DESIGN PORTFOLIO

ZACHARY MARTINEZ

TABLE OF CONTENTS

EDUCATION

August 2019 - May 2023

Texas A&M University

EDUCATION

August 2019 - May 2023

Texas A&M University

Contact

zacharymartinez05@gmail.com (214) 516 1800

606 Townplace Dr. College Station, TX 77840

Undergraduate degree in Environmental Design

Overall GPA: 3.85

August 2023 - May 2025

(Anticipated Graduation Date)

SOFTWARE PROFICIENCY

Texas A&M University

Graduate Degree in Architecture

Overall GPA: 4.00

Social, detail-oriented student with five years of diverse firm experience. Strong passion for both architecture and art. Skilled in architectural drafting, digital modeling, and drawing. Strong ability to balance aesthetics with functionality, collaborate in a workplace environment, and adapt to project demands.

Rhino 3D • Sketchup • Revit • Autocad • Illustrator • Photoshop • Indesign • Enscape • Lumion • V-Ray • Matterport

Agisoft Metshape • FARO Scene

WORK EXPERIENCE

PACT DESIGN STUDIO

June 2022 - Present

Since the summer of 2022, I have worked both full and part time for Pact Design Studio, an architecture firm located in downtown Bryan, Texas. As part of my position as a designer, I have assuumed multiple roles, including but not limited to: conducting feasibility studies, collecting existing conditions and measurements, schematic building design, design development, construction document production, construction administration, project management, conducting client meetings, conducting punch walks, among other roles.

ACADEMIC RESEARCH ASSISTANT

ALLIANCE ARCHITECTS

June 2020 - November 2021

Beginning at the end of my freshman year of college, I worked for my former studio professor, Dr. Weiling He, as an assistant. During this time I completed a variety of tasks which have exposed me to the world of architecture academia. During the Summer and Fall of 2020, I helped Dr. He research and document the architectural works of the firm Caudill-Rowlett-Scott located in the Bryan-College Station area. This involved searching online databases, contacting city archives and libraries, and surveying associated properties. In the Spring of 2021, I aided Dr. He in documenting and securing the rights to images she included in her book, Space: Within and Around.

June 2020 - August 2020, December 2020 - January 2021, June 2021 - August 2021, January 2022

During my time interning at Alliance, I helped with a number of tasks which familiarized me with different steps of the architectural process. Much of my time was spent helping to draw and annotate plans in Revit for ongoing projects. As a result, I’m well-accustomed to the drafting and organizational standards that can be found in the industry. However, I had experience outside of the office as well— I accompanied employees on several site visits, each one at different steps in the construction process. I also helped conduct punchlists on completed projects, as well as survey existing buildings to produce accurate existing conditions.

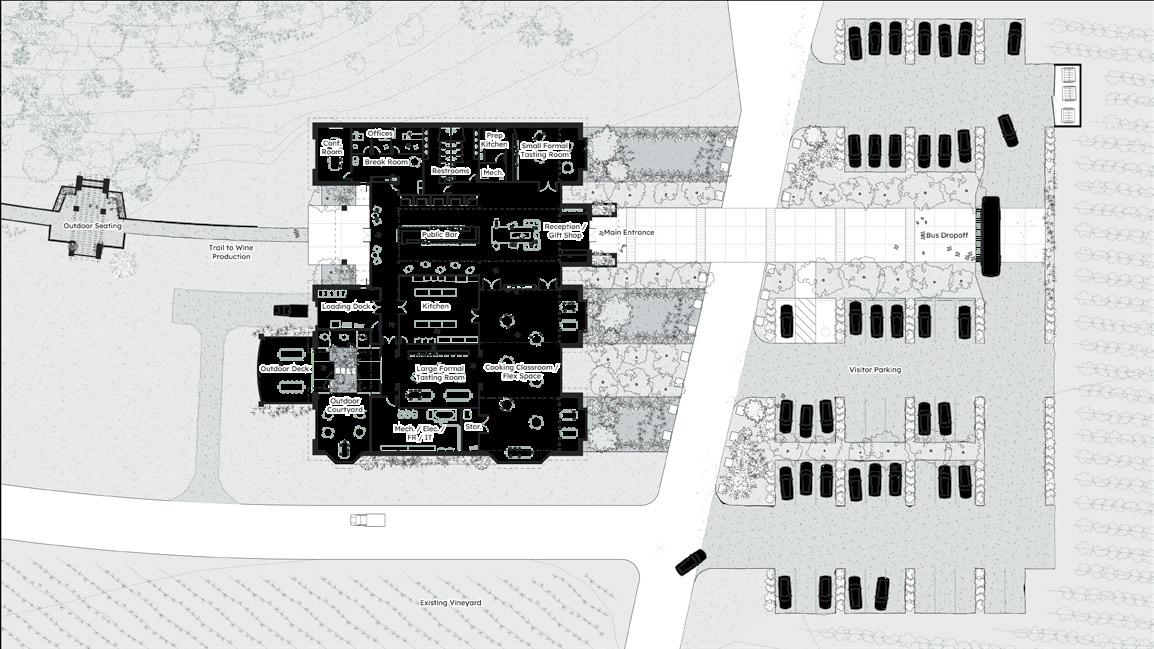

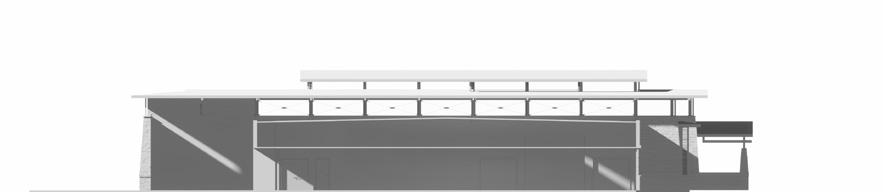

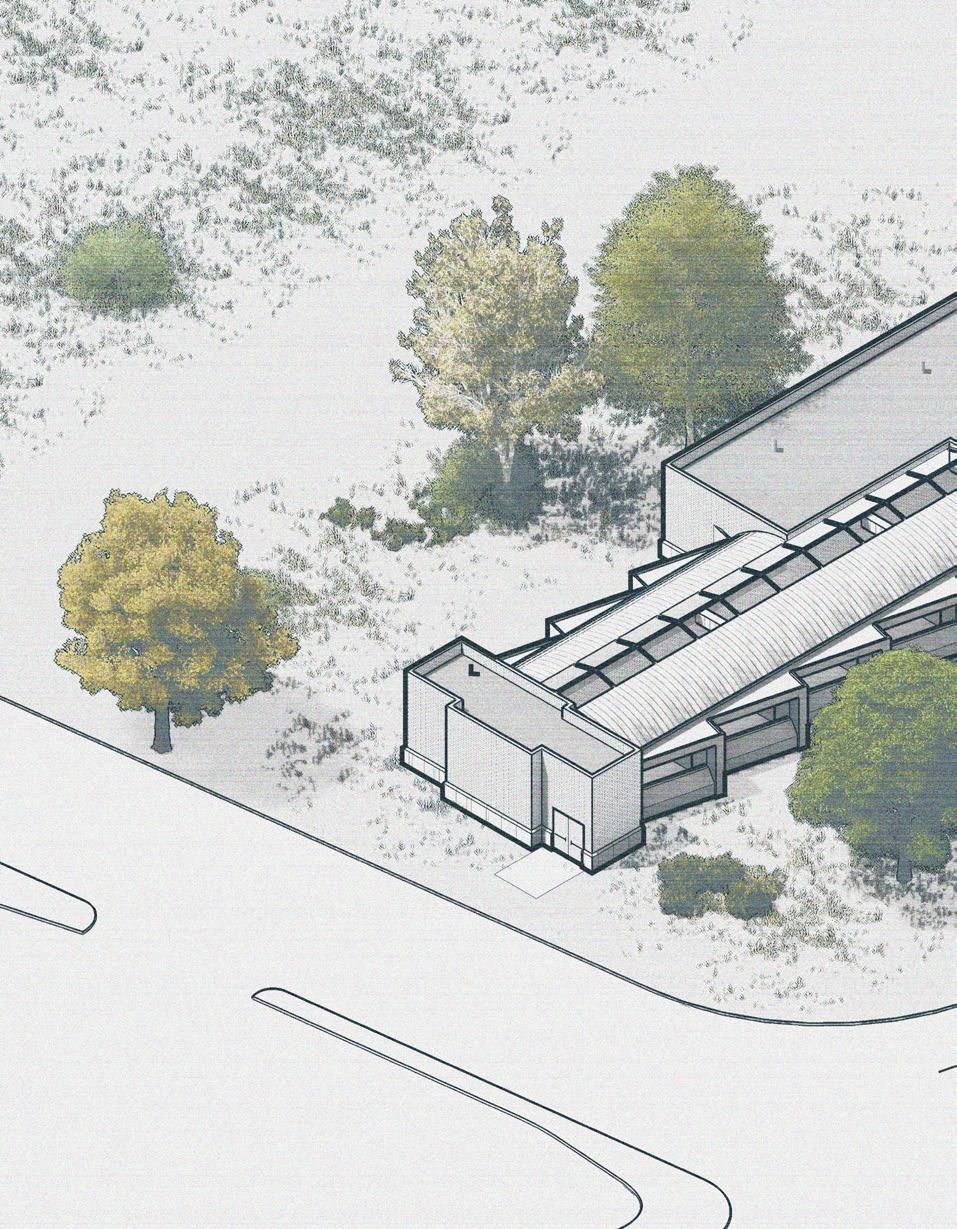

ARCH 606, Fall 2024 | Prof.

