AHAN PATIL PRATT INSTITUTE PORTFOLIO 2021 - 2024

AHAN PATIL Contact: apatil@pratt.edu +1 (347) 881 2328

Experience

PAYETTE BOSTON, MA

Jun 2023 - Aug 2023

Architectural Design Intern`

Participated in design, interviews & construction administration of healthcare & research facilities, fabrication of study models, mockups & on-site installations.

CES: PRATT SOA BROOKLYN, NY

Research Assistant

Aug 2022 - Jan 2023

Minimal Ruled surfaces research - Hot wire cutting foam using robotic arm

ITL: PRATT INSTITUTE

Research Assistant

BROOKLYN, NY

Sept 2021 - Dec 2022

3D Printing, advanced modeling, ZUND* digital cutting, laser cutting, 3D scanning

RESIDENTIAL LIFE & HOUSING

Resident Advisor

BROOKLYN, NY

Aug 2021 - Jan 2023

Working alongside a team of Res-life student advisors to foster community growth on a floor and building-wide scale.

Education

PRATT INSTITUTE: School of Architecture

B.Arch (NAAB) - Morphology Concentration

ROME Study abroad Spring 2023

BROOKLYN, NY

2019 - 2024

Studying the city’s architectural and cultural history by investigation of the remains of antiquity and Rome’s urban artifacts

Honors

Pratt Institute Dean’s List Fall 2019 - Fall 2022

Museum Archived Project Fall 2022

School Archived Project Spring 2022

1st place: Technics final project Fall 2019

BOMBAY SCOTTISH SCHOOL

Primary + Secondary Education

MUMBAI, INDIA

Skills

Rhinoceros 3D, Adobe suite, Grasshopper, Revit, Autocad, MS Office, Google Suite

Vray, Enscape, Animations, Motion graphics, Studio Photo/videography

Design Media Fabrication

3D printing : FDM/SLA/Ceramics, Digital cutting (ZUND*/ Laser), CNC, Robotics, Foam modeling, Wood working & Vacuumforming.

Languages

Engish, Hindi, Marathi Fluent

Italian Intermediate

RISING STRIATIONS

Academic Project : Spring 2022

Type : Community center for RISE

Location : Far Rockaway, NY

Partner : Eial Rosenstock

Critic: Leonard Leung

POR-OUSE

Academic Project : Fall 2022

Type : Wall architecture research

Location : Phoenix, Arizona

Partner : Rajvir Batra, Victoria Bourghol

Critic: Jonathan Scelsa

ARTIST CO-HOUSING

Academic Project : Fall 2021

Type : Live - work Residences

Location : Bedford-Stuyvesant, NY

Partner : Abby Lo Presti

: Thomas Hanrahan

MORPHOLOGY STUDIES

Critic

Academic studies : 2022 Projects : Telescoping aperture Fractal ruled surface 7 17 27 36

Academic Project : Spring 2022

Type : Community center - RISE

Location : Far Rockaway, NY

Partner : Eial Rosenstock

Critic: Leonard Leung

RISING STRIATIONS

The ever increasing climatic changes affect coastal neighbourhoods like Far Rockaway, NY which stresses the social and economic fabric of the community.

This proposal aims to provide local opportunites for food cultivation, preparation and distribution among other programs to create a self sustaining community. Another layer of education for children has been added in form of the classrooms which can transform into a temporary shelter during a flood.

6

7

8

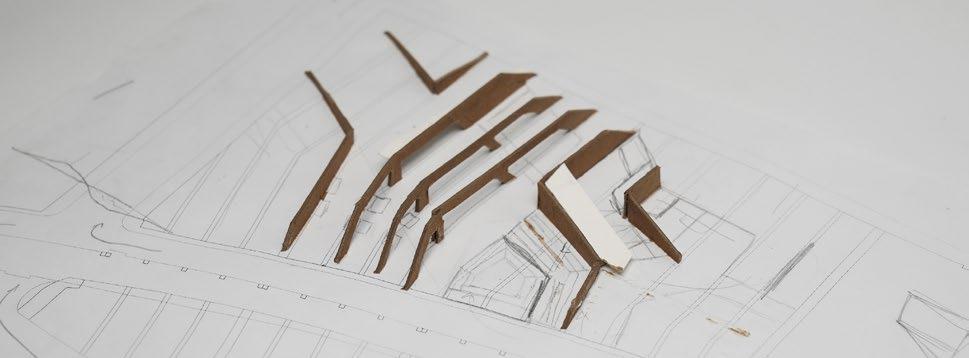

WORKING MODEL 1

WORKING MODEL 2

Load bearing walls rise up from prominent flood directions, Grid extraction along water flow through subway columns

