BEYOND THE HYPE: INDUSTRIAL USES FOR AI

issue the trends

OFF-HIGHWAY AND FARMING GO HIGH-TECH DESIGNWORLDONLINE.COM MOTIONCONTROLTIPS.COM MARCH 2024

•

• Up to 3 PTO

CLICK PLUS PLCs provide control simplicity combined with advanced capabilities including Wi-Fi communication, MQTT support, data logging, and now motion control. Any CLICK PLUS CPU can be con gured as a 3-axis PTO/PWM motion controller with 100kHz high-speed input and outputs (requires DC option slot I/O module placed in slot 0 of the CPU). With the easy-to-use con guration GUI built into the FREE software and the three new motion instructions (Velocity Move, Position Move and Home), CLICK PLUS makes it’s a cinch to control simple motion applications.

AXIS PROFILES:

• Relative/absolute positioning

• Velocity mode

• Trapezoid

• S-Curve

• Registration

• Homing

• Jogging

• Linear mode

the #1 value in automation Order Today, Ships Fast! * See our Web site for details and restrictions. © Copyright 2024 AutomationDirect, Cumming, GA USA. All rights reserved. 1-800-633-0405 Research, price, buy at: www.CLICKPLCS.com Motion control this easy and affordable is soooo sweet!

FREE SOFTWARE with simple motion pro le setup and 3 new easy-to-use motion instructions: • Velocity Move • Position Move • Home 3-AXIS PTO/PWM MOTION CONTROLLER STARTING AT ONLY $155.00 (C2-01CPU + C2-14D1)

OUTPUT PULSE MODES:

linear step/direction outputs

Up to 3

pulse width modulation outputs

PWM

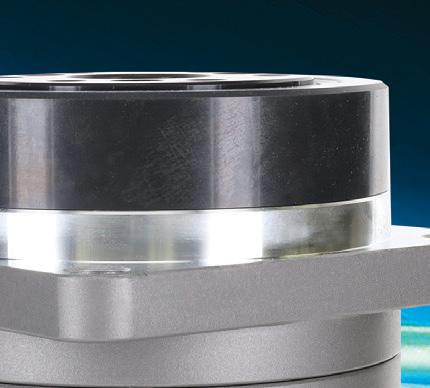

Keyless Shaft Bushings

• Precise & Reliable Shaft Component Mounting

• Single-Screw Models for Fast & Frequent Use

• Steel, Nickel-Plated, and Stainless-Steel

• Variety of Mounting Styles Available

• English & Metric Sizes in Stock

• Engineering Assistance / Fast Delivery

www.zero-max.com 800.533.1731

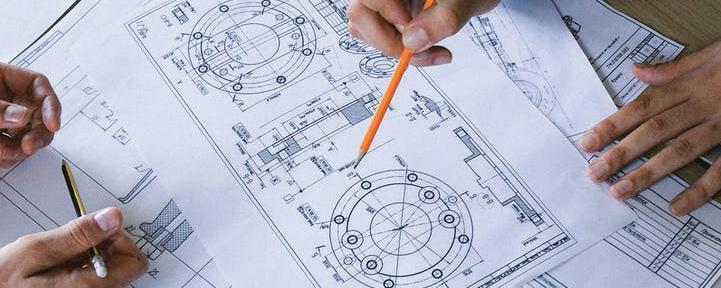

DIGITAL DOMINATES THIS YEAR’S DISCUSSION

The response to our 2024 Design World Trends call was the biggest yet. This print issue contains five features summarizing just a small portion of this year’s observations and insights from experts in motion and automation; tune into designworldonline.com/trends over the next two months to read all the Trends features in their entirety.

In fact, this year’s dominant industry developments tracked 14 different themes:

· New digital transformation initiatives

· Digital manufacturing advancements

· The increased viability of sustainability

· North American EV battery production

· Training, human-centric design, and augmented reality

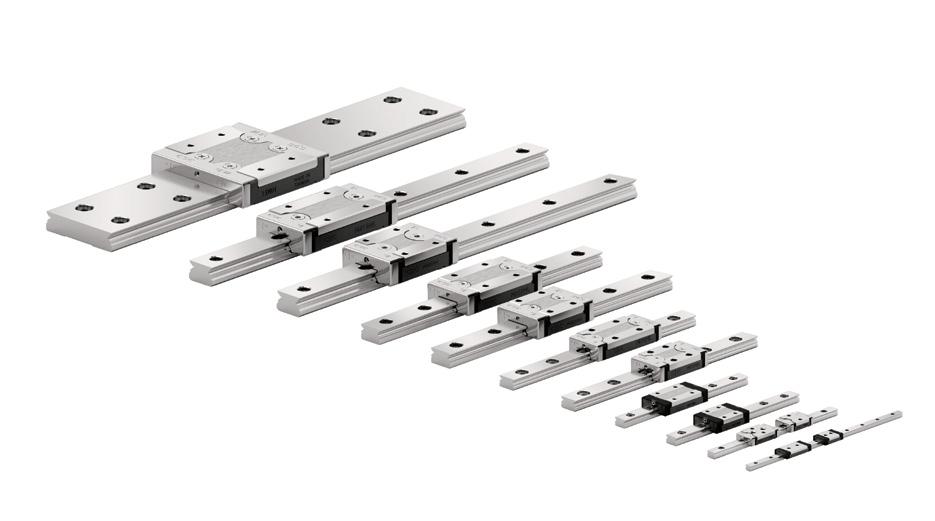

· Trends in linear motion

· The move to reshoring and supply chain security

· Mechanical components

· New motor designs redefining capabilities

· Developments and drives in motion controls

· New industrial uses for artificial intelligence

components (including those for linear motion) that allow manipulation of the physical world for discrete automation.

Quite fittingly, this year’s Design World Trends excerpts an interview we recently had with Ted Lin — a legend in the motion-control industry and engineer who after more than four decades of work is still inventing motor technologies to benefit our industry and humankind.

Figures such as these aren’t often in the limelight, probably because they’re too busy improving technologies and teaching to engage in self-promotion. Such types are often due recognition more than anyone.

Driving changes in packaging automation Burgeoning laboratory automation uses New automation in agriculture and off highway

All these trends have been spurred to one degree or another by the relentless digitization of anything that will allow it.

However, when push comes to shove (or electromagnetics comes to rotary motion if you will) it’s the drives, motors, and mechanical

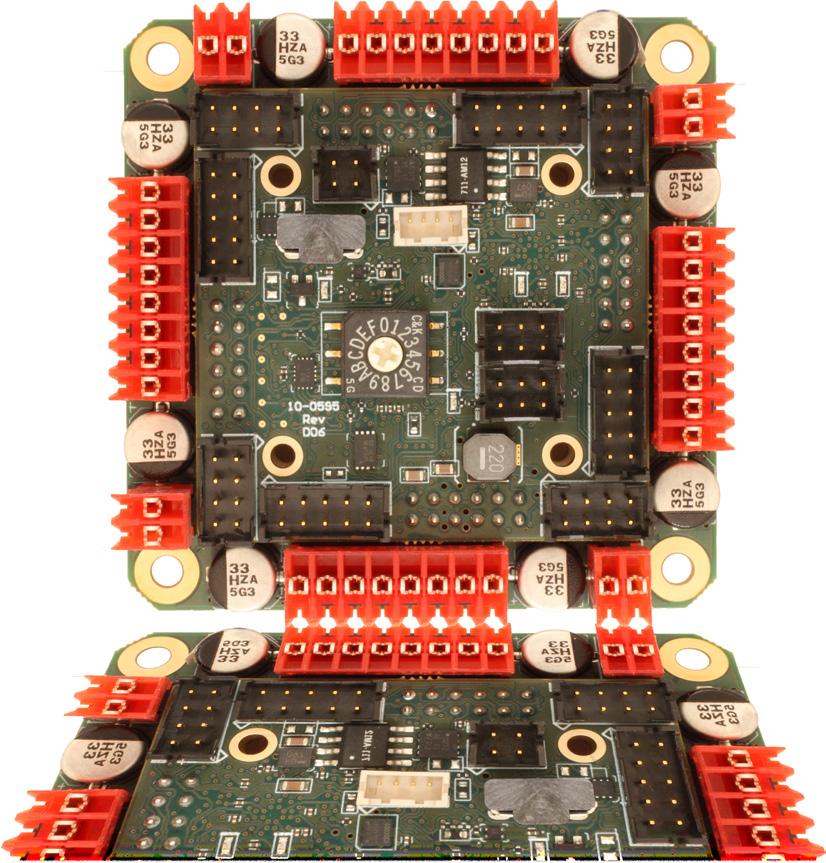

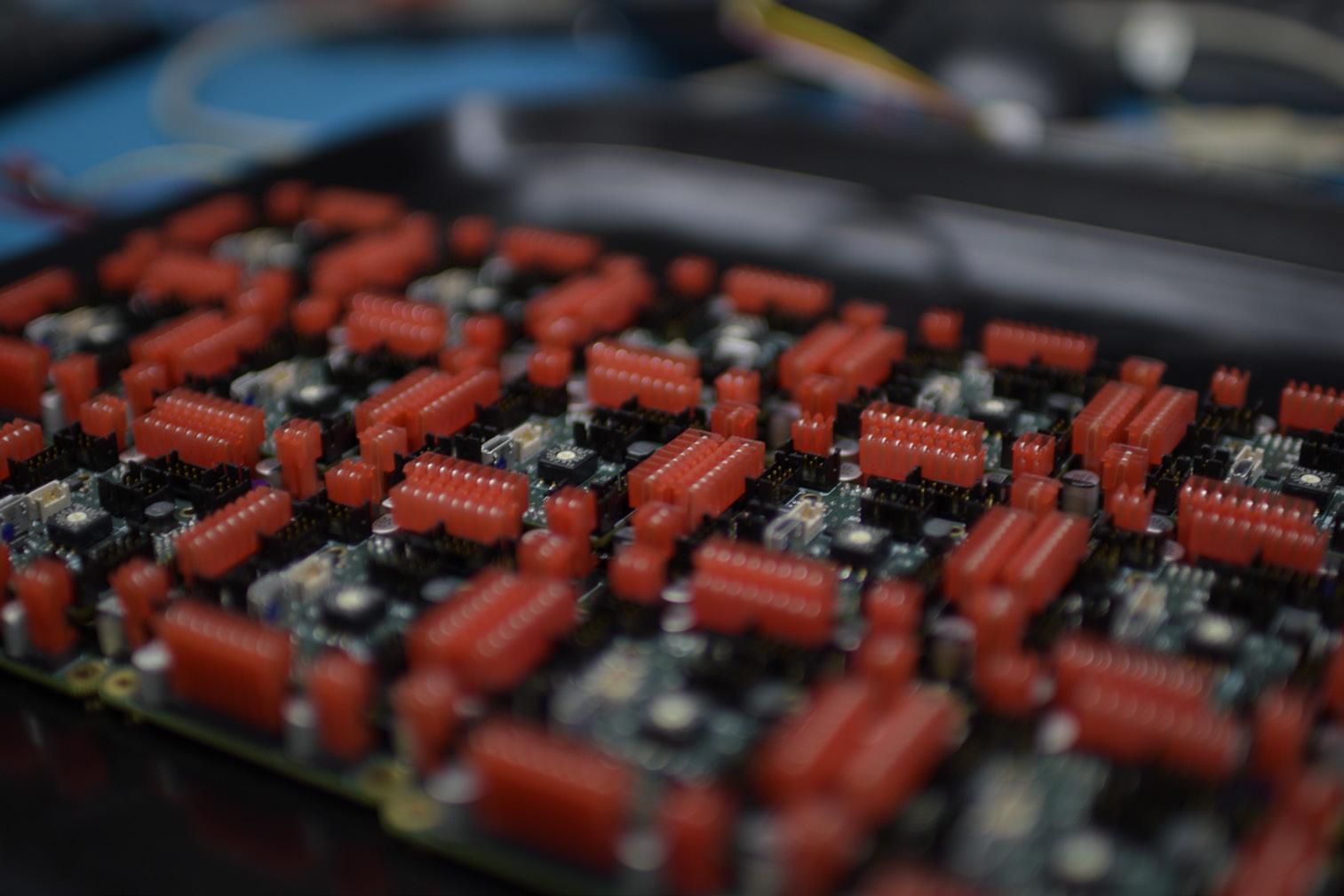

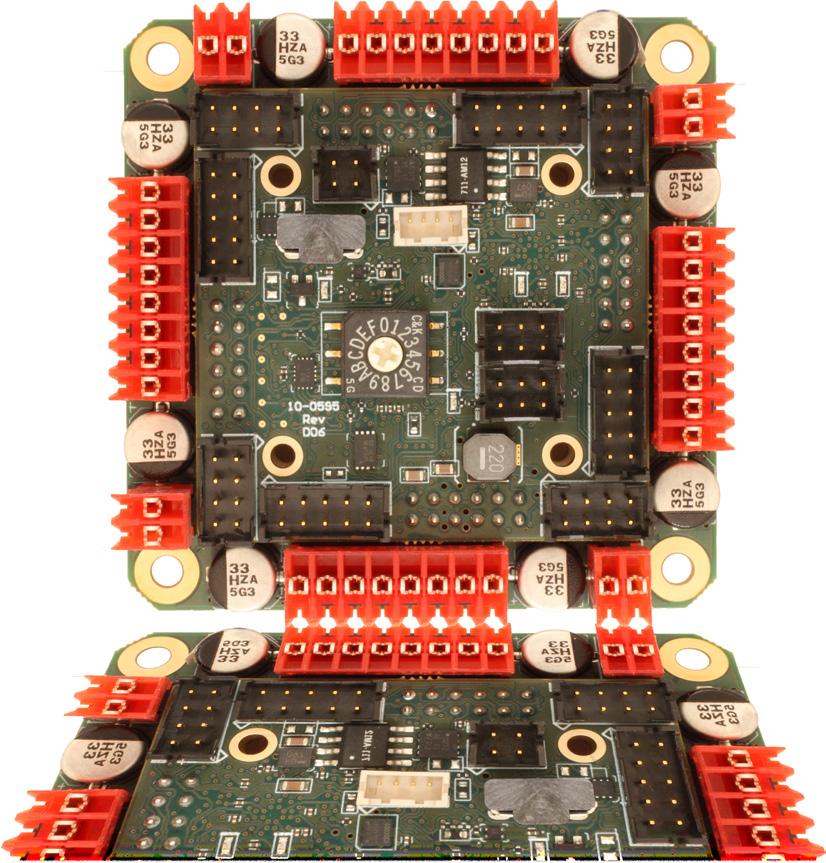

brushed or bldc motors

5 amps per axis

16 analog inputs

16 on/off drivers

home and limit in - live tech support

made in the

WWW.ALLMOTION.COM (510) 471-4000 30097 Ahern Avenue Union City, CA 94587 Technical Support (408) 460-1345 See the EZQUAD SERVO in action! 2.25” 4 AXIS SERVO from NEW! industry trends 4 DESIGN WORLD — MOTION 03 • 2024 Lisa Eitel | linkedin.com/in/elisabetheitel

