Table of Contents

04 06 10 26

A Letter to Our Family

The legacy of integrity and respect

Welcome to Acme-Hardesty

Trusted partner. Sustainable ingredients. Superior solutions.

A Culture of Accountability

It’s about more than simply what we do, it’s about why we do it

Prioritizing Sustainability

Maintaining our commitment to the communities we impact

32 40

62 68 80

Meet Phil Bernstein

The embodiment of integrity

Becoming Acme-Hardesty

An 80-year legacy of success through innovation

Research and Innovation Laboratories

The journey has only just begun

The Culture & Collaboration Center

A new hybrid work environment with collaboration at its core

Shaping Our Future

Reimagining what’s possible in the next eight decades

3

Acme-Hardesty 450 Sentry Parkway Suite 104 Blue Bell, PA 19422 acme-hardesty.com 800.223.7054 sales@acme-hardesty.com

A Letter to Our Family

The legacy of integrity and respect

Dear Employees, Partners, Customers and Friends of Acme-Hardesty,

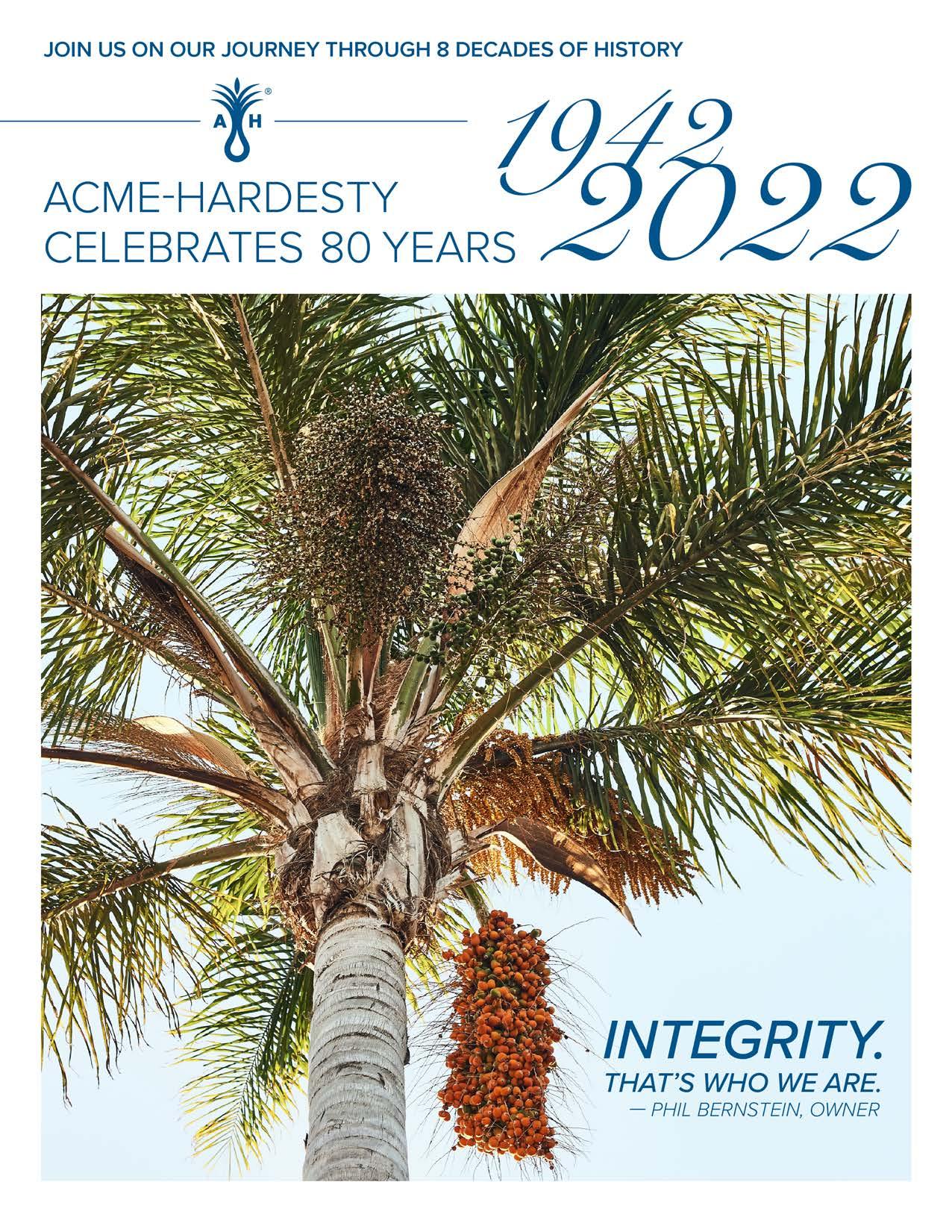

We are pleased to introduce you to this booklet celebrating the 80th Anniversary of Acme-Hardesty Co. We are grateful to be steeped in tradition, yet able to embrace new opportunities on our success journey.

This booklet will tell you about our rich history, but it will also outline how we’ve incorporated culture and sustainability in the present era. We believe it will not only provide an overview but give you insight into our incredibly bright future. It’s been an honor to build an organization on the solid platform of decades of integrity and respect.

allows us to embrace every challenge as an opportunity to grow.

We sincerely hope you enjoy this booklet and learning more about our company. We are proud of our accomplishments, but we will not rest in attempting to make ourselves better every day. Thank you for all of your support.

Best regards,

4 5

Acme-Hardesty began more than 80 years ago. As a division of Jacob Stern and Sons, we’re built upon an even longer history of innovation and growth.

Acme-Hardesty is one of the largest distributors of castor oils and derivatives, palm derivatives, preservatives, and surfactants in the United States; however, we are becoming more well known for our Culture of Accountability. Trusted partner. Sustainable ingredients. Superior solutions.

Acme-Hardesty

6 7

We’ve created a company, rather, a family, that is built upon the premise of respectful relationships and exceeding the expectations of our business partners and stakeholders.

We continue to add new supplier partners and evaluate new products to strengthen our ingredient portfolio. Furthermore, we offer technical expertise and finished formulation prototypes through our Research & Innovation Laboratories.

Acme-Hardesty is always committed to sustainable sourcing while delivering innovative solutions to satisfy our customer’s toughest challenges and business needs.

Yes, Acme-Hardesty provides unique and reliable chemical solutions, however, we are equally invested in our true mission, “Take Care of Families.” Through our sustainable growth we can support more supplier families, more employee families, and even more customer families.

And maybe that’s really what sets us apart. Because for everyone at Acme-Hardesty, it’s about more than simply what we do – it’s about “why” we do it. We are driven by strong cultural beliefs and the simple principles of integrity and respect.

H8 9 A

ACME-HARDESTY Welcome to Acme-Hardesty

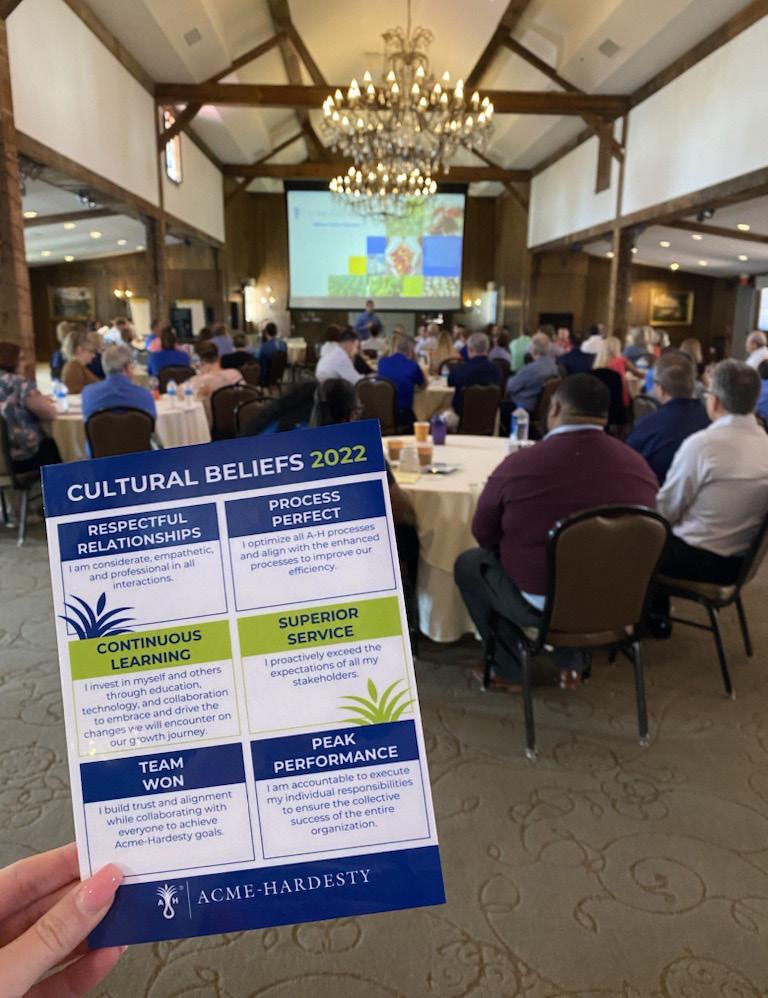

A Culture of Accountability

It’s about more than simply what we do, it’s about why we do it

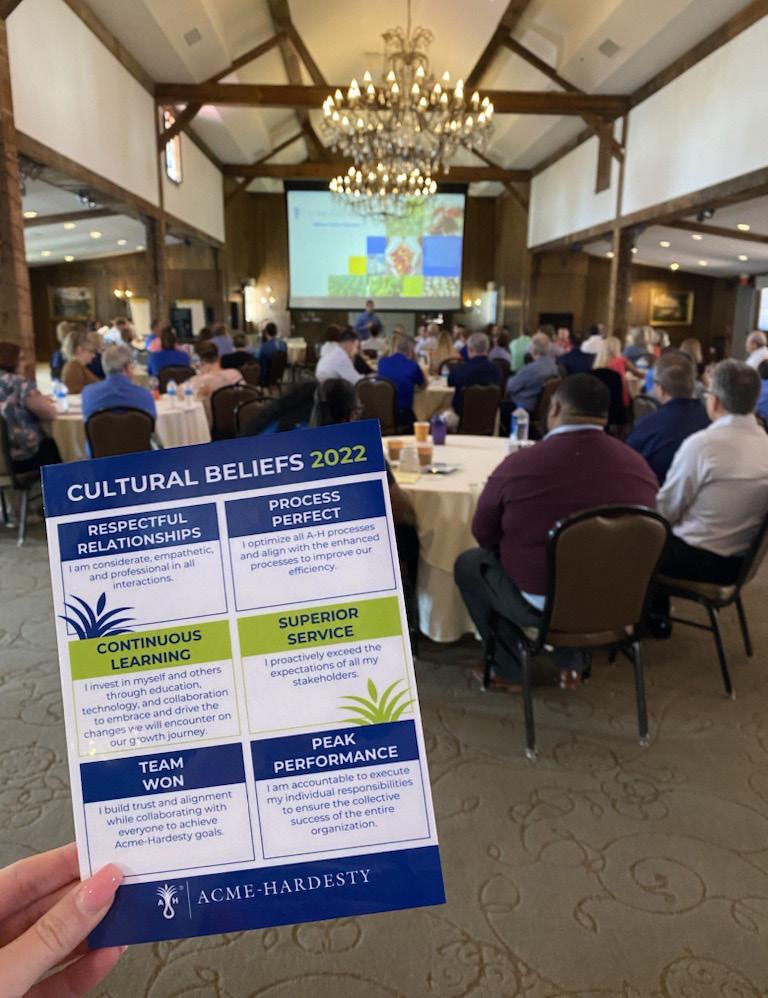

At Acme-Hardesty our name is synonymous with the phrase, “our word is our bond”. Building upon a heritage of more than 80 years, we deliver sustained profitable growth so we can live out our mission, “Take Care of Families”. The families that are part of the Acme-Hardesty family, include those of our employees, customers, suppliers, and partners and we fulfill our promise of care by living our Cultural Beliefs.

