sustainable package designing the perfect

sustainable package designing the perfect

From material research to responsible recycling, Dassault Systèmes’ 3D modeling software streamlines the packaging lifecycle.

Consumer

packaged goods (CPG) companies are under pressure to create more sustainable packaging. Now, faced with the inevitable move to environmentally friendly products, manufacturers are reassessing the materials, the packaging machines, and the recycling responsibility. All of which starts with the packaging design.

Dassault Systèmes provides software that can optimize the design process. Design World asked Raymond Wodar, the company’s global director business consulting for the CPG and retail industry, how the initial design impacts the entire product lifecycle — and how to start the process.

Who in a CPG organization is responsible for sustainable design?

Wodar: In a consumer packaged goods organization, sustainable design is typically a cross-functional effort that involves several departments and roles. The brand marketing function will likely define the parameters for the project and the packaging design and development teams are responsible for incorporating sustainable materials into the design. The teams need to work with internal sustainability or environmental affairs groups that will provide the goals

Stephanie Neil Executive Editor

and standards needed to achieve sustainability targets. Supply chain and procurement teams will also be involved for sourcing sustainable materials and managing the logistics packaging requirements. Other functions may involve advanced R&D topics like materials research and help from outside agencies to determine latest trends and consumer requirements.

packaging oem

Beyond materials, what needs to be considered when creating a sustainable package design?

Wodar: When creating a sustainable package design, several factors beyond just the choice of materials need to be considered to minimize environmental impact and enhance overall sustainability. The design should be optimized to minimize the size and weight of the package to decrease material usage and excess packaging while still effectively protecting the product. A lighter product will also reduce transportation emissions in the supply chain. A thorough evaluation of the entire supply chain will help us understand the environmental impact from production through transportation and distribution. This includes considering how far materials and finished products need to travel and the associated carbon footprint of that journey.

Considerations for end-of-product-life are critical as well. This involves designing for disassembly (if applicable), providing clear recycling or disposal instructions, and considering the lifecycle impact of the packaging once it has been discarded. Using materials that are widely accepted by recycling systems or that can biodegrade in industrial composting facilities is critical.

For a brand manufacturer, the cost profile of the package will be very important so that tradeoffs between material cost, weight, and quality can be properly balanced to provide the consumer a great value while managing internal product margins.

What are the regulatory pressures associated with sustainable packaging?

Wodar: Regulatory pressures related to sustainable packaging are increasingly influencing how companies design, produce, and manage packaging. These pressures come from various levels of government and regulatory bodies and can vary by region. Many regions are implementing extended producer responsibility (EPR) programs that require producers to take responsibility for the

Dassault Systèmes

entire lifecycle of their packaging, including end-of-life disposal and recycling. Companies may need to manage or contribute to the costs of collection, recycling, or disposal. Several countries and states have introduced bans or restrictions on single-use plastics and certain types of packaging. Regulations might limit or prohibit the use of plastic bags, straws, or other singleuse plastic items, pushing companies to seek alternative materials or packaging solutions. Governments are starting to set targets for waste reduction, recycling rates, or the reduction of packaging waste. Companies are often required to meet these targets or face penalties. For companies operating globally, international regulations and agreements, such as the European Union’s Packaging and Packaging Waste Directive, can affect packaging design and sustainability practices.

How can 3D modeling software help?

Wodar: 3D modeling software enhances the design process by providing a detailed, interactive platform to explore and optimize sustainable packaging solutions, leading to more effective and efficient design outcomes. 3D modeling software allows designers to create detailed visual representations of packaging designs. This helps in visualizing how sustainable materials and design choices will look and function in the real world before physical prototypes are made. Before creating physical prototypes, 3D models can be used to simulate how the packaging will behave under various conditions. This includes testing durability, functionality, and fit, which helps in optimizing the design for better performance with sustainable materials. More advanced 3D modeling tools can also integrate with lifecycle assessment (LCA) software to evaluate the environmental impact of packaging designs. This helps in understanding the potential environmental footprint of different design choices and materials.

Engineering Your Linear Motion Solutions

PBC Linear is here to provide innovative solutions through the development and manufacturing of linear motion components, mechanical subassemblies, and customized systems to meet customers’ specific application needs. Our diverse staff of engineers with in-depth industry knowledge and decades of experience collaborate with you to solve your linear motion needs.

Headquartered in a 200,000 square-foot facility in Roscoe, Illinois, USA, where production is streamlined and maximized to produce unmatched quality and designed specifically for the most complex and meticulous applications, resulting in ready to install linear solutions.

