PRODUCTS

PLUS REPOWERING GIVES NEW LIFE TO AGING ARRAYS BATTERY INTEGRATORS ADDRESS NOISE ISSUES RISING STARS MAKING A DIFFERENCE THIS YEAR

JANUARY 27–28, 2026 | HONOLULU,

HI

More than just the largest clean energy event, RE+ is a catalyst for industry innovation designed to supercharge business growth in the clean energy economy. Co-located with Solar Power International, Energy Storage International (ESI), RE+ Power and RE+ Infrastructure.

Best-In-Class Free Air separation (1.525” between conductors) NEC 310.17 compliant • Fits up to (20) conductors, sized up to 1250 kcmil Tiers adapt to different cable sizes • Tool-free snap-together install

First Word Staff

EDITORIAL

Editor in Chief

Kelly Pickerel kpickerel@wtwhmedia.com

Managing Editor

Kelsey Misbrener kmisbrener@wtwhmedia.com

Senior Editor Billy Ludt bludt@wtwhmedia.com

CREATIVE SERVICES & PRINT PRODUCTION

Art Director Allison Washko awashko@wtwhmedia.com

AUDIENCE DEVELOPMENT

Director, Audience Growth

Rick Ellis rellis@wtwhmedia.com

Audience Growth Manager

Angela Tanner atanner@wtwhmedia.com

MARKETING

VP, Marketing Annie Wissner awissner@wtwhmedia.com

Webinar Manager Lindsey Harvey lharvey@wtwhmedia.com

CUSTOMER SERVICE

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative

Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative

Trinidy Longgood tlonggood@wtwhmedia.com

LEADERSHIP

CEO Matt Logan mlogan@wtwhmedia.com

SALES

Ashley N. Burk

737.615.8452

aburk@wtwhmedia.com

Jami Brownlee

224.760.1055 jbrownlee@wtwhmedia.com

Daniel Glazier

773.835.0800 dglazier@wtwhmedia.com

The U.S. solar industry tries cautious optimism

It doesn’t feel like RE+ was just a few months ago. Frankly, by 2025 standards, that ought to be an eternity. We went to the show with the expectation that this one would be different than the jovial, frenetic shows of years past. And it was different, but not by any drastic measure. 2024 was a landmark year with a record number of RE+ attendees and a future painted by solar subsidies and a new wave of domestic manufacturing. Sure, attendance was down at RE+ this year. But more than 37,000 people still showed up. Compare that to the 40,000-plus from last year.

Optimism, whether performed or genuine, was the overwhelming impression we got from talking to people on the show floor. There’s still demand for solar whether federal subsidies are active or not, and while they still are, solar demand remains at an all-time high. Separate from incentives, the industry is selling itself on the ability to deploy solar significantly faster than other forms of new electricity. Energy costs are rising at astronomical rates, in large part due to new AI data center demand. Some solar developers are even being commissioned to build projects alongside these energydevouring data centers, shifting the original purpose of solar from decarbonizing and electrifying the grid to trying to keep pace with new energy consumption patterns.

Solar is now tangled in a mess of fiber optic and PV cabling. This technology was legitimized for its economic advantages in addition to its environmental benefits. But the electric snake is eating its own tail

so a person can generate an uncanny image through a generative AI platform at the cost of the ozone layer.

Solar is still crucial. In fact, with every passing day, it’s more important than it’s ever been that solar PV connects to the grid. Choosing a fossil fuel alternative would only threaten the conditions of our environment at an even faster rate. There are many people still striving to make solar the primary source of electricity in this country, despite growing demands on the grid, despite monumental policy headwinds, despite rising costs of living. These people are streamlining the solar development and construction process; they’re advocating in local, state and federal policy venues for better legislative conditions for solar; they’re striving to make their businesses ideal places to be employed; they’re ensuring the public understands the benefits of this technology.

We’re recognizing a few of these Rising Stars in this issue of Solar Power World, along with this year’s collection of Top Products that are advancing the industry at both the small- and large-scale. To all the innovators and ground-breakers: We hope you know that your work in this industry is valued, because without it we wouldn’t be writing these stories in the first place. SPW

Billy Ludt

Senior Editor bludt@wtwhmedia.com

Industry advocates pivot

Solar advocates turn focus to state policy efforts

Panels

A look into the status of critical minerals for solar

Inverters

EG4’s DIY-centric inverters and batteries go mainstream

Mounting

Alternative mounting options for commercial rooftops

Storage

BESS industry takes steps to limit noise complaints

Solar Power World gathered expert judges for the second-annual Top Products contest. The winners in large-scale and residential categories range from inverters to software solutions. Read the full list, including Honorable Mentions, in this issue’s special section. PAGE 33

Solar Power World’s 2025 collection of people making a difference in the solar industry, as nominated by their peers. PAGE 49

Solar projects have the potential to last for 20+ years, but repowering in their middle age can boost power production and efficiency and update technology to match the times.

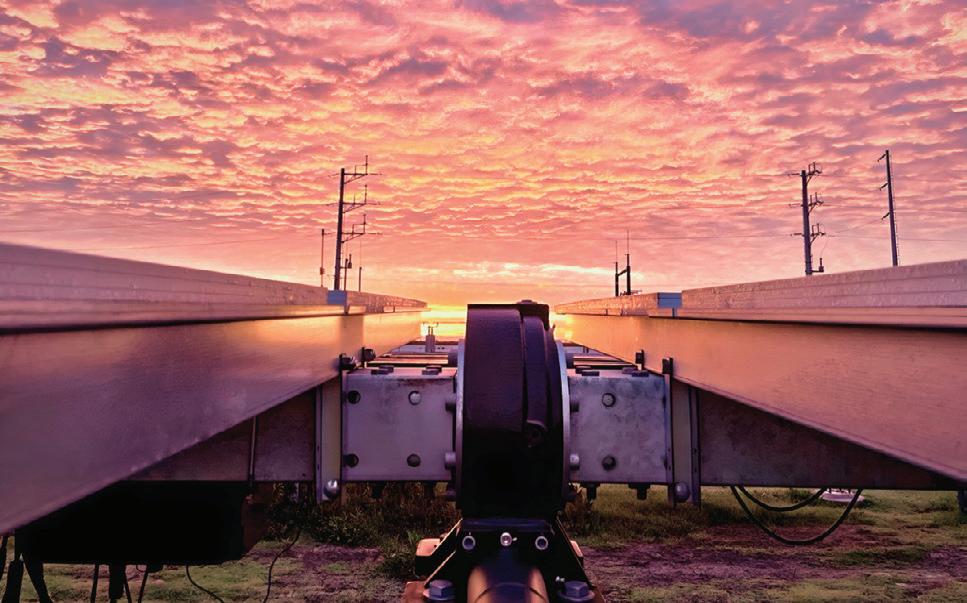

Burns & McDonnell

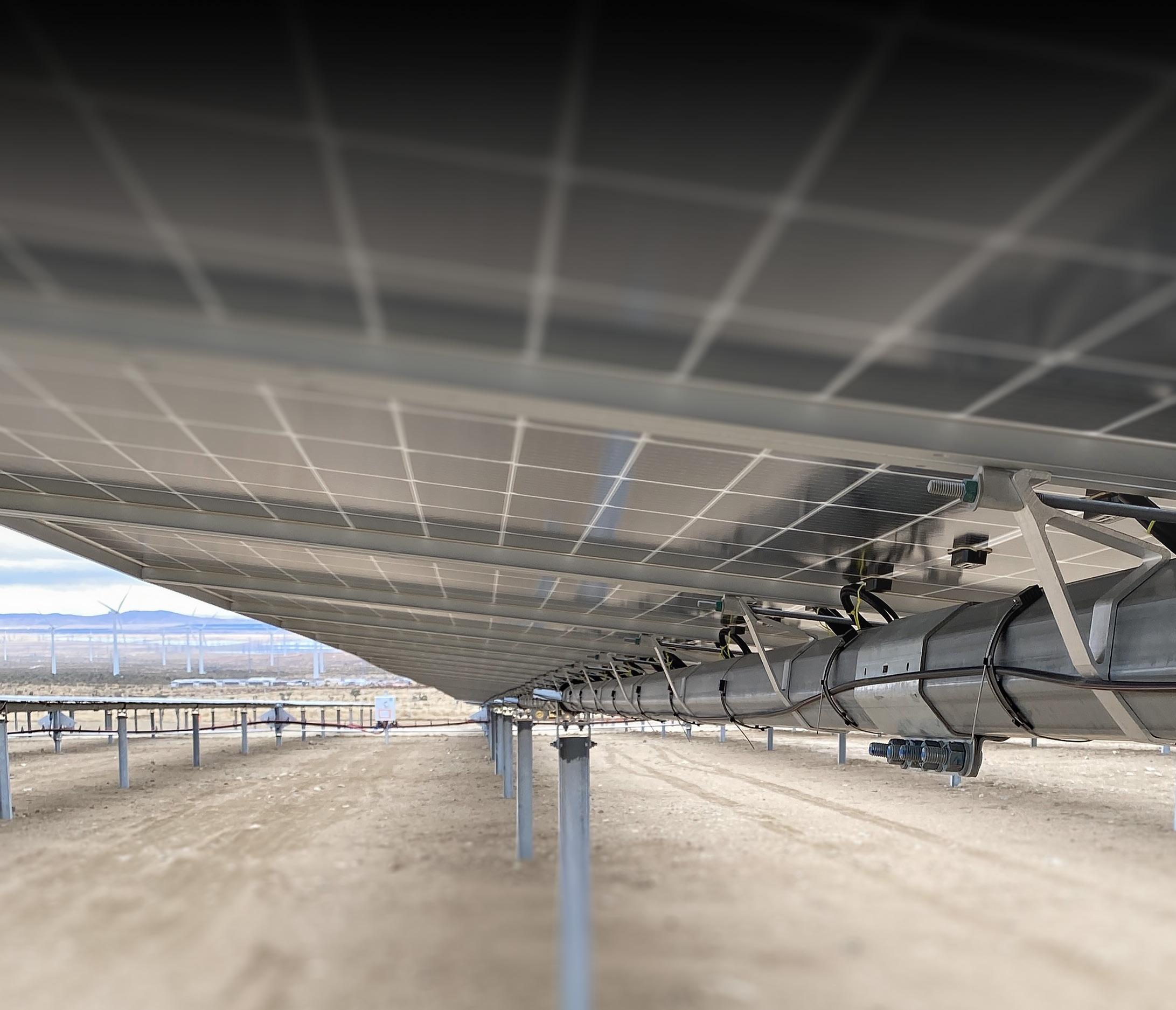

AGING SOLAR PROJECTS FIND NEW LEASE ON OPERATING LIFE WITH repowering

Promising that a solar project will operate without interruption for more than 20 years is a selling point for the technology, but it isn’t entirely truthful. Certain components, including solar panels, are often warrantied for 20 to 25 years and can feasibly continue generating energy at incrementally lower efficiencies as they age. However, PV inverters have the demanding task of converting the sun’s rays into useable electricity and only come with five-, 10- and, on rare occasions, 15-year warranties.

Inverters are often the components on an array that need fixing, but they aren’t the sole culprit in system underperformance. Solar panels can degrade when damaged by microcracks

or hail impact. At higher megawatt ranges, some older tracker projects experience actuator faults, halting the sun-following movement that grants them additional generation.

Many projects are reaching their middle-age of operation, and legacy components aren’t the easiest to source if they malfunction. So solar manufacturers are building product lines specifically for repowering older projects and imploring installers to learn the skillset of reviving downed arrays with newer hardware.

Downtime on a solar project means someone’s losing money, but repowering efforts can lead to renewed levels of efficiency and many more years of high performance.