10

Cultural Beliefs Video

Through living the Acme-Hardesty Cultural Beliefs, our colleagues make a personal choice every day to rise above one’s circumstances and demonstrate the ownership necessary to achieve results. This is why we provide solutions where others may only see problems.

Caren Dres-Hajeski, Vice President of Personal Care and Marketing, recognized the impact of a clearly defined culture saying, “It [our six cultural beliefs] broke down the walls we didn’t even know we had.”

Jacob Stern and Sons Chief Human Resource Officer, Steve Kulchin added, “There is a sense of ownership around the culture. That it's not just something that's on a website. It's not something that the president speaks to at a Town Hall meeting, or that HR reminds people of…It's something that we live with every day.”

12 13

Images captured at Acme-Hardesty’s annual Chairman’s Circle Award Dinner in 2022.

A Culture of Accountability

ACME-HARDESTY

The foundation on which our cultural beliefs are built is Respectful Relationships. “And we live it. We really live it… we all talk the same language, we are all mindful of our communications,” Caren Dres-Hajeski described.

President of Acme-Hardesty, Jeff Kenton, anecdotes Respectful Relationships through a personal encounter when he first returned to the office, “I hadn't seen the guy that cleans up the office in a while. And so, I saw him this morning, and gave him a big hug. I was like, "Jim, it's been a long time." So, we care about each other.”

15

ACME-HARDESTY A Culture of Accountability

Our shared goal at Acme-Hardesty is that we are considerate, empathetic, and professional in all our interactions.

Equally as impactful is a cultural belief that has resonated with many employees. Team Won guides all employees to build trust and alignment while collaborating with everyone to achieve our shared goals.

There is no shame in asking for assistance in the workplace and our people thrive on achieving success together.

Our third cultural belief is Process Perfect which references our desire to maximize our efficiency in how we do things. If someone finds a better way to do a task that maximizes our effort and our success, then our company will make that the new way of doing things.

We optimize all Acme-Hardesty processes and align with these enhanced processes to improve our efficiency.

16 17

A Culture of Accountability

ACME-HARDESTY

Continuous Learning , our fourth cultural belief, is the embodiment of how we believe and invest in life-long learning. At Acme-Hardesty we seek out professionals who display a natural curiosity to learn and grow.

We want individuals who invest in themselves and others through education, technology, and collaboration to embrace and drive changes we will encounter on our growth journey.

Jeff Kenton gave an example of Peak Performance recalling, “We recently had a fantastic customer service representative...But up until her review, it was not known that she had a degree in chemistry and an interest in moving teams...She's now moved to the lab, is doing an outstanding job, and loves what she does even more. That is what we want to create.”

19 ACME-HARDESTY A Culture of Accountability

Fifth is the cultural belief, Peak Performance. Everyone is accountable to execute their individual responsibilities in order to ensure the collective success of the entire organization. In the sports world, this is translated to, “The name on the front of the Jersey is more important than the name on the back.”

That is, we collaborate for shared success. While shared success is dependent on individual contributions, we celebrate our successes as a whole as well as own and learn from our losses.

Our final cultural belief can be summarized as Superior Service. In order to stay relevant and continue our success, we must never accept the status quo. We proactively seek to exceed the expectations of all stakeholders while communicating with our customers to ensure they are informed and delighted with the service we are providing.

Steve Kulchin goes on further to explain the high expectations that Acme-Hardesty has for itself, “we've built our legacy around being a very, very high integrity, highly ethical company.”

20 21

Top left: employees celebrating at Acme-Hardesty's annual Chairman's Circle Award Dinner

Top right: a view of the entrance to the Culture and Collaboration Center

ACME-HARDESTY A Culture of Accountability

The steadfast focus on advancing our company culture has created a competitive advantage. Our people create our organizational culture, and our culture guides us on how best to create results.

Jacob Stern and Sons Director of Human Resources, Guy Kalbach, reflected on this commitment stating, “For one of the first times in my career, and I've had a career for quite some time, I know that feedback will be very direct, very honest, but it's also going to have empathy behind it. The six core cultural beliefs have served to strengthen the relationships and bonds between the Acme-Hardesty Team.”

If you had to choose one word to describe Acme-Hardesty, what would that be?

"So five years ago, somebody asked me the same question and I immediately said integrity because I knew that we believed and we cared. I think if I had to say it right now, I would say respect. And I would say from the top of the company to the bottom, we respect each other and we care about each other. It shows in the way that we communicate with each other and the way that we talk to each other. And it just takes a lot of tension out of what typically can happen in an office workspace. "

— Jeff Kenton, President

Tell me something you want people to know about Acme-Hardesty or remember?

"The culture that we have created as part of the organization and the people themselves. Acme-Hardesty is a place where we have a safe environment. The employees working at this company flourish, they strive for excellence on a day-to-day basis. They're responsible. They're accountable for activities, tasks, and what they're assigned to do. They make positive changes and make Acme-Hardesty a better place to work. "

— Rishabh Shah, Director of Technology

What makes you particularly proud to work at this company or hold your position here?

"I think because we consistently do what's best for our customers and we get a lot of great feedback about that. In a variety of different and challenging situations, we've always done the right thing to resolve an issue and create, what I would call, a true win-win situation. That's where Acme-Hardesty wins, and our customers win too. And we've done that over and over because nothing is ever perfect."

— Bryan Huston, VP Distributor Solutions & PU CASE

What kind of person would you say would be the best fit for an Acme-Hardesty employee?

"Someone who is proactive. If you see a problem, then it doesn't matter if it's in your group or not in your group. Own it, take some ownership of it, figure out a solution and just do it. And we like to empower employees. So, if you like to be empowered, it's another good reason to come work at Acme-Hardesty." —

Caren Dres-Hajeski, VP of Personal Care and Marketing

Caren Dres-Hajeski, VP of Personal Care and Marketing

How would you describe Acme-Hardesty's culture?

"The thing that stands out when you think about Acme-Hardesty is honesty. We always deliver. It hurt us sometimes. We always endeavor to do the best we can. We're always trying to improve. I think people see that. We have a certain humility. We're not the biggest. We work very hard. We try to be transparent. And people have accepted that. And they like that."

— Phil Bernstein, Owner

24 25

Q & A

Since our inception over 80 years ago, Acme-Hardesty has prioritized sustainability in the chemical industry by providing renewable, bio-based alternatives for manufacturers. We understand sustainable sourcing is the present and future of our industry, and we believe manufacturers should be able to reap the benefits of ethical sourcing. Acme-Hardesty champions the development of new and sustainable solutions for real-world applications, and we are dedicated to providing renewable, ethical, and sustainable solutions to the industries we service.

In an ever-changing world, sustainability is an ongoing mission that requires dedication, and Acme-Hardesty is committed to making a difference for people and the planet. As proud members of the Roundtable on Sustainable Palm Oil (RSPO), we work closely to ensure the traceability of raw materials and reduce our contribution to deforestation due to the palm oil industry.

Responsibly addressing the environmental issues associated with palm oil is a top priority for Acme-Hardesty. Our Mass Balance Certification through the RSPO is subject to strict verification, an annual audit, and a five-year reassessment to ensure we are meeting global standards for the production and procurement of sustainable palm oil. Our continued commitment to growing our RSPO-Certified product offering continues to bring value to our customers and the environment.

26

27

Maintaining our commitment to the communities we impact

Acme-Hardesty's 80 Year Success Driven by Passion and Sustainability

As part of our firm commitment to achieving sustainability, Acme-Hardesty is a proud partner of the Indian Sustainable Castor Standard (ISCS) and the Sustainable Castor Association (SCA). These organizations are committed to making castor seed farming more sustainable. To raise castor productivity by working closely with farmers, the Castor Projects will establish more than 1000 farms for castor cultivation in five districts of Gujarat, which accounts for 80% of castor production in India.

Furthermore, as part of the initiative, farms involved in the project will receive certified seeds, fertilizers, technical expertise, and other farm inputs free of cost to farmers. Acme-Hardesty works closely with farmers to gauge progress and show our commitment and passion for sustainability. New farming techniques will lead to higher productivity and will insulate farmers from price fluctuation and sustain their interest in growing castor seed. Of the approximately 600 model farms, there has been a nearly 57% increase in productivity and Acme-Hardesty is proud of its work with local farmers in Southeast Asia to accomplish these substantial outcomes.

Sustainability is at the core of everything we do at Acme-Hardesty, and our strategy focuses on three main pillars of action. First, Acme-Hardesty proactively markets and sells renewable, bio-based ingredients to serve as alternatives to less-sustainable products traditionally used. We put an emphasis on sourcing products from manufacturers with renewable practices, and we aim to increase demand for sustainable products from customers.

Second, Acme-Hardesty strengthens relationships in the communities where we operate. We optimize our supply chain to minimize our carbon footprint. Third, Acme-Hardesty’s bio-based products enable our customers to develop more sustainable solutions. We foster an environment of continuous learning to promote responsible practices and encourage sensible business practices to benefit our customers, suppliers, and employees alike.

