9 PAGE 9

PAGE 10 PAGE 11

We Are

Remotely Operated Vehicles (ROVS)

Long Reach Tooling

Sludge Retrieval Equipment

ABAY Cold cutter

Hydraulic Finger Crabs

DRF & Gypsy Wheel

Cameras & Lights

9 PAGE 9

PAGE 10 PAGE 11

We Are

Remotely Operated Vehicles (ROVS)

Long Reach Tooling

Sludge Retrieval Equipment

ABAY Cold cutter

Hydraulic Finger Crabs

DRF & Gypsy Wheel

Cameras & Lights

Whatever the problem, the team at Forth has the right solution for you.

Our expert team has more than 20 years of experience in providing bespoke solutions to problems across the nuclear industry. We deliver rapid, value-for-money solutions by tackling all problems head-on and with a no-nonsense approach.

With a proven track record of providing working solutions to industry problems across the globe, we are waiting to hear from you about how we can help you by using the high level of expertise across our three sites.

Get in touch at:

Risehow

Hydraulics

Centre, Flimby

Maryport

CA15 8PA

01900 816000

Flass Lane

Barrow in Furness

LA13 0GW

01229 486273

Leconfield Industrial Estate, Cleator Moor

CA25 5QB

01900 816000

www.forth.uk.com

info@forth.uk.com

With the advancements of technology, it is amazing what can be achieved with the creation of new equipment and machinery. Remotely operated vehicles are becoming commonplace across industry, whether they are operated on the ground, in the air or in water. Forth has worked to develop world-first ROVs to improve working processes across all industries, making project work more efficient and cost effective.

Our team built a pioneering, remotely controlled Emergency Response Robot capable of withstanding hazardous environments on a 1.6 tonne JCB compact excavator platform and fitted with a specialist robotics system and wireless technology. The robot is capable of towing a trailer with a fitted hopper that can disperse a bund of sand to contain any type of spillage, and it also has an affixative spraying system attached that is used to assist in the containment of a nuclear spillage. Other features include a large grapple hook that will be used to move any obstruction the robot may come across, as well as a specialist 700bar rescue tool to cut through any obstacles.

Forth designed and manufactured the Tipperbot ROV, an adapted power barrow which can be operated from a range of 20 metres, to sieve out solids from wet ‘sludge’ when undertaking nuclear decommissioning work. Originally created to carry out work to clear the redundant ponds at Magnox’s Hunterston site, the Tipperbot is placed in dry sumps and picks up the remaining nuclear waste in the former ponds and sieves out solids from the liquid.

In order to provide a remote, safe method of sorting and segregating underwater waste in fuel storage ponds, we replaced the electrical components of a JCB 1 tonne Micro Digger with hydraulic running gear to allow for reliable operations in hazardous environments. By adapting the traditional Micro Digger by using our engineering excellence, we were able to conceptualise, build, test and deliver the Underwater Micro Digger in a matter of weeks, which provided the perfect solution for the client, in the first instance Sellafield.

To reduce, sort and segregate waste and debris in fuel storage ponds from a safe distance, Forth produced underwater cropping tool Shark 3. The device has a rotary cropper head which can move 360 degrees, as well as a high resolution camera and robust underwater lighting to allow the operator to understand the environment and make clear decisions about the waste and debris in the nuclear pond. There are numerous opportunities to include end effectors, such as grabbers, saws and infrared cameras.

Forth was commissioned by Sellafield, in collaboration with Manchester University, to find a cost-effective way of carrying out various tasks and providing a clear view of the Magnox Swarf Storage Silos on site. The Avexis Swimming Robot was dropped into an ullage gap of 1m to enter the water in the silo, and was equipped with bumper bars to allow it to push Swarf which had collected behind the silo furniture. With the addition of cutting and removal tools, the Avexis was able to remove large amounts of swarf to provide a rapid, and cheaper, solution to the problem.

