LPC iron man Troy Whitley is another one of our Champions of More who is committed to giving you more. With 40 years under his belt in large-format print and packaging, when you work with Troy, you get more experience. And with LPC’s 9 state-of-the-art printing presses, all equipped with densitronic and color control systems, you get more quality. More flexibility. And more ways to do any job. Even the impossible ones. Troy makes up the backbone of our team that led the pressroom to a 98% success rate. Not even a two-hour commute can stop Troy from giving you more. Because, like all of us here at LPC, he loves his work. And you’ll love ours. LPC. Champions of More.

Lewisburg Printing Company + Huston Patterson

OFFICERS

Chairman: Gary Brewer, Package Crafters, High Point, North Carolina

First Vice Chair: Terri-Lynn Levesque, Royal Containers Ltd., Brampton, Ontario, Canada

Vice Chairs: Joseph Morelli, Huston Patterson/Lewisburg Printing Co., Decatur, Illinois

Mike Schaefer, Tavens Packaging & Display Solutions, Bedford Heights, Ohio

Eric Elgin, Oklahoma Interpack, Muscogee, Oklahoma

Immediate Past Chair: Matt Davis, Packaging Express, Colorado Springs, Colorado

Chair, Past Chairmen’s Council: Jana Harris, Harris

Packaging/American Carton, Haltom City, Texas

President: Michael D’Angelo, AICC, The Independent Packaging Association, Alexandria, Virginia

Secretary/General Counsel: David Goch, Webster, Chamberlain & Bean, Washington, D.C.

Administrator, AICC México: Veronica Reyes

DIRECTORS

West: Sahar Mehrabzadeh-Garcia, Bay Cities, Pico Rivera, Califormia

Southwest: Jenise Cox, Harris Packaging/American Carton, Haltom City, Texas

Southeast: Chad Wagner, Peachtree Packaging & Display, Lawrenceville, Georgia

Midwest: Cassi Malone, Corrugated Supplies Co., Bedford Park, Illinois

Great Lakes: Josh Sobel, Jamestown Container Cos., Macedonia, Ohio

Northeast: Larry Grossbard, President Container Group, Moonachie, New Jersey

AICC México: Jorge Ortega, Soluciones de Empaques S. de R.L. de C.V., Hermosillo, Mexico

OVERSEAS DIRECTOR

Kim Nelson, Royal Containers Ltd., Brampton, Ontario, Canada

DIRECTORS AT LARGE

Casey Shaw, Batavia Container, Batavia, Illinois

Stuart Fenkel, McLean Packaging , Pennsauken Township, New Jersey

Josh Sobel, Jamestown Container Cos., Cleveland, Ohio

Jack Fiterman, Liberty Diversified International Minneapolis, Minnesota

EMERGING LEADER DELEGATES

Jordan Dawson, Harris Packaging , Haltom City, Texas

Evan Clary, National Corrugated Machinery, Hunt Valley, Maryland

Cody Brant, A.G. Stacker Inc., Weyers Cave, Virginia

ASSOCIATE MEMBER DIRECTORS

Chairman: John Burgess, Pamarco

Roselle Park, New Jersey

Vice Chairman: Jeff Dietz, Koenig & Bauer (US), Dallas, Texas

Secretary: Mike Butler, Domtar Packaging , Fort Mill, South Carolina

Director: Brian Foley, Bobst, Phoenix, Arizona

Immediate Past Chair Associate Members: Tim Connell, American Corrugated Machine Corp. Indian Trail, North Carolina

ADVISORS TO THE CHAIR

Matt Davis, Packaging Express, Colorado Springs, Colorado

Joe Palmeri, Jamestown Container Cos., Cleveland, Ohio

John Burgess, Pamarco/Absolute, Roselle Park, New Jersey

PUBLICATION STAFF

Publisher: Michael D’Angelo • mdangelo@AICCbox.org

Editor: Virginia Humphrey • vhumphrey@AICCbox.org

EDITORIAL/DESIGN SERVICES

The YGS Group • www.theYGSgroup.com

Vice President, Association Solutions: Craig Lauer

Creative Director: Mike Vucic

Managing Editor: Therese Umerlik

Senior Editor: Sam Hoffmeister

Copy Editor: Steve Kennedy

Art Director: Alex Straughan

Account Manager: Jillian Mengel

SUBMIT EDITORIAL IDEAS, NEWS, AND LETTERS TO: BoxScore@theYGSgroup.com

CONTRIBUTORS

Cindy Huber, Director of Conventions and Meetings

Chelsea May, Meeting Manager

Laura Mihalick, Senior Meeting Manager

Patrick Moore, Membership Manager

Taryn Pyle Director of Training, Education, and Professional Development

Rebecca Rendon, Senior Manager, Education and Training

Alyce Ryan Membership Marketing Senior Manager

ADVERTISING

Taryn Pyle

703-535-1391 • tpyle@AICCbox.org

Patrick Moore

703-535-1394 • pmoore@AICCbox.org

AICC PO Box 25708

Alexandria, VA 22313

Phone 703-836-2422

Toll-free 877-836-2422 Fax 703-836-2795 www.AICCbox.org

PROVIDING BOXMAKERS WITH THE KNOWLEDGE NEEDED TO THRIVE IN THE PAPER-BASED PACKAGING INDUSTRY SINCE 1974

We are a growing membership association that serves independent corrugated, folding carton, and rigid box manufacturers and suppliers with education and information in print, in person, and online. AICC membership is for the full company, and employees at all locations have access to member benefits. AICC offers free online education to all members to help the individual maximize their potential and the member company maximize its profit.

WHEN YOU INVEST AND ENGAGE, AICC DELIVERS SUCCESS.

Ladies and gentlemen, we have begun our descent to the end of my term as AICC chairman.

Throughout this year, I have compared flying a plane to running a business. We are now on the final approach and preparing to land, and the analogy holds. At first glance, landing a plane and running a business may seem worlds apart. Yet, both demand focus, adaptability, and clear decision-making under pressure.

Landing a plane is a high-stakes operation that requires a pilot to assess multiple variables in real time: weather conditions, air traffic, altitude, payload, and speed. Similarly, a business leader must continuously evaluate market trends, demand, customer behavior, financial health, and operational efficiency. In both cases, situational awareness is critical. A missed signal or delayed response can lead to disastrous outcomes.

Preparation also is key. Pilots rely on checklists and rigorous training to manage expected and unexpected scenarios. Business owners, too, benefit from strategic planning, contingency frameworks, and a solid understanding of their industry. Neither can rely solely on intuition. Intuition is important, but discipline and data play a central role.

Communication is another parallel. Pilots maintain constant communication with air traffic control and their crew, ensuring safe operation. Likewise, business leaders must clearly communicate with stakeholders, employees, partners, suppliers, and customers to keep the organization aligned and resilient.

Finally, the moment of execution matters. Like a successful landing, a major business decision comes down to effective management of many variables ahead of the wheels touching the ground. Pilots and CEOs alike must trust their training and experience, use all available information, and make confident decisions, even amid uncertainty.

My AICC chairmanship theme is appropriate: “Fly the plane. Run your business.” The tools and environments differ, but we have established that the underlying skills required to fly a plane and run a business are strikingly similar. Both demand leadership that can manage complexity and steer toward a safe, successful outcome.

Being the chairman of AICC—this wonderful organization—has been one of the honors of my life. I am thankful for the tremendous flight crew I have—my family, my advisors, the AICC board of directors, AICC members, and my teammates at Package Crafters and Creative Packaging. Extra special thanks go to the AICC staff, who have worked hard to make my journey as your captain truly enjoyable.

Please remain seated until the aircraft has come to a full stop and I turn off the fasten seat belt sign.

SET RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN RUN

BY RYAN FOX AND DOUG LARSEN

Prices usually provide clarity in a market, but with corrugated packaging, they’re often a source of confusion. Containerboard and corrugated sheet pricing is complicated—embedded in a web of nuance, context, and contradictions that defy easy categorization. We’d like to believe there’s a tidy, trackable number that can be published, indexed, and graphed with confidence. But the reality is that price assessments in the corrugated industry hinge on subtle differences in market conditions and inputs, incomplete data, and unpredictable human behavior. In this report, we explore the unseen architecture behind the numbers, the limitations of benchmarks and why true price discovery in corrugated markets remains as much art as science.

