PORTFOLIO

EDUCATION BACKGROUND

Bangor University

2019/09-2022/06

Luoxian Wu

Product designer

About me

Name:Luoxian Wu

Date of birth:16/08/2000

Nationality:United Kingdom

Education:Master of Architectre

Fluent languages: English/Cantonese/ Mandarin

Contact

Email: Wuluoxian@hotmail.co.uk

Phone(UK):+447449588733

Phone(CN)+86 13302854553

BSc(hons) Product design First class degree with honour

University College London

2022/09-2024/01

WORK EXPERIANCE Professional

Morson Projects-Placement

MArch Design for Manufacture

Nefyn Sheds-Placement

2022/02-2022/07

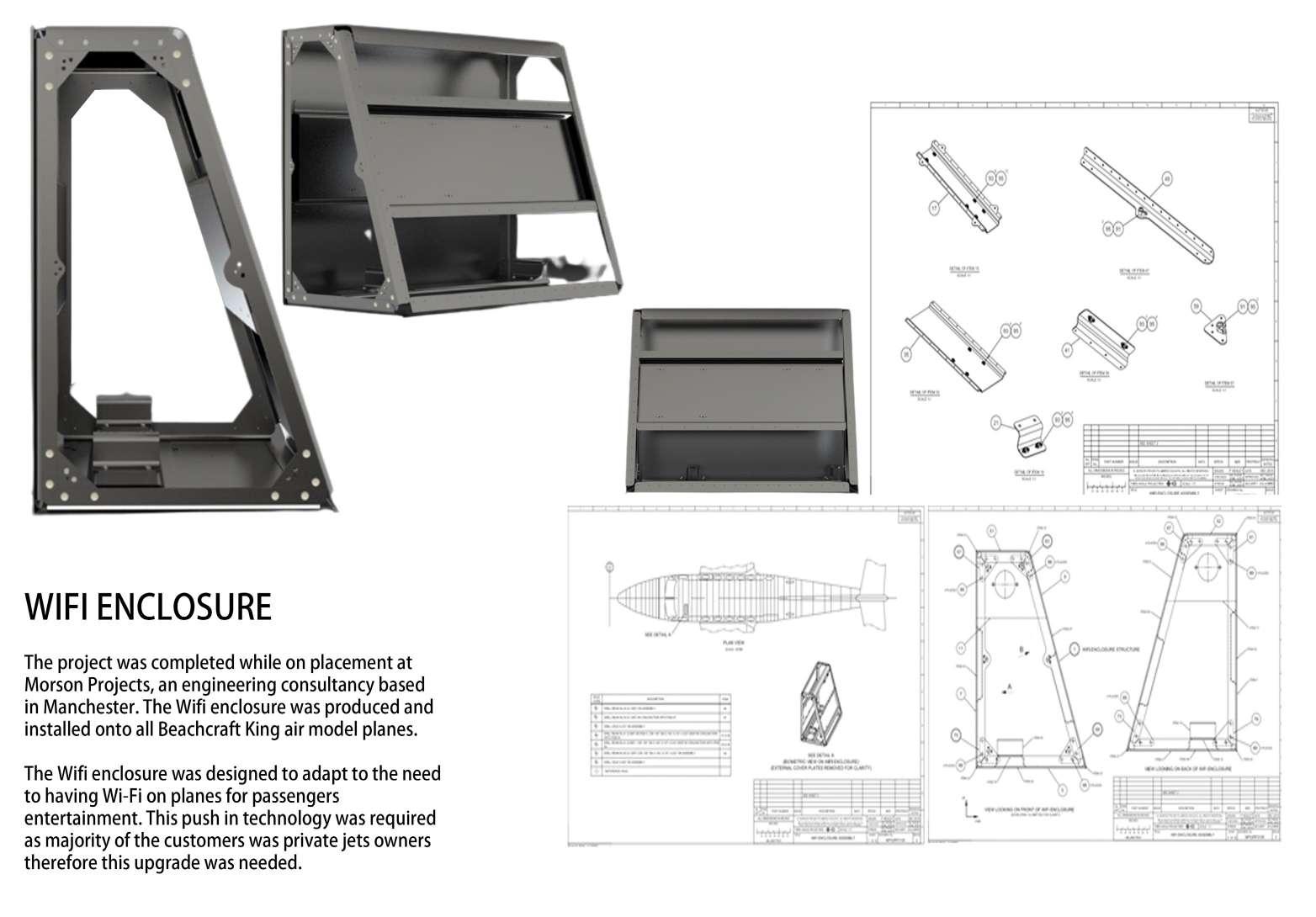

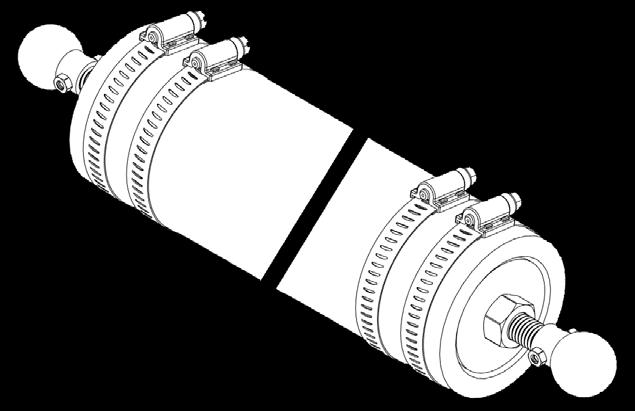

During my time at Morson Projects I worked in the Part 21J DOA division. This division specialised in aircraft renovation, maintainence and airworthyness certification. My role was an intern design engineer working along side the design and engineering team generating designs from 2D sketched using Solidwork and running tests on the components before manufacturing and installation. Prior to the end of my placement I was offered a role as a freelance designer and worked on several NDA projects for the company.

Nefyn shed is a start up company located in North Wales. The company specialises in manufacturing summer houses, sheds and different wood products using timber. My role at the company was industrial and graphic designer where I promoted the company and developed a new line of design for the company.

Atelier One-Live project

2019/01-2019/08 2024-

skills

Atelier One is a well known structural engineering company based in London UK. Since graduation the company saw potential in my bamboo node design and offered resource and guidance to continue development of the node for a live project based in Tulum, Mexico. This project continued from The Arc at Green School Bali, Indonesia