-

-

-

-

-

-

USA

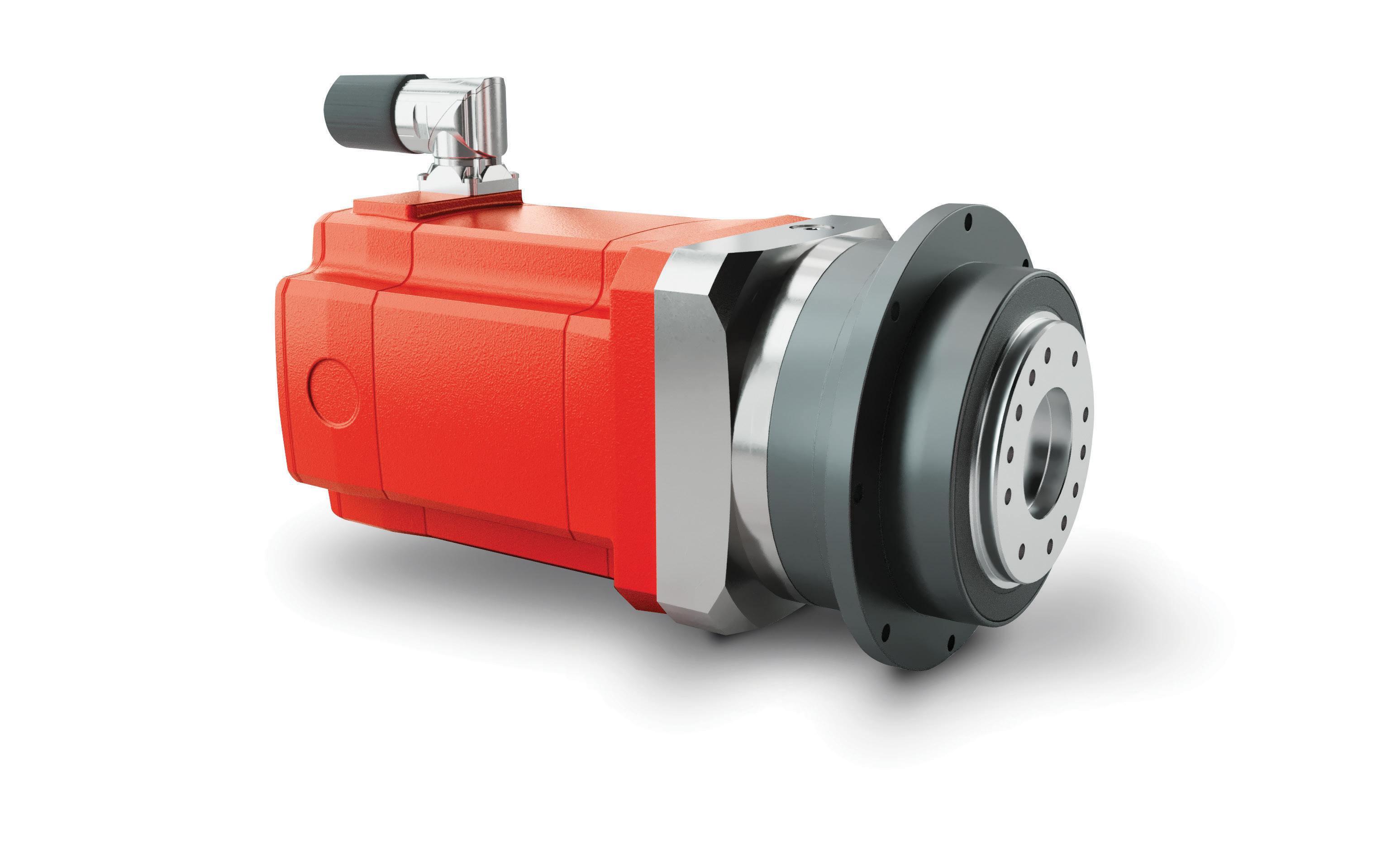

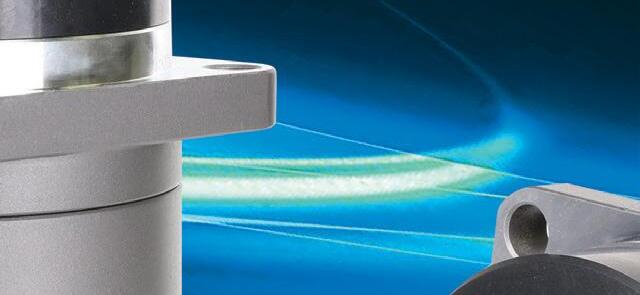

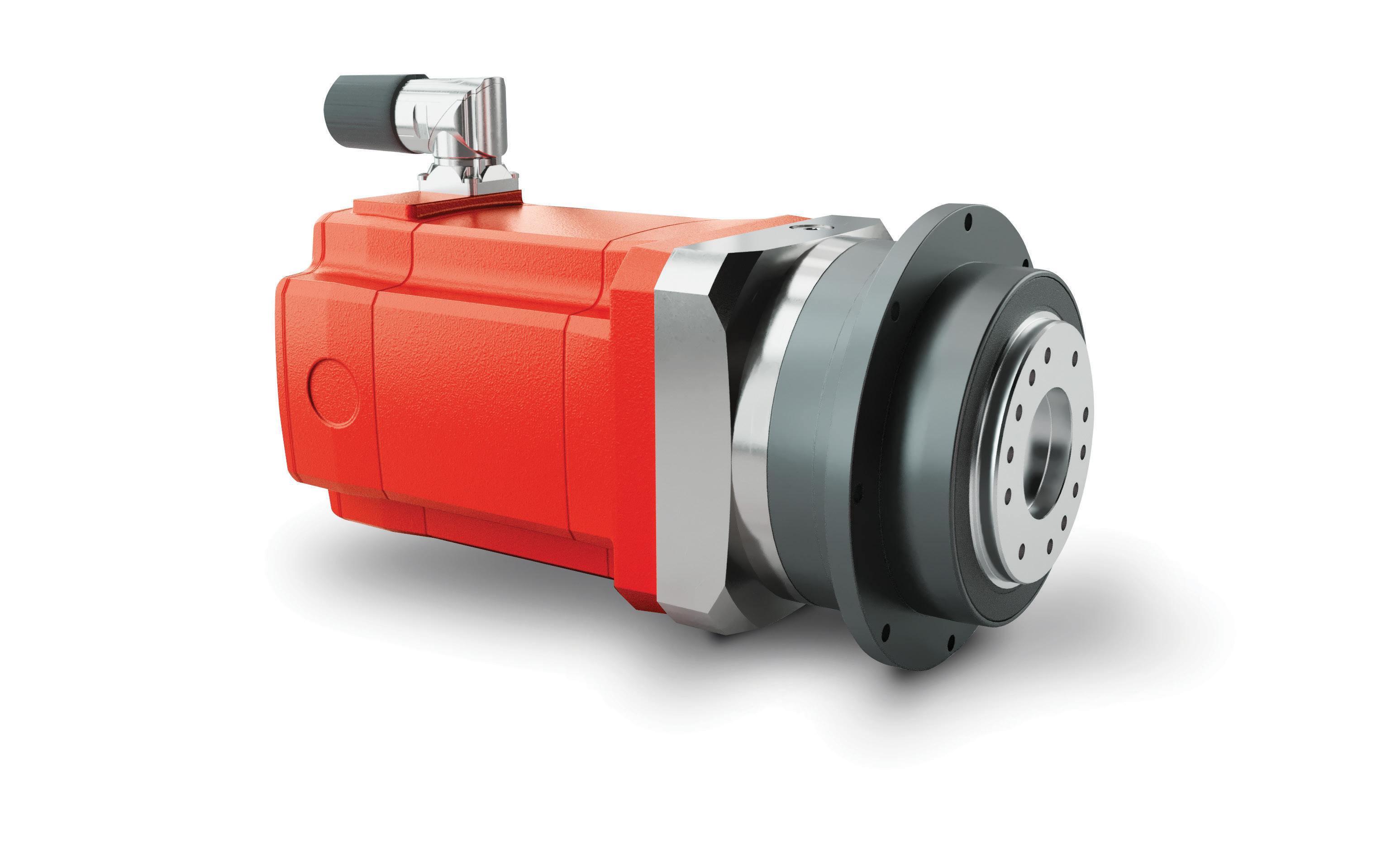

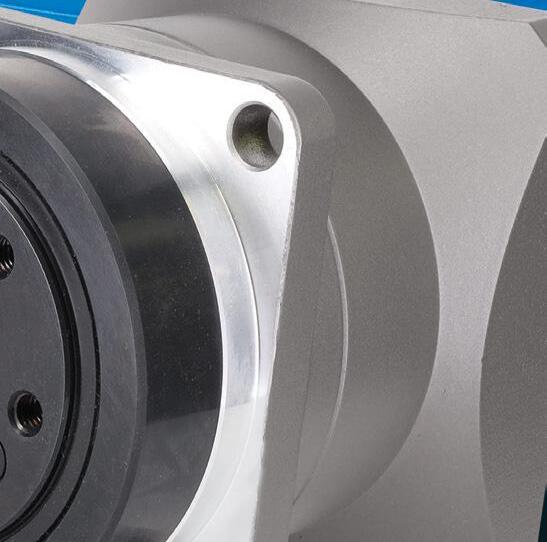

Servo motors and gear units from SEW-EURODRIVE

Servo motors and gear units from SEWEURODRIVE offer a high degree of dynamics and performance with a compact design, making them excellent for confined spaces. Multiple frame sizes and torque ratings makes them the perfect fit in material handling, hoist and gantry applications, and a wide variety of

machine automation applications. Their modular design allows for direct gear unit mounting without adapters or couplings. Pair that with the option of single-cable technology and you’ve got a flexible, precise servo drive solution.

www.seweurodrive.com

Precise. Powerful. Modular.

