CENTENNIAL CONCERT HALL

Inside the Journey of a Masonry Apprentice

Exploring the Dynamic Partners Program with U of M's Faculty of Architecture

Manitoba Masonry Design Awards 2024

Celebrating Excellence in Design and Craftsmanship

MANITOBA MASONRY INSTITUTE

www.Manitobamasonry.ca

The O cial Publication of the Manitoba Masonry Institute (MMI).

EDITORIAL

Editorial Director

Jaime-Lee Denton

Sta Writers

Ingrid Zacharis

Alycia Mann

Daphne Clemmons

Lorraine Pelley

Andrea Danelak (Editorial Advisor)

Design

Patrick Lim

Publishing Firm

Provincial Media Group Ltd. (PMG) tel: 204 292-6784

Publisher Ty Williams

Accounts Receivable

Penny-Jean Keilor e-mail: provincialmediagroupAR @gmail.com

Distribution

Chris Horn Leanne Beggs

How to Reach the MMI

For Advertising Sales e-mail: provincialmedia@hotmail.ca

Attention Representative

Matthew Leschyson

Darryl Enns

Leon Mann

Jodi-Ann Phabian

Photography

Katelyn Johnson

Darla Breton

MMI Magazine Commitee

Kevin Dudych

Peter Schuster

Murray Alston

David Bauer

MMI EXECUTIVE

President:

Michael Coghill - Target Products Ltd.

First VP:

Chris Cunha - Cunha Masonry Ltd.

Second VP:

Jason Alsip - Alsip Building Product Services

Third VP:

Luciano Bergagnini -

Treasurer:

Lee Hotas - Expocrete Concrete Products Ltd.

Immediate Past President:

Norm Blerot - Blerot Masonry (2000) Ltd.

1447 Waverly Street, Winnipeg, MB, R3T-0P7 e-mail: info@manitobamasonry.ca Director of Business Development

REPRINTS

To order additional copies or reprints, please contact the director of business development, Peter Schuster tel: 204 226-2695

SUBSCRIPTION

To subscribe to ON POINT MAGAZINE call: (204) 292-6784

e-mail: circulation@provincialmediagroup.com

MEMBER’S SPOTLIGHT IXL

SPOTLIGHT FEATURES

TYNDALL STONE STEPS ONTO THE WORLD STAGE AND MANITOBA MAKES HISTORY

Contents of ON POINT Magazine are copyrighted and may not be reproduced without the written consent of Provincial Media Group Ltd. The publisher shall not be liable for any of the views expressed by the authors of articles or information published in ON POINT magazine, nor shall these opinions necessarily reflect those of the publisher or the Manitoba Masonry Institute.

The magazine is strictly for information purposes only. The content and expert advice presented are not intended as a substitute for informed professional advice. No action should be taken on information contained in this magazine without first seeking specific advice from a qualified professional. The addresses and company contact information contained in this magazine are for inquiring about a company’s products and/or services. This listed information is not to be used for sending unsolicited marketing or promotional messages.

PROGRAM WORKING IN PARTNERSHIP WITH THE U of M

MUSEUM ARGYLE MANITOBA CELEBRATING EXCELLENCE IN MASONRY: MANITOBA MASONRY DESIGN AWARDS 2024

PRESIDENT’S MESSAGE

As I re ect on the conclusion of my tenure as President of The Manitoba Masonry Institute (MMI), I am overwhelmed with a deep sense of pride for the collective achievements we have realized during my term. Serving as president has been an immense honor, allowing me to collaborate with dedicated individuals who share a profound passion for advancing the masonry industry.

I want to extend my sincerest gratitude to each and every member for your unwavering support and unwavering commitment to our organization. Together, we have reached signi cant milestones and propelled forward in our mission to promote excellence within the masonry community.

Among our accomplishments, I am particularly proud of the partnerships we have cultivated with academia, government o cials, and the design community. These collaborations have played a pivotal role in driving forward research and development initiatives, fostering innovation, and ensuring that masonry remains at the forefront of contemporary building design. Even as we revel in our successes, it is crucial to acknowledge the challenges that await us. The future vitality of our industry hinges upon our ability to attract and cultivate the next generation of masons. Hence, initiatives aimed at supporting apprenticeships and amplifying education within our trade are indispensable for sustaining our growth and meeting the evolving demands of the construction sector.

With great enthusiasm, I am pleased to announce the forthcoming Manitoba Masonry Design Awards (MMDA) on October 24/24, an occasion where we will spotlight the remarkable achievements of our industry and the imaginative application of masonry in modern architecture. This event stands as a testament to the remarkable talent and creativity present within our community, and I urge all designers to partake and celebrate their exceptional work.

As my term draws to a close, I am con dent in the capable hands that will guide the MMI into the future. I hold unwavering faith in the incoming president and the steadfast board members who will continue to steer our organization with integrity and foresight.

In conclusion, I wish to express my heartfelt gratitude for the privilege of serving as President of the MMI. It has been an immensely rewarding journey, and I am profoundly thankful for the opportunity to have contributed to such a vibrant and supportive community.

Warm regards,

Mike Coghill President, MMI

INDUSTRY INNOVATORS, BUILDERS, TITANS & MENTORS

GLEN BRIGGS

Navigating the Shifting Landscape: Glenn Briggs’ Legacy and Reflections on His Distinguished Career in Manitoba Masonry and Retirement

When exploring the depths of Manitoba’s bustling construction industry, one name stands out as a true innovator and stalwart of the masonry trade – Glenn Briggs. With a career spanning several decades, Glenn has not only witnessed the evolution of the masonry industry but has actively contributed to its growth and transformation.

Glenn Briggs embarked on his masonry journey at 16 in Calgary, Alberta, with Blankert Masonry, laying the foundation for his impressive career. After honing his craft at Fields Masonry in Carman, Manitoba, Glenn completed his apprenticeship back in Calgary, showcasing his commitment. In 1984, he joined Len Claeys in Winnipeg, focusing initially on residential

projects before transitioning to commercial endeavors with Ernie Keller Masonry. Glenn’s expertise shone in the massive Portage Place project, involving 4 million bricks and 800,000 blocks. Joining Heymanns’ Construction in 1987, Glenn’s 31 1/2 years witnessed him evolve from a skilled bricklayer to roles like estimator and eventually project manager in 1995. Even as the industry transformed, Glenn’s unwavering commitment and adaptability remained the cornerstone of his success.

Key Accomplishments and Milestones

Reflecting on his illustrious career, Glenn highlights milestones such as becoming a project manager and mastering the art of estimation. These accomplishments not only underline Glenn’s technical prowess but also his dedication to continuous learning and professional growth.

Beyond personal achievements, Glenn takes pride in the tangible legacy of his work. Driving through the city, Glenn can point out buildings he worked on, a testament to the enduring impact of his contributions to Manitoba’s architectural landscape.

As Glenn reflects on his career, he acknowledges the significant shifts in the masonry industry. Over the years, the introduction of alternate building materials and methods has brought about substantial changes, leading to a noticeable departure from traditional brickload-bearing walls. Interestingly, there is now a resurgence in masonry as the industry embraces the inherent strength, beauty, and simplicity of the material. When questioned about innovative practices in his work, Glenn’s response reflects his grounded approach, mentioning that he simply followed along with industry changes and adapted as necessary. His success is underlined by a steadfast commitment to hard work and dedication, emphasizing the importance of consistency and reliability in the field.

Despite these changes, Glenn remains optimistic about the current state of the industry in Winnipeg. While the shift to buildings constructed with alternate materials has presented challenges, the demand for masonry work remains robust, with numerous projects on the horizon.

When asked about the lows in his career, Glenn’s humility shines through as he modestly claims, “I never really had any challenges.” However, a deeper dive into his experiences reveals a profound resilience, particularly during his time working out of town for projects in northern regions.

As a seasoned bricklayer working on projects in places like Lac Brochet, Churchill, and various northern reserves, Glenn faced the difficulty of being away from his family. He acknowledges that while it may not have been a challenge for him personally, it was undoubtedly a significant one for his wife and two children. This highlights the often-overlooked sacrifices made by those in the masonry profession, where projects sometimes require extended periods away from home.

