BEYOND TOOLING

HIGH PRECISION TOOLING

HIGH PRECISION TOOLING

Since 1987 TEMSA has developed its own state-of-the-art technology in order to improve tools’ lifespan whilst keeping costs down. This die design technology allows the use of interchangeable carbide nibs and a PVD-TiN coating on the working area.

On extrusion dies, a well-polished surface is essential: At TEMSA, the mirror polishing is done before and after PVD coating. This grants a better flow of the material, extending the tool’s lifespan and preventing the die from seizing-up.

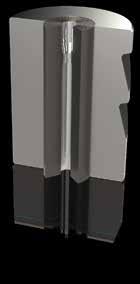

Closed extrusion dies are used when more than 30% cross-section reduction is needed

Depending on the design of the extrusion zone, it is possible achieving an area reduction up to 85%. With specific designs, it is possible to replace worn out carbide nibs with substantial cost savings.

TEMSA’s split nib technology. Air vents designed to reduce pressure. PVD coating can be applied in the reduction area. Different carbide grades in order to improve tool performance. The coating improves the flow and prevents material to adhere on the tool.

Conical nib for easy removal and replacement of nibs using the same casing.

Double high-speed steel hoop to fasten the nib and to hold radial tension. Outer conical shape and PVD TiN coating for easy removal and replacement of nibs using the same casing.

Open hoop for easy replacement of nibs and to increase interference.

Carbide grades: different carbide grades for an optimum performance, G30, G20, G10 and submicron grain size.

PVD, different coatings to be applied depending on the extruded material.

Polishing before and after coating.

Open tools represent one of the most complex tooling typologies within the cold forming sector. The vast experience with these tools, gathered by TEMSA during its business development, is available to its customers: from design to material and coating choice. TEMSA not only manufactures the tools but also designs whole toolsets.

Thanks to precise EDM and HSC machines, CNC lathes and grinders and 3D measuring equipment, together with state-of-the-art CAD-CAM software, TEMSA is ready for any challenge its customers face.

TEMSA designs and manufactures open dies: from a single tool to the entire project.

TEMSA has designed and manufactured a large number of open dies, assisting its partners in the whole process, from the design conception to the final product. This valuable know-how, gathered by TEMSA, is available for the production development of its customers.

Possibility of tooling design

TEMSA’s non-rotating systems and locking bolts have a very precise geometry. The use of EDM technology results in a perfect match between each tooth. TEMSA can produce any toothed profile. Either by wire-EDM or EDM any radius between each tooth is also possible. The EDM technical department is exclusively devoted to shaping the required parts. Because of the multiple robots and standardization systems operating in the department, human interaction only occurs outside the machine.

The electrodes lathing and milling process on different machines on the EROWA system, ensures a precise and perfect indexing of the electrodes on the eroding process.

Advice on carbide and steel grades for different applications.

Mechanical Processing surfaces when it is geometrically possible.

Prefect tangent radius.

EDM and wire-EDM standardized and robotized.

Complex electrode EDM machining with perfect concentricity and alignment between profiles.

Advice on different types of coating.

Mirror polishing before and after coating.

In the processing of the reduction dies, TEMSA mechanically processes all surfaces wherever it is geometrically possible, thereby improving the lifespan of the tool. If EDM processing is unavoidable, TEMSA’s EDM department is fitted with modern electrode and wire-EDM equipment, both entirely robotized. TEMSA reduction dies are polished before and after coating, resulting on the internal required polishing. All designs are checked to verify its feasibility before proceeding to manufacture. TEMSA advises clients whenever improvements could be performed or where errors in the drawings are detected. TEMSA suggests and integrates, with considerable success, new carbide alloys for different types of dies for improved performance. A clear example of success is the end-reducing die after extrusion.

TEMSA is testing different alloys on carbide dies, operating under great stress or abrasion, substantially improving their lifespan

For over 15 years TEMSA has been processing most of its complex geometry dies in grinding and milling machines, and all CNC CAD-CAM and process simulators.

Advice on carbide and steel grades for different applications.

Mechanical processing of surfaces when it is geometrically possible.

Air vents to evacuate air or oil pockets.

TEMSA’s technology for split nibs: perfect concentricity.

EDM and wire-EDM standardized and robotized.

Mirror polishing before and after coating.

Possibility of steel dies with pressed and grinded shapes, not eroded.

Any profile you can imagine will come true in TEMSA. The special profile tools are helpful to go beyond on cold forming. TEMSA has added new CNC grinding centres with the technology needed to rectify irregular shapes and parts with strict tolerances that complemented erosion centres make it possible developing any type of profile

A young and expert team is exclusively dedicated to developing CAD-CAM programs that will make possible to generate any figure, however difficult it may seem. The whole process is standardized and automated, thus reducing human action on the machine.

