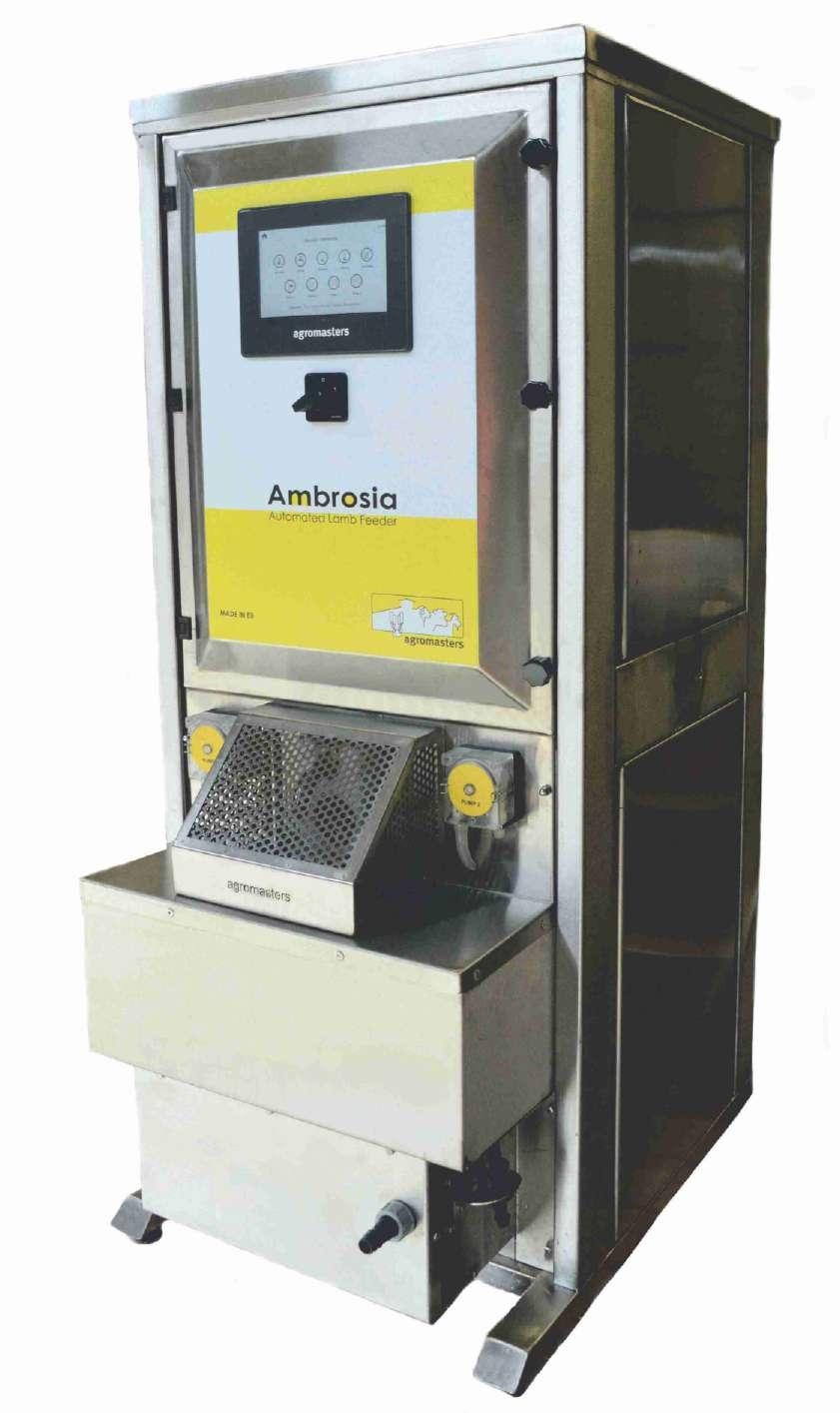

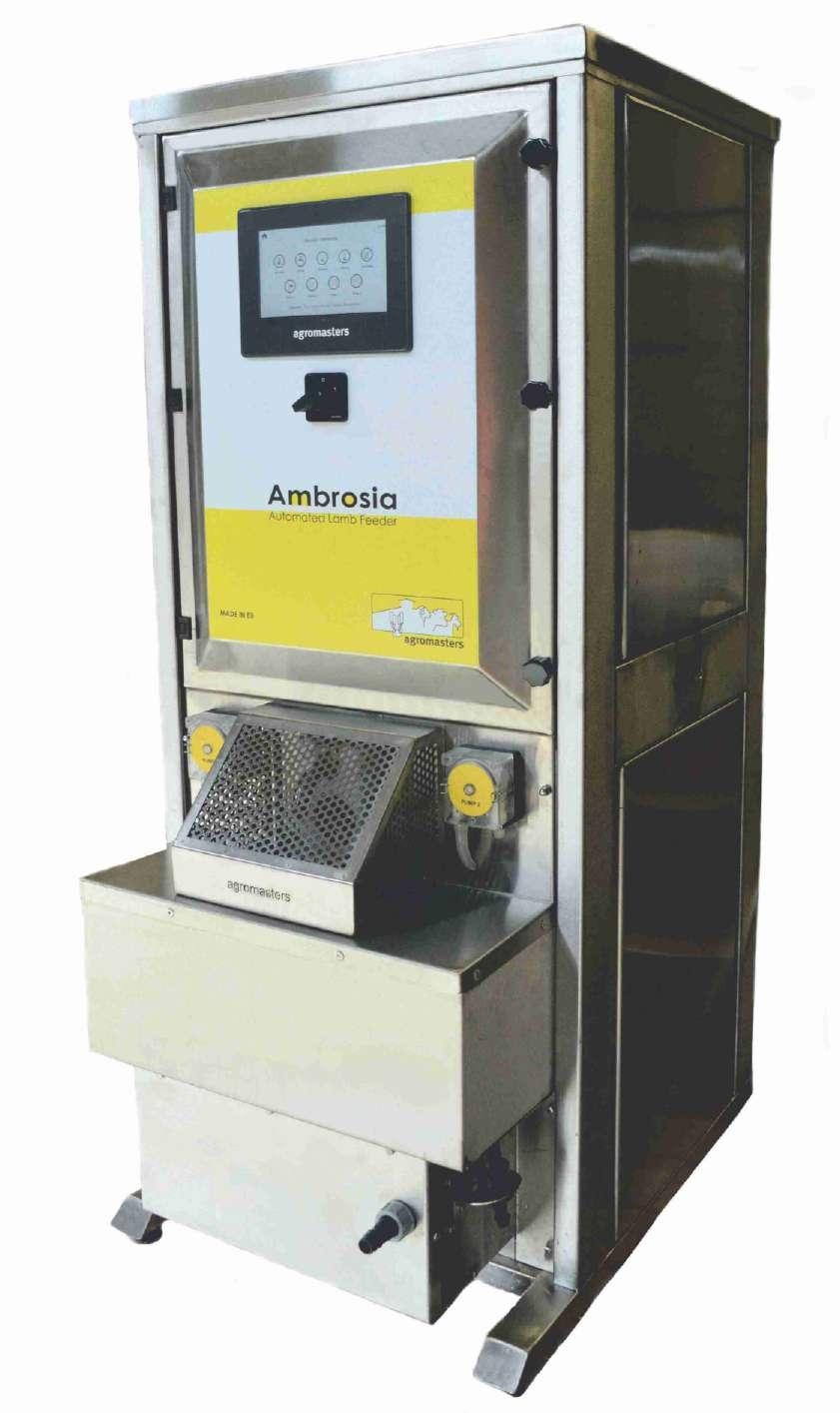

Ambrosia

Robotic lamb & kid feeder

The ultimate solution for the automatic rearing of a large number of lambs & kids.

Ambrosia

Agromasters is a leading Manufacturer & Exporter of innovative & high quality Milking parlours, Milking automations , Feeding equipment, Manure handling systems.