Software knowledge Manufacturing knowledge

Rhino+Grasshopper

Fusion 360

Adobe suite

Solidworks Products Catia V5

Enscape

Keyshot 3D printing

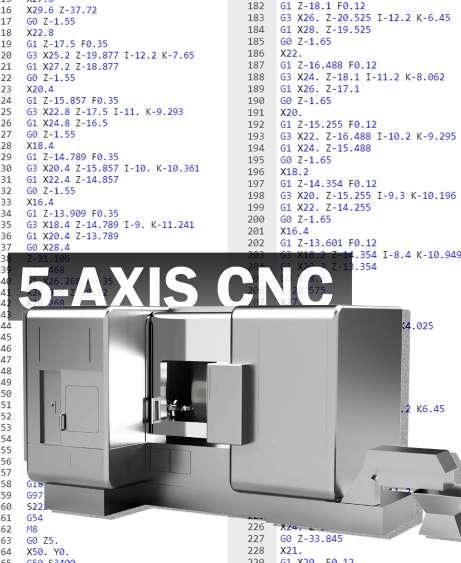

Multi Axis CNC

Ceramic casting

Injection moulding

page

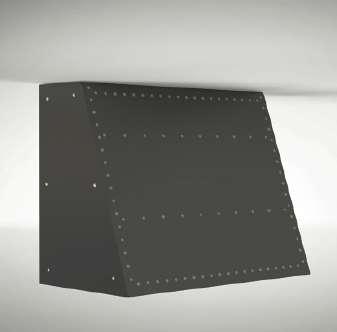

Wifi enclosure and USB hub

Project 1

Wifi enclosesure for Beachcraft Kingsair

Project 2

USB A-C Charging hub

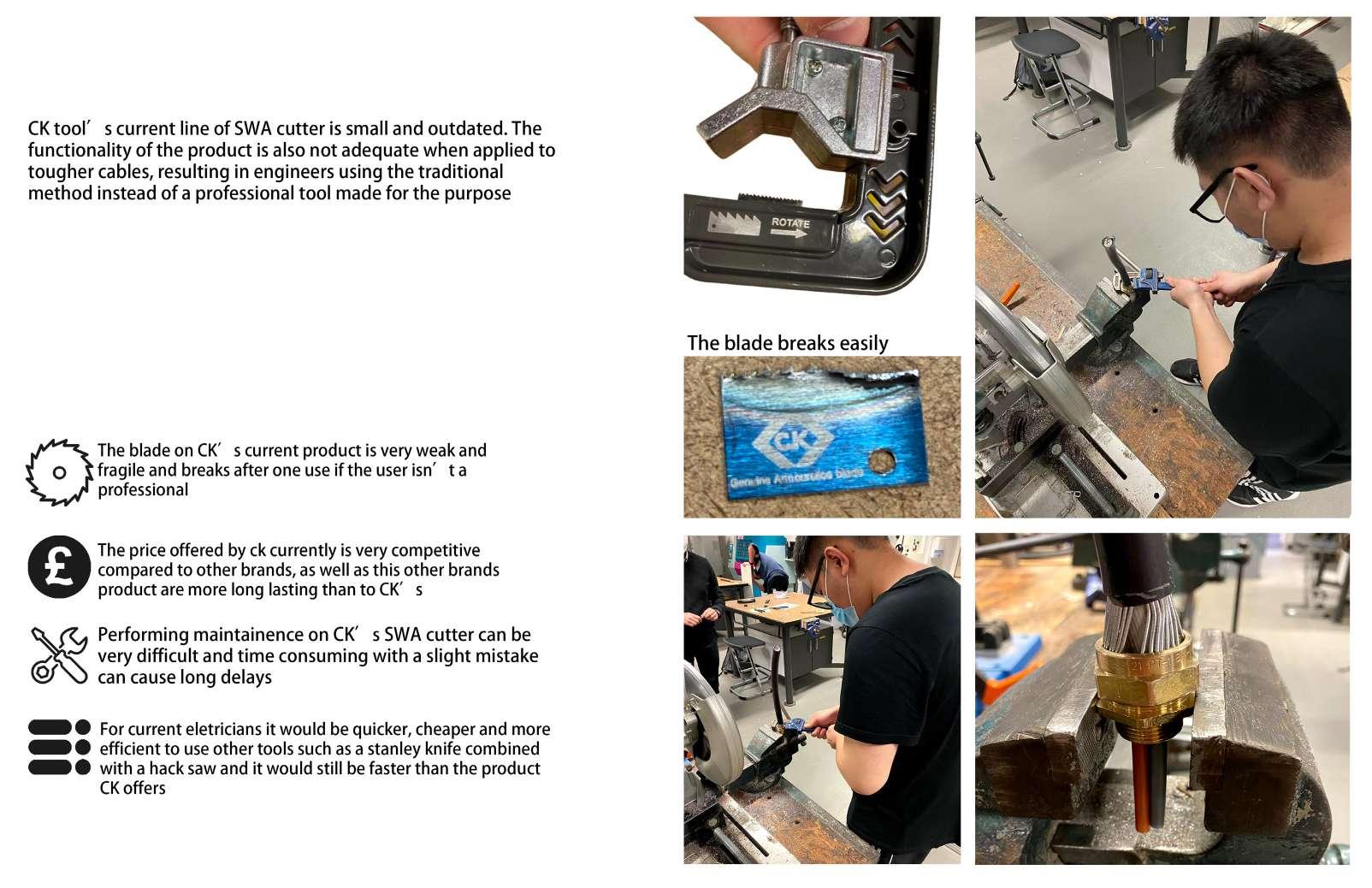

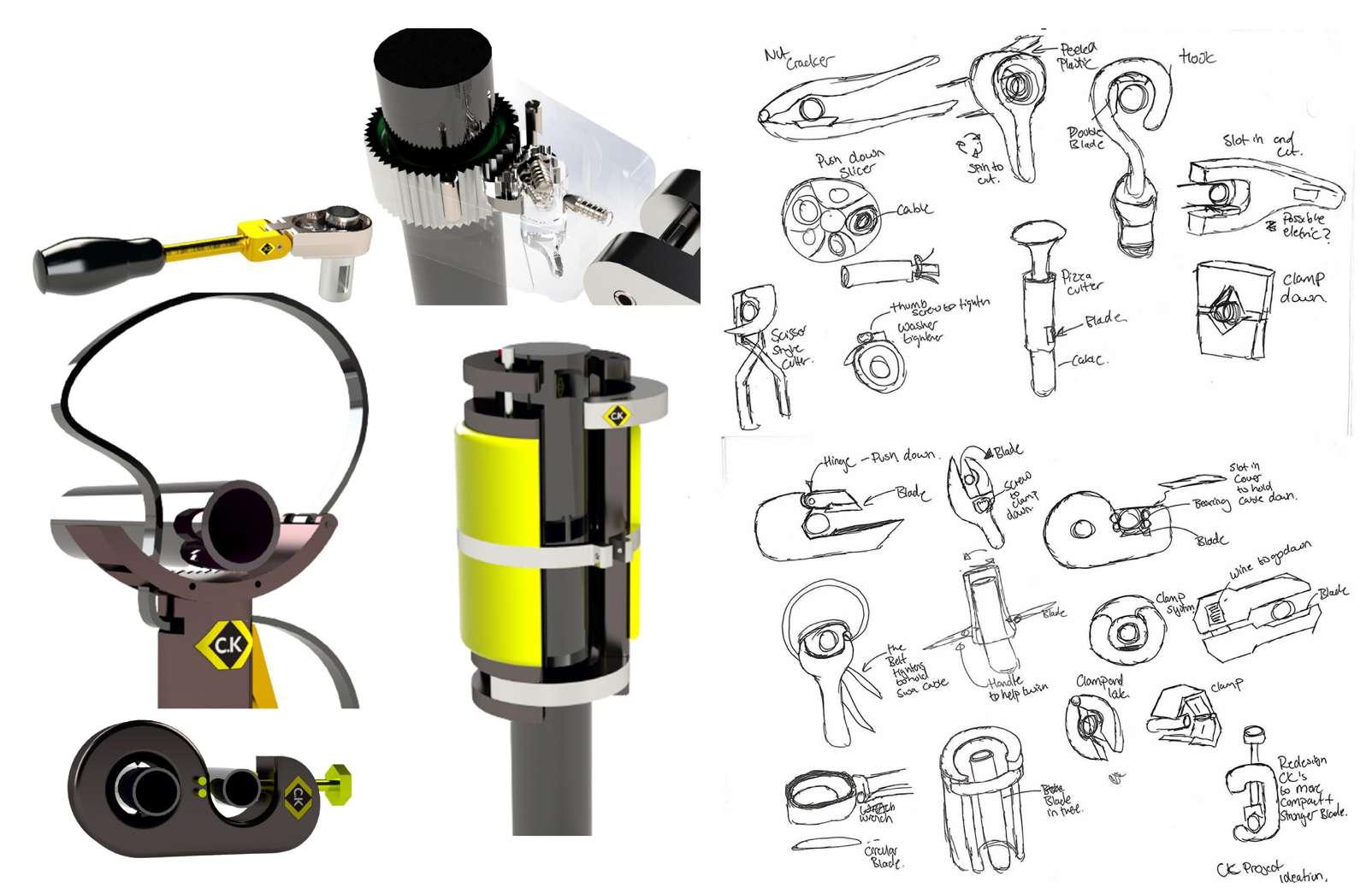

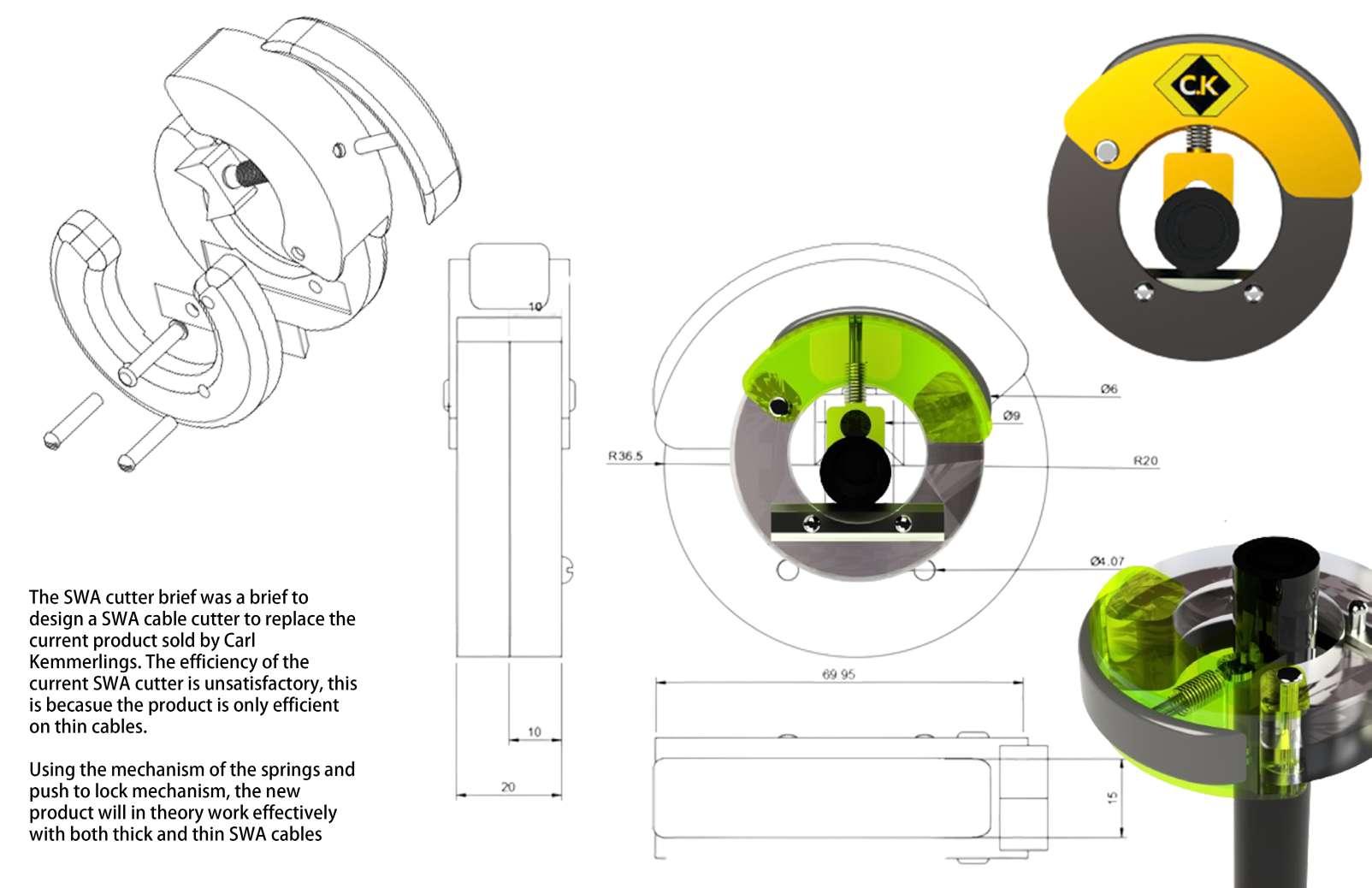

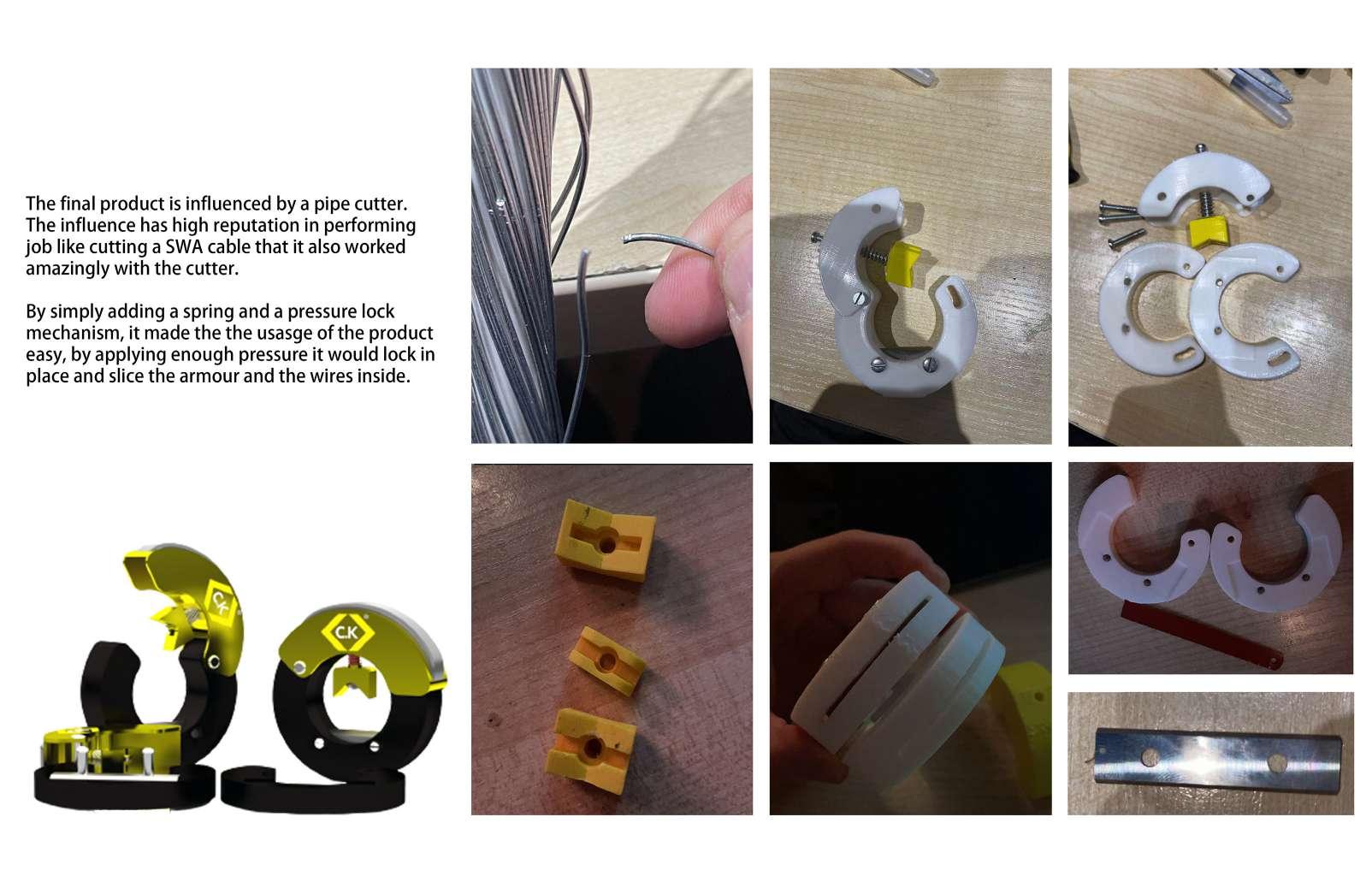

SWA wire cutter

SWA cable cutter for CK tools

PROBLEM AND USER TRIAL