LEAD MASON

Glenn’s openness about this aspect of the job brings attention to the challenges that many in the industry face, especially in an era where a work-from-home culture has made being away from family even more impactful. His candor is not only refreshing but also offers valuable insights for those considering or already working in the masonry field.

Embracing Mentorship and Building Relationships

Glenn credits much of his success to the mentorship he received from industry titans such as Len Claeys and the Heymann family. These mentors not only imparted technical knowledge but also instilled in Glenn the values of hard work and dedication. While these figures may have moved on or retired, their legacy lives on through Glenn’s contributions to the industry.

One project that stands out in Glenn’s memory is the Thunder Bay Hospital. Undertaken with Heymann Construction, this multi milliondollar masonry job in 2000-2001 marked a significant milestone in Glenn’s career. The project, featuring extensive stone, block veneer and interior block, showcased Glenn’s ability to handle large-scale endeavors.

Returning to Thunder Bay years later and witnessing the completed hospital left a lasting impression on Glenn. The intricate workmanship and attention to detail in patient rooms underscored the impact of masonry on creating not just structures but spaces of comfort and healing.

Legacy and Innovation

Glenn’s legacy extends beyond his impressive bricklaying skills. A selfproclaimed “different person” when it comes to showing up and working

hard, he emphasizes the importance of a strong work ethic. His belief in making money not just for oneself but for the company is evidence of the collaborative spirit that underlies successful masonry projects.

Glenn’s reputation as a titan of the industry is well-deserved. His unwavering commitment to being present at work every day, combined with excellent health that minimized sick days, sets a high standard for aspiring masons. In his own words, “You gotta work hard for the company.”

His work ethic is not only a personal philosophy but also a valuable lesson for the next generation of masons. With two sons, Kyle and Devon, following in his footsteps, Glenn’s influence is poised to continue, ensuring that the traditions of hard work and dedication are passed down to the future custodians of the masonry craft.

As Glenn retires in January 2024, he leaves behind a legacy of excellence and dedication to the masonry trade. His four and a half years with Lead Masonry, working alongside a younger generation, symbolize the seamless transition of knowledge and skills within the industry.

Glenn’s journey epitomizes the resilience and adaptability required in the ever-changing field of masonry. From humble beginnings as a 16-yearold laborer to a seasoned project manager, Glenn Briggs has not only built structures but has contributed significantly to shaping Manitoba’s architectural identity. As he looks forward to retirement, Glenn leaves behind a legacy that will endure through the buildings he helped create and the impact he made on the masonry industry in Manitoba. As for what he’s looking forward to most during retirement? Travel. He and his wife are hoping to kick off their expedition in Mexico!

seals in dust, prevents further dusting and provides water resistance to exposed interior masonry. Great for use on a wide variety of new or existing masonry substrates.

more info

MEMBER’S SPOTLIGHT

I-XL Building Products: A Century of Excellence and Commitment to Advancing the Masonry Industry

A pillar in the Canadian architectural masonry market, I-XL is a company with a rich history dating back to its founding in 1912. From its humble beginnings as a family-owned brick manufacturer, I-XL has evolved into a prominent player, renowned for its commitment to delivering high-quality architectural masonry products and services. Exploring the perspectives shared by Paul Dupasquier, a dedicated member of the Manitoba Masonry Institute, unveils the story of I-XL—a tale marked by growth, innovation, and unwavering dedication to the masonry community.

Humble Beginnings

I-XL’s mission is clear – to supply high-quality architectural masonry products to the construction and masonry community. This commitment extends beyond mere product provision, encompassing exceptional customer service, comprehensive technical support, and a steadfast leadership role in the industry.

Over the years, I-XL has experienced significant growth, diversifying its product line to meet the evolving needs of the construction landscape. The introduction of thin brick and stone panel systems and innovative siding solutions has expanded the company’s offerings, catering to a broader spectrum of construction requirements.

Strategic partnerships with leading brands such as Eldorado Stone, King Klinker, Hebron Brick, Interstate Brick, and Shouldice Stone have further elevated I-XL’s standing in the market. These alliances not only broaden the range of offerings but also bring unique and specialized products to the Canadian market.

Geographic expansion has been a key strategy for I-XL as well, with the establishment of a design center in Ontario in 2018 and branches in all western provinces. This growth reflects the company’s influence and its commitment to providing better access and services to a wider customer base.

The cornerstone of I-XL’s success lies in its reputation for reliability, quality, and innovation. Architects, builders, and contractors alike consider I-XL a trusted source, positioning the company as a key player in the architectural masonry market.

It is indisputable that I-XL has made a significant impact and firmly established itself in the market. Paul shares that I-XL has been involved in numerous significant masonry projects over the years. Notable ones include the Park City Development Buildings, the Winnipeg Temple of the Church of Jesus Christ of Latter-day Saints, Donwood School, Village Living at 180 Roslyn, Gillbert Rosset School, Le Market Apartments at 316 Des Meurons, UBC Orchard Commons in Vancouver, BC, 1 Lonsdale Avenue in North Vancouver, BC, Windermere Fire Station No. 31 in Edmonton, AB, and Groves of Varsity in Calgary, AB. The company takes pride in its legacy and prioritizes

collaboration and community involvement to move the industry forward as a whole.

Active Participation in MMI and the Community

I-XL’s membership with the Manitoba Masonry Institute (MMI) is a testament to its commitment to actively engage with key players and thought leaders in the masonry industry. This affiliation allows I-XL to contribute to and benefit from collective efforts towards excellence in masonry practices.

Being associated with MMI provides I-XL with a platform to connect with peers, gain valuable insights into the masonry market, and have a voice in industry discussions and developments. MMI membership enhances the company’s credibility in the masonry community, marking its dedication to quality, innovation, and professional growth.

I-XL actively engages in the local masonry community through participation in industry events, sharing expertise, and contributing to the ongoing exchange of knowledge and ideas. This involvement helps I-XL stay updated on the latest trends and innovations in masonry, benefiting not only the business but also enriching the broader community.

Adapting to the Changing Landscape

In response to changes in the masonry industry and market demands, I-XL has consistently embraced innovation. The company stays on top of the latest developments by adopting new materials and techniques to meet evolving architectural trends and construction standards.

Expanding the product range has been a crucial aspect of I-XL’s evolution. The introduction of technologically advanced options, such as thin brick and stone panel systems, addresses a wider range of construction needs and preferences, while steadfastly promoting traditional masonry products. Emphasizing quality and durability, I-XL ensures its products meet the highest standards, responding to the market’s demand for longlasting and aesthetically pleasing materials.

A customer-centric approach is another pillar of I-XL’s evolution. The company prioritizes customer needs, offering personalized solutions and technical support. This approach ensures that products and services align closely with client requirements and industry standards.

I-XL’s commitment to continuous learning and improvement is also critical to navigating the changing landscape in masonry. There are ongoing training sessions, employee development initiatives, and a culture of knowledge sharing. These practices ensure that the team stays up-to-date with industry trends and technologies.

The diverse I-XL team, spanning technical masonry expertise, customer service, and sales skills, adapts adeptly to evolving market demands and project challenges. Seasoned professionals within the team, serving as

mentors, instill a culture of continuous learning. Their extensive industry knowledge bolsters customer confidence with a proven track record of successful project execution. A collaborative spirit defines I-XL’s work environment, where team members synergize their expertise, ensuring thorough understanding and meeting of client needs.

Long-Term Goals and Aspirations

Looking ahead, I-XL’s long-term goals include continuously introducing advanced masonry products, expanding its presence within Canada.

To stay ahead, I-XL plans to embrace digital transformation, strengthen supply chain management through technology-driven solutions, deepen its commitment to sustainable practices, and expand its product line with innovative and modern masonry materials. The company also emphasizes continuous learning and professional development for its team.

I-XL also envisions its role in advancing sustainability and environmental practices in masonry construction by prioritizing environmentally friendly products, advocating for green building techniques, implementing energy-efficient practices, and partnering with manufacturers committed to environmental responsibility.

