2025 AGRONOMY PLOT RESULTS

The 2025 growing season in the Dakotas was exceptional. Record high rainfall at the Bath Research & Technology plot and continuous rainfall later in the growing season led to many record yields.

Several manufacturers brought us new options to trial in crop protection, pest management, plant performance and stress reduction. The amount of new biological products slowed slightly this year, but bioactive extracts of biological compounds, boosters of soil energy, and enzymes has been a rapidly growing market. We continue to sort through these products and find those that have excellent results in our local crops.

At Agtegra Cooperative, we strive to partner with our farmers to bring new technologies and innovations to the farm and we strive to provide clarity and direction toward best agronomic recommendations. Even with record yields, margins are tight, so evaluating and maximizing the Return On Investment (ROI) for each agronomic input remains critical.

Our Bath, SD plots are a robust testing ground for these products. We utilize a large, strip-scale field environment to test and demonstrate products. Most plots are eight rows wide and long enough to get a solid feel for the agronomics of the products tested, allowing us to take good field notes and provide a yield dataset at season’s end.

The following pages provide convenient access to results from our individual plot studies. Please browse through to find the products and practices that can help you achieve your yield goals, simplify your inputs and workload or simply improve the ROI on your acres. If you find a product that looks appealing and you would like to try it on your farm, please contact your local sales agronomist. On-farm testing is the ultimate proving ground and I encourage you to dedicate a portion of your farm for your own testing!

Lastly, we have a fantastic on-farm trial analysis program called MZB Analytics. This data provides tremendous decision-making power! If you are interested in testing products and gaining ROI by management zone, visit with your local Agtegra agronomist to set up a test on your farm!

Brad Ruden Agronomy Tech Services Manager

The Agtegra Research and Technology Plots are located at the Bath, SD Agtegra location in Brown County, SD in the James River Valley on level prairie soils. All plots at the location are set up as largescale strip trials, generally using 8-row treatments and a plot length varying from 350-430 feet. Variability across each plot has been extensively studied, and each plot is designed to minimize that variability. Data is not replicated, but the large plot size and attention to soil variability management has resulted in consistent data when compared to replicated plots on the same site.

For the purpose of this data summary, we set the corn commodity price at $4.00 per bushel and soybean commodity price at $10.00 per bushel. We used these values wherever “gross return per acre” is calculated for each of the treatments.

Specific prices for treatments and additional charges, like application costs, are generally not shown as pricing is a dynamic function and can change significantly over time. The purpose of the data summary is not to establish a price quote but rather to compare treatments on a gross return per treatment basis.

All treatment yields were calculated on a consistent moisture basis. Test weight and bu/ac were standardized to 15.5% moisture for corn and 13.5% moisture for soybeans.

Corn Plots: All corn plots except the corn rootworm insecticides plot were planted with Dekalb® DKC095-57 VT4Pro™ RIB Complete or Dekalb® DKC101-33 SmartStax® PRO® RIB Complete® at 34,000 seeds per acre in 30-inch rows.

The corn rootworm plot was planted with Dekalb® DKC44-98RIB VT Double Pro® RIB Complete and Dekalb® DKC44-97RIB SmartStax® RIB Complete, with all treatments planted at 34,000 seeds per acre.

Soybean Plots: All soybean plots were planted with Asgrow® AG14XF4 variety, planted at 140,000 seeds per acre in 30-inch rows.

The Aberdeen area had an abnormally dry Fall 2024, which carried through to Spring 2025. Although moderate rainfall was received mid-April 2025, the planting conditions for corn were quite dry. After planting, Aberdeen began to receive good rainfall and far exceeded averages throughout the season.

Starter Fertilizer: Unless noted in the specific plot trial, ARx A7-23 liquid starter fertilizer was applied in-furrow at a rate of 5 gal/ac for corn plots and 3 gal/ac + 2 gal/ac water for soybeans. The starter was applied in-furrow with standard application tubes.

Dry Fertilizer:

• All plots were soil tested in Fall of 2024.

• Phosphorus and potassium: All plots received enhanced fertility levels in 2025, including 250 lbs. MESZ (12-40-0-10S-0.5 Zn) and 100 lbs. potash fertilizer as a base treatment.

• Nitrogen: Nitrogen was applied to all corn trials using Urea treated with RemaiN® nitrogen stabilizer (NBPT), with the exception of the nitrogen stabilizers trial. Total available nitrogen was fertilized to a 250 bu/ac yield goal, fertilizing to 225 units/ac available nitrogen, with corn nitrogen efficiency assumed at 0.9 lb/bu.

Corn production remains focused on maximum yield and maximum ROI. High yields are the result of an intentional, complete series of production decisions, including using key inputs. New emerging foliar diseases, like tar spot, change input needs and our management practices.

Based on our corn production trials, here are Agtegra’s best recommendations of products that produced maximum yields and ROI.

1. Start with a diverse group of proven, high-yielding hybrids for your area. Use the Agtegra variety plot data and consult with your local agronomist for proper hybrid selection.

2. Be sure to include the insecticide traits needed for best agronomic performance in your geography, and consider the need for an in-furrow insecticide to boost performance if corn rootworm pressure is severe. Performance of in-furrow insecticides, even in the lack of heavy rootworm pressure, was significant.

3. Fertilize for your yield goal! Maximum yield takes proper nutrition.

4. Add nutrient availability additives like RemaiN® to nitrogen fertilizer to reduce nitrogen losses from volatility. Consider losses to below-ground nitrogen as well, and treat as needed. Consider treating phosphates, both dry and liquid, to increase and maintain phosphate availability for the crop.

5. Use a high-quality talc/graphite seed fluency product like Stride Bio™ that contains nutrients needed for germination, as well as a proven bio-booster to improve seedling vigor and emergence.

6. At planting, use a high-quality starter fertilizer with added macro- and micronutrients, like ARx A7-23 or ARx 8-20

7. In the starter tank, add ARx Sync™ to boost root growth and ensure starter nutrients remain available for the growing seedlings.

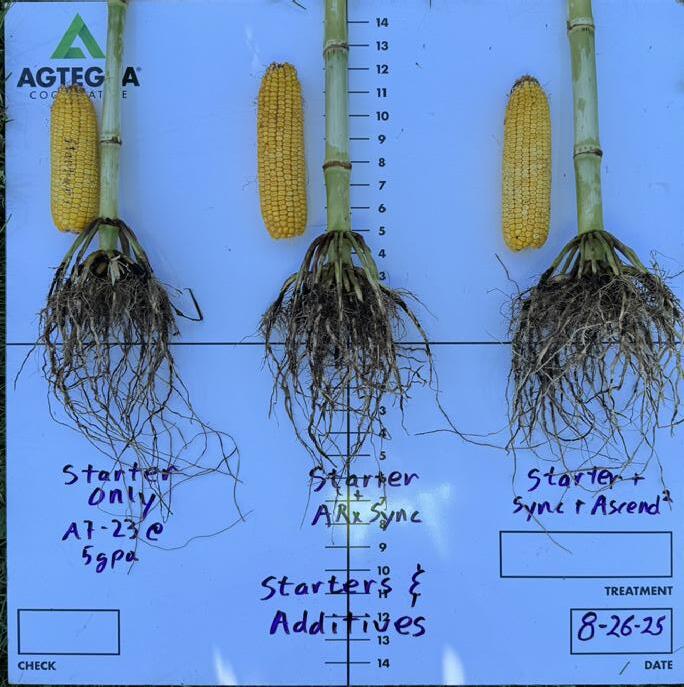

8. PGRs like Ascend2 improve emergence and uniformity, promote robust root systems, and ensure rapid shoot and leaf growth, setting the plant up for maximum growth, nutrient uptake and, ultimately, yield. ARx Sync and Ascend2 are recommended together.

9. Consider a multi-nutrient biological product like Foster™ FC in the starter. These products help release nutrients bound in the soil and make them available season-long.

10. Apply fungicides and foliar nutrition like ARx N-sorB™ or ARx N-fuZe™ and micronutrients like ARx MicroSul™ to the crop to maintain and boost yield. Follow the environmental conditions and tissue testing to dictate need throughout the season.

11. Consider using a foliar fungicide at VT (tassel), like Delaro® 325 SC or Delaro® Pro. Controlling new diseases like tar spot will be critical.

12. Lastly, consider the new class of stress-reduction products, which can be applied in-furrow or foliar with herbicide or fungicide applications. Recent data looks promising for the benefits these products can provide in maintaining aggressive growth focused on yield.

