About Me...

Achievements

Certified Solidworks Associate

Interests

Design (Obviously)

My name is Zach.

I’m a multi award-winning, 2nd year BSc Product Designer at Nottingham Trent University.

I love to create using influences from my experiences in both industrial and graphic design, as well as my passion for musical instruments and technology.

I am hard-working, both in a team setting and as an individual, and always take satisfaction in seeing a project develop from research through to a final solution.

Gold Award and Overall Winner of the Mattii labs Design Competition

Overall Winner of the Alpkit Design Sprint

Highly Commended in the Hydro Aluminium Design Competition

Education

2022-2026

Nottingham Trent University

School of Architecture, Design & Built Environment BSc Product Design SW

2020-2022

St John the Baptist 6th Form - A levels

Maths (A)

Physics (B)

Product Design (B)

2015-2020

St John the Baptist Secondary School

GCSEs at Grades 6-8 including Maths, English & Graphic Design

Guitar (Have achieved Electric Guitar Grade 6 & Classical Guitar Grade 4)

Piano

Headphones & Speakers

Music Tech

Video Games

Dungeons & Dragons

Key Skills

My

Rega Precision Engineering Project

Rega Cetus

4 Week Project

Design and prototype a precision engineered, long-lasting litter picker to be used in beach cleanups.

Focus on sustainability and precision

Key Skills Used:

Key Research

pieces of plastic in the ocean

of those end up on beaches

volunteers in the Great British Beach Clean 2022

Why beach cleanup?

Removing litter from beaches is very important to both me as an individual and for reducing the amount of plastic waste in the oceanstherefore reducing global pollution - making this an essential area to design for.

Rega’s brand

Rega is a UK based designer and manufacturer of high end HiFi products. Their designs often feature clean, minimal aesthetics, with few colours and smooth, edges. Rega tend to use materials like aluminium, steel, resins, ABS and nylons for their product range.

Key users

This would have to be suitable for people of a wide range of ages and heights as beach cleanups are popular with a variety of demographics. This would mean that adjustability and ease of use is a necessity for this to be a successful product.

Sketch Development

Initial Ideation

Key Development

Finalising Ideas

Model Development

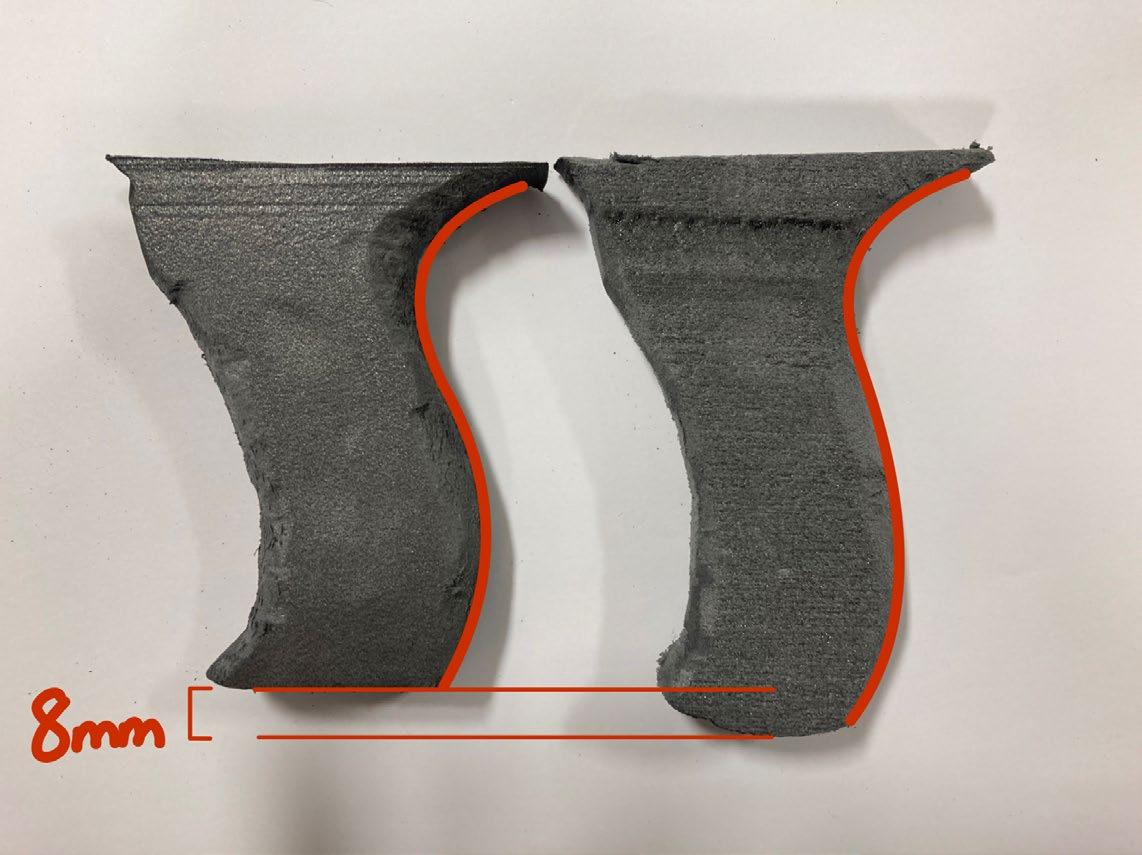

My model making first started with the final sketches. This gave me a framework to work from and to direct my aesthetic choices.