The Narrow Window of Open-Market Insight

To understand containerboard pricing, one must first accept how narrow the visible slice of the market really is. Of the 2.5 million tons of containerboard consumed monthly in North America, only 150,000–200,000 tons are available in the open market. This means assessments are drawn from a small and often fragmented pool. About 90% of all tons are locked into internal transfers within vertically integrated box producers. Another 5% or so are tied up in contracts. Those transactions are essentially invisible to the pricing lens or at least are only partly reflective of market conditions.

Worse yet, some buyers in that slim open market slice operate on wildly different scales. One buyer may source 20,000 tons a month and another just 2,500. That scale differential matters; the

larger buyer inevitably commands lower prices. We’ve routinely observed spreads of $100–$150 between large and small buyers, even in the same region. When Green Markets assessed kraft linerboard at $750 a ton in June, we received credible reports ranging from $680 to $820. Same product, same month, different realities.

Freight, and Fiber Type Location matters. A buyer in the U.S. Mountain region might have freight costs of $150 a ton built into the price, while one in the Southeast or mid-Atlantic may pay only $80. This geographical disadvantage often places western and more remote buyers at the higher end of the pricing spectrum. Freight, once an afterthought, has become a major contributor to price differentials: In 2024, regional disparities widened to $60 or more a ton.

Fiber type introduces another layer of complexity. Though virgin kraft linerboard has traditionally commanded a premium, especially in heavier basis weights or specialty applications, recycled linerboard has proven to be a capable substitute in many commodity grades. In regions such as the Northeast, recycled and virgin pricing for lightweight liners used to make 32 ECT are often within $20 of each other. Some recycled grades even outperform virgin in runnability and consistency, challenging longstanding assumptions.

Behavior, and the Mirage of Transparency

Markets are shaped by both data and human behavior, and in the corrugated industry, the incentive structure discourages transparency. Box plants tied to index-linked contracts are rarely motivated to report low prices, since

doing so might compress their margins or reduce future contract revenue. This is a key reason price assessments often skew high.

Even among open-market buyers, approaches differ. There are aggressive buyers who relish negotiation, treat pricing like a sport and are quick to pounce on soft spots in the market. Others are passive, relying on supplier relationships or contracts to dictate terms. Real market movement begins only when the passive buyers start receiving discounts, an indication that downward pressure is no longer isolated and has become systemic.

The reliance on suppliers is often born out of mutual dependence, a recognition that success flows more smoothly when both parties are aligned. This kind of symbiotic relationship proved its worth during the supply-chain turmoil of the pandemic. Plants that had strong, communicative supplier ties tended to report fewer disruptions, fewer allocations, and greater operational stability.

At the same time, the crisis prompted many independents to diversify sourcing strategies, adding secondary suppliers as insurance policies. The supply-demand dynamics of today look nothing like those of 2020–2022, but the memory of scarcity still lingers. In an industry that often resists change, that experience will shape behaviors long after conditions have shifted.

The corrugated sheet market is a microcosm of containerboard, exhibiting the same fragmentation and disparity. Sheet plants vary widely in scale, from operators converting 1 MMSF a month to others running over 150 MMSF. Price differences between these extremes can exceed 25%. Again, volume drives leverage—a buyer at the high end gets preferential treatment, while the small player pays a premium.

Freight plays a decisive role here too. A typical 53-foot trailer cubes out at about 150 MSF of sheets, and every 100 miles adds roughly $4 per MSF in transportation cost. That’s a significant expense for smaller plants trying to stay competitive. The materials themselves follow a similar trend.

Though recycled sheets enjoy a 20% input-cost advantage, the savings aren’t always reflected in sheet prices, because buyers still view 32 ECT as a uniform specification regardless of composition. What makes sheets more convoluted is the structure of the suppliers. Many sheet feeders are partly owned by larger entities, and some operate with back-end rebates or incentive structures that muddy pricing. Until benchmark indexes move, these suppliers are often reluctant to change pricing, even if market fundamentals suggest they should.

Further complicating the picture is the global marketplace, where Numera Analytics estimates there’s a 30 million-ton oversupply. Exports are more than three times the size of the North American open market, with about 4.8 million tons exported last year, often at prices just above cash cost to keep mills running. Domestic producers are willing to accept significantly lower margins abroad than at home. We’ve seen export pricing for kraft linerboard at around $500 a ton, plus $50 in freight to port, resulting in effective comparisons of $550 for export versus $750 domestic.

Imports follow the same logic in reverse. Mills in Europe, Asia, or elsewhere sell into the U.S. at prices below their domestic rates, accepting low returns to gain share or offload excess volume. In whitetop linerboard, for example, imports are arriving around $100 a ton cheaper than domestic alternatives. For recycled grades, the surplus in North America means

imports must be exceptionally inexpensive to compete.

Tariffs add another variable. Though they’re designed to protect domestic mills, in practice they create artificial price floors and sometimes simply shift the cost burden. Some mills absorb the tariff to retain volume, while others pass it on to customers. The result is unpredictable, often driven more by corporate strategy than economics.

The main takeaway is that no single benchmark can truly capture the full pricing reality in containerboard or sheets. A Green Markets assessment, based on a prototypical buyer sourcing 5,000 tons of containerboard or converting 10–15 MMSF of sheets, offers a useful reference. But it’s still just a reference, not a rule, and is subject to interpretation and clarification.

Behind every price lies a story of freight costs, mill strategy, fiber composition, buyer behavior, and market psychology. Our pricing—informed by data, interpretation, and the broader economic context—distills a spectrum of factors into a single number that seeks to indicate what a reasonable buyer might expect to pay. Though it can’t represent the entire market, it might offer a clearer view of an industry where reality is rarely black and white.

Ryan Fox is a corrugated market analyst at Green Markets, a Bloomberg company. He can be reached at rfox93@bloomberg.net

Doug Larsen is a market analyst for the Green Markets, a Bloomberg company.

Uniform paper temperature and moisture levels are essential for producing high-quality corrugated sheets. Unfortunately, the human eye can’t detect hidden variations ingrained in the paper until an obvious defect is produced.

CoparSolutions’ Thermal Imaging measures IR radiation across the web to identify and display temperature inconsistencies before they become downstream issues. Real-time graphic depiction allows operators to quickly recognize and correct potential problems.

Detect and correct inconsistencies before they become issues

Consistently produce high-quality board

Dramatically reduce waste

Store production data for review and troubleshooting (optional)

Increase corrugator profitability

This column has been missing from several recent issues of BoxScore. The on-again, off-again nature of tariffs and the slow grind through Congress of the extension of the 2017 tax cuts, coupled with the editorial timeline, brought uncertainty down to page level. That all changed on July 3, 2025, with the passage of the so-called One Big Beautiful Bill Act (OBBBA) and with President Donald Trump signing it into law. Regardless of your politics, there are several wins in this bill for AICC members. AICC and its partners on Capitol Hill have been pushing for many measures included in the OBBBA for the past several years. Here is a summary.

• R&D: Businesses can immediately deduct 100% of domestic research and development costs instead of amortizing over five years.

• Bonus depreciation and Section 179: Full expensing (100%) of equipment, machinery, and qualified property—permanent for assets placed in service after early 2025. This is a huge plus for independents because it brings certainty to equipment purchasing decisions.

• Interest deduction limitation is now based on earnings before interest, taxes, depreciation, and amortization, not just earnings before interest and taxes. A permanent change that allows businesses to deduct more interest.

• Individual state and local tax (SALT) deductions are now capped at

$40,000 (indexed), and pass-through entities retain the ability to claim SALT deductions.

• The 20% qualified business income deduction for pass-through entities is now permanent, giving small businesses and S corporations tax planning certainty.

• Bonus enhancements for qualified small-business stock, lifting exclusion limits and increasing eligibility caps.

• A permanent change to $15 million per individual and $30 million per couple, indexed for inflation.

• 100% immediate expensing now applies to new factories and manufacturing equipment.