Concluding the discussion with Paul, he mentions that alongside its commitment to delivering top-tier masonry products, I-XL places a strong emphasis on actively engaging with the Manitoba Masonry Institute. , sponsorship of events, contribution to training programs, and advocacy for innovation in masonry. Collaboration is key to industry growth, and I-XL is dedicated to working alongside MMI members and other industry stakeholders to ensure the masonry industry’s continued success and relevance.

recognizing the need for thermally efficient connection enabling Passive House, Green Building and LEED construction.

“Many of the directions I have pursued have come from listening carefully to the challenges that contractors, architects and building envelope consultants face when using masonry and providing effective and high-performance solutions for sustainable, longlasting buildings. The engineers I was mentored by encouraged efficient value engineering and these principles are embedded in all the products that FERO produces.” explains Dr. Mike about where he gets his inspiration for his inventions.

Build Without Compromise

All of the innovations and products FERO provides address challenges in masonry construction and are intended to make masonry construction more thermally efficient and effective.

“My favourite project has been the clocktower in St. Albert. It allowed us to complete a detailed study that challenged many of the long-held beliefs about bricks.” he emphasizes. For more information about the study visit https://www.t8nmagazine.com/ perron-street-clock-tower/ https://www.stalbertgazette.com/local-news/a-trip-throughtime-1281009

https://www.stalbertgazette.com/local-news/clock-towertelling-more-than-time-1280977

When asked if he had any mentors, he responds with,” I had many mentors, colleagues and friends in the engineering field and the masonry field throughout my career. Too many to name all of them! I tried to have a new joke at the ready every time I presented or attended masonry conferences! In particular, my good friend John Glanville inspired me and mentored me. He was my supervisor at the University of Alberta and the leader in masonry education in Manitoba. In fact, FERO endowed a memorial scholarship in his

ANTHONY (TONY) ESHMADE

It is with heavy hearts and profound sadness that we bid farewell to Anthony (Tony) Eshmade, a remarkable soul who departed this world on July 24 at the age of 89. Tony is survived by his loving daughters, Margaret and Jan Eshmade, and his cherished sister Janet (Dan). Preceding him in death were his beloved wife Bertha and son-in-law Chuck Howard.

In 1959, Tony embarked on a journey from England to Canada, a country that provided him with countless opportunities. Despite building a fulfilling life in Canada, Tony remained deeply connected to his British heritage, fostering a special bond with the United Kingdom. In his final months, he reminisced about his childhood, sharing poignant memories of growing up during wartime, and he urged his family to embrace their roots and connect with relatives across the sea.

Tony’s professional journey was marked by passion and dedication as a civil engineer. He contributed his expertise to prestigious firms, including Crosier, Krauss and Greenberg Consulting Civil and Structural Engineers, Underwood McLellan and Associates Ltd., and eventually establishing his own firm, A. F. Eshmade and Associates Ltd., in 1971. He was a valued and astute member of our masonry community. His tireless work ethic and commitment to his family were evident as he navigated the challenges of entrepreneurship, ultimately retiring in 2018 after a long and successful career.

Beyond his professional pursuits, Tony had a keen interest in photography, capturing moments with a skillful eye and a constant companion—his camera. His love for aviation led him to obtain a private pilot’s license, and he delighted in taking his daughters on airborne adventures. In his

final days, Tony’s fascination with airplanes persisted, even requesting binoculars to observe the skies.

One of Tony’s proudest accomplishments was providing his daughters with a university education, a reflection of his unwavering commitment to family. He will be remembered as an outstanding and thoughtful father, deeply caring for those he held dear.

Acknowledgments extend to Joe Solomon, a loyal friend and colleague, and to Ethel and Alvin Hook, whose steadfast support made a positive impact on Tony’s final months. The outpouring of kindness, visits, and support from friends has been truly remarkable, bringing solace and joy to Tony during difficult times.

In the tapestry of life, Tony’s legacy will forever be woven with threads of love, passion, and enduring kindness. May he rest in peace, leaving behind cherished memories that will live on in the hearts of those who were fortunate enough to know him. We in the masonry industry are glad to have crossed paths with him both professionally and personally.

Restoring the Legacy at the Manitoba Centennial Concert Hall

By now it is no secret that Manitoba has its fair share of outstanding masonry projects. Some emphasize the province’s skyline to usher you back into the city after a long trip away, while others are a bit more subtle in stature, but loud in design, impact, and legacy. Among them is the monumental Manitoba Centennial Concert Hall. A structure of physical and historical significance, it has housed some of the city’s most extraordinary performances. Despite this, the building faced the inevitable wear and tear of time, primarily evident in how the structure’s stone panels, once vibrant, began to loosen and shift, signaling the need for intervention.

Fortunately, a monumental restoration project has breathed new life into the historic Manitoba Centennial Concert Hall. Led by Gus Koutoulas and his team at Alpha Masonry, this endeavor has not only preserved a cherished landmark but has also showcased the intricate craftsmanship and dedication required for such a feat. The interview with Gus provides a captivating insight into the process behind the restoration, shedding light on

the challenges faced and the triumphs achieved.

The project began with an assessment of the hall, revealing that its iconic stone panels, dating back to the 1960s, were not properly secured. Over time, these panels had begun to shift, necessitating immediate attention to prevent further damage. Gus and his team embarked on a two-year endeavor to dismantle, secure, and restore each stone panel.

What ensued was a symphony of craftsmanship and engineering prowess. The heavy stone panels, weighing in at a staggering 450 pounds each, required careful handling and precision. With monorails in place, the team delicately removed the panels, ensuring no damage occurred during the process.

Over the course of two years, the team worked tirelessly to reinstall approximately 5,500 stone panels, with close to 700 new panels replacing those that were damaged beyond repair due to years of wear and tear. Gus highlighted the importance of addressing these issues to prevent further deterioration and preserve the hall’s architectural integrity for future generations to appreciate.

Once the panels were removed, the true extent of the restoration work unfolded. New elevator bearings and membranes were installed to reinforce the structure, while foam insulation was applied to even out the surfaces. The stones, both old and new, underwent rigorous sanding and repair to seamlessly blend together, ensuring the hall retained its historic charm.

Throughout the restoration process, Alpha Masonry collaborated closely with Croisier Kilgour, the engineering firm, and Bochstael Construction, the general contractor, to ensure the project’s success. The support of the owner of the hall was also instrumental in facilitating the restoration efforts.

The restoration journey was not without its challenges. Gus recounts the painstaking process of carefully cutting mortar joints to free the stones without causing damage. Working amidst scaffolding and adverse weather conditions added to the complexity of the project. Gus was also simultaneously managing a project in Vancouver at the time, namely, the Sun Tower, a restoration endeavor that he is proud to have completed with his colleagues. Yet, with unwavering determination and skill, the team overcame each obstacle, delivering a masterpiece of restoration.

The completion of the project was met with widespread acclaim from the community. The hall, once marred by the signs of wear and neglect, now stands as a beacon of pride. Every detail, from the cautiously matched mortar colors to the seamless integration of old and new stones, speaks volumes about the dedication and craftsmanship invested in the restoration.

Beyond the physical transformation, the Manitoba Centennial Concert Hall holds a special place in Manitoba’s cultural landscape. It serves as a venue for a myriad of events, enriching the lives of the community. Even amidst the challenges posed by the COVID-19 pandemic, the hall remains a symbol of resilience and hope.

Gus’s passion for his craft and commitment to excellence shines through in every aspect of the restoration. His journey from a family of Masons in Greece to becoming a renowned figure in the masonry industry is evidence of his unwavering dedication to quality and preservation.

When asked about where he gets his satisfaction in a project like the restoration of the concert hall, Gus explains, “My primary satisfaction lies in ensuring the delivery of top-notch quality in every aspect of our restoration projects. It’s paramount to me that our clients are not just content but genuinely pleased with the outcome.” Currently, Gus and the Alpha Masonry team are deeply involved in the restoration of the Legislative Building, where the focus is on ensuring the project aligns with the team’s vision, prioritizing the preservation of the building’s original fabric. This commitment sometimes contrasts with the preferences of architects who may prioritize aesthetic changes over historical integrity. For instance, there’s been a debate about removing some stones to match colors, but as stewards of heritage buildings, we strive to retain 90% of the original appearance, blendingin replacements seamlessly. This dedication to authenticity is essential for maintaining the building’s historic significance.

