HERCULES

A high perfomance parlour for large dairy farms

The flagship of milking systems for sheep & goats made in agromasters .

The flagship of milking systems for sheep & goats made in agromasters .

Agromasters is a leading Manufacturer & Exporter of innovative & high quality Milking parlours, Milking automations , Feeding equipment, Manure handling systems.

Since 1978 Agromasters has been significantly contributing worldwide in the dairy farming sector by offering custom made & technologically advanced products for cows , calfs , sheep , goats ,lambs & buffaloes.

Thus Agromasters via its outstanding know - how supports daily, thousands of dairy farmers worldwide that desire to grow their business by achieving optimum milk yields & simultaneously ensuring animal welfare

Our products’ design & manufacturing take place in our facilities, thus ensuring the highest quality of our equipment

HERCULES rotary milking parlour, is manufactured especially for dairy farms with more than 500 animals . A superior quality parlour with cutting edge milking tehnology

Your benefits at a glance - ΗΕRCULES

Ideal milking parlour solution for farms with capacity from 500 up to 5000 animals .

A rotary parlor can milk up to 1440 animals in just one hour

Reduces milking time dramatically.

Lowers labour costs vertically. One or two milkers are required for its proper operation.

There is no need for special concrete constructions , since Rotary platform is installed on straight floor.

Extremely fast entry & exit of animals with non-stop platform operation.

Effective & fast milking with rotation speeds from 3-7 minutes ( according to lactation period ).

High quality milking components made in agromasters.

Internal milking platforms provide better management of the animals & easier access to the udder .

Hercules

Rotary Platform

Agromasters manufactures for more than 25 years advanced rotary milking systems for sheep and goats, which is the flagship of our range of products.

Designed for continuous, around-the-clock milking, the Hercules Rotary is ruggedly built and precision engineered to deliver unrivalled throughput and maximum efficiency for the dairy operation.

Hercules Rotary is manufactured with up to 100 milking points & can be escorted with entry level automation or with advanced flock management system.

How it operates

The farmer set the machine in milking mode , activating simultaneously platform rotation & automatic feeding. Then one by one, animals enter the platform & guided toward the individual stalls. While the platform is on the move, each feeding trough is automatically filled with a certain amount of food, then each animal places its head in the stall & stays in place, through a head lock mechanism. The same process is followed for all animals.

The milking process begins internally. Once milking is complete each head-lock opens automatically just before reaching the exit gate & animals are returning to the barn. This process is continuous, with animals entering & exiting the rotary parlor

Rotary platform

3

Rotary stall with feeding trough

A high perfomance parlour for large dairy farms

Rotary Platform

Rotary platform

Technical specification

Each Hercules Rotary platform consists of the following below :

Rotary stall. Individual stall with automated animal locking and unlocking mechanism, escorted with aluminum or stainless steel trough.

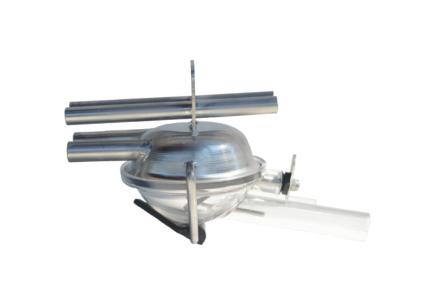

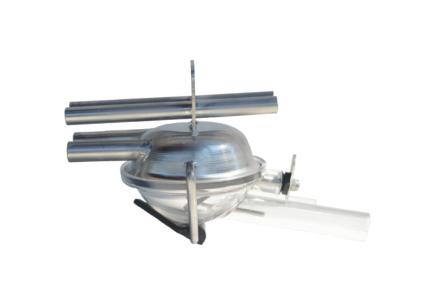

Rotary Gland . It is the heart of the parlour. It transfers milk, vacuum, along with electrics & data to the closed circuit

Gate.The animals enter & exit the parlour through a custom made Entrance - Exit Gate

Double Feed Distribution system. It delivers on each trough 2 types of cereals in predefined quantity.

Double Feed Conveying system. It is used for conveying different kinds of livestock feed towards the milking parlour.

Rotary control panel . The 7 inches touch screen , allows quick, efficient and reliable operation of the rotary milking system. Its software was designed with main emphasis in optimum user experience, ease of operation & efficiency.

