AGRIMACHINERY.AFRICA

ENTER THE FUTURE

The age of self propelled spreaders, sprayers

The age of self propelled spreaders, sprayers

So that your business can bene t and grow sustainably adding value through audit assurance remains our focus. Our audit design, execution and close-out aims to accurately assess compliance risks, objectively evaluating your control systems and procedures. Our audit team draws on 25 years of industrial experience. Our collaborated industrial knowledge, specialised levels of insight and strict compliance to audit principles enables us to execute best in class audit programmes and or stand alone audit reports.

We recognize the complexity of environmental compliance and respond by staying abreast with legislative changes and interpretations. We benchmark and interact with our clients and our network of legal specialist and provide a unique range of compliance and environmental technical audit solutions. We endeavour to improve time and cost e ciencies and have considered physical constraints such as site accessibility, travel distances and other unforeseen events such as the national state of emergency.

In response that we have deployed ISO 9001 aligned, tailormade audit protocols to suit the varying demand of our clients which include:

• Site based – integrated audit protocols (meetings, interviews, checklists, feedback)

• Remote based - intensi ed and interactive desktop reviews

• Remote based - Online opening meeting, interviews and close out meetings

• Remote based - Secure online documented evidence submission platforms

• Semi remote based - Drone ( y by) and live streaming camera site visits,

• Semi remote based - After-hours auditing to limit exposure.

Our Audit reports link to clear interpretable documented evidence, strong visualization and an alignment with existing document controls on site.

ENVASS has been able to present as much as 50% year-on-year audit programme cost savings to our clients through tailored protocols and audit integration.

• Water Use Licence’s compliance and or technical audits

• Waste Management Licence’s compliance and or technical audits.

• Environmental Management Programme Performance Assessment.

• National Norms and Standards compliance audits and review.

• Atmospheric Emission Licence’s. compliance and or technical audits

• Biodiversity Management Plan implementation audits and reviews.

Massey Ferguson was the winner of the Trator do Ano 2023/2024 with MF 8S............5

Jacto recently present some of its main products, such as Uniport 2530, 3030 and 4530 self-propelled sprayers and OTMIS.....................................6

McCain Foods Limited, one of South Africa’s leading frozen food manufacturers, has officially opened its Farm of the Future Africa in Lichtenburg, North West, the second of three locations planned by 2025......8

Manuchar, a leading distributor of chemicals in emerging markets with headquarters in Antwerp, Belgium, announces it has reached an agreement for a joint venture with Anorel (Pty) Ltd. in Southern Afri-

Special Correspondent: Paul Akeyo

Marketing Manager: Ken Okore

Advertising Executives: Nelson Denga

Eliud Njomo

Philip Wekesa

ca..........................................10

Jacto has established itself as one of the most innovative agricultural equipment manufacturers in the world and is present in more than 110 countries................................14

Brazil agriculture machinery manufacturer Stara has unveiled a new planter which CEO Átila Stapelbroek Trennepohl, says will revolutionize planting in Brazil and beyond......................................11

A transformed fertilizer market is needed in response to the food crisis in Africa..........25

When it comes to agricultural machinery, tyres are a crucial component. They are responsible for carrying heavy loads,

providing traction, and ensuring the stability and safety of the equipment

..............................................34

Agritechnica 2023...............30

Global farming show............33

Design & Layout: Nicholas Amanya

Circulation Assistant: James Oyoo

Quality Assuarance: Tony Marua Tom Mbaka

Office Assistants: Catherine Oyoma

James Mworia Published

Severe land degradation in Africa negatively impacts nearly half of all productive land, affecting well over 650 million people.

Practices resulting in land degradation have removed almost a third of the world’s arable land from production over the last 40 years, and sub-Saharan Africa (SSA) is experiencing the brunt of this crisis.

Continued inaction to improve and restore land could lead to further losses of USD 4.6 trillion over the next 15 years. To restore degraded lands, regenerative agriculture practices such as crop diversification, tree planting, reduced tillage, mulching, and water conservation techniques spur benefits for both agribusinesses and society.

These techniques improve yields via increased soil nutrient and organic content, reduced soil erosion and improved water retention. Broader environmental benefits also emerge through these practices, including more resilient ecosystems, carbon sequestration, improved water management and stronger biodiversity.

Regenerative agriculture practices are a smart way to stem risk in supply chains.

Risks, including climate risks, are on the rise, potentially inhibiting growth and creating supply disruptions for large agribusinesses. Regenerative practices are comparatively cost effective, relying largely on knowledge, time and labour.

These practices enable farmers to adapt to a variable climate more easily through adopting climate-smart techniques and crop choices. Businesses in SSA already reap the rewards of regenerative agriculture in programmes reaching over 100,000 farmers, with yield increases from 68% to

300%.

Companies such as Anheuser-Busch InBev (AB InBev), Linking Environment, Agribusiness & Forestry (LEAF) Africa, Nespresso, Olam, Touton and Twiga Foods have already implemented regenerative agriculture programmes in the region. Olam has seen an 80% increase in cotton lint yields through regenerative techniques, which include mulching and crop rotations.

Touton boosted annual yields by 68% through its agroforestry programme, using shade-tree planting. Through a Nespresso training programme, the individual farmers who have fully embraced regenerative practices such as pruning and rejuvenation6 are seeing up to 300% yield increases.

Within just a few years, regenerative farming systems in SSA could greatly increase yields and reduce input costs to farmers. Some benefits can be seen within a single cropping season, though time frames vary significantly, and other impacts can require longer to realise.

The natural benefits of regenerative farming also reduce dependence on expensive inputs such as irrigation, fertilisers and pesticides, cutting input costs for farmers and providing alternative fodder sources for livestock. The annual savings to farmers across

SSA may be as high as USD 17 billion by 2040.

Increased uptake of regenerative agriculture in Africa could support nearly 5 million jobs by 2040 in addition to increasing revenue and food security for smallholder farmers. Farmers adopting regenerative agriculture can benefit from higher and diversified revenue streams, and may generate additional financial capital that can be reinvested at farm level or help respond to external shocks.

Off-farm employment could also increase alongside yields, as larger harvests require more labour to transport, process, transform and sell products. The economic benefits for farmers and the surrounding economies from regenerative agriculture is projected to increase food security through reduction of prices and accessibility of varied and increased food options.

Regenerative agriculture could also sequester large amounts of carbon dioxide, making it a low-cost and effective solution to combat climate change. By 2040, this carbon benefit could equate to a 4.4 GtCO2e increase in SSA soil-based stock alone. Another 106 MtCO2e per year could be sequestered by restoring degraded land with agroforestry systems.

Massey Ferguson was the winner of the Trator do Ano 2023/2024 with MF 8S. The same tractor was chosen in the “Tractors over 200 hp” category. MF also won in the machines up to 100 hp category with MF 4707 Cab tractor for the second consecutive year. The announcement took place on May 1st at Agrishow.

The MF 8S.265 tractor is powered by AGCO Power 7.4-liter six-cylinder engine, the latest in engine technology. It reaches full power even at low revs such as 1500 rpm, offering excellent economy and quiet operation. The new automatic Dyna-7 transmission offers efficient operation of a total of 28 forward and reverse speeds in four ranges and seven seamless gears.

With the exclusive Protect-U

design, the tractor has 24 centimeters of space between the cab and the engine, isolating the internal environment from noise, heat, and unwanted vibrations. With noise levels of just 68dB, it is one of the quietest cabs on the market, as well as the most comfortable. With an interior volume of 3.4m³, it is also one of the most spacious.

The MF 4707 cab tractor was designed to increase performance and versatility in field activities. It counts on our AGCO Power engine. The electronic engine features turbo and intercooler where the fuel is burned efficiently for savings of up 10% of fuel per hectare. Another positive aspect of the MF 4707 cab tractor is the versatility of its 12×12 transmission – the only one on the market in this category with mechanical or electro-hydraulic shuttle. The transmission counts with the latest technolo-

gy and is very cost effective.

Ideal for silage, grain and horticulture, this tractor has the best working gear matching on the market. With the Power Shuttle, it is possible to perform forward-reverse shifting with the tractor on the go and without using the clutch. This tractor has a lift capacity of 3,000 kg and a flow rate of 65 lpm. The cab has a 360-degree visibility, providing improved comfort and safety at work.