Continuing the trend of recent years, maximum yield and gross return per acre were obtained with a complete system approach in our 2025 production systems trial. There is significant interaction among the components to a maximum yield program, but the bottom line remains that no single input can maximize a program for corn production; a planned system of inputs is needed.

Hybrids that are in the 95-101-day range of maturity are extremely responsive to tassel timing fungicide applications. The addition of Delaro® 325 SC + foliar nitrogen and nutrients provided the single largest gain in gross revenue when added as a single component, while removing it from a complete program of inputs resulted in the single largest loss in revenue.

Following the general trend of recent years, the need for V5 fungicide applications has diminished. Yield responses were minimal in 2025, barely paying for the fungicide cost. In high-residue, corn-on-corn, high-stress or highly-managed fields, there is still a good fungicide opportunity at V5.

Managing nitrogen losses remains a critical management factor. The second-largest single component gain in yield was from treating urea with RemaiN® nitrogen stabilizer. As in previous years, early vigorous stand establishment with additives like ARx Sync™ and Ascend2 was a key input, while Stride Bio™ proved to be an excellent investment. Plants emerged much more evenly and developed an early, robust root system prior to the later summer stresses. Continued moisture throughout the 2025 season resulted in good, season-long nutrient availability, and added biologicals like Foster™ helped keep the nutrient mineralization active all season long.

Removing any single input caused a reduction in gross and net return per acre. Adding each single input to a basic production system raised yield, but often less than the removal of the component from full programs. This leads to significant interactions among inputs and the continued proven value of the systems approach to corn production.

Protegam YLD/ ARx MicroSul

Protegam YLD/ ARx MicroSul

Protegam YLD/ ARx MicroSul

Protegam YLD/ ARx MicroSul Protegam YLD/ ARx MicroSul Protegam YLD/ ARx MicroSul

The 2025 season never really experienced drought, with subsoil remaining very wet for an extended period of time. All forms of nitrogen loss were experienced at the plots in 2025: nitrogen loss through volatilization, leaching, or denitrification.

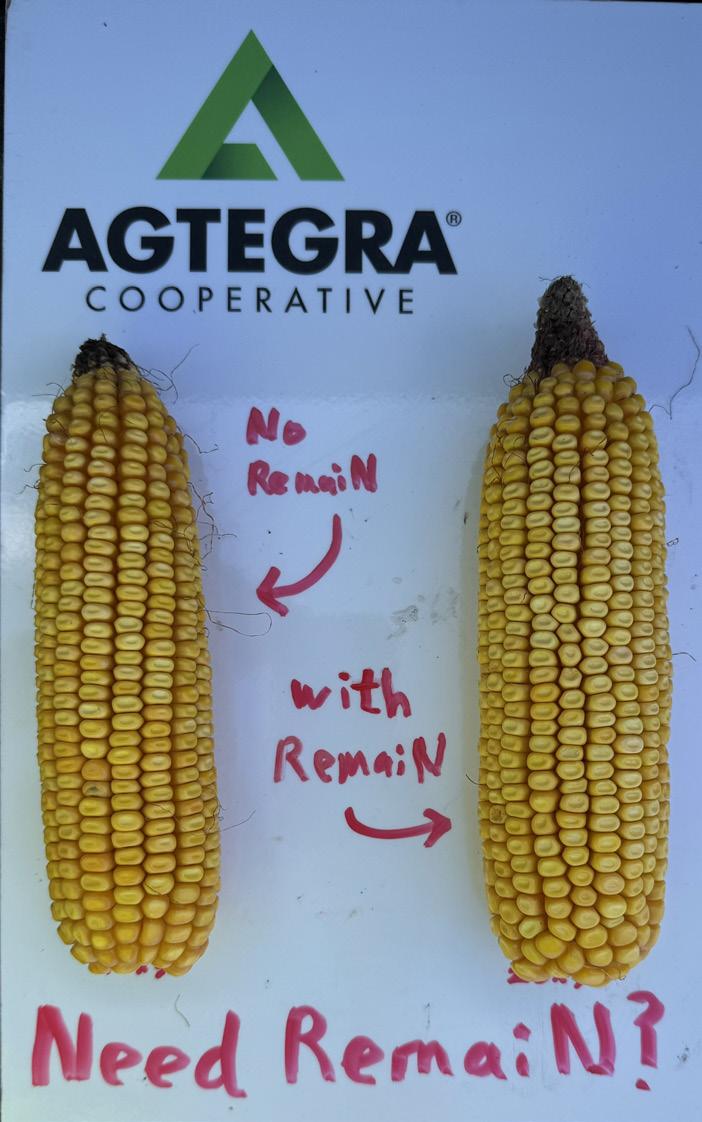

Agtegra has a proprietary NBPT nitrogen stabilizer product called RemaiN® that, when applied to urea before crop emergence, resulted in a 10.15 bu/ac gain compared to untreated urea. With corn value set at $4.00/bu, RemaiN® provided a $40.60/ac average increase in gross income, a very positive ROI.

The nine-year average yield gain to RemaiN® treated urea, including 22 research trials, shows average gains of 13 bu/acre versus applying urea without a treatment.

RemaiN Best Management Practices | Cutting the rate of RemaiN® in half reduced yield by 8.25 bu/ac compared to using the full rate. This results in $33.00/ac in lost gross revenue, easily outpacing the minimal savings in application cost per acre. Use RemaiN® at its full labeled rate of 64 oz/ton for urea, or 32 oz/liquid ton UAN.

Something NEW! A novel application method for DCD looks promising | Reducing below-ground nitrogen losses with an application of dicyaniamide (DCD) is a rate-dependent process. Surface application of Function™ (liquid DCD) at 32 oz/ac, along with the pre-emergence herbicide, proved to be a good agronomic performer. Yield gains of 10.63 bu/ac were seen using Function™ with herbicide, followed by an application of RemaiN®-treated urea. This method looks very promising and deserves wide-scale testing next season.

When applying a nitrogen stabilizer to dry urea on corn

Urea treated with 2 qts/ton RemaiN

Untreated urea

Nine-year average compares corn yields from 2017-2025 across 22 trials. Dry urea was treated with 2 qts/ton of RemaiN before surface application in Spring at planting +/- one week. Yields standardized to 14.5% moisture.

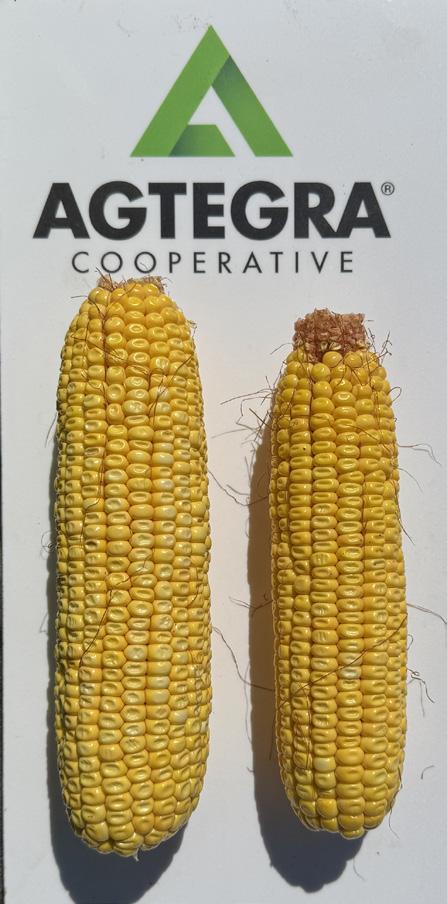

The left image shows corn treated with RemaiN versus untreated. The middle image shows the same treatment, with the untreated cob being smaller than the larger, treated cob. Images taken at the Bath plots.

Yellowing and burning that extends down the center of the leaf starting from the tip is indicative of a classic nitrogen deficiency.

Splitting up a nitrogen application program for corn and applying a portion of the nitrogen preemerge, followed by applying the remaining nitrogen post-emerge through top dress at around the V5 growth stage, showed a positive yield response.

Split nitrogen application offers several potential advantages for farmers and the environment, including:

• Enhanced Nutrient Use Efficiency: Applying nitrogen more closely to crop uptake patterns helps plants utilize nitrogen more effectively.

• Volatility and Leaching: Potential reduction in the amount of nitrogen that can be lost through volatility or leaching.