“There’s no one magic bullet solution that really fits everything,” said Kyle Burns, electrical engineer at large-scale solar EPC Burns & McDonnell. “It’s really on a case-by-case basis. There are a bunch of tracker manufacturers and a bunch of module manufacturers and a bunch of inverter manufacturers. There’s so many permutations in between there, between different equipment vendors, that there is a lot of specialization on each individual project that makes each one so different.”

A sea of string inverters

Brandon Davis, sales director of distribution at SMA America, said residential solar projects installed 10 to 15 years ago primarily used string

BILLY LUDT • SENIOR EDITOR

inverters. Their popularity fell when rapid shutdown requirements were adopted and the market shifted to using microinverters and optimizers. Now, those warranties on older string inverters are either sunsetting or inactive.

“I’ve seen various testaments that 400,000 inverters need to be replaced in the next five years,” Davis said.

String inverters of that era were heavier, likely didn’t have system monitoring and lacked modern safety features, like arc fault and ground fault circuit interrupters. They also had lower power classes than the string inverters of today.

They’re not easily replaced nowadays, Davis said, because many residential installers have worked mostly with microinverters and don’t have the string inverter skillset.

The difficulty of replacing components on an existing rooftop solar array depends heavily on what project records have been kept. If there are project records, then a technician will have a better idea of how everything is laid out. If not, then there’s a lot of troubleshooting ahead.

Technicians can work with manufacturers’ applications engineers by sending existing plan sets to determine which inverter product is the right fit for replacement and what else might need modified. It can save someone from tearing up a whole array, instead of just fixing what needs replaced.

SMA’s solution for replacing older string inverters on residential arrays is the Sunny Boy Smart Energy, a hybrid inverter capable of working at the lower power classes of legacy string inverters. The Sunny Boy has monitoring and backup capabilities that weren’t available with previous inverter models.

“Yes, it takes time, and yes, you’ve got to learn, and there’s iteration in doing it,” Davis said. “But once you get through three to five projects, you can start to take some of the stuff that we have as a product and actually upsell. Give customers more features, more value, more benefit and make a little more money on something. Take something that feels like a headache and turn it into an opportunity.”

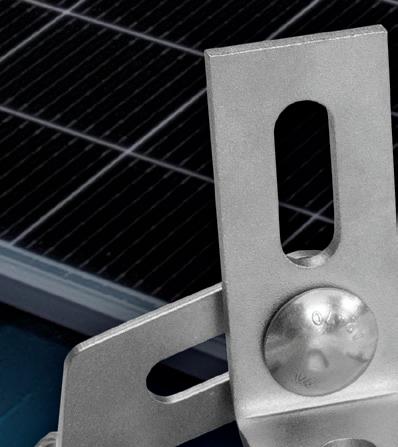

Kinematics is repowering older solar tracker projects with updated controls and actuators. Kinematics

Remedying past faults tenKsolar famously ceased production of its hardy all-in-one solar module and racking product in 2017 after the kitted technology experienced widespread microinverter failures. Five years later, tenKsolar returned to market under new ownership and a new name: Global RAIS.

Global RAIS is reintroducing tenKsolar’s interconnected-cell solar module and racking product in phases, and one of its early goals is repowering those faulty microinverters. The company partnered with inverter manufacturer NEP to modify its 800-W microinverters for repowering purposes.

Greg Cox, co-founder and president of Global RAIS, estimates that about 20% of microinverters on tenK projects have failed, representing about 90,000 microinverters that need replacing.

Many tenK projects have a microinverter architecture different from other flat rooftop projects, because they were grouped together in what is called a redundant inverter bus (RIB). That orientation makes them operate as a single unit. In the initial repowering projects, old failing RIBs were removed and replaced with NEP microinverters. Those legacy solar projects now have the bonus of microinverterlevel monitoring showing real-time production.

“We’ve seen systems that were heretofore producing 30%, 40% of their capability, back up to 100%,” Cox said.

Some of these arrays being repowered date back to 2011.

“If you’re an owner of an array, you’ve got two options. You can either try to repower it, or you can scrap it and put something else there, which is expensive and, honestly, it doesn’t make sense because the modules are still producing power,” Cox said.

Trackers out of rotation

The economies of scale are much heavier in the utility solar market. As with every solar project, malfunctioning components are a cause for downtime, but solar trackers introduce new wrinkles in array upkeep.

Over time, slew drives, the mechanical component that rotates single-axis solar trackers, can experience slowdown or fail entirely. Some legacy manufacturers have folded, so their drives are no longer available for replacement.

The United States alone is home to millions of rows of solar tracker projects. Matt Schneider, a utility solar consultant and founder and principal of Solar Perspectives, estimates that 1 MW of a downed solar project is worth

$35,000 in annual losses. At a larger scale, independent power producers are beholden to the utilities their projects are interconnected to, and if they don’t meet the generation in a power purchase agreement, they can face penalties and even pay for replacement power to make up for the loss.

“Over 10 years, a repower will pay for itself 10-times over,” Schneider said. “It’s all economics.”

Kinematics, a longtime motion control manufacturer, has geared some of its product line to repowering

underperforming solar tracker projects. Kinematics has offered both slew drive and tracker control replacements on existing projects, an effort that was bolstered by acquiring tracker control company P4Q earlier this year.

“In the last two or three years, we have doubtless been part of this market passively, inasmuch as: If there’s a part that fails, somebody’s going to get a spare to do the replacement,” said Magnus Asbo, chief product and strategy officer at Kinematics. “What is changing is that the volume is enough that we want to

Operations

participate more directly and bring some expertise to it.”

Kinematics developed actuator and tracker control systems capable of replacing third-party components. For repowering controls, each tracker has a control unit that connects to a larger network control unit. All of those will be replaced, but by introducing newer controls, legacy tracker projects can be updated with features like hail stow angles, backtracking and overcast light optimization.

Asbo said there is more than 1 GW of U.S. solar tracker projects needing some degree of repowering — a number expected to grow annually.

Repowering ahead

Replacing components on a solar array won’t always be the solution for system owners. In some cases, repowering one component can cascade into replacing others, like inverters incompatible with certain modules. Modern hardware, like large-format solar panels, can affect the civil aspects of existing arrays. Sometimes a project’s return on investment makes more economic sense without repowering.

While the demand for repowering projects is increasing, the practice of building solar has also become more standardized as utility-scale arrays grow exponentially. Those early arrays look more like boutique endeavors compared to where the market is now.

Future O&M and repowering needs for the projects going in the ground today may be more one-size-fits-all.

“People are getting much more experience with designing solar. It’s becoming a much more mature industry,” said Adam Doiron, engineering and project leader at Burns & McDonnell. “I think the challenges are going to decrease from a scale perspective.

“If you told somebody that you were in solar for utility-scale 10 years ago, you were talking about 10-MW systems, and now 10 MW is just a small commercial site,” he continued. “It really changes things based on just the volume that exists now vs. a while back. And, usually, the repowering efforts are for older systems that were just a little more technically unique at the time.” SPW

Technicians replace faulty microinverters on a tenKsolar project. Global RAIS has partnered with NEP to address widespread microinverter failures on the legacy PV technology.

Global RAIS

Billy Ludt • Senior Editor

Solar microgrid powers LA Clippers’ brand-new home arena

Asold-out event at the Intuit Dome in Inglewood, California, seats nearly 18,000 people. The Los Angeles Clippers and headlining musical acts regularly play within its walls, and even if the grid goes down, the dome can keep the show going, because it’s powered by a solar microgrid.

Solar PV installed on Intuit Dome’s curved roof and two neighboring parking garages produces 2.5 MW of power paired with 12 MWh of energy storage. In a grid outage, the system can power the arena for two-and-a-half hours just from stored energy.

"I've done stadiums, big convention centers, a lot of unique things," said Scott Williams, executive VP of Baker Electric, which installed the project. "We pride ourselves on taking on the hard jobs, and this was definitely a hard job."

Live from Inglewood Intuit Dome officially opened its doors to the public in August 2024, just in time for the next NBA season. As its name

suggests, the all-electric, LEED Platinumcertified arena has a rounded exterior covered in gridshell. On the rooftop, the Intuit Dome logo is prominently framed by clusters of solar modules arranged in the shape of a nautilus shell. That rooftop array is accompanied by solar carports on the south garage where coaches and players park and another separate parking deck.

Baker Electric, an employee-owned electrical and solar contractor based in Escondido, was hired for the Intuit Dome array after the first installer exited the project. Baker had spent several years on the original public bid for the solar + storage project, and was one of three remaining companies vying for the contract, but initially wasn’t selected for the job. Development carried on in the interim, so when Baker returned to the project, it was working on a shortened timeline.

This first-of-its-kind microgrid meant there weren’t exactly examples of other sports arena solar + storage setups to model from.

“You don't have any load data. You don't know what their economics are truly going to look like,” said Nick Jackson, senior director of commercial solar at Baker Electric. “You’re working with a bunch of assumptions and hypothetical analyses and not necessarily hard 15-minute green button data from years of usage — of the customer knowing exactly their energy costs.”

Baker collaborated with the project’s architects, electrical engineers and mechanical teams to design a system that would fit the Intuit Dome’s energy footprint. Then it was a matter of building the array.

“It's a very complicated project. There was really no solution for the array on top of the dome, because it's a curved surface,” Williams said.

The challenge was to find racking that could hold flat solar modules in place along a curved roof — a roof that is between a 20 to 30° slope at its edge. Forty-five days after being contracted, the company custom-fabricated an attachment

Baker Electric installed 2.5 MW of solar at the newly built Intuit Dome. Paired with energy storage, this arena has its own microgrid. Baker Electric

that would work for the roof when paired with IronRidge racking.

Baker’s electricians were just some of many tradespeople working on this new-build arena. Once the rooftop array layout was finalized, ironworkers started laying metal plates and Baker followed with solar racking. Installers placed more than 3,000 posts along the underconstruction Intuit Dome roof, which were then encapsulated in foam and covered in roof membrane. The posts had to work where they were placed, because they weren’t moving after that.

“I don't feel … people really understand [the difficulty of] trying to apply vertical posts on a curved surface that's changing, basically, two stories of elevation, across that entire dome,”

Williams said. “When you do it with something flat, that's a lot easier.”

Modules were assembled into tables at ground-level and hoisted more than 200 ft to the top of the dome. The array is composed of LG 440-W solar panels, SMA Sunny Tripower Core 1 string inverters and three Tesla Megapack 2XLs for energy storage. Baker subcontracted Teichert Solar to manufacture and install carports on the adjoining parking decks.

Building a legacy of sustainability

The same posts keeping the solar modules in place on the Intuit Dome are also holding up its sky-facing logo. When the sun sets, the lights beneath the sign illuminate the roof and the PV surrounding it.

“In the construction industry, we build a lot of nondescript properties that get used by a select few and appreciated by none,” Jackson said. “But whenever there's an opportunity to build a stadium or an arena or anything where the general public has an engagement with it on a regular basis, it's on TV, it's in the news, you now get to put your name on that for the entire life of that property.”

Since completing the project, Williams said Baker has been fielding inquiries from other sports teams about bringing solar to their stadiums. He also regularly watches the Clippers play at the Intuit Dome under the stadium lights his team helped power.

“Personally, it's definitely an iconic project of my career that I'll always talk about,” he said. SPW

The solar project atop the Intuit Dome required a specialized combination of racking and mounting components to attach to its roof. AECOM

kelsey misbrener • managing editor

The Trump Administration’s attack on renewables has rocked the solar industry this year. The full impact of anti-solar legislation and executive orders may not be fully understood until 2026, when the residential tax credit ends, material restrictions begin and start-construction deadlines arrive for the large-scale ITC.

