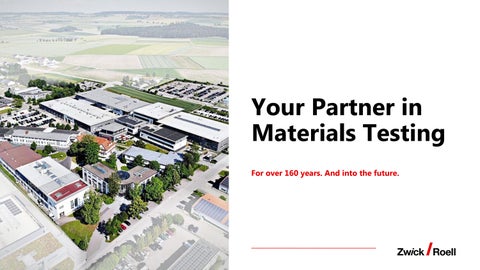

Your Partner in Materials Testing

For over 160 years. And into the future.

Corporate video

• You will find the video at ZRUK employee information on our SharePoint in employee information

Innovation Based on Tradition

Invention of the planimeter and the integrator by Jakob Amsler-Laffon.

Founding of the company Roell by Paul Roell and Alfred Korthaus.

We manufacture the first testing machine with electrical force measurement.

The Mannheim Machine Factory (MFL) develops the first testing machine. Alois and Bernhard Zwick founded the company Zwick in Ulm-Einsingen, Germany.

Merger to form the ZwickRoell Group.

Development of the first PC-controlled testing machine.

We develop the first Windows 95 compatible testing software worldwide.

optiXtens – first optical extensometer that does not require markings.

We build the largest pendulum impact tester in the world.

New testXpert III testing software is introduced.

We develop the new measurement and control electronics testControl II.

testXpert Analytics with Test Data Management and Condition Monitoring.

Through active acquisition, ZwickRoell builds strong product portfolio and strengthens its technology, know-how and global presence. ZwickRoell at a glance

Company Join ZR since Business activities are specialized in the field of …

Indentec Since 1985 Hardness testing machines

Toni Technik Since 1986 Building materials testing machines

ZwickRoell Testing Systems Since 2006

High-temprature creep testing machines, optical extensometers (formerly Messphysik Materials Testing GmbH)

GTM Testing and Metrology Since 2007 Load cells, torque transducers and multicomponent transducers

Latze Härteprüfung

Since 2015 Service for hardness testing with a DAkkS accredited calibration lab

EMCO-Test

Other 7 subsidiaries

Since 2021 Hardness testing machines

Made by ZwickRoell

Min. 10 years spare parts availability guaranteed

85% in-house production depth CO2 neutral since 2014 H e a d q u a

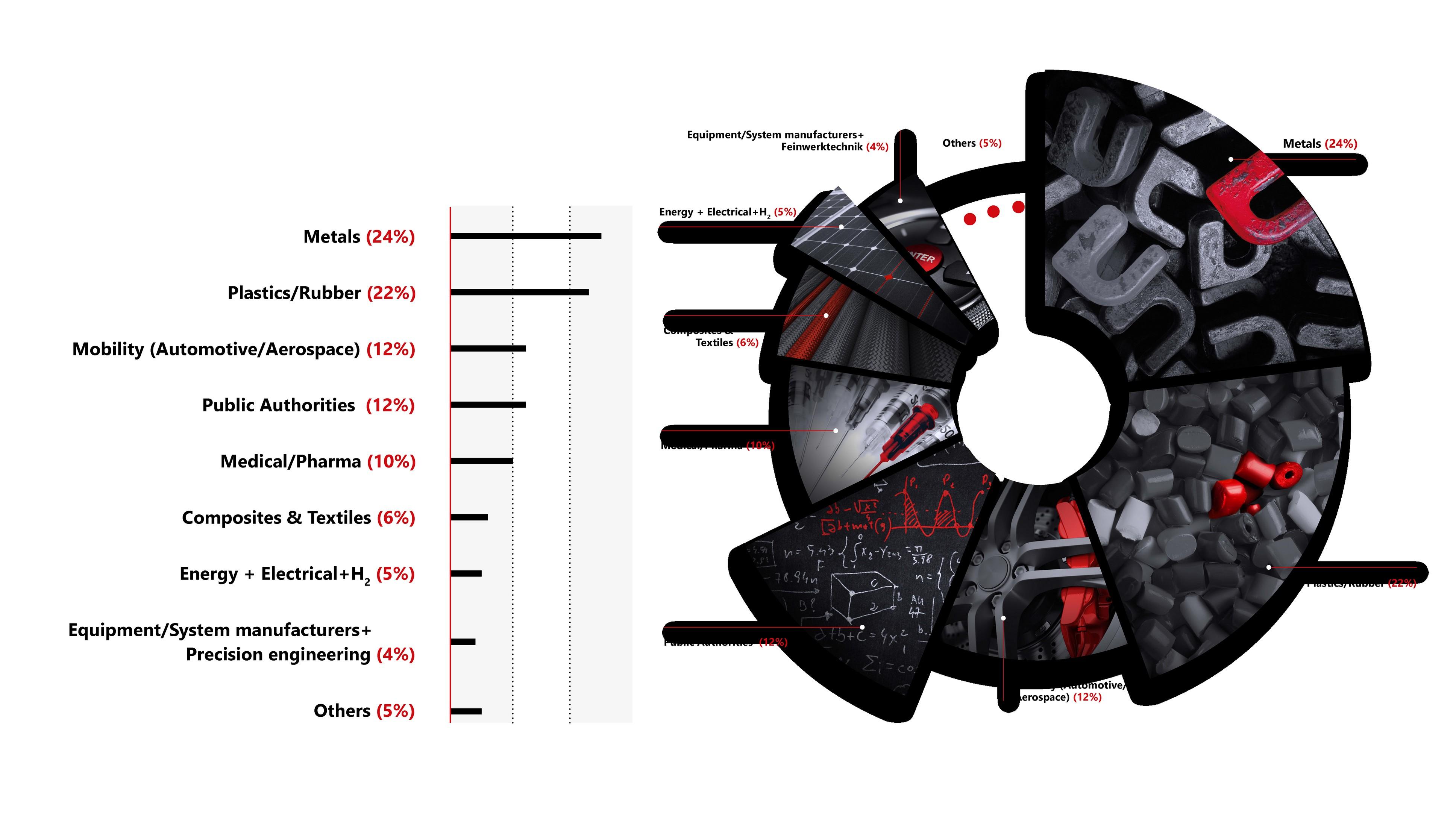

ZwickRoell –Perspective in Numbers:

+15 product groups

85 million

tests performed with our machines every year

Custom-fit solutions and reliable test results that you can rely on.

For over 160 years. And into the future.

Our more than 1,800 employees make sure of it with competence, openness and passion.

Solutions for +20 industries €

Klaus Cierocki Chairman of the Board

+600 standard test programs in testXpert

304 million in sales in 2023

We are represented with production sites, subsidiaries and sales partners in over 50 countries.

ZwickRoell North America

HQs in Ulm, Germany

ZwickRoell UK

GTM, Germany

ZwickRoell Fürstenfeld, Austria

ZwickRoell Taicang, China

ZwickRoell Asia Pacific

EMCO-Test, Austria

ZwickRoell - Subsidiaries around the world

ZwickRoell - Production sites

ZwickRoell - Sales partners

We take pride in our employees

+200 product- & industry experts

seventy-five trainees

1,700 employees worldwide

7 members of standards committees

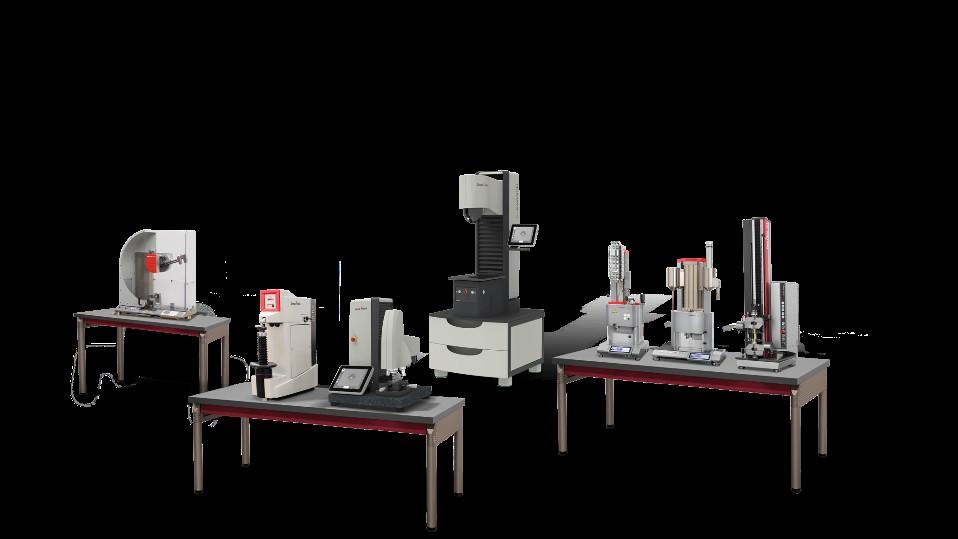

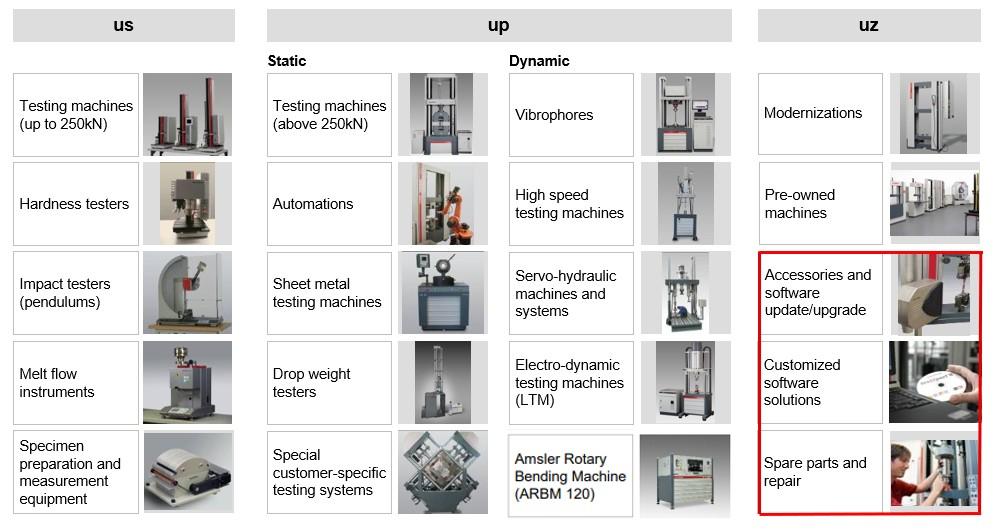

The right solution for any test requirement

Pendulum impact testers