Columns. The Platform rotates onto columns with nylon rollers , which regulate simultaneously the height of it

Drive unit. It provides smooth and steady rotation of the entire assembly. The rotation is made by means of a special wheel, which regulates the traction of the rotation.

Platform floor. It is anti-slip & provides safety for the animals made of 2 mm Aluminum sheet.

Tubings. Rotary platfom is escorted with all necessary Stainless steel Milk - Washing tubes & connections

4 Hercules

Rotary Gland

Key features

It is the entry point of the main vacuum line & from its 2 exits, distributes vacuum to the closed circuit of the milking system

When Milk reaches a certain level in Hector Receiver, the Milk pump is activated , milk rises upwards, passes through the interior of the gland & ends up in the Cooling tank.

Available with 8, 10, 12 & 16 electric slip rings according to the size of the parlour, capable of supplying power to all important automations of the milking system .

Made of highest quality raw materials.

It can be manufactured upon order according to the size of parlour .

Easy installation

Minimum vacuum drop & back pressure

It can be adapted to all milking parlour brands .

5

Rotary platform

The Agromasters Rotary Gland is the heart of the Rotary platform. It transfers milk, vacuum, water, along with electrics and data. It is manufactured exclusively from top-quality materials that can withstand continuous and non stop operation for many years.

A high perfomance parlour for large dairy farms

Entrance & Exit

Gate

Key features

The Entrance - Exit Gate doesn’t allow animals to overtake each other or loose their way.

It is fully hot galvanized and constructed by heavy duty materials

It comprises of antislip hot galvanized floor.

It is divided in 2 Pieces

The left side of the Gate is the extension part from ground that has an elevation angle of 25 °.

The right side of the Gate is the horizontal part with 0 ° Elevation angle that directs animals to follow a certain direction towards the head locks .

Rotary platform

6 Hercules

Double Feed

Distribution System

Key features

The feed distribution system comprises of a 200kg Feeding tank , fully hot galvanized . The interior of the tank consists of 2 different chambers that can store up to 2 different types of cereals. The 4 legs of the feeding tank are adjustable in order to deliver the amount of feed at the desired height. The agromasters feeding tank can deliver predefined amount of food ( with accuracy of tenths of a second) which can be configured from the HMI of the Rotary control panel . By this way farmer can follow specific nuitrition for each animal by delivering accurate quantity of 2 different types of cereals on every single aluminum or stainless steel trough .

As soon as each feeding trough passes from a certain point, a sensor activates the automatic feeding process . Terminal switches determine whether the feeding tank is getting emptied in order to activate the refilling process through the feed conveying system.

Rotary platform

Rotary platform

7

A high perfomance parlour for large dairy farms

Conveying System Double Feed

Agromasters manufactures feed conveying systems used for optimized management of loading/unloading operations & transport of various types of feed to the milking parlor or feeding belt.

With the double feed conveying system, dairy farmer can load automatically the feeding tank with 2 Different types of cereals, where they can be transferred directly from silos or a volumetric.

Key features

Excellent feed conveying capability.

Easy and quick assembly.

Breakage risks significantly reduced. Low maintenance .

Adaptable to any dairy farm .

Feed conveying system parts

PVC tube

Spiral Electrical panel

Volumetric 500 kg

Speed reducer

Rotary platform

Rotary platform

1 2 3 4 5 1 2 3 4 5

8 Hercules

Rotary

Control panel

Rotary control panel is an electronic device that gives its users significant & analytical information related to Rotary parlour operation.

The Rotary control panel software was designed with main emphasis in the optimum users experience , ease of operation,efficiency & reliabity

Indications

Indication of Drive Unit operated Frequency in Hz.

Indication of Drive Unit current consumption in (A). Indication of time needed for complete platform rotation, which is variable from time to time.

Indication of total milking time.

Indication of total number of animals that entered the parlour which are automatically counted via our high tech sensor.

Visualized Washing tube indication in red color and simultaneous buzzer operation when washing tube is connected to the rotary platform, while user wants to initiate rotation of the platform.

Visualized Indication of locked animal & buzzer operation when animal cannot be unlocked at the exit of the rotary. Then platform stops

Visualized Empty seat indication & buzzer operation when there is absence of animal in a specific milking point . Then platform stops.

Separate window with indication of total number of animals that entered the platform & total milking time .

Operations

By pressing Milking button on HMI, milking process is initiated (after turning switch of Poseidon 2 in milking mode).

