% merit increase.

• Mark Hanson has been an accountant with the company for three years and is paid in the middle of the range. He has performance issues and has been rated Needs Improvement. He is not eligible for an increase during this compensation planning cycle. His compensation could be reviewed again in six months, assuming improved performance, to determine if an off-cycle pay increase is warranted.

The performance rating distribution is typically based on employee ratings from the prior year. As a result, once all salary increases are established utilizing the merit pay chart, some adjustments may need to be made for some ratings if the final allocations exceed the budget. This is typically done at a department level initially and then rolled up to a leadership level for final review to ensure pay equity.

Affordability

Consider the labor market and how fast or slow salaries are moving in the market across different geographical areas, industries, and job levels. Remember, a key to understanding your pay position is ensuring you have relevant survey data to benchmark positions and assess how much inflation and other economic factors impact the market.

BOXSCORE September/October 2023 14

Tom

Ask

PERFORMANCE RATING PAY IN RANGE DISTRIBUTION Exceeds Expectations 6.50% 5.50% 4.50% 25% of employees Meets Expectations 4% 3.50% 3% 70% of employees Needs Improvement 0% 0% 0% 5% of employees Expected Distribution 49% 35% 16% 100% of employees

Ask Tom

So, what are some options for pay if you have a small budget and are not able to increase base pay? Consider the following:

• Instead of a base salary increase, provide a lump sum equivalent to the base salary increase. These increases are considered supplemental wages and are taxed at a higher rate. Since lump sum increases are a one-time payment, they do not increase fixed costs over time.

• Determine if any benefits can be added (e.g., transportation stipend, tuition reimbursement) that would benefit a large percentage of the employee population.

• Consider increasing the employer cost share of benefits as another option.

• Provide increased paid time-off programs (employees rarely abuse them).

• Implement companywide recognition programs that can be given out on a quarterly or semiannual basis. Although these awards tend to be smaller (e.g., $500 or $1,000) they can provide a small and welcome boost for employees and their families.

My efforts here once again have been to stimulate your thought processes regarding ways to improve your hiring, retention, and employee motivation strategies. This webinar recording is available at NOW.AICCbox.org for All Access Pass holders or for individual purchase. Explore the various webinars AICC includes in its All Access Pass at AICCbox.org/Pass

Contact AICC Director of Education and Leadership Development Taryn Pyle at tpyle@AICCbox.org or Education and Training Manager Chelsea May at cmay@AICCbox.org with questions.

Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@AICCbox.org

BOXSCORE September/October 2023 16

Learn More | kolbusamerica.com Discover the power of From E-flute up to AAC-flute Set-up time < 60 seconds Over 50 FEFCO box styles Digital print available Automatic loading and stacking Inline glue strip application Multi-out production Grow to meet your market needs with the versatility of the BX Motion.

Modular Machine Concept for the complex demands of corrugated board processing

BX Motion

A.G. Stacker

Adducco Communications

Akers Packaging Services

American Corrugated Machinery

Arvco

Athena SWC

Bay Cities

BCM Inks

Buckeye Boxes

Jay & Terese Carman

Central Package & Display

Commonwealth Packaging

Mike D'Angelo

DeLine Box & Display

Domtar

Equipment Finance

Freedom Corrugated, LLC

Geo. M. Martin Company

Nick & Deborah Griffin

Haire Machinery

Harris Packaging

Independent II

Jamestown Container

JB Machinery

Greg & Karen Jones

Klingher Nadler LLP

Kolbus

L.D. Davis

McLean Packaging

Michigan City Paper Box

NV Publications

Oklahoma Interpak

Ox Box

Package Crafters

Packaging Express

Paige Packaging

Pamarco/Absolute

Royal Containers

Southern Missouri Container

Standfast Group

Sun Automation

Tavens Packaging & Display

Torosian Technical Services

Greg & Bette Tucker

Tyoga Container

Viking Industries

Wasatch Container

Welch Packaging Group

BUILD SOMETHING THESE DONORS ARE HELPING TO READY TO GIVE?

www.PackagingEd.org/Donate

The Science of Converting Cold Leads: How Many Touches Are Necessary?

BY TODD M. ZIELINSKI AND LISA BENSON

Prospecting is one of the most challenging components of sales, even for the best hunters. There is one often misunderstood and seldom tracked metric that holds the potential to redefine the success of a business. This often underappreciated metric we are referring to is the number of touch points required to transform a prospect from a new name on your target list to a qualified prospect that says, “Let’s have a chat.” Qualified, of course, means that the lead meets your criteria for product mix, annual spending, etc.

Success doesn’t necessarily come with speed. It requires a blend of endurance, strategic planning, and patience. In the fast-paced, immediate-gratification world we live in, patience may seem antiquated, but this virtue must be embraced when selling industrial custom packaging or retail point-of-purchase (POP) displays, which can take months to close. The journey from cold prospect to scheduled appointment requires communication, process adherence, and astute timing. Understanding this and nailing down these data points will allow you to better predict and plan for future revenue growth.

