2024 AGRONOMY PLOT RESULTS

Taking Yield to the Next Level:

Good Agronomics and a Systematic Set of Inputs Leads to Higher Yields.

In today’s era of complex crop management decisions, Agtegra’s custom agronomy resources and personalized service can make a big difference. At Agtegra Cooperative, we strive to be a partner working side-by-side with our farmers to bring new technologies and innovations to the farm, while keeping an eye on maximizing the return on investment for each agronomic input. In the era of lower commodity prices and tight margins, this eye to efficient agronomy inputs is a critical partnership.

In 2024, just as in previous years, Agtegra was approached by many providers of ag inputs, bringing us a multitude of new options in crop protection, pest management, plant performance, and recently, stress reduction. Similarly, the explosion of “biological” products such as living biological organisms, extracts of biological compounds, boosters of soil biology, enzymes and more have been unprecedented. While these products are focused on improving some aspects of plant growth and development, the pace of these new options coming to the market has made it challenging to attain some clarity and direction toward best agronomic recommendations.

In our Research and Technology Plots at our Bath, SD location, we try to do some of the foundational work to sort through product claims and performance and provide that needed clarity for you! We utilize a controlled, large, strip-scale field environment to test and demonstrate products. We strive to find new technologies that hold promise to improve crops, the crop environment, increase yield and crop quality, and improve top ROI for growers.

The following pages provide convenient access to results from our individual Research and Technology Plot studies. Please browse through and find the products that speak to your individual crops on your farm.

If you find a product that looks appealing and you wish to try that product on your farm, I encourage you to contact your local sales agronomist to get the product secured for your use. I also encourage you to dedicate a portion of your field for your own on-farm testing! Leave an untreated check strip or test your current management program in a split field with a new product. This will allow you to see the real differences on YOUR farm…in YOUR fields!

If you are interested in gathering more detailed data on ROI, please contact your local Agtegra Sales Agronomist or your Agtegra Ag Technology Specialist to visit about setting up an on-farm trial through MZB Analytics. Understanding ROI, by management zone, in your own fields, provides tremendous decision-making power!

Brad Ruden Agronomy Tech Services Manager

About the Bath Research & Technology Plot

Plots and Plot Location

The Agtegra Research and Technology Plots are physically located at the Bath, SD Agtegra location. This location is in Brown County, SD in the James River Valley on deep, level prairie soils. All plots at the location are set up as large-scale strip trials, generally using 8-row treatments and a plot length varying from 350-430 ft. Variability across each plot has been extensively studied and each plot is designed to minimize that variability. Data is non-replicated. The large plot size and attention to soil variability management has shown us that plot data has been extremely consistent when compared to replicated plots on the same site.

Pricing and Calculations

Corn and soybean commodity prices naturally vary depending on the seasonal and other cycles of the commodity pricing world. For the purpose of this data summary, we chose to set the corn commodity price at $4.00 per bushel and soybean commodity price at $10.00 per bushel. We used these values wherever “gross return per acre” is calculated for each of the treatments.

Gross Return = (Treatment Yield - Check Yield) * Commodity Price

Yield data is shown for all treatments, so you may recalculate your own return per acre using your own commodity prices.

Specific prices for treatments and additional charges, such as application costs, are generally not shown, as pricing is a dynamic function, and can change significantly over time. The purpose of the data summary is not to establish a price quote, but rather to compare treatments on a gross return per treatment basis. All treatment yields were calculated on a consistent moisture basis. Test weight and bu/ ac were standardized to 14.5% moisture for corn and 13.5% moisture for soybeans.

Seed Varieties Planted

Corn Plots: All corn plots, except the corn rootworm insecticides plot, were planted with Dekalb® 09557 VT4Pro™ RIB Complete Corn, planted at 34,000 seeds per acre in 30-inch rows. The corn rootworm plot was planted with Dekalb® DKC44-98RIB VT Double Pro® RIB Complete, Dekalb® DKC4497RIB SmartStax® RIB Complete and Dekalb® DKC093-76RIB SmartStax® Pro RIB Complete, with all treatments planted at 34,000 seed per acre.

Soybean Plots: All soybean plots were planted with NK13-Y4XF soybean variety, planted at 140,000 seeds per acre in 30-inch rows.

Fertilizer Applied

Starter Fertilizer: Unless noted in the specific plot trial, Agtegra ARx A7-23 liquid starter fertilizer applied in-furrow at a rate of 5 gal/ac for corn plots and 3 gal/ac starter + 2 gal/ac water for soybeans. The starter was applied under the seed with standard application tubes.

Dry Fertilizer:

• All plots were soil tested in Fall of 2023 and analyzed at Agvise® Laboratories.

• Phosphorus and Potassium: All plots received 200# MESZ (12-40-0-10S-0.5 Zn) and 100# Potash (0-0-62) fertilizer as a base treatment.

• Nitrogen: Nitrogen was applied to all corn trials using Urea (46-0-0) treated with RemaiN® nitrogen stabilizer (NBPT), with the exception of the Nitrogen Stabilizers Trial, where treatments varied. Nitrogen was fertilized with 220 units per acre of available nitrogen, with corn nitrogen use efficiency assumed at 1.0 lb/bu. Urea application rates were calculated using the following calculation:

• (220 # goal - (Soil test 0-6” nitrogen + ½ soil test 6-24” nitrogen + 20 lb mineralization))/.46

CORN TRIALS

Photo

Agtegra’s

Step by Step Recommendation for High Yielding Corn

Corn production focused on maximum yield and maximum ROI, is a system of inter-related inputs. A intentional, complete series of production decisions, including using key inputs had led to the highest yields in our corn production trials. Here are our best recommendations:

1. Start with a diverse group of proven high yielding hybrids for your area. Use the Agtegra variety plot data and consult with your local agronomist for proper hybrid selection.

2. Be sure to include the insecticide traits needed for best agronomic performance in your geography and consider the need for an in-furrow insecticide to boost performance if corn rootworm pressure was severe.

3. Fertilize for yield! Do not consider cutting back on basic N, P, and K because of input costs. Maximum yield takes proper nutrition.

4. Add nutrient availability additives like RemaiN® to nitrogen fertilizer to reduce nitrogen losses. Consider treating phosphates, both dry and liquid, to increase and maintain phosphate availability for the crop. Products like P.Max® have proven ROI.

5. Buy and use a high-quality talc/graphite seed fluency product, like Stride Bio™, that contains nutrients needed for germination as well as a proven bio-booster to improve seedling vigor and emergence. At a minimum, replace standard talc/graphite with Protivate™ NU-4 Dri to provide seed fluency and added nutrition.

