Wind Area (flat glass installation):

6 module: 0.149m2

4 module: 0.130m2

Specifications and Features

2 module: 0.107m2 pr

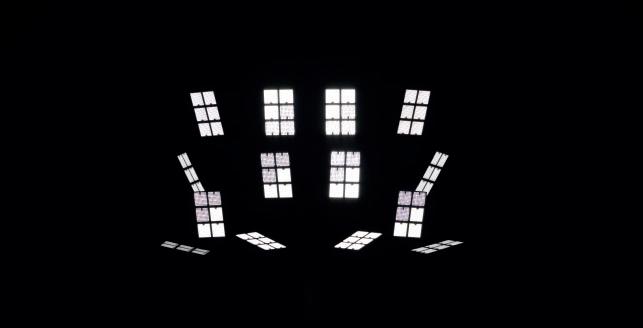

Imagery

Die-cast/profiled aluminium and steel are used to produce an

elegant and unobtrusive low profile design.

Ratings:

UKCA, CE, CB, SAA, IP66

Finish:

Powder coated Black/Red

Driver:

• 1500W driver is 3ch. DALI2/DMX driver, 7.0kg (inlcuding mounting arrangements), IP66 rated

• 400W - 1200W data available on request

• Integral or remote options available

Example applications:

• Sport

• Rail

• Ports

• Amenity

• Open Areas

Warranty & Lifetime: 5 years standard warranty 60,000 hours L80B10 25°C

Light Efficiency> 135lm/W

Luminous Flux 190,000lm

Colour Temperature5200K (3000 ~ 5700K optional)

CRIRa70 (80/90 optional)

Beam AngleSee product selection

Total Power Consumption1500W±40W

Output Current4.8A (constant current)*6

Net Weight 6 module = 29.6Kg, 4 module = 22.0Kg, 2 module = 15.6Kg

Light DimensionsL1077mm × W653mm × H290mm

Light Package DimensionsL1160mm × W710mm × H335mm

Power Factor≥0.95

IP RatingIP66

Input VolltageAC 200-440V

Product Selection

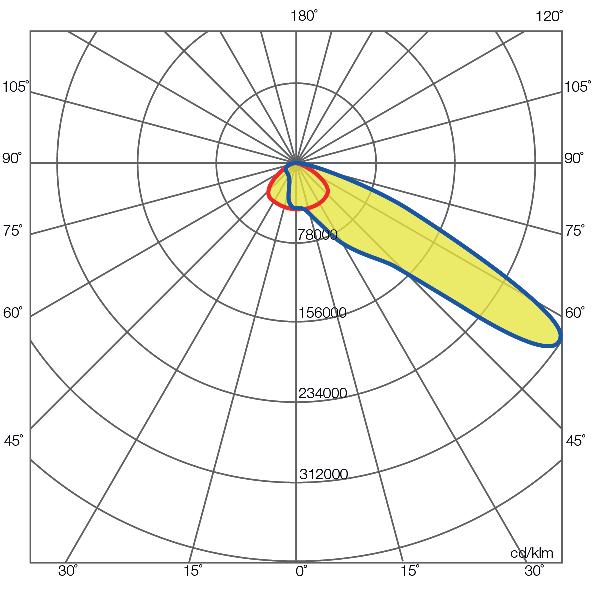

Distribution:AL6102 Distribution:

Luminaries come in 2,4 or 6 module variants: (See Product Selection for details)

