`The bridge between matter and spirit is matter becoming spirit`

PAOLO SOLERI

`The bridge between matter and spirit is matter becoming spirit`

PAOLO SOLERI

The project juxtaposes the varied backgrounds of each of the team members and aimed to blend the fields of biology, computation, and architecture. This endeavour would not have been possible without the support of my team, Faraz Alian and Sarah Aljishi. I would like to express my gratitude to Faraz for contributing to the research through computational design and Sarah for grounding it through her material explorations.

I would also like to take this opportunity to thank our Year 1 collaborators, Dana Molzhigit, Rita Morais, Shylaja Regunathan and especially Hansa Baliga for their valuable support. I would like to extend my sincere thanks to my design tutors, Kostas Grigoriadis and Javier Ruiz Rodriguez for their guidance in the final project. I would also like to thank my Year 1 tutors Nina Jotanovic and Shneel Malik, for always keeping us inspired through rigorous discussions and encouragement.

I express my deepest gratitude to Pradeep Devadass for his time and assistance in realizing the fabrication methodology. I would also like to thank Guillem Perutxet Olesti and Jingyuan Meng for their assistance with the robots and scripting. The challenges faced by the design practice and fabrication methods could not have been overcome without them and all the help provided by the fabrication experts in B-MADE.

I am deeply indebted to my family, especially my mother and my brother Ayaz for their endless support and understanding that empowered me to do better at every step of the way. I could not have undertaken this journey without the unwavering support of my team at Anastomosis Design Lab, especially Tamer Khalil, Mohannad Jad and Sophia Qassim for all their motivation and understanding. This endeavour would not have been possible without the support of my friends, especially Gitanjali Ravi and Harsh Shah.

And last but definitely not the least, I would like to express my gratitude to my course directors Prof Marcos Cruz and Dr Brenda Parker for taking the initiative to establish the Bio-Integrated Design Lab. The stimulating environment with such a diverse set of minds has kept me inspired and excited throughout the programme.

The skillset that I have acquired over the course of the last two years has enabled me to look forward to more exciting adventures over the next phase of my academic and professional journey.

Alhamdulillah.

As climate change increases temperature fluctuations, the stangant role of architectural boundaries becomes questionable, from protective dividers between the exterior and interior to spatial conditions that can host microenvironments. The research aims to investigate the realm of hybrid spatial conditions by bridging computer-aided design and manufacturing through bio-integrated design strategies. Architecture should not just be a wall but a point of contact between the exterior and interior where micro-climates can be shaped in architectural skins. The Almanac highlights key design explorations over the two years, focusing on arid environments, which led to the final project, Xerilith. The research proposes a workflow methodology that interchanges rapid prototyping (RP) and computer-aided manufacturing (CAM) technologies to challenge the conventional means of architectural production. Through this, a performative interface is created utilizing a thoughtful choreography of environmental data, computational design and fabrication techniques that can operate on various scales. The material research agenda focusses on a circular ecosystem by using site-sourced materials and organic binders to create a nutrient-rich media that can be used for additive manufacturing. Where the fabrication agenda explored a bespoke additive manufacturing technique using desert sand as a particle bed system where nutrient-rich media that can be robotically extruded.

From early human caves to the most recent skyscrapers, architecture has been perceived as a protective barrier protecting the interior human activities from the exterior weathering conditions (Sean Lally, 2014). However, today, as climate change presents existential threats and habitation challenges to humans, it calls for an urgency to rethink the traditional ossified understanding of architecture. Our environment is essentially a multi-layered constitution of particles, waves, chemical interactions and gradients of energy systems that behave conjointly to create the climatic conditions around us. (Sean Lally, 2014). So, instead of approaching architecture as an inert mass, can we integrate these forces of nature to derive dynamic and integrated living-built environments?

Through out history humans have built structures that not just represented their identity but also expressed how they perceived nature. These interlinks introduced distinct microclimates and symbiotic ecosystems that sustained fluctuating climates through testing times. With the ever-increasing hostile micro-biome conditions today, the key to investigating novel hybrid spatial conditions and establishing a dynamic understanding of architecture is to develop a workflow methodology that bridges the digital and physical realms. Phygital biosphere is an exploration of digital fabrication as an agency to link nature and architecture through bio-integrated strategies. The primary goal of the research is to challenge the conventional means of architectural production by developing a workflow methodology that interchanges rapid prototyping (RP) and computer-aided manufacturing (CAM) technologies. By exploring living materiality the research aims to create a performative interface through a thoughtful choreography of environmental data, computational design and fabrication techniques that can operate on various scales.

This almanac is a comprehensive representation of the research conducted during the Bio-ID program at the Bartlett School of Architecture. It sets the research’s premise and development process through a series of tests and experiments that realized the framework for the thesis, Phygital Biospheres.

The research challenges the current additive manufacturing methodologies by pushing the boundaries of conventional robotic extrusion techniques. The techniques developed throughout the research aim to create scaling-up opportunities currently limited by the mechanical properties of materials such as clay and ceramics.

However, The research is contextualised by exploring the additive manufacturing technique using desert sand and organic binders in xeric environments. The desert sand is considered ineffectual for the construction industry due to its fine aggregate and low binding properties (Golden ELizabeth, 2018). Climate change leads desert environments to higher dry spells with increasing temperature and rainfall fluctuations. Xerification challenges the future of Anthropocene and urban developments in desert environments (Sergio Araya, 2011). Therefore, the thesis questions, can particle bed additive manufacturing using nutrient-rich media be a viable fabrication methodology for desert environments?

The research focuses on robotically extruding nutrient-rich media in a sand-based suspension setup that utilises the germination process as bio-reinforcement for architectural components. The aim is to address the current challenges and limitations of additive manufacturing to propose a circular fabrication methodology for desert environments.

Therefore, the almanac is structured over the following chapters to present a coalesce of environmental factors, design explorations and material ecology to propose a viable fabrication technique for desert environments. The second chapter investigates the traditional desert vernacular to identify key environmental factors as design parameters to reimagine the role of architectural skins as a performative interface. The third chapter presents key design investigations to address the impacts of climate change in xeric environments. The fourth chapter questions Paolo Soleri’s concept of arcology to depart from utopic visions to data-driven urban clusters derived through advanced computational design. The fifth chapter draws parallels between the procedural nature of organic life and additive manufacturing to develop a bio-integrated fabrication methodology for desert environments. The sixth chapter presents material ecology using desert sand and organic binders to create nutrient-rich media that can allow plant growth in architectural skins. The seventh chapter studies the optimisation of digital toolpaths for robotic additive manufacturing through a series of digital script designs. The eighth chapter archives the experiments conducted to develop a viable robotic extrusion methodology using the digital tools and material developed throughout the research. The ninth chapter illustrates the prototype and testing phase of the fabrication process. In the end, the closing chapter discusses the results and key findings of the research.

The thesis addresses the current limitation of scaling up 3D sand printing by bioreinforcement of the composition. The composites need fibres to improve their mechanical properties, which can be incorporated via 3D printing. However, the limitations of the nozzle size or extruder damage pose a challenge. Therefore, the research hypothesises that allowing the seeds to germinate in the 3d printed nutrient-rich media can enhance their mechanical properties over a period due to the filamentous growth of roots. The research presented in this almanac aims to achieve novelty in the field of additive manufacturing by integrating biology to make architecture environmentally responsive and ecologically active.

As the thesis aims to bridge the digital and physical realms through the integration of biology within the desert environments, three primary domains of methods linked the research to a final prototype. The Computational Design agenda, led by Faraz Alian, focused on environmental CFD analysis and recursive growth methods to generate geometries. The Lab Research agenda, led by Sarah Aljishi, focused on developing and testing the nutrient-rich media using locally sourced materials such as desert sand and organic binders. The fabrication agenda, led by Zain Ansari, focused on developing additive manufacturing techniques using nutrient-rich media.

‘Architecture is much more than the building of an object on a site: it is a reinvention of the site itself’ (Sean Lally, 2014). Throughout history, natural and built contexts have been considered independent entities of external and internal conditions (Sergio Araya, 2011). Nature is evolutionary, where various organisms develop coping mechanisms to adapt and survive (Sergio Araya, 2011), whereas architecture has always been approached as a firm boundary with a rigid and permanent character (Sergio Araya, 2011). In order to create a synergy between the natural and built realms, the meaning of architectural boundary must be redefined with a shift in paradigm from its inert existence to how it behaves. To do this, it must be reimagined as an interface of microclimates and ecosystems that perform cohesively to create harmony. This chapter aims to contextualize the research by identifying vital environmental factors as design parameters to create a performative architectural interface for desert ecosystems.

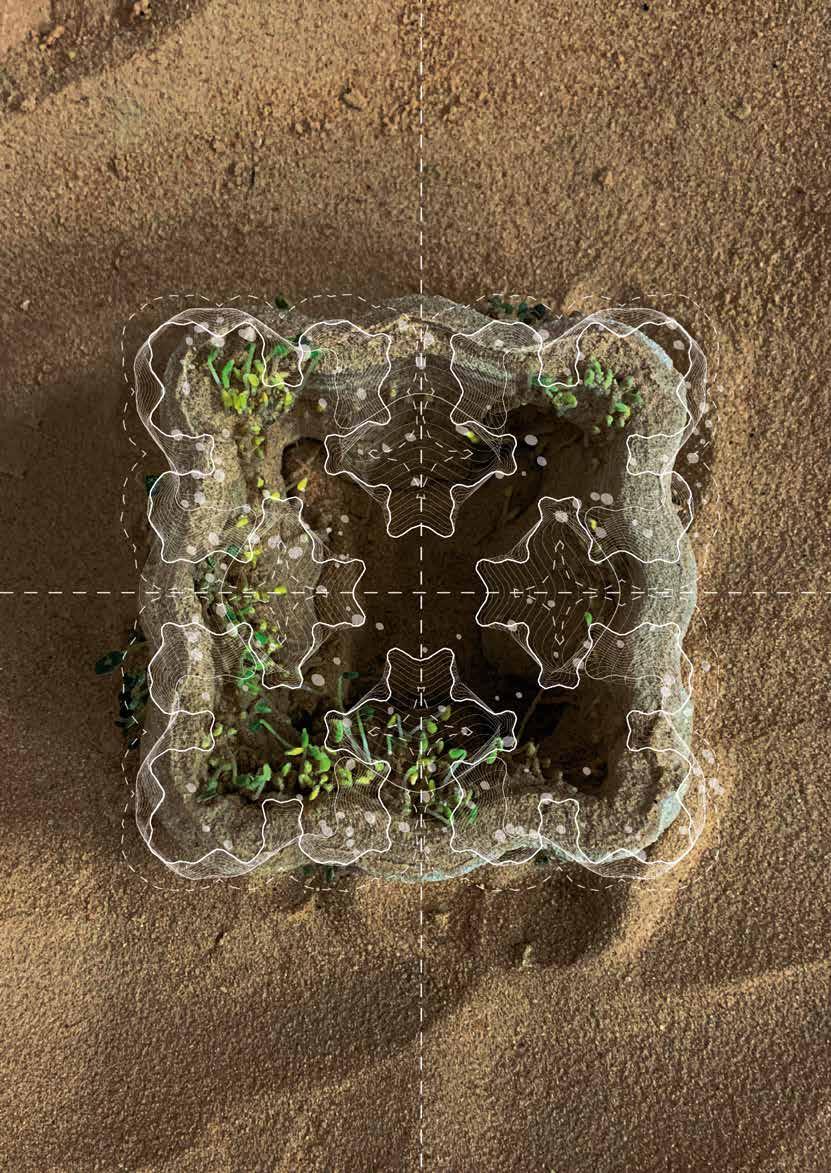

2.2 (Bernhard Edmaier, 2019)

The development of deserts is impacted by three physiological factors (Schwimmer and Haim, 2009):

A- Rain Shadow: Separation from oceanic moisture due to the massive range of mountains.

B- Lack of Storm Systems: Storms create unstable environments that help to create favourable conditions of moisture necessary for precipitation.

C- High-Pressure Belts: Persistence of dry stable air masses which resist convective currents.

Due to these factors, the deserts are classified into three categories (Schwimmer and Haim, 2009):

A- Rain Shadow Deserts

B- Sub-tropical Deserts

C- Coastal Deserts

Temperature and moisture availability are key environmental stressors in xeric urban environments (Schwimmer and Haim, 2009). Therefore, built environments in desert regions must be addressed through an integrated physiological approach that can dissipate heat and conserve water. In order to achieve this, the research focuses on the three primary stressors as design parameters to propose a responsive architectural methodology.

Thermal barrier

Explore geometries and textural properties to control thermal activities in buildings.

Aerodynamics

Develop aerodynamic strategies that can redirect and channel wind through building envelopes.

Desert environments are sensitive ecosystems where the survival of natural life is heavily dependent on three key environmental factors: air, temperature and water. As the research aims to take these factors as design parameters, it is crucial to learn from various organisms how they develop resilient coping mechanisms in such environments. For this purpose, two case studies are analysed, the desert beetle and cactus.

2.4 (Nørgaard & Dacke, 2010) 2.5 (Nørgaard & Dacke, 2010) 2.6 (Nørgaard & Dacke, 2010) 2.7 (Nørgaard & Dacke, 2010)

2.8 (India and Magnus, 2017) 2.9 (India and Magnus, 2017) 2.10 (India and Magnus, 2017) 2.11 (India and Magnus, 2017)

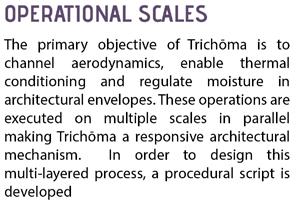

Cactus is defined by the protuberances and ribbed structures that play a vital role in air circulation and water retention in severe heat (Courtney, no date). These pleated surfaces increase the volume of moisture absorption through stretching and retracting mechanisms while reducing direct exposure to sunlight (Courtney, no date).

It can be observed that surface textures and their operation on multiple scales induce microclimates to play a vital role in establishing a performative interface for the survival of these two desert organisms. In contrast, the current approaches to designing buildings in desert urban contexts ignore such environmental parameters and rely heavily on mechanical cooling.

For the last 10,000 years, unbaked earth has been one of the vital building materials used in different arid regions worldwide (Jean Dethier, 1982). Unbaked earth has been used to achieve various architectural forms defining the cultural identity of the building communities (Jean Dethier, 1982). Due to its thermoregulatory properties, unbaked earth construction has proven to be highly energy-efficient and adaptable to various arid climates (Jean Dethier, 1982). Apart from materiality, the desert vernacular was also highly dependent on strategic planning, where spatial voids played a significant role in moderating microclimates in architecture (Babsail and Al-Qawasmi, 2015). Therefore, it can be observed that the material’s versatility, when paired with strategic planning, helped desert communities establish an ecological harmony between the natural and built environments.

Desert urban environments have lost their traditional identities and have become hybrids of exotic characters in their architectural form, spatial arrangements and construction techniques (Babsail and Al-Qawasmi, 2015). Today, the abandonment of local traditions and importation of alien materials are pushing urban desert settings to face significant energy consumption challenges required to cool buildings (Babsail and Al-Qawasmi, 2015). So how can we use advanced computation and fabrication technologies to understand the past and predict a culturally and environmentally responsive built environment for the future?

The research focuses on developing and integrating a feedback loop between architecture’s digital and physical domains to develop a performative architectural interface for xeric environments. This is achieved by quantifying key parameters to produce a database of results through digital simulations and material experiments integrated seamlessly into the architectural design process.

About 50% of the energy consumption in desert buildings is subjected to air-conditioning, resulting in heavy reliance on conventional fossil fuels (el Azhary et al., 2018). The lag time vs. thermal differences is considered to calculate the loss and gain of heat in architectural skins to optimize the thermal performance in buildings.

Air movement in desert environments is an essential factor that allows passive cooling in the desert vernacular and enables a gaseous exchange (Alp, 1990). This thermal and gaseous exchange can enable buildings with a dynamic interface when orchestrated on different scales. Factors such as wind speed and surface protuberance size are considered to understand the circulation of air on different scales.

Water availability is crucial for organisms’ survival in desert environments (Beysens et al., 2013). Where architectural skin act as a virtual interface between the built and hot, humid air (Beysens et al., 2013). If addressed strategically, architectural skins can be utilized to harvest atmospheric moisture due to thermal differences between the two mediums (Beysens et al., 2013). Collecting dew on facades can help increase the moisture levels in the architectural skins, providing two benefits: passive cooling and survival of plants. Therefore, the surface texture is considered a design parameter to develop an interface for dew capture on architectural skins.

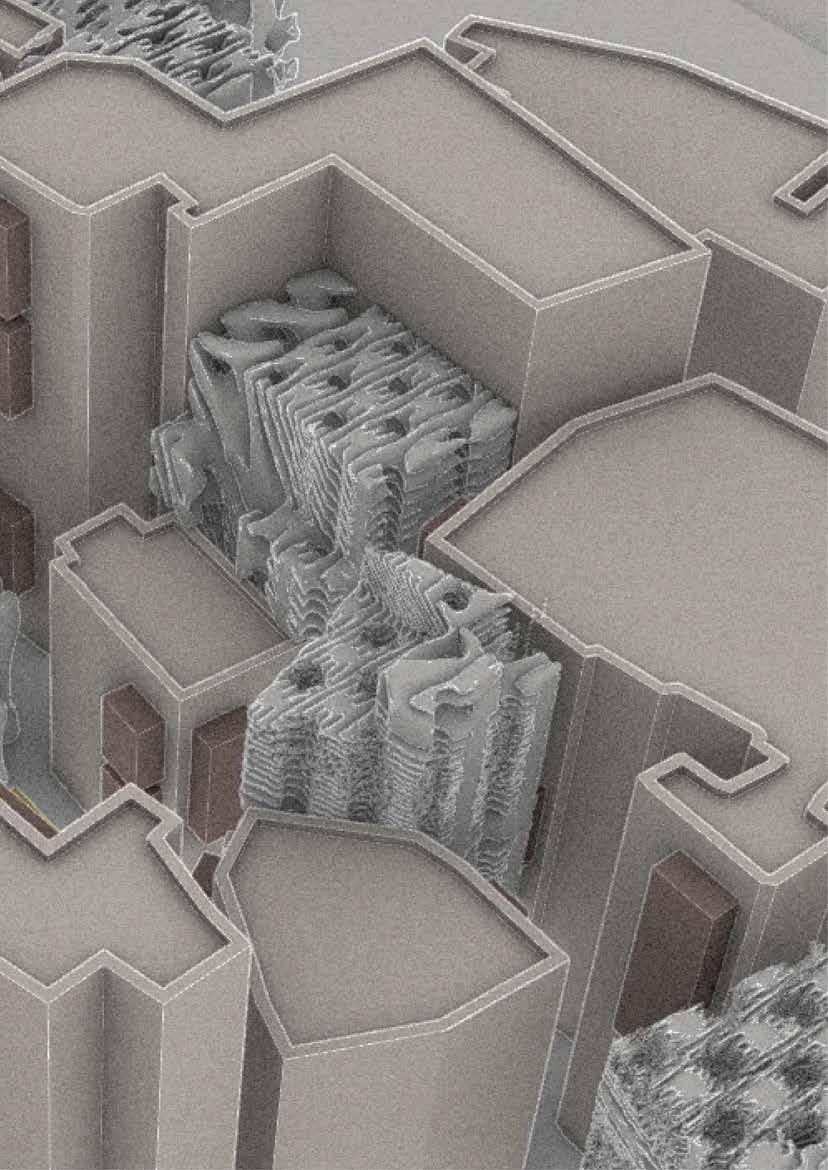

As the research aims to induce microclimates using thermal performance, aerodynamics and dew capture, scale becomes an essential factor while approaching the design process. Three integral operational scales in the built environment are addressed while orchestrating the design parameters to develop a performative architectural interface for xeric environments.

Using environmental simulations such as solar and wind analysis to optimize the foundations of urban planning

Solar radiation and wind analysis are used to map openings and protuberances that allow good light penetration and wind circulation.