• Specific incentives for qualified production property support domestic manufacturing, offering job creation and competitive domestic products.

• R&D expense treatment aligns with generally accepted accounting principles, or GAAP, allowing immediate recognition and improving deferred tax asset management.

• The Freedom to Invest in Tomorrow’s Workforce Act, included in the bill, expands qualified expenses under 529 savings plans to include postsecondary training and credentialing. Those 529 plans are no longer only for university education.

I encourage all AICC members to consult with their tax advisors and financial planners to ensure that you take advantage of all that the OBBBA has to offer. For a thorough rundown, check out Mitch Klingher’s Strength in Numbers column on p. 64.

Eric Elgin is owner of Oklahoma Interpak and chairman of AICC’s Government Affairs subcommittee. He can be reached at 918-687-1681 or eric@okinterpak.com

VISIT US AT BOOTH #407.

See what’s next in corrugated innovation with A.G. at CorrExpo 2025. From high-speed equipment to advanced digital systems, our fully electric, fully integrated full line solutions are designed to keep you ahead — no matter the challenge. Maximize uptime. Simplify changeovers. Future-proof your line.

MORRISETTE PACKAGING

KEVIN O’BRIEN

Director of Manufacturing Operations 5925 Summit Ave. Browns Summit, NC 27214 336-375-1515

www.morrisette.com

COMBINED RESOURCES, INC.

JUSTIN DURANTE

Sales and Marketing Manager 345 S. Fairbank St. Addison, IL 60101 630-916-1804

www.combinedresources.us

SOUTHEASTERN CORRUGATED

GABRIELA HATFIELD

Business Development Manager 370 Old Laurens Rd., Suite 400 Simpsonville, SC 29681 864-757-1361

www.southeasterncorrugated.com

BORINQUEN CONTAINER CORPORATION

LIVETTE GONZALEZ

President and CEO

800 Calle El Mangotín Hatillo, Puerto Rico 00659 787-898-5000 www.borinquengroup.com

PRAGATI PACK INDIA PVT., LTD.

ANANTH KUMAR G. COO

Plot No. B5 and 6, IDA Gandhinagar Kukatpally, Hyderabad Andhra Pradesh 500037

India

www.pragati.com

AICC brought together over 20 industry professionals for the Unlock Financial and Operational Synergy Seminar. This dynamic intermediate-level program covered ways to bridge the gap between financial and operational reporting, fostering cross-functional collaboration that leads to measurable business improvements.

Led by Mitchell E. Klingher, certified public accountant and partner at Klingher Nadler LLP, the seminar delivered practical insights and hands-on tools to help participants better align financial metrics with operational performance. Mitch’s expertise—rooted in more than 30 years of experience working with packaging businesses—set

the tone for a collaborative, thought-provoking environment in which attendees were encouraged to engage, ask questions, and explore new perspectives.

The agenda maximized learning and networking. Day one included an interactive afternoon session followed by an optional group happy hour and dinner at local favorite Buona Via. Day two featured a morning seminar session, culminating in a facility tour of Acme Corrugated in Hatboro, Pennsylvania—a highlight that offered a real-world view of the seminar’s principles.

Participants explored new ways to evaluate the financial success of their companies, learned best practices for interpreting data across departments, and identified

Unlock Financial & Operational Synergy will be offered at the AICC Fall Meeting in Chicago. Learn more at www.AICCbox.org/meeting

actionable insights they could immediately bring back to their teams.

As attendees return to their companies, they bring with them enhanced technical knowledge and a renewed appreciation for the power of cross-departmental collaboration.

The seminar took place from May 14 to 15, 2025, at Acme Corrugated.

To learn more about upcoming AICC seminars and events, visit www.AICCbox.org/calendar.

Prints 4,500 sheets per hour at 600dpi. Smallest footprint on the market.

Delivering one of the lowest total costs of ownership on the market $

Consumes up to 50% less ink and energy usage than other single-pass inkjet presses. domino

Imagesmaynotincludeoptionalextrasorupgrades.Theinformationcontainedinthisdocumentisnotintendedasasubstituteforundertakingappropriate testingforyourspecifi cuseandcircumstances.NeitherDominoUKLimitednoranyofDomino’sgroupofcompaniesisinanywayliableforanyreliance thatyoumayputonthisdocumentwithregardstothesuitabilityofanyinkforyourparticularapplication.Thisdocumentdoesnotformpartofanyterms andconditionsbetweenyouandDomino,andDomino’sTermsandConditionsofsale,andinparticularthewarrantiesandliabilitiescontainedwithin them, shall apply to any purchase of products by you.

BY RALPH YOUNG

Previously, I have reported on other technical trade associations through which a significant portion of my knowledge has been obtained over many years. Of course, this does not come directly from the associations but, for almost 50 years, from the people who have been willing to share their expertise for the betterment of the industry. For your sake, we continue to exchange this wisdom with some of the best minds in the industry. At the time of this writing, I was participating in the summer meeting of the Corrugated Board Technical Committee (CORBOTEC) of the Technical Association of the Pulp and Paper Industry (TAPPI).

B 31R-23-31MW 5.21%

B 42R-33-42R 6.25%

B 31R-23-26R 6.31%

C 31R-23-31R 6.00%

C 31R-23-26R 6.55%

C 42R-23-42R 5.87%

C 42R-23-69R 6.91%

C 31R-23-31R 5.99%

E 31MW-23-31R 6.22%

B 26R-23-26R 6.03%

B 31R-23-31R 6.11%

B 26R-23-26R 6.62%

C 42R-33-42R 6.91%

B 42R-33-42R256 7.98%

C 69R-23-69k 6.24%

C 42R-23-42R 6.61%

B 31MW-23-31MW 5.80%

C 31R-23-31R 6.58%

C 31R-23-31R 6.44%

C 42R-33-42R 7.14%

C 31R-30-31R 6.82%

B 31R-23-31R*L 6.63%

C 42R-23-42R 7.48%

B 31R-23-26R 6.51%

C 31R-30-31R 7.71%

C 31R-23-26R 7.20%

C 31R-26-31R 6.37%

C 42R-23-42R 6.78%

C 42HP-33-42HP 6.81%

C 31R-30-31R 6.43%

Besides Ask Ralph, there are additional resources such as TAPPI Connect and the Institute of Packaging Professionals (IoPP), IoPP’s PackChat service, and the International Association of Diecutting and Diemaking (IADD). Speaking of IADD, it just completed its yearly Odyssey Expo. Rick Putch from National Steel Rule and Steve Rote from Metsä Serla delivered a two-day seminar on troubleshooting in the die making and die cutting processes. Feedback indicated it was the best teaching ever.

Back to CORBOTEC. Besides the best networking, this year’s meeting offered presentations on anilox rolls, printing plates, cutting dies, ink metering systems, and press characterization. We focused on image reproductions but left out digital. It’s not all containerboard and corrugators.

So, in the spirit of knowledge-sharing, let’s take a look at a recent question I received through Ask Ralph:

“I’m wondering if you could provide some guidance regarding where we should target our moisture content of combined board. We’re running C-flute 31-23-31 100% recycled board. Paper is coming in at 7.6% average.

“We’re using a Denver moisture analyzer. We cut circles of combined board, place into the fixture, and it determines the moisture in the board and provides it as a percentage. We have just started testing combined board off the stacker. We are not testing paper because we receive COAs (certificates of analysis) from our mill noting moisture content.

“Our medium 23# has been at 9.0–9.06, so right where it should be.

We are not utilizing our corrugator sensors to check temps like we should be. That being said, we are still not too far out of line. Die cut slots are clean, and print is acceptable.

“However, humidity levels are starting to creep back up, so we are trying to get ahead of it before cold temps are back.

We know that will dry out our board a bit.

“This is a snapshot of our levels for the past two weeks” (see chart at bottom left).

“You’re doing everything right. That’s the moisture instrument I always recommend. Is your medium coming to you with 1%–1.5% higher moisture content (MC) than the liner?

“These values seem a little low for combined board given that you are combining and converting 100% recovered fiber containerboards. However, if your die cuts and slots are clean, your scores are not cracking, [and] you’re running flat board and getting good print, then it sounds like the numbers are working for you. Since the MC seems to be a bit low, you’ll really want to keep an eye on the level when the temps change.