Why Is This Important?

Prior to the COVID-19 pandemic, companies were trending away from road warriors making in-person cold calls. Travel is expensive and time-consuming. Every trip, even a few hours away, is 100% cost if the sale doesn’t materialize. Faceto-face meetings can play a significant role in the sales process, but they must be more strategic and follow initial contact and qualification through phone calls or digital interactions.

Today, many companies have held onto elements of virtual sales, but a lot of them lack a process, consistency, and tracking. Sending out occasional emails isn’t enough to convert a prospect. Multiple touches at regular intervals are required. Touch points include all phone calls, voicemails, video calls, text messages, email communications (e.g., personal and bulk emails), social media interactions, and even direct mail. It is crucial to understand how many touches are required for conversion because the data is helpful for multiple purposes:

• Sales forecasting: These data points can help with sales forecasting and pipeline management, leading to more accurate predictions for future sales performance, which can guide decision-making.

• Resource allocation: Having an accurate picture of the work involved in converting a lead allows companies to better allocate time, effort, and resources to lead-generation activities.

• Sales strategy refinement: Understanding the conversion timing can assist with refining your sales strategy by making sure each touch is meaningful and helps to move the lead closer to conversion. It can also allow communication to be tailored to the customer’s buying journey.

• Performance metrics: With data showing the number of touches to conversion, these performance

metrics can be used to assess the effectiveness of sales and marketing efforts. If the number of touch points grows, it may indicate a change in contacts or process is required.

How Many Touches Does the PaperBased Packaging Industry Require?

Understanding the sales process and the time and effort it takes to convert a cold lead into a qualified relationship is essential for anyone selling paper-based packaging products. A salesperson may need to invest hours of activity with multiple touch points before a lead becomes sales-ready. The time and number of touches required for conversion can vary depending on the product or service offered.

Although everyone’s experience may be different, our customer data shows the following differences per company based on what they are purchasing (see table below). We should note that these are averages; some outliers convert in days, and some may take a year or more. Also, this involves three to seven contacts per company. Additionally, it is outbound phone call-heavy (65%) and uses direct line and cellphone numbers. Phone calls allow open-ended questions to be asked and useful information to be uncovered when one listens more than speaks. To succeed, the sales team must be consistent with its outreach over time, not just make a touch or two a month via email.

BOXSCORE September/October 2023 18 Selling Today

PRODUCT TOUCHES TIME FROM COLD TO MEETING Brown Box ~20 (60–90 Days) POP Displays 30–50 (180+ Days) Retail Packaging 25–40 (90–180 Days) Folding Cartons 15–20 (90–180+ Days)

CorrWhite is our waxable white coating created to minimize rod wear while maintaining the necessary after-wax brightness and opacity. Frequently used as a base coat on kraft liners for color applications, CorrWhite offers exceptional brilliance and a light coat weight providing the best value in the market. Responsive and agile, Magnum Inks & Coatings offers excellent technical expertise and outstanding service. Contact us and learn how the right partner can make all the difference in your printing/coating processes. MagnumInks.com | sales@magnuminks.com | 877.460.8406 ©2023 Magnum Inks & Coatings. All rights reserved. The Corr of your printing success.

The following data from Crunchbase supports phone-heavy outreach:

• Organizations that don’t cold call experienced 42% less growth than those that do.

• Voicemails eventually lead to a callback (11% after the first, 22% after the second, and 33% after the third).

• The majority (57%) of C-level buyers prefer to be contacted via phone.

Notably, our data finds that the size of the company being approached can play a crucial role in the conversion process. Smaller companies with less bureaucracy tend to be easier and quicker to convert, while larger corporations with more layers may require more time and effort. Additionally, the higher the contact person’s position in the company, the harder it is to convert them.

Sales of POP displays are cyclical and tend to be more project-based—this is where astute timing matters. Getting to the right person when they have a project can move the process along faster. If they

don’t have a project when you speak with someone, nurturing the lead consistently will be key to converting them.

When looking at inbound leads, these numbers drop significantly, averaging around two to three touches and less than a week for conversion. When someone has come to your website and filled out a form, they are looking for a packaging vendor. This indicates the importance of a balanced approach using outbound and inbound strategies.

One caveat is that other variables may not have been considered here, and results can vary from company to company, region to region. The sales team’s approach and varying skill levels can impact these numbers. Some industries may be harder to penetrate than others. The packager’s messaging, value proposition, and delivery will also influence the number of touches required to secure an appointment with a qualified opportunity.

Ultimately, the key to a successful sales process is understanding the number of

touches and time commitment required for your approach and adapting strategies accordingly. Sales teams not currently measuring touches can gauge their prospecting performance against the above averages. If they find themselves falling short, it’s an indication their strategy may need to be reassessed. These insights provide an invaluable road map to enhance the efficiency and effectiveness of their lead-conversion process.

Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com

BOXSCORE September/October 2023 20 Selling Today

The Magical Repurposing of Corrugated

BY JULIE RICE SUGGS, PH.D., AND ALLI KEIGLEY

What comes to mind when you think about corrugated board? I am sure your mind is racing with tons of ideas because you, as corrugated professionals, know it has a multitude of uses in the packaging world. Naturally, a corrugated board’s design depends on the function it needs to perform, such as holding up products in a point-of-purchase display, working hard as a shipping container for e-commerce purchases, or silently selling a product on retail shelf packaging.

What you may not know is that the characteristics of this substrate (e.g., inexpensive, lightweight yet sturdy, easily recyclable or renewable, reusable, readily available) lend themselves exceptionally well to not only packaging applications but also arm immobilizers (of all things!).

Since this may seem like a random topic, let me give you a little backstory. Recently, my 8-month-old daughter had surgery on her cleft lip, and she needed arm immobilizers to prevent her from damaging the surgical site. The idea here is similar to that of a cone worn by pets to prevent them from chewing their stitches. And like my cat that has worn that cone, my daughter hated this act of restraint. She was given a brand of arm restraints at the hospital, No-No®; they are made from polyethylene foam and a polypropylene rigidifying cuff (see top photo at right). Although an improvement from past versions—medical metal frames placed around the infant’s arm and taped in place to keep the elbow straight—these No-Nos were still bulky, too big, and uncomfortable for my daughter.

Forgoing the doctor’s instructions to wear the arm restraints for two weeks was not something we ever considered, but we knew we needed a better option than the current setup. My mom, an

advanced practice nurse, scoured the internet to find something we could use as a replacement. We quickly discovered our commercial product could be easily replicated using on-hand materials such as corrugated board. Although we chose not to venture out and make these on our own, we did purchase some (thanks, Amazon) made with wood and the same basic construction (see bottom photo at right).

If we had been ready to MacGyver these arm restraints for our little one, we would have needed only a few items to make it happen—corrugated board (reused from something as convenient as a box of pre-grilled hamburgers from a cookout), Velcro cable wraps, sticky back Velcro, and foam shelf liner. With these materials and some minor tools—a serrated kitchen knife, scissors, a stapler, straightedge, and measuring tape—we then would measure and cut the corrugated, roll it into a tube, cut and attach the foam liner, attach Velcro, and add Velcro cable wrap to have infant-ready arm restraints.

While you may not be in the market for arm immobilizers anytime soon—and I hope not—the point of this recollection is to show the magic of corrugated board for accommodating unique needs. Along with this creative repurposing, corrugated can be used for packaging and sending plants via mail, furniture designs, innovative architecture, and even bicycles.

So, the next time you have a corrugated box and nothing on your agenda, put on your creative hat, and make something you’ve never thought of associating with corrugated board! And if you want to dive deeper into the material itself and learn more about grades, fluting, manufacturing, converting, surface treatments, and

more, check out our fabulous corrugated course today at bit.ly/3PmYCrr or check out AICC’s many corrugated courses at learning.AICCbox.org

Julie Rice Suggs, Ph.D., is academic director at The Packaging School. She can be reached at 330-774-8542 or julie@packagingschool.com

Alli Keigley, who contributed to this article, is production coordinator at The Packaging School. She can be reached at alli@packagingschool.com

BOXSCORE September/October 2023 22 Andragogy

Photos by Julie Rice Suggs, Ph.D.

When to Be Closing

BY SCOTT ELLIS, ED.D.

What is your most frequently quoted movie? Is it Caddyshack ? Perhaps it’s The Big Lebowski. By far, the most quoted mantra for sales professionals must be from Glengarry Glen Ross : “Always Be Closing.” What sets the best packaging salespeople apart is not the “ABC” principle but knowing when to be closing. By the way, this is said with a Talladega Nights level of “all due respect.”

My introduction to the packaging industry was an investigation into what abilities and traits are unique to those who consistently sell at a high level. My toolbox included measurement and interview tools to isolate the abilities and traits that equipped eight diverse individuals to average a million dollars a month in sales. This was back in the day when a million dollars was a lot of money.

The project assessed math and language problem-solving skills and found that top performers had the expected verbal reasoning but also possessed even stronger math skills. Spatial reasoning was measured in the hopes that specifications communicated in two dimensions resulted in working three-dimensional products. Lastly considered were a range of general personality traits and those specifically related to sales.

Consistently productive salespeople shared a constellation of traits, though their methodology varied. Measures of sales performance normally render scores for sales disposition, comfort with cold calling, and sales closing. While all top performers were above average in all three of these measures, the highest scores were for closing. Looking deeper, it was not surprising to find that diplomacy,

self-confidence, and the ability to stay motivated with minimal supervision were common to the group. One factor that stood out was a level of uncooperativeness that operated without the loss of diplomacy. In short, these people know when to close. They know when not to take no for an answer. They push when others would retreat to attack another day.