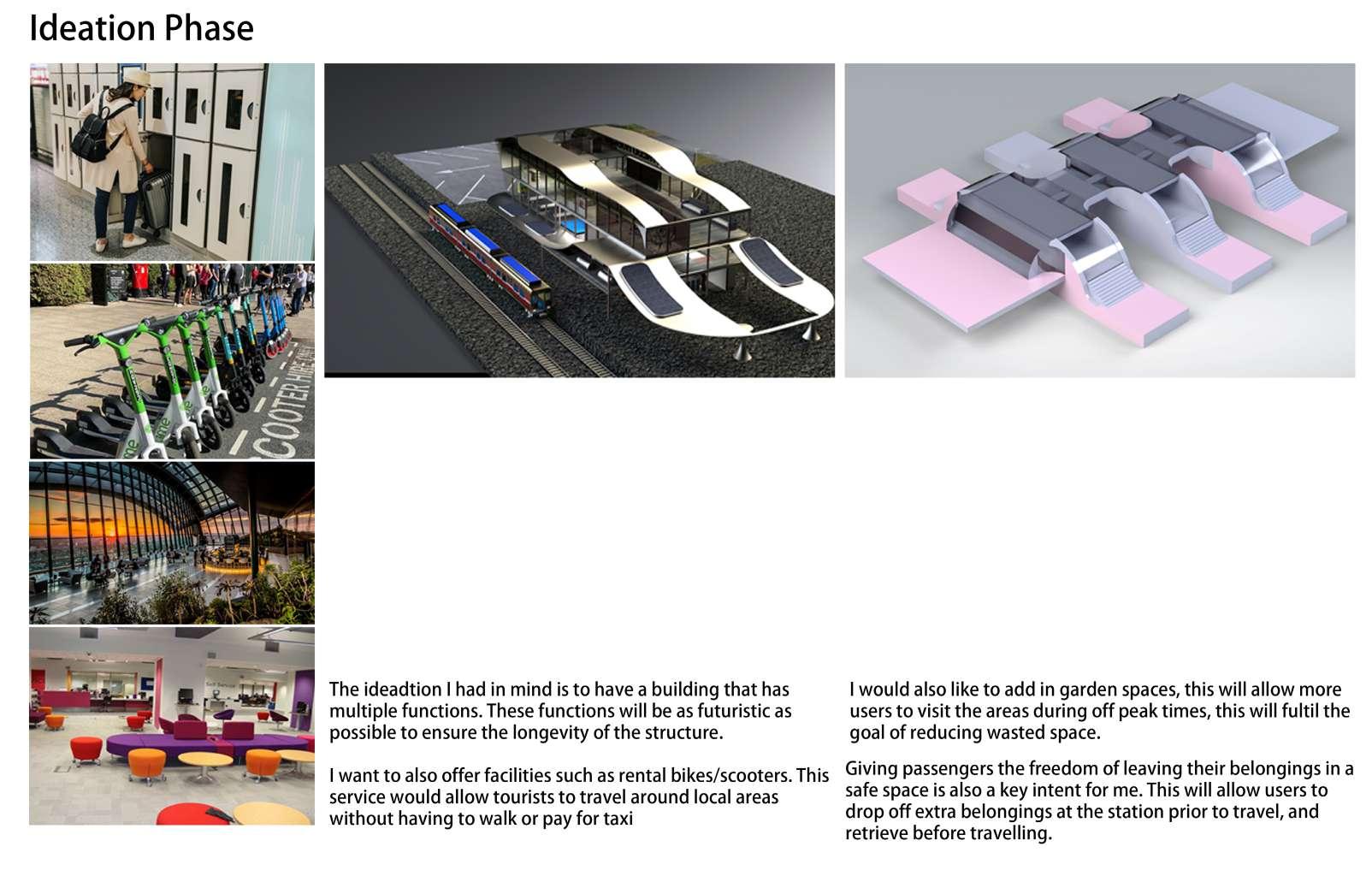

IDEATION

FINAL CONCEPT

CONCEPT PROTOTYPE

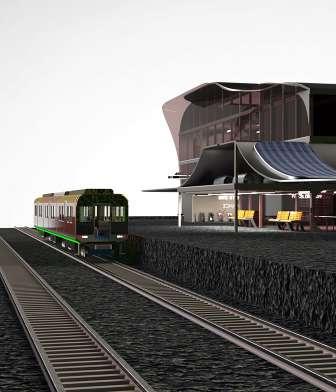

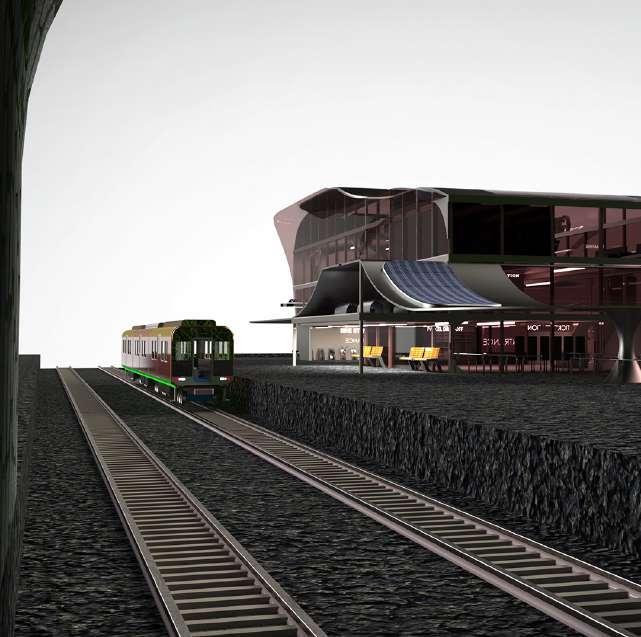

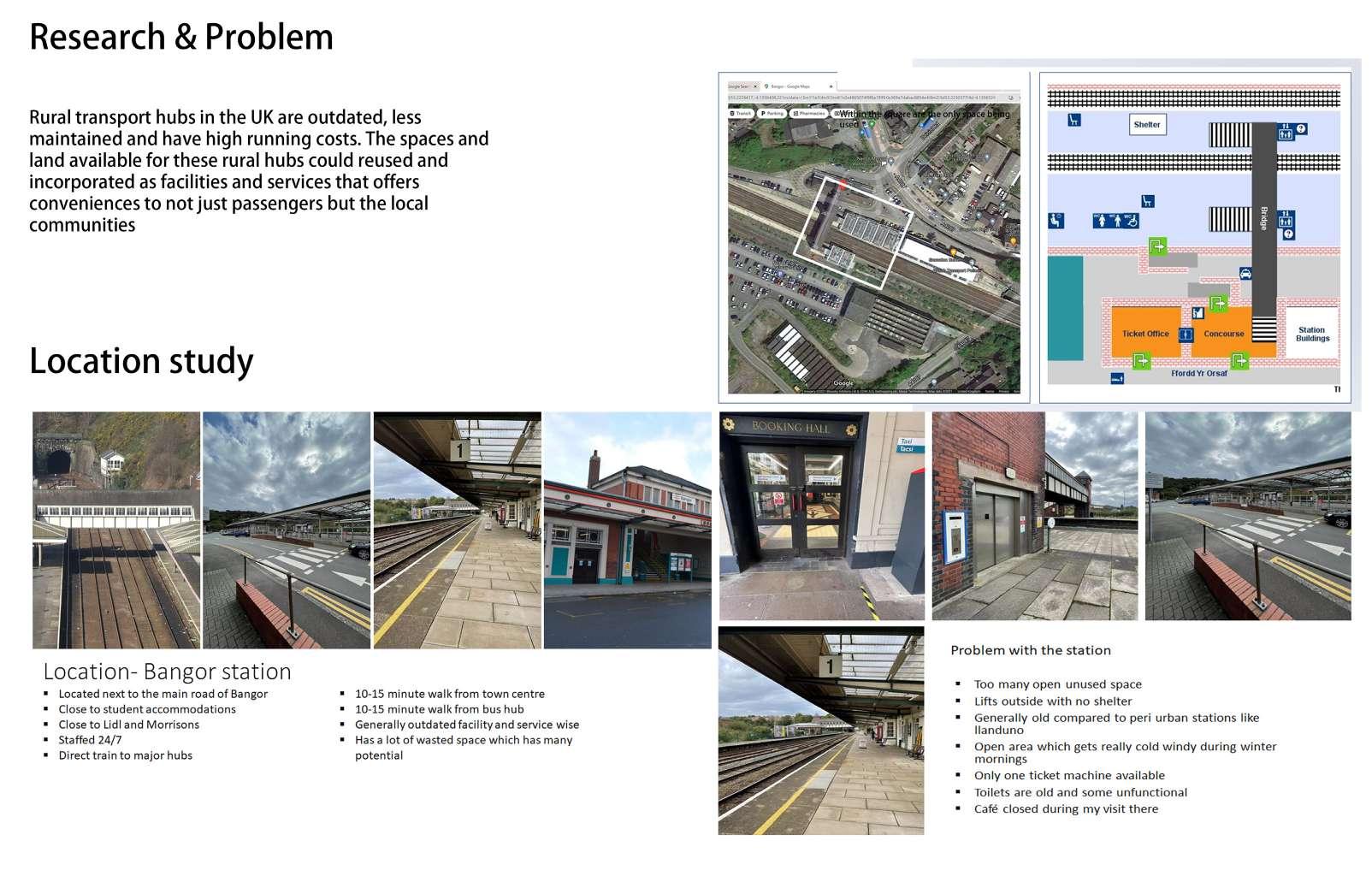

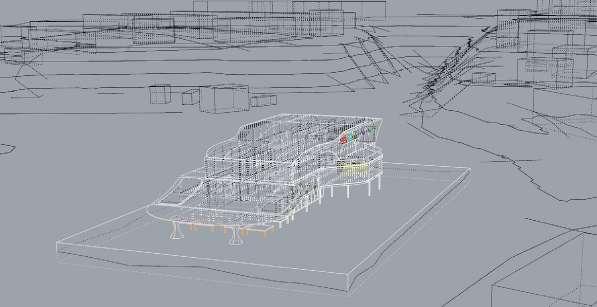

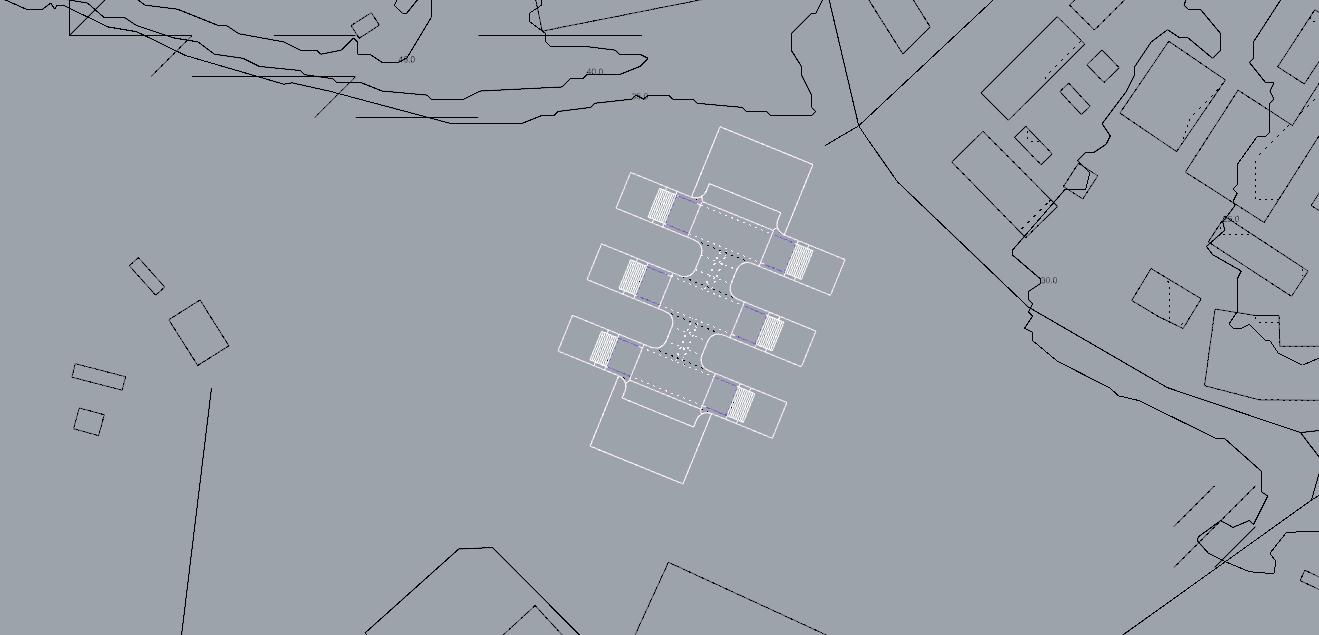

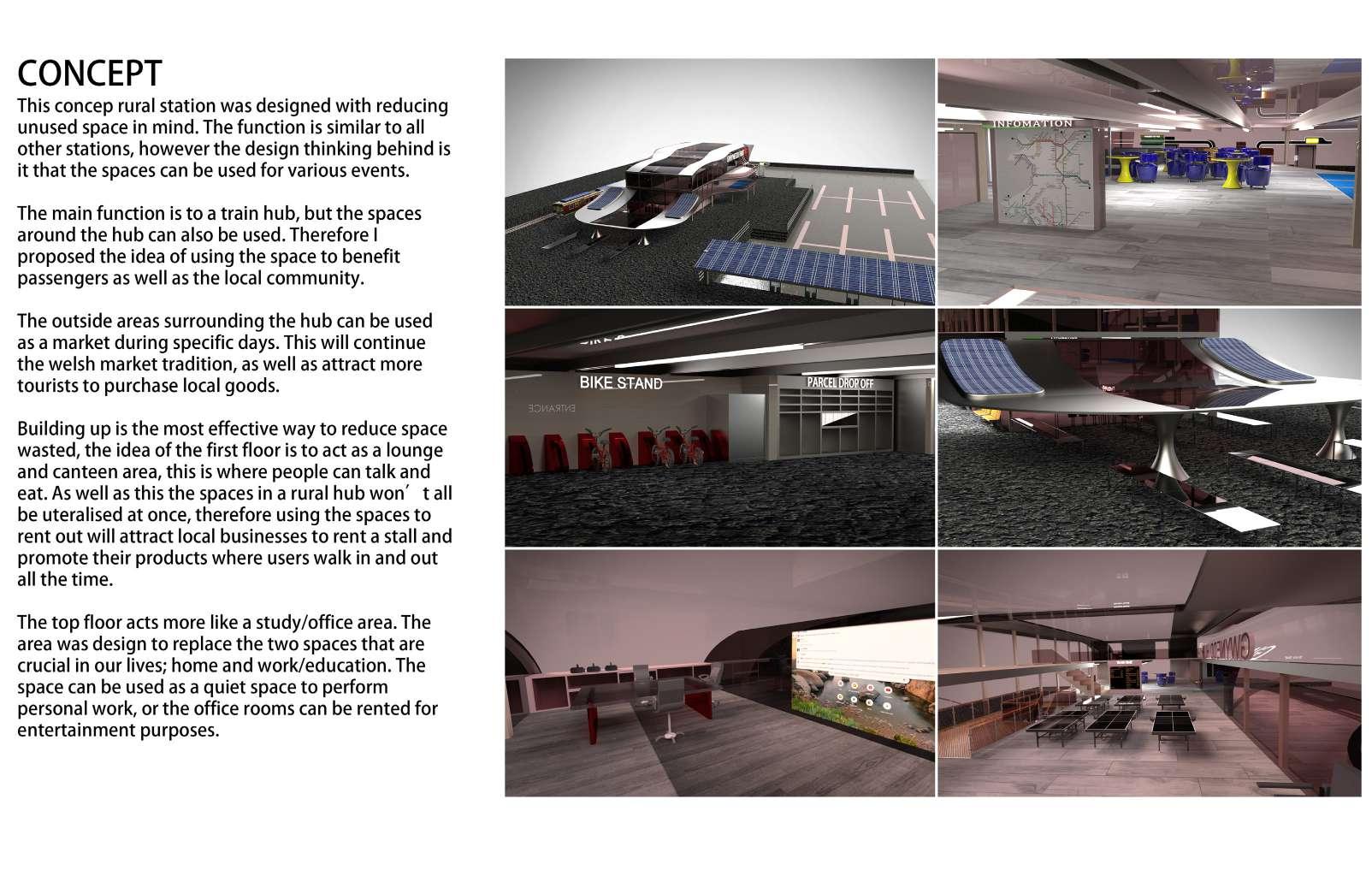

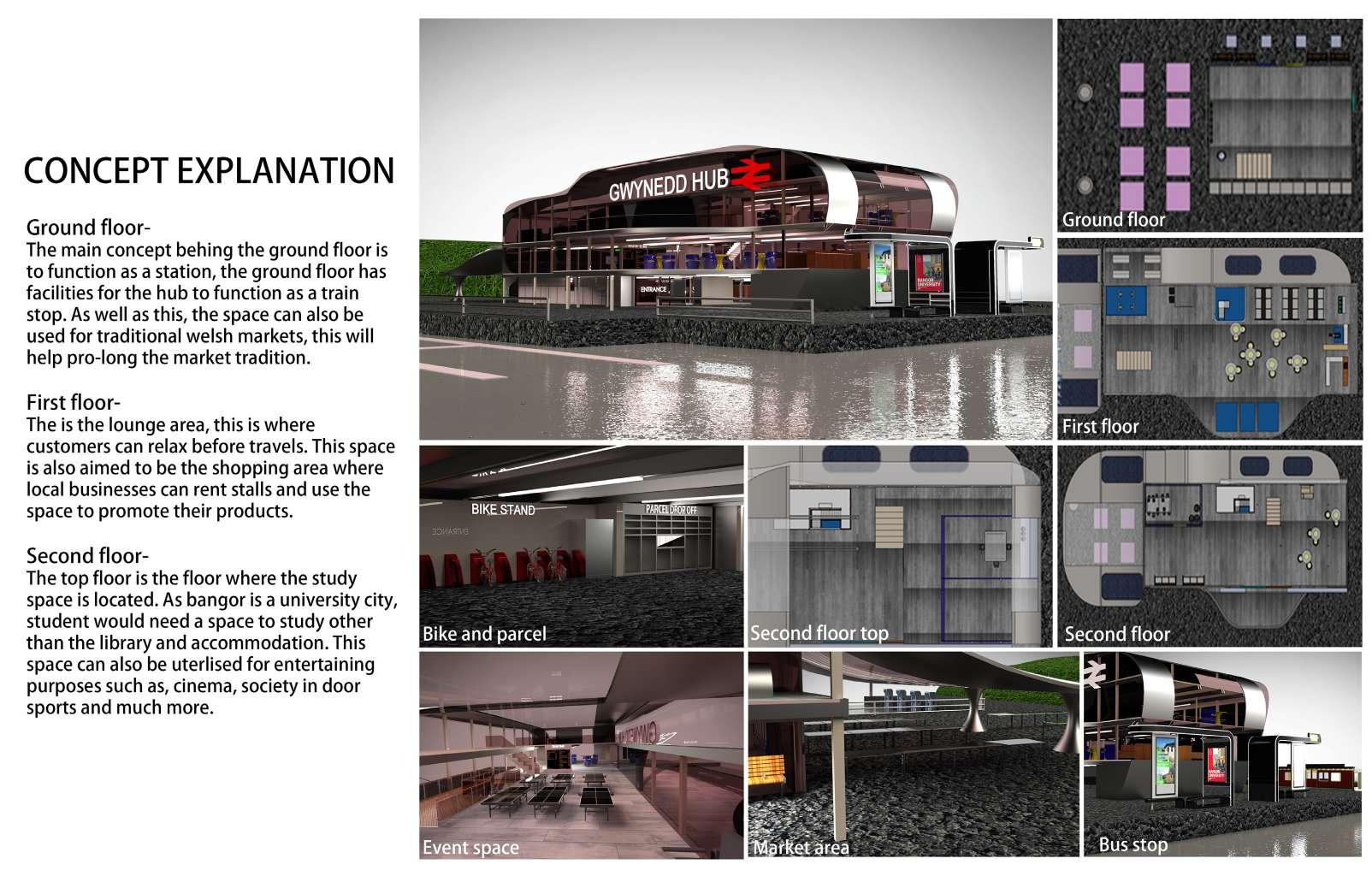

Conceptual train station for Network rails

03. Gwynedd Hub

04. Adaptive bamboo structure

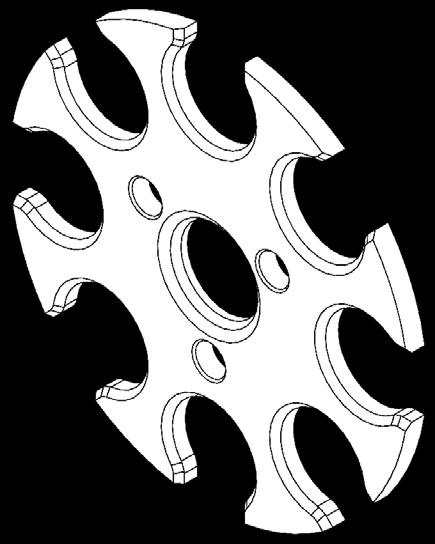

Modular component for bamboo

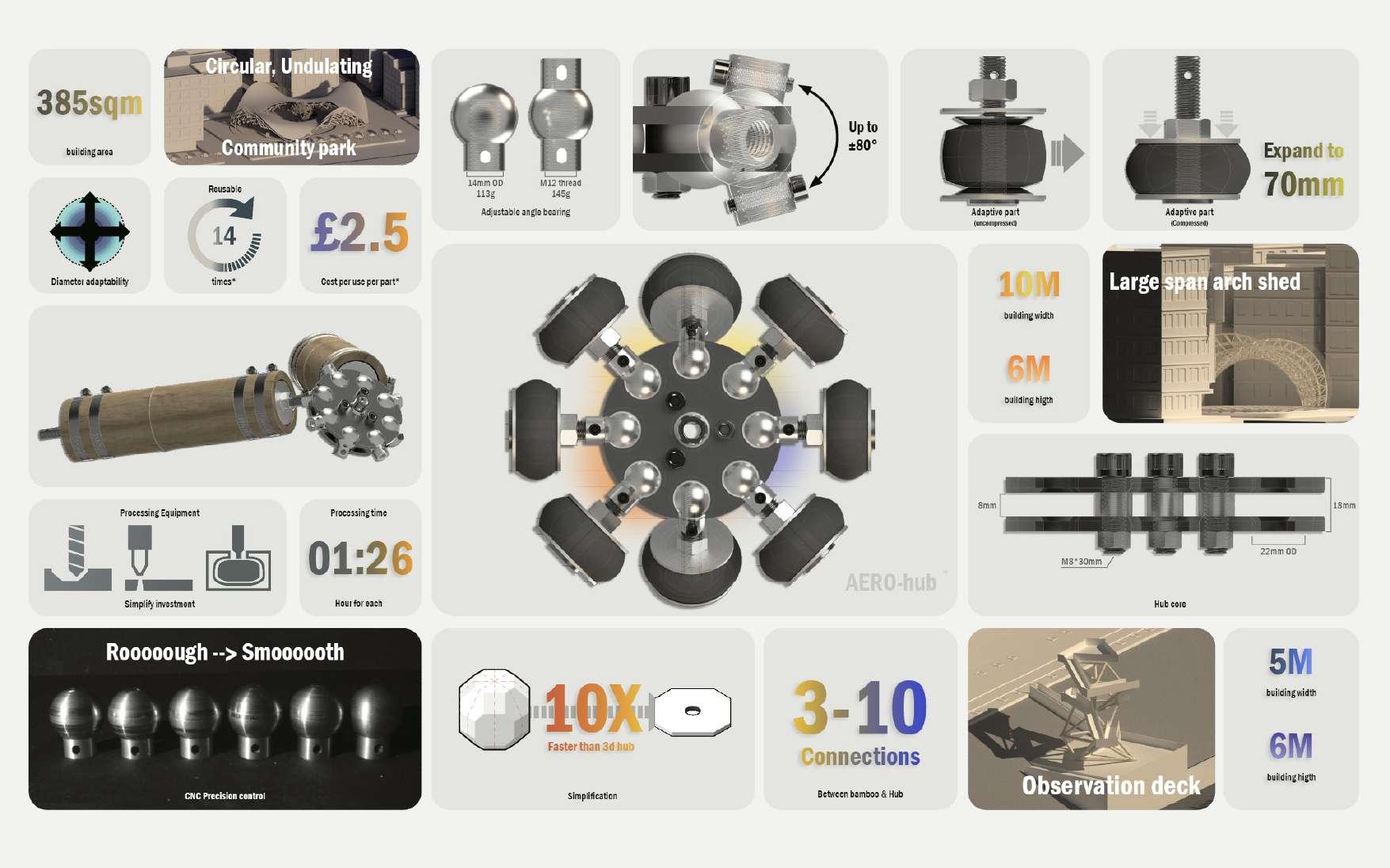

HUB Simplification

Design Strategy

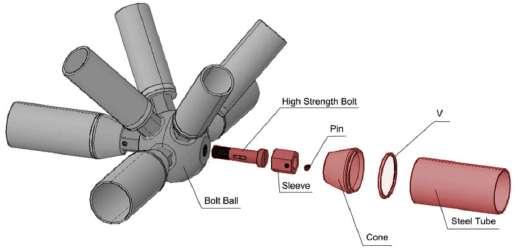