PBC Linear has the ability to provide smooth and reliable linear motion solutions for a wide array of applications ranging from very small pick-and-place assemblies and scanners used in lab automation to heavy-duty lift systems in industrial manufacturing. Other applications utilizing our components and/or systems are kiosks, unattended retail systems, scanners, printers, and etchers.

packaging oem

What does a virtual twin do?

Wodar: A virtual twin is not only a digital replica of a physical object, system, or process, but it integrates real time data, simulations, and analytics to provide a comprehensive and dynamic model that mirrors the real-world counterpart. The most powerful part of virtual twins is the ability to perform ‘what-if’ scenario analysis. This allows for simulation of various scenarios and testing of different conditions without impacting the physical entity. Imagine testing how a package will behave when dropped, or when stacked in a pallet, or when going through temperature extremes, without needing to use a physical prototype. This is useful for assessing the impact of design changes, operational adjustments, or environmental factors. More advanced virtual twins can predict future performance or potential issues based on historical data and simulation results.

Can creating a virtual twin using 3D modeling software accelerate the time-to-market for a sustainable package design?

Wodar: Yes, using a virtual twin created with 3D modeling software streamlines and accelerates the entire process of sustainable package design. By enabling rapid design iterations, accurate simulations, and efficient collaboration, it reduces the time required to bring a new sustainable packaging solution to market. Designers can simulate how different design changes impact the packaging functionality, sustainability, and consumer appeal without the need for physical prototypes. This includes testing how the packaging performs in various conditions. This highly compresses the time needed to validate the design. Virtual twins also enable the testing of different sustainable materials to evaluate their performance, recyclability, and environmental impact, leading to

better material selection and design optimization.

What are the other benefits of using a virtual twin in sustainable design?

Wodar: Virtual twins offer a wide range of benefits in sustainable design, from cost savings and quality improvements to enhanced collaboration and environmental impact reduction. By leveraging these advantages, organizations can drive innovation, optimize design processes, and achieve their sustainability objectives more effectively. Using virtual twins minimizes the need for physical prototypes, saving costs associated with materials, manufacturing, and testing. By optimizing designs and processes virtually, companies can reduce material waste and energy consumption, leading to lower production costs and a smaller environmental footprint. Virtual twins enable designers to fine-tune every aspect of the design for optimal

Christoph Burgstedt | Adobe Stock | Generated with AI

Intelligently

Reduction of variants through constant torque over a wide speed range

packaging oem

performance, durability, and sustainability. This leads to higher-quality products that meet or exceed performance expectations.

What is the Dassault Systèmes product that CPGs would use to accomplish this?

Wodar: It is called the Perfect Package industry solution experience. The comprehensive solution helps CPG companies design and optimize packaging in record time. Capabilities include structural design, modeling and simulation (MODSIM), project management, specifications management, lifecycle analysis, and more.

Is understanding the production of the sustainable package part of the process?

Wodar: Yes, understanding the production of a sustainable package is integral to ensuring that the packaging is truly sustainable. It helps in making informed decisions about materials, manufacturing processes, and cost implications, ultimately leading to a more effective and environmentally responsible packaging solution. Different materials may require specific manufacturing processes. Understanding these processes helps ensure that the packaging can be produced efficiently and sustainably. For instance, some materials may need specialized machinery or processes that could impact production costs and the environmental profile. Also, assessing the energy consumption, water use, and waste generated during production is vital for understanding the overall environmental impact. Sustainable production practices aim to minimize these factors.

What is the responsibility of the machine builder in this sustainability journey?

Wodar: The machine builder's role is integral to the sustainable packaging journey. Their involvement in designing, producing, and supporting efficient and adaptable machinery helps ensure that packaging manufacturers can meet

their sustainability goals effectively. By collaborating with other stakeholders and focusing on energy efficiency, material compatibility, and innovation, machine builders contribute significantly to the advance of sustainable packaging solutions. Builders must ensure that their machinery can handle and process sustainable materials, such as biodegradable films, recycled paper, or alternative substrates, without compromising performance or quality.

In a circular economy, does recycling of the package come into the design process?

