ENGINEERING SOLUTIONS

MOTORS, DRIVES

Paul Avery, Yaskawa America Inc., Waukegan, Illinois

A VFD user should know these induction motor calculations Understand more about alternating current motor specifications and calculations when using the motor with a variable frequency drive.

T

he benefit of using a variable frequency drive (VFD) is the ability to control an alternating current (ac) induction motor in a very specific way that will benefit various applications. Those benefits can be in energy savings, precise operation or operating the motor over a wide variety of speeds. The relationship between the VFD and the motor begins before the VFD has even been selected. As a matter of fact, you can’t select the drive before you know what motor will be used on the application. The ac motors come in various designs from the bread-and-butter Design B, four-pole, totally enclosed fan-cooled induction motors to the more recent permanent magnet and synchronous reluctance designs. Selecting the right motor for the job includes many considerations like the installation environment and available power. The most important aspect is to know how much torque is going to be required to rotate the motor shaft to and move the application at the speeds needed. A mechanical engineer should do the math to figure out the “force at a radius” values. An article about motor calculations typically contains formulas for figuring out torque requirements for differing loads; this article doesn’t cover that detail. Plant and industrial manufacturing experts should consider these five things to select or use an induction motor wisely: • Usng the motor nameplate • Easy way to figure out a motor’s capability • V/f curves for induction motors when using VFDs

Plant engineering — www.plantengineering.com

PLE2508_MAG_MOTORS_YASKAWA_V4msFINAL.indd 39

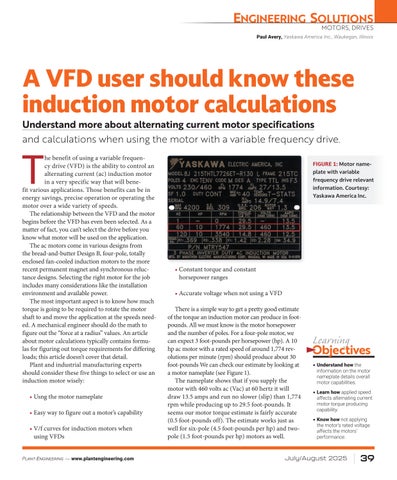

FIGURE 1: Motor nameplate with variable frequency drive relevant information. Courtesy: Yaskawa America Inc.

• Constant torque and constant horsepower ranges • Accurate voltage when not using a VFD There is a simple way to get a pretty good estimate of the torque an induction motor can produce in footpounds. All we must know is the motor horsepower and the number of poles. For a four-pole motor, we can expect 3 foot-pounds per horsepower (hp). A 10 hp ac motor with a rated speed of around 1,774 revu olutions per minute (rpm) should produce about 30 • Understand how the foot-pounds We can check our estimate by looking at information on the motor a motor nameplate (see Figure 1). nameplate details overall The nameplate shows that if you supply the motor capabilities. motor with 460 volts ac (Vac) at 60 hertz it will • Learn how applied speed draw 13.5 amps and run no slower (slip) than 1,774 affects alternating current motor torque producing rpm while producing up to 29.5 foot-pounds. It capability. seems our motor torque estimate is fairly accurate • Know how not applying (0.5 foot-pounds off). The estimate works just as the motor’s rated voltage well for six-pole (4.5 foot-pounds per hp) and twoaffects the motors’ pole (1.5 foot-pounds per hp) motors as well. performance.

Learning

Objectives

July/August 2025

| 39 7/28/25 10:06 AM