Instead of abandoning all hope, solar advocates are shifting focus to state action.

"Federal government, Congress, they're walking away from these opportunities. But that doesn't mean there isn't an opportunity here," said Sachu Constantine, executive director of Vote Solar. "We've long made the case that the actual decisions about deployment, about what resources go into our grid, are made at the state-level."

It's not the first time strategies have shifted. During Donald Trump's first presidency, a "blue wave" in 2018 awarded many governor seats to Democrats. Solar advocates zeroed in on state policies then, mostly pushing for renewable portfolio standards (RPS) requiring utilities to add solar to their portfolios. Now, enormous data center energy demand combined with overall home electrification are creating new, urgent priorities.

"It's a more mature industry than it was back then. RPS is not really the driving factor these days," said Sean Gallagher, senior VP of policy for SEIA. "It's economics and the need for speed, and the attractiveness of solar and storage in terms of both affordability and reliability."

State budget sensitivity

HR1 didn't just decimate solar incentives. It stripped money from the states for crucial programs like Medicaid, student loan funding, SNAP benefits and school meals. States will be pressed to find money for many social programs impacted by HR1, so funding for renewable energy may be hard to come by.

Luckily, many efforts that could help reduce the overall cost of solar may not cost states much at all.

"A lot of this is not brand new, but it's sort of a renewed emphasis on these nuts and bolts, things that states really can do

to both facilitate and expedite bringing more resources online," Gallagher said.

SEIA outlines some main objectives for all solar markets in its “Post-HR1 State Policy Roadmap.” For the larger market, these include enforcing interconnection timelines by penalizing utilities not in compliance, developing "flexible interconnection" policies to bring more solar online without requiring major grid updates and streamlining requirements for solar + storage projects on state lands.

On the small-scale front, SEIA is especially focused on helping residential installers navigate a post-25D market. The group will encourage AHJs to adopt automatic instant permitting via SolarAPP+, ensure policy is in place for companies to adopt third-partyownership structures to capture the 48E ITC and work to expand statewide virtual power plant options.

"How can we really reduce cost, particularly in the residential sector, so that we can transition solar from a product that's sold to a product that's bought?" Gallagher said of SEIA’s focus.

Early state leadership

A few governors have already taken a stand to communicate that their states are still open for solar business.

"It's what we've seen historically — when there's been disruptions at the federal level, the leading states will step in and ensure that their trajectory toward their goals is at least maintained, if not further supported," said Kevin Cray, VP of existing markets and regulatory affairs at the Coalition for Community Solar Access (CCSA).

Colorado Gov. Jared Polis issued executive actions over the summer to help residents determine which renewable energy tax credits they qualify for, as well as ensure state agencies cut

red tape and prioritize renewable energy projects.

"We must provide confidence to the clean energy industry that Colorado is open for business as tariffs, shifting federal rules, supply chain crunches and market uncertainty risk delaying investment in these affordable domestic energy resources," wrote Polis in his executive letter.

CCSA worked directly with Polis' office to offer recommendations for supporting solar in the face of federal uncertainty and was pleased to see its main points reflected in the letter.

"Some of the recommendations around flexible interconnection and stuff like that were very specific, and I think create some of that near-term certainty needed for investments to still move forward," Cray said.

In Arizona, Gov. Katie Hobbs put forth an executive order in September called "Removing Barriers to Delivering Affordable Energy for Arizona," with goals of streamlining permitting and speeding energy deployment, including renewables. It establishes the Arizona Energy Promise Taskforce, which will develop plans to facilitate large-scale growth and expand Arizona’s clean energy economy.

SEIA and CCSA see these actions as great examples for other states to follow, especially Colorado's specificity.

"That's something that we're certainly running state to state with at this point — trying to get other governors, administrative agencies, etc., to take similar steps as far as some of the exact provisions of the executive action," Cray said.

Playing defense

While states that already lead on solar will continue to do so, influential utilities and oil and gas companies in others

We've long made the case that the actual decisions about deployment, about what resources go into our grid, are made at the state-level.

will be looking to take full advantage of the support of this "drill, baby drill" administration. Solar advocates will need to play defense to mitigate the damage.

"What's unfortunate in some of those red states is that the big actors — let's say the Duke [Energys] of the world, the Georgia Powers, the Southerns, FPLs — they know that solar is the best option. But they also know that in this environment, with the rhetoric coming out of the federal government, they can continue to try to cram some gas into the rate base," Vote Solar's Constantine said.

"Wherever we can, we want to get into the planning process early — the Integrated Resource Plans, where the regulators approve or shape the procurement plans for the utilities,” he continued.

Some of those negative actions are already popping up. Although Arizona's governor supports solar power, the Arizona Corporation Commission unanimously voted to repeal the state's RPS the month before she issued her executive order. And the Public Utilities Commission of Nevada recently voted to approve a new rate design that changes the solar netmetering structure to 15-minute netting and adds mandatory demand charges to all customers. Instead of balancing solar production against usage over a full month, customers will now only get credit for excess energy within each 15-minute window. SEIA said the decision "discourages private investment in reliable, affordable, clean energy at a time when the grid needs every electron it can get to power Nevada’s economy."

Still, the country needs massive amounts of new energy on the grid, and it needs it quickly. The U.S. Energy Information Administration is forecasting continued average electrical consumption growth of 1.7% through 2026, after growth was nearly flat from 2005 to 2020. Solar has consistently been the fastest-growing source of electricity to meet that demand. Advocates plan to cut through the presidential administration's rhetoric and stick to those facts to win as many policy battles as possible in this trying time.

"We have to bring a real clear focus now on the economic proposition that solar provides and the speed to power that we can do. We have our work cut out for us. But, as you saw at RE+, I think the industry feels like we're going to figure out a way to manage through this," Gallagher said. SPW

• Fast and easy placement with 7" scratch resistant wheels.

• Head adjusts for pitches 7/12 to 18/12. Folds flat for easy storage.

• Lengthen by adding 6' ladder sections. 12" rung spacing.

• Fully OSHA compliant when using a proper safety harness.

• 3" toe engagement. Replaceable rubber bumpers.

• Powder-coated aluminum construction.

KELLY PICKEREL EDITOR IN CHIEF

The topic of critical minerals is common in the news lately, especially when parsing the latest escalations in the U.S.-China trade war. When the U.S. government imposed high tariffs earlier this year on Chinese goods, China responded by placing export restrictions on certain crucial metals. One of those metals is tellurium, a rare element needed for cadmium-telluride (CdTe) thin-film solar

panels, and which China controls 75% of global supply.

While silicon-based solar panels are overwhelmingly the dominant choice installed globally, thin-film makes up nearly one-quarter of U.S. manufacturing capacity, thanks to First Solar’s three manufacturing hubs in Ohio, Alabama and Louisiana. First Solar is the largest — and, essentially, the only — CdTe thin-film

manufacturer in the world, with additional solar panel factories in India, Malaysia and Vietnam. The company deposits cadmium and telluride on glass to produce efficient solar panels predominantly used in the utility-scale market. Although not the largest market-holder globally, First Solar’s CdTe solar panels are important to the U.S. market and make up a significant chunk of its installed utility-scale capacity.

Panel Technology

That’s why export restrictions on one of CdTe thin-film’s key ingredients could pose problems for CdTe manufacturing if the trade war continues. Here’s what we know about the world’s supply of tellurium, and how First Solar is navigating the market.

Global supply of Te

Tellurium (Te) is a rare metallic chemical

element first discovered in the late 1700s in a Transylvanian gold mine. The element is named after the Latin word tellus meaning “Earth,” and it is considered one of the rarest stable solid elements in the Earth's crust. The United States designates certain elements as “critical” due to their high risk of supply chain disruption and importance to energy production, and Te is on the list

along with silicon, lithium and cobalt. Te is typically found as a “telluride,” combined with other elements.

The world’s supply of Te is largely recovered during copper refining, and treatment of 1,000 tons (2 million lbs) of copper ore yields approximately 2.2 lbs of tellurium. The world’s supply of tellurium is mainly used in CdTe solar panels and other thermoelectric devices.

Copper mining at Kennecott and Bingham Canyon Mine in Utah. Rio Tinto

Panel Technology

Since tellurium is recovered by mining copper, the Te supply for solar panels depends on a stable demand for copper. A 2022 article in the journal Resources, Conservation & Recycling estimated the maximum annual recovery of tellurium from copper refining at 1,930 metric tons. A U.S. Geological Survey report from January 2025 determined that 980 metric tons of Te was produced in 2024 — excluding U.S. production from two copper refineries that produce small amounts of Te.

A 1999 report prepared by World Industrial Minerals for NREL estimated that between 90 and 130 metric tons of tellurium is necessary for 1 GW of solar panels. Based on improved manufacturing efficiencies and processes over the last

25 years, the Resources, Conservation & Recycling article put those numbers closer to 57 metric tons needed for 1 GW of panels.

First Solar expects to have nearly 21 GW of global manufacturing capacity by the end of this year — 14 GW in the United States and 7 GW across Asia.

A review of that math: First Solar can make 21 GW of solar panels annually. The world only produced enough tellurium in 2024 to make 17.1 GW of solar panels. The maximum amount of tellurium the world could refine each year would produce 33.8 GW of solar panels — but China controls 75% of Te supply.

Could the solar industry be at risk of a Te shortfall?

A

critical time for solar panel production

Although First Solar doesn’t appear to be slowing down its production — the company is sold out through 2028 — the scientific community has been anticipating a Te shortage for years.

A 2011 New Scientist article stated that the Dept. of Energy expected a Te supply shortfall by 2025. North American mineral company First Tellurium (formerly known as Deer Horn Capital) predicted in 2018 that changes in copper recovery and refining would affect tellurium availability, forcing refiners to look at gold and silver for worthwhile tellurides.

First Solar refrained from providing Solar Power World with comments on its telluride supply chains, but public announcements from the last few years do show that Te and other critical mineral supplies have been front-of-mind for “America’s Solar Company.”

An obvious big move is First Solar’s expanded relationship with First Tellurium, whose advisory board is peppered with former First Solar executives. First Tellurium is developing a project in British Columbia that is the only known property in North America with a resource for silver-gold-tellurium. The company is also exploring the prospect of tellurium in Colorado, where sampling at a site southwest of Denver found the highest tellurium grades in a nationwide exploration program.

Rio Tinto has mined copper from its Kennecott operation in Utah for over 120 years and began producing tellurium for First Solar there in 2022. The site likely contributes enough Te for less than 1 GW of First Solar panels annually, but any domestic supply is welcome.

First Solar has also long focused on solar panel recycling, which will help with available tellurium levels. The company has operated recycling plants at its manufacturing facilities since its first days, First Solar global recycling director Sukhwant Raju told Solar Power World in 2018.

“There is a finite amount of tellurium,” he said. “They wanted to make sure there was a way to recover the valuable stuff so it becomes sustainable growth for First Solar. It’s

A copper telluride filter cake at the Kennecott tellurium plant. Rio Tinto

not just about being green, but how do we stay sustainable in the long-term?”

A First Solar environmental report from 10 years ago estimated that 12.5% of its Te supply came from recycled materials — a number that has undoubtedly increased in the last decade with improved recycling efforts and more recycled panels entering the circular economy. The company also says that 1 kg of telluriumbased semiconductors can be recycled 41 times — producing clean energy for over 1,200 years beyond its initial solar panel iteration.

So, could there be a Te shortage, especially if China restricts exports of the valuable metal? It’s possible there may be less “new” tellurium available for CdTe solar panels if mining efforts stay the same while demand for First Solar panels increases. But First Solar has been taking steps to avoid this dire situation, whether through new mining endeavors or improved recycling processes.