drop weight testers Hardness testing machines

plastometers

materials testing machines

testing systems

Modular Innovation

Core competence

• Extensometers

• Load cells

• Measurement and control electronics

• Specimen grips and test tools

• Testing software

• Temperature conditioning devices

• High-temperature furnaces

• Specimen preparation

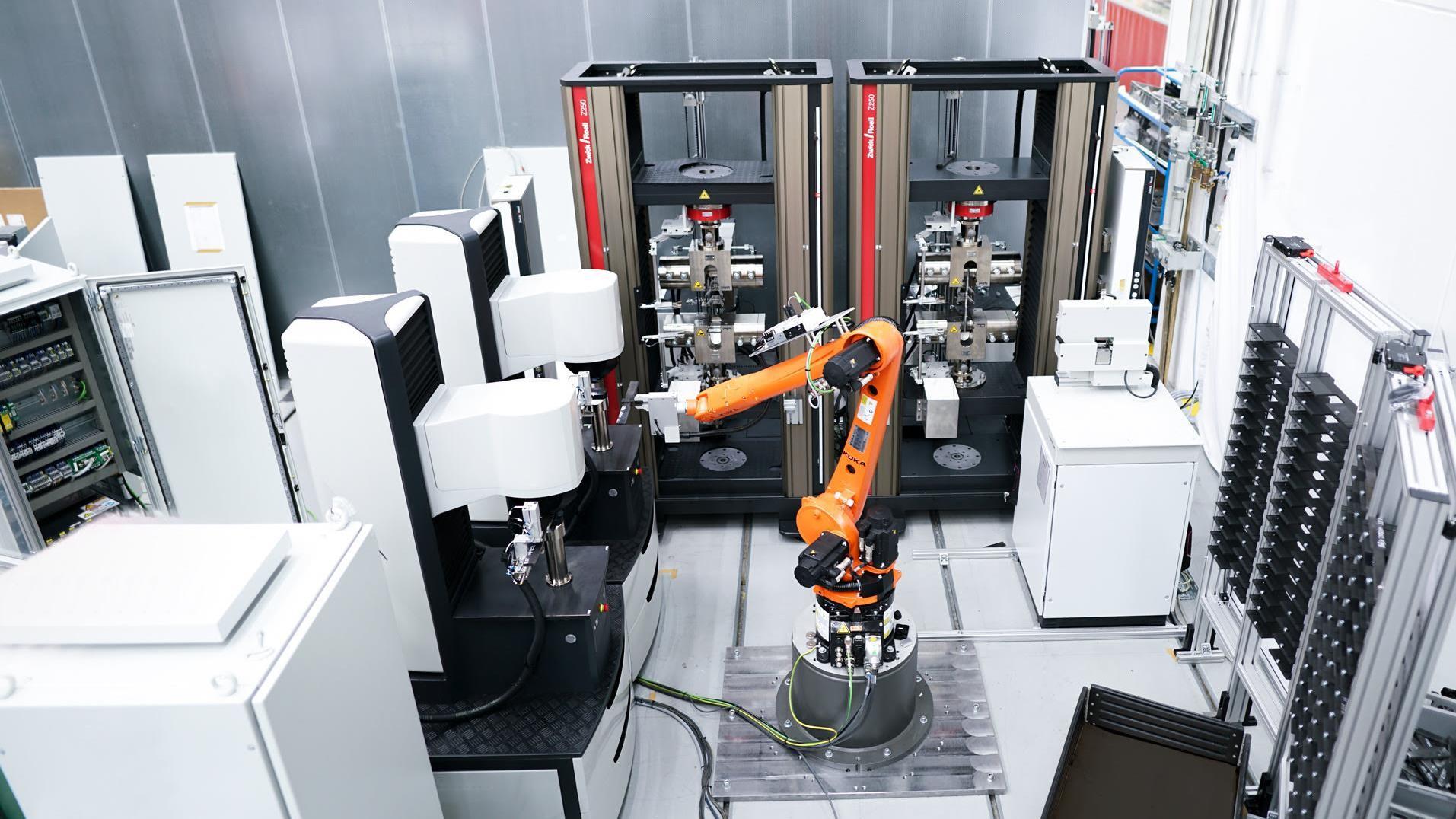

We support the latest trends in automation –for reliable test results.

+50 new systems are delivered per year

+600 automated testing systems delivered worldwide

40 years experience in automation

7 automation models

ZwickRoell testing labs & Xperience Centers worldwide

Laboratories:

• 15 demo labs worldwide

• 60 test engineers

• 100 testing machines/ instruments

• 2,000 accessories

• 20 industries

• Web demos

Xperience Centers: Singapore (SGP), Atlanta (USA), Birmingham (UK), Metz (FRA)

testXpo – International forum for materials testing

3,500 m2 exhibition area

+180 exhibits +25 co-exhibitors

9,200 snacks & appetizers over 4 days 2,000 visitors from +50 countries every year