Wodar: Yes, in a circular economy, the design process is significantly influenced by how the package will be recycled. The principles of a circular economy aim to minimize waste and make the most of resources. This requires considering the entire lifecycle of a product, including its end-of-life stage. Key considerations in the design process for packaging in a circular economy include choosing materials that are recyclable and can be separated easily from other components. Biodegradable or compostable materials might also be considered. OEM

Find more packaging news, trends, and research on WTWH Media’s Packaging OEM by visiting packagingoem.com or scanning the QR code

Raymond Wodar Dassault Systèmes

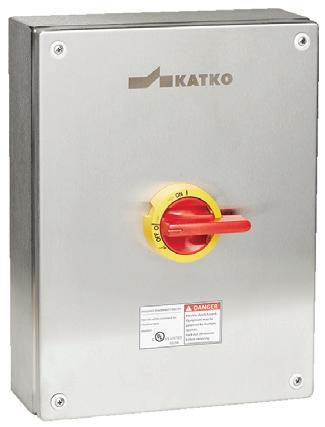

Door Mounted Motor Disconnect Switch

• Dual AC/DC rated; see below specifications

• Integrated door or side panel mounting

• Rear facing terminals for easy installation

• Loadsafe RT Series

• Switch make/break operation is semi- independent from operator’s actuation speed

• Silver contacts ensures safe and durable operation

• UL 60947-4-1

scan the qr code to learn more

908-806-9400 908-806-9490 (FAX) info@altechcorp.com

www.altechcorp.com/HTML/MDS-A.html

KHK USA offers the broadest selection of stock metric gearing in North America. Designed for use in industrial automation applications, conveyor systems, packaging equipment, robotics, and general machinery applications, KHK’s selection of spur gears, helical gears, internal ring gears, gear racks, bevel gears, screw gears, worms & wormwheels, ratchets & pawls, gear couplings, right-angle gearboxes, and gear lubrication systems are available in various materials and sizes. KHK’s website offers free 3D CAD models for all gear products, complete product specifications, and 24/7 shopping. With KHK USA, stock gears are delivered from stock, with no minimum order or credit card surcharges.

khk usa inc.

259 Elm Place, Mineola NY 11501 516-248-3850

www.khkgears.us

PBC Linear is here to provide innovative solutions through the development and manufacturing of linear motion components, mechanical subassemblies, and customized systems to meet customers’ specific application needs.

Headquartered in a 200,000 square-foot facility in Roscoe, Illinois, USA, where production is streamlined and maximized to produce unmatched quality and designed specifically for the most complex and meticulous applications, resulting in ready to install linear solutions.

PBC Linear has the ability to provide smooth and reliable linear motion solutions for a wide array of applications ranging from very small pick-and-place assemblies and scanners used in lab automation to heavy-duty lift systems in industrial manufacturing.

Other applications utilizing our components and/or systems are kiosks, unattended retail systems, scanners, printers, and etchers.

Robotics Weeks

AUTOMATED WAREHOUSE

From mobile robots and automated storage to picking, palletizing, and sortation systems, warehouse operators have a wide range of options to choose from. To get started or scale up with automation, end users need to evaluate their own processes and environments, find the best fit for their applications, and deploy and manage multiple systems.

6402 E. Rockton Road Roscoe, Illinois 61073 USA

+1.815.389.5600

Pbclinear.com pbc linear

Automated Warehouse Week will provide guidance, with expert insights into the evolving technologies, use cases, and business best practices.

REGISTER TODAY roboweeks.com

ROBOTICS ENGINEERING

Robotics Engineering Week features keynotes and panels, delivered by the leading minds in robotics and automation, addressing the most critical issues facing the commercial robotics developers of today.

Combating the Changes of Evolving Automation Technology with Conveyance

In the ever-evolving packaging landscape, OEMs constantly seek ways to enhance efficiency, flexibility, and reliability in their packaging lines. At the forefront of this technological evolution is Dorner Conveyors, a leading innovator in conveyor solutions. With a commitment to integrating cutting-edge technologies and adapting to the latest industry trends, Dorner is well-prepared to continue as the preferred choice for OEMs looking to build or upgrade their packaging lines.

Pioneering Integration with Robotics

One of the most significant advancements in packaging technology is the integration of robotics. Dorner Conveyors excels in facilitating seamless interactions between conveyor systems and robotic components. Dorner's conveyor solutions are meticulously engineered to interface with a wide range of robotic arms and automation systems, enabling precise and efficient product handling, sorting, and packaging.

This compatibility ensures smooth operation across various stages of the packaging process, minimizing manual intervention and optimizing workflow efficiency. Dorner's conveyors are designed with built-in features that support automation, such as smooth transfer points, adjustable speeds, and the ability for real-time data communication.

Dorner's precision is the catalyst for this integration. Dorner's fabric belted conveyors utilize a v-guided underside of the belt, which tracks in the conveyor's frame to ensure that the belt is centered, ensuring that the product is as precise as possible to interact with the robot on the packaging line.

This integration allows for enhanced precision in packaging applications, contributing to higher productivity and reduced operational costs. Whether for a high-speed production line or intricate packaging tasks, Dorner's conveyors ensure that robotic systems perform at their best, providing OEMs with a robust solution for modern packaging demands.