America’s top solar panel producer will probably be just fine. SPW

Rio Tinto installed First Solar CdTe solar panels outside its Utah copper mine. Rio Tinto

Kelsey Misbrener • Managing Editor

EG4 meets the moment in solar with budget-friendly off-grid products

Catching the solar industry's attention sometimes means spending money on an enormous booth at RE+. Other times, word of mouth can bring a brand to the forefront without too much flashy marketing.

Hybrid inverter + battery storage manufacturer EG4 Electronics is one of those companies the residential solar industry can't stop talking about right now — and the transformation from a modest, far-flung RE+ booth in 2024 to hefty square footage in the main exhibit hall in 2025 reflected that come-up.

"They weren't really on my radar, and then I just kept hearing people ask about it, ask about it, ask about it. So then it makes you go, 'OK, well, what is this?'" said Gage Mueller, senior energy consultant at Texas-based Solstice Solar.

EG4 and its parent company Energy Access Innovations (EAI) were created in rural Sulphur Springs, Texas, by CEO

started his solar journey in the DIY community, installing a fully off-grid system on his family's home in 2013. From there, he opened a long-tail solar installation company in West Texas. Ever the entrepreneur, he gave the company to one of his brothers to start a new endeavor — a solar product distribution company called Signature Solar that sold the products he wished he had access to at his installation firm.

Focusing on the DIY market meant fielding many questions from homeowners, so Signature established a call center with NABCEP-trained customer representatives.

"We were taking over 10,000 consultative phone calls a week with people building systems. The idea for an OEM new-generation storage manufacturer came within the first year," Showalter said.

He and his team noticed many of the residential solar products on the market weren't the best fit for its customer base. Many were tailored to the customers in the largest solar state of California — homeowners with relatively low energy demand, high energy prices and decent net-metering rates to sell power back to utilities (prior to NEM 3.0).

"When you define the problem by that market, it becomes irrelevant to the rest of the country, because the energy costs are much, much higher in California than the rest of the country, and people use less energy, so you end up with higherpriced hardware that isn't designed to put out high power," Showalter said.

So he set out to create a product that would work for a market like his hometown in Texas — high energy demand, lower but rising energy costs, and little to no incentive to export power to the grid.

James Showalter. Showalter

Workers assemble EG4 inverters at its factory in Commerce, Texas. EG4 Electronics

Partnering with a Chinese OEM called LuxpowerTek, in 2020 Showalter launched EG4 — which stands for "energy generation for everyone" — to close that gap he saw in the market. EG4 makes hybrid inverters such as the FlexBOSS, the 18k and 12k, as well as wall-mounted batteries. Showalter's DIY roots mean the products are designed with the off-grid solar customer at front-of-mind.

"We're an off-grid system that [was] designed to hook up to the grid. Most of the systems out there are grid-tied systems that they're trying to go back and add off-grid functionality to," he said. "Our inverter, for instance, can start a five-ton air conditioner right out of the box. That's not even a design protocol for most of the other battery ESS providers."

Installer experience

EG4 isn't the first to prioritize the off-grid or hybrid solar customer, but installers having issues with other manufacturers have found success with the company.

"The companies that I was using before, their service seemed to tank around the time EG4 was coming out, and EG4 service has been pretty spoton," said Rudy Wright, CEO of East Texas installer Wright-Way Solar Technologies.

The first generation of EG4's products weren't UL-rated or grid-interactive, and they also had quality issues, according to Wright and Landon Liles, VP of operations for West Texas Solar. But the installers say the company has addressed those problems in its current models.

"The RMA (return merchandise authorization) process is super simple on the very few issues that we have had with the inverters. But the batteries have been, I would say, foolproof," Liles said.

Aside from reliable service, the biggest draw of EG4 has been the low prices.

"Their 14-kWh battery hit the market at one-third of the price-per-kilowatthour of the one I was selling prior to that," Wright said. "I was willing to sell American-made at a 20 to 30% premium. But by the time you're at a 66% premium … I have to get off the boat of Americanmade and jump into China import."

West Texas Solar has had nearly 100% battery attachment rates on solar jobs for the past two years, with customers wanting more backup power as utilities pivot away from export compensation. EG4’s larger, low-cost battery checked those boxes.

"We realized that grid-tied-only was not working out for them, and assuming that utilities are going to buy your power back is a wrong assumption," Liles said. "We needed bigger battery banks that don't cost an arm and a leg."

Now, West Texas Solar is installing at least two EG4 outdoor-rated batteries on every job.

“Having it truly outdoor-rated allows us to take up a lot less space in the garage or on the walls, and we can put it under our ground-mounts, or kind of get creative with our placement of the batteries," Liles said.

The user-friendly elements of EG4's products are another selling point for West Texas Solar. Homeowners can click a button for pre-loaded settings that meet

EG4’s wall-mounted battery and hybrid inverter are gaining popularity in the residential market.

Inverter Technology

their needs, including nighttime battery use or self-consumption.

"From the installation to the commissioning to the support in the design, it's been good, and I hope it stays that way," Liles said. "I know that they are continually adding new products, and I hope there's compatibility with old products to new products. People want to add on to their systems — hopefully that all meshes well and it doesn't get too software-heavy."

2026 plans and FEOC

As the end of the 25D residential ITC approaches this year, budget-friendly solar products like EG4’s are only going to become more important.

"With the tax credit going away, with homeowners not wanting to rely on the grid anymore — now this is an affordable option, even without the tax credit," said Mueller of Solstice Solar.

At the same time, more residential installers may turn to third-party ownership financing structures to claim the 48E ITC — and will need to comply with foreign entity of concern (FEOC) requirements limiting products from China and other countries.

EG4 is working on options for both categories of installers going into 2026.

"A lot of companies are going to raise the price for higher FEOC compliance, and they're going to douse their 25D folks. We created a dual solution," Showalter said.

Last summer, EG4 opened a 310,000ft2 manufacturing facility in Commerce, Texas, to start assembling product in the United States. The company also acquired U.S. off-grid solar manufacturer OutBack Power to “combine OutBack’s legacy of engineering excellence with EAI’s global resources.”

In the fall, EG4 formed a supply partnership with LG Energy Solution to purchase 13.5 GWh of Michigan-made battery cells through 2030 that it will

Refined Features for Extremely Secure Cable Support

assemble into batteries at its Commerce facility for a "hyper-compliant" product, to be paired with its next-generation inverter. The company will still have Chinese batteries available for installers looking for cheaper options and not concerned with FEOC restrictions.

“We have a unified home EMS inverter and energy management platform, but we have a domestic content battery that's rigorously compliant that we can bolt on, or we have a Chinese battery,” Showalter said.

Despite its humble DIY-focused beginnings, EG4 is becoming a recognizable name in solar during this time of slashed federal incentives and waning utility compensation.

"I think that's what they initially started doing, was off-grid, and that's what their passion was. And they still carry that with them, but have realized that they can compete with everybody else too," Liles said. SPW

Billy Ludt • Senior Editor

Commercial solar racking goes beyond steel and aluminum

Commercial rooftop solar projects are built predominantly on metal racking, whether ballasted in place with concrete or mechanically attached to the roof. However, other types of materials have proven to be viable as the primary racking structure for flat-roof applications.

Some manufacturers have shifted away from extruded metals into specialty molded plastics or even incorporating concrete, which would traditionally be a ballast, into the racking itself.

Sun Ballast brought its proprietary concrete-racking technology to the United States in fall 2023. The company was founded in 2011 by Maurizio Iannuzzi, an Italian solar contractor, after he sought a simpler solution for the complicated flatroof market in Italy.

“He came up with the idea to integrate ballast and racking into this single component and actually started manufacturing it for himself, so he could install it and be more efficient,” said Edoardo Brignoli, CEO of Sun Ballast USA. “In the mornings, he was manufacturing

racking, and in the afternoon, he was installing them.”

The product Sun Ballast is a system of threes: it comes in three orientations (flush-mount, east-west and a 5 to 10° south-facing tilt), with three components (the concrete ballast-racking, a rubber mat to lay under and clamps to mount the modules) and in three weights (32, 64 and 96 lbs).

What makes Sun Ballast different from off-the-shelf concrete is how it’s cured. The concrete has a 5,000-psi mix, which is standard for use in weight-bearing construction projects.

“People learn the hard way that not all concrete is created equal,” Brignoli said. “It is not uncommon for us to run into jobs where installers or EPCs are having to go on a roof 10 years later, after the initial install, and basically scoop up sand, which used to be block at one point, but broke down with freeze-thaw over the years.”

The company is targeting the Northeast as a testing ground for Sun Ballast to prove it can withstand the region’s winters.

“We thought, ‘If we can figure out New England, we can pretty much figure out the rest of the country,’” he said. Sun Ballast is cast domestically, and since concrete is non-conductive, it is awaiting approval for UL 3741 compliance — which would allow contractors to satisfy fire safety requirements without installing rapid shutdown devices on the roof.

Plastic, polymer and fiberglass racking

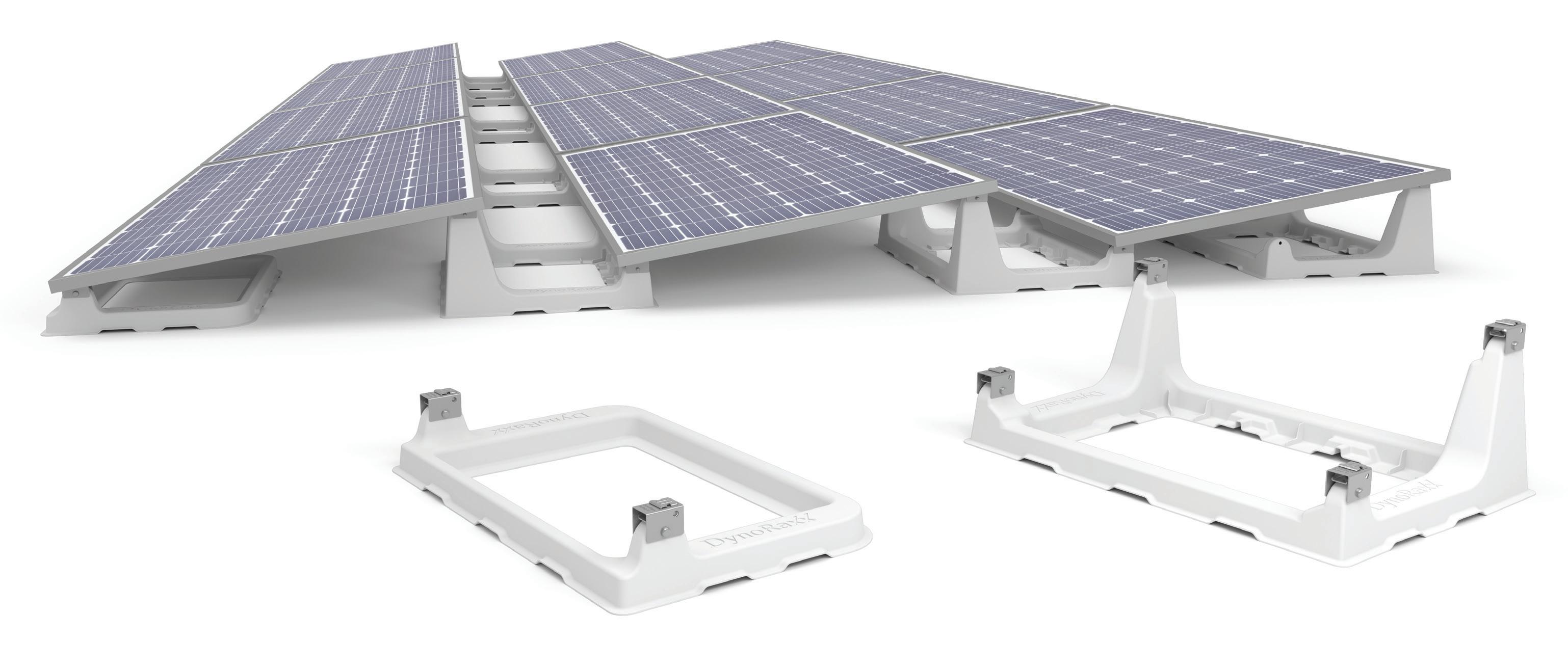

DynoRaxx first entered the solar mounting market in 2007 with a steel racking structure, but company reps found the assembly to be cumbersome. In 2011, it introduced a racking made from a proprietary molded fiberglass compound. DynoGrip Evolution Flat Roof System is a ballasted racking that is installed without using any tools.