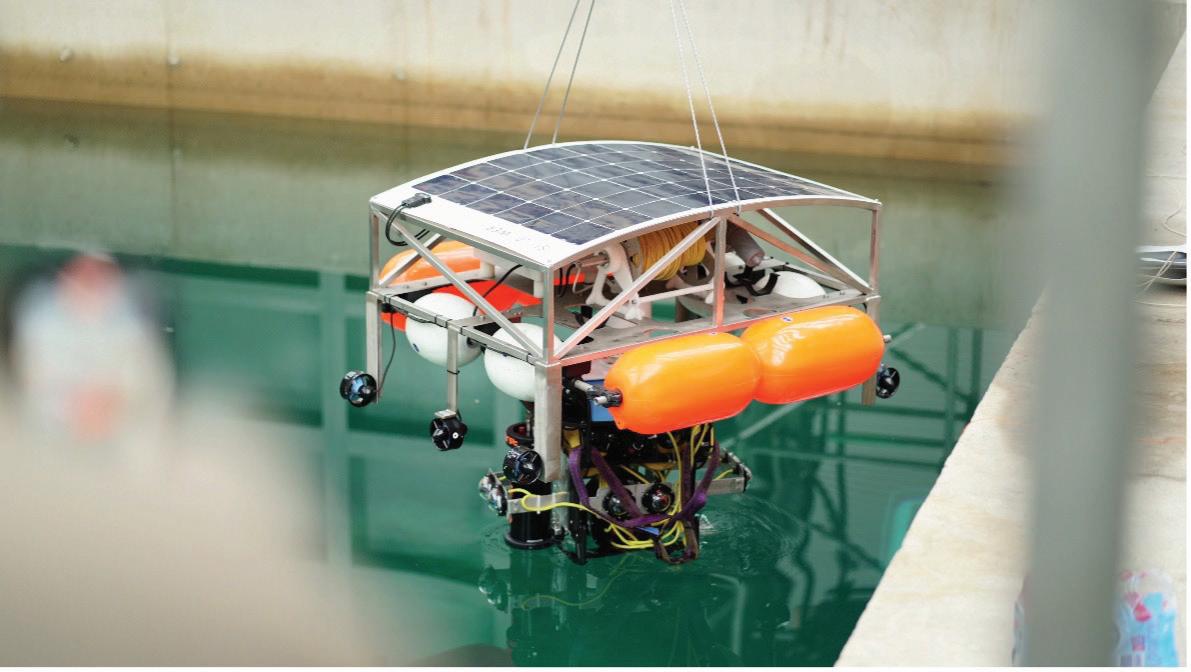

Forth is in the process of developing an innovative autonomous underwater survey robot, Autonomous Aquatic Inspection and Intervention (A2I2), aimed at saving industries across the world hundreds of millions of pounds each year. A2I2 is an intelligent, tetherless robot fitted with sonar technology to detect and avoid obstacles underwater, and in hazardous environments such as storage ponds on nuclear sites.

Forth designed and manufactured the Panther Track Robot to be utilised for any solution necessary with the capabilities to adapt to various terrain and change operations being endless. The robot is adaptable by including various end effectors, and is remotely operated by a control panel. This control panel is watertight, airtight, dustproof, chemical resistant and corrosion proof.

Forth has developed a number of innovative long reach tools to make jobs across the nuclear industry easier to complete. The extended reach enables work to be carried out into deeper cavities much quicker and with more precision. Examples of our developments include a chipping hammer made of carbon fibre and carbon steel which works effectively at dislodging and removing debris in an underwater environment, and a long reach retrieval tool complete with multiple fittings which can be deployed to be used in various facility settings.

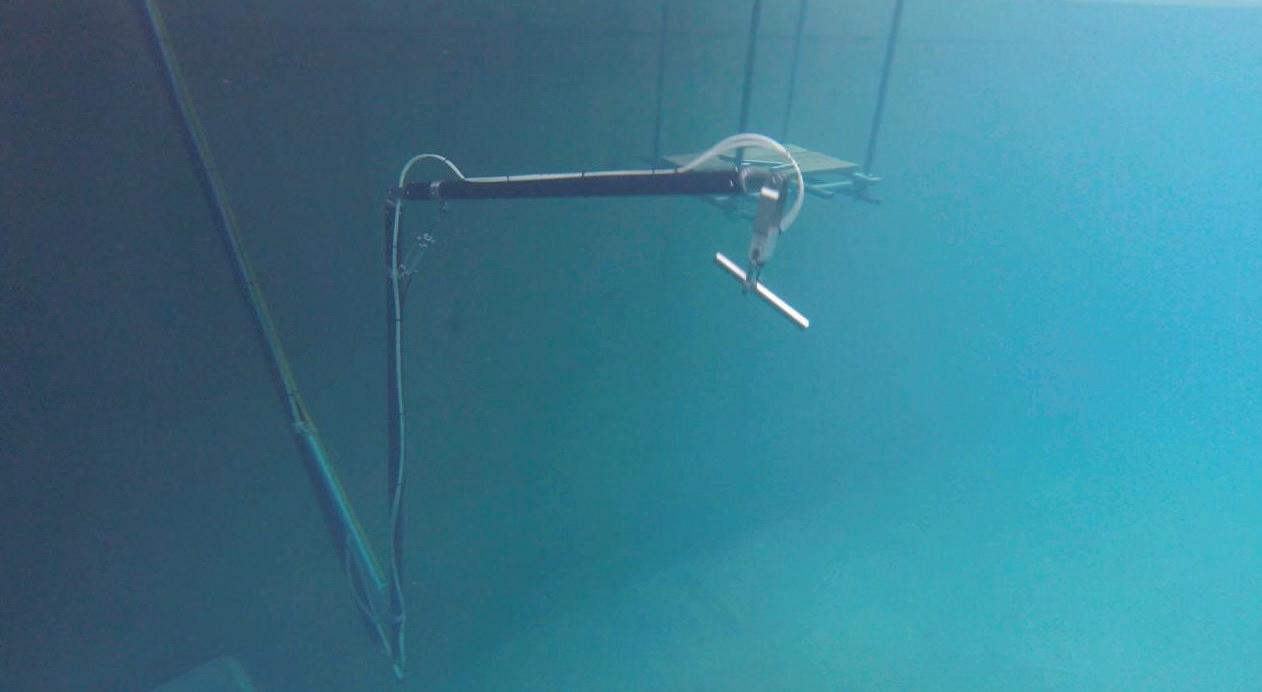

Magnox approached Forth with a problem statement to remove spent fuel rods from hazardous pools of fuel at Hinkley Point Power Station from a safe, remote distance to prevent humans manually having to sift unwanted materials from liquids. The human approach was extremely time-consuming and would slow down operations. The team at Forth designed and created a robotic arm to operate exactly like its human counterpart, complete with gripper technology to act as a hand, which was controlled remotely and significantly speeded up the whole process.