28 29

ACME-HARDESTY Prioritizing Sustainability

At Acme-Hardesty, we believe honesty and integrity are crucial to our relationships and serve as the foundation for the way we operate. A strong cultural foundation is essential to how Acme-Hardesty achieves results. We take pride in our commitment to our Cultural Beliefs and have made them a fundamental part of how we operate. With a commitment to the Acme-Hardesty culture and an emphasis on prioritizing innovation and creativity, each of our employees demonstrates the ownership necessary to achieve results and deliver sustained profitable growth.

Looking toward the future, we at Acme-Hardesty believe the best is yet to come. Our work in finding the highest quality, sustainable ingredients for our customers is never done.

We embrace a strong commitment to protecting the environment and are focused on advancing the sustainability of the products we provide.

We will continue to expand our partnerships with manufacturers who implement the latest technologies, minimize their carbon footprint, and use sources that do not deplete limited resources.

Acme-Hardesty will continue to be transparent with the steps we are taking to make our company and communities better for all.

30 31

Maintaining our Commitment to the Future Through Sustainability

ACME-HARDESTY Prioritizing Sustainability

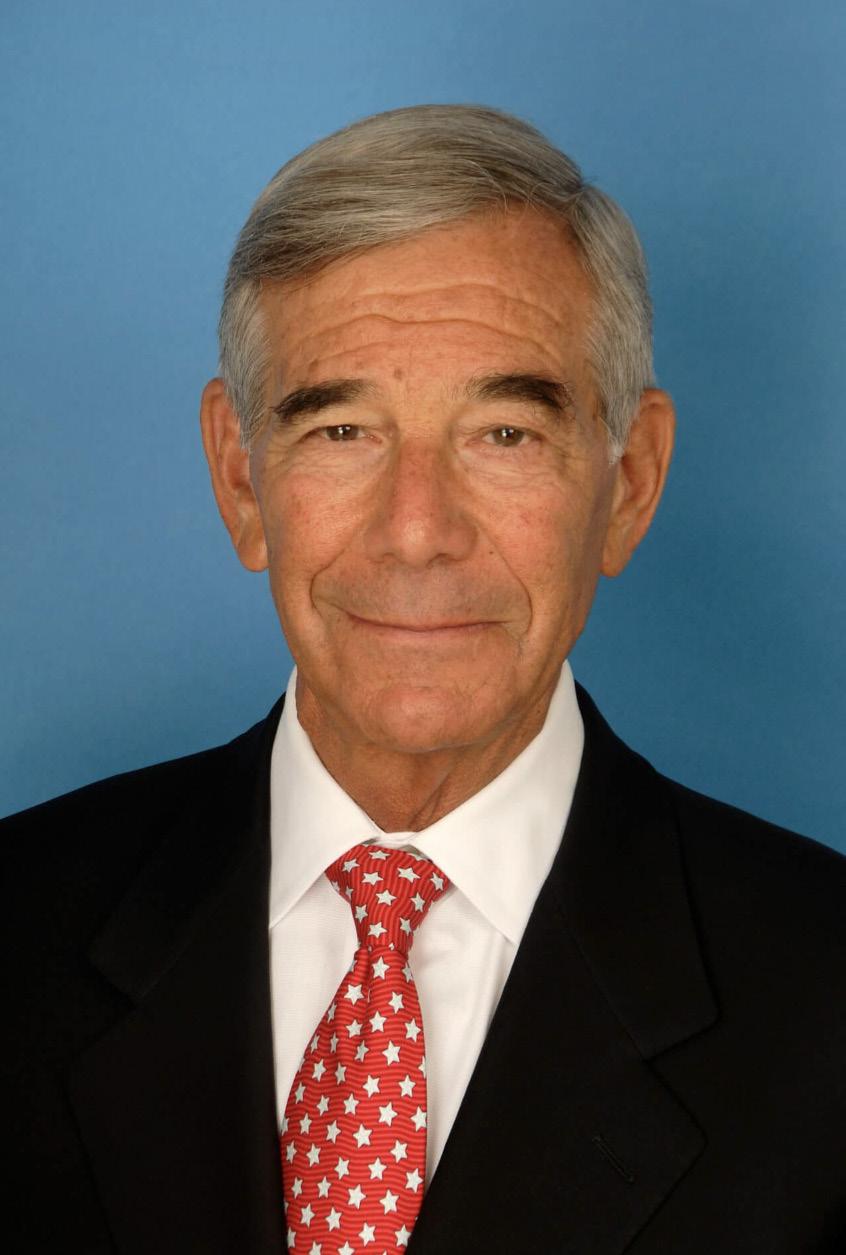

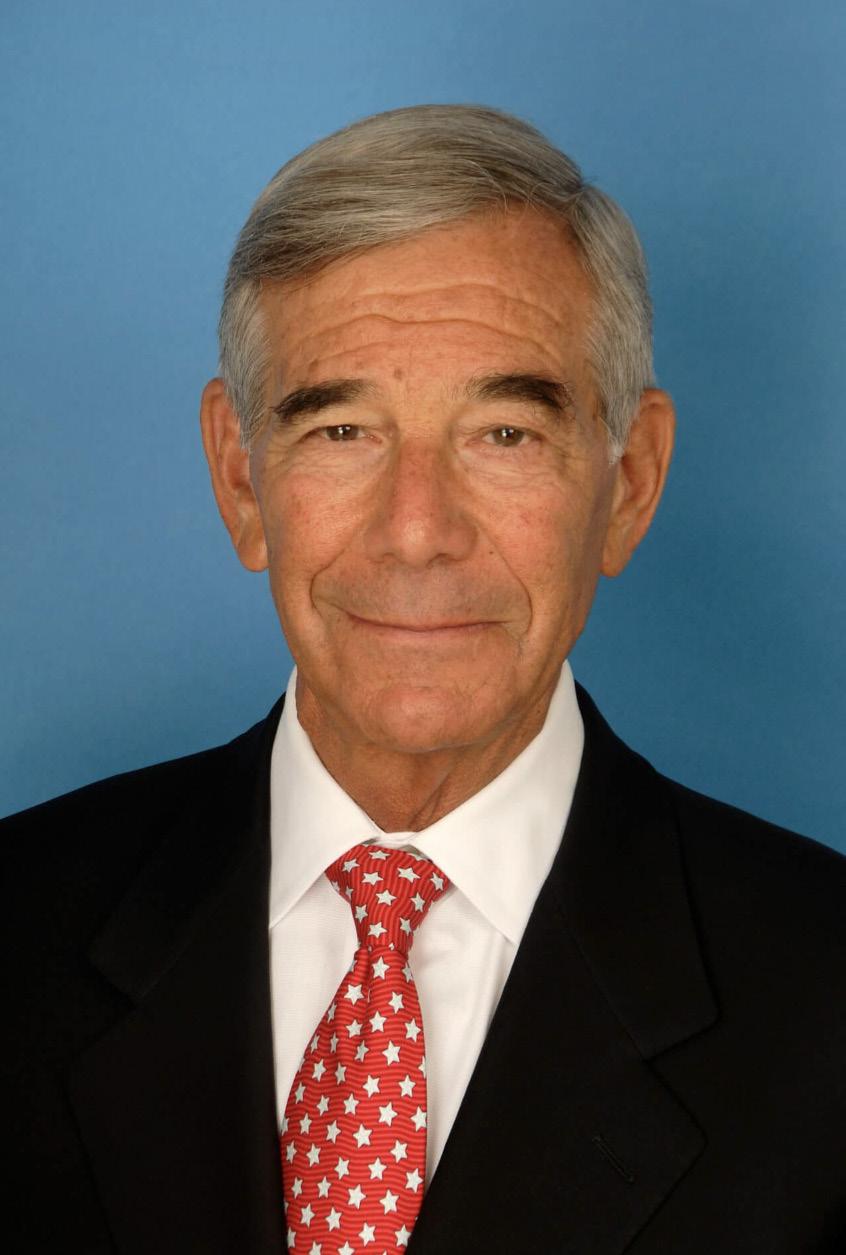

Meet Phil Bernstein

The embodiment of integrity

Phil Bernstein is a fifth-generation family member, Chairman, and single shareholder of Jacob Stern & Sons, Inc. Today, he and his wife Leslie live in Santa Barbara, California. Phil graduated from Wesleyan University in 1964 after having already worked for Jacob Stern & Sons, Inc. full-time for five months. He worked at the plant during the summer in high school and college and knew he was interested in what the company was doing and in its future.

Phil Bernstein even remembers meeting Bill Hardesty, a future

In 1970, Phil found the feed fat market for the by-products coming from the Acme-Hardesty plant. With help from a network of sales representatives and the purchasing and management capabilities of Jeff Peeler, this business was built to where Jacob Stern became the largest supplier in the country of blended fats to the animal feeding industry. This business was later sold.

32

Phil later became president of Acme-Hardesty in February of 1971. He recalled this event, “My dad and my uncle were in my office. This was highly unusual because it was a little before eight o'clock when I started. They never started that early. And I thought something's up. So, the man whom they had just hired two years before to run the business, his name was Jim Kane, had just passed the night before on a business trip. So, that was the bad and saddening news. The good news was that they were naming me as the new President of Acme-Hardesty.”

With that, Phil Bernstein was the first family member to run Acme-Hardesty since the start of the company. Bernstein recalled having a very “basic” vision at the time he was named President of Acme-Hardesty, “I had to turn to people I knew who had experience in the business.” Bernstein continues, “So, the first thing I did was, I called the man who had run Acme-Hardesty through the 60s. His name was Earl Seabold.”

34

ACME-HARDESTY Meet Phil Bernstein

Later that year in 1971, Phil Bernstein engineered the purchase of Snow and Company in California. This business, under the name Snow Commodities Co., was built into a large marketer of feed ingredients along the entire west coast from Canada to Mexico and, sometimes, internationally.

In 1980, Phil purchased all of the Jacob Stern stock that was owned by other members of his family to become the sole shareholder. With the help of Dick Sheffer and Henk Peeters, other experienced and trusted colleagues, he also managed the transformation of Acme-Hardesty from a manufacturer to an importer/distributor. He recalled the small team running the company at the time, “And at that point, there were five of us in the company. Dick and I, and three people running the office. And one outside salesperson.”

During the mid-eighties, with Phil’s financial guidance, the management team of Harold and Jeff Peeler and John Lindquist re-engineered the physical plant and processes of the Texas division. This led to the emergence of the company as the largest dealer in inedible tallow in the world with the capability to deliver special qualities of tallow to demanding customers, many being major international personal products manufacturers.

37

ACME-HARDESTY Meet Phil Bernstein

In 2002, Phil Bernstein attracted Jon Atkatz to join Jacob Stern as CEO. Jon’s skills and management attention allowed Phil to take on a more chairman-like position. Bernstein recalled his time working alongside Jon Atkatz stating, “We worked very closely together. And we started to upgrade management at Acme-Hardesty.”