Those who are always closing are perceived as self-serving and overly aggressive. Knowing when to stay, to push, or to offer a solution is the distinctive mark of great salespeople. This takes people skills or what Daniel Goleman termed “emotional intelligence” (also known as “emotional quotient” or

EQ). This is a measurable quantity of people skills he defined in his first book on the topic as “in practical terms … being aware that emotions can drive our behavior and impact people (positively and negatively) and learning how to manage those emotions—both our own and [those of] others.”

Research and practical experience have shown that EQ can be improved. This is good news because no shortage of technically skilled but interpersonally challenged workers has been reported. How does one approach such an individual? Well, one guarantee is you will not be the first to broach the subject. Past employers, coaches, and spouses will

BOXSCORE September/October 2023 24 Leadership

Build Better

Precison & Durability Saves

have discussed this relationship-limiting situation. In fact, all of us can improve our EQ, and it may be a good exercise for the entire sales team.

An EQ resource was recently added to the Packaging University, the online learning platform of AICC. I contacted Daniel A. Feldman, Ph.D., author of The Handbook of Emotionally Intelligent Leadership, which includes an assessment of EQ. Having received permission to utilize the assessment online, a student is now able to take the assessment and gain clear feedback for improvement in areas of strength and weakness. The class includes several exercises to develop key skills and gain feedback on progress. The course is titled Emotional Intelligence for Career Development.

It applies to all of our jobs and could be a part of any department’s continuous improvement efforts. In this model, team members take the course individually and then discuss its practical application as a group.

In summary, the research into what sets top salespeople apart included excellence in various abilities and traits. I believe that chief among them is development of the ability to recognize and adapt to one’s own emotions and those of others. Conscious effort to improve my own EQ has enriched my business and personal relationships. As Carl Spackler in Caddyshack once said, “I’ve got that going for me, which is nice.”

Scott Ellis, Ed.D., delivers training, coaching, and resources that develop the ability to eliminate obstacles and sustain more effective and profitable results. He recently published Dammit: Learning Judgment Through Experience. His books and process improvement resources are available at workingwell.bz . AICC members enjoy a 20% discount with code AICC21.

BOXSCORE September/October 2023 26 Leadership

apexinternational.com

WhyAgonize.com Info@AskHitek.com 262-842-1700 Manual or Fully Automatic Flat Die Storage Systems by BCM Rack up more space, productivity and efficency CUTTING DIE STRIPPING DIE BLANKING DIE CUTTING PLATES MAKE READY SAFELY IN CASSETTES

Design Space

Collaborating to Create Award-Winning Displays

BY JESSICA BUCK

Creating successful retail packaging and displays requires a collaborative effort that involves multiple individuals and departments. From initial concept development to production, supply chain management, and delivery, the process is complex and time-consuming. Every project requires a team of experts who work together to design and manufacture unique, visually appealing, and environmentally friendly point-of-purchase displays and packaging.

A chain of effective communication is a critical element during any project life cycle, especially when timelines can vary from immediate turnarounds to longterm planning. Time and action calendars are essential to staying on track through each department, and innovative technology automates various actions to save crucial time prepping files and workflows. Breaking down the creative process, we’ve captured firsthand how our structure, graphics, and 3D departments play an integral role in executing successful programs that help your favorite brands shine on the shelf—and online.

Design Process

Our team of 3D designers start with an initial concept using 3D Studio Max. Next, the structure team gets started on a line drawing that is presented to the client for approval. This provides a clear understanding of product capacity and display footprint. We carefully consider the number of pieces and types of corrugated and non-corrugated components needed to bring the project to life. Throughout phase one of the design process, our 3D and structure departments maintain

constant communication with the graphics team who create production art and ensure everything is optimized and ready for printing.

Using state-of-the-art automation software, our team develops tailored workflows that streamline various tasks typically handled manually by designers, resulting in significant time savings in the long term. We efficiently convert and prepare files in multiple formats by consolidating all of the necessary details for the printer’s comprehension.

During phases two and three, we focus on meticulously crafting and perfecting the project’s structure. This includes conducting thorough International Safe Transit Association testing with the product to guarantee that the board grade and shipping materials are highly effective for transportation. Once final, detailed step-by-step assembly instructions are created for our packout team, who will fold up each piece, load product according to a planogram, and palletize for shipment. To streamline the process, we utilize innovative software that maps out the precise placement of each pallet on the appropriately sized delivery truck once it is ready for shipment. Think of it as a strategic game of Tetris, where each pallet is strategically positioned to secure the others on board, reducing the risk of damage during transit.

Importance of Collaboration

Collaborating across departments guarantees seamless communication throughout the entire project journey and opens up numerous opportunities for creative input based on each team’s expertise—from ensuring the artwork complies with print

specifications and branding to providing recommendations on structure engineering to optimize it within retail guidelines. The absence of information, assets, or products can hinder and delay the production process when it is communicated through unofficial channels. Therefore, we provide best-practice sheets to ensure all assets and necessary information are obtained and confirmed.