• Reduced Denitrification Potential: By reducing excess nitrate accumulation, split application of nitrogen can decrease the conditions favorable for nitrous oxide production during denitrification, which happens in saturated soils.

• Improved Crop Yields and Quality: Optimizing nitrogen availability leads to better crop growth, sustained yields, and improved quality.

• Topdressing: Applying urea at V5 allows growers to get partially into the season and adjust nitrogen loads based on changes to yield goals.

At our plots at Bath, we tested splitting the nitrogen application using urea as the nitrogen source. 70% of the total nitrogen fertilizer recommendation was applied pre-emergence, and the remaining 30% was top-dressed at the V5 growth stage. Simply splitting the nitrogen application with untreated urea resulted in marginal gains of around 6 bu/ac compared to untreated urea applied all in one application.

As expected, using a nitrogen stabilizer like RemaiN® on both applications resulted in a substantial gain in yield compared to untreated urea. The gain to the added nitrogen stabilizer was lower with the split nitrogen timing (around 7 bu/ac) than when urea was applied in a single application pre-emergence (10 bu/ac). This hints at improved efficiency of the split nitrogen program, but the difference in yield in 2025 between single application and split nitrogen may not have proved to be economical when the added application cost for the split application program is considered.

UAN Nitrogen as Herbicide Carrier: Best Management Practices | UAN (28-00-00) can be used as the herbicide carrier along with corn pre-emergence or burndown herbicides. UAN has several advantages, like keeping atrazinecontaining herbicides from sticking to the spray tank, as compared to a water carrier alone. In addition, applying 20 gal/ac UAN provides around 60 pounds of nitrogen to the soil, reducing the demand placed on the urea nitrogen application.

UAN used in the herbicide application pass is still susceptible to nitrogen loss from volatility or leaching. UAN can be treated with RemaiN® nitrogen stabilizer at an extremely low cost as the treatment only requires 1 qt RemaiN® per ton of UAN (1 qt/187 gallons UAN).

Yield data from the plots showed that 5.46 bu/ac yield was lost when this early UAN was left untreated, even if the remaining nitrogen (as urea applied at top-dressing timing) was treated. This is an excellent ROI.

ALL PLOTS:

• Spring applied 250# MESZ, 100# Potash

• 5 GPA A7-23 Starter + ARx Sync

• Fertilized to 225# total nitrogen/ac

• 320 lb/ac urea total

ALL PLOTS:

• Spring applied 250# MESZ, 100# Potash

• 5 GPA A7-23 Starter + ARx Sync

• Fertilized to 225# total nitrogen/ac

• Equal nitrogen to 320 lb/ac urea total

Starter alone provides a tremendous boost to corn development, helping establish sound, strong plants. The 2025 results continue to show value, even in a wetter year. A solid starter fertilizer program with additives improves stand and promotes rapid, even emergence, which is the key to maximum yields.

ARx Sync™ is a proprietary organic acid additive that assists in nutrient availability, plant vigor and nutrient transport. We recommend ARx Sync™ on every acre! The ROI for this product remains very solid.

Biological Additives can increase general nutrient availability and uptake, especially focusing on phosphorus availability.

• Foster® FC was a was a solid performer again in 2025 and is our recommended product in this category. Foster increases general nutrient availability throughout the season, including a strong emphasis on phosphate availability.

• Products specific to phosphate availability, including Zume® and a new product called PHOSFORCE ™, looked visually solid in the field and performed well in other plots. Wet soils in the two enzyme treatments limited yield in this starter plot in 2025. PHOSFORCE is potentially a longer-acting enzyme and may have utility in phosphorus management programs.

Plant Growth Regulators (PGRs), such as Ascend2™, provide a three-pronged boost to plants: root, shoot and leaf growth. Improvement in plant vigor is definite, and the PGR helps build up the entire plant, which showed a yield benefit and improved ROI. Cygin™ Pro was also a solid performer.

Treatment Results and Best Practice

Recommendations:

• ARx starter fertilizers are the base for solid performance. Adding a starter to corn every year is a must-have best management practice in the Northern Plains. Early-season photos show the added effects.

• ARx Sync™ added to starter should be the first additive. ARx Sync™ provides a base program assuring maximum availability of the starter fertilizer. This is a must on every single acre.

• ARx Sync™ + PGR is the perfect way to stack technologies. ARx Sync™ and Ascend2™ added to starter was a top performing program. Synergy between the components was consistent.

• ARx Sync™ + Biological + PGR is also beneficial. ARx Sync™ + Foster + Ascend2™ appeared to have an additive effect.

As corn hybrids continue to stretch yields to higher levels, there is a concurrent increase in plant mass per acre produced. The corn residue is amazingly persistent due to new traits and improved stalk strength. Crop nutrition that is tied up in the corn residue is a valuable fertility resource that can go untapped in the soybean crop that generally follows a corn crop. We know that corn residue contains a significant amount of crop nutrients, especially potassium.

Soybeans are a hungry crop, and releasing the tied-up nutrients in the current corn residue is proven to increase soil test nutrient levels and soybean yield the following season.

Soil samples were taken from this plot at the beginning of the season and again at the end of August after residue breakdown. Soybeans used up any additional nitrogen, so no additional nitrogen was found. However, soil potassium levels increased over 80 points on the soil test, and available Olsen-test phosphate levels were significantly raised. Potassium is a critical nutrient for overall nutrient transport in the soybean crop, especially for water balance and nutrient flow for seed fill in the soybean crop.

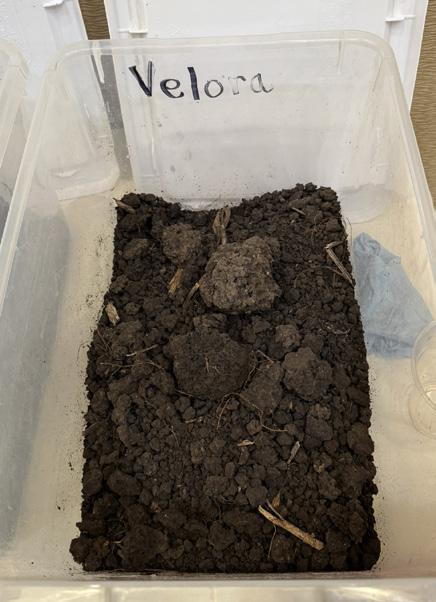

The most striking result from the plots was the effect found on the structure of the soil in treated versus untreated plots. The soil from treated plots had greatly improved texture and crumbled easily. Soil in untreated plots remained bulky and blocky. Improved soil structure means improved biological activity, water holding and water movement capabilities of the soil, resulting in positive effects on plant growth and yield.

Residue management products have low use rates, low cost, no unpleasant odor, and good flowability and mixing. Products can be applied in the fall along with a burndown or fall residual herbicide, such as Valor®. Residue managers can also be applied in the early spring, but fall-applied showed the greatest increase in yield.

Agtegra Research & Technology plot intern Erin Jacobson stands in an untreated plot (left) versus a treated plot (right), showing the height difference between the two sections, a result of the increased nutrients available.

All residue collected from 4 ft. of row length between adjacent corn rows. Residue dried in a plastic tub for two days.

63% dry matter back to the

When applying Velora ® to corn residue ahead of soybean planting

Fall-treated Velora + UAN

Spring-treated Velora + UAN

Velora applied at 12.8 oz/ac with 3 gal/ac UAN. Data from 2025 Agtegra Research & Technology plot in Aberdeen, SD. Untreated yielded 67.76 bu/ac, spring-treated 69.95 bu/ac and fall-treated 72.69 bu/ac.

Untreated residue Residue treated with Velora biological Residue treated with Velora and UAN

Untreated K available Velora Fall-applied K available Velora Spring-applied K available

K: Potassium 250# MESZ and 100# potash per acre pre-plant. AG14XF4 planted at 140,000 seeds/acre.

soil Soil treated with Velora biological

We continue to look at this segment of the crop protection and crop growth additives market. We evaluate products and find those that meet the standard we have for performance.

Foster® FC biological and other multi-component biologicals that have activity on nutrient availability and are applied in-furrow with starter fertilizer, or even on seed, meet this standard.

Another segment of the market, namely nitrogen-fixing biologicals, has provided some interesting and varying results in our plot data. To date, these products have not met our standards for broad-based recommendation to our growers. The concept of biological nitrogen fixation is solid, but proper management of this category of biologicals is critical to obtain consistent results.