This allowed Phil Bernstein to be able to start focusing on other interests, such as his growing family and volunteer activities. Through many trials and tribulations with Phil Bernstein behind the wheel, Jacob Sterns & Sons and Acme-Hardesty have always been able to adapt and come out on top against competition and economic downturns.

Bernstein credits his wife, Leslie, whose support and understanding provided him the base from which he was able to work with and learn from all of the good folks under his care.

While he was busy traveling the world and solving problems wherever they existed, she maintained a home and raised four great children. He is grateful to all those who have supported him and his goals, but especially to her.

“I offer the end of this history, not as an end, but as a beginning. My own involvement with the Acme-Hardesty business has been nothing short of challenging, exciting, and fulfilling. It has been an education and it has been full of remarkable relationships with outstanding people. I look at the company today and see unlimited opportunity. I also see a beginning of the next stage in the life of the company as new people lead it to reach its potential.”

38 39

ACME-HARDESTY Meet Phil Bernstein

Becoming Acme-Hardesty

An 80-year legacy of success through innovation

What happens when you take 100 pounds of animal fat and you split (hydrolyze) it? Many people in the chemical business understand what this means - you get roughly 90 pounds of fatty acids and about 10 pounds of glycerine. You are probably wondering why this is even important. Well, back in 1949, companies would sell glycerine to the makers of ammunition for the United States government. Glycerine from tallow went right to the makers of bullets and bombs as the United States was gearing up for the Korean War. This detail is an important piece of the Acme-Hardesty history.

In the 1940s, there was a lot of tallow and very little export of that tallow from the United States. Jacob Stern & Sons had already been in business for just about 92 years. Jacob Stern, who founded Acme-Hardesty in 1942, had relationships with most renderers from the Missouri River to the east coast. There were hundreds of these renderers at that time, while today, there are probably fewer than two dozen in the entire country.

At the time, Jacob Stern mostly sold to soap manufacturers, candle makers, and manufacturers of fatty chemicals. These soapers included Procter & Gamble, Lever Brothers, Fels Naptha, and Colgate. Back then, the soap manufacturers, and others, did not maintain their own purchasing departments, but bought through dealers like Jacob Stern & Sons. This business position provided the opportunity to do more with tallow than just sell it to others.

Bill Hardesty, co-founder of Acme-Hardesty, had believed he figured it out. Phil Bernstein recalled, “[his] proposition to my grandfather was that we take the tallow that Jacob Stern had access to, and split it to get the glycerine, to sell to people who were making ammunition and munitions…” Hardesty was a chemical engineer by training and reckoned that there was a fortune to be made by selling raw material to the government to support the war effort. Glycerine, at the time, was worth close to a dollar a pound. The tallow splitting idea had appeal and, before long, open kettles were added to the Jacob Stern facility at Tioga St. and Aramingo Ave in Philadelphia, PA. Bill Hardesty went on to start another fatty acid business in Dover, Ohio. To this day, that plant still exists, in a greatly transformed state, and is owned by Arizona Chemicals.

41

At that time, tank cars only held a maximum of 45,000 pounds; then later, sometime after the Korean War, were increased to 60,000 pound cars, which was considered a huge innovation.

During the war, households were encouraged to save used fat from frying bacon and deliver it to collection points in open cans. Thus, tallow, as a raw material, was delivered to the Jacob Stern plant in every sort of conveyance imaginable. The birth of Acme-Hardesty involved adding tanks for the reaction of the tallow with splitting agents and heat. These tanks were called Twitchell kettles.

They were open top and very dangerous. What came out of the bottom of each batch was “sweet water”, or glycerine, approximately 12- 14%. This was tapped off and sold to the ammunition makers. The fatty acids were a by-product of the reaction. The glycerine did not have to be concentrated for sale as its purity was not a concern. It was filtered and boiled a bit to drive off some moisture, but the war effort did not require 99.7% USP glycerine, today’s standard highgrade of glycerine, to make bombs.

42 43

In the 40s, tallow was received from great distances in everything from tank cars to wooden barrels.

By the mid-50s, things had changed markedly. This was driven by the industrial boom as well as the economic growth following World War II. During this time, the Philadelphia plant had grown tremendously to include more splitting capacity, hydrogenation, and distillation of the fatty acids. So, between the Korean War years and the mid-50s, there was a huge change in the market. The demand for fatty acids increased at a time when the world stopped making bombs and bullets, and naturally, the value of glycerine declined significantly. Tallow, at the time, sold for only 3 or 4 cents per pound, meaning the value of the parts of tallow were not very high either.

During the late 50s, the glycerine that was tapped off of the splitters was deemed valueless and went directly into the city sewer. The reason for splitting tallow had evolved into producing fatty acids to sell to manufacturers of all kinds of products as the post-war economy boomed. The uses and the market for fatty acids expanded at a tremendous rate for a number of years. The number of plants around the country selling fatty acids in the late fifties and into the early eighties was around a dozen, Acme-Hardesty being one of them.

45 1950

ACME-HARDESTY Becoming Acme-Hardesty

Even though Jacob Stern & Sons was a family-owned company, there were no members of the family who worked at Acme-Hardesty until Phil Bernstein was handed the presidency in 1971. This took place after the untimely death of the president of Acme-Hardesty. When the company learned of their president’s death, Phil Bernstein was asked to take over the company as there was no one else who had any understanding of the business. Bernstein was qualified, by virtue of many years of working in the plant and his familiarity with a number of the people who worked for Acme-Hardesty.

In 1971, Acme-Hardesty had about 100 employees, of whom ten were supervisory or quality control personnel. Acme-Hardesty ran the plant seven days a week, 24 hours a day, 365 days a year. Acme-Hardesty believed that, by running the plant on Christmas day, they would have a “leg up” on competition.

Although there really was no “leg up.” Acme-Hardesty had developed into an efficient producer and over the next ten years worked its way up to becoming the fourth largest producer in the country.

Some would say, Acme-Hardesty had started the business the wrong way. Acme-Hardesty was a glycerine producer first and a fatty acid producer later. All of the growth in processes and equipment were added onto the old splitting plant that was integral to the old Jacob Stern & Sons tallow facility.

This is where Acme-Hardesty used secondhand equipment in order to spend less than the competition. There were others who followed the same route such as, A. Gross Co. in Newark, (now out of business) and Darling & Co. (sold to Uniqema).

46

1971

ACME-HARDESTY Becoming Acme-Hardesty

It took several years for Acme-Hardesty to turn the message into a plan. Just to list a few: air and water pollution, a rash of fires in the plant, constant quality problems – mostly stemming from the type of plant that Acme-Hardesty ran and constant labor difficulties. It was the labor difficulties that ultimately led to the new model of Acme-Hardesty.

Although Acme-Hardesty’s labor union closed the plant during a month-long strike, the company found a way to buy from others and continue to keep its customers supplied.

During the month-long strike, Acme-Hardesty learned a lot. Needing to meet the sales commitments, Acme-Hardesty bought from its competitors and drop shipped to its customers, which was deemed very successful. Acme-Hardesty found that it excelled at what it did best, which was to take care of their customers.

Manufacturing was not the strength of the company. Acme-Hardesty only had so much capital to invest in plants and equipment. Not to mention, the environment was changing to make it less attractive to try to squeeze out a return on investment the “old way.”

Acme-Hardesty needed to find its “sweet spot.” The plan that emerged was to shut the plant down and become a middleman/dealer. On October 30, 1980, Acme-Hardesty ceased to be a producer and the new era began. In fact, what Acme-Hardesty did was change the business model.

Acme-Hardesty thrived in its role, bringing the supply and the buying markets together.

48 49

1980

ACME-HARDESTY Becoming Acme-Hardesty

In late 1982 Phil Bernstein, who was President at the time, had the bright idea of sourcing from Malaysia whom Bernstein had contacts with. Bernstein recruited Henk Peeters, who was located in San Francisco at the time, and ran the west coast tallow exporting operation, to make contact with the Malaysian producers to see if any of them were ready to export to the U.S.

Henk Peeters was the right person for the task. He had spent many years as a young man in Asia and was wellknown in the fats and oils community. Through his contacts, Acme-Hardesty started importing one container at a time from Southern Acids in 1983. Gus Lim was the go-between then as he is now. Acme-Hardesty’s timing was spot on because it was not long before the market for all fats, oils, and fatty chemicals got hot. Acme-Hardesty’s domestic sources had dried up one by one and we were able to replace them from Southern Acids.

Acme-Hardesty could have gone out of business had they not replaced this source. The biggest challenge was getting customers to accept perfectly good products from an unknown part of the world. When Acme-Hardesty mentioned Malaysia to its customers, many would ask, “Don’t they have lions and tigers there?”

Acme-Hardesty’s sales job was further impacted by the lead time required to move the product that distance. Therefore, Acme-Hardesty was forced to learn more about warehousing and distribution. It was Acme-Hardesty’s ability to solve these problems, obtain the market information, and source from an unknown part of the world, that has led to our success.

The transition from manufacturer to “dealer, distributor, and middleman” had been accomplished.

50 51

1982

ACME-HARDESTY Becoming Acme-Hardesty

In the mid-1980s, Acme-Hardesty decided that they could no longer deal through others to source castor oil and castor derivatives. President Bernstein went to Brazil, which at that time was the dominant producer/exporter in the world of these products, and introduced himself to the Wei family of Braswey. Over several years, Acme-Hardesty became closer and forged a trading relationship that still exists. While Brazil is no longer the market leader that it once was, Braswey is still an important source for us. Establishing Acme-Hardesty in Brazil was a true leveraging of the company's skills and culture, by using market knowledge and profiting from the changes in the market.

Acme-Hardesty is still accomplishing this with others today, such as Nidera and Akzo, being prime examples. Even with the success of Acme-Hardesty in Brazil, there was a pressing need to avoid being complacent. As the company was building the business in Brazil, India was overtaking Brazil as the number one producer of castor products.

Everyone in the business wanted to get in on the castor action in India. Phil Bernstein recalls on one trip, sitting in a hotel conference room for two days and meeting a procession of so-called “castor derivative producers.” He went on to say, “I think we met no fewer than twelve [producers] on that stop alone.”

Acme-Hardesty did business with anyone whom they deemed to fit their high standards and slowly eliminated any bad actors when they methodically disappointed the company. There were many expensive lessons to get to the few good suppliers Acme-Hardesty has today. Bernstein recalled these lessons, calling them “learning from our mistakes.”