As an employee-owned company, we actively foster and promote our core values of creativity, passion, integrity, responsibility, safety, and fun on a daily basis. These values not only enhance the well-being and satisfaction of our employees but also foster a positive and thriving work culture. Additionally, they enable us to deliver comprehensive and integrated packaging and logistics solutions, which have been proven to drive sales and exceed client expectations.

Jessica Buck is associate marketing manager of content and research at Bay Cities.

BOXSCORE September/October 2023 28

Photo courtesy of Bay Cities.

Productivity — Quality — Pro tability JB Machinery Inc., | +1-203-544-0101 | jbmachinery.com Since 1998 JB Machinery has been developing innovative solutions to maximize productivity, quality and PROFITABILITY. ... And friendships that have spanned decades. Celebrating a quarter century of innovation Visit us at FEFCO booth 101, October 25-27, 2023

Headline

BYLINE

Leadership

Education, EL Program Translate to Actionable Growth

BY JUSTIN WOODS, MBA

The corrugated industry is constantly evolving, and in today’s fast-paced world, it demands innovation, agility, and competent leadership. So, as a past AICC Emerging Leader (EL), I wish to share my experiences with leadership and continuous education.

Becoming part of AICC’s EL program was a watershed moment in my professional journey. The program provided a platform to network with like-minded professionals. The insights and experiences shared by industry veterans were enriching and allowed me to view the corrugated industry’s challenges through different lenses. This perspective helped formulate innovative strategies at Vail Industries.

As part of the management team at Vail Industries, I understand the critical role of effective leadership in ensuring the company stays ahead of the curve. The transition from an individual contributor to a leadership role was a crucial point in my career. One of my first initiatives was to focus on the team’s dynamics by

creating an environment in which innovation thrives and individuals feel valued. The EL program, specifically the quarterly C-suite remote sessions, helped me realize that a motivated team is an asset, and the creativity of team members can lead to groundbreaking solutions for the challenges the corrugated industry faces.

One of the key takeaways for me was to learn to delegate and trust the members

AICC Emerging Leader Contribution

of my team in various functional areas to contribute. This seems pretty straightforward, but the desire to strive for perfection often meant I was taking on too many responsibilities. Through the C-suite meetings, I learned firsthand that the true decision-makers in companies build a competent staff so they can focus on the big-picture problems their organizations face. This means taking the time to mentor

BOXSCORE www.AICCbox.org 31

and train those around them in understanding the process we as individuals have developed so they can provide the value that sets the organization apart from the competition.

In my situation, this meant giving up most of the design and estimating duties that made me a successful sales professional and replacing them with prospecting and marketing efforts. This meant I needed to share the focus on design for manufacturing and line efficiency at the customer location by first walking the team through the process and learning what they needed from me in my new project requests. This would help them develop the skills in the future to provide the suggestions that matter to customers proactively in their direct communications as well as with the new projects I am bringing to the company. This effort has cut down on turnaround time and led to increased margins for the organization as cost savings are shared in a way that reduces the customer’s total expense, while improving margins for the

organization beyond what is possible in the “apples-to-apples” bid process.

Understanding the importance of continuous education, I turned to AICC for resources to enhance not only my own but my team’s skill set. AICC’s educational materials, including webinars, seminars, and courses, have been invaluable. For instance, AICC’s sales training programs enhanced my understanding of how to ask the right questions at the right time and how to leverage social media platforms such as LinkedIn in a positive way, enabling me to make more effective sales calls and thus reducing the sales cycle and accelerating Vail’s growth.

Another area where my experience with AICC’s resources proved invaluable was workforce development. With the skills and knowledge acquired through AICC, I could drive recruitment strategies focusing on developing talent with the right blend of technical know-how and creative thinking. Moreover, through training programs and workshops, we ensured that

Member Benefits

On the Road Again

One of AICC’s goals is to make your job easier. We provide a lot of resources, online and in person, and we know it can be difficult to keep up with everything we offer and even harder to make sure all of your team members know what is available to them.

As we head into our 50th year, AICC wants to see you. We will be making stops around the United States to visit members and walk your team members through the benefits available to them. We will have lunch for your team, invite a few other members and

prospects, and make sure everyone knows how to access free online education and is informed about AICC’s free live webinars, various peer groups, and other benefits.

If you are interested in being a stop on the roadshow, contact AICC Director of Membership and Marketing Virginia

our existing workforce continually evolves and adapts to the dynamic demands of the corrugated industry.

My journey to a leadership role at Vail Industries, supplemented by the enriching experience as an AICC EL and the continuous learning through AICC’s educational resources, has been immensely fulfilling. The corrugated industry requires leaders who not only are technically sound but also possess the vision to drive innovation. Through collaboration, continuous learning, and fostering an environment that encourages creative problem-solving, we can ensure the corrugated industry continues to thrive and meet the ever-evolving global market demands.

BOXSCORE September/October 2023 32 AICC Innovation

Justin Woods, MBA, is sales manager at Vail Industries.

