•A compact, economical option suitable for both homeowners and hobbyists to commercial firewood producers, the TW-LS is built to withstand daily firewood production without skipping a beat.

•The LS-270 and LS-390 come standard with hydraulic wedge/log lift, table grate, and center mounted controls for ease of use.

• This fuel-efficient splitter can be equipped with either an 8.5HP or 11HP engine and 3.5” or 4” hydraulic cylinder.

• The TW-LS Series produces excellent firewood without the hefty start-up price tag; add optional Autocycle to bring your firewood production to the next level.

Power

•LS-270: fuel-efficient and quiet 8.5HP Honda GX270

• LS-390: 11HP Honda GX390, featuring high power output, low oil consumption, and excellent exhaust emissions performance

Hydraulics

• Equipped with hydraulic wedge/log lift

• Oversized hydraulic tank for all day splitting

•Continental hoses

Features

• Table grate (32” x 34”)

• Self-entering splitting chamber for easy oneperson operation

• Adjustable 4-Way wedge

•37,700 pounds of splitting force

• Choose 3.5” or 4” hydraulic cylinder, 24” stroke

• Available engine upgrade

• Autocycle (adds second spool valve) Options

Increase production speed and efficiency by adding Autocycle to the LS-270 or LS-390.

Engine Power (HP) 8.5/11

Pump Flow (GPM) 16

Cylinder Bore (in) 3.5/4

Stroke (in) 24

Splitting Force (lbs) 37700

Cycle Time (sec) 5/8

Avg Output (cord/hr) 1

Weight (lbs) 1350

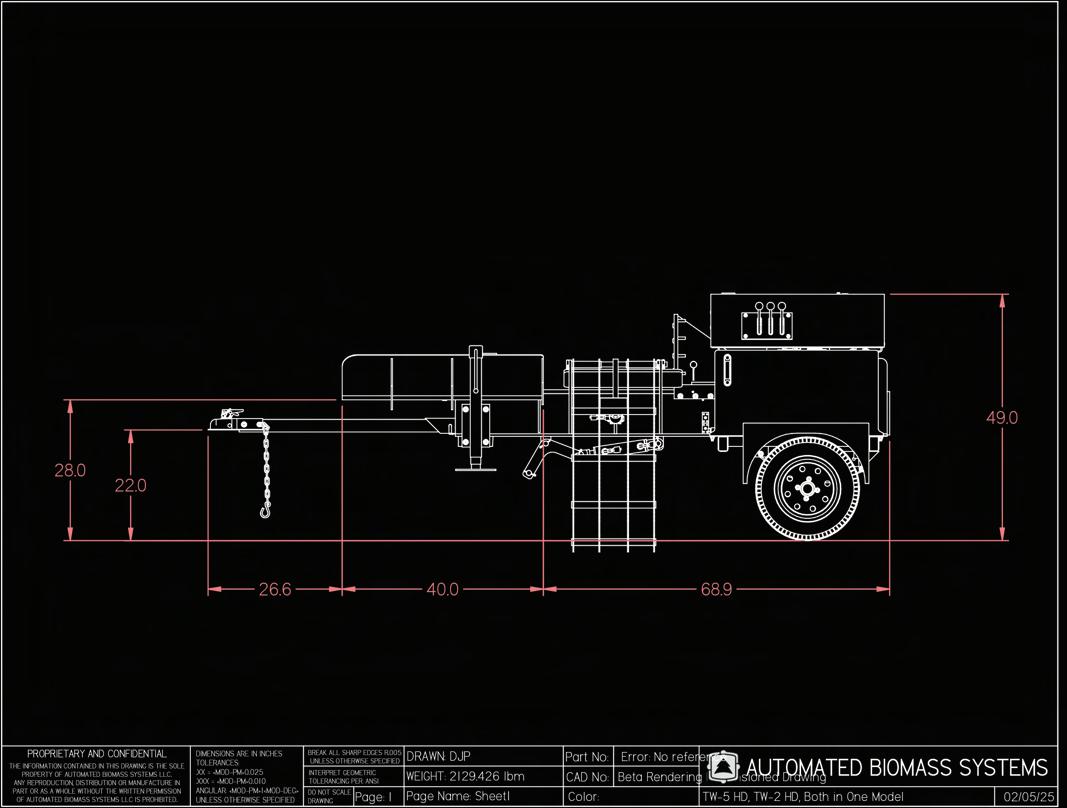

• The HD Series mid-sized log splitters feature a hydraulic wedge and log lift, engine and cylinder options for maximum splitting force and quick cycle times, and the ability to output up to 1.5 cords per hour.

• The TW-2 HD and TW-5 HD are built tough to work as hard as you do, and are capable of withstanding the elements for years of daily firewood processing.