6. At planting, use a high-quality starter fertilizer, with added macro and micronutrients, like ARx A7-23 or ARx 8-20 at around a 5 gal/ac rate, or slightly higher if yield goals allow.

7. The first additive to the starter tank is ARx Sync™, our proprietary liquid humic-type product to boost root growth and assure starter nutrients remain available for the growing seedlings.

8. PGR’s like Ascend2 add a consistent performance gain, improve emergence rate and uniformity, promote robust root systems, and assure rapid shoot and leaf growth, setting the plant up for maximum growth, nutrient uptake and ultimately yield the rest of the season.

9. Consider a multi-nutrient focused biological product like Foster™ FC from Rosen’s® in the starter. These products help release nutrients bound in the soil and make them available season-long for the rapidly growing crop.

10. Apply fungicides, additional foliar nutrition, like ARx N-sorB™ or ARx N-fuZe™ and micronutrients like ARx MicroSul™ to the crop to maintain and boost yield as yield potential, environmental conditions and possible tissue testing dictate through the season.

11. Lastly, consider the new class of stress reduction products, which can be applied in-furrow or foliar with herbicide or fungicide applications. Recent data looks promising for the benefits these products can provide in maintaining aggressive growth focused on yield.

Trial: Corn Omission & Addition

Agtegra Acre: An Intentional, Comprehensive Systems Approach

Corn production is a system of inter-related inputs. In 2024, like previous years, maximum yield and ROI involved applying inputs in an intentional, complete production system.

Our corn seed varieties have changed over the past 10 years and are more responsive to tassel timing fungicide applications. The addition of Delaro® 325 SC Fungicide + ARx N-fuZe™ foliar nitrogen with micronutrients provided the single largest loss in gross revenue when removed from the full system approach and added the single largest gain in gross return when added to the system as a single input. The need for V5 applications has diminished in recent years, but the weather pattern in 2024 showed a respectable ROI for the basic fungicide plus ARx MicroSul™ at V5. In high residue, corn on corn, high stress or highly managed fields, there is still a good fungicide opportunity at V5. Overall, tassel fungicides and foliar feeding are becoming more important. Increased plant health is allowing late season grain fill from hybrids with improved ability to flex kernel size.

The plot results from 2024 show that, beyond fungicide and foliar feeding, early stand establishment with additives like ARx Sync™, a starter booster, and Ascend2, a PGR, was a key input. Plants emerged much more evenly and developed an early, robust root system prior to the later summer heat and drought. Key agronomic inputs in the trial were the addition of biologicals to the production system, and stabilized, highly available nutrients. Agtegra is working on developing additional proprietary micronutrient products with additional additives to promote and address current production demands, including herbicide application and environmental stress. These products will be focused specifically for V5 and tassel timing application windows.

Removing any single input caused a reduction in Gross and Net return per acre. Adding each single input to a basic production system raised yield, but often LESS than the removal of the component from full programs. This shows that there remains many significant interactions among inputs and a SYSTEMS APPROACH will likely maximize yield.

Deletion/Addition: Building the Agtegra Corn System

Trial: Corn Nitrogen Stabilizers

Managing Nitrogen Losses in Applied Fertilizer

The 2024 season was unseasonably wet and relatively cold after planting and remained wet for an extended period of time. Because weather is unpredictable and soil types can vary within a small area, any field can be at risk of nitrogen loss through volatilization, leaching or denitrification. Plants can only use nitrogen in ammonium and nitrate forms. With extended wet periods, volatilization during urea conversion early, leaching from movement of nitrate N through the soil and denitrification from saturated soils all affected nitrogen availability in the plot.

Volatility was again a major form of nitrogen loss, and Agtegra’s proprietary nitrogen stabilizer, RemaiN®, when applied to urea and compared to untreated urea (before crop emergence), resulted in a 10.80 bushel gain. This is very similar to the 11.54 bushel gain seen in 2023, but less than the 24.98 bushel gain we saw in 2022 when conditions were extremely wet and very warm. With corn value set at $4.00/bu, this equals $43.18, a very positive ROI! This is less than the $51.93/ ac additional gross revenue seen in 2022 or the $149.88/ac additional gross return in 2022 (when corn was $6/bu).

• The eight-year average yield gain to RemaiN® treated urea, including 20 research trials, shows average gains of 13.01 bu/acre vs applying urea without a treatment.

RemaiN on UAN

UAN is often used as a herbicide carrier for application of corn pre-emergence herbicides. UAN contains nitrogen in the form of 50% urea and 50% ammonium nitrate. The urea component of the fertilizer is susceptible to volatility losses, similar to dry urea. Data from the plots show that RemaiN® applied at the recommended rate of 32 oz/ton (1 qt/ton) to UAN can be effective at reducing volatility, and yield increases of 7.05 bu/acre were seen when treated UAN followed by treated urea were applied vs untreated nitrogen sources.

RemaiN Best Management Practices

Cutting the rate of RemaiN® in half reduced yield by 8.25 bu/ac compared to using the full rate. A minimal cost savings of just over $6/acre resulted in $33.00/ac in lost gross revenue. Even with lower commodity prices, the actual cost of reducing stabilizer rates is significant!

RemaiN® has an advanced formulation, with an additional carrier that provides improved coverage and better penetration into urea, which means faster drying even in cold conditions, better flowability, and spreadability.

8 Year Average Yield Gain

When applying a nitrogen stabilizer to dry urea on corn

Urea treated with 2 qts/ton RemaiN

Untreated Urea

Untreated roots (top 2) vs. 1/2 rate RemaiN® (middle 2) vs. full rate RemaiN® (bottom 2). Urea applied top dress. Much more root development and higher yields resulted.

215 228

Yellowing and burning that extends down the center of the leaf starting from the tip is indicative of a classic nitrogen deficiency.

Untreated (top). Treated with RemaiN® (bottom). Protecting nitrogen from volatility can be clearly seen when looking down corn rows later in the season. Nitrogen deficient rows dry up earlier and limit ear development later in the season. Ear height and size is also much more uniform in the treated plots.

Untreated urea (left); ½ rate RemaiN® on urea (middle); full rate RemaiN® on urea (right). The full rate RemaiN® ears are more filled to the tip, have more rows of kernels and greater kernel depth, all leading to larger yields.

Trial: Corn Starters & Starter Additives

Getting Corn off to a Solid Start!

Starter fertilizer should be standard practice in the Northern Plains! Starter alone provides a tremendous boost to corn development, helping establish sound, strong plants. A solid starter fertilizer program, with additives, improves stand and promotes rapid, even emergence, the early KEY to maximum yields.