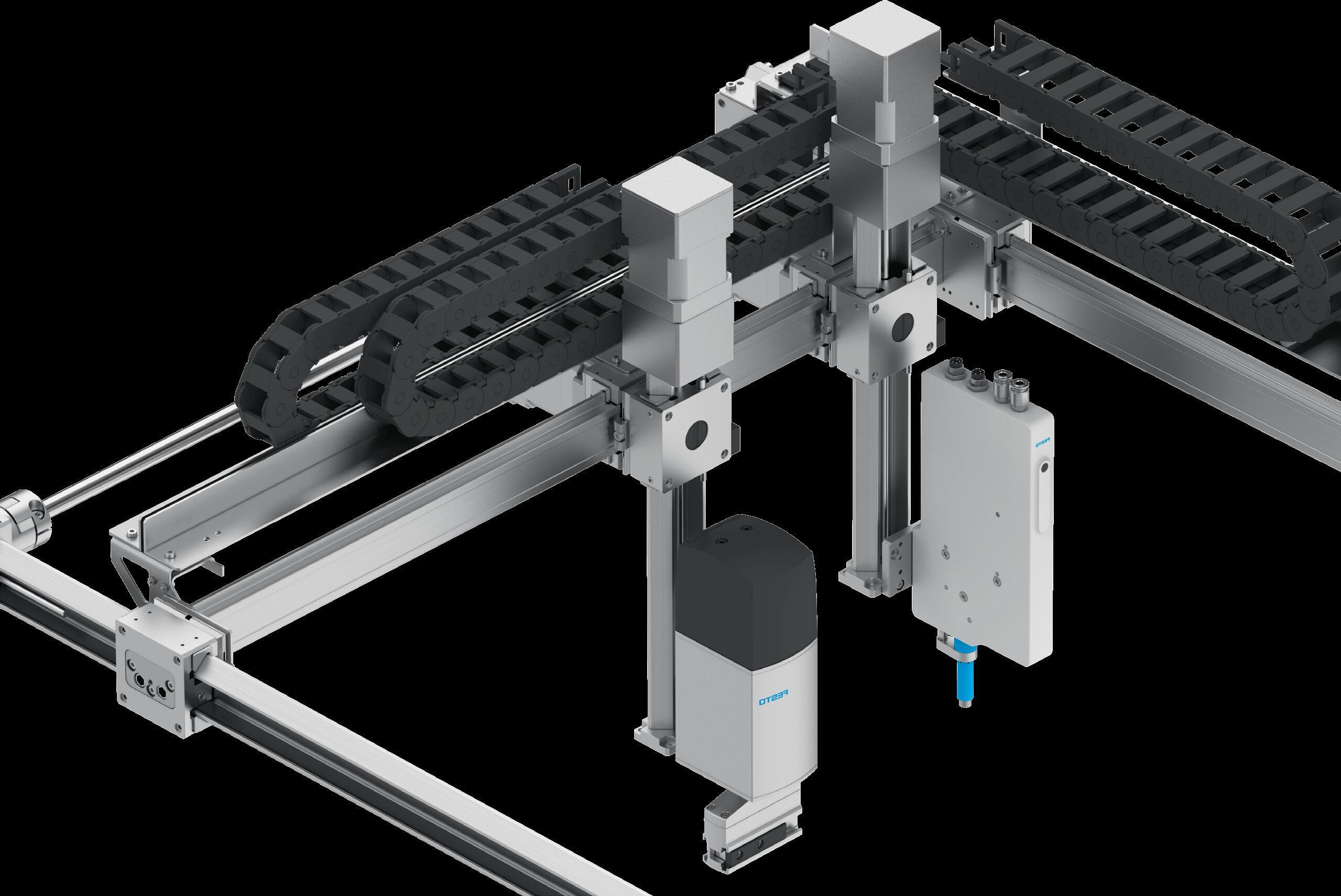

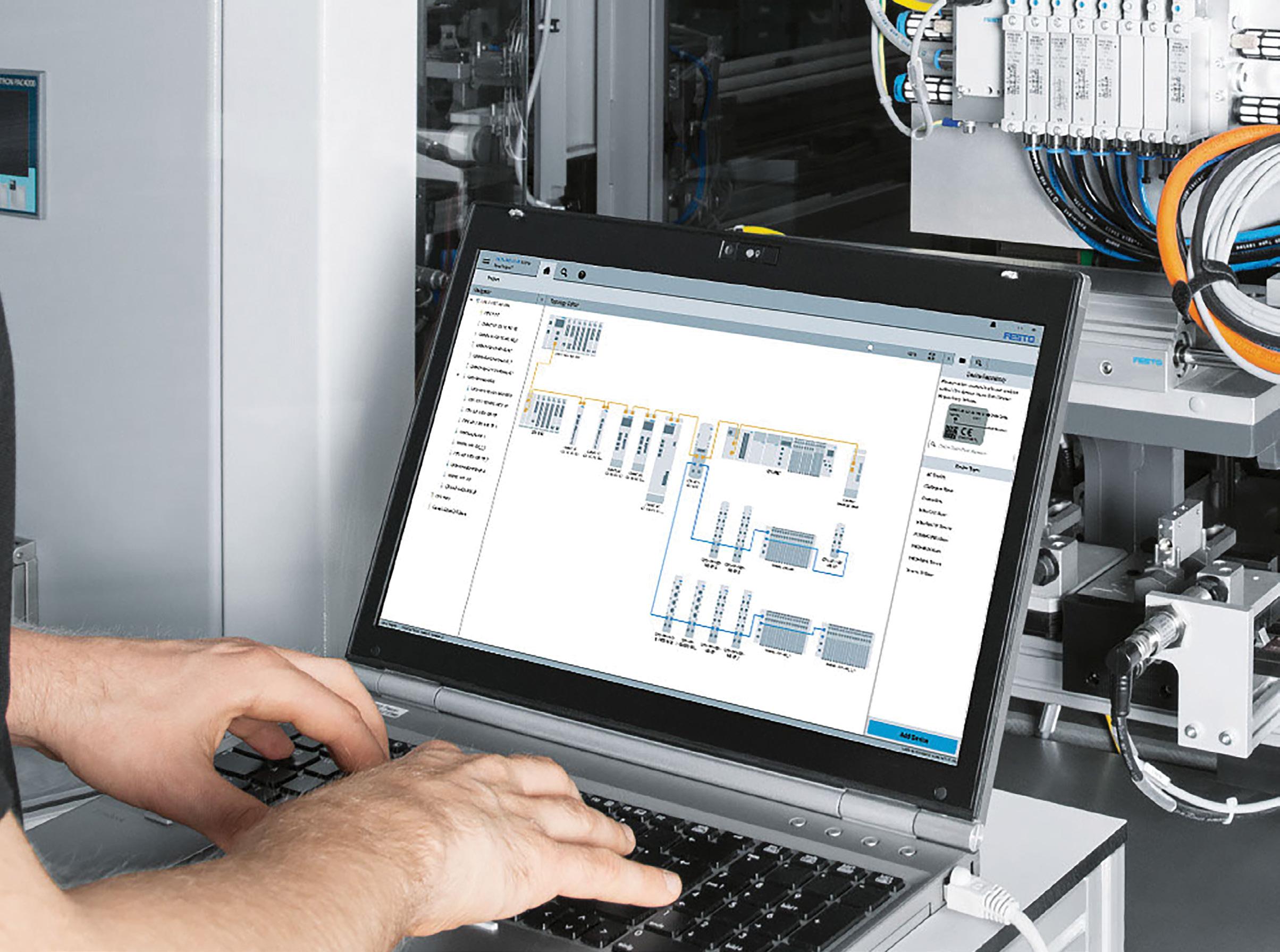

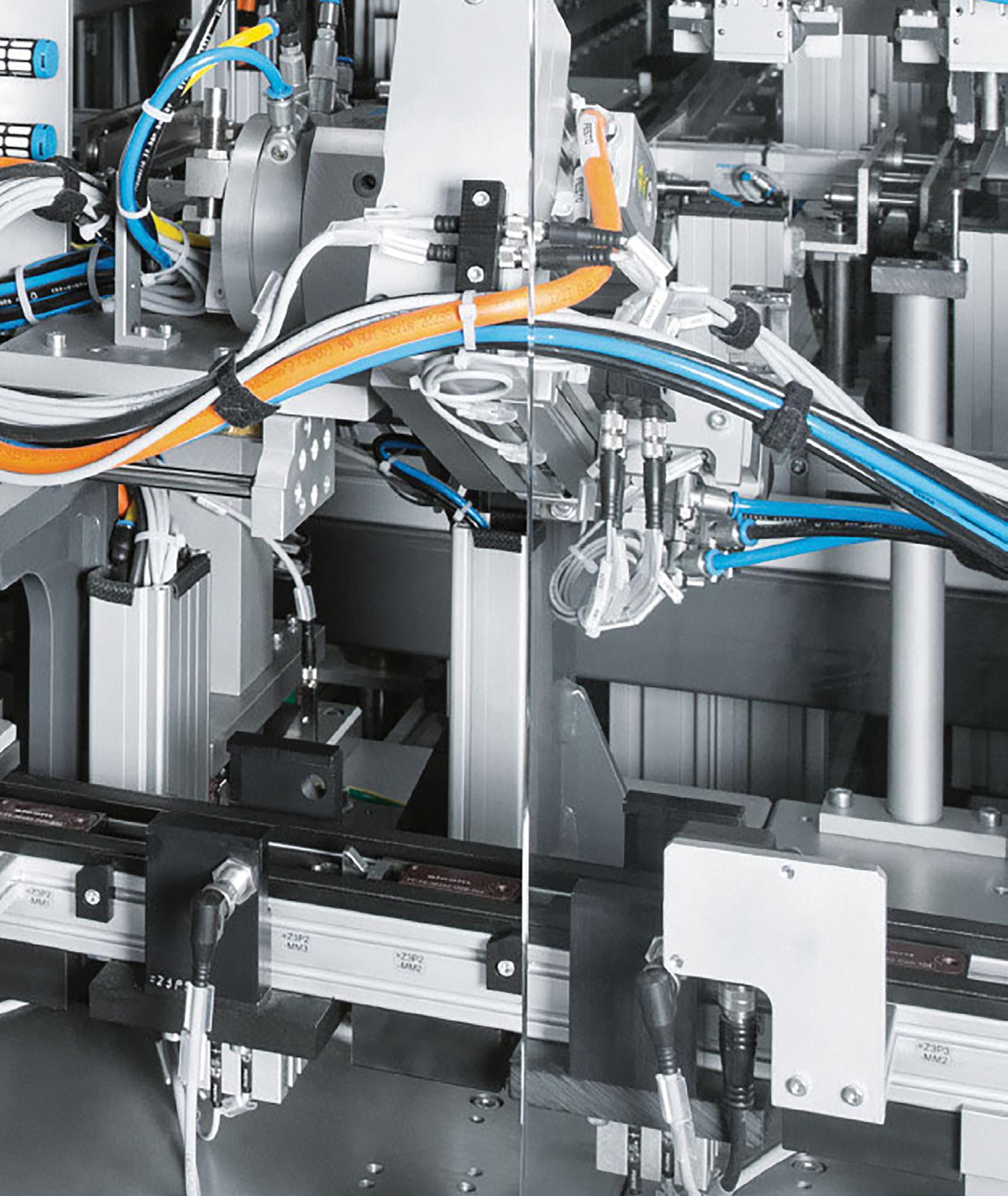

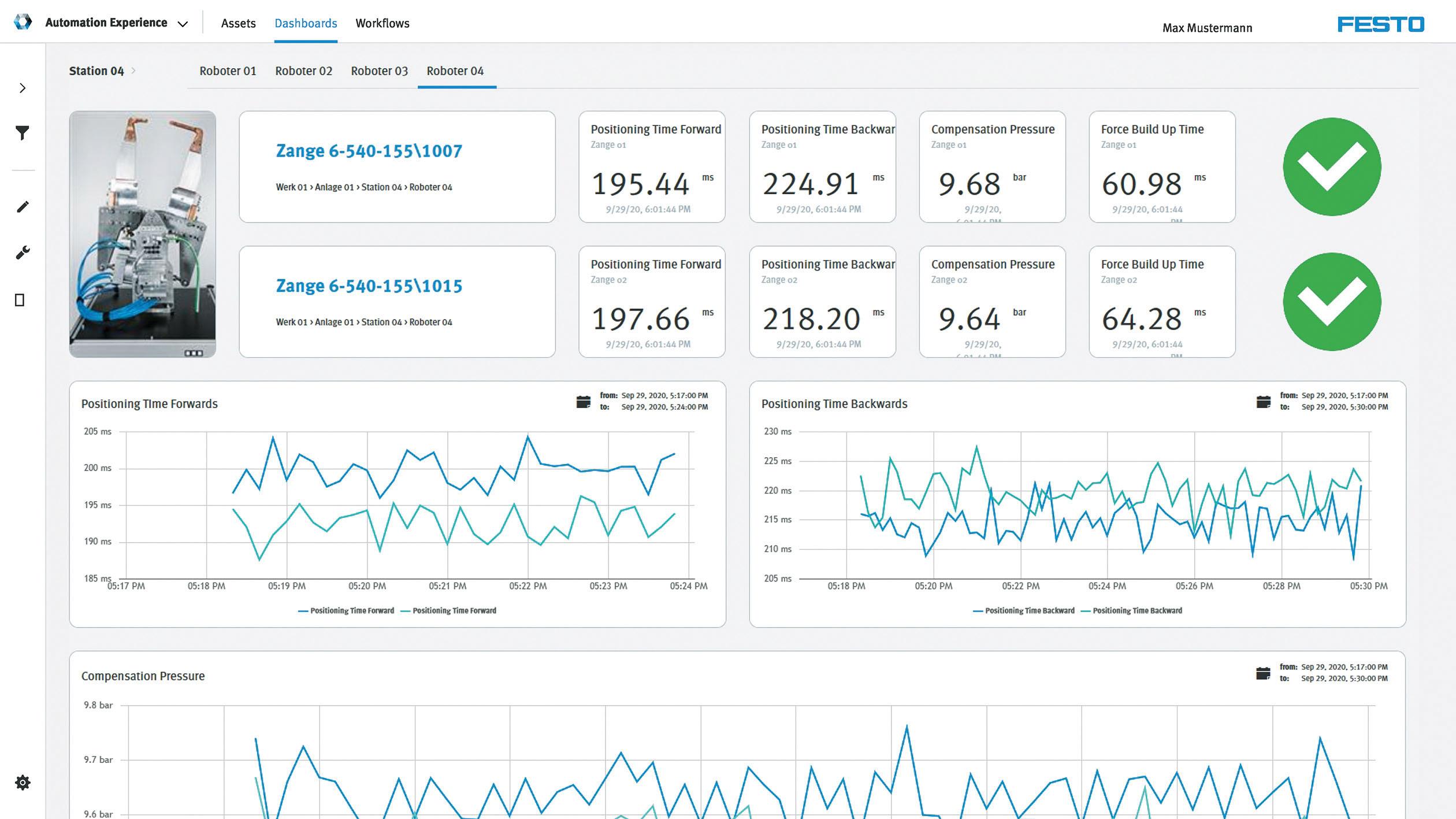

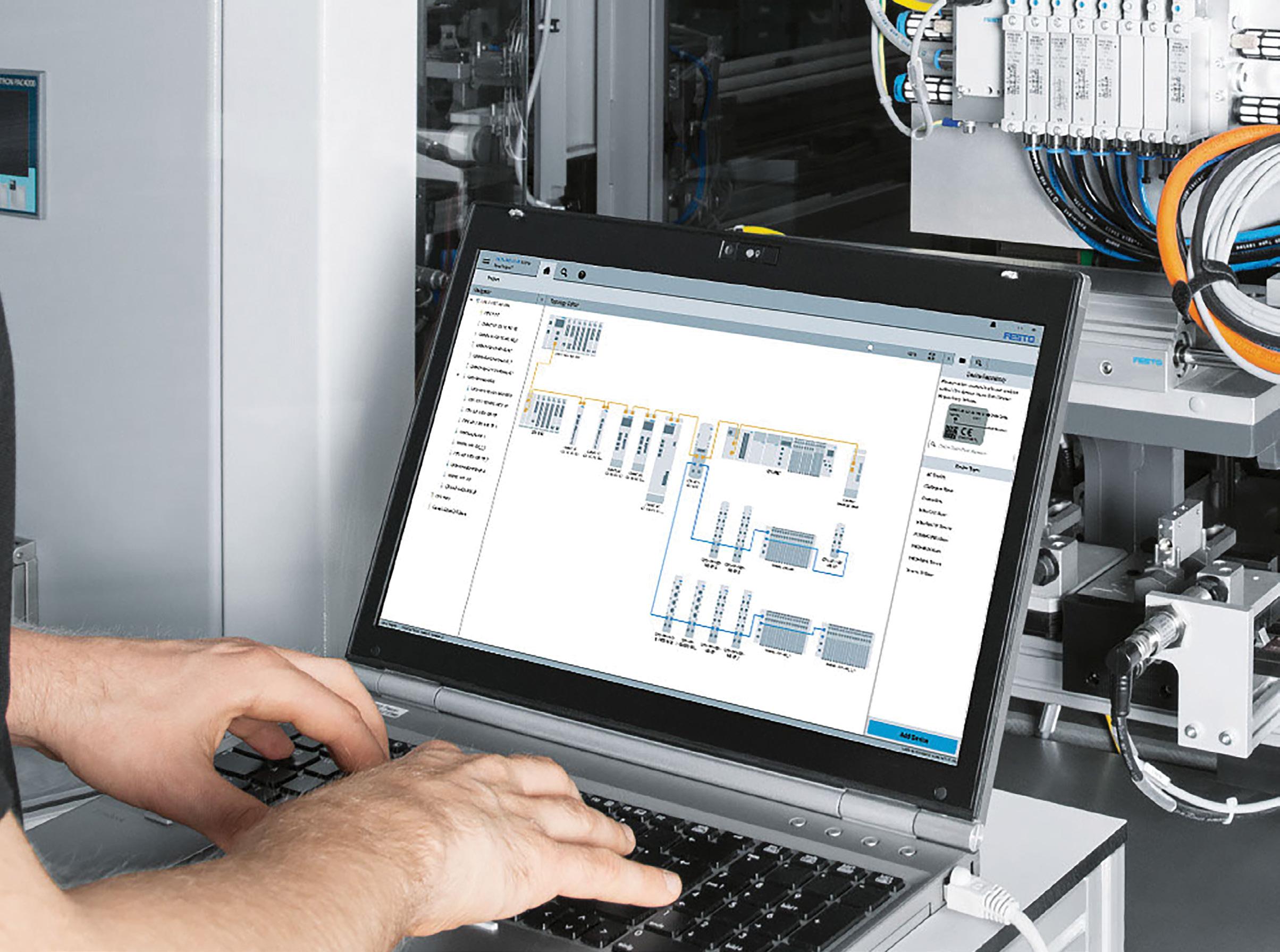

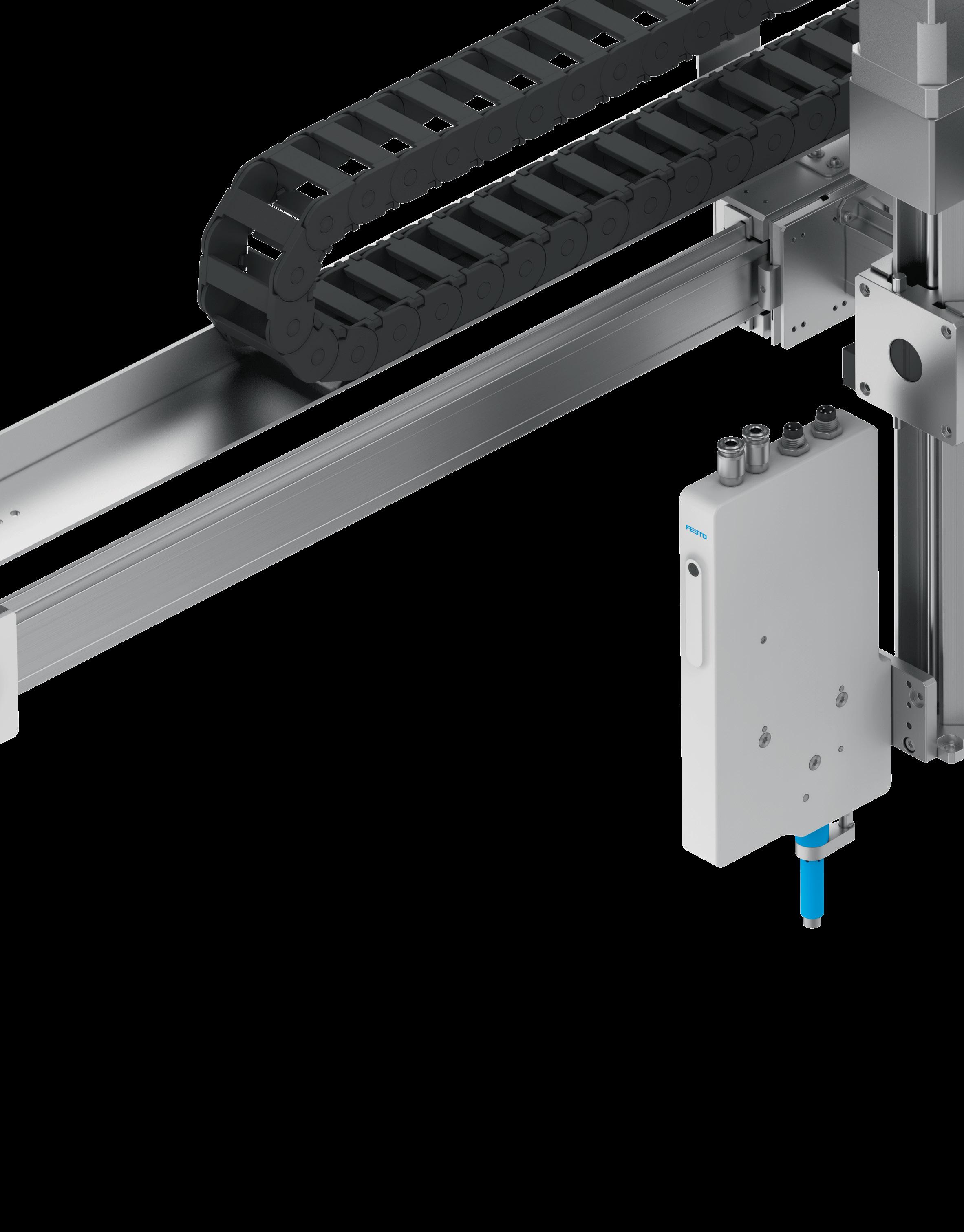

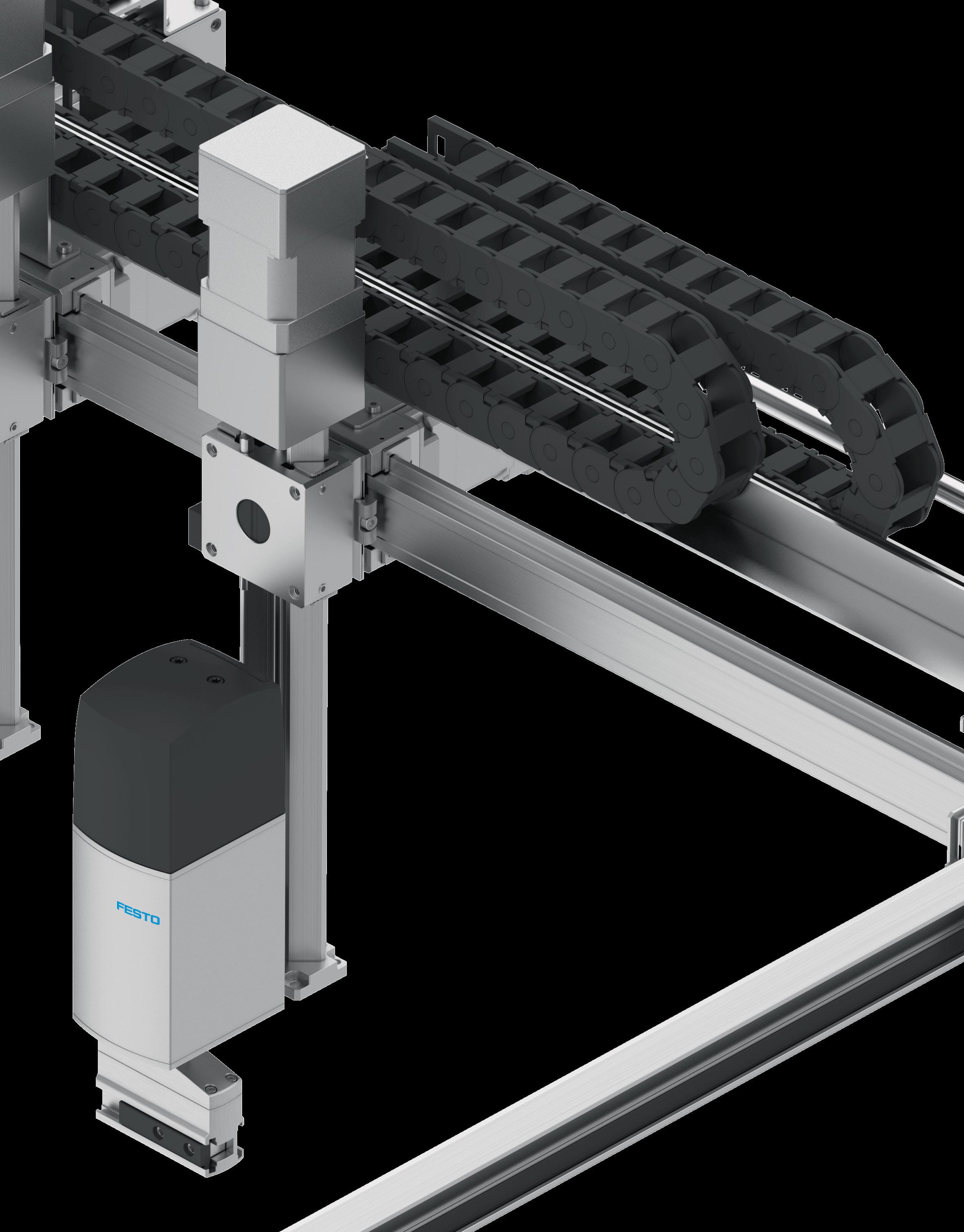

04 E DITORIAL 07 STAFF & AD INDEX 08 AGRICULTURE AND OFF HIGHWAY 14 ARTIFICIAL INTELLIGENCE 24 DRIVING CHANGE IN PACKAGING AUTOMATION 32 NEW MOTOR DESIGNS 40 LABORATORY AUTOMATION 48 LIN ENGINEERING WINDUP CONTENTS 37 17 volume 10 number 1 industry trends On the Cover: Festo AX, a new machine learning and artificial intelligence (AI) software platform, ensures maximum uptime, product quality, and energy efficiency in a host of applications. 6 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

EDITORIAL

VP, Editorial Director Paul J. Heney pheney@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

Senior Editor Rachael Pasini rpasini@wtwhmedia.com

SALES

Ryan Ashdown rashdown@wtwhmedia.com 216.316.6691

Jami Brownlee jbrownlee@wtwhmedia.com 224.760.1055

Mary Ann Cooke mcooke@wtwhmedia.com 781.710.4659

Jim Dempsey jdempsey@wtwhmedia.com 216.387.1916

Mike Francesconi mfrancesconi@wtwhmedia. com

630.488.9029

Jim Powers jpowers@wtwhmedia.com 312.925.7793

CREATIVE SERVICES & PRINT PRODUCTION

VP, Creative Director Matthew Claney mclaney@wtwhmedia.com

Graphic Designer

Shannon Pipik spipik@wtwhmedia.com

Director, Audience Development Bruce Sprague bsprague@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Representative Tracy Powers tpowers@wtwhmedia.com

Customer Service Representative JoAnn Martin jmartin@wtwhmedia.com

Customer Service Representative Renee Massey-Linston renee@wtwhmedia.com

Customer Service Representative Trinidy Longgood tlonggood@wtwhmedia.com

ONLINE DEVELOPMENT & PRODUCTION

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

Senior Digital Media Manager Patrick Curran pcurran@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

LEADERSHIP TEAM

Senior VP, Engineering Courtney Nagle cnagle@wtwhmedia.com 440.523.1685

CEO Scott McCafferty smccafferty@wtwhmedia.com 310.279.3844

EVP Marshall Matheson mmatheson@wtwhmedia.com 805.895.3609

CFO Ken Gradman kgradman@wtwhmedia.com 773.680.5955

FINANCE

Controller Brian Korsberg bkorsberg@wtwhmedia.com

Accounts Receivable Specialist Jamila Milton jmilton@wtwhmedia.com

MARKETING

VP, Digital Marketing Virginia Goulding vgoulding@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Webinar Manager Matt Boblett mboblett@wtwhmedia.com

WTWH Media, LLC

1111 Superior Ave., Suite 2600 Cleveland, OH 44114

Ph: 888.543.2447

FAX: 888.543.2447

only US funds are accepted. Single copies $15 each.

Subscriptions are prepaid, and check or money orders only.