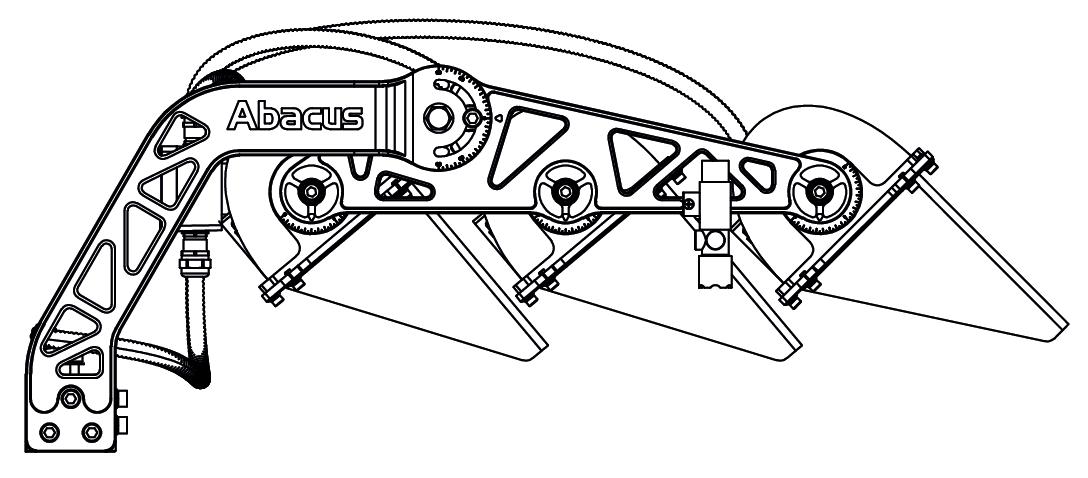

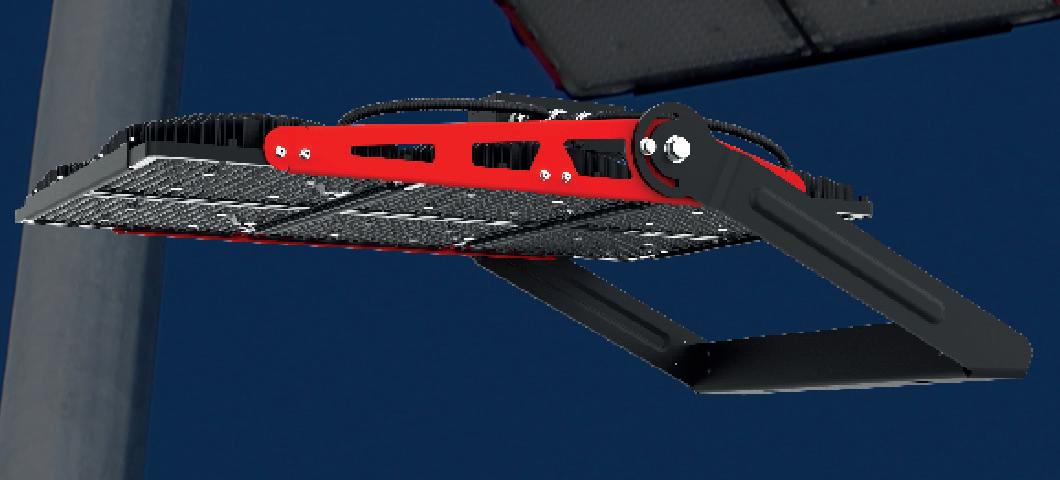

The Challenger 3 LED floodlight is a powerful and versatile lighting solution. With advanced optics and LED technology, it provides exceptional illumination for sports fields, arenas and large outdoor spaces. Its modular design allows for easy installation and maintenance, making it a reliable choice for high mast lighting solutions and stadia worldwide.

• Advanced design reduces light pollution and improves spectator viewing

• Precise optical control designed specifically for sport

• Robust for all environments with an IP66 and IK10 rating

• Lens and lumen packages available in a versatile design for multiple applications

• Dali and DMX options

• Full cut off low spill design for control of light

Technical Specifications

Power (W)1000W1500W1800W

Weight (without driver)25.7kg33.8kg33.8kg

Lumen output up to 162,865 up to 244,298 up to 274,637

LED Chips numbers224 pcs120 pcs288 pcs

Light Efficiencyup to 159lm/W

Beam angle17°, 25°, 50°

Colour Temperature4000 - 6000K (5700 standard)

Colour Rendering Index (CRI)≥70 (≥90 optional)

Colour Heat sink: RAL 9017, Bracket: RAL 9017 & Abacus red

IP RatingIP66

IK RatingIK10

Operating Temperature Range-40° - +50° (module)

Optional accessories Front glass, shields, aiming device

Driver information 1500W driver is 3ch. DALI2/DMXdriver, 7.0kg (inlcuding mounting brackets)

01210 = 1000W (2 modules)

(Ra70/5700K)* AL7102312 = 1200W (2/3 modules)

0315 = 1500W (3 modules)

= 1800W (3 modules) 01 15 /757

3 module:2 module:

• Unrivalled lumen to weight ratio providing the highest power output from the lowest possible weight.

• Lightweight fitting is ideal for sporting arena retrofit solutions when upgrading to LED

• 2 modules make up the combined weight of 33kg - equivalant to 2 metal halide luminaires

• No exposed cables

• Constructed from light weight and crash resistant automotive grade aluminium

• Optional RGB modules for interchangeable light

• Customisable scene control system

• Cloud connectivity for control from any location

• 10 year Warranty

Power (W)Up to 1200W

Luminous OutputUp to 150,000 lmUp to 96,000 lm

Colour Temperature5000K - 6000KN/A

Colour Rendering Index (CRI)70 - >90N/A

IP RatingIP66

Operating Temperature Range-40ºC to +45ºC

(2 module assembly)0.278m²

• 2x modules

• 2x module clamps

• 2x end caps

• 1x mounting bracket

Components

Module Clamp Assembly:Module:

Mounting Bracket:

33.2KG 300,000 lumens

Driver:

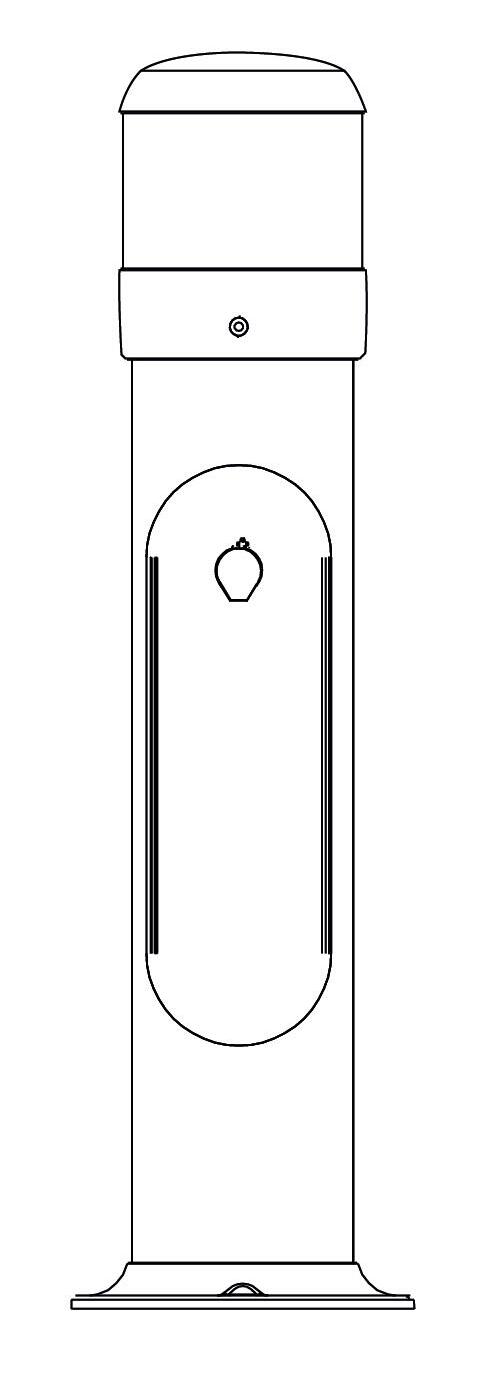

This next generation of LED bollard takes the existing tried and tested design of the LED Quartz and combines it with the latest cutting edge optical and GRP technologies.

Our Glass-fibre Reinforced Polyester (GRP) range provides a passively safe, non-conductive alternative to steel.

With power consumption reduced by almost 50% against the original product, significant performance gains and market leading bollard spacings greater than any other product on the market, the Quartz Evo redefines the benchmark of modern bollard lighting.

• Non-conductive GRP material

• Revolutionary low glare optic design giving unrivalled uniformity and bollard spacing

• Symmetrical and asymmetrical options to suit all requirements

• Wider door width for ease of installation and maintenance

• 15.2 kg combined weight for ease of install

• Quarter turn closing mechanism for ease of use

• Vandal resistant, IP66 flush door and fixings

• Flange plated and root mounted options available

• 3 hour emergency battery backup option available

The Abacus Orion Pro LED floodlight stands out as a pioneering lighting solution, delivering efficient and high-quality illumination for a wide range of outdoor spaces. It excels in achieving British standard BS5489, making it ideal for retrofit projects. Thanks to its advanced LED technology, the Orion floodlight not only provides superior brightness but also achieves significant energy savings, contributing to a reduced environmental footprint.

With its high-output 360-degree light distribution and precise optics, the Orion Pro ensures excellent beam control, offering pinpoint lighting precision while minimising light pollution. Overall, the Abacus Orion Pro represents a sustainable and dependable lighting solution that seamlessly integrates performance, durability, and energy efficiency.

Key Features

• Direct retrofit to twin lamp 400W Orion 1

• Available in 180° asymmetrical and 360° symmetrical beam distributions

• Low profile, sleek design

• Less than 1% upward light

• IP66 and IK10 rated

• 2 Zhaga interfaces for flexibility

• DALI 2 and D4i as standard

• Integrated spigot - 76mm or 89mm shaft compatible

• Colour temperature 4000K as standard (other options available)

• Up to 50°C high ambient temperature on request

• White polyester powder coated canopy & spigot

• Dimmable lumen output to suit designs

Retail

Open area

Car parks

Amenity

Luminous Flux20,000 lm 40,000 lm 72,000 lm

Colour Temperature4000K (other options available on request)

Colour Rendering Index (CRI)Ra70 (Ra80 optional)

Colours White: RAL9003 alternative colour options available onrequest

LifetimeL90B10 > 80,000hrs @25deg ambient

Dimension650mm x 203mm

Weight 13kg±10%

Working Temperature-30°C ~ 40°C (50°C optional)

IP RatingIP66

IK RatingIK10

Max spigot length135mm

Spigot diameter lengthes76mm/89mm Windage0.0735m²

The York Hinge converts a fixed column into a raising and lowering column which complements our existing range of base-hinged columns. York Hinge columns are designed for use in areas that are naccessible with bulky equipment or have no room available for our standard raise and lower column to be installed.

YH/PNE/TOOL/48

The 48 diamerter unit does not require a separate pump unit and can be lowered by hand safely due to the reduced column size and weight.

• Vandal resistant design requiring two specific security keys for access and operation

• A portable, one size fits all tool design allows for simple, single person operation

• Ongoing financial costs are kept low due to the maintenance free design of the hinge

• Ideal for use in inaccessible areas such as bridges or petrochemical platforms where the standard raise and lower column cannot be used

• Lowers the top section of the column in any set direction with no outwards swing of column sections

• For use on columns up to 6m

• Two versions available to fit 76mm and 48mm diameter shafts

• Headload up to 25kg at 6m using the larger unit and 15kg at 3m with the smaller unit

• Vandal resistant security bolt locks the hinge in place

• Increased cabling capacity over previous designs due to external lowering device.