ARx Sync™ is a proprietary organic acid additive that assists in nutrient availability, plant vigor and nutrient transport. We recommend ARx Sync™ on EVERY acre! The ROI for this product remains very solid.

Biological Additives can increase general nutrient availability and uptake, especially focusing on phosphorus availability.

• Foster® FC (dry biological from Rosen’s®) was a was a solid performer again in 2024 and is our recommend product in this category. Foster increases general nutrient availability throughout the season, including a strong emphasis on phosphate availability.

• Test results with additives specific to phosphate availability, including Zume®, a phosphate focused enzyme product and Levesol® DFC, a chelator that protects phosphate form being bound up by cations in the soil, showed lower results compared to the broad-based Foster® FC product.

• We also tested liquid experimental biologicals with Azospirillum bacteria (Accolade®, from Verdesian®). Results appear acceptable, but repeated testing is needed.

Plant Growth Regulators (PGR’s), such as Ascend2™, provide a three-pronged boost to plants: ROOT, SHOOT and LEAF growth. Improvement in plant vigor is definite, and the PGR helps build up the entire plant, which showed a yield benefit and improved ROI! Cygin™ Pro from CHS® was also a solid performer.

Treatment Results and Best Practice Recommendation:

• Biologicals have a solid place in starter programs.

• ARx Sync™ + Foster® FC was an excellent program with solid ROI, mirroring results seen in 2023.

• Stacking technologies: ARx Sync™ + Biological + PGR.

• ARx Sync™ + Foster® FC + Ascend2 was the top performing program! Synergy between the components was consistent.

5 Year Average Yield Gain

When applying A7-23 or 8-20 starter fertilizer, ARx Sync & Ascend² to corn

Corn plant development at V12. Roots (Left to Right) are No Starter, A7-23 starter only, Starter + ARx Sync™, and Starter + ARx Sync™ + Ascend2™. Note the increase in brace root development with starter, increased plant and root mass from ARx Sync™, massive roots, shoots, and stems with larger leaves when Starter and ARx Sync™ is paired with Ascend2™ PGR.

No Starter Starter Only Starter + ARx Sync™

Trial: Residue Management

Beneficial and Valuable Nutrition Right in our Fields

Corn residue is increasingly persistent due to new traits and improved stalk strength. We know that residue, specifically corn residue, contains a significant amount of crop nutrients, especially potassium, but also phosphate, among others. A residue management biological product can have a place in any production systems where nutrient tie-up is a factor, but especially in corn-on-corn or soybean following heavy corn residue. Soil samples taken from this plot at the beginning and end of the season confirm that significant nutrition can be released from residue, if it is successfully broken down. Robust™, a biological booster from Rosen’s®, showed significant effects on breaking down residue.

Soil samples were taken Fall 2023 and again at the end of August, after residue breakdown. Soybean used up any additional nitrogen in yield gains but also benefited from improved soil phosphorus (+ 6 ppm Olsen P test), and a 68-ppm gain in soil potassium. Potassium is a critical nutrient for overall nutrient transport, especially for water balance management in the soybean crop, which became critical in the dry conditions at the end of the growing season.

In addition to soil nutrients, the structure of the soil was improved when a residue management product was applied. This was unexpected but shows the improvement of structure that can happen with improved biological populations in the soil.

Residue management products produced positive yield results after application either in the Fall or early Spring in our plots. In addition to higher yields, these products also have good handling characteristics, including low use rates and cost points, no unpleasant odor, and good flowability and mixing.

Residue management products are compatible with herbicide residuals and can be sprayed with pre’s. Note the improved soil structure where a residue management product was applied, indicating better nutrient and biological activity on the soil. Soil crumbles easily compared to the blocky soil in the untreated plot.

residue

treated with biological

treated with biological and UAN

residue

WATCH THE VIDEO >>

to see the residue breakdown results from our plot trial during the 2024 season.

www.youtube.com/@agtegracooperative

Residue treated with Robust™ and UAN Fall applied

In-Row Residue Untreated

Residue treated with Robust™ in Fall 2023

Residue treated with Robust™ and 28% in Fall 2023

Corn residue management effects on soil sample results:

Nutrient Measurement

+ 6 + 68 + .22 + .1%

Measurement

Trial: Corn Nitrogen Fixing Bacteria (Biologicals)

Still A Bit Inconclusive, But A Story Is Starting To Develop

Agtegra continued to test and research various biologicals, both in-furrow and foliar, to stay on top of technology in the fast-developing market that is bombarding growers today. This segment of the market, namely the nitrogen fixing biologicals, has provided some interesting and varying results. The concept of biological nitrogen fixation is solid, but proper management of this category of biologicals is absolutely critical to obtain consistent results.

In 2024, nitrogen was applied to the test plot at a rate needed to provide 220# total nitrogen for the 100% nitrogen plots and was limited to 176# total nitrogen in the 80% nitrogen plots. Biologicals were applied according to label, either in starter fertilizer or foliar at the V4 growth stage.

In-furrow biologicals can have significant handling issues, with short lifespan in high salt solutions, like starter fertilizers. The nitrogen-fixing bacteria are not as stable in these solutions as the broad spectrum, general nutrient releasing biologicals tested for several years in the Starters and Additives Trial. Applying nitrogen-fixing biologicals at V4 avoids mixing with starters, and allows application with a herbicide mix, which generally is a much more biological-friendly carrier.

The nitrogen-fixing foliar applied biologicals, including Envita® WG from Azotic®, Utrisha® N from Corteva®, or Maneuver® from Rosen’s® (which combines Foster® FC biological consortium plus a nitrogen fixing component), provided very good yield gains when applied to the 80% nitrogen rate plots. Yields essentially equal the 100% nitrogen plot without any biologicals, meaning the biological apparently was providing additional nitrogen. Yield gains in the 100% nitrogen plots with added biologicals were minimal, and did not produce significant positive ROI.

These plot results are very different than the 2023 results seen at the Bath Research and Technology Plots. In 2023, highest yield gains were only seen in the plots where 100% nitrogen fertilizer was applied, followed by a biological at V4. The reduced nitrogen rate plots with an applied biological last year did not provide significant yield gains to the biological treatment, where the 100% nitrogen plots showed very significant yield gains.