• Equipped with integrated valve cover, table grate, increased hydraulic power, and new standard spring suspension, HD Series log splitters are portable, ergonomic machines capable of extremely high production and efficiency.

• Additional wedges allow for custom firewood production.

Power

• TW-2 HD: fuel-efficient 8.5HP Honda GX270

• TW-5 HD: 11HP Honda GX390 gas engine

• High power output, low oil consumption

• Oversized 25 gallon hydraulic tank with internal baffles to maintain cool, filtered fluid

•Continental hoses

• 16 GPM pump flow

Features

• Table grate (32” x 34”)

• Self-entering splitting chamber for easy oneperson operation

• Log lift with 500 pound loading capacity

• Adjustable 4-Way wedge

• Choose 4” or 5” hydraulic cylinder, 26” stroke

• 2-Way and 6-Way wedge options Options

The HD Series’ ergonomic operator platform is 36” off the ground, ensuring a comfortable position for all-day splitting.

Engine Power (HP) 8.5/11

Pump Flow (GPM) 16

Cylinder Bore (in) 4/5

Stroke (in) 26

Splitting Force (lbs) 37700/ 58905

Cycle Time (sec) 8/10

Avg Output (cord/hr) 1.5

Weight (lbs) 1750

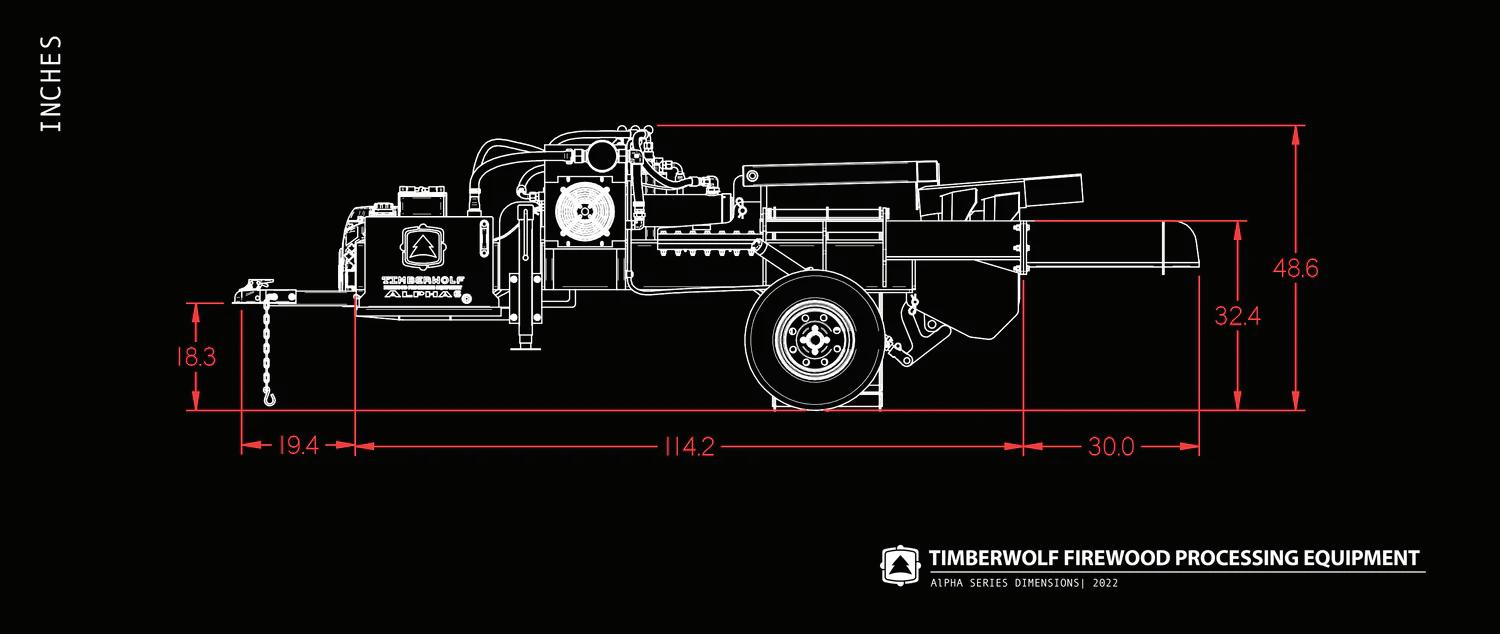

• Timberwolf’s top-of-the-line commercial box wedge splitter, the Alpha 6 is capable of outputting up to 2 cords of uniform-sized wood per hour.

• Powered by a 22.1HP engine, the Alpha offers 58,905 pounds of splitting force along with a 7 second cycle time.

• The Alpha 6 is equipped with hydraulic log and wedge lift, table grate, dual jacks for increased stability during operation, and regeneration manifold for faster splitting.