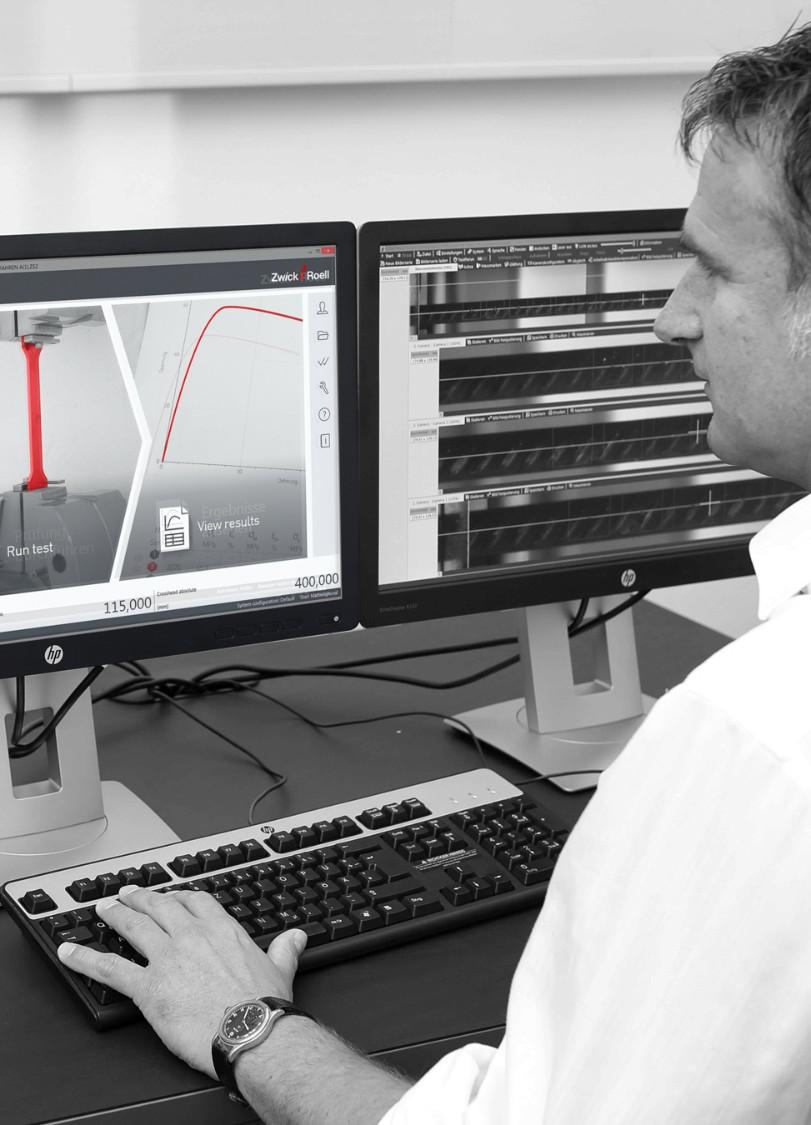

testXpert III –testing software

• Simple, future-proofed, flexible

• First Windows-based testing software worldwide

• 45,000 installations

• 600 standard test programs

• 100% standard compliance

• Ready for Industry 4.0

• test data management & condition monitoring

• Over 100 intelligent features

Services and After Sales

Your trusted partner for the entire machine life cycle

We support you from every angle: we not only meet the widest range of test requirements, but we support you throughout the entire life cycle of the testing system with tailored support services - anywhere in the world.

• Consulting and application technology

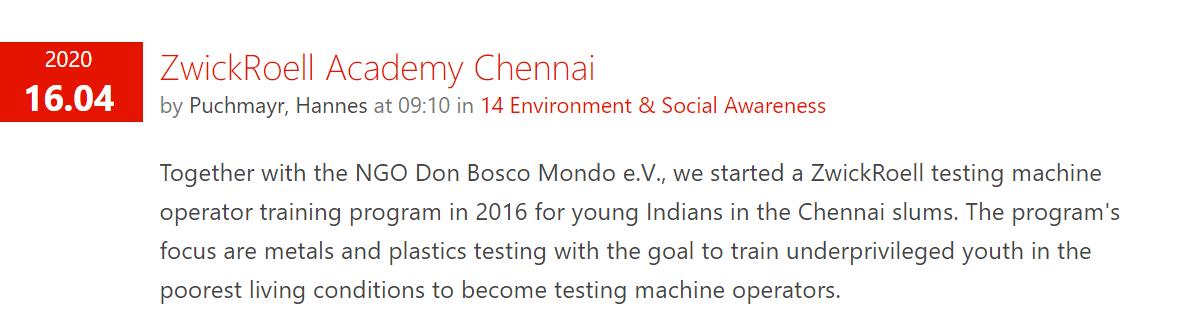

• ZwickRoell Academy

• Maintenance and inspection

• Calibration

• Software services

• Online services

• Hotline and customer support

• Repairs and spare parts

• Laboratory for Materials and Components Testing

• Machine removal and relocation

• Modernization

Sustainability Commitment

280,000 Euro

ZwickRoell Runs the World-donations since 2017

Diverse projects supporting environmental protection and sustainability

ZwickRoell Academy Chennai CO2 neutral since 2014

1. History of ZwickRoell

ZwickRoell United Kingdom & Ireland (ZRUK)

Quality (LW)

Tom Perrin

UKAS (BS)

Nigel Wrigley

ZwickRoell Ltd.

Benno Sadowski (BS) / Lee White (LW)

Joint Managing Directors

Non-Executive Director

Roger Evans

Business Development Manager (LW)

Human Resources (BS)

Maren Sadowski

ZRUK, Training & Development Lead (LW)

Marcus Barrow

Data / Facilities (BS)

Ian Woodham

Marketing (LW)

Daniel Jones

Head of Finance (BS)

Lyskova

03/06/2025 Worcester / Maren Sadowski

Office Manager (BS)

Adam Al Rasheed

Sales Manager (LW)

Brian Lever

Hardness

Mark Deven

Subsidiaries (dormant companies)

Service Manager (BS)

Jonathan Phillips

Blanka

ZwickRoell United Kingdom & Ireland (ZRUK)