In 2025, we upped our yield goal for the Research & Technology Plots. Nitrogen was applied to test plots to provide 225# total nitrogen for the growing crop — this represented our “100% nitrogen” plots. We reduced this total nitrogen load to 180# available nitrogen per acre for the “80% nitrogen” plots. Biologicals were applied according to label, either in starter fertilizer or foliar at the V4 growth stage.

Nitrogen-fixing biological products provide application headaches. In-furrow biologicals in this category have a short lifespan in starter fertilizers, especially compared to the more broad-spectrum biologicals we tested in the Starters & Additives trials. Foliar application may overcome some of the application issues, allowing applications with an herbicide mix, which is a much more biological-friendly carrier.

We have tested several nitrogen-fixing products for three years now and have had some varying results, especially in 2023. The 2024 and 2025 results were similar:

• In 2023, highest yield gains were only seen in the plots where 100% nitrogen fertilizer was applied, followed by a biological at V4. The reduced nitrogen rate plots did not provide significant yield gains from any biological treatment.

• In 2024, the nitrogen-fixing foliar-applied biologicals, including Envita® WG, Utrisha® N, or Maneuver® (which combines Foster® FC biological consortium plus a nitrogen-fixing component), provided solid yield gains when applied to the 80% nitrogen rate plots, with yields essentially equaling the 100% nitrogen plot without any biologicals.

• Biologicals were able to “cover” a 20% reduction in applied nitrogen this year

• Yields may be capped with 80% nitrogen as the upside beyond the 100% nitrogen rate is not seen

Differences in nitrogen volatility after planting may have skewed those two years of data. We experienced extreme nitrogen loss from volatility in 2023, which may have affected the 80% nitrogen plot to the point where biological could not make up the lost nitrogen. In 2024, nitrogen losses after planting were less significant, and good yield gains with the nitrogen biologicals at 80% nitrogen rates were seen.

In 2025, foliar application of Envita® Dry, Utrisha® N, or an in-furrow application Maneuver® to plots with 80% of the full rate of nitrogen, resulted in final yields equal to or exceeding the 100% nitrogen rate check. Maneuver® looks particularly good, but it must be noted that it is a combination product containing a multi-component biological plus a nitrogen-fixing component, as compared to the other “nitrogen-only” products. The application of Source® provided a positive yield gain compared to the 80% nitrogen check, but not equal to the level of the 100% nitrogen rate check.

Although 80% nitrogen rate plots are impressive, the 100% nitrogen treatments are more so. In the plots with 100% of the applied nitrogen rate, the added biologicals Envita® Dry foliar, Utrisha® N foliar, or Maneuver® in-furrow and PheNom® in-furrow all provided an 8-10 bu/ac gain in yield compared to the 100% nitrogen rate check. These gains are lower than those seen in the 80% nitrogen plot, but the added yield from the 100% nitrogen rate alone and the additional gains from the biologicals indicated that greatest economic gain was attained with a 100% nitrogen fertilizer rate applied plus the added nitrogen-fixing biological. Applying a biological with reduced nitrogen rates appears to be able to reach yield similar to 100% nitrogen, but there is no upside beyond the 100% rate.

Given this data, we make the following recommendations when managing corn with nitrogen-fixing bacteria:

1. Strictly follow the handling guidelines on the labels. These are generally very delicate bacteria, and they DO NOT survive well in starter fertilizers or any solution with high salt, such as UAN carrier. Foliar application at vegetative stages of growth can avoid the harsh carrier issues.

2. We do not believe these products can be relied on consistently to replace any significant amount of applied nitrogen fertilizer. Best management is achieved by using these products as a supplement to a full nitrogen program, supplementing potential high yield environments.

3. The consistent performance of these products is less than we desire. Stability of response is becoming a clearer picture, but there are still many inconsistencies. It is difficult to be comfortable with a broad recommendation.

Highest yields were with full (100%) nitrogen programs, so Gross Return per acre may be higher overall in 100% nitrogen programs.

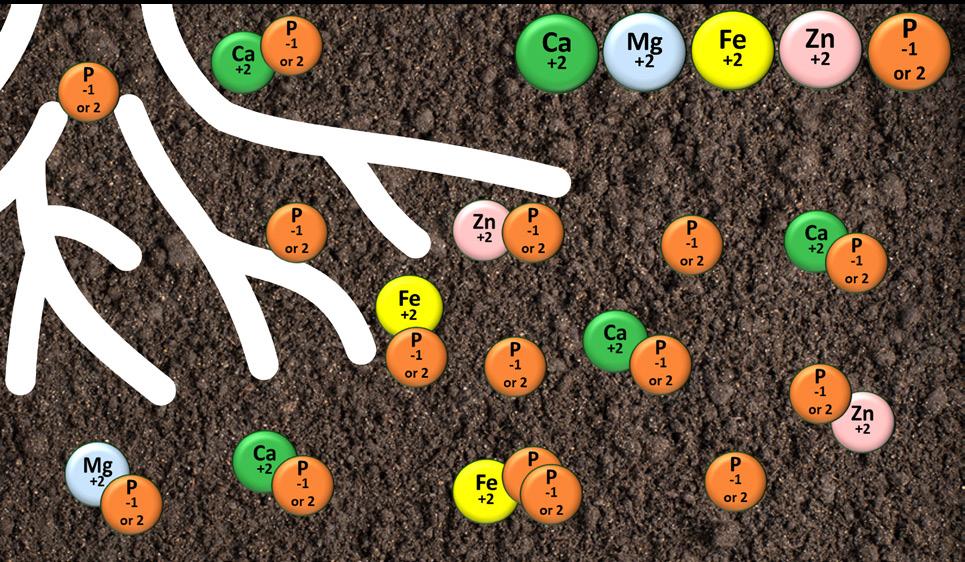

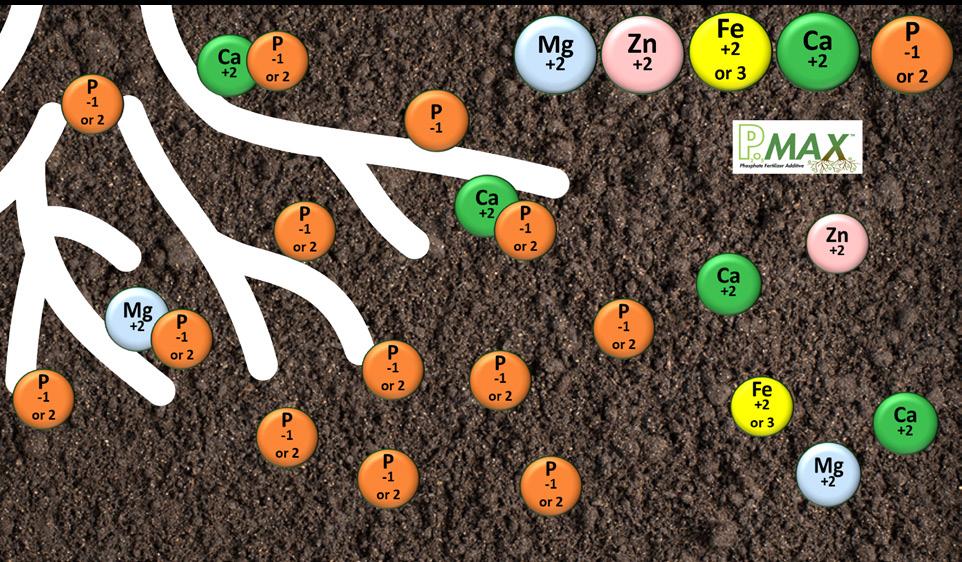

[ PHOSPHATE TIE-UP MANAGEMENT ]

Higher-than-average phosphate prices this past fall caused many to look critically at phosphate fertilizer rates. Phosphate tie-up can reduce the effective nutrient availability of phosphate fertilizers by up to 70%.

Fertilizing soil ahead of the corn production cycle is the minimum management plan. We must also consider that the following soybean crop is phosphate hungry. Reducing phosphate levels below total crop removal is tempting to reduce management costs, but can be detrimental long-term as phosphate recharges the soil slowly and reduces the phosphate “bank account,” transferring the problem to future crops. Instead, consider treating dry phosphate with a phosphate protection product in the fall or spring. Consider adding a product to the starter fertilizer to improve phosphate availability and uptake. Products like P.Max® protect against phosphate tie-up and can also be applied with starter fertilizers. Levesol® DFC also provided a solid yield gain versus untreated phosphate. In liquid starter applications, there are a few options to increase phosphate availability — and they proved effective in the plots. Enzymes added to starter fertilizer can act on releasing tied-up phosphate. The new enzyme product PHOSFORCE™ looked promising this first year of testing, adding greater than 5 bu/ac yield versus untreated. Our lead in-furrow recommendation is Foster®, which provided a greater than 5 bu/ac response.