• The splitter comes standard with 4-Way wedge; add a box wedge with floating auto-retract arm to create uniform splits with no need for manual resplitting.

• 22.1HP Honda GX700

• 28 GPM pump flow to power through the toughest logs

• Standard with 5” hydraulic cylinder

• Log lift with 500 pound loading capacity, install on either side of machine

• Wedge lift with 8” travel

• Regeneration manifold allows rod to extend more rapidly, for faster splits

• 40” x 36” table grate

• Floating auto-retract arm eliminates need for manual resplitting

• Adjustable 4-Way wedge

• 58,905 pounds of splitting force

• 2-Way and 6-Way wedges

• 4.5” box wedge for cord wood

• 3.5” box wedge for packaged firewood

• 2.5” box wedge for cooking wood

The Alpha’s box wedge option with auto-retract arm pulls the unsplit portion of the log back into the splitting chamber, allowing operators to burn through the largest blocks without rehandling.

Engine Power (HP) 22.1

Pump Flow (GPM) 28

Cylinder Bore (in) 5

Stroke (in) 26

Splitting Force (lbs) 58905

Cycle Time (sec) 7

Avg Output (cord/hr) 2

Weight (lbs) 2550

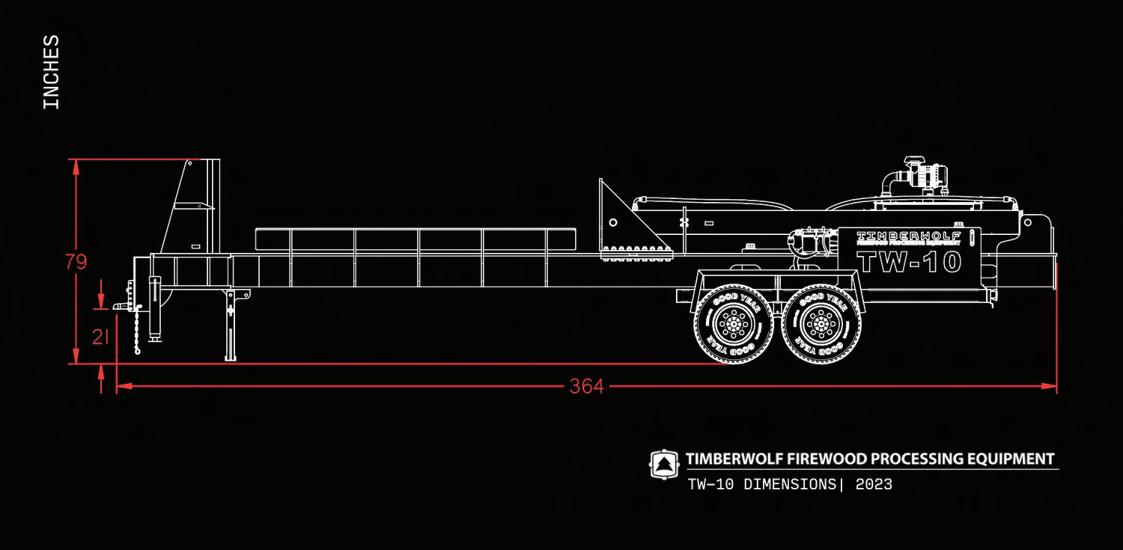

• The TW-10 is an extra-large log splitter capable of splitting logs as long as 12’ and up to 5’ in diameter, into quarters, so they can be fed into a firewood processor or wood chipper.

• This heavy-duty built splitter has a 30’ long frame made of 3” thick American steel, and is powered by a 74HP diesel engine.

• The TW-10’s impressive power comes from the huge 8” hydraulic cylinder that offers 150,000 pounds of splitting force.

• Timberwolf’s biggest log splitter is operated via remote control, so operators can split the largest logs from the comfort and safety of their truck.

• 74HP Hatz diesel engine

• Designed for maximum power and efficiency with little fuel consumption Power

• Massive 8” hydraulic cylinder built in the USA

Features

• Dual 7000 pound axles

•Autocycle

• Drives the push block with 150,000 pounds of splitting force

• 110 gallon hydraulic tank

• Huge 4-Way wedge

• 54 second cycle time

•Remote control operated

• Bring the splitter to the worksite!

• Equipped with ball coupler and full braking system

• Removable jack

• Highway tires

The TW-10 is built for maximum power: good luck finding a log this machine cannot split!

Engine Power (HP) 74

Pump Flow (GPM) 33

Cylinder Bore (in) 8

Stroke (in) 12

Splitting Force (lbs) 150000

Cycle Time (sec) 54

Weight (lbs) 13640

•A compact processor capable of industrial-level firewood production, the Pro-LP is an economical choice for homeowners, hobbyists, and professional firewood businesses.