Regarding longevity, Gus expresses that his company’s approach guarantees sustainability. He recently witnessed the resilience of Alpha Masonry’s work during a hurricane in Saint Thomas, where a bank they engineered withstood the storm while other structures faltered. Similarly, the materials and methods employed in the restoration, including quality stainless steel ties and galvanized support lines, ensure durability for at least a century.

Looking ahead, Gus envisions the restored Manitoba Centennial Concert Hall standing tall for generations to come, proof of the enduring legacy of craftsmanship and heritage. With the intentional care and attention invested in its restoration, the concert hall stands as a timeless testament to Manitoba’s rich history and vibrant culture.

cruises. He explains, “I like to

and see new places, its hard to

too long.”

Redefining Insulation: Do More for Less… Faster.

Blerot is an entrepreneur who works in both the construction industry and the agricultural (AG) sector. We asked him if there are any lessons that the construction industry can learn from the AG sector and vice versa. He responded, “Construction and the AG Industry are similar as they are growing rapidly in new technology, more than ever before, with each following the same three rules from Data Collection to Interpretation, to Application, and now each industry is pursuing AI in the office, field, and marketing. Collaboration is key with any industry, be it with our Governments, Associations, partners in business, Unions, and employees as we look for the best results for our environment, communities, and our own well being.”

Over the past 13 years Quik-Therm has collaborated with many of North America’s nest Building Science organizations. As a result of its investment in building science Quik-Therm has been able to design and develop several physics based, multi-functional weatherization insulation technologies that do more for less…faster.

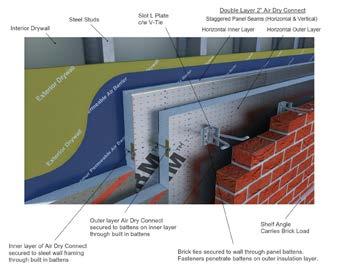

Quik-Therm’s embedded ¾” plywood structural furring every 16”OC provides a simple, rigid backing for fastening brick ties. No need for mastic, or long brick ties through exterior insulation. Just two #10 fasteners with 1” embedment through a zero-clearance brick tie.

the Install. Stay Cool.

Blerot describes masonry this way, “I have been in the Masonry industry for almost 40 years now. I have enjoyed the projects we have worked on and the people we have met along the way. Masonry holds endless possibilities to new and existing buildings; be it veneers or structural masonry. It is timeless.”

SPOTLIGHT FEATURES

KEEWATIN PRAIRIE COMMUNITY SCHOOL

Project Address:

Mason:

Designer:

Supplier 1:

Product installed:

Supplier 2:

Product installed:

1570 Elgin Ave, Wpg

Alpha Masonry

Stantec Architecture

I-XL Building Products

Hebron Sea Grey 6 Smooth Modular

Alston Brick Supply Inc.

Elgin Butler Glazed Brick 4x4x16”, #2300-A Lemon Twist, #4364 Dark Yellow, #4550 Pumpkin Orange, #8800 Classic Red, #4124 Maroon.

RRCP - INNOVATION CENTER

Project Address: Mason:

Designer:

Supplier 1:

Product installed:

319 Elgin Ave, Wpg

Alpha Masonry

Number Ten Architecture

Alsips Building Products & Services

Glen-Gery from the Sioux City collection - Revere Pewter, velour texture

SPOTLIGHT FEATURES

FIONN MACCOOL’S

Project Address:

Mason:

Designer:

Supplier 1:

Product installed:

Supplier 2:

Product installed:

1180 Grant Ave, Wpg.

Gebhardt Masonry

Barret Architecture Inc.

White Cap Distribution

General Shale Thin Brick (Interior)

White Cap Distribution

Canada Brick (Exterior)

SPOTLIGHT

WHYTE RIDGE BAPTIST CHURCH

Project Address:

Mason:

Designer:

Supplier 1:

Product installed:

Supplier 2:

Product installed:

2405 McGillivray Blvd

Lead Masonry

Raymond C. Wan Architecture

I-XL Building Products

Hebron Brick - Onyx IronspotVelour Finish

I-XL Building Products

Hebron Brick - Sea Grey -

Velour Finish

SPOTLIGHT FEATURES

ED SCHREYER SCHOOL

Project Address: Mason:

Designer:

Supplier 1:

Product installed: 85 Fifth St S, Beausejour, Alpha Masonry

Pico Architecture I-XL Building Products

Interstate Midnight Black, Ash, Pewter, & Platinum - Matte texture Modular size

ECOLE SAGE CREEK

Project Address:

Mason:

Designer:

Supplier 1:

Product installed:

Supplier 2:

Product installed:

315 Sage Creek Blvd, Wpg

Cunha Masonry

Number Ten Architecture

Timberstone Distribution

Acme Norman, Onyx Smooth & Velour

Timberstone Distribution

Pewter Velour, Glazed Brick from Cloud Ceramics

EASTON PLACE MEDICAL CENTER

Project Address:

Mason:

Designer: Supplier 1:

Product installed: 15 Wersch St, Selkirk

Lead Masonry

Thomas Design Builders

Gillis Quarries

Tyndall Stone - Random Length, Grey Finish, Rubbed

SPOTLIGHT FEATURES

LE MARKET APARTMENTS

Project Address:

Mason:

Designer:

Supplier 1:

Product installed:

Supplier 2:

Product installed:

316 Des Meurons

Lead Masonry

Number TEN Architectural Group

I-XL Building Products

Shouldice 4" Urban Stone, Color: Galaxy

I-XL Building Products

Shouldice 4" Urban Stone, Color: Executive Grey and Balon

TYNDALL STONE STEPS ONTO THE WORLD STAGE AND MANITOBA MAKES HISTORY

The recent designation of Tyndall Stone as a “World Heritage Stone” marks a significant milestone not only for this distinguished natural resource but also for the entire masonry industry. Jeffrey Dolovich, Vice President, Sales & Marketing at Gillis Quarries in Manitoba, shares insights into the profound impact of this recognition.

“The Gillis family and all those associated with them have always taken immense pride in our contribution to Canada’s architectural landscape,” Dolovich reflects. “Being the first stone in Canadian history to receive international recognition of this magnitude adds a whole new level to our pride.” Indeed, Tyndall Stone now stands shoulder-to-shoulder with iconic stones like Carrara marble, Portland Stone, and Makrana stone on the world stage. As Jeffrey points out, it is the only Canadian stone to be featured on a worldwide list comprising just 32 stones—a testament to its exceptional quality and historical significance.

For over a century, Tyndall Stone has quietly made its mark across the globe, adorning landmarks from the Canadian Embassy in Berlin to the Canadian Museum for Human Rights. Its distinctiveness as a natural resource indigenous to Canada, and more particularly Manitoba, has played a pivotal role in shaping the country’s architectural identity. The use of locally sourced natural stone has been a cornerstone of architectural principles for several

years. Tyndall Stone’s journey from the quarries of Manitoba to the halls of global recognition is a testament to the enduring legacy of Canadian craftsmanship and ingenuity.

The Road to Submission

Jeffrey sheds light on the motivations behind the submission and the intricate process involved. “41 years ago, two young grad students forged a friendship amidst the confines of the University of Toronto’s paleontology lab,” he recounts. “Fast forward eight years, and these friends—now esteemed colleagues—Dr. Brian Pratt, Professor of Geological Sciences at the University of Saskatchewan, and Dr. Graham Young, curator of paleontology at the Manitoba Museum, embarked on a mission to nominate Tyndall Stone for global recognition.” At the core of the dynamic duo was a deep-seated admiration for Tyndall Stone, cultivated over years of study and research. Pratt and Young’s collaboration culminated in a significant paper published in the Journal of Geoscience Canada, shedding light on the stone’s unparalleled qualities and historical significance. Tyndall Stone’s properties, which is comprised of mottled fossiliferous dolomitic limestone, its distinctive aesthetic and widespread utilization both domestically and internationally, render it a deserving contender for global recognition.