Ray Holliday Partner: Amira Soto

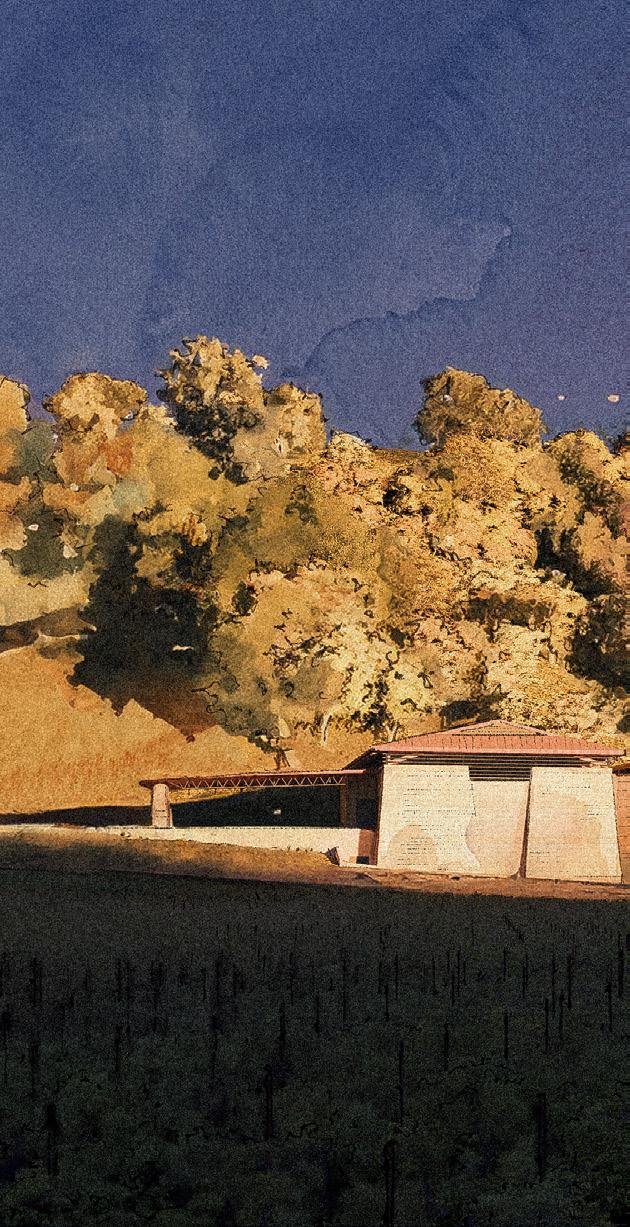

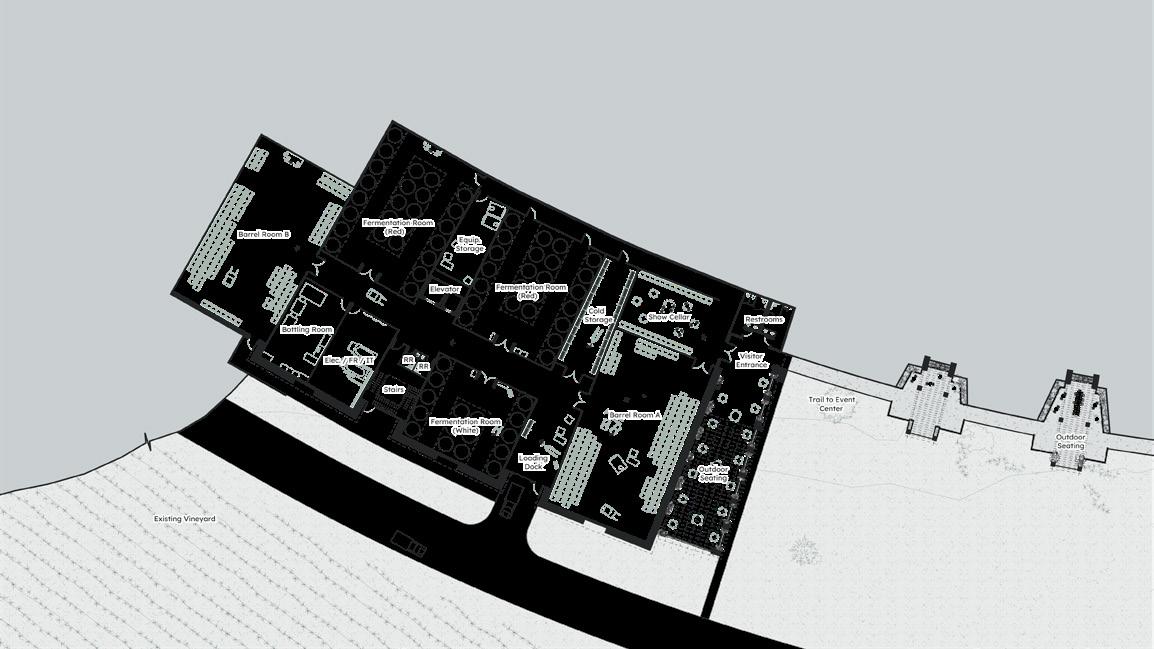

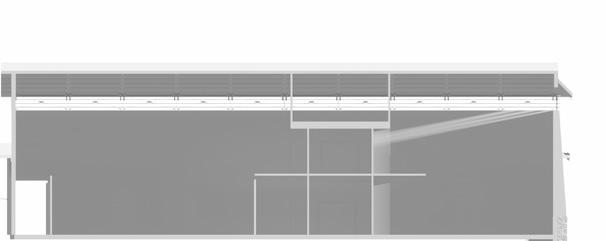

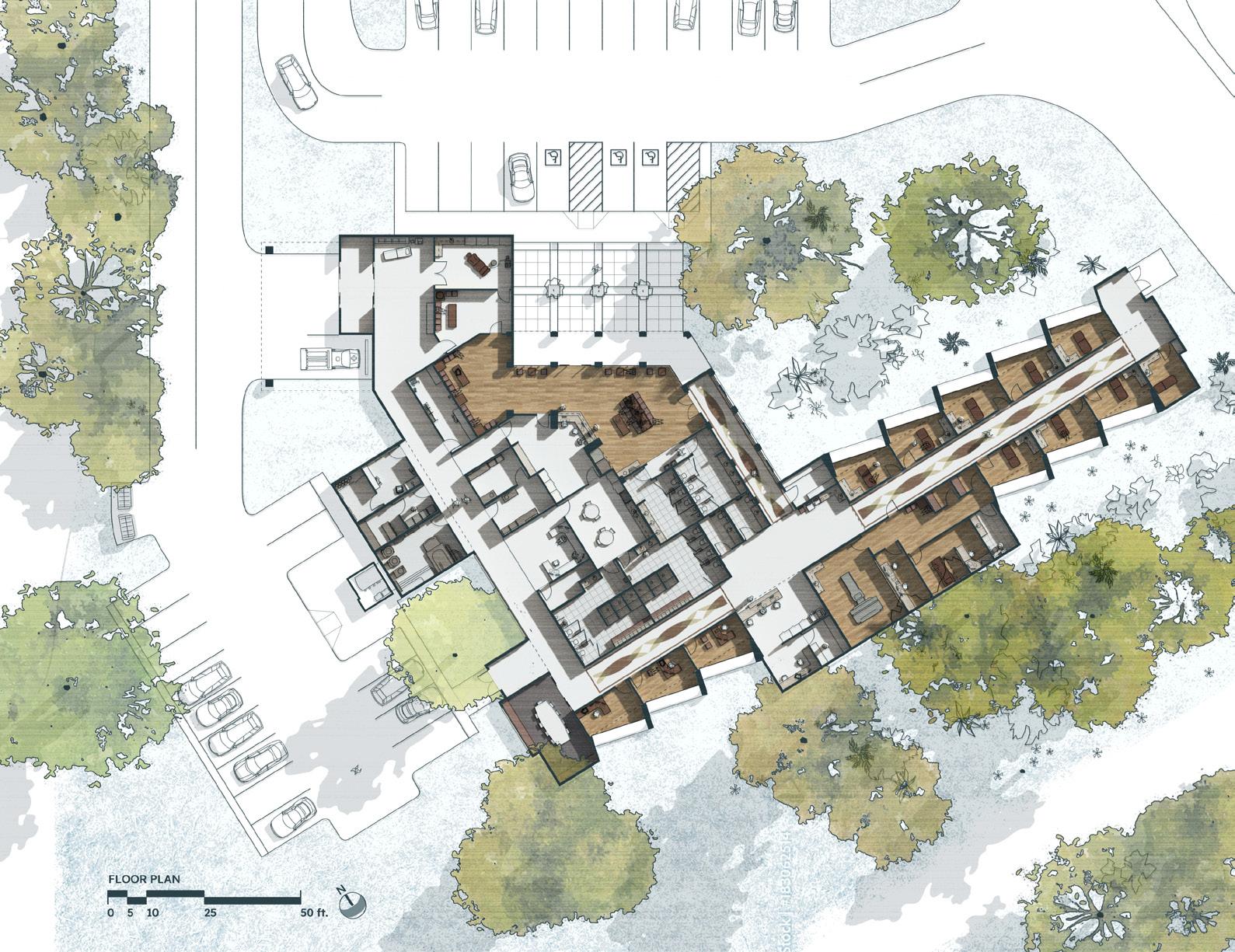

The Odette Estate is one of many wineries that operates out of Napa, California— A region known for its fertile soil and year-round moderate temperatures. The premise of this project was for students to design a completely new complex, consisting of an event center and wine production facility, for Odette. The program includes patron tasting rooms, a kitchen, barrel storage, fermentation rooms, and other critical steps of the wine-making process.

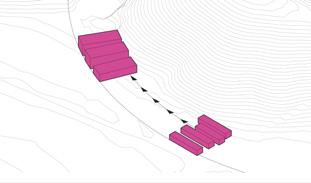

The site of the new winery sits at the base of a gentle slope in the Napa valley— A distinct feature which serves as the main catalyst for the parti. Conceptually, a series of grids were drawn that run both radial and tangent to a shared arc that embraces the nearby hill. These grids then served as the basis for final massing. The tangent lines, realized as the event center, pull visitors in from the adjacent parking lot into the main lobby. A foot path follows behind the building, tracing the main arc of the complex to create a promenade for visitors to leisurely explore. The radial lines, realized as the wine production building, sits at the end of this foot path, directing visitors’ attention outward to the surrounding valley, celebrating the landscape to which Odette owes its livelihood.

This hill also serves a practical purpose during the winemaking process: Workers bring crushed grapes, known as must, into the facility via the plan west entrance of the production building. They can load them into the top of the fermentation tanks without the use of any additional pumping equipment due to the elevation difference between the loading dock and the floor containing the tanks. This technique is known colloquially as “gravity pouring” and aids significantly in the efficiency of the winemaking process.

