Zhang Lei

AZL Architects

Founder and principal architect of AZL Architects Professor, School of Architecture & Urban Planning, Nanjing University

After teaching design, studying abroad, and researching architecture in the 1990s, Professor Zhang Lei founded an architecture studio at Nanjing University in 2000, gradually shifting his focus to architectural practice. After nearly a decade of continuous development, his studio has not only grown into a pioneering design firm with international influence, but it has also become an influential representative of contemporary Chinese architecture. AZL Architects was formally established in 2009 with offices in Nanjing and Hangzhou. The goal of Zhang Lei’s unremitting efforts include actively responding to the needs of sustainable human development; contributing a forward-thinking analysis of resources, cultures, cities, residences, commerce, and markets; showing the charm of design with wisdom and responsibility; and maximizing environmental, social, cultural, and economic benefits.

AZL Architects was recognized as one of ten architecture offices for the 2008 Design Vanguard by Architectural Record magazine. In 2012, Zhang Lei was named a candidate for the 4th Swiss Architectural Awards. Zhang Lei has participated in major international exhibitions on contemporary Chinese architecture in the Netherlands, France, Germany, Italy, and the United States. His works are widely published in international magazines such as GA Document, Domus, Lotus, Architectural Record, Architectural Design, and Architectural Review, to name a few.

Selected works

2003 Model Animal Genetic Research Center of Nanjing University, Nanjing, China

2007 Brick House, Nanjing, China

2007 Concrete Slit House Nanjing, China

2011 Zhengdong New District Urban Planning Exhibition Hall, Nanjing, China

2011 Nanjing CIPEA No.4 House, Nanjing, China

2014 Wangjing Garden Chapel, Nanjing, China

2015 Longhu Financial Center C4-06, C4-15 Mansion, Nanjing, China

2016 Shitang Internet Conference Center, Shitang, China

2017 Lei House, Tonglu, China

2018 Song House, Shanghai, China

2019 Future Stitch Smart Factory, Haining, China

2019 Bingding Wood Kiln, Jingde Town, China

2019 Museum of Nanjing University, Nanjing, China

2019 Museum of Chinese Drama of a Hundred Plays, Nanjing, China

2020 Tengchong Multifunctional Cultural Center, Tengchong, China

2020 Shijiazhuang CBD Exhibition Hall, Shijiazhuang, China

2020 Nanjing Ruralation Tangshan Museum Resort, Nanjing, China

LEI HOUSE

Location: Tonglu City, Zhejiang Province, China

Architect: AZL Architects

Principal Architect: Zhang Lei

Design Team: Ma Haiyi, Zhong Huaying, Liu Ying, Yuan Ziyan

Gross Floor Area: 296 square meters

Design Period: 2016 – 2017

Completion: October 2017

Photography: Yao Li, Hou Bowen

Compared with the enormous amount of urban development in China’s cities over the last three decades, the country’s villages rooted in traditional agriculture still maintain the overall rural characteristics of “architecture with no architects.” They represent a kind of primal order influenced by the traditional social background that is now clashing with urban civilization. The LEI House is a typical case worth referring to. It is located in Shanyinwu Village of Tonglu County in the eastern city of Hangzhou, not far from the village center. Most of the houses in the village have been rebuilt within the last ten years and show signs of the typical “new rural” style. From an architectural perspective, features of the local architectural tradition are nearly invisible.

The site of the project is an ordinary village house. It stands on a platform about 200 square meters in size, backed by the hillside and facing a valley and a water reservoir. The owner plans to live in the house while also providing accommodation for travelers. Ms. Lei, the homeowner and founder of the successful local bed and breakfast brand “Ruralation,” is an influential “next generation rural returnee.” She hopes to demonstrate the value of projects such as this one as a model for rural economic development and environmental improvement. This is also an opportunity for the development of the village that the inhabitants have longed for.

The layout of the site follows the arrangement of basic village farmhouses. It faces the valley and main road on the south side, while forming an open courtyard backed by the hills. The square-shaped three-story building aligns with the neighboring houses on both sides. Except for the

easily visible vegetables and flowers planted in the yard and on the roof, this gray stone object is difficult to notice compared to its white-and-red decorated neighbors.