2.21 2.22 2.23

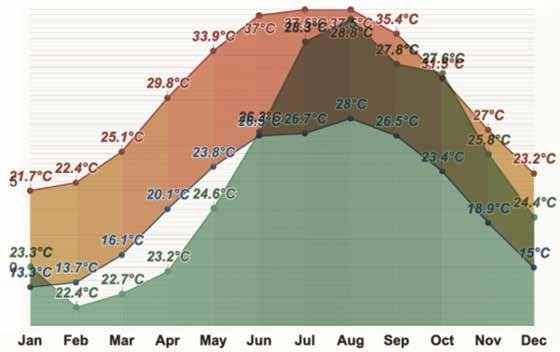

Desert ecosystems are predicted to be one of the most vulnerable to global climate change (Bombi et al., 2021). Rising temperature, decreasing rainfall, and increasing atmospheric CO ₂, is expected to strongly affect the structure and function of desert ecosystems (Bombi et al., 2021)

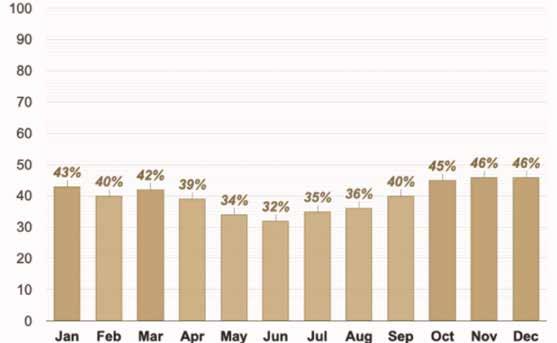

Saudi Arabia is susceptible to the impacts of climate change that pose increasing risk to its water security, such as the decrease in frequency and amount of precipitation and increase in temperature. (Portal, no date)

Xeric inhabitants are exposed to extreme differences in ambient temperatures, such as severe hot days and cold nights, where the survival of natural ecosystems is directly controlled by water availability (Schwimmer and Haim, 2009). That makes temperature and precipitation one of the key stressors in xeric urban environments.

So how can we use advanced computation and fabrication technologies to understand the past and predict a culturally and environmentally responsive built environment for the future?

Addressing this question has been a primary objective of the research presented in the almanac. This section presents critical investigations conducted over the last two years to understand and explore various aspects of arid environments as design parameters.

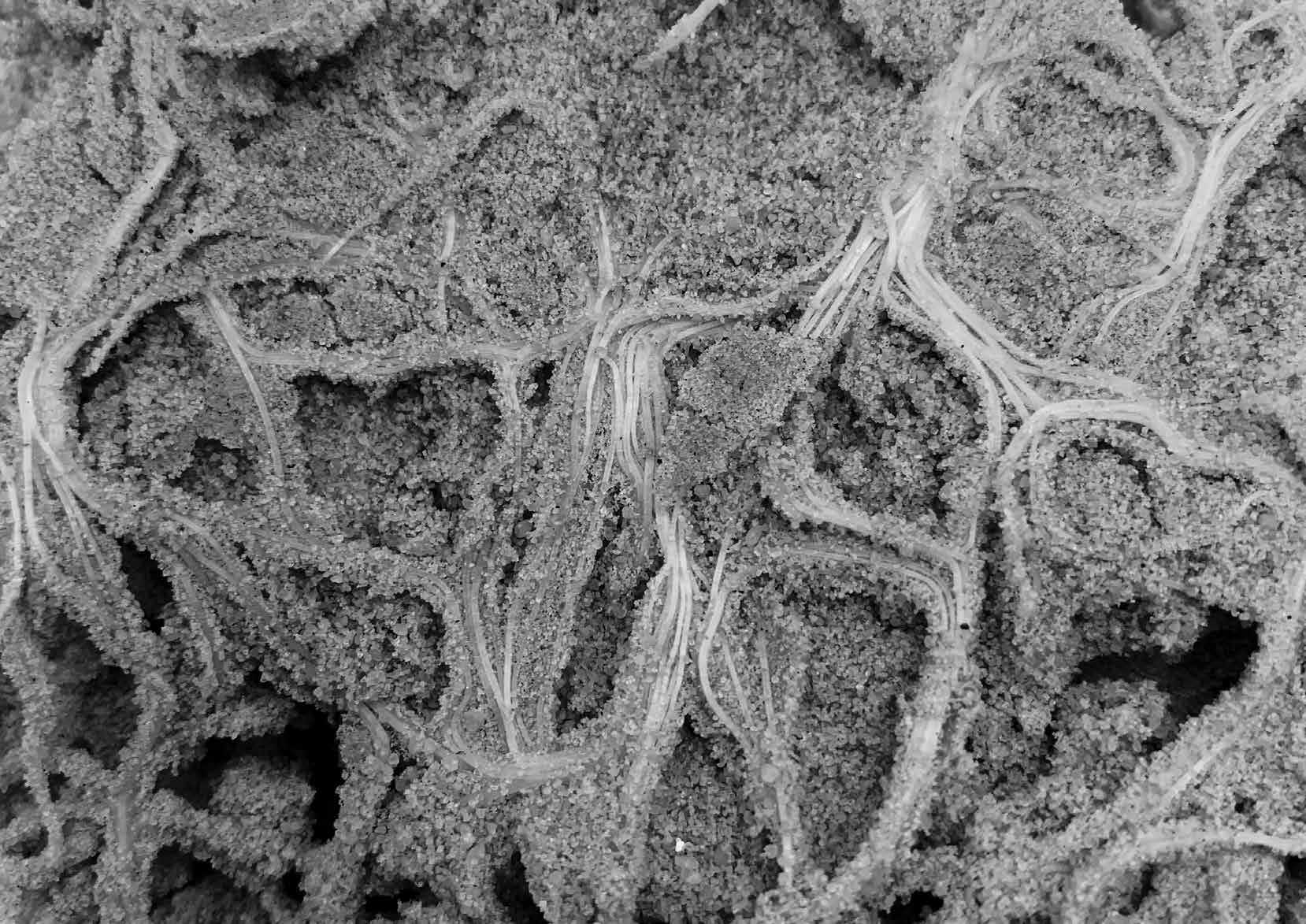

Arrakis is a Y1 project that explores bio-integrated design strategies to harvest atmospheric water in arid conditions, from exploring the fringes of Jeddah to understanding arid terrains, plant growth and survival mechanisms and harvesting water from hot desert air through meshes. The system can be used to create pods in desert landscapes. The water absorption and retaining capabilities of the Arrakis 1 walls can help create micro-ecologies in arid regions. Studying plants such as Calotropis Procera and Abutilon Palmeri to understand various bio-mechanisms that make these plants highly resilient in extremely arid conditions. Trichomes are hair-like structures that support the absorption and retention of water and other minerals required by the plant. These structures form a protective coat on the leaves’ outer surface to help prevent water loss in highly arid conditions.

The system can be used to create pods in desert landscapes. The water absorption and retaining capabilities if the Arrakis 1 walls can help in creating micro-ecologies in arid regions.

The system can be used to create pods in desert landscapes. The water absorption and retaining capabilities of the Arrakis 1 walls can help create micro-ecologies in arid regions.

Hydra is a Y1 project in collaboration with Will Scott and Shenghan Chen. As climate change takes its course, numerous threats are speculated to reshape the existing environment and ecosystems. One of the challenges the tropical cities and villages faces is the increasing frequency of annual floods and droughts. This shift is causing water shortages and loss of agriculture in such regions, leading to mass migrations in the coming years. Hydra is a proposal for a stormwater management system that aims to act as a water barrier during flood season and harvest atmospheric moisture during drought season. The project aims to explore an architectural script that can potentially channel and interact with water in extreme environmental settings.

The precipitation and river flow in the Bago River Basin have changed, resulting in floods and droughts in this watershed because of climate change impacts. In summer, many areas in the Bago River Basin are known for their scanty annual rainfall, remarkably high rates of evaporation and consequent insufficiency in renewable water resources, and reduced water storage capacity. Water yields declined at the basin outlet during the summer and winter but increased during the rainy season. In the dry period, especially in March, because there is less water in the river, the river’s flow is reduced to a velocity ranging from 6-40 cm/s. In the rainy season, a greater quantity of water in the river at the flood level of 860 cm causes the river to regain its flowing rate of 137 cm/s, and as the flood level becomes higher to the point of 900 cm, there is an increase in the flow rate, for instance to 200 cm/s.

(Journal of Earth Science & Climatic Change, Aung Ye Htut, Sangam Shrestha, Vilas Nitivattananon and Akiyuki Kawasaki)

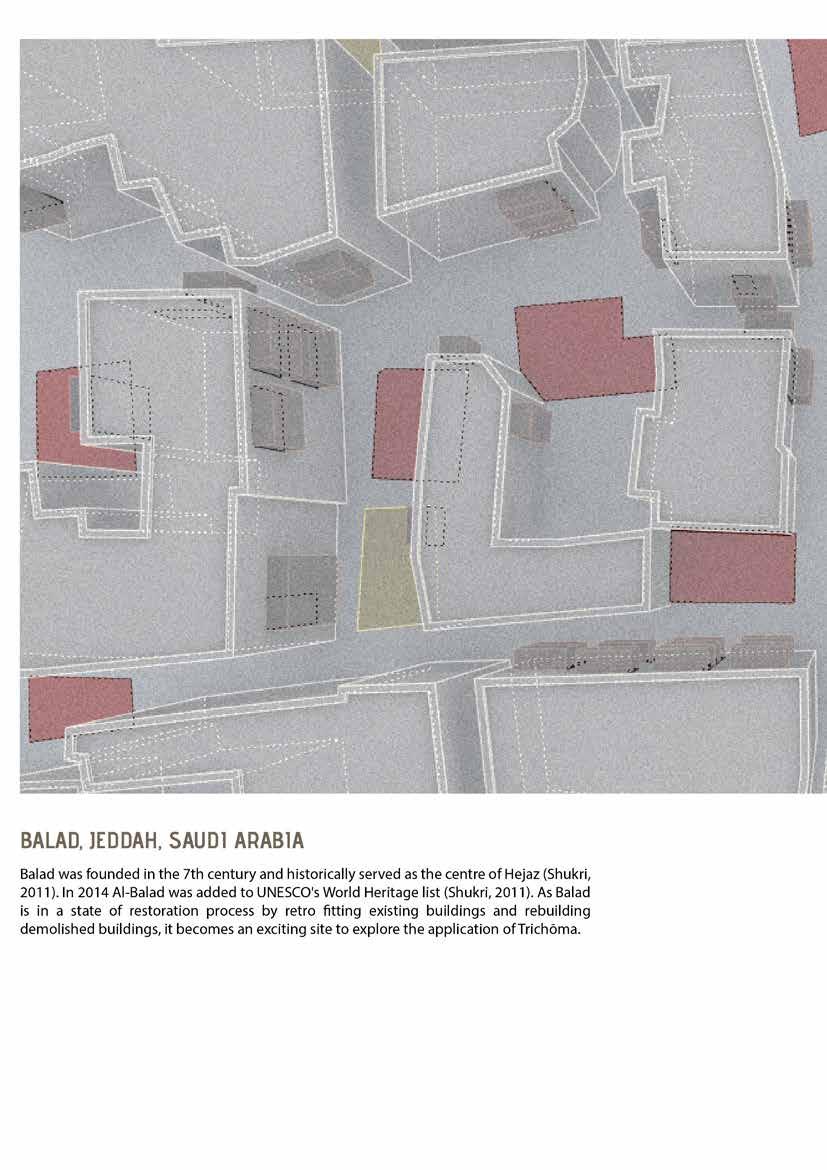

Trichoma is a Y1 project in collaboration with Lina Sarma, who led the CFD analysis and Agathe Cheve, who led the scientific research agenda. It aims to present an architectural system called ‘Trichoma’ by drawing parallels between biology and architecture. This project aims to liberate architecture from its traditional association with inert mass towards a responsive behavioural mechanism that can function on various scales. The primary aim of this project is to integrate biology with environmental data and vernacular architecture through advanced computation and fabrication techniques.

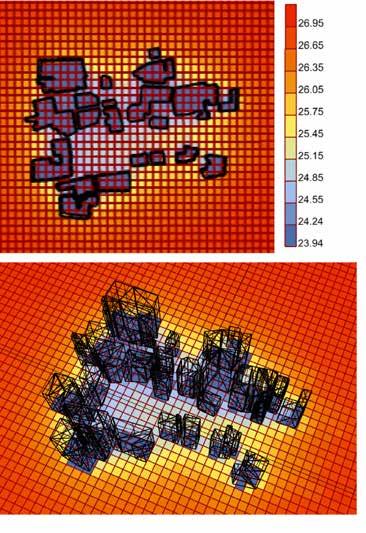

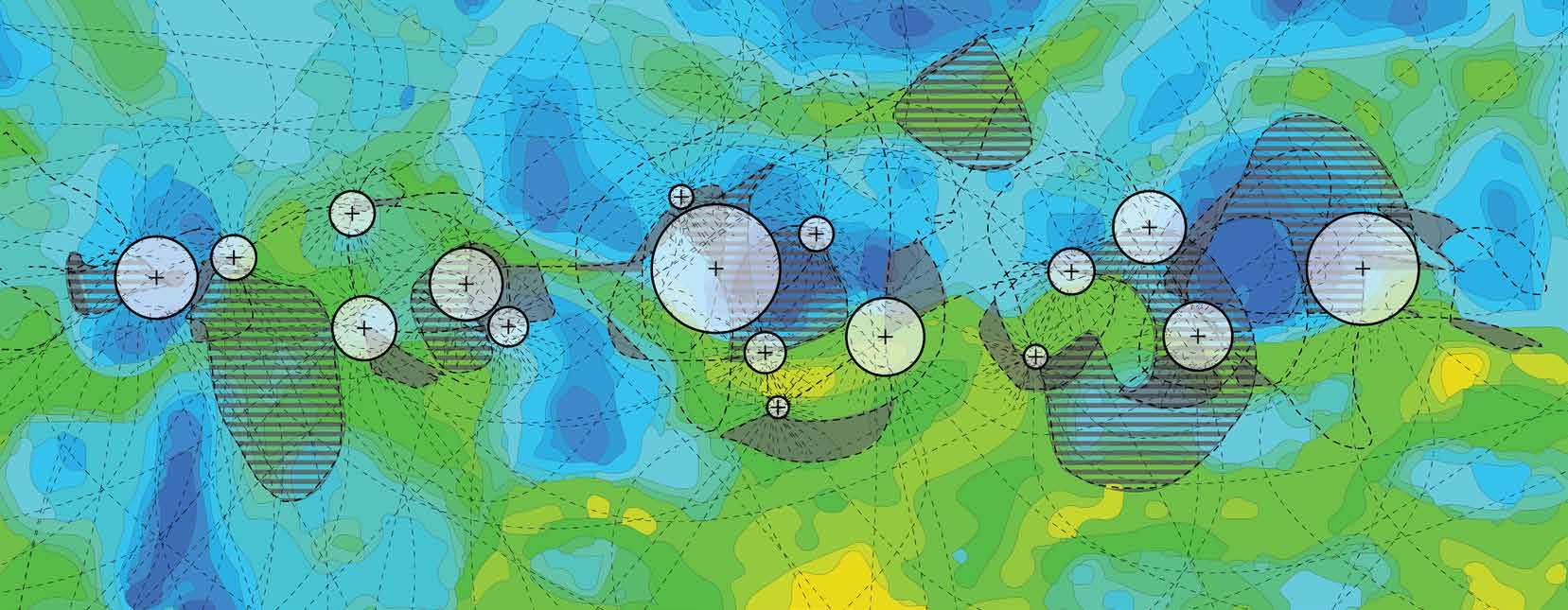

Additionally, by using the Universal Thermal Comfort available within the Ladybug plugin, the humidity within the context was analysed. The images show how, when taking into account the humidity levels, wind and temperature, the analysis exposes the areas that receive more wind gusts and higher humidity compared to those that receive less wind and are colder in turn. The analysis considers the orientation of wind and context, thus providing some notion of how the environment around them would influence the structures between the context. The index numbers on the side show the total temperature in Celsius degrees influenced by wind and humidity, with most of the region not impacted by wind and buildings maintaining an average of 26 degrees Celsius.

(Lina Sarma)

(Lina Sarma)

To have a more detailed perspective of the context and the impact of wind, additional wind analysis tests where done. The average wind velocity during the months when it’s the highest in the region is recognised at 9 meters per second (m/s) and was thus used as the basis velocity in this and other wind influenced analysis of the region in the project. The analysis is done taking into account the data gathered from the wind rose to more accurately predict the pressure areas. It is apparent that the North side and the taller buildings in the side receive the most pressure of wind leaving the South side less impacted. However, even within this analysis it is apparent that the pressure continues to affect some of the inner buildings entering the city.

3.30 3.31

3.33

Xeric Pavillion is a Y2 booster module project where the focus was fabrication. The project will bet situated in arid environments facing high temperatures and humidity levels. The fabrication agenda seeks to explore multi-material gradients with textural properties such as porosity and fibrosity that utilize biological processes as a tool to induce microclimates. Therefore, phygital biospheres aim to blur boundaries between the physical and digital realms through living materiality and digital fabrication to create microclimates.

In the Arrakis project, through exploring gyroid geometries, the script enabled simulation and tested the relationship between digital porosities and aerodynamics through exploring gyroid geometries. The exploration of multigradient porosity and capillary action in the project Hydra helped the architecture to create a system that can address fluctuating seasonal floods and droughts. In Trichoma, the filamentous textures created an interface for microclimates in architectural skins, whereas the Xeric Pavillion highlighted the challenges of compressive strengths in sand-based hydrogels structures. All these projects tackled various environmental and architectural difficulties in Xeric environments that led to the development of the final year project Xerilith.