Puncturing walls to create pathways, local markets & bioswale

1’:32”

9

WORKING MODEL 3

FINAL MASSING MODEL

FINAL MASSING MODEL

Non sacrificial programs : greenhouse, restaurant & classrooms

Refining access : ground & upper level

1

3

10

LVL 0:

8

- BEACH GRASS NURSERY

MARKET

- BIOSWALE

- COMMUNAL POOL

1

9 - LOCAL FARMERS

10

11

LVL

- GREENHOUSE

- DINING

2

- KITCHEN

- OPEN CLASSROOM

- ENCLOSED CLASSROOM

- STAFF OFFICE

- BATHROOMS 4 9 11 1 2 3 8 7 7

4

5

6

7

11 10 5 6

Non sacrificial programs : Food production & Educational

Sacrificial programs : Public markets, Gathering spaces and Community

Classrooms transform into temporary shelter while the greenhouse and kitchen

12

Educational spaces are set 15’ above sealevel to avoid flooding Community pools activate the ground level to engage the community kitchen allows the local community to be self sufficient until the flood recedes

13

14

INTERIOR RENDER

EXTERIOR RENDER

MULTIPLE ACCESS POINTS

DEPLOYABLE SHELTER

15 SECTIONAL CHUNK MODEL

: 1/8”

1’

Academic Project : Fall 2022

Type : Wall architecture research

Location : Phoenix, Arizona

Partners : R.Batra, V.Bourghol

Critic: Jonathan Scelsa

POR-OUSE

Clay bricks are one of the oldest building materials used to make highly energy efficient structures due to their heat resistance and non permeability towards pressure and frost.

In this research study - the brick’s form, function and production are all challenged to reimagine traditional masonry construction. The use of robotic 3d printing exploits the fluidity of clay to produce complex geometries serving new programmatic functions to a core building component.

16

17

WALL MOCKUP 3’x3’x3’

WHY CLAY BRICKS

Green state - Earthen clay is malleable and can be shaped into a variety of forms using molds, extruders

When baked - Its solid, dense nature provide strength, durability & sound insulation without warping during extreme climate.

By adapting these properties for robotic extrusionsnew more functional forms can be generated.

TRADITIONAL EXTRUSION

Precise, standardised bricks are extruded at a high production rate making it highly efficient for large scale construction

Limited in form, orthogonal shapes produced as a constraint of the large format extrusion process

ROBOTIC EXTRUSION

Controlled clay extrusion across all 3 axis : enabling complex geometries to be optimised for material conservation and efficient production.

Limited printing speed due to geometric complexities, extrusion flow & drying rate

18

Direct path for Light & Air

Controlled movement of Light & air

WALL PROGRAM - THERMAL REGULATOR

Developing a new form in order to re-program the wall as a thermal mass and air circulation device. Through a mixture of porosity and solid infill the walls exchange heat with air that travels through the lattice. In extreme hot climates this wall system absorbs heat during day and dissipates heat at night.

19

Traditional brick screen wall

Porous brick wall

EXTRACTING SURFACE

MATERIAL THICKNESS

20

BRICK MASSING

BASE GEOMETRY

POROUS BRICK

SOLID

LESS RIGID ORIENTATION

MORE RIGID ORIENTATION MIRRORED AGGREGATE

21

SOLID INFILL BRICK

POROUS + INFILL BRICK MODULE

22

SCREEN BRICK

SOLID INFILL BRICK

ALUMINUM REUSE - INTEGRATED VENTS

GLAZING TEST - VARIABLE SATURATION & LAYERS

VARIABLE WALL THICKNESS

OUTER - 40mm

CENTRAL - 20mm

INNER - 60mm

MORTAR JOINT

CLAY CORE

POROUS CAVITIES

LOCAL SAND INFILL

Poruous cavities open into the interior acting as a vent to bring in air

Deep footing into the ground promotes geothermal heating and cooling within desert conditions

23

SECTION - PRIMARY WALL SYSTEM

24

PROTOTYPICAL HOUSE - INTERIOR RENDER

25

ALUMINUM REUSE - ROOF ASSEMBLY

Academic Project : Fall 2021

Type : Live - work Residences

Location : Bedford-Stuyvesant, NY

Partner : Abby Lo Presti

Critic: Thomas Hanrahan

ARTIST CO- HOUSING

Located in Bedford Stuyvesant there is a significant increase in artists moving to this neighbourhood to form their own niche communities and collaborate together

