DYNAMIC TENSEGRITY SYSTEMS

MSc Dissertation - 2009 -10

Emergent Technologies and Design (EMTECH)

Architectural Association School of Architecture, LONDON

DISHITA TURAKHIA

ARCHITECTURAL ASSOCIATION SCHOOL OF ARCHITECTURE

GRADUATE SCHOOL PROGRAMMES

COVERSHEET FOR COURSE SUBMISSION 2009/2010

PROGRAMME:Emergent Technologies and Design

TERM:Autumn 2010

STUDENT NAME: Dishita Turakhia

SUBMISSION TITLE: MSc Dissertation | Dynamic Tensegrity Systems

COURSE TUTOR: Mike Weinstock

SUBMISSION DATE:15/10/2010

DECLARATION:

“I certify that this piece of work is entirely my own and that any quotation or paraphrase from the published or unpublished work of others is duly acknowledged.”

SIGNATURE OF STUDENT:

DATE: 15/10/2010

ACKNOWLEDGEMENTS

First and foremost, I am extremely grateful to our Emtech course director, Michael Weinstock for his tremendous encouragement, guidance, support and inspiration through out the one year of course study. I would also like to thank George Jeronimidis and Toni Kotnik for their immense support and much valued feedback at every stage of the project development. I also would like to thank course tutor Christina Doumpio ti for her effort and time devoted in helping the project take shape. I would also like to thank all the AA Emtech Staff, my colleagues and class-mates for everything that I was able to learn while working with and around them.

I can never thank enough my parents, Girish Turakhia and Meena Turakhia for their forever encouraging support and all their love and belief in me that constantly inspires me at every stage of my work. I would like to acknowledge the support and efforts of my group mate and dear friend Riddhi for all the help and assistance o ffered. Lastly, I want to thank all my family and friends both here and back home who have always been my suppor ting pillars.

03

ABSTRACT

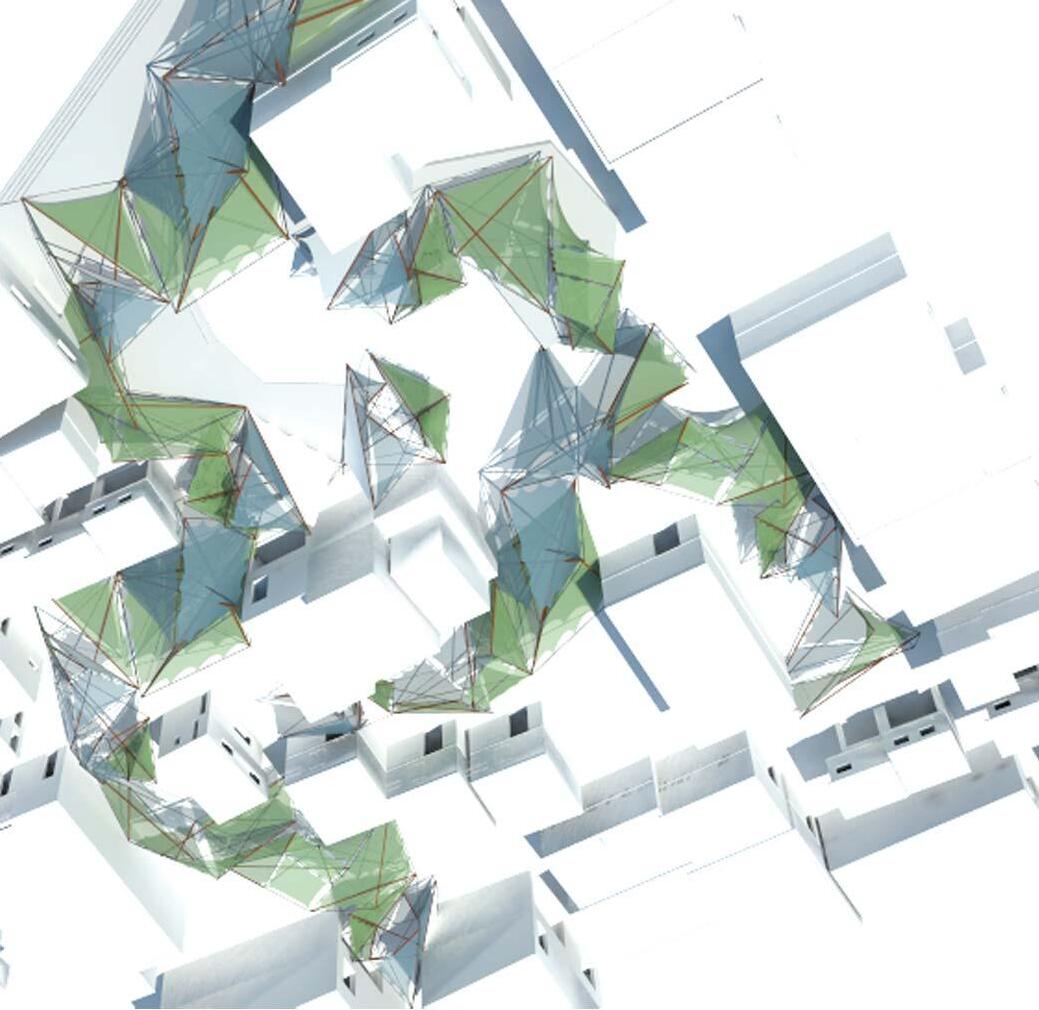

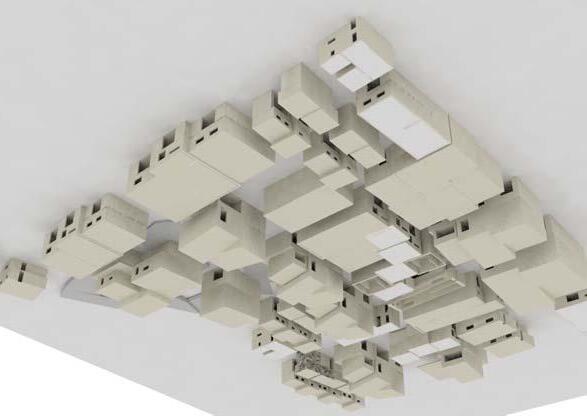

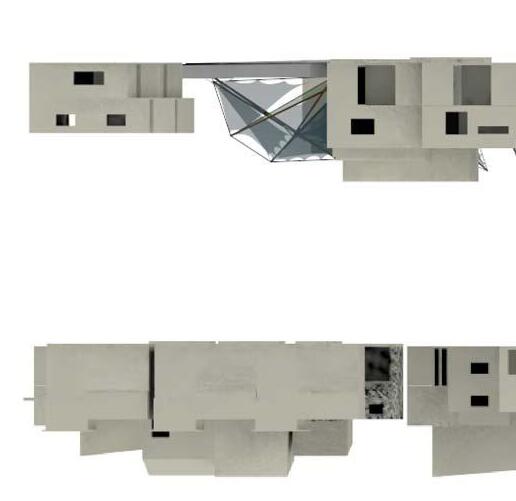

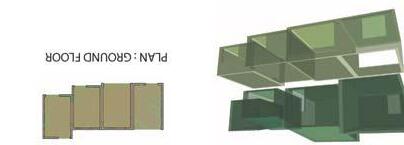

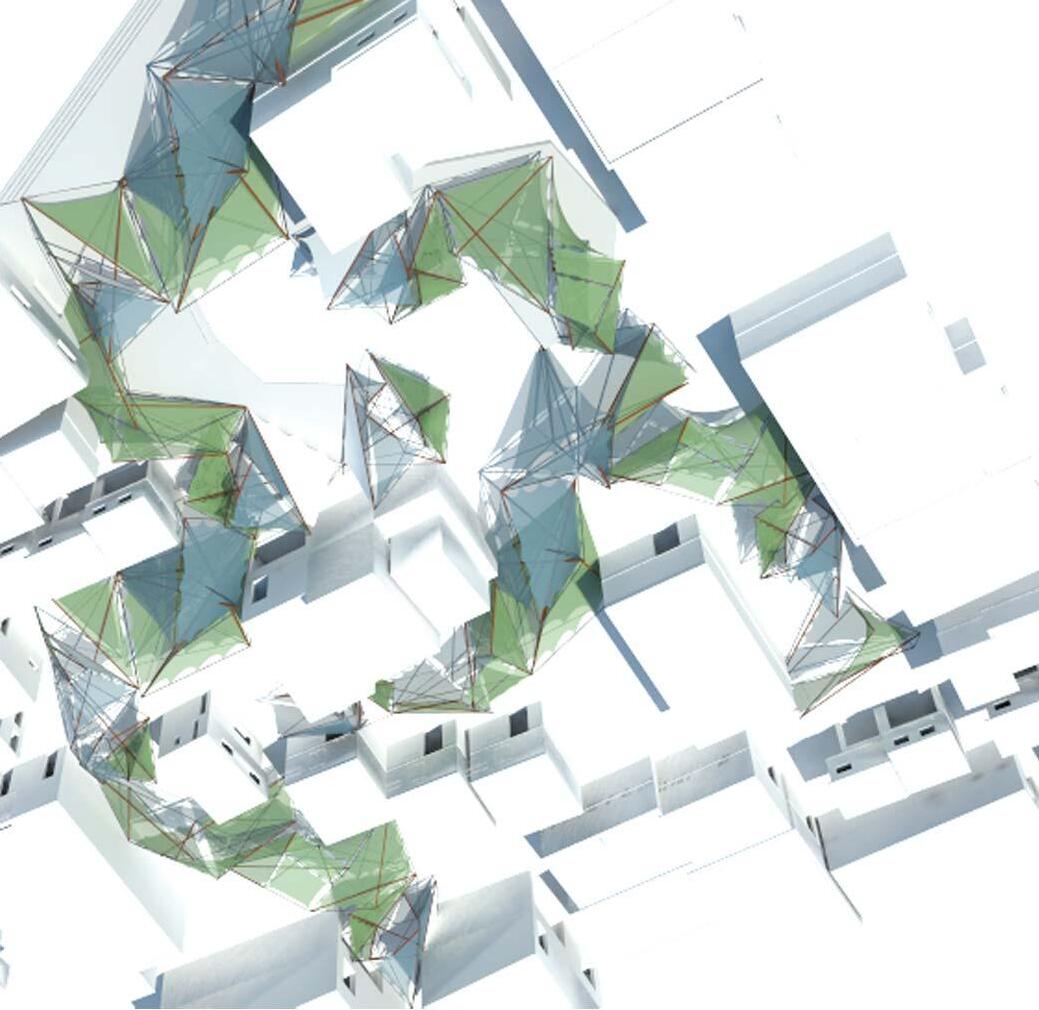

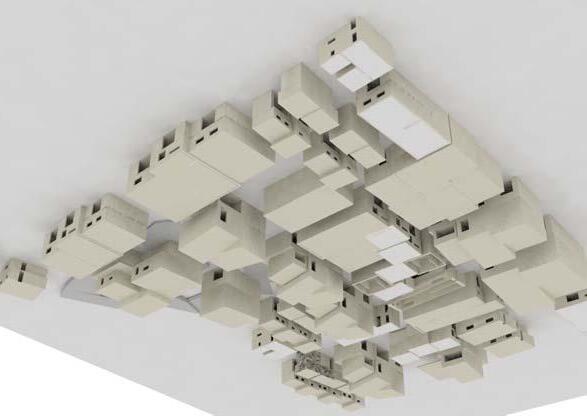

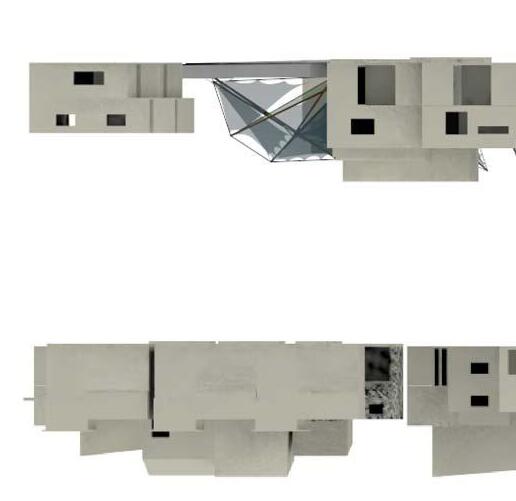

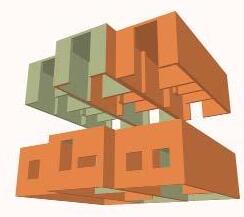

The research intends to develop Dynamic Tensegrity Structures for designing programmatically driven habitable structures in a highly dense and mixed use urban context. The primary purpose of the ‘dynamic’ nature of the system proposal is to serve the rising needs for flexibility, adaptability and mul ti-func tionality of space, due to lack of expansion of land in congested site contexts. Thus the resultant reconfigured structure would provide for optimal spatial use as per the user needs at various time scales. The research aims at providing a feasible solution to the considered contextual situation by addressing the various limitations of the system development- namely computational, analy tical and fabrication.

05

6

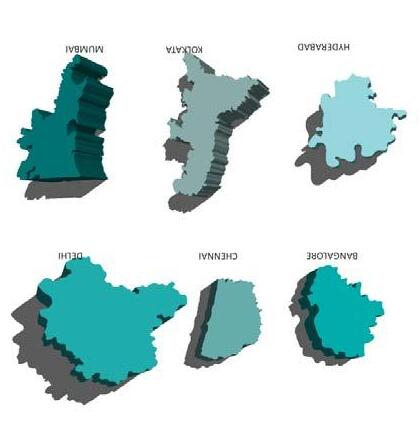

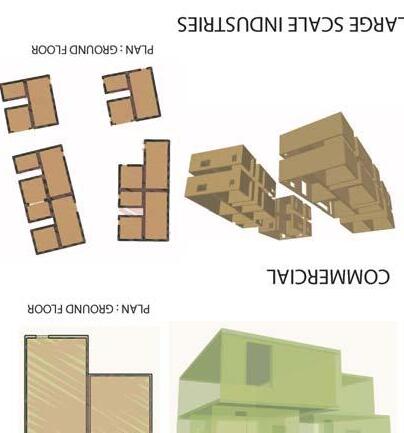

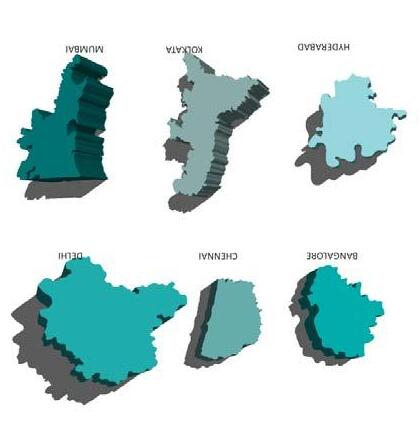

For ever-expanding megaci ties, rapid changing social context is an area of major concern for architectural structures. With shi fts in lifestyles and social condi tions, the land-use pattern of the city is undergoing a major transition continuously. Advancing economies and occupations result in periodically re-diagrammed urban map of the city with overgrowing satellite towns enveloping the main city thus increasing the loads on energy consumption and infrastructure.

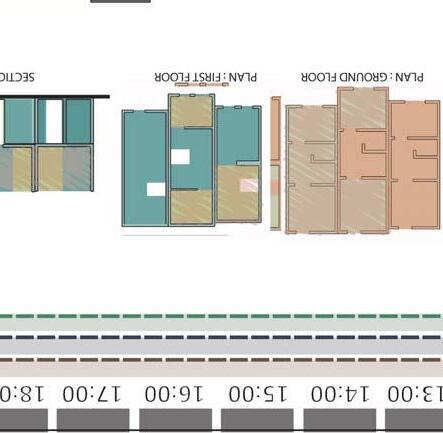

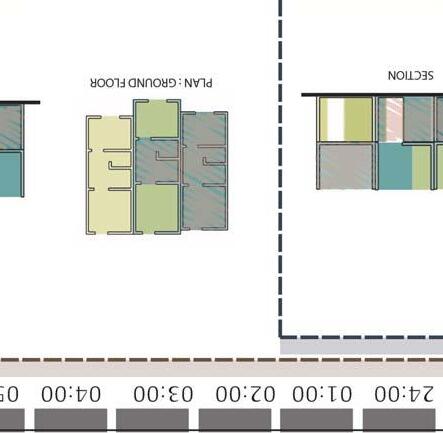

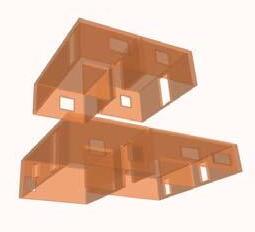

For congested ci ties, that lack any further urban space for expansion and any further resources to support the infrastructure, it is essential to design multi-use structures that are programmatically adaptive spaces. These essentially can be small scale adaptive structures for rehabilitating the low-cost social communi ties which transform into economy generating spaces like house-hold factories and manufacturing units by day and residential housing units for the families by night. Another possibility for adaptive infrastructural structures is public health and learning centers by day and social congregational and recreational spaces by night. These adaptive temporary structures can also be highly useful for disasterbased rapid rehabilitation spaces.