User can increase or decrease the speed of Drive Unit by just entering the desired value in Hz

User can select between No1 or No2 feed distribution systems or both . He can set on the HMI, how many seconds or ten of seconds the 2 high speed motors will operate (which will affect the quantity of food that will be delivered on each trough.

Rotary control panel keeps in memory all errors during platform operation for a specific period of time.

Visualized emergency button on the 7 inches touch screen

Actual buttons for Start, Stop & Emergency . Switches for Rotation direction & Automatic Feeding activation.

Rotary platform

9

A high perfomance parlour for large dairy farms

Rotary parlour

HMI 7 inches

Operated Frequency indication in

Buttons ( for Frequency variation )

Set Drive unit operated Frequency in Hz

Average time for complete platform rotation

Total number of animals entered Rotary

Milking Button ( Start & Stop)

Total milking time

Select

Return to homepage

Empty seat indication

Set Quantity of food / animal

Locked animal indication

Washing tube Position

Emergency events Recordings

Emergency Button

Select manual or Automatic feeding

Current consumption indication in A (Drive Unit)

Hz (Drive Unit)

2)

Food distribution system ( 1 or 2 or 1 &

Enable or Disable sound Service menu 1 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 10 1 2 3 4 5 6 7 9 8 10 11 12 13 14 15 16 17 18 19 Rotary platform

10 Hercules

A high perfomance parlour for large dairy farms

Hercules

Animals ‘ entrance in the platform (Head locking)

Drive unit

Animals’ exit from the platform (Head unlocking)

Pictures

Rotary Gland

Trough emptying underneath Entry - Exit Gate

11

Nylon Rollers

Hercules

Milking cluster athena into milking position

Double feed distribution system & Conveying system

Hector Terminal unit

Rotary control panel

Triton III Washing cups

12 Pictures Hercules

Stainless steel or plastic feeding trough

Control Panel Hercules

Milking system

Hercules control panel is the main electrical panel of the agromasters milking system. It gives power to the most important automation parts of the parlour like :

Milk pump controller , Rotary control panel , Feed conveying panels , Zeus Pulsation control unit , Poseidon washing unit II , Hermes ACR controller, Lights .

Milk pump controller

2 x Feed conveying panel

Rotary control panel Zeus pulsation control Unit

Poseidon washing unit I

Hermes ACR controllers

Milk pump controller

2 x Feed conveying panel

Rotary control panel Zeus pulsation control Unit

Poseidon washing unit I

Hermes ACR controllers

13

A high perfomance parlour for large dairy farms

Terminal Unit Hektor

Milk Receiver

The Hector I Milk Receiver has a capacity of 40 or 60 liters & has been designed to ensure optimum hygiene thanks to the glass construction.

The glass allows observation of the milking & washing process.

The top & bottom lids are made of stainless steel and they are accompanied with the necessary gaskets to ensure perfect tightness.

The unique design of the level control system allows its uninterrupted operation even after 30 years, without maintenance.

The stainless steel shutter allows the user to empty the remaining amount of milk.

Milk pump

Τhe Apollo Milk pump is self-cleaning & it is made exclusively from 100% 304 Stainless steel components & comes with electrical panel.

Automatic operation. The Agromasters milk pump starts its operation when milk in the glass receiver reaches a certain level through the level control system

Manual operation. When there is a small amount of milk in the Receiver after the end of the milking process, user activates manual function to send milk to the Cooling tank .

Sanitary trap

Sanitary trap is 100 % made of stainless steel.

It separates the milking from vacuum side of the machine. that might be sucked up through the vacuum lines

It also protects the vacuum pump from moisture and dirt

Milk lter

Agromasters manufactures all types of milk filters in terms of length, width, single or double depending on the size of the milking parlor.

14

Hercules

Triton III

Washing Cups

Milk & wash assembly

Τriton III washing cups are high quality products for sheep & goats , that clean and disinfect effectively milking clusters. They are placed on the washing line of the milking system & intended for low or high line systems.

It is a lightweight stainless-steel product with an integrated stainless steel milk entry .

The specially designed product ensures quick and accurate positioning of the milking cluster into wash position with minimal vibrations.

Easy removal of milking clusters when parlour is being prepared for milking.

No consumables required due to its stainless steel construction

Milk & Washing line

Milk & wash assembly

All agromasters milking parlors are equipped with stainless steel milk & water pipes of various diameters depending on the size of the installation.