• P.Max® Ultra-treated dry MESZ versus untreated MESZ (applied to the ground surface as a spring application) resulted in a 6.12 bu/ac gain, or $24.48/ac additional gross revenue.

• Foster® in starter fertilizers resulted in a yield gain of 5.19 bu/ ac over untreated starter for an added value of $20.78 in gross revenue per acre without any added application cost.

Without phosphate additive, much of the applied phosphate is tied up with cations in the soil.

With a phosphate additive like P.Max Ultra, soil cations are attracted to the polymer, freeing up phosphate.

ALL PLOTS:

Fall-applied surface applications with light tillage or spring surface applications; non-incorporated.

MESZ (base) Spring Applied

MESZ + PHOSFORCE Enzyme In-Furrow

MESZ + Foster Biological In-Furrow

• 250# MESZ, 100# Potash, applied spring

• 5 GPA A7-23 Starter + ARx Sync additive • Fertilized to 225# total nitrogen/ac

5 GPA A7-23 A7-23 + ARx Sync (base)

+ Zume (Phosphate Enzyme)

+ PHOSFORCE (Phosphate Enzyme)

+ Foster (Biological)

+ Ion Stryke (Biological)

+ Biopath (Biological)

Adding talc and/or graphite is a standard planter box treatment for nearly every grower. These products are critical to agronomic efficiency by improving seed flow and singulation, are inexpensive, and can positively improve plant stand uniformity.

However, talc and graphite do not provide crop nutrition or provide any bioenhancement product to the seed. Enhanced talc/graphite replacement products can add value to the treatment. These products often contain micro quantities of phosphorus and zinc, which are needed to jumpstart germination. The premium products tested in our plots also proved to enhance germination and seedling vigor, leading to more rapid canopy closure.

Premium treatments like Stride Bio™, our top recommendation, improved plant growth all season, ultimately leading to yield gains. Stride Bio™ provides enhanced nutrition, good seed fluency, and, most importantly, stress reduction through the patented Yield Burst technology. This product showed a 5.47 bu/ac gain versus talc + graphite alone. This is greater than the 4.69 bu/ac gain we saw in 2024. The economic value remains very solid — $21.88 additional gross return per acre.

Strong biological consortia, but must add talc/graphite

Living biological organisms do not survive well in talc and graphite carriers. Certain talc and graphite replacements do use a different, inert biological powder as a carrier. Yield results look very good for a new product in this category, called Dash™ PBC However, the product is used at an extremely low use rate, and there is not generally enough seed fluency from this product alone. This means that added talc/graphite must also be applied, raising costs per acre and adding more handling requirements.

The base biological additive in this form is also quite expensive. Our best recommendation is to add a biological product like Foster® in the starter fertilizer and apply Stride Bio™ as the premium seed enhancement product in the seed hopper. However, if a grower is not using starter fertilizer, adding the biological in the seed fluency additive makes sense as the value of biological treatment is very solid.

Ascend® ST3 is a new PGR that is specifically designed to be applied on seed with seed treatment machinery. It is an auxin-forward formulation and proved to be a solid performer in the plots. Yield enhancement of 4.90 bu/ac, although less than the gain seen in previous years, still provided a solid return on investment. We would recommend adding the Ascend2 PGR in the starter fertilizer for convenience and performance — however, the seed-applied alternative is also effective and provides value when the starter option is not available.

Seed applied products were compared using the Canopeo™ app at the V6 growth stage to visualize the difference in canopy coverage. (Photos are from 2024)

Stride Bio™ is 80/20 talc graphite. It contains Calcium, Magnesium, Sulfur, Iron, Manganese, and Zinc. It also contains stress reducers to upregulate genes for seedling vigor and early growth. $32/ac gross return vs. talc/ graphite alone!

*based on $4 corn 3-year average!

Fungicides provide disease control in corn when applied at either the V5 or VT application windows. These products can also reduce plant stress, especially if applied with a foliar nutritional product.

There is a new set of focused products on the market that are dedicated directly to reducing plant stress from environmental conditions or following herbicide application. These products work to enhance plant metabolism. We tested several products, along with a fungicide and foliar nutritional products, at the V5 and VT growth stages. Results were positive in 2025, showing that these products are certainly worth our attention.

Dedicated stress reduction products from various suppliers were tested. These products are generally naturally derived extracts of seaweed or other organic matter, amino acidcontaining products, dissolved organic matter, or enzymes.

• At the V5 growth stage, when applied with an herbicide, fungicide and foliar nutritional in one pass, all products applied provided a significant boost in growth and yield, with gains of 6-9 bu/ac.

• At the VT application stage, yield gains from application of the products were stunning in 2024, with yield gains as high as 13.5 to nearly 15 bu/ac. In contrast, 2025 yield differences were more in the range of 6-10 bu/ac due to high rainfall amounts.

• It appears that micronutrient and general nutrient deficiencies must be addressed first, then a stress reduction or bioenhancement product, like those tested, can provide the full effect toward enhanced plant growth and development.

Products are seaweed or other organic matter-based products All applications made with Stratego YLD + ARx MicroSul + Laudis Herbicide with ARx Tarex adjuvant

ALL PLOTS:

• 250# MESZ and 100# potash per acre preplant

• Nitrogen: treated urea added to soil test to 225# total availability

• Variety: DKC095-57, planted at 34,000 seeds/ac

Products are amino acids, extracts,

All applications made with Stratego YLD + ARx MicroSul + Laudis Herbicide with ARx Tarex Adjuvant

The trend in our trials has been that premium fungicides at VT, like Delaro® 325 SC or similar, outperform basic fungicides, and VT fungicide response continues to increase, whereas V5 fungicides are maintaining a low level of response.

Early stressors like disease pressure or plant stress at the V5 timing were not present this season; however, mid-season and late-season stress was. Periods of high temperatures were accompanied by adequate moisture and reduced the effects of yield loss. The greatest threat to corn yield happened late in the season when southern rust and tar spot appeared at tassel timing and the following weeks. The diseases affected the highly-responsive corn hybrids, including the Dekalb 10133 hybrid planted in the plot.

Fungicides can provide two distinct actions when applied to the plant:

• Stress reduction: Top-tier products like Delaro® 325 SC or TrivaPro® help the plant reduce water loss, maintain lower canopy temperatures, and maintain positive photosynthesis during periods of high heat.

• Disease control: Whether looking at stalk rot, gray leaf spot, northern corn leaf blight, rust, or tar spot, diseases can be controlled with top-tier fungicides.

V5 Fungicides | The 2025 season was one of the only seasons in recent history where yield gains from V5 fungicides were so minimal that the ROI to the application was neutral or negative due to V5 crop health.

Tassel Fungicides | The presence of southern rust and tar spot at the plot affected the fungicide response to a tassel timing application. In addition, untreated corn leaves rolled during the heat of the day, causing an open canopy that let in more sunlight, resulting in higher canopy temperatures and stressed plants. By adding a fungicide like Delaro® 325 SC plus a foliar feed like ARx N-sorB™, we effectively control crop diseases and help reduce plant stress. Yield gains from VT fungicide + foliar feed in 2025 hit record levels, varying from 17.82 bu/ac gain seen with Delaro® 325 SC up to 29.43 bu/ac with Miravis® Neo

ALL PLOTS:

• 250# MESZ and 100# potash per acre preplant

• Nitrogen: treated urea added to soil test to 225# total n/a

• Variety: DKC101-33, planted at 34,000 seeds/ac

• Nitrogen: treated urea added to soil test to 225# total n/a

• Variety: DKC101-33, planted at 34,000 seeds/ac

The Agtegra featured program: Delaro 325 SC + ARx N-sorB provided a 17.82 bu gain, or $71.28 gross return!

Southern rust and tar spot were found in the plot in 2025, increasing fungicide response significantly!