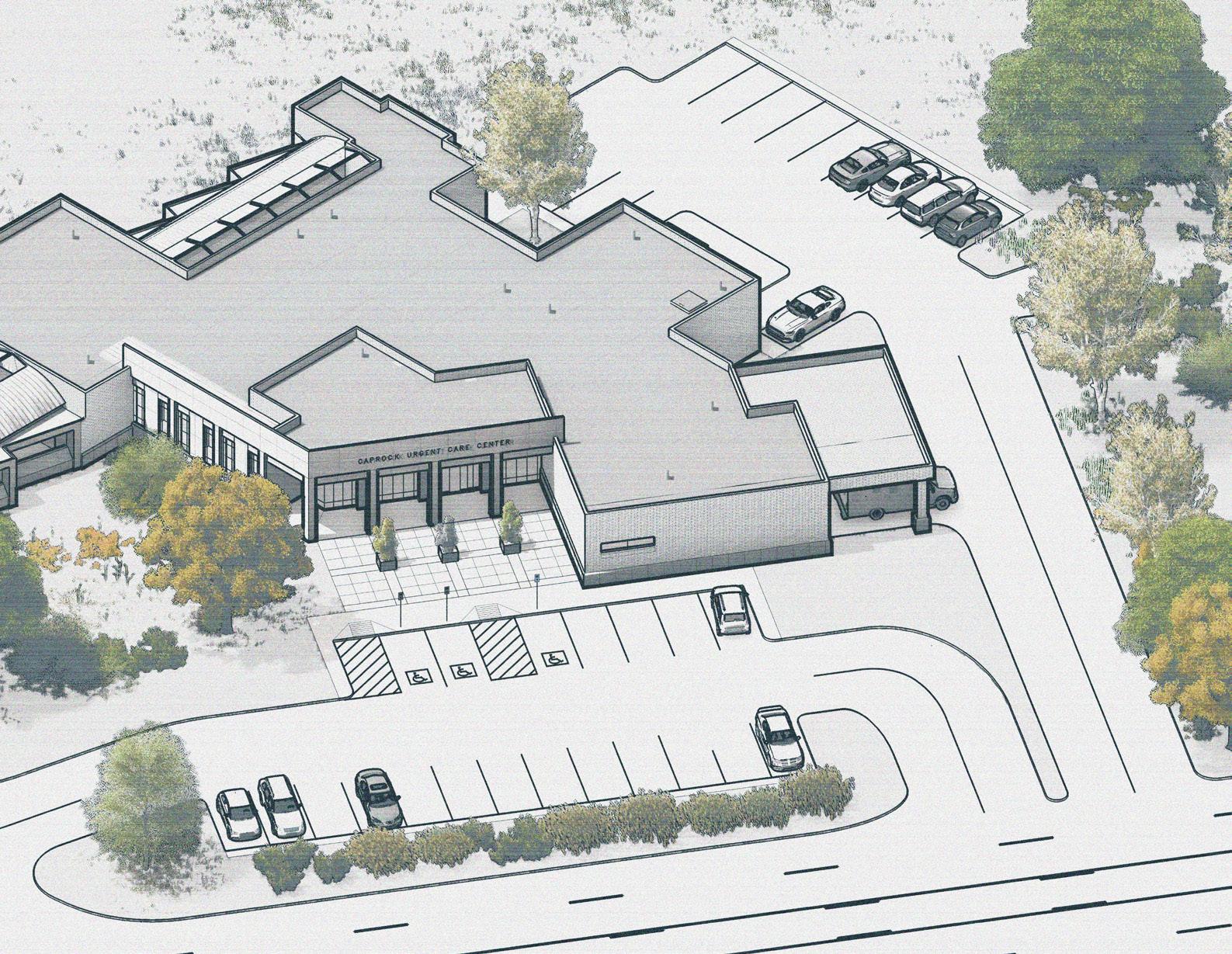

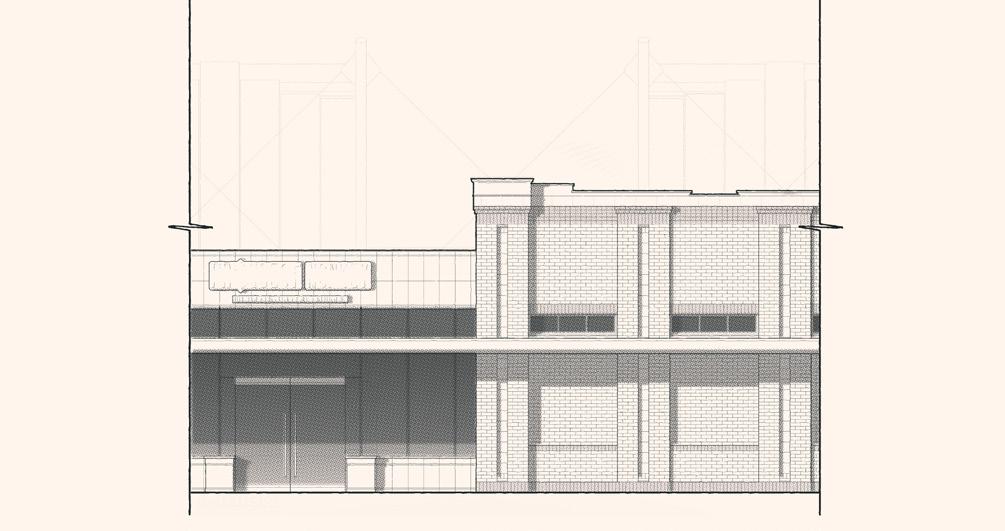

ARCH 305, Fall 2021 | Prof. Kirk Hamilton

Students were tasked with designing an urgent care center for a vacant plot in the city of Huntsville, TX which would respect the needs of patients, the surrounding environment, and, to a degree, necessary building systems. Intially, research was conducted to determine important factors to consider in the design process. The result was an evidence-based research paper which recognised wayfinding, natural light, and biophilia as the foremost design elements this project would consider.

The care center’s V-shaped floorplan makes for a distinctive silhouette, inspired by the irregular borders of its site. The main entrance is recessed inside this shape to give incoming patients a sense of safety, with the building “embracing” them while they wait in the lobby. Each of the eight general exam rooms have wall-to-wall windows which frame the surrounding trees and environment— a feature that utilizes the psychological benefits of nature explored during research. Additionally, the windows are angled to recieve minimal direct sunlight, which aids in both HVAC efficiency and patient comfort. Patient Circulation is kept simple, with all rooms branching off a shared corridor which spans the length of the building. This layout ensures all patients can navigate the facility without the concern of getting lost— a scenario which could easily cause stress in an environment that patients may already be unfamiliar with. General patient-related rooms are kept close together on the east side for convenience, while more urgent areas such as the minor operation room and ambulance entrance are isolated on the west to reduce foot traffic and maintain privacy. Exterior materials consist of a muted tan brick with a cast stone wainscotting— a combination chosen to allow the facility to visually mesh with its natural environment. On the inside, laminate wood flooring is used in spaces frequented by patients to further tie back to nature.