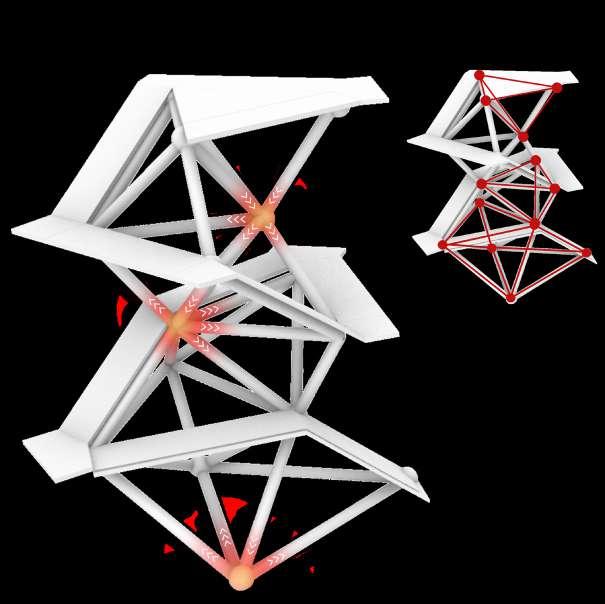

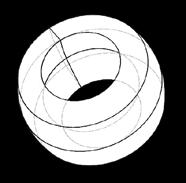

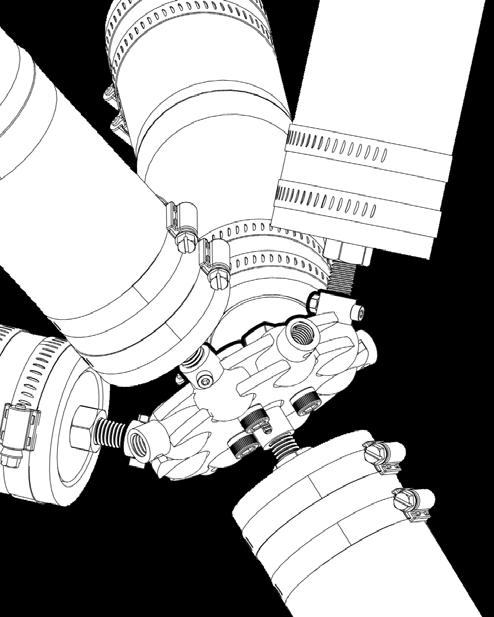

9 Axis Connection Chemical Fixed Architectural Modular Space frame Non-adjustable angle

Why research mero system?

■Mero's KK-SYSTEM demonstrates the connectivity capabilities required for space truss nodes. The use of Mero hub with its directional characteristics shows great potential in the use of hub system for bamboo space frame assemblies.

■At the same time, the processing complexity of the parts and standardized materials are the parts that need to be replaced by non-standardized materials in this solution.