Humphrey at vhumphrey@AICCbox.org

703-535-1383.

or

Photo by Geoff Katler.

The best of two worlds

Two companies team up

your

Koenig & Bauer Celmacch’s expertise with converters have enabled us to develop machines for you with the highest technological standards in the industry. This supports maximum reliability, quality and flexibility. Our range of products meet different investment strategies and productivity requirements, ranging from entry-level models to machines that are equipped with the highest levels of automation, sophistication and the highest throughput. Contact us for information on how you can become the next success story. k kevin.erbe@koenig-bauer.com

for

success!

Civic Duty Notice 2022 Economic Census

The due date for responding to the 2022 Economic Census has passed, but it is not too late to respond. Businesses that received an invitation to respond but have not yet replied are receiving past due notices with instructions on how to respond and, if needed, how to receive assistance. Response to the economic census is required by law.

Economic census data serves as the foundation for the gross domestic product and other leading economic indicators for the nation. Trade associations, economic development agencies,

governments, and individual businesses use the data to make decisions and create policies. By completing the economic census, companies contribute to a wealth of valuable data that can help grow their business. Data compiled from the 2022 Economic Census is possible only because of the participation of businesses such as yours. Your response makes a difference. All responses are confidential.

Visit www.census.gov/programs-surveys/ economic-census.html or scan the QR code at right to get started.

BOXSCORE September/October 2023 34 AICC Innovation

Scan the QR code to respond to the 2022 Economic Census today!

100+ Webinars for All Team Members ALL ACCESS PASS www.AICCbox.org/Pass Subscribe Today Learn Industry Trends, Current Market Challenges, & Best Practices

Independent II : ‘Built by a Few, Succeeding With Many’

BY STEVE YOUNG

Company : Independent II

Established : 2006

Joined AICC: 2007

Phone : 502-315-2525

Website : www.independent2.com

Headquarters : Louisville, Kentucky

President : Finn MacDonald

The story of Independent II in Louisville, Kentucky, begins with one Neil MacDonald, who retired in 1997 following the sale of his company, Independent Container, to Greif. His 30-plus years in the box business in the Louisville market built long-standing relationships with many good customers. So, before his formal departure, he did what any shrewd entrepreneur would do: He gave his home phone number to all of them.

“Our existing customer base was probably the loudest reason to incorporate Independent II,” says Finn MacDonald, Neil’s son and president of the company. “My father did the job of retiring; he just left his phone number with most of the customers.”

As Finn recalls, those customers were not shy about exploiting this valuable resource: “During retirement, Neil received a lot of phone calls, just about ‘Hey, who can we call …?’ or ‘We need a little help.’ There’s a point where any seller is going to say, ‘I’m your guy. I’m your help.’ ”

Independent II was thus incorporated in July 2006 in a 100,000-square-foot building with what Finn calls “typical grassroots equipment”—a 38" flexo, a 50" flexo, and a 66" x 80" die cutter. “We were able to hire some talent, earn some new business, and really start up a sheet plant,” Finn says, adding that the former Independent Container’s longtime, loyal customers stepped up and embraced the resurrected company and its stellar

service. “We turned the ignition on, and we were probably 10 million square feet in month one. That’s the power of that existing business; that’s the power of being in Louisville for such a long time. When we opened the doors, sure enough, there were orders and there were sheets being delivered. It was a quick start.”

So quick, in fact, that Louisville Business First for seven consecutive years—from 2010 to 2016—cited Independent II in its “Fast 50” list of fastest-growing private companies.

Finn, 51, came to Independent II in 2010. His route there was circuitous. He graduated in 1994 from the University of Puget Sound in Tacoma, Washington, with a degree in English/communications.

BOXSCORE September/October 2023 36 Member Profile

Photos

courtesy of Independent II

Team Independent II (from left) includes Tim Rosetti, shipping and warehouse manager; Anthony Jennings, plant manager; Justin Gittings, production supervisor; Finn MacDonald, president; Kelly Papp, director of business operations; Michelle Huber, digital print supervisor; and Gracie Collins, director of quality, safety, and improvement.

He then followed a disparate career path, from photojournalist to museum founder to owner of a historic inn. Cut from the same cloth as his father, Neil, Finn inherited the successful entrepreneur’s instinct for customer service, explaining simply: “Each of these career choices required an entrepreneurial vision, tireless work, and a dedication to always taking care of the customer.”

He carried this keenly focused customer service eye to Independent II when he joined the company. “At that time, Independent II was really shifting into fast-growth mode,” he recalls. “The market here was beginning to ask for more than just brown boxes, and seeing an opportunity to expand what the business offered its customers, how it was produced, and assembling the team to do it was a leadership challenge that appealed to me.”

Independent II ’s long-standing customer focus was the starting point for Finn’s transformation and expansion of the company. “Independent II was built on ‘Take care of the customer by saying yes and getting it done,’ ” he says. “It’s the hierarchy of business, and it’s in our molecular DNA.”

