Fertilizer production line, compound fertilizer granulation line. rotary drum granulator dryer cooler coating machine BB fertilizer blending line equipment supplier manufacturer factory. Fertilizer machine price, 15–15–15fertilizergranulator.

15–15–15- NPK compound fertilizer production line Introduction:

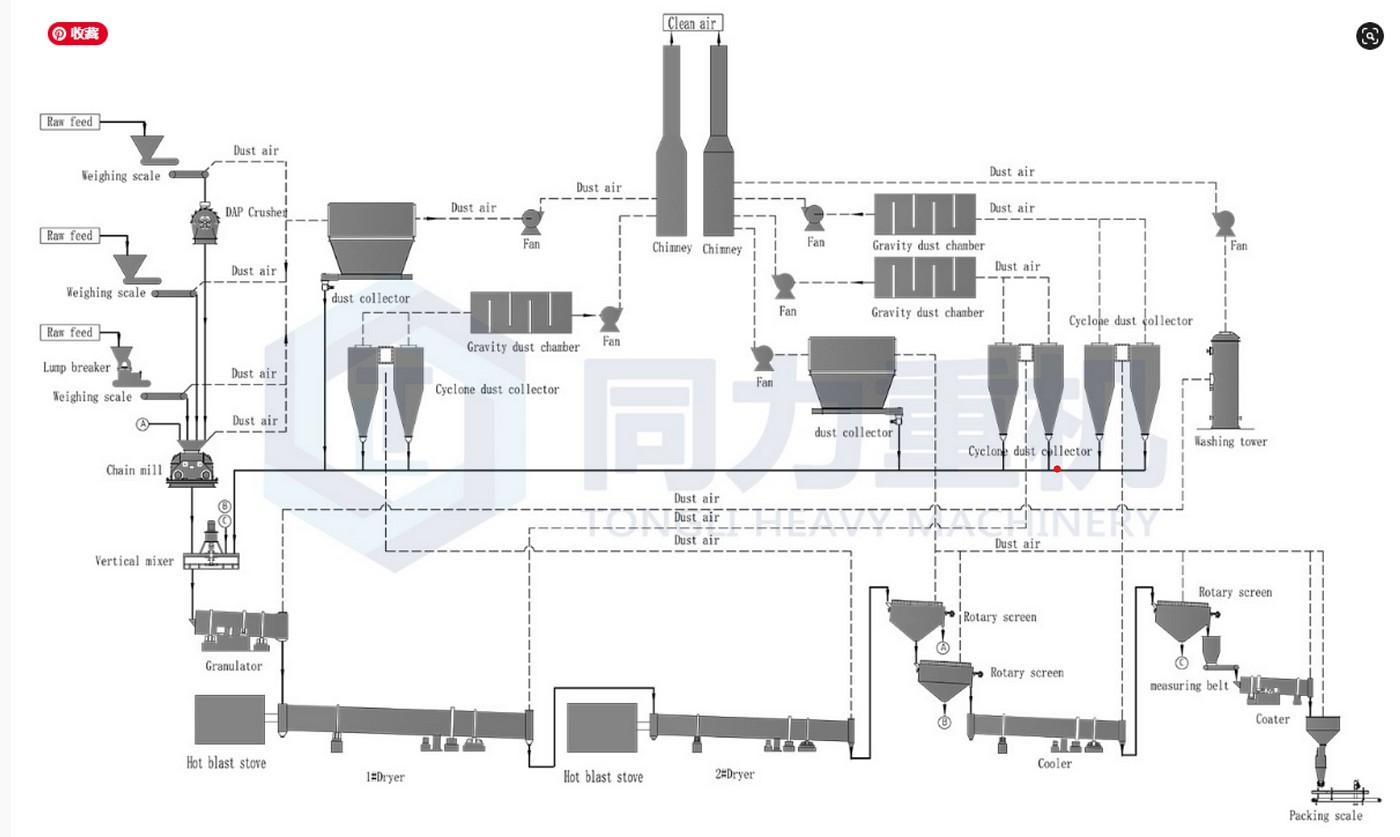

Fertilizer production equipment incorporate state-of-the-art technologies and automated processes control that significantly enhance the production efficiency. These systems streamline the entire fertilizer manufacturing process, from raw material feeding silo to automatic product packaging, resulting in faster fertilizer production cycles and reduced labor requirements. The automated fertilizer control systems enable precise monitoring and adjustment of parameters, ensuring consistent quality and reducing the chances of human errors. The improved efficiency translates into higher fertilizer production volumes, enabling agricultural industries to meet the growing demands for fertilizers and support increased crop cultivation.

Compound fertilizer production line, BB fertilizer blending line

manufacturer

The automated fertilizer control systems enable precise monitoring and adjustment of parameters, ensuring consistent quality and reducing the chances of human errors. The improved efficiency translates into higher fertilizer production volumes, enabling agricultural industries to meet the growing demands for fertilizers and support increased crop cultivation. The fertilizer production line is composed of the following equipment, rotary drum granulator, rotary drum dryer, rotary drum cooler and rotary drum coating machine, Tongil adopts the state-of-art fertilizer making technology and integrated to the equipment design to revolutionize the fertilizer production. some of the equipment involved are follows:

Compound fertilizer rotary dryer manufacturer supplier factory

Drying is typically achieved using Fertilizer production machine rotary drum dryers, fluidized bed dryers, or other specialized Fertilizer manufacturing drying equipment. The controlled application of heat during the drying process ensures that the granules reach the desired moisture content suitable for storage and packaging.

Following the drying stage, the hot granules are cooled to normal temperature. Cooling is essential to ensure the stability and quality of the NPK fertilizer. Various cooling methods, including rotary coolers and fluidized bed coolers, are utilized to rapidly and efficiently cool the granules while preserving their physical characteristics.

Fertilizer making machine production equipment supplier

manufacturer

Fertilizer making machine production equipment supplier

manufacturer