Going further to say, “they were not insignificant.” While other companies were investing in fixed assets, Acme-Hardesty’s investment was pursuing intellectual capital. Acme-Hardesty sought to make money from what it knew best and by serving the markets well: by providing value. The lessons learned in the past have been ingrained into the company’s culture and its daily process when making decisions today.

52 53

This depends on people, Acme-Hardesty’s most important and valued assets. The key to Acme-Hardesty’s long-term success has been the drive to change and evolve.

ACME-HARDESTY Becoming Acme-Hardesty

The next big change took place in the early 1990s when Acme-Hardesty felt that it needed bulk fatty acids to truly grow its business. By 1990, Acme-Hardesty had many imitators bringing containers into the U.S. and, even though it was growing in volume, profits and organization, Acme-Hardesty needed a way to stay ahead of the competition. Other companies were bringing bulk fatty chemicals into the U.S. and Acme-Hardesty knew that it could market them successfully at lower cost than previously.

The new business had begun as the key to volume and was definitely dependent on bulk shipments. Hudson Tank Storage and Stolt Tankers helped Acme-Hardesty bring its first parcel into Newark, NJ in early 1991.

Acme-Hardesty was not alone for long, as Acidchem and other competition were beginning to catch onto this innovative change. Acme-Hardesty was able to make this change due to the flexibility that its business model allowed and to take advantage of market changes, if not create them wholly.

Acme-Hardesty would not be complete without the mention of a specific, outstanding line of products. The company had been in the concrete business since 1979 when the lone outside salesman, Tony Gulotta, asked for the opportunity to sell oleic acid to the concrete block manufacturers in Pennsylvania.

This application for a fatty acid had been developed by the U.S Department of Agriculture as part of a program to find new end-uses for domestically produced agricultural commodities. This particular end-use was practically brand new and Acme-Hardesty introduced it to many in the market.

Although other, much larger companies were quick to add it to their product line, Acme-Hardesty was first on the ground and found the market attractive from the beginning. Margins were excellent but the selling costs were not ideal.

Acme-Hardesty expanded the product line modestly, and aggressively in terms of geography. This opened solid market shares in many parts of the United States including the Midwest, Texas, and the Southeast. Acme-Hardesty was strongest in its home territory where Mr. Gulotta became one of the deans of the concrete additive business.

54 55

1990

ACME-HARDESTY Becoming Acme-Hardesty

Much like the addition of the concrete chemicals line, Acme-Hardesty added product lines through partners, like Sharon Laboratories, who produce preservatives such as parabens, specialty, natural and natural-like preservatives.

Acme-Hardesty’s relationship with Sharon Laboratories dates back to 1989 when the company hired Mike Zohar.

Zohar’s job at Acme-Hardesty was to develop new products for the business so that it would not be totally reliant on fatty acids. The timing was ideal, as Sharon Laboratories, the small Israeli-based business, had reached a scale where it could then consider exporting its product. President Bernstein reflects, “it took years of painstaking work and investment to get Sharon to the point it is today.”

Acme-Hardesty is proud to have a relationship with such longevity as it does with Sharon Laboratories as well as globally recognized customers such as L'Oreal.

The plastics additives business began in the early 1990s to further expand Acme-Hardesty’s product line. Acme-Hardesty believed that many of the products that it could introduce to plastics manufacturers would put Acme-Hardesty in a position to also offer basic fatty acids into the plastic additives business. This line was meant to be profitable on its own and a “door-opener” for the core business. Acme-Hardesty retained Frank Dorn who developed the Jenkinol marketing approach. Under Frank Dorn’s guidance, Acme-Hardesty learned about these products and how to present them to the various producers of plastic films and forms.

Although the strategic thinking was correct, it had taken many years to get a rationalized business going in this area. At that time, Acme-Hardesty learned that its core competency is commodity products and not the small volume technical sell items. Our company is still driven by the want to change and evolve, and starting in 2018, we expanded into small volume technical sales. Looking forward, President Bernstein believes, “that the future is brighter than ever with our current plan.”

56 57

Acme-Hardesty negotiated a three-year exclusive agreement with one of the Salim Group companies, a new manufacturer located in Indonesia. Acme-Hardesty did a great job for these companies by reaching the target quantity in the U.S. market in roughly a year and a half. The partnership, unfortunately, was flawed from the beginning because Salim had never intended to have a long-term relationship with Acme-Hardesty.

Before the end of the three-year contract, Salim had its own people in place to take over the business here in the United States. While Acme-Hardesty was able to purchase from them for a short time as they were getting established, Acme-Hardesty eventually lost their supply and had to scramble in the market to buy alcohols.

58 59

Another development that took place around the same time (in the early 1990s) was Acme-Hardesty’s entrance into the fatty alcohols business.

This situation persisted until 2005, when the new agreement with VVF kicked in, a current competitor.

Acme-Hardesty is now well established in the marketplace as a source of fatty alcohols.

Again, a return to what Acme-Hardesty does best, which is, bringing suppliers and customers together through their expertise. And that’s why we do it! How could the history of a company not include the people who made this history?

Acme-Hardesty is the story of an opportunistic beginning, a transition through a period of finding out what it did best, and a maturation into an organization that is positioned to be greater than ever.

60 61 2005

The people of Acme-Hardesty are moving this company to greater distances and heights than ever imagined

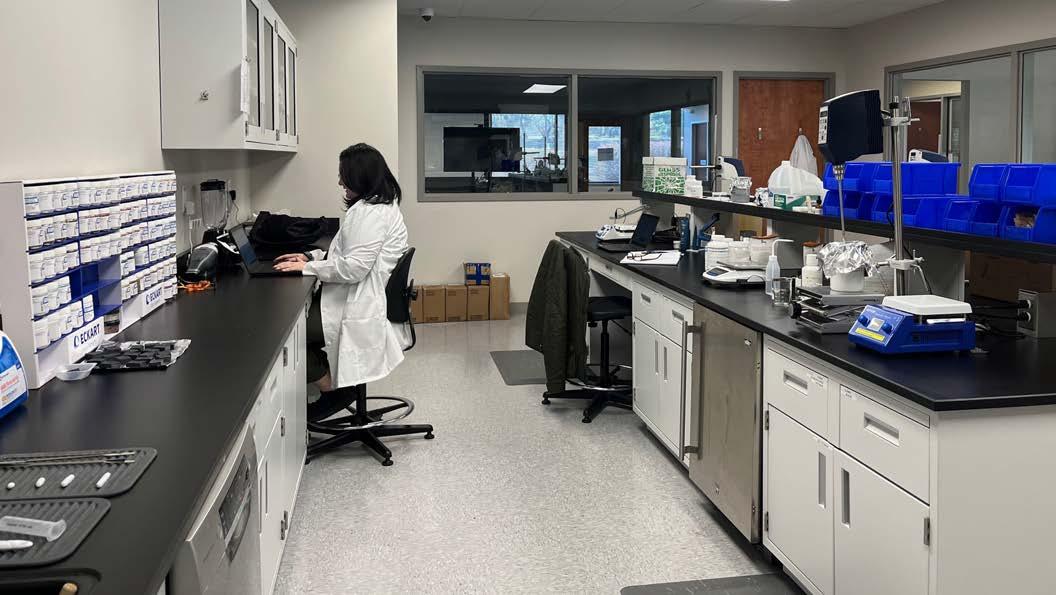

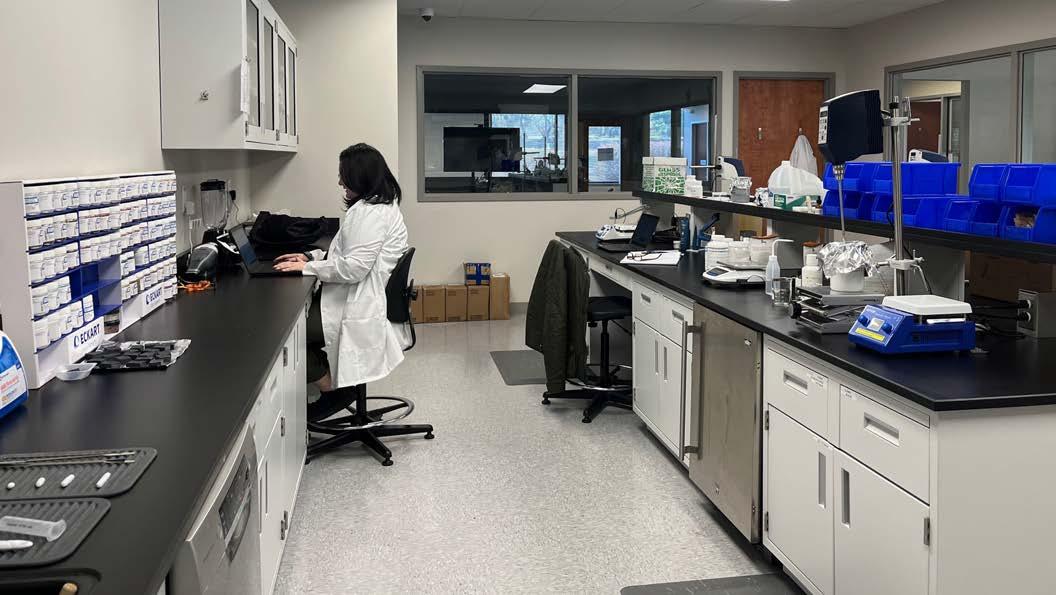

Research and Innovation Laboratories

The journey has only just begun

"Acme-Hardesty continues to proactively exceed the expectations of our customers and suppliers and differentiate ourselves from traditional distributors.

The Collaboration Center’s new laboratory capabilities further strengthen our ability to provide value-driven solutions to our customer base."