While this ethos served them well, he recalls, it had its limits. “We did not spend a lot of time figuring out how to get things done more efficiently,” he says. “We had not spent the time investing in equipment and processes to make it easier.”

One of the critical limits to the company’s future was its physical location. Independent II operated out of two buildings: a 100,000-squarefoot manufacturing facility and a 200,000-square-foot warehouse across the street. “We were our No. 1 shipping customer for years because we had to ship our finished goods 100 yards across the street to our warehouse,” says Finn.

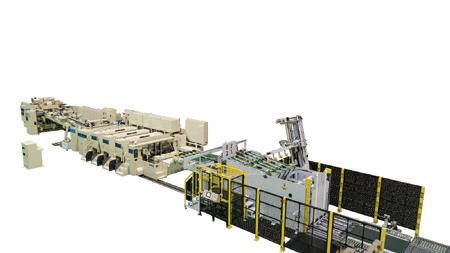

In spite of the layout, Independent II in its former location was running 40 million square feet per month with a respectable lineup of equipment: two BW

Papersystems flexo folder gluers with die cut sections—a three-color 37" x 96" and a two-color 50" x 110"; two Ward rotary die cutters—a two-color 66" x 80" and a three-color 66" x 113"; a Baysek die cutter; a Post Torosian specialty folder gluer; and two Solarco Boxmatic machines—a 98" one-color with inline feed and a 90" two-color.

Finn and his Independent II team knew that investing in new equipment or plant flow in that packed environment was unfeasible. “We knew an expiring lease was coming, and we hadn’t found a successful way to connect the two buildings,” he recalls. “So that put a move front and center as our only option.”

With that decided for them, Finn and his team then faced the next two questions: To lease or to build? And where would it be located? “It was critically important for the company and our customers to retain our labor force and to not move too far,” he says. “You know if something looks great but it’s 35 minutes away, it doesn’t look great to anybody making that drive.”

Finn found a solution in what he calls a “hybrid site,” two blocks down the road with an existing building and an adjacent lot. “There was a building in half of the space and an empty greenfield next to it,” he says. “So if we tear one building down, shovel it over to the greenfield site, and level it, we get 340,000 square feet. We fit perfectly in that little puzzle piece of land just two blocks away.”

According to Finn, the ramp-up to the move was theoretically three years, with design, build, and machinery acquisition and plant layout. “Then we developed our timeline, which was 18 months, and we woke up to reality when supply chain and allocation issues hit us. We

were literally finishing the new building, moving from the old site, and trying to produce and warehouse in both over a four-month period,” he recalls. “So, it was the best-laid plan that didn’t survive the fourth quarter of last year.”

In January, Independent II moved into its new 340,000-square-foot facility, where its 125 employees work two shifts to generate an annual corrugated production of more than 50 million square feet. Anthony Jennings, plant manager, oversaw the equipping and layout of the new plant. He came to Independent II five years ago from another independent corrugated box company in the Southeast. Finn calls him the “architect” of the new facility. Commenting on some of the challenges leading up to the relocation, Jennings says, “We had a great plan with new equipment coming into this building first, but with supply chain issues and everything that was going on globally, we had some hiccups here and there. We had to hit a lot of curveballs.”

Jennings credits Production Supervisor Justin Gittings with a lot of the heavy lifting in getting the move done smoothly. “He held it together over at the old building while I was here laying out the plant;

BOXSCORE www.AICCbox.org 37 Member Profile

Michelle Huber, digital print supervisor, (center) and operators display a sample from Independent II ’s Domino x630i digital printer.

then, when we needed his leadership here, he made that move over,” he says.

Jennings explains that key hiring decisions were made to enable a smoother transition. “We did some strategic hiring on the leadership side. About eight months ahead of the move, we made a couple of hires so that we would be comfortable running two facilities at one time,” he says.

Jennings justifies the new positions by noting Gittings’ supervision of the machine centers running a majority of the production. “Knowing that we were expanding equipment here made that decision easy,” he says. “Justin is captain of 65% of our business, so we were able to justify additional positions. … We’re starting to hit our stride now, so I think it was a pretty successful move.”

Finn and Jennings also used Independent II ’s membership in AICC to consult with other members who had also taken on major expansion and equipment installation projects. “Through our membership, we got realtime feedback on suppliers and services that are vital in making good investment and planning decisions,” Finn says. “AICC’s No. 1 benefit is interaction with and access to peers and plants.”

