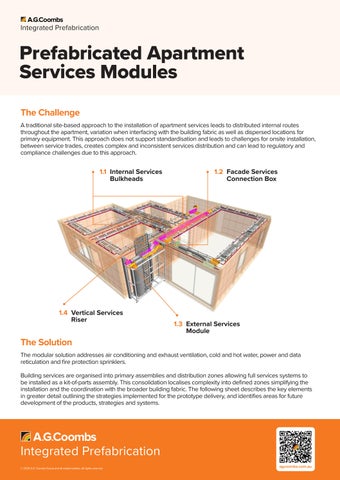

Prefabricated Apartment Services Modules

The Challenge

A traditional site-based approach to the installation of apartment services leads to distributed internal routes throughout the apartment, variation when interfacing with the building fabric as well as dispersed locations for primary equipment. This approach does not support standardisation and leads to challenges for onsite installation, between service trades, creates complex and inconsistent services distribution and can lead to regulatory and compliance challenges due to this approach.

The Solution

The modular solution addresses air conditioning and exhaust ventilation, cold and hot water, power and data reticulation and fire protection sprinklers.

Building services are organised into primary assemblies and distribution zones allowing full services systems to be installed as a kit-of-parts assembly. This consolidation localises complexity into defined zones simplifying the installation and the coordination with the broader building fabric. The following sheet describes the key elements in greater detail outlining the strategies implemented for the prototype delivery, and identifies areas for future development of the products, strategies and systems.

1.1 Internal Services Bulkheads

The Challenge

An independent services trade approach to internal distribution leads to highly distributed routes throughout an apartment and the associated building fabric.

This approach does not support standardisation and leads to challenges between service trades, services distribution and the building structure and finishes. Onsite installation is typically at high-level and overhead, leading to poor body position and strain of operative’s bodies and increasing the risk of falls and injuries.