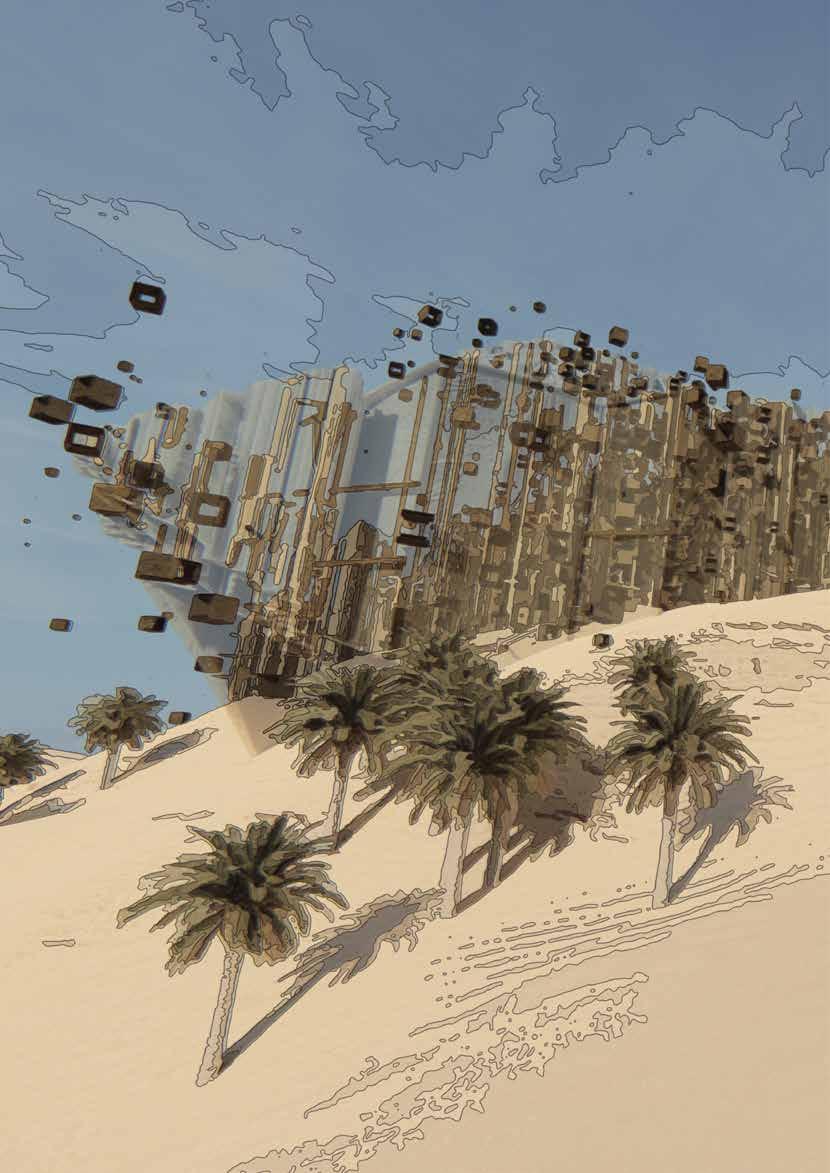

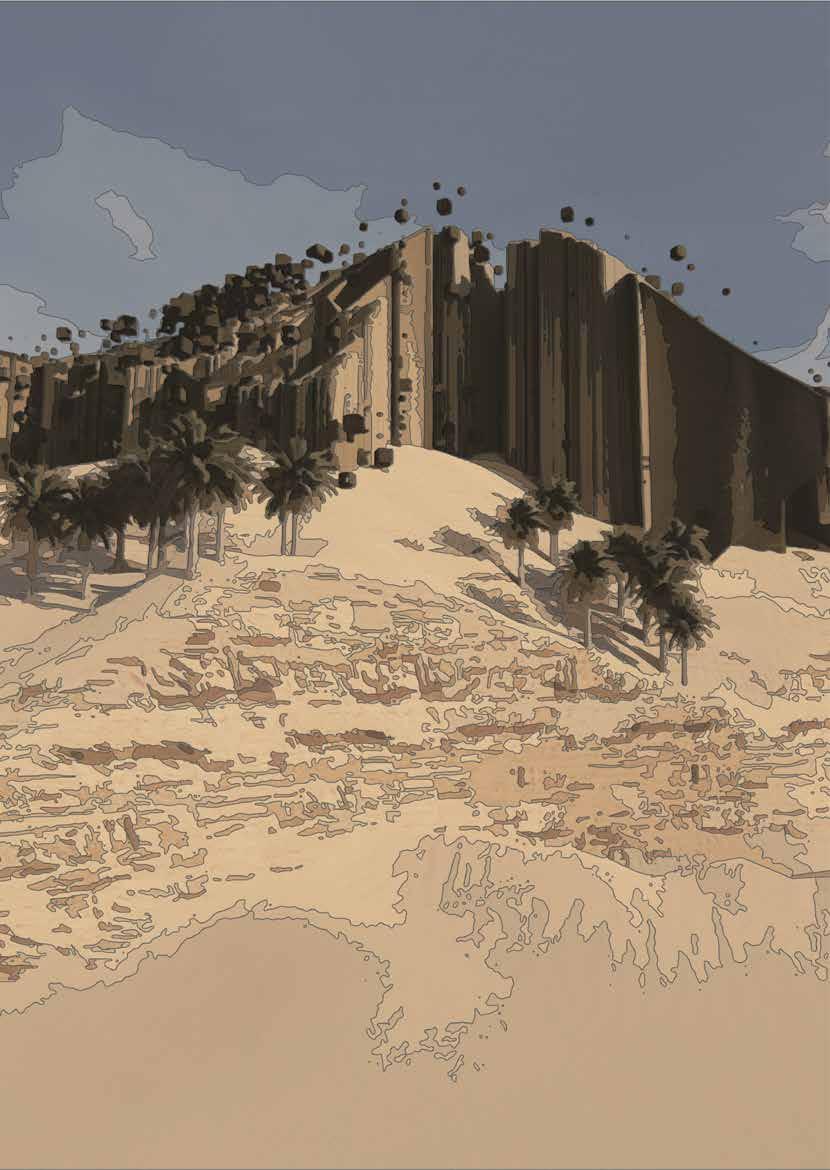

With urbanization, cities are growing at an unparalleled level worldwide; due to this, social and environmental factors are spiralling out of control, which must be addressed if a disaster is to be prevented (Grierson, 2003). The term ‘Arcology’ was coined by the architect Paolo Soleri. His model aims at a more balanced relationship between the urban fabric and the efficacy of performance within a unique notion of the contemporary city (Grierson, 2003). Arcology is at its base, an idyllic vision of a city in which it is contained in a colossal vertical structure, which would provide residential, farming, and commercial zones to reduce the environmental burden caused by humans (https://www.arcosanti. org/arcology, 2021). It is a view driven and built upon by a concrete, brutalist approach. This thesis questions the idea of arcology and how it can establish a harmony between the natural and built environment. Arcologies are approached from an idealistic utopic vision within a dense concrete architecture setting. We can re-assess this concept using modern times’ computational design, material research, and fabrication methodologies. As arcologies remain conjectural and only exist in the illustrations of Paolo Soleri, the integrity will always be in doubt until one is built (Millard, 2018). The project aims to reenvision Paolo Soleri’s vision through a bio-integrated approach using living architectural components.

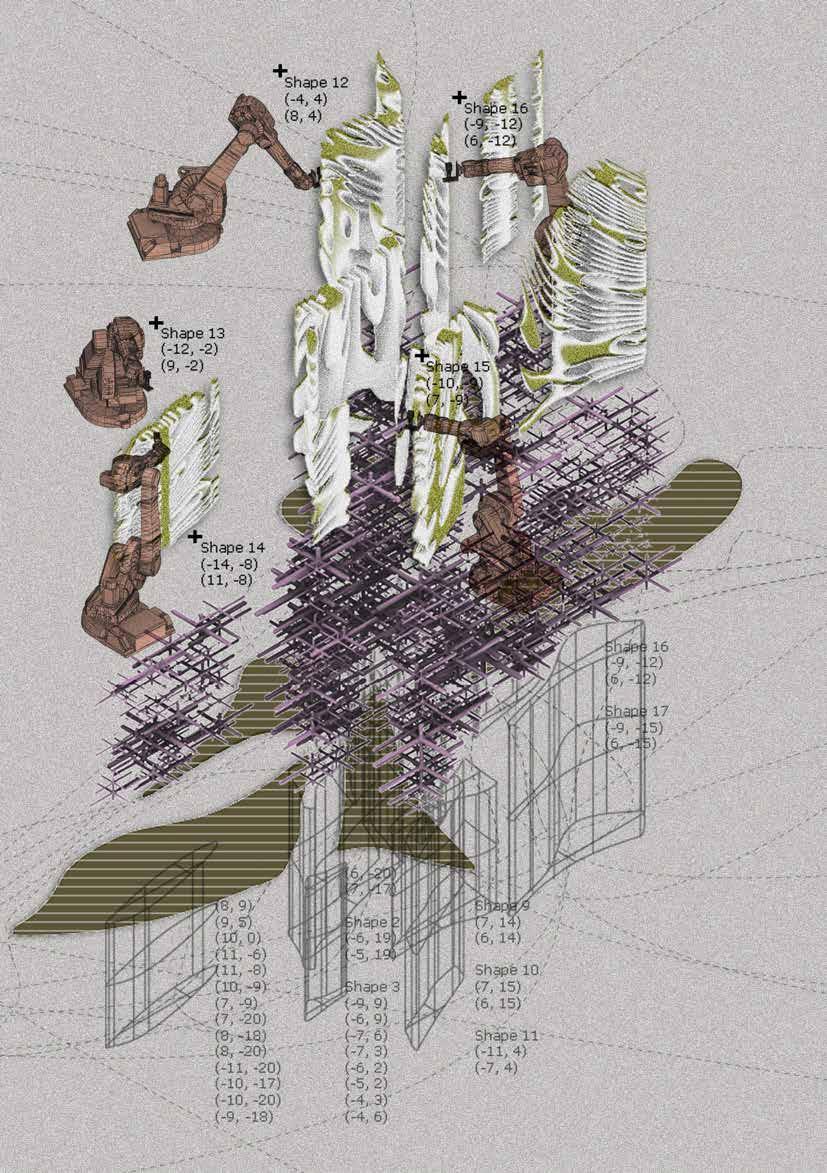

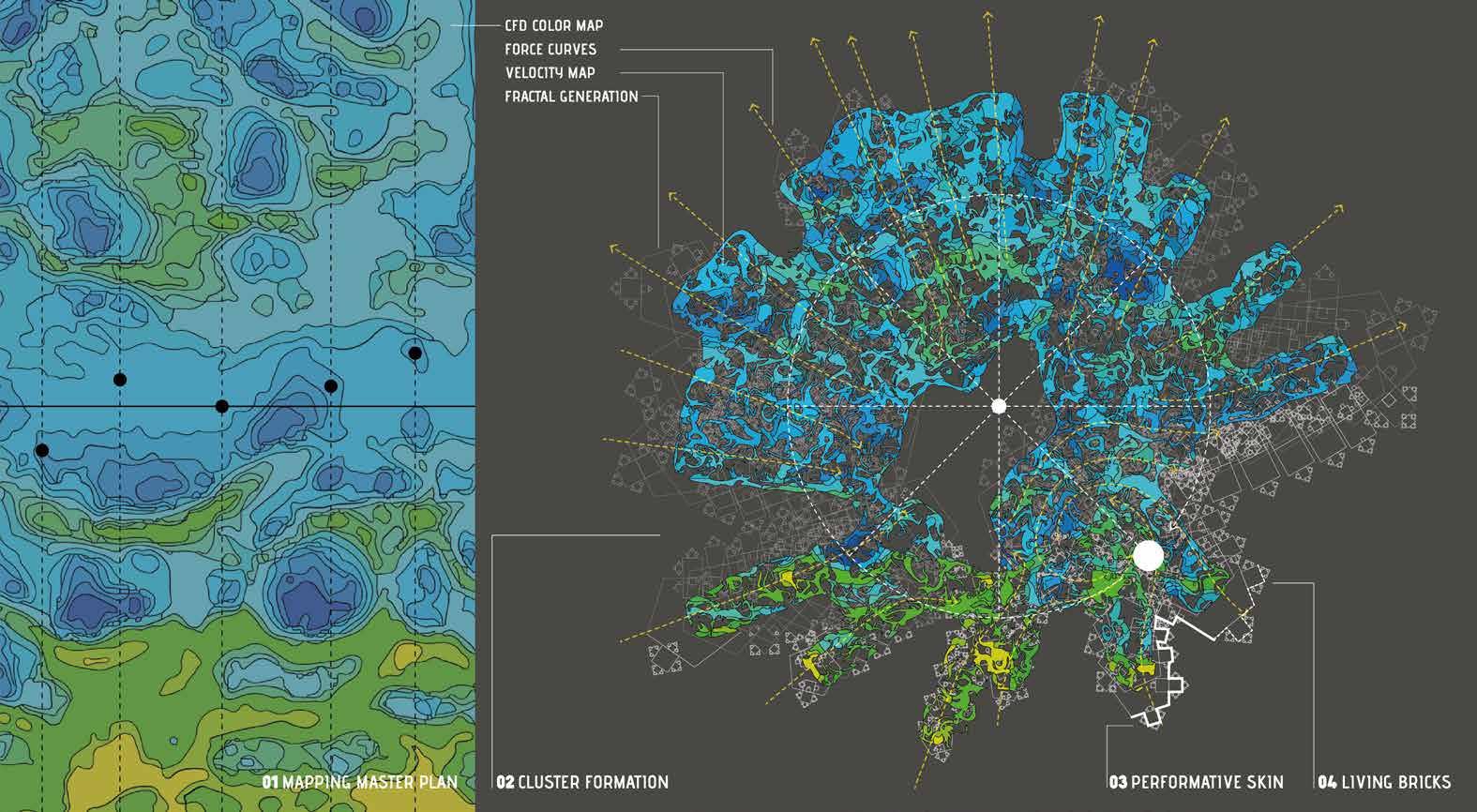

This chapter critically accesses the three primary environmental factors of xeric environments: temperature, wind, and moisture, to generate geometries for Xeric Arcology. The arid vernacular is reassessed. The project contextualizes the research by exploring the concept of Xeric arcology in ‘the line’, Neom, Saudi Arabia. Faraz Alian conducted the environmental analysis to collect data that can be used as parameters to explore a procedural design script for Xerilith. The chapter lays the framework for a procedural design methodology to study generative urban morphology using fractal geometry as a design tool.

The project aims to question the concept of arcology. The arid vernacular is re-imagined through computational, fabrication and material research, which helps achieve this. From incremental sprawls to compact urbanism, even urban courtyards are data-driven voids. The irregular boundaries are re-conceptualized as environmentally responsive skins, and the mashrabiyas are redefined with bio-integrated bricks.

The site chosen for this project is ‘the line’ in Neom, Saudi Arabia. It consists of a 170km stretch of connected cities, without roads and cars, built around nature in response to some of the challenges we face today, such as pollution, traffic, human overcrowding, and infrastructure. It is a new take on urbanism wherein it is a linear city compact in correspondence with environmental data. These factors make the site very interesting to explore xeric arcology. Therefore the project presents a proposal for ‘the line’, Neom. (Neom)

As the project intended to explore arid environments, the site presented a series of environmental challenges considered for design parameters. It comprises four landforms, grading from coasts to the desert and sabkhas to mountains. These landforms create a fascinating opportunity to design via data-driven architectural scripts.

Faraz Alian conducted the environmental analysis to derive further data used as parameters to generate urban morphologies.

4.8 FARAZ ALIAN 4.9 FARAZ ALIAN 4.10 FARAZ ALIAN 4.7 FARAZ ALIAN

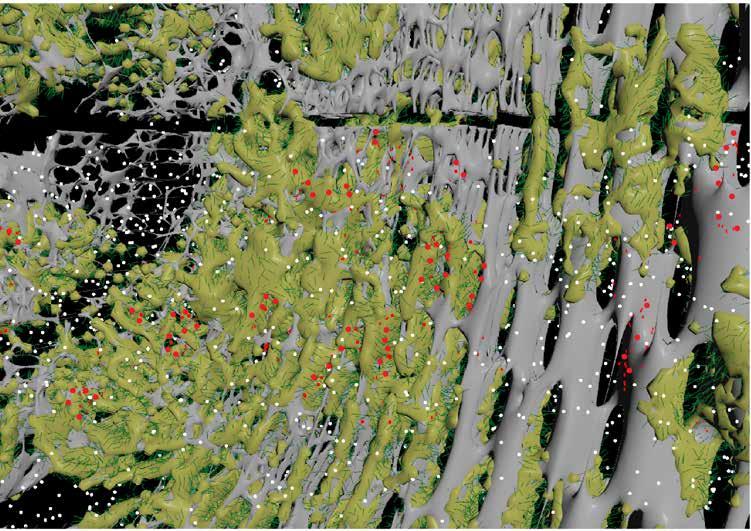

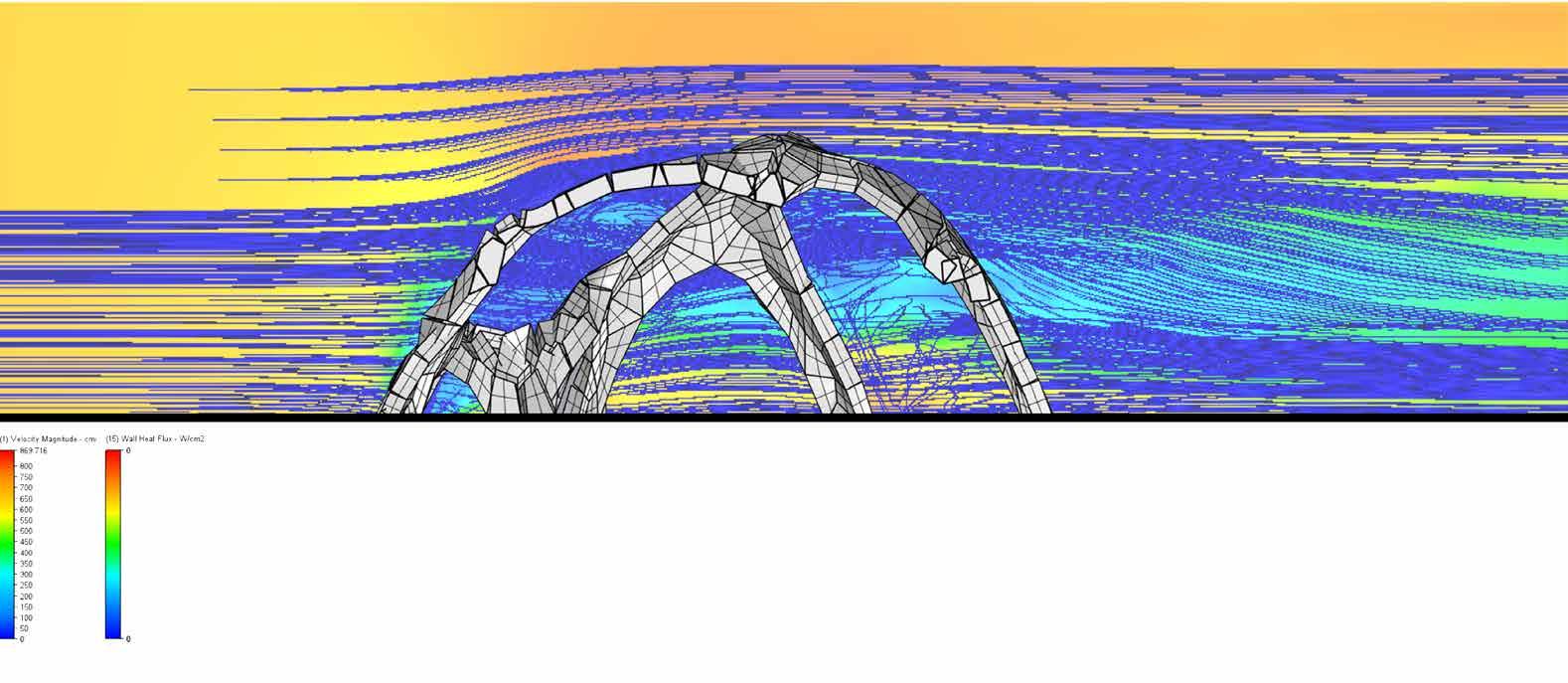

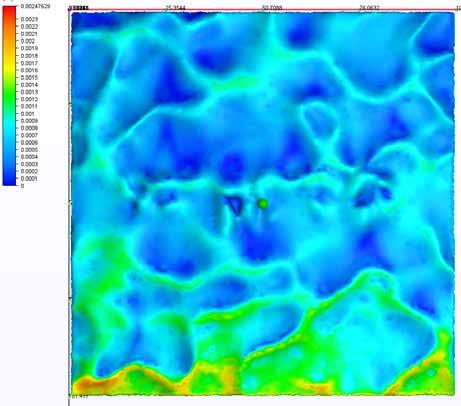

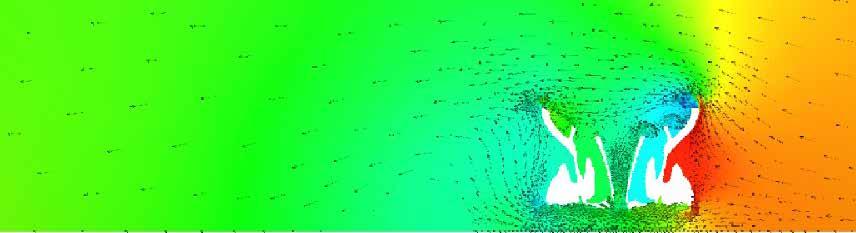

A series of procedures were designed to create a seamless link between the natural and built environment. The mapping of the master plan and the urban Xerilith clusters on-site were derived from data through CFD analysis.

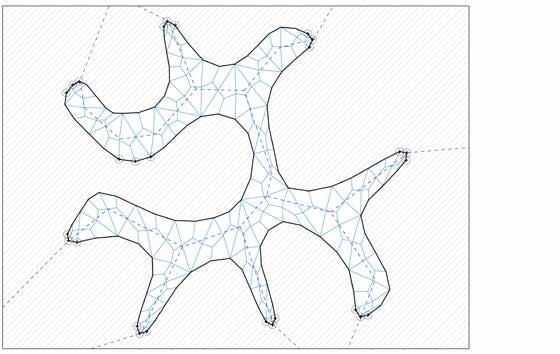

Cluster formation: Based on a series of scripts designed to map site force curves. The wind velocity maps were also derived through CFD analysis. The urban morphologies were created using fractal hands-on Houdini.

Performative skin: Using a solar and wind analysis of the architectural skin onto which maps are then projected. Openings in the bricks were devised by following a colour map derived through

the environmental analysis of the skin.

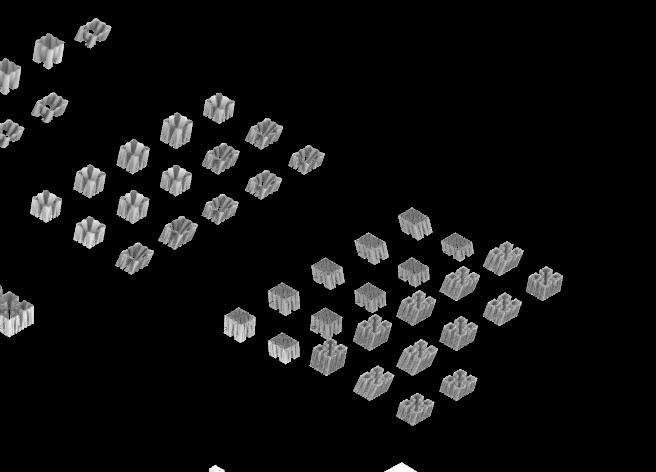

Living bricks: These bricks are designed using fractal systems on Houdini and designed to channel in the wind and capture dew.