“As you mentioned in our call, the TAPPI standard 0304-37 should provide some good information, as well.”

For more on this or any other subject, you are always welcome to contact me at any time to discuss any technical concerns.

Ralph Young is the principal of Alternative Paper Solutions and is AICC’s technical advisor. Contact Ralph directly about technical issues that impact our industry at askralph@AICCbox.org

BY TOM WEBER

The purpose of this article is to assist AICC members with resolving an internal or customer-generated thermoformed blister card sealing issue. The first information to obtain is what blister coating is being used and the type of blister material—usually polyvinyl chloride (PVC) or a version of recycled polyethylene terephthalate (RPET). You can determine if the blister is PVC or RPET material by several simple tests. You can crease a PVC blister, and it will turn white at the crease; you can burn it, and it will smoke and char badly. The PET or RPET material will not char, and it will turn white in the heated area. It will also drip. Blister gauge should be at 0.0075" min to 0.03" max thickness before thermoforming. Flange width should be 0.312" minimum.

If there is still a question regarding the type of blister coating, put a few drops of ammonia on the blister coating, let it remain there for five or 10 minutes, and then wipe it off. If it eats into the coating, the coating is an aqueous coating; if it does not destroy the coating, it is solvent-based.

Your investigation should begin with the sealing process: the sealing trilogy of time, temperature, and pressure. The one element that must be maintained in the sealing of a blister card is the interface temperature. Blister coatings are designed to be reactivated at specific temperatures. Most solvent-based coatings will reactivate at 180°–190°F, and the aqueous versions will reactivate at 190°–205°F.

This reactivation of the coating creates a hot, sticky mass known as “hot tack”; this hot mass sticks to the plastic blister,

and as the coating cools, the blister and card bond.

If too much heat is applied or the dwell time is excessive, the blister coating viscosity will be reduced, and the coating will penetrate into the card, leaving an insufficient coating on the card surface to adhere to the blister. Of course, the dwell time must be long enough to reactivate the coating.

The heat tapes that you should obtain are to be used to determine the interface temperature. The heat tape is removed from the sheet, and with the card facing up, it is placed in the flange area. It will not register a reading if not placed in the flange area.

The card is then turned over and placed in the tray face down. The sealing process commences. The last square on the tape that turns black determines the interface temperature. Occasionally, the placement of the tapes will not be in line with the flange area; therefore, you will not get a reading. The tape must have pressure on it to work.

The next step is to take your pyrometer and check the heat platen. Usually, the temperature on the machine reading indicator varies from the true reading of the heat platen. Also, check the platen in different areas; the platen could have a burned element, thereby causing a fluctuation in sealing around the flange area. If the situation would allow, the heat platen could be taken off the sealing machine, laid on a flat surface, and checked for warping with a straight edge placed diagonally on the platen.

Look at the unsealed area of the blister flange that is not sealing; if it is “glossy” like the unsealed areas of the

entire card, you can assume no pressure or heat is being applied in the flange area. If the configuration of the blister would allow it, turn a new blister around in the tray and see if it fails in the same area. If the failure moves to a different area, it could be a blister problem. Also note how many cavities are being sealed at one time. Now is the time to check the platen pressure with your pressure film.

Say you’re measuring heat platen pressure using two pieces of pressure film: Both have a glossy and dull side; one piece is opaque and the other, translucent. To register a reading, the two pieces of film must be placed dull side to dull side. The card is then placed face down over the two pieces of pressure film. The sealing machine is put in motion. The translucent top piece of pressure film usually sticks to the face of the card, and resulting pressure shows up on the bottom opaque piece. A minimum pressure of 80 psi is required in the face seal area.

Any light-colored areas on the opaque piece indicate a lack of heat platen pressure on that area of the card. Incidentally, wooden trays are noted for this problem because they warp badly with the fluctuation of relative humidity in the atmosphere. If the problem is on a carousel sealing machine, check the rails and tray fixtures for the degree of vertical fluctuation.

Heat platens can either be milled tooling or flathead platens. The milled tooling does not put as much heat into the blister card as a flathead platen. Flathead platens without a Teflon cover can easily burn the back of a blister card. The rubber or cork used on trays should be checked for

damage and compression caused by too much platen pressure. The rubber on the seal tray surface should range from 50 to 90 durometer.

Keep in mind that the thickness of the blister card can have a bearing on heat transmission through the back of the card. Significantly aged (over 90 days old) blister cards have a tendency to dry out. Therefore, temperatures and dwell times will have to be increased to attain a successful seal.

The board we use is known as blister board low-density board, which means it has a “fluffy” surface so the blister coating can easily bind with the surface layer of clay coating, whereas carton board has a harder and more calendered, smoother finish. See the diagram (above right) and note the various interfaces of a sealed blister card.

The weakest interface and the one that should fail is Bond A to the base sheet; the fracture at this juncture results in fiber tea (successful seal). A failure at any other juncture would be considered a failed seal—and we would initially be held responsible—but if the bond between Bond A and the base sheet would be too strong, it would be a board problem. The split between Bond B and Bond A (clay split) is often a result of this situation. With clay split, you will have white coating on the blister flange, but there will be no board fiber attached.

This is why I would suggest you perform your own lab tests on all incoming board before the board goes into production.

One of the most prevalent sealing problems today is the sealing of RPET blisters (oriented). The plastics and the quantities used in the film vary greatly; therefore, film properties change from batch to batch. In addition, the heat history of the film the thermoformer receives has a significant bearing on the thermoforming process.

When the thermoformer processes PVC film, it can use temperatures high enough to reach the glass transition point: Once past this point, the film reaches the optimum forming temperature—the film can be stretched and formed without creating orientation or stress.

When processing RPET film, the thermoformer cannot achieve the optimum forming temperature because the film surface will become crystallized and will not seal. Therefore, the film is processed at a lower temperature. The result is a formed blister that contains stress, a cold-formed blister. Memory remains in the film; during the sealing process when heat is applied, the blister flange softens, and the stressed film tries to return to its original shape.

As a result of this stress, the blister flange will ripple and pull away the card, it will pick off ink from the inside of the blister wall, and the flange will curl back up toward the vertical blister wall. When dealing with RPET blisters and a sealing problem, you can save time and effort if you have two pieces of polarized film. By placing the blister between the two pieces of film, one piece at held at a 45-degree angle, you

will immediately see the stress areas in the blister. The stress will show up as colored rings. The more purple rings that show, the more stress is present in the blister. Check the flange area, in particular. This method, in many cases, will direct you to the source of the problem immediately. It also gives you something definite you can show a customer. The technical term for the purple rings is birefringence.

A few other points to consider in troubleshooting a sealing problem are the number of cavities on a sealing tray and the shape of the blister. Long, narrow flanges can create sealing problems, and thin, narrow flanges will also ripple if too much heat is applied.

If the above methods fail to solve the problem, please gather all of the information with associated samples and send to my attention for our collective further review and investigation.

Tom Weber is president of WeberSource LLC and is AICC’s folding carton and rigid box technical advisor. Contact Tom directly at asktom@AICCbox.org

BY TODD M. ZIELINSKI AND LISA BENSON

Relationship building has long been a critical aspect of sales in the corrugated industry. Many companies’ growth is thanks to the persistence and expertise of seasoned salespeople who’ve spent decades learning customer preferences, solving problems on the fly, and closing deals with a handshake.

But what happens when those people retire? It’s not a distant concern. It’s already happening, and many companies aren’t prepared.

While there are no industry-specific data on the age of the corrugated packaging salesforce, we can make

reasonable assumptions by examining related statistics. As of 2024, nearly one-third of all employees in paperboard container manufacturing are 55 or older, according to the U.S. Bureau of Labor Statistics. When we look at sales roles across all manufacturing sectors, we find the same pattern—almost 1 in 3 salespeople are 55 or older.

It stands to reason that the corrugated sector is facing a similar demographic reality. That means up to a third of your sales team may be within five to 10 years of retirement. And many companies have no formal process for capturing their institutional knowledge, let alone a plan to replace retiring sales staff.