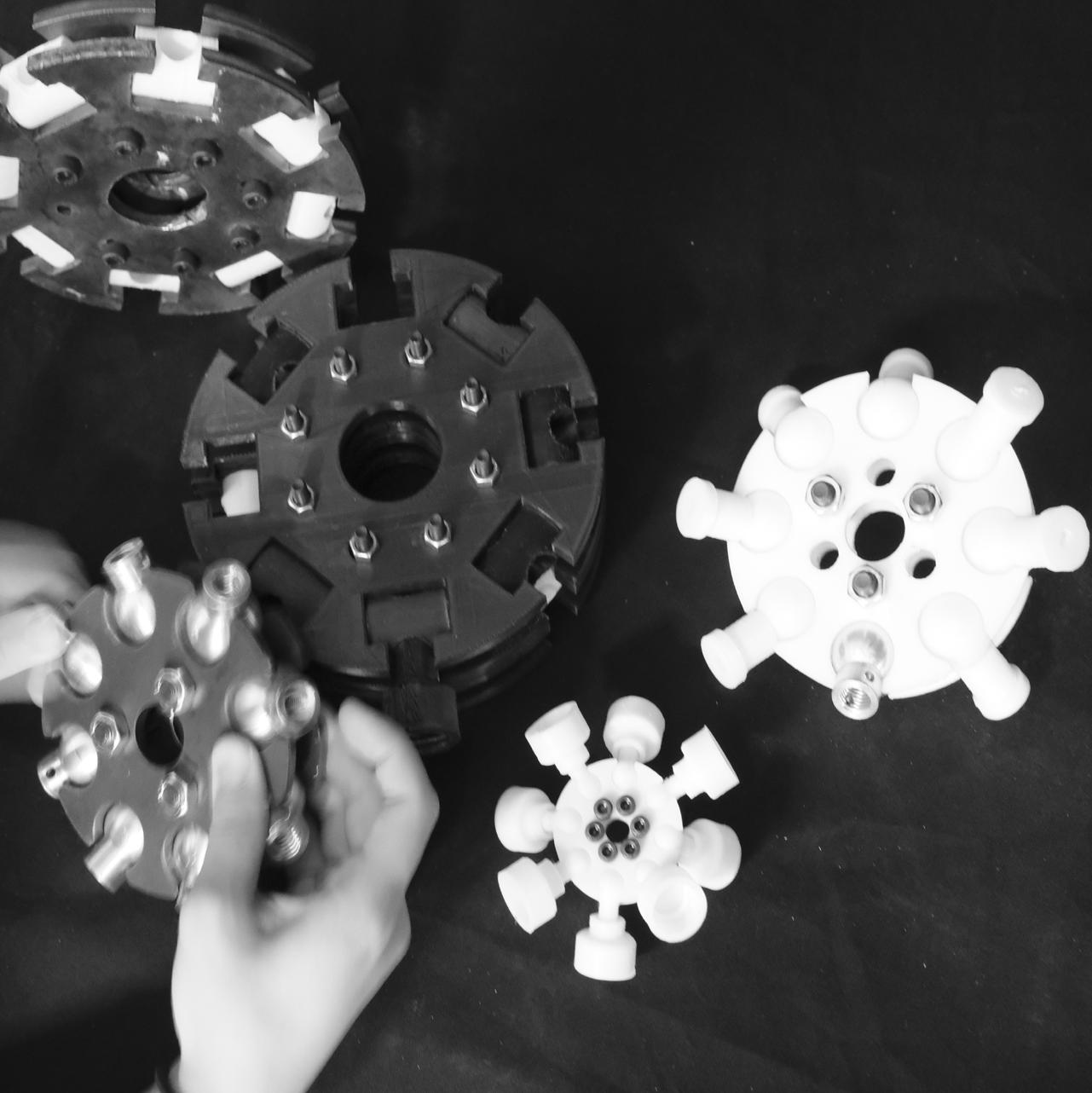

Node design of bamboo structure

Design strategic

1.What are the basic requirements for a simplified version

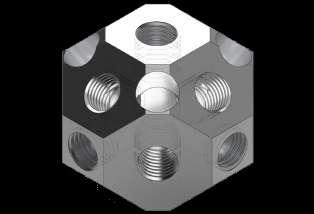

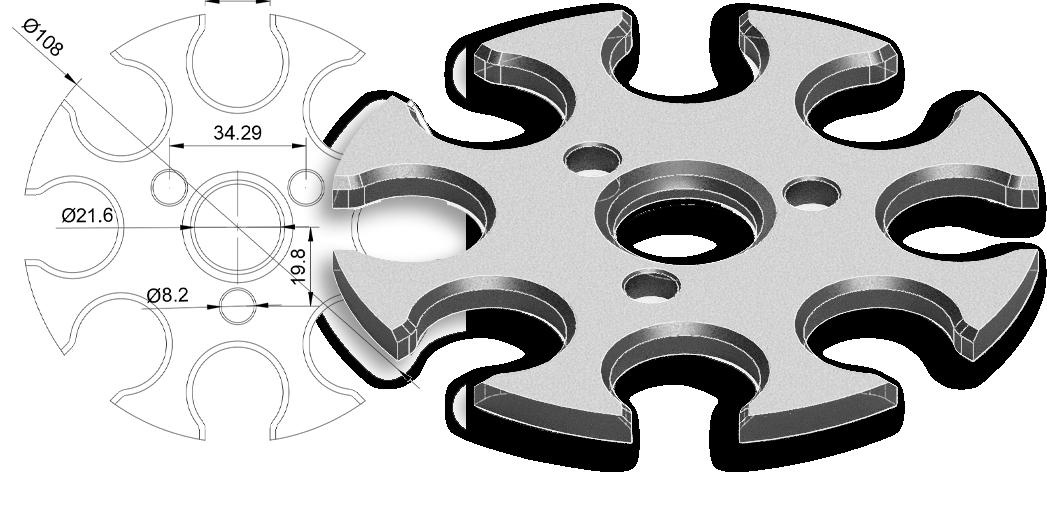

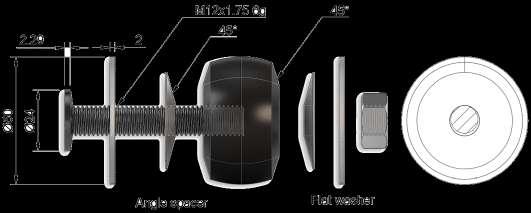

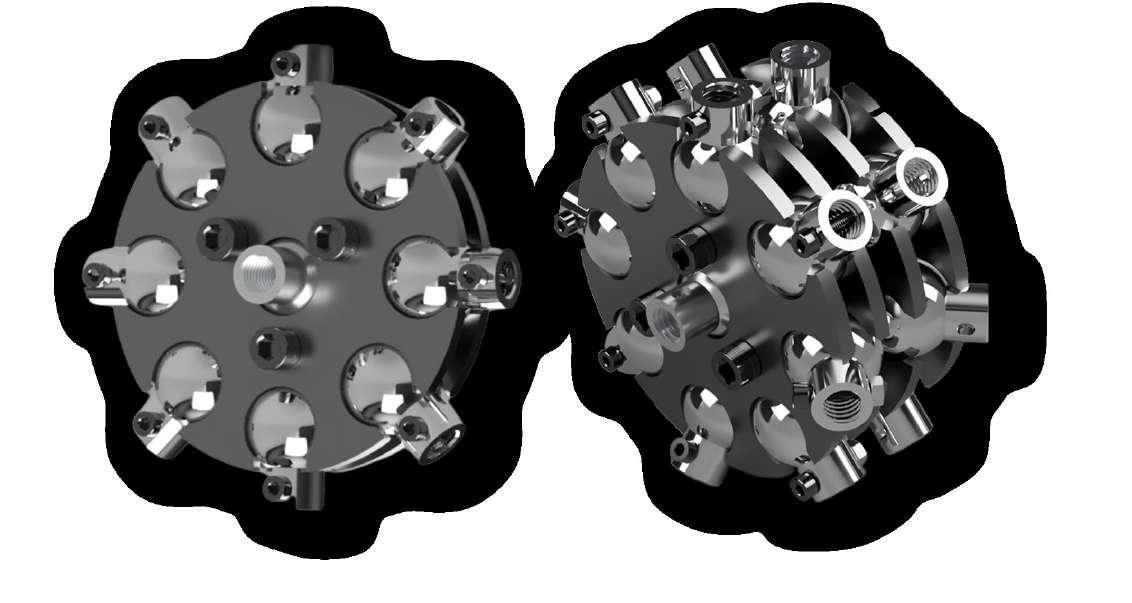

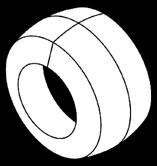

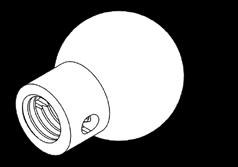

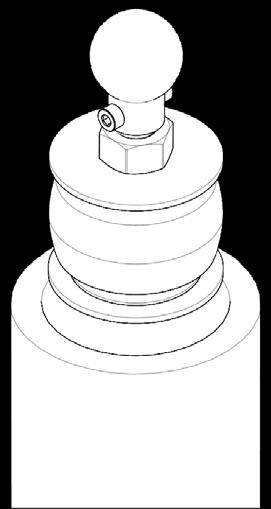

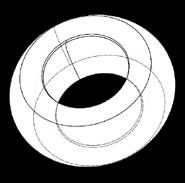

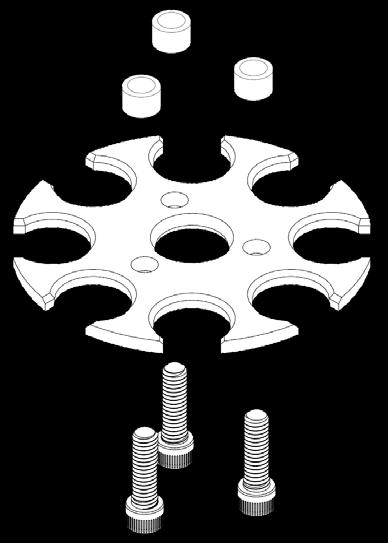

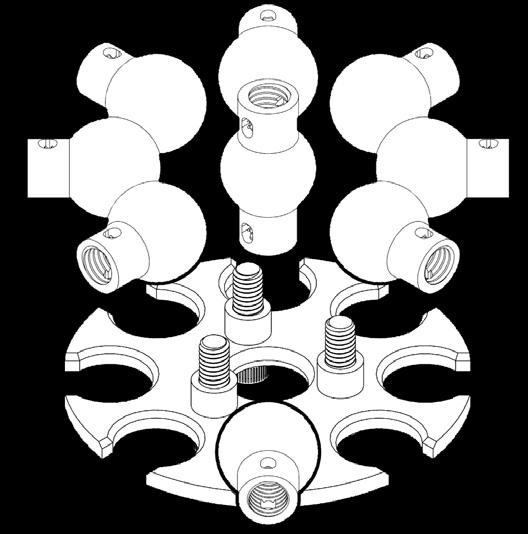

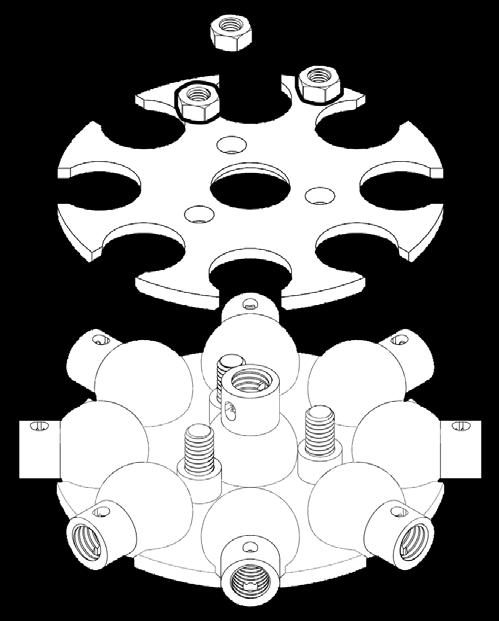

■The final design was based on the simplification of the Mero space hub, Through simplifying from 13 nodal directions to 9 nodal directions, the component still reached the maximum potential with options to sandwhich more component onto each other to generate more directions if required. From there the node design is then refined more to from a flat node to a spherical node that allwos flexible movement within the hub housing, which generated a smaller overall component.

2.Simplified approach to costs

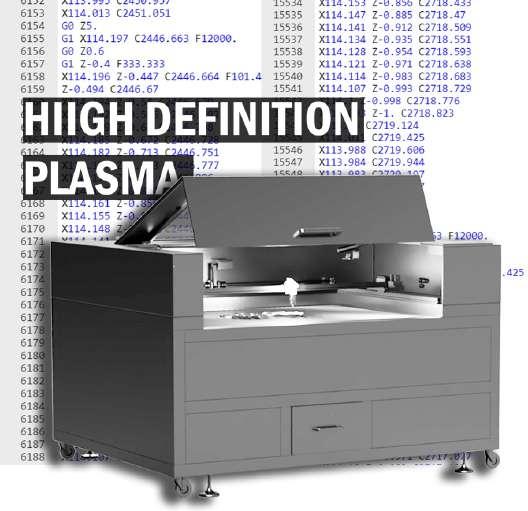

■The simpification resulted in a 2-dimentional component that houses the fuction of a 3- dimentional component, this simpification also lead to a cheaper manufacturing cost as the hub itself can be fabricated using high definition plasma technology which economically efficient compared to a 5-axis CNC machining. With the selection of steel over aluminium this also brung the price down but at the cost of weight, however when working in conjunction with bamboo this weight still performs better than steel tube.

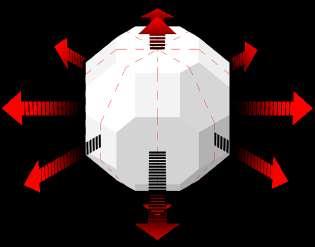

Destination

The Aero Hub, an innovative hub and node conceptual component meticulously crafted to harness the inherent strength and affordability of bamboo in both structural integrity and spatial formation. This unique design is a result of a meticulous development process focused on achieving simplicity and costeffectiveness. The fabrication process, driven by these key goals, has yielded a versatile, re-usable, reconfigurable, and adaptable component. Elevate your projects with the Aero Hub, a sustainable solution that seamlessly combines form and function.