Rishabh Shah Director of Technology: R&D, Quality Assurance and Regulatory Affairs

63

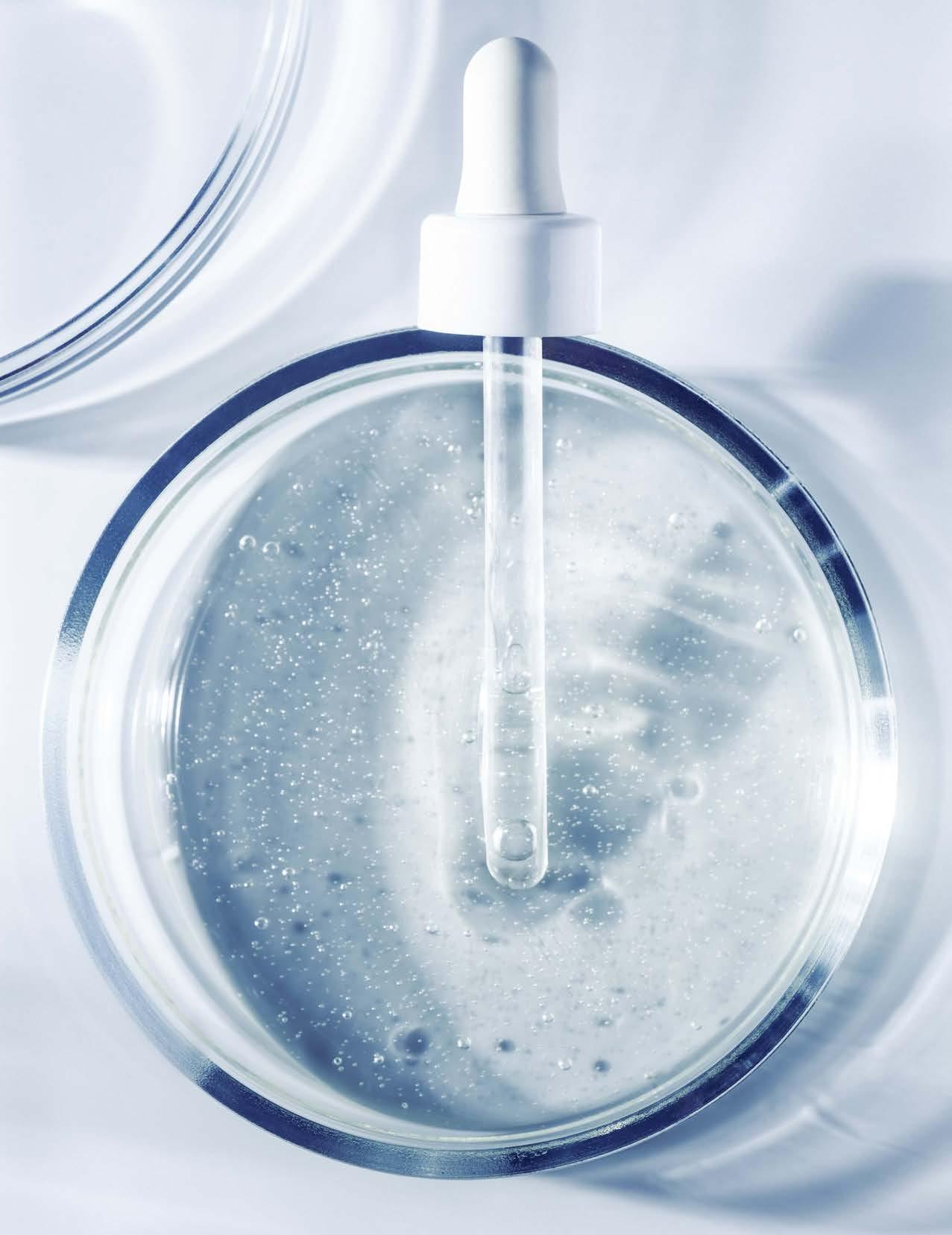

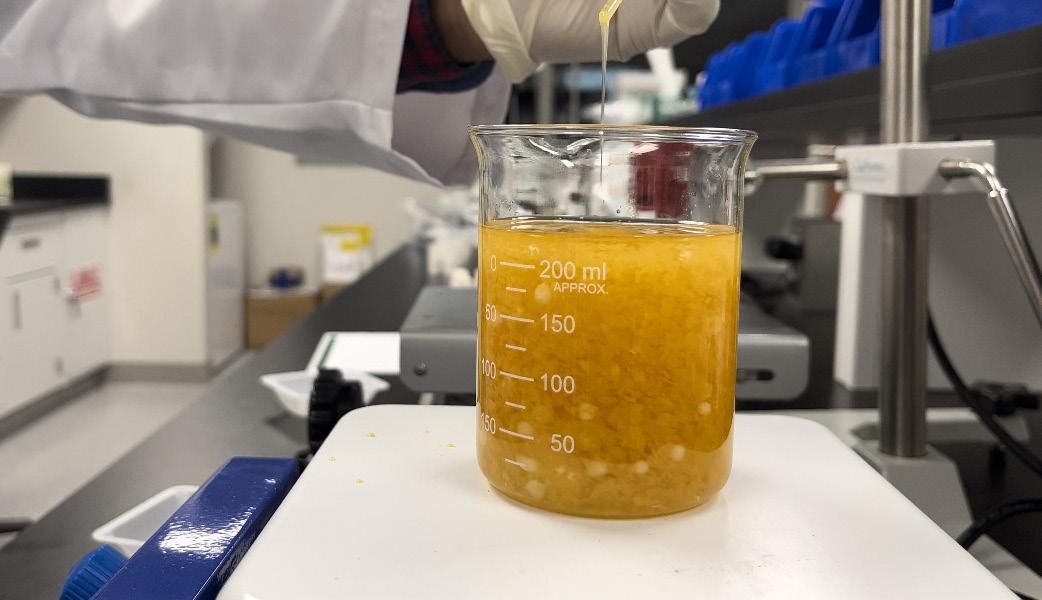

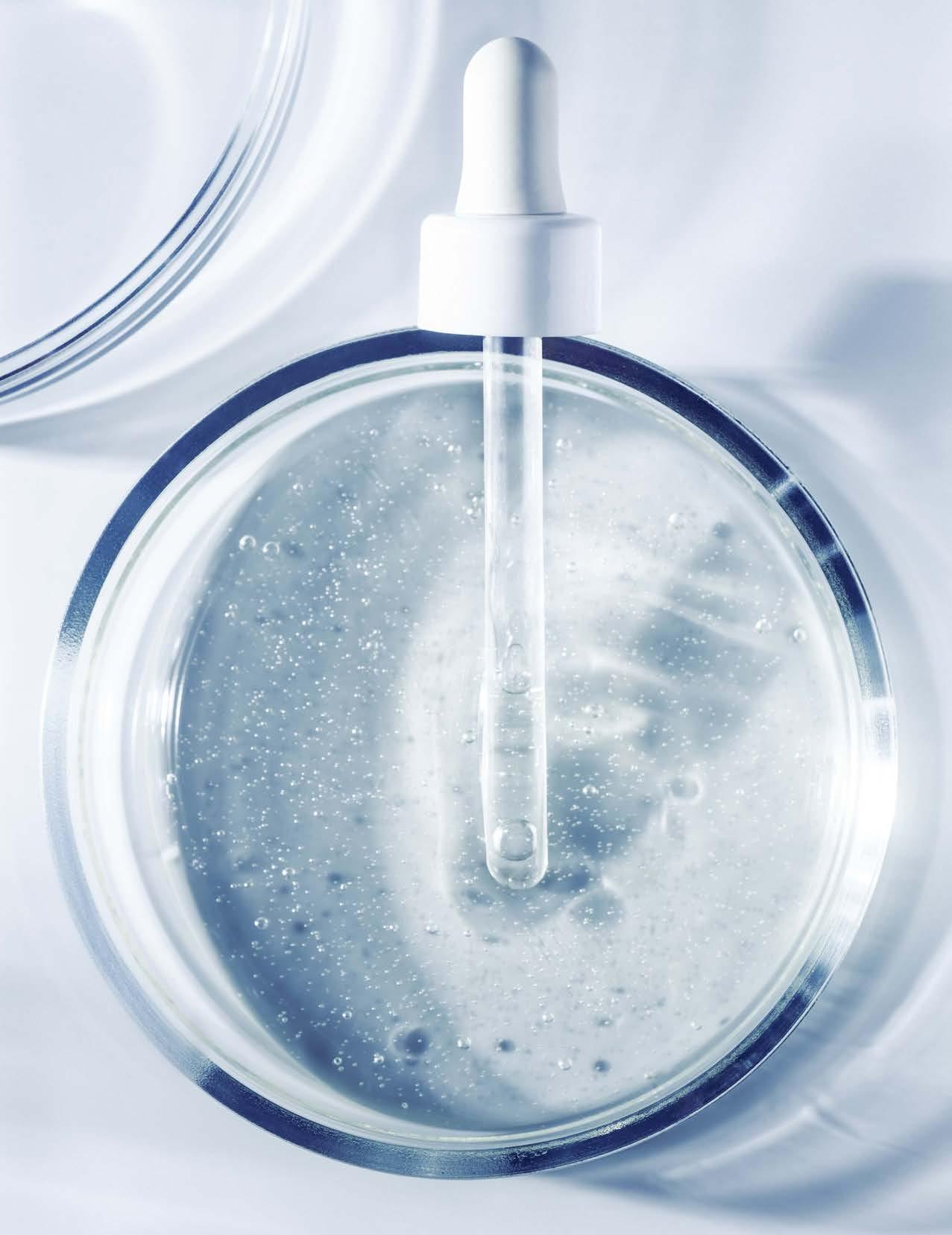

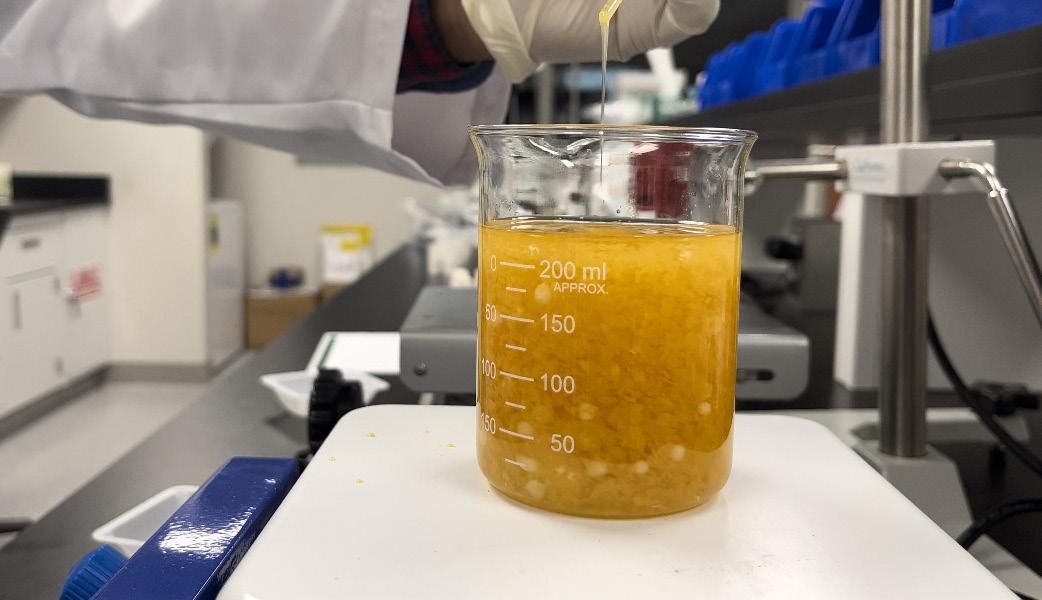

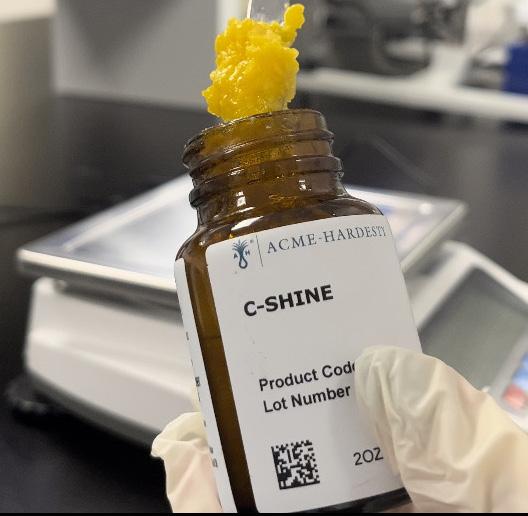

Acme-Hardesty has created two unique parts of the Research & Innovation Laboratories to bring a stronger focus to the specific industries we serve.