LEI House features a brick and concrete structure that is commonly used by local artisans. The three stories, the simple vertical volume, and few window openings, together with the exceptionally compact interior space are reminiscent of traditional local rammed earth houses. Thanks to the availability of free of charge stone bits from a local stone processing factory and skilled craftsmen in the area, the construction of this castlelike house, which provides the homeowner with a sense of security and belonging, had very limited additional costs. The efficient use of the interior space and the flexible arrangement of the stairwell inside the house smoothly connects the functional spaces on each floor. Natural light enters from the top and side windows, reaching each corner of the house and providing an interesting spatial experience.

Arriving on-site at the mere cost of transportation, the blue-grey stone slates are the scraps of a nearby stone processing factory, whose stone is usually used to decorate urban buildings, roads, and public squares. The dry masonry work is not only a continuation of the local “She Minority” tradition of wall and dam construction, but also an introspection on new brick veneers for farm houses. The successful use of the stone bits in LEI House led to the rise in price for such “scrap” pieces from the neighboring stone factory. Perhaps the factory that previously only provided materials for urban construction turned out to have unexpected opportunities from an untapped local demand.

The Bauhaus-style bamboo chandelier actually came from a skilled bamboo craftsman in the village. It is the result of numerous tries by Ms. Lei and the craftsmen. The rooftop garden of LEI House utilizes a thick soil in which vegetables thrive without fertilization or pesticides, while most of the neighboring farmers depend heavily on those chemical additives.

Confronted with new technologies, especially the sudden appearance of superior industrial products, native construction techniques practiced by individuals easily lose popularity. The heavy use of “concrete blocks” in the surrounding wall and in the landscape design of LEI House aims to reestablish the connection between technology and craftsmanship. The hollow concrete blocks are usually a cheap construction material in rural areas, but after being reconfigured by the architects and the craftsmen, they perform just as well as masonry in terms of spatial composition and expressiveness.

A masonry logic is also applied in the 3D printed tea pavilion in the courtyard. The 3D printed polylactic acid (PLA) units replace the usual building blocks and aim to further emphasize the transparency of the hollow bricks. The translucent space and material are achieved through the combination of precise digital control and flexible manual adjustment of scale and of single components. No matter which technological invention, its efficiency will always be judged on two levels: Firstly, its own physical properties form the basis. Yet, even more important is the setting of its parameters, as well as the possibility of optimization. This could be a way of eliminating the contradiction between technology and craftsmanship.

A limited budget, the lack of professional management teams and the continuous outflow of skilled local craftsmen are common problems

faced by rural construction. Based on 3D printing technologies, an industrialized prefabrication system, off-site processing, and supply chain logistics, the on-site assembly minimizes the damage caused by construction to the local environment. In the front yard of LEI House, the 3x3x3-meter cubic tea pavilion was constructed out of 400 squareshaped units. They were produced within one month through the cooperation of three suppliers in Beijing and Nanjing. Two inexperienced workers were able to complete the final assembly within three days. Efficiency-oriented and supported by modern technology, the architects explored the direction of rural construction under its constrained conditions.

The time and material consumption of 3D printing directly affected the project’s timeline and construction costs. In line with the practical conditions of rural construction, often small and lacking professional equipment, losing “weight” became the core pursuit of the design of the pavilion. With the adjustable density of 3D printed objects, the corresponding parameters were set according to the load-bearing requirements of each building unit and to create a translucent effect. The transparency and texture of the pavilion contrast sharply with the heavy volume of the dense castle-like stone walls of the main building. In the rural setting, their extremely simple forms enhance each other, creating a pure, pristine yet reserved and mysterious atmosphere of a village of the future.

On humanity’s long way back to Mother Nature, rural settlements provide a naturally advantageous spiritual shelter. With their anticommercial tradition, low-tech approaches, and the desire to reshape their communities, the craftsmanship in rural architecture and technologized villages can be an effective path to remodeling sustainable human spaces.

FUTURESTITCH SMART FACTORY

Location: Haining City, Zhejiang Province, China

Architect: AZL Architects

Principal architect: Zhang Lei

Design Team: Qi Wei, Liu Junming, Jing Huairui

Interior Design Team: Du Yue, Ma Haiyi, Liu Ping, Li Ji, Zhu Wenjian, Pu Sirui

Landscape Design Team: Chen Junjun, Zhao Min, Jiang Zhiyuan

Gross Floor Area: 26,800 square meters

Design Period: 2017 – 2018

Completion: October 2018

Photography: Yao Li, AZL Architects

“The Uncommon Thread” is the slogan of the American sports fashion brand STANCE. Their goal is to perfect socks, usually the most trivial item in a person’s wardrobe. STANCE’s “Punk & Poets” culture attracts a large number of sports stars and leaders in the fashion industry. The brand’s major partners include the National Basketball Association (NBA), Major League Baseball (MLB), the National Collegiate Athletic Association (NCAA), and Disney.