I then moved on to foam modelling. This allowed me to test the initital handle shape against a variety of hand sizes and adjust the shape accordingly.

I then moved on to CAD and 3D printing. After testing my first 3D printed model, I found some adjustments that needed to be made to allow the mechanism to function properly.

Finally, I used a 3D printer with a greater resolution for my final prints. This allowed for better dimensional accuracy for easier adjustability and an improved surface finish.

Technical Detail

Final Product

Alpine Alert

4 Week Project

Design a self-powered product to be used off the grid using innovations in plastic, made for the domestic or sports & leisure markets.

Focus on materials and sustainability

Key Skills Used:

Key Research

Mountain rescue are called around 5 times monthly

1.5m UK residents go on ski holidays annually

1 skier is injured in every 500 visits

Why mountain safety?

When conducting some initial research into this area, I found that many of the existing solutions were very expensive, especially as many had a subscription service attached. Additionally, the movement from skiing/snowboarding etc. would mean that charging on the go would be suitable.

Self-powering products

Many existing self-powered products take advantage of electromagnetic induction. This is likely due to its high efficiency and good availability. While other powering methods may be suitable (e.g. solar, wind), these are not as efficient.

Existing emergency products

A standout emergency product was the emergency beacon. This product uses radio signals to send messages to an operator, who can then alert rescue services to the issue. This was particularly interesting as many of the current examples were bulky and expensive

Product Development

Starting from initial sketches and into concepts, I landed on this small, handheld design.

I then did some rough sketch modelling using cardboard to correctly scale the item.

Then, moving on to CAD, I developed the design further with alternative button shapes and sizes and exploring the size of screen to include on the product.

To ensure this design was correctly scaled and was ergonomically sound, I 3D printed my final design and tested it on a variety of hand sizes.

Graphic Development

Colour Selection

To make the key information on screen as readable as possible, I made sure to use contrasting colours that would stand out from the snowy environment.

Typeface Selection

I also wanted to make sure that any information on-screen was as easy to read as possible. Therefore, I settled on a bold, sans-serif type. Something like (3) would be ideal to fit this criteria.

Seen here are some examples of what on-screen graphics may look like. To the left, this text-only example uses the bold text and colours to clearly display any key infornmation the user may need while operating the product.

To the right is an example of a graphic showing a map of the user’s current location. This clearly shows the information the user may need in an emergency while removing any other potential distractions from the interface.

Technical Detail

Electronics have an estimated total cost of £70.

Therefore, total manufacture cost comes to £89.79.

With an ~89% markup, RRP would be £169.99

Material Choices

As one of the main aims of this project was to explore innovations in plastics, I chose to use a PC-reinforced PET. This gives the positive properties of the PET (good injection moulding, recyclability), while improving properties like the impact resistance and compressive strength. Also, the central board (2) uses a bio-based nylon - PA410 - for its high tensile strength, impact resistance and extreme temperature performance.

Design Considerations

To ensure good injection mould results, I made sure to include draft angles and curved edges on all pieces. Additionally, the lip/groove around the shell edges have been toleranced to allow for a friction fit.

