11 minute read

PROCEDURAL FABRICATION

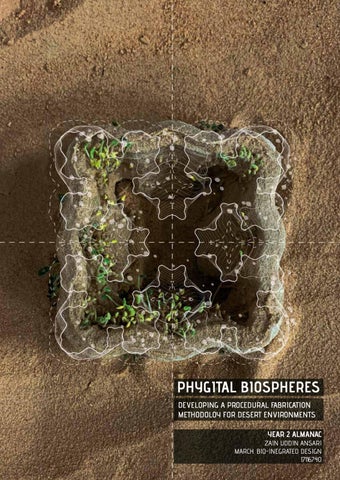

from PHYGITAL BIOSPHERES

by Zain Ansari

Growth test was conducted on the 3d printed bricks where the roots were allowed to grow for over a pereiod of 10 days. It can be seen that the nutrient rich media and its water retention capacity allows root growht over a period of time. When removed from the particle bed and moisutre level decreased the root growth stopped leaving behind fibres in the bricks.

Advertisement

The bricks were also tested with the coating develpoed in the material development phase. It can be seen that the coating provieds a protective barrrier as well as reinforces structural integrity of the bricks.

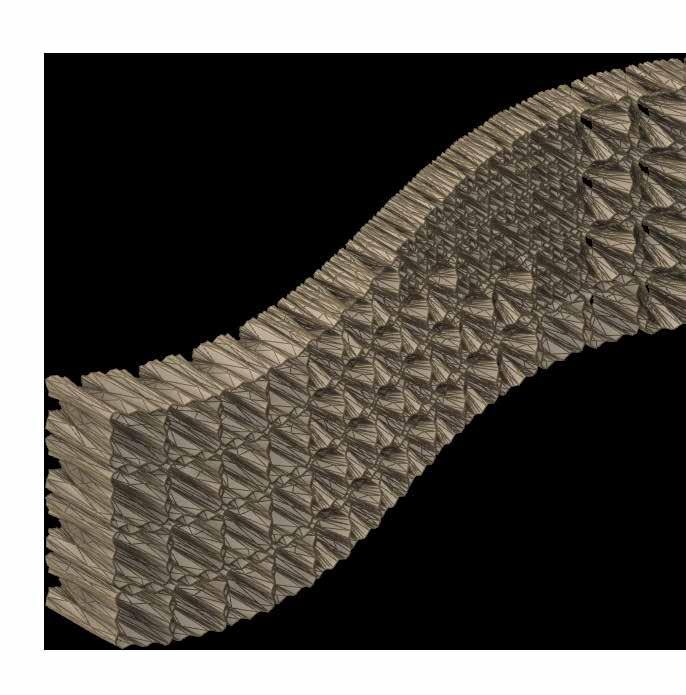

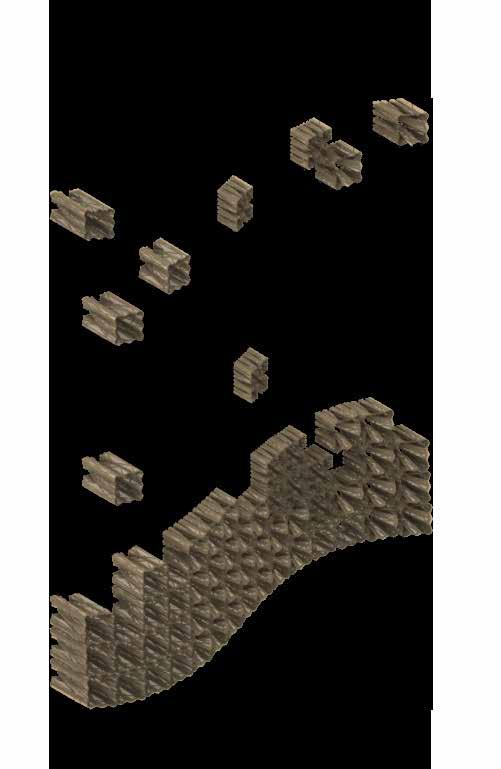

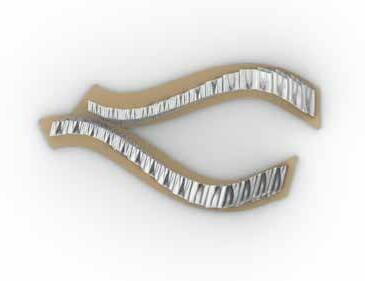

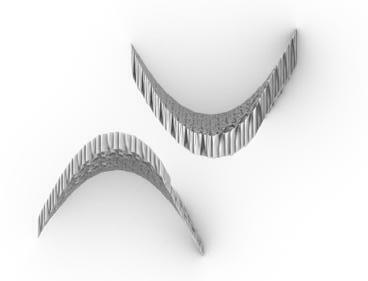

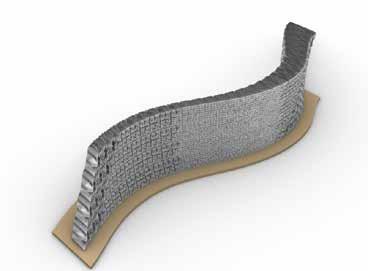

XERILTIH INSTALLATION

the follwoing are the explorations for designing the installation for Xeritlith.

Ectempos dent volupta tendere eosam laut minctem posam, tet resto beribus dendicias in prat eum vent. Ersperi tassunti comnis verum fugia culluptatis quae volupti berspietur? Quias debis doluptatist, sequasperum ipis et, ius ius asitem arciandi ab in ea qui ipsant a destores et accus, cum iducitatia nulpa si dolupta ssitatist, si dis que et perrumet lab imolum et eum faceped est iminctis nulpa doluptam volupta nostias aliquas inullam rerunt. Borit ide quis doluptae. At fugia eum seque parum fugitis

RESULTS AND FINDINGS

The research aimed to develop a bespoke fabrication technique for desert environments by bridging the digital and physical realms; therefore, the question is ‘can particle bed extrusion technique using nutrient-rich media be a viable fabrication methodology for xeric environments?’ This section aims to highlight the key findings of the research studying desert ecosystems in line with the arid vernacular architecture and brings forth the role of skin as an interface to inhibit micro-climates in natural organisms and architecture. The research highlighted the critical environmental factors – temperature, wind, and moisture, that must be addressed while approaching design and fabrication for xeric environments. A series of design investigations were explored using these factors as design parameters to generate architecture scripts, where digital porosities were explored through computational design and textural prop through material research. These studies showed the importance of data-driven design and material research to bridge the digital and physical worlds. These became the framework for the final project ‘Xerilith.’ Xerilith aimed to re-imagine Paolo Soleri’s concepts of arcology through bio-integrated methodologies. Fractal systems were explored to generate design scripts that created a seamless relationship between macro, meso, and micro scales. The fractal system also enables research to explore the idea of digital porosity in a controlled manner. This led to developing a procedural framework for fabrication in desert environments.

The 3D printed footbridge and digital grotesque case studies enabled the research to develop a bespoke fabrication technique for xeric environments using three primary components: nutrient-rich media, digital tool design, and particle bed robotic extrusions. Material experiments were conducted to develop a circular approach using site-specific materials and organic binders to create a nutrient-rich media that could be extruded robotically. The tests conducted during the material development phase enabled it to be optimized and calibrated for robotic extrusions. The nutrient-rich media proved to promote seed germination, root growth, and structurally stability, which can be used to fabricate architectural components. A series of scripts were designed in Grasshopper to calibrate the motion trajectories of the robot. The set of explorations allowed in-depth control of the robot. The additive manufacturing methodology was developed as a bridge between the digital and physical components of the research. The material floor tests proved that the optimum composition for the nutrient-rich media was sand, sodium alginate, calcium carbonate, and kaolin, and the optimum extrusion parameters were 2.5 bar pressure at 25mm/sec speed of the robot. The test observed that liquid consistency plays a vital role in the extrusion and layer adhesion. It was also observed that the higher liquid consistency of the material allowed better extrusions and was more structurally stable due to the absorption of sand particles in the particle bed system. During the prototype phase, wall designs were generated using Grasshopper script that allowed to map the environmental data on surfaces to map the porosity of the bricks. It can be observed that during rapid production, two factors play a vital role - 1. material flow and 2. maintenance of the robot, I.e., the cleanliness of the extruder.