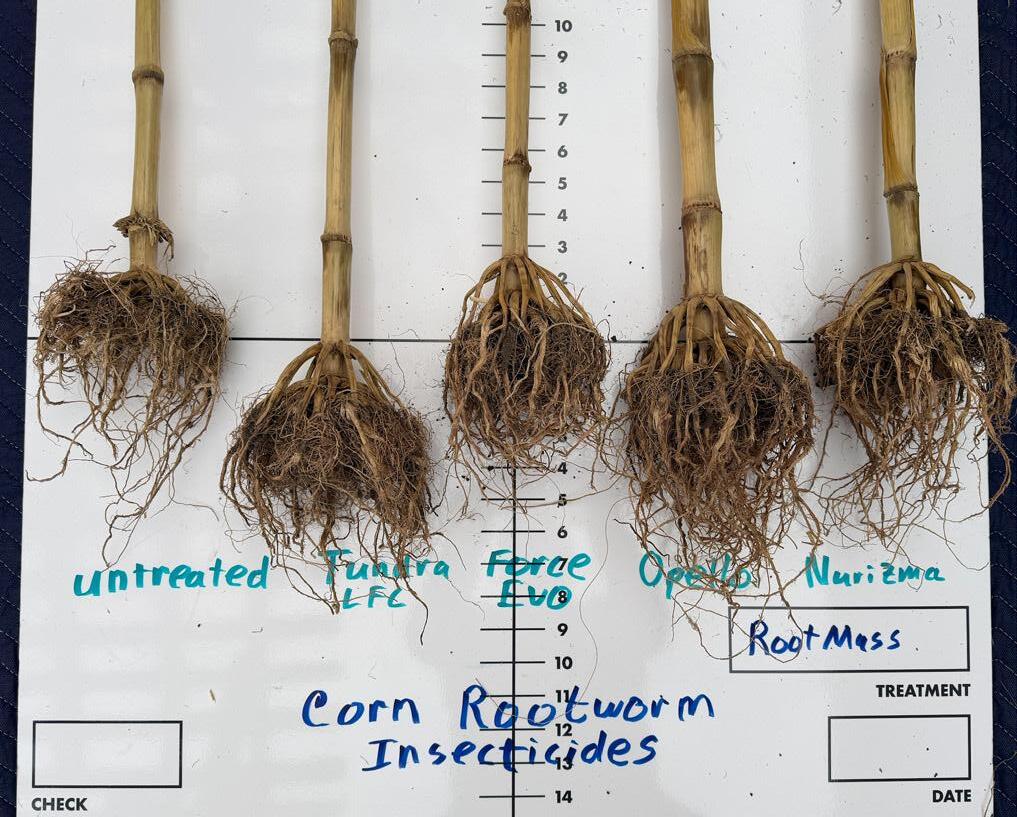

In 2025, corn rootworm pressure was significantly lower compared to 2023 and 2024, but still continues to be a pest in the plots. The prevalence of excellent-yielding and cost-effective Double Pro® corn hybrids has perpetuated beetle populations. SmartStax® hybrids have provided good control, and the new SmartStax® Pro and VT4Pro™ hybrids with RNAi technology provide excellent control. Trait selection remains the number one method to controlling rootworm.

We rotated the corn rootworm trial to a new plot adjacent to the previous plot, which lowered both western and northern rootworm beetle populations. The purpose of this test was to investigate the performance of in-furrow rootworm insecticides under a susceptible corn hybrid on a field with a lower level of rootworm pressure. The insecticide treatments may have had a larger effect on the other non-rootworm pests this year as differences in roots were observed, even without significant rootworm pressure.

• The plot was planted corn-on-corn with a susceptible hybrid planted adjacent to a SmartStax® hybrid with insecticide treatments applied to both hybrids.

• Only moderate rootworm feeding pressure was present in the field. Untreated Double Pro® corn showed a root feeding level of 1.03 on a 0-3 scale (with three meaning near total root feeding), far less than the 2.32 rating seen in previous years.

• Trait selection makes a stark difference in rootworm feeding potential and should be the first management choice to discuss with your agronomist.

• Bifenthrin-containing insecticides, like Tundra® LFC, added to rootworm management and performed well. Per acre, they are the most affordable products.

• Force® Evo performed very well in the plots, providing superior control over the bifenthrin products and winning the plot yield results under both Double Pro® and SmartStax® corn.

• Nurizma™ is a newer insecticide that performed very well in the plot.

• Force® Evo or Nurizma™ require an additional investment in injection technology to apply as these products are not compatible for blending directly into fertilizer and staying in suspension.

• The most promising product was Opello™ (Plinazolin). It’s formulated as a true liquid-in-furrow (LIF) formula and can be directly mixed in starter fertilizers. It is a new mode of action and provided the best overall reduction on total root feeding from all insects.

• Insecticides applied to rootworm-traited corn, like SmartStax® corn, can provide an economic return, but with light pressure, and this return is potentially only with the less expensive insecticide choices. There was not enough economic gain to pay for Force® Evo, Nurizma™, or Opello™ with SmartStax-traited corn.

Rootworm feeding is rated on a 1-3 scale. Each of the three main crowns of roots is rated 0-1 on the percentage of roots eaten off to less than 3/4”, and the overall sum is determined.

ALL PLOTS

Spring applied 250 # MESZ, 100 # Potash 5 GPA A7-23 Starter + Sync RX + Additive Fertilized to 225# total nitrogen/acre

ALL PLOTS

Spring applied 150# MAP, 50# Potash

5 GPA A7-23 Starter + ARx Sync + Additive Fertilized to 200# total nitrogen/ac

Phase I: Laying the Foundation

• Uniform emergence

• Early season vigor

• Root development

• Nitrogen fixation begins at V3

Phase II: Building the Factory

• New trifoliate every 3 - 5 days

• Potential nodes (main stem) at V2

• Lateral buds at V3

• Maximum flowers at V4-V5

• Number of pods at R1 - R3

Phase III: Operating Efficiency

• Managing stress

• Maximizing photosynthesis

• Maximum seeds in pods at R3-R4

• Seed size and pod fill at R5 - R6

• Plant health, stalk strength and even dry down

Maximizing yield in soybeans is more difficult than chasing higher yields in corn. However, maximizing yields is an attainable goal. 2025 was humbling on showing maximum ROI with additional inputs, but the multi-year trend shows the value of these products and the value of refining management strategies.

Soybeans still require a set of foundational agricultural practices to get a solid established crop. Among these are maintaining proper soil pH, soil drainage to prevent saturated soils, excellent weed control, and background crop nutrition specifically applied for the soybean crop.

Soybeans are extremely sensitive to low pH soils and cannot maximize growth or nutrient uptake in acidic soils. Stratified pH in our soils, with a very acidic layer near the surface, may be a hidden yield reducer in soybeans. Correcting low pH is more critical for soybean production than corn production. A few key facts to consider are:

• Apply basic crop nutrition — especially phosphate and potassium — every season. There’s too much potential demand and too much yield to be lost if phosphate becomes yield-limiting. Potassium is critical for maximizing soybean pod fill and yield.

• Work with your local agronomist to choose seed varieties that fit the agronomic profile for yield potential in your area and the trait needs for pest management, especially weed management.