Contracts

Office

Hope Barney-Smith

Fasiha Batool

Samuel Davies

Hayley Davison

Aimee Falvey

Mileva Mathew

Christian Norremark

Max O’Leary Mullock

Simon Pearce

Kerry Piper

Julia Rogowska

Alex Watkins

Thorsten Wynne

Valter Bastos

Mark Bentham

Jagmit Dhiman

Thomas Dodd

Luke Edmunds

Terry Harris

Jacky Ho

Steven Jenkins

Mohammed Kasim

Kwei Yeung Lau

Jeffrey Lewis

Blair Mitchell

Simon Park

Krzysztof Przybyla

Paul Ross

James Sills

George Slater

Benjamin Smith

Darren Spence

Matthew Tilly Alan Wilkins

Evan Mc Donagh Joshua Nkiambi

ZwickRoell at a glance

Supervisory Board and Executive Board

Today, the ZwickRoell Group is led by a professional and experienced Management team that continues to develop innovations based on a long history and tradition in the testing machine industry.

Dr. Jan Stefan Roell Chairman

Anna Ruhland Sascha Menges

Ping Bu Loke CTO

Organizational

Head of Quality Manager

W. Richardt

Compliance/Data Protection/Certific.

J. Zimmermann

Project management – S. Duong- Visser

Export control – T. Maucher

PMO – M. Arnold

Construction Project - B. Faber

Finance

M. Bort

co

Controlling

M. Bort

rw

Accounting

R. Schließer

H. Rapp hr – Human Resources

W. Bierer

Rinas

Board of Management

K. Cierocki

Common Work Council Ulm

Chairm. M. Farré (Dep. H. Duval)

Common Work Council Haan

Chairm. O. Hust (Dep. Da Costa)

cl – Calibration Lab

DAkkS-accredited calibration laboratory

K. Metzger

Flock

Sobiranski

Glück

use – Dev.

Schierloh

Sales: J. Künstler

ME: T. Walter

Kindermann

Schilling

uzv - International

T. Klemm

uze – Development

Dr. G. Futterknecht

uzm – Assembly c. Hehn

– Sales Region North

Letschert ecz - Service Region North S. Geiss ecf – Technical Sales North kom. S. Vespermann ecb – Service Region Central kom. T. Ott

Ohmann

C. Schröder

W. Bierer

SW: M. Tobisch

HW: P. Berger

– Sales Region Central C. Eberhardt-Motzelt ecw – Technical Sales Central R. Knapp

– Sales Region South

F. Stützle eca – Service Region South

Maier

G. Gerdes ecv – Technical Sales

Wölke

Neidl

H. Brenner

Responsibilities for Products

2. Organisation and Structure

1. History of ZwickRoell

Guidelines and Shared Values

You will find details in our New Starter Employee Pack

2. Organisation and Structure 3. Rules and Responsibilities

1. History of ZwickRoell

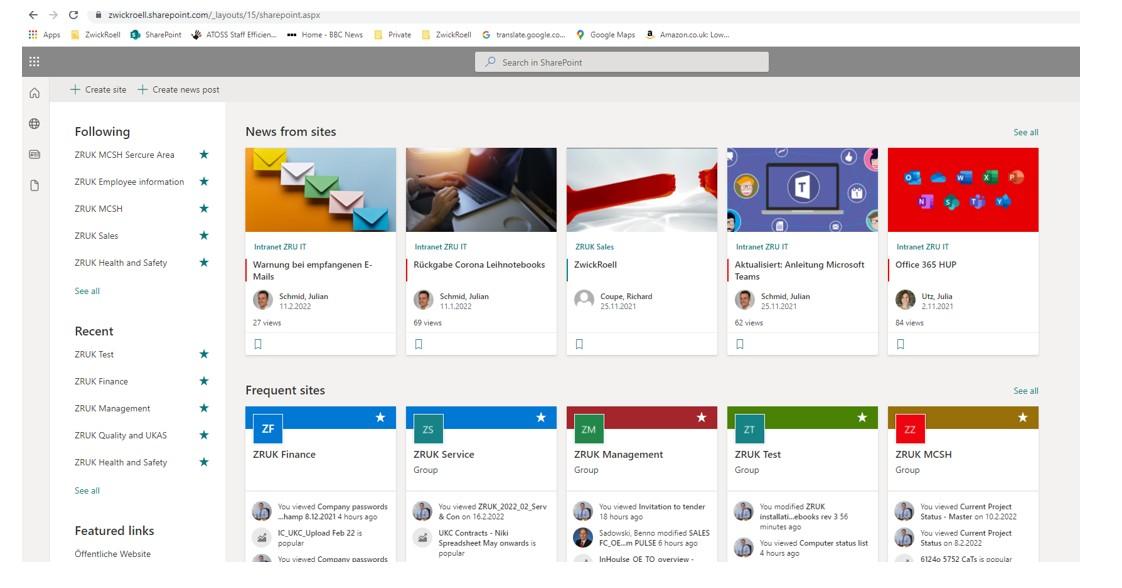

IT Systems

Windows 11 operating system

Pegasus Opera accounts software

ZwickRoell SharePoint / OneDrive - https://zwickroell.sharepoint.com/_layouts/15/sharepoint.aspx PULSE – CRM - https://pulse2.zwick.de/PULSE2 ATOSS time recording program - ATOSS Staff Efficiency Suite (zwickroell.com)

Remote access Pulse Secure – https://vpn.zwickroell.com

Microsoft authenticator 2 factor authentication

IT Security training portal - https://cloud.metacompliance.com

Health and Safety E-Learning Courses - Wirehouse Employer Services (wirehouse-es.com)

Website www.zwickroell.com

Surname and initial e.g. Jayne Smith would be SmithJ

Email address e.g. jayne.smith@zwickroell.com

Pegasus Opera - additional login required

SharePoint / OneDrive logs in automatically

Zwick intranet – additional login required

ATOSS logs in automatically

Pulse – CRM – automatically loaded with Outlook

File locations One Drive

• Personal One Drive location

• Used instead of saving items to C: Drive desktop etc as it is saved to the cloud so recoverable in the event of Notebook failure or loss.