In many corrugated businesses, customer information lives in the salesperson’s head. Details about preferred board grades, quoting nuances, seasonal demand patterns, and buyer personalities and preferences may not be written down, structured, or shared. Sales representatives who have been with the company for 20 or 30 years often operate independently, managing accounts based on relationships and intuition.

When they retire, the impact can be significant in the following ways:

• Longtime customers won’t get the same service and may look elsewhere.

Optimizing the flexo process for maximum productivity, quality and efficiency.

• Transition to new reps may not be smooth, creating challenges for operations, quoting, or customer service as well as customers.

• Internal teams may need to scramble to rebuild the knowledge that has been lost.

This can result in lost revenue, weakened customer loyalty, and stalled growth.

Even if you want to hire a replacement, finding someone with corrugated knowledge and the ability to hunt for new business will be challenging. Fewer young people are entering sales. Finding new customers, cold calling, learning on the job, and spending years to gain the knowledge of their predecessor doesn’t appeal to younger workers. At the same time, newer hires tend to expect structured processes, clear handoffs, and some level of technological support, which many companies haven’t fully implemented. Additionally, many young people prioritize flexibility, purpose, and personal alignment over job security or company loyalty.

This isn’t about work ethic; it’s just that younger people have a different set of expectations that may not align with how sales has always been structured. While there may be a generational gap, the larger issue is the process gap.

If you have key salespeople who will be retiring in the next five to 10 years, you can start now taking small, deliberate steps to protect your customer relationships and prepare for future transitions. Here are several ways to do that:

• Start capturing sales knowledge: Make it a habit to document key account information. Use templates for quoting preferences. Record short interviews or debriefs with senior reps. Ask them to walk through their

sales approach to top accounts and document it.

• Use a customer relationship management system (CRM): Not every company needs a complex CRM, but most need something more effective than spreadsheets. A CRM such as Pipedrive can track conversations, quotes, and account activity without overwhelming your team. Choose a CRM that integrates with your email so those conversations are captured, as well. If salespeople resist data entry, assign someone else to handle input. The goal is to have visibility and capture data, not create extra work.

• Outsource front-end sales tasks: One way to support your sales team is to bring in outside help for front-end sales: lead generation, appointment setting, and pipeline management. This will keep your pipeline full and moving while your internal team focuses on closing and retaining customers. It’s not a replacement for your sales team; it’s a supplement. Fragmented salespeople are less productive. If you bring on a new sales member who needs to focus on learning your products and services and closing sales, having them prospect as well is setting them up for failure and being overwhelmed.

• Practice division of labor: Similarly to outsourcing, you alleviate the fragmentation of your salesperson by allowing them to concentrate on selling. Allow a junior sales team member with the appropriate skill set to conduct prospecting tasks and pass on qualified leads to the salesperson. This is a good way to start developing your talent pool of people who may be able to step into the sales role when needed.

• Cross-train your internal staff: Customer service and operations teams should have access to account details. If your best sales rep retires tomorrow, someone should be able

to step in without starting from zero. Even simple shared documents or dashboards can make a difference.

• Invest in succession planning: Reach out to local colleges and offer internships. Start a mentoring program that pairs junior employees who are interested in sales with senior representatives for ride-alongs or customer meetings. Don’t wait until someone gives notice to think about who might take their place. Succession planning is critical to the success of your employees and your business. Putting someone who may not be a fit or prepared in a sales role because you are in a bind after a senior salesperson leaves won’t benefit anyone, especially your customers.

The loss of a top rep shouldn’t put your business at risk, but if you haven’t prepared, it will. The good news is that this problem is fixable. You need to start capturing what your best people know and put some basic structure and process in place so that tribal knowledge lives beyond them.

Whether it’s documenting sales strategy, investing in tools that fit your workflow, or using outside support for prospecting, the point is the same: Don’t wait until you’re forced to react. Start planning now to make sure your company’s future isn’t tied to a single person’s memory.

Todd M. Zielinski is managing director and CEO at Athena SWC LLC. He can be reached at 716-250-5547 or tzielinski@athenaswc.com

Lisa Benson is senior marketing content consultant at Athena SWC LLC. She can be reached at lbenson@athenaswc.com

• Only standard hand tools are required for all maintenance

• Direct drive with no chains or sprockets

• No tools for media change required

» just zip it up

» media change out in minutes

• Filter is accessible for visual inspection during operation,

» no shutdown required

• Filter media advantages

- high dust collection efficiency

- low pressure loss due to constant deep cleaning of the filter media in minutes

- long service life

• No pressure fluctuations within the system

• No compressed air required to clean the filter media

www.engineeredrecycling.com

info@engineeredrecycling.com

BY JULIE RICE SUGGS, PH.D., AND ALLI KEIGLEY

There’s nothing quite like the thrill of game day. The roar of the crowd, the sea of jerseys (Go Panthers!), the smell of stadium snacks, and of course, the excitement of ripping open a limited-edition fan box just before kickoff.

Growing up, this was my absolute favorite thing to do with my dad—grabbing an overpriced (but well worth it) snack served in an intricate takeaway box that felt like part of the fan gear itself. That moment, sitting in the stands beside my dad, hands full of nachos grabbed from a cleverly folded cardboard tray, wasn’t just about food. It was about tradition, connection, and the unforgettable atmosphere of the game.

Now, teams and brands are leaning into that same experience, using corrugated packaging to deepen fan engagement, spark nostalgia, and bring sustainability to the forefront of game day. Let’s take a closer look.

In 2024, the Philadelphia Eagles elevated their season ticket holder experience by introducing a thoughtfully designed packaging initiative. They partnered with local packaging suppliers to create custom corrugated collector boxes for season ticket holders. These boxes featured printed game schedules, team imagery, even pop-up inserts—providing fans with a tactile keepsake experience before the first whistle blew.

The Manchester City Football Club embraced innovative packaging to enhance fan engagement and promote sustainability. In collaboration with sportswear manufacturer PUMA, they introduced merchandise kits in custom corrugated mailers featuring augmented reality (AR) markers. When scanned, these markers

allow fans to unlock behind-the-scenes content and stadium experiences, blending smart technology with eco-friendly design. The AR integration was part of Manchester City’s strategy to connect with fans in the digital realm. By scanning the AR markers, fans can access exclusive content, including virtual stadium tours and player interviews, enriching their connection to the club. The use of corrugated mailers aligns with sustainable practices because they are recyclable and biodegradable. This initiative reflects Manchester City’s commitment to environmental responsibility through their use of innovative packaging solutions while amplifying the fan experience.

The Seattle Seahawks have significantly advanced sustainability efforts at Lumen Field by adopting 100% paper-based, biodegradable products across their operations. The stadium utilizes compostable food service packaging and vessels, including ocean-degradable straws introduced in 2017, to minimize environmental impact. These initiatives are part of a broader commitment to sustainability, demonstrated by Lumen Field’s achievement of Total Resource Use and Efficiency precertification in 2024, making it the second NFL stadium to attain such status. The facility diverts over 90% of its waste from landfills through comprehensive recycling and composting programs, supported by partnerships with local vendors and organizations such as DTG Recycle. Additionally, Lumen Field has implemented advanced waste sorting technologies to enhance efficiency and reduce contamination in composting efforts. These measures underscore the Seahawks’ dedication to environmental stewardship and sustainable practices.

Along the same lines, the Green Bay Packers have been actively working to enhance sustainability at Lambeau Field by introducing eco-friendly initiatives aimed at reducing plastic waste. These efforts include the implementation of corrugated signage and recyclable concessions packaging throughout the stadium. The use of corrugated materials for signage not only supports the Packers’ commitment to environmental responsibility but also strengthens the fan experience by providing clear and accessible information.

Corrugated packaging hits the sweet spot among sustainability, strength, and visual impact. With high-quality print capabilities, teams can design vibrant graphics that capture the energy of the sport. It’s lightweight, easy to assemble, and even more importantly, recyclable—providing alignment with environmental goals.

Whether it’s a fan box, food tray, or merchandise mailer, corrugated is proving it’s more than just packaging—it’s part of the game plan.