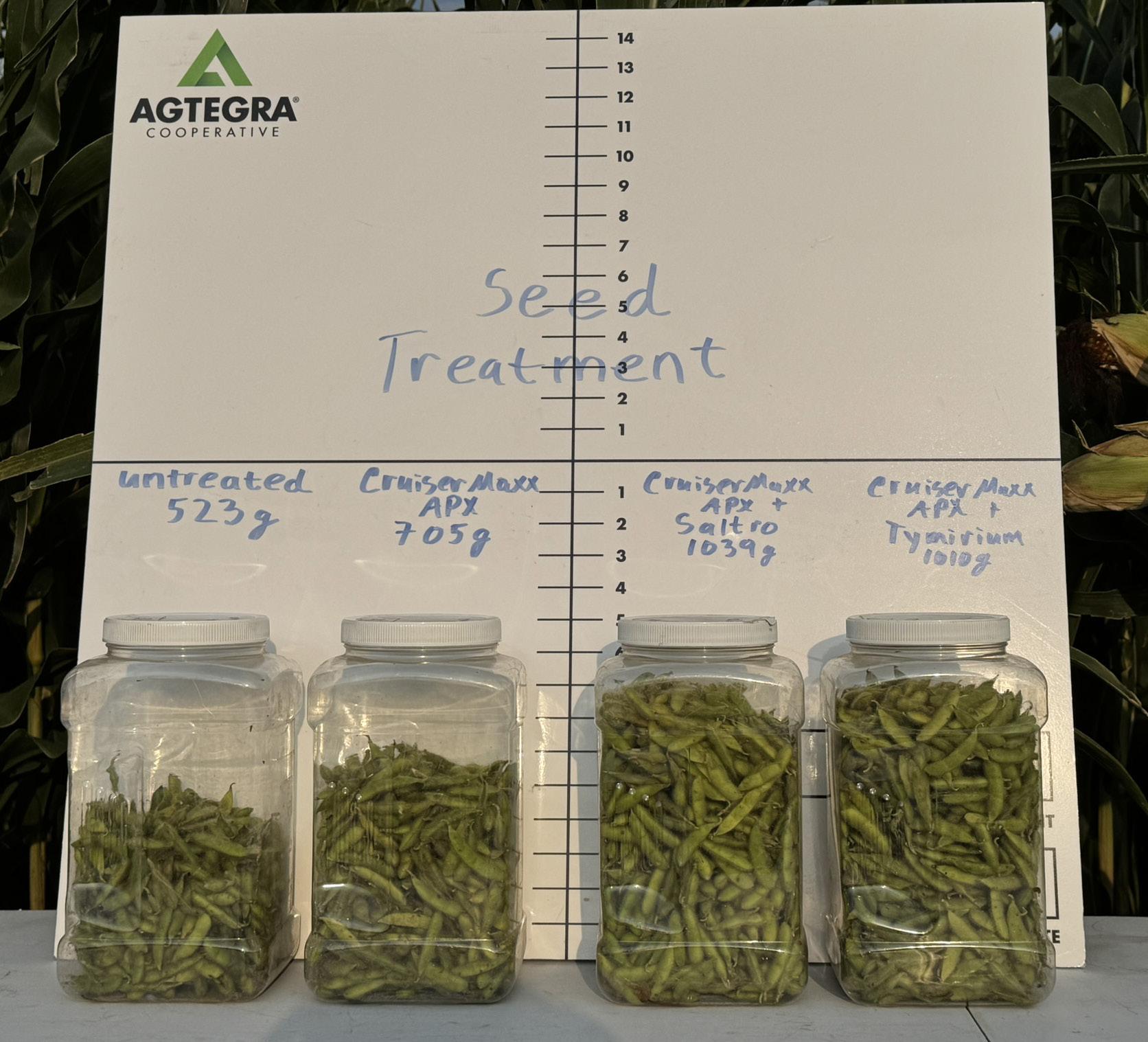

• Seed treatments are the number one crop protection additive to boost soybean yields. Applying a full fungicide and insecticide treatment like CruiserMaxx® APX has shown nearly a 4x ROI for the past 13 seasons running. ROI has never been negative for the treatment in our plots!

• Inoculate every soybean, every year. Use an inoculant like Agtegra’s ARx Vigorate™ to maximize nitrogen fixation.

• Apply a starter fertilizer! One to three gal/ac of ARx A7-23, along with 2-3 gal/ac of water, will help soybean plants get started quickly. Early plant establishment and root development are critical to soybean performance later in the season.

• Apply foliar nutrition like ARx N-sorB™ or ARx N-fuZe™ and micronutrients like ARx MicroSul™ to the crop to maintain and boost yield. Follow the environmental conditions and use tissue testing to dictate need through the season.

• Consider a stress management product or a PGR application. Soybeans are extremely responsive to a foliar application of a PGR, like Ascend® SL.

• Manage white mold. Consider the application of a fungicide for white mold at the R2 and again at the R3-R4 growth stage. Applications of Endura® fungicide have been the gold standard for treatment if white mold pressure is suspected. Fungicides like Delaro® 325 SC or Delaro® Pro can also improve plant health.

• The newest fungicide, Zorina®, looked excellent in the plots.

In 2025, soils were excellent at planting time but became cold and wet before crop emergence, causing significant delays in crop development. After emergence, crop growth was good to excellent through the vegetative stages and into pod set. However, an early, mild September frost event caused the crop to severely cut back on seed and pod fill in the upper canopy, which led to much lower yields than expected.

Overall best management of soybeans involves adding a planned series of inputs to help the crop establish an early, strong stand — and continuing to feed the plant and remove disease pressure to shield the crop from later season plant stress events.

Plant Establishment | Laying the Foundation

• Seed Treatment: In 2025, differences in final stand of more than 10,000 plants per acre were seen between full fungicide and insecticide versus untreated plots.

• Fertility Levels: High-quality liquid starter and additives like ARx Sync™ kept nutrients available to young plants, and was key to early, rapid plant growth.

• Boosting the Plant: Adding a PGR on-seed or in-furrow, plus using a seed-applied fluency agent that has micronutrient and bio booster, improved soybean emergence in 2025. Among the seed-applied talc/graphite fluency agents, the top performer was once again Stride Bio™.

Plant Development | Keeping the Plant “Factory” Productive

• Plant Vigor, Stress and Disease Protection: Improving pod set, or reducing plant stress to retain existing pods, plus adding needed plant nutrition, are the primary goals of a foliar feeding plus stress reduction application. South Dakota does not regularly experience a critical level of foliar diseases in soybeans, but the application of Delaro® 325 SC and ARx N-fuZe™ at the R2-R3 growth stage provided proven excellent pod set and pod retention midseason.

In 2025, we looked great at planting! But then came the rain and cold. Emergence and vigor matter every single year — nothing can replace a poor plant stand, even on a year with good moisture.

Soybean seed treatment with a full fungicide + insecticide treatment has remained a hallmark of highly productive soybeans, and 2025 followed suit with previous years. Soybean planting was a breeze — good soil conditions favored rapid planting progress into dry-to-moist soils.

Then we had hard rain at the Bath plots, accompanied by cold temperatures. Diseases like Pythium and Phytophthora do not disappear year-to-year, and they love moist soils. Phytophthora, especially, likes cool, wet soils, while Rhizoctonia thrives in warmer, moist soils. All these diseases were present in the 2025 plots.

• CruiserMaxx® APX provides proven protection from all of these diseases. It will be our primary offer again for 2026 as it has consistently remained at the top of yield tests.

• At the Bath site, full fungicide and insecticide seed treatment has provided an ROI averaging $40/ac for 14 years running!

• The value and ROI of a full fungicide and insecticide treatment was clear, with excellent yield response (+4.37 bu/ ac) and stand counts improved by 10,000 or more plants per acre vs untreated seed.

• If Sudden Death Syndrome (SDS) or other additional diseases are present, additional fungicides such as Saltro® or the new Victrato® treatment, both from Syngenta, may be added to CruiserMaxx® APX. Yield results look stunning and easily overcome the added cost.

+4.36 bu average gain to full fungicide and insecticide treatment +1.49 bu average gain to fungicide-only treatment

Average gain to full fungicide & insecticide treatment, with ZERO negative ROI, is very consistent year-over-year

Summary of statistics completed using ARM Software (Gylling Data Management) Site data from agronomy trials at Bath, SD location. Planting rate 140,000 seeds/ac. CruiserMaxx Vibrance or APX used for Full F&I

[ EVERY SOYBEAN SEED, EVERY YEAR ]

Soybean inoculants provide active and effective Bradyrhizobium bacteria for fast, efficient nodulation of soybean plants. Inoculant needs to be fresh for peak effectiveness!

Maximum yield in soybeans requires a significant amount of nitrogen for emergence. Fresh inoculant with highly active strains of bacteria provide large, active nodules to feed soybeans. Soybean inoculant remains a solid investment, even with low commodity prices.

Agtegra’s soybean inoculant, ARx Vigorate™ will be available in 2026!

• ARx Vigorate™ showed an incredible four-year average yield gain of 3.38 bu/ac over uninoculated plots. The ROI for ARx Vigorate is stunning.

• We have tested ARx Vigorate™ in our plots alongside our previous standard, Preside® Ultra, for many years. These two products topped our testing each year; however, in a four-year average dataset, ARx Vigorate™ provided a yield gain of 1.03 bu/ac over Preside Ultra®, improving our standard.

• A single-bladder product, ARx Vigorate™ will provide performance and efficiency gains.

• ARx Vigorate™ has shown to produce large nodules that are close to the main stem. These nodules remain active later into the season versus competing products.

Uninoculated ARx Vigorate

Note the number of nodules close to the main root.