Fiberglass material means the racking isn’t affected by thermal expansion like its metal counterparts. DynoGrip has been installed in regions with high sun

FastRack, a glass-reinforced nylon solar racking from Sollega.

Mounting Technology

exposure, and is UV- and fire-resistant, meeting the UL 2703 rating. The racking elevates ballast blocks half an inch from the roof for air circulation and water drainage.

“In most instances, where solar was a retrofit into a building that’s been existing, they don’t really take into account placing modules and how much that affects drainage on the roof,” said Nathan Rizzo, who invented the racking. “We’re not damming or stopping the natural flow of water on the roof.”

In its 14 years on the market, DynoGrip has only undergone one change, which removed fiberglass rails and replaced them with tool-less clamps pinned to the upward supports for mounting modules.

“It speaks pretty well to the product that we initially designed and our goal with it — that it really was the evolution of solar and it didn’t require a lot of iterations,” Rizzo said.

DynoGrip racking is manufactured to be stacked on one another and palletized for simpler logistics.

FastRack, a modular rail-less racking from Sollega, uses a similar method for shipping. The first model of FastRack that launched in 2012 used a high-density polyethylene in the rail-less, modular racking before switching to glassreinforced nylon 6 in 2014.

“If you go and look under the hood of your car, you’re going to see some components that actually are made out of the same material,” said Elie Rothschild, CEO of Sollega. “The reason being is its

expansion-contraction is minimal, and it has a very high heat stability.”

FastRack is composed of the primary rack, or bucket, which can house ballast blocks or mechanically attach to the roof; then there are bolts, which are placed at locations for 5, 6 or 10° panel tilts; panel clamps; and slide-on bonding jumpers. The lightweight buckets can hold up to 1,700-lb loads.

Glass-reinforced nylon has an operating lifespan of between 40 and 50 years, and it is fully recyclable. Rothschild said Sollega is considering using post-industrial recycled materials to

manufacture its racking, which already has a smaller carbon footprint than extruding metals. Additionally, glassreinforced nylon is non-conductive, so FastRack earned UL 3741 compliance by default.

Non-traditional materials like concrete, fiberglass and glass-reinforced nylon present certain advantages for commercial solar logistically and for ease of installation by keeping component counts low. Metal remains the popular choice for flat-roof projects, but other racking options give installers alternative approaches to solar construction. SPW

DynoGrip Evolution Flat Roof System from DynoRaxx.

Concrete solar racking from Sun Ballast.

Kelly Pickerel • Editor in Chief

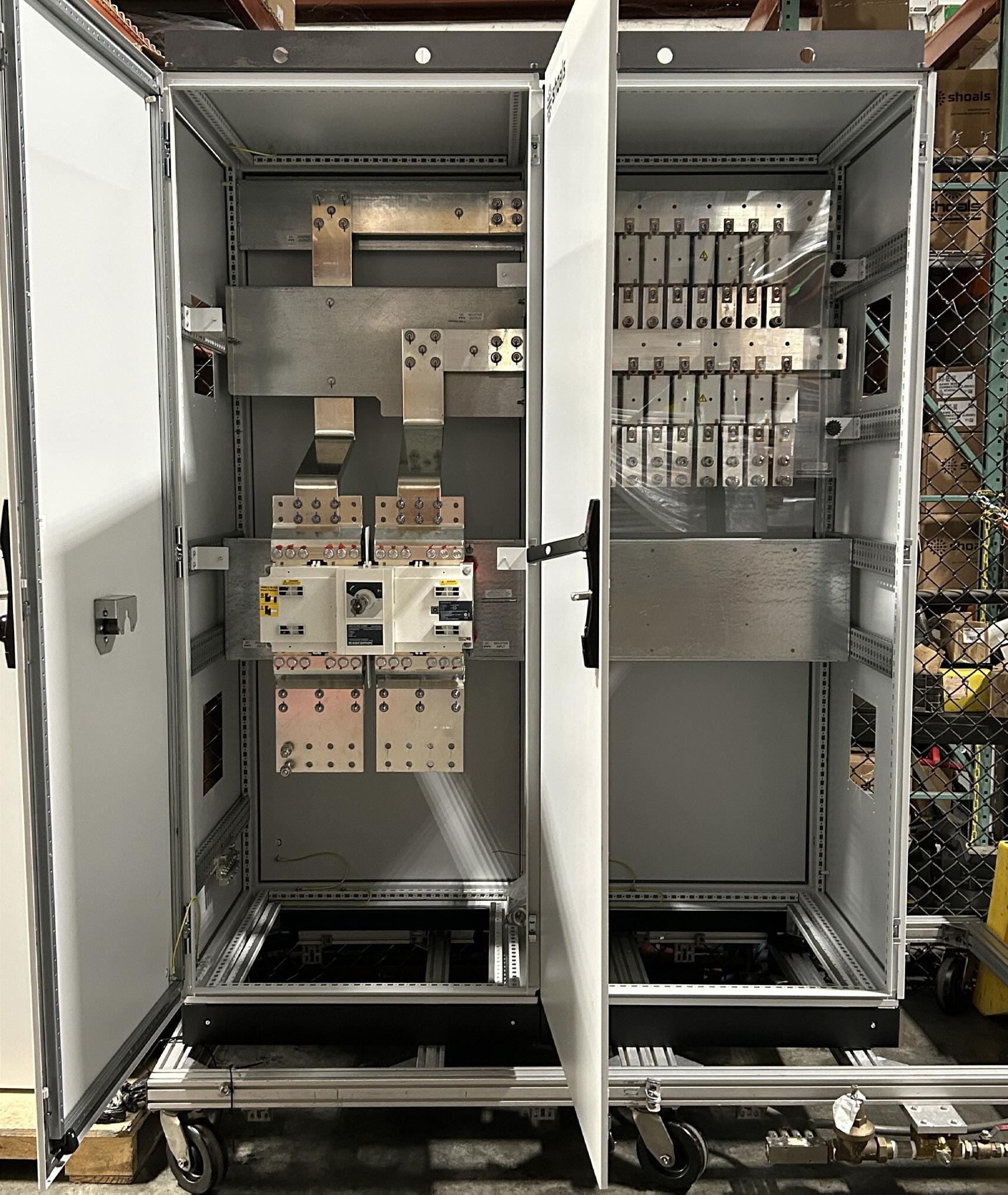

Cutting through the noise: Designing batteries for community acceptance

The NIMBY arguments against solar and storage range from the absurd (solar panels suck up all the energy from the sun!) to the indisputable (projects alter rural landscapes). Regardless of the opinion, it’s the priority of the solar + storage developer to hear community concerns and find solutions. One logical issue community members may have with large-scale battery energy storage systems (BESS), especially as more are being installed in urban areas, is their noise level. Residents will be living and working near these systems long after the project developer moves on to the next site.

It's a valid concern, said Thomas Corbishley, principal consultant for acoustic consulting company Noise Monitoring Services.

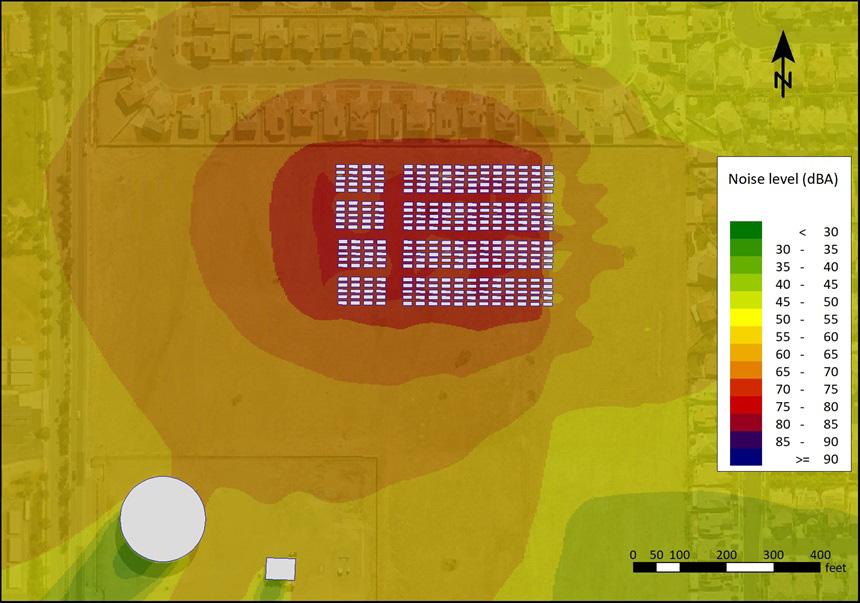

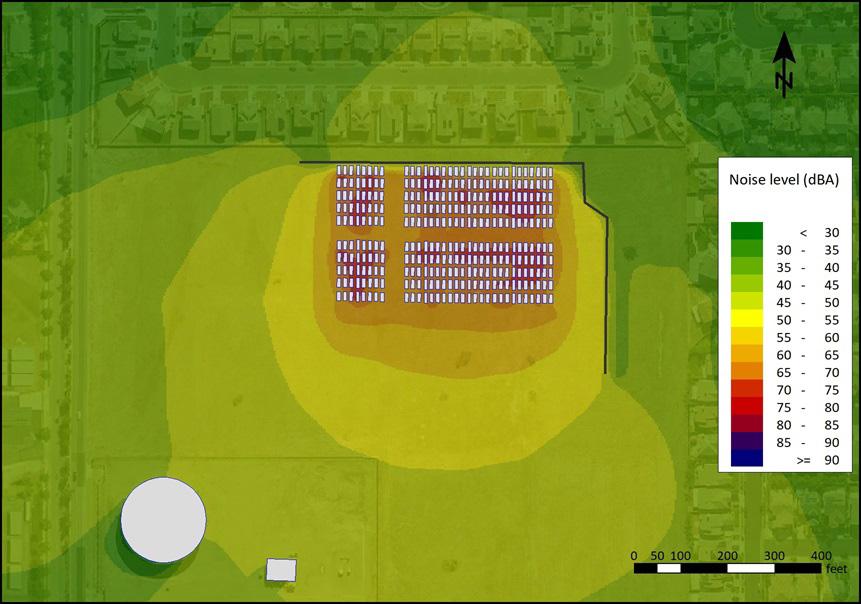

“Sites using the loudest equipment can generate noise levels of 70 dBA at 50 ft from the batteries. This level is well above typical permissible sound levels for residential areas,” he said. “For a comparison, freeway noise is typically 70 to 80 dBA at the same distance. However, roadway noise is less intrusive as it is broadband in nature — [meaning that] road noise is not tonal like BESS equipment can be.”