Moving towards a post familial organisation, this project aims to bring focus towards younger creatives who benefit from surrounding themselves with like minded people and integrated studio spaces for those moments of spontanous creativity

26

28

29

MICRO-COMMUNITY LAYOUT

3 Micro-communities on 2 floors each = 6 floors of residential units and co-working studios

Each micro-community has studio spaces dedicated towards a particular category of artist

Live unit specifications: 550 sqft 2 bedrooms, 1 bathroom

3 layouts of live units are arranged systematically to create a variety of residual space which becomes the co-working studios

Co-working studios provide open double height spaces for a collaborative experience. While more intimate meeting rooms allow for more focused tasks

30

31

LOWER LEVEL UPPER LEVEL

UNIT

32

PLAN: LAYOUT 1/3

WALL TYPES : WINDOW, EXTERIOR, INTERIOR

STRUCTURAL COLUMN GRID

33

+ HVAC

MEP

SYSTEMS

Micro communities have their own studio spaces programmed towards serving the specific type of work each community enagages in

Balconies on upper floors overlook into larger studio work space inspiring collaboration while providing privacy for more focused work upstairs

34

Located on busy Myrtle Ave, the facade brings light in through operable fins, providing users with privacy from the street and spectacular views

Rooftop terrace creates opportunity for artists to relax and unwind among nature

35

Academic Project : Spring 2022

Type : Forms in space : Research

Critic : David Burke & Kyle Day

TELESCOPIC APERTURE

Experimenting with a variety of forms to build a collapsable screen. Hexagonal shape allows for an even split of blades and swivels into an acute angle. The flexible strip between 2 arms uses the bending moment to hold them into position once set into motion by user.

Using gears to actuate the blade provides even movement and allows one hex to be interconnected within an arrayed screen

36

37

SCREEN DEPLOYED CLOSED SCREEN STOWED

ACTUATION MECHANISM OPEN

AGGREGATED SCREEN

Academic Research: Fall 22’ - Spring 24’

Type : Ruled surfaces research

Project Partner : Tyler Haas

Production Consultant : Greg Sheward

Research faculty : Haresh Lalvani

FRACTAL RULED SURFACES

Robotically wire-cut 3D curved surfaces are ruled surfaces which mimic minimal surfaces. The latter use least material to cover space and are also stronger, permitting large areas to be covered with less material. Developing a class of corrugated ruled surfaces and extend these to fractal ruled surfaces as part an ongoing research on hypersufaces

Examples of wire-cut hex saddle modules are shown which, combined with related modules, can be configured in periodic and non-periodic spatial configurations as one of many architectonic possibilities.

38

39

40

41

1/6th Hex - FRONT VIEW

1/6th Hex - FRONT VIEW

1/6th Hex - SIDE VIEW

1/6th Hex - SIDE VIEW

STRAIGHT PROFILE - FULL Hex - FRONT VIEW

CONCAVE PROFILE - FULL Hex - FRONT VIEW

ROBOTIC CUTTING PROCESS

- Selected profiles for ruled surfaces are modeled in Rhino + Grasshopper

- G-code is produced for robots software

- Cuts are performed in sequence of: Top surface, 4 sides, Bottom surface to release module from foam stock

- White bead EPS foam stock is put into place on a custom jig to extract multiple shells of the 1/6th module

2’ Tall blocks of White foam produce 6 - 12 modules - depending on scale and orientation

6 modules = 1 full hex

42

ROBOT CUTTING ACTION

1/6th HEX MODULE

RELEASED FROM BLOCK

43

1 3 2

1 - TOP SURFACE CUT

1 - LIFT

CUSTOM JIG - OPTIMISED PROTOTYPING MINIMAL SURFACE AGGREGATION

2 - ADD 3” PLATE 3 - EXTRACT

2 - SIDE CUTS

3 - BOTTOM CUT

44

RULING EDGE - 32 FRACTAL HEX

CLOSE UP - 32 FRACTAL HEX

FRONT VIEW - 32 FRACTAL HEX

45

INTERIOR PERSPECTIVE - PAVILION

LUMINOUS WALL CONSTRUCTION STUDY

CROSS RIBBED FULL HEX - PAVILION ARCHITYPE EXPLORATION

Linked in Mail apatil@pratt.edu Ahan Patil