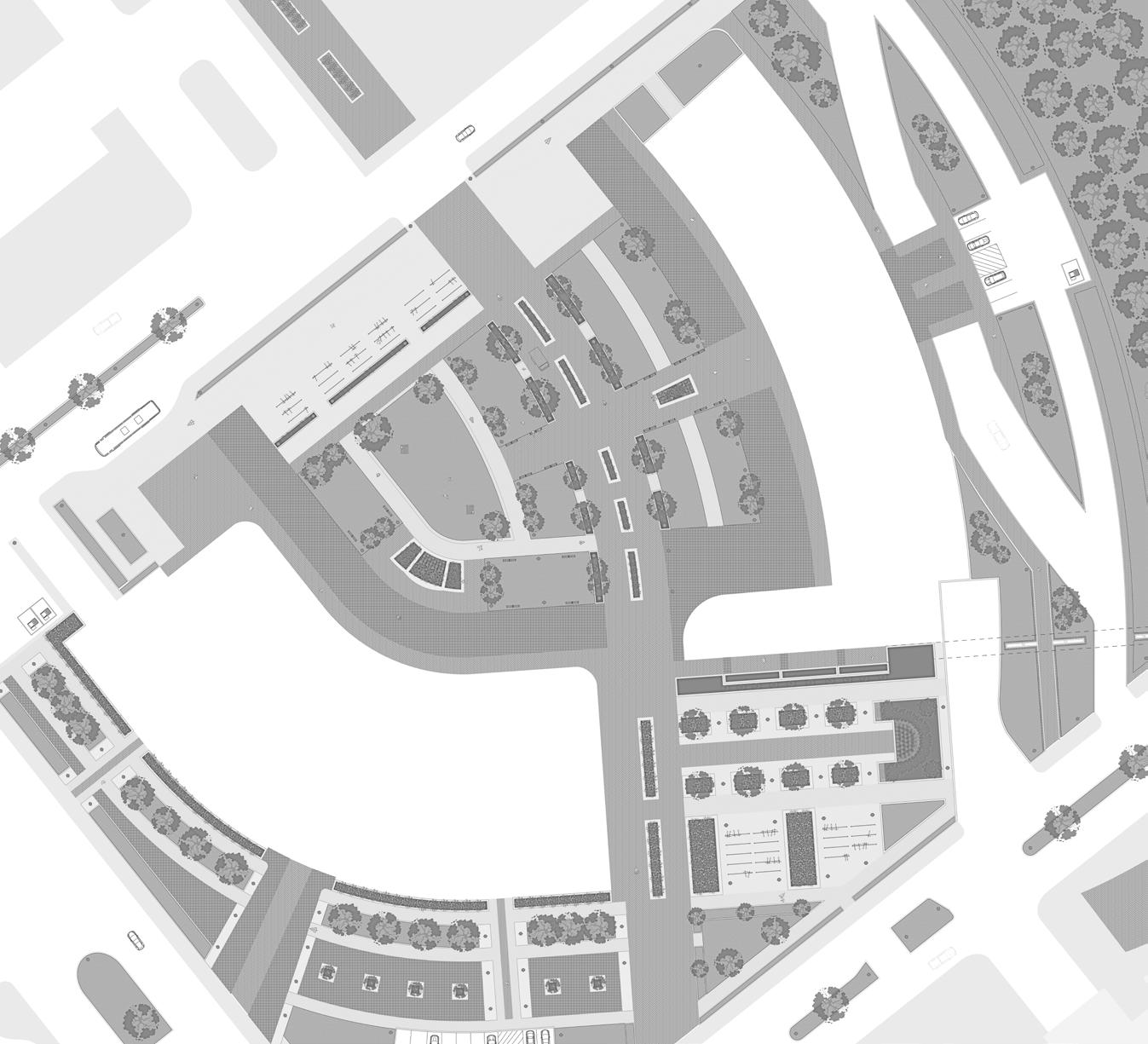

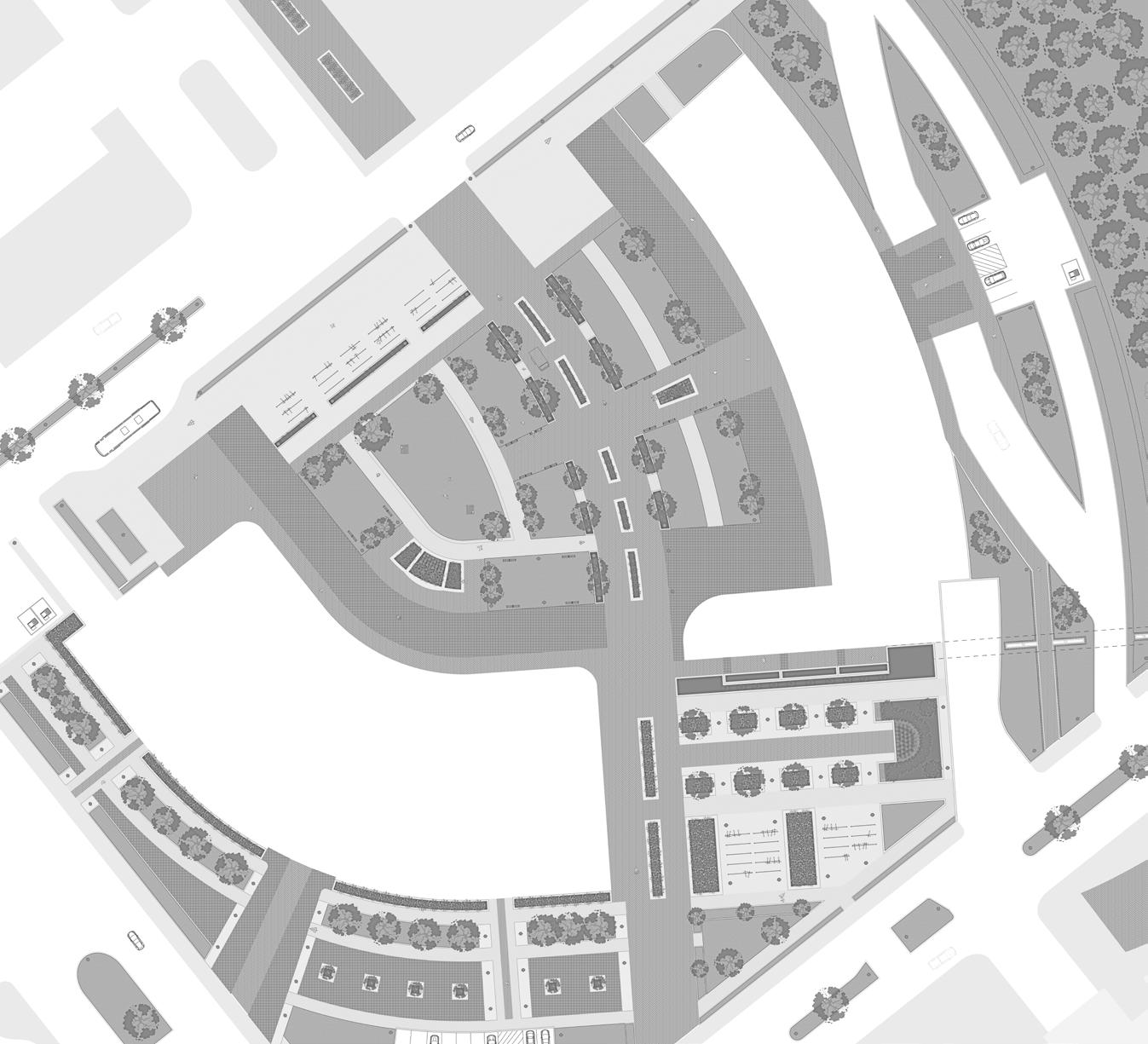

ARCH 607, ARCH 608, Fall 2024, Spring 2025

Professor: Andrew Hawkins

Committee Chair: Michael Obrien

Committee Co-Chair: Dr. Ahmed Ali

Committee Member: Dr. Ji Won Nam

Background

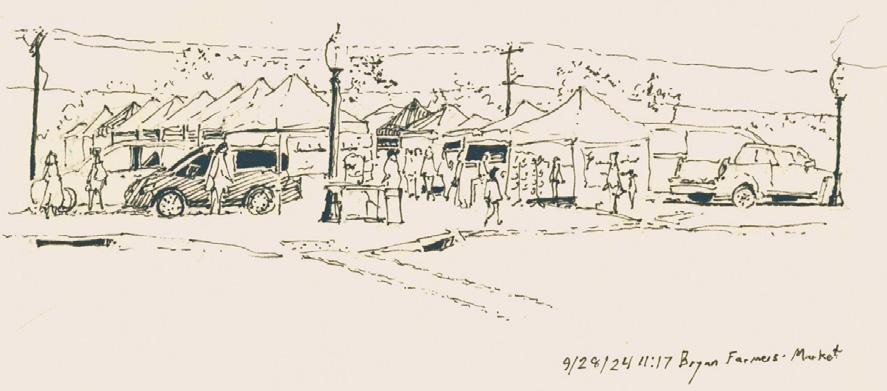

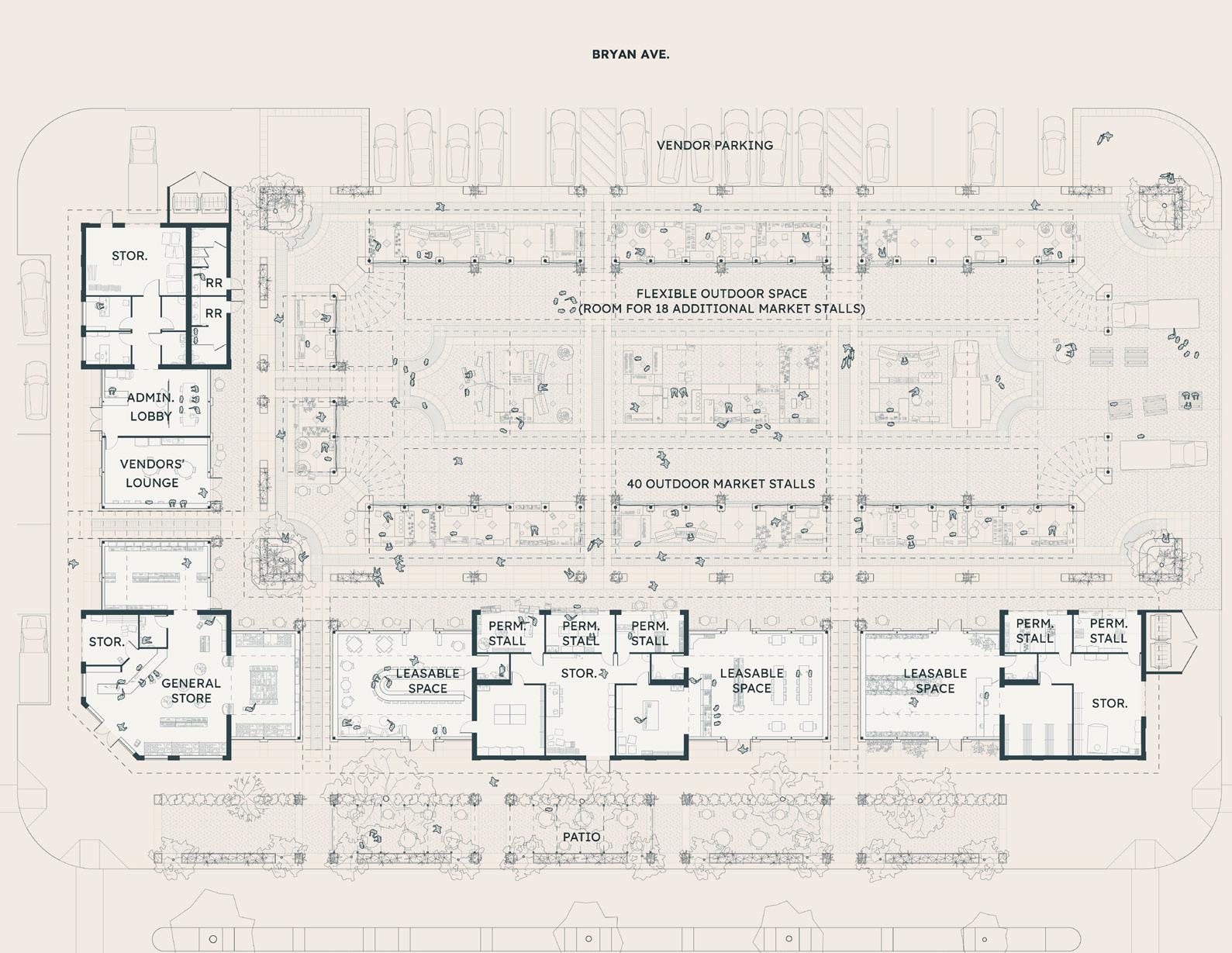

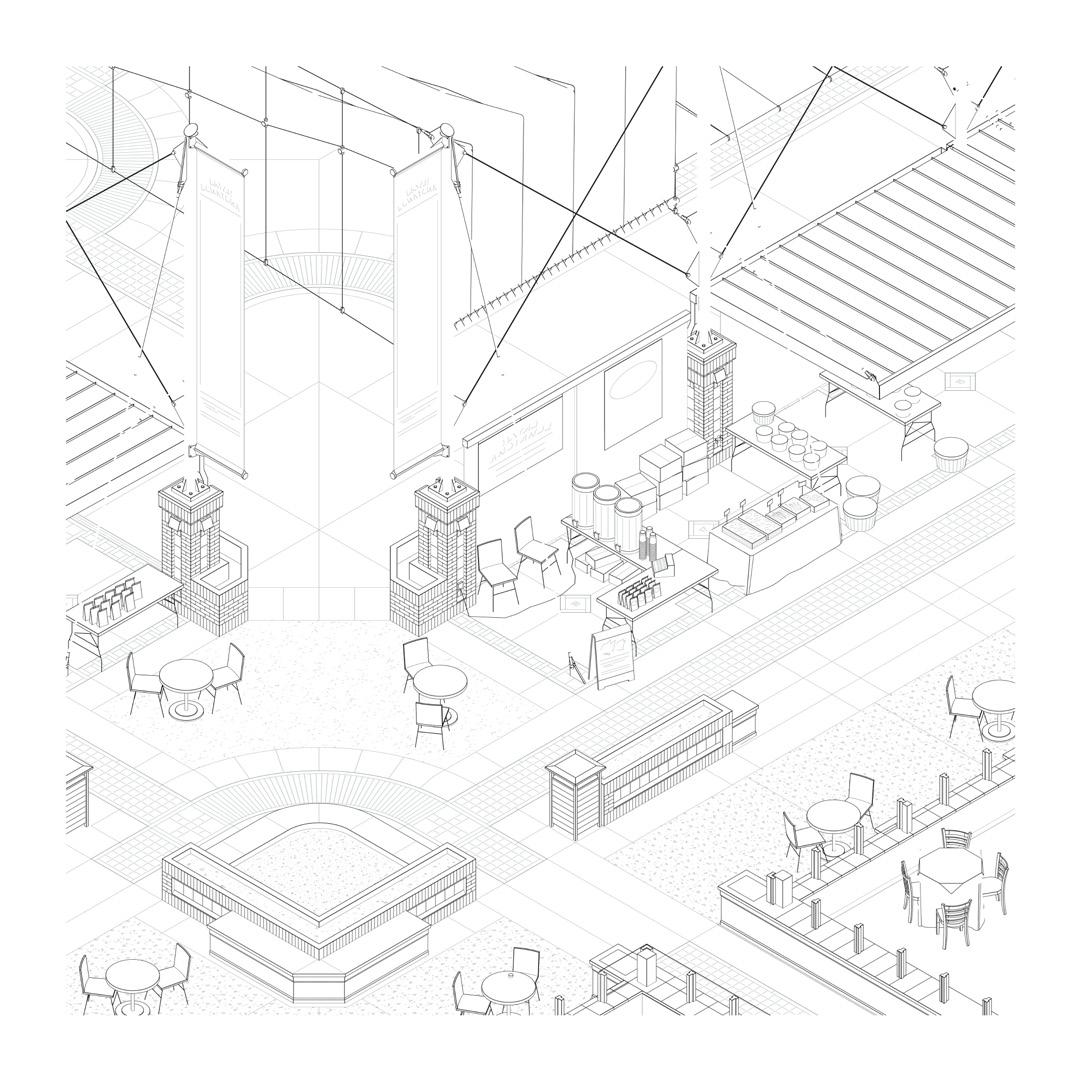

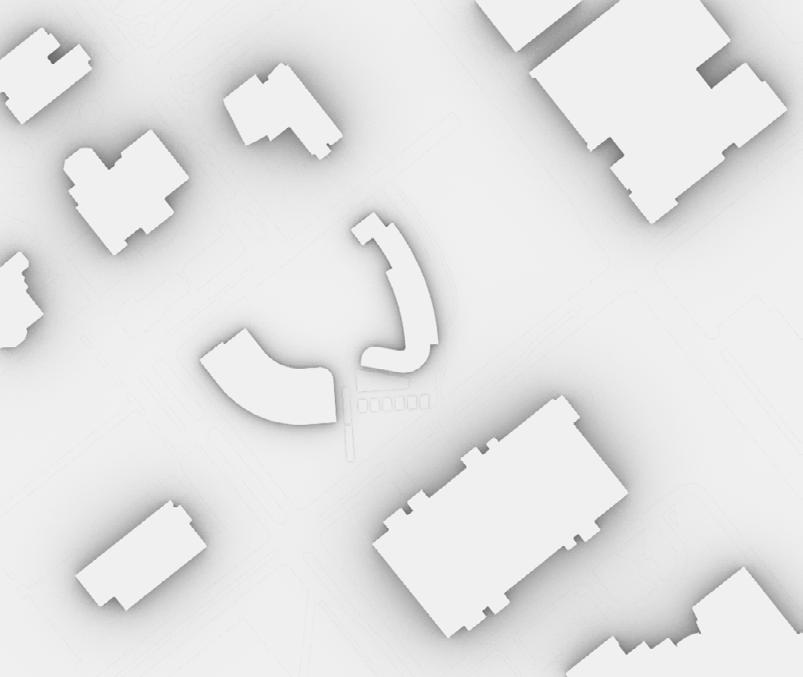

This project began as a simple recognition of the value that American downtowns hold— They provide commerce, convenience, socialization, and identity to a city in manner wholly unique to itself. The weekly farmers’ market in Downtown Bryan, Texas, exemplifies this value, creating a thriving environment with nothing more than a series of temporary tents pitched in a vacant lot. This begs the question— What impact could the market achieve if equipped with permanent facilities and amenities?