Subscriber Services: To order a subscription or change your address, please email: designworld@omeda.com, or visit our web site at www.designworldonline.com

POSTMASTER: Send address changes to: Design World, 1111

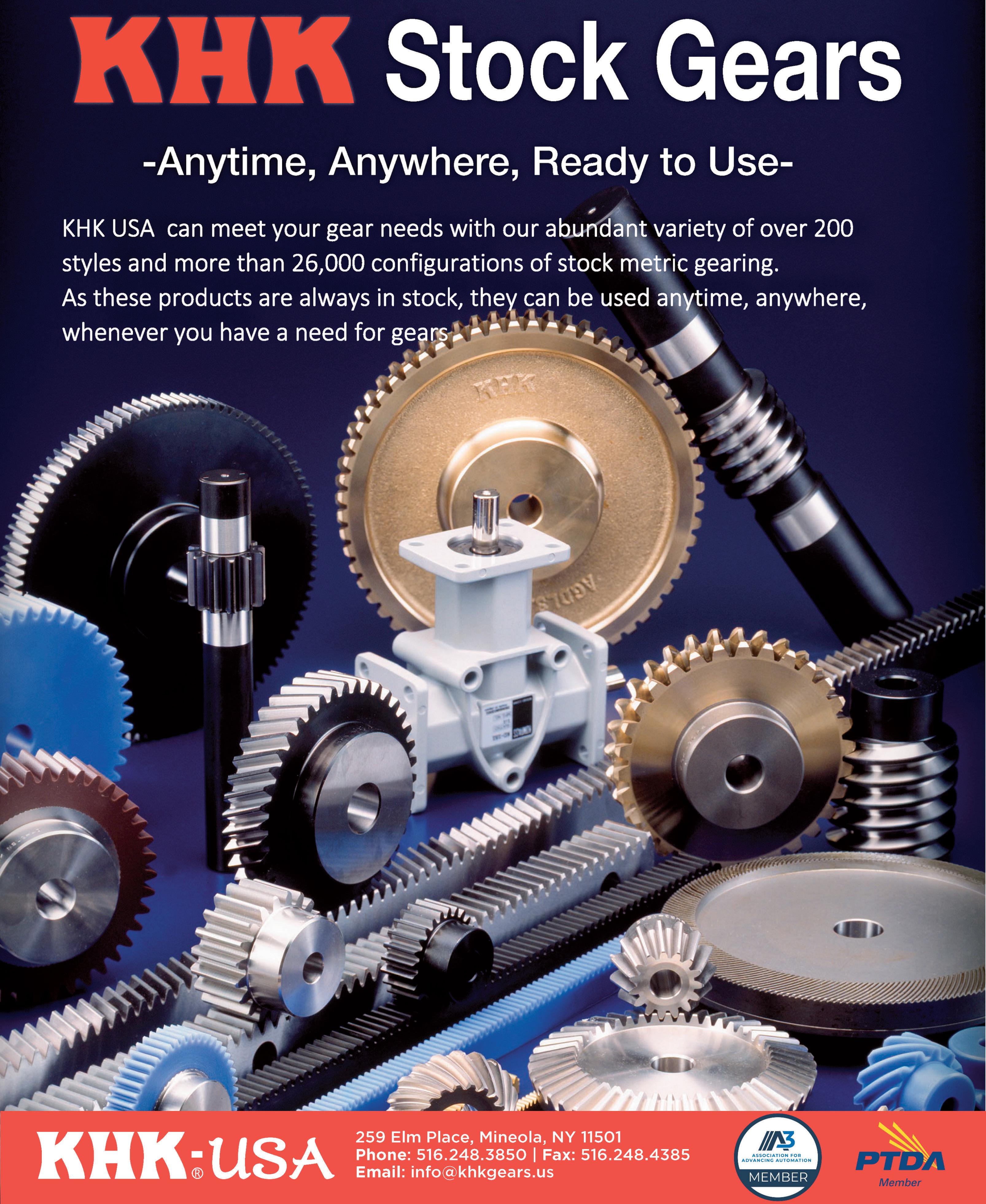

Ace Controls 11 AllMotion 4 Automation Direct 1 Altech Corp BC Canon U.S.A. Inc .............................................................46 CGI Inc. .............................................................................22 Chieftek Precision 22 CMT 34 Del-Tron 42 Diequa 36 DigiKey 3 Dura-Belt ..........................................................................47 Encoder Products Company 43 FESTO 18 KHK USA Inc. . 19 Harmonic Drive 30 Maxon Snipe, IFC Mitsubishi Electric Automation ........................................23 NB Corp. 10 NBK America 13 Parvalux, By maxon 38 PBC Linear IBC PI (Physik Instrumente) LP 21 Pyramid, Inc. .....................................................................16 Renishaw ..........................................................................19 Ruland Manufacturing 31 SEW-Eurodrive 5 SMW Autoblok Corp. 25, 27, 29 Sorbothane 45 Stock Drive Products/Sterling Instrument 39 Zero-Max, Inc. ....................................................................2 AD INDEX volume 10 number 1 DESIGN WORLD does not pass judgment on subjects of controversy nor enter into dispute with or between any individuals or organizations. DESIGN WORLD is also an independent forum for the expression of opinions relevant to industry issues. Letters to the editor and by-lined articles express the views of the author and not necessarily of the publisher or the publication. Every effort is made to provide accurate information; however, publisher assumes no responsibility for accuracy of submitted advertising and editorial information. Non-commissioned articles and news releases cannot be acknowledged. Unsolicited materials cannot be returned nor will this organization assume responsibility for their care. DESIGN WORLD does not endorse any products, programs or services of advertisers or editorial contributors. Copyright© 2024 by WTWH Media, LLC. No part of this publication may be reproduced in any form or by any means, electronic or mechanical, or by recording, or by any information storage or retrieval system, without written permission from the publisher. Subscription Rates: Free and controlled circulation to qualified subscribers. Non-qualified persons may subscribe at the following rates: U.S. and possessions: 1 year: $125; 2 years: $200; 3 years: $275; Canadian and foreign, 1 year: $195;

2011- 2020 2013 - 2017, 2021 2014- 2016 2014 Winner

AUTOMATION IN AGRICULTURE AND OFF HIGHWAY

8 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com industry trends

automation

In smart agriculture applications, companies are leveraging motion systems to improve reliability in their designs. Advances in automation technology as well as related advances in sensors, imaging, and communications have meant improvements to the kinds of motion control systems employed in agricultural applications as well as other off-highway uses.

That means that the smart agriculture market is only poised for more growth in the coming years. In the U.S. alone, the smart agriculture market is expected to grow at a CAGR of 10.4% from 2024 through 2030.

Design World editors recently asked a number of leading manufacturers involved in the agriculture and off-highway automation industries about these trends. Here’s what they had to say.

What are the most significant advances in agricultural automation?

Guitart: Electrification of off-highway equipment is becoming easier with advancements in high-efficiency, sustainable electric motors that can bring innovation to the sector, support decarbonization, and improve machine reliability and productivity.

Giunta: Vertical farming, in my opinion, is critical for the future of North American agriculture with automation. Being able to provide a fresh product at the ideal time for consumption with reduced trucking times allows the consumer to enjoy a healthier and chemical-free product.

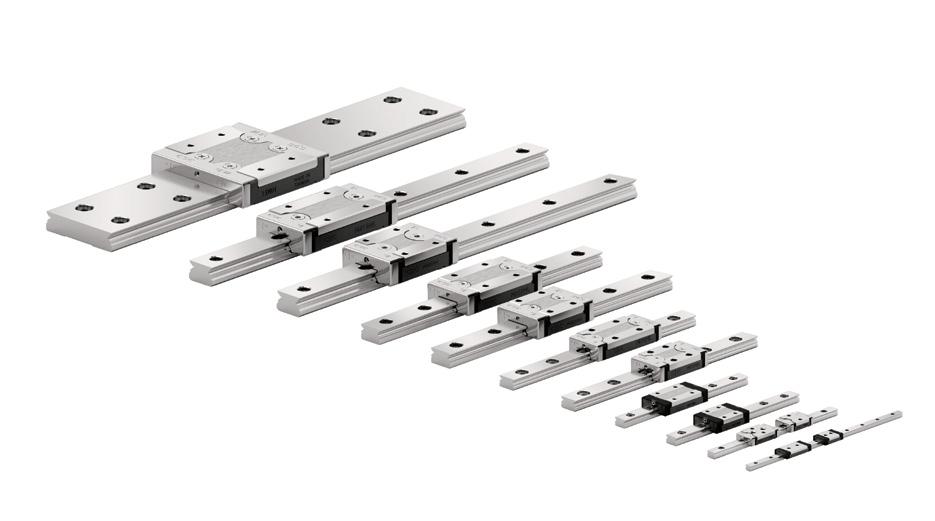

Caldwell: The vertical farming, indoor greenhouse, and variety of smart-farming operations align exceptionally well with robotic automation. There are a variety of tasks that can be completed with a range of products including our industrial and collaborative robots, linear motion range, and a variety of external axis solutions.

What components and systems are advancing automated farming?

Field: The most significant technologies for achieving autonomous operations in agriculture are geolocation, telematics, machine vision, and communications back to the operator. And, of

farming

9 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

Image: AdobeStock

...All In Less Space

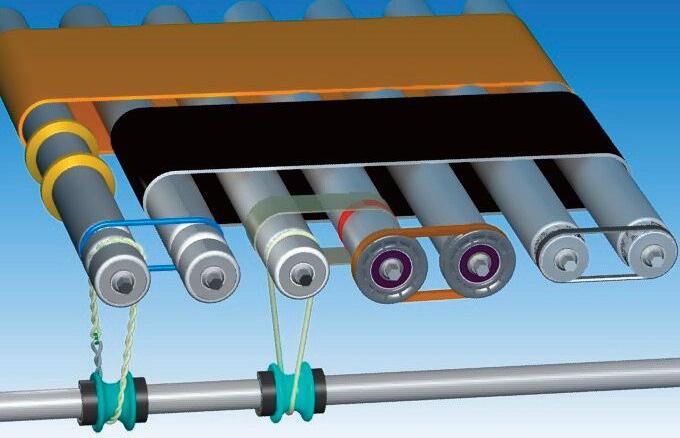

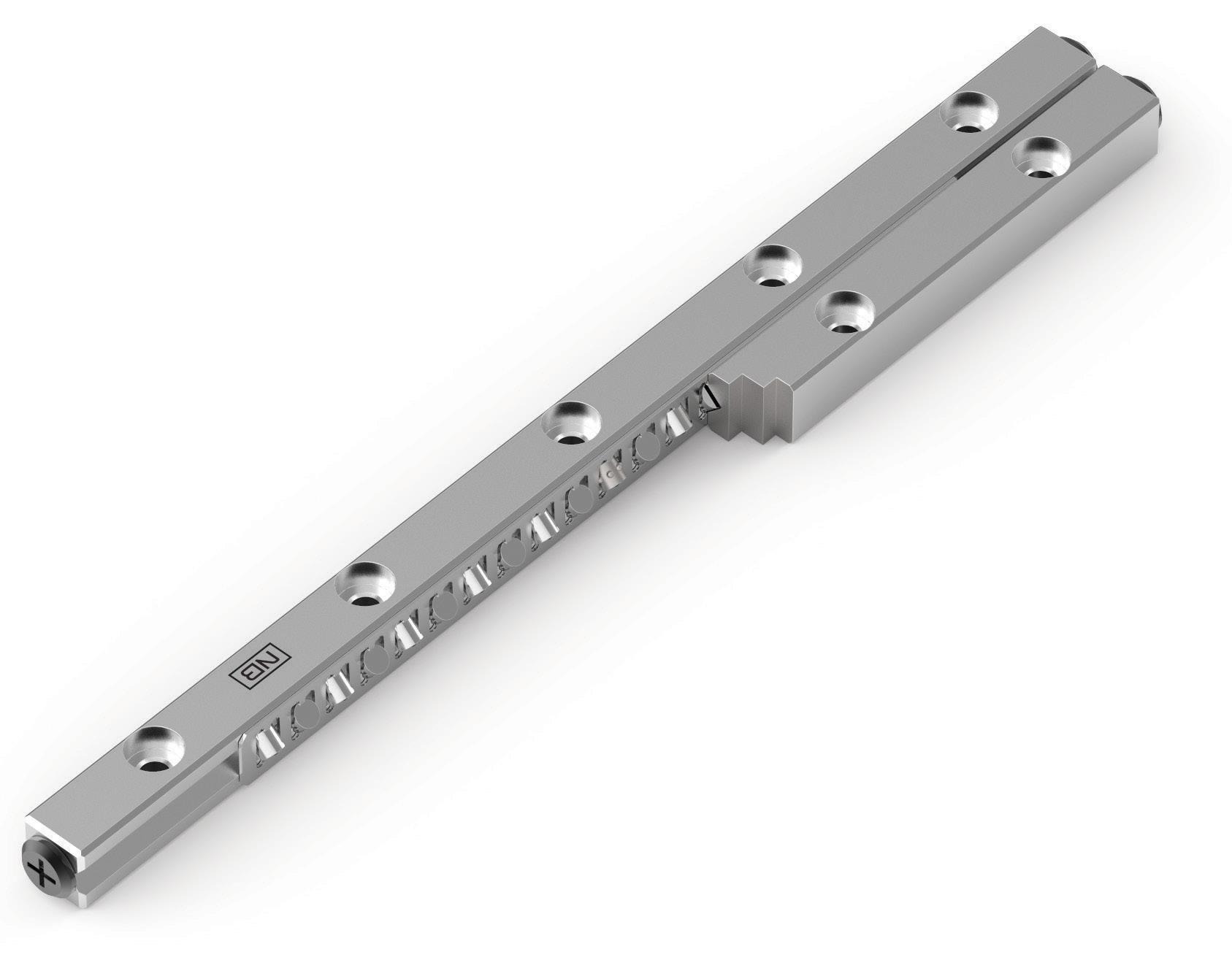

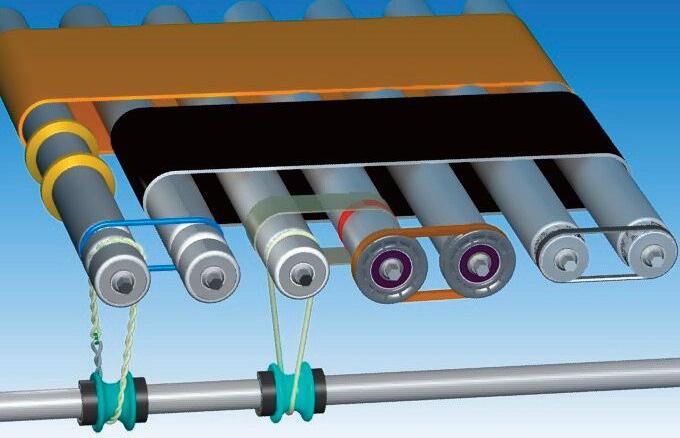

STUDROLLER®

Ultra High Capacity, Zero Slippage, Lower Cost.

For rapid acceleration and deceleration:

• 30~600mm rail lengths

• 2~12 mm rollers

• 150 million cycle endurance

Load capacity is increased up to 250% over competition’s by greater roller-to-rail contact

Number of rollers is 20% to 55% greater than competitions.

STUDROLLER’s nodules preventing slippage - in any position. (Patent Pending)

Stainless Steel retainer

Raceway’s depressions track

Now Available in All Stainless Steel.

course, there are the processors, sensors, controls, and other key components that make up these core technologies. Had there not been advancements in the way of faster speeds, smaller footprints, less power consumption, holistic IoT systems for collecting and analyzing data and more, autonomous operations would not be possible today. More capabilities are on the horizon, as the industry looks to implementing radar technology and beyond.

Autonomy and automation are getting tons of investment today in the agricultural equipment market, with companies at different phases of implementation. Greater efficiency is one goal, but other benefits include higher crop yields, more precision, and a reduction in the amount of environmental impact by using fewer chemicals and less water. There are autonomous vehicles in use today that can operate at a greater level of accuracy and precision than vehicles on the road, plant seeds within a centimeter accuracy, control the rate of seed dispensing, analyze the health of crops, and put down fertilizer only where it’s needed—just to name a few of the capabilities of the newest equipment offerings.

Umeno: Our motion control technologies are playing a pivotal role in shaping the future of farming, as the agricultural landscape undergoes a revolution driven by rising costs, labor shortages, and environmental concerns. Innovative solutions such

as vertical farming and smart farming operations are gaining traction, demanding precise and efficient automation.