Julie Rice Suggs, Ph.D., is academic director at the Packaging School. She can be reached at 330-774-8542 or julie@ packagingschool.com

Alli Keigley, who contributed to this article, is production coordinator at the Packaging School. She can be reached at alli@packagingschool.com.

The SUN625 HD delivers even more production volume without compromising container quality. These enhancements ensure consistent output while reducing the need for downtime — all contributing to a more reliable and efficient operation.

The SUN625 HD retains the fixed-frame, vertically opening design that made the original a success. With structural upgrades, increased load capacity, enhanced speed, and reduced wear, the SUN625 HD redefines productivity and durability in high-volume production environments.

BY MATT EICHMANN

Too many organizations are still clogged with silos that slow execution, smother innovation, and turn decision-making into a game of telephone. Despite all of the talk about agility and collaboration, working cross-functionally remains one of the most misunderstood—and underleveraged—leadership skills out there.

Today’s challenges rarely sit neatly within one department. Whether you’re launching a new product, solving a customer problem, or responding to shifting market demands, progress requires cross-disciplinary thinking. That’s why more companies in the corrugated sector—and beyond—are forming cross-functional teams to bring together diverse expertise, drive alignment, and move faster with greater clarity.

But here’s the twist: Forming a cross-functional team doesn’t guarantee results. In fact, numerous studies show that many of these teams underperform due to poor coordination, unclear goals, weak accountability, and lack of governance. Done well, cross-functional teaming is a performance accelerant. Done poorly, it drains motivation and breeds frustration.

Matt Eichmann is facilitating the Next Generation Executives Program (see callout on p. 51). Professionals transitioning into top-level leadership in the next few years are encouraged to apply for this unique opportunity to enhance their capabilities, connect with industry leaders, and shape the future of independent packaging.

Let’s flip that script. Here are five practical moves to get traction when working across functions:

1. Lead With Clarity, Not Control Cross-functional teams thrive when everyone understands the why. Start by clearly articulating the team’s purpose and defining a shared goal. Then, let each group contribute from its unique strengths. Anchor the work in a common “what’s in it for me” to secure real buy-in. Don’t micromanage—create the conditions for ownership through active inquiry and the expectation that everyone brings their perspective to the task at hand. And be crystal clear on accountability; only one person can be accountable for the performance of a team—cross-functional or not. Make that explicit from day one.

2. Overcommunicate Early, Translate Often

Each function—sales, operations, finance— has its own language. Don’t assume shared understanding. Align early on terminology, expectations, and how decisions will be made. Explain new ideas simply before diving into complexity. Author James Humes said, “The art of communication is the language of leadership.” Take that seriously. Overcommunication early prevents misfires later.

3. Influence Across, Not Just Down In cross-functional settings, power flows sideways. You won’t gain traction by pulling rank. Build trust by giving before you ask—offer insights, deliver quick wins, and ask thoughtful questions. Influence is earned by showing up as a partner, not a boss.

4. Make the Work Visible

Shared goals are good. Shared visibility is better. Shared incentives are best. Use visual tools—dashboards, scoreboards, simple checklists—to track progress and surface interdependencies. This keeps everyone aligned and makes it easier to resolve blockers as they arise. Visibility drives accountability.

5. Reward Team Wins, Not Territorial Ones

If your recognition systems reward solo acts over shared outcomes, you’re reinforcing the wrong behaviors. Celebrate those who collaborate, bridge functions, and move the needle together. And don’t forget to learn from what worked—and what didn’t—once a cross-functional effort wraps up. Don’t just move on to the next challenge. Pause, assess, and reflect to improve the next round.

Bottom Line?

Learning to work cross-functionally—with intention, clarity, and empathy—is no longer optional. It’s a competitive advantage, especially in the corrugated industry, where execution, innovation, and staying close to the customer are mission-critical. Cross-functional collaboration is not only a soft skill but also a power skill. Master it, and you’ll accelerate your impact, unlock innovation, and break through the bottlenecks that could be holding your organization back.

Matt Eichmann is founder of Catalyst Point Leadership Advisors. He can be reached at 614-512-2940 or matt@catalyst-point.com

A multi-award-winning modular printing solution Up to 3 flexo units + single pass inkjet + rotary die cutter

Analog or Digital? Get to know an actual case study

Kento Hybrid Converter: Feeder, primer, 3 flexo units, digital single-pass module, OPV, rotary die cutter Our tech team ran a head-to-head multi-factor comparison, including both pre-print and post-print options for a new retail corrugated packaging. Contact us for details and a demo.

Flexo printing for solid backgrounds, white ink, special colors

Digital printing for high-quality images and personalization

Come to our “Kento Open House” event Sept. 1 -16

award-winning printing line for corrugated We are corrugated

Rotary die cutting for increased overall equipment efficiency

download a brochure ask for a live demo

BYLINE

AICC is proud to announce a monumental milestone in its commitment to member education: Employees of member companies completed more than 25,000 courses through Packaging University, the Association’s robust online learning platform.

“We celebrate this number because it shows how independents are getting maximum return on their membership,” says AICC President Mike D’Angelo. “With AICC’s Packaging University, you are investing in your team and your company’s future success.”

Since 2017, AICC has empowered members with unlimited access to selfpaced online courses at no additional cost. With more than 150 courses organized into “colleges” tailored to key roles in a box plant, Packaging University has become a vital training tool for companies looking to rapidly and effectively upskill their teams. It’s a one-of-a-kind benefit designed for the independent packaging industry.

“This milestone is more than a number; it’s a reflection of our members’ dedication

to excellence,” says Gary Brewer, president of Package Crafters and Creative Packaging and AICC chairman. “Packaging University serves as an educational bedrock for the success of our membership.

Surpassing 25,000 completed courses is a testament to our members’ commitment to learning and their desire to help shape the future of our industry.”

The flexible and accessible structure of Packaging University has proven invaluable to companies looking to enhance training across all experience levels.

“Being able to train both new and existing employees efficiently and effectively is a crucial aspect for keeping your business thriving,” says Josh Sobel, account manager at Jamestown Container Cos. and AICC’s Education Committee chair. “Jamestown Container utilizes Packaging University across multiple business segments to ensure our employees are trained with the most up-to-date and useful information. The presentation makes it quick and easy to

put together a beneficial training program for your employees, regardless of their experience level, so that they can succeed in our industry.”

With the continued evolution of the packaging industry, AICC remains committed to providing best-in-class education. Packaging University stands as an unmatched pillar of that commitment—empowering the independent packaging workforce with the knowledge and tools to thrive.

To explore the full catalog of courses or begin training today, visit learning. AICCbox.org

BY THERESE UMERLIK

In the heart of Biddeford, Maine, where industry and community intertwine, Volk Packaging Corporation (VPC) is a testament to enduring values and unwavering dedication.

More than just a manufacturer of corrugated boxes, VPC has guided the company’s every decision, investment, and interaction to ensure service, quality, and reliability. This spirit, which has been the cultural cornerstone of VPC for over five decades, is best expressed in the motto of its founder, Benjamin Volk: “Our customers are our bread and butter.”

VPC began in 1967 when Benjamin and his son, Kenneth, launched their corrugated box plant as the first tenant in the new Biddeford Industrial Park. Their choice of Maine, driven by the thriving textile industry of the era with its large mills, underscored a strategic vision for entrepreneurial growth. Box production

commenced in 1968 with five employees, two of whom would remain with the company for three decades.

The family commitment deepened in 1974 when Douglas Volk, Kenneth’s brother, moved from Massachusetts to Maine. A couple of years later, the box plant nearly doubled in size from 20,000 to 33,000 square feet and its workforce to approximately 25 individuals.

A pivotal transition at VPC occurred in 1986 when Benjamin retired, entrusting the presidency to Kenneth, with Douglas assuming the role of vice president. This leadership change was accompanied by another expansion, as production square footage grew to 65,000 square feet.

As the corrugated industry evolved, presenting increasing competition from integrated companies, VPC made a bold and strategic move in 1991. With AbbottAction, Romanow Container (now

Company: Volk Packaging Corp.