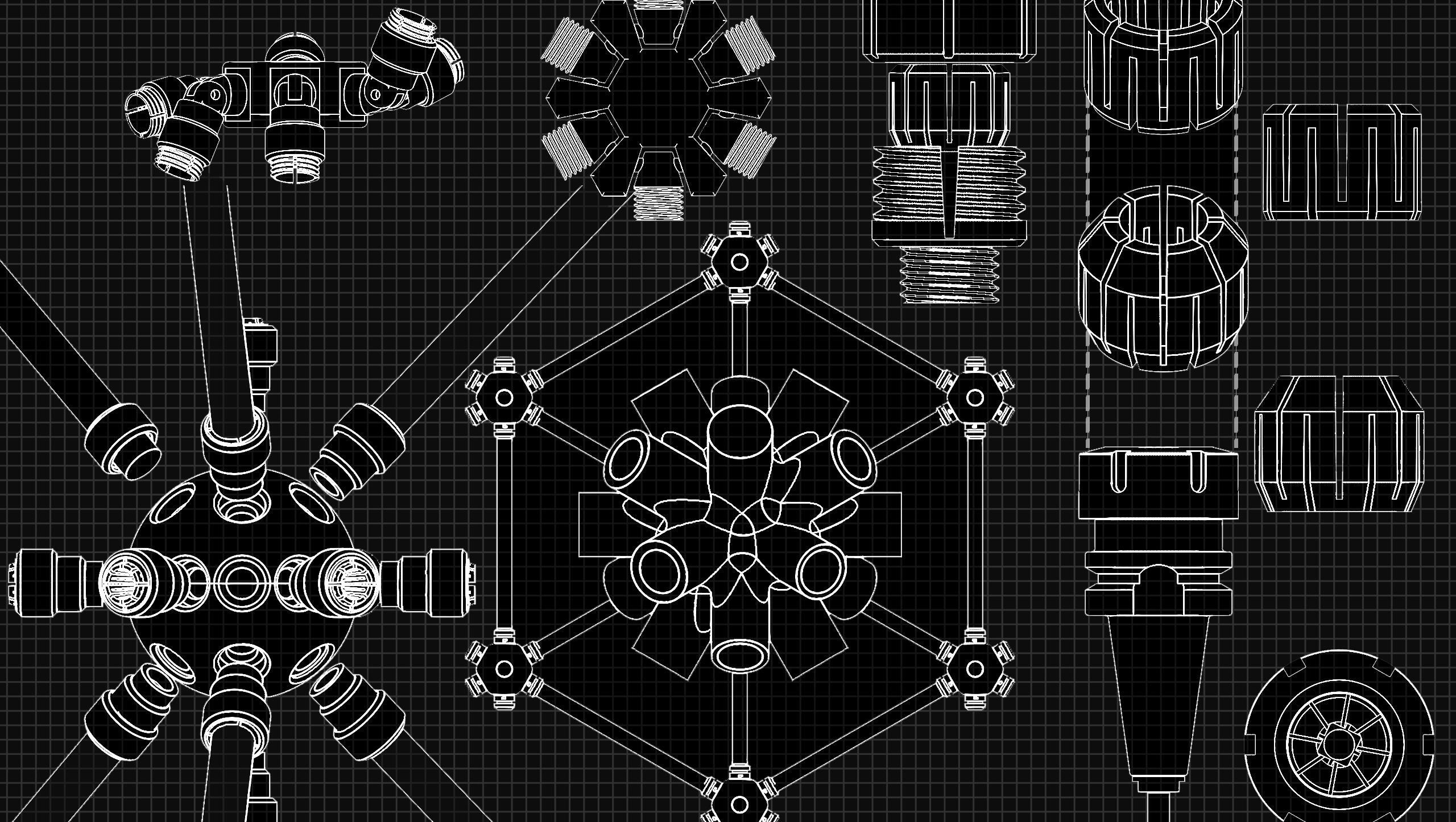

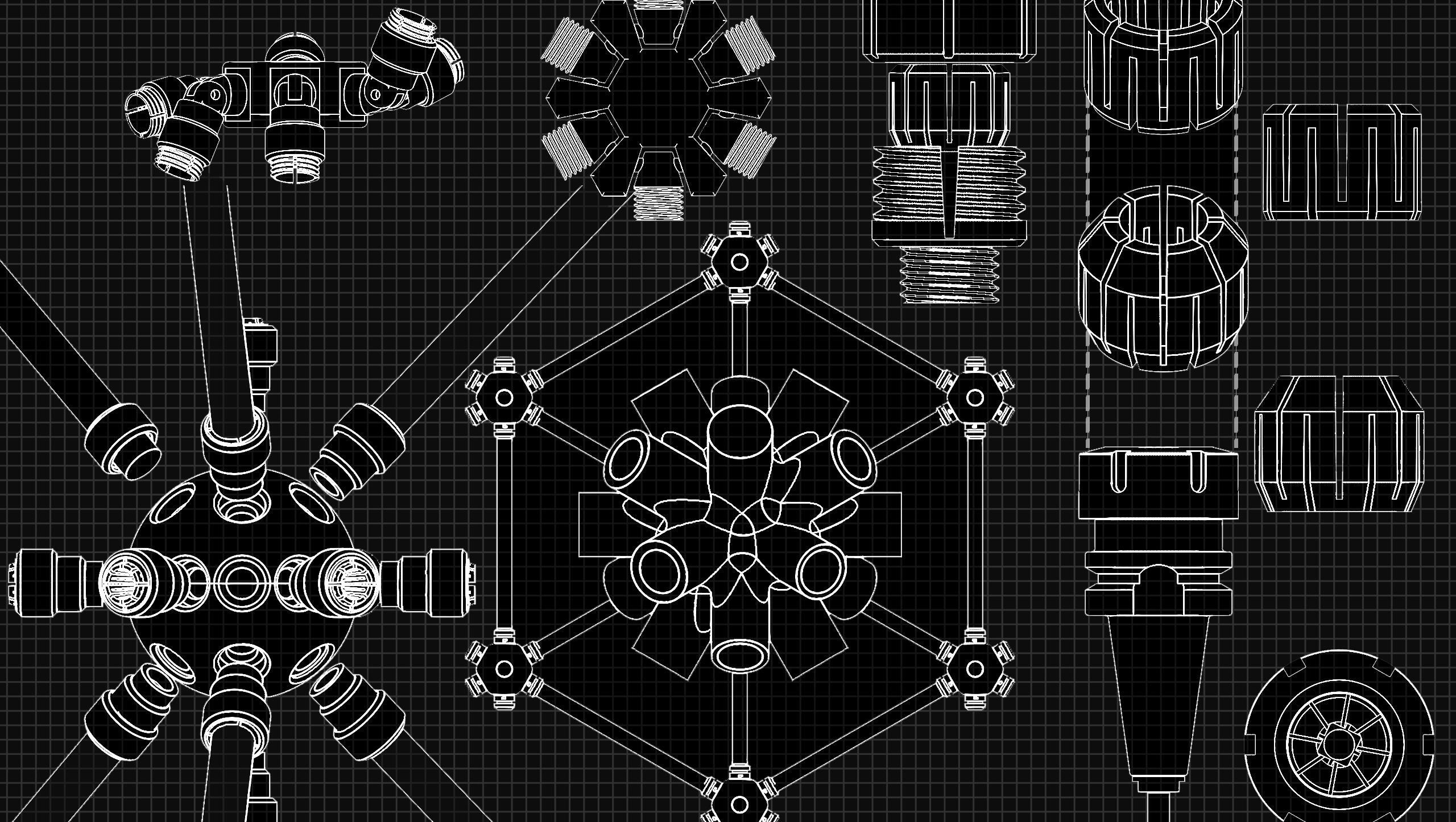

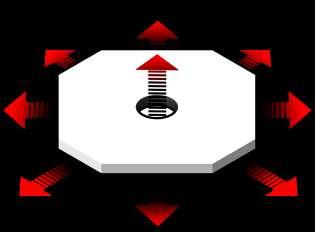

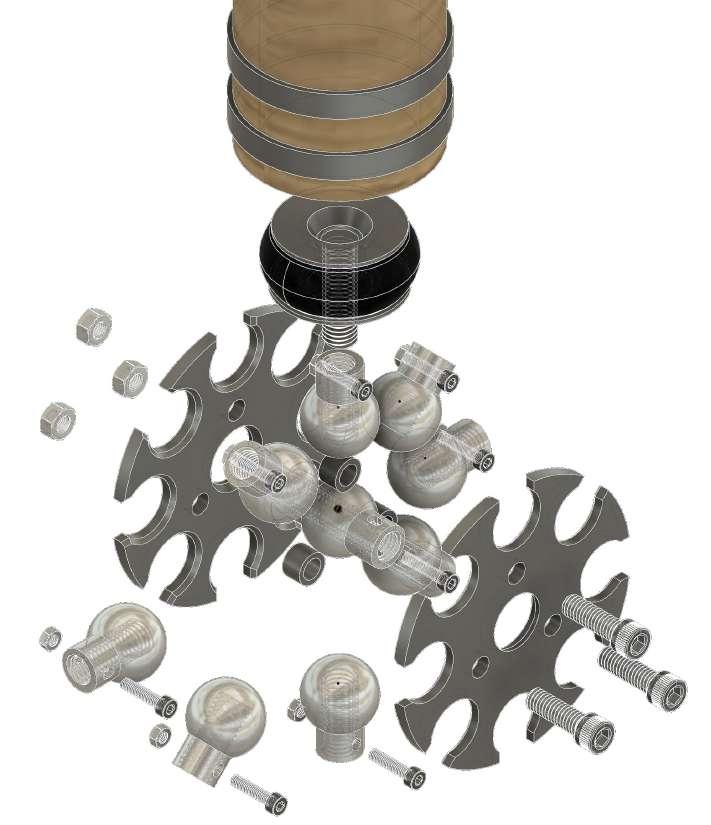

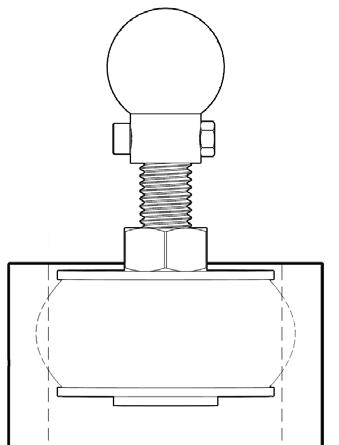

HUB diagram

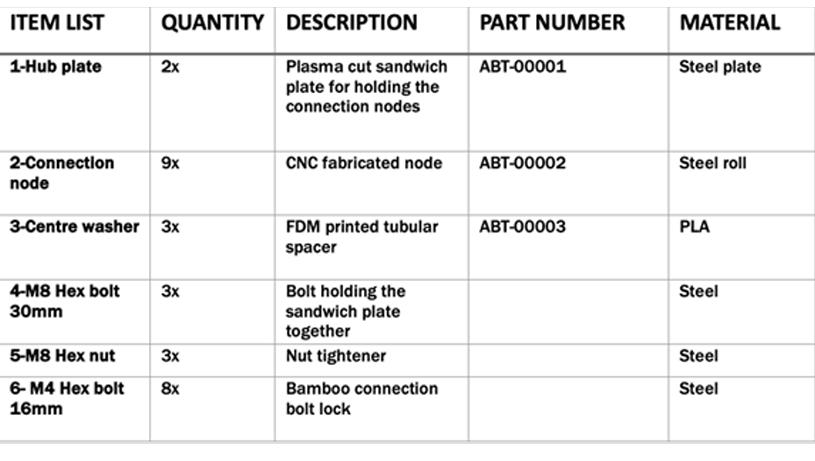

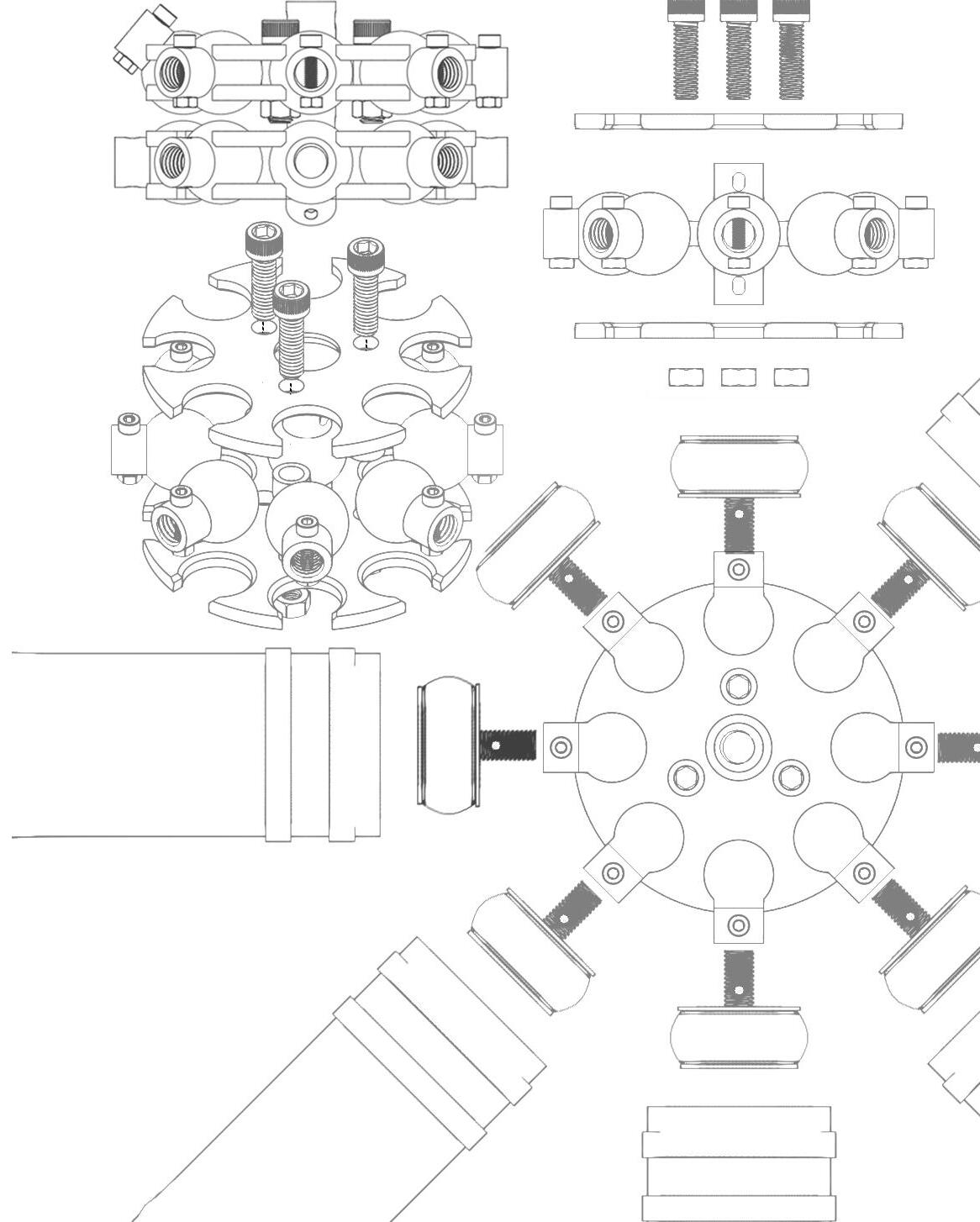

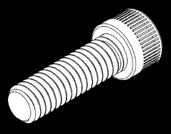

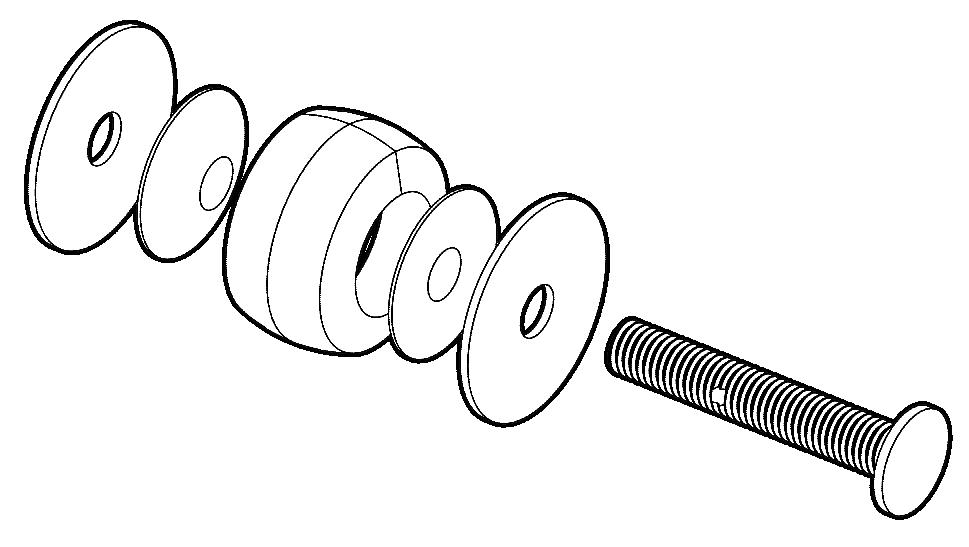

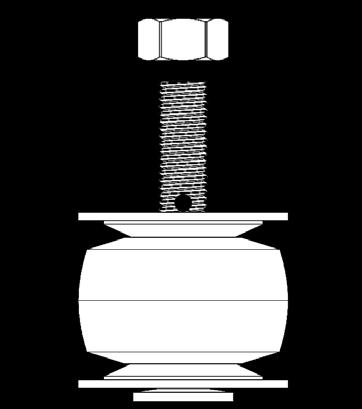

Assembly component list

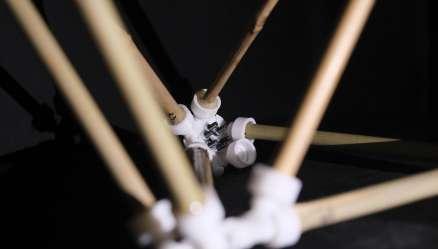

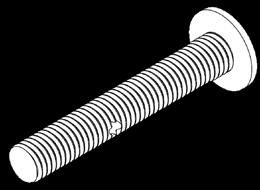

■ Assembly of the final component requires 3x M8 threaded bolt partnered with 3x M8 threaded nut to sandwhich the two steel hub plate and 9x steel node together, partnered with 3x M8 threaded nut to assemble into the final hub. The hub evolved from a 3 dimentional concept into a 2 dimentional prototype which can be manufactured efficiently and cost effectively. At the same time having the potential to achieve the same function and form as the 3 dimentional concept.