After seeing the two seasons if data, we speculate that the results from 2023 were skewed by the environment. We experienced extreme nitrogen loss to volatility in 2023, with extended warm and wet conditions following planting and subsequent fertilizer application. We feel that the nitrogen loss to volatility was so extreme in 2023 that the reduced nitrogen rate plots in the trial were critically short of nitrogen, and in fact, were so critically short of nitrogen that they became less responsive to the added nitrogen from the biological products. The full nitrogen rate plots last year, on the other hand, provided enough nitrogen, even with the extreme volatility, that remaining available nitrogen to the plots was in the responsive range to the added nitrogen-fixing biologicals.

In contrast, in 2024, we experienced less volatility after fertilizer application than we experienced in 2023. This allowed the reduced nitrogen rate plots to remain in a responsive growth pattern to the applications. In contrast, the full nitrogen rate plots showed apparent adequate nitrogen supply levels for the yield, even without the biologicals. This higher available nitrogen in 2024 reduced the response to biologicals in the full nitrogen plots.

Given this data, we make the following recommendations. We have three rules of thumb to follow when managing corn with nitrogen fixing bacteria:

1. Strictly follow the handling guidelines on the labels. These are generally very delicate bacteria, and they DO NOT survive well in starter fertilizers or any solution with high salt, such as UAN carrier. Foliar application at vegetative stages of growth can avoid the harsh carrier issues.

2. We do not believe these products can be relied on consistently to replace any significant amount of applied nitrogen fertilizer. Best management is achieved by using these products as a supplement to a full nitrogen program, supplementing high yield environments.

3. The consistent performance of these products is less than we desire. Stability of response is becoming a clearer picture, but there are still many inconsistencies. It is difficult to be comfortable with a broad recommendation.

Trial: Corn Phosphate Availability

Phosphate Tie-Up = Lost (or Delayed) Value to Applied Fertilizer

Phosphate tie-up is a significant issue with applied phosphate fertilizers. Tie-up can reduce the effective nutrient availability of phosphate fertilizers by up to 70%!

Adding 30 lbs of phosphate to compensate for phosphate tie-up does provide a yield gain, even a significant one, but is not a recommended management practice. Instead, treating phosphate either in the Fall or Spring with a product like P. Max®, protects against phosphate tie-up. Levesol® DFC also provided a solid yield gain vs untreated phosphate.

• P.Max® Ultra treated MAP versus untreated MAP (applied to the ground surface as a spring application) resulted in a 9.58/ac bushel gain. With corn at $4.00/bu value this equals $38.32/ ac additional gross revenue.

• Fall applications of phosphates with incorporation are more operationally efficient than spring surface applications. However, P.Max® Ultra still provided a 5.15 bu gain vs untreated phosphate fertilizer when applied in the Fall, resulting in $20.60 additional revenue per acre.

• Levesol® DFC treated MAP versus untreated MAP resulted lower yield gains vs P.Max® Ultra, but results still showed a positive ROI.

Benefits:

Impregnating fertilizer with P. Max® Ultra EZ FLO will ensure your phosphate fertilizer is protected. Take care of phosphate deficiencies and replace phosphate removed by this year’s crop.

• Promotes early season root growth, vigor and better overall plant structure

• More phosphate available leads to higher yield potential

• Increase your fertilizer efficiency and ROI

Features:

• Protecting polymer that helps keep phosphate more readily available

• Specifically designed for dry fertilizer impregnation

• Regardless of the amount of phosphate fertilizer applied, P.Max® increases the plants ability to turn applied phosphates into more bushels at harvest

Use rate: 3 qt/ton

Trial: Corn Seed Applied Additives

Talc & Graphite Replacement: Doing More In The Planter Box

Basic talc and graphite products meet equipment standard for the planter equipment manufacturer, are inexpensive, and, if applied properly, do provide agronomic benefits by improving seed flow and singulation. However, talc and graphite does not provide crop nutrition or provide any bio enhancement additive. Seed applied talc and graphite replacements do provide an opportunity to do more to help seed germinate and seedling emerge and are extremely efficient. Many contain the micro quantities of phosphorus and zinc needed to jump start germination. The premium products tested in our plots also provide proven bio enhancements to improve germination and seedling vigor.

The value of using seed applied talc and graphite replacements was extremely solid in our plots! Providing nutrition and bio enhancement products to every seed and boosting seedling vigor with premium products like Stride Bio™ led to improved canopy closure by 6.34% at the V5 growth stage. These plants showed improved growth all season, ultimately leading to yield gains.

Stride Bio™ provides enhanced nutrition, good seed fluency, and most importantly, stress reduction through the patented Yield Burst™ technology from Rosen’s®. This product showed a 4.67 bushel gain versus talc + graphite alone. While lower than 2023 results, the value remains very solid. With corn at $4.00/bu value this equates to $18.68/ac additional gross return.

Living biological organisms do not survive well in talc and graphite carriers. Certain talc and graphite replacements use a different, inert biological powder as a carrier. Results look very good for some new products, but consistency of performance vs talc/graphite based products is yet to be fully determined and cost per acre may limit widespread use.

Stride Bio™ is 80/20 talc graphite. It contains Calcium, Magnesium, Sulfur, Iron, Manganese, and Zinc. It also contains stress reducers to up-regulate genes for seedling vigor and early growth.

Canopy Coverage

Seed applied products were compared using the Canopeo™ app at the V6 growth stage to visualize the difference in canopy coverage.

showed bigger ear development than talc/graphite alone or

with basic crop nutrition but no bio enhancer.

Stride Bio™, a talc and graphite replacement with bio enhancer,

talc graphite

Corn seed applied with Protivate™ NU-4 Dri showing 45.33% coverage.

Corn seed applied with Stride Bio™ showing 50.94% coverage.

Corn seed applied with Seed + Graphite® showing 49.49% coverage.

Corn seed applied with Stride Bio™ and Ascend® SL showing 51.37% coverage.

Corn seed applied with Talc Graphite showing 44.60% coverage.

Trial: Corn V5 Foliar & Tassel Stress Reducing Spray Additives

Additional Focused Stress Reduction in Corn

Fungicides provide disease control in corn when applied at either the V5 or VT application windows. These products are also a key component of reducing plant stress, especially if applied with a foliar nutritional product. However, there is a newer set of focused products on the market that are dedicated directly to reducing plant stress from environmental conditions or following herbicide application. We tested several products, along with a fungicide and foliar nutritional, at the V5 and VT growth stages. Results were extremely positive in 2024, showing that these products are certainly worth our attention and are worth testing in on-farm trials on growers’ acres.

Dedicated stress reduction products from various suppliers were tested. These products are generally naturally derived extracts and/or amino acid containing products.

• The products YieldOn™ from Syngenta, Crop +™ from Verdesian, Transit Foliar® from Valent® Biosciences, and ReLeaf™ OS from ATP® were applied in the plot. Two additional experimental products from CHS® and Syngenta® were also tested.