• Cast steel construction

• Finishing options include galvanising, painting or powder coating

• Maintenance free design

• One man operation

• The York Hinge itself is as strong as the column. Wind loading capacity is not compromised

• The York Hinge can be retrofitted to existing fixed columns, contact our team for further information

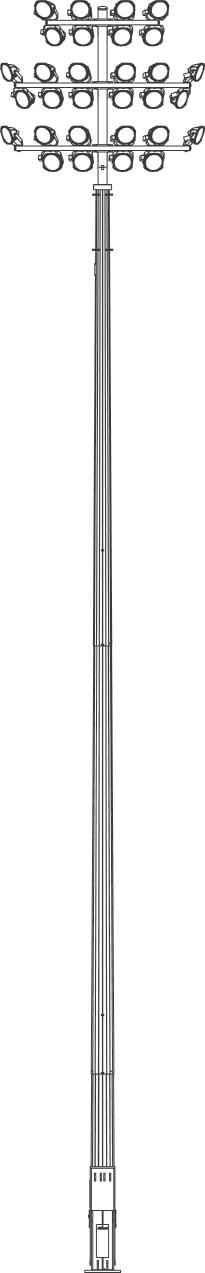

Our products

Base-hinged masts

– Mid range base-hinged 10m to 20m

– Grand range base-hinged 20m to 50m

Fixed masts

– Club range 15m to 30m

– Area range 20m to 50m

– Stadium range 30m to 70m

Lowering headframe masts

– 15m to 50m

Telescopic masts

– Club range to 20m

– Stadium range to 50m

Wind turbine masts

– Base-hinged range to 25m

– Fixed mast structures

Telecommunication mast structures

– Monopole structures to 60m

Since the first model was introduced over 50 years ago, Abacus base-hinged masts have become some of our most popular products worldwide. Robust, simple to install and easily accessible, they’re incredibly cost-effective – especially since they require minimal ongoing maintenance.

The unique operating system –the first and still best of its kind on the market – is as safe as it is simple, with its gravity lock and quicklowering mechanism.

All masts are designed to the British High Mast standard, Institution of Lighting Engineers’ Technical Report No. 7. All models are hot-dip galvanised to ISO EN 1461. Base-hinged raising and lowering masts with gravity locks are installed and operated using an independent hydraulic cylinder counterbalance unit.

Masts are assembled and installed at ground level using low-capacity equipment.

– Quick and simple to assemble and install – up to three times faster than fixed or winch-lowering models

– Safe – no climbing, as all maintenance and floodlight adjustments can be done at ground level

– Virtually maintenance free – thanks to straightforward design and robust engineering

– Attractive – with no ladder or platform to interrupt the mast’s clean, modern lines

– Versatile – with eight models, all designed for different load weights

– Particularly suitable for high-wind or hurricane-prone zones, as masts can be lowered in advance of storms

Safe and simple maintenance at ground level. No climbing, no high level platform with difficult access.

Up to 50m high and built to last, with low-cost maintenance.

For many years, the base-hinged mast has been a popular choice amongst clients. As such, we decided to build upon its success and take the concept one step further.

This involved developing and patenting an automatic sequencing system within the mast – a feature that enables several masts to be raised and lowered at the same time, all from a single central point.

Together with positional sensors, a Programmable Logic Control (PLC) unit co-ordinates and monitors the whole raising and lowering process. Hydraulic cylinders fitted to the base of the mast work together with a mechanised pivot, allowing the mast to raise or lower smoothly in a single failsafe operation.

Because automatic sequencing eliminates the need to move a counterbalance unit from mast to mast, it’s the ideal solution in situations where several masts need to be quickly lowered at the same time.

Hurricane and typhoon wind zones offer one example of an ideal application for automatic sequencing. Before the arrival of tropical storms, high-cost capital equipment can be protected by lowering the structures to safety.

Manufactured to order

Lid/base

Lid/base

Foundation assembly Bolts and base template FA/GL1000 Top templateFC/GL1000 CounterbalanceRLH17

* Headload capacity at wind speed of 45m/s. ** Assumes a Challenger® 3 type floodlight, 16kg and 0.20m² wind area. *** Refer to the bracket specification on your quotation for actual mast height requirement; mast may be shorter to accommodate height of the bracket, maintaining floodlight’s central mounting height.

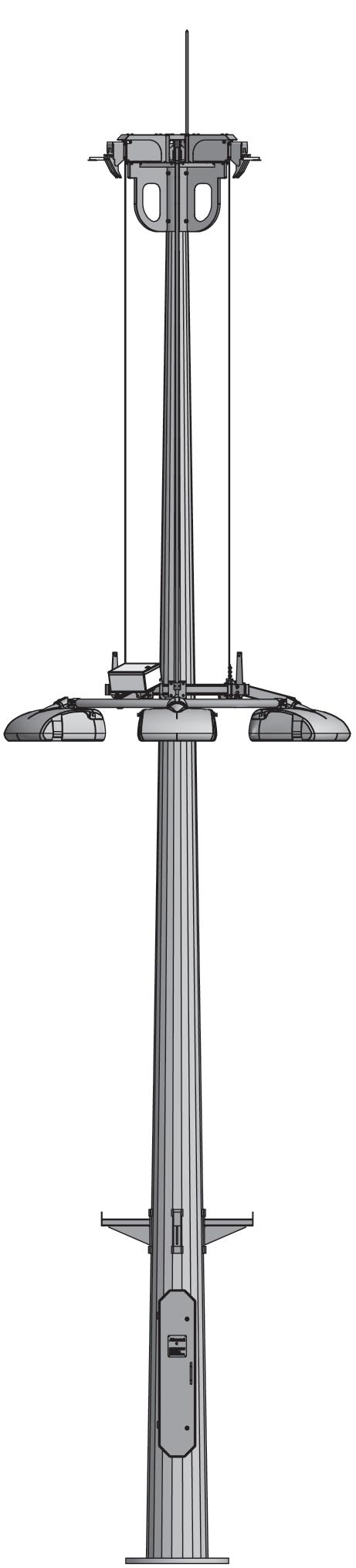

The engineered headframe, with its secure three-pulley system, is available with or without our innovative latching system. A single multi-core electric cable has its own independent pulley, meaning it doesn’t become entangled with other cables in the mast.