All the necessary stainless a) connections, b) supports, c) milk taps, d) curves, are used to form the proper closed milk & wash circuit.

15

A high perfomance parlour for large dairy farms

Poseidon

Washing Unit I

Washing units , wash tanks & others

The Poseidon I washing Unit is a high-quality electronic device designed by agromasters for the automatic washing of milking parlors.

It is considered as the main panel of the installation and is an efficient & economical solution for medium-sized parlour .

It consists of a Stainless steel enclosure that contains all the electronic & Hydraulic parts of the appliance.

Since It is electrically coupled with the Vacuum pump & drain valve, it allows you to manage both the milking and washing phase.

Poseidon Washing unit is escorted with plastic bottle for manual dosing of detergents as a more cost-effective solution.

Technical features

Poseidon washing unit I controls parlour's milking & washing process via one single switch.

It is electrically coupled with Aeolus Service monitor, Vacuum pump , drain valve & air injector.

It is available with 2 washing programs :

1st program - 1 phase (rinsing with cold water )

Flexibility in adjusting parameters of washing programs . Indication on the LCD display of each operation during washing.

2st program - 4 phases (circulation washing with alcalic or acid)

Indication of total washing time.

Indication of washing temperature . Protection against short circuit & voltage overload.

16

Hercules

Washing Unit II Poseidon

Washing units , wash tanks & others

The Poseidon Washing Unit II is a high quality electronic device designed by agromasters large goat & sheep milking for the automatic washing of parlours .

It is considered as the main panel of the milking system . It consists of a Stainless steel enclosure that contains all the electronic & Hydraulic parts of the appliance.

Since It is electrically coupled with the Vacuum pump & drain valve , it allows you to manage both the milking and washing phase.

Poseidon Washing unit II is escorted with 2 peristaltic pumps for automatic dozing of detergents as a more advanced solution .

Technical features

Poseidon washing unit II controls parlour’s milking & washing process via one single switch

It is electrically coupled with Aeolus Service monitor, Vacuum pump , drain valve & air injector.

Flexibility in adjusting parameters of washing programs .

It is available with 4 washing programs :

1st program - 1 phase (rinsing with cold water )

2st program - 4 phases (circulation washing with acid )

3st program - 4 phases (circulation washing with alkalic )

4st program - 5 phases (circulation washing with alkalic & acid )

Indication on the LCD display of each operation during washing.

Indication of total washing time.

Indication of washing temperature .

Protection against short circuit & voltage overload

Optionally avaibable automatic water heating system escorted with 2 resistors 6 kw each and electrical panel

Pump 1 11 2 3 Cold water - Cold water - Hot water - Temperature sensor wire - Perist. Pumps Output 1 & 2 - Detergent -Acid Hot water Solenoid Valve Hot water Solenoid Valve Hot water Solenoid Valve Cold water Temperature Resistors Acid Detergent Check high water level Pressure Probe 1 Pressure Tube 2 Peristaltic pump 1 Tube Peristaltic pump 2 Tube Temperature sensor wire Pressure Tube 1 Check low water level Pressure probe 2

17

A high perfomance parlour for large dairy farms

Zeus PCU NT Pulsator

The Zeus Pulsation control unit is designed for the accurate synchronization of electric pulsators in a milking parlor for sheep and goats.

It is capable of supplying power to a maximum of 24 electric pulsators.

Technical features

Zeus pulsation control unit

It is equipped with LCD Display

Indication of total current consumption on each channel . Indication of Voltage supplied to pulsators.

Phases configuration

Pulsation rate configuration (10-190 pulses / min)

Pulsation ratio configuration (10:90 – 90:10)

Indication of front and rear pulsation ratio

Choice of 2 different groups of settings

The enclosure is manufactured from aluminum & inox

NT Electric pulsator facilitates fast and smooth milking & maintain udder health.

They are manufactured in 2 or 4 exits. A Zeus pulsation control unit can synchronize up to 24 NT pulsators.

Technical features

NTelectric pulsator

NT pulsator is designed for unique milking experience.

It provides highly reliable operation

It is easy to install & requires no maintenance .

It sends interrupted vacuum during milking so that it imitates the basic movements of lamb during lactation

NT pulsator has minimum demands in terms of vacuum and very low energy consumption ( 200 mA

Vacuum assembly

18

Vacuum assembly

Hercules

Aeolus Service Monitor

Aeolus Service Monitor is a multifunctional vacuum measuring device & at the same time, an aid for the dairy farmer that wants to monitor and control the proper operation of the milking system.