The “noisiest” components of a BESS are typically the cooling systems, inverters and transformers. A BESS’s cooling and ventilation system includes noise-making fans and pumps, which operate frequently. Solar installers are familiar with inverter noise, which is more of a consistent buzz that can be noisier on a larger installation. Transformers also create a low-frequency hum that is still notable.

“For large shipping-container-sized batteries, we've measured noise levels up to 92 dBA at 1 meter from the fans,” Corbishley said. “The fans often produce a humming sound. This type of tonal noise can be very intrusive and annoying to people.”

But there are ways these energy storing noise-makers can be designed to limit their acoustic annoyances, both during manufacturing and project siting. The earlier noise mitigation steps are taken, the more acceptable a BESS will be to a community.

A battery is only as noisy as its parts Sharon Santhosh, application engineer at global BESS integrator and designer Wärtsilä Energy Storage, said questions around battery noise have increased in recent years.

“Five years ago, acoustic studies were occasional; now, nearly every project includes noise criteria,” she said. “Local authorities and nearby residents are becoming more aware of operational noise and its effect on quality-of-life and community wellbeing, so noise is now a limiting factor for permitting and community acceptance. We see stricter thresholds, especially for nighttime, often 30-40 dBA at the nearest home and 70-90 dBA at the unit, which makes early-stage noise modeling essential.”

BESS are typically at their loudest at night, when batteries are actively working and cycling. This is the opposite of when other ambient noise sources like road traffic are at their loudest levels, which can add to their nuisance.

Since Wärtsilä has some control over the manufacturing of its Quantum energy storage systems, the company can customize acoustic performance to meet project requirements. For example, enclosures can be designed to use high-quality wall materials and properly sealed access points to prevent sound leaks. Santhosh said the company can also incorporate noise silencer kits and anti-vibration materials and pads

Conscious efforts at BESS noise mitigation can be taken at both the manufacturing and project design phases. Wärtsilä Energy Storage

Storage Technology

Predicted noise levels at a BESS facility before (top) and after noise mitigation efforts (bottom).

Noise Monitoring Services

between the base and equipment to stop mechanical noise transfer. Wärtsilä’s GEMS optimization software can adjust fan speeds depending on system needs that can assist with noise levels at different times of the day.

Corbishley with Noise Monitoring Services said these small tweaks can do a lot to help with noise pollution.

“We've performed tests that demonstrate running the battery fans at 70% of their standard operating speed reduces sound levels by 4 or 5 dBA — a noticeable reduction,” he said. “At one site we worked on, the fan speed could be reduced to 50%. This typically reduces sound levels by 10 to 13 dBA, which is a very significant reduction.”

The type of BESS used can also influence noise levels. Transitioning to liquid-cooled systems uses fewer fans, which diminishes some noise. The timeduration of a system also determines noise levels, said Martin Rheault, VP of business development and sales for North American BESS integrator EVLO Energy Storage.

“The use-case of a specific BESS project also plays a role — whether the system delivers lower power over a long period (four or eight hours) or higher power over a shorter timeframe will

“These systems typically operate at lower power output over extended periods, which reduces the need for intensive cooling by HVAC equipment, and therefore results in lower acoustic impact of those energy storage projects,” he said.

Being a courteous neighbor EVLO has found noise requirements to be just one community factor increasing on BESS siting — along with fire safety, property value impacts and wildlife considerations.

influence cooling needs and its noise levels,” he said. “The more power, the more cooling required, the greater the sound output.”

Rheault said the trend toward longer-duration energy storage (systems operating at more than eight-hour intervals) will decrease noise levels too.

“Responsibility for minimizing these impacts is shared between the BESS provider and the project owner,” Rheault said. “While the provider integrates these considerations into system design, the project owner can also plan for optimal site selection and mitigation strategies. Together, this ensures that energy storage remains a solution with minimal footprint on surrounding communities, while optimizing the benefits of BESS as flexible energy assets.”

Murray Stacy, VP of Sound Fighter Systems, a provider of outdoor soundabsorbing products used in industrial and commercial settings, said his company has been called to more

Storage Technology

BESS sites lately. Its SonaGuard system is designed for maximum acoustical performance and long-term outdoor exposure and mitigates BESS site noise. Instead of treating source-specific noises at a battery project, the SonaGuard absorbs sound from all areas.

“Many people’s first exposure to sound walls has been with highway sound walls, which were traditionally sound-reflective concrete, but have now progressed to the more advanced sound wall components found in products like our SonaGuard barrier system,” Stacy said. “The SonaGuard sound panels are tuned to mitigate the most common frequencies associated with the noise sources on BESS sites, in addition to many other outdoor noise sources such as electrical substations, power generation and data centers.”

The consultants at Noise Monitoring Services have conducted surveys at many existing BESS projects, primarily in California and Arizona. When changes can’t be made to the manufactured

product itself, Corbishley said the most common noise mitigation options his company suggests is installing sound walls like Sound Fighter Systems’ SonaGuard. Re-orienting equipment to direct sound away from the nearest residences can also make a big difference. HVAC systems are typically only on one side of a BESS, so they can be oriented away from nearby housing. Additionally, increasing space between battery units and sensitive areas can reduce perceived sound.

“While the biggest gains come from mitigating noise at the source, installation and site layout are crucial parts of acoustic mitigation,” said Santhosh with Wärtsilä. “Mechanical isolation between the unit and its foundation can prevent vibration from amplifying noise. Orientation also matters by facing inverters or ventilation outlets away from nearby receptors and spacing containers to allow for sound dissipation; overall noise exposure can be reduced significantly.”

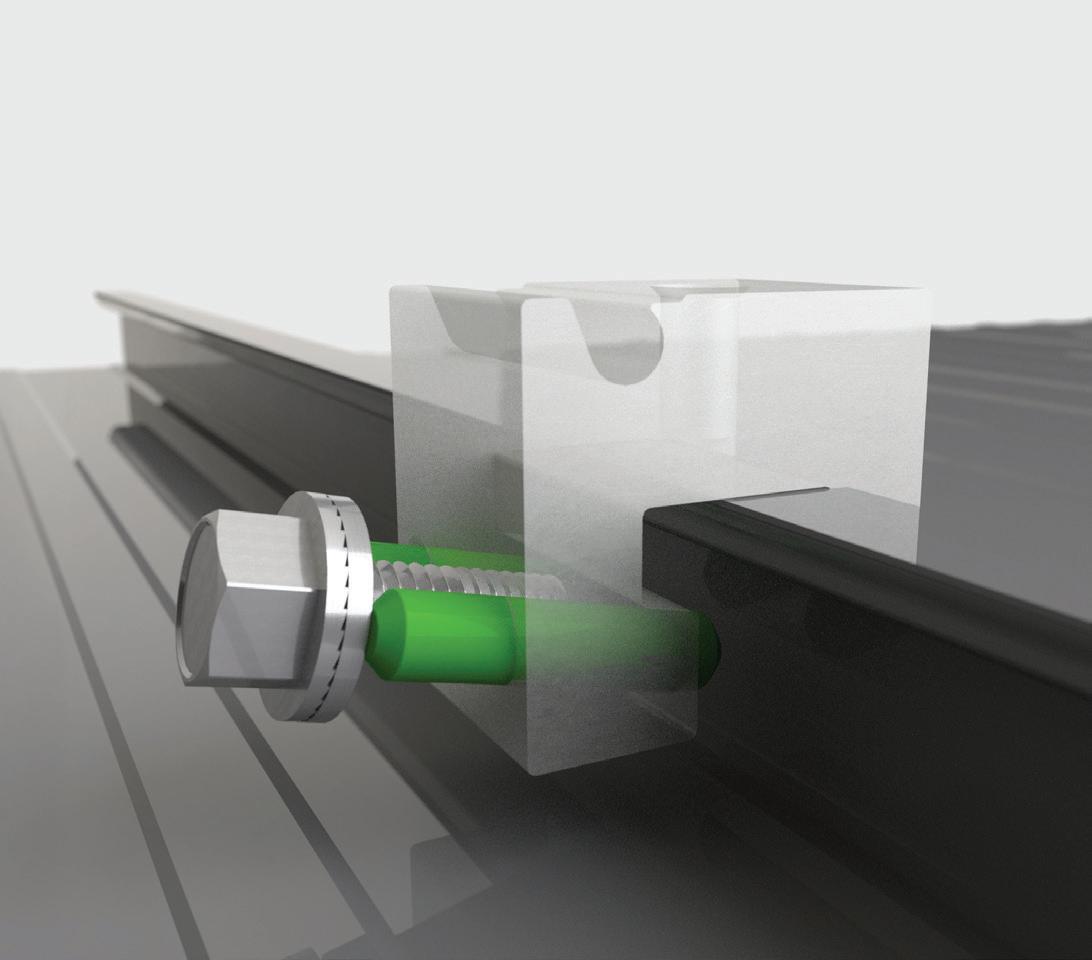

SET SCREW ALTERNATIVE

As more BESS projects are installed across the country and in more urban settings, Stacy with Sound Fighter Systems said acknowledging community concerns will go a long way.

“Transparency, empathy and community buy-in from the start is a prudent strategy,” he said. “Too often, noise is an afterthought without any budgetary considerations, then site owners try to Band-Aid the problems with the cheapest treatments possible. Such remedies seldom resolve the noise issue and often agitate the community due to the owner’s perceived lack of empathy, lack of knowledge or both.

“Instead, deploy aggressive and progressive pre-emptive noise mitigation tools, and share with the community that you are proactively utilizing the best technology available on their behalf,” Stacy continued.

Noise levels should be considered at every step of BESS deployment — initial manufacturing, project design and long-term operations.

“Designing for low noise isn’t just about compliance; it’s about building community trust and ensuring energy storage remains a welcomed, longterm part of the local environment,” Santhosh said. SPW

Financing for everything under the sun.

At First Horizon, we offer the best of big bank capital resources and small bank client relationships through a dedicated team of renewable energy finance specialists. If you’re looking for project debt and tax equity financing for solar, wind, or battery storage renewable energy projects, we’ve got you covered with a tailored package of cash and capital solutions that help you build bottom-line confidence and accelerate top-line growth.

Big bank muscle. Small bank hustle.

Minimize upfront investment

Optimize cash flow

Enhance productivity

Learn more at firsthorizon.com/renewable

Downtime Costs Thousands. Find Ground Faults in Minutes.

The Fluke GFL-1500 Solar Ground Fault Locator

Meet the Fluke GFL-1500 Ground Fault Locator Fast, Safe, and Built for 1500 V Systems

Every minute offline costs you. The Fluke GFL-1500 FaultTrack™ Technology, sends a traceable signal straight to the fault. No guesswork, fewer disconnects, and faster fixes. Don’t Guess. Trace It.