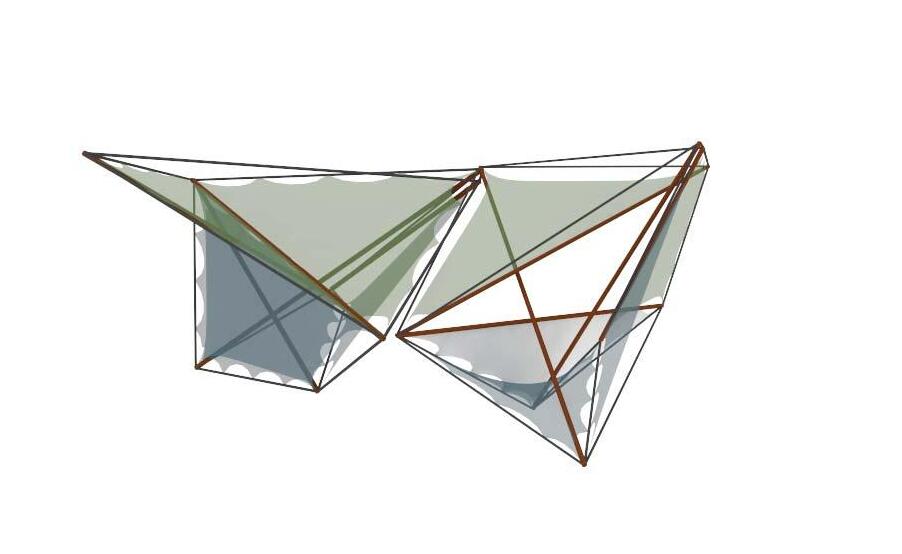

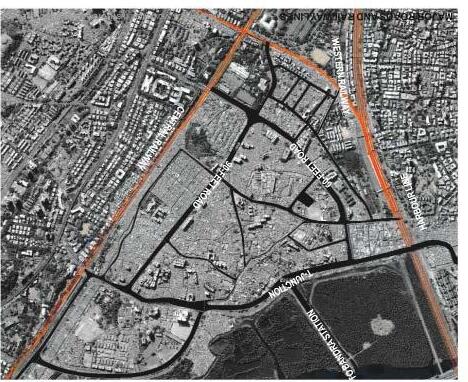

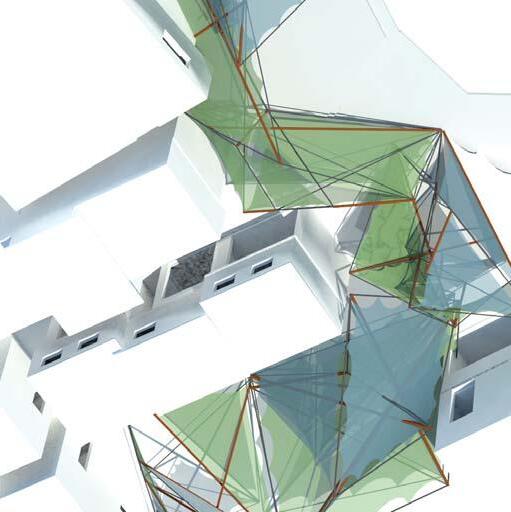

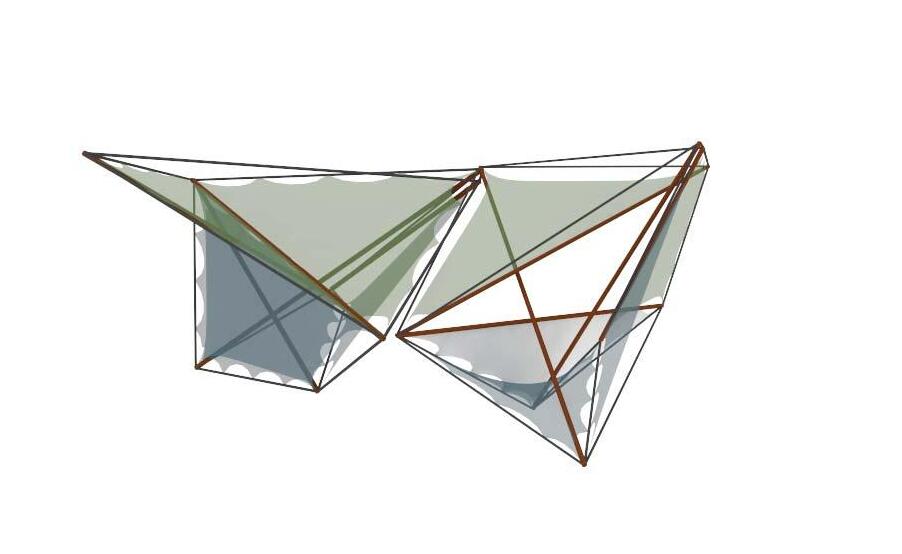

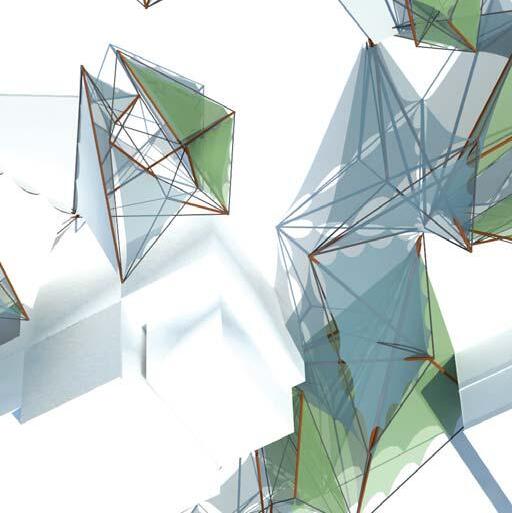

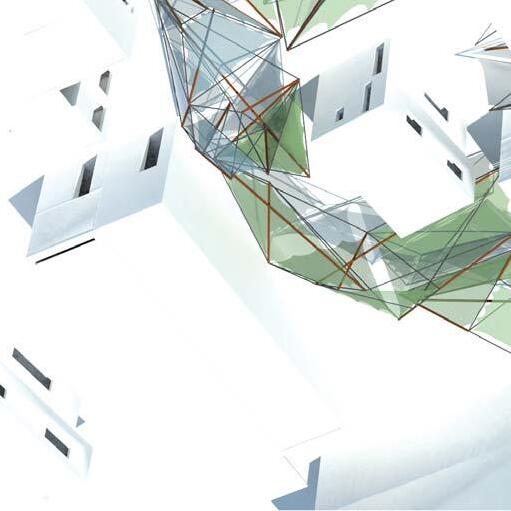

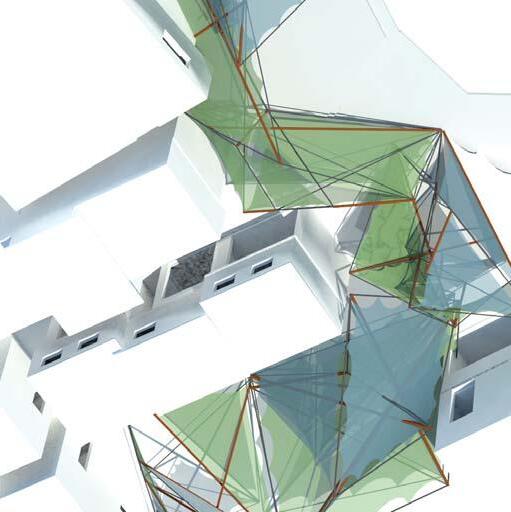

The proposed design case, however, attempts at addressing the issue of lack of flexible and mul ti-use adaptive habitable spaces in densely populated urban contexts with a continuous influx of varied social groups. This concern is addressed essentially by developing dynamically configured Tensegrity Structures. The project further investigates the

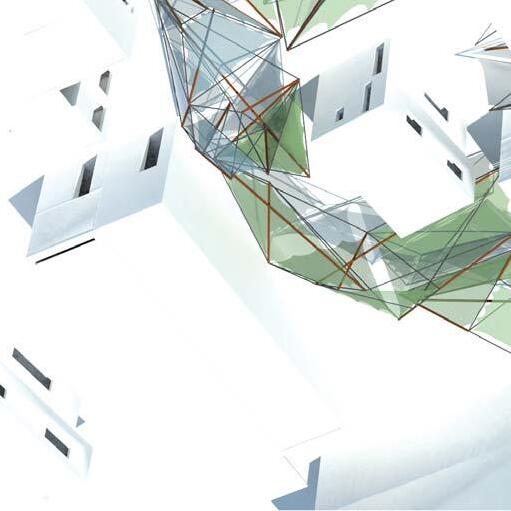

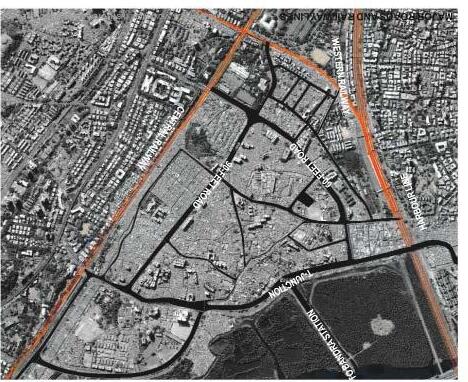

various organization strategies of the designed Tensegrity modules evolved using algorithmic design process. The organization logic reflects the juxtaposi tion of existing spatial condi tions and required re-configured enclosed spaces, both of which are listed following a thorough study and analysis of site condi tions at varied time scales.

The further investigation involves understanding change connec tion parameters of the components and the respective resultant alteration in the spatial nature of the design. The process followed for developing these Tensegrity modules involves generative algorithmic approach to produce highly varied morphologies within a limited set of principles and parameters, followed by an intensive evaluative analysis and elimination procedure to filter out the most optimized and useful modules. The strength and stability of the design system is tested digitally using material properties and constraints in analy tical so ftwares like Strand in order to understand the load bearing capacity and buckling thresholds for the design.

The resultant filtered morphologies selected based on structural and spatial quali ties are further organized within the selected context of over-crowded, congested and ever-expanding city of Mumbai. The final design proposal addresses the construc tion and installation techniques from a critical view-point to be able to propose a viable design solu tion to the addressed problem in the chosen context.

7

INTRODUCTION

8

SYSTEM

PROCESS

DESIGN (TENSEGRITY) (DYNAMIC TENSEGRITY) (MUMBAI SLUMS)

ARCHITECTURAL

CASE STUDIES

BIOMIMETIC

FORM FINDING

ROBOTICS

DIGITAL (PARAMETRIC)

EXPLORATION

EVALUATION

PHYSICAL

GEOMETRY GENERATION

RELAXATION TO STABLE FORM

VOLUME

HEIGHT

BASE AREA

STRUT INTERSECTIONS

COMPONENT SIZE

REGULAR

CLASSIFICATION

DYNAMISM + MULTIPLICITY

IRREGULAR

ROTATIONAL

TELESCOPIC

EVOLVING URBAN CONTEXT

TYPES OF USES AND USERS

SETTLEMENT TYPOLOGIES

TIME-LINE OF CHANGE

MATERIAL AND DETAIL

DESIGN APPLICATION

FABRICATION AND INSTALLING

SYSTEM BEHAVIOUR

DESIGN DEVELOPMENT

INTEGRATED PROPOSAL

9

DIAGRAM

10

CHAPTER 1 DOMAIN

Introduc tion

Case Studies

Conclusion

CHAPTER 2 METHODS

Introduc tion

Key Concepts

Case Studies

CHAPTER 3 EXPERIMENTS

Preliminary Exploration

Generative Algorithm

Structural Tests

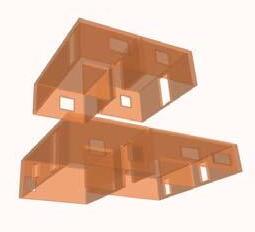

CHAPTER 4 DESIGN DEVELOPMENT

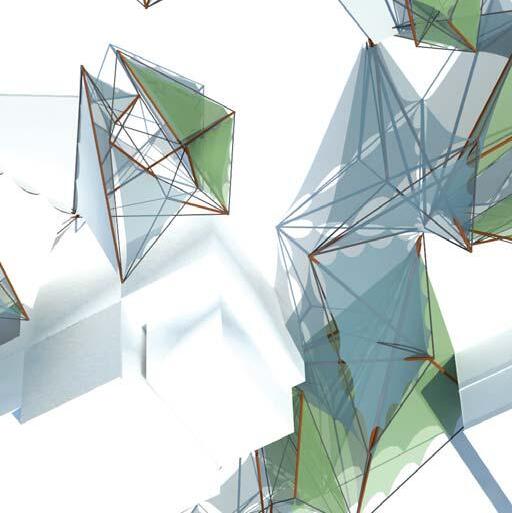

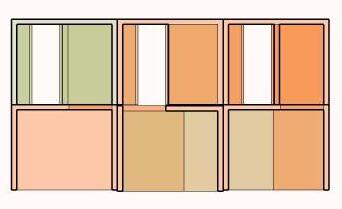

Spatial Exploration

Mul tiplicity

Membranes

Module Organization

CHAPTER 5 DESIGN PROPOSAL

Revised Design Strategy

Site

Time-line Study

Organization Strategy

Test Proposal

Construc tion Details

CHAPTER 6 CONCLUSIONS

Learnings

Limitations

Further Scope

APPENDIX

REFERENCES

11

CONTENTS

13 14 19 27 29 30 34 42 47 48 54 64 69 70 72 76 79 81 82 83 86 88 90 94 101 102 103 104 107 171

12

CHAPTER 01.

DOMAIN

01 INTRODUCTION

Need For Flexibility in Architecture

State of Art Examples

Tensegrity: Tool for Flexibility

02 CASE STUDIES

BioTensegrity - Dynamic Models of Tensegrity in Nature

Architectural Applications of Tensegrity

03 CONCLUSION

This chapter aims at developing the argument and theoretical base for the research project concluding to the primary intention and hypothesis of the dissertation. The introductory sec tion focuses on cri tically addressing the di fferent concerns and aspects of the study and the explored premises of the respective concepts. The case studies focus on studying the existing examples of the system application in both natural and architectural contexts. The conclusion sec tion further reiterates the thesis intent and design concern based on the case studies and analysis.

13

INTRODUCTION

NEED FOR FLEXIBILITY IN ARCHITECTURE

Amidst rapidly changing social contexts, architectural structures require distributed intelligence embedded in ac tive material systems, programmable virtual representations of themselves (digital models) that are capable of changing their internal parameter and performances in relation to the life of the inhabitants and events in the external world [1.1]

This need for Socio-Spatial Response arises from the new way of lifestyles reflecting not only the mobility and speed of modern life but also its temporary nature and potential of expandability. Cedric Price, quite ambitiously explores the potential of this concept by stating “What if the buildings or a space could be constantly generated and regenerated!” [1.2]

This intriguing fascination of dynamic structures is also described by Neil Leach in his essay[1.3] wherein he states “in most advanced form, it would be an architecture that is open to those processes themselves, an

adaptive, responsive environment, that does not crystallize into a single, inflexible form, but is able to recon figure itself over time, and adjust to the multiple permutations of programma tic use that might be expected of it”.

Using dynamism to improve efficiency, multi-func tionality and adaptability of space has become a design pre-requisite in order to cater to the rising need of domestic flexibility. Of all the architectural programs, this dire need of design adaptability is most evident in residential spaces. “A home cannot be defined by its functions but is a pa ttern of regular activities and neither the space nor its appurtenances have to be fixed. A home is an organiza tion of space that has some strcture in time, in which people interact in a pa ttern of events and phenomena that integrate space and performance. ”[1.4] With increasingly changing lifestyles and advancement

14

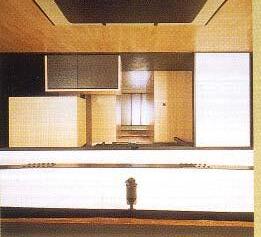

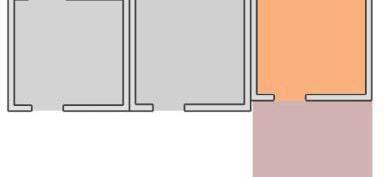

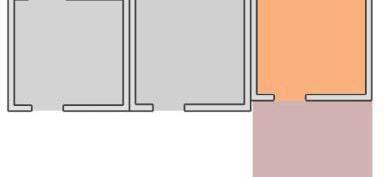

FIG 1.1. Images showing different combinations and configurations of internal arrangements and use of hinged partitions in the Fukuoka Housing in Japan by Steven Holl

in technological connec tivity, the lines and needs for conventional func tionally demarcated spaces is rapidly diminishing. Tradi tional notions of family units are being exploded as it fractures into small groupings, dispersed in the urban landscape. With constantly changing equations between space user and spatial use in this rapidly evolving age, there is a need for a house or living space to have the potential of variability, reconfigurability and personalization based on user needs and requirements. This concept of adapting to the dynamic context is also discussed by Richard Rogers; he says, “Shelters will no longer be sta tic objects but dynamic objects sheltering and enhancing human events. Accommodation will be responsive, ever-changing and ever-adjusting.” [1.5] This need is further gravely realized in highly dense and congested urban contexts where lack of expansion space results in overlapping of programs within limited spaces. This results in mul ti-use of a given space and need for program based adaptability of the space and structures.

The further investigation briefly studies the various concepts, theories and designs exploring dynamic spatial re-configuration at varied scales and time spans.

References:

1.1 Adam Somali - Fischer, Interactive Architecture, Architectural Design - 4D Space

1.2 Cedric Price, Interactive Architecture, AD 4-D Space

1.3 Neil Leach, Swarm Techtonics, Digital Techtonics

1.4 Gillian Crampton Smith, Interactive Architecture, 4D Space.

1.5 Robert Kronenburg, Transportable Environments (1997), pg 45.

FIG 1.1. Transportable Environments (1997), pg 50.

FIG 1.2 http://solardecathlon.cca.edu/?p=78

15

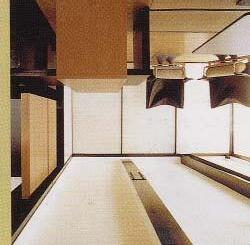

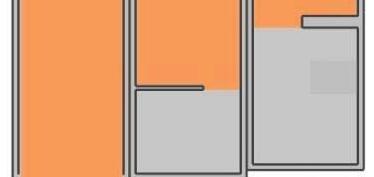

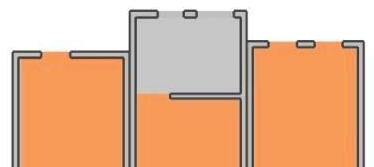

FIG 1.2. Series of different structural & spatial configurations in the GucklHupf by HansPeter Wörndl showing dynamic change of spaces.

STATE

ART

The concept of transformation and flexibility in domestic space has been explored widely and extensively over a long time since the beginning of twentieth century. The Schröder House[1.6] designed by Gerrit Rietveld (1924) was one the ground breaking realization of a transformable adaptive and flexible domestic design, having a system of sliding par titions that helped in achieving an extremely flexible interior arrangement almost on a daily basis. On the other hand, Buckminster Fuller’s 4D Dymaxion house(1927)[1.7], made of Duralumin explored a completely di fferent concept of efficient dynamism with deployable housing unit prototype for low-cost mass produc tion based on techniques drawn from aircraft and vehicle industries. Steven Holl’s no tion of ‘hinged space’ being most dynamic, interactive and movable and thus being the epitome of the transformable is exempli fied in his built housing project for Fukuoka

in Japan(1989)[1.8], with rooms designed with removable corners and rotating walls. While most of the flexibility explorations of a house are conventionally deemed to be in its floor plan, Iain Borden[1.9] describes the potential of transformations of domestic spaces vertically by exploring vertical circulatory elements. Yet another signi ficant model of kinetic structure is the GucklHupf by HansPeter Wörndl(1993)[1.10], exploring and experimenting the no tion of house reac ting with its environment through structure and skin, by disintegrating from its cocoon-like form and opening up into its surrounding.

These paradigms in architecture explore this concept of flexibility at varied scales of architecture and time from being daily internally reconfigurable to having this concept explored at an long time spanned external level. The primary intention of this brief case study was to grasp and extract these application methods and apply at an altogether di fferent scale

16

OF

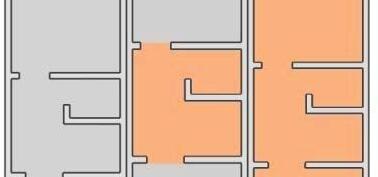

FIG 1.3. Images showing different combinations of internal arrangements in the living space and sitting room of the Schroder House designed by Gerrit Rietveld

1.4. Different versions and designs of the deployable Dymaxion House designed by Buckminster Fuller for low-cost mass housing.

of structural level. The research aspires to address and develop the no tion of structural re-configurability resul ting from varying program needs of the space and user.

References:

1.6 Huber-Jan Henket, The Reitfeld-Schroder House (AD, The Transformable House) (2000), pg 12-15

1.7 Dennis Sharp, Maximum Deployment in a Dymaxion World (AD, The Transformable House) (2000), pg 16

1.8 Steven Holl, Hinged Space (AD, The Transformable House) (2000), pg 50

1.9 Iain Borden, Stairway: Transforming Architecture in the Golden Lane (AD, The Transformable House) (2000), pg 20

1.10 Sally Godwin, Hans Peter Worndl: The Glucklhupf (AD, The Transformable House) (2000), pg 86

FIG 1.3. http://static.rnw.nl/migratie/www.radionetherlands.nl/features/cultureandhistory/rietveld001214

FIG 1.4. http://www.sustainy.com/?p=675

FIG 1.5. http://aedesign.wordpress.com/author/alfredomaldonado2009/

1.5. Flexible & transformable external facade of the Fukuoka Housing Complex in Japan designed by Steven Holl.

17

FIG

FIG

a lightweight lattice of interlocking icosahedrons and could be skinned with a protective cover.

TENSEGRITY IN ARCHITECTURE

With most of the flexibility arising as a result of interior reconfigurations or skin variation, there is evidently little exploration in structurally dynamic adaptability potential of a building. Since, a space is embedded in its structure that is typically static[1.11]; it is essential to approach the design by developing a structurally flexible and reconfigurable system to achieve the spatial and func tional variation. In order to attain this flexible structural system that responds to user based spatial needs, the system needed to be not only morphologically varied and temporary but extremely strong and instantly reactive to certain key parameters. Tensegrity systems display all these characteristics and hence the research

aims at addressing the flexible design concern by exploring the potential of Tensegrity structures and applying in the varying programmatic urban context. With feasibility of this exploration being the primary concern and limitation of the Tensegrity System owning to its temporary nature, the research aims at addressing various other limitations like lack of ease of fabrication and on-site installation in the considered urban context. The research also questions the limited architectural exploration of Tensegrity Structures restricted to either sculptures or temporary tents in spite of the huge scope of varied applications.

References:

1.11 Klien Dytham, Interactive Architecture, Architectural Design - 4D Space FIG 1.6 http://www.arkinet.com/articles/agenda-the-bucky-bar-opens-tonight

18

FIG 1.6. Geodesic Tensegrity Installation to a habitable scale proposed by Buckminster Fuller as dome that deploy

01 BIOMIMETIC (BIO-TENSEGRITIES)

Anatomical Level

Cellular Level

Molecular Level

02 ARCHITECTURAL

Sculptures

Bridges

Installations

In order to study proper ties, characteristics, applications and potential uses of Tensegrity Structural System, it was essential to cri tically analyze the existing examples of this system. The primary goal of this exercise was to extract logics of processes and optimally applying these concepts for design development.

19

CASE STUDIES

BIO-TENSEGRITY

BIOMIMETIC EXAMPLES: Dynamic Tensegrity Structures in Nature

Biological models essentially provide for a coherent case study for understanding dynamic open systems.[1.12] Complex collec tive behavior of a dynamic system generally emerges from interactions among components that exhibit simple behavior. Tensegrity systems too, like other complex systems are widely existent in nature exhibi ting dynamic mechanisms in processes at various scales from anatomical level to cellular level and molecular level. It is important to study these examples not only for a better investigation of the system but also to understand the dynamic behavior of these systems as most of the Tensegrity natural systems display locomo tive or kinetic mechanisms. Since the basic aim of the research focuses on Dynamic Tensegrity Structures, it is crucial to study natural mechanisms that display dynamic proper ties in optimal way.

