PORT OF PORTLAND HEADQUARTERS/ LONG-TERM PARKING GARAGE

about the port of portland

The Port of Portland is a 725-employee, 24/7 operation with $1.6 billion in marine, aviation and industrial real estate assets. Located in Portland, Oregon, the Port owns and operates Portland International Airport and two general aviation airports, as well as four marine terminals located on the Columbia and Willamette rivers. In addition to responsible day-to-day management, the Port pursues annual environmental objectives and targets to reduce its environmental footprint.

The Port’s environmental programs include: water resources, natural resources, waste management and recycling, air quality and energy conservation. More on each of these programs can be found at the Port’s website: www.portofportland.com

Port of Portland’s Mission

To enhance the region’s economy and quality of life by providing efficient cargo and air passenger access to national and global markets.

OWNER

Port of Portland

LOCATION

Portland International Airport/Portland, Oregon

SIZE

205,500 GSF of office space/3,500 parking spaces

COMPLETION

Spring 2010

PROJECT COST

Headquarters: $85 million

Parking Garage/Terminal Tunnels: $156 million

LEED CERTIFICATION

Registered for LEED Platinum

ARCHITECT

ZGF Architects LLP

CONTRACTOR

Hoffman Construction Company

CONSULTANT TEAM

MEP engineer:

PAE Consulting Engineers, Inc.

structural engineer:

KPFF Consulting Engineers, Inc.

civil engineer:

HNTB Corporation

landscape architect:

Mayer/Reed lighting design:

Luma Lighting Design

graphics/wayfinding:

Mayer/Reed

environmental:

Ash Creek Associates

audio-visual:

Delta A/V Systems, Inc.

living machine® system:

Worrell Water technologies acoustical: Sparling geotechnical:

GRI Geotechnical Resources Inc.

program

The Port of Portland’s commitment to sustainable practices is showcased in its new Headquarters Building and Long-Term Parking Garage. Sustainable design was a critical driver, with LEED Platinum Certification serving as a project goal. In addition, the building allows the Port to consolidate most of its workforce, bringing together approximately 240 employees located in a downtown Portland headquarters facility with 230 employees occupying offices in the airport terminal. This will save additional operating costs and provide the Port with an opportunity to lease the airport terminal space to other users. It also adds parking capacity to Portland International Airport.

The new 205,000 GSF building consists of three floors of office space atop seven floors of public, airport parking. The new offices reflect a 21st century culture – “One Port”– in an effort to increase collaboration and foster a team environment. Cost-effective solutions were a primary concern, as well as telling the Port of Portland story through environmental graphics and artwork. ZGF worked closely with the Port to develop new standards for office space to accommodate a shift from a closed office environment to a primarily open plan.

PORT OF PORTLAND HEADQUARTERS/ LONG-TERM PARKING GARAGE

site

The 10-story headquarters building and parking structure is sited immediately to the east of Portland International Airport’s main terminal building and is connected to the existing parking structure, serving as a new gateway to the airport. The building is visible to those arriving and departing the airport, either by roadway or by air.

Terminal 6

Portland International Airport

Port of Portland Headquarters/Parking

Terminal 6

Portland International Airport

Port of Portland Headquarters/Parking

site plan

1 Portland International Airport Terminal Building

2 Short-Term Parking

3 Long-Term Parking

4 Port Offices

5 Control Tower

architecture

The office and parking structures have been unified into one form to allow for an efficient use of space. The building’s design speaks to both the marine and aviation industry aspects of the Port’s operations. The north and east elevations form the primary face upon arriving at the terminal via Airport Way. For example, the curving, canted north façade could be the prow of a ship or the wing of a plane. The unique lapped-glass curtain wall is intended to harken back to the construction of early ships and boats.

The metal and glass exterior of the building relates to the palate of materials used throughout the rest of the airport, as well as to materials common to aviation and marine vessels. The office floors make use of extensive amounts of high-performance glazing on the north and south sides with appropriate external shading on the south to maximize daylighting and views for all the work spaces. Solar control on the south is also provided by automatically controlled perforated, interior horizontal blinds.