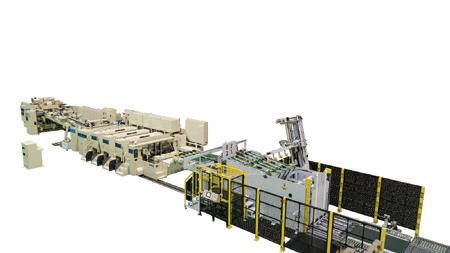

Independent II ’s new plant is a showcase of cleanliness, efficient layout, and state-ofthe-art production capability. In addition to the existing equipment moved over from the old location, significant investments were made in new equipment and plant flow, with ACS conveyors and load-tiering systems governing the movement of work in process and finished goods. On the converting side, the most notable additions are two Isowa flexo folder gluers: an Isowa Falcon 37" x 95" four-color with die cut section and an Isowa Ibis 47" x 120" threecolor with die cut section. Both machines have Alliance pre-feeders and load formers and EAM Mosca bundlers. These two machines comprise what the team refers to as the “Isowa Island” midplant. Finn

explains the operating principle that governs the center: “When we really looked at our labor and how one flexo would contribute to our game versus two, we opted for two sitting in a mirrored fashion. Paper could flow to them, nothing would get in the way, and we could get 65% of our day done in a shift. So that was the big swing, the big vision.”

Gittings confirms the machinery choice: “In our conversations when we were getting these machines, I’m hoping in six months we’re at our goals; we did it in three. We hit a million square feet on the Ibis on one shift in the first two months, and we’ve hit over 100,000 kicks on the Falcon in one shift.”

Tim Rosetti, shipping and warehouse manager, joined Independent II in February 2022. Far from being overwhelmed by the production speeds now being realized, Rosetti says the new plant, with everything under one roof, has improved on-time deliveries by a factor of 15–20 percentage points. “Now we have a solid warehouse layout,” he says. “We can handle the business we’re doing, but we’re also ready for growth. We are up to 94% on-time shipping, and when I started, we were in the high 80s.”

The amped-up productivity in the new plant serves Independent II ’s market aspirations, as well. “Our slogan to the market is ‘Brown, Brand, and Digital,’” Finn explains. “Those three words represent the diversity that we’re trying to achieve in the marketplace. Brown still dominates. It’s what we’ve been doing the longest, and brown is what we’ll always do.” This mix plays well into the northern Kentucky and southern Indiana area, which Finn describes as a “great mix of brown, branded, and digital consumers in food and beverage, e-commerce, consumer goods, spirits, and home appliances.”

Independent II ’s equipment roster has been curated to serve its diversification beyond its brown-box roots. As Finn

explains, the “brand” in the company’s market pitch is supported by its two-, three-, and four-color printing capabilities in its Isowa and MarquipWardUnited (BW Papersystems) machines. But Finn qualifies the company’s graphics work. “We’ve got a fleet of converting equipment, but outside of the new Falcon, which is a four-color machine, our top-line printers had been three-color, and a lot of that had not been process- or built-color but had been just for multiple colors on a sheet. We have learned to handle basic brand well, and we have grown that segment of our business.”

The logical next level, Finn notes, would be a move to higher-end process printing, yet here again, he balances the company’s capabilities with the market’s expectations. “We moved out of brown and got into branded, but then that next step was process printing, prepress management, and developing a sales force that can sell complexity if you have a market that can accept it,” he says. “All of this is achievable, but in Louisville, we had to be realistic.”

Enter the Domino x630i single-pass digital printer. Installed almost three years ago, the four-color aqueous-based printer is an important part of Independent II ’s aspirations to grow the brand and digital segments of its business by $10 million in the years ahead. Michelle Huber, digital print supervisor, oversees the department, and she and Finn agree that the Domino checks a lot of boxes for Independent II ’s operational and customer service goals. Says Finn, “It takes a lot more than three people to grow and evolve traditional direct print to process printing. With the Domino digital press, it takes Michelle and her two operators the process of receiving and ripping a file and then hitting the green button. All of a sudden, we can have four-color through a single-pass machine.”

Finn explains that the preprinted digital sheets go directly to the company’s die cutters, where they are handled efficiently and there are no printing plates to receive,

BOXSCORE September/October 2023 38

Member Profile

Italy knows a thing or two about quality & innovation.

maserati

michelangelo

lamborghini

Ducati

botticelli

LEONARDO DA VINCI

ferrari

alfa romeo

encore fd 618

Say Ciao to the Encore FD 618.

Next-level machinery, world-class quality.

hairegroup.com

mount, or wash up in the process. As of press time, the Domino was slated to receive a coating section this summer, an addition that Huber says “will be positive for the client because a lot of clients want a coating or shinier, brighter print. It will help us grow.”

Independent II ’s management team is a cohesive unit with a shared sense of purpose to serve the customer. Kelly Papp, director of business operations, joined Independent II only recently, and she brings with her 20 years’ experience at another Louisville-area independent. “We’re really blessed with a professional, experienced customer service team,” she says. “What we’ve been working really hard on is improving our communication and processes internally.”

This, Papp adds, is a natural extension of Independent II ’s growth into the brand and digital segments. “It takes time to develop experience handling not only brown boxes but handling brand through displays, fulfillment, and everything like that, so we are actively spending time upfront validating our customers’ expectations,” she says.

Another new team member, Gracie Collins, is a recent Indiana State University