The evaluation of the Trator do Ano was carried out by a technical committee made up of professors with PhDs in the area of agricultural mechanization from important public universities in Brazil, such as the Federal University of Ceará (UFC), Federal University of Mato Grosso (UFMT), Federal University of Santa Maria (UFSM), Paulista State University (Unesp) of Jaboticabal.

Jacto recently present some of its main products, such as Uniport 2530, 3030 and 4530 self-propelled sprayers and OTMIS, Jacto’s brand for precision agriculture, to South African farmers during Nampo.

Founded in 1948 in Brazil, Jacto exports to more than 100 countries, and it has established itself as one of the benchmarks in spraying, fertilizer spreading and planting on the world stage. The company has been present in South Africa for more than 30 years, and it has gained more and more space among the preferences of local farmers. Currently, Jacto considers South Africa as one of the most strategic markets globally, and the company plans to expand its product portfolio in the region in the coming years. Soon, Uniport 5030 NPK fertilizer spreader equipped with important features to spread fertilizers in wider ranges with quality and overlap reduction will be sold in the country.

“South African agricul-

ture is going through a growth phase, but of challenges too. We work to be by the farmers’ side and offer solutions to reduce costs and increase crop productivity. We have a wide range of products for different types of crops always aimed efficiency, cost, and environmental impacts”, explained Stephan Strydom, Sales Coordinator for the African Continent.

Uniport 2530: sprayer with a 2,500-liter tank and 30-meter

Uniport 2530 features a 2,500-liter tank and 30- to 36-meter booms that increase operational efficiency by 5% and reduce losses to crop damage by 7% when compared to 28-meter booms.The set formed by the 4×4 hydrostatic transmission, the 11,300kg weight and the 198-cv diesel engine enable Uniport 2530 to spray on slopes of up to 35% with full tanks. In addi-

tion to that, the piston pumps with electronic controller allow regulating spray volume in a fast and precise way.

Uniport 3030: sprayer equipped with nozzle-by-nozzle control

Uniport 3030 features a 3,000-liter tank and 28-, 32- or 36-meter booms that increase operational efficiency by 14% and reduce crop losses by 17%. The 6.7 243-cv engine with automatic rotation control allied to the 4×4 transmission ensures a consumption ranging from 0.4 and 0.7 l/ha, 35% less than in the main competitor. The nozzle-by-nozzle controllers cut agrochemical consumption by up to 10%, thus reducing overlap and resulting in saving.

Uniport 4530: Jacto’s best technology delivering efficiency and savings

Uniport 4530 has a 4,500-liter tank and 36- or 42-meter booms, and when equipped with 36-meter booms, it increases operating efficiency by 14% compared to 32-meter

booms, and also reduce losses to crop damage by 17%. The 4×4 independent automatic transmission provides increased traction capability in different soil types, and the 6.7 243-cv diesel engine allows travelling at up to 55 km/h and having a 35% smaller consumption compared to the main competitor.

OTMIS

Uniport family sprayers are equipped with OTMIS technology, Jacto’s brand for precision agriculture. OTMIS gathers technologies developed to improve operational efficiency, reduce costs with inputs and fuel, minimize environmental impacts and maximize profits.

One of the highlights of OTMIS line is Omni 700, a system that can be used to navigate machines in field, by integrating lightbar, autopilot, automatic section controller and nozzle-by-nozzle automatic control features.

Uniport 2530 features a 2,500-liter tank and 30to 36-meter booms that increase operational efficiency by 5% and reduce losses to crop damage by 7% when compared to 28-meter booms.

Uniport 3030 features a 3,000-liter tank and 28-, 32or 36-meter booms that increase operational efficiency by 14% and reduce crop losses by 17%.

McCain Foods Limited, one of South Africa’s leading frozen food manufacturers, has officially opened its Farm of the Future Africa in Lichtenburg, North West, the second of three locations planned by 2025.

McCain’s Farms of the Future initiative, first launched in Canada in 2020, is aimed at gaining a better understanding of regenerative agricultural practices as well as their impact, costs and benefits. The regional farm is set to become a research hub that will focus on regenerative agriculture techniques for South Africa’s potato production industry, a sector that contributes ap-

proximately R 6.6 billion to the country’s GDP.

Regenerative agriculture encompasses an ecosystem-based approach to farming that strives to enhance farm resilience, yield and quality by improving soil health and biodiversity, and reducing the impact of synthetic inputs.

“The Farm of the Future Africa project reaffirms McCain’s commitment to the growth of South Africa’s agricultural and agri-processing industries,” says McCain Foods, Vice President, Global External Affairs and Sustainability, Charlie Angelakos.

“Significant progress has been made since the unveiling

of the farm last year, and we are proud to share these developments with all of our stakeholders, from farmers and local government representatives, to customers and partners. This flagship initiative not only showcases South Africa’s sector expertise but also the implementation of industry-leading regenerative agricultural practices that boost productivity and profitability, while accelerating sustainability.”

The farm will also serve as an effective platform for recruiting and training talent, in line with Agriculture, Land Reform and Rural Development Minister, Thoko Didiza’s, recent call for sector players to create mechanisms that will help the new generation of farmers succeed. Additionally, stakeholders will be granted access to the labs and facilities onsite, further facilitating the promotion of local research and development.

Comments, Unathi Mhlatyana, Managing Director, McCain Foods South Africa, “Our investment of R100 million into Farm of the Future Africa demonstrates our commitment to producing planet-friendly food and ensuring that sustainability is integrated into every touchpoint of our business’ value chain.

Farm of the Future Africa will test and feature innovative processes and technologies, specifically tailored for the Southern Hemisphere, in a collaborative hive that will bring together academics, industry and technology partners and farmers, working together to reimagine the way we grow a potato – approaches that are better for farms and the planet.”

Wandile Sihlobo, the Chief Economist of the AgriculturalBusiness Chamber of South Africa (Agbiz) and Farm of the Future Africa advisory board member, acknowledges the challenges the agricultural sector is currently facing and the steps needed to enable the industry to thrive.

“Potatoes are an essential staple for South Africans and an increase in the local production of sustainable spuds will have a tremendous impact on national food certainty, direct and indirect employment and the livelihoods of Mzansi’s farmers. It will also assist us in effectively combating the effects of climate change, ensuring security of supply.”

In line with McCain’s Resource-Efficient Operations sustainability pillar, solar energy is being effectively used to power the farm’s main office

and various machine sheds. The company is also investigating opportunities to utilise solar technology to aid in the continuous deployment of field irrigation.

“Our farmers are at the heart of our business,” says Mhlatyana.” By implementing the Farm of the Future Africa project, we will have the capability to conduct cutting-edge research that can maximise yields, promote economic growth and strengthen sustainability. Our goal is to share this valuable knowledge with our farming partners as we embrace and prepare for our future, together.”

McCain has made a global commitment to implement regenerative agricultural practices across 100% of its potato acreage by 2030 as part of its sustainability goals.

Regenerative agriculture encompasses an ecosystem-based approach to farming that strives to enhance farm resilience

share the same values as us, and demonstrate the same entrepreneurial spirit.”

Mark Jacobs, Region Manager Africa Manuchar: “We are excited to partner with Anorel (Pty) Ltd., a company with a strong track record of knowledge and entrepreneurship in the distribution of Crop Nutrition products in South Africa. This joint venture will support the further growth of our Crop Nutrition business as one of the pillars of our group strategy and highlights the tremendous growth potential in the African market.”

Manuchar, a leading distributor of chemicals in emerging markets with headquarters in Antwerp, Belgium, announces it has reached an agreement for a joint venture with Anorel (Pty) Ltd. in Southern Africa.

This joint venture fits Manuchar’s ambition to strengthen its leading chemical distribution platform and broaden its product portfolio.

Anorel (Pty) Ltd., located in Cape Town, South Africa, distributes a wide variety of fertilizers. Over the past 23 years, Anorel (Pty) Ltd. has established valuable and long-term relationships with its customers in South Africa. By joining forces with Anorel (Pty) Ltd., Manuchar will have an excellent platform to further develop its activities in the distribution of fertilizers to the high-precision agricultural industry in Southern Africa.