• At the V5 growth stage, when applied with a herbicide, fungicide and foliar nutritional in one pass, all products tested provided a very significant boost in growth. Yield was also enhanced, with gains of 1.34 to 7.46 bu/ac. Final yield gains did not match the scale of the improved growth and plant development seen, possibly because of later season plant stress from drought.

• At the VT application stage, yield gains from application of the products were stunning, with yield gains as high as 13.5 to nearly 15 bu/ac with top performing products. Visually to the plants, these applications did not show large differences, but yield gains from improved stress tolerance and improved ear fill were striking.

• There are significant differences in the cost per acre among the various products tested, and these differences may impact use.

• It appears that micronutrient and general nutrient deficiencies must be addressed FIRST, then a stress reduction or bio enhancement product, like those tested can provide the full effect toward enhanced plant growth and development.

• Agtegra is investigating the potential of pairing one or more of the technologies along with our proprietary foliar nutritional products.

Improved root growth from V5 application of products such as Crop +™ (left), Transit Foliar® (middle) and YieldOn™ (right) were striking in the plot. Untreated plants are the right two plants in each image.

Trial: Corn V5 Foliar & Tassel Fungicides Plus Micronutrients

Focused Nutrition and Stress Reduction in Corn

The Bath location had a variable season in 2024, with a cold and wet emergence period, a short period of excellent mid-season growing conditions and high heat and drought later in the season. Later season rains did help improve yield. However, the area still experienced significant periods of very hot weather. Fungicides can provide two distinct actions when applied to the plant.

• The first action is disease control. Whether looking at stalk rot control with a fungicide at V5 timing or gray leaf spot, northern corn leaf blight, rust or the future possibility of tar spot control at tasseling, disease control will be solid with top-tier fungicides.

• The second action of fungicides, especially top-tier products like Delaro® 325 SC, TrivaPro®, Miravis Neo® or Velytma®, is stress reduction. These fungicides help the plant reduce water loss, maintain lower canopy temperatures, and maintain positive photosynthesis during periods of high heat.

Historical data has shown the response to V5 fungicides has been trending downward in the past several seasons at Bath, whereas the response to tassel fungicides has been increasing. The ability of modern corn varieties to flex and fill the ear late in the season has allowed a late season plant health response to grow.

• V5 Fungicides: This year, the V5 crop stage again appeared responsive to a micronutrient + fungicide application. Fungicide and micronutrients at this application timing may have had some effect on stalks diseases, but also improved plant growth and development and reduced plant stress. Yield gains in the fungicide plot were less than seen in the Omission and Addition Plot, likely due to the earlier planting date for the fungicide plot. Basic fungicides like Protegam® YLD from Winfield United® perform well at V5.

• Tassel Fungicides: Untreated corn leaves roll during the heat of the day, causing an open canopy that lets in more sunlight, resulting in higher temperatures and stressed plants. By adding a fungicide like Delaro® 325 SC plus a foliar feed, like Agtegra ARx N-fuZe™, corn leaves stay open longer, providing shade and keeping temperatures cooler and ultimately reducing plant stress. Yield gains from VT fungicide + foliar feed of around 11 bu/acre were seen in the fungicide plot, and as much as 19 bu/acre in the Omission and Addition trial. Generally, the trend in our trials has been that premium fungicides at VT, like Delaro® 325 SC, or similar, outperform basic fungicides.

The Agtegra featured program: Delaro® 325 SC + ARx N-fuZe™, provided an 11.17 bu untreated, or $44.68 gain in GROSS RETURN! This program in 2023 provided 11.95 bu gain vs untreated, so return is consistent.

Diseases to Watch

Common Rust vs. Southern Rust

Corn in SD and ND is generally not highly affected by foliar diseases. However, in 2024, Southern Rust made significant inroads into the region, reaching northward across SD and even into Southern ND. The disease developed late enough in the season that yields were not likely affected. Southern rust does not overwinter in the Dakotas, so must “blow in” to the region each year from southern states. The development is worth tracking each year, as Southern Rust can potentially be more damaging to yield than common rust.

Tar Spot is a newer disease to the region and has only been identified in southeastern South Dakota in the past two years. This disease is one to learn, as it can overwinter here and poses a significant threat to corn yield if it develops. Fortunately VT fungicides are highly effective at controlling this disease.

2023 Corn Tassel Timing Delaro + ARx N-fuZe: Leaf Rolling

An untreated strip and a Delaro® 325 SC and ARx N-fuZe™ treated strip was sprayed on July 19, 2023 at the Bath plot. Photos were taken July 26, 2023 at 11:38 AM when the air temperature was 99F and at 3:30 PM when the air temperature was 106F. The Delaro® 325 SC + ARx N-fuZe™ treatment kept the leaves from rolling up, which allowed sunlight absorption for continued growth. Temperature at ear height was also 2.6F cooler in the treated area. Similar results happened in 2024.

11:38 AM 3:30 PM

Untreated:

• Rolling leaves

• Factory Closed Treated:

• Flat leaves

• Factory Open

Untreated:

• Rolling leaves

• Open canopy

• Higher temp Treated:

• Flat leaves

• Closed canopy

• Lower temp

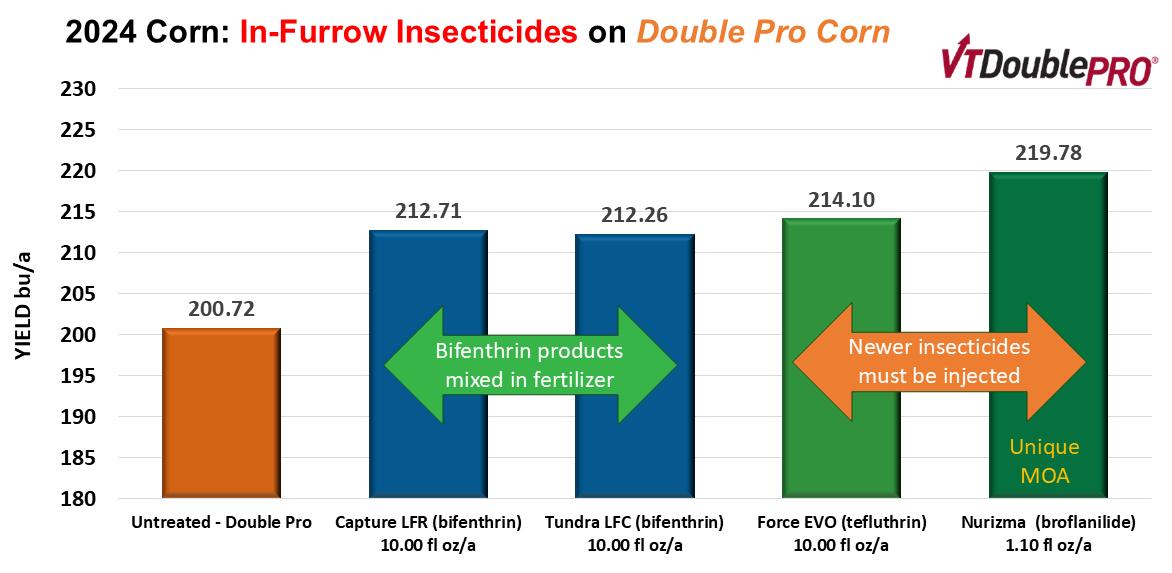

Trial: Corn Rootworm Insecticides

Rootworms: An Old, but Major pest in the Northern Plains!