• The Pro-LP is equipped with a 26.5HP engine, 4” cylinder, and live deck that converts into a log lift, features which allow the processor to output up to 2 cords of wood per hour.

• Unique round log trough that centers and stabilizes logs during cutting and splitting.

• Includes standard 4-Way wedge, automatic bar and chain oiler, log measuring grid, and integrated tail lights.

• 26.5HP Kohler EFI engine

• Fuel-efficient and economical

• 28 GPM pump flow Power

• Hydraulic wedge lift

• Hydraulic live deck, converts into a log lift

• Oversized hydraulic tank for all-day processing

• Log clamp and saw bar

• Round log trough

• Table grate

• Log measuring grid

• Saw: 25” cut/.404 chain Features

Options

• 4-Way wedge

• 6-Way wedge

The Pro-LP is a compact processor capable of producing up to 2 cords of firewood per hour, making it an economical choice for both homeowners and firewood businesses.

Engine Power (HP)

Pump Flow (GPM)

Cylinder Bore (in) 4

Trough Length (ft) 16

Max Log Length (ft) 24

Cycle Time (sec) 8

Avg Output (cord/hr) 2

Weight (lbs) 3300

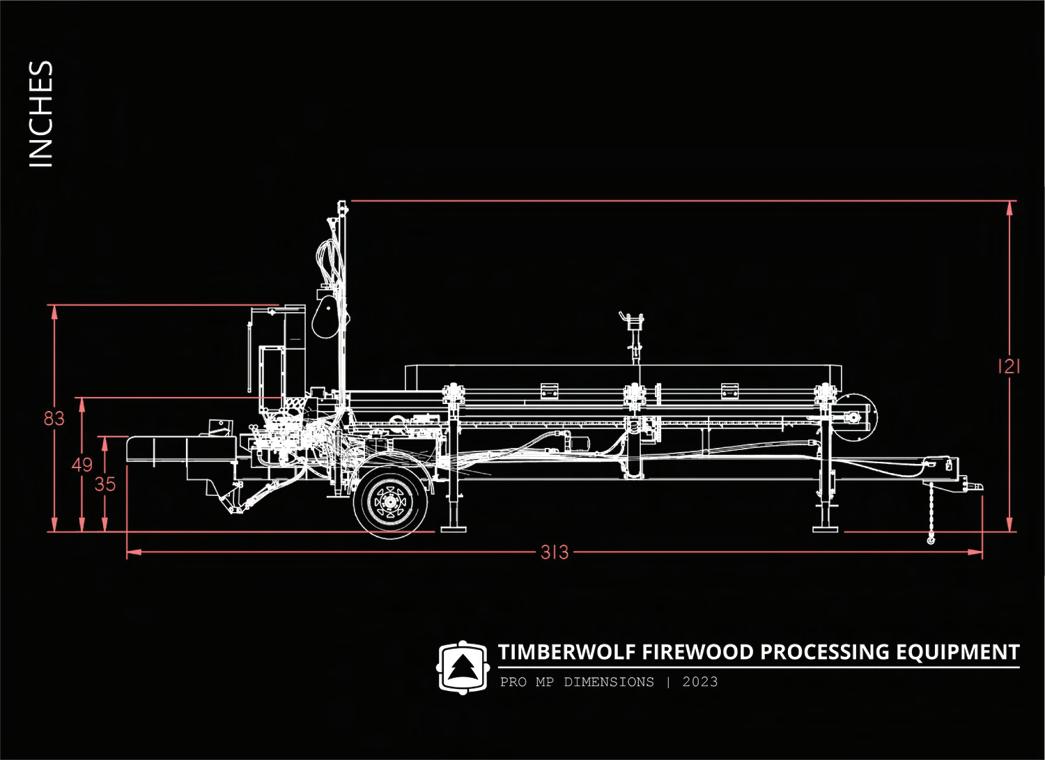

• A mid-sized processor capable of outputting up to 2 cords per hour, the Pro-MP offers commercial-grade power and speed at an affordable price.

• Standard with driven top roll clamp and back roller that enables the processor to handle logs long as 32’ and wide as 24” in diameter.

• Highly accessible and ergonomic frame for easy feed trough adjustments and resplits, standard wedge lift, and equipped with 6’x12’ 3-strand live deck.

• 12’ integrated conveyor option to easily load cut firewood into a truck of trailer.