Pinpoint faults fast with non-contact tracing Work safer with fewer disconnects Restore production with confidence

Fluke PV Solar Testing Solutions

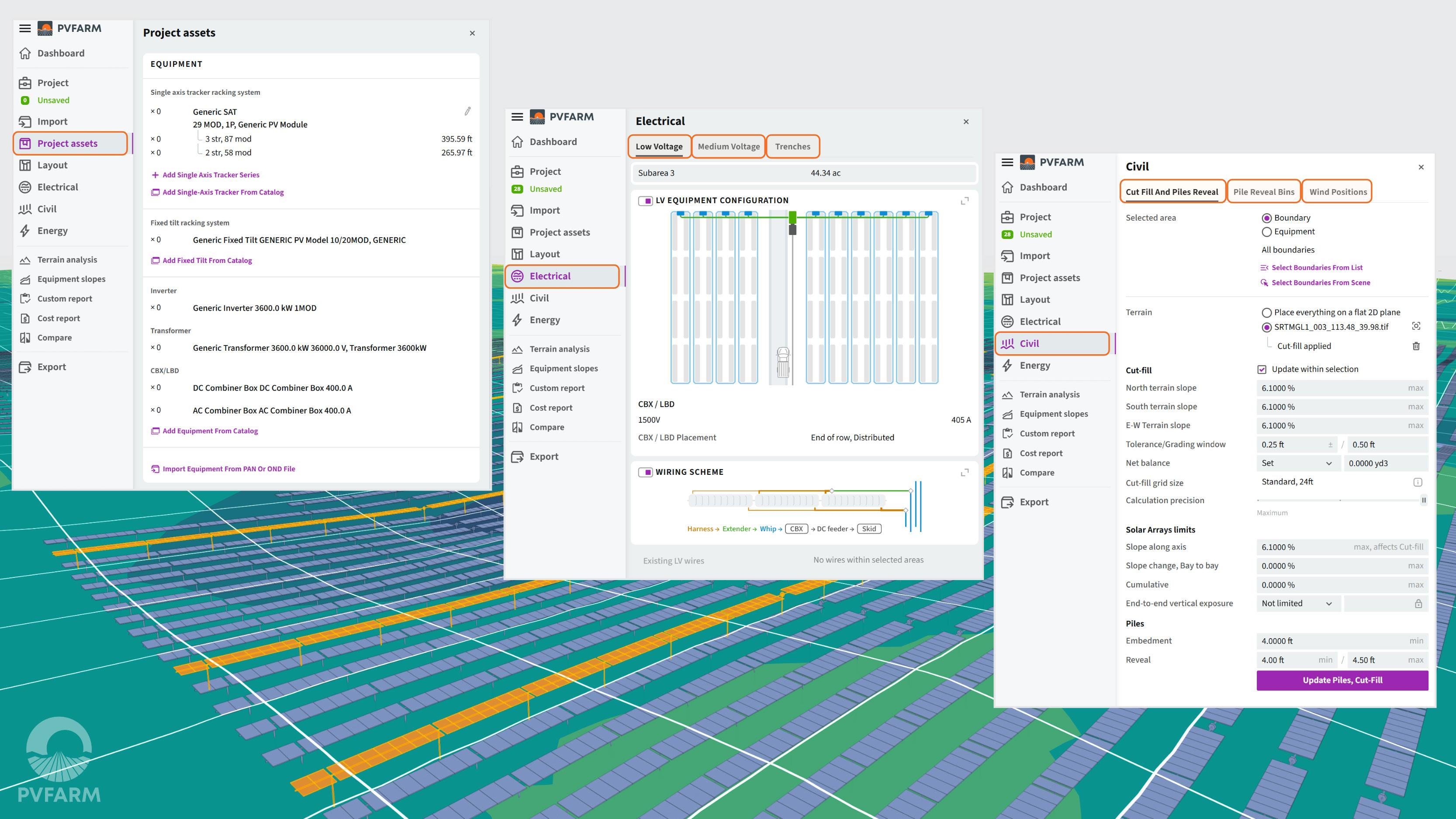

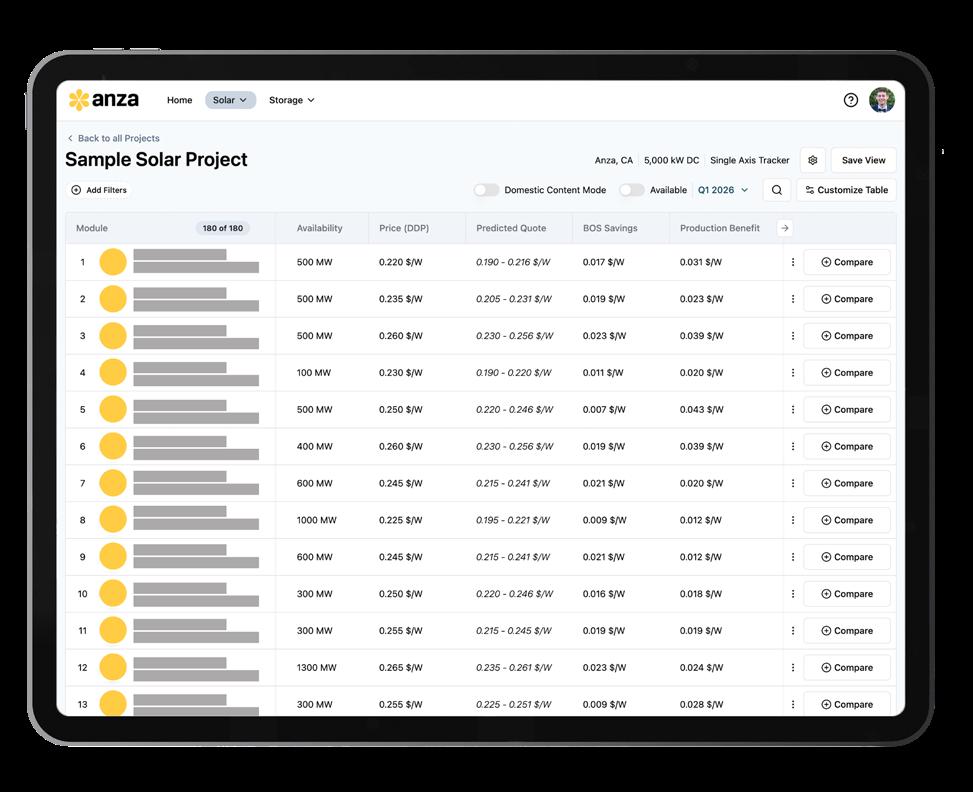

The end of each year brings the opportunity to reflect on the accomplishments of the last 12 months, and we're reflecting on the products that made exceptional installations happen. Solar Power World is proud to unveil this year's winning class of Top Products for the solar and storage industry. The 2025 Top Products contest celebrates the most innovative and significant products available to the U.S. market that are making a difference to the industry today. The competition

was judged by industry professionals with experience in all markets, representing the research, product development and installation sectors. Products were assessed on their originality, market promise and benefits to installers and developers.

Following two market tracks — largescale and residential — five products were awarded Best in Show. These products received the highest scores from our judges, who awarded points based on each product's purpose, development and real-life application. Five additional

products in each market track were awarded Honorable Mentions based on their performance.

Biographies of our 2025 judges are on the following pages. Solar Power World thanks them for their dedication to a fair competition. Judges with a direct connection to a submitted product were prevented from ranking the product. The product's score was averaged without the conflicting judge's input.

Congratulations to the 2025 Top Products presented by Solar Power World!

RESIDENTIAL JUDGES

Charlie Saginaw, Southwest Regional Sales Manager, JA Solar

Charlie Saginaw, a University of Texas at Austin graduate and native Texan, has excelled in the solar industry for nearly a decade, specializing in solar installer and distribution sales. He is currently the Southwest regional sales manager for solar panel company JA Solar. Previously, Charlie held positions at BayWa r.e., CivicSolar and was the first sales hire at Bodhi in 2022. Charlie’s career highlights his commitment to relationship building, market share growth and reliability through proactive communication. Charlie is also an avid cyclist and once biked 4,600 miles in one summer, traveling from Austin, Texas, to Anchorage, Alaska, to raise money for cancer research.

Will White, Solar Application Specialist, Fluke Corp.

Will White is a seasoned professional in the renewable energy sector, with two decades of experience spanning installation, sales, design, project management, curriculum development and teaching. Since 2022, Will has served as a senior application specialist at Fluke, supporting the company’s renewable energy testing portfolio. His technical area of focus is distributed energy resources, including energy storage, electric vehicle supply equipment and PV systems of all scales. Will has been a NABCEPcertified PV Installation Professional since 2006 and previously held certification as a NABCEP Solar Heating Installer. He holds a B.A. in Business Management from Columbia College Chicago and an MBA from the University of Nebraska-Lincoln.

LARGE-SCALE JUDGES

Emily Hwang, Director of Applications Engineering, Yaskawa Solectria Solar

A seasoned professional of almost 20 years, Emily Hwang has been part of Yaskawa Solectria Solar for the last decade and currently holds the role of director of applications engineering. Emily has a passion for applying the NEC and ensuring that all PV products are installed correctly, efficiently and, most importantly, safely. A graduate of the University of Pennsylvania, Emily earned a B.S. in Electrical Engineering and a master’s in Telecommunications and Networking. She is a NABCEP-certified Solar PV Installer and has served on many committees and boards including Women in Cleantech and Sustainability and Engineers Without Borders. Speaking at least four languages, Emily is an outstanding solar communicator and trainer, presenting at many industry events and functions throughout the years.

Ben Jones, VP of Design and Engineering, DSD Renewables

Ben Jones has had a variety of experiences spanning over 30 years in different industries and currently serves as SVP of technical sales and account management for DSD Renewables. Ben feels that the depth and variety of his professional track record has prepared him well to leverage that experience in developing a solar market penetration strategy and executing the tactical steps necessary to ensure lasting success. He was a part-time NABCEP instructor at Red Rocks Community College in the early 2010s and held positions at CPV, S:FLEX and GE Solar before coming to DSD Renewables in 2019. A member of DSD's executive team, Ben works across the organization to ensure build scale-ability, sustainability and exceptional value.

Troy Renken, VP of Product and Engineering, Shoals Technologies Group

Troy Renken is the VP of product and engineering at Shoals Technologies Group. He brings extensive leadership experience in engineering and product management across a range of industries. Over the course of his career, Troy has held senior roles at Shoals Technologies Group, Hayward Holdings, Medical Enterprises Distribution, ZPower and Emerson Climate Technologies. His technical expertise spans mechanical, electrical, firmware, software, chemical and hydraulic engineering, and he has led multidisciplinary teams to deliver innovative product solutions. Troy holds a B.S. in Electrical Engineering from Trine University.

SOLAREDGE – SINGLE-SKU HOME HUB INVERTER

The top-ranked product for the residential market as chosen by our judges is the single-SKU Home Hub inverter from SolarEdge, which just hit the market this year.

The Home Hub itself is SolarEdge’s legacy residential inverter offering, but the latest version has an almost fool-proof commissioning process. The inverter can be configured to any required size (3.8, 5.7, 7.6, 9.6, 10 or 11.4 kW) while maintaining 12.5 kW of continuous power output across all configurations. The nameplate rating is permanently locked during commissioning through simultaneous scanning of two QR codes. The five-step commissioning process ensures proper configuration: The installer first downloads the SolarEdge Go app, then installs Home Hub, commissions through dual QR code scanning to configure nameplate rating, applies the appropriate nameplate sticker and finally exports the commissioning report.

This latest Home Hub also allows for system upgrades, and homeowners can add more solar panels later without purchasing a new inverter, subject to utility approval for power class changes. But all that ability is already baked into the single-SKU offering.

This provides a dramatic simplification of an installation company’s inventory. Instead of stocking multiple inverter sizes, only one unit is needed. This also eliminates costly change orders. And the system’s future-proof option allows for easy system expansion.

While other solar products do offer single-SKU solutions, SolarEdge says its approach is fundamentally different due to the dual QR code scanning, which prevents errors and allows for verification and traceability. This updated function came straight from SolarEdge’s installer and distributor network. Select installation partners participated in controlled field trials to validate the technology before it was fully released earlier this year, and the response has been extremely positive, as evident by this Best in Show win. SPW

“One of the many challenges of residential solar installations is managing the correct inventory of inverters. They come in many different sizes, and you must make sure you have the right one for the job. A huge advantage of the SolarEdge single-SKU inverter is a significant reduction in part count. This makes it much easier for installers to ensure they have the right inverter on site. Having fewer part numbers simplifies inventory, which reduces costs.”