Corn rootworm pressure is nothing new to corn production in the United States. However, in 2023 and again in 2024, the rootworm pressure in the Northern Plains has been significant. The prevalence of excellent-yielding, cost-effective Double Pro® corn hybrids has created broad acreages that are potentially susceptible to corn rootworm. SmartStax hybrids will provide good to excellent control of this pest, and the new SmartStax® Pro and VT4Pro™ hybrids add another unique mode of action against this insidious pest, with RNAi technology. Under extreme pressure, even the SmartStax® hybrids experience some level of feeding pressure.

The Bath Research and Technology plots showed lower than expected populations of Northern Corn Rootworm beetles (green) in 2024, and an increased population of Western (striped) rootworm beetles. Extreme feeding was seen in untraited and untreated corn plots, showing the prominent level of infestation in the plot area. The purpose of the test was to investigate the performance of in-furrow rootworm insecticides under susceptible corn hybrid on a field with EXTREME rootworm pressure.

• The plot was planted corn-on-corn with susceptible hybrids for four years running.

• Extremely high feeding pressure was present in the field, causing low yields. Roots were nearly 90% trimmed off in the untreated plot, leaving less than ¾” roots.

• Trait selection makes a stark difference in rootworm feeding potential and should be the first management choice to discuss with your agronomist.

• Even a SmartStax® hybrid in the field was fed upon, reducing potential yield. However, the effect of the trait was clear, with significantly improved yields versus a comparable Double Pro® hybrid.

• VT4Pro™ and SmartStax® Pro hybrids showed little feeding from rootworms, showing the strength of the newer RNAi technology.

• Bifenthrin-containing insecticides Capture® LFR and Tundra® LFC assisted rootworm management and performed well. The Capture® LFR product used in testing was very old product, and it appeared that the age of the insecticide may have reduced effectiveness compared to the Tundra® LFC product, which was a 2024 product.

• Force Evo® from Syngenta® performed very well in the plots, providing superior control over the bifenthrin products.

• Nurizma® is a newer insecticide from BASF® that performed extremely well in the plot and appears to set a new standard for control.

• It is possible that even SmartStax® hybrids will perform best with an added in-furrow insecticide, if feeding pressure is extreme.

Northern Rootworm Beetle

Western Rootworm Beetle

Untreated Double Pro® corn showed extreme rootworm damage at the Research and Technology Plots rootworm management plot in 2024.

Traits Matter! Untreated Double Pro® compared to SmartStax® Pro roots. SmartStax® provides good control and the new RNAi Technology in VT4Pro™ or SmartStax® Pro hybrids provided excellent rootworm control and are a sound management choice for high pressure fields.

Rootworm traits compared (left to right): Double Pro®, SmartStax®, SmartStax® Pro and VT4Pro™

Note the improved performance of the RNAi technology in the SmartStax® Pro and VT4Pro™ hybrids.

Rootworm damage to Double Pro® corn treated with various insecticide treatments. Note the improved performance of top-tier insecticides like Force Evo® (top right) and Nurizma® (bottom right).

SOYBEAN TRIALS

Phase I: Laying the Foundation

• Uniform emergence

• Early season vigor

• Root development

• Nitrogen fixation begins at V3

Phase II: Building the Factory

• New trifoliate every 3 - 5 days

• Potential nodes (main stem) at V2

• Lateral buds at V3

• Maximum flowers at V4-V5

• Number of pods at R1 - R3

Phase III: Operating Efficiency

• Managing stress

• Maximizing photosynthesis

• Maximum seeds in pods at R3-R4

• Seed size and pod fill at R5 - R6

• Plant health, stalk strength and even dry down

Soybean Growth: Critical Timings for Yield Enhancement

Maximizing yield in soybeans is an attainable goal, and similar to corn, involves a series of planned inputs applied in an intentional manner. Soybeans require a set of foundational agricultural practices to get a solid established crop. Among these critical, foundational practices are maintaining proper soil pH, soil drainage to prevent saturated soils, excellent weed control and background crop nutrition specifically applied for the soybean crop. These factors must be addressed before we can maximize the yield components of soybean production.

Soybeans are extremely sensitive to low pH soils and cannot maximize growth or nutrient uptake in acidic soils. Stratified pH in our soils, with a very acid layer near the surface may be a hidden yield reducer in soybeans. Correcting low pH is more critical for soybean production than for corn.

Year after year, maximum yield and response to other inputs has happened where basic crop nutrition, especially P and K, are applied every crop season, for the crop being raised. Taking care of the nutritional needs of soybeans… for the soybean crop… is a foundational factor often overlooked in soybean production.

Stabilized and available crop nutrients, biologicals, bio stimulants and fungicides, seed treatment, in-furrow or seed applied PGR, fungicide + micronutrients and a new addition of specific stress reduction additives are all possible in-season elements to the recommended Agtegra soybean system.

• Soil pH had been on a downward slope prior to 2021

• High fertility levels in the plots

• Urea and UAN applications

• Low tillage

• Likely pH

STRATIFICATION in the 0-2” layer

• 0.3 to 0.5 point LOWER in this layer

• Lime in 2021

• pH now is an order of magnitude higher

SOYBEAN

Lime applied

Trial: Soybean Omission & Addition

Soybean ROI: What Factors Maximized Yield and Return

Soybean production in 2024 was a world of two phases:

1. Rapid, early development of vigorous soybean plants with deep roots needed to overcome cold and wet soils. If early establishment was good and a robust root system developed, the crop had the ability to survive the high heat that the later summer brought.

2. An extremely dry period around late flowering and pod fill brought reduced disease pressure later in the season, resulting in lower response to fungicides, but reduced top end yield.