It shows on an illuminated liquid crystal display the continuous accurate –time vacuum level in the milking system.

It notifies the user with a light and acoustic indication if the vacuum may go beyond the minimum and maximum predefined values set by the user (adjustable).

It reminds you when it is time for a) liners replacement, b) Vacuum pump service

c) General service.

Moreover, it can transfer vacuum measurements remotely to other instruments like frequency regulator of the vacuum pump.

Technical features

Aeolus Service monitor

Aeolus service monitor is displaying continuous real-time system vacuum level. Build in alarm for low and or high vacuum indication . Moreover it can be connected with external siren . Vacuum level is displayed with accuracy of decimal digit.

If vacuum level is too high, a red led is flashing intermittently . If vacuum level is too low, a purple led is flashing. Reminds you when to service vacuum pump (It counts operating time of vacuum pump).

Reminds you when liners have to be replaced (It counts total hours of milking operations).

Reminds you when service for the whole milking parlour will be required .

Display of time remaining until the upcoming service will be needed. Reduces risk of unplanned emergency service & helps maintain peak system performance.

Memory holds data from up to 200 events . It retains information even if power fails, and continues working when power is restored.

It can transfer remotely vacuum measurements to agromasters frequency regulator in order to control vacuum pump thus achieving a constant vacuum in desired levels & saving energy.

Vacuum assembly

19

A high perfomance parlour for large dairy farms

Vacuum Pump

Optimum performance during milking

The Rotary vane vacuum pump is the key element for the good operation of the milking system. With more than 25 years of experience in vacuum systems production , agromasters offers a wide range of belt driven vacuum pumps for sheep & goat parlours.

Due to the precise & high quality construction of the Pump rotor & housing , agromasters vacuum pumps create efficient and stable vacuum with no fluctuations .

Each vacuum pump is escorted with : a) Base plate , b) Vacuum tank with integrated non return valve , c) Belt stretcher slide , d) Protection cover, e) Silencer, f) Oil can, g) Belt , h) Pulley , I) electrical motor , j) Vacuum regulator

Agromasters Vacuum pumps are available in 350 liters , 750 Liters , 1500 liters , 2000 Liters & 3000 Liters capacity

Vacuum regulator

pump assembly Vacuum pump assembly 20 Hercules

Vacuum

Milking Clusters Athena

Milking units

The Athena milking cluster is our standard solution for milking fast & effectively sheep & goats.

The Odysseus stainless steel milk claw is handcrafted, manufactured exclusively by agromasters . A high quality product designed for lifetime use

The circular shape of the milk claw & anatomic design contribute quick & easy handling. The polycarbonate lid to allows observation of milk flow.

It is very easy to clean since it can be disassembled with a single movement.

The Odysseus milk claw is manufactured for :

Alternate milking (double pulsation outlet)

Simultaneous milking (single pulsation outlet )

The automatic valves in conjunction with the SS shut off spring of the milk claw, contribute to the optimal vacuum shut off, thus avoiding unwanted vacuum consumption & suck up of dirt

The softness and elasticity of our silicone liners offers superior performance & gentle milking. Also the transparent shells allow observation of pulsation process.

Alternate Milking

Simultaneous milking

Odysseus Milk claw

21

A high perfomance parlour for large dairy farms

ACR System Hermes

The Hermes ACR controller is a high quality solution for automatically removing milking cluster from sheep and goats with accuracy when the volume of milk flow drops below a pre-configured minimum flow rate.

The integration of HERMES ACR controllers in any type of milking system can help to maintain milk quality, increasing milking efficiency & reducing animal health issues, which is usually coming from over-milking periods.

Technical features

Simplicity & efficiency. Simple push-button control (Manual, Milk, Detach).

Led indications. Indication with red LED of all available operating modes.

Easy configuration.A wide range of settings is available on HERMES Controller, according to animals being milked (Cows, Goats Or Sheep). Settings like Vacuum on & off delay, Initial & final Delay, Sweep delay, and Resistance sensing can be easily configured via an external programmer.

Stainless steel enclosure. ACR PCB is integrated into a specially constructed Stainless steel enclosure that offers optimum foreclosure & protection against humidity & water and maximum durability.