– Headframe supported by three stainless steel cables for longer-term stability than twin cable systems

– Option to install mechanical latching system on three arms, to release strain on cables when headframe is in the operating position

– Headframe supplied prepared ready for installation, complete with three cables looped for dropping into the mast shaft and junction box for the multicore cable mounted on headframe

– Single 275kg or single 550kg winch located in the base of the mast. The winch is self-sustaining, with a gravity latch on the input shaft

– A 10mm earth terminal is provided in the base of the mast

– Single multicore cable for all lanterns is located on an independent pulley, stopping multiple cables from becoming entangled inside the mast

– Single multicore – with 18 cores on the 275kg winch mast (for up to 8 floodlights/lanterns), or 25 cores on the 550kg model (for up to 12 lanterns)

– A multicore electric cable, with integral signal cables for CCTV and WiFi, is available on request

– Electrical cable is supplied with a plug and socket at lower end. This means you can detach the cable and power the headframe at

ground level using a separate extension cable

– A lightweight dual-speed reversible power tool is supplied with its own mounting bracket, which is clamped directly to the body of the mast. A remote hand-held box with non-latching buttons controls the unit, enabling the operator to stand at a safe distance when lowering

Incorporating the finest precision-engineering for a long, hassle-free life, the telescopic mast represents the pinnacle of technical achievement in high mast lighting. Driven by a 7m double-acting ram producing 45 tonnes of lift-thrust, the mast works in conjunction with a secondary leaf chain-management system. A supporting negative-chain system and linear string encoder, linked to a remotely located PLC (Programmable Logic Control) unit, mean the masts can be controlled and monitored from the safety and comfort of a main control room.

The masts are delivered to site part-assembled. The headframe is pre-wired in-house before shipping. The headframe wiring is then connected on-site to the main multi-core cables running through the mast’s centre section, using an instant plug-and-socket system.

The 40m telescopic masts installed at the Al Shamal stadium in Qatar. Located in four corner turrets designed to emulate a traditional fort, each carries up to 100 Challenger® 3 floodlights for HDTV broadcasts. After use, each mast retracts into its own turret and out of sight at a height of 22m.

The Club telescopic range is perfect for medium-sized sports, recreational or commercial facilities where full-height permanent masts aren’t feasible or necessary. Incorporating innovative, user-friendly engineering solutions, our range is as flexible as it is practical – with masts that more than double in height from their retracted position.

Operated using compressed air, these pneumatic masts can be raised and lowered either remotely (from the club house, for example) or individually from the base of each mast.

The masts are delivered fully assembled, with integrated electrical and mechanical equipment ready for fast onsite installation.

– Pneumatic telescopic masts, operated using compressed air

– Anodised aluminium finish

– Option for internal multi-core cable available on request

– Anemometer controlled retraction if the design wind speed is exceeded

– Lowers to more than half the operating height, minimising any visual intrusion

Abacus Lighting is a premier provider of state-of-the-art cricket lighting solutions, ensuring that every game is played under optimal lighting conditions. With a rich history in sports illumination, Abacus Lighting combines cutting-edge technology with bespoke design to meet the unique demands of cricket grounds, from local pitches to international stadiums.

Our cricket lighting systems are engineered to deliver uniform brightness, eliminating shadows and enhancing visibility for players, officials, and spectators alike. Utilising advanced LED technology, our lights provide exceptional clarity and colour rendering, crucial for both day-night matches and high-definition broadcasts.

Abacus Lighting offers comprehensive services, including custom lighting design, installation, and ongoing maintenance. Our expert team collaborates with clients to create tailored solutions that adhere to the highest standards of safety and performance, while also being energy-efficient and environmentally friendly.

– Retrofitting Services: Upgrading existing systems to modern, energy-efficient alternatives with minimal disruption.

– High-Performance LED Technology: Superior LED lights with high brightness, excellent color rendering, and energy efficiency.

– Compliance with Standards: Lighting systems that meet national and international cricket standards and broadcasting requirements.

– Installation and Maintenance: Professional setup, regular maintenance, and support to ensure peak performance.

– Smart Lighting Controls: Intelligent systems for easy management, remote monitoring, and real-time adjustments.

– Environmental Sustainability: Eco-friendly options that reduce carbon footprint and promote sustainability.

– Comprehensive Project Management: End-to-end project management from consultation to implementation.

With a strong heritage in sports lighting, Abacus Lighting combines state-of-the-art technology with customised designs to meet the specific needs of golf courses, from local clubs to prestigious championship venues.

Our golf lighting systems are meticulously designed to deliver consistent and uniform illumination, enhancing visibility and reducing shadows across the entire course. Utilising cutting-edge LED technology, our lights offer superior clarity and color rendering, crucial for evening play and high-definition broadcasting.

– Tailored lighting designs to fit the unique layout and requirements of each golf course.

– Robust lighting fixtures designed to withstand various weather conditions and provide long-lasting performance.