– Will White, judge

ENPHASE ENERGY – 4TH-GENERATION ENPHASE ENERGY SYSTEM

The solar industry’s microinverter expert has also figured out residential storage, and the fourth-generation of the Enphase energy system has been awarded a Best-in-Show distinction in this year’s Top Products competition.

This latest streamlined package from Enphase consists of three key components: the IQ Battery 10C, IQ Meter Collar and IQ Combiner 6C. Together, they simplify design and installation while providing whole-home backup and long-term reliability.

The 10-kWh LFP battery has 7.08 kW of continuous power output, and a

redesigned internal architecture achieves 34% greater energy density while reducing wall space requirements by 62%, compared to earlier generations, giving homeowners more storage in less space. The IQ Meter Collar installs behind the utility meter to enable whole-home backup without the need for a separate backup sub-panel. The IQ Combiner 6C integrates interconnection equipment, pre-installed current transformers and breakers into one enclosure, consolidating multiple functions and reducing installation steps.

The fourth-generation system addresses two big challenges slowing

residential storage adoption: Installation complexity and space limitations. By consolidating functions and eliminating unnecessary hardware, the system reduces labor requirements, minimizes wall space and makes whole-home backup achievable without costly or time-consuming workarounds.

To further strengthen market appeal, the IQ Battery 10C began shipping with domestic content from contract manufacturing facilities in August 2025. Every system is backed by a 15-year Enphase limited warranty for long-term peace of mind. SPW

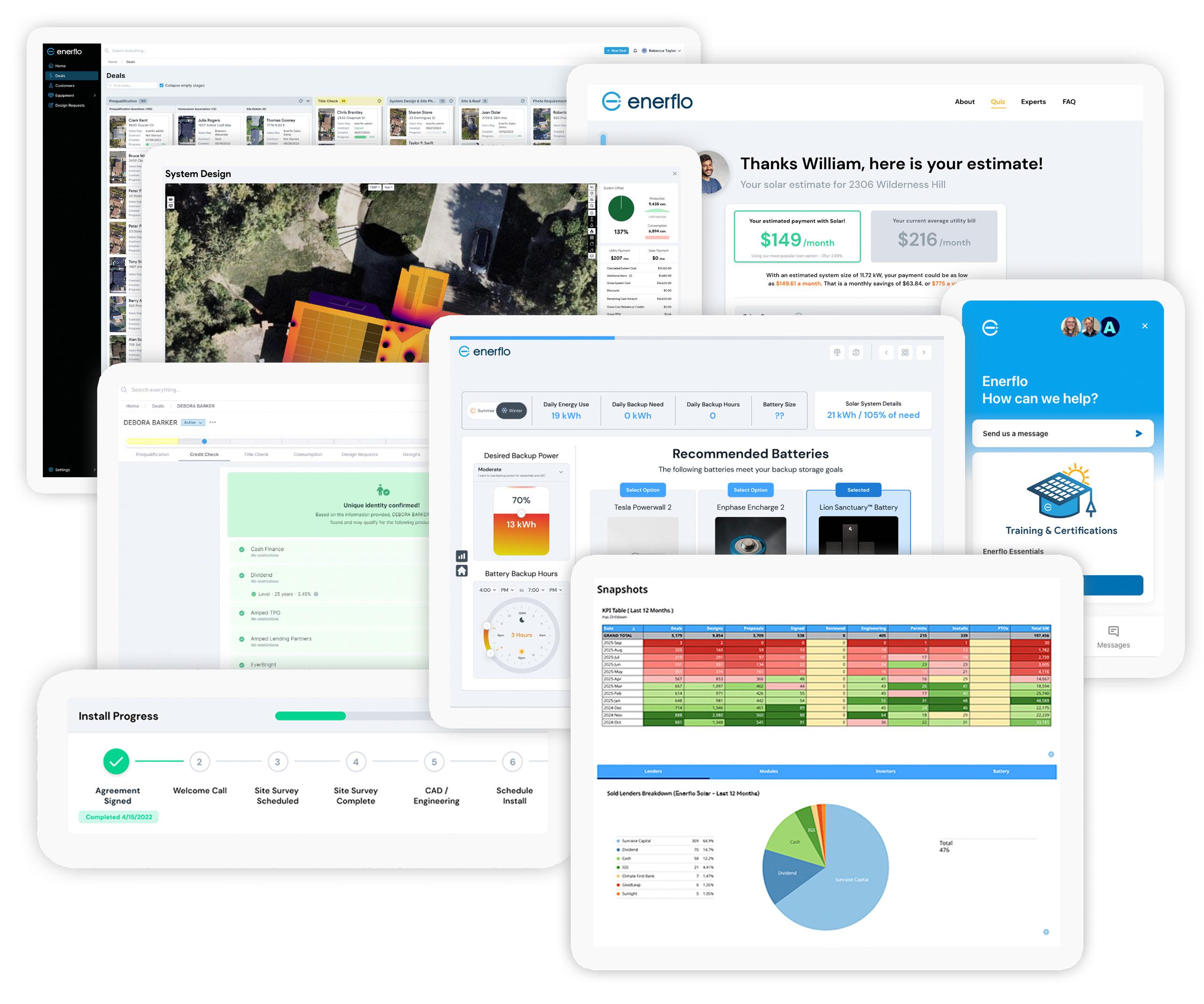

ENERFLO – SALES AND PROJECT MANAGEMENT PLATFORM

In the second year of SPW’s Top Products competition, Enerflo’s software places for the second time in the Bestin-Show category. A brand-new set of judges found the open-API software platform a helpful tool for residential solar sales and installation professionals aiming to streamline workflows, reduce soft costs, close more deals, complete projects faster and scale with confidence. Unlike closed ecosystem platforms, Enerflo supports integrations, giving solar companies the freedom to choose the tools that work best for them. Enerflo centralizes and standardizes project data, enabling seamless workflows across the entire project lifecycle — all managed from a single platform with one login.

The Enerflo platform is made up of three core components, with a new fourth component in beta: Sales Core (canvassing through project submission), Install Tracker (project management through PTO), Customer Portals (a homeowner-facing hub for updates, communication and transparency) and the beta-version Virtual Sales Rep (a flexible online lead gen tool).

Since launching in 2019, Enerflo has continued to deepen integrations and expand platform capabilities, now offering bundled solutions like canvassing, AI-powered solar designs with 97% U.S. coverage and proposals generated in under two minutes.

With the recent passage of the

One Big Beautiful Bill Act (HR1), the pressure to cut soft costs, prove longterm homeowner value and streamline operations is higher than ever. Enerflo helps solar companies pivot quickly with flexible, integrated tools that support diverse finance options, solar + storage bundling and complete project visibility. Through strategic partnerships with lenders such as Dividend, LightReach, EnFin and GoodLeap, and the integration of tools like Smart Pulls and Title Checks, Enerflo reduces costly delays and ensures financing aligns with customer qualifications early in the sales process. These features improve project accuracy, reduce change orders and cancelations, and keep timelines on track. SPW

FRANKLINWH ENERGY STORAGE – APOWER S

Batteries reign supreme this year, taking three of the Top 5 spots for SPW’s Top Products in the residential market. The aPower S from FranklinWH is one of those Best-in-Show winners, featuring the largest storage capacity at 15 kWh. Not only that, a single aPower S unit can access 20 kW of solar panels.

The aPower S is the next generation of FranklinWH’s aPower series and was developed to adapt to the larger power consumption of modern homes. FranklinWH has a significant customer presence in the established California market, and many homeowners with

legacy solar + storage systems are also looking to expand to meet increased power needs. The higher capacity (and higher power acceptance) of aPower S allows for high-power users to go solar + storage with fewer products.

Released earlier this year, aPower S has already met customer expectations, even in alternative setups. One customer with a ground-mount array and small generator installed the aPower S for its direct DC solar input to internal inverters, coupled with the system’s black-start capability. The FranklinWH system allows trickle-DC solar input while using

the generator to feed the battery and home simultaneously during low light conditions.

Overall, this new aPower iteration reduces the bill of materials and equipment needed for expanding existing solar + storage systems. It can also accommodate a large solar input of up to 20 kW, which eliminates the need for additional devices and solutions to handle that large power. And the unique backward and cross-version compatibility allows customers to easily expand systems in the future without overhauling their current setups. SPW

GROWATT – APX HV US BATTERY

Another battery caught the 2025 Top Products judges’ eyes, but this time it was for its flexible expansion capabilities. The APX HV US Battery from Growatt received high marks to secure a Best-in-Show distinction.

The APX HV US is a high-voltage, 5-kWh battery ideal for customers looking to expand their existing energy storage setups. Powered by Growatt’s advanced soft-switching technology, each battery module can charge and discharge independently, allowing new and old modules to work seamlessly together. A user could start with 10 kWh and later add another 10 kWh without worrying about reduced performance. The system also supports modules with different states of charge (SoC), which greatly simplifies installation — installers no longer need to spend time equalizing battery levels on-site, saving both time and effort. With a redundant design, the system ensures reliability by allowing other modules to continue operating normally even if one battery pack fails, delivering flexibility and efficiency.

Growatt considered beta customer feedback to improve the wiring layout between battery rows to make installation easier and more efficient before APX HV US was officially released in 2023. Since first launch, the battery has been improved with updated firmware logic, retesting under UL 9540 requirements and extending the operating range down to -20°C to ensure reliable low-temperature performance. The battery also includes a built-in aerosol fire suppression system for added safety in the rare event of thermal runaway. SPW

“THERE ARE MANY MODULAR BATTERY SYSTEMS ON THE MARKET, BUT FEW HAVE THE ABILITY TO OPERATE INDEPENDENTLY WITHIN THE INSTALLATION. THE APX HV US BATTERY HAS THE ABILITY TO INCREASE STORAGE CAPACITY AT ANY TIME DURING THE LIFE OF THE SYSTEM, AND EACH BATTERY MODULE CAN OPERATE AT A DIFFERENT STATE OF CHARGE. THESE FEATURES ALLOW SYSTEMS TO ADAPT TO CHANGING FAMILY NEEDS AND EVER-EVOLVING MARKET DYNAMICS. IT ALSO HAS A BUILT-IN FIRE SUPPRESSION SYSTEM FOR ADDITIONAL PEACE OF MIND.”

– WILL WHITE, JUDGE

SOL-ARK – PREMIUM 18K-2P HYBRID INVERTER

The Sol-Ark Premium 18K-2P hybrid inverter has been awarded an honorable mention in the inverter category.

The American-made hybrid inverter is batteryagnostic and provides up to 18 kW of continuous backup power, supporting more than 40 kW of solar through AC coupling. With 36 kVA of surge capacity, it ensures even large household systems remain operational during grid outages.

The Sol-Ark Premium 18K-2P hybrid inverter was developed after the company determined that 20% of its older inverter models were installed in parallel configurations, indicating a clear demand for higher continuous battery power in premium residential applications. So Sol-Ark engineers rigorously tested the premium inverter after receiving UL certification to ensure the unit could work across diverse applications. Only then was the inverter unveiled to the public in 2025. SPW

PEGASUS

– GLIDE

The Glide software platform from mounting manufacturer Pegasus has won an honorable mention this year.

Glide is more than just a mounting company’s design software. The unified platform manages the entire solar installation journey, from proposal to purchase order, so users can manage jobs efficiently without re-entering data or repeating steps.

One click individually rotates a single panel or a full row within an array, and calculates all structural and BOM as a contiguous array. It’s just as easy to add or remove panels, insert pipe-vent spacing between panels and assign wind zones to specific panels. Users can also design a single project with various arrays that have different roof types, such as a house with both comp shingles and a flat-roof carport.