Since 1978 Agromasters has been significantly contributing worldwide in the dairy farming sector by offering custom made & technologically advanced products for cows , calfs , sheep , goats , lambs & buffaloes

Thus, Agromasters via its outstanding know - how supports daily thousands of dairy farmers worldwide , that desire to grow their business by achieving optimum milk yields & simultaneously ensuring animal welfare .

Design & development of ours products takes place in our owned facilities, thus ensuring the highest quality.

Our company latest product development is Ambrosia lamb & kid feeder. A high quality & fully automated feeder that can feed daily a large number of kids & lambs with almost no human intervention

1

7 inches touch screen & easy to operate user interface.

Autonomous operation without human intervention

Automated washing with automatic absorbion of alcalids & acids

Scheduled automatic washing initiation up to 3 times a day

Removable Stainless steel lids for easy access to the interior of machine

45 liters Stainless steel podwer tank

Stainess steel construction

Removable Stainless steel lids for easy access to the interior of machine

45 liters Stainless steel podwer tank

Stainess steel construction

2

Unified construction of 28 liters SS water tank & SS milk container for keeping always milk warm

Ambrosia

3

What makes ambrosia feeder unique

The Ambrosia automated lamb & kid feeder offers a fully automated process for feeding up to 30 lambs or kids simultaneously, Which means up to 800 animals per day

3 6 7 8

1 2 4 5 9 4

It can prepare and distribute automatically endless milk portions to the animals according to the existent demand.

Can accurately prepare a portion of milk (1.5-2 liters) at a predetermined temperature and distribute it via a closed circuit of nipples.

Every 2.5 minutes the feeder is programmed to return the remaining amount of milk to the milk container, then mix it with an additional amount of hot milk & redistribute it to the lambs.

The machine comes with automatic washing & offers disinfection with 1) alkaline, 2) acid or 3) both with no human intervention

In its most Advanced version, the Ambrosia lamb feeder can be turned into a robotic feeder (only required to fill the tank with powder).

The agromasters feeder is manufactured exclusively from stainless steel & high quality parts that can withstand continuous and non stop operation for many years.

The stainless steel chasis consists of 6 stainless steel lids that can be easily removed for checking or service .

The ultimate solution for the automatic rearing of lambs & kids.

The ambrosia feeder is equipped with an 7 inches touch screen & a unique operating system , which is easy to use , efficient & fast . Moreover on the main menu user can distinguish all necessary information regarding the operation of the machine.

Ambrosia Pictures Ambrosia 5

Ambrosia main components

Ambrosia lamb & kid feeder

Water inlet

Stainless steel powder tank ( 40 liters)

Powder motor

Powder spiral

Stainless steel Water tank ( 28 liters )

Water tank sensor

Circulation valve

7 inches HMI touch screen

Electrical panel

Peristaltic pump 1

Peristaltic pump 2

Hot water outlet

Milk container

Resistor 3 kw (1)

Resistor 3 kw (2)

Level switch Circulation Pump

Drainage valve

1 4 5 6 10 7 9 8 11 12 2 3 13 14 15, 16 18 20 21 22 19 17

The ultimate solution for the automatic rearing of lambs & kids.

1 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 21 10 20 22

Mixer Milk pump Milk container sensor

6

Ambrosia feeding station

Ambrosia lamb feeder can support maximum up to 30 feeding stations . Each feeding station is escorted with a holding bracket , teat holders nuts , plastic connections & a blocking valve .

The pinch valve is closing automatically and restrict flow of milk or water to the animals when:

Milk portion is being prepared

During washing process

During reheating process

Holding bracket

Teat holder & nut

Non return valve

Nipples milk tube

Plastic cross

Pinch valve

Pinch milk tube

Plastic T

Ambrosia 1 2 3 7 8 4 5 6

1 2 3 4 5 6 7 8

7

Ambrosia complete system

Ambrosia lamb feeder operation is based on free flow process of milk , that presuposes the milk portion is already prepared and ready for distribution towards the nipples .