References: 1.12 Donald Ingber

FIG 1.7. http://www.magicalrobot.org/BeingHuman/2010/04/introduction-to-biotensegrity

http://www.ttem.org/forum/index.php?topic=1807.0

20

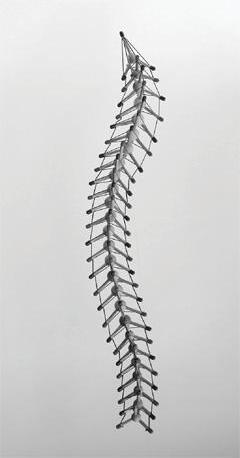

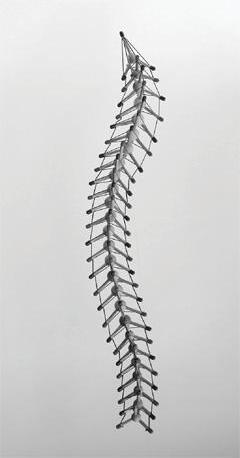

FIG 1.7. Tensegrity analogy models of Human Vertebrate column.

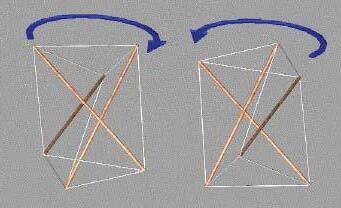

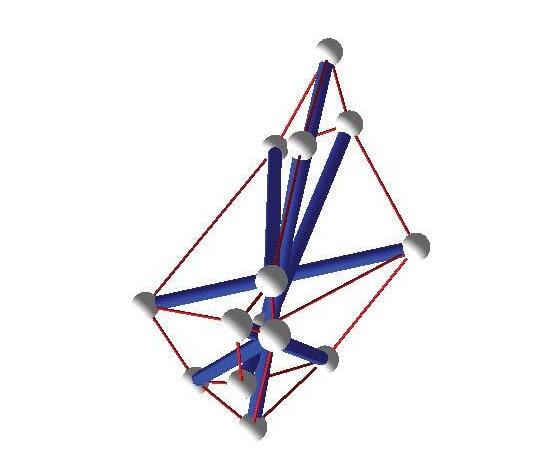

FIG 1.8. Diagram of 8 strut Octa-hedral Tensegrity model depicting the expansion and contraction mechanism of ribcage during respiration

1.9. Images showing expansion and contraction of rib-cage and diaphragm during respiratory process.

ANATOMICAL EXAMPLES

On an anatomical level, the human body provides a good example of a prestressed Tensegrity structure. Bones act as struts resisting the pull of tensile muscles, tendons and ligaments. Moreover, the stability of the shape of the body, or its stiffness, of the body is a func tion of the tone, or prestress, of its muscles. As Ingber puts it, “We are 206 compressionresistant bones that are pulled up against the force of gravity and stabilized through a connec tion with a continuous series of tensile tendons, muscles, and ligaments”. [1.13]

Core Body Torso

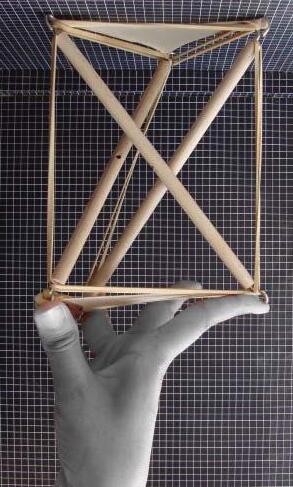

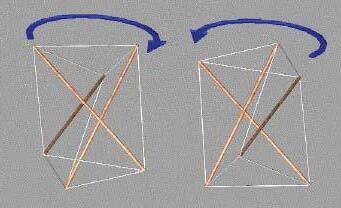

The core of the body, the torso has bilateral symmetry, oscillates (breathes) and is bounded on all sides by bony structures. Breathing causes the thoracic cage to expand and contract following the pumping action of the diaphragm. By abstracting the shape somewhat it is feasible to map the force vectors of the torso onto an expanded octahedron Tensegrity. The diagram alongside shows a Modi fied X-Octa Tensegrity, which contracts

and expands in the same way the torso does, and there is a central cavity, as found in the body, created by the geometry. As two parallel struts are pulled apart (equivalent to the expansion of the ribs) both other parallel pairs counter intui tively expand and pull away from each other as well. Built from only six struts (suitably modi fied) they correspond to the boundary planes of the torso– the transverse planes of the clavicle and the pelvis, the coronal planes of the spine and sternum, and the sagi ttal planes of the ribs on both sides. [1.14]

The study of this bio-tensegrity demonstrates uniform dynamic volumetric changes resulting with mere changes in tension of the cables.

References:

1.13 Donald Ingber, How cells (might) sense microgravity

1.14 Donald Ingber, How cells (might) sense microgravity

FIG 1.9. http://www.oum.ox.ac.uk/thezone/animals/life/respire.htm

21

FIG

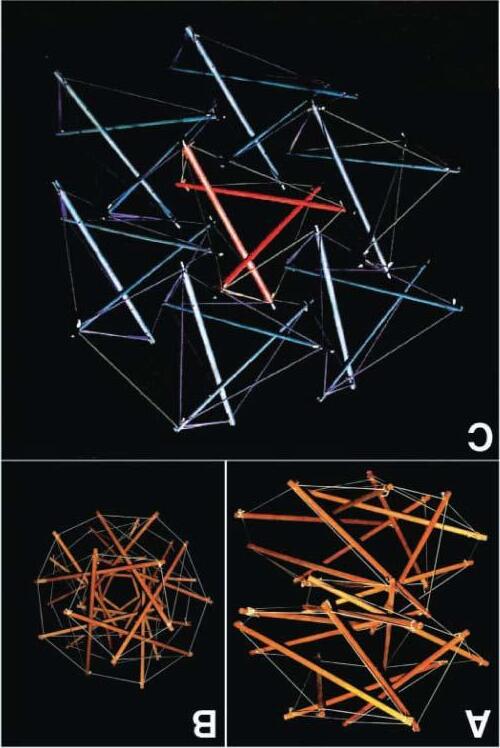

CELLULAR LEVEL EXAMPLES:

The cell possesses a molecular framework called the cytoskeleton enclosed within the surface membrane that mechanically stabilizes the cell. The cytoskeleton is comprised of three di fferent types of molecular protein polymers, called micro filaments, intermediate filaments and microtubules. This network of molecular struts and cables allows the cell to alter the balance of tension and compression throughout its structure in order to maintain its shape, even when external forces are imposed upon it.

Cytoskeleton:

The cellular Tensegrity model proposes that the whole cell is a prestressed Tensegrity structure, wherein tensional forces are borne by cytoskeletal microfilaments and intermediate filaments, and these forces are balanced by interconnected structural elements that resist compression, most notably, internal microtubule struts and extracellular matrix

(ECM) adhesions. The tensional prestress that stabilizes the whole cell is generated actively by the contractile actomyosin apparatus. Although the simple six-strut Tensegrity model of the cell has been very useful, the living cell is more complex because it is a ‘mul ti modular’ Tensegrity structure. The cell is composed of mul tiple smaller, self-stabilizing Tensegrity modules that are linked by similar rules of tensional integrity. As long as these modules are linked by tensional integrity, then the entire system exhibits mechanical coupling throughout and an intrinsic harmonic coupling between part and whole. However, destruction of one unit in a mul ti-modular Tensegrity, however, results only in a local response; that par ticular module will collapse without compromising the rest of the structure.

References:

FIG 1.10 http://www-3.unipv.it/webbio/anatcomp/freitas/2007-2008/biocell_LSBUSB07-08.htm

FIG 1.11 http://jcs.biologists.org/cgi/content/full/116/7/1155

FIG 1.12 http://jcs.biologists.org/cgi/content/full/116/7/1157

22

FIG 1.10. Diagrammatic representation of cytoskeleton expansion and contraction stages with Tensegrity concept.

FIG 1.11. Multi-modular model of Tensegrity organization of cytoskeleton that enables dynamic behavior.

FIG 1.12. Multi-modular hierarchical organization and composition of Tensegrity modules.

1.15. The stereoscopic images showing the surroundings of one triangle (a) and the rhombohedron flanked by eight of the triangles (b). The red triangle is at the back of the rhombohedron.

MOLECULAR LEVEL EXAMPLES:

Several geodesic Tensegrity structures naturally occur on the molecular level. Basement membrane proteins, polyhedral enzyme complexes, clatrin-coated transport vehicles, viral capsides, lipid micelles, individual proteins, and RNA and DNA molecules all employ hexagonal arrangements.

DNA MOLECULE

Prof. Nadrian C. Seeman constructs stick figures of DNA where specific

sticky ends are attached to DNA branched junc tions, whose edges are double-stranded DNA. This approach has already been used to assemble a cube, a truncated octahedron , nanomechanical devices and 2-D crystals and 3-D crystals from DNA. This method of construc tion was originally stimulated by Seeman’s desire to characterize Holliday junc tions. Holliday junc tions are four-arm branched DNA molecules that are found to be structural intermediates in genetic recombination. In the last few

years, the symmetry, crossover topology and sequence-dependent thermodynamics of Holliday junc tions have been characterized and analyzed.

References:

FIG 1.13. http://www.dreamstime.com/3d-dna-model-image2260749

FIG 1.14. http://tensegrity.wikispaces.com/DNA

FIG 1.15. http://tensegrity.wikispaces.com/DNA

23

FIG 1.14. The stereoscopic images showing the molecular structure of the tensegrity triangle (a) and the connection between two of them through a sticky end (b).

FIG 1.13. DNA Molecule Diagram

FIG

TENSEGRITY IN ARCHITECTURE

KENETH SNELSON SCULPTURES:

Needle Tower:

The needle tower was built by Kenneth Snelson in 1968 at the Hirshhorn Museum of Art. The structure was a succession of Tensegrity modules, decreasing in size, organized around a ver tical axis, very similar to the organization of the human spine.

The Dragon:

A cantilevered Tensegrity structure built in 2000, wherein the forces of gravity are balanced in the structure by the tensile continuum of forces. The stresses that arise in the lower parts of the cantilever are distributed to the whole structure, allowing large cantilevers.

References:

FIG 1.16. http://kennethsnelson.net/1970/needle-tower/ FIG 1.17. http://www.brooklynrail.org/2009/04/art

24

FIG 1.16. Kenneth Snelson’s Needle Tower, 1968 made of Aluminum & stainless steel measuring 60 x 20 x 20 feet or 18.2 x 6 x 6m present at Hirshhorn Museum & Sculpture Garden, Washington, D.C

FIG 1.17. Kenneth Snelson’s Dragon Sculpture made of stainless steel measuring 30.5 x 31 x 12 feet or 9.3 x 9.4 x 3.6m

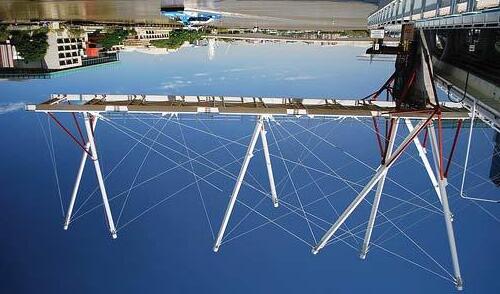

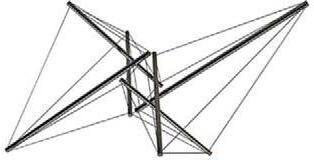

THE TANK STREET BRIDGE:

The tank Street Bridge is designed by Baulderstone Hornibrook Queensland and Cox Rayner Architects, in Brisbane Australia in collabora tion with ARUP. This bridge of 425m is the first Tensegrity Bridge for pedestrians and bicycles ever built solely as a Tensegrity structure. The bridge was built from both ends, without any supports since the Tensegrity property of the structure takes into account the gravity forces and thus allows large cantilevers.

References: http://www.archdaily.com/12914/tank-street-bridge-or-kurilpa-bridge-baulderstone-hornibrookqueensland-cox-rayner-architects/

FIG 1.18.http://www.archdaily.com/12914/

FIG 1.19. http://www.archdaily.com/wp-content/uploads/2009/01/1833331501

25

FIG 1.18. Image of The tank Street Bridge

FIG 1.19. Digital model of the connection end of the tank bridge

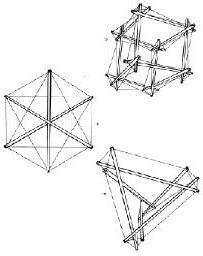

TENSEGRITY TOWER:

(Herbert Klimke, Soerren Stephan)

The Tensegrity Tower was conceived by architects Gerkan, marg and Partners for a fair in Rostock, Germany, in collaboration with engineers Schlaich, Bergermann and Partners. The modules of the tower consisted of three 10m long struts and nine cables. The produc tion method, fabrication technique and assembly logics followed in the project were extremely crucial and helpful in understanding the prac tical constraints and hindrances in the execu tion of a large Tensegrity Design project. The procedure was executed in 3 steps:

- Assembly of modules using temporary supports for posi tioning the struts

- Complete Pre-Stressing using three jacks of 100t capacity.

- State of interconnec tion of modules

References: 1.

1.20.http://www.del-uks.com/wiki/index.php/Nowhere_2007

FIG 1.21. http://www.mero.de/fileadmin/downloads/bausysteme/publikationen/tens_tower_e.pdf

FIG 1.22. http://www.mero.de/fileadmin/downloads/bausysteme/publikationen/tens_tower_e.pdf

26

FIG

FIG 1.20. Digital diagram of Tensegrity Tower showing modular organization

FIG 1.21. Detailed view of the Modular Connection of the Tensegrity Tower

FIG 1.22. Six tier modular Tensegrity Tower of three strut Tensegrity module

CONCLUSION

As per the research and case-studies, it can be observed that the high dynamic potential of the Tensegrity system has not be u tilized or even explored in the Architectural fields. The only applications of the System seen is for bridges, installations or sculptures. However, there is wide potential nd scope of developing this system into habitable structures and thus the research aims at achieving this goal of designing habitable and usable dynamic Tensegrity structures.

References: FIG 1.23.http://www.knowledgerush.com/kr/encyclopedia/Buckminster_Fuller/

27

CONCLUSION

FIG 1.23 The American Pavilion of Expo ‘67, by R. Buckminster Fuller, now the Biosphère, on Île SainteHélène, Montreal

28

CHAPTER 02.

METHODS

01 INTRODUCTION

Non Linear Dynamic Systems

Tensegrity as Non Linear Dynamic System

Digital Methods and Tools

Simulation of Tensegrity Structures

02 KEY CONCEPTS

History

Defini tions

Characteristics

Advantages

Disadvantages

Classi fication

Theories and Methods

03 CASE STUDIES: Methods

Physical Exploration

Robo tics

Digital Locomo tion Simulation

Conclusion

This chapter focusses on setting up a theoretical base for need to develop system specific digital tools and processes in order to study, analyze, experiment and explore the complex system behavior. It then briefly summarizes the key concepts and characteristics of Tensegrity followed by case studies from parallel fields of research that focus on developing contemporary methods to explore dynamic system behavior.

29

INTRODUCTION

CAUSALITY PRINCIPLE

INPUT

Direct Relation and Proportion

STRICT CAUSALITY

Linear Systems OUTPUT

NON LINEAR DYNAMIC SYSTEMS

Manuel DeLanda, in his wri tings describes the signi ficant di fference between conventionally studied Linear Systems and the recently researched Non-linear complex system behaviors.[2.1] The Linear Systems tend to be characterized by a single global state, but the systems which are both non-linear and non-equilibrium display mul tiple stable states and these may come in a variety of addi tional forms, namely steady, periodic and chao tic states. These concepts are also explained by Causality Principle[2.2] which describes relationship between the causes and effects. A Strict Causality displays a predictable linear behavior with the result being directly propor tional to the input parameters; A Weak Causality also displays a fairly predictable yet imprecise behavior based on the input factors; Distributed Causality which is displayed by most of the non-linear dynamic systems wherein small variations of the ini tial condi tion of the system may produce large variations in the long term behavior of the system. These mul tiple stable states characterize not only

WEAK CAUSALITY

DISTRIBUTED CAUSALITY

Direct Relation

INPUTOUTPUT

INPUTOUTPUT

Unpredictable Relation and Proportion (Cause)(Effect) (Cause)(Effect) (Cause)(Effect)

Non-Linear Dynamic Systems

inorganic material behavior, but also organic social behavior.[2.3] “We are beginning to understand that any complex system, whether composed of interacting molecules, organic creatures or economic agents, is capable of spontaneously genera ting order and actively organizing itself into new structures and forms” , DeLanda says.[2.4] It is precisely this ability of matter and energy to self-organize and exist in mul tiple stable state, that is of greatest significance due to its potential application in various fields of design and development. The spontaneous generation of form as well as the morphogenetic potential of a material system can be best expressed by studying and analyzing its complex and variable behavior.

References:

2.1 Manuel DeLanda, Material Complexity, Digital Tectonics - (2004), pg 14

2.2 Heinz-Otto Peitgen, Hartmut Jurgens, Dietmar Saupe, Chaos and Fractals- (1992), pg11

2.3 Manuel DeLanda, Material Complexity, Digital Tectonics - (2004), pg 16

2.4 Manuel DeLanda, Material Complexity, Digital Tectonics - (2004), pg 15

FIG 2.1 http://www.citrinitas.com/history_of_viscom/computer.html

30

FIG 2.1 Illustration created in Processing which are the result of a non-linear physics-based model of keywords connected by springs.

BASIC SEED

RELAXED FORMS

TENSEGRITY AS NON LINEAR DYNAMIC SYSTEM

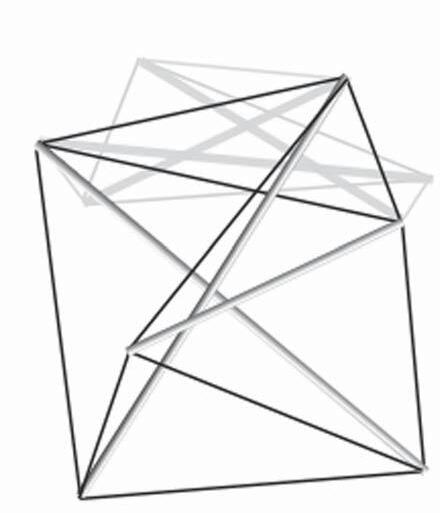

Although the conventionally studied classical Regular Tensegrity Structures can be classi fied as Linear Systems, the recent investigation in the field of developing and designing the Irregular Tensegrity has led to understanding the complex behavior of Irregular Structures.[2.5] While the primary parameters governing the morphological stable state of the system are the properties of its compressive and tensile components, the connection logic and nodal degrees kinetic freedom of the configuration also contribute signi ficantly to the resultant stability. These parameters essentially govern the Distributed Causality behavior of the system where a slight variation in the ini tial condi tions affect drastically the morphology of resultant varied stable state. Tensegrity structures, with its potential to configure itself into mul tiple stable states based on equilibrium states of its components, provides for a very efficient system to be explored for dynamic structural behaviors. Quite paradoxically, the kinematics of the system informs the static and final form of the configuration of the

system. The primary objec tive of studying Irregular Tensegrity Structures is to design a structurally dynamic Tensegrity system that inherently possesses a potential to adapt to the varying contexts and its respec tive demands, requirements and spatial needs.