Established: 1967

Joined AICC: 1977

Phone: 800-341-0208

Website: www.volkboxes.com

Headquarters: Biddeford, Maine

President and CEO: Derek Volk

SupplyOne), R&R Corrugated Packaging Group, and Valley Container, VPC helped launch Newcorr Packaging, a sheet feeder in Northborough, Massachusetts.

As one of the few sheet feeders on the East Coast boasting two corrugators, Newcorr secured VPC’s access to high-quality board to ensure consistent product quality and service. In addition, Newcorr has provided VPC an advantage over competitors, which can be constrained by single-machine bottlenecks and delays.

In 1992, Derek Volk, Kenneth’s son, entered into the family business full time. He became vice president of sales five years later, injecting new energy and perspectives into the company.

A significant physical expansion occurred in 1997 when VPC acquired property across the street in the Biddeford Industrial Park, paving the way for the current 141,000 square feet of state-of-the-art

corrugated packaging production. The facility reflects VPC’s commitment to upgrading machinery and technology and its early dedication to sustainability and environmental stewardship. Investments included a Hycorr rotary die cutter, scrap recycling system, heat recapture technology, and the installation of 80,000 square feet of rooftop solar panels. It was only a couple of years later in 1999 when VPC installed a Serenco jumbo flexo with a die cut station. Leadership transitions continued into the new millennium. Kenneth retired in 2007 but maintains connections with many longstanding customers. Douglas, who became CEO in 2007, retired in 2019 and has since become a successful author.

Derek is also a writer. He coauthored a book with his son, Dylan, titled Chasing the Rabbit: A Dad’s Life Raising a Son on the Spectrum, about their challenges and triumphs with autism. Derek’s second book, titled Go for Third: Leadership Lessons From the Softball Field to the Workplace, explores the leadership principles he gained on the field that can apply to business and beyond. (For more information, visit www.goforthird.com )

Today, Derek, as president and CEO, is a hands-on owner-operator, steering this respected third-generation family business. Under his leadership, VPC now employs nearly 120 individuals, many of whom have dedicated decades of their professional lives to the company.

“An amazing 10% of our workforce have spent at least half of their life working at the company, with our senior employee, Michelle Morin, marking 44 years of service in 2025,” Derek says. “She is our sixth employee who has spent at least 40 years with us and will break our record for longevity in August.”

Despite the profound challenges posed by the Great Recession and the COVID-19 pandemic, 2020 marked Volk Packaging’s 12th consecutive year of growth, a streak that continued to 15 years before a slight dip in 2023, a testament to its resilience,

adaptability, and the enduring demand for its products.

The human element is a cornerstone of VPC’s success. Its family-owned and family-operated structure fosters an environment of loyalty and dedication. With over 120 employees, including 14 sales representatives boasting a combined 200-plus years of experience, four designers, and six customer service representatives, the depth of expertise is immense. VPC takes pride in the longevity of its workforce, a loyalty they believe directly translates into superior quality for its customers. As of June 2025, VPC associates collectively boast over 1,000 years of service, with 21% of employees having worked at VPC for over 20 years, 48% for more than 10 years, and 60% for over five years.

“My father always told me to never forget that the employees work with you, not for you, and that we all work for the customer,” Derek says.

VPC serves a diverse base of over 1,000 manufacturers, distributors, and producers throughout New England. This broad customer base is a strategic benefit because no single customer accounts for more than 6.5% of their business. In addition, this diversification ensures that no single large order can monopolize VPC’s machinery, guaranteeing consistent and timely service for all clients.

VPC’s design department works with customers, creating custom packaging solutions that prioritize product protection while remaining sustainable, affordable, and aesthetically appealing. For businesses

requiring standard solutions, VPC also offers a comprehensive packaging supply program with over 20,000 products. VPC’s commitment extends beyond its operational walls to giving back to its employees and the wider community. This dedication manifests through significant charitable donations, team-building activities for employees (including their biannual Corrugated Olympics) and their families, and active volunteering in community programs. Its values are clearly represented in VPC’s acronym CARE: customer-centric, accountability, respect, and excellence.

VPC supports veterans and active-duty service members through several Mainebased veteran organizations. Among them are:

• Maine Veterans Project, which is dedicated to reducing veteran suicide.

• Travis Mills Project, which provides a fully accessible retreat for combat-wounded, disabled veterans, and their families, having served 1,945 families from 46 states.

• 40 years of experience with separators, cyclones, conveyors, and more

• Sequential, Zero-defect and various types of Scrap Systems

• Each system is guaranteed to meet customer specifications

• Turnkey Systems-handling all grades of paper and paperboard

• In ground and overhead return conveyor systems direct to balers

• Replace your undersized or aging cyclone over a two or three-day weekend

• Representing a complete line of shredders, wet scrubbers and filters

• NFPA compliant systems, ISN Network

50 East Court, Mandeville, Louisiana 70471

Phone (985) 875-7777 Fax (985) 875-7778 Email: sales@airsystemsdesign.com

• House in the Woods, founded by Gold Star parents, which uses the Maine outdoors to help military families process shared experiences of service and sacrifice.

Notably, VPC donates printed custom boxes to every veterans home in New England so the families have respectful moving boxes when a vet passes. Additionally, VPC has donated almost $50,000 to its local Veterans of Foreign Wars through the Volk Packaging Heroes Wall. (For more information on how to honor a hero, visit www.volkboxes.com/ heroes-wall .) Although these are not the only organizations VPC and its employees contribute to, they represent the largest and most direct support.

Sustainability has also been integral to VPC’s operations for its 58 years. It has been recapturing and recycling corrugated materials as well as recycling water and plastic products used in manufacturing and exclusively using nonchemical water-based inks for printing. In 2024 alone, Volk Packaging’s recycling efforts saved over 15,000 trees by diverting more than 600 tons of corrugated waste. It also has earned the Sustainable Forestry Initiative and the Forest Stewardship Council certifications and offers Supershield, an environmentally responsible, 100% Food and Drug Administration- and Canadian Food Inspection Agency-approved alternative to wax-coated corrugated.

In 2021, Derek expanded VPC’s entrepreneurial footprint by founding Volk Paxit, a spin-off born from VPC’s role in repackaging medical supplies during the COVID-19 pandemic. Recognizing a broader market need, Volk Paxit now offers repackaging, prepackaging, kitting, and fulfillment services, assisting businesses grappling with labor and logistics challenges. A year later, Volk Paxit relocated to a spacious, newly renovated warehouse in Sanford, Maine, providing

KemiTM liners, Metsä Board’s premium white top kraftliners, have played a significant role in the evolution of corrugated packaging in the Americas. Known for their superior printing surface and high performance, KemiTM liners are a coated white top kraftliner that revolutionized the corrugated packaging industry by combining performance with visual branding.

KemiTM liners, then known as Kemiart, were launched in the American market in 1991. Innovation continued introducing double coated white kraftliner in 2011. Most recently, in 2023, the Kemi mill underwent further developments to increase its capacity to 465,000 tons, while enhancing energy and water efficiency.

At 465,000 tons, our facility is now the world's largest production plant for coated white-top kraftliner. Customers worldwide specifically request "Kemi" when they mean our first-class white kraftliners such as MetsäBoard Classic WKL, MetsäBoard Pro WKL and MetsäBoard Prime WKL.

With a legacy spanning over five decades, Metsä Board will continue to help set the standard for excellence in packaging, allowing every box to tell a story of quality and sustainability.

Growth, with a future

ample room for inventory management, processing, and shipping.

Volk Paxit has invested in technologies for e-commerce integration and maintains a staff of around 20 full-time workers. This expansion into Sanford is projected to create up to 20 additional hires, with much of the 95,000-squarefoot facility serving as a warehouse for VPC, and potential for manufacturing overflow.

“We have been thrilled by the growth of Volk Paxit and the ability to provide our customers with even better service through what we can do at Paxit,” Derek says.

VPC’s commitment to growth and efficiency is exemplified by its significant investments in cutting-edge machinery. Most recently, an additional $8 million investment has further enhanced its capacity and capabilities. This includes the acquisition of a large 4-color flexo folder-gluer and a new rotary die cutter with 5-color printing, including inside print functions; both machines come from Haire Group’s APSTAR HG2 line. They are designed to expedite customer service and meet the soaring demand across New England, upstate New York, and eastern Canada. The flexo

folder-gluer touts advanced features such as a die cut station, scrap management, and a dual servo-slotter. Both of the new machines were installed in 2024.