This procedural design script generates the micro, meso and macro-scale arcologies for xeric environments.

The master plan was derived from CFD analysis using Ansys and Autodesk CFD by Faraz Alian. The analysis allowed us to map the master plan of the line using site forces. The master plan is essentially taking further the idea of the line by creating a generative design script.

A script was created on Grasshopper that maps the movement of the sun to generate force curves and height maps that can be used as organisational grids for urban infrastructures.

The project explores the idea of a performative interface through colour mapping of environmental data on the generated geometries. These colour maps are then used as reference points to map and influence the apertures of architecture modules. This enabled a gradient of notches on the façade that can perform on multiple scales.

It uses environmental data and sun movement to map lines of forces that become the foundation for organising elements for the architecture. The position of the sun determines the height map.

4.15

Mapping urban Courts

Deriving curves From force lines

Mapping heights of masses influenced by the position of the sun

Using fractal scripts designed in collaboratoin with Faraz Alian to map urban morphologies for Xerillith. The force curves derived from the environmental analysis are used as guidelines to map fractals on an urban scale.

4.18

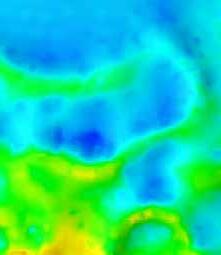

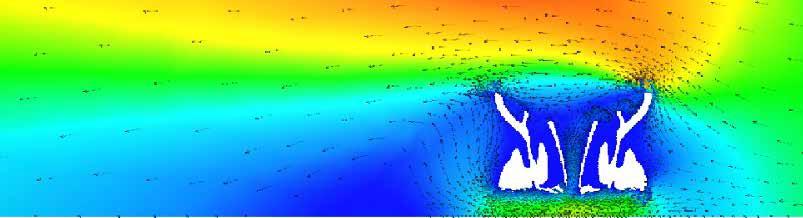

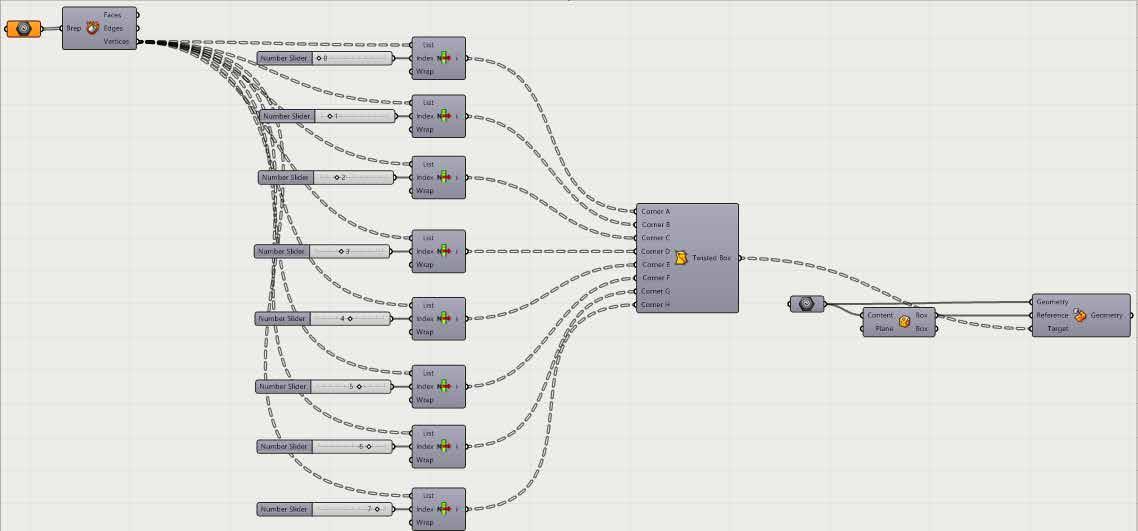

The formation of a cluster is marked using scripts designed in Grasshopper and Houdini to incorporate environmental factors as design parameters. Fractal geometries are explored as a generative design tool to derive architectural forms. The fractal formation interacts with curves generated through site forces. Extrusion and Boolean functions were used to map the heights to create shade and shadow.

Setting parameters to manipulate architectural envelopes for ideal environmental conditions. Creating an environmentally responsive script to influence protrusions on walls to create shade and shadow for thermal differences. Generating crevices to accumulate and channel dew formation on the wall and adding pores allows a thermal mass transition from exterior to interior.

4.23

Lines are taken from the fractal growth, then extruded and subdivided. A solar radiation map is projected on the skin to map the average annual solar radiation to create a solar radiation map onto bricks of different intensities or cavities that are morphed. This workflow creates an environmental-driven skill for Xerilith arcology.l

Using grasshopper scripts to project solar radiation on architectural skins using the sun’s position. This script allows mapping average sun exposure in architectural envelopes, which can be used as data to lay out architectural components.

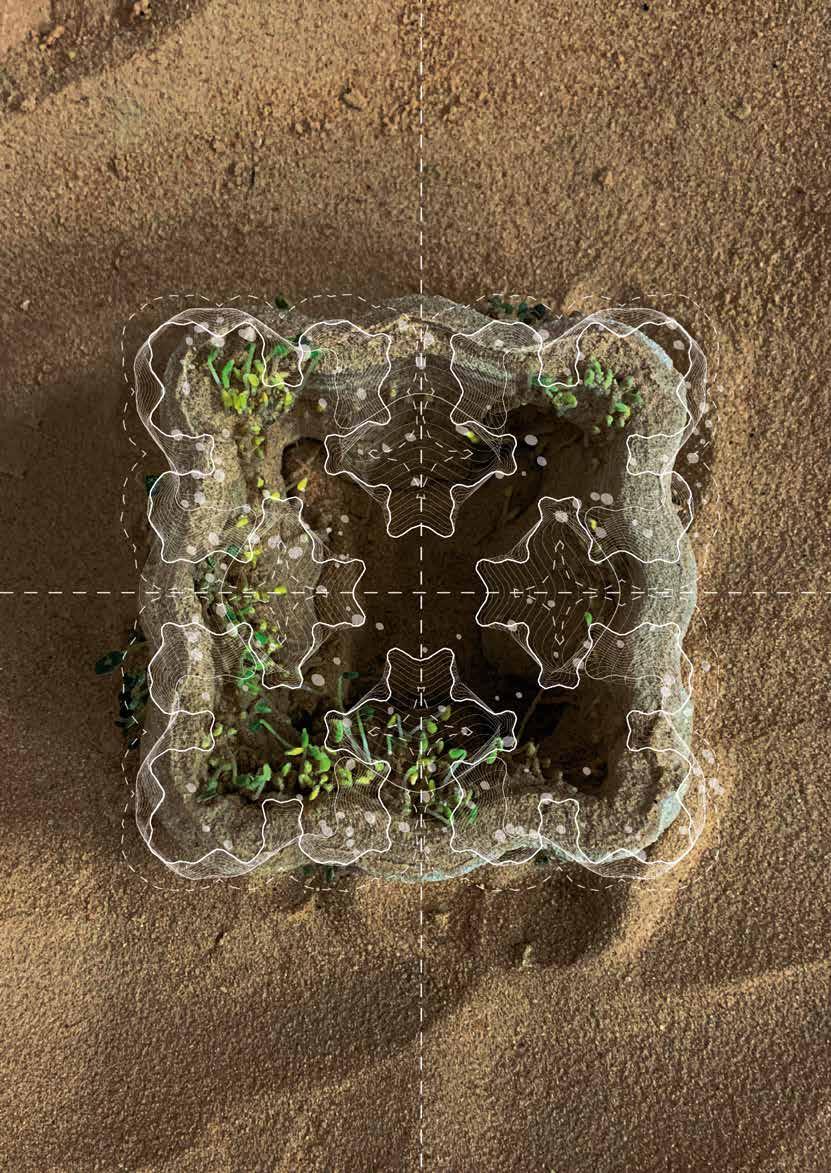

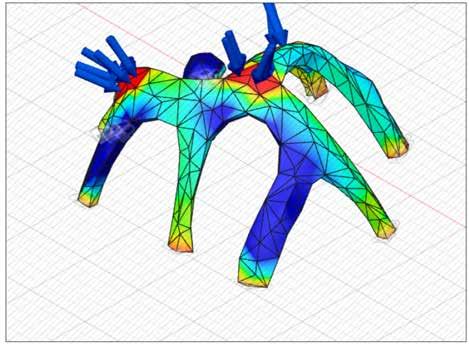

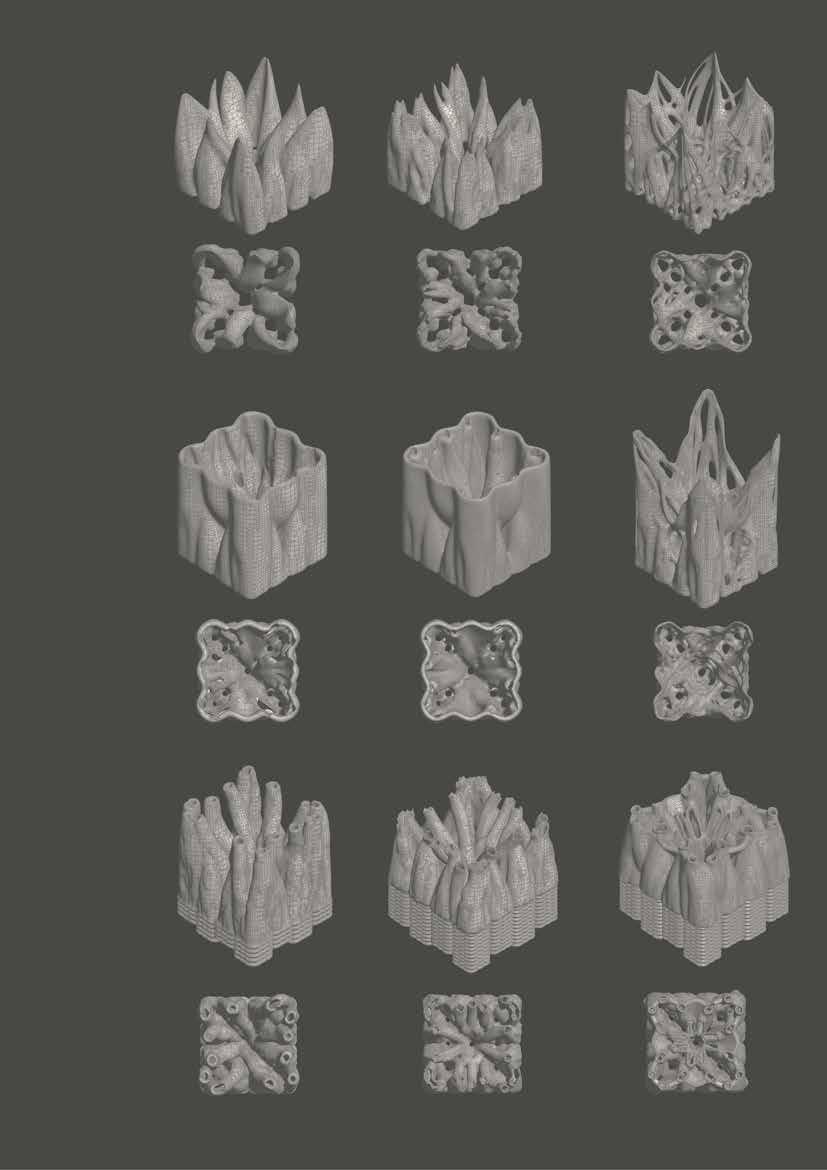

The bricks are designed using L systems to create a dynamic architecture script. The main plan is to have a micro-component in the entire scheme because this is where the point of contact happens with the environment and architecture. The aerodynamic cavities allow inhibiting microclimates in the bricks. It also allows warm wind to settle on the surface, which helps in dew collection. The holes, aperture sizes, and dew deposition promote passive cooling in architectural skins.

Iterations were developed on Houdini for the bricks to achieve a more enhanced performative interface. The scripts were derived in collaboration with Faraz Alian. In these iterations, the idea of crevices, protuberances and pores were defined further to establish a more refined control of micro-climates in architectural skins.

Faraz Alian conducted CFD analysis to get environmental data on the bricks. It can be seen from the analysis that the funnel allows channelling of wind through the brick, and it is also evident from thermal mass analysis that heat transfer from exterior to interior depends on the aperture size of the brick. The larger the aperture, the higher the heat.

Nature is a multi-layered system where various parts and components work simultaneously to perform functions (Imperiale Alicia, 2014). Only in a very dense environment can both plant and animal life exist. The degree of vitality of an organism is proportional to its compactness. Life is hostile to tenacity (Imperiale Alicia, 2014)..

Evolution suggests a pulsatory behaviour that has devised a miniaturizing process for each step moving from matter to mind. Miniaturization, according to Paolo Soleri, was condensing many people into a smaller space, which can also be termed minimization; done to reverse the damage of urbanization, which has caused a change in the natural system (Imperiale Alicia, 2014). It is a concept wherein, in nature, when organisms grow, they densify and miniaturize, and the system becomes complex.

Now that man is working on the complete characterization of the ultra-organism of the human group, another miniaturization is mandatory (ROYCE LANIER, 1979).

This chapter argues the current horizontal fabrication process with a predefined start and end. The research aims to establish a dynamic framework defined by a set of bespoke procedures that are parameterized and manipulated to optimise the fabrication process.

In the context of design practices, design to fabrication involves an approach to design in which designers explore the creative opportunities brought by integrating digital models and production machines (Raspall, 2015) . It is a procedural framework that synthesizes four key components: the goals, instruments, scope, and design workflows of design to fabrication projects (Raspall, 2015).

Design to fabrication allows and requires the creation of both the product and the fabrication process. In contrast with more conventional design practices, where the interaction with materiality is separated by a clear-cut distinction between design and production, procedural fabrication requires an active engagement with material processes from the initial stage. It enables the production of unique components and mass customization through robotic fabrication in architecture.

In process-driven fabrication, the typical hierarchy of form and materiality is reversed. The material explorations are the starting point, and the design is kept open until later in the process. Material-Based Design Computation by Neri Oxman argues for a design centred on the performance of materials rather than on the form inspired by natural processes.

In specific design computation and robotic fabrication, procedural fabrication is enabled by intensive information technologies. The computational design offers direct access to the geometry’s numerical information, such as the coordinates of strategic points, which are required to determine the motions and actions of fabrication machines. Integrating design computation with robotics in a continuous digital workflow opens new possibilities for design exploration. It promotes projects where constraints from the physical production become integral components of the design process. Thus, combined design computation and industrial robotics create a versatile and open platform upon which designers can develop custom applications.

Research in design to fabrication has significantly advanced the instruments that enable a fluid connection between design environments and production machines (Raspall, 2015). Current research enquires how these technological advances can be deployed to a wide range of material processes (Raspall, 2015).

From a purely technical perspective, design to fabrication refers to the automation of the extraction and processing of information from three-dimensional models and the generation of instructions to operate computer numerical control (CNC) machines. In the context of design practices, design to fabrication involves an approach to design in which designers explore the creative opportunities brought by integrating digital models and production machines (Raspall, 2015).

The workflow in design to fabrication studies how the material dimension, which is the centre of the design to fabrication, is addressed throughout three stages of the design process.

During the first stage, designers define knowledge of material transformation and their output control. Here, the goal is to create an archive of curated material information, which can then be rapidly assessed and shifted (Raspall, 2015).

The second stage is devoted to developing the selected material system and automating its construction process. Through prototyping, the workpiece’s tools, motions, speeds, and final characteristics are calibrated so that the fabrication process can be simulated and thus become highly predictable (Raspall, 2015).

The third and final stage involves testing this process in a larger-scale prototype. This stage aims to investigate the challenges involved in the materialization process, including timing, assembly sequence, connection details, tolerances, and aesthetic effect, amongst other factors (Raspall, 2015)

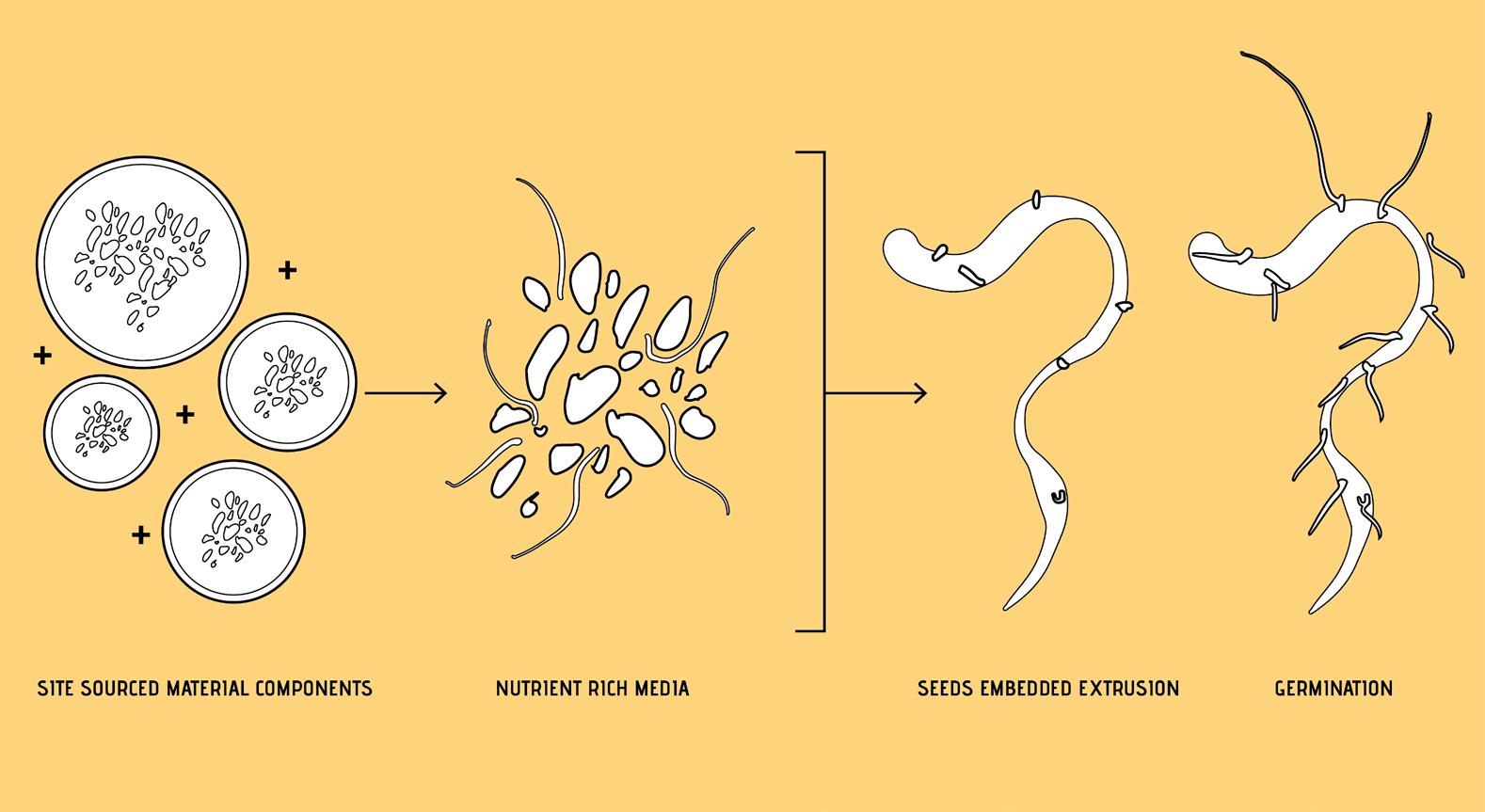

This research aims to develop a procedural framework for fabrication for desert environments by calibrating material parameters with digital tool design to extrude site-specific material compositions robotically. It involves understanding the patterns and trends of climate change in a desert environment and integrating biology in the procedural fabrication methodology from design to fabrication. To do so, the framework is constructed over three stages: material ecology, digital tool design and additive manufacturing.

The first step is to develop site-specific material components in a nutrient-rich media. The strategy lies in the preparation of materials using organic binders. A series of material tests follow this to define the parameters for calibrating robotic extrusions.

STAGE

The workflow of the tool movement of the robot is scripted in the digital interface. The toolpath calibration of the tool follows this based on the material component position. The toolpath has an integrated parametric control to offer flexibility in material behaviour and component development.