Power

• MP: 22HP Kohler EFI fuelefficient engine with 22-2.6 GPM pump flow

• MP X: 26.5HP Kohler EFI with 3-stage pump (22-18-2.6 GPM)

• MP XL: 38HP fuel-injected Kohler with integrated oil cooler, 22-18-2.6 GPM pump flow

Features

• 2/3-stage gear pumps for fast, simultaneous functions

• Hydraulic wedge lift

•Continental hoses

• 30 gallon hydraulic tank (MP XL: dual tanks)

• Manual autocycle

• Top roll clamping system

• Hourglass-shaped back roller to handle longer logs

• Saw: 25” cut/.404 chain

• Table grate

• Portable: towable by any half-ton truck

• 4” or 5” American-made hydraulic cylinder

• 12’ integrated conveyor

• 4-Way wedge

• 6-Way wedge Options

Available in three models, Pro-MP Series Processors output up to 2 cords of firewood per hour and are the best commercial processor for the money.

Engine Power (HP)

Pump Flow (GPM)

22/26.5/38 22-2.6/ 22-18-2.6

Cylinder Bore (in) 4/5

Trough Length (ft) 16

Max Log Length (ft) 32

Cycle Time (sec) 5/7

Avg Output (cord/hr) 2

Weight (lbs) 5500

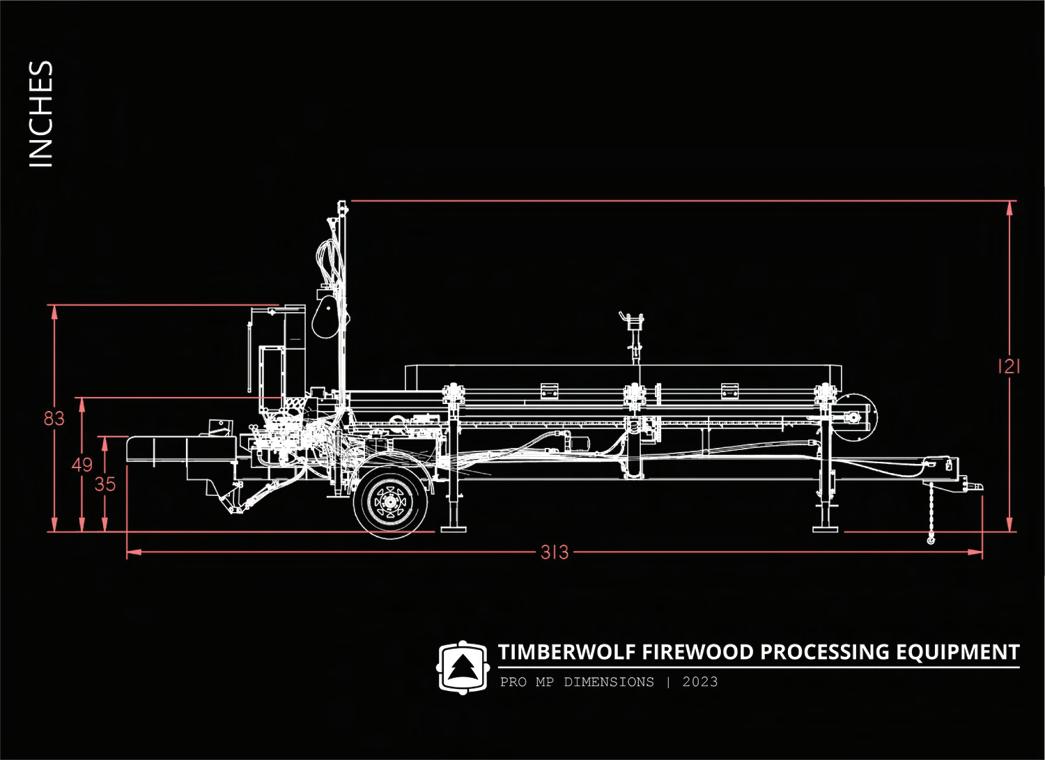

• The Pro-MP Diesel is a portable firewood processor with the ability to output up to 3 cords per hour, while handling logs wide as 24” and in excess of 32’ in length.

• Combines the frame of the popular Pro-MP with a 56HP diesel engine to boost productivity and efficiency.

•Standard with Timberwolf patented driven top roll clamping system and back roller to secure and stabilize long logs, hydraulic wedge lift, and 6’x12’ 3-strand live deck.

• 12’ integrated conveyor option to easily load cut firewood into a truck of trailer.

• 56HP Hatz diesel engine

• 22GPM Anfield gear pump

• 22-18-2.6 GPM pump flow Power

• Dual 30 gallon hydraulic tanks

• Wedge lift for seamless splitting adjustments

•3-strand hydraulic live deck

• Manual autocycle

•Continental hoses

Features

• Top roll clamping system

• Hourglass-shaped back roller to handle longer logs

• Saw: 25” cut/.404 chain

• Table grate

• Highly adjustable for safe and simple operation

The Pro-MP Diesel is the ultimate mobile firewood processor, weighing in at under 6000 pounds, towable by any half-ton truck.