Manuchar employs 2,600 employees worldwide. From its headquarters in Antwerp, Belgium, it operates a local

chemicals distribution network across North & Latin America, Africa, Europe, the Middle East and Asia. Manuchar has been present in South Africa since 2003. Manuchar South Africa’s 97 employees are based in Johannesburg, Durban and Cape Town.

The closing of the agreement between Manuchar South Africa and the shareholder of Anorel (Pty) Ltd. is foreseen in the 2nd quarter of 2023, subject to antitrust approval.

Steven Atkinson, Country Manager Manuchar South Africa: “Manuchar South Africa already has a strong presence in Home Care, Fabric Care, Personal Care, Human Nutrition, Animal Nutrition, Water Treatment and Textile.

Over the past years we have also developed our Crop Nutrition business. By joining forces with Anorel (Pty) Ltd. we will accelerate our growth in Crop Nutrition, bringing even more products and benefits to our customers and suppliers. We have a great fit with Anorel (Pty) Ltd.’s management. They

Steven Cafmeyer, CEO Anorel NV in Belgium and owner of Anorel (Pty) Ltd.: “Anorel is specialized in water-soluble fertilizers and biostimulants. We passionately research and develop new technologies resulting in a wide range of innovative products meeting the needs of the water-soluble fertilizer industry.

Manuchar brings its global logistical and commodity procurement strengths to complement Anorel (Pty) Ltd. in a specialized joint venture serving the needs of a diverse South African Market. We are looking forward to partnering with Manuchar enhancing our mutual offerings of services and solutions to the horticultural market in Southern Africa.”

Oscar Cafmeyer, M.D. Anorel (Pty) Ltd.: “Since I moved from Belgium to South Africa four years ago, together with the support from the Belgian HQ Anorel NV, we have experienced strong growth in the South African market. We are very proud to partner with Manuchar, a leading chemical distributor. Building on each other’s strengths will enable us to accelerate our growth and allow us to become a reference in the South African fertilizer market.”

Brazil agriculture machinery manufacturer

Stara has unveiled a new planter which CEO Átila Stapelbroek Trennepohl, says will revolutionize planting in Brazil and beyond.

Named Estrela, the machine is the most comprehensive planter on the market. It is equipped with the Stara Integrated Terrain Copy System (it means the terrain copy is controlled on Topper), an easy and fast transport process, and in-furrow spraying directly from the factory, which by way, doesn’t need to be adapted to your equipment.

It is the only one with two fertilizer sections on the market. The planter has only seven lubrication points. For this reason, lubrication is not required during planting operations (there are no grease fittings).

Also, the piece of equipment provides you with a complete set of solutions and technologies to deliver higher yields to the crop field.

In addition, it is equipped with the DPS-E (Stara Precise Seed Placement – Electric) that ensures the best singulation of seeds on the market with seed compensation on turns.

Check out more information about our newest product:

It is an innovative concept from Stara. The system performs the triple terrain copy by providing the best plantability of the category. There is triple terrain copy with three articulation points.

The planter features a chassis with three modules: a central e two side ones with pneumatic springs that transfer the central module weight to the side modules. As a result,

the cutting power of the planter is the same along the planter structure, and there is planting uniformity from end to end. The modules add 24° of articulation: 12º upwards and 12º downwards.

It is a new row unit from Stara that matches the individual articulation of the row unit (A) to the articulation of module (B). The system is an innovative feature from Stara to guarantee the best terrain copy.

It makes sure there is constant pressure in the seed

row units. As a consequence, there are few trepidations, more stability, and seed placement is carried out with uniformity. The pressure adjustment of the matched row unit and the hydraulic control of the seed row unit pressure is on Topper.

Estrela features the new Stara seed meter that can provide you with a higher precise distribution. The DPS-E stands out because it is easy for cleaning and maintenance purposes, just as its interior access for seed disk and ejector changing. The system also features seven seed ejecting points and the well-known variable rate system.

All technology integrated into the DPS-E delivers the best seed singulation on the market. In addition to all the features mentioned above, it adds the seed rate compensation on turns. The advantage is that the seed population and the internal and external row unit spacing are the same, resulting in high distribution quality, regardless of the turn angle. Precision of 3.5 seed/meter.

Estrela is equipped with the in-furrow spraying factory-installed. NO NEED FOR ADAPTATIONS. The spraying tank features three layers. The central thermal layer is isolated by two other layers built in polyethylene. Therefore, the thermal efficiency of the hopper is provided during its lifespan.

As a result, there is higher protection against the heat and brightness, and at the same time, it ensures the biological activity of the products and the cleaning process becomes easier.

It also adds an automatic adjustment of the rate according to the equipment speed, resulting in quality and uniform spraying. Not to mention the mixing system. This feature keeps the solution constantly moving in the tank.

The automatic shut-off is applied along the three sections, with a module, to integrate the nozzle bracket to the row unit, the anti-drip system integrated, and protection against impacts.

Estrela is really fast to be folded. Its sections are folded in less than one minute. The transport width of Estrela is 3.20 m when the chassis is 21-25 and 4.15 m when the chassis is 27-33. Additionally, the transport becomes easier among fields and farms.

Estrela has got every comfort and convenience Stara can provide you with. They add optimum potential planting needs by the best planter on

the market.

One of the special features is Conecta, Telemetria Stara, the Stara monitoring system, and a technology package that deliver easier operations and higher yields, Topper 5500, The planter also comprises the Control System, the Row-byRow Shut-Off System, the Zero Crop Damage, and Syncro.

Estrela is equipped with the in-furrow spraying factory-installed. no need for adaptations.

be ordered separately.

As supplier of a complete range of agricultural machines for the cultivation of potatoes and root crops, Dewulf will be introducing full ISOBUS on nearly all CP and Structural potato planters from autumn 2022.

Manufacturer-independent system

ISOBUS operation is manufacturer-independent and therefore available both via the tractor and via an additional display in the cabin. This means that joysticks in the tractor can be used to control the planter. If the tractor is not equipped with ISOBUS, an individual ISOBUS cable set can

Additional GPS-controlled display options for the tractor include License Section Control and License Variable Rate. The latter, for example, makes it possible to use task cards to configure which areas of the field fertiliser should be applied. These functions are accessible and can be individually adjusted according to specific needs at any particular time.

Display options

Additional GPS-controlled display options for the tractor include License Section Control and License Variable Rate. The latter, for example, makes it possible to use task cards to configure which areas of the field fertiliser should be applied. These functions are accessible and can be individually adjusted according to specific needs at any particular time.

Delivery of ISOBUS will be possible from January 2023, so the updated planter will be ready for use for the next planting season.