STAGE

At this stage, various robotic parameters are defined to control pressure, speed, and layer adhesion for testing material flow and behaviour in the fabrication of the component.

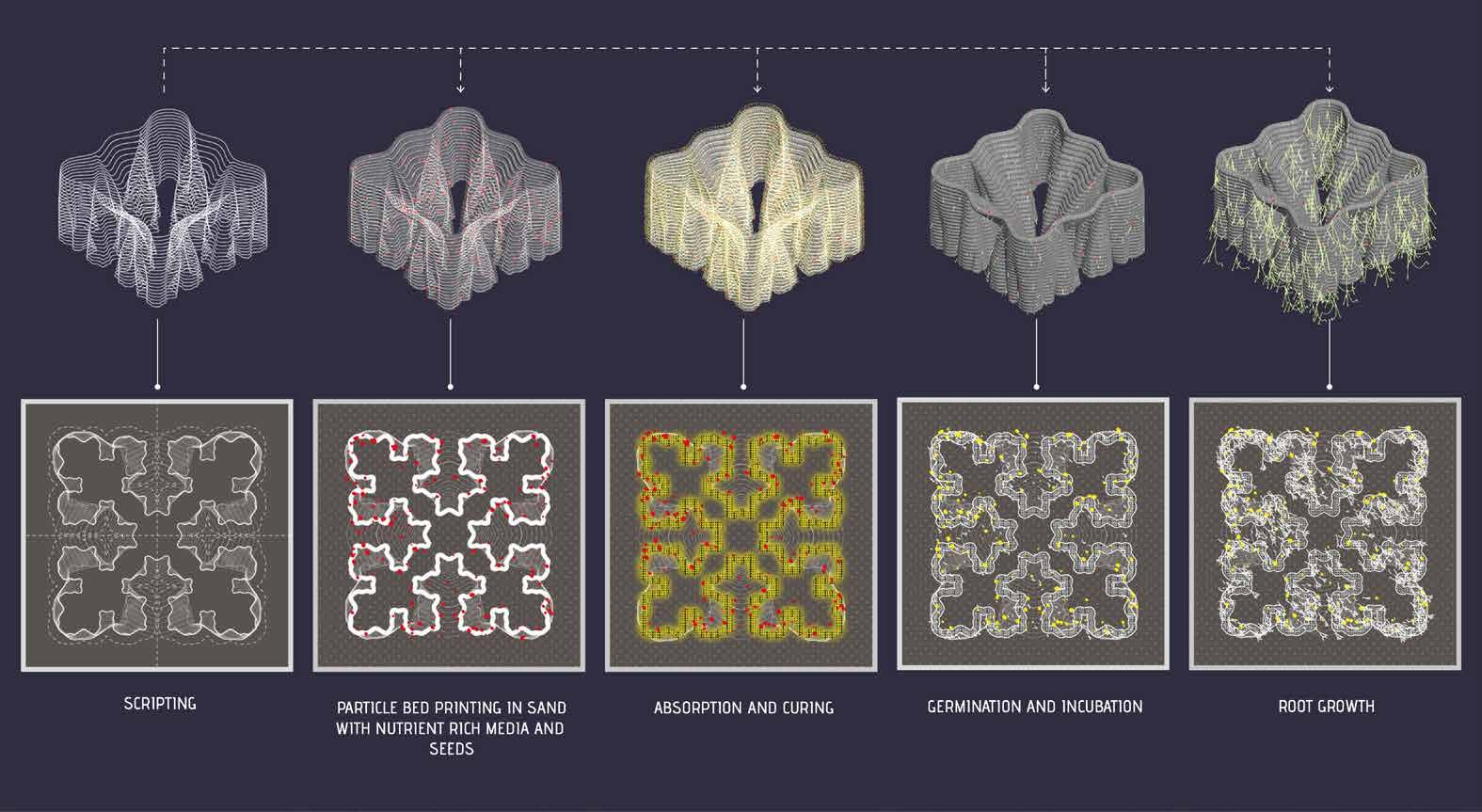

The research addresses how procedural fabrication helps to establish an environmentally responsible construction methodology for desert environments. For the same, a procedural framework for fabrication was developed. Firstly, the architectural component is scripted using L-systems. It is followed by particle bed printing in sand using nutrient-rich media embedded with seeds. After absorption and curing, the seeds are allowed to germinate. During germination and incubation, the growth of roots is controlled using different control methods. The root growth reinforces the extruded geometry over time. The bricks are extracted from the sand particle bed, and the root growth process is stopped. This process uses bio-reinforcement over a duration of time for growth, and beyond that, it becomes a part of the architectural component.

The construction industry is a significant supporter of greenhouse gases. According to the 2021 Global Status Report for Buildings and Construction, in 2020, the industry accounted for around 37% of carbon emissions (Global alliance for buildings and construction, 2021). The most common building material, concrete, is one of the most unsustainable ones (Golden Elizabeth, 2018). The source of building materials may become scarce over time, and therefore there is a need to find suitable materials that are more environmentally friendly. Local and natural materials are viable options. However, they are not the same. Natural materials, such as wood and marble may not be available locally and hence are not sustainable due to the additional energy required for transport (Kuriakose, 2020).

On the other hand, local materials are accessible within or close to the site. For example, the soil from the site can be used for rammed earth construction or adobe bricks, thus making sure the embodied energy is low. The production methods using local materials are traditional and are achieved through straightforward techniques, requiring minimal power, and the sources of these materials are so abundant that their supply is considered infinite, or they are renewable (Golden Elizabeth, 2018).

The sixth chapter discuss a series of experiments conducted in collaboration with Sarah Aljishi to develop a material ecology. Desert sand and organic binders are used to create nutrient-rich media for plant growth in architectural skins. The series of tests conducted with the material allowed us to understand the compressive strengths of the moisture retention, which allows the material to become a nutrient-rich medium where seeds can be germinated while maintaining its structural integrity. The coating that was developed provided a protective barrier to prevent the brick from disintegrating in contact with moisture, creating the brick’s hydrophobic capacity. All these parameters provide calibration of the material to be used in robotic extrusions.

Traditional materials offer several significant advantages over contemporary building products. Their production is often achieved through simple processes, requiring minimal power. Most are either renewable or derived from ubiquitous resources so their supply is considered virtually inexhaustible. The application of traditional materials in building construction often relies on lowtech methods using manual labour, reducing reliance on expensive power tools and equipment (Golden ELizabeth, 2018).

In addition to having a negligible environmental impact, many materials can be designed to fulfil multiple functions within a building, reducing the number of discrete elements typically required in a conventional construction assembly. For example, straw shaped into bales performs thermally and structurally, providing a high degree of insulation. Similarly, heavy earth masonry or rammed earth walls can function simultaneously as structure and temperature regulating thermal mass (Golden Elizabeth, 2018)

6.4 6.5 6.6 6.7

Sand, as trivial as it may be and sound, is a crucial part of our lives. From the buildings we live in, to the screens on our phones, it is a material that is required everywhere. Requiring sand does not seem like a problem, as our planet is covered in sand. Nevertheless, this desert sand is virtually useless when it comes to construction. The fine aggregates are unsuitable for binding in concrete, and their water absorption and retention are extremely poor (Ji, Liu, and Ding, 2021). Sand found in beds, banks, and floodplains of rivers and lakes is used in most industries, and the demand for the material is so much that riverbeds and beaches are torn apart. With climate change on the horizon, the future chances of desertification are not too far. Therefore, this project aims to develop a technique to use this material in a building.

China clay or Kaolin is a type of clay used to produce chinaware and porcelain. It is used in the manufacture of paper, rubber, and paint. When Kaolin is mixed with 2530% water, it turns into a plastic that retains its shape even after the removal of stress on it (Britannica, no date). The quantity of water required for the plasticity and viscosity varies with the particle size of the clay (Britannica, no date)

Sodium alginate is a natural binder made of polysaccharides derived from the cell walls of brown seaweed, such as Laminaria hyperborean (Szekalska et al., 2016). It can form a stable gel through the carbohydrate functional groups and is primarily used in the food and pharmaceutical industries (Lacoste et al., 2018). Alginate has exceptional properties when it comes to biodegradability, biocompatibility, non-antigenicity, and chelating ability and is of particular interest for a broad range of applications as a biomaterial (Kazi and Yamamoto, 2019).

Nutrient-rich media enhance growth and provide the optimum nutrition for an organism to grow. Developing the nutrient media created a favourable condition for the seeds to germinate in the material. The hydrogel was created, making use of sodium alginate and Carrageenan. The findings of an experiment conducted by Behboud and Moradi showed that seeds coated with a film of sodium alginate enhanced the germination percentage and early seedling growth of sweet corn (Behboud, Moradi and Farajee, 2021). Carrageenan is the major component found in red seaweed and algae cell walls, promoting plant growth and eliciting defence responses (González et al., 2012). The combination of sand and the nutrientrich media promotes the root growth and is eventually bounded by it forms layered materiality.

The materials were mixed in different ratios along with seeds and manually extruded to form the first set of tests. The effective combinations were selected based on the material’s texture, extrudability, water retention, and seed germination. In the subsequent explorations, clay was used to bind the particles together and improve the material’s properties. A blend of clay and sand-based material was used to produce a mix of structural and nutrient material for plant growth. As seen in the pictures, many of the samples were unsuitable. (Sarah) 6.9 source:sarah aljishy 6.10

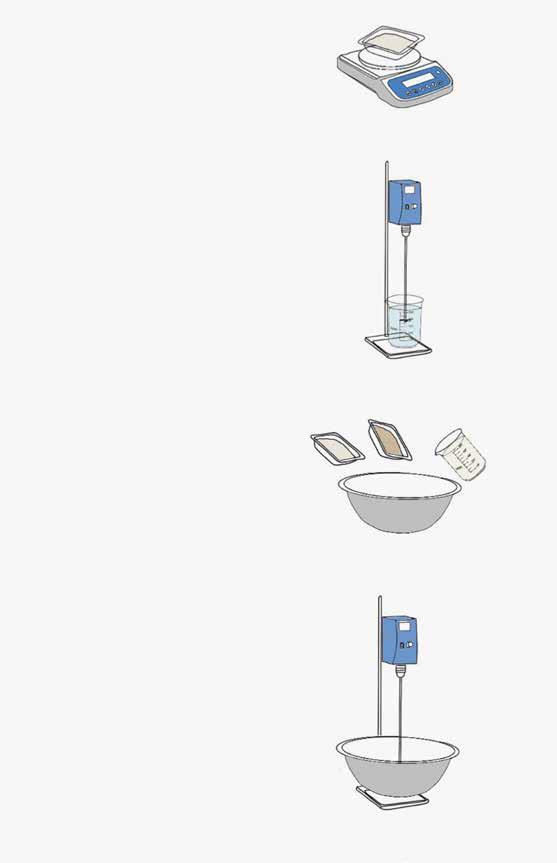

WEIGH DRY INGREDIENTS 1 2 3 4

MIX SODIUM ALGINATE WITH WATER TO PREPARE GEL

ADD SAND, CLAY, CACO3 AND SODIUM ALGINATE GELL TO THE MIXING CONTAINER

MIX WITH AN ELECTRIC MIXER TO ACHIEVE A HOMOGENOUS MIXTURE

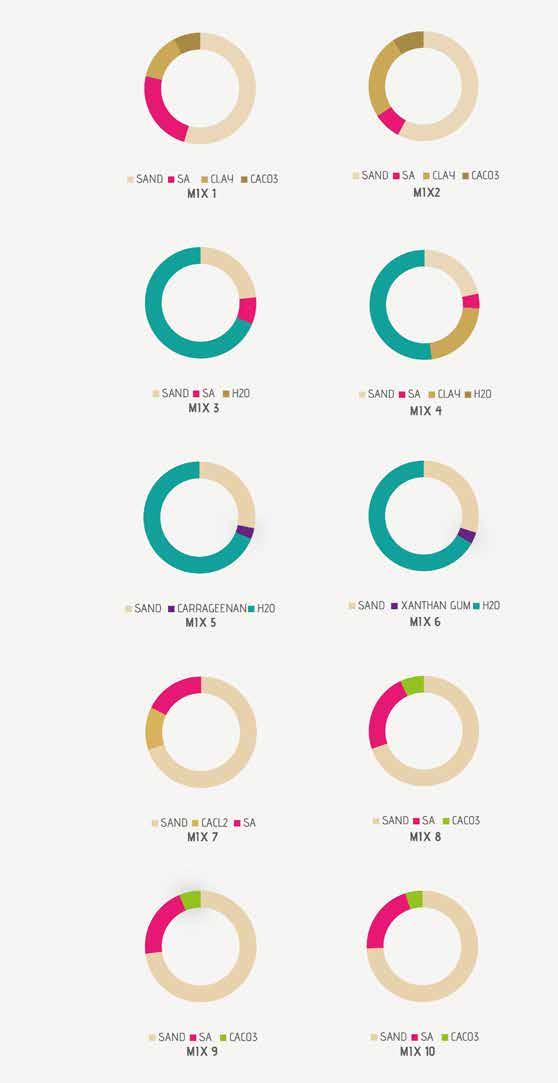

The following compositions were tested as the material due to the site conditions. The most successful mixes based on the already mentioned selection criteria are 1,2,8,9,10. The mixes have a high degree of stability and structural integrity. Several tests have been conducted to assess the material’s strength, water retention, and thermal conductivity. (Sarah)

A series of test were designed and conducted to test conditions and characteristics of material for it to be used in robotic extrusion.

The material was observed over a period of one week and the shrinkage was minimal and not taken into consideration.

Minute adjustments were made to check different mixes for testing. The following process was employed. Four different mixtures were used to create ten samples, as shown in Table 1. The apparatus was designed to pressure samples at 2.3*f0. The samples were then moulded into 12cm × 2cm × 2cm and allowed to air dry for 48 hours before testing. (Sarah)

This test aims to measure how well the material can absorb humidity in Saudi Arabia. The test evaluated how geometry can help absorb humidity and inform design decisions. Three geometries were used for this experiment. First, three samples were printed using the robots. The samples were air-dried for 48 hours before tests. The humidifier was installed in a clear box with each sample. The samples were then exposed to humidity for 24 hours, approximately 200g of evaporated water. After 24 hours, the samples were extracted and weighed. (Sarah)

Results: The experiments show that the material is hydrophilic and can absorb water. The constant water supply causes the material to saturate and break apart. However, as the arid climate is dry and only experiences humidity at night, the material will not saturate, and a hydrophobic coating will be applied to prevent water absorption. (Sarah)

The nutrient-rich media consisting of sodium alginate and carrageenan were embedded with saltbush seeds and then placed into the pockets of the material. Saltbush is a halophytic perennial shrub found in arid regions, does not require many nutrients to grow and has high resistance to salinity (Walker et al., 2014). Plant roots consist of a complex underground dynamic system that can be manipulated (Scherer, 2019). The experimentation aimed to determine the germination and root growth process over four to six days. There were two controls designed consisting of one set of seeds watered and the other set watered lesser. They were then left to germinate for the next six days. The results showed that the watered seeds grew well, whereas the other group showed stunted growth. (Sarah)

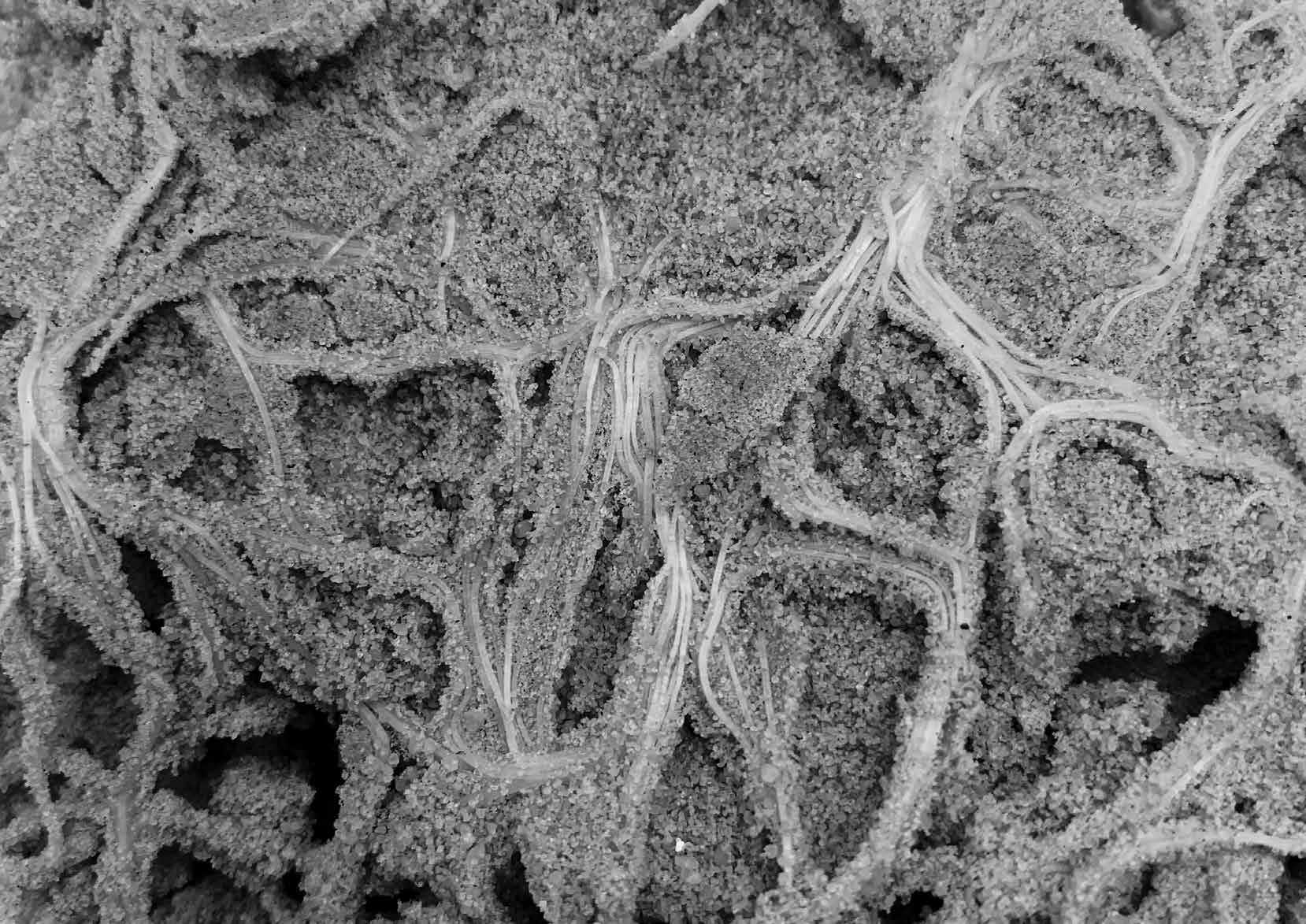

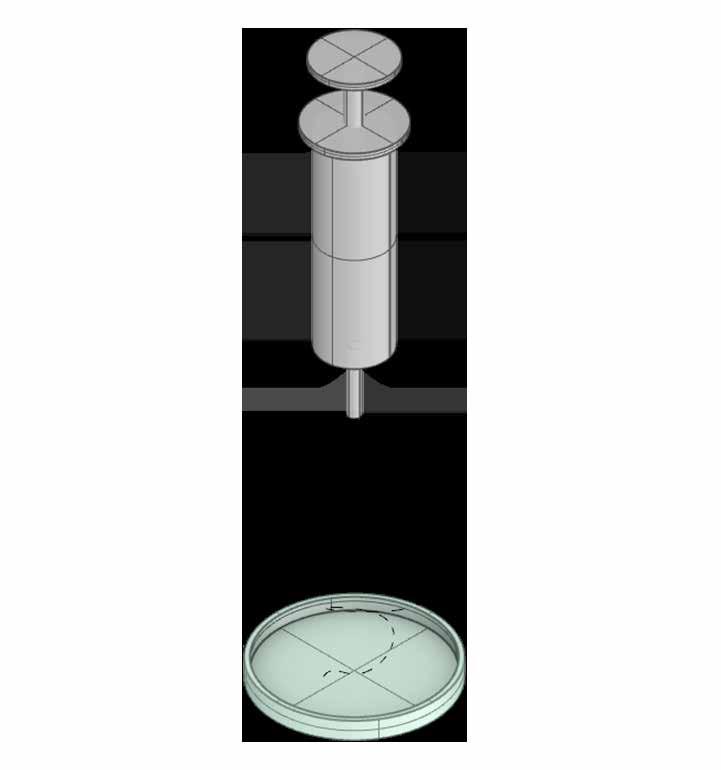

The material was prepared and manually extruded in sand via a syringe. It was then embedded with seeds and checked after a few days. There was evidence of germination, and the growth of the roots was seen intertwined with the material. It also created an opportunity for using this technique in robotic extrusion.