Called on as an emergency for long-standing client Sellafield, Forth built a long reach inspection and recovery system within the space of just three days. The tool was required to locate, dislodge and recover an item that had become astray eight metres out of reach, so Forth made the system with endless interchangeable parts to mean that only one set of carbon poles were needed for any job.

To be used to carry out daily operations around the plant in a safer and more accessible manner, Forth developed a 1” Lightweight Breaker Bar for its partners at Sellafield. The team had to carefully calculate the forces required for the daily tasks to ensure the carbon fibre could withstand tough environments. The tool was made lightweight as possible with the carbon fibre starting at 5mm wall thickness at the pressure points, tapering off to 3mm at the opposite end.

The Trunnion Spreader was manufactured to attach to Forth’s long reach carbon tools to aid a client to repair damaged trunnions which were six metres underwater, enabling them to be successfully and safely transferred using the skip handler.

This extendable pole measuring at three metres long has a full 360 degrees orientation and motion designed to allow operators to use from a safe, remote distance and not to be in the shine path of radioactive material. pennies stuck to the floor. The design of the tool was based from the principle of the decking cleaner and converted it could handle tougher environments.

To make the often labour intensive and time consuming job of cleaning skips quicker and safer, Forth designed and built the Long Reach Skip Cleaner to remove fuel converted into a robust stainless steel tool to ensure it

A leak from a sump in the Redundant Settling Tank area of Sellafield was causing a large degree of concern with a reduction of an estimated 2,000 litres of liquor per day, so we were contacted by the Decommissioning Alliance to provide a solution to the problem. We designed and developed a sludge retrieval system which was capable of removing 15m3 of sludge and 15m3 of solid waste to address this problem.

A sludge and debris eduction system, Eductor Type D, was created by making use of the Venturi flow meter effect. The technology is capable of displacing approxing 675 litres of water, sludge and debris per minute.

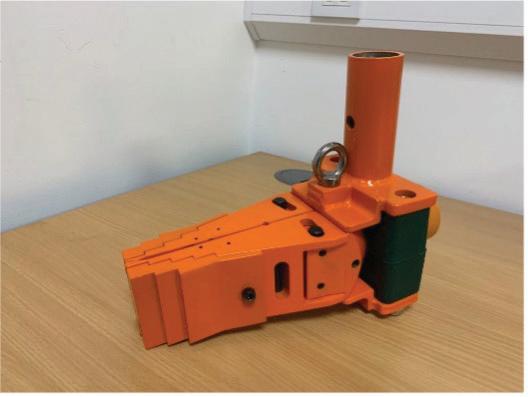

Hydraulic finger grabs were developed for RST Cutters to remove fuel waste, with four different variants with interchangeable jaws created to ensure the tool could be adapted to fit the requirements of the job.

The team at Forth created an ABAY Cutter, a replica of a RST Cold Cutter, built of stainless steel to reduce and restrict waste down into a manageable size to be transported from a leaking asset. Using this method, the waste would be drained and concreted quicker to reduce any risk of contamination to the ground. Forth designed and built interchangeable tools and modified ‘off-the-shelf’ kit MOTS to deliver fast, engineered solutions to facilitate this removal.

With our team of experts spread over three sites across Cumbria, Forth has the capacity and capabilities to run whatever trials, training and simulation projects necessary to ensure work efficiency in the industry is at its peak. At our HQ in Flimby, we have one of the largest wet test facilities in the UK in the form of our deep recovery facility which holds 1.2 million litres of water as it measures 22.5m in length, 10m in width and 6m in depth. The pool is regularly used for research and development purposes by some global industry leaders.

With the items being discontinued, Forth designed a bespoke Gypsy Wheel for a marine client for a working boat. The team took on the job to make and install the gear that drives the chains to open the storage doors on the ship, providing a solution when there was no alternative available to the client.

We regularly adapt and add lighting to machinery and equipment, and commonly add to the likes of long reach tools and ROVs to provide better viewing for the operator. We have a range of mobile, powerful underwater lights we can apply to machinery to instantly illuminate large areas.

Forth has developed a wide variety of cameras to be utilised in any situation within a nuclear setting. Some examples include: an Endoscope

Pipeline Inspection System fitted with a waterproof camera and six LED lights which can, for instance, be used to inspect drain sewers; a rugged, yet intelligent, Pan, Tilt, Zoom (PTZ)

Pipe Camera System which allows the operator a clear 360 degree view of surroundings and can be deployed; a miniscule 23mm Camera System which is perfect to inspect confined spaces; a specialist PTZ 50mm Underwater Camera which allows clear and reliable viewing underwater.