DISCUSSION

The research presented in the almanac titled, Phyigital biospheres speculated to bridge the digital and physical realms through a bio integrated fabrication technique. This creates an exciting opportunity to develop back and forth workflow methodologies between the natural and the built environments. The series of experimental explorations allowed the research to manifest into an initial prototype. Where the robotically extruded nutrient rich media embedded with seed showed promising results of root growth. Therefore, the prototype opens exciting opportunities developing this technique further through a quantifiable control of the methodology. Computational scripts can further be explored to create controlled environmental response through geometries. Material research can be further be developed to control effect of root growth and structural Integrity of architectural components. Robotic tool paths can be further explored for nonplanar printing to calibrate surface textures with micro climates.

BIBLIOGRAPHY

https://www.arcosanti.org/arcology (2021) What Is Arcology? | Ideology of Paolo Soleri | Arcosanti. Available at: https://www.arcosanti.org/arcology/ (Accessed: June 19, 2022).

Millard, H. (2018) Paolo Soleri and Arcology: An Analytical Comparison to Frank Lloyd Wright and Louis Kahn. Available at: https://scholarworks.uark.edu/archuht.

Arakaki, A. et al. (2015) “Biomineralization-inspired synthesis of functional organic/inorganic hybrid materials: Organic molecular control of self-organization of hybrids,” Organic and Biomolecular Chemistry. Royal Society of Chemistry, pp. 974–989. doi:10.1039/c4ob01796j.

Awadhiya, A., Kumar, D. and Verma, V. (2016) “Crosslinking of agarose bioplastic using citric acid,” Carbohydrate Polymers, 151, pp. 60–67. doi:10.1016/J.CARBPOL.2016.05.040.

Behboud, R., Moradi, A. and Farajee, H. (2021) Film coating with sodium alginate improves seed germination of sweet corn (Zea mays var. Saccharata) under osmotic stress conditions, Journal of Plant Process and Function.

Britannica, T.E. of Encyclopaedia. “kaolin. “ E.B. (no date) https://www.britannica.com/ science/kaolin. Available at: https://www.britannica.com/science/kaolinite (Accessed: June 12, 2022).

Calkins, M. (2009) Materials for Sustainable Sites A Complete Guide to the Evaluation, Selection, and Use of Sustainable Construction Materials.

Cantaert, B. et al. (2017) “Use of Amorphous Calcium Carbonate for the Design of New Materials,” ChemPlusChem. Wiley-VCH Verlag, pp. 107–120. doi:10.1002/cplu.201600457.

Global alliance for buildings and construction (2021) 2021 GLOBAL STATUS REPORT FOR BUILDINGS AND CONSTRUCTION Towards a zero-emissions, efficient and resilient buildings and construction sector. Available at: www.globalabc.org.

Golden Elizabeth (2018) Building from Tradition - Local Materials and Methods in Contemporary Architecture.

González, A. et al. (2012) “Seaweed Oligosaccharides Stimulate Plant Growth by Enhancing Carbon and Nitrogen Assimilation, Basal Metabolism, and Cell Division,” Journal of Plant Growth Regulation 2012 32:2, 32(2), pp. 443–448. doi:10.1007/S00344-012-9309-1.

Ji, Y., Liu, C. and Ding, Z. (2021) “Research and Analysis on Present Situation of Desert Sand Concrete,” in International Academic Conference on Energy Conservation, Environmental Protection and Energy Science. EDP Sciences. doi:10.1051/e3sconf/202127102004.

Kazi, G.A.S. and Yamamoto, O. (2019) “Effectiveness of the sodium alginate as surgical sealant materials,” Wound Medicine, 24(1), pp. 18–23. doi:10.1016/J.WNDM.2019.02.001.

Kuriakose, B. (2020) Sustainability Lessons From the Traditional Building Materials, https:// www.bennykuriakose.com/post/sustainability-lessons-from-the-traditional-buildingmaterials#viewer-fkbah. Available at: https://www.bennykuriakose.com/post/sustainabilitylessons-from-the-traditional-building-materials#viewer-fkbah (Accessed: June 20, 2022).

Lacoste, C. et al. (2018) “Sodium alginate adhesives as binders in wood fibers/textile waste fibers biocomposites for building insulation,” Carbohydrate Polymers, 184, pp. 1–8. doi:10.1016/J.CARBPOL.2017.12.019.

Masi, E.B. et al. (2021) “Root Reinforcement in Slope Stability Models: A Review,” Geosciences 2021, Vol. 11, Page 212, 11(5), p. 212. doi:10.3390/GEOSCIENCES11050212.