Delving into the stone’s origins unveils a captivating tale dating back 450 million years to the Paleozoic era and the age of Pangea. Within the depths of warm shallow limey seabeds, ancient marine life carved intricate tunnels, later infused with magnesium and dolomite-rich waters. Upon lithification, this process birthed a mesmerizing tapestry, unique to Tyndall Stone. The presence of trace fossils or mottling imbues Tyndall Stone with its signature tapestry, a rarity among limestone varieties. Situated exclusively in Garson, Manitoba, this geological marvel stands as a Canadian treasure, literally! Tyndall Stone’s designation celebrates not only its aesthetic allure but also its role as a living testament to Earth’s ancient past.

The pivotal role of Doctors, Pratt and Young in Tyndall Stone’s nomination cannot be overstated; their expertise and dedication were instrumental in securing this achievement. The process of submission was undoubtedly rigorous, requiring meticulous documentation and persuasive argumentation to garner international recognition. Donna Gillis, the

company’s Operations Superintendent, also played a crucial role, providing invaluable collaboration and peer review throughout the process. Her diligent efforts in navigating academic publications underscored her commitment to this endeavor. It was a lengthy arduous process taking place over a number of years.

Cultural and Industrial Significance

Tyndall Stone holds profound significance within both geological and masonry communities, deeply intertwined with the historical and cultural fabric of Manitoba and Canada. Its utilization in various structures, from educational institutions to healthcare facilities and government buildings, underscores its role in providing beauty, comfort, and a distinct Canadian identity. Masonry contractors take pride in its installation. The stone’s designation as an IUGS Heritage Stone further solidifies its status as an integral component of global architecture, celebrating its contribution to science, culture, and education. Additionally, initiatives like educational programs involving fossil panels highlight its enduring legacy and educational value for future generations, symbolizing a connection between past and present.

The designation amplifies Tyndall Stone’s significance locally, particularly in Manitoba, where emotional ties run deep. While the international recognition enhances its allure and importance in Canadian architecture, the longstanding support from Manitoba’s architectural community remains steadfast. The designation’s broader impact extends beyond the province, influencing regions like Saskatchewan and Alberta, where Tyndall Stone has left its mark. Overall, it validates what Manitobans have always known: Tyndall Stone is a cherished symbol of Canadian roots, now recognized on a global scale.

The recent celebration at Winnipeg Art Gallery, meticulously organized by Jackie Ilagan and Gillis Quarries, drew 250 esteemed guests including dignitaries, architects, engineers, and artisans pivotal to Tyndall Stone’s journey. Amid Gustavo da Rosa’s architectural marvel, speeches from industry stalwarts like Keith Gillis highlighted the evening. Mel Juravsky’s pioneering contributions were praised, while guests departed with Tyndall Stone coasters and cherished memories. This intimate gathering emphasized shared pride and gratitude within the Tyndall Stone community

for its historic designation.

Reactions were immediate and heartfelt, with attendees expressing immense pride and excitement at Tyndall Stone’s international recognition. Congratulations flooded in through various channels, reflecting the masonry community’s shared joy and pride in Canada’s stone achieving this prestigious status.

Looking Forward

The impact of this designation on the demand for Tyndall Stone remains uncertain. While Jeffrey and the Gillis Quarries team as a whole are proud to share this recognition, it’s crucial to respect its scientific significance and avoid over-promotion. There’s potential to attract more Canadian clients, but its influence on international markets is yet to be seen. Nevertheless, there’s intrigue in exploring avenues like marketing to overseas markets as an exotic stone or appealing to Manitobans abroad seeking a piece of home. They are committed to integrating the Global Heritage Stone Resource designation into our promotional efforts. This will include prominently featuring it on their website, across their social media channels, and in presentations to the design community. By consistently highlighting this prestigious recognition, the community aims to raise awareness of Tyndall Stone’s significance on the global stage.

While concluding, Jeffrey expressed that playing a role in Canada’s history and architectural legacy drives Gillis Quarries to go on year after year. In his own words he shared, “being part of Canada’s history and architectural legacy fuels Gillis Quarries’ ongoing commitment. We take immense pride in our role and find joy in the journey. The designation holds profound significance for the Gillis family, our team, and the myriad professionals who have contributed to Tyndall Stone’s story. We are deeply moved by this recognition and we are having too much fun to stop!”

When asked if there was anything else he wanted to share or leave in the minds of readers, Dolovich shared a short story:

Bruce Hutchinson, born 1901, was one of Canada’s foremost journalists for almost 75 years. He was the assistant editor of the Winnipeg Free Press and his legacy lives on through his writings. Hanging proudly in the Peace Tower of Parliament Hill is a sculpture carved out of Tyndall Stone, typical of neo-Gothic architecture accompanied by a quote from Mr. Hutchinson’s Governor General’s award winning book:

“No Canadian can stand and look at this cluster of buildings without feeling that somewhere on this hill, perhaps a happy accident, architects, masons and stone carvers have managed to grasp and materialize the beauty of Canada, the vastness of it’s land, his loneliness, it’s youth and it’s hope.”

If this doesn’t speak to the significance of Tyndall Stone as a Global Heritage Stone Resource, I don’t know what does!

From century old character buildings to Manitoba’s newest construction projects, we are bringing the age-old art of masonry into the 21st century. With an incredible attention to detail and competitive pricing, we are proud to be Winnipeg leaders in the renovation, restoration and construction of masonry buildings.

P.O. Box 48100, RPO Lakewood | Winnipeg, MB R2J 4A3 | 204-296-2054

Building A Profitable Portfolio of Purpose-Built Apartment Buildings With

the Help of ICF

Technology

In Winnipeg, MB, Paragon Living is positioning itself as a design-build company reshaping the landscape with its unique approach to constructing purpose-built apartment buildings. Led by President Nigel Furgus, Paragon Living is creating a profitable portfolio of properties by harnessing the advantages of Insulated Concrete Forms (ICFs).

INN O VATIVE BU ILDING S T R ATEGIE S

Paragon’s strategy focuses on constructing 75% of its properties to buy and hold, with the remaining 25% designated for forward sales or fee-for-service. The cornerstone of these projects is purpose-built apartment buildings, such as the Bridgewater and Young Street buildings, distinguished by being designed constructed with Logix insulated concrete forms (ICFs).

WIT H L OGI X IC F

Firstly, Paragon achieves a 10%-20% construction cost

cutting and fabrication on-site. The Bridgewater and Young Street buildings, constructed with 13,133 and 5,758 LOGIX ICF blocks respectively, are testaments to this approach

ENHANCED ENE R G Y EFFICIEN C Y AND FINANCING INCENTIVE S

Building with Logix ICF not only reduces construction costs

BRICK MUSEUM IN ARGYLE MANITOBA

Two Tickets For Bricks, Please: The Fascinating Story of Settlers Rails and Trails Brick Museum in Argyle

In the heart of Argyle, a small community in Manitoba, a remarkable museum stands as a testament to the rich history of brick manufacturing. Settlers Rails and Trails Brick Museum, also known as the “Brick Building,” has become a unique attraction, offering visitors an immersive journey through the heritage of Manitoba’s brick and block industry. In a recent interview with Shayne Campbell, the passionate curator and driving force behind the museum, we gained insights into the origins, challenges, and exciting future plans of this hidden gem.

From Childhood Dream to Community Treasure

When asked to give a brief background on the origin of the Brick Museum, Shayne did not hold back and the enthusiasm in his tone was palpable. “At the age of 12, while attending Brant Argyle School, I was presented with a unique opportunity to embark on a school project that would eventually evolve into what we now proudly call the Settlers Rails and Trails Museum. This endeavour fulfilled a childhood dream I had long harboured, and from its inception in 1991, the museum has been a repository for artifacts, stories, and photographs that illuminate the vibrant history of our community.”