Design

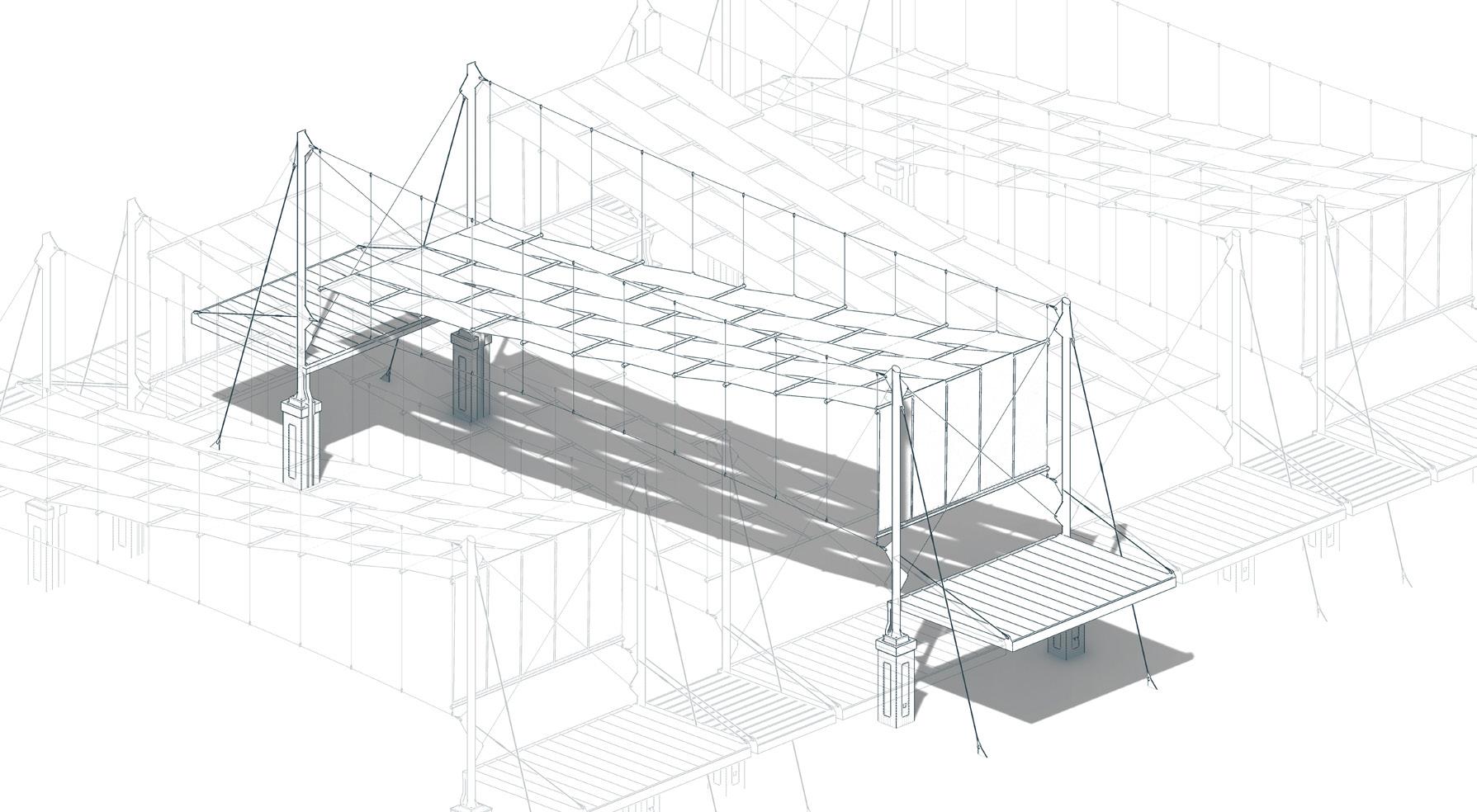

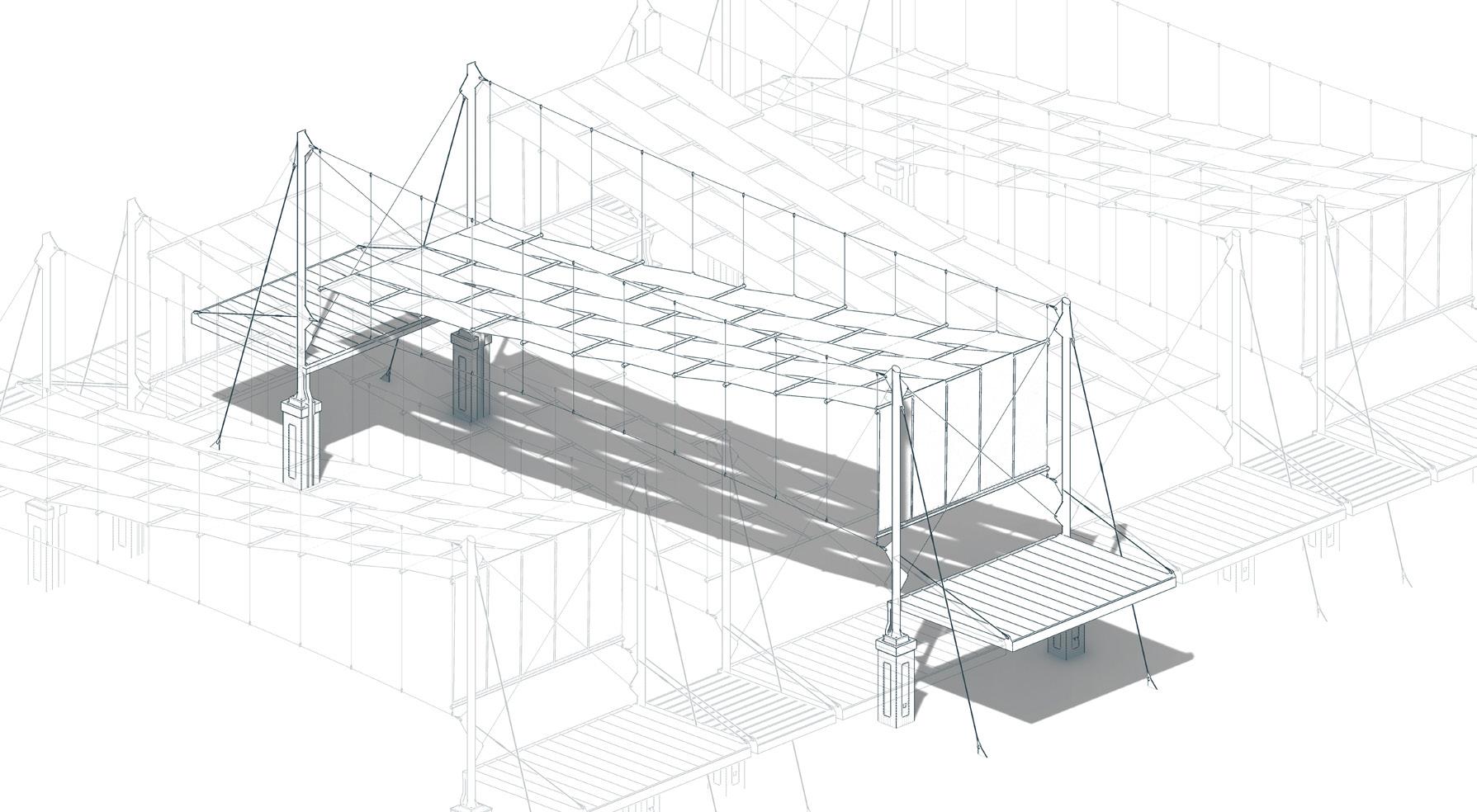

The redesigned market consists of two main components: the streetfront indoor facilities— consisting of leasable business space and market administration— and a plaza, prominently defined by a canopy structure that covers 40 permanent vendor stalls.

Groups were tasked with designing a new hotel and school of hospitality for Texas A&M’s main campus, with emphasis on mass timber as a constrution material. Careful consideration was taken to integrate both the buildings’s strucuture and its systems into the overall design concept. Group work was split in two, with Camryn and Kensey focusing on the hotel’s design, and Bonnie and I focusing on the hospitality school’s design. Each drawing or render, unless otherwise noted, was created by me.

The project’s site finds itself in a crucial position on Texas A&M’s campus— Caught on the threshhold between main and west campus, one will find students passing through to reach classes as well as Aggie football fans walking to and from Kyle Field on game days. However, despite this important role in college life, the site —as it stands— remains highly underutilized. Individuals wishing to pass through must make a lengthy march through the existing parking lot, exposed to the elements and sweltering Texas heat.

With this in mind, the new Aplin Center aims to offer visitors an experience that not only serves the needs of the included hospitality school and hotel, but also those of the campus as a whole. The building allows existing pedestrian circulation to directly inform its shape, resulting in an ergonomic and environmentally-aware design. Beginning on the northwest side of the site near the existing bus stop, there exists a direct path that guides passerbys alongside the building, under protected overhangs, and into an underground tunnel which seamlessly joins with the existing tunnel beneath Wellborn, Pickard’s Pass. By offering this valuable solution, the Aplin Center cements itself as not just another building, but a critical liaison that unifies A&M’s campus into one.