The new FutureStitch Smart Factory is located in the economic development zone of Haining City in the eastern Chinese province of Zhejiang. The factory was completed on October 12, 2018. This modern 26,800-square-meter facility is STANCE’s flagship production location and will increase the brand’s product range from socks to a wide range of sports-related products. With the production process and logistical requirements at its base, the design of the factory also hosts a distinctive feature — it doubles as an art gallery.

Taylor Shupe, the founder of STANCE, studied for one year at the Hopkins Nanjing Center at Nanjing University, where he accumulated quite a deep understanding of Chinese culture.

Taylor wanted the Smart Factory to not only function as a production base, but to also be equipped with an architectural concept that matched the brand slogan: The Uncommon Thread. He imagined a creative and artistic factory with a deep sense of belonging and pride. With a large

number of works of art and an abundance of sports areas and outdoor gardens, STANCE provides its employees with ample room for daily activities and other experiences. Avi Cohen, the chief technology officer of STANCE, is a senior expert in the field of hosiery and pays great attention to technical details. With significant experience in technological processes and the production industry, Avi defined the specific design conditions such as the layout of equipment and the scale of the space from the very beginning.

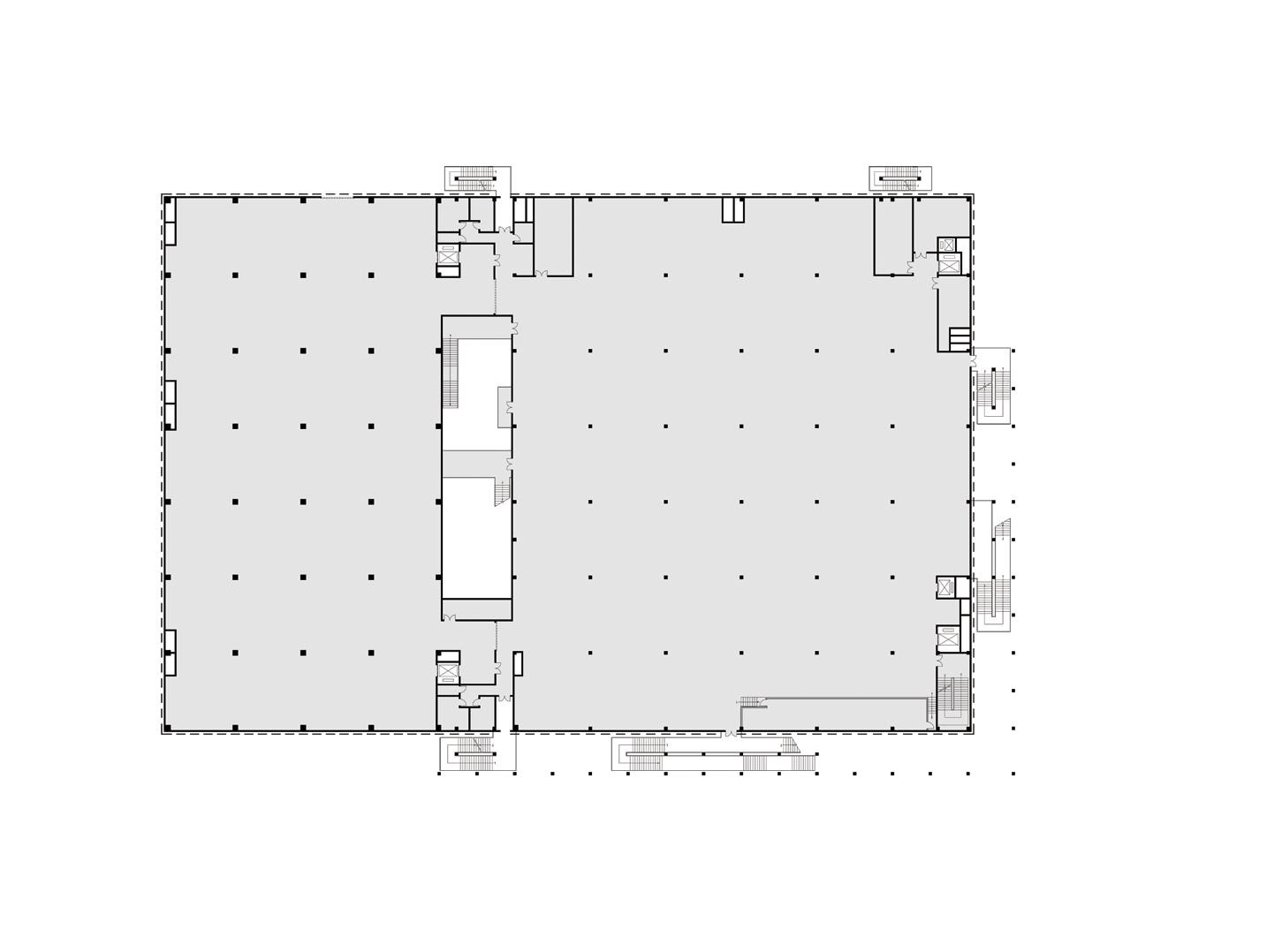

The FutureStitch Smart Factory will add 500 hosiery machines over the next three years to increase its annual sock production output to 60 million pairs. The rapid development of the company will bring about changes in the spatial requirements and the adjustment of the facility’s functional blocks. To ensure the integrity of the production and provide a flexible space for the future development of the brand, auxiliary facilities such as evacuation stairs and corridors were placed outside of the workshop units. The exterior corridors allow for adjustments of the emergency exits in the future, while also providing outdoor resting areas for the workers.

The design idea for the exterior staircases was inspired by the Maiji Mountain Grottoes in the northwestern Gansu province, built 384-487 A.D., and furthermore by the Centre Pompidou in Paris, which was completed in 1977.

This unique network of outdoor stairs on the eastern and southern façades of the building is part of a specialized corridor system.