Initially conceived as a personal museum, a passion project fuelled by a deep-seated love for preserving the past, it took on a new life in 2009 when it transitioned into a private organization. In that pivotal year, this cultural treasure was generously gifted to the community, signifying a shift towards collective ownership and engagement. The establishment of a dedicated board of directors marked a crucial turning point, leading Shayne to formalize the museum’s status as a non-profit charity.

The idea of a brick museum was sparked by a visitor, Gord McDiarmid,

who saw the potential in Argyle as the perfect location for a brick collection. Shayne and his board of directors embraced this idea, willingly. Over the years, a collective effort of board members, brick enthusiasts, researchers, and lovers of ‘all things Manitoba’, has resulted in a notable and unique work of art. The museum has experienced substantial growth. This journey, from a childhood dream to the thriving cultural hub the Brick Building is today not only reflecting the spirit of the masonry community, but it also showcases a shared history of the beauty of Manitoban heritage.

A Journey through Time: The Exhibits

Visitors to the museum are treated to a comprehensive exploration of Manitoba’s brick and block manufacturing history, spanning from the 1860s to the 1990s. This includes the oldest brick in possession—an exquisite relic originating from the Saint Boniface Nunnery in Winnipeg, now repurposed as a museum. This historical gem is steeped in a legacy that traces back to the 1840s when the building itself first graced the landscape.

The exhibits feature not only bricks but also historical images, videos illustrating the brick-making process. Shayne said that one of the key elements emphasized at the museum involves providing visitors with a hands-on experience. Within the exhibits, a curated selection of bricks is showcased, specifically chosen for their tactile nature, allowing individuals to engage with and handle them. As visitors move through the exhibits, they not only absorb historical information presented but also encounter the tangible tools that were integral to the individuals who once worked and continue to work in this industry. This immersive approach enhances

the overall museum experience, bridging the gap between the past and the present in a way that transcends traditional museum engagement (You won’t find caution tapes everywhere that scream, “DO NOT TOUCH”)!

The museum also includes a LEGO building table for children, fostering an interactive and educational experience. The big kids and the little kids get to fully enjoy themselves each time they visit.

Partnerships and Collaborations

The success of the Settlers Rails and Trails Brick Museum is not a solo endeavour. Shayne highlights the collaborative efforts with local historians, brick makers, masons, and heritage groups. The museum has spent seven years building connections across the province, engaging with individuals who contribute valuable insights, artifacts, and expertise.

The museum actively collaborates with current brick makers and masons, ensuring a balance between historical representation and contemporary practices. This collaborative spirit has been crucial in overcoming challenges, such as tracking down bricks from demolished buildings. Shayne shares that sometimes the process of tracking down bricks can be interesting. “Whenever we reach out to museums and local heritage groups—there’s 70 locations across Manitoba and 196 companies that we’re potentially researching—we’ve always had fantastic effort from people, but first we have to get past the awkward first question of why we’re looking for bricks. Once you explain to them, they’re excited and intrigued.”

Though the Brick Building is lauded and is a cultural celebration for brick enthusiasts and curious museum goers, it is not free from challenges. One such challenge Shayne shared, is the scarcity of labeled bricks from historical buildings. Many structures were demolished long ago, and the bricks were often overlooked as items of historical significance. Despite this obstacle, the museum has persevered through extensive research, reaching out to communities and individuals to fill gaps in their collection.

Looking to the Future

As the Settlers Rails and Trails Brick Museum continues to captivate visitors with its unique exhibits, the team envisions a bright future. Plans are underway for a permanent structure, aptly named the Brick Building, set on the museum’s 12-acre park property. This new facility will not only house the brick exhibit but also accommodate other exhibits, archives, and facilities. Additionally, the museum aims to embrace modern developments in brick

manufacturing, exploring innovative materials and methods. The University of Manitoba has been instrumental in shedding light on new ideas and techniques. For example, a novel approach resembling spores, namely mycelium bricks, introduces a fascinating organic element to display design. Procedurally, there is development in the field that involves the creation of bricks without the need for traditional firing processes. Efforts are underway to incorporate displays featuring bricks made from organic substances, highlighting the ever-evolving nature of the industry.

The Settlers Rails and Trails Brick Museum stands as a testament to the power of passion, community collaboration, and the preservation of history. From its humble beginnings as a school project to becoming a provincial treasure, the museum invites visitors to explore the fascinating world of bricks and blocks. As it looks ahead to a permanent structure and new exhibits, the museum continues to inspire curiosity, education, and appreciation for the often-overlooked artistry of brick manufacturing.

Shayne emphasizes the vital role of the community and expresses gratitude to everyone who has contributed, whether through brick donations, historical information, or volunteering time. If you ever get the chance to chat with him about bricks, you’re in for a treat; just don’t ask him to pick a favourite because he will diplomatically praised several in lieu of favouritism!

If you’re looking to uncover Manitoba’s rich history in a unique and engaging way, a visit to the Brick Building is a journey through time waiting to be experienced.

The Brick Museum at The Settlers Rails and Trails Museum is located in Argyle, MB. Visit their website at www.argylemuseum.wixsite.com.

SOLID FOUNDATIONS

THE JOURNEY OF A MASONRY APPRENTICE

The art of masonry is a tradition that sits right at the centre of Manitoba’s construction industry and some individuals are wondering how they can get in! Brian Gebhardt, Masonry instructor at Red River College Polytech and a seasoned professional in the field, offers a glimpse into the world of apprenticeship, where age-old practices meet contemporary demands. In an exclusive interview with ON POINT Magazine, Gebhardt sheds light on the journey of becoming a bricklayer, a craft deeply rooted in history yet thriving in the modern era.

Brian’s narrative begins with a reflection on the timeless essence of apprenticeship. “It’s no different today than it was in the Middle Ages,” he remarks, highlighting the enduring nature of the craft. Despite its longevity, the masonry industry in Manitoba sees a modest influx of new talent, averaging just under 12 apprentices annually. This scarcity underscores the significance of personal connections in recruitment—a theme echoed by Brian’s observation that many apprentices enter the trade through familial or social ties.

Indeed, the path to becoming a bricklayer often starts with a mentorship network within the industry. Brian recounts the common refrain among apprentices: “I know someone in the industry.” Whether it’s a relative, neighbor, or friend, personal connections serve as the gateway to a fulfilling career in masonry. This phenomenon, Brian notes, mirrors historical precedents where bricklaying offered upward mobility for commoners seeking a prosperous livelihood.

However, the allure of masonry extends beyond mere economic opportunity. Gebhardt emphasizes the

intrinsic value of the trade, particularly for individuals who may not excel in traditional academic settings. Many of our students did not excel in high school.Top of Form,” he shares. Yet, within the realm of masonry, they find a platform to thrive—a sentiment echoed by Brian’s own journey into the trade over three decades ago.

The apprenticeship process in Manitoba is a testament to the industry’s emphasis on practical skills and hands-on experience. Brian elucidates the initial steps, where aspiring bricklayers undergo a trial period as Mason’s Tenders, formerly known as Barrow-Men. This introductory phase assesses fundamental attributes such as punctuality, teamwork, and adherence to instructions—a nod to the timeless adage of “showing up in your work

boots ready to work.”

While the apprenticeship landscape has evolved over the years, Gebhardt reflects on past initiatives such as preemployment courses, which once provided a pathway into the trade. However, shifting dynamics, including changes in government funding and economic incentives, have reshaped the accessibility of such programs. Despite these challenges, Brian remains steadfast in his commitment to nurturing the next generation of masons, advocating for greater recognition of vocational education within the educational system.

Indeed, the journey of a bricklayer is as much about tradition as it is about adaptation—a delicate balance between preserving age-old techniques and embracing innovation. As Brian aptly summarizes, “It’s about recognizing the value in the trade.” In a world where skilled craftsmanship is increasingly rare, the resilience of masonry apprenticeship in Manitoba stands as a testament to the enduring legacy of an ancient art form.

