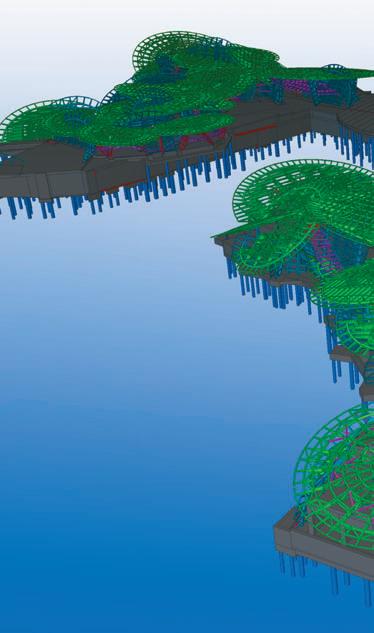

Tekla UK BIM Awards Tekla’s UK BIM Awards, an annual celebration of collaborative workflows and model based processes, honoured some impressive projects this year. Winner Arup — National Museum of Qatar The National Museum of Qatar, in Doha, is the flagship in an important series of cultural and educational projects being commissioned by the Qatari government. It is currently on site, having been in design since 2008. Architect Ateliers Jean Nouvel drew inspiration from the desert rose, a crystalline formation found below-ground in saline regions of the desert. When imagined as a building, the result is a four storey, 300m by 200m sculpture of intersecting disc shapes up to 80m in diameter. The structural solution settled on radially and orthogonally-framed steel trusses, supporting fibre-reinforced concrete cladding panels to create the required aesthetic and performance of the building envelope. The key challenges for the design resulted from the highly complex geometry of the disc interaction. No two discs are the same; no two discs intersect each other in precisely the same way. The galleries and other key spaces in the building are created by the interstices between the discs; any alteration to the architecture involves mov-

The project architect drew inspiration from the desert rose

ing discs and thereby moving the structure within the discs. This has led to an evolution of systems and processes required to handle, manipulate and develop geometric ideas from the architect, and establish engineering solutions, before communicating them in their most useful form to the wider community.

Structural modelling The structural team developed a parametric Generative Components script-based tool to automatically create wire-frame geometry in the correct position within the architectural Rhino envelope. The basic wire-frames were further populated with property and loading data using spreadsheet-based automation. Custom-designed spreadsheet macros were further used to combine separate disc models into larger combined models for structural analysis. Element strength checking was also automated as far as possible, to make practicable the design of the 250,000 separate steel elements. The analysis models were used as the basis of the production Tekla model, directly translating geometry, section data and key annotation such as disc-to-disc interface nodes.

The design featured an incredible 250,000 separate steel elements

The Tekla model was issued to the contractor at tender stage for accurate pricing. The model has been kept up to date and reissued as the design has been completed, and contains the live drawing files needed to communicate information in 2D. During the site phase, the contractor has adopted and developed this model to a fabrication level of detail. Requests For Information (RFIs) raised result in either a sub-model being issued, which is incorporated in the contractor’s live model, or a proposal from the contractor incorporated back in the original design model. In the latter instance, the proposed model is exported and used directly to modify the analysis and design, to confirm acceptability. The design model makes use of Tekla phases and classes to keep track of issue status of recent updates. Also at tender, the Tekla model was used to interrogate concrete volumes in order to produce accurate steel reinforcement figures.

Superstructure steelwork connections The scheme for the building involves many intersecting steel framed discs and therefore results in numerous connections between discs with largely different geom28

November / December 2012

p28_29_31_AEC_NOVDEC12_TeklaHK.indd 28

www.AECmag.com

9/11/12 11:04:50