The exterior of the new parking structure not covered by curtain wall is screened by vertical pieces of channel glass. The translucent channel glass spans from floor-tofloor in a staggered pattern on the east and south and in a grouping of three pieces on the north, which relates to the scale and pattern of the curtain wall. The open spacing of the channel glass maximizes daylighting of the garage and provides an element of screening while unifying the office building and parking garage with glass elements that will glow with light at night.

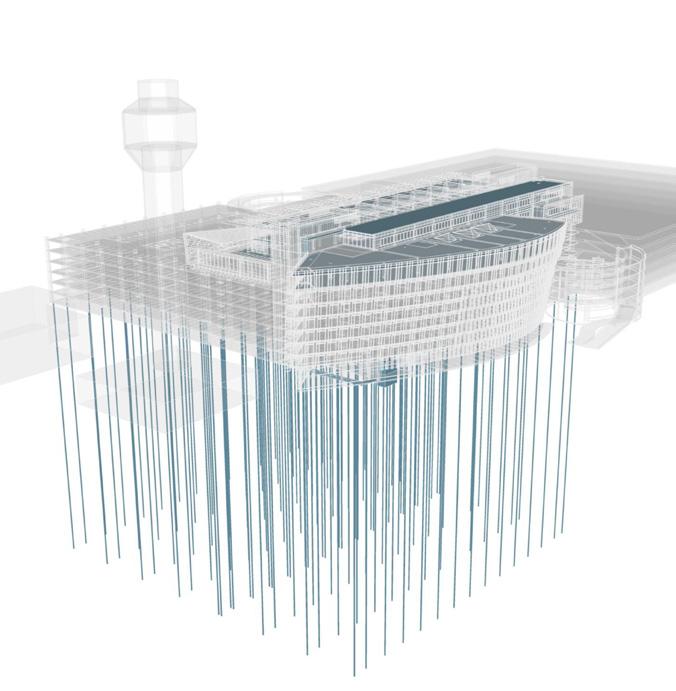

sustainable design

Constructing a new building provided the Port of Portland with an opportunity to further its commitment to sustainable and environmentally responsible building practices and operations. Designed to be LEED Platinum certified, the building incorporates the following strategies:

• Ground source heating and cooling with approximately 200 wells

• Passive radiant ceiling panel heating and cooling

• Daylighting with integrated lighting controls

• Glazing and fixed exterior shading and interior auto mated shades on the southern exposure

• The Living Machine® system, an organic wastewater treatment approach from Worrell Water Technologies

• One intensive green roof and one extensive eco-roof. Native and adapted plants for landscape and pervious pavers at entry and other areas as applicable

• Water-efficient fixtures

• Low-VOC paints and materials

• Recycled-content and regionally manufactured materials

Recognizing efforts made to reduce the building’s energy consumption, the U.S. Environmental Protection Agency (EPA) accepted the project for the ENERGY STAR Challenge. The following metrics were presented to the EPA:

• Energy use intensity (kBtu/sf/yr): 155.4 kBtu/sf/yr (source), 46.5 (site)

• Percent CO2 reduction (from average building): 40%

• ENERGY STAR rating: 86

• Energy savings (kBtu, from average building): 24,033,181 kBtu

• CO2 savings (metric tons, from average building): 868 Metric Tons CO2

• Energy cost/square foot: $0.94

Underneath the building, more than 200 pipes in a continuous loop system provide ground source heating and cooling, complementing the passive radiant ceiling panel heating and cooling inside. This is the first coupling of these heating and cooling systems in the United States. Features like daylighting, window glazing, fixed exterior shading, water-efficient fixtures, and a 10,000-square-foot eco-roof help save energy, water and money. All combined, the building will use 75 percent less water and 36 percent less energy compared to a standard building of the same size.