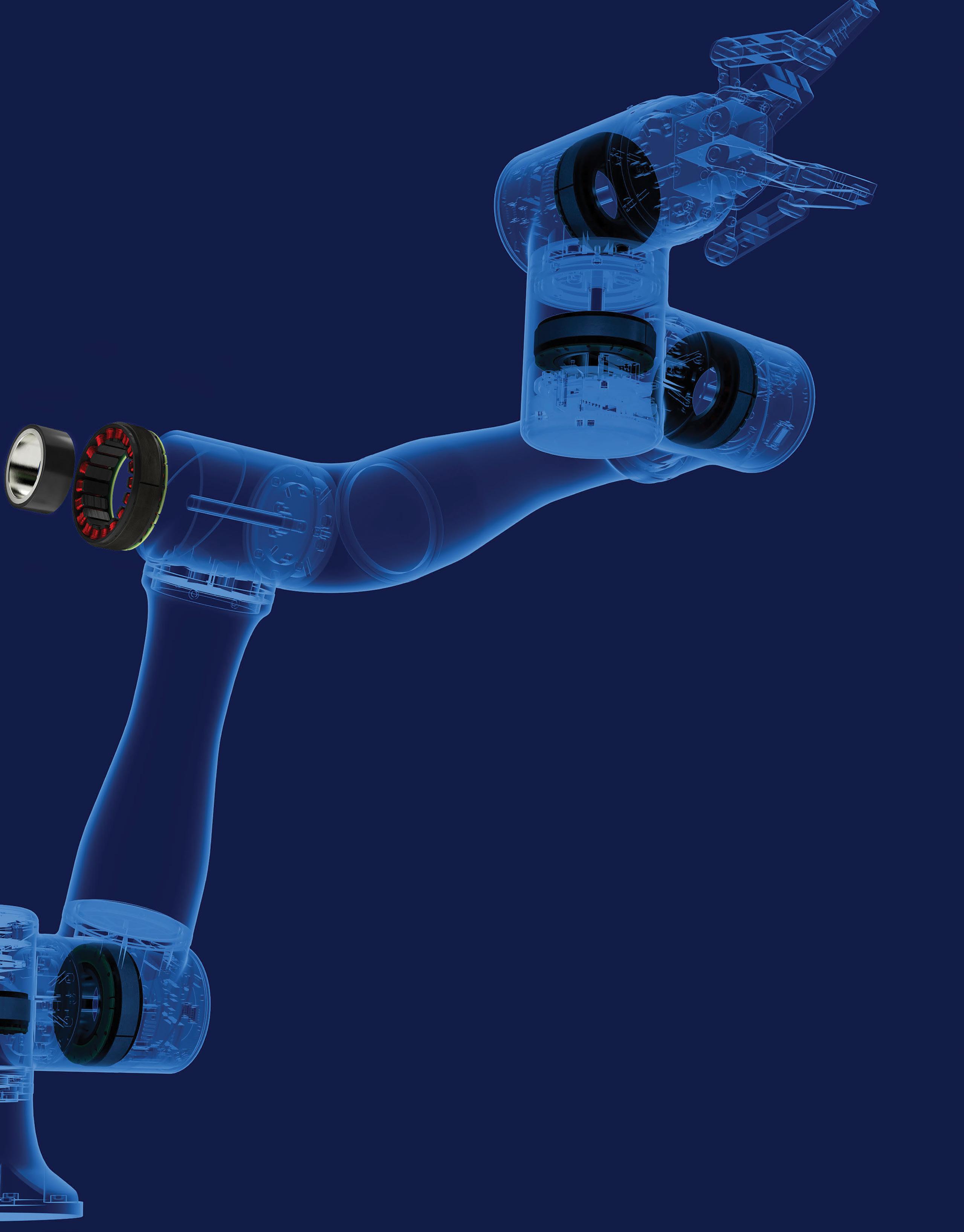

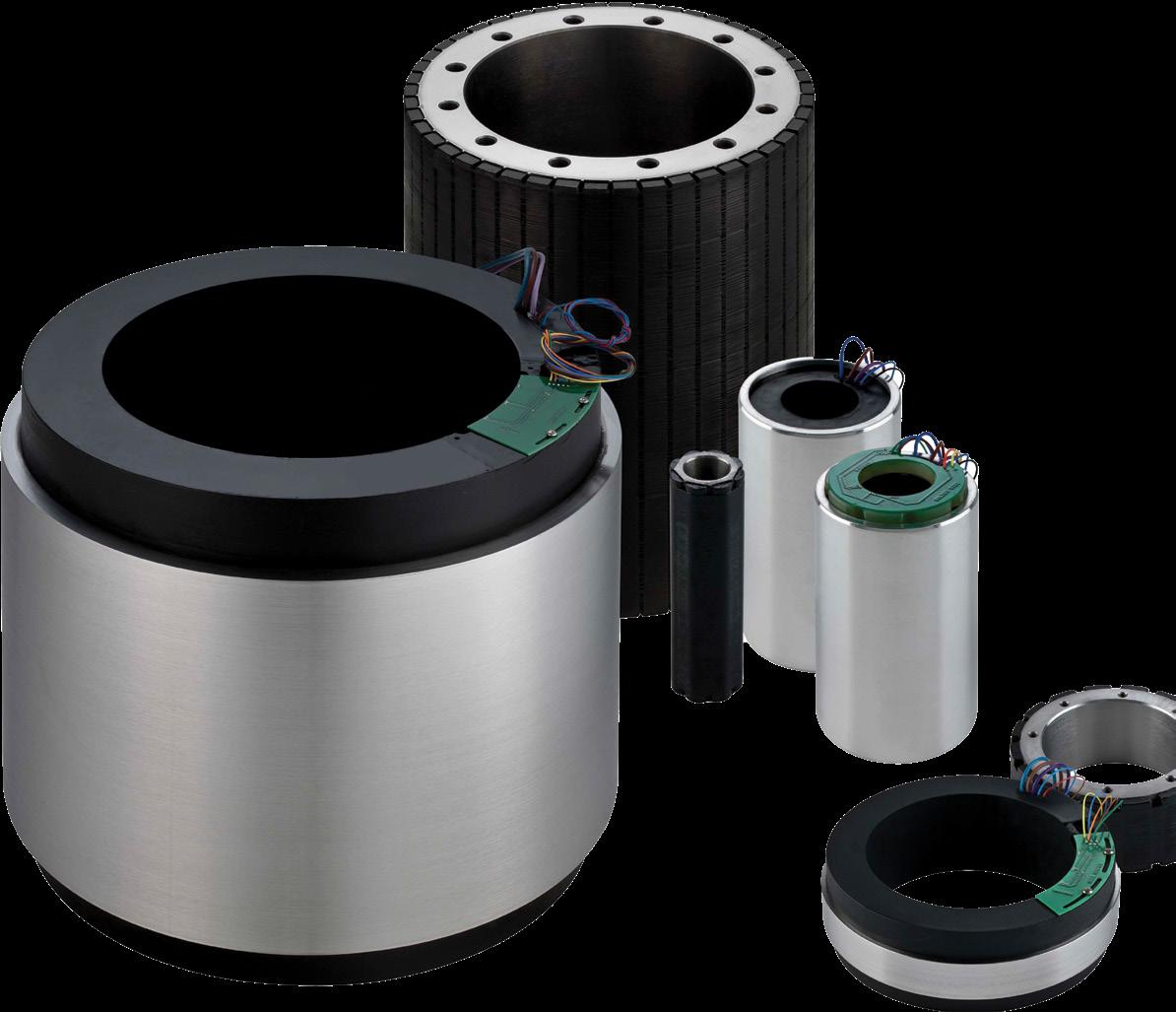

Especially in controlled environments like greenhouses where delicate crops like herbs, mushrooms, and tomatoes demand gentle handling to avoid damage. Kollmorgen offers a comprehensive range of housed and frameless motors, each designed to meet the specific needs of different agricultural applications. These include the AKM and AKM2G Series Servo Motors, which deliver superior torque density in a compact design, making them ideal for higher payload applications. Our frameless motors provide direct-drive smooth motion and efficiency in a compact form factor, and the TBM2G Series Servo Motors, which are specifically designed for robotic arm joints, are ideal for an agricultural robot.

Mayers: Intelligent cameras certainly pave the way for future-oriented image-processing tasks such as plant growth monitoring, weed detection or checking whether certain object conditions are met. Artificial intelligence can also be used, for example, to classify fruit varieties or to identify damaged parts, such as apples with marks or color deviations. To cover all possible variances with classical image processing would be time-consuming and costly. AI like we offer with the IDS NXT vision system can quickly solve these challenges.

automation 800-521-3320 www.acecontrols.com WHEN PERFORMANCE MATTERS trust ACE Controls with your motion and vibration control problems AUTOMATION CONTROL MOTION CONTROL VIBRATION CONTROL SAFETY PRODUCTS 11 DESIGN WORLD — MOTION 03 • 2024

Image: AdobeStock

farming

Schafer: The motion-controller demands are higher for agriculture applications that for vision systems and robots. Modifying trajectories on the fly when harvesting, sorting, and packaging is required. Reduced latency and accuracy demand the latest multicore CPUs for fast throughput. Kollmorgen’s PCMM controllers provide the computational power to meet these needs, all leveraging the same software.

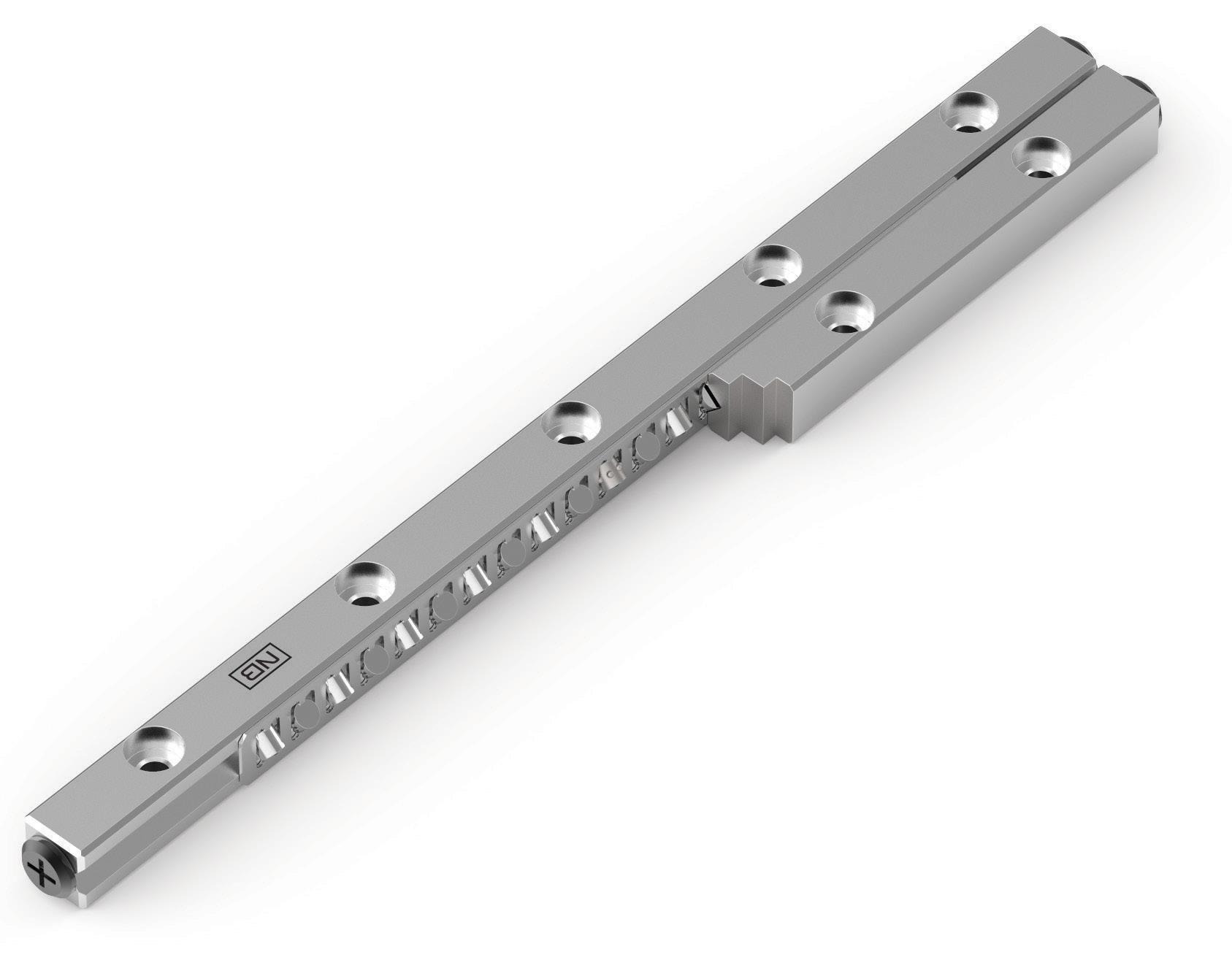

B. Burke: Bishop-Wisecarver DualVee linear guides feature a self-cleaning geometry that tends to sweep away debris in dirty and contaminated environments. These durable linear guides are commonly found on field applications such as automated harvesters and in food processing applications and equipment. An increase in automation is happening in farming and food processing, particularly with autonomous vehicles operating with littl eot no supervision. These automation solutions provide around-the-clock production.

Dengel: Our components have been sourced by several agricultural businesses to use in farming robots. These systems incorporate vision systems, AI, and mechanical systems to select weeds to be removed or to select pests to be treated or to harvest produce at its peak ripening.

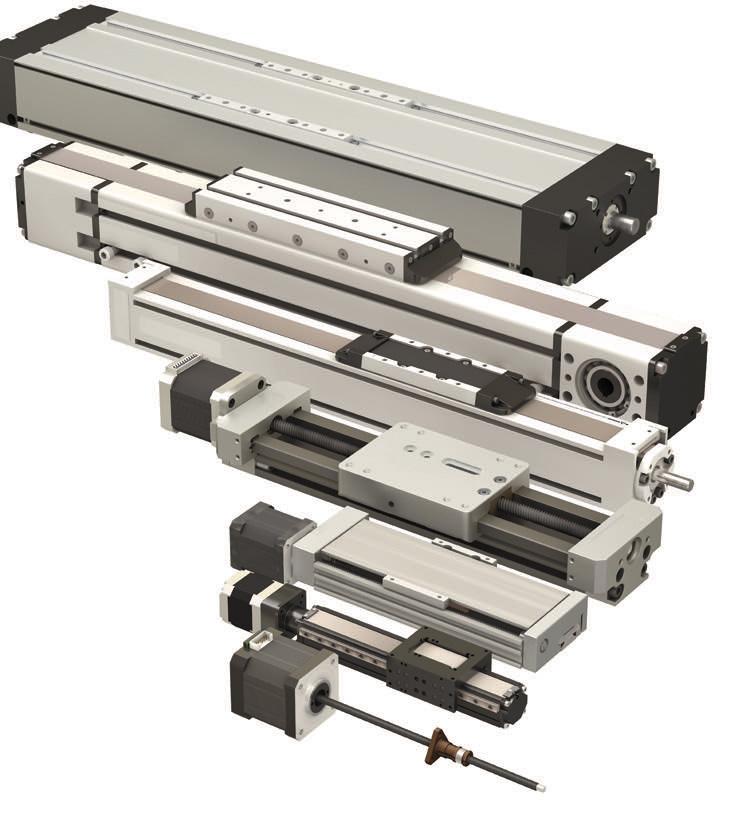

Marques: We’ve designed our actuator systems to be easily combined into long multi-axis configurations. Products like these are changing how much automation we’re seeing in greenhouse operations and vertical farming, because it allows many plants to be tended, sampled, or harvested by an automated mechanical system.

MEET THE EXPERTS

Brian Burke | Product manager III Bishop-Wisecarver Corp.

Chris Caldwell | Product manager — material handling Yaskawa Motoman

Brian Dengel | General manager • KHK USA Inc.

Karen Field | VP content marketing • Avnet

Travis Gilmer | Product line manager — Linear Actuators Thomson Industries Inc.

Michael Giunta | VP of sales and marketing Macron Dynamics Inc.

Ramon Guitart | VP of engineering — electric motors Infinitum

Alex Marques | Product manager Bishop-Wisecarver Corp.

David Mayers | Sales director • IDS Imaging Development Systems Inc.

Dusty Schafer | Manager — software engineering • Kollmorgen

Yoshi Umeno | Industry manager — global medical and robotics Kollmorgen

Bishop-Wisecarver has supplied at least four companies developing self-driving tractor systems, at times providing design support as a collaborator for new product development. Sometimes our bearing components are used to support steering conversion kits (retrofitting tractors for automated GPS guidance), while other companies rely on our durable actuation for vision-guided crop-picking attachments.

Guitart: Infinitum’s Aircore Mobility motors are being deployed for power take-off (ePTO) applications in agricultural equipment to improve efficiency. Engineers can add power from 50 to 250 kW, without significantly increasing the size and weight of the drivetrain. Using an axial flux design, Aircore Mobility motors generate more torque and faster speed in a smaller package. Modular disc design lets engineers build multi-stator, multi-rotor motors in parallel to achieve higher output power and increased performance. Our design also allows for a highly efficient oil-cooling system that cools the interior stator, helping increase power density by three to five times.

•

•

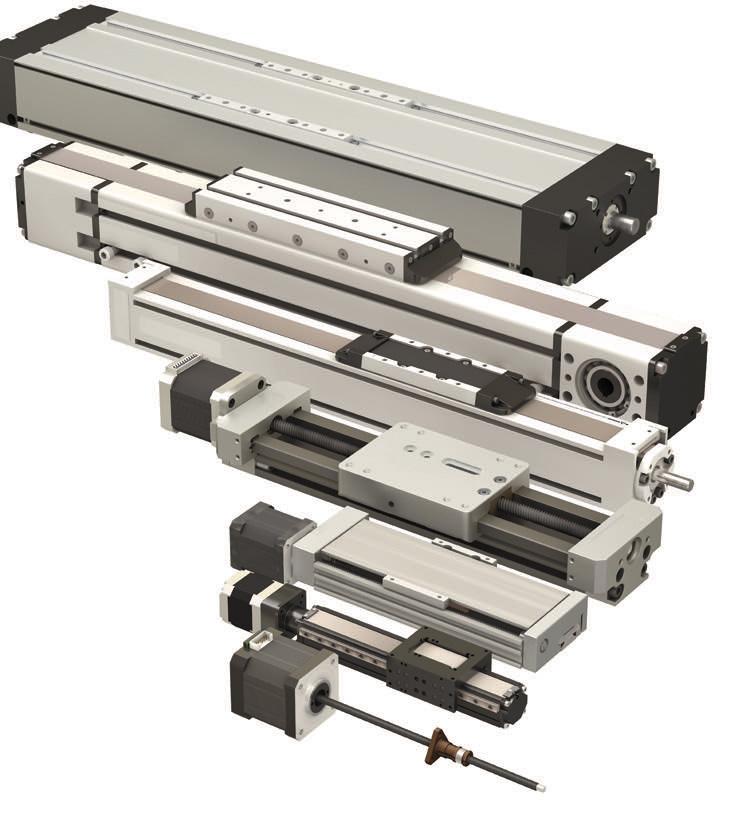

Gilmer: For autonomous ground vehicles, we’re seeing the industry trend toward three major points of interest; increased controllability, electrification, and reduced complexity. Thomson is positioned to offer products that integrate control technologies into the axis of motion with electric linear actuators, an all-in-one design which hits all three trends simultaneously.

Common control architectures include bus integration with force and position feedback, which are critical for autonomous operation. Reduced complexity and overall footprint are just as critical to enable these technologies to effectively replace the combined space of a human and the vehicle, especially in material handling scenarios. Everything is powered electrically, which follows the trend of moving away from either manual or maintenance-dependent fluid power.