As per the moisture absorption and retention test, it is evident that the material has hydrophilic capabilities. However, the hydrophilicity weakens the material, and a hydrophobic coating is introduced to prevent this. The materials used were chitosan and zein (Sarah). The method is adapted from an experiment conducted by Kansal and Hamdani (Kansal et al., 2020).

The coating was prepared by Sarah Aljishi based on an experiment conducted by Kansal (Kansal et al., 2020).

A 4%(w/v) chitosan stock solution was generated by dissolving 4 g of chitosan in 2%(v/v) acetic acid to make a total volume of 100 mL, and this solution was agitated for 24 hours at room temperature. Dilutions of a 4%(w/v) stock chitosan solution were prepared to make 0.5, 1, 2, and 3%(w/v) chitosan solutions. To make 5 mL of 2% (w/v) chitosan solution, 2.5 mL of 4% (w/v) chitosan solution was mixed with 2.5 mL of 2% (v/v) acetic acid solution while continuously stirring. The solution was agitated for another 10 minutes to ensure homogeneity (Sarah) (Kansal et al., 2020)

40% of the stock solution (40%, w/v) was made by dissolving 40g of zein powder in an ethanol/water mixture at 85% and 15% (v/v), respectively, to add up to a volume of 100ml. The solution was stirred overnight at room temperature. From the 40% concentration, further dilutions were made to form 20% solution which was done by mixing 2.5 mL of 40% (w/v) zein solution with 2.5 mL of 85% (v/v) ethanol solution. Stir the solution for 10 min prior to use. (Sarah) (Kansal et al., 2020)

The samples are prepared, cleaned, and dried, measuring 500mmx500mmx2mm. The material was placed on top of a metal mesh, and the chitosan was poured onto the samples. These were allowed to air dry for 24 hours, and the zein coating was applied.

To test out the material, they were placed in water for 5 mins, after 24 hours, and then extracted and weighed.

Results: The coating was applied to multiple samples, and the increase in the weight of the samples was less than 3g which showed that the coating worked. 20% zein layer worked better regarding adhesion and application than 40%, which started chipping off even before placing it in water. Even though the sample swelled up, there was no visible breakage or saturation. The double coating still absorbed minute amounts of water. If the surface is smooth and homogenous, the coating would be even without chipping. Overall, the method was effective and prevented around 99% water absorption compared to the uncoated material.

The fabrication method aims to explore additive manufacturing by particle bed printing, where sand is used to bind together the material and provide additional support. Standard 3D printers have their extruders perpendicular to the build plate plane and cannot move or rotate their angle (Cuevas Diego Garcia and Pugliese Gianluca, 2020).

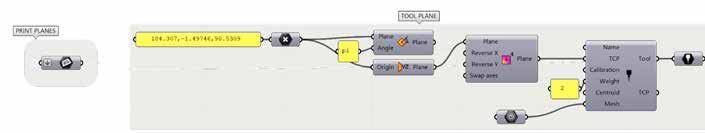

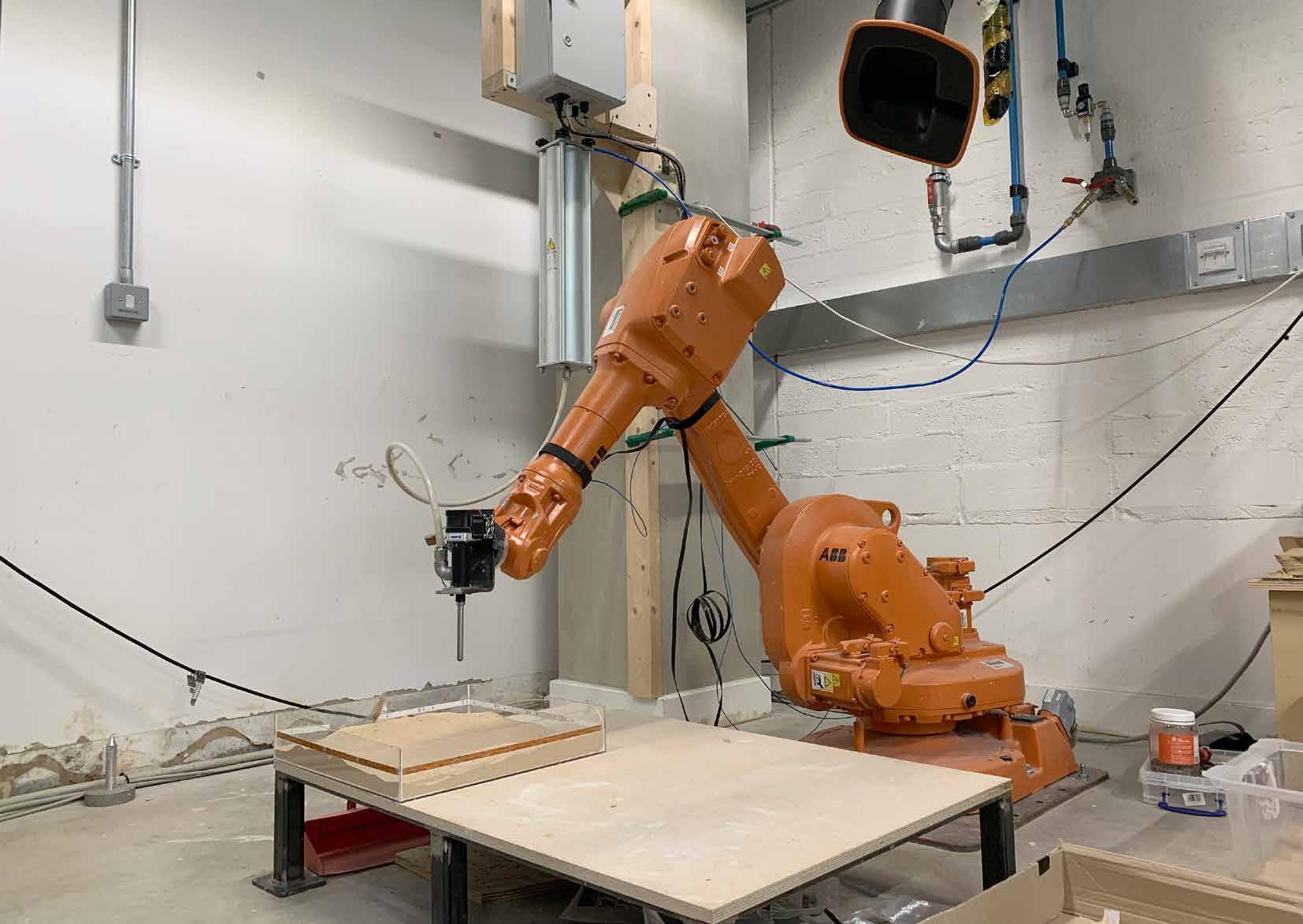

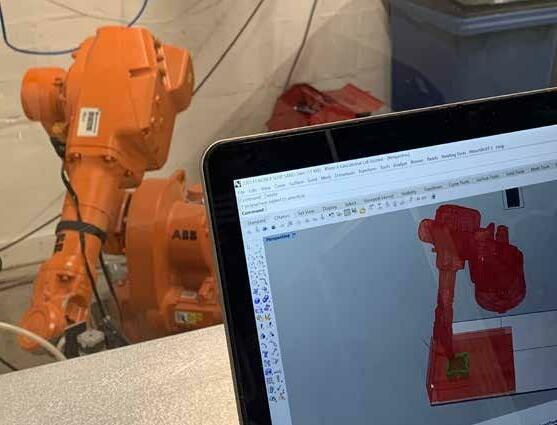

On the other hand, a robotic arm has six axes, known as degrees of freedom which can enable multi-plane printing, providing a flexibility that conventional 3D printers cannot achieve (Keating and Oxman, 2013). Multi-axis printing provides more benefits because by rotating the 3D platform concerning the extruder, intricate 3D structures with acute overhangs can be printed without formwork or support material (Ishak, Fisher and Larochelle, 2016). It also minimizes waste because it eliminates the support material and postproduction processes (Keating and Oxman, 2013). Programming a robot comes with challenges as there is no standard code for them. Each manufacturer has its language. For this project, the robot arm was from the brand ABB, model - IRB 1600 with wasp extruder, and the custom code was developed on Grasshopper. Typically, 3D printers have a single coordinate, while robot arms have a two-co-ordinate system (Cuevas Diego Garcia and Pugliese Gianluca, 2020). The software and hardware are linked with the script, which tells the machine how to proceed, and the extruder where to deposit the material, as the sequence of movement and extrusion is vital to printing (Cuevas Diego Garcia and Pugliese Gianluca, 2020).