Water Efficiency

A 8th floor landscape deck with adaptive plants and micromist irrigation

B Low-flow fixtures

C Eco-roof with adaptive plants and micromist irrigation

D Living Machine® system

Energy Efficiency

E Reflective membrane roof

F High-performance glazing

G Radiant heating & cooling ceiling

H 200 wells provide ground source heating & cooling with auxiliary cooling tower for peak periods

The Living Machine ® System

1 Office building: toilet, sink & shower

2 Primary & equalization tanks

3 Tidal flow wetland

4 Polishing vertical flow wetland

5 UV sterilization disinfection

6 Clean effluent tank

7 HVAC office cooling tower

The Living Machine® system is a new approach for organic wastewater treatment and water re-use that treats wastewater on-site to be reused in the building for non-potable uses. It’s a proprietary, on-site ecological wastewater treatment system developed by Worrell Water Technologies that produces quality recycled water out of both gray and black water without the chemicals, odor, offensive by-products or high-energy usage required by conventional systems. The Living Machine® system uses a patented, automated tidal wetland process to produce treated water that will be re-used in the building for toilet flushing and in the HVAC cooling towers.

entrances/lobbies

The public entrance to the Port offices is at-grade on the north near the entrance to parking, and it features a paved entry court for vehicle drop-off. The two-story lobby provides access to meeting space for public and Port business and includes a significant installation of public art. The lobby for the Port offices is on the 8th floor and serves as reception for the Commission conference room and Port offices as well as secure access to the staff offices.

Level 1 Floor Plan

Community Space/Lobby/Conference room

Open Office/Workstations

Core/Support space

Circulation

Parking

Living Machine® system

artwork

Northwest artists were selected to provide the public art for the building. They include: Linda Beaumont, sculpture and terrazzo floor; Norie Sato, fixed glass wall; Jim Blashfield, multi-media; Tony Johnson and Adam McIsaac, Commission room doors; and Pete Beeman, kinetic sculpture. In addition, the Port is moving its art collection to the new building, and it includes paintings and sculpture by notable Oregon artists such as Henk Pander and Louis Bunce.

workplace environment

Coupled with the Port’s consolidation was an effort to shift from a closed office environment to an open plan, a change the Port’s leadership hopes will lead to a more unified workplace and organizational culture. To that end, a majority of the building’s office floors feature an open layout, with a mere 15% of the building reserved for those whose job functions demand a private office.

Providing a healthy work environment was a primary goal for the project. Materials selected include Forest Stewardship Council-certified wood paneling and linoleum and low-Volatile Organic Compound paints and finishes. Priority was also placed on providing natural light and improved air quality. Every workstation has access to exterior views by using low 42”-high panels of recycled metal and fabrics that are made with natural materials. Chairs can be taken apart and each piece recycled at the end of use.

atriums

ZGF gathered input from all Port staff to determine work process needs. Common trends emerged, including the desire for a universal conference room setup so everyone could use any conference room and be familiar with equipment and other operational requirements. Open atriums provide visual connections between the floors and will assist wayfinding and enhance communication.

daylighting/views

The organization of the office building consists of three parallel bars of offices oriented in the east-west direction for maximum solar efficiency, separated by two atria. These three functional bars are expressed on the exterior as a sweeping curve maximizing light and views of marine and aviation facilities to the north and east. It has a strong central east-west spine carrying all of the core elements and an inflected south bar – shaped like an airplane wing – looking out to the airport and airfield beyond. This arrangement produces relatively narrow office floors so that everyone’s workstation has access to natural daylight and views. The atria and light promote communication and interaction among workgroups.

outdoor amenities

An outdoor landscaped terrace runs the entire length of the 8th floor offices. One of the major art installations for the building is an interactive sculpture on the terrace. The roof of the 9th floor on the north side of the building features an extensive eco-roof that provides a significant area for rainwater treatment. It also creates a green surface that serves to mitigate stormwater, reduce the building’s heatisland effect and provide a green amenity.

section

Community Space

Open Office

Core/Support Space

Circulation

Parking Tunnel

North-South East-WestCommunity Space/Conference Room

Open Office/Workstations

Core/Support Space

Circulation

Green Roof

Sun Screen

Skylights

Atrium

Level 8

Level 9