Final Product

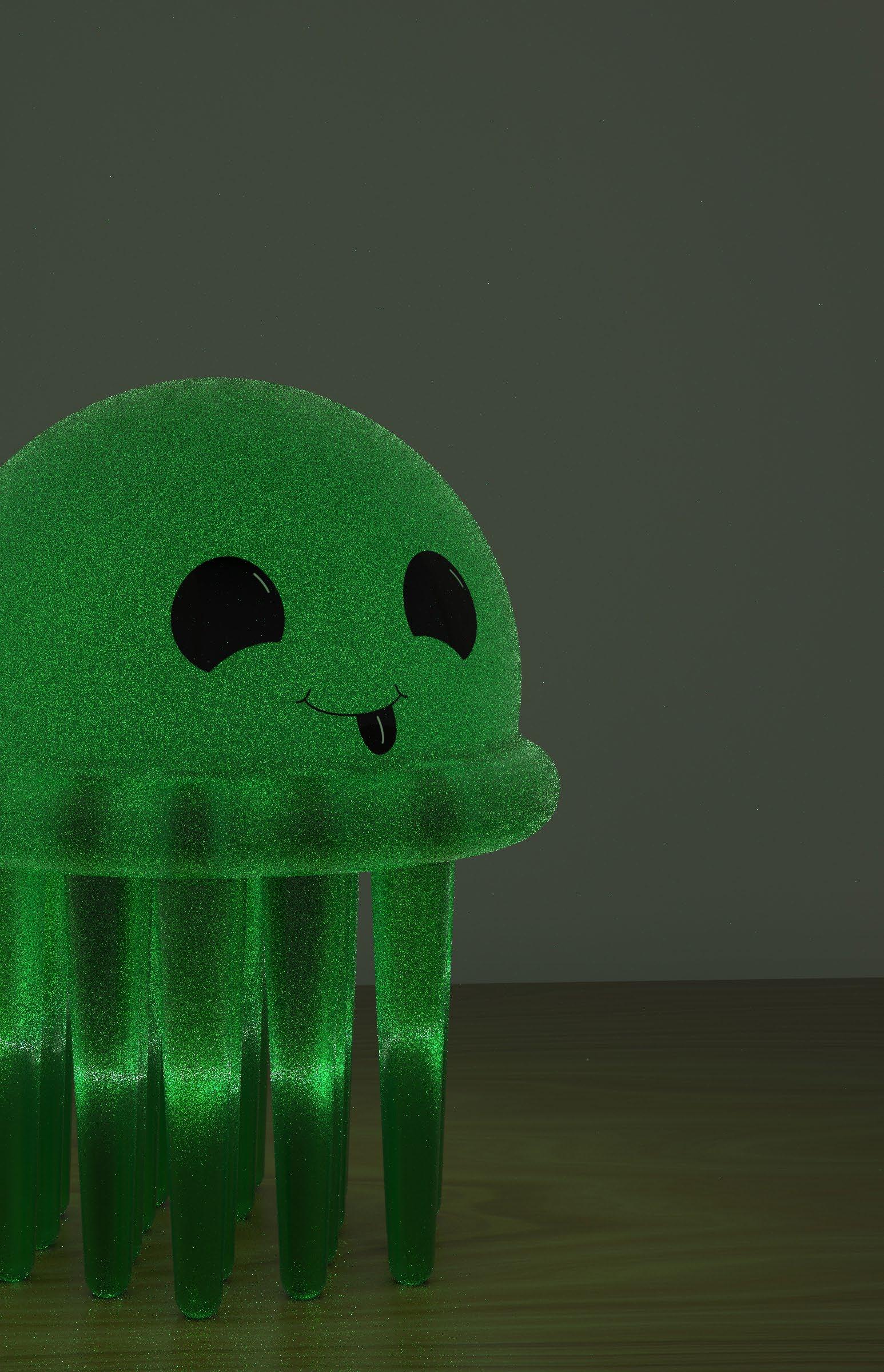

Jellii

4 Week Project

1st year

Design a sensory product for children using upcycled silicone fingers taken as a waste product from the aviation industry.

Focus on marketability and upcycling

Key Skills Used:

Key Research

73% of children aged 3-12 are afraid of the dark

Dimmer night lights have the least effect on circadian rhythm

Most existing night lights are battery or wall powered

Why a sensory product?

I chose to design a sensory product for this project as I felt that there was a wide scope for innovation. I saw this especially in the children’s market, focussing in on night lights as a large portion of children are afraid of the dark.

Mattii Labs

The silicone fingers used in this project are produced as a waste product from the aviation industry. Mattii Labs is a company taking these waste fingers and reusing them in other products, currently in the pet care market.

Key development

Due to the joint focus on sustainability and marketability, I wanted to make the silicone fingers a key part of my design without making them feel forced into the product. This lends itself very well to the jellyfish design I developed, allowing for good integration as the tendrils.

Packaging & Marketing

Because of the focus on marketability and recyclability, I ensured the box materials would be both recyclable and easy to print on to.

Some minimal branding would be printed on to the box so as not to take away from the main product inside.

Advertising and marketing would also be fairly minimal, utilising social media and targeted ads on parenting websites.

Final Product

Alpkit Presta

1 Week Group Sprint

Take the existing Alpkit Presta day backpack and reduce the carbon footprint, taking the entire life cycle into consideration.

Focus on sustainability and brand identity

Key Skills Used:

Overall Winner!

Key Research

Carbon reduction per backpack

Weight reduction

Carbon reduction over a 1 year period

Life Cycle Analysis

A key part of this project was completing a Life Cycle Analysis (LCA) to find the initial carbon footprint of the product, then completing an updated version at the end of the week for our developed backpack. The above infographics demonstrate the key findings from this.

Alpkit’s Brand

As brand language was a major focus of ours, we looked at existing promotional material, in store information and their website. The main points gathered from this is the more casual language, fun annotations, simple colour schemes and playful fonts.

Product Teardown

To be able to successfully complete an LCA, we underwent a teardown of the existing Presta backpack. This gave use the current materials used and the weights and quantities of each, as well as the current joining methods and stitches used across the product.

Sketches & Models

Sketchwork

I was responsible for all of the sketches and linework for this project, bar some of the ideation. I used both digital and physical methods, allowing for accurate traces of the overall shape while giving versatility to add our new features.

Model Making

For this sketch model, we used packing peanuts in a plastic bag, which we then shaped and held using duct tape. We then added details and additional features using cardboard, paper, string and markers. This allowed us to get a good grasp on what a real version of our modified product would look like.

Final Product

Left image is my personal re-rendered version, the rest are group work.