HUB

diagram

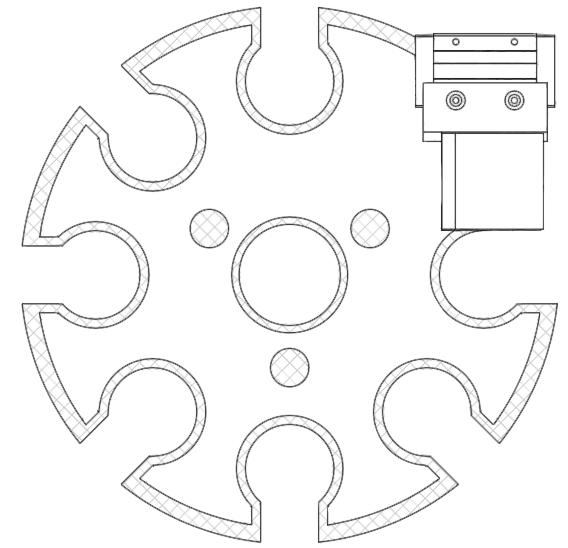

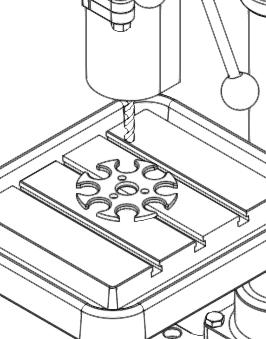

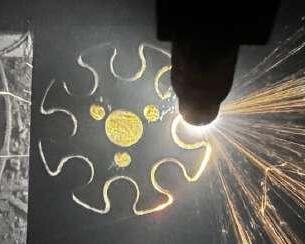

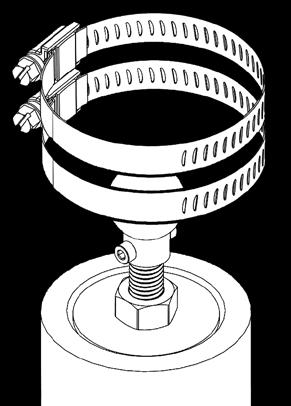

NODE fabrication - Plasma cutter Processing

■The chosen mehtod of hub fabrication was using high definition plasma cutting technology. The use of plasma meant that the hub can be manufactured efficently and economically.

■Them sandwhich plate was fabricatied using steel sheet and plasma cutting technology. the process took less than a minute for a single plate. A single plate of steel (300x300) can cut up to 5 hubs

■After cutting the hub out from the plate, another process is required, inorder to have the nodes pivot freely, the node connection point must be champfered allowing more space to freely move. However if this is done by CNC it can be processed in one single machine operaion

diagram

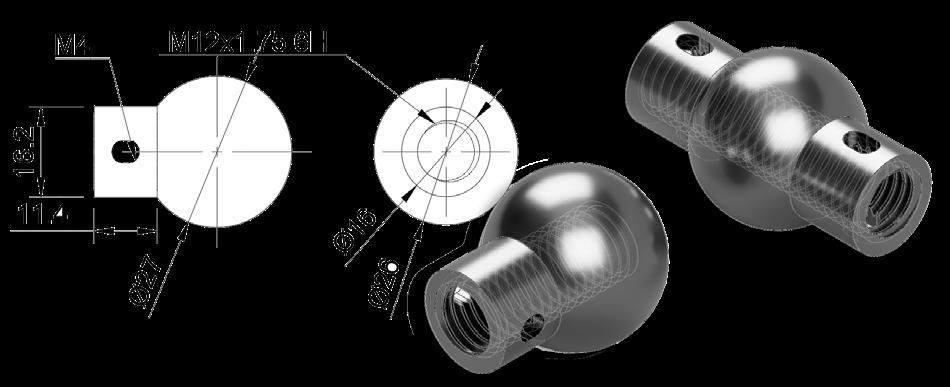

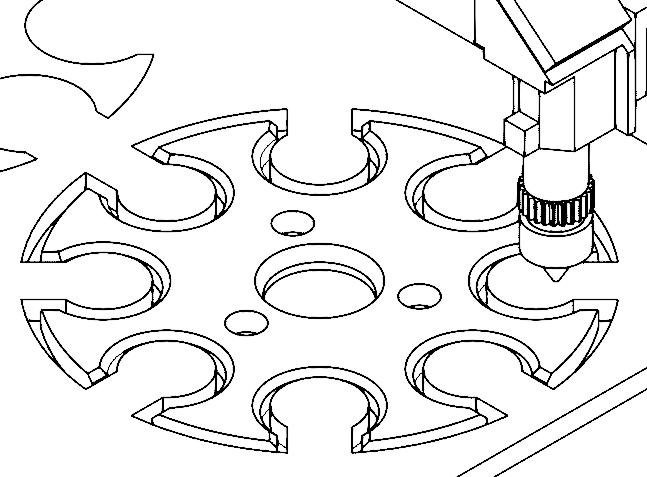

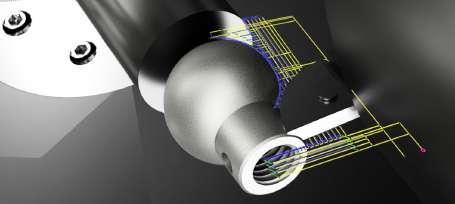

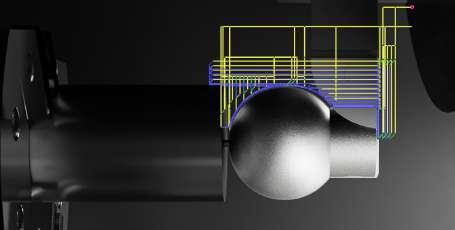

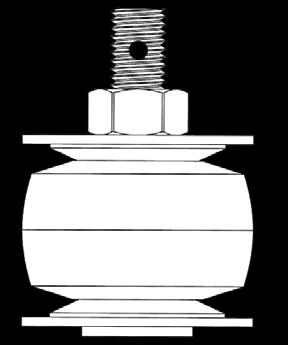

NODE fabrication - 5-Aixs CNC

■The most efficient method to manufacture the node was to CNC using a 5-axis CNC. This fabrication process is also the only process within this design that requires an expensive machine to produce the part. However it was neccessary as it is the most efficient method to manufacture the node.

Machining

40mm OD steel round bar cutting

Facing operation

Drill and threading

Cutting the node into shape

Parting tool were used to create the sphere

parting the node from the stock

Toolpath optimisation

Precision control

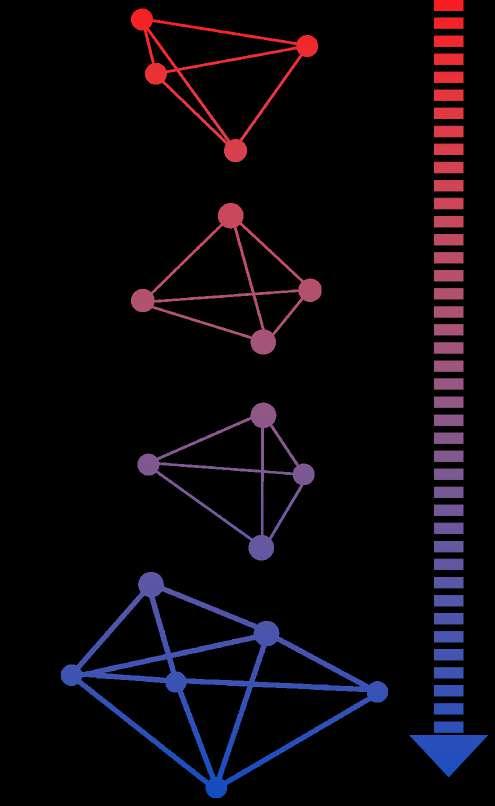

Space truss design

1.Force

analysis-Observation Tower

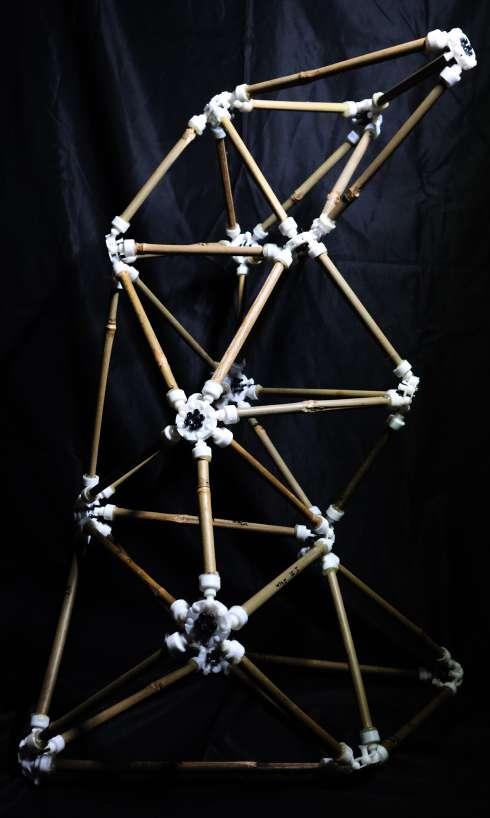

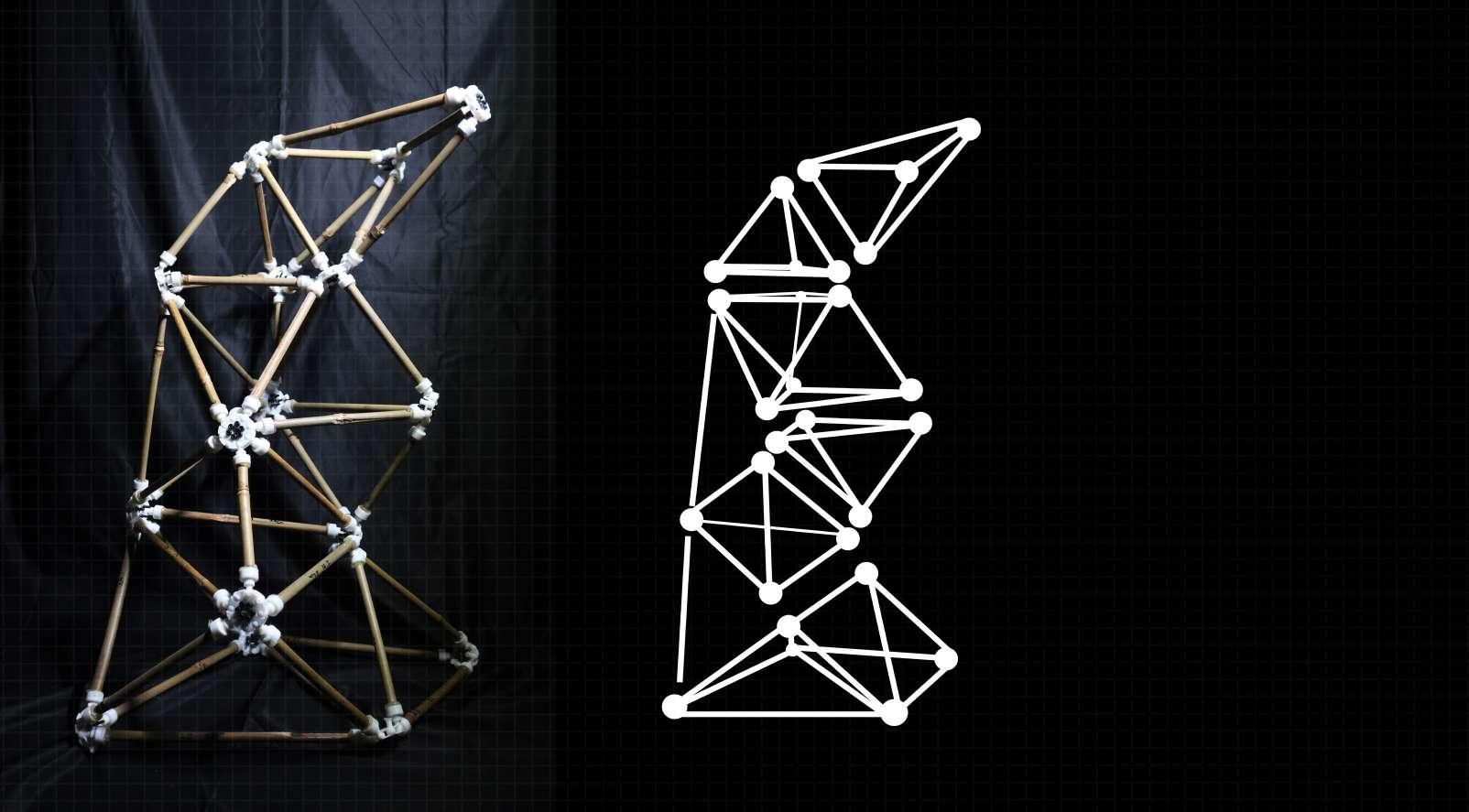

■ Using the theory of warren truss system of equilateral prism to generate a self standing structure where compress is formed at the top but released through out the structures system. This also follows the kuratowski’s and wagner’s theorems where even if the points were to move the structure would still be able to stand without issues

Compression begins to build up from the top of the structure. Top is where the pressure is situated.