– Specialised optics to minimise glare and ensure comfortable visibility for players and spectators.

– Lighting that not only illuminates but also enhances the visual appeal of the golf course during evening hours.

– Advanced control systems allowing for easy management of lighting schedules and intensity, promoting energy savings.

– Special lighting setups for tournaments, events, and other activities held on the course.

Back in the 1970s, British Rail adopted the Abacus base-hinged column as the standard across all its platforms, car parks, and rail sidings. This pioneering move set a new benchmark in the industry, and the legacy of those installations can still be seen today in most Network Rail stations. Over the years, our product range has continued to expand, incorporating new technologies to address contemporary challenges. Innovations like the York Hinge, which facilitates easy raising and lowering for retrofitting, and GRP columns designed for passive safety, demonstrate our commitment to evolving with the industry's needs.

Superior illumination and energy efficiency: our rail lighting systems are designed to provide exceptional visibility, enhancing safety and comfort for both passengers and staff. Utilizing advanced LED technology, our solutions offer uniform brightness, reducing shadows and glare while significantly lowering energy consumption. This commitment to energy efficiency not only reduces operational costs but also minimizes environmental impact, supporting sustainable practices in the rail industry.

Durability, reliability and customisation: Durability and reliability are hallmarks of Abacus Lighting products. Engineered to withstand the harshest conditions, our rail lighting fixtures are resistant to vibrations, extreme temperatures, and weather elements, ensuring uninterrupted service. We recognize that each rail project has unique requirements; thus, we offer customizable solutions tailored to specific needs, whether for station platforms, tunnels, or maintenance depots.

Compliance and safety: Meeting stringent industry standards and regulations, our products ensure maximum safety and compliance. Abacus rail lighting solutions are designed to enhance operational safety and minimize risks across various applications. On station platforms, our bright, evenly distributed lighting improves passenger experience and safety, creating a welcoming environment and reducing accidents. Reliable lighting in tunnels and underpasses is critical for safe train operations, while well-lit maintenance depots enhance the safety and efficiency of inspection and repair tasks.

Kuchyna Air Base is a strategic military facility located in the heart of Slovakia, near the city of Nitra. Built in the early 1950s, the air base has played a crucial role in defending the airspace of the country and its allies. With its modern infrastructure, advanced technology, and highly skilled personnel, Kuchyna Air Base is wellequipped to handle a wide range of military operations and exercises.

Apart from its military functions, Kuchyna Air Base is also a hub for aviation enthusiasts and professionals, providing a range of training and education opportunities. The base has state-of-the-art simulators, training facilities, and a diverse fleet of aircraft, making it an ideal destination for pilots, engineers, and aviation enthusiasts.

The logistics of aircraft movements on active airfields such as these requires that safety is the first priority during operations. Lighting is a key component of safety in sectors such as this in which personnel are exposed to moving vehicles on a regular basis. Ensuring that sufficient lighting levels are maintained ensures operations can continue safely well into the darker hours.

Recently, $100 million has been invested into the base’s modernisation, which has included new LED apron lighting. The famous Slovak International Air Fest (SAIF) is held annually at Kuchyna Air Base, which set the deadline for early August 2022.

Abacus Lighting installed six 28m static masts at the air base.

Kuchyna Air Base’s lighting systems are an essential component of its operational infrastructure, as the base is required to operate around the clock, even in adverse weather conditions.

The new masts assist in ensuring safe and efficient navigation for aircraft, vehicles and personnel.

Manchester Regional Arena comprises of an indoor and outdoor track and field facilities; the centre is an excellent resource for the local community.

The outdoor track includes covered seating for 6,500 spectators and is the venue for the Paralympic World Cup, the AAA’s annual National Athletics Trials and a host of regional athletics events. The arena regularly welcomes school and community sporting events with an 8-lane 400-metre outdoor track and an indoor athletics hall.

The arena approached the Abacus lighting team to upgrade its existing lighting systems to enhance the sustainability of its facilities and effectively control light pollution for the venue and surrounding area.

Abacus Lighting installed cutting-edge technology Challenger 1 LED onto existing static masts

• Challenger 1 LED Floodlights (track & pitch)

• F-Lum Midi (canopy)

• Designed to 500lux with 0.7 uniformity.

• Start to finish solution.

Abacus used the existing static masts to elevate 76 of our pioneering high-performance challenger 1 LED floodlights, giving consistent light levels across the pitch and virtually eliminating maintenance factors.

As part of the start to finish solution provided, Abacus managed the project from design through to installation/commissioning and also saw the upgrading of the stand lighting with the use of our F-Lum Midi luminaire.

The Challenger 1 LED was the perfect selection for this lighting project, offering a long lifetime and high system efficiency, enabling Manchester Regional Arena to reduce energy usage, energy bills, and maintenance. While still delivering the optimum lighting environment for their venue.

Challenger 1® LED floodlights:

• Flat glass, double asymmetric floodlight.

• Elegant and unobtrusive low profile design.

• Integral or remote driver options.

• Available in 2, 4 and 6 module variants from 400W to 1500W.

• Abacus designed medium and narrow light distribution, specifically for sports lighting.

The Abacus Lighting team surveyed the site and conducted an extensive design feasibility study demonstrating the benefits of upgrading the existing lighting system to key stakeholders at Haverfordwest County AFC.