Any technologies making factory farming more humane?

Caldwell: Making factory farming more humane can take several directions. Yaskawa robots have been deployed extensively in the dairy industry, milking cattle. There are several benefits to automated milking, including increased sanitation, more consistent monitoring, and enhanced vision-based inspection that can more rapidly identify infections or other health issues.

Beyond this application, there are several other factory farming applications targeted at humane treatment of animals.

12 DESIGN WORLD — MOTION 03 • 2024 industry trends AN ISO 9001 CERTIFIED COMPANY pyramidbelts.com • 641.792.2405 • sales@pyramidbelts.com POWER TRANSMISSION-PART CONVEYING PYRATHANE® BELTS LINE SHAFT CONVEYOR BELTS - Original Equipment and Connectable CUSTOM MADE IN INCH, METRIC and O-RING SIZES

Round, Flat and Connectable Polyurethane Belts

Very Clean Operation Lifetime Warranty Against Manufacturing Defects

Eliminates Tensioning Devices

Exceptional Abrasion Resistance

•

•

Thoughts on the electrification of off-highway equipment?

Umeno: Driven by environmental concerns, operational efficiency demands, and stricter regulations, we’re poised to play a pivotal role in the transition from traditional hydraulic systems to electric drivetrains. The drawbacks of the traditionally used hydraulic systems such as leakage, heat generation, and complex maintenance requirements that contribute to higher operating costs and environmental impact can be mitigated by shifting towards electric drivetrains.

We’re uniquely equipped to support the off-highway industry’s electrification journey with our comprehensive portfolio of electric motors and drives, specifically designed for demanding environmental and high torque applications while driving with our powerful line of housed and frameless motors or coupling with gearboxes or ball screws to simulate the actions of hydraulic actuators. Kollmorgen’s team of engineers possesses deep knowledge of electric actuator design and integration, assisting manufacturers in seamlessly transitioning from hydraulic to electric systems.

Field: While there have been some prototypes of full-electric technologies, developments today exist primarily at the research level. One key challenge is that heavy-duty farm machinery requires large diesel engines. Only the smallest can be operated without a combustion engine, as the required battery pack would likely be prohibitively large and provide only a few hours of work on the field. Coupled with long battery charging times, the value isn’t there yet. And that’s unlikely to change anytime soon, without extensive (yet unknown) improvements in battery and charging technology. •

307 East Church Road, Suite 7, King of Prussia, PA 19406 phone: 484-685-7500 fax: 484-685-7600 e-mail: info.us@nbk1560.com www.nbk1560.com Maximize your performance with the widest range of precision couplings 13 DESIGN WORLD — MOTION farming automation

USE OF ARTIFICIAL INTELLIGENCE

14 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com industry trends

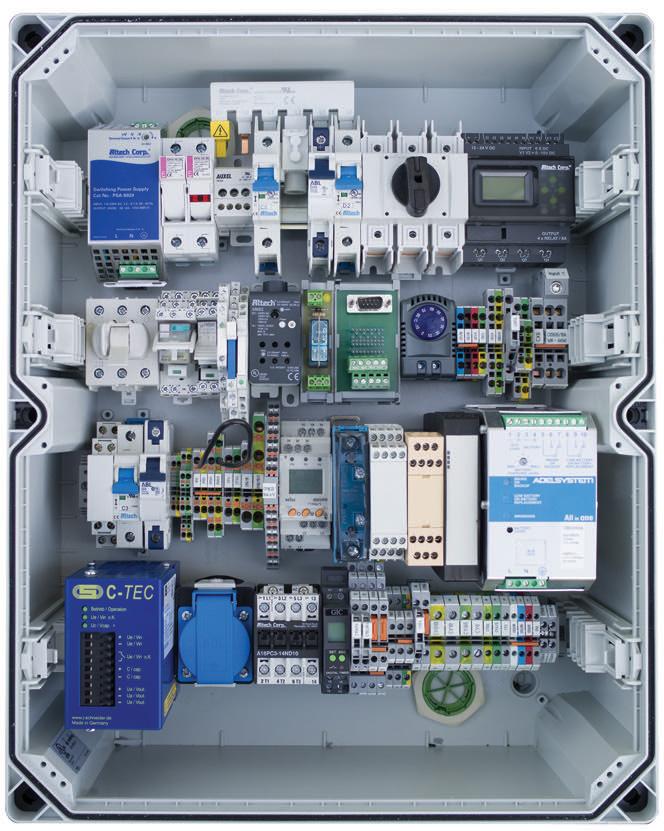

According to Gartner’s research, up to 25% of organizations surveyed annually since 2019 said they plan to leverage artificial intelligence (AI) within the next 12 months. However, only up to 5% have deployed AI to production. Companies know that generative AI can dramatically improve operations, but inexperience and potential risks postpone the benefits. Predictive maintenance, efficiency, and autonomy drive AI adoption, and more manufacturers are developing AI-enabled devices in support. Sensors, cameras, edge devices, and automation software have traction, and we expect an explosion of new AI capabilities in the coming years. To get a pulse on what’s happening now, Design World recently asked several industry experts about trends they’re seeing in this space. Here’s what those experts had to say.

What new offerings leverage the power of AI?

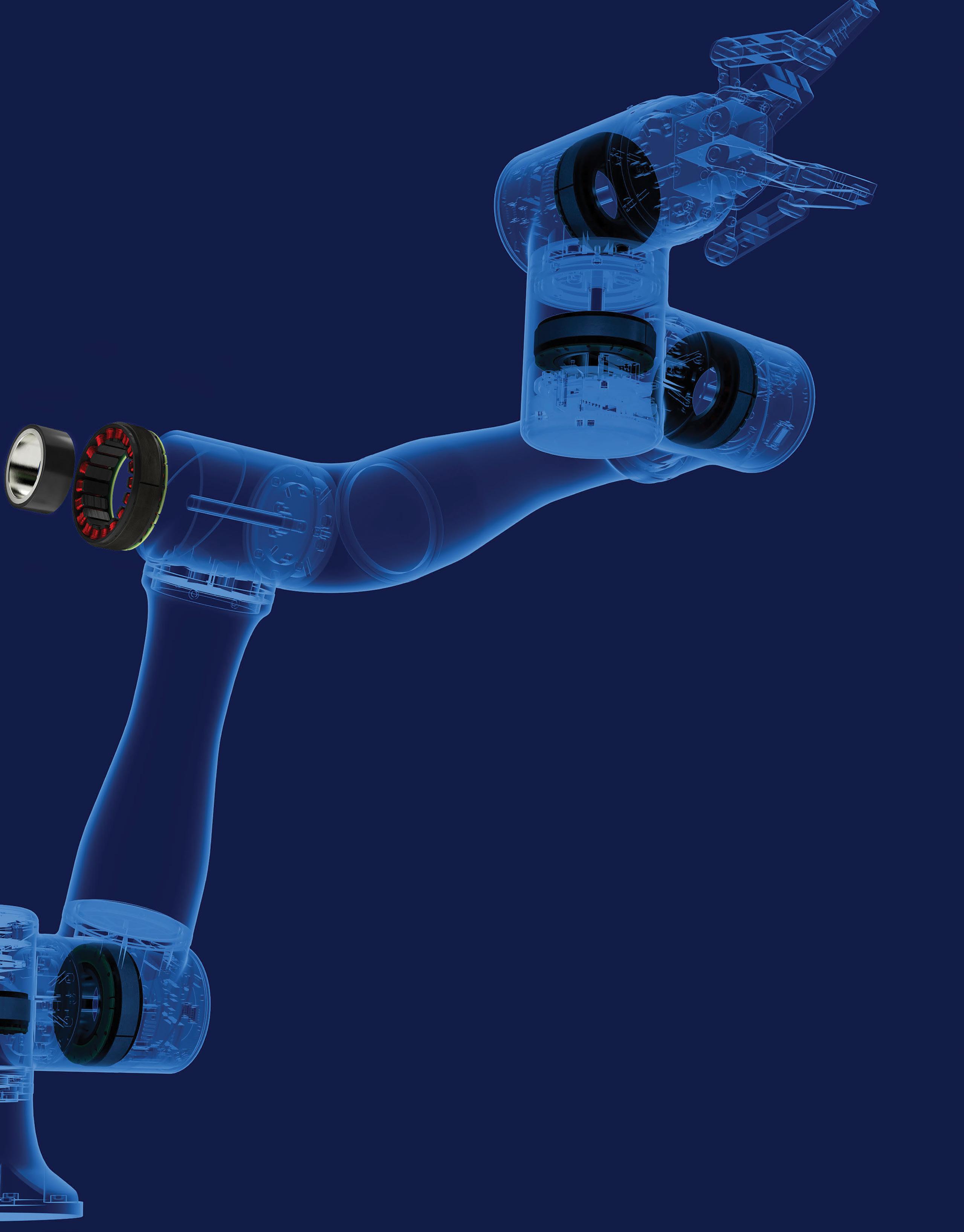

Caldwell: For the last several years Yaskawa has been eager to partner with various technology partners that leverage AI for vision-guided robotics and other applications. Most recently, Yaskawa announced Motoman NEXT, an AIbased platform with an integrated Autonomous Control Unit (ACU) that allows for more direct integration of AI within the robot controller. Motoman NEXT is primarily intended to be an enabling platform for the development of automation solutions in new markets and for new applications and end-users. The inclusion of an ACU and the more direct partnerships with a variety of leading automation and technology providers should enable a much greater fusion of sensors, technology, and ease of use.