The Solution

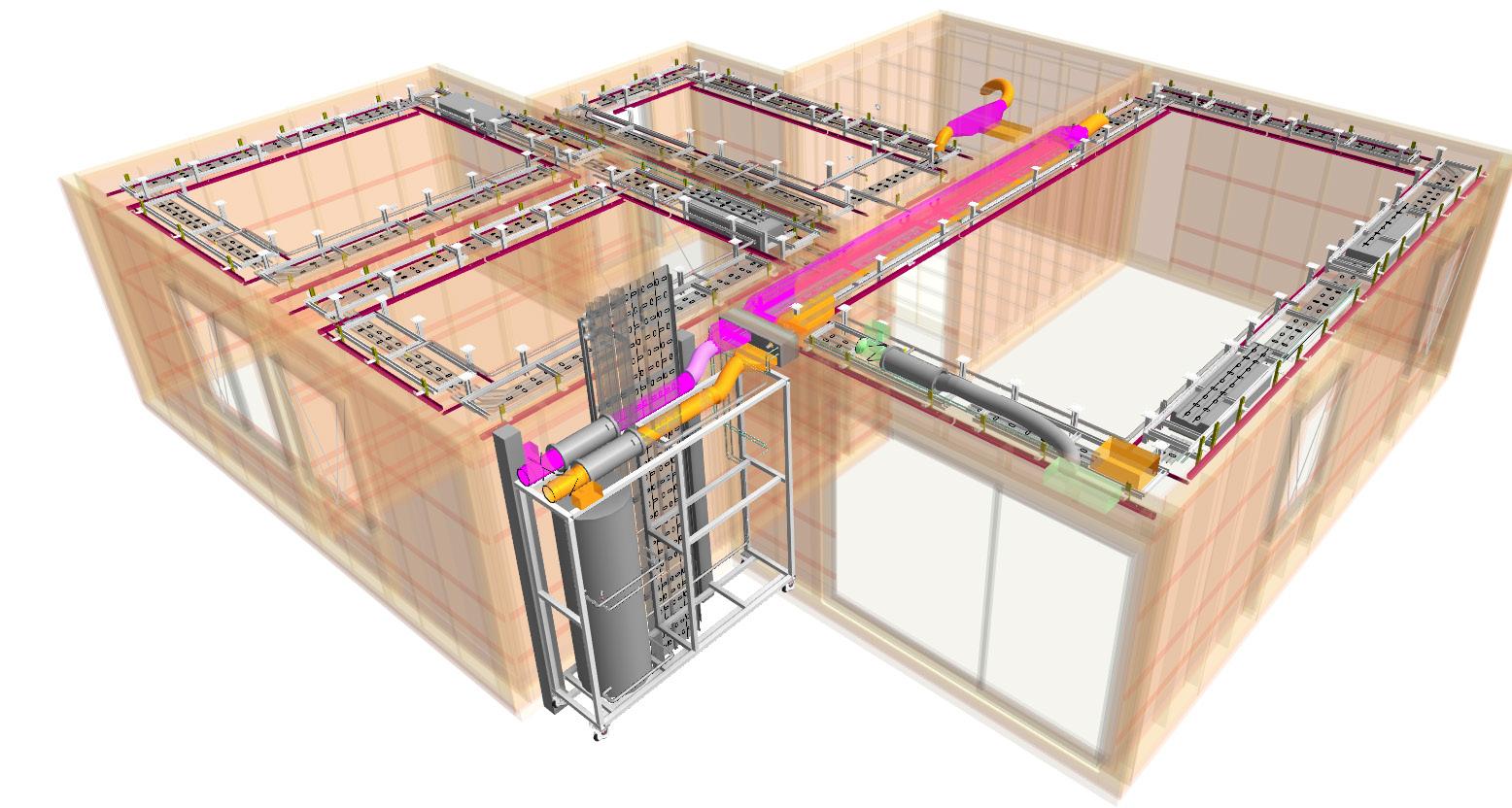

A series of prefabricated services modules pre-fitted to frames within factory conditions. The services distribution looks to consolidate main services routes into a small number of bulkheads, leaving remaining modules relatively simple.

Module frames are standardised, while the services within them are specific for the apartment requirements and room location. Services are fitted within a factory setting, allowing more compact assemblies to be provided, and ensures operatives are working in safer and more ergonomic environments.

On-site assembly, and ongoing services access are considered in equipment and distribution locations and positions within the bulkhead modules.

Future Development

The accessible location of the cable trays, coupled with the modular cabling provides a fast site installation. Further development could assess the extent of cabling that could be pre-fitted within a factory setting before delivery to site.

Sub-assemblies of services components (i.e. cable tray corners, sprinkler t-pieces) can increase repeatability, and reduce factory assembly time.

Test and refine connections to allow on-site installation times to reduce. Develop macro and micro adjustability strategies to accommodate both fabrication and installation tolerance requirement.

1.2 Facade Services Connection Box

The Challenge

Minimise onsite work. Services are pre-fitted to the internal and external modules, meaning onsite connections between module elements are critical. Airtightness, thermal continuity and services performance must be maintained.

The Solution

A prefabricated services connection box that contains stub sections of services with ends presented for easy on-site connection. The selected methods of connection for the prototype are as follows:

• Ductwork Push-fit self-sealing connections

• Sprinklers Victaulic couplings (proprietary grooved pipe system)

• Domestic Pipework Flexible hose standard threaded connections

• Refrigerant Pipework Flexible hose standard threaded connections.

The services connection box has an oversized flange to the external face, allowing the box to be sealed with the building air-tightness line. The box would be filled with insulation to retain thermal performance locally.

Future

Development

Review existing products that provides a similar function for adaptability. Fire rating requirements were not confirmed at the time of the prototype design. If fire rating is required,assess if the current products on the market can be adapted to suit the connection box principles.

1.3 External Services Module

The Challenge

Major equipment is typically highly distributed throughout an apartment and the associated building fabric. This approach does not support standardisation and leads to challenges between service trades, services distribution and the building structure and finishes.

The Solution

A prefabricated consolidated services module, housing many of the primary services components required for the apartment. Products, equipment and assemblies located within the External Services Module are:

• Hot water heat pump, sized in accordance with Homes NSW specification requirements

• A/C Condenser unit, with piped distribution to internal units

• Domestic pipework feeds, including cold, hot and tempered water

• Sprinkler pipework feed

• Extract fans and associated motorised dampers for kitchen and bathroom extract systems.

• Switchboard with pre-terminated modular wiring connections

The External Services Module is integrated with the vertical rising services, and connects horizontally, via the Façade Services Connection Box, to the internal services bulkheads.

Future Development

Overlay 1 and 3-bedroom requirements to assess similarities and where variation is required. Capacity requirements may increase (or decrease) equipment size and therefore module size requirements.

Integrate residential storage requirements with the switchboard and communication system enclosures. Cladding and door integration.

1.4 Vertical Services Riser

The Challenge

Traditional primary services distribution internal to apartment buildings leads to complex services coordination within common corridor areas, as well as challenging fire stopping requirements between common areas, corridors and apartments. Access is restrictive behind corridor ceilings and densely serviced common corridors. Shared risers are typically building specific, minimising opportunities for standardisation and repeatably.

The Solution

The apartments have an external vertical services distribution strategy. Connections between vertical service riser sections, as well as connections to the apartment services (via the External Services Module) are positioned to ensure access for installation and future maintenance. Vertical Services Module sections are assembled in lengths to match the floor-to-floor heights. Each module projects above the balcony FFL to ensure joints between modules are accessible. The selected methods of connection for the prototype are as follows:

• Surface Water and Condensate drainage pipework – Push-fit self-sealing connections

• Sprinklers – Victaulic couplings (proprietary grooved pipe system)

• Domestic Pipework – Proprietary press-fit couplings with flexible hose standard threaded connections for apartment connections.

• Cable trays for power and communications – Abut each other, no direct connections required.

Connections from the Vertical Services Riser to the External Services Module are made via stub sections of services located at optimum heights, with ends presented for easy on-site connection.

For more information contact:

Russell Yarnton

DfMA & Buildability Leader – Integrated Prefabrication ryarnton@agcoombs.com.au www.agcoombs.com.au