VPC is also installing a high-speed, efficient production line featuring equipment from WSA, Ducker-Ringwood, A.G. Stacker, and Inspire Automation, incorporating conveyors, transfer carts, robotics, bundlers, double bundlers, unitizers, a bundle breaker, and a stretch wrapper. VPC’s journey is a testament to steady, consistent growth.

Beyond the impressive business metrics, VPC stands out for its strong faith-based approach, reflected in a mission statement that reads more like a community than a corporate directive: “Led by God, managed by a family that cares for our customers, co-workers, and community. Making boxes while making a difference.”

This unwavering commitment to its values has seen them through challenging times, including the period of severe economic downturn after 9/11 that nearly forced a merger. VPC’s decision to remain independent, guided by faith, has since led to remarkable growth and job creation. This integrity is recognized externally; in 2021, VPC was named one of the “Best Places to Work in Maine” for the second time. This is one of many business and community awards VPC and the Volk family have received.

In essence, VPC is more than just a box manufacturer; it’s a living embodiment of its founder’s motto. As Derek likes to say, “If I die and my obituary says, ‘He sold a lot of boxes,’ I’ll be disappointed.”

It’s built on the enduring principles of customer-centricity, technological innovation, community support, and a commitment to its employees. As it looks to the future, VPC is poised for continued success, driven by its rich history, its cutting-edge machinery, its deep community ties, and an unwavering dedication to its “bread and butter”—its valued customers.

Therese Umerlik is managing editor of BoxScore

BY M. DIANE M c CORMICK

AICC’s education pathway offers a more focused way to train and lead

The road to leadership can be filled with potholes, especially in a complex industry such as boxmaking.

Now, the new AICC Pathway to Success is filling gaps between existing programs while striving for the high level of learning and engagement established by AICC’s existing leadership outlets.

“Better leaders aren’t born,” says Terri-Lynn Levesque, vice president, administration, at Royal Containers, and incoming AICC chairperson. “They are built through a trajectory. That’s how you’re going to grow within this industry.”

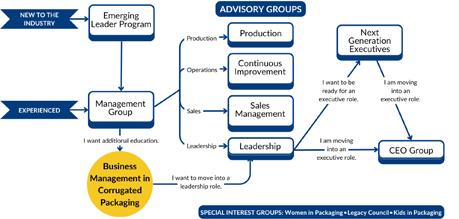

The AICC Pathways to Success, newly depicted in the useful diagram below, rounds out AICC’s learning and networking opportunities with three new elements—a Management Group for midcareer professionals, an MBA-level certificate steeped in industry principles, and an executive coaching program for future C-suite inhabitants.

Building on and converging with AICC Packaging University’s excellence in learning, the pathway continues providing exclusive educational opportunities that keep career-minded talent in the industry.

And it comes, as always, from ideas generated by AICC members. “We truly are addressing specific needs of the industry that provide value to an enormous part of our membership,” says AICC Senior Manager of Education Rebecca Rendon.

AICC’s Emerging Leaders (EL) program, CEO Group, and advisory groups—specific to production, continuous improvement, sales management, and leadership—are well established. All generate opportunities for future and current leaders to learn from each other and keep pace with industry trends.

These ever-evolving and expanding leadership options, plus Packaging University courses and university partnerships, “bring awareness to our industry,” says Levesque, an Emerging Leader alumna.

Josh Sobel, account manager at Jamestown Container Cos. and AICC Education Committee chair, agrees that education “is huge in this industry.”

“Attracting young talent to the corrugated industry isn’t the easiest thing,” he says. “When you hear about it in college, it’s not something you think would be a glamorous business. When you get talent in your business, you have to figure out a way to keep it, and training them to be successful in whatever they do is probably the best way to keep people around.”

After she aged out of the EL program, Levesque found that joining AICC’s Leadership Advisory Group, with its regular meetings and plant tours, fulfilled her search for opportunities to continue developing as a leader. Through the group, she connects with peers one-on-one to problem-solve and plug into industry trends.

Still, even the advisory groups can have a shelf life, she says, and she wonders, “What’s next?”

The issue was that “all these great things” offering leadership education and engagement were disconnected, says Taryn Pyle, AICC director of education and talent development.

Challenge accepted, said AICC staff and members. Working in collaboration, they created three new offerings—the Management Group, the Business Management in Corrugated Packaging certificate, and the Next Generation Executives program.

The connecting lines among the programs are now illustrated in the AICC Pathways to Success diagram on page 39.

The Management Group, inserted between ELs and the advisory groups, helps midcareer pros “learn how to manage people and resources,” says

Rendon. “It doesn’t matter what type of management role you’re in or how long you’ve been in it.”

She adds that it’s a strong transition for EL graduates looking for “the next challenge” in career growth, educational opportunities, and peer networking that produces actual tips and practices they can implement in their own workplaces.

“It offers a place to go in the middle part of their career,” she says. “They’re ready for their next role. They’re not newbies in the industry anymore. The Management Group is a matured EL group, essentially.”

The Management Group is led by well-known, highly respected industry managers. One portion will target boxmakers, creating a safe space to discuss plans out of earshot of suppliers, while segments on such topics as finance and budgets will be applicable to AICC’s membership roster of box plants and suppliers.

BUSINESS MANAGEMENT IN CORRUGATED PACKAGING

The second new addition to the AICC pathway is the new Business Management in Corrugated Packaging certificate. The 18-month certification track immerses participants in high-level leadership principles, but with a difference: It’s meant for industry professionals who don’t have MBAs but who plan on growing their careers in packaging.

“You’re going to learn about marketing as it relates to packaging, and you’re going to learn about finance as it relates to a box plant,” says Rendon. “All of these have a lens of packaging, and that adds to the value of the program.”

Certificate students choose a concentration, attend an in-person corrugated-focused seminar, and craft a customized slate of courses.

The certificate culminates with a capstone project, presented to a board, that addresses a challenge specific to the industry or the candidate’s company.

“The funds go directly back into the industry—supporting education, developing talent, and strengthening our workforce for the future.”

—Rebecca Rendon, senior manager of education, AICC

“They’re going to come out of that having a strong understanding of not only corrugated but also these MBA fundamentals,” says Rendon.

The third addition to the AICC Pathways to Success is the Next Generation Executives program, suggested by a board member who needed to advance a team member quickly. The group provides executive coaching for industry professionals slated for the C-suite—and as always, with a boxmaking-specific focus.

“It covers all the challenges that would affect a person who is going to lead a company,” says Pyle. Although tailored to box plant members, any AICC member could get value from it, she adds.

Unlike generalized executive coaching programs, Next Generation Executives

connects participants with “people in your industry who know your pain points,” says Rendon.

Next Generation Executives is ideal for future box plant owners and the second-, third-, and fourth-generation businesses paying outside agencies to prepare children, nieces, and nephews to assume leadership.

“Why not create a program that is a benefit to our members? It’s specific to our industry, and it gives them all of the skills they’re going to need when they step into that role.” Rendon says.

The AICC Pathways to Success answers the “never-ending question” discussed among AICC members about how to move the EL program forward and help graduates explore new elements of their leadership styles, says Sobel.

“It’s giving these young professionals some direction and helping them move forward,” he says. “The ELs spent three or four years in the program, but what were they going to do after that? Providing them with these opportunities is big and helps them with direction.”

The focus on the industry and training from experienced corrugated professionals makes AICC’s new programming stand out from other programs such as MBAs, where “you know you’re going to get a great overall business training, but you might not get that training in the corrugated industry,” says Sobel.

The Foundation for Packaging Education will provide scholarships for the Next Generation Executives program and the Business Management in Corrugated Packaging certificate. “It’s a full-circle investment,” says Rendon. “Members and industry leaders contribute to the foundation, and those same members get the opportunity to benefit as recipients. The funds go directly back into the industry—supporting education, developing talent, and strengthening our workforce for the future.

“Placing someone in a peer group is one of the simplest and most effective ways