As the pressure makes way downward the tension is released through the prismatic structure.

The tension release continues as it makes it way downward to the bottom where its fully released.

The tension is fully released at the bottom of the structure where the energy is released into the foundation.

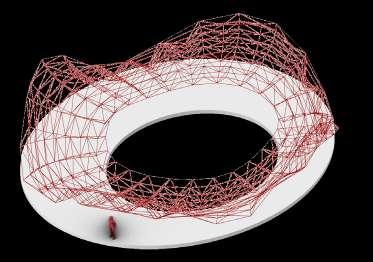

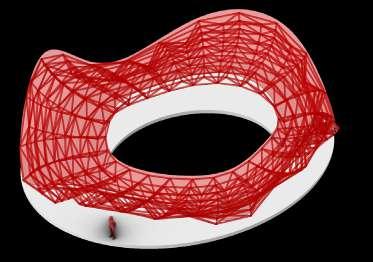

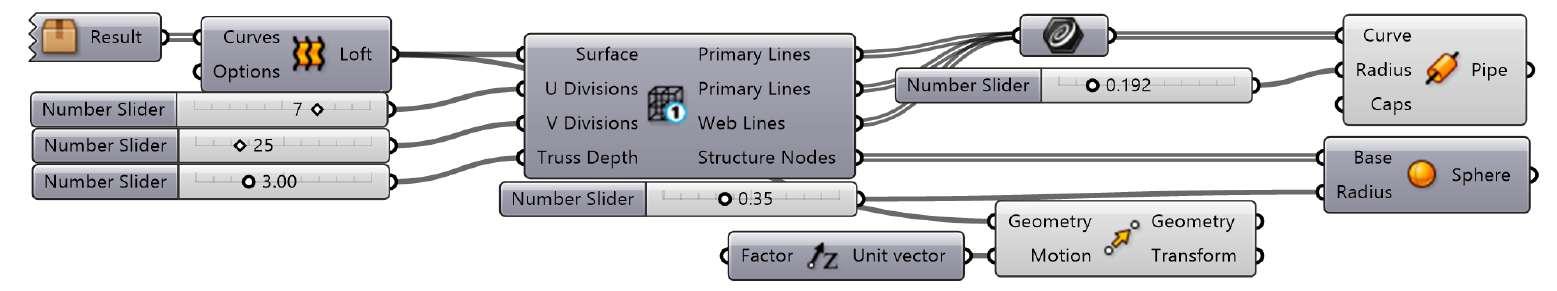

Space truss design

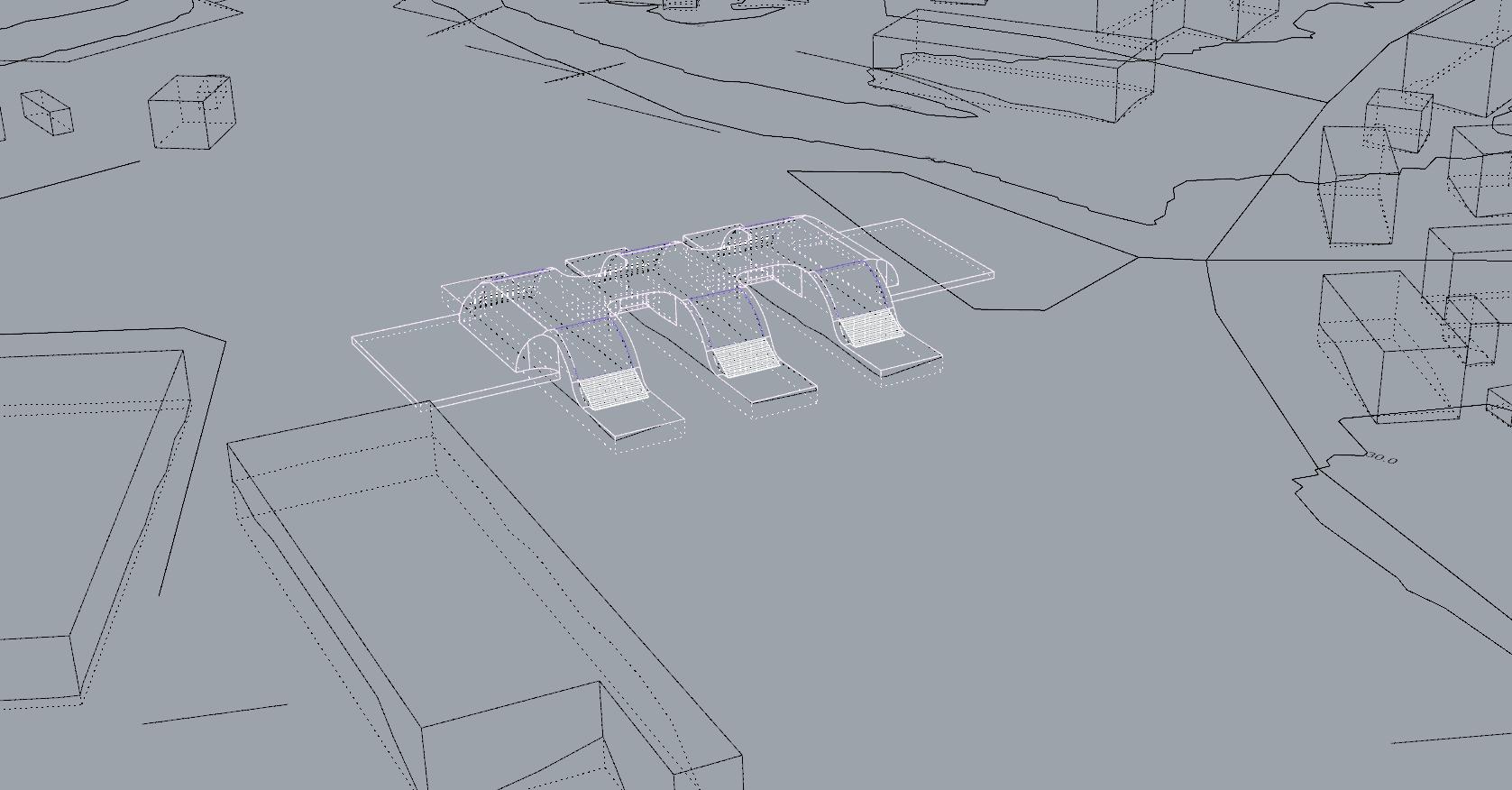

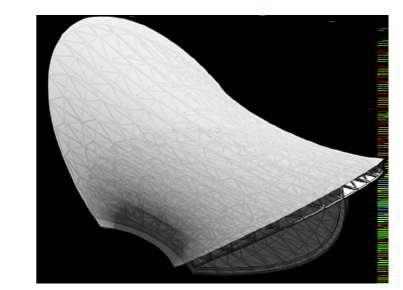

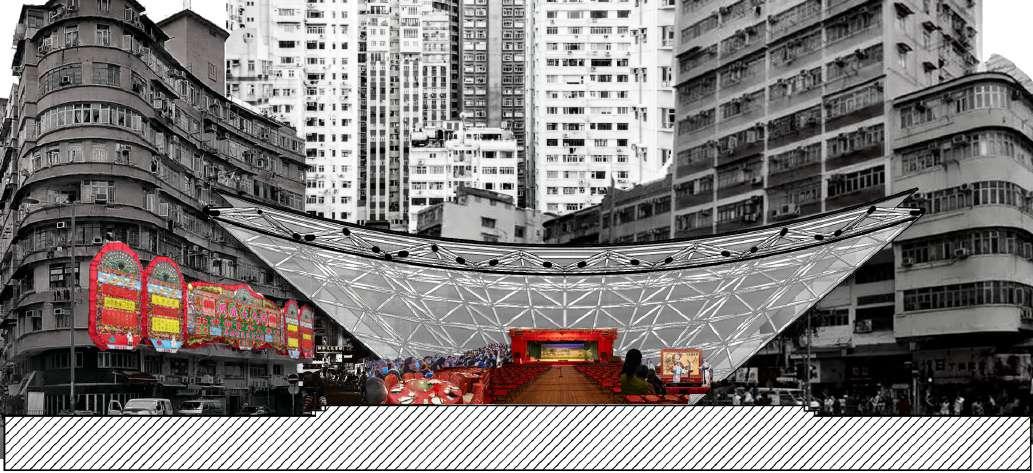

2.Structure generation-Undulating roof

1.Set up surface

2.Generate Truss system

3.Adjust part size

Lofting the surface to generating the overall pavillion shape.

Space truss structure code fransfers the lofted surface to lined forming the shape of the pavilliobn in points and lines format.

Join curve joins the Z axis line and X axis line together to form the outer frame

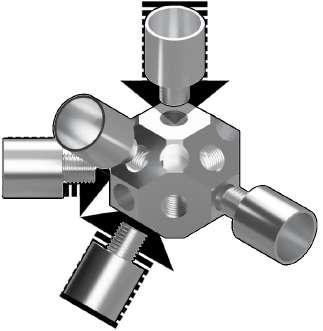

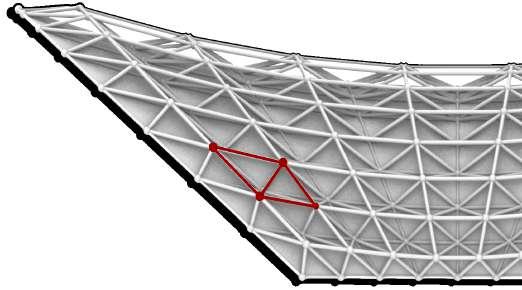

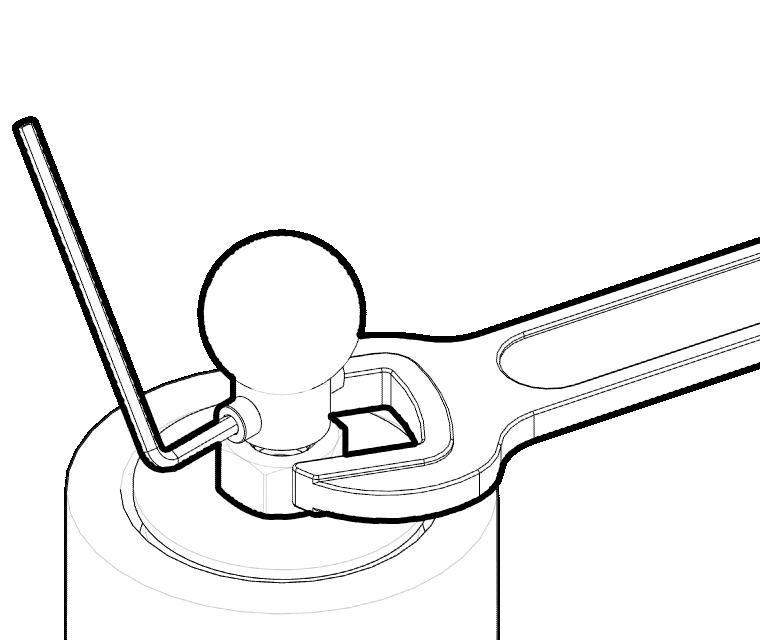

■ Testing the pipe and node to simulate the hub and bamboo joint and where location of both node and hub. At the same time this can also show the lengths that the bamboo needs to be in preparation toward the possible model assemblies.

Selected attempt

2.Aim of design

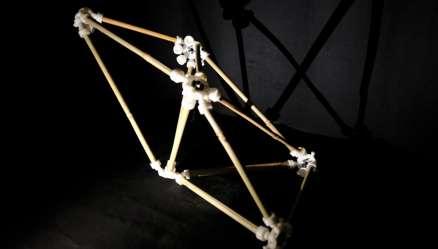

■A section of the full scale theatre was pulled out and simplified to tial with the components potentials in response to the design theory. The scale was then further simplified to create a 1:1 scale model using the developed component. This results in a 1.8 meter high 1:1 scale assembly.

Arch space

■The chosen design is a large spatial area formed using the space truss code along side the warren truss system.

■This section was randomly chosen to explore its potential for standalone assembly, testing its ability to self-stand and reach capacity.

Assembled prototype

Initial prototype

Showing node potential

Testing model

Testing model

Render of section of full scale model

3

8-Connecting Hub

The triangle prism is then built section by section once the shape is formed the components will lock in place

As the structure gradually builds up, gravity and the weight of the top of structure will begin to apply pressure on the foundation which will then form the structure and stand on its own Step 1

Building the foundation of the model. This

6-Connecting Hub

●

●

●

1:1 Model at the bartlett fiftheen show