Engine Power (HP)

Pump Flow (GPM)

Cylinder Bore (in) 4/5

Trough Length (ft) 16

Max Log Length (ft) 32

Cycle Time (sec) 5/7

Avg Output (cord/hr) 3

Weight (lbs) 5500

• 4” or 5” American-made hydraulic cylinder

• 12’ integrated conveyor

• 4-Way wedge

• 6-Way wedge Options

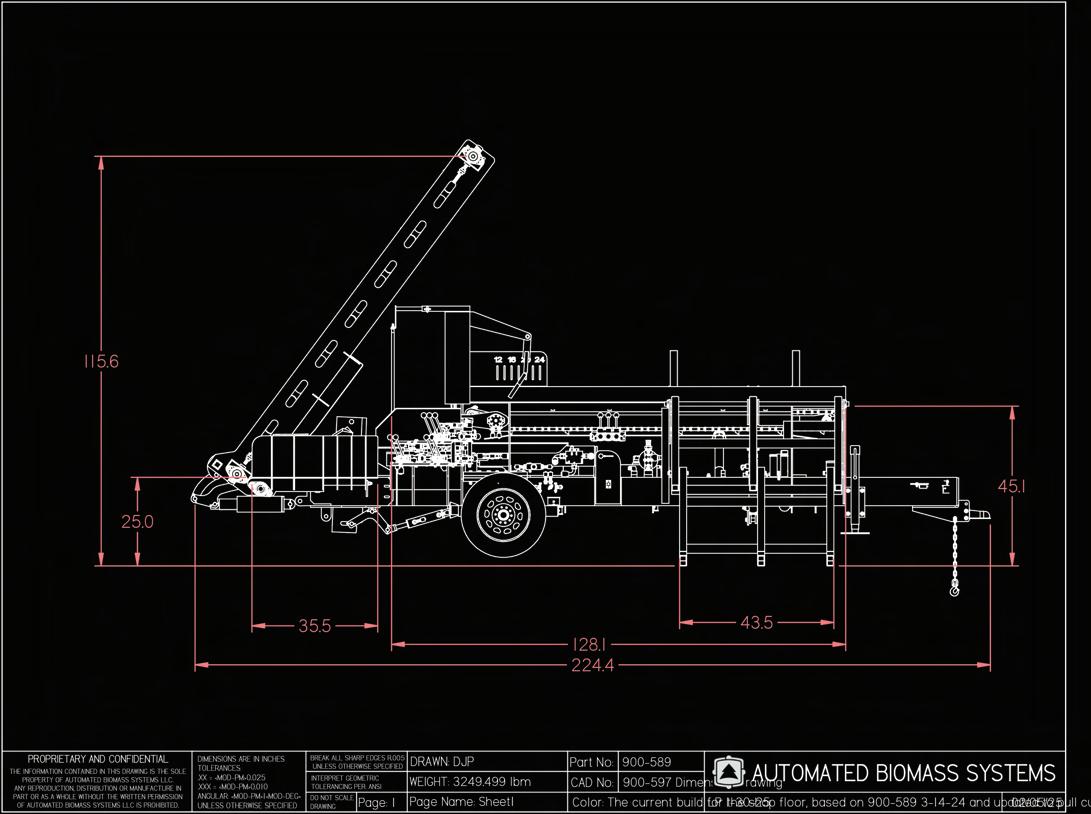

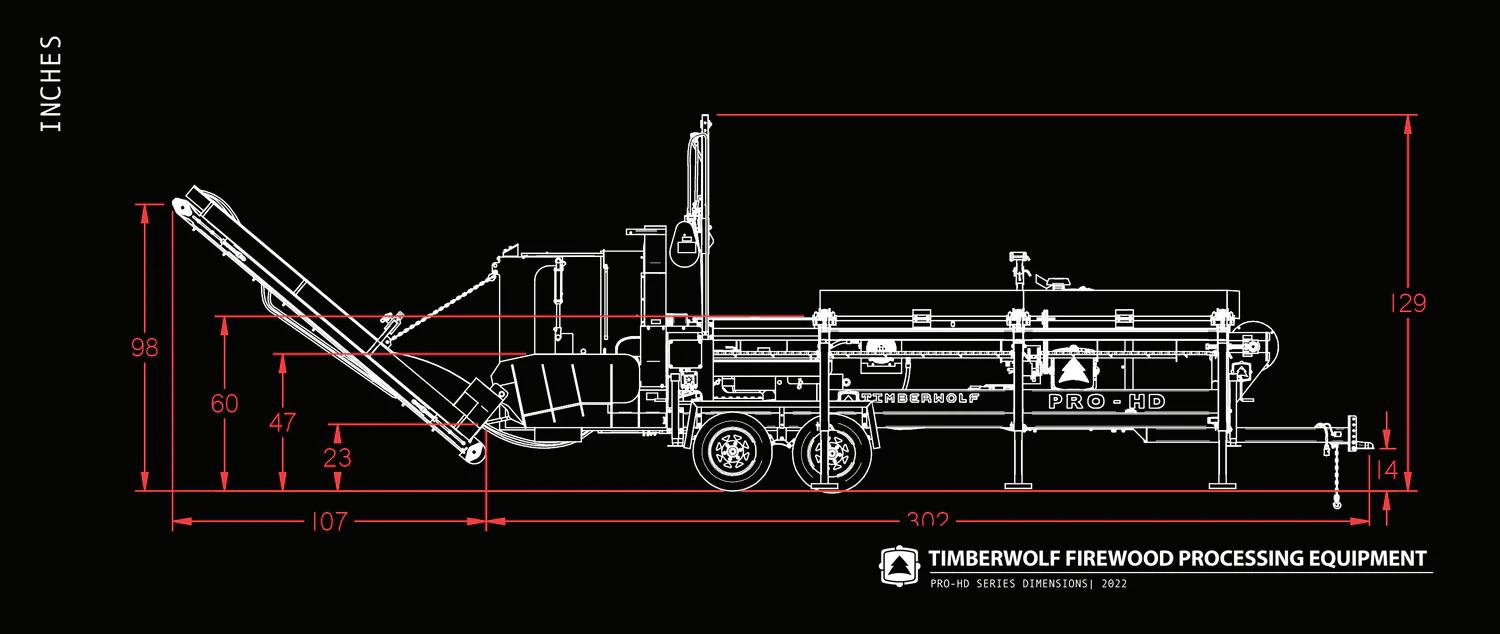

• The Pro-HD XL is a heavy-duty, dual axle commercial firewood processor powered by a 74HP engine and 3-stage gear pump, capable of outputting up to 5 cords of firewood per hour.

• Standard with driven top roll clamp and back roller that enables the processor to handle logs long as 32’ and wide as 24” in diameter.

• Equipped with regeneration manifold and new Parker F-11 Bent Axis Piston Saw Motor to dramatically improve splitting performance: the 2025 Pro-HD XL cuts up to 3x faster than older models.

• Optional integrated conveyor available to move cut firewood onto a waiting truck or trailer.

Power

• 74HP Hatz diesel engine

• Unrivaled power, efficiency, and performance

• 33GPM splitting pump provides 3000 PSI of splitting pressure

• 3-stage Permco gear pump

• Splitter: 33 GPM

• Saw: 22 GPM

•Auxiliary functions: 14 GPM

• 70 gallon hydraulic tank with internal baffles

•Continental hoses

Features

•Electric autocycle

• Regeneration manifold

• Top roll clamping system

• Hourglass-shaped back roller to handle longer logs

• Saw: 25” cut/.404 chain

• 4” or 5” American-made hydraulic cylinder

• 12’ integrated conveyor (10’10” max height)

• 5-strand live deck

• 4, 6, 8, and/or 12-Way wedges available

The Pro-HD XL is designed to be the ultimate firewood processor: heavy-duty built with incredible power, unsurpassed speed, and tough enough to handle even the gnarliest logs.

Engine Power (HP)

Pump Flow (GPM)