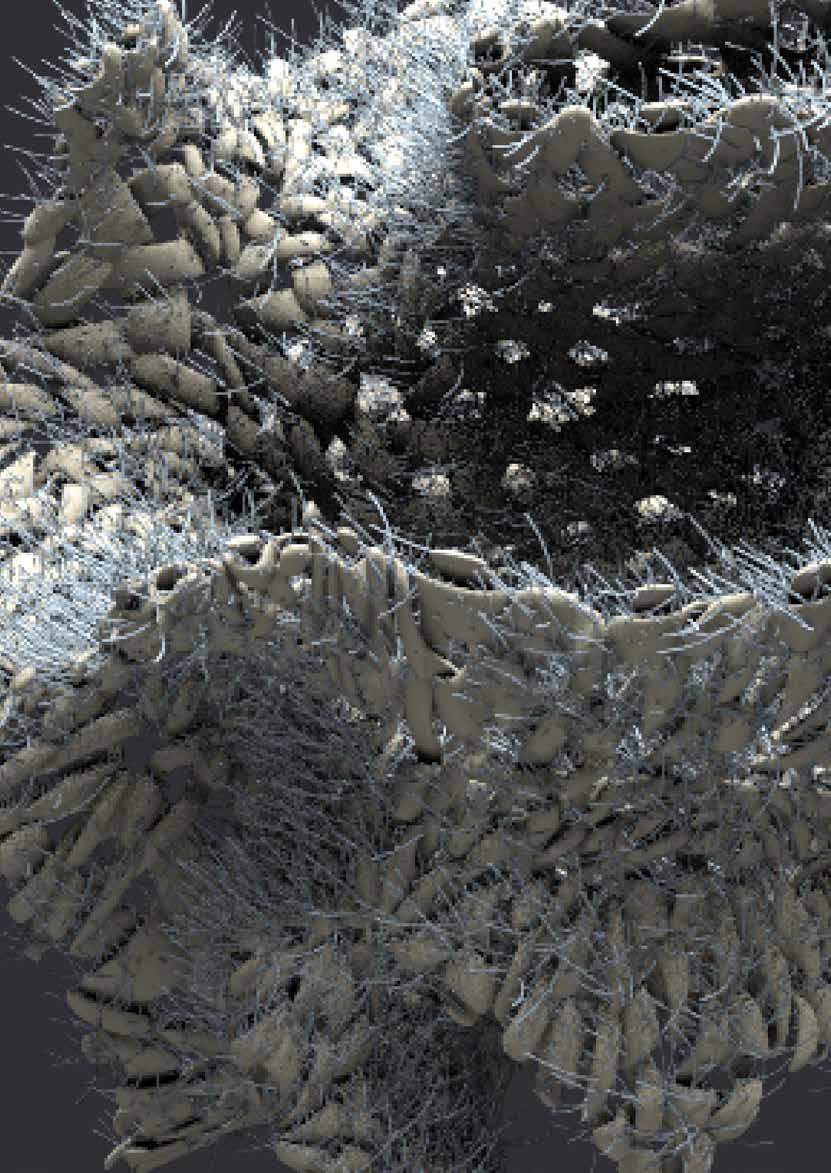

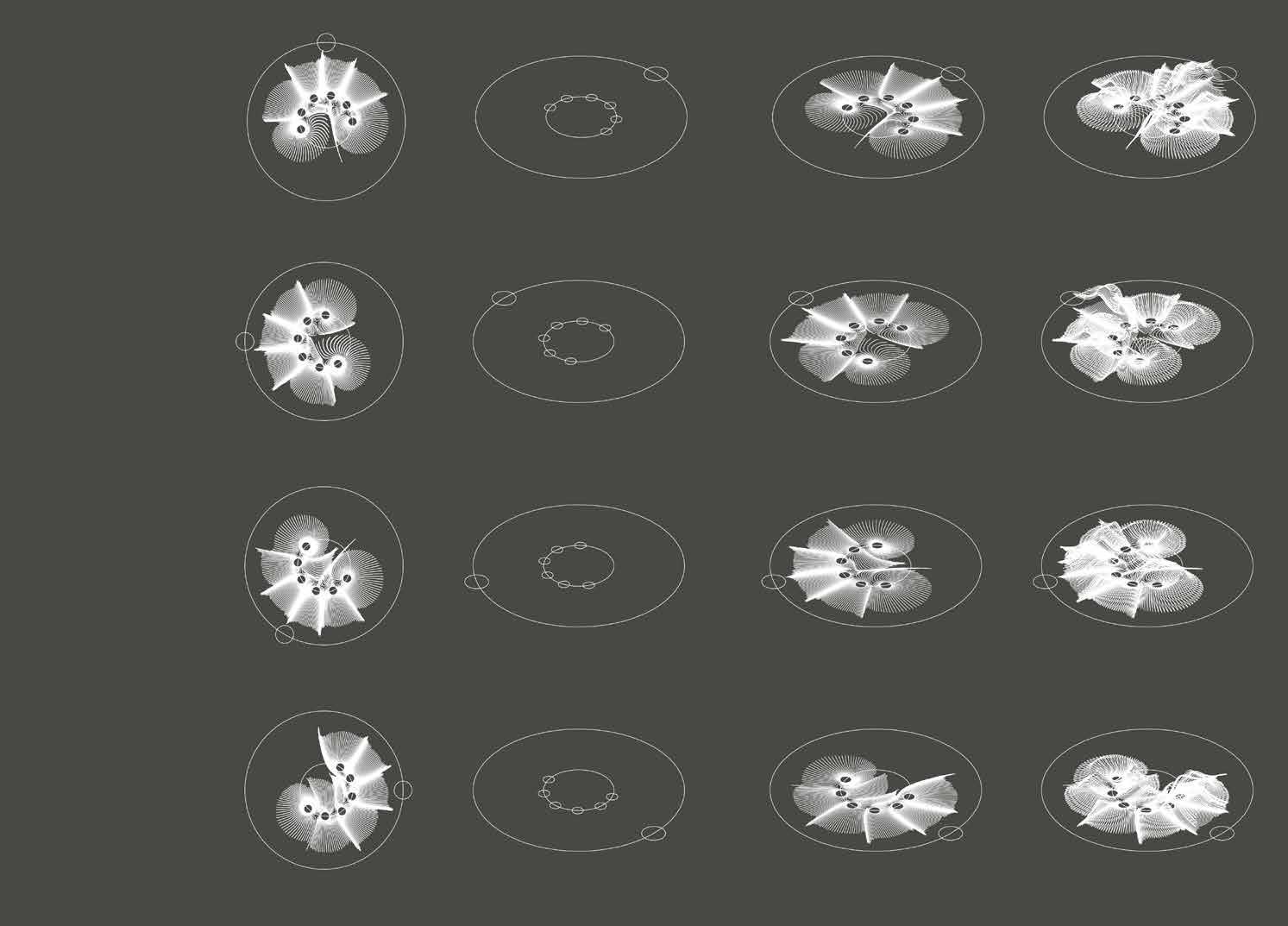

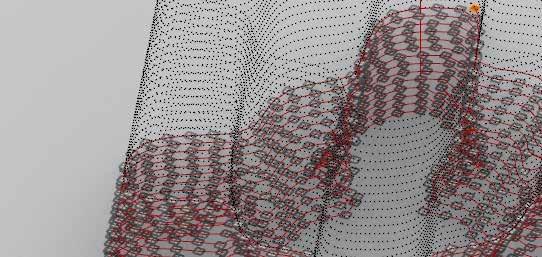

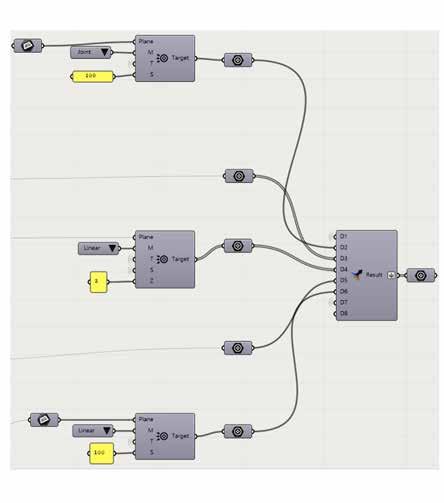

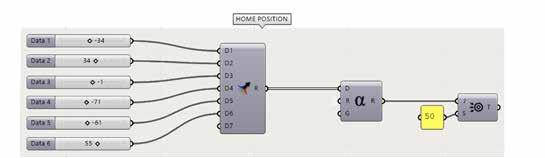

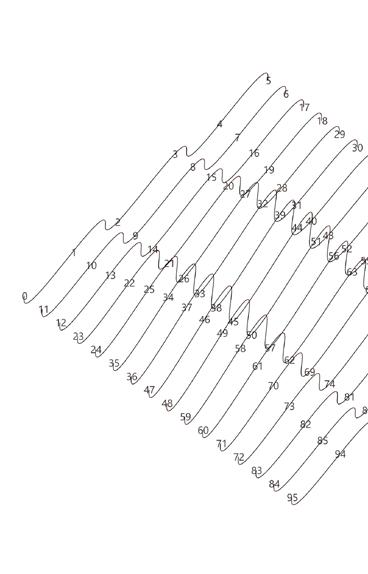

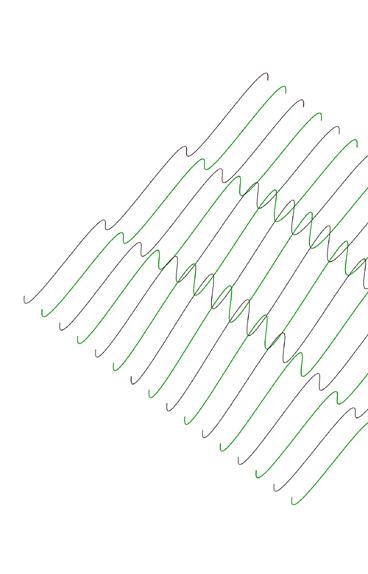

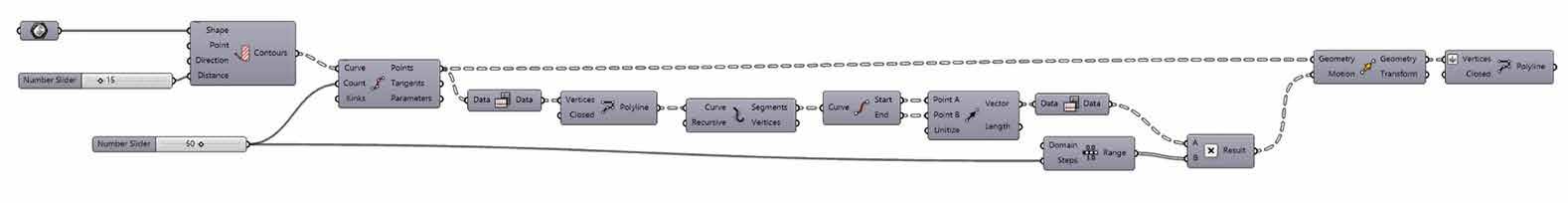

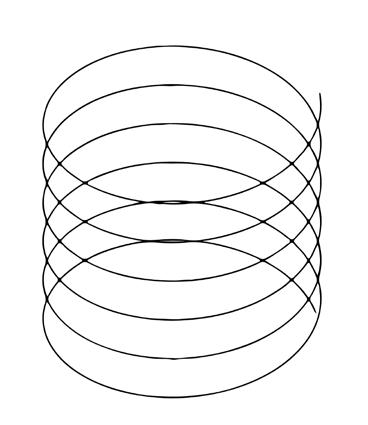

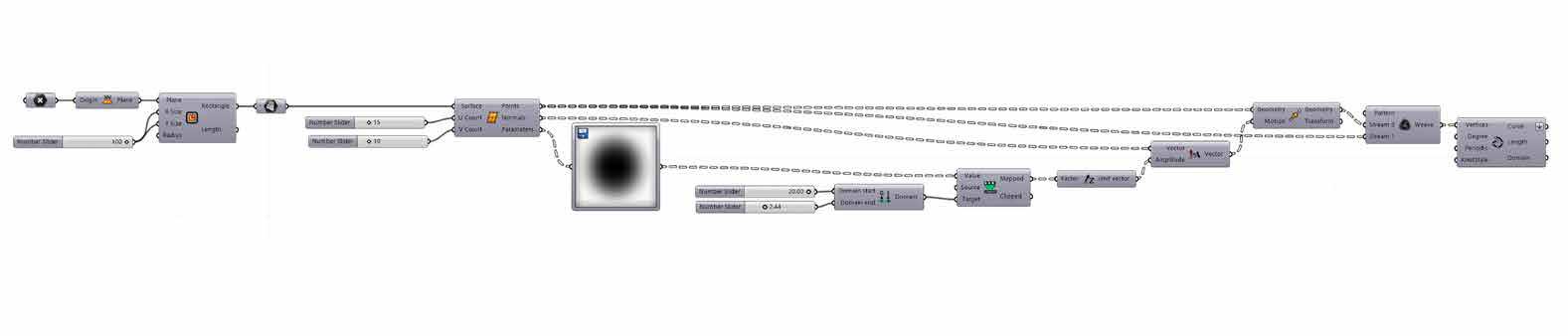

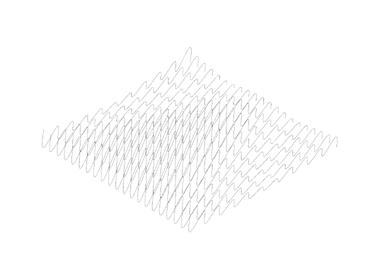

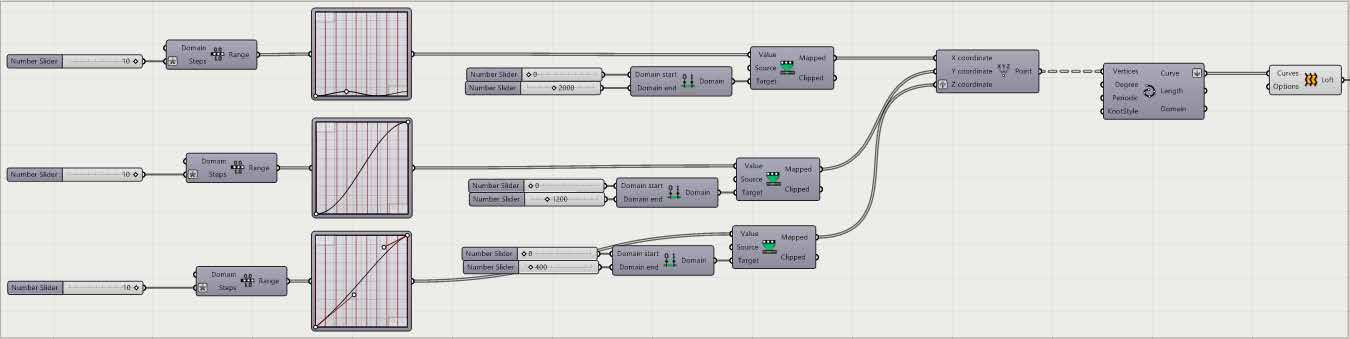

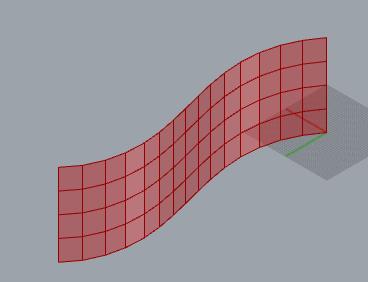

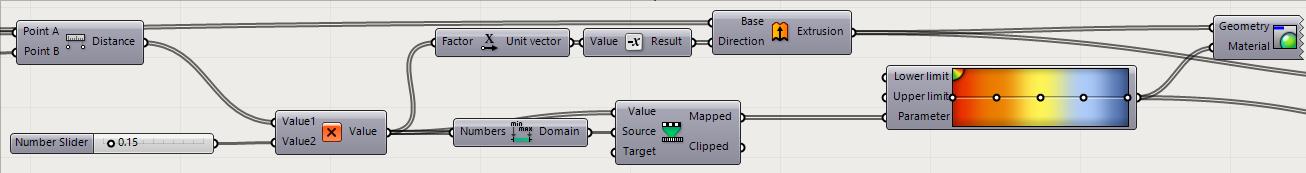

A series of scripts and parameters were designed to develop a digital tool design for fabricating Xerelith robotically. First, parametric toolpaths were scripted to control the motion trajectory of the robot. Then a series of scripts were developed to convert the mesh geometries developed on Houdini to 3D printable contour lines. Then the contour lines were further parametrised for toolpath optimisation, and different scripts were explored to create surface textures, controlling the toolpath.

The toolpath is a set of coordinates the tip of the machine follows in space in the machining process (Farrokhsiar and Gursoy, 2020).

Parameters are contours –initial layer settings, print plane settings, tool plane, home position, lead in-plane, lead out the plane, and robot speed.

GEOMETRY INPUT POSITION OF THE ROBOT

GEOMETRY INPUT POSITION OF THE ROBOT

The purpose of the algorithm is to receive and convert the 3D object to mesh which will then be converted into a contour by a series of polylines with the tool called ‘Contour’ on Grasshopper (Kontovourkis and Tryfonos, 2018). ‘Contour’ cuts the 3D object into sections, creating planes perpendicular to the selected direction. This method is widely used in architecture and furniture design as it converts a 3D object into 2D curves, which can then be printed.

A toolpath had to be designed to control the process of printing the model, which is decided by the designer and is mainly real-time settings such as the robot’s moving speed and the extrusion speed (Farrokhsiar and Gursoy, 2020). Additionally, the 3D model is designed on Rhino; the toolpath is derived in Grasshopper, after which the code is generated using a Grasshopper plugin for Robots, and finally, debugging, simulating, and uploading the RAPID code to the robot using ABB Robot Studio (Kontovourkis and Tryfonos, 2018; Farrokhsiar and Gursoy, 2020).

Usually, the vector direction can be in any given way, but when there are contours that are in two different directions, they are joined together to create a more secure and balanced form (Cuevas Diego Garcia and Pugliese Gianluca, 2020)

Material extrusion for the tool path development is developed on point-point motion driven by each contour layer known as polylines, and when one polyline ends, the other one starts (Kontovourkis and Tryfonos, 2018). A continuous toolpath was generated using Grasshopper script to create a continuous flow of robotic extrusion.

The key parameters that determine the result of the 3D printing process are the layer height which defines the space between the sections, the line width affected by the width of the extruded material, and the wall thickness, which determines the number of polylines, all which are fed into grasshopper (Kontovourkis and Tryfonos, 2018).

Layer height: Layer height controls the distance between the position of the extruder head between each vertical layer, and the smaller the height layer, the better the quality of the print; however, this vastly increases the print time.

Deposition Speed: This is the speed at which the extruder head moves and is dependent on the ability of the machine to interpret in the X-Y plane to build a layer.

Flow rate is the percentage at which the material

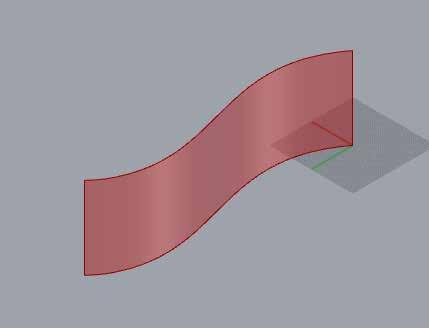

‘Loft’ command is generally the way to start a project involving four different aspects to control the command: order, direction, seam, and styles. The order of the curves is critical to control before designing a pattern. (Cuevas Diego Garcia and Pugliese Gianluca, 2020)

Just as curves are made on control points on Rhino, surfaces are made from curves that can be controlled, known as iso-curves. These curves are used to create paths for the 3D printer and work with the topology of the surface rather than section planes as used in previous contour methods. (Cuevas Diego Garcia and Pugliese Gianluca, 2020)

The flow controls the amount of material deposited during the printing process. Therefore, the speed is essential to monitor when it comes to models of different heights as shorter heights will have more material accumulated instead of uniform thickness throughout. (Cuevas Diego Garcia and Pugliese Gianluca, 2020)

Waves explore design possibilities through weaving patterns. (Cuevas Diego Garcia and Pugliese Gianluca, 2020)

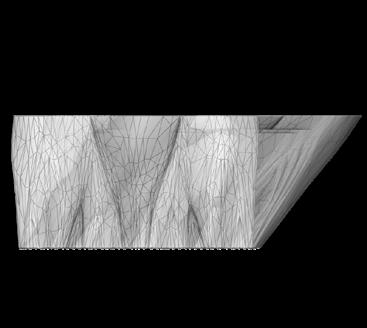

Scripting the toolpath to direct the motion trajectory of the robot to achieve further definition in the extrusion in the form of surface textures. Various scripts in Grasshopper were experimented with, by using point attractors and image mapping.

The weave is a function created by picking two sets of points and using a Boolean-defined pattern to create a woven design. WAVE GENERATION CODE WAVE PATTERN TOOL PATH ROBOTIC EXTRUSION

Attractors are like magnets in a virtual space, where they attract and can also repel objects (ModeLab, 2015). Any model created in Rhino or Grasshopper can be used as an attractor. The most used quantities are vectors, points, curves, and images. Attractors can also influence position, scale, colour, and rotation parameters. Depending on the type of attractor, it must always be converted into a numerical value; for example, for points or curves, it is distance; for vectors, angles and images, the amount of black and white is obtainable (Cuevas Diego Garcia and Pugliese Gianluca, 2020). When it comes to weaving patterns, attractors help create exciting geometries by varying the height of the peaks.

The easiest way to transform a geometry is by utilizing a picture. In Grasshopper, the component ‘image sampler’ helps to read the image in the form of pixels and extracts different parameters known as filters or channels like RGBA colours. This component allows environmental maps to be converted into geometries.

Additive manufacturing (AM) is the “process of joining materials to make objects from three-dimensional (3D) model data, usually layer upon layer, as opposed to subtractive manufacturing methodologies” (Guo and Leu, 2013) (ASTM F2792-10, 2010). It is a method wherein 3D designs can be built by depositing material, layer by layer, from a computer-aided design (CAD) file comprising complex geometries, simplifying the fabrication process. The key benefit of the 3D-printing process is waste reduction - it is especially relevant for critical raw materials, such as rare-earth elements (Popov et al., 2018). Further benefits include freedom of rapid design/model development (Morris, 2007), a possibility of improving function ability / lightweight structure (Herderick, 2011) and personalized design (Herderick, 2011). This project aims to create and propose a bespoke fabrication methodology for xeric environments using desert sand.

Arm-based systems offer high kinematic flexibility to enable the fabrication of complex structures, such as doubly curved forms that require control of the orientation of the end effector. This increased dexterity can allow arms to perform more sophisticated operations and adapt to varying construction environments. Arm systems also have a substantial ratio of physical reach to platform footprint, enabling more straightforward access to complex sites and allowing huge work volumes. (Keating et al., 2017)

Their use can reduce the reliance on human resources and minimise hazards to workers, speed up processes, reduce waste, shorten construction timescales, and reduce costs. While the prospects for some, such as bricklaying robots, are uncertain due to prohibitive costs and complexity, the future for others, notably drones and 3D printing robots, seems assured as the economic and other benefits are obvious. (Bogue, 2018). In the context of large-scale, working with large filament cross-sections and high printing speeds, on-site construction poses considerable challenges in configuring the printhead, specifying printer kinematics, deciding on the rheological properties, and the printing strategy itself. (Mechtcherine et al., 2019)

The most challenging aspect of fully autonomous superstructure construction is assembling structurally load-bearing elements. In conventional construction, load-bearing elements are typically made of steel, timber, or concrete, transported from the manufacturing plant, and assembled on a site typically prepared with the necessary formwork, scaffolding or other auxiliary structures and equipment that help workers assemble the structure. Such an extensive array of auxiliary construction tasks hinders the goal of a fully autonomous construction sequence. Therefore, many projects propose robots that can navigate the structure as they build it, acting as its scaffolding. (Melenbrink, Werfel and Menges, 2020)

8.5 https://iaac.net/project/3d-printed-bridge/ 8.6 https://iaac.net/project/3d-printed-bridge/

CASE STUDY 1:

The world’s first 3D printed footbridge was built and assembled in Madrid, Spain, by IAAC. It has a span of 12m and a width of 1.75m (Valencia Nicolás, 2017). It is constructed from steel microfibre reinforced cement making using particle bed printing. The concept behind the bridge was to show the complexities of nature, which allowed for the optimum distribution of material and minimized the amount of waste generated by recycling the material during the process (Salet et al., 2018). The footbridge contains eight cross-section segments of the reinforced cement. The microfibre helped prevent shrinkage and cracks due to high cement content and internal stresses due to the complex geometry. A single element was produced during each cycle, and the piece was then further kept in a temperature-controlled chamber to ensure that the external layers achieved enough hydration. Once the production of all blocks was complete, all the pieces were transported outside utilizing a forklift, supported by a metal platform to provide additional support to prevent cracking by dynamic forces. Steel ties anchored the webs to avert any failure arising from wind and solar radiation. Once the compressive strength was reached, it was placed on a steel frame. While the frame was unnecessary, as this is the first trial of a 3D printed structure, it is better to have additional support as the long-term effects are unknown, and neither are the regulations or standards (Salet et al., 2018).

8.4 https://iaac.net/project/3d-printed-bridge/

8.8 source: www.designboom.com 8.9 source: www.designboom.com

CASE STUDY 2:

Digital grotesque is a project designed at the Chair for Computer-Aided Architectural Design at the Swiss Federal Institute of Technology (ETH), using additive manufacturing to assemble an entire room (Hansmeyer & Dillenburger, 2012). It is the first immersive experience fabricated at a human scale, made from sandstone. The design process involves an algorithmic procedure called “mesh grammar” rather than traditional CAD software. With the advancement in technology, the entire room could have been made of 6 elements; however, the segments would have to be transported. The dimensions were restricted to 120*120*cm pallets. The pieces were hollowed out, and, in some places, the material thickness was as little as 1cm to minimize the weight. A mesh was added within to provide structural stability. Two loads were taken into consideration. The first was orientation in the 3D printer as the pieces are taken out, and the other load is when the pieces are assembled. The details on each segment are truncated cones and funnels for proper support and horizontal and vertical shafts for the steel bars to pass in the form of a grid Furthermore, the resin was added to provide some more backing (Hansmeyer & Dillenburger, 2012).

These case studies show that additive manufacturing opens the door to printing in architecture, which requires little manual intervention. Construction can be fully visualized in 3-dimensional forms rather than conventional plans, sections, and elevations. This kind of printing also brings about a level of precision and control.

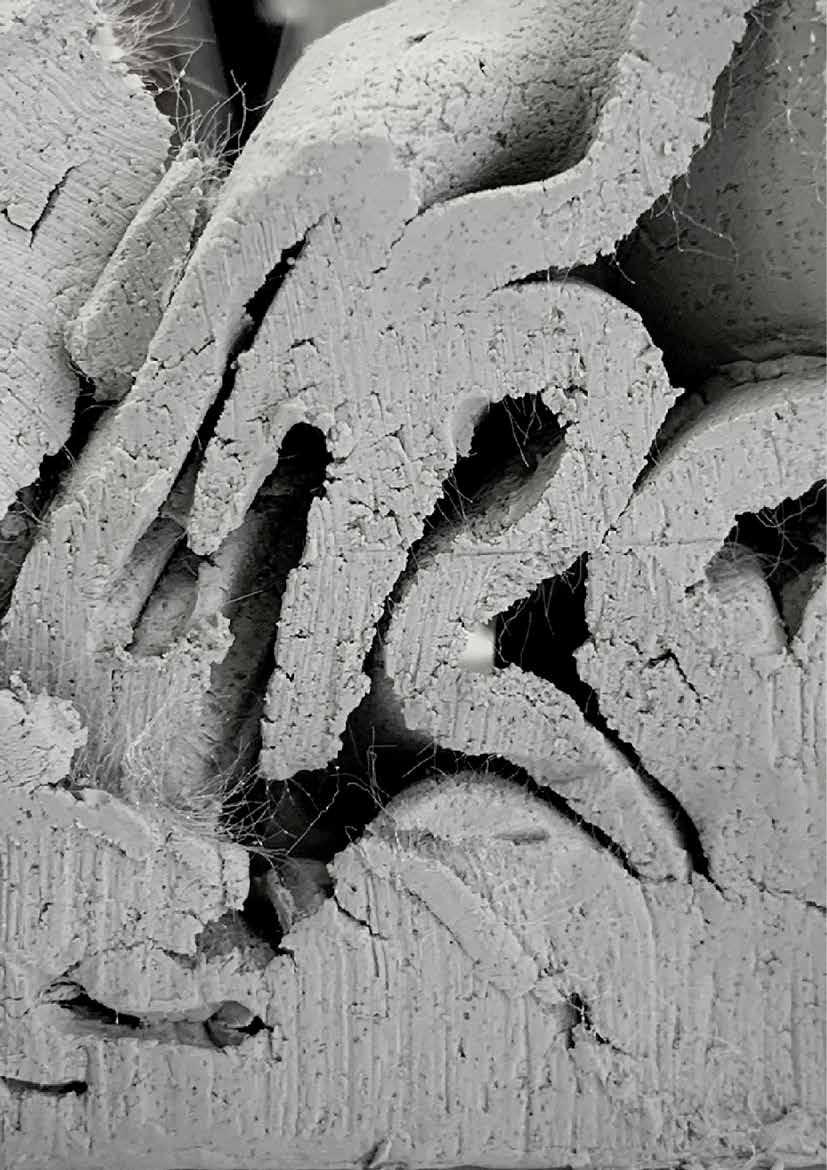

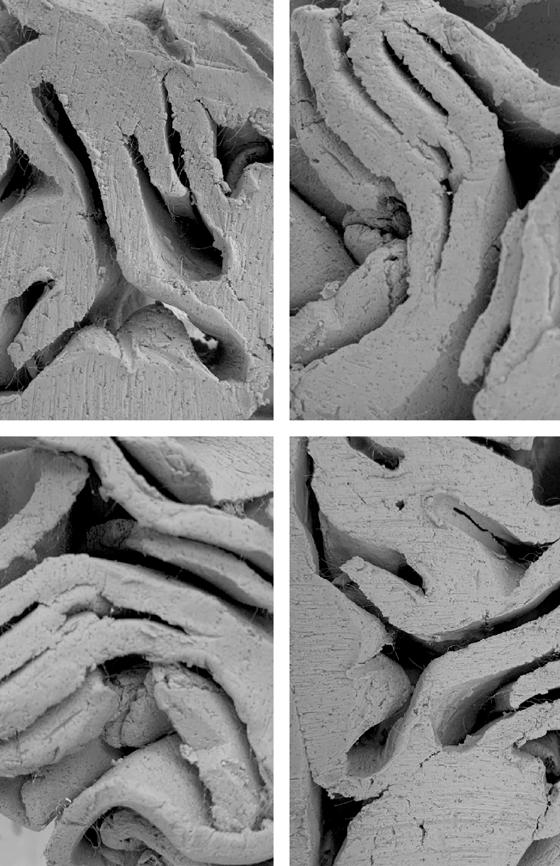

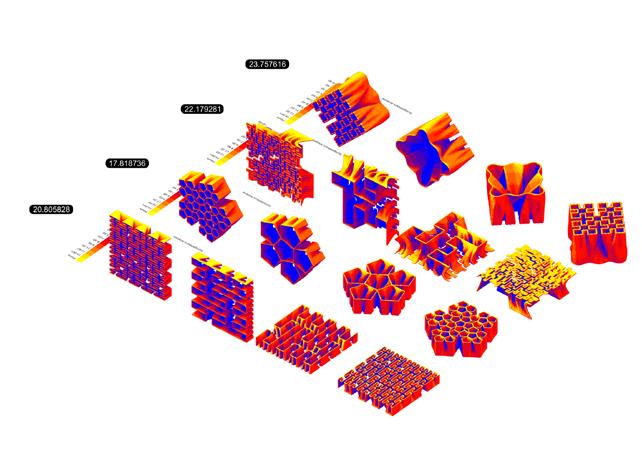

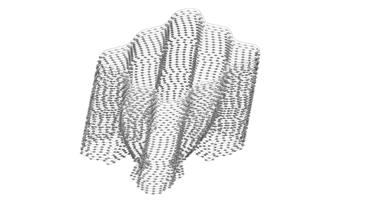

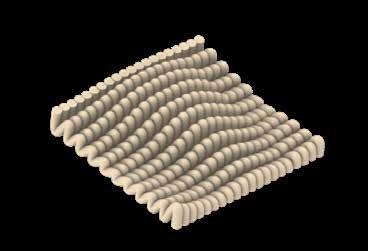

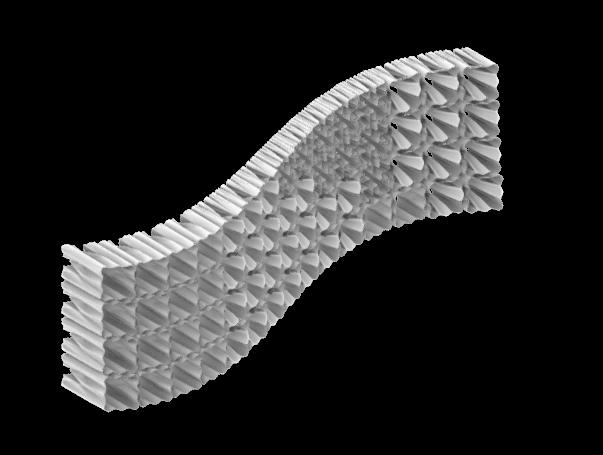

Sand-based particle bed extrusions are used pneumatically to extrude a nutrient-rich media using a robot. The process allowed us to create overhangs, heights and curing of nutrient-rich media as it binds with the desert sand in the particle bed. The sand bed creates favourable conditions for germination and root growth over the bricks.