References: 2.5 Manuel DeLanda, Material Complexity, Digital Tectonics - (2004), pg 14

31

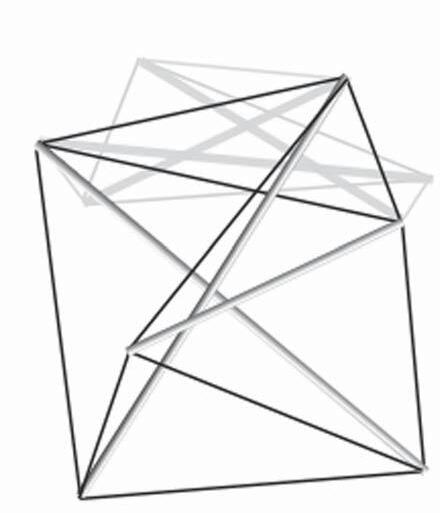

FIG 2.2 Diagram illustrating nonlinear behavior of Tensegrity System with multiple stable relaxed states existence from same unstable basic seed

DIGITAL TOOLS AND METHODS

SYSTEM

BEHAVIOR SIMULATION

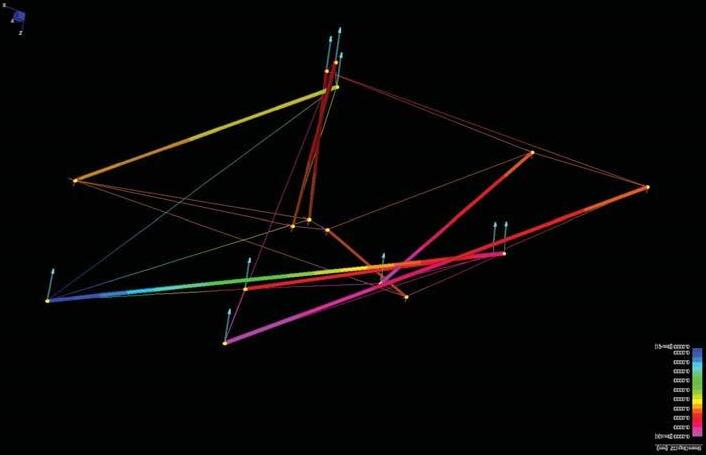

DIGITAL METHODS AND TOOLS

One of the most challenging constraints in studying the behavior of a complex dynamic system is the tedious nature of the conventional analog methods that comprises of tradi tional physical testing and mathematical analysis procedures. This results in the need for developing advanced digital tools and processes that can cope with the complexity of the system behaviors without complicating the usability of the tool interface. Thus while on one hand, digital analy tical methods facilitate for studying material and structural system behavior, properties and characteristics for enabling in-depth understanding and precise prediction of the system performance under varied conditions; on the other hand, digital simulations facilitate for optimal solu tions and performance. Kristina Shea, in her essay “Directed Randomness” explains the importance of computational generative design and its use with instantaneous

SYSTEM BEHAVIOUR ANALYSIS

GENERATIVE DESIGN

Optimised Output

STRUCTURAL PERFORMANCE

feedback to generate new forms and design solutions with optimized space usage, structural performance, thermal conditions, lighting effects and fabrication ease. Use of structural shape grammar combined with simulated annealing so ftwares like eifForm, enable producing results with structural efficiency, economic material use, member uniformity, satisfied structural feasibility constraints combined with aesthetics. Exploring the potential of this methodology for formal, morphological and structural configurations and variations is one of the main areas of research of the intended study.

References: FIG 2.3 http://www.citrinitas.com/history_of_viscom/computer.html

32

FIG 2.3 Illustration created in Processing which are the result of a non-linear physics-based model of keywords connected by springs.

DIGITAL METHODS FOR TENSEGRITY:

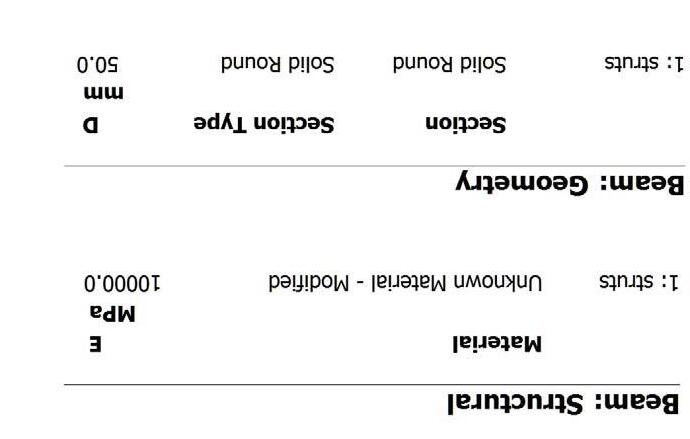

Tensegrity Structural Systems constitutes 3-dimensional stable mechanical structures that maintain its stability due to an intricate equilibrium of forces established between its rigid and disjoint compressive and continuous tensile components. Tensegrity structures not only exhibit an exceptionally high strength-to-weight ratio but also possess the unique property of retaining its stability in zero-gravity spaces. However, the determination of stable configurations that result from the connec tivity patterns between the compressive and tensile components is highly challenging. Thus the form-finding processes of the Tensegrity structures involve computational support juxtaposed with algorithmic approach to overcome the limitations of the available mathematical methods that have restricted scope of exploration. This research involves use of Evolu tionary Algorithmic approach to thoroughly investigate a set of arbitrary Tensegrity Structures which are di fficult to design using tradi tional methods and

determine new irregular forms with optimal architectural relevance. The procedure involves use of Dynamic Relaxation methods for simulating the material properties and system performance to obtain stable forms based on the input mechanical constraints and kine tic freedom. The rigorous analysis, evaluation, elimination and selec tion procedure aims at achieving optimal set of digitally developed and tested modules provide for the basis for next stage of design development and complexity based on organization logics of the emergent design.

References:

2.5 John Rieffe , Automated discovery and optimization of large irregular tensegrity structures

FIG 2.4 http://www.cabinetmagazine.org/issues/23/wertheim.php

33

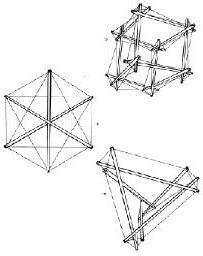

FIG 2.4. Examples of symmetric tensegrity structures produced by Robert Connelly and Allen Back using Maple and the open source visualization software, Geomview.

This sec tion briefly summarizes chronologically the various investigations undertaken and the respective inferences concluded by different researchers and scientists on Tensegrity systems. While studying the defini tions enabled a deeper system understanding, the contemporary research methods helped in developing theoretical physics base for scripting the algorithmic form finding process during the dissertation project.

BACKGROUND

Until the last century, the technique of construc tion and the philosophy of building have been very simple with everything being held in place by weight, so the continui ties of stress were basically compressive. Tensegrity structures are based on a quite an inverse concept wherein instead of the “weight and support” strategy, a “system of equilibrated omni-direc tional

stresses” is integrated. Furthermore, the system need not be supported as it is self-equilibrated and pre-stressed, thus independent of gravitational forces for equilibrium.

Tensegrities are spatial, reticulated and lightweight structures that basically consist of isolated compression members (rigid bars) suspended by a continuous network of tension members (cables). These highly intriguing structures, especially for their unique visual quali ties and topological characteristics, were first developed by artist Kenneth Snelson in 1948 as well as independently by David Emmerich. Buckminster Fuller further developed Tensegrity structures from Snelson’s ideas by applying engineering principles to the study. He also coined the term Tensegrity from “tensile integrity” as the integrity or stability of the system comes from the tension members. As implied by their name, Tensegrity structures to dynamic loading and exhibit non-linear behavior.

34

HISTORY

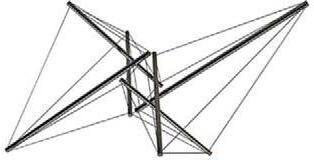

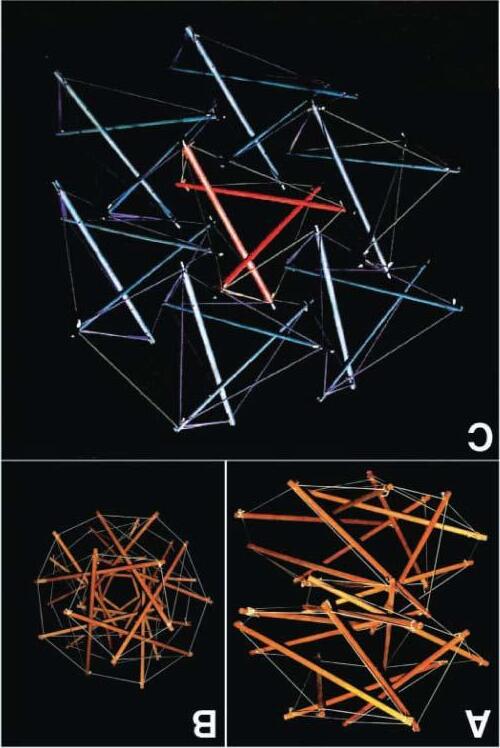

FIG 2.4 Earlier explorations of Tensegrity structures progressing from 3-strut to 8 strut models

FIG 2.5 Sketches of Kenneth Snelson Experiments explaining forces in a 3-strut Tensegrity module

FIG 2.6 Diagram explaining analogy of Inflated and Pneumatic structures behaving like Tensegrity Systems.

DEFINITIONS

FIG 2.7 Diagram explaining basic forces and components forming a Tensegrity structure

COMPRESSIVE STRUTS

TENSILE CABLES

DEFINITIONS

-Buckminster Fuller(1961)

-David Emmerich

-Kenneth Snelson(1965)

-Anthony Pugh(1976)

-Schodeck(1993)

-Bin-Bing (1998)

-Kanchanasaratool& Williamson (2002)

-Ariel Hanaor

-Miura & Pallegrino(2002)

-Rene Motro(2003)

FIG 2.8 Diagram listing chronological research and respective researchers. Refer Appendix for detailed study listed.

DEFINITION:

Although Tensegrity System has been highly researched with varied patented defini tions, the most widely accepted and comprehensive defini tion can be summarised by Anthony Pugh’s (1976) explanation, “A tensegrity system is established when a set of discontinuous compressive components interacts with a set of continuous tensile components to define a stable volume in space.”

A brief description summarizing all the di fferent patented defini tions by the researchers who have explored and experimented varied aspects of Tensegrity Systems, is listed in the Appendix sec tion for further reference.

References: Darrell williamson, robert e. Skelton, and jeongheon han, tensegrity structures and their application to architecture chapter 4. Definitions and basic principles equilibrium condi tions of a tensegrity structure

FIG 2.3 http://www.citrinitas.com/history_of_viscom/computer.html

35

OF

CHRONOLOGY

RESEARCH

CHARACTERISTICS

SYSTEM:

TENSILE NODAL FORCES

COMPRESSIVE

NODAL FORCES

In relation to the theory of systems, it has components (two kinds, in compression and in tension), relational structure (between the different components), total structure (associating relational structure with characteristics of components) and form (projected on to a threedimensioned referenced system).

STABLE SELF EQUILIBRIUM STATE:

The system is stable because it can re-establish after a disturbance, and self-equilibrated because it doesn’t need any other external condi tion; it is independent of external forces (even gravity) or anchorages due to its self-stress ini tial state. It is stable even in orbit.

COMPONENTS:

In contrast to the term “element”, the component can be a strut, a cable, a membrane, an air volume, an assembly of elementary components,

etc. The components are either in compression or tension as opposed to component being in compression and tension. There is continuous tension and discontinuous compression in the system because the compressed components must be disconnected, and the tensioned components are creating an “ocean” of continuous tension.

FALSE AND PURE TENSEGRITIES:

Motro defines a system as one of Tensegrity when all its compressed components are inside the system, and a compressed element is inside when the points between its ends do not belong to the boundary (or envelope). Thus, in a Tensegrity system, the action lines lying on the boundary surface are tension lines.

References: Darrell williamson, robert e. Skelton, and jeongheon han, tensegrity structures and their application to architecture chapter 4. Definitions and basic principles equilibrium condi tions of a tensegrity structure

36

FIG 2.9 Diagram explaining directional nodal tensile forces alongside and compressive nodal forces shown below.

FIG 2.10. Images showing physical models of False Tensegrity Structure on the left and True Tensegrity Structure on the right.

PROPERTIES OF TENSEGRITY STRUCTURES:

Very lightweight in comparison to other structures with similar resistance, or if preferred, they have a high resistance in comparison to other structures with similar weight.

No redundant parts, although new tendons can be added to consolidate the structure.

Do not depend on gravity due to their self-stability, so do not need to be anchored or leaned on any surface. The systems are stable in any posi tion.

The force of gravity, basis of the conventional architecture, is nulli fied. The majority of Tensegrity systems are enantiomorphic. This means that they exist as right and left-handed mirror pairs, “dextrose” and “sinistrose” respectively.

Elemental Tensegrity modules can be joined in order to create masts, grids or conglomerates made of the same or di fferent figures.

If the self-stressing is higher in a Tensegrity system, its load-bearing capacity is higher too. Using the analogy of the balloon, if a balloon is more inflated, the tension forces in the skin are greater and it is harder to deform it.

The degree of tension of the pre-stressed components is propor tional to the amount of space that they occupy.

As the components in compression are discontinuous, they only work locally. The compression is located in speci fic and short lines of ac tion, so they are not subject to high buckling loads. Due to this discontinuity in compression, they don’t su ffer torque at all.

Tensegrity is the minimal structure that can support a weight and oppose horizontal forces, that uses compression and tension, but experiences no torque.

The systems exhibit the property of synergy where the behavior of the whole systems is not predicted by the behavior of any of their components taken separately.

The resilience ( flexibility) or stiffness of the structure depends on the materials employed, and by their method of assembly. They can be very flexible or very rigid and quite strong. Due to this characteristic, they are very sensitive to vibrations under dynamic loads.

They have the ability of respond as a whole, so local stresses are transmitted uniformly and absorbed throughout the structure.

The response to the loads is non linear. Structures are more flexible under light loads, but their stiffness increases rapidly as the load is higher, like a suspension bridge.

Some Tensegrities, under axial load, experience a rotation around this axe. The direction of this rotation depends on the handedness of the system (enantiomorphic characteristic).

References: Darrell williamson, robert e. Skelton, and jeongheon han, tensegrity structures and their application to architecture chapter 4. Definitions and basic principles equilibrium condi tions of a tensegrity structure

37

FIG 2.11. Diagram explaining enantiomorphic property of prismatic dihedral symmetric structures.

ADVANTAGES

ADVANTAGES OF TENSEGRITY

The mul tidirectional tension network encloses fortuitous stresses where they take place, so there are no points of local weakness.

Due to the ability to respond as a whole, it is possible to use materials in a very economical way, offering a maximum amount of strength for a given amount of building material.

The systems do not experience any kind of torque or torsion, and buckling is very rare due to the short length of their components in compression.

One of the primary advantages of Tensegrity is the deployability and being able to be assembled in short time spans

Modularity is another prime characteristic of the system that makes the system potential of having complex system organization and hierarchies.

The fact that these structures vibrate readily means that they are transferring loads very rapidly, so the loads cannot become local. This is very useful in of absorption of shocks and seismic vibrations.

The spatial defini tion of individual Tensegrity modules, which are stable

by themselves, permits an exceptional capacity to create systems by joining them together. This conception implies the option of the endless extension of the assembled piece.

For large Tensegrity constructions, the process would be relatively easy to carry out, since the structure is self-scaffolding.

Burkhardt sustains that the construc tion of towers, bridges, domes, etc. employing Tensegrity principles will make them highly resilient and, at the same time, very economical.

The kinematic indeterminacy of Tensegrities is sometimes an advantage. In foldable systems, only a small quantity of energy is needed to change their configuration because the shape changes with the equilibrium of the structure.

The response to the loads is non linear. Structures are more flexible under light loads, but their stiffness increases rapidly as the load is higher, like a suspension bridge.

Some Tensegrities, under axial load, experience a rotation around this axe. The direction of this rotation depends on the handedness of the system (enantiomorphic characteristic).

38

FIG 2.12. Highly stable tensegrity structure that can be deployed and reconstructed in very less amount of time.

DISADVANTAGES OF TENSEGRITY

According to Hanaor Tensegrity arrangements need to solve the problem of bar congestion. As some designs become larger, the struts start running into each other.

The same author stated, after experimental research, “relatively high deflections and low material efficiency, as compared with conventional, geometrically rigid structures”

The fabrication complexity is also a barrier for developing the floating compression structures. Spherical and domical structures are complex, which can lead to problems in produc tion.

The inadequate design tools have been a limitation until now. There was a lack of design and analysis techniques for these structures.

In order to support cri tical loads, the pre-stress forces should be high enough, which could be di fficult in larger-size construc tions.

References: Darrell williamson, robert e. Skelton, and jeongheon han, tensegrity structures and their application to architecture chapter 4. Definitions and basic principles equilibrium condi tions of a tensegrity structure

DISADVANTAGES

39

FIG 2.13. Kenneth Snelson’s Sculpture in a process of being installed spanning the water body.

CLASSIFICATION

CLASSIFICATION

CONNECTION BASED

MORPHOLOGY BASED

TENSEGRITY GEODESIC ASSEMBLIES OF MODULES

SINGLE MORPHOLOGY

REGULAR IRREGULAR REGULAR IRREGULAR

CLASS 1CLASS 2

CLASS 1CLASS 2 MORPHOLOGIESMORPHOLOGIESASSEMBLIESASSEMBLIES

X SHAPETENSEGRITY POLYHEDRA PRISMATIC REGULAR TENSEGRITY CELLS

TENSEGRITY CIRCUITS DOUBLE X TRIPLE X TENSEGRITY CLOUD TENSEGRITY TOWERS TENSEGRITY RINGS

The primary aim of classifying the Tensegrity structures on various factors was to study the domain of the system, understand the proper ties and potentials of each classi fied typology based on available research and eventually narrow down the research process for selected typologies that essentially have greater design development potential.

CONNECTION BASED:

A. Tensegrity

B. Geodesic

MORPHOLOGY BASED:

A. Single Morphologies

B. Assemblies

A. SINGLE MORPHOLOGIES

The next level of classi fication of these single modules is based on the parametric properties of the components and the connec tion pattern resulting in Regular and Irregular morphologies.

1. Regular Morphologies

These regular structures can be further classified based on number of struts connecting at each node. A Tensegrity structure is classi fied as a structure of class ‘k’ when I has k number of struts connec ting at each node.

FIG 2.14. Diagram showing the classification of Tensegrity Structures. Refer Appendix for detailed classification listed.

i. Class 1 : These Tensegrity structures essentially have only one strut connecting at each node and at least 3 cables.

a. X-shape:

b. Prismatic Regular Tensegrity Cells:

c. Tensy-Polyhedra

ii. Class 2 : These Tensegrity structures essentially have 2 struts connecting at each node and at least 4 cables.

a. Tensegrity circuits

2. Irregular Morphologies

B. ASSEMBLIES

1. Regular Assemblies

i. Class 1

a. Double-x , Triple-x:

b. Tensegrity towers:

c. Tensegrity cloud:

ii. Class 2

a. Tensegrity rings

2. Irregular Assemblies

40

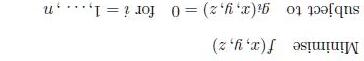

THEORIES AND METHODS

ANALYTICAL METHODS

KINEMATIC METHOD

STATICAL METHOD

STRUT LENGTH IS CONSTANT AND CABLE LENGTH IS DECREASED CABLE LENGTH IS CONSTANT AND STRUT LENGTH IS INCREASED

STRUTLENGTHISCONSTANTANDCABLELENGTH

TOPOLOGYANDFORCESINMEMBERSISGIVEN

TOPOLOGY AND FORCES IN MEMBERS IS GIVEN OR KNOWN

EQUILIBRIUM STATE IS CALCULATED AND FOUND OUT

ANALYTICALNON LINEAR DYNAMICANALYTICALFORCE DENSITY ENERGY REDUCED

SOLUTIONPROGRAMMINGRELAXATIONSOLUTIONMETHODMETHODCO ORDINATES

CONNELLY AND TERRELL PELLEGRINO MOTRO AND BELKACEM KENNER LINKWITZ AND SCHEK CONNELLY SULTAN

FIG 2.15. Diagram showing the classification of methods used to study Tensegrity Structures. Refer Appendix for detailed classification listed.

CONTEMPORARY RESEARCH AND THEORIES

Although Tensegrity structures have been around for 50 years, it is only recently that they have been analyzed from an engineering viewpoint with focus on system dynamics and mechanics. Most of the research uses Newtonian and Lagrangian dynamics to analyze Tensegrity structures exploring the form finding relationships (limited to symmetric examples) and force displacement associations. However, latest experimentation uses kinematic constraints to determine equilibrium Tensegrity posi tions using various kinematic methods.

Hanaor, in 1992, was one of the first ones to suggest that a kinematic method would be useful for posi tion finding. However, he stated: “Unfortunately, to the best of the author’s knowledge, no func tional algorithms are available to date using the kinematic method.”

Oppenheim and Williams, in 1997 describe in their ar ticles on Tensegrity prisms, use of kinematics and static matrices for incremental posi tion finding of variable geometry truss Tensegrity structures. They also discussed the force displacement relationships in elastic Tensegrity structures and investigated vibrations in these structures.