The newest class of stress reduction products played a significant role in adding yield in our research trials. The Agtegra Acre approach for soybeans has consistent components, especially early in the season, but may need flexibility in adding inputs later in the season for maximized ROI.

Phase 1 Establishment: Laying the Foundation

• Crop Nutrition: use dry fertilizers FOR your soybean crop, not a leftover after corn. Nutrition is foundational.

• Seed Treatment: Maximum stand counts, uniform germination and strong emergence only happen with a full F&I seed treatment, like CruiserMaxx® APX. Losses in plots without seed treatment were very significant.

• Inoculant: Using a high-quality inoculant like Preside® Ultra in soybean production is a critical management factor. Inoculant was applied to all treatments in this test plot.

• Fertility Levels: High quality liquid starter like A7-23 and additives like ARx Sync™, which help keep nutrients available to young plants, was key to early rapid plant growth.

• Boosting the Plant: Adding a PGR in-furrow and a seed-applied fluency agent plus micronutrient and bio booster to the seed greatly improved early plant vigor resulting in rapid, deep root development. This aided in surviving the summer heat. Stride Bio™ is a top recommendation.

Plant Development: Keeping the Plant “Factory” Productive

• Plant Vigor, Stress and Disease Protection: An application of Delaro® 325 SC fungicide plus ARx N-fuZe™ at the R2-R3 growth stage in soybeans can provide proven disease control and reduce plant stress, allowing better pod set. However, in 2024, the significant drought during pod fill resulted in reduced disease pressure and reduced the response to the fungicide and nutritional application.

Picture is of the pod mass from 2 foot of plant row, collected in September. The difference between the standard program on the left and the premier program on the far right is striking.

Trial: Soybean Seed Treatment

Emergence and Vigor Matter… Every Year! Nothing can replace a poor plant stand.

Soybean seed treatment with a full fungicide and insecticide treatment has remained a hallmark of highly productive soybeans, and 2024 was no different than previous years.

Earlier planting can result in excellent yields, but soybeans still need a minimum soil temperature to germinate. Diseases like Pythium and Phytophthora do not disappear, year to year, and they love moist soils. Pythium, especially, likes cool, wet soils. Warmer soils later in the spring mean Rhizoctonia is now gearing up to attack young soybeans. Lastly, insects are now active as well!

• CruiserMaxx® APX provides proven protection from all of these diseases. It will be our primary offer again for 2025 as it has consistently remained at the top of yield tests.

• Other products, such as the new Acceleron® formulation from Bayer®, also looked good in the plots.

• The plot at Bath experienced significant, but uniform planter down force issues, which affected initial stand and limited yields and differences between treatments.

• This plot showed a 3 bu/ac advantage to CruiserMaxx® APX vs untreated seed. A neighboring plot, without the planter issues, showed a 4.48 bu gain to CruiserMaxx® APX, which is more in line with year-to year average gains.

• Full fungicide and insecticide seed treatment provided ROI averaging over $40 per acre, for now 13 years running at the Bath site!

• The value and ROI of a full fungicide and insecticide treatment was clear, with excellent yield response and stand counts improved by 10,000 or more plants per acre vs untreated seed.

• If Sudden Death Syndrome (SDS) or other additional diseases are present, additional fungicides such as Saltro® or the new Tymirium active ingredient marketed as Victrato® may be added when fully registered. There is a significant investment in these top-end treatments, but results look stunning and easily overcome the added cost.

Untreated (left) vs. treated (right) compared using the Canopeo™ app to visualize the difference in canopy coverage. CruiserMaxx® APX seed treatment improves early season plant vigor and growth. Canopy coverage was improved by nearly 10%. Early establishment is critical to robust plant and node development as the season progresses.

Close-up of the stems from untreated plots (top) vs CruiserMaxx® APX (bottom). CruiserMaxx® APX produces much larger, much more uniform plant stems. Large uniform stems are needed to support robust plants and reduce lodging later in the season.

This picture shows four bundles of soybean plants taken from a 2 foot section of row. The bundles are (left to right) Untreated, CruiserMaxx® APX, CruiserMaxx® APX + Saltro®, or CruiserMaxx® APX + Victrato®. Note the improved growth, especially between Untreated and CruiserMaxx® APX. Saltro® and the newest product, Victrato® (when fully registered), are Syngenta® additives that can be used for higher disease pressure areas.

Untreated (left) vs CruiserMaxx® APX plants (right), early July 2024. Note the larger root system and improved plant development where CruiserMaxx® APX was applied.

Trial: Soybean Seed Inoculants

Soybean Inoculants: The Often Overlooked, Solid Performer!

Soybean inoculants have a place on every soybean seed, every year!

• Soybean inoculants provide fresh, active, and effective Bradyrhizobium bacteria for fast, efficient nodulation of soybean plants.

• An added inoculant, like Preside® Ultra helps provide soybeans with needed levels of nitrogen in the plant.

• Preside® Ultra also contains Take Off® technology, a bio additive that leads to faster, uniform emergence of the soybean crop.

• Soybean inoculant remains a SOLID INVESTMENT, even with low commodity prices! Less than a ½ bu/a gain is needed to offset the cost of the product.

• Preside® Ultra will be our best offering again in 2025.

• Preside® Ultra provided a yield gain of 2.06 bu/a over uninoculated seed in 2024, providing better than a 5:1 Return on Investment!

Untreated

Treated with Melee®

Treated with Preside® Ultra

Untreated (left) vs. Treated with Preside® Ultra (right). Note the improved top growth when soybeans are inoculated.

Untreated

Treated with Preside® Ultra

Trial: Soybean Seed Applied PGR and Talc & Graphite Replacements

Adding Value - Talc & Graphite with Micronutrients and Crop Boosters

The increased ROI and value of seed applied talc and graphite replacements versus standard talc & graphite products was seen in both corn and soybeans in 2024!

Providing nutrition and bio enhancement products to every seed, in addition to providing the needed seed lubrication for proper planting, is extremely efficient. One product can serve both corn and soybean needs. Seeds also need micro levels of crop nutrition to initiate germination.

Seedling vigor was critically important in soybeans and corn in 2024. Improving emergence in the cold spring soils, getting roots deep into the soil mid-season and ahead of the later season heat was key to improved yields.

Stride Bio™ provides enhanced nutrition, good seed fluency, and most importantly, stress reduction through the patented Yield Burst™ technology from Rosen’s®

Stride Bio™ had a 2.95 bushel gain versus talc + graphite alone in 2024. With soybean pricing at $10/ bu, this provides significantly greater than $20/ac additional net return. In two years of testing, the results are even more striking, with an average gain of 4.10 bu/acre over talc graphite alone.