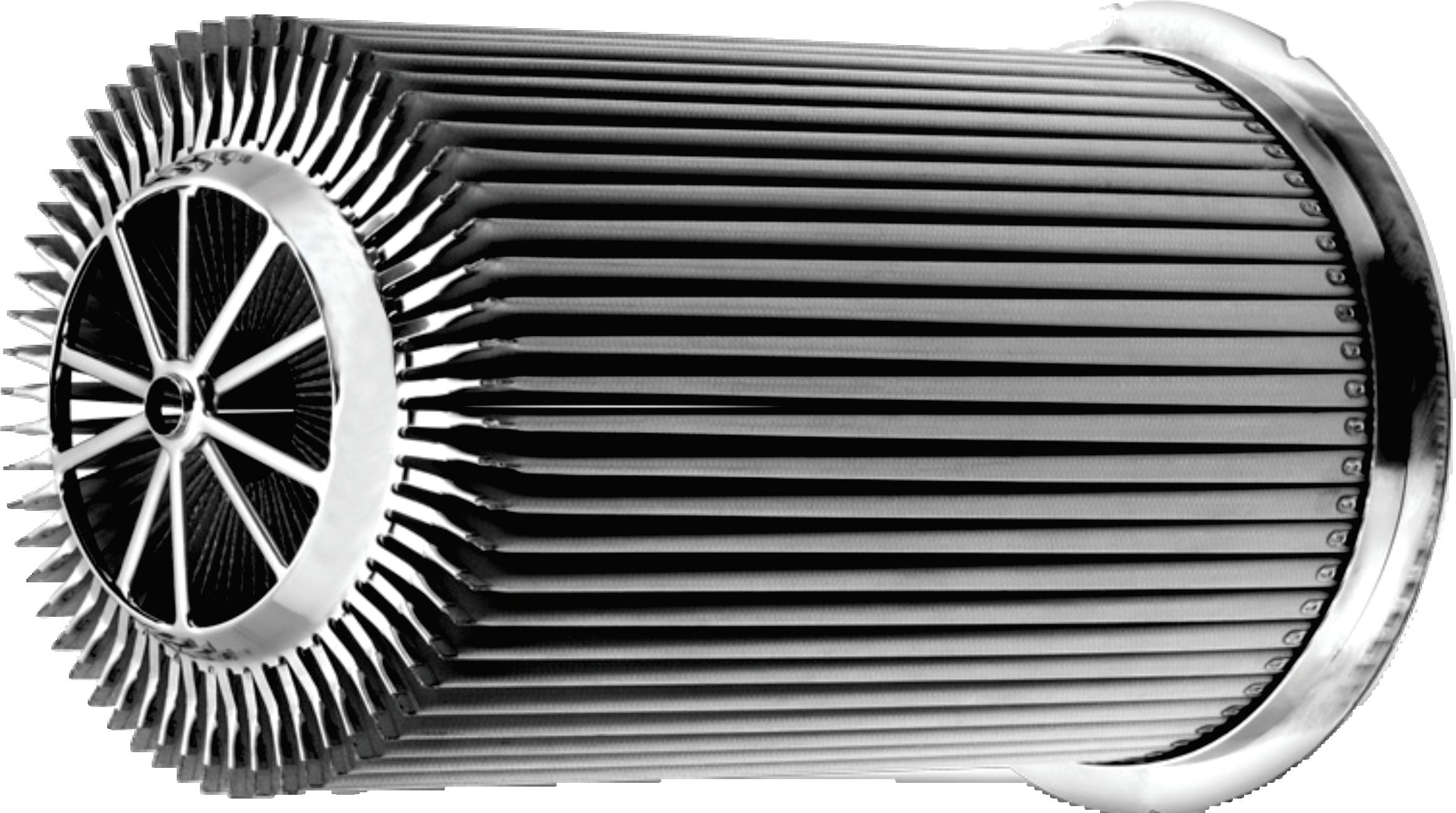

Jacto has established itself as one of the most innovative agricultural equipment manufacturers in the world and is present in more than 110 countries. With a strong investment in research and development, Jacto excels in the race for profit through the efficiency of applying agricultural aids. The company is best known

for his Uniport self-propelled machines and one of the top performers in its range is the Uniport 5030 NPK. This fertilizer spreader’s characteristics make it an essential tool for the farmer who farms with precision to save costs, while preserving his soil. This spreader’s characteristics include an excellent application width for fertilizers and soil correctives, faster manoeuvrability than

other similar implements, greater operational efficiency, and reduced crop damage.

The Uniport 5030 NPK has a storage capacity of 5,000 kg and an application width of up to 50 metres. The accuracy and quality of application is achieved due to the rotation control of the application belt and the height of the gates that

open and close automatically. This also ensures that the granulometry of the fertilizer is preserved.

Control of the drop point of fertilizers on the discs and the exclusive shape of the blades, with two layers to provide the correct overlap for an excellent distribution.

This fertilizer spreader can also be connected to the SmartSet software, which makes adjusting the application more practical, easier, and faster by means of a mobile phone.

Just like other Jacto implements, the Uniport 5030 NKP has a Unitrack steering system, which enables faster and more precise movements and boasts a 35% smaller turning radius.

This system reduces crop damage during manoeuvres by up to 40%. The system allows all four wheels of the spreader to turn, and it eliminates entering and exiting fields, significantly reducing turning time.

Border control

The Uniport 5030 NPK also uses a system that reduces errors with the application of fertilizer at the field’s borders. This helps limit the spread of fertilizer on unwanted areas. The system, which is mounted on the right side of the spreader, concentrates the distribution profile at the end of a field to prevent the fertilizer ending up in areas that the farmer wants to avoid.

Jacto’s self-propelled implements were initially designed for rough terrain in Brazil. It is therefore equipped with intelligent hydrostatic transmission (4x4) and independent automatic traction control, which offers better traction on different types of terrain.

Some of the other specifications for the Uniport 5030 NPK are as follows:

• Flow rate for granular fertiliser: 20-600 kg/ha.

• Dimensions: Length 7.76 m; width 3.20 m; height 3.90 m; length between axles 3.80 m; ground clearance 1.50 m; and track width adjustment 2.603.15 m.

INQUIRIES: Jacto, web: www. jacto.com

The Uniport 5030 NPK also uses a system that reduces errors with the application of fertilizer at the field’s borders. This helps limit the spread of fertilizer on unwanted areas.

The new AERO 32.1, with a working width of 27, 28 or 30 meters, pushes the limits of performance and precision in fertilization.

Precise application rate adjustable on 4 sections

Fitted with a boom of 24 dif-

fusers divided into 4 sections, the AERO 32.1 fertilizer spreader makes it possible to precisely deliver the right dose of fertilizer in the right place. Each section is fed by a hydraulically driven metering unit that can be switched on, off and adjusted individually.

Precise fertilizer distribution ensured whatever its properties, synonymous with significant savings when purchasing type of input.

distribution is properties, significant purchasing this input.

It is thus possible to modulate up to 4 fertilizer application rates or to shut-off the desired sections in a single pass. The AERO 32.1 also incorporates weighing. Two weighing cells measure the quantity remaining in the hopper and allow, if necessary, regulating the speed of the metering units to adjust the application rate. No more calibration test!

The AERO 32.1 can spread with precision right up to field edges even fine, light or compound fertilizers, such as urea and “bulk” type mixtures, which are usually more difficult to

distribute over large widths with centrifugal spreaders.Precise fertilizer distribution is ensured whatever its properties, synonymous with significant savings when purchasing this type of input.

Weather windows are ever shorter, leaving little time for cultivation operations, especially fertilization. With its boom system, the AERO 32.1 makes it possible to fertilize crops whatever the weather, included in windy conditions.

Since the ballistic quality of the fertilizer or seed no longer matters, operators no longer need to refer to spreading tables!

Simply use the fine metering roller (available as optional equipment) to spread slug pellets, microgranules or even

small seeds for broadcasting cover crops.

The booms of the AERO 32.1 are hydraulically controlled. They fold at the rear of the hopper for transport. Well within the machine’s dimensions, they are the guarantee of maximum compactness for travel with complete peace of mind.

The management of the machine and booms is carried out via the CCI 800 or 1200 terminal or any other ISOBUS terminal already available, not to mention the possibility of associating the use of a CCI A3 joystick.

With the AERO 32.1, fertilizer spreading is carried out without compromise, for maximized profitability while respecting the environment. Appreciable assets in the current context of the fertilizer market.

Fertilizer usage is crucial for the improvement of soil yield. But excessive fertilization can also cause serious problems to land health. Using the right amount of product at the right time is therefore a primary mission for farmers. Fortunately technology is providing an helping hand.

New fertilizer technology is therefore focused on improving the efficiency and utilization rate of fertilizer, rather than simply increasing soil’s nutrient level. Additives like adjuvants, organic acids, and microbial solutions are being used to enhance effectiveness.

The new technology overcomes the negative nutrient interactions in the soil which limit the availability of fertilizers. Each nutrient is unique in the soil. Nitrogen is very volatile and subject to loss.

Phosphorus and micronutrients are notorious for becoming unavailable before the crop has an opportunity to use them. The availability of potassium is limited by soil type, temperature, and pH; usually only 1–2% is readily available.

Improvements in fertilizer technology include the adoption of better application equipment like Y-drops, streamer nozzles, strip tillage

One of the highlights of OTMIS line is Omni 700, a system that can be used to navigate machines in field, by integrating lightbar, autopilot, automatic section controller and nozzle-by-nozzle automatic control features.

equipment and variable rate applicators, to name just a few. These tools help with timing and placement of fertilizer to minimize losses to the environment. Likewise, the use of new chemistry is quickly being adopted to slow the loss of nitrogen and to keep phosphorus from locking up in the soil.