Sultan, Corless, and Skelton, in 2001 studied finding the equilibrium

posi tions of Tensegrity structures where prestress is allowed using a virtual work approach. They also published a paper on applica tion of a Tensegrity structure as a flight simulator.

Stern and Duff y investigated the self-deployability property of the system with articles presenting equations governing prisms and ini tial Tensegrity posi tions.

Pellegrino and Calladine analyzed statically and kinematically indeterminate structures with matrices.

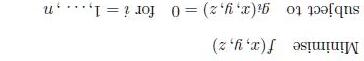

CLASSIFICATION OF ANALYTICAL METHODS:

A. Kinematic Method

1. Analy tical Solu tion

2. Non-Linear Programming

3. Dynamic Relaxation

B. Statical Method

1. Analy tical Solu tion

2. Force-Density Method

3. Energy Method

4. Reduced Co-ordinates

41

CASE STUDIES

PHYSICAL METHODS

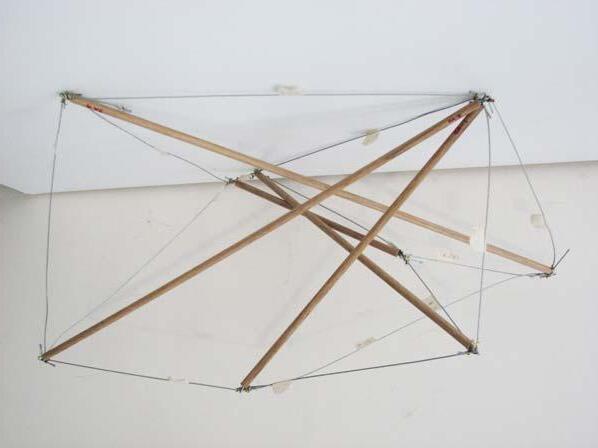

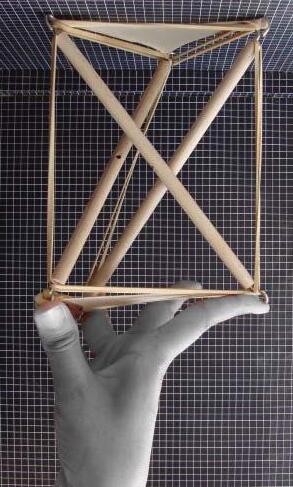

TENSEGRITY WORKSHOP AT SHEFFIELD UNIVERSITY: KONSTATINOS SAKANTAMIS, DR. LARSEN, E. GUTIERREZ

This two part workshop was aimed at developing exclusively only physical methods for form finding and exploring Tensegrity structures. Use of Cocoon methods for experimenting with Tensegri ties that can be developed inside membranes explored immense number of possibilities that Physical experimentation can o ffer using various methods. In addi tion to enhancing the understanding of the system, it also helped in architectural and spatial exploration of the system by designing enclosed spaces. The second part of the workshop further developed on the process and focused on assigning programmatic func tions to these spaces and sculptures thus applying the system to functional designs.

References: JKonstatinos Sakantamis, Dr. Larsen, E. Gutierrez, locomotion of a tensegrity robot via dynamically coupled modules

42

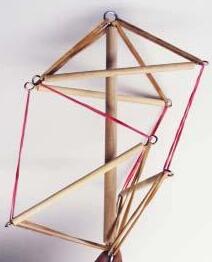

FIG 2.16. Images showing the physical experimentation process to study and design Tensegrity modules combined with cocoon concept.

FIG 2.17. Images showing series of physical models explored at a larger scale to build habitable Tensegrity modules.

ROBOTICS

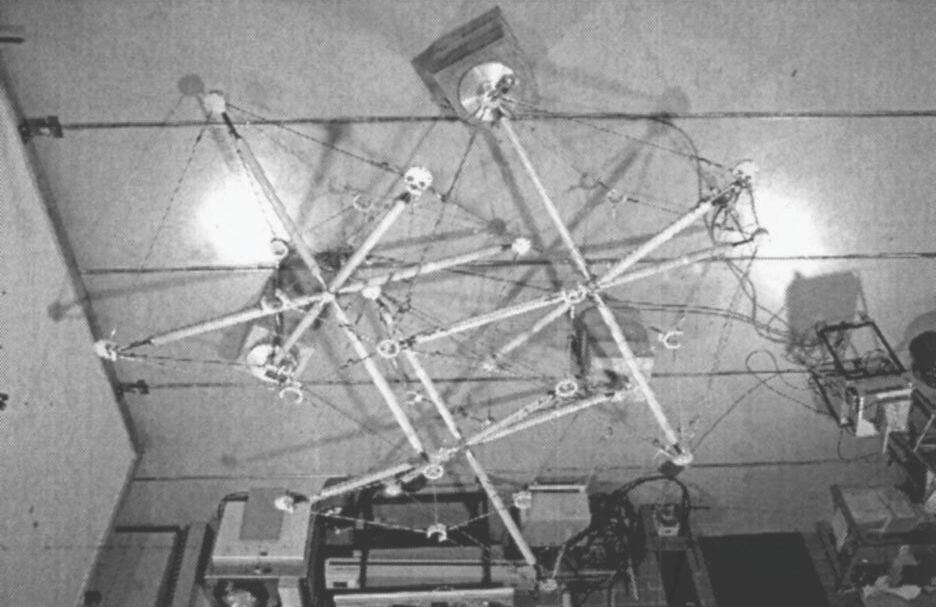

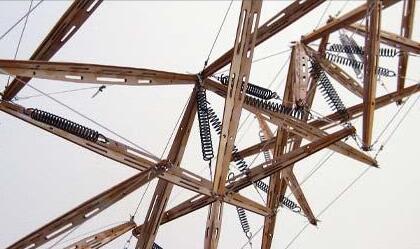

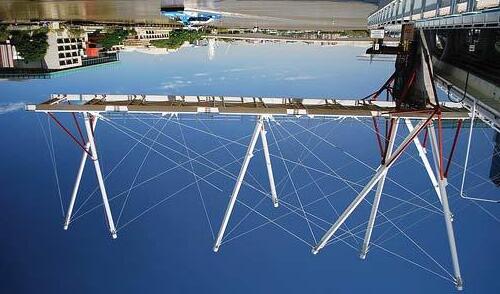

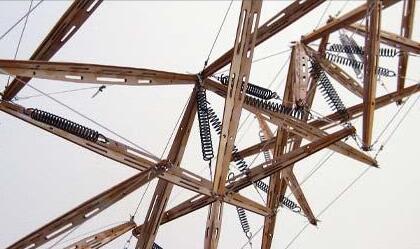

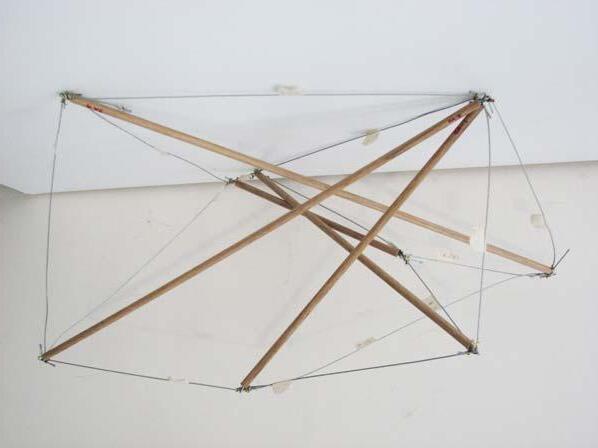

ADJUSTABLE TENSEGRITY STRUCTURES:

KRISTINA SHEA, BERND DOMER, IAN SMITH

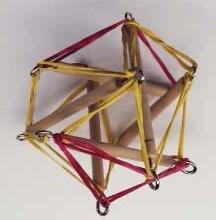

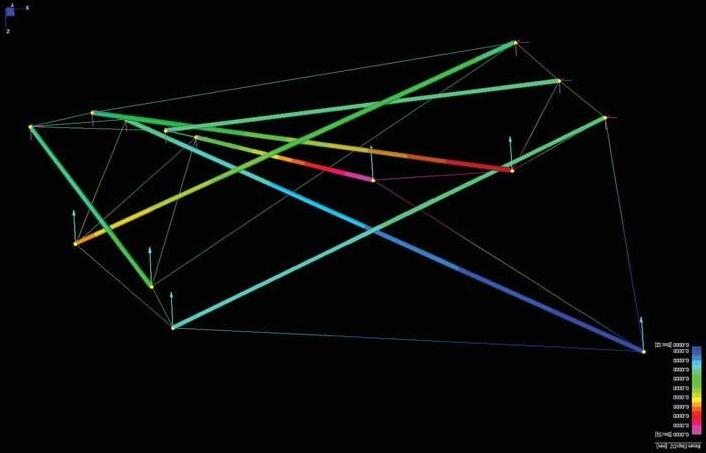

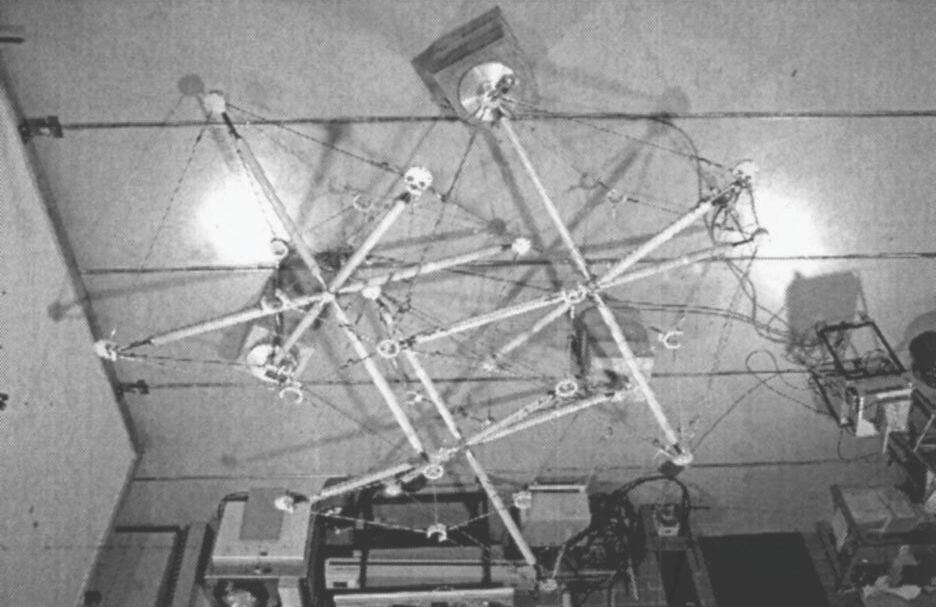

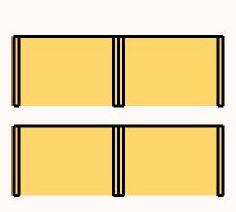

This experiment was aimed at exploring the deployable property of lightweight Tensegrityspace structures for construc ting reusable and modular structures. A full-scale prototype of an adjustable Tensegrity was designed, assembled and tested at Swiss Federal Institute of Technology (EPFL). In their paper, they describe the primary logics of the process. The results show that Tensegri ties behave linearly when subjected to vertical load at single point and non-linearly under several ver tical loads at nodes. The prototype consisted of three modules with each module composed of 4 struts and 24 cables. Telescopic struts are used to modify the geometry and self-stress of the system. 6 degrees of freedom are fixed at 3 supports of this modular geometry that consisted overall 33 joints and 90 elements (struts+cables). By measuring the cable frequency with a laser-based method, tension in individual cables was checked and calculated using

dynamic relaxation method. Numerical modeling was carried to compare physical behavior with analy tical calculations and to be able to predict the behavioral effect of adjusting telescopic struts.

Important highlights and learnings of case study:

- The most important aspect of the design was the joint detaililng, which needed to be pin-jointed, modular and light in order to retain the ease of deployability of Tensegri ties.

- While simulating the geometric non-linear behavior of the Tensegrity structures, it was necessary to consider the nodal fric tion forces.

- Changing the self stress to adapt to changing environments requires Tensegrities to be equipped with sensors and actuators.

References: John rieffel, ryan james stuk, francisco j. Valero-cuevas and hod lipson, locomotion of a tensegrity robot via dynamically coupled modules

43

FIG 2.18. Image of the Tensegrity model operated on robotic motors to produce rotational motion at the joints of struts.

FIG 2.19. Image of the rotational joint detail of the strut and cables joinery.

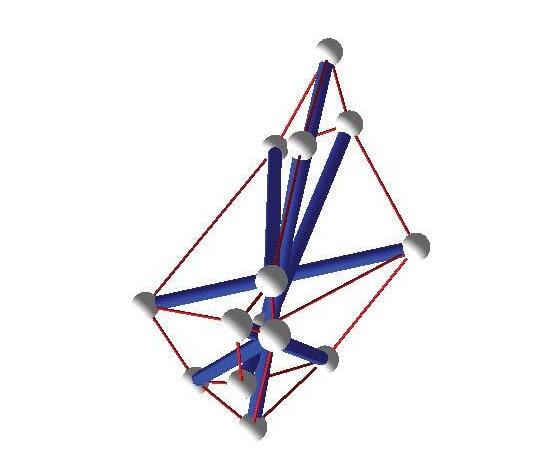

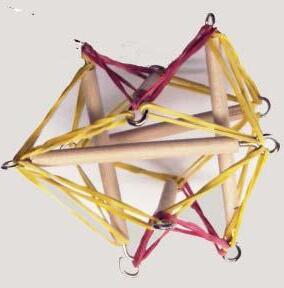

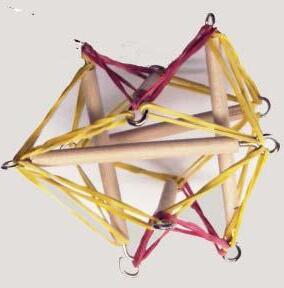

LOCOMOTION OF TENSEGRITY ROBOT:

JOHN RIEFFEL, RYAN STUK, FRANCISCO

VALERO CUEVAS, HOD LIPSON

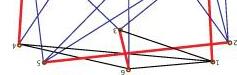

This investigation exploits the potential of the dynamically stable Tensegrity structures in the field of robo tics due to its relatively high strength-to-weight ratio, resilience to deformation and collapsibility. The modularity of components provide for modular design essen tial in robotics. In the experiment, each module is considered autonomous agent with no explicit inter-modular communication except the tension in the interconnec ting cables, which is the only information transmi tted and received between the modules. Thus the locomo tion arises through the complex inter-play of dynamic forces throughout the structure. Individual modules cable of sensing and a ffecting local tension are designed using servo robot motors capable of continuous rotation and load sensing. These modules are then connected using nylon strings as

time = ~0

time = ~7500 steps

time = ~15 000 steps

tensile elements. Artificial Neural Networks were used for capturing time-sensitive dynamics of the design. An analy tical approach using evolu tionary optimization was used to evolve morphology with the given number of sensors and its locomo tion and gait was successfully simulated and analyzed.

Important highlights of the Experiment:

- The experiment successfully integrates a complex dynamic Tensegrity system with suitable responsive sensory and control system and used the resultant morphological communication for producing locomo tion.

- The experiment also effectively combines the physical tests with digital simulations to produce the mechanical result by using one method to solve the complications of the other.

References: John rieff

44

el, ryan james stuk, francisco j. Valero-cuevas and hod lipson, locomotion of a tensegrity robot via dynamically coupled modules

FIG 2.20. Digital image of locomotion simulated by a digital Tensegrity robot.

FIG 2.22. Images showing different time stages of locomotion simulated for Tensegrity robot.

FIG 2.21. Image of the Tensegrity robot used for generating locomotion using Telescopic struts

CONCLUSION

As seen in the case studies and the characteristic properties of Tensegrities, it is fairly tedious and time consuming to explore the vast design space of form-finding using the conventional physical modelmaking methods. It is highly vital to approach this design problem in a more scientific and speci fic process, using algorithmic digital generative form-finding process. This not only enables to explore and test the wide form-finding domain, but also eliminates any biased preferences, thus allowing the result to be generated through purely scientific principles. The process also helps in detailed analysis and investigation of system behavior leading to conclusions and observations that would help in further devising processes to directly generate the desired result.

References: FIG 2.23 http://vi.sualize.us/view/7ff4037a987cac6d2b28a47ab4889870/

45

FIG 2.23. Digitally generated image representing complex behaviors

46

EXPERIMENTS

01 PRELIMINARY EXPLORATION Parameters

Regular Tensegrity

Irregular Tensegrity

Critical Analysis

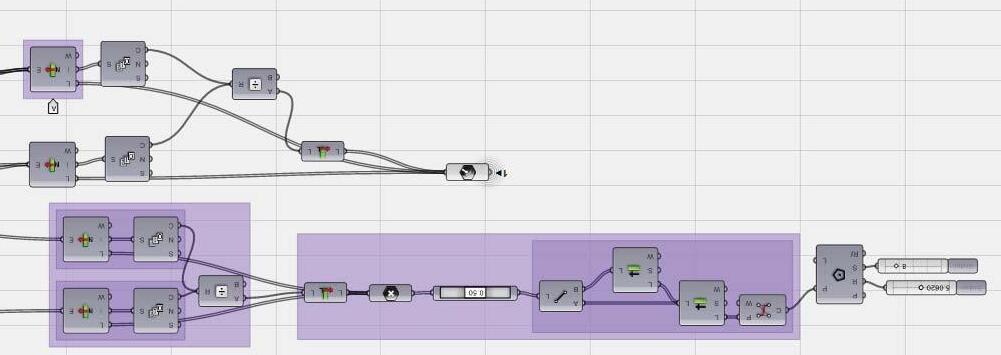

02 GENERATIVE ALGORITHM

Pseudocode

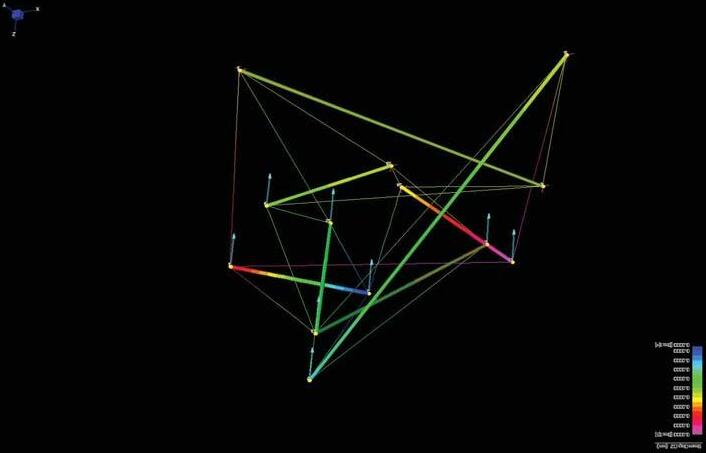

Morphology Generation Evaluation Stage 1

Evaluation Stage 2

03 STRUCTURAL TESTS

Linear Static Analysis

Linear Buckling Analysis

47 CHAPTER 03.

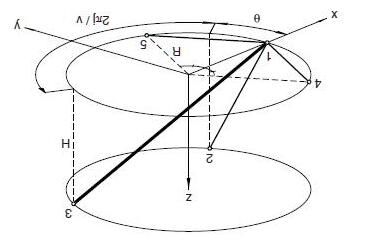

PARAMETERS

GOVERNING PARAMETERS

NOMENCLATURE Example

STRUT LENGTH DIMENSIONS

CABLE LENGTH

CONNECTION

LOGIC NUMBER OF FORM CABLES

NUMBEROFFORM FINDING

NUMBEROFNONFORM NUMBER OF NON FORM FINDING CABLES

NODE FIXED IN X,Y,Z PLANE

DEGREES OF

FREEDOM NODE FIXED IN Y,Z PLANE

NODEFIXEDINZPLANE NODE FIXED IN Z PLANE

PARAMETERS

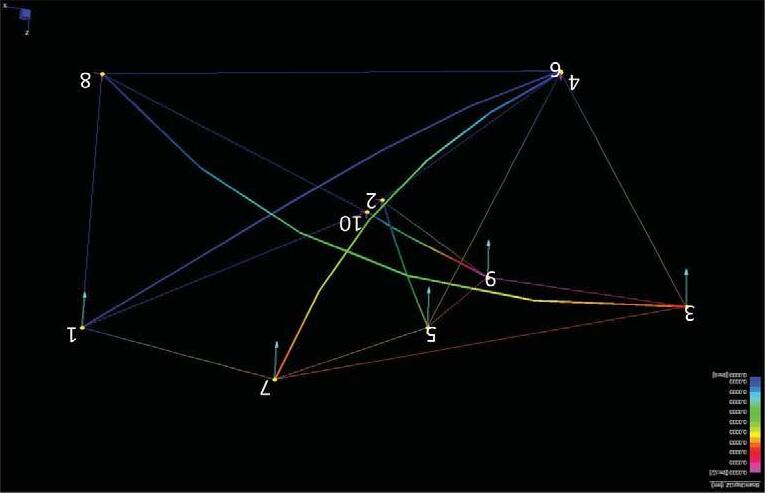

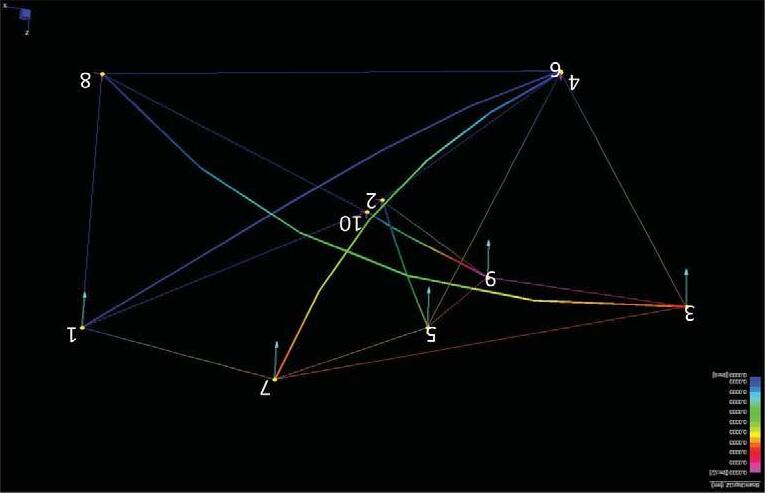

In order to understand and predict the Tensegrity system behavior, it was necessary to first study the parameters that govern the stable morphology of geometry. The preliminary set of experiments intended to study the effect of variation of these governing parameters on the form and stability of Tensegrity geometries. This experiment was carried out by varying component proper ties in unstable basic seed geometry and consequently observing the resultant variation effect in the stabilized morphology of the geometry.