33-22-14

Cylinder Bore (in) 4/5

Trough Length (ft) 16

Max Log Length (ft) 32

Cycle Time (sec) 3/4.5

Avg Output (cord/hr) 5

Weight (lbs) 9200

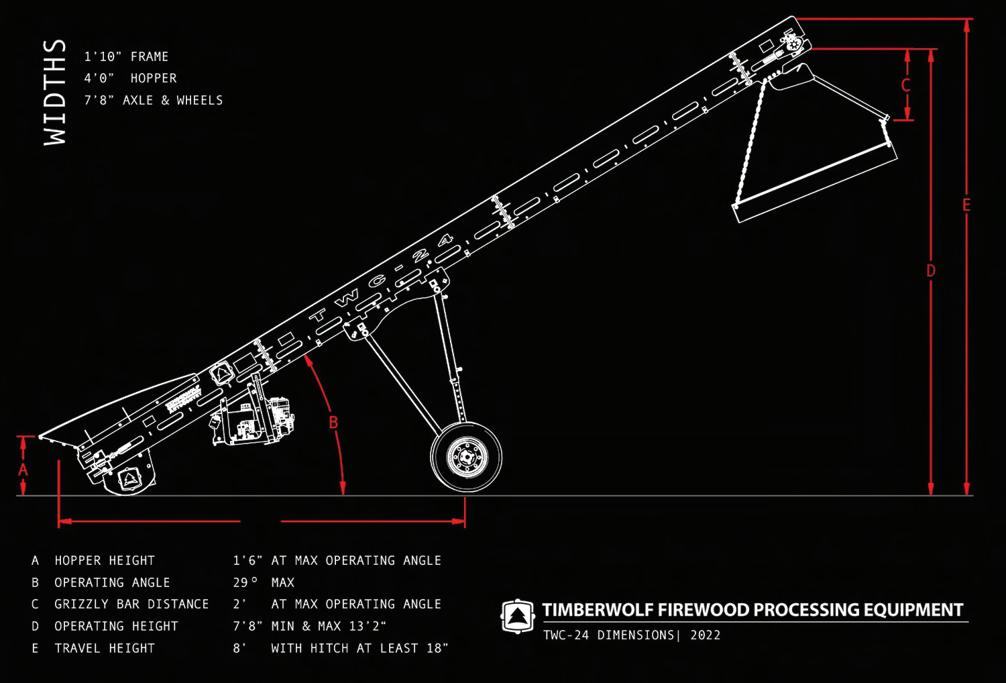

• Timberwolf customers often recommend investing in a conveyor prior to upgrading their log splitter as they have an incredible ability to boost production and profit.

• Available in sizes ranging from 12’ to 32‘ in length, all TWC conveyors can be transported in tow and have at least 3’ of vertical range.

•Standard with hydraulic lift cylinders, telescoping axle arms, tapered rollers for self-adjusting belt tracking, and 4.9HP engine to power the hardy paddle belt.

•Easily manuverable with manual and driven osciallating axle options.

• Fuel-efficient, quiet, and extremely reliable 4.9HP Honda engine Power

Features

• Hydraulic lift cylinder controlled by 2-spool valve

• Ground skid, maintains contact with the ground during operation for maximum stability

• 20” wide paddle belt

• Rubber belt fines deflector located below modular hopper

•Reduces debris build-up

• Add bolt-on Grizzly Bars to your TWC-16, TWC-24, or TWC-32

•Easily move your TWC-24 or TWC-32 with a driven or manual osciallating axle option

•Axle allows for lateral movement, streamlining biomass processing

With a TWC Conveyor, stability issues, belt misalignment, and manuverability problems are a thing of the past.

• Affordable and heavy-duty disc screener that can be powered by power pack or connected to any firewood processor via integrated auxiliary port.

• Integral hex discs constructed from 3/16” steel and intentionally spaced to allow debris and fines to fall through.

•Optional bolt-on hopper can be installed for easier loading of materials onto deck, also serves as a funnel.

•Optional chute can be added to create a smooth transition for clean wood being loaded and offloaded, streamlining your firewood operation.

Power

• Power pack with economical 4.9HP Honda engine

• Optional power pack can be moved separately from machine for safety

• Processor power auxiliary port

Features

• 4’ by 10’ frame

• Sturdy spinning hex discs

• Designed for stationary use, and equipped with wheels for easy manuvering around the yard

• Power pack

• Chute (bolt-on) Options

• Hopper (bolt-on)

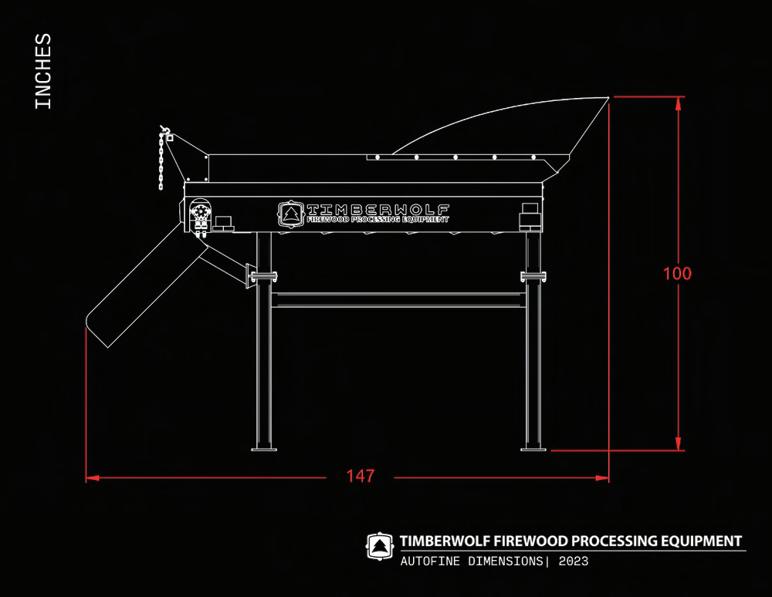

•Vital for serious businesses, the AutoFine allows you to deliver a superior product without sawdust, dirt, or other fines

Bring your firewood business to the next level with the AutoFine, add a hopper and chute for even more efficiency.