The incorporation of new CNC grinding centres, machining centres and other high-speed equipment, assisted by state-of-the-art CAD-CAM programs, will help solving the challenges of achieving complex shapes and profiles.

Advice on carbide and steel grades for different applications.

Mechanical processing of surfaces when it is geometrically possible.

EDM and wire-EDM standardized and automated.

Complex electrode EDM machining with perfect concentricity and alignment between profiles.

Large number of shapes with very high geometric complexity.

Mirror polishing before and after coating.

Possibility of steel dies with pressed and grinded shapes, not eroded.

CAD-CAM in all machining processes.

Trilobe, pentalobe and hexalobe dies are manufactured at TEMSA’s EDM department. This department is fitted with fully automated feeders and EROWA robots. EDM & wire-EDM machines, electrode machining centres, CNC lathes and 3D measuring equipment are all standardized and connected to the same EROWA system. This allows for measurements to be performed only once at the beginning of the process. These measurements go directly to a palletized robot that automatically feeds the machines with the tools to be processed.

TEMSA manufactures carbide trilobe, pentalobe and hexalobe dies following its own data tables or using the specifications from the costumer

CAD-CAM, Powermill, Mastercam, Fikus, SimCT, amongst others, can generate any requested shape. These processes, supported by modern simulation software, greatly reduce human error and grant a higher accuracy.

Header dies are a fundamental part of cold forming. They are exposed to a very high pressure and to very heavy wear conditions and cracking. For this reason, TEMSA has developed over the years design improvements in order to increase tools’ performance, easy replacement of damaged components and cost reduction. Performance is improved using different qualities of carbide or applying different surface coatings. Being able to replace damaged elements whilst leaving the undamaged components also reduces cost. Header dies carry out different functions like heading, reducing, extruding, drilling or cutting.

TEMSA will help you in the design of modular heading dies for interchangeable carbide nibs

Header dies have been redesigned to a modular concept where you can remove worn out parts, carbide nibs, steel headers and punches, segmented hexagons, etc.

Conical nib for easily removal and replacement of nibs using the same casing.

Double high-speed steel or carbide hoop with a back-guide thickness for easier replacement and reusing with the case.

Open hoop for easier replacement of nibs and to increase interference.

On the segmented header dies are identical thanks to EDM wire cutting process. Worn-out segments can be easily replaced by new ones.

Headers can be produced with a double and triple hoop.

Different PVD coatings depending upon the extruded material.

Polishing before and after coating.

The manufacture of cutting and trimming dies with different profiles is carried on high precision grinding centres, high-speed hard machining centres, wire and electrode EDM and CNC lathes for hard lathing (steel and carbide) based on TEMSA’s technology. The technical department will help selecting the most suitable steel or carbide tool for the material to be cut.

A young and expert team, using state-of-the-art CAD-CAM software, such as POWERMILL, MASTERCAM, FIKUS & SIMCT , supported by modern simulation software, will develop the necessary programs that make possible generating the requested profiles.

All possible profiles are generated by the completely standardized and automated erosion and machining centres

Centres of high precision grinding, high-speed machining centres and hard CNC lathes (steel and carbide) with TEMSA’s technology, facilitate the implementation of complex profiles.

Advice on carbide and steel grades for different applications.

Perfect tangent radius.

Mechanical Processing surfaces when it is geometrically possible.

Large number of shapes with very high geometric complexity.

Coating, the most suitable for the materials to be cut.

Mirror polishing before and after coating.

CAD-CAM in all machining processes.

± 0.005 mm tolerances.

TEMSA designs and manufactures all kind of drawing dies, round, square, hexagonal and special shapes. Any shape you need, TEMSA can do it. Based on the experience and the know-how, TEMSA is able to give advice on the appropriate carbide grade for the product to be drawn. TEMSA has introduced new CNC grinding centres with the necessary technology for grinding and polishing drawing dies in one-step which, complemented with the EDM systems , any shape is possible. An expert young team is exclusively devoted to develop CAD-CAM programs that can generate any possible shape. The whole process is automated and standardized, thus reducing human interaction with the machine.

EDM, wire-EDM machines, CNC grinding centres and high-speed machining assisted by state-of-the-art CAD-CAM systems can solve challenging complex profiles.

Advice on carbide and steel grades for different applications.

± 0.005 mm tolerances.

Perfect tangent radius.

EDM and wire-EDM standardized and robotized.

Complex electrode EDM machining with perfect concentricity and alignment between profiles.

Large number of shapes with very high geometric complexity.

Mirror polishing before and after coating.

CAD-CAM in all EDM and machining processes.