Nudelman, F. and Sommerdijk, N.A.J.M. (2012) “Biomineralization as an inspiration for materials chemistry,” Angewandte Chemie - International Edition, pp. 6582–6596. doi:10.1002/anie.201106715.

Scherer, D. (2019) “Interview with Diana Scherer: Weaving roots at the interface between art, fashion and science,” PLANTS, PEOPLE, PLANET, 1(3), pp. 142–145. doi:10.1002/ppp3.48.

Szekalska, M. et al. (2016) “Alginate: Current Use and Future Perspectives in Pharmaceutical and Biomedical Applications,” International Journal of Polymer Science, 2016. doi:10.1155/2016/7697031.

Walker, D.J. et al. (2014) “Atriplex halimus L.: Its biology and uses,” Journal of Arid Environments, 100–101, pp. 111–121. doi:10.1016/J.JARIDENV.2013.09.004.

Cuevas Diego Garcia and Pugliese Gianluca (2020) Advanced 3D Printing with Grasshopper.

Farrokhsiar, P. and Gursoy, B. (2020) “Robotic Sketching: A Study on Robotic Clay 3D Printing,” in XXIV International Conference of the Iberoamerican Society of Digital Graphics.

https://en.wiktionary.org/wiki/toolpath (no date). Available at: https://en.wiktionary.org/ wiki/toolpath (Accessed: June 13, 2022).

Ishak, I., Fisher, J. and Larochelle, P. (2016) “Robot Arm Platform for Additive Manufacturing: Multi-Plane Printing,” in Proceedings of the 29th Florida Conference on Recent Advances in Robotics.

Keating, S. and Oxman, N. (2013) “Compound fabrication: A multi-functional robotic platform for digital design and fabrication,” Robotics and Computer-Integrated Manufacturing, 29(6), pp. 439–448. doi:10.1016/J.RCIM.2013.05.001.

Kontovourkis, O. and Tryfonos, G. (2018) “Integrating parametric design with robotic additive manufacturing for 3D clay printing: An experimental study,” in 35th International Symposium on Automation and Robotics in Construction.

ModeLab (2015) Working With Attractors |. Available at: https://modelab.gitbooks.io/ grasshopper-primer/content/1-foundations/1-3/2_working-with-attractors.html (Accessed: June 14, 2022).

Anastasia Kolomiets, B. et al. (2018) “Benefits of Titanium Additive Manufacturing for Industrial Design Development. Trends, Limitations and Applications,” Global Journal of Researches in Engineering: J General Engineering, 18.

ASTM F2792-10 (2010) “Standard Terminology for Additive Manufacturing Technologies,” Book of Standards , 10.04. Available at: https://www.astm.org/f2792-10.html (Accessed: June 9, 2022).

Bandyopadhyay Amit et al. (2019) Additive Manufacturing.

Bogue, R. (2018) “What are the prospects for robots in the construction industry?,” Industrial Robot, 45(1), pp. 1–6. doi:10.1108/IR-11-2017-0194. Herderick, E. (2011) Additive Manufacturing of Metals: A Review.

Ji, G. et al. (2019) “A 3D Printed Ready-Mixed Concrete Power Distribution Substation: Materials and Construction Technology,” Materials 2019, Vol. 12, Page 1540, 12(9), p. 1540. doi:10.3390/MA12091540.

Keating, S.J. et al. (2017) “Toward site-specific and self-sufficient robotic fabrication on architectural scales,” Science Robotics, 2(5), p. 8986. doi:10.1126/SCIROBOTICS.AAM8986/ SUPPL_FILE/AAM8986_SM.PDF.

Lowke, D. et al. (2018) “Particle-bed 3D printing in concrete construction – Possibilities and challenges,” Cement and Concrete Research, 112, pp. 50–65. doi:10.1016/J. CEMCONRES.2018.05.018.

Lowke, D. et al. (2020) “Particle bed 3D printing by selective cement activation – Applications, material and process technology,” Cement and Concrete Research, 134, p. 106077. doi:10.1016/J.CEMCONRES.2020.106077.

Mechtcherine, V. et al. (2019) “Large-scale digital concrete construction – CONPrint3D concept for on-site, monolithic 3D-printing,” Automation in Construction, 107, p. 102933. doi:10.1016/J.AUTCON.2019.102933.