The factory’s interior hosts a visitors route that follows the entire manufacturing process. Starting from the lobby, it runs independently and connects the different production areas on each level, exhibiting modern manufacturing and logistical processes, from the storage of raw materials to the final packaging. The visitors route also passes by the triple-height STANCE gallery at the center of the factory, and ends at a basketball court and garden on the rooftop. The organic mix of production workshops, public art spaces, and sports facilities along the route emphasizes STANCE’s brand and welcomes a large number of visitors.

The workers’ areas are concentrated on the south side of the building. After changing clothes in the locker rooms on the ground floor, the staff take designated elevators to move through the building. Most of the workers will reach production facilities on each floor through the outdoor stairs and corridors. The simple design of the red steel staircases and their flow of commuting workers create a lively production atmosphere with a sense of ritual.

The main entrance hall of the Smart Factory is located on the building’s east side, serving as the entrance for administrative management and guests. On one side of the entrance hall is the design and development center where the confidential development of future STANCE products takes place. Through a long corridor that leads from the second floor of

the entrance hall past the packaging facilities, visitors will reach the lofty STANCE art gallery. The visitors route creates a rich spatial experience from the bottom up, alternating between production and artwork. Eventually, it reaches the rooftop basketball court that can also serve as a stage. In the future, you could possibly encounter a NBA player or enjoy a concert here.

On the large east-facing wall of the art gallery, 100 portraits of the workers taken by photographer Luo Yuqian express a silent power that contrasts with the other artwork that surround them. Those in the photographs are the real daily users and the spirit of this space.

Structure and Space

The supporting structure of the outdoor stairs on the eastern and southern façades is connected by V-shaped steel frames, forming an enlarged rhythmic woven texture, and establishing an intrinsic formal relationship between the structure and the identity of the hosiery space. The largescale sculpture in the southern square of the building created by Zio Ziegler, an illustrator from California, complements the woven façade elements. A mural inside the art gallery by the same artist continues the mysterious pictographic tradition influenced by aboriginal culture, while serving as another manifestation of The Uncommon Thread.

First floor plan

1. Lobby

2. Warehouse 3. Workshop

Laboratory

Restroom

Locker

Shower

Second floor plan

Fourth floor plan

First mezzanine plan

Third floor plan

South elevation