• Company wide One Drive syncronised with SharePoint

2. Organisation and Structure

3. Rules and Responsibilities 4. IT Systems

1. History of ZwickRoell

Any deliberate falsification of calibration results is strictly forbidden and considered Gross Misconduct by the company and may therefore lead to your summary dismissal from the company.

1. History of ZwickRoell

2. Organisation and Structure

3. Rules and Responsibilities

4. IT Systems

5. Quality ISO & ISO/IEC 17025

6.

Health and Safety at work act 1974 as amended

• ZwickRoell Ltd. take our responsibilities very seriously

• Safety representative - Mr Ian Woodham

• ZwickRoell Ltd. Health and Safety policy and manual is available to all on SharePoint in the Customer information pack folder.

21) ZRUKg Health and Safety Policy April 2024.pdf

http://www.hse.gov.uk/a-z/index.htm is a useful guide to all things Health and Safety

Welfare, Health and Safety

Health and Safety at work act 1974 as amended

Provision and use of Personal Protective Equipment (PPE).

ZwickRoell Ltd. will provide all necessary PPE required to carry out duties this may include but is not limited to Safety Shoes, Safety Glasses, Gloves, work wear, safety helmets, ear defenders, hi visibility clothing.

It is imperative that employees comply at all times with the Health and Safety requirements (including PPE) of our customers while on their site. In certain circumstances, for example clean rooms, additional PPE will be required that is supplied by the customer. Failure to wear PPE as requested will be considered a disciplinary matter.

The employee is responsible for keeping PPE in good clean safe condition and report as soon as possible any damage or loss.

Health and Safety

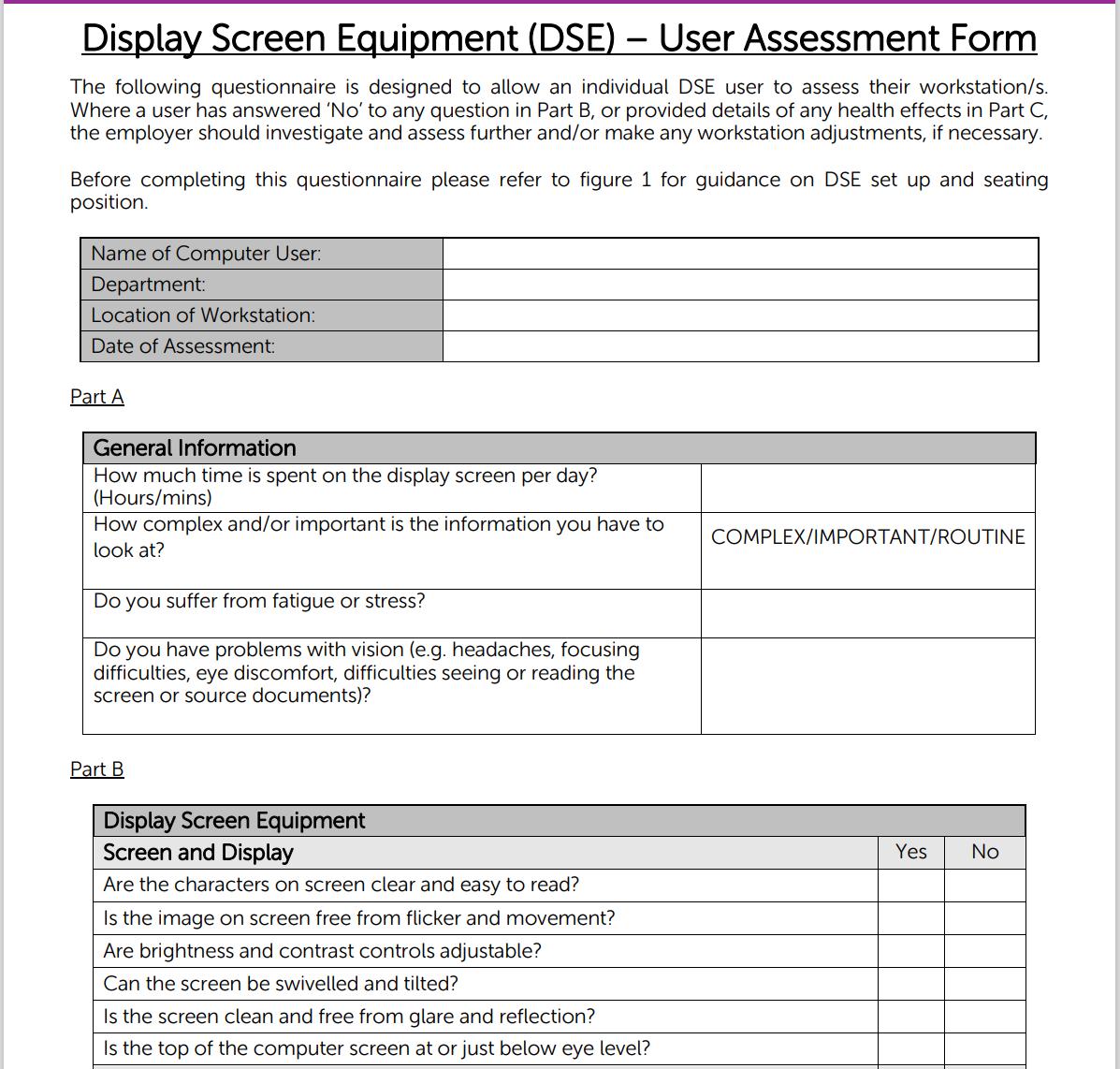

A Display Screen Equipment Assessment (DSE) will be done for desk working employees