The new Uniport 5030 NPK from Jacto for example allows accuracy in fertilizer application greater operational efficiency and reducing crop dents in maneuvers by up to 40%. The spreader allows Control of the drop point of fertilizers on the discs and the exclusive shape of the blades, with 2 layers to provide the correct overlap for an excellent distribution.

Uniport 5030 NPK also has Inbuilt technology tool called SmartSet to assist the farmer in adjusting the

application range of your spreader. In four easy steps, you get the necessary regulation data for a variety of fertilizers.

Overall the Uniport 5030 NPK works to reduce the application errors in the border operations, minimizing the application of fertilizers in unwanted areas.

Uniport family sprayers are equipped with OTMIS technology, Jacto’s brand for precision agriculture. OTMIS gathers technologies developed to improve operational efficiency, reduce costs with inputs and fuel, minimize environmental impacts and maximize profits.

One of the highlights of OTMIS line is Omni 700, a system that can be used to navigate machines in field, by integrating lightbar, autopilot, automatic section controller and nozzle-by-nozzle automatic control features.

John Deere on the other hand has ExactShot a technology which allows farmers to reduce the amount of starter fertilizer needed

during planting by more than 60%. The technology uses sensors and robotics to place starter fertilizer precisely onto seeds as they are planted in the soil, rather than applying a continuous flow of fertilizer to the entire row of seeds.

ExactShot uses a sensor to register when each individual seed is in the process of going into the soil. As this occurs, a robot will spray only the amount of fertilizer needed, about 0.2 ML, directly onto the seed at the exact moment as it goes into the ground.

Across the U.S. corn crop, Exact-

Shot could save over 93 million gallons of starter fertilizer annually and prevent wasted fertilizer from encouraging weed growth or increasing the risk of running off the field into a waterway.

The benefits of precision fertilizer application are enormous. First, you can expect better yields from more consistent crop growth and quality. Secondly, it reduces crop contamination and risk of crop scorch.

The environment can benefit as well. For example, it will help reduce air pollution from ammonia and tiny airborne particles. Precision application of fertilizer is helpful in reducing greenhouse gas emissions.

Before investing in precision application systems and technology it is important to ascertain the level of precision you need, whether you’ll use liquid or solid materials, the type of soil,what crops you grow any nearby watercourses or neighbouring properties.

John Deere on the other hand has ExactShot a technology which allows farmers to reduce the amount of starter fertilizer needed during planting by more than 60%.

From a humble beginning in 1988, BKT has grown in leaps and bounds to become one of the most recognizable industrial and agricultural tire manufacturer in the world.

Chairman and Managing Director Arvind Poddar, talks about the company’s journey since inception.

Mr. Poddar, can you tell us something about the history of BKT and whose idea was to enter the tire, and more specifically the Off-Highway Tire business?

BKT’s journey began in 1988 in Aurangabad, Western India, when my father, Late Mr. Mahabirprasad Poddar, and my elder brother, Late Mr. Suresh Poddar, established the company to produce 2-3-wheeler tires for the Indian market. In 1991, we were joined by another family member, Late Mr. Pramod Poddar, my first cousin, further strengthening our team with his valuable expertise.

As the 2-3 wheelers market became increasingly crowded,

Mr. Pramod Poddar recognized a promising opportunity in the international Off-Highway Tire (OHT) business. As a forward-thinking family, we made the strategic decision to gradually shift our focus from 2-3 wheelers and concentrate on the OHT business. Following our initial success, we expanded our production capacity by establishing another plant in Bhiwadi, Northern India, ensuring consistent supplies to meet growing demands. However, during the first decade, our growth was limited as we focused on establishing our products in the market.

At the closing of our fiscal Year 2006-2007, our turnover was Euro 84 million (at today’s exchange rate). In 2007, we started a transformative path, outlining a comprehensive new strategy that emphasized product quality and brand building. This dedicated approach propelled us to cross the remarkable milestone of Euro 1 billion turnover in 2022, consolidating

our position as an exceptional force in the industry.

This achievement is a testament to the unwavering commitment of our team and the visionary leadership of Late Mr. Mahabirprasad Poddar, Late Mr. Suresh Poddar, and Late Mr. Pramod Poddar. Moving forward, we remain focused on pushing the boundaries of innovation, delivering superior quality products, and marking a path of sustained growth and success.

Today, our journey has led us to a remarkable growth and numerous milestones. We take pride in operating four state-of-the-art tire manufacturing plants, equipped with advanced technologies, alongside a dedicated and fully equipped research and development center that includes an in-house testing track. This infrastructure empowers us to continuously innovate and deliver cutting-edge solutions. BKT’s influence extends across all segments of the Off-Highway tire business, catering to diverse industries and applications. With an extensive portfolio comprising over 3200 SKUs, we offer the widest range of specialized tires in these sectors. This range of products enables us to meet the unique needs and demands of our customers, reaffirming our position as a leading provider in the Off-Highway tire market.

Do you have any other brand or association with any other company?

No, we have only BKT brand. As a company, we maintain a singular focus on our own brand and do not have any direct or indirect associations with any other company or brand. Our dedication lies solely in building and promoting the BKT brand, ensuring that it represents our values, quality, and commitment to excellence. By maintaining this exclusivity,

we can channel all our efforts and resources into continuously enhancing and expanding the BKT brand’s presence in the market, without any distractions or dilution of our identity.

Mr. Poddar, transparency towards stakeholders is one of the pillars that distinguishes your history: is this where your undisputed leadership stems from?

We are extremely proud of the success that BKT has achieved as an international brand in the Off-Highway tire sector, thanks to a series of distinctive characteristics. Among these, sound financial management undoubtedly represents one of the factors that have allowed us to achieve this goal, giving us the opportunity to constantly invest in comprehensive growth and technological innovation.

This is further demonstrated by the recent opening of the Bhuj factory to over 100 journalists from around the world, which serves as a clear example of our transparency and consistency in everything we assert, ready to engage in discussions and follow through on every statement.

How can a multinational corporation as large as yours be close to people? What value do you attribute to Corporate Social Responsibility?

The corporate culture of BKT represents our DNA and guides every activity and strategic decision, providing us with an ethical compass that directs us towards achieving our goals. We create a motivating and engaging work environment for all our employees because we recognize that each individual is an integral part of the company’s success. Furthermore, we are strongly committed to reducing the environmental impact of our production activities and improving the health and safety of our employees.

To accomplish this, we have implemented a series of sustainable company policies and practices, including the use of renewable energy in our factories and the reduction of CO2 emissions.

We firmly believe that sustainability is a significant social responsibility for every company, and we are dedicated to doing our part to contribute to a better future for our planet. Additionally, we are actively working on developing increasingly sustainable tires that can deliver high performance without compromising the environment. Sustainability is a fundamental component of our company mission, and we will continue to invest in innovative solutions to foster a greener and more sustainable world.

So, what is the key to the success of a brand like yours? How do you manage to maintain such a strong presence worldwide for such a long time?

BKT is a successful brand in the Off-Highway tire industry, also thanks to its strong global presence in the OEM channel as well as in the aftermarket where we deal with partner distributors in more than 160 countries. This extensive market coverage, combined with the quality of our products and services, has allowed us to earn a reputation par excellence in the industry.

Our effective and transparent communication with our customers further supports this reputation. While there are other indian brands claiming to have the same quality as our products, the facts demonstrate that BKT is truly unique. We are confident that our end customers and tire dealers working with the BKT range recognize our superiority in terms of quality and performance, which speak for themselves. The loyalty of our customers and their choice to

rely on us for their Off-Highway tire needs are a testament to our success.

The mere geographical origin of a company does not inherently bestow identical product quality or ensure quick results, as some brands may seek to insinuate or attain. The ascendance of any brand, including BKT, requires years of unwavering dedication, resolute efforts, and commitment to excellence.

We persistently strive to expand our portfolio, not only in terms of product with the superior quality, but also in the breadth and enduring nature of our offerings. Our pursuit to excellence knows no bounds as we continually endeavor to surpass previous benchmarks and elevate our industry standards.

Some newer brands claim that their quality is same as BKT and prices much cheaper. How do you react to this?