So when milk is exiting from the left outlet of the machine it travels along the closed circuit of nipples . In case the milk is not consumed by the animals , after 2, 5 minutes the residual amount of milk will return to the right inlet of the machine and end up to the milk container .

Then milk will be mixed with an additional amount of hot milk to complete the portion at a predetermined temperature and ambrosia lamb feeder will automatically redistribute it to lambs or kids again.

The milk portion preparation process & the reheating - re-circulation is taking place 24 hours a day according to the demand .

On the closed circuit diagram above there are 8 feeding stations . Each feeding station consists of 3 nipples, In total 24 nipples.

On this installation can be fed 600 to 720 animals. Each nipple can feed 25- 30 kids or lambs per day

Output Return

The ultimate solution for the automatic rearing of lambs & kids.

Ambrosia lamb & kid feeder Main milk line

8

9 10 9 10

Ambrosia HMI user interface

The ambrosia lamb feeder is a high tech machine made in agromasters .The core of the machine is the 7 inch touch screen .

The ambosia’s software was designed with main emphasis in the optimum users experience , ease of operation, efficiency & reliabity.

The Ambrosia operating system is split into 4 different screens : Main menu , Calibration , Manual , Settings . On each screen different parameters can be set according to users preferences and requirements.

On the top of the Main menu (2) there are 5 different indications ( Heating , Water , Powder , Mixing , Drainage ). Whenever one of these operation are being carried out , a green indication is lighting up.

On the middle of the screen (4) there are 5 different circled buttons:

Feeding. By pressing this button , feeding process is initiated. Washing. By pressing this button , washing process is initiated, according to parameters were set on settings menu. Calibation, Manual & Settings. By pressing one of these buttons , user is redirected in different screens respectively.

On the bottom & left of main menu (5,6) is displayed the temperature in the milk container and water tank respectively

On the bottom & right of main menu (8,9,10) is displayed the number of portions prepared per day (8) , Number of washing processes (9) that had been carried and the current date (10).

Home button Current operation indication Time indication Main menu Milk container temperature Water tank temperature Status display Total milk portions per day Washings per day Date indication 1 2 3 4 5 6 7 8 9 10

Main menu

agromasters 4 5 6 7 2 8 9 10 3 1

9

Ambrosia

Calibration

Before first time operation , dairy farmer have to calibrate the amount of powder that machine extracts for every milk portion .

The quantity of water that machine extracts for each milk portion is standard .

A plastic measuring cup should be placed underneath feeding supply to collect powder.

By pressing start button powder supply will be activated and counting process (in seconds ) will be initiated. Then press stop button in order to end powder supply . If the quantity of powder is the one you desire then press accept value if not press reset

Settings & Manual

agromasters

agromasters

agromasters

On manual menu on the right, user by pressing each button can activate each of 9 important operations the machine.

On settings menu on the left , user can set parameters like :

First time feeding settings (Powder, water, stirring & drainage) in sec

Normal feeding settings (Water temperature , stirring time) in sec

Washing settings (washing temperature , Program 1 or 2 or both or scheduled washing )

User can choose between program 1 or 2 or both & insert the time that peristaltic pump 1 & 2 will be rotating to absorb alkaline & acid respectively .

Moreover there is the option of scheduled washing , where user can simply insert the time (hour & minute) that wishes to initiate washing process. 3 in total washings can be scheduled during the day.

So if washing is set at 15:00 and is 15:00, while Ambrosia feeder is in feeding mode, feeding will stop immediately and washing will be initiated .

10

The ultimate solution for the automatic rearing of lambs & kids.

Korifi , Imathias , 59300 Esopou 22 , Thessaloniki , 54627 +30 2310 520 820 , 550 992 +30 23330 41123

Removable Stainless steel lids for easy access to the interior of machine

45 liters Stainless steel podwer tank

Stainess steel construction

Removable Stainless steel lids for easy access to the interior of machine

45 liters Stainless steel podwer tank

Stainess steel construction