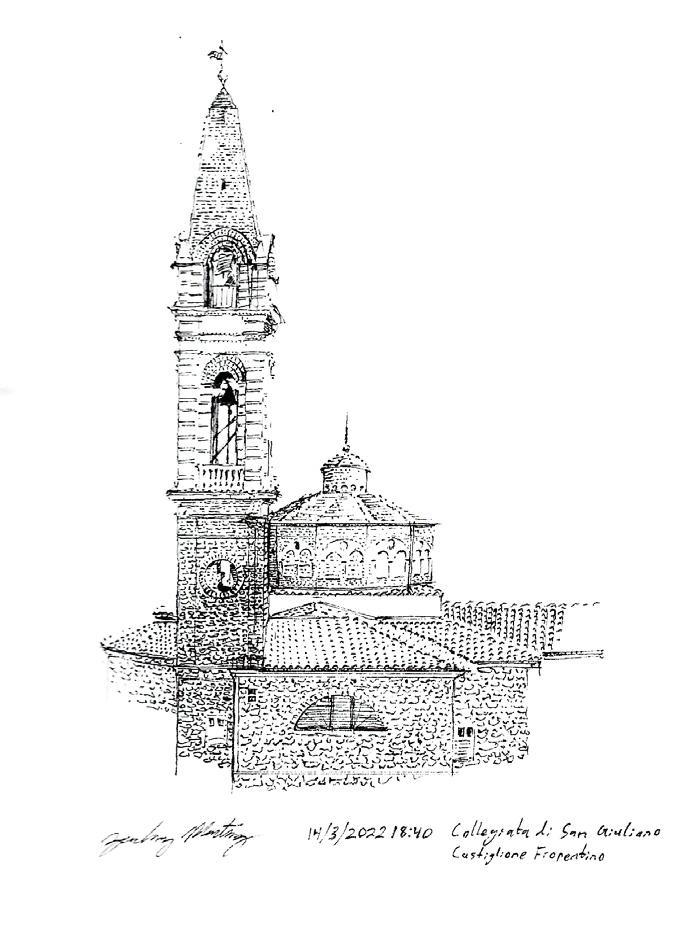

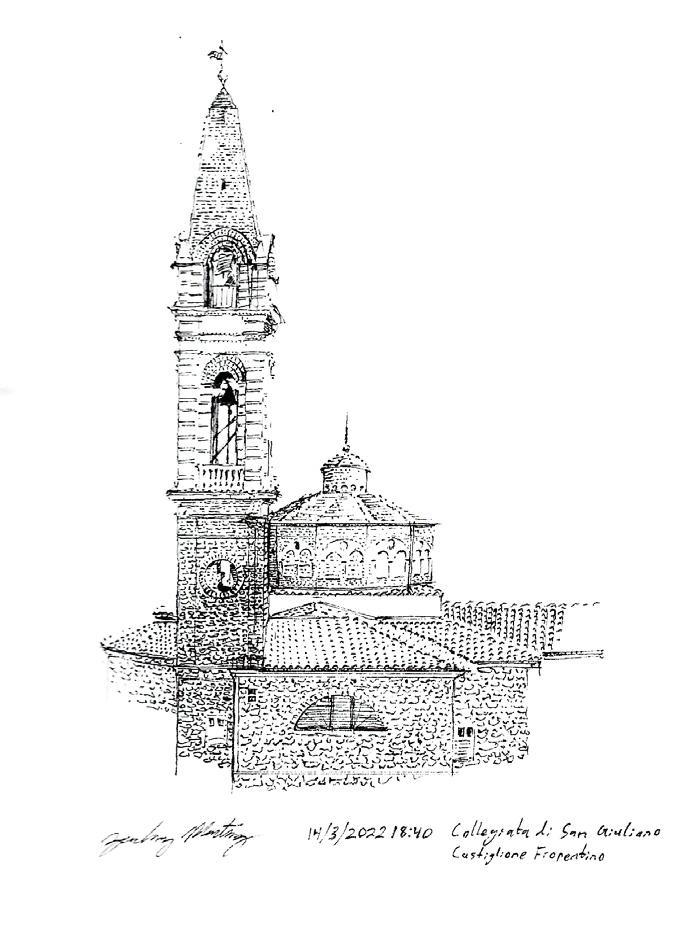

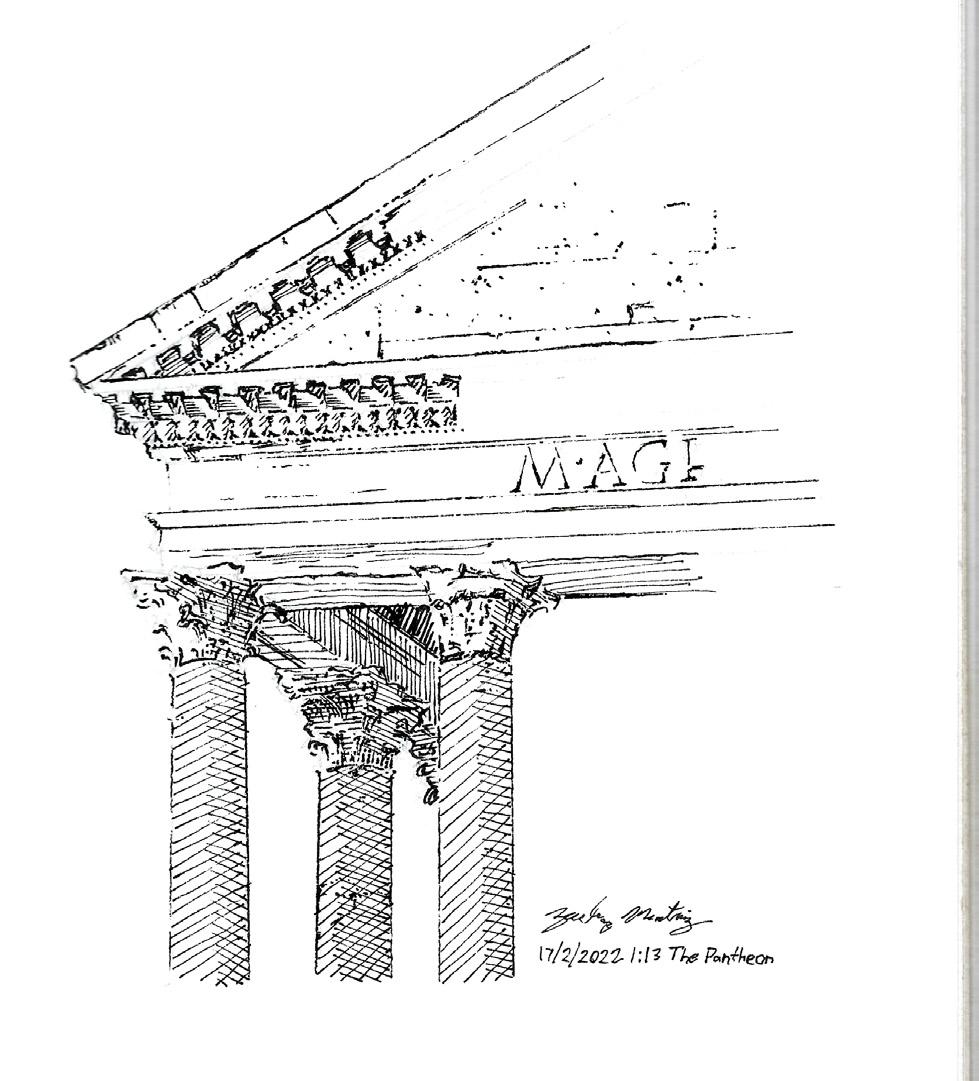

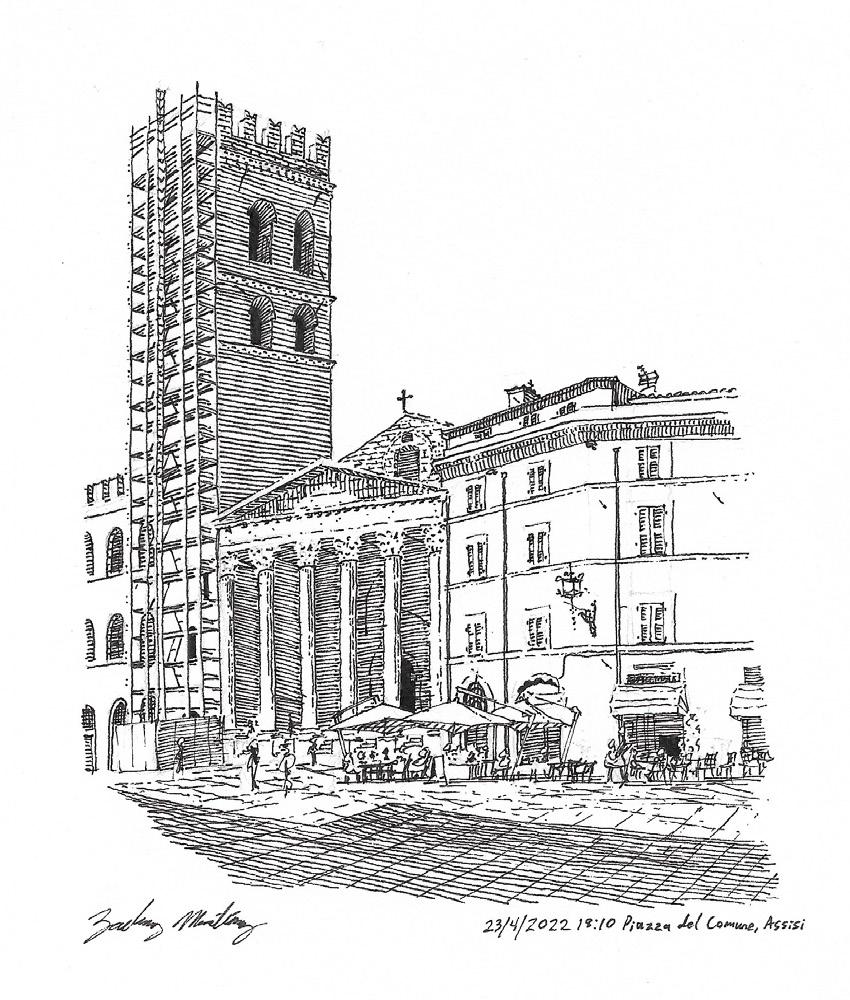

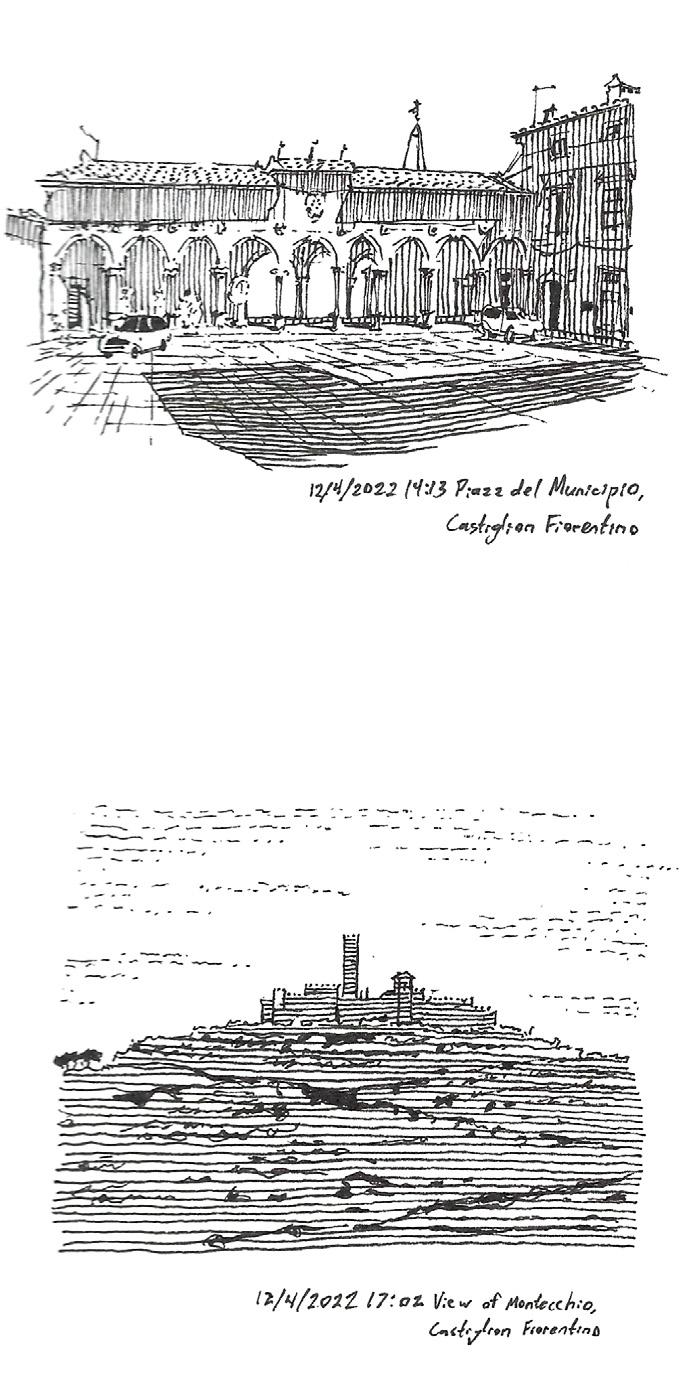

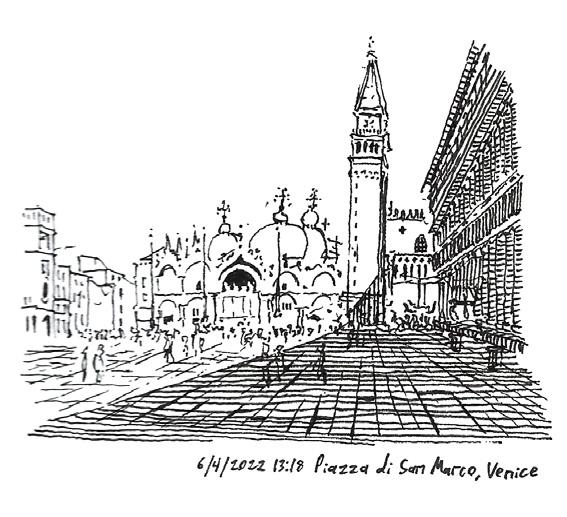

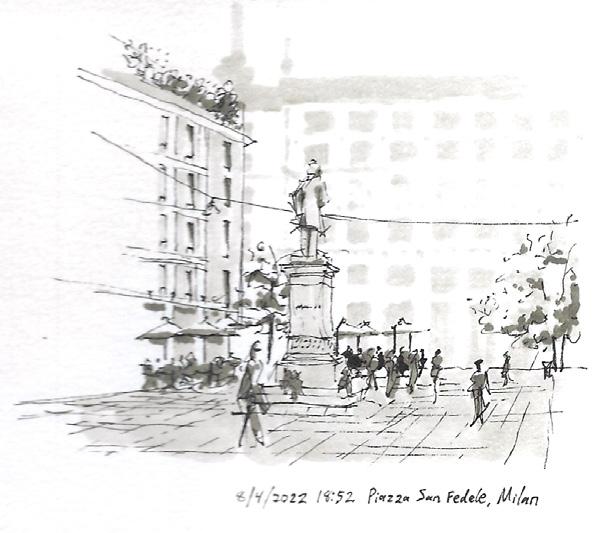

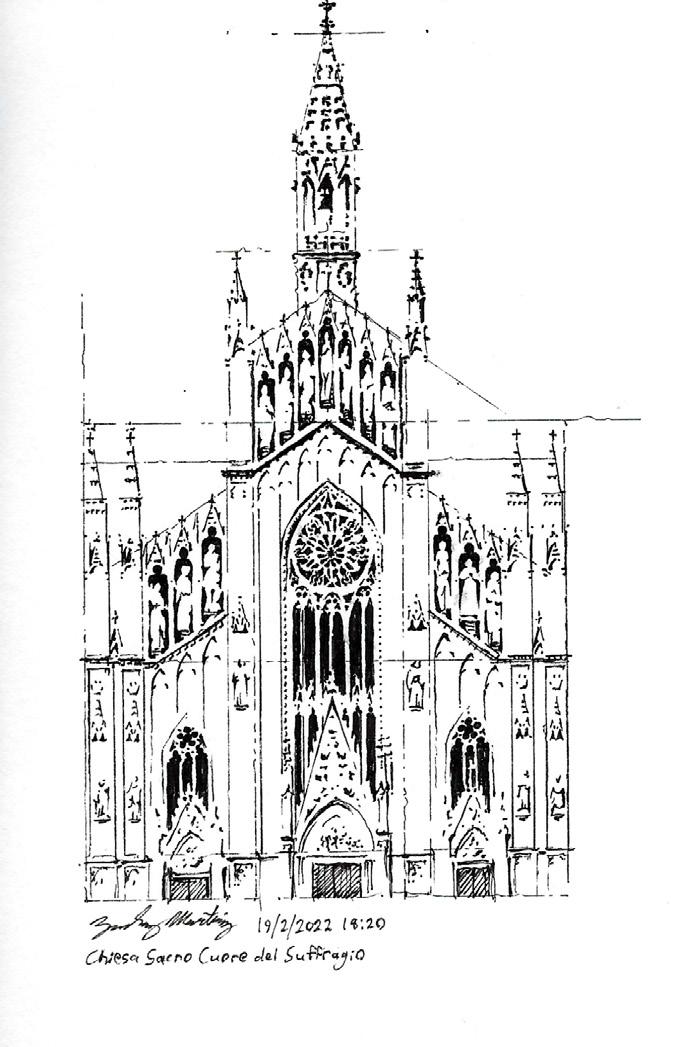

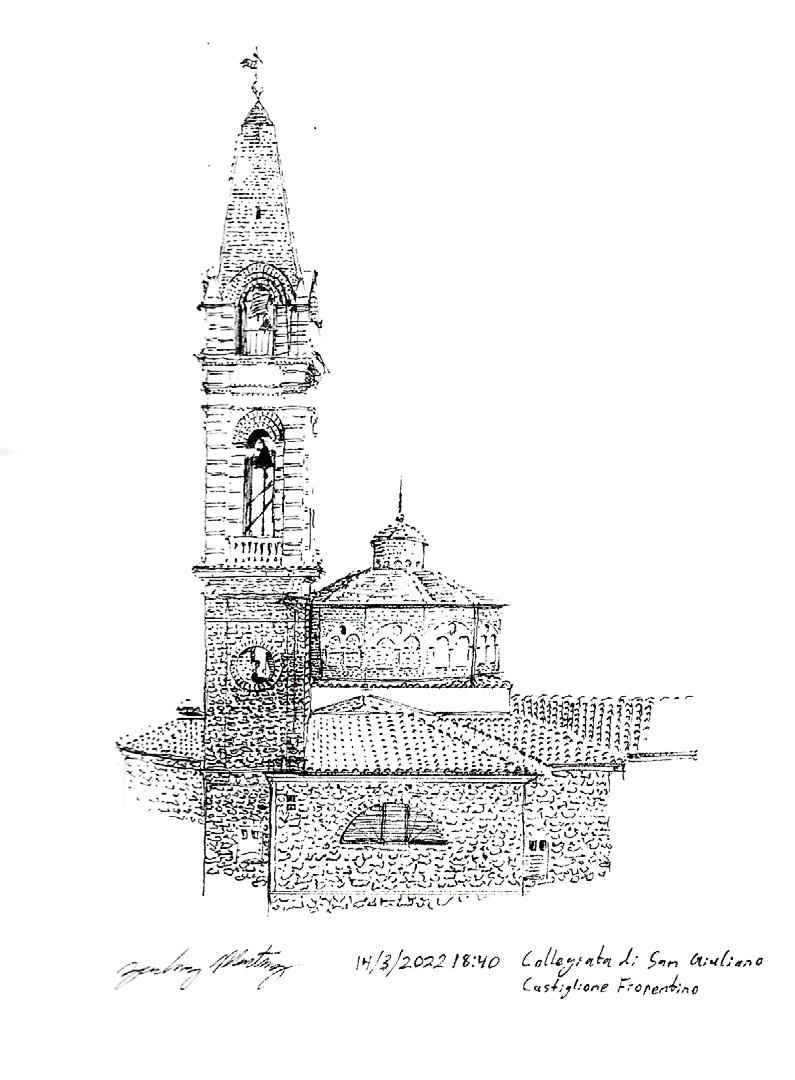

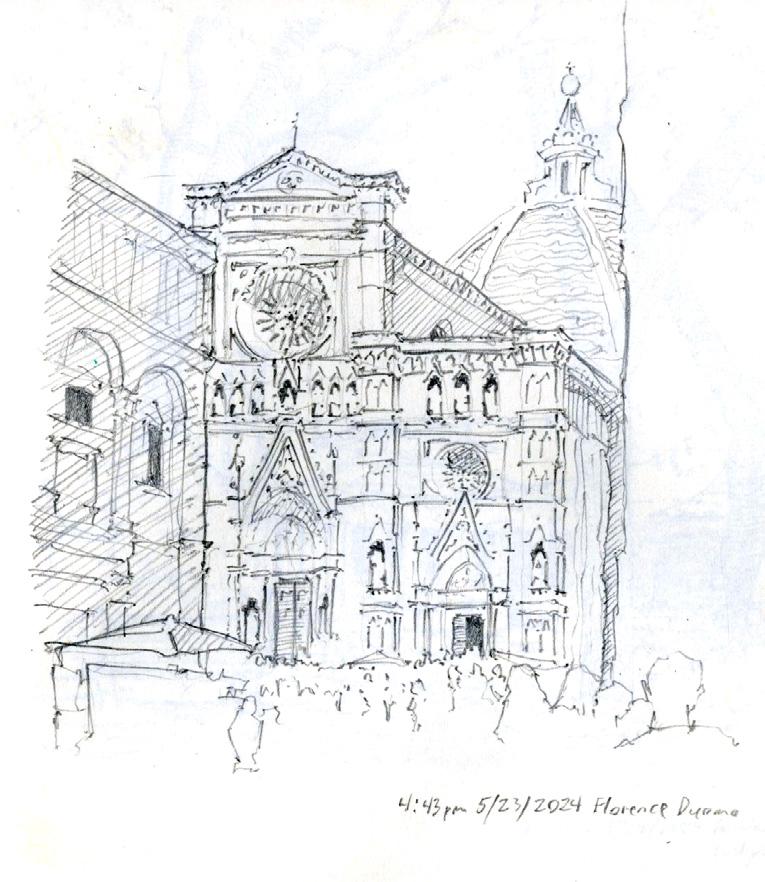

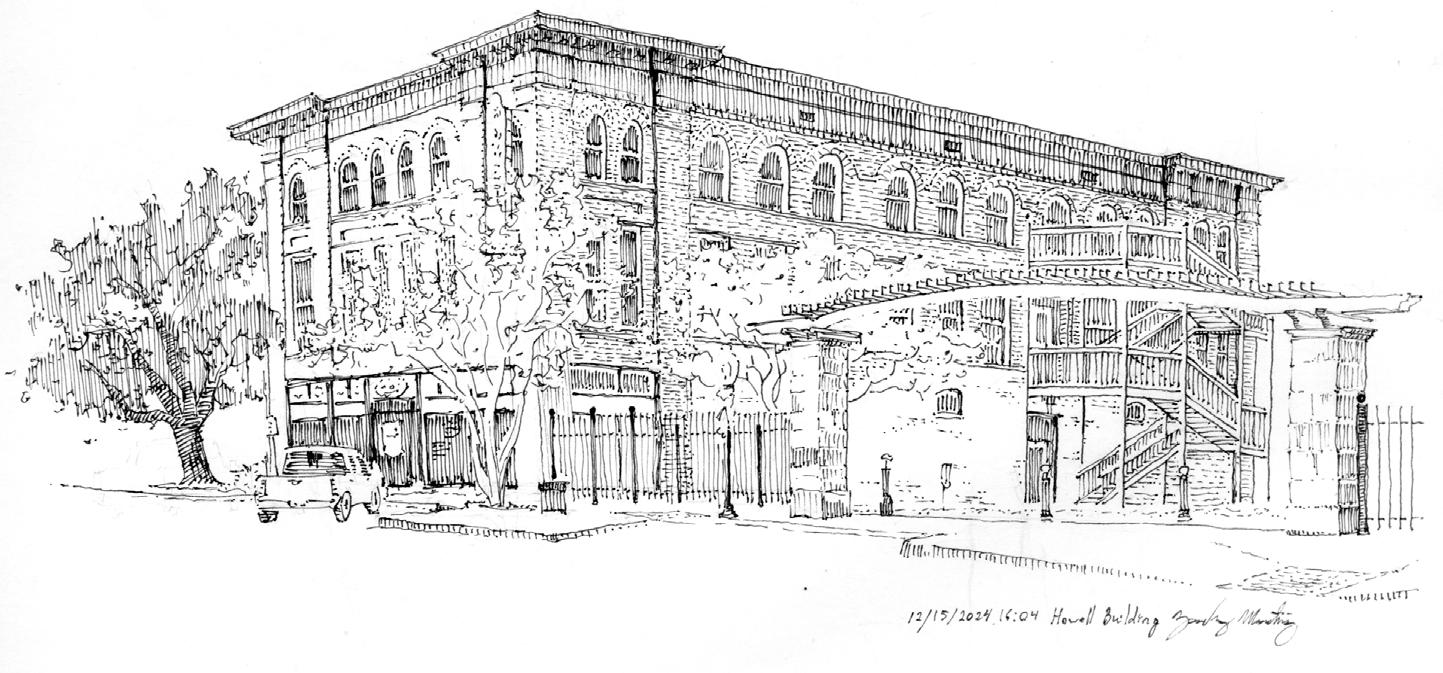

Spring 2022 - Present

While participating in Texas A&M’s study abroad program in Italy, I challenged myself to sketch the various urban environments that my classmates and I found ourselves among. With this challenge, I set myself only one rule: All sketches would be done onsite, and could not be finished later from a reference image. Admittedly, this rule was oftentimes challenging to meet— I was constantly at the mercy of the weather, which wasn’t always comfortable or cooperative, especially for works that took hours to complete. However, I believe the results are far superior to anything I could have accomplished from the security of a studio desk. Witnessing my subjects first hand was a multi-sensory experience that I could communicate through my art— I drew the leisured movement of pedestrians, the bitter cold as it numbed my hands and face, and the ambient sounds of city life— all immortalized within the pages of my sketchbook.

Location: College Station, Texas

Client: Texas A&M University

Size: 8,700 SF Renovated, 13,400 SF New Construction

Budget: $15,500,000

Year of Completion: 2024

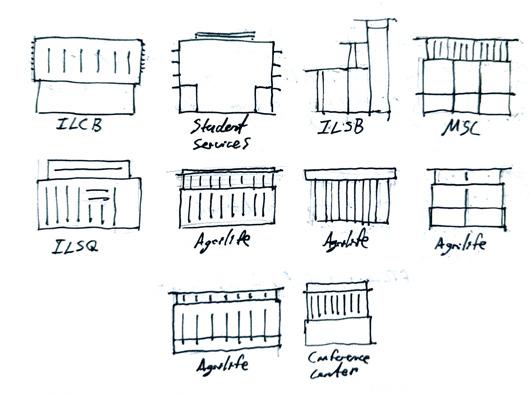

Serving as a hub for state-of-the-art nuclear research, this project extensively renovated and added on to the former range science building near Easterwood Airport. I helped with various phases of the projects development, conducting diagrammatic elevation studies of other contemporary A&M projects, iterating on schematic designs, producing renders of the new construction, and drafting details.

KICKER