Financial Considerations and Career Prospects

The conversation delves into the financial realities of pursuing a bricklaying apprenticeship. Brian reveals that while the initial investment might seem daunting, with courses costing up to $6,000 for a full calendar year, the long-term benefits far outweigh the costs. He emphasizes that apprenticeships offer a unique advantage wherein individuals are paid while they learn, with starting wages hovering around $22 per hour. Moreover, upon completing the apprenticeship, bricklayers can command lucrative salaries, sometimes reaching $42 to $43 per hour, with full benefit packages valued at an impressive $53 per hour.

Brian highlighted that there’s a one-time registration fee of $50 for schooling, each level costs about $500 for a total of $1500 for all three levels. However, the federal government supports red seal trades, offering incentives upon completing each level. At the end of level 1, apprentices receive $1000, $1000 at the end of level 2, and $2000 upon completing level 3, totaling $4000 from the government. This means that even if apprentices pay the registration fees themselves, they still end up $2500 ahead.

Additionally, as part of a government initiative to address the underrepresentation of listed minorities in the trades, there are extra financial incentives. For example, female apprentices receive double the incentives, allowing them to receive up to $8000 from the federal government upon completing all three levels.

Employers can also benefit financially from taking on apprentices. They can receive a federal tax credit of up to $2000 per apprentice, and in Manitoba, there’s a provincial incentive as well, possibly amounting to $1000. Additionally, there’s a federal program where businesses can receive up to $20,000 for hiring apprentices, with special considerations

for hiring individuals from underrepresented groups, such as Indigenous people, which could mean receiving $10,000 per apprentice.

Overcoming Perceptions and Promoting Trades Education

Furthermore, Brian mentioned that apprentices are supported even during periods of financial strain. If an apprentice finds themselves short on funds, they can access a tax-free $4000 loan from the government, though it must be repaid.

On top of these financial incentives, there are also provisions for covering expenses related to competitions and training. For instance, the Manitoba Masonry Contractors Association (MMCA) covers travel expenses, registration fees, and provides a per diem of up to $1000 for apprentices participating in competitions. This support helps alleviate financial burdens for apprentices as they progress in their training.

In addition to financial resources, students can visit the apprenticeship section of the MMCA to obtain resources about program options, skill development, and industry opportunities. (https://manitobamasonry. ca/mmca/)

The Role of Apprenticeships in Skills Development

Brian passionately advocates for apprenticeships as the ultimate training ground for skilled trades. Unlike traditional educational pathways, apprenticeships offer a hands-on learning experience tailored to the needs of the industry. Through a combination of practical work and classroom instruction, apprentices acquire invaluable skills that directly translate to the workplace; you can work in the training being in-school and on the job. The apprenticeship is 4800 hours total, of which 800 hours are in school and 4000 hours are on the job where an apprentice works under the guidance of a certified mason. The onthe-job training is the most vital in terms of skill development. Brian highlights the importance of apprenticeship programs in addressing the industry’s evolving needs, ensuring a steady supply of skilled labor to meet future demands.

One of the challenges highlighted in the discussion is the persistent stigma surrounding trades education. Brian reflects on his own journey into bricklaying, citing the lack of exposure to vocational opportunities during his school years. He emphasizes the need for greater awareness and promotion of trades education, particularly among high school students. Brian underscores the need to challenge societal norms that prioritize university education over skilled trades, presenting apprenticeships as a viable alternative with significant earning potential and career prospects.

Throughout the conversation, Brian emphasizes the importance of guidance and support for aspiring apprentices. While the apprenticeship program itself provides a framework for skills development, Brian acknowledges the need for mentorship and guidance from employers. He stresses the role of employers in nurturing apprentices and providing them with opportunities for growth and advancement within the industry. Additionally, Brian highlights the availability of resources and support networks aimed at facilitating the transition into apprenticeship programs, ensuring that aspiring tradesmen receive the necessary assistance to navigate the complex process effectively.

In essence, Brian’s insights offer a compelling narrative of the transformative power of bricklaying apprenticeships. Beyond the technical skills acquired, apprenticeships serve as a gateway to financial stability, personal growth, and professional fulfillment. By challenging misconceptions and promoting the value of trades education, Brian advocates for a more inclusive approach to skills development, one that recognizes the diverse pathways available to individuals seeking rewarding careers in the trades. As the demand for skilled labor continues to rise, apprenticeships emerge as a beacon of hope, unlocking opportunities for generations to come.

PARTNERS PROGRAM WORKING IN PARTNERSHIP WITH THE U of M

University of Manitoba’s Partners Program Fostering Collaboration and Bridging the Gap Between Academia and Industry

Within the borders of the University of Manitoba’s commitment to providing a holistic educational experience lies the Partners Program, a unique initiative that serves as a vital communication hub connecting students, staff, professionals, and the broader community. In an insightful conversation with Brandy O’Reilly, the program coordinator, we delved into the program’s origins, its evolution, and the significant impact it has on fostering collaboration and preparing students for the dynamic world beyond academia.

A Nexus of Communication and Collaboration

The Partners Program, described by Brandy as a vital “communication

hub,” plays a multifaceted role, serving as a non-curricular catch-all for diverse activities. It acts as a conduit for interactions between students, faculty, and industry professionals, emphasizing practical experiences and real-world applications. Covering events, education, community building, research, media, and public relations, the program is a practical complement to academic learning, addressing the historical gap between theory and practice.

Brandy underscores the program’s practicality, offering a balance between theoretical knowledge and hands-on skills crucial for real-world success. The Partners Program originated in the late ‘80s and early ‘90s, born from a faculty retreat seeking stronger industry ties. Its genesis involved key players like Gerry Price and representatives from Smith Carter, driven by the university’s commitment to producing graduates ready for seamless integration into their respective professions.

Memorial to Enslaved Laborers at UVA, image provided by 2023 MMI sponsored lecture speaker Eric Höweler

Notably, the Masonry Institute of Manitoba’s (MMI) participation in the Partners Program amplifies its impact, contributing to the dynamic collaboration between academia and the masonry industry.

One of the significant initiatives born out of the partnership between the Partners Program and the Masonry Institute of Manitoba (MMI) is the sponsored lecture series. This series brings in renowned speakers from around the world to share their expertise and experiences with students, faculty, and industry professionals. The series not only provides valuable insights into ongoing projects but also facilitates a unique space for collective learning, where students, academics, and professionals engage in conversations that transcend traditional boundaries.

Recently, the collaboration has expanded to include a Researcher in Residence program. Currently hosting a researcher from Berlin, the program allows students and professionals to participate in workshops, offering a hands-on experience that enhances their learning. This collaborative effort is particularly noteworthy as it provides opportunities that might be challenging within the constraints of a university budget.

The collaboration between the MMI and the academic faculty has proven to be a transformative and enriching experience, offering unique opportunities for students and faculty alike. One of the most notable achievements of the collaboration is the profound impact it has had on students’ academic and professional journeys. The direct engagement with industry professionals has inspired students to approach their projects with renewed passion and creativity. There have been instances where students, after participating in MMI events, have dedicated themselves to their work, leading to exceptional achievements such as significant progress on their theses. Brandy also shares anecdotes from students who, upon entering the workforce, realized the disparity between what they have learned in the classroom and the practicalities of construction. Through initiatives like the Co-op program, students now have the opportunity to gain work experience and apply their skills before graduating, preparing them for the challenges they will encounter in their professional journeys.

The collaboration has not only benefited students but has also opened avenues for faculty members to explore new dimensions in teaching and research. The integration of industry professionals into studio critiques and workshops has enriched the academic environment, providing faculty with fresh perspectives.

Another remarkable outcome of the Partners Program is its contribution to breaking down the silos between different facets of the industry. Brandy highlights the importance of conversations between masons, who bring an artisanal approach to their work, and designers, who often conceptualize projects without hands-on experience. The MMI has played a crucial role in facilitating these conversations, allowing for a better understanding of the practical aspects of construction.

Mutual Benefits and Future Aspirations

When asked about the mutual benefits derived from the partnership, Brandy emphasizes the exposure that students receive to industry entities like MMI. Many students may not be aware of such organizations until they enter the workforce, making these connections invaluable. Moreover, the collaboration offers professionals the chance to engage with students at an earlier stage in their academic journey, fostering a sense of community and mentorship.