To manufacture a tire of utmost quality, meticulous attention to every facet of its creation is required, beginning with the sourcing of superior raw materials, the establishment of state-of-the-art production infrastructure, and the implementation of stringent in-process quality checks. Furthermore, an exceptional team of skilled individuals plays an indispensable role in the pursuit of tire manufacturing excellence. Considering the above, it becomes evident that providing to the market such an equivalent quality level, but at a lower price, is not a sustainable proposition, for it would mean compromising on these crucial elements that contribute to the unparalleled quality and performance of our products.

How can one be certain of their competitive advantage, especially in a rapidly changing market?

To maintain a competitive

advantage in an ever-evolving market, the quality of BKT products represents just one facet of our approach as a premium brand. Our dedication to innovation is a fundamental element that sets us apart from a myriad of other brands. However, we don’t merely offer high-quality products; we also strive to adopt superior marketing strategies.

Over the years, we have developed strategies that aim not only to raise awareness of the BKT brand but also to create an engaging experience for our customers. Through participation in trade fairs and industry events, advertising campaigns, sports sponsorships, and other targeted initiatives, we consistently position BKT as a leader in the industry and solidify our reputation.

Looking towards the future, we will continue to invest in research and development, cutting-edge technologies, and impactful marketing strategies. We are determined to continuously exceed our customers’ expectations and strengthen our leadership in the Off-Highway tire industry. Our goal is to provide a comprehensive solution that surpasses mere

expectations, reaffirming our position as the undisputed benchmark in the field.

Does dominating a market sector mean having winning strategies or simply being the strongest? Have you ever considered creating sub-brands to secure a larger market share?

This question gives me the opportunity to address an important matter. We have heard rumors and learned through interviews about brands that, despite their best efforts, try to associate themselves with BKT without having any connection to us.

Throughout our journey, we have never felt the need to compare ourselves to others, not even in the distant past. We know who we are, our roots, and we have always been clear about our objectives, staying true to our path without deviations. With our unwavering resources, we have taken every necessary step, always looking ahead. When you are aware of your own identity, nature, and purpose, there is no need to look at others or, even worse, constantly mention them.

Our gentlemanly nature is

reflected in our approach to the business world, as we always carry values of composure and responsibility. However, we do not tolerate the use of our brand as bait to attract attention or gain credibility that should be earned through concrete actions and demonstrating real value.

We firmly believe that the difference between them and us is significant and undeniable, both in terms of product quality, industry experience and knowledge. We will continue to focus on our mission of providing high-quality solutions to our customers, maintaining our position as an industry leader, and investing in research and development to constantly innovate our product range.

Over the years, we have developed strategies that aim not only to raise awareness of the BKT brand but also to create an engaging experience for our customers.

So that your business can bene t and grow sustainably adding value through audit assurance remains our focus. Our audit design, execution and close-out aims to accurately assess compliance risks, objectively evaluating your control systems and procedures. Our audit team draws on 25 years of industrial experience. Our collaborated industrial knowledge, specialised levels of insight and strict compliance to audit principles enables us to execute best in class audit programmes and or stand alone audit reports.

We recognize the complexity of environmental compliance and respond by staying abreast with legislative changes and interpretations. We benchmark and interact with our clients and our network of legal specialist and provide a unique range of compliance and environmental technical audit solutions. We endeavour to improve time and cost e ciencies and have considered physical constraints such as site accessibility, travel distances and other unforeseen events such as the national state of emergency.

In response that we have deployed ISO 9001 aligned, tailormade audit protocols to suit the varying demand of our clients which include:

• Site based – integrated audit protocols (meetings, interviews, checklists, feedback)

• Remote based - intensi ed and interactive desktop reviews

• Remote based - Online opening meeting, interviews and close out meetings

• Remote based - Secure online documented evidence submission platforms

• Semi remote based - Drone ( y by) and live streaming camera site visits,

• Semi remote based - After-hours auditing to limit exposure.

Our Audit reports link to clear interpretable documented evidence, strong visualization and an alignment with existing document controls on site.

ENVASS has been able to present as much as 50% year-on-year audit programme cost savings to our clients through tailored protocols and audit integration.

Ask our highly capable team of auditors for a suggestion or a quote on any of the following:

• Water Use Licence’s compliance and or technical audits

• Waste Management Licence’s compliance and or technical audits.

• Environmental Management Programme Performance Assessment.

• National Norms and Standards compliance audits and review.

• Atmospheric Emission Licence’s. compliance and or technical audits

• Biodiversity Management Plan implementation audits and reviews.

• Mine Closure Audits based on GNR 1147.

• Internal ISO 14001 Systems and GAP Audits.

• NEMA Environmental Authorisation listed activities audits and reviews.

• Regulation 34 Audits and Recommendation for EMP amendment.

• Compliance Due Diligence & Gap Assessments.

• Occupational Health and Safety Audits.

Any of the above to be packaged into a Tailor made audit programme, cost e ectively suitable for you!

Projections for machinery and equipment exports in the agribusiness industry are positive for the next 12 months.

After the International Business Round held early May,

during the 28th edition of Agrishow, the largest agricultural technology fair in Brazil, the estimate is of USD 47 million in business, being USD 6.67 million during the event and other USD 40 million expected throughout the next year.

These data were disclosed by the Brazil Machinery Solutions (BMS) Program, which resulted from a partnership between ApexBrasil (the Brazilian Trade and Investment Promotion Agency) and ABIMAQ (the Brazilian Machinery

the audience and revenue. In line with Agrishow, the business originated in the International Round also exceeded initial expectations by 213%,” says Paulo Guerra, Commercial Promotion and Institutional Relations Manager at ABIMAQ.

In total, more than 500 meetings were held. On the occasion, attendees could enter into trade agreements with players in markets such as South Africa, Belgium, Chile, Colombia, Ghana, Hungary, Nicaragua, Peru, Kenya, and the Dominican Republic.

Export promotion

In addition to the International Business Round, BMS promoted the participation of foreign journalists for the international coverage of Agrishow 2023. The initiative was carried out with press professionals from India, Peru, and Turkey, who could learn about the main technologies and differentials of the Brazilian agricultural equipment and machinery industry through the Image Project.

and Equipment Association). The dynamic counted on the participation of 56 Brazilian companies and 15 buyers from 10 countries.

“These data show the resumption of agribusiness

negotiations, which started at last year’s event, in addition to reinforcing the credibility of Brazilian technologies focused on the industry.

The fair as a whole broke estimates records, concerning

The Brazil Machinery Solutions Program aims at promoting machinery and tools exports, in addition to strengthening Brazil’s image in the international market and establishing strategic partnerships to boost the industry development.

“The presence of the international press at the event plays a fundamental role in positioning Brazil as a protagonist in the global scenario and strengthening trade relations with other countries. Brazilian technologies and trends developed for the industry and that have visibility abroad create interest and have a positive impact on the agriculture sector in other nations,” concludes Paulo Guerra.

One clear message from my dozen meetings last week with African leaders who were in Washington for a summit with the U.S. government was that fertilizer prices are out of reach for most farmers, putting the crop cycle and rural stability at risk.

Across 45 countries globally, 205 million people are in acute food insecurity, meaning they have so little access to food that their lives and livelihoods are in danger. One key obstacle to food production in many developing countries is access to fertilizers, which enrich the soil with the nutrients needed for healthy crops.

Sufficient primary raw materials – nitrogen, potash, phosphate, and natural gas – and fertilizer production facilities are essential to farmers across the developing world, but high fertilizer prices are blocking the 2023 and 2024 crop cycle.

The challenge is particularly evident in Sub-Saharan Africa. Fertilizer prices have tripled since early 2020 and remain volatile, putting a stable supply of fertilizer out of reach of many small farmers.

Fertilizer exports from Belarus and Russia – important fertilizer suppliers for Africa – have been disrupted by the war, while some other exporting countries have restricted the supply through export taxes, bans and licensing requirements, in part to protect their own farmers.

With agricultural prices high, farmers in more advanced countries can afford to plant more and order more fertilizer, benefiting from subsidies that often cover the cost of the natural gas needed for fertilizer and the diesel fuel needed for farm equipment.

African leaders used the summit to emphasize that

farming families in developing countries will not be able to survive, much less compete. This is the same crisis they have raised throughout the year in the G7, G20 and G24 meetings, the World Bank/IMF Annual Meetings, and the UN climate and biodiversity meetings in Egypt and Canada.