NOMENCLATURE

GOVERNING PARAMETERS

The primary governing parameters of the stable form of the geometry are the component properties. The lengths of the compressive struts and tensile cables have a defini tive role in the resultant stable morphology. A slight variation in the lengths of either struts or cables resulted in considerable variation in the resultant stable morphology. This property was very signi fi cant in exploring the dynamism of Tensegrity modules in the further research.

The cables were divided further into 2 categories based on their role in form-finding of stable geometries from unstable seeds. The cables that

In order to document the variation of parameters, it was essential to develop a nomenclature that identified each geometry based on its set parameters. This would further help in comparison study of the various relaxed geometries from the same parent basic seed.

48

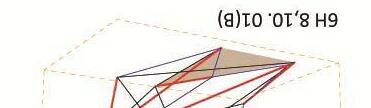

8H BS 8,10 NODE (7 8 9) ( ) NUMBER LETTER NUMBER NUMBER , NUMBER NUMBER NUMBER BS NODE NUMBER OF STRUTS BASIC SEED ID BASIC SEED NUMBER OF FORM NUMBER OF NON NODE FIXED IN NODE FIXED IN NODE FIXED IN FINDING CABLES FORM FINDING CABLES X,Y,Z PLANEY,Z PLANEZ PLANE

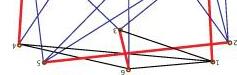

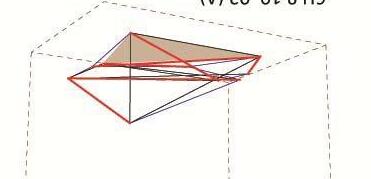

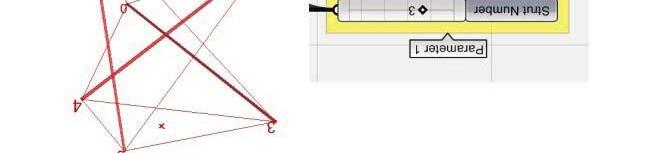

FIG 3.1. Diagram explaining the set of parameters that govern the stability of a Tensegrity structure.

FIG 3.2. Diagram explaining the nomenclature method adopted to represent the digitally explored modules.

MAXIMUM VOLUME

connected the nodes vertically (connec ting top plane nodes with bo ttom plane nodes; shown in blue) were the form-finding cables and were given elastic properties during relaxation process. The cables that connected nodes in the same plane (connected either top nodes only or bo ttom nodes only; shown in black) were the non-form finding cables and were given non-elastic (truss like) properties during relaxation. The struts (shown in red) also were given non- elastic (truss-like) proper ties while relaxing the unstable seed. The number of elastic and non-elastic cables at each node also played a crucial role in the stabilized morphology. Thus the connection logic of the basic seed is an important stability governing parameter.

The non-linear dynamic behavior of the system was further depicted when the variation in degrees of freedom was experimented with. In order to achieve a stable geometry from the basic seed at-least 6 degrees

MINIMUM VOLUME

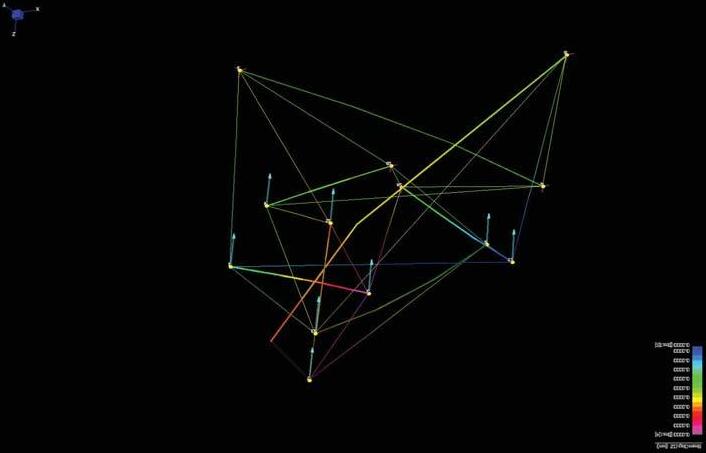

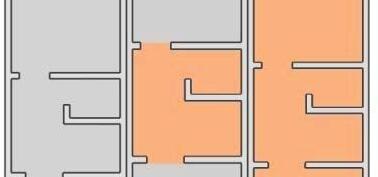

FIG 3.3. An example here shows an unstable 6 strut basic seed with 8 form-finding and 10 non-form-finding cables which was relaxed with 3 different set of nodes namely; node set -7,8,9; node set – 8,10,12 and node set – 7,10,12. Further, 3 orders of same sets were tried out where each node was fixed in different translational axes and relaxed. It was observed that mostly varied morphologies were generated with certain combination producing maximum volume and some combination resulting in flattened minimized volumetric geometries. However, sometimes different combinations resulted in similar relaxed morphologies. Further experimented also showed that certain combinations failed in producing any stable forms.

of freedom among 3 nodes needed to be fixed. Hence a set of 3 nodes was randomly chosen and each of the three nodes was fixed in x-y-z planes, y-z planes, and z plane respec ti vely. Thus 6 degrees of translati onal mo tion were fixed while rotational movement was allowed. This firstly helped in fi xing the geometry in space for relaxation and secondly depicted the multiple stability property of Tensegri ties. Even changing the order of node fixation within same set of fixed nodes resulted in highly varied relaxed geometries.

49 BASIC SEED RELAXATION

SET 8, 10, 12 NODE SET 7, 10, 12

SET 7 ,8

NODE

NODE

,9

SIMILAR MORPHOLOGIES

REGULAR MORPHOLOGIES

REGULAR MORPHOLOGY VARIATION

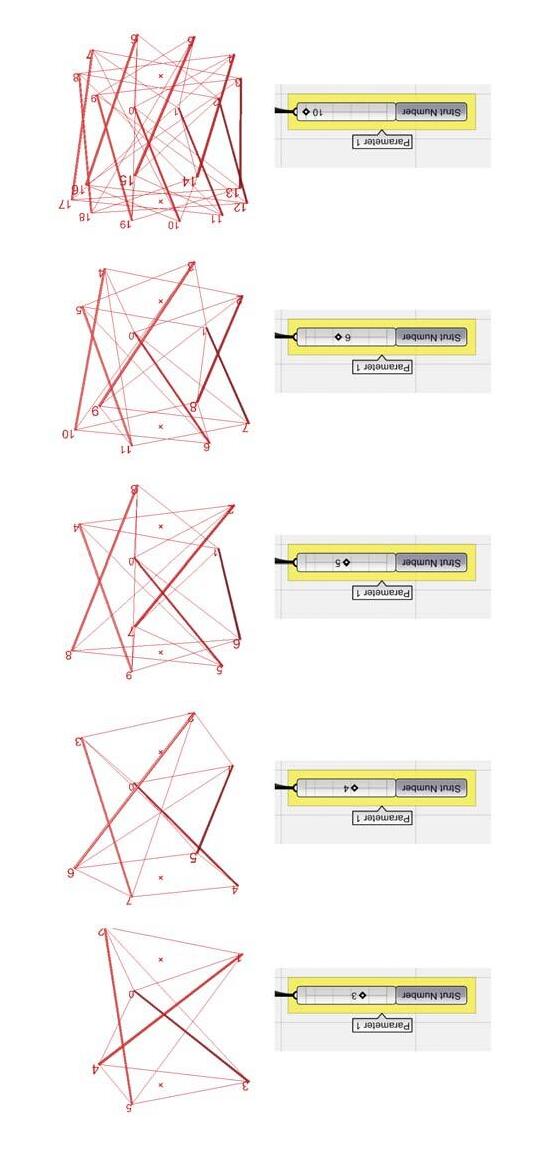

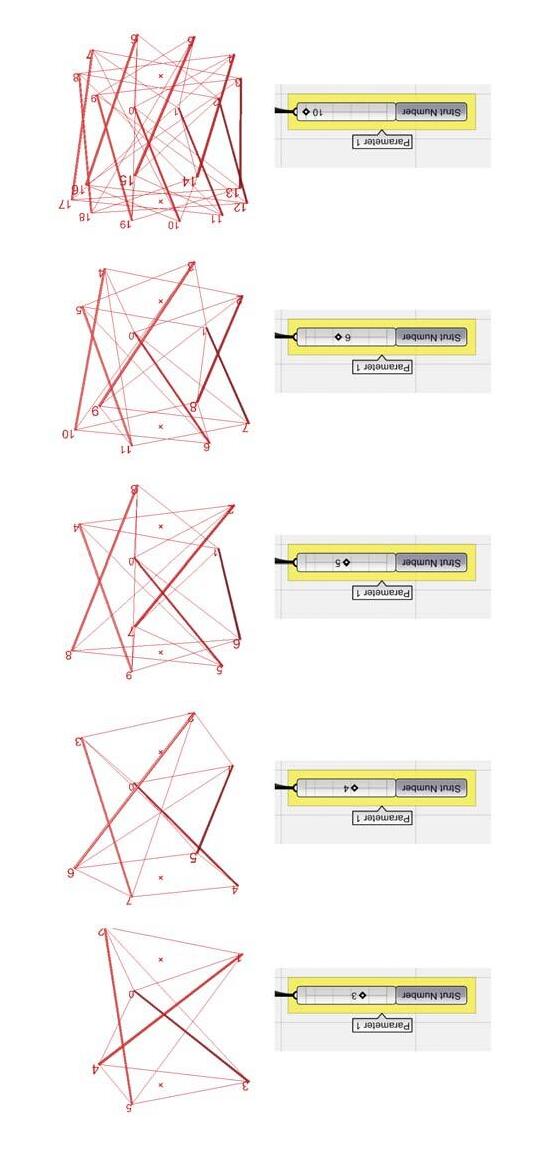

STRUT NUMBER

DIHEDRAL PRISMATIC TENSEGRITY RADIUS

STRUTNUMBER HEIGHT

TENSEGRITY RINGS

STRUT NUMBER RADIUS

HEIGHT

TRUNCATED

STRUT NUMBER POLYHEDRA RADIUS

HEIGHT

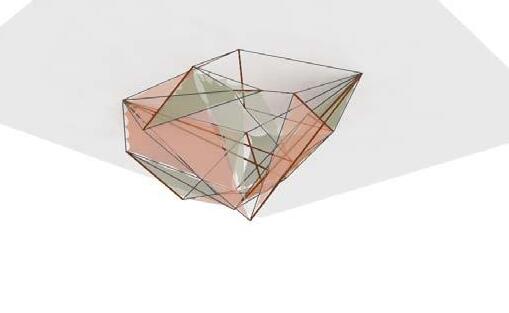

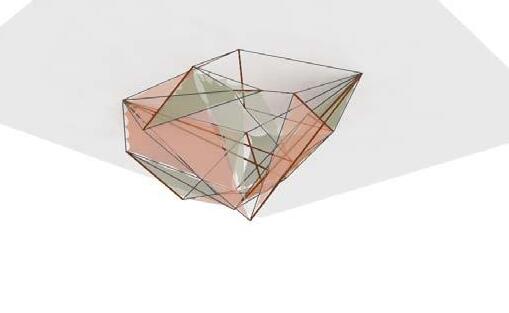

REGULAR MORPHOLOGIES

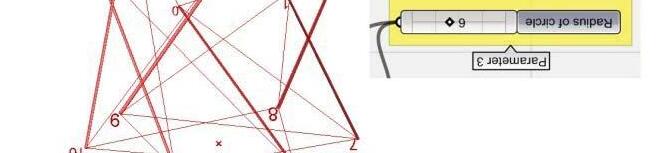

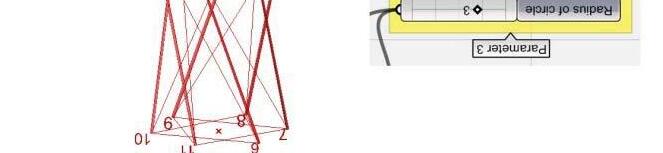

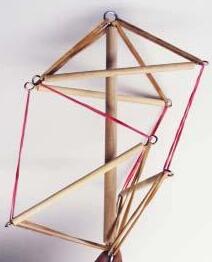

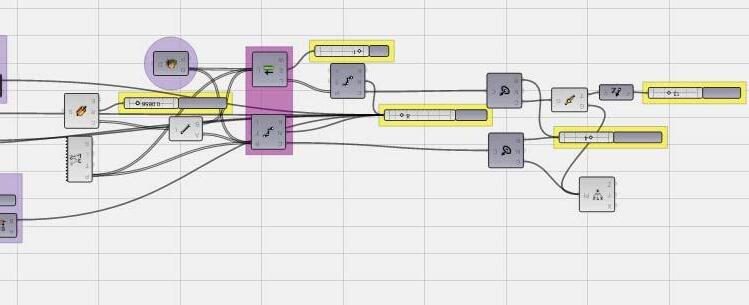

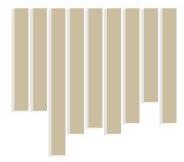

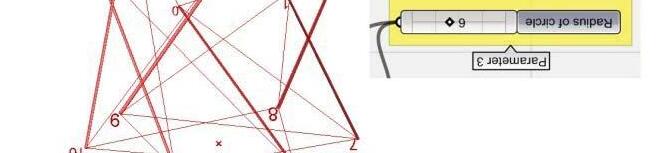

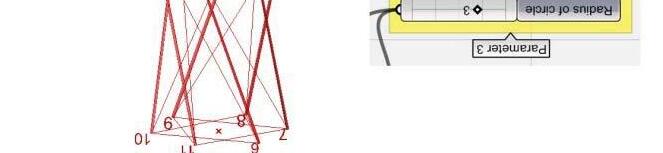

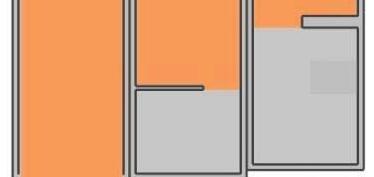

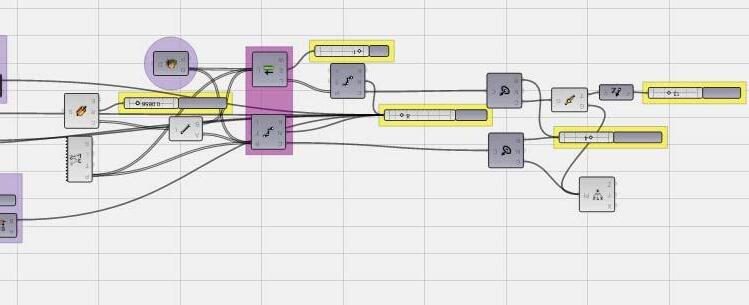

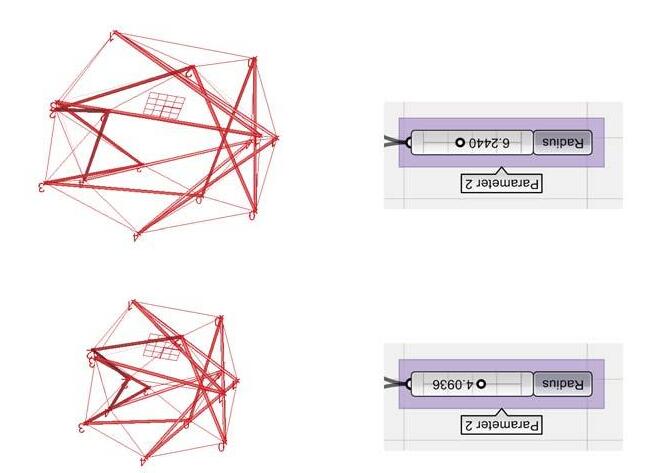

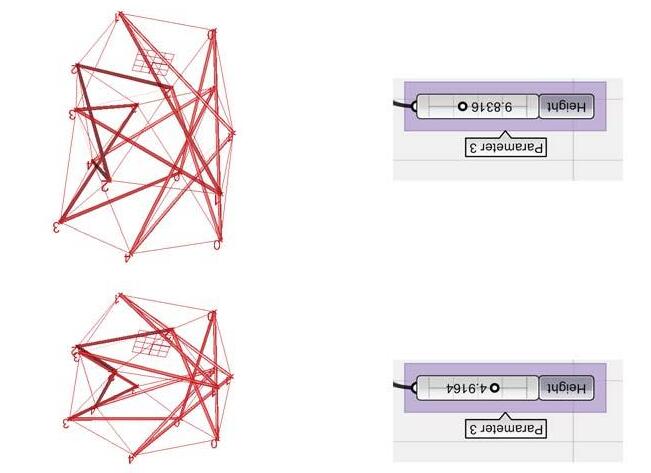

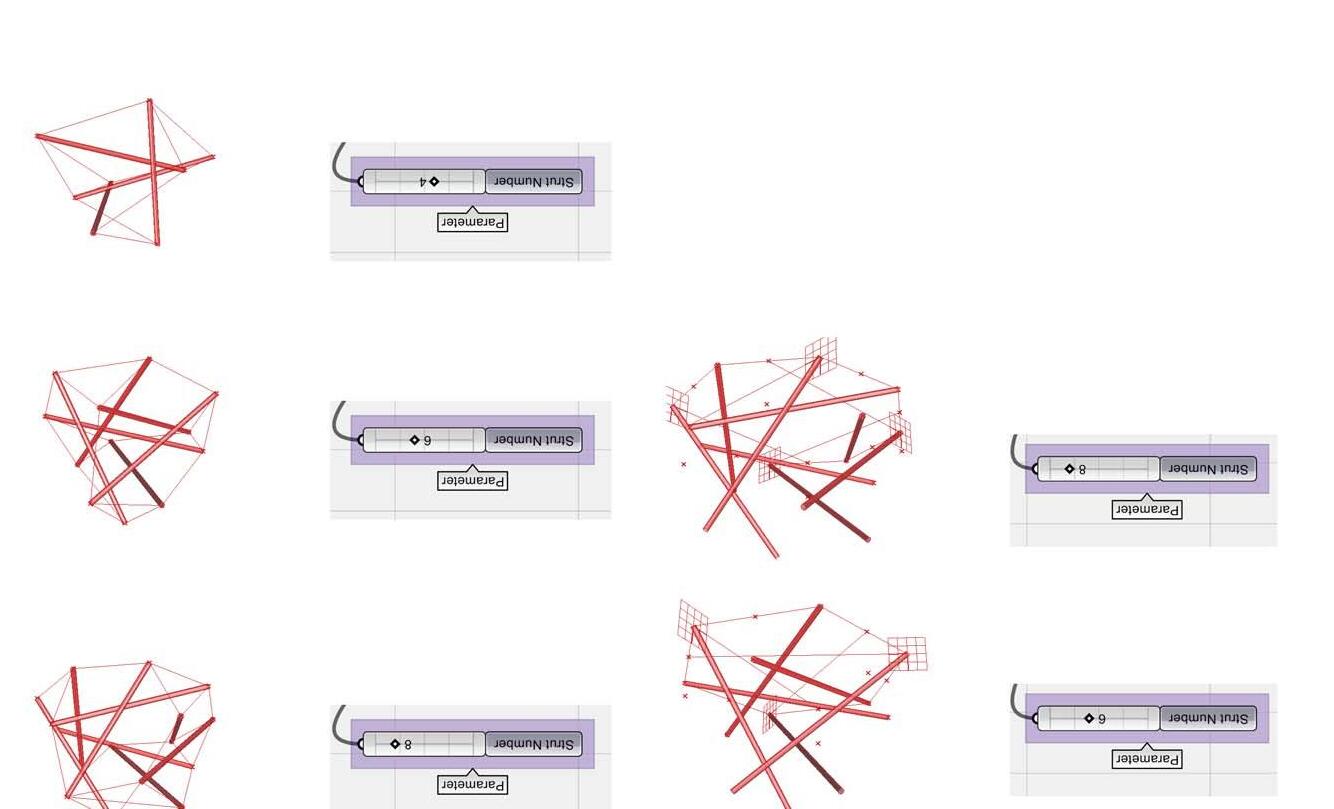

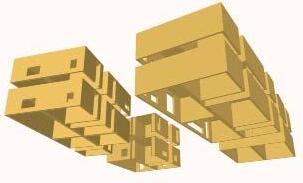

The next step of investigation involved testing both regular and irregular morphologies under the same set up of experiment for a comparative analysis. The symmetric characteristic feature of regular morphologies implied that any variation in the connec tion logic and nodal degrees of freedom would not result in any variation as the result was essentially the same. Hence the only varying parameter was the component dimension. As the geometry had to be essentially regular, the dimensions of all the component sets had to be propor tionately varied. The digital experimentation was carried by parametrically changing these component properties in Grasshopper interface in Rhinocerous and spatial variation was physically explored using respec ti ve models of each type of regular Tensegrity explored.