Udder stimulus function. When an animal is delaying to take out milk initial Stimupulse will be automatically activated. In order to tease out, any last residues of milk final stimopulse will be activated.

Pulsation. The HERMES ACR Controller has additional outputs to drive pulsation solenoids.

Sweep Function. This function will energize the vacuum to the cluster after the detach sequence to clear the line of any milk residue.

Soft start & Takeoff. Soft starts allow the operator to position the unit before the vacuum energies. Soft takeoff is the period between vacuum shut-off and cluster removal.

Sleep mode . In the event of unit inactivity the HERMES ACR Controller will go into sleep mode, thus achieving maximum power saving.

Entry level automation

22 Hercules

A high perfomance parlour for large dairy farms

Wiring Diagram

Pulsation tube

Control Valve Tube

23

Entry level

A C R Cylinder SS Milk Pipe

automation Control Valve Pulsator

Milk flow sensor & shut off valve

Hermes ACR Controller

Zeus pulsation control unit

Rotary

Performance table

When Automatic cluster remover System is integrated on a Rotary installation, only 1 milker is needed for milking process

Rotary is the type of Milking parlor with highest yields & minimum required milkers ( 1-2) for its proper functioning no matter what is the size of the parlour

Rotary parlors can milk twice the number of animals comparing to Rapid exit & Linear parlors with the same number of milking units

When Automatic cluster remover system is integrated on a Rapid exit installation, only half milker are needed for milking process

(from the shown numbers)

The total milking time of the flock must not exceed 75 - 90 minutes for each milking. In practice, the estimated performance of each Milking parlor diverges approximately -10%.

Factors that affect the performance of each Milking parlor is: a) Type of Milking parlor ; b) Lactation period , c) Ability of milker

Compliance with ISO 5707: 2007 for the design, manufacture and installation of milking parlors constitutes an integral part of its proper functioning

24 NUMBER MILKING ENTRY MILKING EXIT TIME ANIMALS OF PLACES UNITS TIME TIME TIME PER GROUP PER HOUR 2 18 18 * * * 3,0 min 360 MILKERS STALL ROTARY PARLOURS Rotary 18 2 Rotary 24 24 24 * * * 3,0 min 480 2 Rotary 36 36 36 * * * 3,0 min 720 2 Rotary 48 48 48 * * * 3,0 min 960 2 Rotary 60 60 60 * * * 3,0 min 1200 2 Rotary 72 72 72 * * * 3,0 min 1440

RAPID EXIT MILKING PARLOURS NUMBER MILKING ENTRY MILKING EXIT TIME ANIMALS OF PLACES UNITS TIME TIME TIME PER GROUP PER HOUR 1 1x12x6 12 6 1,0 min 4,0 min 0,1 min 5,1 min 140 1 1x12x12 12 12 1,0 min 3,5 min 0,1 min 4,6 min 155 1 1x24x12 24 12 1,5 min 5,5 min 0,1 min 7,1 min 202 2 1x24x24 24 24 1,5 min 3,5 min 0,1 min 5,1 min 282 2 1x32x16 32 16 2,0 min 6,0 min 0,2 min 8,2 min 237 MILKERS STALL

3 1x32x32 32 32 2,0 min 3,5 min 0,2 min 5,7 min 275 2 2x12x24 24 24 1,0 min 3,5 min 0,2 min 4,7 min 306 2 2x24x24 48 24 1,5 min 5,5 min 0,2 min 7,2 min 390 4 2x24x48 48 48 1,5 min 3,5 min 0,2 min 5,2 min 553 6 2x32x32 64 32 2,0 min 6,0 min 0,2 min 8,2 min 468 6 2x32x64 64 64 2,0 min 3,5 min 0,2 min 5,7 min 673

Hercules

Korifi , Imathias , 59300 Esopou 22 , Thessaloniki , 54627 +30 2310 520 820 , 550 992 +30 23330 41123

The flagship of milking systems for sheep & goats made in agromasters .

The flagship of milking systems for sheep & goats made in agromasters .

Rotary platform

Rotary platform

Rotary platform

Rotary platform

Milk pump controller

2 x Feed conveying panel

Rotary control panel Zeus pulsation control Unit

Poseidon washing unit I

Hermes ACR controllers

Milk pump controller

2 x Feed conveying panel

Rotary control panel Zeus pulsation control Unit

Poseidon washing unit I

Hermes ACR controllers