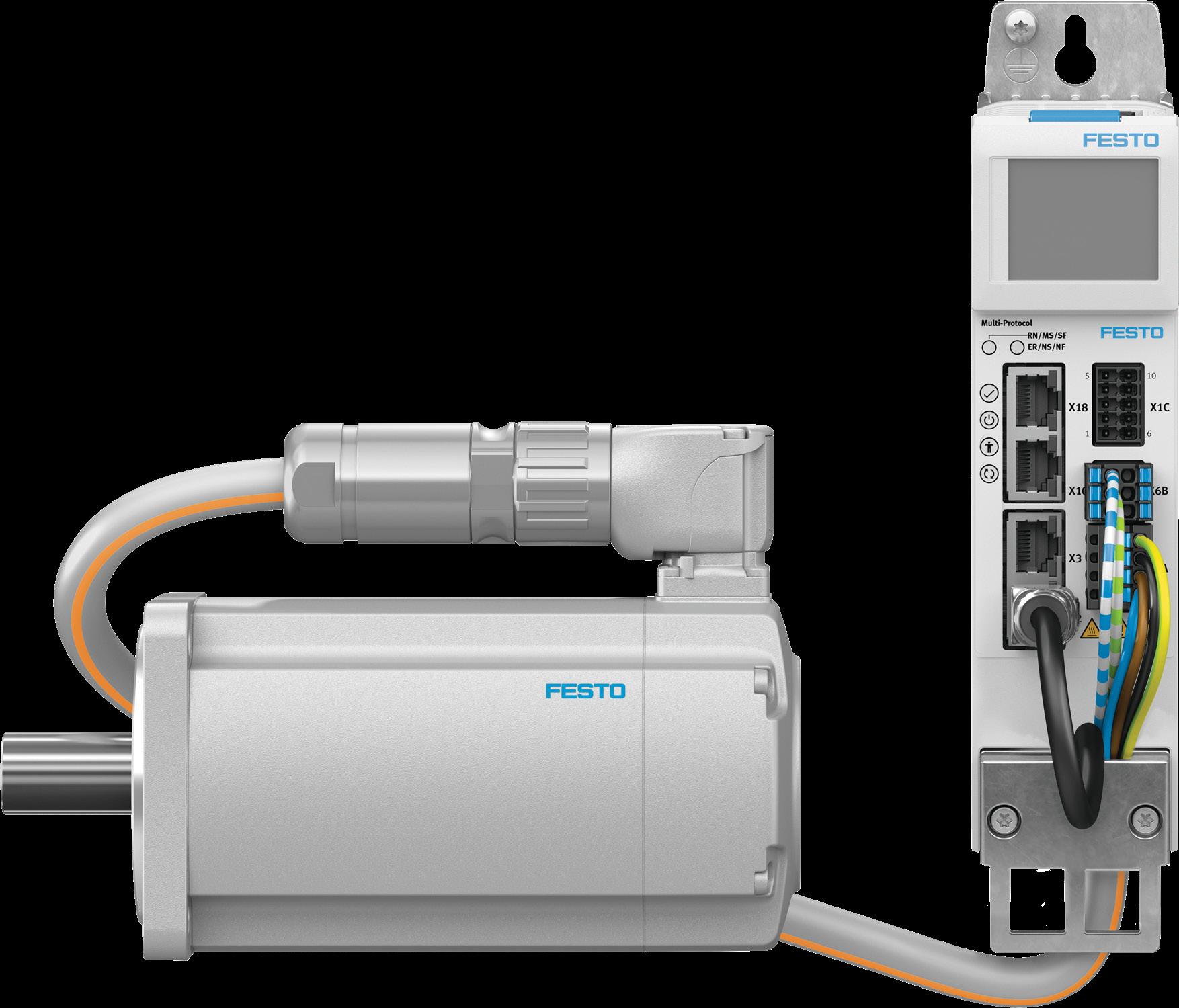

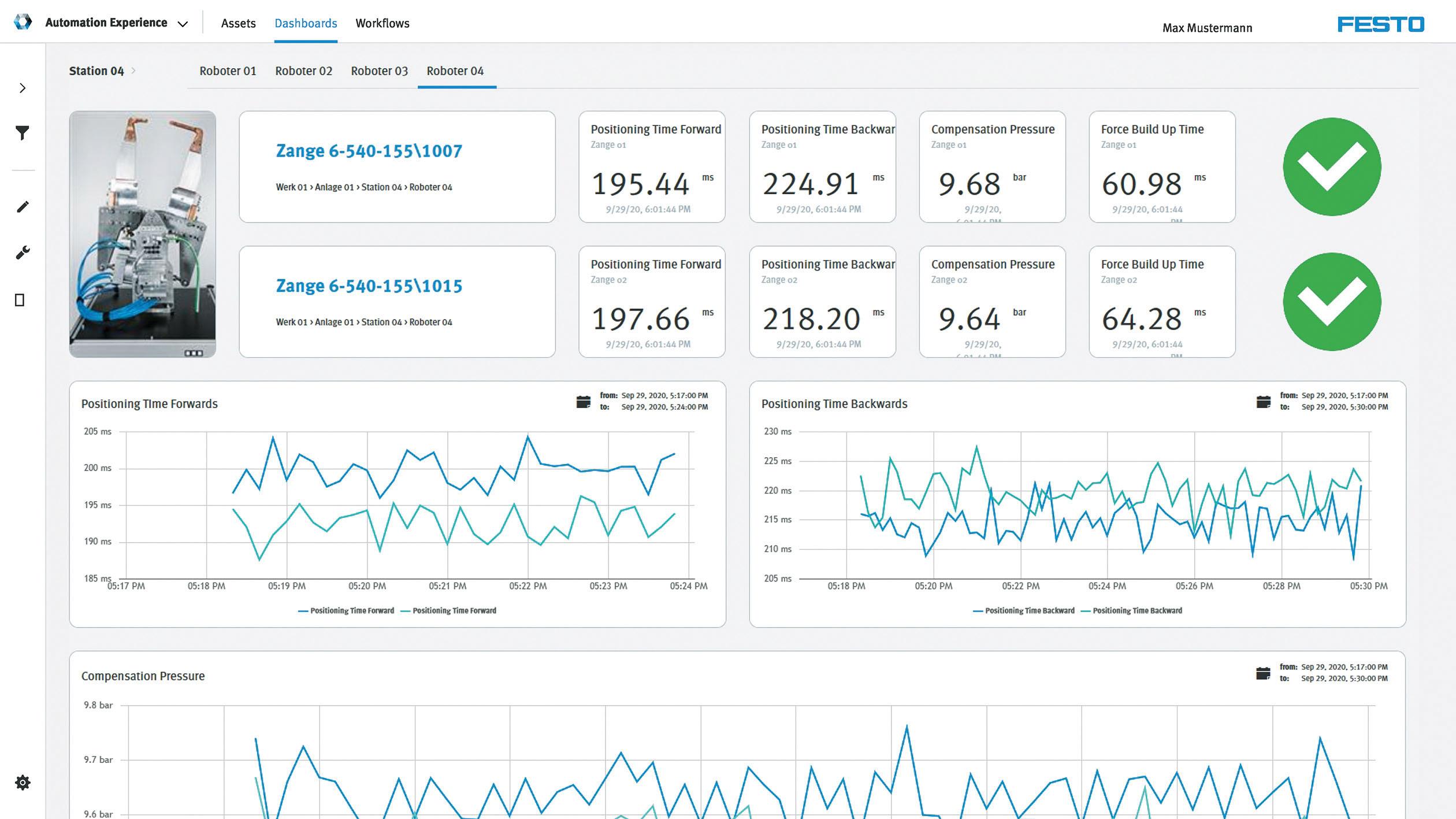

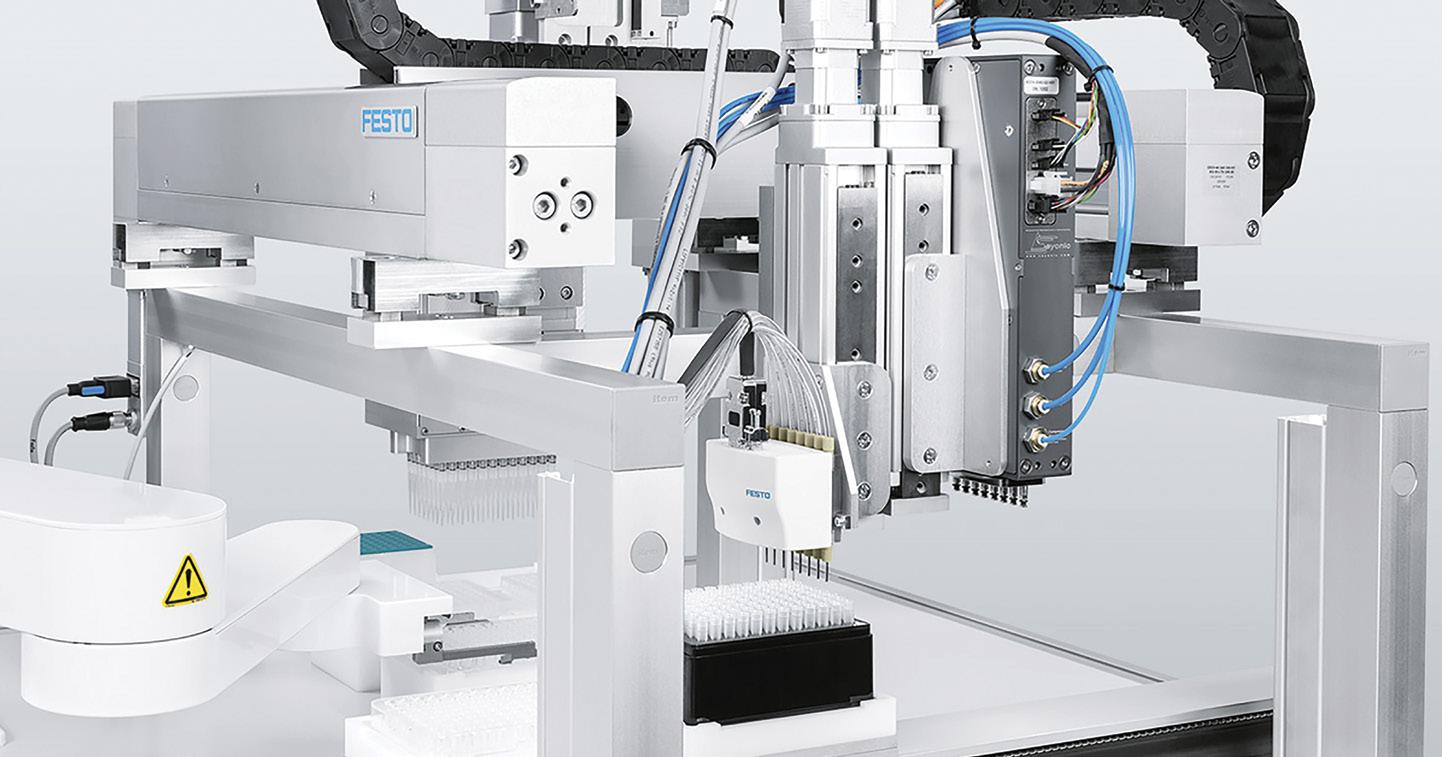

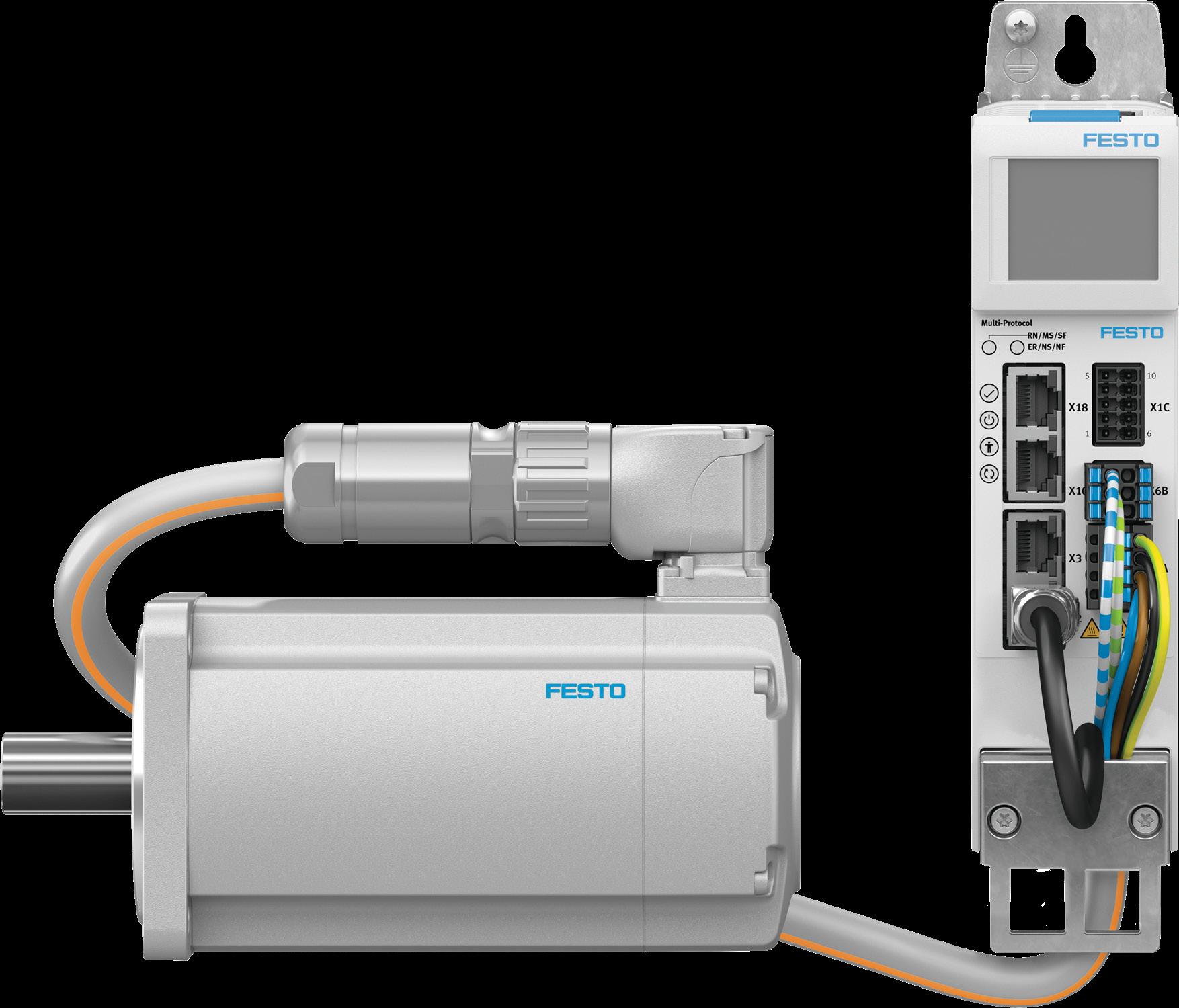

Latino: We have a suite of software solutions under the brand name Festo AX Industrial Intelligence. This software uses AI for machine analytics with a primary focus on predictive maintenance, predictive quality, and compressedair savings.

trends in ai 15 DESIGN WORLD — MOTION 03• 2024 motioncontroltips.com | designworldonline.com

By implementing a configurable AI-powered robotic kitting solution, businesses can relieve employees of a labor intensive task that is prone to causing injuries. Image: Ambi Robotics

Rangarajan: HP shares the belief that advancements in AI and its continued integration across the additive manufacturing (AM) digital and physical workflows are key to unlocking the maximum potential of 3D printing technology. As such, HP has made it a priority to introduce new AI-powered offerings that help customers optimize production and bring more compelling

product designs to market. One example is the new HP 3D Digital Sintering software, announced in spring 2023, designed to address the costly challenge of dimensional and volume shrinkage. AI-accelerated simulation convergence and physics-based modeling make predicting, reporting, and compensating for variability of 3D printed parts during sintering easier, which in turn reduces time, cost, and speed of final

part production without the need for a build and test approach. For hardware, HP’s 3D Center product offering helps improve OEE by enabling predictive alert recommendations.

Sachdev: Our newest AI-enabled vision sensor is the In-Sight SnAPP. It comes with pretrained edge-learning algorithms that can help engineers get up and running

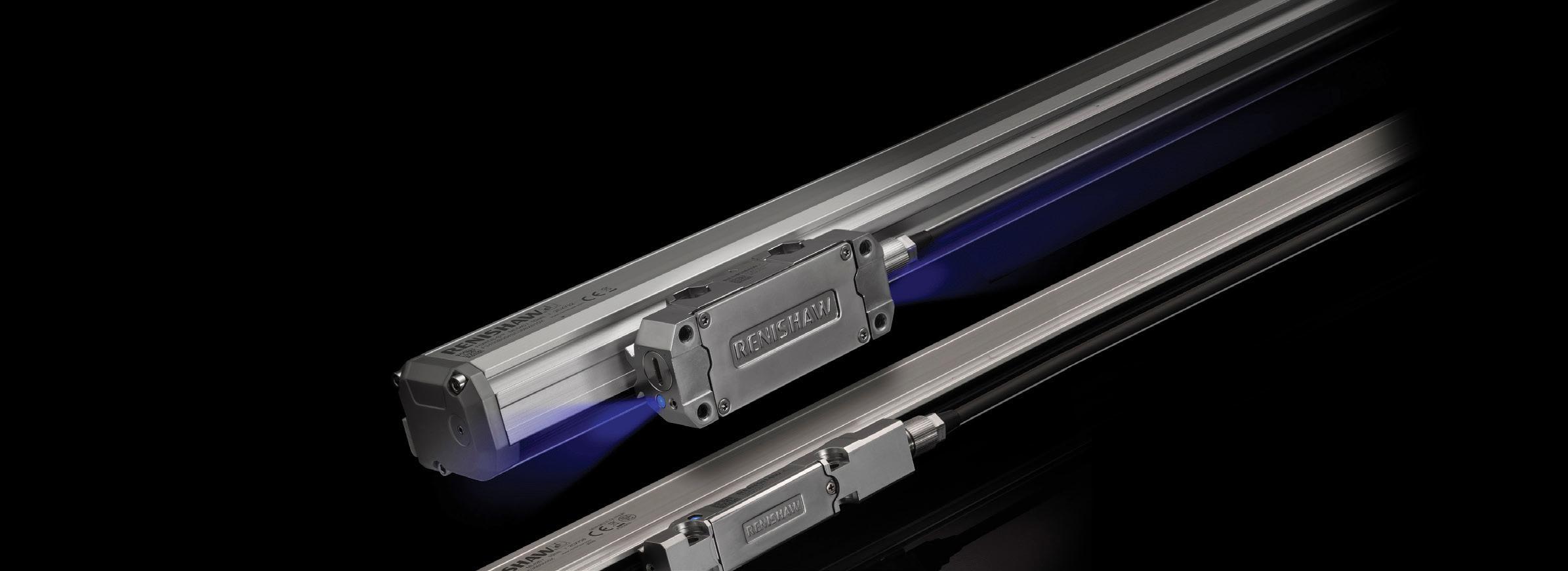

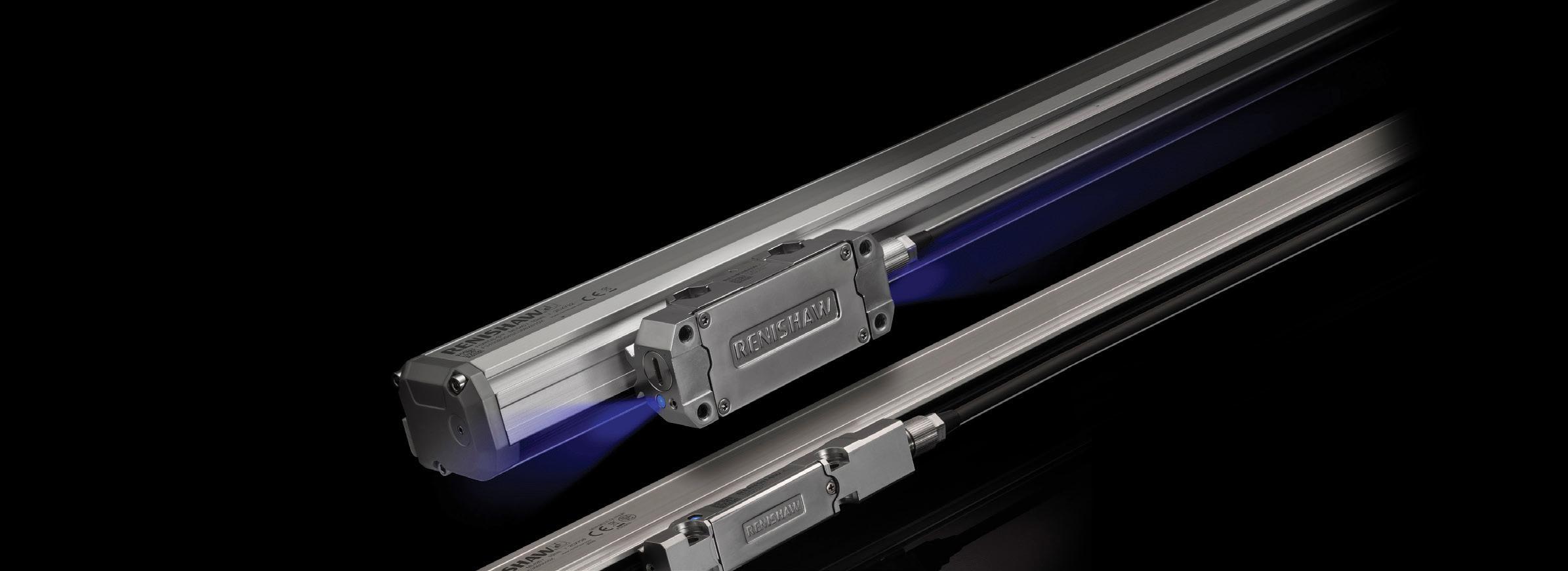

Superior encoders for position and motion control

industry trends

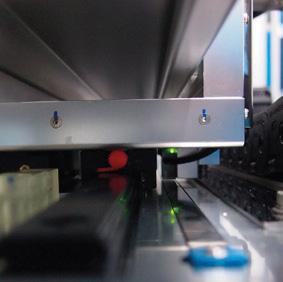

THK OMNI edge uses AI to analyze realtime linear motion data, detect patterns, and predict maintenance needs and failures before they occur.

At an auto plant, Festo AX continuously monitors welding guns. Festo AX decreased unplanned downtime on the welding line by 25%.

a comprehensive line up of encoder solutions, Renishaw brings the expertise needed to address your manufacturing challenges. Whether your application calls for optical, magnetic or laser technology, our encoders achieve the highest levels of accuracy, durability and reliability. Powerfully positioned for innovative motion control. Your partner for innovative manufacturing www.renishaw.com/encoders usa@renishaw.com Renishaw Inc., West Dundee, IL 60118 © 2023 Renishaw Inc. All rights reserved.

With

within minutes — no programming and no vision-system experience needed. The edgelearning algorithms can also learn a specific application with only a handful of training images. We’ve had customers deploy it on their lines in less than four hours.

Mayers: We recently launched a new camera for the IDS NXT AI vision system. The intelligent industrial camera IDS NXT malibu features Ambarella’s CVflow AI vision system on chip and takes full advantage of the SoC’s advanced image processing and on-camera AI capabilities. Consequently, image analysis can be performed at high speed and displayed as live overlays in compressed video streams via the RTSP protocol for end devices.

An integrated ISP with automatic features (especially for brightness, noise, and color correction) also ensures excellent image quality. IDS is the first manufacturer to make this chip available for industrial applications.

Yudilevich: MaterialsZone leverages the power of AI through its Materials Knowledge Center, a secure database for storing materials data. The data within the knowledge center is accessible, standardized, and ready to use for statistical analysis and in AI models. Our Co-Active Visualizer provides statistical dashboards for simplified lab data analysis, and our Predictive Co-Pilot employs AI and machine learning (ML) models to optimize experiment planning and save time and costs. The predictive co-pilot has an explainable AI component that

uses the SHAP values method to rank the importance of the different features in the model and visualize and quantify the effect of each feature on the target parameter. These offerings enhance data accessibility, simplify analysis, and optimize lab experiments.

Caldwell: We have been able to leverage AI to compound the benefit of our Yaskawa Cockpit robot health checker. While the Robot Health Checker function within Cockpit can compare a variety of signals from a robot (encoder temperature, hours used, duty cycle, grease life), traditionally, these comparisons were only made with standard data using assumed conditions. Leveraging AI allows for specific installations to improve the quality and accuracy of their ongoing preventative maintenance programs to ensure zero or minimal downtime of their automation solutions.

Varley: Later this year, we’re releasing an optional upgrade to our robots that will improve high-speed positioning and path control for applications needing enhanced performance. As more devices provide feedback that can be fed into AI algorithms, robot performance and the range of addressable applications can both be increased.

What AI are you seeing in industrial applications?

Rangarajan: Businesses across industries today are looking to increase their use of powerful and sophisticated AI models. Manufacturing is no different, with AI

already being used to great effect. From material development and product design right through to process monitoring, optimization, and production, AI is poised to help address the growing demand and availability of 3D-printed parts especially.

Latino: Modern industrial installations leverage technologies that are quite inducive to supporting AI. Access to data is paramount, and today’s networking technology makes it easier than ever to access data. This does not mean that only modern installations can support AI. Legacy installations can also benefit but may need additional infrastructure. Connections to edge computers or cloud systems are more common, and AI may utilize one or both for analytics, modeling, and so on.

Mayers: Interest in AI-based solutions is as great as ever, and the nature of inquiries is changing. In the past, it was mainly about the basic possibilities of AI and cameras. Now, the questions center much more on the specific implementation. Our customers have a much deeper understanding of the topic, and therefore we now provide advice at a completely different level. Clients are interested in the technical capabilities of the system and their value userfriendliness. This may be because AIbased camera solutions are not only used by image processing experts, but by all kinds of users. This is one of the reasons AI vision is so attractive.

Where's the most promise for edge AI/ML software?

Halstead: AI is very good at finding patterns in large amounts of data, but it’s not very good at creating a new concept. So, a factory with lots of sensors feeding data that can be analyzed will benefit. Creative tasks? Not so much.

trends in ai 03 • 2024 motioncontroltips.com | designworldonline.com

IDS NXT malibu is part of the user-friendly all-in-one AI vision system called IDS NXT.