R3-stage soybean nodules (active nodule on the left vs. inactive nodule on the right)

[ JUMP START THE

A seed fluency agent with a bio booster, other biostimulants and plant growth regulators may improve seedling vigor, emergence and plant stand uniformity. This is our second year of testing technologies to applied on-seed to boost emergence.

• Plant Growth Regulators (PGRs), when added to seed or starter fertilizers, signal the plant and trigger improved root growth and early plant vigor. The support of cell division, leaf expansion and root formation provides an earlyseason boost.

• Seeds also need micro levels of crop nutrition to initiate germination. Stride Bio™, an enhanced talc/graphite replacement product, provides enhanced nutrition, good seed fluency, and most importantly, stress reduction through the included, patented Yield Burst™ technology.

• Outstanding results were found with Stride Bio™, combined with either Ascend2® or Cygin® Pro PGR.

Note: The two trial sets shown were on neighboring but very different soils this year. The Ascend2® study was wet nearly the entirety of the season and became delayed in growth and maturity as a result. The Cygin Pro half of the study experienced much better soil conditions, resulting in much higher yields. We caution on comparing the PGR products tested against each other. The valid concept in the trial is adding Stride Bio™ and a PGR together on seed to improve early-season plant health.

Seed applied products were compared using the Canopeo™ app at the V6 growth stage to visualize the difference in canopy coverage. (Images were taken in 2024. The 2025 plot was uneven due to flooding damage.)

This trial was water stressed from periodical saturation. Yield was affected as the high moisture delayed the crop, causing it to be more affected by the early September frost. Ascend® ST3 is now available for use in soybean seed treatment and replaces Ascend SL.

This trial was not as affected by flooding as the Ascend SL trial. Yield comparison should not be made between the Cygin Pro and Ascend SL datasets as the soil conditions were significantly different.

Stride Bio™ is 80/20 talc graphite. It contains Calcium, Magnesium, Sulfur, Iron, Manganese, and Zinc. It also contains stress reducers called Yield Burst to up-regulate genes for seedling vigor and early growth.

A planned series of inputs are highly effective at advancing soybean production to higher yield levels. 2025 was a challenging year, but the system of inputs still proved valuable.

Even in times of tight margins, starter fertilizer in soybeans should become standard practice in the Northern Plains. The boost from starters has proven to be key in getting an early boost to soybean development, helping establish sound, strong plants.

• A7-23, with additives, is a premium starter fertilizer that is seed safe; improves stand counts; and promotes rapid, even emergence, which is key to maximum yields.

• ARx Sync™ is an organic acid-based additive that assists in nutrient availability, plant vigor and nutrient transport. We recommend ARx Sync™ on every acre! ROI in four years of testing at the Bath plots has averaged $12 per acre!

• Plant growth regulators (PGRs), such as Ascend2® or Cygin® Pro boost root, shoot, and leaf growth. Soybeans are tremendously responsive to PGRs, with significant improvement to plant vigor. The PGR helps build up the entire plant, which showed a benefit and improved ROI.

• Biological or enzyme additives can increase general nutrient availability and uptake, especially focusing on phosphorus availability in-furrow. Testing on phosphorus-specific enzymes was challenging due to saturated soils at the plot; however, PHOSFORCE™ looks promising. Foster® FC remains our best recommendation from a biological standpoint.

• The effects of each component added in the trials appear to be synergistic. Starter + ARx Sync™ is a base program, but the effect of adding Ascend2® and Foster® FC appears very solid.

Recommendation: Foster® FC is a consistent performer when added to Starter + ARx Sync™

These plots were saturated for extended periods in 2025.

Recommendation:

Fighting off diseases in 2025 was not an issue as foliar diseases did not appear and white mold pressure was low to moderate. High weed pressure meant significant focus was placed on top-end herbicide programs and reducing herbicide stress.

Applying stress reducers at the R1-R2 growth stage maximized pod retention with herbicide applications. Later-season stress reduction was focused on pod fill.

R1-R2 Stress Reduction Additives | Soybeans responded to a foliar feeding and stress-reduction program when applied at the R1to early-R2 growth stage. Micronutrient deficiencies are important to address at flowering. Applying basic fungicides like Protegam® YLD or Aframe™ Plus, or even a top-tier fungicide like Delaro® 325 SC, at this stage can be beneficial for disease control. Adding a micronutrient can increase ROI.

We tested several products along with Delaro® 325 SC fungicide and ARx MicroSul™ on R1 to early-R2 soybeans during our last herbicide pass. These products are mostly naturally derived extracts and/or amino acid-containing products.

• Ascend® SL products performed extremely well in this plot, with improved pod retention.

• Focused stress reduction products from various companies were evaluated. Most performed well, with Transit Foliar® being the lead performer.

R3-R4 Stress Reduction Additives | Foliar disease pressure was minimal at the plot in 2025, as was white mold, so R3 fungicide benefits were minimal.

• Foliar feeding at this growth stage, especially with nitrogen and potassium to assure robust post-fill, is an important consideration. We tested ARx N-sorB™ with added potassium acetate liquid, plus added focused stress reduction products.

• PGR additives performed well. Focused stress reduction products performed moderately, but ROI for the added costs was minimal.

Soybeans did not respond to a foliar fungicide applied for white mold at the R1 growth stage, but laterseason applications successfully improved yields.

White mold appeared in the plot in late August. The early R1 application of Delaro® provided only a 1.01 bu/ac yield gain, which was not enough to pay for the fungicide cost.

Later-season R3 applications proved more profitable. Delaro® provided around a 2.0 bu/ac yield gain, and $19.90 in gross return per acre — a positive ROI. More white mold-focused products, like Omega® 500F (+2.78 bu) and the industry standard Endura® (+2.34 bu), were even more profitable.

The newest fungicide evaluated was Zorina®. This combination product of the SDHI Endura®, plus the triazole active ingredient in Revytek® fungicide, gave a very solid yield gain of 4.27 bu/ac versus the untreated check. This product is worth noting as it should provide consistent plant health bonuses in addition to excellent white mold control.

The gold standard in white mold control continues to be a two-application program of Endura® — 6.5 oz at R1-R2 followed by another 6.5 oz at R3. This season, the program provided a 5.98 bu gain. White mold did appear later in the season, and the two-pronged fungicide program eliminated the disease in the plot. This yield gain, although particularly good, is more limited on ROI when application costs for the two applications are added to the ROI calculation.

The year-to-year response to fungicide has proven to provide positive ROI, especially with white mold being a continued threat to high-yield soybeans.

MZB Analytics is a reporting platform that helps farmers and Agtegra agronomists turn field data into actionable insights. It packages agronomic and economic information into easy-to-read reports and dashboards, allowing growers to:

• Evaluate crop performance, inputs and costs across fields and management zones.

• Identify agronomic issues — nutrient deficiencies, seeding problems, etc. — and pinpoint where corrective action is needed.

• Benchmark yield efficiency by comparing the performance of individual fields against others in the MZB Analytics system through a Yield Efficiency Score.

These results compare both plant population and planting date in corn and soybeans. This data was generated from fields in 20 counties in eastern SD and southeast ND over 3 years. Earlier planting dates show higher yields in both corn and soybeans. Higher plant populations in corn show positive yield results, while soybeans show just modest results.

Keeping in mind many of these fields are enrolled in our MZB program, and in corn, higher plant populations are generally associated with higher yielding zones. In soybeans, we have agronomists pulling down planting rates in high-yielding zones that contain white mold, thus the slightly higher yields at both ends of the plant population ranges.

Talk to your Agtegra Agronomist to enroll!

Each year, we partner with Agtegra farmers to conduct large-scale trials to compare new seed hybrids and varieties against tried-and-true hybrids and varieties.

The summarized data represents the top-performing hybrids and varieties that were trialed in each relative maturity range. Yields for products within the same relative maturity range were averaged across each plot. Each hybrid or variety was then ranked by their percentage above average yield.

Selecting the right seed hybrids and varieties for your farm can be complex. Work with your local Agtegra Agronomist for a custom seed portfolio recommendation.

In 2025, we planted and harvested over 30 field trials alongside farmers across North and South Dakota.

To dig in deeper on each individual seed trial, visit our website at www.agtegra.com/plot-results.

YS OB E A N S

Group 0.5 % Above Average Yield # of Plots

Group 1.0 % Above Average Yield # of Plots

Group 1.5 % Above Average Yield # of Plots

Group 2.0 % Above Average Yield # of Plots

Group 2.5 % Above Average Yield # of Plots

Group 3.0

Above Average Yield # of Plots