The program’s impact on the masonry industry as a whole is evident in the enhanced understanding between designers and masons. The exposure to world-renowned speakers and hands-on workshops allows for a more comprehensive encounter with construction processes. It encourages innovative thinking and opens avenues for collaboration that might not have been explored otherwise.

Despite budget constraints, the Partners Program, with the support of MMI, continues to thrive, providing a platform for meaningful conversations and experiences. The program’s longevity and success stem from the passion and dedication of individuals who recognize the importance of bridging the gap between academia and industry.

Looking ahead, the future of this partnership holds promising opportunities for further growth and development. The goal is to enhance the collaboration by creating more touchpoints, potentially involving MMI professionals in studio critiques and workshops. The aspiration is to continue providing value to both parties, with MMI gaining insights into academic perspectives and students benefiting from real-world experiences and mentorship.

The commitment shown by MMI, especially during challenging times such as the COVID-19 pandemic, highlights the resilience and dedication of the partnership. The ongoing support and engagement between MMI and the academic faculty underscore the mutually beneficial nature of the collaboration.

As the conversation with Brandy O’Reilly comes to a close, the significance of the Partners Program, and the Faculty of Architecture at the University of Manitoba, in shaping well-rounded professionals becomes clear. It stands as a testament to the positive outcomes that arise when academia and industry collaborate, fostering an environment where theoretical knowledge seamlessly integrates with practical skills, preparing students for the complexities of their chosen professions.

Sponsored Lecture Series and Research Residency: Engaging the Masonry Community

Brick House, image provided by 2021 MMI sponsored lecture speaker Adam Caruso

Giant’s Causeway Visitors’ Centre, image provided by 2019 MMI sponsored lecture speaker RÓISÍN HENEGHAN

CELEBRATING EXCELLENCE IN MASONRY: MANITOBA MASONRY DESIGN AWARDS 2024

The Manitoba Masonry Design Awards, scheduled for October 24, 2024, at Hotel Fort Garry’s Provencher Ballroom, promise to be an extraordinary celebration of masonry ingenuity and craftsmanship in architecture, restoration, and design. This event, recognizing exceptional projects showcasing the enduring beauty and functionality of masonry, will unfold in a historic setting. A recent interview with Peter Schuster, Committee Chair of these prestigious awards, provided insights into the event’s evolution, submission process, judging criteria, and its impact on the masonry industry.

Established in 2005, the Manitoba Masonry Design Awards aim to honor the skills of Masonry Designers, Engineers, and Masons contributing to the creation and preservation of noteworthy structures in the province. The awards span various categories, including Structural Masonry

Design, Sustainable Design, Interior Design, and the prestigious Masonry Excellence and Masonry Legacy Awards, ensuring the recognition and celebration of all aspects of masonry innovation.

For those eager to submit projects, the process is streamlined and easily accessible through the official website: www.manitobamasonry.ca. The submission deadline is April 30, 2024, with eligibility criteria requiring

projects to be completed in Manitoba between January 1, 2018, and December 31, 2023.

Peter emphasized improvements to the submission process, highlighting the shift to an entirely electronic platform for enhanced efficiency and accessibility. He encourages participants to share insights into their design process, adding depth to submissions and aiding judges in understanding

the work comprehensively.

The judging process for the 2024 awards, conducted by a panel of industry experts, embraces technology. Utilizing photography and virtual platforms, judges will evaluate entries with a focus on structural integrity, artistic expression, sustainability, historic preservation, and more.

Past winners, including projects like the Canadian Museum for Human Rights, Investors Group Field, and the Winnipeg Humane Society, have consistently met key criteria, emphasizing effective communication of the design process and seamless integration of masonry into the project’s overall aesthetic.

The awards’ profound impact on the masonry industry lies in providing a platform for recognition, inspiring professionals to push the boundaries of creativity. The gala event fosters community and collaboration, contributing to the growth and development of the masonry industry.

Looking ahead, the 2024 awards aim to recognize the design community in the ever-changing construction environment, aligning with contemporary design trends.

If you are considering submitting an entry or attending the Manitoba Masonry Design Awards for the first time, Peter offers the following advice:

1. Size Doesn’t Matter:

There is no project too big or too small to submit. Even portions of a project featuring masonry are welcomed for consideration. Don’t hesitate to showcase your work, regardless of its scale.

2. Tell Your Story:

Help the judges understand your design intent and the unique aspects of your project. Providing context and insights into your creative process can make your submission stand out.

3. Join the Celebration:

Attend the awards ceremony and immerse yourself in a memorable evening with fellow masonry enthusiasts and design professionals. It’s an opportunity to celebrate your industry, network, and gain inspiration from your peers.

As the 2024 awards approach, the masonry community eagerly anticipates a night of celebration, recognition, and inspiration, reinforcing the industry’s commitment to innovation and preservation. We look forward to your submissions and seeing you at the industry’s big night!

Truss & Ladder Reinforcements & Masonry Accessories

Truss and ladder reinforcements are designed to be embedded in the horizontal mortar joints of singlewythe masonry walls and manufactured to provide a tight, secure fit and maintain wall straightness throughout your project. They are also used in vertical stack joints and window sills to ensure straightness during concrete curing.

TRUSS REINFORCEMENTS

• two side-rods welded to a continuous diagonally shaped cross-rod with alternating welds not exceeding 8” (200 mm) O.C.

• produced from wire conforming to ASTM A 82 cold drawn steel wire

LADDER REINFORCEMENTS

• manufactured in 10’ 8” lengths of wire conforming to ASTM A 82 cold drawn steel wire consisting of two parallel and deformed longitudinal wires welded to a perpendicular cross wire spaced 16” O.C.

• outside parallel spacing is approximately two inches less than the nominal thickness of the masonry wall

TIME-HONOURED ANCHOR SYSTEMS

Since 1960, Centennial Wire has been producing the highest quality anchor systems. With our in-house capabilities—from corrugating to punching to bending— we can custom create a broad range of anchors to meet the needs of your project.

Call us for a competitive quote on all your wire needs. Toll free 1.866.356.9473 Toll free WORLD-CLASS PRODUCTS,

Conveniently

TRUSS REINFORCEMENTS

LADDER REINFORCEMENTS

Cleanup is a breeze.

When your work is done, grab the secondary hose to thoroughly and easily clean the MudMixer®.

Stand back and watch the MudMixer® do what it does best. Mixture will continuously fill your forms as you feed the hopper.

After rolling the MudMixer® into position, simply drop and fold the desired bag of

Cleanup is a breeze. When your work is done, grab the secondary hose to thoroughly and easily clean the MudMixer®.

mortar, or stucco mix into the hopper. Adjust the water dial to achieve the proper water flow for the desired mixture.

Stand back and watch the MudMixer® do what it does best. Mixture will continuously fill your forms as you feed the hopper.

Cleanup is a breeze. When your work is done, grab the secondary hose to thoroughly and easily clean the MudMixer®.

CRAFTSMANSHIP UNVEILED: TECHNICAL RESOURCES FOUND HERE

When it comes to masonry work, having access to reliable and accurate technical information is crucial for success. Fortunately, the manitobamasonry.ca website offers a wealth of helpful resources under the Technical Resources tab.

One of the key information that can be found under the Technical Resources tab of the website are sample specifications. The specifications can be downloaded for use in overall project specifications. These specifications are unique to the Manitoba region.

In addition to material information, the manitobamasonry.ca website also offers detailed guides on various masonry techniques and practices. Here you can find links to all of the latest Masonry publications and software, readily available for todays designers. These resources can help improve the skills and knowledge of masonry professionals and enthusiasts alike.

Furthermore, the website features information on standard masonry details, with all of the local knowledge and practices included in these details. They are available for download at the click of a mouse.

Overall, the Technical Resources tab on the manitobamasonry. ca website is a valuable resource for anyone involved in masonry design. Whether you’re a beginner looking to learn the basics or an experienced professional seeking advanced guidance, you can find everything you need to enhance your skills and knowledge on this comprehensive website.

B = BRICK