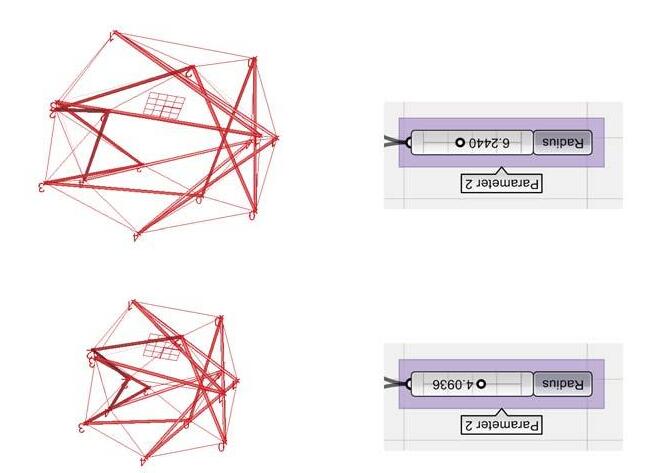

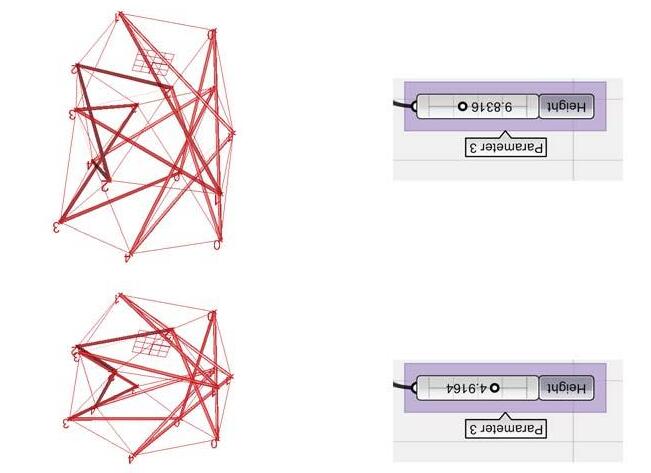

The dihedral prismatic regular Tensegrities were varied in strut numbers, planar radius (which essentially was variation in lengths of non-form finding cables), and variation in height (which was variation in lengths of form-finding cables). The same set of parametric experimentation was carried out for other selected Regular Tensegrities namely; Tensegrity rings and Truncated Polyhedral Tensegri ties which has been detailed out in the Appendix sec tion.

A considerable alteration in the enclosed volume was observed in each resultant varied geometry. However, the spatial condi tions and di fferentiation was almost non-existent as all the geometries has consistently similar morphology.

50

FIG 3.4. Diagram explaining the set of parameters that govern the stability of a Tensegrity structure.

FIG 3.5. Images of physical models of the regular morphologies explored for the spatial conditions exhibited.

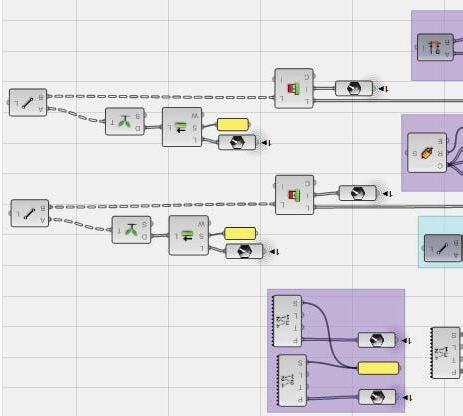

FIG 3.5. Diagram of the Grasshopper parametric digital model or regular tensegrity structure explaining the changing strut number and its corresponding resultant morphology change.

FIG 3.6. Diagram of the Grasshopper parametric digital model or regular tensegrity structure explaining the changing morphology height and its corresponding resultant morphology change.

FIG 3.7. Diagram of the Grasshopper parametric digital model or regular tensegrity structure explaining the changing morphology diameter/radius and its corresponding resultant morphology change.

51 STRUT NUMBER HEIGHT RADIUS

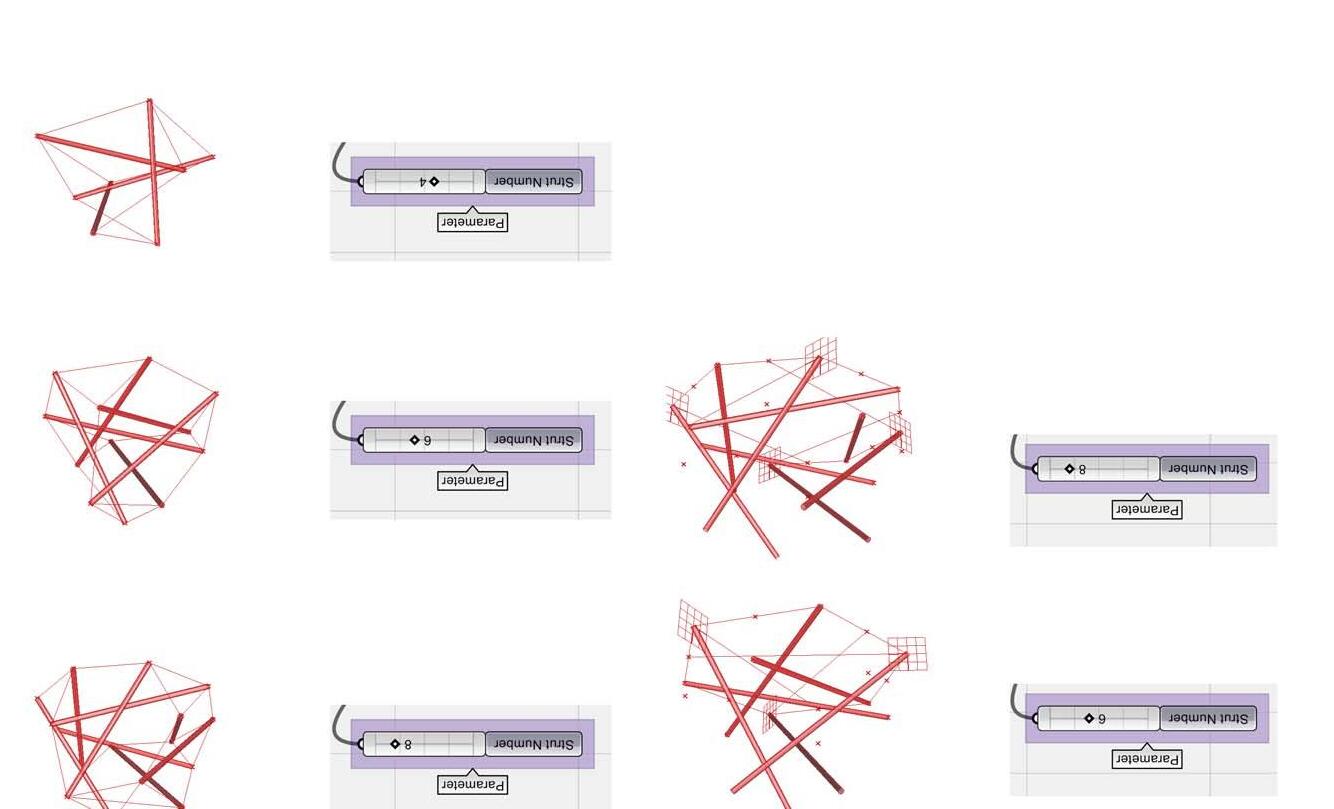

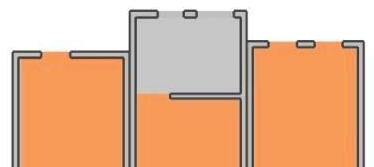

IRREGULAR MORPHOLOGIES

BASIC SEED

RELAXED FORMS

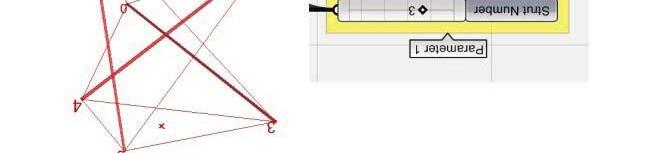

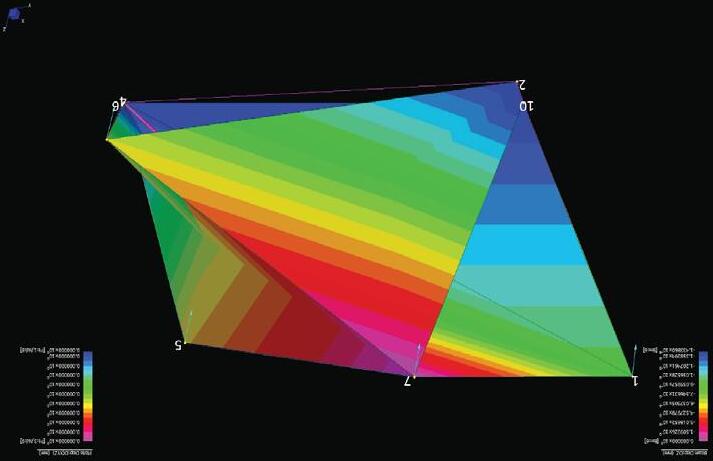

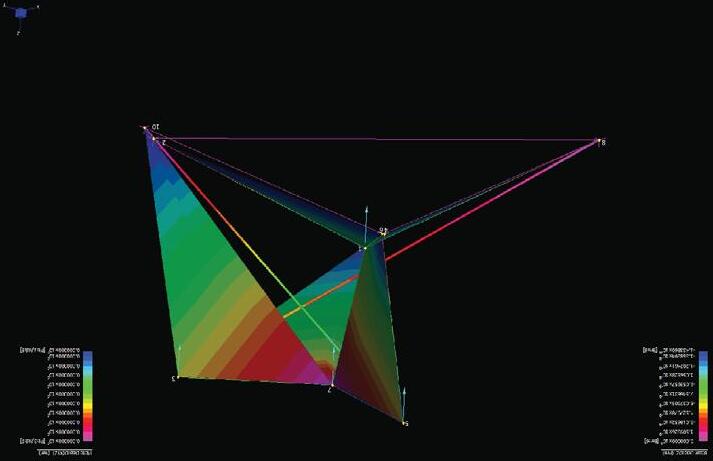

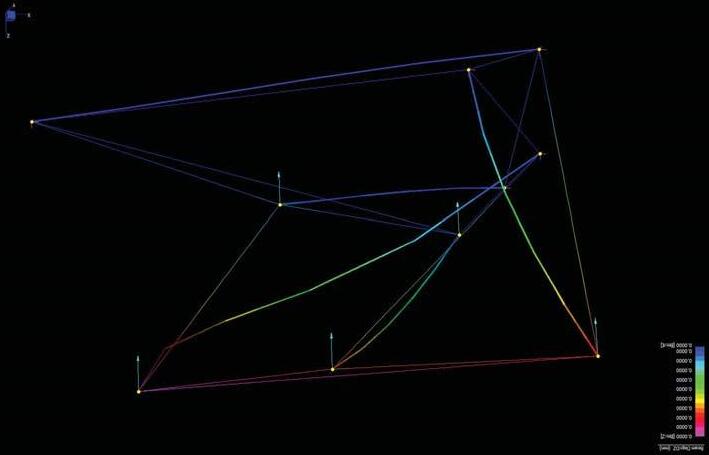

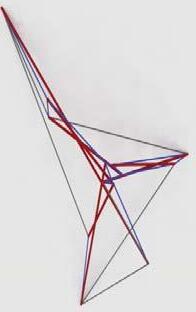

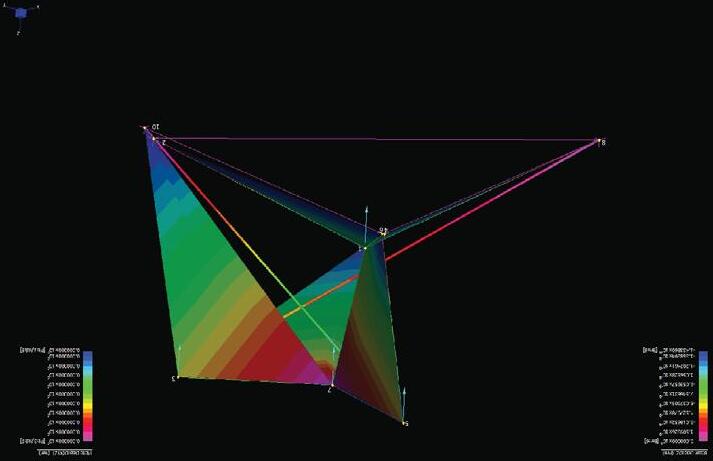

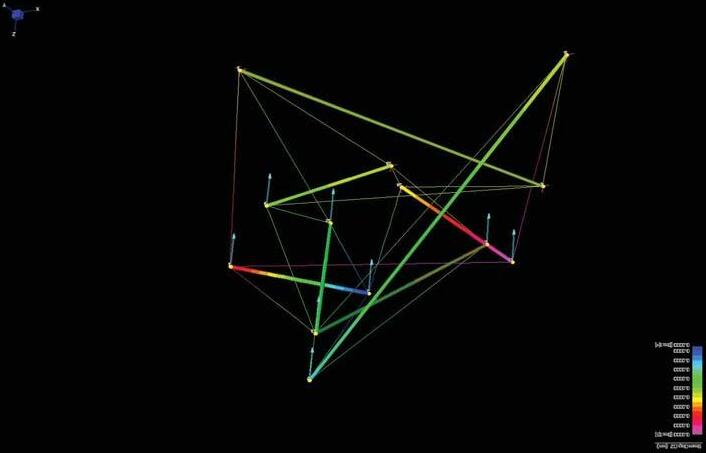

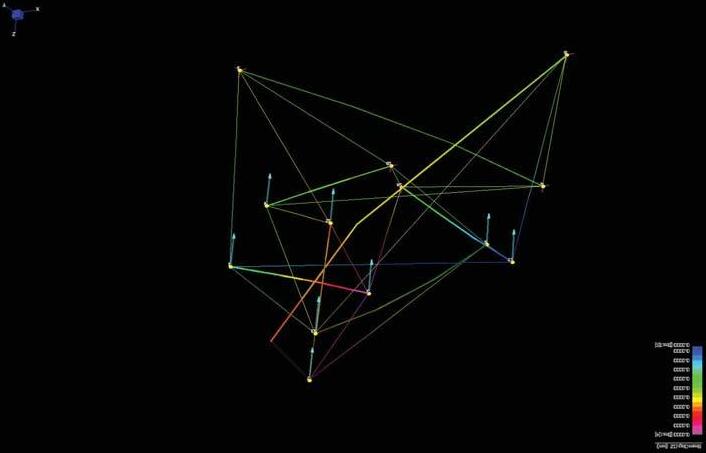

IRREGULAR MORPHOLOGIES

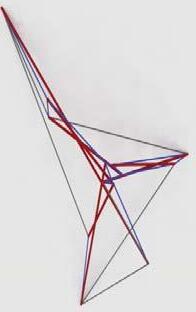

The similar experimentation set up was tested on Irregular morphologies by varying strut number from 4 strut to 9 strut. Subsequently, variation in component dimensions i.e. strut and cable length was tested for resultant variation followed by variation in nodal connec tion logic and degrees of freedom. The diagrams above show examples of the resultant variation; a detailed analy tical study of which is listed in the Appendix sec tion for detailed reference. The variation was limited to one parameter at a time and was carried out in Rhinoceros, while Rhino-membrane plug-in was used for relaxation process.

52

FIG 3.9. Images of physical models of the irregular morphologies explored for the spatial conditions and multiple stable states exhibited.

FIG 3.9. Digitally produced stable states of tensegrity geometry from the single basic seed shown above.

COMPARATIVE ANALYSIS

A comparative analysis between the Regular and Irregular morphologies resulted from the preliminary experiment conclusions was carried out. It was observed that regular morphologies generated proportional variation in the volumes and orientation of resultant geometries. The regular geometries were also more predictable and behaved linearly as opposed to non-linear behavior of irregular Tensegri ties. However, architecturally, irregularly generated morphologies could be di fferentiated in terms of spaces in contrast to the uniform spatial condi tions of regular Tensegri ties. Also, the potential of creating limitlessly varied morphologies of the system provide for possibility of diverse design applications in various topological contexts. This characteristic diversity in irregularly generated modules provides potential of higher complexity and further variation when organized in di fferent hierarchical manner.