PREFIN SHED METAL COPING

4" / 1 -0" SPRAY-APPLIED FOAM INSULATION BOX BEAM HEADER

JOIST,

EXISTING 6 STEEL STUDS @ 16" O C

A R + WATER BARR ER

PEMB SID NG

PREFINISHED METAL COPING

4 X 4" HSS BY METAL BUILDING

MANUFACTURER

4" X 8" HSS BY METAL BUILDING

MANUFACTURER

METAL PANEL BY METAL BUILDING

MANUFACTURER

PREF NISHED METAL FLASHING W/ HEMMED EDGE AND SEALANT

ROOF PANEL BY METAL BU LD NG MANUFACTURER

6" XPS

CONTINUOUS INSULATION

STAND NG SEAM DECKING BY METAL BUILDING MANUFACTURER

PREF NSIHED METAL FLASH NG W/ HEMMED EDGE AND SEALANT

STAND NG SEAM DECKING BY METAL BUILDING

MANUFACTURER

PURLIN BY METAL BUILDING

MANUFACTURER

RIGID FRAME BY METAL BU LD NG

MANUFACTURER

FIBERGLASS BATT INSULATION

CONTINUOUS INSULATION BY METAL BU LD NG

MANUFACTURER

Z-GIRT BY METAL BUILDING MANUFACTURER

PREF N SHED FLASH NG W/ HEMMED EDGE

STEEL PARAPET K CKER, REF STRUCT.

PREFINISHED METAL COP NG

SEALANT

T.O. PARAPET 2 26 - 0" T.O. PARAPET 3 29 - 0"

T.O. STEEL 3 25 - 0"

SPRAY-APPLIED FOAM NSULATION PARAPET BEYOND

PREFINSIHED METAL FLASHING W/ DRIP EDGE WINDOW, AS SCHEDULED

SIDING (VERT.) 1 1/2 R7 CI

FIBERGLASS BATT INSULATION

3 5 8 STEEL JOIST FASTENED TO EXISTING STUD FRAM NG

3 5/8" STEEL JOIST FASTENED TO EX STING STUD FRAMING AT 1 2" / 1 -0" SLOPE

ACOUSTICAL TILE CEILING SYSTEM

PREFINSIHED METAL FLASHING W/ DRIP EDGE

5 8" GYP. BOARD W RUBBER BASE FOUNDAT ON W GRADE BEAM

EXISTING FOUNDATION W GRADE BEAM

EXIST NG BEAM DECKING, AND JOIST

RIGID FRAME

BEYOND BY METAL BUILDING

MANUFACTURER

ACOUSTICAL T LE CEILING SYSTEM

GYP. BOARD W/ RUBBER BASE

EXIST NG FOUNDAT ON W/ GRADE BEAM 1 1/2" Z GIRT @ 4 O C

T O STEEL 2 (F V ) 22 - 0

GYPSUM SHEATH NG

PACK CAVITY W TH F BERGLASS BATT NSULATION

CAVITY WITH

CKER, REF STRUCT.

EXISTING JOIST, DECK NG AND BEAM

EXISTING 6" STEEL TRACK

EXIST NG STEEL BEAM AND WALL BRACE 6" STEEL TRACK

EXISTING 6 STEEL STUDS @ 16" O C

1/2" GYPSUM SHEATH NG

1 1/2" Z GIRT @ 4 O C

SPRAY-APPLIED FOAM INSULATION

SHED METAL COPING

CEIL NG

AIR + WATER BARRIER