If current trends continue –

high prices for natural gas and coal, commodity crops and fertilizer and elevated consumption of the available supplies by those with higher incomes and subsidies than Africa’s – the more-industrialized economies will increase their market share and dominate even more of the world’s total crop production and agricultural fossil fuel use.

This will leave little room for farming in Sub-Saharan countries, especially poorer households, resulting in a long and deep food and jobs crisis, especially in rural Africa.

The world’s ability to quickly realign energy and fertilizer supply chains in ways that leave room for poorer farmers will be one of the determin-

ing factors in the length and severity of the food crisis in Africa and the displacement of rural populations already under pressure from climate change. This entails substantial change in both advanced economies and developing countries.

The first key step is to leave room for developing countries in global natural gas and

fertilizer markets. Over time, greater production is vital to replace Europe’s dependency on Russia, but in the short run, it is important for the advanced economies to avoid locking up the current supply to overly guard against risk of shortages. Natural gas markets are being drained for future winter heating and chemical production, leaving too little for current

fertilizer production, disproportionally affecting smaller fertilizer producers.

Avoiding stockpiling and increases in production should be augmented by efficiency gains and reduced subsidies for consumption. This applies to many parts of the energy supply chain, and also to fertilizer where application rates are an important part of efficiency.

They are much too low in Sub-Saharan Africa, reducing crop yields, while staying wastefully high in other parts of the world despite high fertilizer prices. This is partly due to crop subsidies. Sub-Saharan Africa has an average fertilizer application rate of 22 kilograms per hectare, compared to a world average seven-times higher (146 kilograms per hectare). Some countries, such as China and Chile, are closer to 400 kilograms per hectare.

On average globally, less than half of the nitrogen fertilizer applied at the farm contributes to plant growth, with the

rest polluting our waterways. There are several explanations for the excessive use of fertilizer by higher-income farmers. The canard that more is better is one explanation.

Fertilizer is not a large cost factor given other inputs such as labor and equipment, so the amount being applied is less scrutinized. Farming practices are hard to change. Subsidies for fertilizer-hungry crops are another factor. In 2020, the U.S. used as much nitrogen just for the corn burned to make ethanol as half of all the nitrogen used across Africa for agricultural purposes.

Africa must help in this realignment by improving its internal trade and logistics barriers. The continent produces approximately 30 million metric tons of fertilizer each year, twice as much as it consumes.

And yet, approximately 90 percent of fertilizer consumed in Sub-Saharan Africa is imported, mostly from outside the continent. This reflects

inefficiencies in shipping and port costs, distribution chains, information availability and other trade frictions. Each factor needs a concerted effort by African nations to fix the system.

Better trade infrastructure and trade facilitation measures such as harmonized rules have an important role. When technically and economically feasible, local production can complement trade by reducing transport and logistics costs.

A large urea fertilizer plant recently opened in Nigeria to convert natural gas into fertilizer, but a portion is used to subsidize inefficient Nigerian buyers and a large portion is exported to Latin America, leaving farmers in Africa dependent on other markets.

In the meantime, several external programs are helping on the margins. Private fertilizer donations and shipments via the Black Sea Grain Initiative have helped to ease some supply challenges.

Other initiatives include the $6 billion IFC Global Food Security Platform, which is providing credit access to address liquidity constraints in the private fertilizer supply chain, and the $30 billion World Bank food and nutrition security package focused on developing countries.

The International Monetary Fund’s new Food Shock Window provides a channel for emergency financing for countries with urgent balance of payment needs related to food and fertilizer.

The G7 and World Bank are also engaging in critical partnerships such as the Global Alliance for Food Security to support countries in distress and address the key issues contributing to this crisis.

We must make sure these efforts increase availability without inadvertently destroying the decades-long effort to build up private fertilizer markets in Africa. This means continuing to support market development and enabling the private sector.

In Kenya, for example, a World Bank program providing

fertilizer e-voucher subsidies helps eligible smallholder farmers purchase fertilizer from private retailers at a subsidized rate , increasing productivity by more than 50 percent, enhancing crop diversification, and building private sector capacity.

In responding, we should not miss the opportunity to build more resilient and sustainable fertilizer and agricultural markets for the future. More efficient application rates would help reduce greenhouse gas emissions.

The production and use of nitrogen fertilizer alone accounts for about 2 percent of global greenhouse gas emissions, so it is important to minimize waste. There is also a need to invest in green fertilizer production and efficient use.

The technology to produce ammonia needed to manufacture nitrogen fertilizer with renewable energy has not yet been widely adopted. Among others, in Egypt, Kenya and South Africa, green ammonia plants are in development. Technologies to reduce

nitrous oxide emissions during fertilizer use can also be more widely applied. Increasing research and outreach efforts for digital and precision agriculture practices, technical assistance, and incentives for adopting climate smart agriculture, and investing in soil health can boost the efficiency of fertilizer application and absorption.

Importantly, we must also take advantage of existing opportunities to use public spending to build longer-term food systems resilience. Fertilizer subsidies in both developed and developing countries can be repurposed towards measures that reduce overuse, decreasing the sector’s carbon footprint while increasing fertilizer availability.

If the countries that overapply fertilizer reduced their consumption to adequate levels, access could increase in countries consuming well below the world average.

In sum, it’s urgent to make fertilizers more accessible and affordable to avoid prolonging the food crisis. Lives and livelihoods depend on the choices of policymakers.

With an expected 2,600 exhibitors from over 50 countries, Agritechnica 2023, the world’s leading trade fair for agricultural machinery, will take place in Hanover, Germany, 12-18 November.

The organizer, the DLG (German Agricultural Society) has today announced that all major companies operating in the international agricultural machinery sector are among the 2,200 exhibitors already signed up and listed in the preliminary exhibitor database at www.agritechnica.com.

Professional visitors can once again look forward to a

comprehensive Agritechnica exhibition with its numerous market leaders and leading industry experts.

With more than 2,600 expected exhibitors across 23 halls, including 20 country pavilions, on over 400,000 square meters of exhibition space as well as a broad international technical program, Agritechnica will this year be the central venue and major highlight for the global agricultural machinery industry.

“The exhibitors from more than 50 countries include all market leaders. With the international dealer center, the B2B marketplace ‘Systems & Components’ and the start-up area

With the main theme “Green Productivity –inspiration and solutions”, Agritechnica gets to the heart of the current challenge for socially acceptable agriculture.

‘DLG-AgrifutureLab’, Agritechnica 2023 will offer a complete overview of farm equipment and related topics, working as a much sought after business platform with international networking, especially after the hiatus due to the pandemic,” says Timo Zipf, Agritechnica project manager.

Technical program focuses on reconciling productivity with ecology

With the main theme “Green Productivity – inspiration and solutions”, Agritechnica gets to the heart of the current challenge for socially acceptable agriculture. It must be made possible to increase productivity using fewer resources at lower intensity, while also protecting the environment and nature.

In the technical program of Agritechnica 2023, the DLG is working with exhibitors from the fields of technology, farm input and services in various formats, such as spotlights and forums, to address the central question: “How can agriculture produce food, feed, raw materials and

energy eco-efficiently?”

International platform of trend topics and innovations

In view of changing social, economic and climatic conditions, innovation in agricultural technology is crucial for future viability. As part of Agritechnica, the DLG is recognizing the importance of agricultural machinery in shaping sustainable agriculture with three different awards.

The “Innovation Award”, in gold and silver, honors innovations ready for the agricultural machinery market, while the “DLG Agrifuture Concepts” innovation award focuses on pioneering concepts. The “Systems & Components Trophy – Engineers’ Choice” awards scheme focuses in particular on innovative technical systems and components for agricultural machinery.

With the DLG-AgrifutureLab, Agritechnica will once again offer start-up companies attractive opportunities to present their visions and products to the international agricultural

machinery industry.

Systems & Components

“Systems & Components” will again be held as part of Agritechnica in 2023. As a technical forum, industry venue and B2B platform for the supplier industry, the event is an ideal complement to Agritechnica, showcasing the latest developments and innovations in components for the agricultural machinery and off-highway sectors.

DLG has developed a new platform “Inhouse Farming –Feed & Food Show” as part of Agritechnica focusing on self-contained food production of the future.