CRITICAL ANALYSIS

53

PSEUDOCODE

FIXED PARAMETERS

CLASS CLASS 1 STRUCTURES ONLY 1 STRUT AND 3 CABLES AT EACH NODE

MOVEMENT 3 FIXED BASE POINTS

O1S3CS

VARIATION

DIGITAL APPARATUS

NUMBER OF STRUTS

NUMBER OF SEEDS

6 DEGREES OF FREEDOM FIXED TRANSLATIONAL VECTORS FIXED, ROTATION (, FREEDOM ALLOWED)

MIN = 3 STRUTS

MAX = 9 STRUTS

MIN = 5 VARIED BASIC SEEDS

MAX = 10VARIED BASIC SEEDS

MIN = 3 NODE COMBINATIONS

NODAL SEQUENCE PERMUTATION

MAX = 5

MIN = 3 VARIATIONS

MAX = 6 VARIATIONS

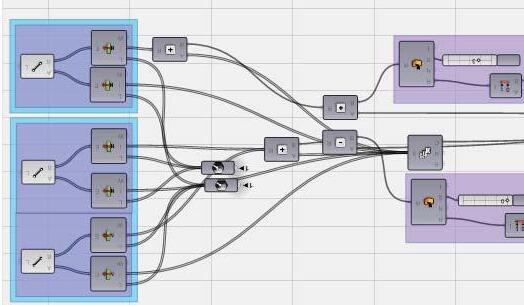

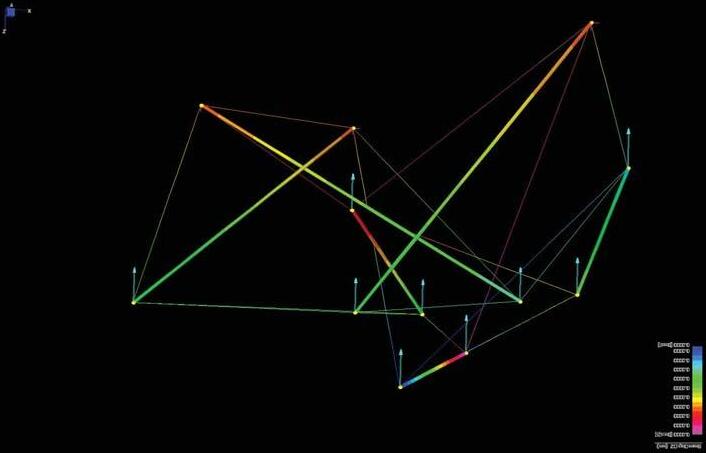

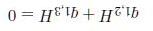

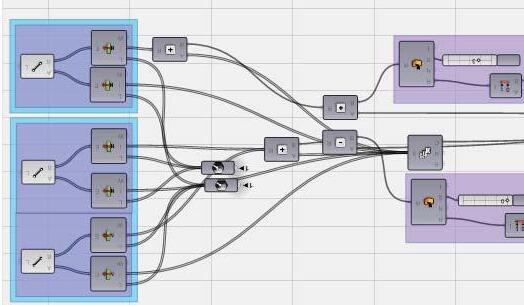

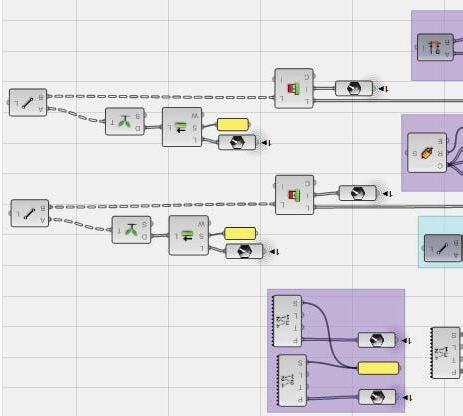

The next step involved setting up the digital apparatus for the experimental exploration of irregular morphologies. Since the design domain was so wide and limitless, it was essential to fix the above listed parameters to limit the boundaries of experiment that involved first generating a widely variant set of unstable basic seeds which would be later relaxed in its mul tiple stable states respectively followed by intensive evaluative elimination process. In order to generate randomly variant ini tial population, a generative script was written in Rhinoscript following the pseudo-code shown alongside. The detailed algorithmic pseudo-code followed is described in the Appendix sec tion for further reference.

STEP 1

The first step involved generation of the unstable basic seed based on the input parameter of number of struts. Considering N number of strut is input in the script, the process generates 2N number of symmetric nodes divided in 2 plane (each plane with N nodes) in a circular equidistant manner. These nodes are then randomly connected by 4N number of links such that each node has 4 set of links. These links are then randomly assigned component proper ties with the limitation of each node bearing one strut and 3 cables. The struts and cables are now randomly exchanged and shu ffled without changing the limitation of number of struts and cables at each node but producing a variant basic seed morphology.

54

FIG 3.10. Diagram explaining the set of fixed parameters and constraints decide for the digital form-finding experiment.

STEP 1

BASICSEED GENERATION

STEP 2

RELAXATION FOR STABLE FORM

STEP 3

PROPERTY OF RELAXED FORM

INPUT = NUMBER RIGID PROPERTY INTERSECTIONS OF STRUTS (N)

STRUTS ASSIGNEED CALCULATE STRUT

CABLES ASSIGNED PRESTRESS VALUES NODES GENERATION

ATLEAST 3 VOLUME OF BOUNDING NODES FIXED BOX OF FORM

ATLEAST 6 DEGREES OF FREEDOM FIXED CONNECTING LINKS

ASSIGNING SSGG PROPERTY

GEOMETRY RELAXED (i RhiMb ) (using RhinoMembrane

BASE AREA OFFORM RELAXED FORM OF FORM

MAXIMUM CLEAR RANDOM SHUFFLING HEIGHT OF GEOMETRY

BASIC SEED

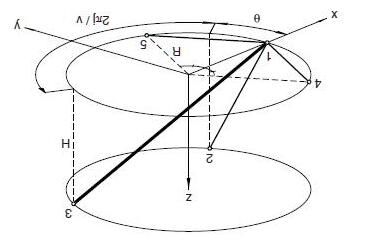

STEP 2

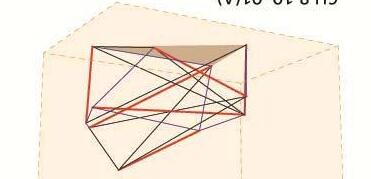

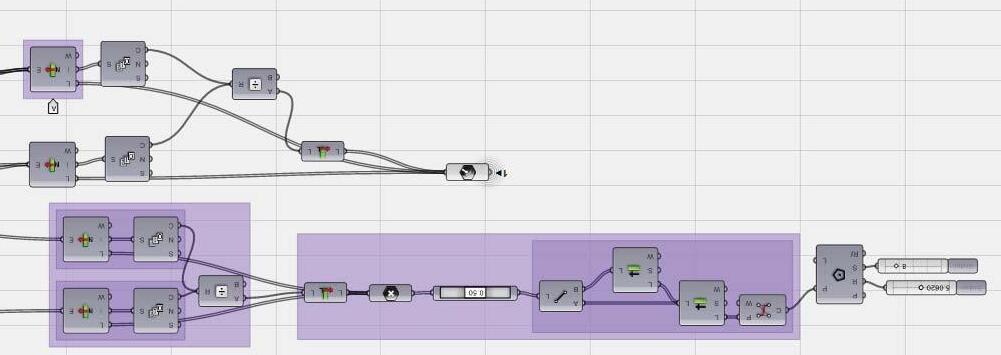

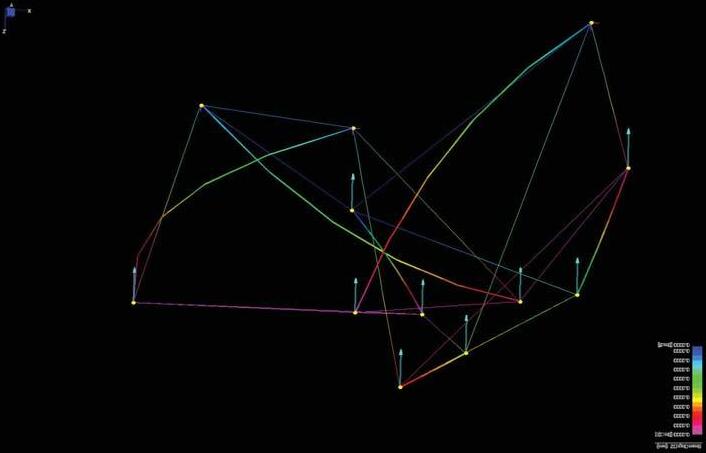

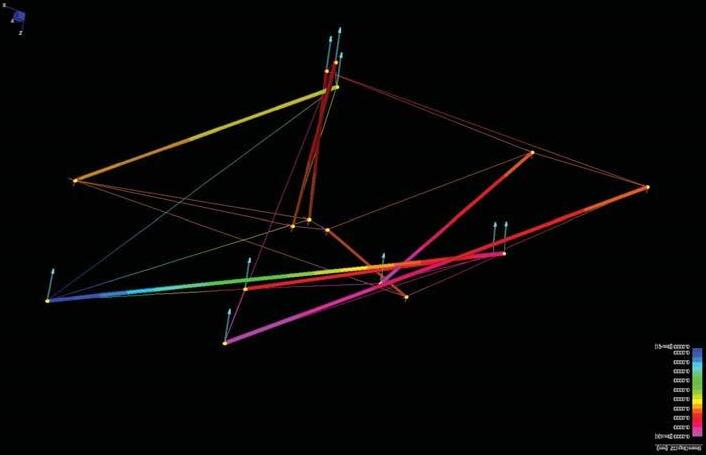

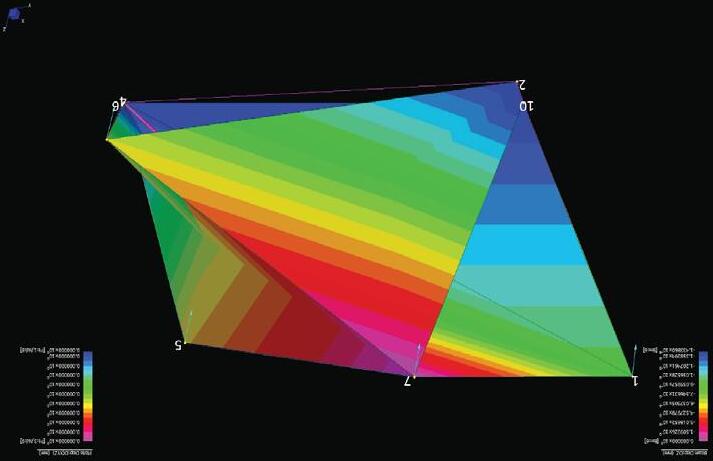

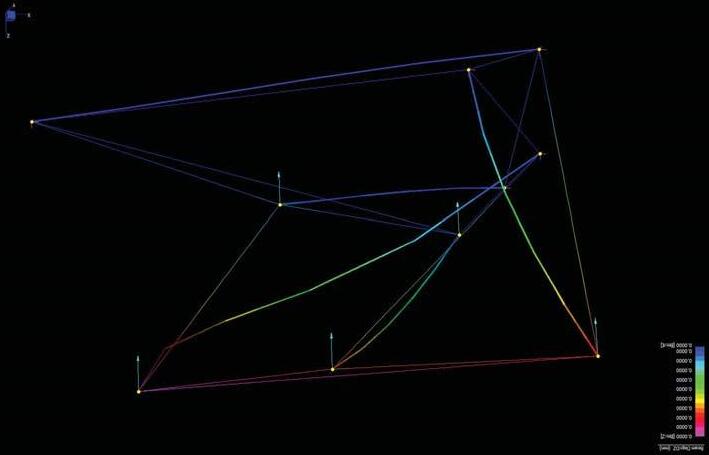

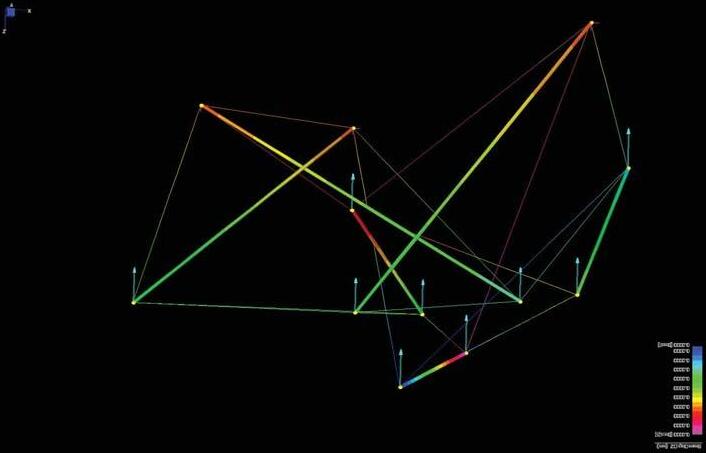

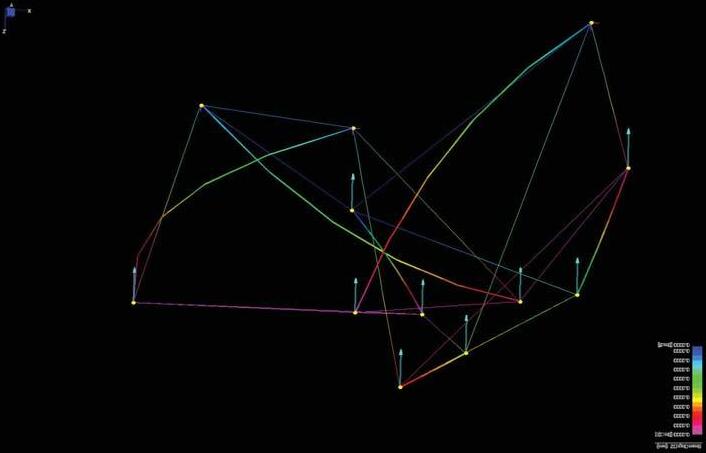

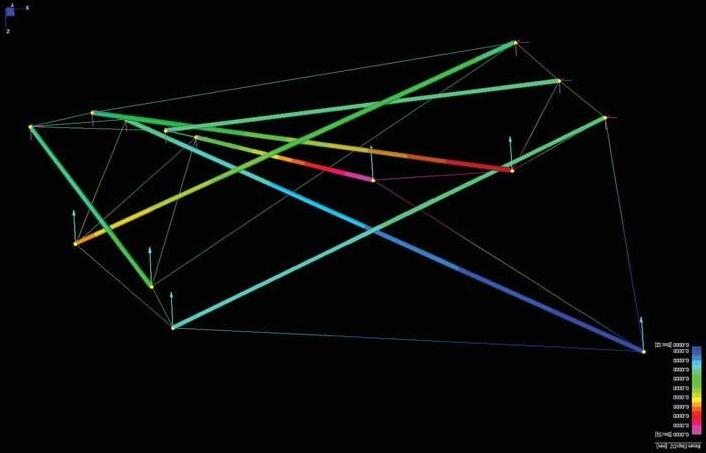

The second step involved obtaining relaxed morphologies from the unstable basic seeds by firstly assigning non-elastic properties to struts and non-form finding cables, and assigning elastic properties to formfinding cables. As mentioned before, the form-finding cables were the links connec ting nodes vertically and non-form-finding cables connected the nodes horizontally in same plane. This was followed by selecting randomly set of 3 nodes and fixing these nodes in x-y-z planes, y-z planes and z plane respec tively, thus fixing 6 degrees of freedom in translational motion. The basic seed was then relaxed using Rhino-membrane plug-in interface.

3.11. Brief Psuedo-code of the process followed in the digital generative algorithmic form-

STEP 3

In order to further compare and evaluate the produced geometries, each of the resultant morphologies were digitally tested for their characteristic spatial properties of enclosed volume, base area and clear height. An algorithmic script was wri tten to calculate these properties to be able to calculate the closest proper ties as precise calculation was not only tedious but computationally time-consuming. For volume calculation, bounding boxes enclosing the geometry were generated where each bounding box was aligned with each one of the outer plane of the geometry. The minimum volume of these bounding box was chosen as the geometry volume. Same concept was used to algorithmically calculate base area (by selecting maximum of the various 3-point planar areas) and clear height (by choosing minimum of the various internal single point to 3 point planar distance).

55

FIG

finding of irregular Tensegrity.

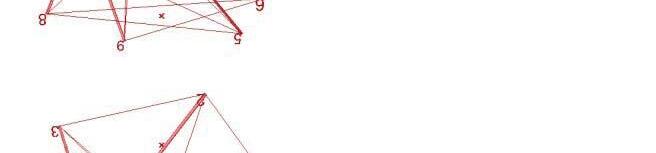

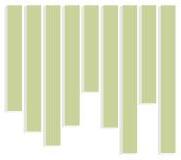

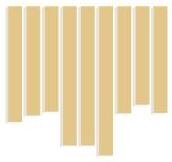

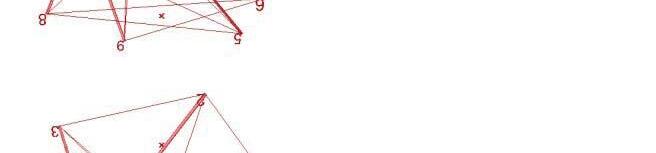

BASIC SEEDS

5 STRUTS UNSTABLE BASIC SEEDS

6 STRUTS UNSTABLE BASIC SEEDS

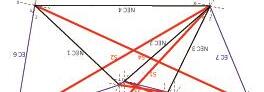

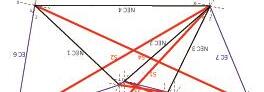

BASIC SEED GENERATION

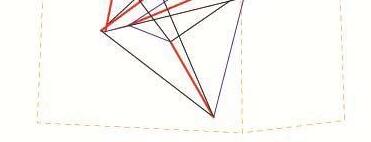

Using the generative script, 40 unstable basic seeds were created with 5 struts, 6 struts, 7 struts, 8 struts and 9 struts geometries. Each basic geometry had an unique connec tion logic and thus would produce high variation in respec tive relaxed modules. It was observed that 6 and 8 struts geometries had a tendency to relax into similar relaxed geometries and produce less variation while odd numbered strut geometries like 5, 7 and 9 struts produced more variant relaxed geometries. Also the number of form-finding and non form-finding cables played a crucial role in stability of geometries. It was observed that geometries with higher ratio of number of form-finding cables and number of ver tical struts produced lesser number of stable geometries.

56

5A BS4,11(i) 1 2 3 4 5 6 7 8 9 10 5B BS6,9(i) 1 2 3 4 5 6 7 8 9 10 5C BS8,7 (i) 1 2 3 4 5 6 7 8 9 10 0 5D BS8,7(ii) 1 2 3 4 5 6 7 8 9 10 0 5E BS6,9(ii) 1 2 3 4 5 6 7 8 9 10

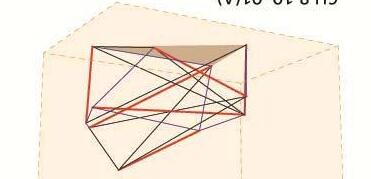

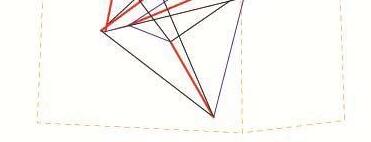

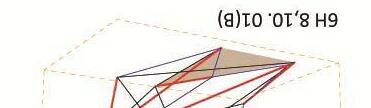

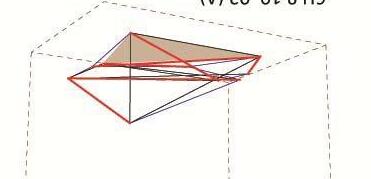

6B BS 10,8(ii) 1 2 3 4 5 6 7 8 9 10 11 12 ii) 1 2 0 6A BS 10,8(i) 1 2 3 4 5 6 7 8 9 10 11 12 0 1 6C BS 6,12.(i) 1 2 3 4 5 6 7 8 9 10 11 12 0 1 1 6D BS 6,12 (iv) 1 2 3 4 5 6 7 8 9 10 11 12 i)7 1 1 2 6E BS 6,12 (ii) 1 2 3 4 5 6 7 8 9 10 11 12 0 1 2 6F BS 6,12 (v) 1 2 3 4 5 6 7 8 9 10 11 12 0 1 1 6G BS 6,12(iii) 1 2 3 4 5 6 7 8 9 10 11 12 1 6H BS 8,10(i) 1 2 3 4 5 6 7 8 9 10 11 12 0 1 1 6I BS 8,10(ii) 1 2 3 4 5 6 7 8 9 10 11 12 1 2 1 2 3 4 5 6 7 8 9 10 11 12 6J BS 8,10(iii)

FIG 3.12. Diagram showing the set of all basic seeds randomly produced based on strut numbers.

7 STRUTS UNSTABLE BASIC SEEDS

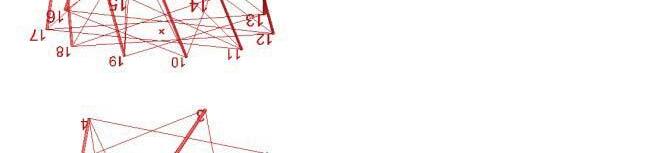

9

8 STRUTS UNSTABLE BASIC SEEDS

UNSTABLE BASIC SEEDS

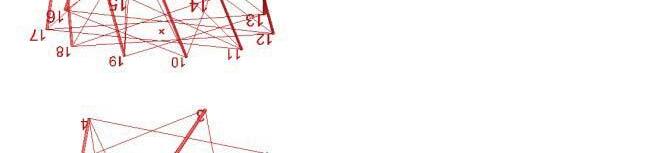

57 9A BS 14,13(i) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 0 1 8 5 6 9B BS 12,15(i) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 0 1 8 9C BS 16,11(i) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1 6 7 8 9D BS 12,15(ii) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 0 1 1 6 7 8 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 9G BS14,13(iii) 1 3 4 5 6 1 9H BS12,15(iv) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 3 14 5 6 7 9J BS14,13(iv) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1 3 4 5 1 1 9F BS14,13(ii) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 1 1 1 5 6 7 1 9E BS 12,15(iii) 1 2 3 4 5 6 7 8 9 10 11 1213 14 171615 18 1 0 1 1 8 9I BS12,15(v) 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 0 1 1 1 1 1 1 8

STRUTS