As the masts and supporting infrastructure were already in place, we could set about installing LED floodlights to improve the illumination of the pitch and provide safe visual conditions for players and spectators.

Particular attention was taken to ensure that the surrounding areas, such as the nearby St David’s Church would not be affected by light pollution from the pitch.

Now featuring modern LED technology, the club will benefit from the significantly improved efficiency by as much as 30% compared to their older installation. When considering the overall cost savings for an LED floodlight system upgrade, it’s helpful to note that the typical lifecycle for this system is between 20 to 25 years before a complete replacement is required.

Challenger 1® LED floodlights:

• Flat glass, double asymmetric floodlight.

• Elegant and unobtrusive low profile design.

• Integral or remote driver options.

The Bridge Meadow ground is a multi-purpose stadium known as Ogi Bridge Meadow Stadium and home to Haverfordwest County AFC. The ground has benefited from some investment in recent years to feature an all-seated covered stand that runs for most of the length of the pitch.

The all-seated stands are separated by a press, and TV camera gantry also benefiting from eight floodlighting masts, split between four on each side of the pitch.

The football club approached Abacus Lighting to upgrade their lighting systems to enhance the sustainability of its facilities. We used their existing static mast infrastructure to replace their metal halide floodlights with energy efficient LED lighting.

• Available in 2, 4 and 6 module variants from 400W to 1500W.

• Abacus designed medium and narrow light distribution, specifically for sports lighting.

Toyota manufacturing plant is located in the heart of Derbyshire, and is one of two manufacturing bases in the UK. The existing high mast lighting luminaires were coming to their end of life after years of service. This caused inconsistent lamp changes, which increased costs year on year, alongside poor lighting levels on site. As a result of this, the dispatch team on site struggled to clearly see DIS labels on cars, causing loss of both time and efficiency.

Abacus were tasked with providing a new LED lighting solution which did not overload the existing high mast structures on site, which complied with both environmental concerns from the ecologist and ensured zero complaints from any residential properties in the surrounding area. With Toyota being a world-renowned company, they did not want to affect their brand identity in the area.

The Toyota dispatch yard is also operational 24 hours a day, so it was imperative Abacus minimised any disruption to site whilst installation was taking place.

THE SOLUTION

• 120 x Challenger 1 LED floodlights: 3000K and 480W

Abacus conducted maintenance inspections in order to ensure fixings, bracketry and masts were all suitable for a retrofit.

Minimal elevation on the Challenger 1 LED luminaires, alongside precise lighting design considerations, minimised any impact on residential properties, keeping in line with guidance notes. Abacus utilised a special 3000K Challenger 1 floodlight to minimise visual perception of brightness compared to Toyota’s existing SON lamps, as well as keeping overspill to a minimum on edge rows to appease any concerns from the ecologist. 480W Challenger 1 floodlights were utilised across the high mast infrastructure, which in turn is estimated to save Toyota dispatch yard around £15k per year in comparison to their existing high mast lighting.

A dedicated project manager and supervisor from Abacus were on hand at Toyota dispatch yard to carefully plan around the working environment, so any disruption to the yards operational performance was minimised.

Challenger 1® LED Challenger1

Challenger 1® LED floodlights:

• Flat glass, double asymmetric floodlight

• Elegant and unobtrusive low profile design

• Available in 2, 4 and 6 module variants from 400W to 1500W

• Abacus designed medium and narrow light distribution, specifically for sports lighting

• Integral or remote driver options

THE CHALLENGE:

Malta Airport, located on the Mediterranean island of Malta, is the country’s primary international gateway. Serving as a vital transportation hub, it connects Malta to numerous destinations across Europe and beyond. With a modern terminal complex, it offers a wide range of passenger amenities and services, including shopping, dining, and car rental facilities. The airport plays a crucial role in Malta’s tourism industry, welcoming millions of travelers each year to explore the island’s rich history, culture, and natural beauty. It also facilitates cargo transportation, contributing to Malta’s economic growth. Malta Airport is known for its efficiency and connectivity in the heart of the Mediterranean.

Abacus Lighting were tasked with providing a lighting solution to both Aprons 2 and 8.

THE SOLUTION:

Apron 2

• 2 x HL250 masts

• 10 x hanger mounted Challenger 1 floodlights (1000-1500W)

Apron 8

• 16 x Challenger 1 floodlights retrofitted on existing 12m masts (500W-1500W)

The new floodlighting system boasts advanced LED technology, offering exceptional illumination and visibility during nighttime and adverse weather conditions. This ensures that aircraft maneuvering, maintenance, and ground operations on Apron 2 and Apron 8 can be conducted with precision and security, reducing the risk of accidents and improving overall performance.

Moreover, the energy-efficient LED lights are environmentally friendly, aligning with Malta Airport’s commitment to sustainability and reducing its carbon footprint. The installation of this advanced floodlighting system not only improves the airport’s functionality but also contributes to its goal of becoming a more eco-friendly and technologically advanced aviation hub.

Challenger 1® LED floodlights:

• Flat glass, double asymmetric floodlight.

• Elegant and unobtrusive low profile design.

• Integral or remote driver options.

• Available in 2, 4 and 6 module variants from 400W to 1500W.

• Abacus designed medium and narrow light distribution, specifically for sports lighting.