This section explores a series of tests to calibrate the material flow with the extrusion process.

The initial tests were conducted using a syringe and different material compositions to understand material flow and their adhesion during the extrusion process.

To further explore the compression tests of the extruded material, a scaffold was developed using a framed structure and a plastic film to create an inverted dome scaffold. The material was extruded manually using a syringe on the scaffold. Different densities and layer heights were explored to understand the compressive strength of the extruded geometry. From the test, it was derived that compact extrusions with multiple numbers of layers had higher compressive durability compared to the ones that were not.

A free-form design with overhangs and cantilevers can cause the material to collapse. Different AM techniques such as suspension and particle bed printing help reduce the extensive formwork that would be required otherwise. Particle bed printing involves two steps: One is to layer the dry particles, and two, depositing the paste or the material onto the bed via an extruder/nozzle to bind the particles and provide support (Lowke et al., 2020). Compared with other AM methods, this method has no constraints regarding the form of 3D geometry as the dry particles are stable, and cantilevers, overhangs, arches, and suspended beams can be printed (Lowke et al., 2018). In addition, regarding production costs and ecological evaluation, the additional process step for removing the non-adhesive material after printing and the possibility of reusing this material must be considered. This technology, therefore, seems predestined for highly automated production in the precast plant. Given the ecological impact, the unbound material must be fully recyclable.

The following experiments were conducted to check material flow and deposition to test material interaction with the particle bed, for which a 20cmx20cmx15cm particle bed was created and the material was extruded using a syringe layer by layer in a vertical movement.

Three tests were conducted using three different composites

Test one used clay, sand, sodium alginate, and calcium carbonate

Test two used sand, sodium alginate, and calcium carbonate

Test three was sodium alginate and calcium carbonate

The tests were performed to check these three compositions and particle beds’ binding properties, material flow, and compressive strength. It was observed that the liquid consistency of the third composition allowed absorption of sand particles in the medium, which further enhanced the structural properties of the extrusion, but the downside was that extrusion completely lost its form. Whereas in compositions 1 and 2, the material flow’s consistency was thicker, allowing minimum absorption of the sand, and the form of the extrusion remained intact over the curing period after the extraction from the particle bed.

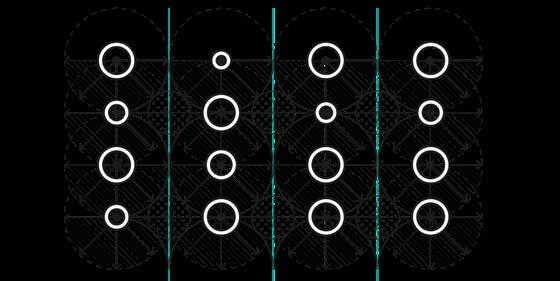

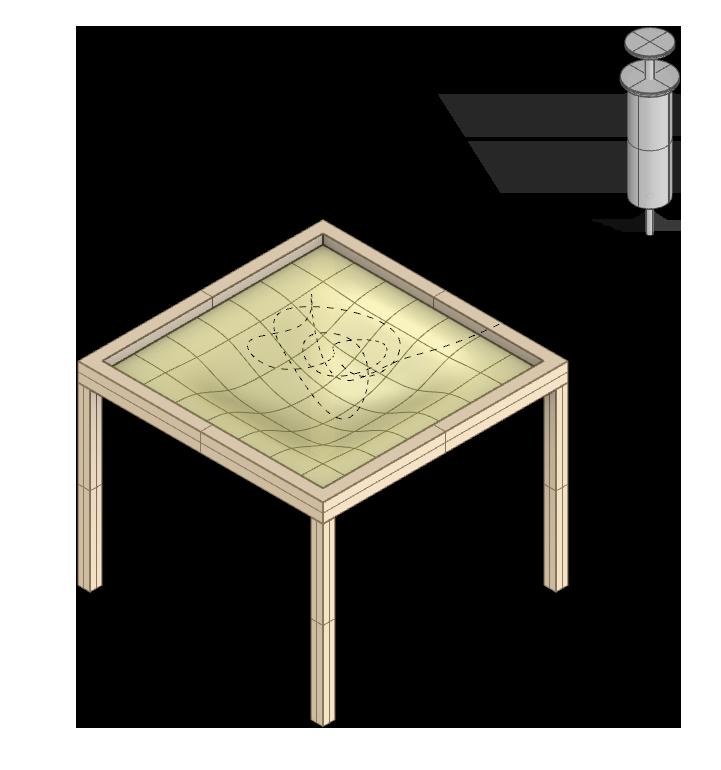

The following experiments were conducted to check the material flow and deposition to test material interaction with the particle bed using robots, for which a 20cmx20cm x15cm particle bed was created, and the material was extruded.

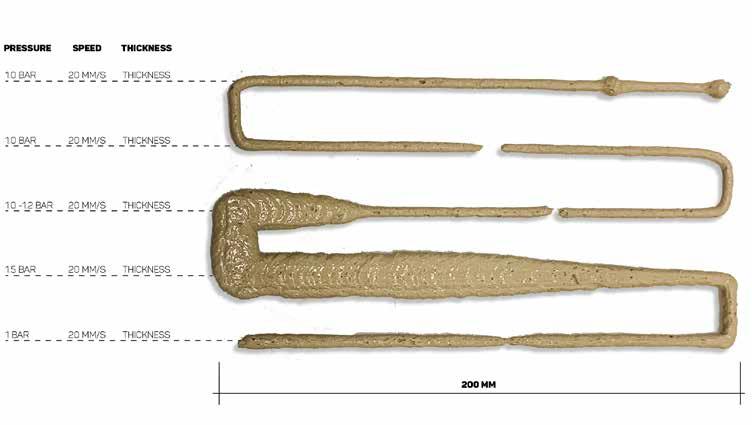

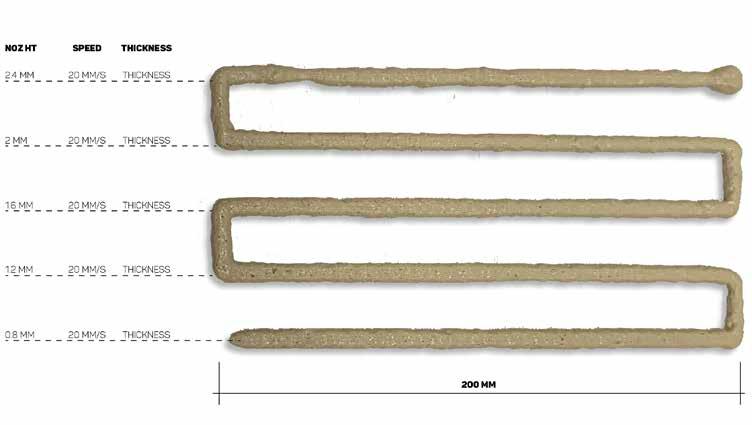

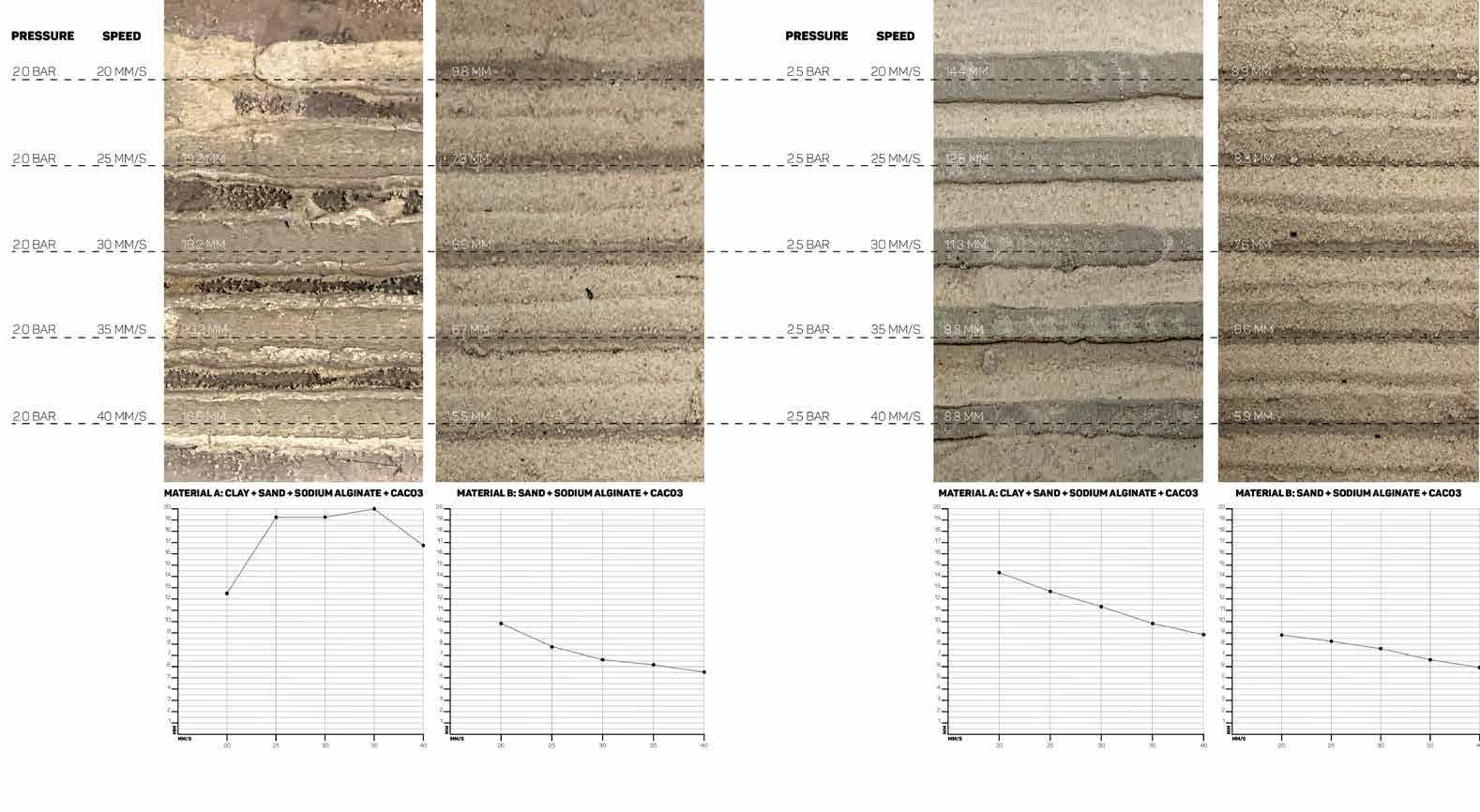

A line test was conducted using diff material compositions to check the effect of speed and pressure on thickness, and data were observed to identify the optimum conditions for extrusion, which was extruded on acrylic plates.

To check the effect of speed and pressure on thickness, a line test was conducted using different material compositions, and data were observed to identify the optimum conditions for extrusion extruded on the sand bed.

After identifying optimum conditions, different geometries were printed as a trial test in a particle bed. The test was to check layer adhesion and vertical deposition of the layers.

This section discusses the protocol designed to extrude nutrient rich media in a desert sand-based particle bed. A series of tests and experiments were conducted at the BMade to optimise speed, pressure, layer adhesion, deposition height and curing period of the extruded geometries.

ABB1600 robot is used with wasp extruder at B-made Gordon street. A particle bed of 56cmx50cmx15cm is made. The parameters are optimized using speed and pressure to obtain layer thickness and adhesion. Nutrientrich media is embedded with seeds and is extruded in the particle bed. Extruded bricks are submerged in the sand for a while to allow the germination process and root growth, and water is provided over time.

ROBOT SPACE AT BMADE GORDON

TANK

PRESSURE CONTORL MAIN POWER SWTCH

ROBOT BASE

WASP EXTRUDER

ROBOT SPACE AT BMADE GORDON

TANK

PRESSURE CONTORL MAIN POWER SWTCH

ROBOT BASE

WASP EXTRUDER

The material is prepared and loaded in the tank and then later connected to the robot to intitate extrusion

The program consisting the designed tool path exported from grasshopper is loaded via robot studio to initiate the robotic extruision

Two kinds of sands were used as particle beds: the first was moist sand, and the second was dry desert sand to test the layer adhesion.It was noted that moist sand hindered layer adhesion and prevented layers from binding, whereas desert sand provided an ideal support system for the nutrient-rich media to be extruded with proper layer adhesion.

It was used as a standard of 60% factor of the nozzle size (4mm); the deposition height was 3.6mm per layer. It was noted that this height enabled adhesive capacity of the layers while extrusion and allowed vertical deposition up to 40 layers.

The primary reason to use a particle bed system was to allow overhanging geometries to be extruded. The proposed particle bed allowed varying angles of cantilevers and overhangs without losing the form of the geometry.

During the extrusion, the seeds were manually added to the layers, which were then allowed to germinate over a period of time to observe root growth formation.

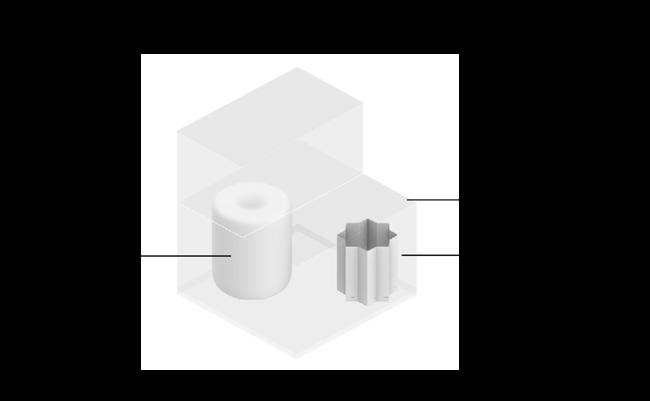

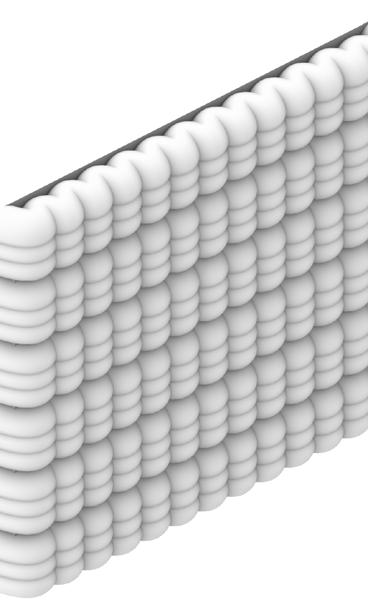

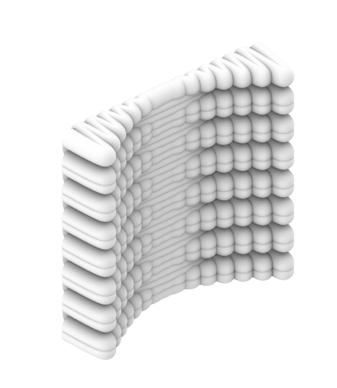

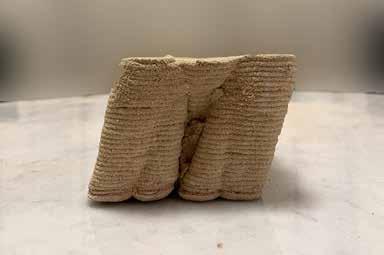

The chapter illustrates the testing phase of the prototype development for Xerilith after examining the parameters. The prototyping consists of the consolidation of three stages: material ecology, digital tool design and additive manufacturing. The geometries and tool path were designed along with the material exploration and fabrication methodology, which were tested against the parameters defined in the previous chapters. The bricks were designed to generate tool paths extruded using the robot in a particle bed robotic extrusion setup, which was conducted for prototyping. Test prints were done on bricks designed. This chapter also highlights the 3d printing of the bricks as well as the final installation, design, and execution.

To create a scalable prototype, the script design in the design component is applied on asurface to get subdivisions where the environmental maps are used to project brick with varying aperture sizes on the wall.

Following are a series of scripts design to create a prototype for the xeriltih wall.

Using the maps from the script each brick is robotically extruded. The size of each brick is !0cm X 10cm elevationallt with variying depths.

Following tests were conducted on the bricks to check different parameters that can be further calibrated for future explorations.

As explored in the material devlopment phase, the nutrient rich media has neglegible shrinkage when submerge in sand for the curing period. It was observed that the optimum curing period is between 5 to 10 days. The curing and structural integrity of the brick also depends on the layer thickness and width.

following thermal tests were conducted on three brick apperture sizes it was seen that the thermal conductivity of the brick depended on the aperture size. The larger the aperture the higher the thermal conductivity.

Growth test was conducted on the 3d printed bricks where the roots were allowed to grow for over a pereiod of 10 days. It can be seen that the nutrient rich media and its water retention capacity allows root growht over a period of time. When removed from the particle bed and moisutre level decreased the root growth stopped leaving behind fibres in the bricks.

The bricks were also tested with the coating develpoed in the material development phase. It can be seen that the coating provieds a protective barrrier as well as reinforces structural integrity of the bricks.

the follwoing are the explorations for designing the installation for Xeritlith.

Ectempos dent volupta tendere eosam laut minctem posam, tet resto beribus dendicias in prat eum vent. Ersperi tassunti comnis verum fugia culluptatis quae volupti berspietur? Quias debis doluptatist, sequasperum ipis et, ius ius asitem arciandi ab in ea qui ipsant a destores et accus, cum iducitatia nulpa si dolupta ssitatist, si dis que et perrumet lab imolum et eum faceped est iminctis nulpa doluptam volupta nostias aliquas inullam rerunt. Borit ide quis doluptae. At fugia eum seque parum fugitis

The research aimed to develop a bespoke fabrication technique for desert environments by bridging the digital and physical realms; therefore, the question is ‘can particle bed extrusion technique using nutrient-rich media be a viable fabrication methodology for xeric environments?’ This section aims to highlight the key findings of the research studying desert ecosystems in line with the arid vernacular architecture and brings forth the role of skin as an interface to inhibit micro-climates in natural organisms and architecture. The research highlighted the critical environmental factors – temperature, wind, and moisture, that must be addressed while approaching design and fabrication for xeric environments. A series of design investigations were explored using these factors as design parameters to generate architecture scripts, where digital porosities were explored through computational design and textural prop through material research. These studies showed the importance of data-driven design and material research to bridge the digital and physical worlds. These became the framework for the final project ‘Xerilith.’ Xerilith aimed to re-imagine Paolo Soleri’s concepts of arcology through bio-integrated methodologies. Fractal systems were explored to generate design scripts that created a seamless relationship between macro, meso, and micro scales. The fractal system also enables research to explore the idea of digital porosity in a controlled manner. This led to developing a procedural framework for fabrication in desert environments.