Health and Safety

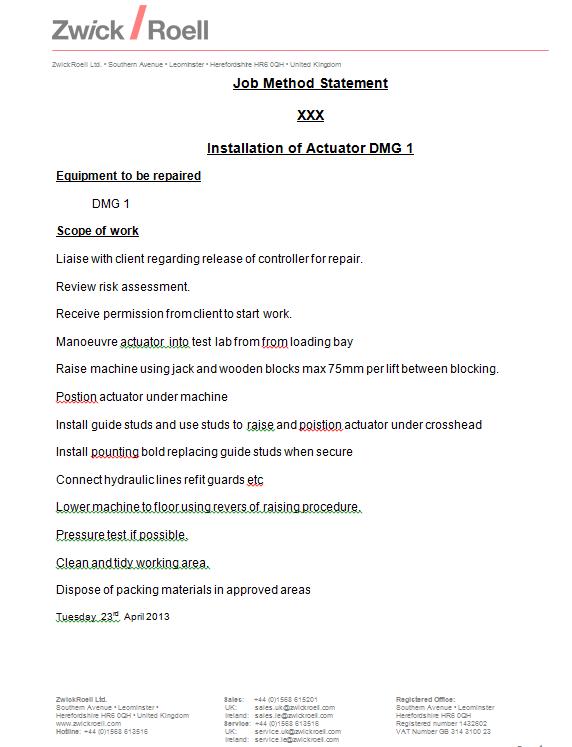

Risk assessment

Location. University of Strathclyde Activity: Investigate fault with BUP Machine

Persons or environment medium at risk ZwickRoell employees, Bridon employees.

Hazard SOMETHING WITH THE POTENTIAL TO CAUSE HARM Risk THE LIKELY HARM THAT WILL OCCUR

Control measures or safeguards put in place

Working Environment including( including outside, car park area) Slips, trips, falls, contact with fixed objects, raised curb 4 4 16 H Ensure work area is clean and tidy clean any spills, ensure gangway areas are kept clear at all times

Pay particular attention to weather conditions and surfaces, pay attention to raised curbs (if any).

4

H Control circuits are low voltage, however ensure mains is disconnected from controller before removing panels from pump and controller if applicable.

Machine / pump Electrocution, physical injury, Manual handling 3 2 6 M Certified operator to test machine in accordance with manufactures procedures. Use supplied PPE perform dynamic manual handling risk assessment if required

Test Machine Skin contamination / slips trips falls 4 4 16 H Ensure systems are de-pressurised before removing components. Use suitable container to collect spills, use PPE to minimise risk of skin contamination. Clean up all oil spills