The Surface Formulations Laboratory supports formulation development and technical assistance for the Personal Care, Household, Industrial, and Institutional Cleaning, Polyurethanes, Coatings, Adhesives, Elastomers, Sealants, Agriculture, Lubricants, and Metalworking industries. A second laboratory will target formulations for ingestible solutions to support the Life Science industries.

64 65

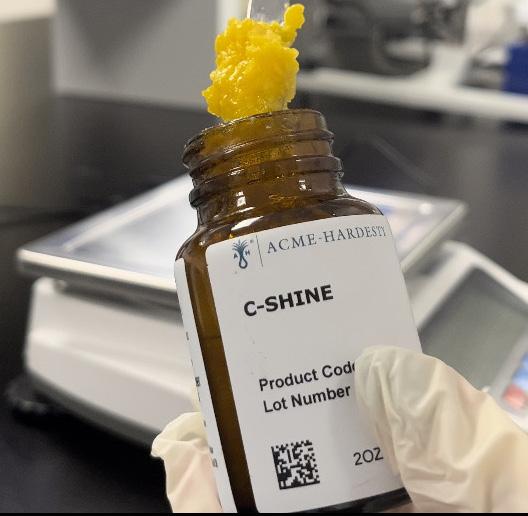

Top left: example formulation from Research and Innovation Laboratories.

Bottom left: Acme-Hardesty's research chemist pouring raw material on scale.

Top right: snapshot from our Surface Chemistries Lab

Acme-Hardesty chemists, in both laboratories, will bring value to customers and principals by focusing on applications specific to creating prototypes, conceptual formulations, and innovations for new and existing ingredients.

In addition, technical service roles in the lab will be geared toward helping customers resolve quality or process-related issues. Customers and principal partners alike, can rely upon the Acme-Hardesty technical team as an extension of themselves.

The expansion of the Research & Innovation Laboratories serves to illustrate Acme-Hardesty’s commitment to our cultural belief of Superior Service and proactively exceeding the expectations of our stakeholders. Speaking whimsically, Shah stated:

67

"This is where the magic happens."

ACME-HARDESTY Research and Innovation Laboratories

Collaboration Center

A new hybrid work environment with collaboration at its core

At the core of Acme-Hardesty’s culture of accountability, is a focus and investment in collaboration. After all, a company without collaboration is comparable to a stamp without its postcard. What defines our Culture and Collaboration Center or CCC (a common acronym used within conversation at Acme-Hardesty)?

“Understand the past and you can shape the future.” Acme-Hardesty has been voted a Top Workplace in the Philadelphia area since 2017. Our office pre-renovation was truly a great place to work. It was an action-packed, fun, energetic, and smiling place for employees.

Now, our office is still in the same location, remodeled to preserve the action-packed, fun, energetic, and smiling place we all know and love, but enhanced to lend itself to proactive communication, dynamic learning, and cross-team collaboration.

68 69

The Culture and Collaboration Center was created out of the shifting office landscape during and after the pandemic. This new hybrid working environment drastically changed the way Acme-Hardesty employees were able to interact.

The Director of Technology, Rishabh Shah, described this shift, “We were sitting at this pivotal time where we had to change things around, change the processes that we used to work on over the past many years.”

Instead of clinging onto the old and quickly outdated ways of working before the COVID-19 pandemic, Acme-Hardesty, like our company has done time and time again, adapted and created a new way of working during this tumultuous time.

70

ACME-HARDESTY The Cultural and Collaboration Center

Dynamic Hybrid Work Adapts to the Times

“That's where the idea came up about the creation of the CCC, where all the employees can collaborate. They can enhance engagement with each other through processes that we have put together via a virtual & in-person hybrid work structure.

The end goal was for us to make sure we created a safe environment where people can visit work (at CCC) and how best we can deliver innovative solutions to our partners and valued customers,” explained Shah. “I am extremely proud of Acme-Hardesty’s quick and considerate response during the pandemic.”

When initial concepts were being drawn up, the main goal of whatever work environment created, was one of an increase in communication. This began in our principal platform of communication, Microsoft Teams (commonly referred to as MS Teams).

73

ACME-HARDESTY The Cultural and Collaboration Center

Employees were engaged in a naming competition for the newly remodeled office location. This allowed for collaboration and idea generation across business units while cluing our Senior Leadership Team into what their employees expected from this new office. And so, the Culture and Collaboration Center was born. The Culture and Collaboration Center was fitted without offices, without traditional furniture, and without closed doors shutting us in. In the CCC you can find open doors, constant changes in seating and meeting locations, and of course, giant-sized games.

Furthermore, “Our IT team came up with a solution of creating an app-based service where employees can go into their apps and reserve a spot. Now we are able to reserve a space, such as a cube space, that we have, or one of the conference rooms as well. It's very intuitive, it's fun.” Rishabh Shah elaborated. Shah continued about the Center saying, “When you talk about collaboration, you want to make sure that employees can work with other employees. Teams can get together, work upon building that camaraderie and communication.” Lastly, the new CCC was fitted with two Research and Innovation Centers totaling over 800 square feet!

74 75

ACME-HARDESTY The Cultural and Collaboration Center

More details about these new R&D capabilities began on page 68. Acme-Hardesty is proud that the CCC has already become a must-use function for many of its employees. It will continue to be a useful way to work together, even while miles apart.

Rishabh Shah perfectly captures the CCC’s ultimate mission stating, “As of today, Acme-Hardesty supports more than 80 plus families directly and many more. We [Acme-Hardesty] are a partner in collaboration as well. For us, supporting our mission by supporting families is of the utmost importance. That's one of the reasons why we have created the CCC.” Acme-Hardesty prides itself as a company that embraces change and always adapts to the times. The calculated shift to a hybrid workforce is a prime example of the company investing in its people and resources. We are proud to have the Culture and Collaboration Center at the heart of our business, created out of necessity but sustained through Key Metrics and Cultural Beliefs.

76 77

Acme-Hardesty Website

1942 1955 1970s 1980s

1991 2014 2018 2022

Acme-Hardesty’s inception, the start of a dynamic story.

Originally solely manufacturing glycerine, journeyed into selling fatty acids in response to the drop in demand of glycerine.

Phil Bernstein becomes President of Acme-Hardesty. We expanded and built a continuous fractionation and distillation facility, key to the current manufacturing business model in the 1970s.

A new era begins in distribution. Acme-Hardesty played to its strengths, moving out of manufacturing. We were no longer a producer, but instead a sustainable supplier in the USA and sourcing from Malaysia began.

A pivotable year in our history as it was the year we started bulk shipments to Newark, NJ. Today, Acme-Hardesty still has bulk warehousing in Newark, NJ.

Acme-Hardesty receives our RSPO Company Certification advancing our sustainability journey.

Acme-Hardesty began its movement into specialties and further specialized its business units to support its sustainable profitable growth strategy.

Our future is driven by our people and sustained through our Cultural Beliefs and Key Metrics.

78 79

Shaping Our Future

Reimagining what's possible in the next eight decades

Acme-Hardesty is proud of its history and storied past that has brought us to where we are today. The unwavering commitment to our Cultural Beliefs, and dedication to providing the best service to our customers by many generations of devoted employees, is what has driven us to have the longevity of 80 years in business.

Owner Phil Bernstein once said, “We [Acme-Hardesty] have a reputation for integrity, and for keeping our word.” Employees from all aspects of the company work together to help one another achieve the goals that are set. "If we were a sports team, the name on the front of the jersey would be more important than the name on the back of the jersey,” John Carney, VP Strategy and Business Development, compared.

80 81

There is a renewed level of excitement and passion with Acme-Hardesty, one that cannot be understated nor go unnoticed. “We've evolved! In 2018, we sharpened our strategy with the addition of focused business units, and now we're adding specialty products for each business unit: Personal Care, Life Sciences, Polyurethane CASE, Household, Industrial & Institutional, etc. So, the company again, continues to evolve and get better and grow,” narrates Bryan Huston. Acme-Hardesty has always been flexible and adaptable, which is a testament to the company’s longevity as Huston pointed out. Today, Acme-Hardesty is thrilled with its current trajectory and continued evolution into various market segments.

82 83

Where Are We Now video

Our

present

ACME-HARDESTY Shaping

Future

Acme-Hardesty stands steadfast behind its employees who continue to make the company successful and continue its mission far into the future.

Looking into the future, Acme-Hardesty anticipates growth but not at the expense of its Cultural Beliefs or commitment to sustainability. Guy Kalbach, Director of Human Resources at Acme-Hardesty, spoke of this desire to grow stating, “Growth can be defined in many different ways. In a business, oftentimes you define it as financial growth. We also focus on the growth of the organization’s culture so we can take care of more families [Acme-Hardesty’s mission].” In doing so, Acme-Hardesty is reimagining new ways to adapt and innovate within specialized markets and is motivated by providing customers with the greatest experience possible.

84 85

future

ACME-HARDESTY Shaping Our Future

To continue, this means hiring people that fit the Cultural Beliefs that Acme-Hardesty has worked continuously to foster within our company. CEO of Jacob Stern and Sons, Doug Shreves, speaks on the company's long-term goals and aspirations in hiring qualified and passionate individuals describing, “If you're looking to work for a company where you can really make an impact and at the end of the day, feel like you are helping to grow a company and make a real impact in your career, this is it. This is the place to go. We will give you the tools to be successful. And I can assure them of that.”

Acme-Hardesty stands steadfastly behind its employees who continue to make the company successful and continue its mission into the future.