PEMB SID NG (VERT.) 1 1 2 R7 C

T.O. STEEL 1 13 - 10 1/2"

EXISTING WALL BRACE

PREFINSIHED METAL FLASH NG W/ DR P EDGE

F BERGLASS BATT NSULAT ON PACK CAV TY W TH FIBERGLASS BATT NSULATION 1 1/2" Z GIRT @ 4 O C PEMB SID NG (VERT.) 1 1 2" R7 C

EXISTING 6" STEEL STUDS @ 16" O C

EXISTING 6 STEEL STUD @ 16" O C

FIBERGLASS BATT NSULATION

PEMB SIDING (HORIZ.)

3 5/8 STEEL JOIST FASTENED TO EX STING STUD FRAMING

BATT INSULATION

AIR + WATER BARRIER

ACOUSTICAL TILE CEIL NG SYSTEM

B.O CEIL NG 9' - 0"

SPRAY-APPLIED FOAM NSULATION BOX BEAM HEADER

3 5 8" STEEL JOIST FASTENED TO EXISTING STUD FRAM NG AT 1/2" 1 -0" SLOPE

ACOUSTICAL TILE CE L NG SYSTEM

R + WATER BARRIER

PREFINSIHED METAL FLASH NG W/ DR P EDGE 1/4" / 1'-0"

W NDOW, AS SCHEDULED

EXISTING BEAM DECKING, AND JOIST

ACOUSTICAL TILE CEILING SYSTEM

PREFINISHED METAL FLASH NG W/ HEMMED EDGE AND SEALANT

ROOF PANEL BY METAL BUILDING MANUFACTURER

6" XPS CONT NUOUS NSULATION

STANDING SEAM DECK NG BY METAL BU LD NG MANUFACTURER

5/8" GYP. BOARD W/ RUBBER BASE

STING FOUNDAT ON W GRADE BEAM

EX ST NG FOUNDAT ON W/ GRADE BEAM

T.O. FIN SH FLOOR 0"

5/8" GYP. BOARD W/ RUBBER BASE FOUNDATION W/ GRADE BEAM

EXIST NG FOUNDAT ON W/ GRADE BEAM

Location: College Station, Texas

Client: Texas A&M University

Size: 950 SF

Budget: $300,000

Year of Completion: In progress

In the summer of 2024, I contributed to the renovation of the Texas A&M Mitchell Tennis Center. The project, structured in two phases, encompassed the renovation of the men’s and women’s locker rooms, the training room, and the player lounge. My primary responsibility centered on the redesign of the player lounge, where I developed the parti, selected finishes, produced renders, and drafted construction documents for the space. The room consists of three main zones- the break room, lounge, and common area. Four masses, located along each wall of the room, visually organize appliances in the room, including casework, fridges, a media center, and a display wall for team accolades.