Suppliers of aquaponics, alternative proteins, vertical farming and cellular agriculture, among others, will present not only their products but also their perspectives, innovations and business opportunities “from feed to food”, closely networked with agricultural practice.

DLG has developed a new platform “Inhouse Farming – Feed & Food Show” as part of Agritechnica focusing on self-contained food production of the future.

Registration continues for exhibiting industries that will take part in the Agrilevante 2023 event in Bari from 5 to 8 October.

Great expectations for an exhibition dedicated to technologies for agricultural supply chains typical of the Mediterranean area, and which aims to repeat the levels of public attendance and international prestige achieved in 2019, before the suspension due to the health emergency.

Agrilevante returns to the international exhibition calendar and celebrates its seventh edition from 5 to 8 October at the Bari exhibition centre.

Organising body, FederUna-

coma surl, opened registration for exhibiting companies on the specially prepared on-line platform, thus starting the march towards the October event, one of the most important for the agricultural sector in the entire Mediterranean area.

After the suspension of the 2021 edition due to the health emergency, the biennial Agrilevante – which has always been organised with the support of the Presidency and the Department of Agriculture of the Apulia Region and in collaboration with the Nuova Fiera del Levante – aims to confirm the results of the 2019 edition, when the number of exhibiting companies reached 360, representing 19 countries, and visitors from 65 countries

Agrilevante returns to the international exhibition calendar and celebrates its seventh edition from 5 to 8 October at the Bari exhibition centre.

exceeded 80 thousand.

The international character is the strong point of this exhibition, which includes the active collaboration of the ICE Agency for the organisation of foreign delegations, and which offers technologies for all the main production chains of the Mediterranean and African regions: grains, olive oil, wine, fruit and vegetables, livestock, and nonfood and energy raw materials.

Operators from Southern Europe, the Balkans, the Middle East, North and Sub-Saharan Africa will find a vast selection of tractors, harvesting machines, equipment, irrigation and treatment systems, and advanced electronic devices for every type of processing and every model of agriculture in the Fiera del Levante pavilions.

Along with the more than 8,000 models of machinery and equipment, significant interest will be aroused by the exhibition of prized breeds of cattle, horses, sheep, goats and poultry breeds.

The presence of a section dedicated to technologies for Agriculture 4.0 will also draw interest, while in the coming weeks the programme of conventions, conferences, and workshops will be drawn up in collaboration with prestigious institutions such as the University of Bari and the Mediterranean Agronomic Institute, and with important organisations in the agricultural sector and the agro-mechanical supply chain.

The theme of the 4th Edition of the Global Vertical Farming Show in Dubai is aimed at Transforming Food Systems to achieve better nutrition, enhance Food Security and improve climate change outcomes – via vertical farming integration in Agriculture.

The Global Vertical Farming Show, a highly successful event that brings together modern farming pioneers to collaborate and grow, is returning to Dubai for its 4th edition. The event has already set a high standard in its previous editions and promises to be ground-breaking once again.

GVF 2023 – Dubai is a trailblazing event that will gather the complete vertical farming ecosystem to explore the market, introduce brands, and create long-term strategic partnerships over two power-packed business networking days.

The region’s biggest and ONLY exclusive Vertical Farming Event

Vertical farming is increas-

ingly critical in accelerating food production, maintaining high-quality crops, and contributing to sustainable urban farming, playing a crucial role in enhancing food security worldwide.

The growing interest in vertical farming worldwide is evident, with massive facilities already in operation in Asia, Europe, the Middle East, and the United States, and new projects being announced regularly.

The Middle East is a leader in this field, with the world’s largest Vertical Farm, ECO 1 by Bustanica, opened last year through a joint venture between Crop One Holdings and Emirates Flight Catering and policymakers truly supporting the recent developments.

The growing interest in vertical farming worldwide is evident.

Along with the more than 8,000 models of machinery and equipment, significant interest will be aroused by the exhibition of prized breeds of cattle, horses, sheep, goats and poultry breeds.

When it comes to agricultural machinery, tyres are a crucial component. They are responsible for carrying heavy loads, providing traction, and ensuring the stability and safety of the equipment.

Agriculture tyre has come a long way in recent years, with the introduction of VF (Very High Flexion) tyres revolutionizing the industry. In this blog post, we’ll explore the hidden benefits of VF agricultural tyres and why they are becoming increasingly popular among farmers.

VF agricultural tyres offer a significant advantage in terms

of efficiency improvement. They can carry heavier loads at the same inflation pressure as standard agricultural tyres. This means fewer trips are required to complete the same amount of work. This saves time. This also reduces fuel consumption and wear and tear on the machinery.

VF tractor tyre has the potential to increase crop yield. VF tyres have a broader surface area that enables them to distribute the weight of the machinery more evenly, decreasing soil compaction. This allows the soil to retain more water and nutrients, providing the ideal crop-growing conditions. Additionally, the improved flota-

tion of VF tyres enables farmers to access their fields earlier, resulting in a longer growing season and potentially higher yields.

Safety is always a top priority when it comes to agricultural machinery. VF farm tyre provides improved stability and traction, reducing the risk of accidents and crop damage. Moreover, the wider contact area of VF tyres lowers ground pressure. This helps in preventing tyre slippage and reduces the possibility of getting stuck in wet or muddy terrain.

The designers have devel-

oped VF Ag tyre to endure heavy loads and offer outstanding durability, resulting in a longer tyre lifespan than standard agricultural tyres. This can significantly reduce the cost of replacing tyres and the downtime required for maintenance and repairs.

VF Agri tyre has environmental benefits. Reducing the number of trips required to complete work can help reduce greenhouse gas emissions from machinery. The reduced soil compaction and improved soil health can also lead to better carbon sequestration in the soil, helping to combat climate change.

The VF technology has a positive impact on soil health. Since VF farm tractor tyres require lower inflation pressure, they create a larger tyre footprint that minimizes soil compaction.

VF agricultural tyres offer a range of hidden benefits to farmers in the UK. From improving efficiency and increasing yield to enhancing safety and environmental sustainability, VF tyres are a valuable investment for farmers looking to optimize their agricultural machinery.

CEAT Specialty’s experienced technicians are responsible for assessing your requirements and guiding you in choosing the optimal tyre, including determining whether a VF tyre is the most appropriate and effective option for your needs.

With a vast selection of tyres

available, selecting the appropriate one can be daunting, but feel free to seek expert advice. When choosing the best tyre, no questions are considered wrong.

VF farm tyre provides improved stability and traction, reducing the risk of accidents and crop damage. Moreover, the wider contact area of VF tyres lowers ground pressure.

business solutions company, well placed to meet increased global demand as well as the ongoing challenge of providing sustainable, traceable food and feed products to customers around the world. This would be underpinned by a rigorous focus on creating value for all stakeholders.”

Note 1: Glencore to receive 32.8 million shares valued at approximately $3.1 billion as per the last closing price of $93.79 on Monday, 12 June 2023.

Note 2: before the commencement of Bunge’s announced $2 billion share buyback programme.

Background

Glencore plc, the Canada Pension Plan Investment Board and British Columbia Investment Management Corporation, the shareholders of Viterra Limited, have concluded an agreement with Bunge Limited to merge Bunge and Viterra in a cash and stock transaction to create a premier diversified global agribusiness solutions company, as announced by Bunge today.

Under the terms of the agreement, Glencore will receive approximately $3.1 billion in Bunge stock and $1.0 billion in cash for its c. 50% stake in Viterra1 resulting in Glencore then holding c. 15% in the combined group2. The transaction would result in a larger, more diversified business, with significant synergy and re-rating potential. Glencore has agreed to not sell any stock in Bunge for a period of 12

months following the completion of the merger, and thereafter to only sell Bunge shares in orderly sales. Glencore will review periodically its strategy in respect of the shareholding.

The merger, subject to satisfaction of customary closing conditions, including receipt of regulatory approvals and approval by Bunge shareholders, is expected to close in mid-2024.

Gary Nagle, CEO, Glencore, commented:

“The merger of Viterra with Bunge is expected to realise significant value for Glencore. Our investment in the agriculture sector dates back over 40 years and has grown from being a small grains trader to being part of a world leading, fully integrated global agriculture network.

The combined group would be a premier pure-play agri-