86 87

The future is people.

The future is people. At Acme-Hardesty, bringing in the best candidates, continuing technology education and learning, and competitive, focused strategies will send the business roaring into the future. “We want people to train. We want people to learn. We want people to try new things,” President Jeff Kenton declared. The belief that everyone can always learn something new and can always better themselves is fundamental to Acme-Hardesty’s success today as well as its success in the future.

By creating this open, communicative, and respectful work environment, all employees see a bright future for Acme-Hardesty. In closing, Guy Kalbach recalled his appreciative feelings about working for Acme-Hardesty, “I remember earlier on in my career, those Sunday evening blues where I'm like, ‘Oh man, I have to go to work tomorrow.’ I don't have those anymore, so I'm eternally grateful to the organization and the people that work here for that.” YOU can shape Acme-Hardesty’s future!

88

"The future depends on what we do in the present."

ACME-HARDESTY Shaping Our Future

– Mahatma Gandhi

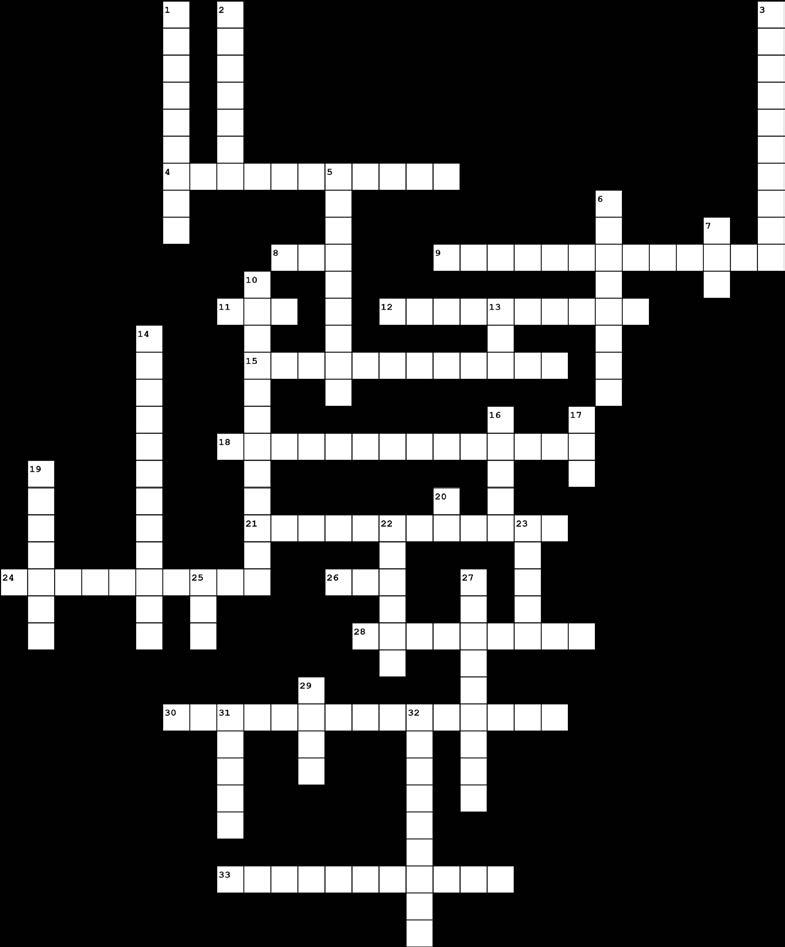

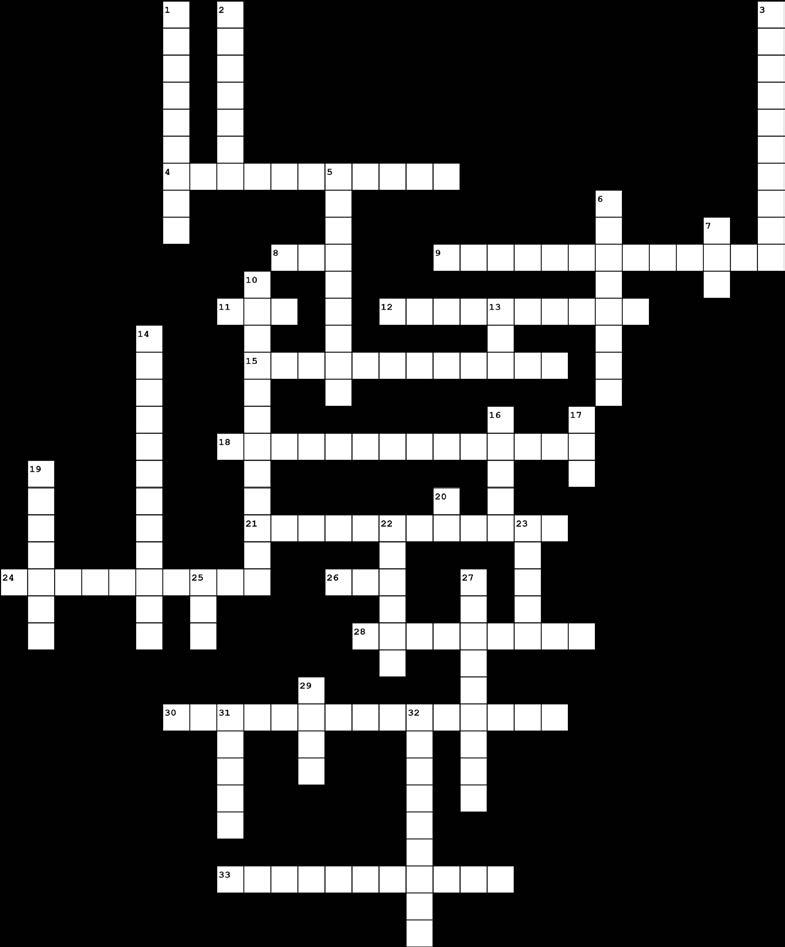

ACME-HARDESTY CROSSWORD PUZZLE CAN YOU SPOT THE RESEARCH & INNOVATION LABORATORY DIFFERENCES?

DOWN

1. Country that produces the most palm oil

2. The transport of goods over a short distance

3. CNO

5. Our largest product (in pounds) by volume

6. Storage for bulk products

7. Abbreviation for Free on Board

10. C16 carbon chain

13. Abbreviation for Intermediate Bulk Container (or tote)

14. C8 carbon chain

16. Consists of bulk goods conveyed by water, air, or land

17. Abbreviation for Delivered Duty Paid

19. Short name for isotainers

20. Abbreviation for Truckload

22. A flat transport structure, which supports goods in a stable fashion while being lifted by a forklift

23. The country that produces the most castor oil

ACROSS

4. This acid is in hundreds of personal care products, including moisturizer, sunscreen, makeup, soap, and baby care

8. Abbreviation for Bleachable Fancy Tallow

9. PKO

11. An animal or marine

derived triglyceride

12. Our President, Jeff Kenton’s favorite ingredient

15. C14 carbon chain

18. Fatty acid of castor oil

21. CPO

24. C10 carbon chain

26. Abbreviation for Less Than a Truckload

28. Charges that the charterer pays to the ship owner for its delayed operations of loading/ unloading

30. AHCOHOL™ 1618

33. This country produces 1.2M tons of coconut oil per year

25. Abbreviation for Cost Insurance Freight

27. Storage for package goods

29. 55 gallon steel or plastic container

31. Solidification point of a fatty acid

32. Is generally the detailed organization and implementation of a complex operation

10 changes to keep score!

91

1. Chemist’s hair is up in a ponytail. 2. Chemist’s glasses have been placed on top of orange lanyard.

3. Jacket has been removed from chair. 4. Charcoal soap bars removed. 5. Sample (potassium hydroxide) moved off of counter. 6. Syringe removed from drying rack.

7. Spatula added to beaker. 8. Squirt bottle turned. 9. Laptop closed.

90 Complete This Crossword Puzzle!

10. Samples removed from the blue bin.

BACK IN 1942 80 YEARS AGO

WHAT THINGS COST?

New House....................$4,700

Gallon of Milk..................$0.60

Loaf of Bread..................$0.09

Dozen Eggs....................$0.48

Stamp...............................$0.03

Yearly income...............$1,885

Gallon of Gas..................$0.19

Movie Ticket..................$0.25

TOP MOVIES

· Mrs. Miniver

· For Me and My Gal

· Random Harvest

· Yankee Doodle Dandy

· Reap The Wild Wind

POPULAR BOOKS

The Runaway Bunny

The Porky Little Puppy

The Robe

The Song of Bernadette

WORLD POPULATION ....... USA POPULATION .............

2.4 billion

134.9 million

TECHNOLOGY

· Silly Putty Was Created

· Duct Tape was invented

· World’s first nuclear reactor was built in Chicago

· Nutella was created due to WWII chocolate rations

· Napalm was invented by combining gasoline and palm oils

CURRENT EVENTS

· Time’s Man of the Year was Joseph Stalin

· The US and 25 other nations sign the Declaration of the United Nations

· Congress creates the Women's Army Auxiliary Corps (WAAC)

· President Roosevelt proposes a maximum income of $25,000 per year

· The Manhattan Project begins in the US to construct a nuclear weapon

LIFE EXPECTANCY

SPORTS CHAMPIONS

· World Series: St. Louis Cardinals

Male: 64.7 years

Female: 67.9 years

IN STYLE...

Women

Shoulder pads

Defined waistlines

Skirts above the knees

Victory roll hairstyle

Men Fedora hats

V-neck vests

Gabardine jacket

Zoot Suits Knit

· Stanley Cup: Toronta Maple Leafs

· NFL: Washington Redskins

· Kentucky Derby: Shut Out

· NCAA Basketball: Stanford

1940s SLANG

· Ace — Top notch expert

· Bad news — It's trouble

· Buzz — Excitement

· Flip your lid — Get angry

· Cat's Meow — The best

— ON THE RADIO —

BORN IN 1942

· Joe Biden

· Harrison Ford

· Stephen Hawking

· Paul McCartney

· Aretha Franklin

· Judge Judy Sheindlin

· Barbara Streisand

· White Christmas by Bing Crosby

· Sleepy Lagoon by Harry James

· Moonlight Cocktail by Glenn Miller

· Tangerine by Jimmy Dorsey

92 93

"So the sky's the limit, because we can go anyplace. We've got such a fantastic team that can analyze opportunities and get us set up to explore them."

94 95

— Phil Bernstein

96

A DIVISION OF JACOB STERN & SONS. INC.

Caren Dres-Hajeski, VP of Personal Care and Marketing

Caren Dres-Hajeski, VP of Personal Care and Marketing