Melenbrink, N., Werfel, J. and Menges, A. (2020) “On-site autonomous construction robots: Towards unsupervised building,” Automation in Construction, 119, p. 103312. doi:10.1016/J. AUTCON.2020.103312.

Morris, J.A. (2007) Personal Fabrication and the Future of Industrial Design.

Nerella, V.N. et al. (2017) “CONPrint3D: Beton-3D-Druck als Ersatz für den Mauerwerksbau/ CONPrint3D: 3D-Concrete-Printing as an Alternative for Masonry,” Bauingenieur, 92(09), pp. 355–363. doi:10.37544/0005-6650-2017-09-39.

Nerella, V.N., Hempel, S. and Mechtcherine, V. (2019) “Effects of layer-interface properties on mechanical performance of concrete elements produced by extrusion-based 3D-printing,” Construction and Building Materials, 205, pp. 586–601. doi:10.1016/J. CONBUILDMAT.2019.01.235.

Ngo, T.D. et al. (2018) “Additive manufacturing (3D printing): A review of materials, methods, applications and challenges,” Composites Part B: Engineering. Elsevier Ltd, pp. 172–196. doi:10.1016/j.compositesb.2018.02.012.

Popov, V. et al. (2018) “Prospects of additive manufacturing of rare-earth and non-rareearth permanent magnets,” Procedia Manufacturing, 21, pp. 100–108. doi:10.1016/J. PROMFG.2018.02.199.

Saetre, E. (no date) Development of Additive Manufacturing Technology Implications on the design process and the transportation industry, moving from prototyping to production.

Salet, T.A.M. et al. (2018) “Design of a 3D printed concrete bridge by testing,” https://doi.org/ 10.1080/17452759.2018.1476064, 13(3), pp. 222–236. doi:10.1080/17452759.2018.1476064.

Valencia Nicolás (2017) World’s First 3D Printed Bridge Opens in Spain, ArchDaily. Available at: https://www.archdaily.com/804596/worlds-first-3d-printed-bridge-opens-in-spain (Accessed: June 4, 2022).

Babsail, M.O. and Al-Qawasmi, J. (2015) “Vernacular architecture in Saudi Arabia: Revival of displaced traditions,” Vernacular Architecture: Towards a Sustainable Future - Proceedings of the International Conference on Vernacular Heritage, Sustainability and Earthen Architecture, (January), pp. 99–104. doi:10.1201/b17393-20.

Bombi, P. et al. (2021) “Climate change effects on desert ecosystems: A case study on the keystone species of the Namib Desert Welwitschia mirabilis,” PLoS ONE, 16(11 November). doi:10.1371/JOURNAL.PONE.0259767.

Cactus Adaptations - How Are Cacti Adapted To The Desert? - Smart Garden Guide (no date). Available at: https://smartgardenguide.com/cactus-adaptations/ (Accessed: April 25, 2022).

Guadarrama-Cetina, J. et al. (2014) “Dew condensation on desert beetle skin,” European Physical Journal E, 37(11). doi:10.1140/EPJE/I2014-14109-Y.

Lioubimtseva, E. (2016) “Climate change in arid environments: revisiting the past to understand the future:,” http://dx.doi.org/10.1191/0309133304pp422oa, 28(4), pp. 502–530. doi:10.1191/0309133304PP422OA.

Portal, C.C.K. (no date) What is Climate Change ? | Climate Change Knowledge Portal. Available at: https://climateknowledgeportal.worldbank.org/country/saudi-arabia/ overview (Accessed: April 23, 2022).

Raspall, F. (2015) “A procedural framework for design to fabrication,” Automation in Construction, 51(C), pp. 132–139. doi:10.1016/j.autcon.2014.12.003.

ROYCE LaNIER (1979) “Man and architecture: The highmindedness of Paolo Soleri,” Urban Ecology, 4(3), pp. 235–244. doi:10.1016/0304-4009(79)90005-6.

Schwimmer, H. and Haim, A. (2009) “Physiological adaptations of small mammals to desert ecosystems,” Integrative Zoology, 4(4), pp. 357–366. doi:10.1111/J.1749-4877.2009.00176.X.

Sean Lally (2014) The Air From Other Planets.

WWF (no date) World’s deserts threatened by climate change, UN warns | WWF. Available at: https://www.wwf.mg/en/?71560/Worlds-deserts-threatened-by-climate-change-UN-warns (Accessed: April 23, 2022).