Stride Bio™ is 80/20 talc graphite. It contains Calcium, Magnesium, Sulfur, Iron, Manganese, and Zinc. It also contains stress reducers to up-regulate genes for seedling vigor and early growth.

Canopy Coverage

Seed applied products were compared using the Canopeo™ app at the V6 growth stage to visualize the difference in canopy coverage.

Seed Applied Talc Graphite

Seed Applied Protivate® NU-4

Seed Applied Stride Bio™

Trial: Soybean Starter Fertilizers & Additives

The Path to Maximum Soybean Yield Starts Early!

Starter fertilizer in soybeans should become a standard practice in the Northern Plains, as it has proven to be a key to getting an early significant boost to soybean development, helping establish sound, strong plants.

A solid starter fertilizer program including starters like Agtegra’s A7-23, with additives, improves stand and promotes rapid, even emergence, which is the early KEY to maximum yields. Improved growth all season, with large, deep taproots, helped soybeans survive the later season drought stress.

ARx Sync™ is an organic acid additive that assists in nutrient availability, plant vigor and nutrient transport. We recommend ARx Sync™ on EVERY acre! The ROI for this product remains incredibly solid. ROI in four years of soybean testing at the Bath plots has averaged $12.64 per acre!

PGR: Plant growth regulators (PGR), such as Ascend2® or Cygin® Pro boost ROOT, SHOOT and LEAF growth. Soybeans are tremendously responsive to PGRs, and significant improvement in plant vigor is seen. The PGR helps build up the entire plant, which showed a benefit and improved ROI!

Biological Additives can increase general nutrient availability and uptake, especially focusing on Phosphorus availability. Foster® FC (dry biological from Rosen’s®) was a solid performer with ease of handling.

Using a full fungicide and insecticide seed treatment like CruiserMaxx® APX along with a high-quality soybean inoculant like Preside® Ultra on every soybean acre is a foundational best management practice and must be in place to maximize the starter fertilizer or any additives.

2024 Treatment Results:

• To test the validity of the results across sites, two separate trial sites were established at the Research and Technology Plots in 2024. Results from the two plots were strikingly similar, showing the consistency of performance for the products tested!

• ARx Sync™: provided a 1.80 bu average gain in 2024. With a low product cost per acre, this product is providing consistent, solid ROI.

• Biologicals have a solid place in our arsenal. Foster® FC, a broad-spectrum biological from Rosen’s® has proven itself to be a solid performer. Performance gains realized on soybeans are lower than on corn, but ROI remains positive.

• PGR Additives: ARx Sync™ + a PGR, such as Ascend2®, provided excellent gains in yield.

• Cygin® Pro is a competitor PGR to Ascend2® and results are consistently good for that product as well as Ascend brands.

• Synergy! The effects of each component added in the trials appear to be synergistic, and nearly additive to each other. Starter + ARx Sync™ is a base program, but the effect of the biological and the PGR additives appears very solid.

4 Year Starter Fertilizers & ARx Sync ROI: Consistency Matters!

Trial: Soybean Foliar Fungicides and Stress Reduction

Keeping Soybeans Healthy - All Season!

The late 2024 growing season was nearly an “opposite” type of season vs the 2023 production system. In 2023, timely rains in August helped with pod set, but also brought a low level of disease pressure to the plots. Fighting off diseases during pod fill, and also reducing stress, resulted in foliar fungicides paying significant dividends. In 2024, the weather at pod fill was extremely dry, reducing the potential response to a fungicide for disease control and also dampening the ability of a fungicide to provide significant plant health benefits.

Fungicides 2024

• Soybeans did respond to a foliar fungicide when applied at the R2-R3 growth stage. Top-tier combination fungicides such as Delaro® 325 SC (Bayer®), TrivaPro® (Syngenta®), Miravis Neo® (Syngenta®) or Revytek® (BASF®) provided a 2.16 to 3.26 bu gain over untreated plots. These yield gains, although solid, did not provide outstanding ROI, when application costs and the cost of the added foliar nutrition product are included.

• Fungicides remain a solid part of high-yield management programs, and the year-to-year response to fungicide has proven itself to provide a solid ROI for growers. The risk of a disease outbreak, especially for white mold, can easily add significant ROI to the application.

Focused Stress Reduction Additives with Fungicides

The hot, dry weather experienced during end of July and into August placed the soybean crop under a significant amount of plant stress during the critical pod fill stage. Fungicides, as mentioned, are a key component of reducing plant stress, but the newer focused products on the market dedicated directly to reducing plant stress appear to provide significant benefits as well.

We tested several products, along with Delaro® 325 SC fungicide and ARx N-fuZe™ foliar nutritional on R2 soybeans. These products are generally naturally derived extracts and/or amino acid containing products.

• The products Yield-On® (Syngenta®) and Transit Foliar® (Valent® Biosciences), along with an experimental product coded GEA 1019 (Syngenta®) were top performers in the plot and provided excellent returns.

• Crop +® (Verdesian®) and Re-Leaf® OS (ATP Nutrition®) also performed well.

• Additional years of testing are needed, but there appears to be a consistent, positive effect of these dedicated products, and they are worth investigating and testing on a larger field scale. This is perhaps the most intriguing set of products we are testing this year. The potential to look at these products on a larger field scale and possibly investigating integrating this type of technology into our existing Agtegra proprietary nutritional products is an exciting area of study.

Pods were collected from a 2 foot row. Adding stress management products to a herbicide or fungicide pass holds promise for higher yields!

Delaro® 325 SC Only

Delaro® 325 SC & Crop +®

Delaro® 325 SC & Transit Foliar®

Delaro® 325 SC & Yield On®

SEED TRIALS

2024 Top Performing Seed Products

Each year, we partner with Agtegra farmers to conduct large-scale trials to compare new seed hybrids and varieties against tried and true hybrids and varieties. In 2024, we planted and harvested over 30 field trials alongside farmers across North and South Dakota (see map for counties included). The summarized data represents the top performing hybrids and varieties that were trialed in each relative maturity range. Yields for products within the same relative maturity range were averaged across each plot. Each hybrid or variety was then ranked by their percentage above average yield.

Selecting the right seed hyrids and varieties for your farm can be complex. Work with your local Agtegra Agronomist for a custom seed portfolio recommendation. To dig in deeper on each individual seed trial, visit our website at www.agtegra.com/plot-results.

90-Day Maturity

SSP / DKC092-14 VT4P

95-Day Maturity

100-Day Maturity

105-Day Maturity

Group

Group