3 15 H Clean area of propellant before staring work

3 6 M All waste materials to be disposed of by approved site procedures/routes

N0: 1711/03

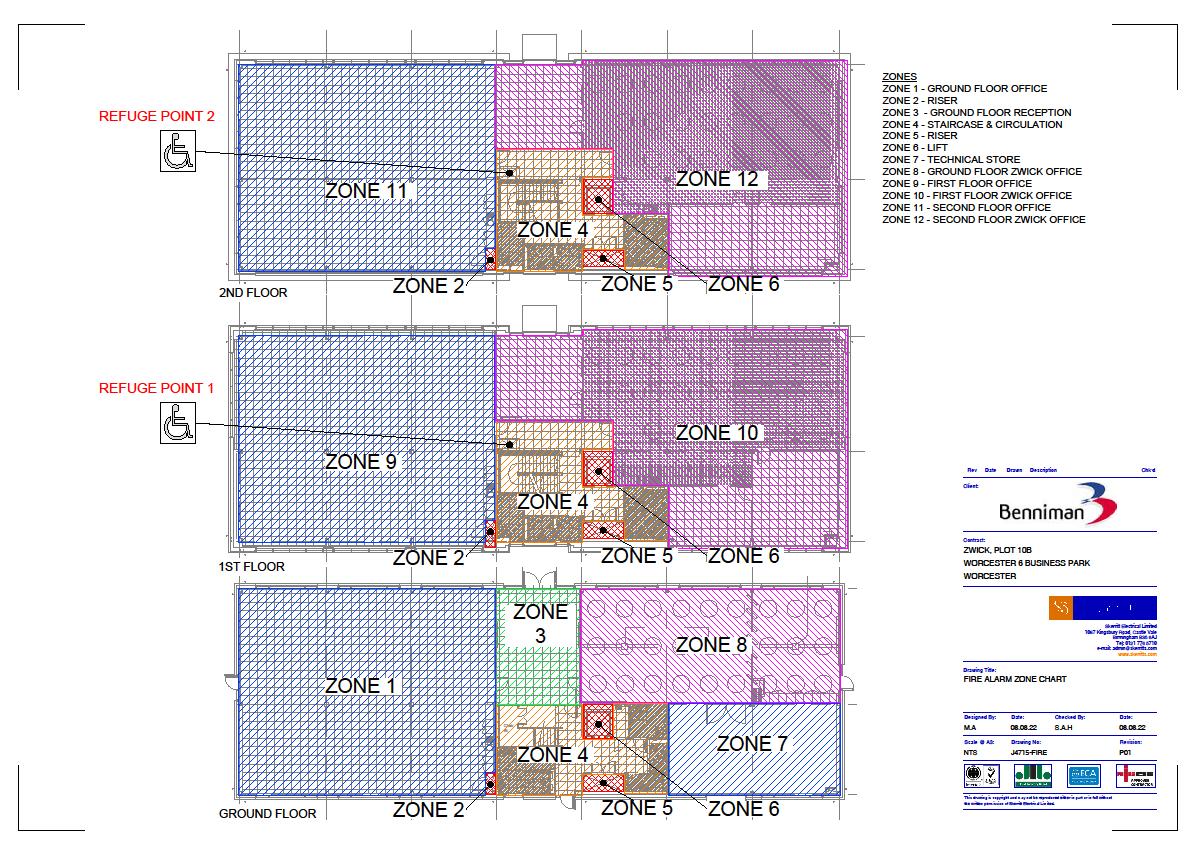

Fire and Emergency Evacuation

Fire precautions Worcester Office

• The building is a designated no smoking area and is installed with

Fire alarm

Heat and smoke detectors

Fire extinguishers

Fire blanket

• The fire alarm is routinely tested Thursday’s at approximately 10:00 and this consists of an approx. 15 second alarm.

• If the alarm sounds for longer than 15 seconds on Thursday morning or at any other time the building should be evacuated with staff and visitors gathering at the designated assembly point. Use the clearly marked emergency exits do not stop to collect personal belongings and don’t use the lift.

• The evacuation assembly point is, point1 the Taxi rank in front of the building.

• Do not attempt to fight the fire unless it is safe to do so call 999 and request for the fire brigade do not assume some has already done so multiple calls are better than no calls.

Security and end of day locking up Worcester Building

• We have a digital sign in system for Staff Visitors and Contractors. This will allow us to accurately track who is in the building at any given time, this is vital for completing a roll call in the event of an emergency evacuation.

• Once initialised in the EntrySign system, your existing grey door entry system cards is used on the card reader mounted under the screen attached to the test machine

• From then on simply touch your card on the reader each time to enter and leave the building, a red pop box appears.

• This is important for Fire Evacuation Roll Call please remember to touch IN and OUT, there is a running total against Staff visitors etc and if you forget to touch IN we will not know you are in the building and if you forget to touch OUT we could be searching the building putting people at risk.

Worcester Office Fire plan Fire Exits marked with

Health and Safety

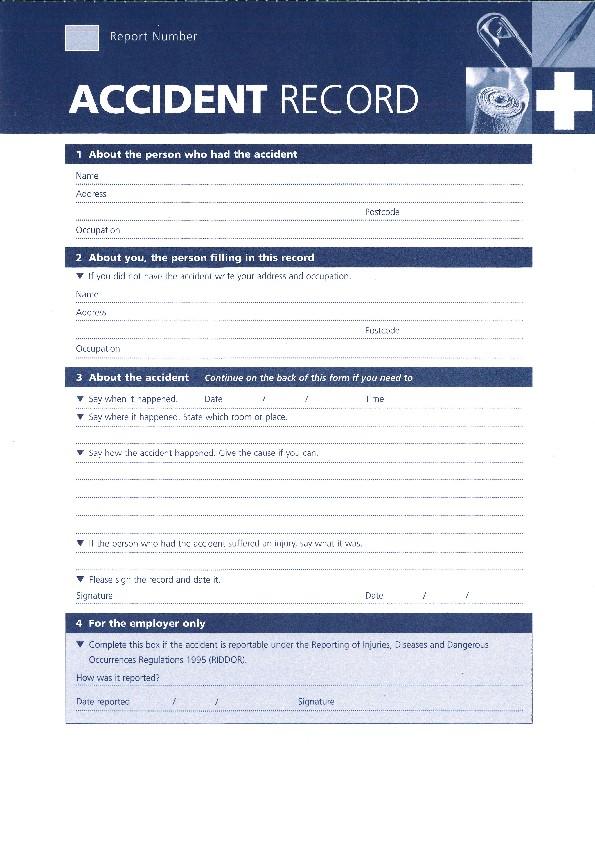

First Aid

• A First aid kit and accident book are located in the kitchen area of each floor, a first aid kit and defibrillator are located in reception.

• ZwickRoell Ltd. has “First Aid at Work” trained employees

• Ian Woodham

• Julia Rogowska

• Christian Norremark

And a “Mental Health First Aider”

• Ian Woodham

• The accident book should be filled in for all incidents accidents and near misses both on and off site on customer premises.

Accident form should be filled in for each incident and near miss

Welfare Arrangements

Washrooms and toilet facilities

• One unisex shower room

• Disabled toilet

• Ladies washrooms

• Gents washrooms

Welfare Arrangements

Kitchen and dining area

• Kitchen containing

• Fridge

• Microwave

• Toaster

• Coffee machine

• Boiling water for hot drinks etc

• Tea coffee squash etc

Please treat the area with respect clean up after yourself including cups glasses etc.

Do not leave out of date food in the fridge.

Please refer to your team leader for role specific induction

Welcome to ZwickRoell Ltd.