Aberdeen Harbour, located in the northeast of Scotland, is a historic and bustling port that plays a crucial role in the region’s maritime and economic activities. Nestled along the North Sea coast, the harbor has a rich history dating back centuries, evolving from a small fi shing port to a major international shipping hub. The harbor’s strategic location has contributed to its prominence, serving as a gateway for trade and commerce between Scotland and various global destinations.

Today, Aberdeen Harbour is not only a vital center for offshore oil and gas support services but also accommodates a diverse range of maritime activities, including shipping, fishing, and ferry services.

Focused on extending the harbor’s facilities, the Aberdeen Harbour expansion project included the construction of new quays, deeper berths, and improved infrastructure to cater to larger vessels, especially in the offshore oil and gas sector.

As part of this development, the need for new port lighting arose to ensure safe and efficient operations, particularly during night shifts and adverse weather conditions.

Quay Area:

• 12 x GL XXX masts

• Challenger 1 LED 1500W & 500W

Perimeter Fence Line:

• Medium duty flange plated 8m columns

• S-LUM luminaires

Gatehouse:

• 3 x 10m columns

• F-LUM Midi floodlights

Wireless control system installed throughout. The system can be dimmed through a computer system in the gatehouse.

The fabrication of robust masts and columns ensures the structural integrity of the expanded Aberdeen Harbour. These components are designed to withstand harsh maritime conditions, guaranteeing long-term durability and reliability.

The incorporation of a new LED lighting system further enhances the Aberdeen Harbour’s operational effi ciency. Abacus Lighting’s stateof-the-art technology not only illuminates the expanded port but also significantly reduces energy consumption and maintenance costs.

Abacus Lighting’s involvement in the Aberdeen Harbour expansion collectively contributes to a safer, more energy-efficient, and technologically advanced harbor, reinforcing Aberdeen’s position as a key maritime hub.

Les Quennevais Sports centre is a modern purposebuilt sports complex situated in the heart of Jersey near St Brelade’s Bay. Les Quennevais is also the home of Jersey Bulls FC.

Abacus Lighting forged a working relationship with the State of Jersey several years ago and we were delighted to be approached to work with them on this new project for their Sports Centre and a future project with a local school.

Sports pitch floodlighting generally involves lighting levels between 75 Lux and 500 lux; our lighting engineers understood the usage of the pitch and designed and lighting solution to achieve their desired levels of 500 lux and lighting uniformity of 0.7 with the flexibility to reduce the lighting levels for training and increase for competitions.

Our lighting solution involved the installation of our HL330-based hinged masts with Challenger 1 LED fl oodlights.

• Challenger 1 LED x 36 installation of HL330based hinged masts x 8

• Designed to 500 Lux with 0.7 uniformity

Challenger 1® LED floodlights:

• Flat glass, double asymmetric floodlight.

• Elegant and unobtrusive low profile design.

• Integral or remote driver options.

• Available in 2, 4 and 6 module variants from 400W to 1500W.

• Abacus designed medium and narrow light distribution, specifically for sports lighting.

The benefits of the Abacus Lighting hinged masts include a virtually maintenance-free solution for the Les Quennevais Sports Centre, a faster installation, and the fixed headframe means the floodlights stay stable, even in strong winds.

The Challenger 1 LED offers the sports centre cutting-edge floodlight technology with unrivalled performance, a sleek modern design, and excellent and effective light control to prevent light pollution. Installation included a full hard wired control system utilising DALI lighting control system – allowing the lighting to use a digital signal for more precise and flexible control.

The design produces light similar to daylight and ensures a full flow of light without glare, along with energy-saving benefits and an impressive lifespan.

HL330-based hinged masts :

• All models are hot-dip galvanised to ISO EN 1461

• Base-hinged raising and lowering masts with gravity locks are installed and operated using an independent hydraulic cylinder counterbalance unit.

With a throughput of over 21 million passengers per year, Auckland Airport is the largest and busiest airport in New Zealand.

The airport is one of New Zealand’s most important infrastructure assets, providing many jobs for the region and handling the majority of the country’s international arrivals and departures.

A new apron lighting system was required in order to facilitate the many planes, vehicles and passengers that make use of the airport each day. The busy nature of the airport and the potential costs which could be incurred due to prolonged downtime meant that ease and speed of maintenance was a key factor on this project.

• 8 x GL620 30m base-hinged masts

Abacus base-hinged masts were installed across the airport apron. These base-hinged masts allow airport maintenance staff to safely lower them to ground level in just a few minutes using a hydraulic counterbalance device. From here, all relevant inspections, cleaning and maintenance can be carried out without the need for working at heights or the use of expensive plant.

Once maintenance is completed, the mast is then raised and locked into position from where the counterbalance is then removed. A single counterbalance unit is able to operate all eight of the masts at Auckland Airport. This speed of operation proves perfect for airport applications as downtime and cost of maintenance is kept to an absolute minimum.

Abacus Base-hinged masts:

• Abacus base-hinged masts allow for safe and simple maintenance at ground level with no requirement for expensive plant and machinery

• Ideal solution for airport applications

• Proven mast design spanning over 55 years

• Constructed of galvanised steel, they boast an impressive life span of over 25 years (subject to regular maintenance)

Oddicroft Lane

Sutton-in-Ashfield

Nottinghamshire NG17 5FT

United Kingdom

Tel: +44 (0)1623 511 111

Email: sales@abacuslighting.com

Web: www.abacuslighting.com 20240625