Adaptability to New Technologies

As technology advances, the packaging industry faces increasing demands for flexibility and adaptability. Dorner's

conveyor systems are built with these evolving needs in mind. The modular design of our entire breadth of conveyors allows for easy customization and reconfiguration, accommodating emerging technologies such as IoT-enabled systems, advanced sensors, and machine learning applications.

This adaptability ensures that Dorner's conveyors can integrate with the latest technological innovations, making them a future-proof choice for OEMs. By leveraging Dorner's adaptable solutions, OEMs can stay ahead of technological trends and incorporate new features into their packaging lines without overhauling existing infrastructure. This forward-thinking approach enhances operational efficiency and supports long-term growth and scalability.

Superior Performance and Reliability

When it comes to performance and reliability, Dorner Conveyors sets the benchmark. Their extensive range of conveyor systems includes low-profile, sanitary, and heavy-duty models, each designed to meet specific operational requirements. With a focus on high-quality materials and robust construction, Dorner's conveyors are engineered to withstand the demands of high-speed and heavy-duty applications. Dorner's advanced controls and monitoring systems also provide realtime performance data, enabling proactive maintenance and minimizing downtime. This ensures that packaging lines operate smoothly and efficiently, contributing to consistent product quality and overall operational success.

Tailored Solutions for Diverse Needs

Understanding that every packaging line has unique requirements, Dorner offers customized solutions to meet specific needs. Our Engineered Solutions team collaborates closely with OEMs to design conveyor systems that seamlessly integrate with existing equipment and workflows. Whether you need conveyors for complex packaging tasks or highvolume production, Dorner provides tailored solutions that enhance operational efficiency and can help achieve your goals. Working with Dorner gives OEMs access

to expertise and a wide range of options for optimizing their packaging lines. This personalized approach ensures that each conveyor system is designed to address the unique challenges and objectives of the application, delivering optimal performance and value.

Commitment to Continuous Innovation

Dorner's commitment to innovation drives its continuous development of advanced conveyor technologies. Their investment in research and development ensures that their products incorporate the latest advancements, positioning them as a leading choice for OEMs seeking to stay ahead in the packaging industry. By partnering with Dorner, OEMs benefit from a conveyor solutions provider dedicated to pushing the boundaries of technology and performance. This commitment to innovation enables OEMs to build packaging lines that are not only efficient and reliable but also equipped to handle future challenges and opportunities.

In summary, Dorner Conveyors is a leader in providing advanced, adaptable, high-performance conveyor solutions for packaging lines. With their expertise in integrating robotics and new technologies and their focus on reliability and customization, Dorner is the ideal partner for OEMs looking to enhance their packaging operations and achieve long-term success. Trust Dorner to deliver innovative solutions that drive efficiency, flexibility, and excellence in your packaging line projects. OEM

on Dorner’s Packaging Conveyors visit our website dornerconveyors.com or visit booth N-5623 at Pack Expo International in Chicago. For more information

NORD LogiDrive Complete Drive Solution

with New IE5+ Motor Technology

LogiDrive® is a complete decentralized drive package that greatly reduces engineering and commissioning efforts. With this modular system, the number of variants can be minimized, making maintenance easier and reducing Total Cost of Ownership (TCO) for the operator. The LogiDrive interface is intuitive and allows for easy control and monitoring of all units within the system. When paired with the NORDCON APP with NORDAC ACCESS BT Bluetooth stick, LogiDrive systems can provide real or nearreal time drive status to proactively predict maintenance issues and keep systems running smoothly. LogiDrive systems can be configured with IE3, IE4, and latest IE5+ permanent magnet synchronous motors that maintain extremely high efficiency, even at partial loads.

Energy Efficient

• Compliance with the most stringent efficiency regulations

• Considerable reduction of Total Cost of Ownership (TCO)

• High efficiency, even in partial load ranges and at low speeds

• Permanent Magnet Synchronous Motor (PMSM) technology

Variant Reduction

• Standardization of gear motor versions designed for intralogistics and airport technology

• Simplified engineering and selection

• Constant torque over a wide speed range through variable frequency drive technology

Service and Maintenance Friendly

• Considerable reduction of spare parts inventory

• Plug-and-Play technology

• Compact, space-saving design

• 25% weight reduction with lightweight aluminum housing

• Replacement of individual components possible

NORD offers unmatched product versatility, fast, reliable sales and support, and direct access to our engineering team. We also offer online tools for easy configuration and ordering of gear motors and spare parts, as well as 24/7/365 emergency breakdown service. OEM