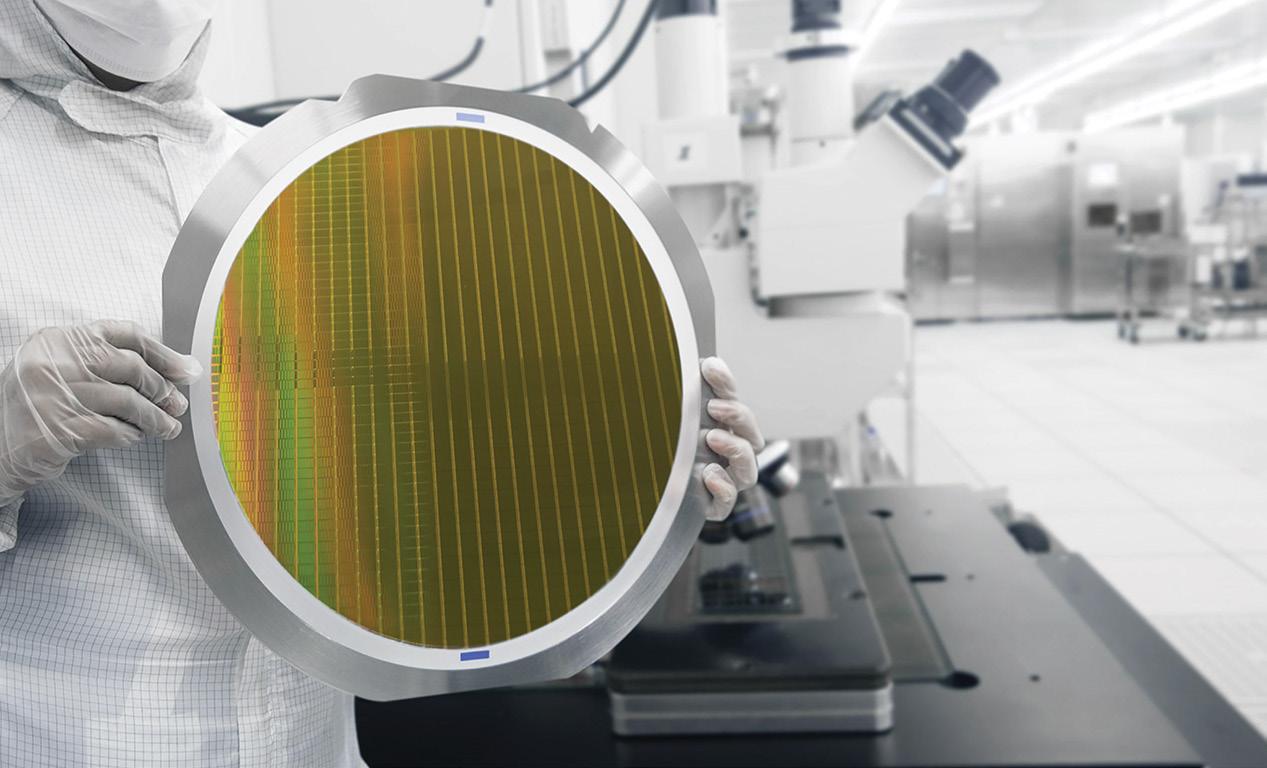

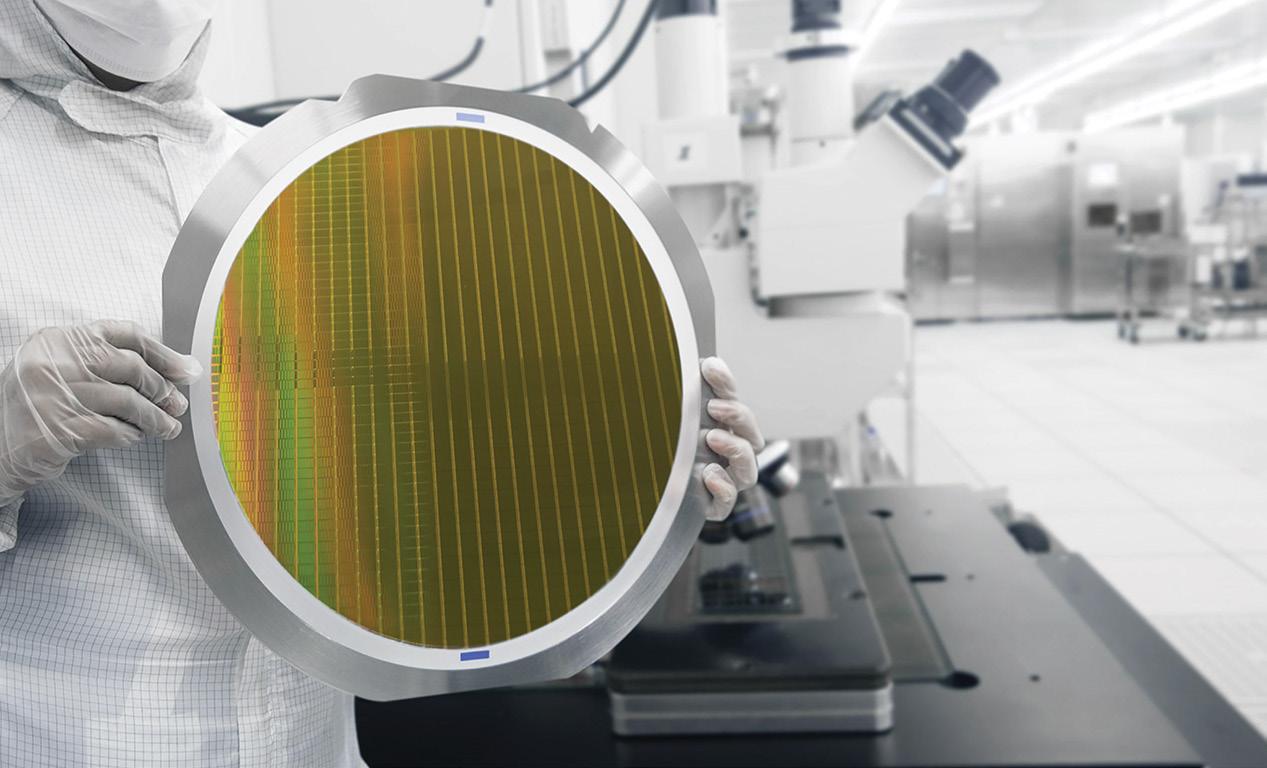

Festo AX provided early detection of wafer defects in a wafer sawing process. The AI solution lowered annual waste per machine by $100,000.

Realize your vision with Festo’s approach to smart automation. Partner with Festo today.

www.festo.com Industry Leadership Superior Quality Products Global Training & Support

Innovate today for a new tomorrow

Mayers: There is a high demand for edge AI/ML capabilities, and we are committed to answering this with systems such as IDS NXT and the new IDS NXT malibu camera. These systems exemplify technological advancements with their integrated AI, providing realtime, on-site image processing and decision-making. This is a gamechanger for industries requiring immediate data analysis, such as in automated manufacturing, where split-second quality control decisions are crucial. Additionally, the IDS NXT malibu camera’s ability to stream compressed video in realtime is a significant stride in efficient data management and processing.

Varley: For the robotic products that are manufactured by Mitsubishi Electric Automation, we offer the Smart Plus card. This allows access to AI-driven features, such as Predictive Maintenance and Enhanced Force Sense Control. The predictive maintenance function has benefited from years of data analysis to make our wear calculations as accurate as possible. Both AI-driven functions lead to better and safer machines.

By using the results of the predictive maintenance function, users can keep the robots running at peak efficiency and reduce the risk of machine crashes that can result from a maintenance-related problem that wasn’t discovered by traditional preventive maintenance schedules. Enhanced Force

Sensing control allows a wider range of applications to be automated and potentially dangerous tasks to be taken care of by robots instead of operators.

Dengel: AI/ML can be used to set up factory floors for lights-out operations. This increases productivity and allows for labor to be redeployed into other roles. AI can also be used to simplify and customize user experiences to their unique needs.

Caldwell: Overall, the most promise for AI/ML software is expanding automation beyond the traditional dull/dirty/dangerous tasks where it has traditionally been focused. Historically, automation has been targeted at highly repeatable work, and to great success. But the next wave of automation coupled with AI/ML will be with highly servicebased unfulfilling tasks. Food service, textiles, farming, and other unstructured but unfulfilling work will be achievable with smarter automation. There are several benefits, including improved and more reliability, reduced downtime, and long-term margin improvement due to traditional service life measured in decades despite ROI in two to three years.

Latino: AI running on the edge has the possibility to detect faults quickly due to very low latency in collecting sensor data and immediate processing at the field level. Predicting field device failure and product quality as soon as possible is most

Everything in sight: Dashboards for predictive maintenance offer an overview of the machine status.

Image: Festo

promising. Some users claim thousands of dollars lost per hour due to a single device failure. Therefore, these AI solutions should have a quick ROI.

Sachdev: AI is having a huge impact on machine vision applications through increased capabilities and better ease of use. We sell vision systems that employ two different types of AI: deep learning and edge learning. Deep learning systems use AI neural networks to learn how to accomplish a sorting or inspection task, distinguishing good parts from bad when defects can be extremely variable, for example. And edge learning systems come with pre-trained algorithms that make training incredibly easy so they can be deployed in minutes, not hours or days. In both cases, the addition of AI means the vision system provides better ROI, so we expect to see AI adoption continue growing.

While AI can improve many types of inspections, it can make a bigger impact in some specific areas, such as inspecting packaging, welds, EV batteries, and food and beverage products. The common thread is that AI excels at learning how to differentiate cosmetic blemishes from functional defects. Croissants coming down a production line, for example, can have a wide level of variability in color and shape that traditional rules-based systems can struggle to tell apart from actual problems. AI systems can learn to recognize that slightly more bent or browned pastries are completely acceptable.

20 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

industry

trends

Has AI improved predictive failure and maintenance programs?

Munirathinam: Industrial manufacturing requires precise and efficient production with optimized machining to maximize value-adding activities. AI-based predictive failure maintenance programs enhance the efficiency and effectiveness of maintenance programs while reducing repair costs and contributing to a sustainable future. AI-powered solutions such as Schaeffler’s Medias Xpert mobile app and OPTIME condition monitoring system showcase the potential for growth in leveraging AI to prevent equipment failures, optimize maintenance programs, and promote sustainability.

Latino: There are Festo AX installations today that have predicted failure in industrial applications around pneumatic cylinders, valves, nozzles,

and actuators. This has been done by developing models for these systems that include sensor data. As an industry component designer and manufacturer, we've also developed engineering data relevant to these applications. We're in a unique position for AI/ML because of our design, manufacturing, and data science experience.

Munirathinam: AI-powered diagnostics for the full product lifecycle is another application transforming asset management. Many of our industrial customers have approached Schaeffler for assistance in preventing equipment failures, including help with realtime failure analysis to assess the impact as well as recommendations for immediate repair and long-term prevention. This type of diagnosis demands expert industrial experience and end-to-end technical expertise to guide customers effectively. Our AI-based diagnostic

tool and mobile app Medias Xpert identifies damage and empowers customers to diagnose bearing failures by just taking pictures on their phone, understand root causes of issues, and receive suggestions for effective countermeasures right in the palm of their hand.

Mayers: AI-based camera systems can process realtime data … and as embedded devices even directly at the source. Utilizing AI leads to faster and more accurate anomaly detection and pattern recognition. Minimizing the delay in transmitting data for processing is also crucial to allow for more rapid identification of potential problems and therefore detecting potential risks and defects before they become an issue.

Munirathinam: For maximizing performance, AI and condition monitoring make predictive

trends in ai

maintenance easy. Schaeffler’s OPTIME Condition Monitoring solution consists of wireless sensors, a cellular gateway, and digital services based on proprietary Schaeffler algorithms. Multiple OPTIME sensors are included to monitor pumps, fans, gearboxes, and motors. With this solution, most of these balance-of-plant assets can now be monitored on a continuous basis. OPTIME automatically detects problems, issues the appropriate alarms, and provides information about the possible cause of the problem. Employee safety is also improved as wireless sensors eliminate

MEET THE EXPERTS

the need to access hard-to-reach machinery.

Rangarajan: The time required to develop and deploy alarms has significantly reduced with the shift from statistical to AI-based approaches. Coupled with an easy-to-deploy cloud architecture that extracts, transforms, stores, and delivers proactive and predictive alert data from 3D devices in the field, AI is improving the customer experience with proactive repairs and enhanced OEE for end users. •

Chris Caldwell | Product manager — material handling Yaskawa Motoman

Frank Latino | Global product manager — electric automation Festo

Arvind Rangarajan | Global head of software and data HP Personalization and 3D Printing

Gian Sachdev | Marketing head — Americas demand generation • Cognex

David Mayers | Sales director • IDS Imaging Development Systems Inc.

Ori Yudilevich | CTO • MaterialsZone

Patrick Varley | Product marketing manager — robotics Mitsubishi Electric Automation Inc.

Richard Halstead | President • Empire Magnetics Inc.

Brian Dengel | General manager • KHK USA Inc.

Karthikeyan (Karthikk) Munirathinam | Director of digitalization Schaeffler Americas

industry trends

IDS NXT malibu is an intelligent industrial camera capable of live AI in video streams.

DRIVING CHANGE IN PACKAGING AUTOMATION

Many trends in general automation have impacted the packaging industry. Some of these include the multiple benefits of better efficiency and increased speed and accuracy of automation systems in general, leading to improved packaging machinery.

At the same time, there is more concern with sustainable practices and design, which means more emphasis on biodegradable materials used in packaging applications as well.

Design World editors recently asked a number of leading manufacturers involved in the packaging industry about automation trends they’re seeing. Here’s what they had to say.

Describe your involvement in packaging.

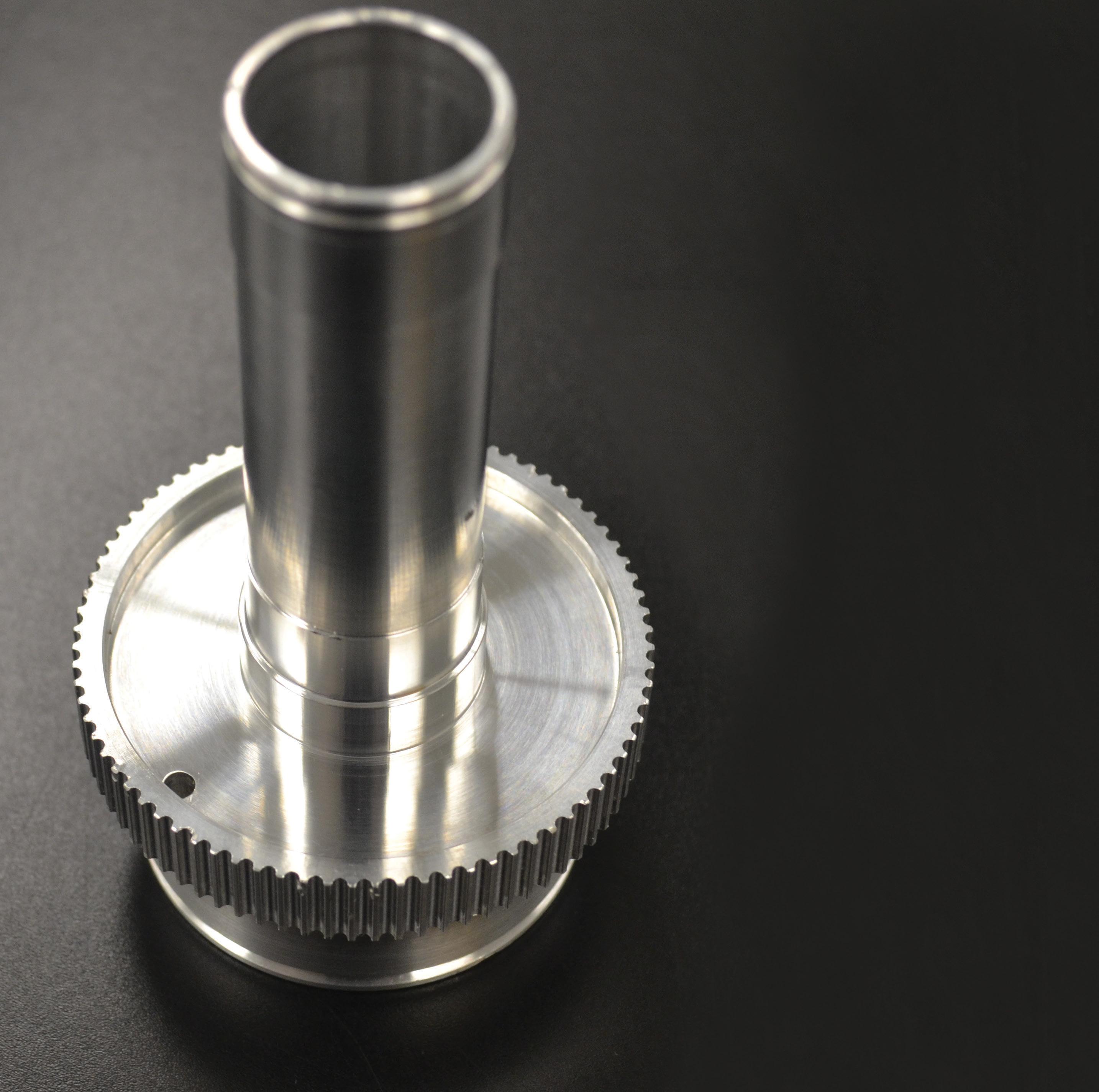

Dengel: KHK USA is a supplier of gearing into the design of OEM and bespoke packaging systems. Gears will always be a necessary component of packaging equipment.

Manley: The rapidly evolving landscape demands that our team stays on the cutting edge of technology and knowledge. Our role is multifaceted, extending beyond conventional sales responsibilities to being the crucial link between our customers and new product development teams.

24 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

industry trends

In the dynamic area of packaging, trends shape the industry. Currently, the most prevalent trend is the electrification of equipment, driven by the primary goal of achieving net-zero carbon emissions and enhancing facility efficiency. This shift poses challenges, particularly when transitioning from legacy pneumatic or mechanical systems. Issues such as a skills gap and staffing constraints become clear. It’s in response to these challenges that Festo has experienced a surge in demand for our engineering support services.

At the heart of our response to this demand is the deployment of our Automation Technology Engineers. These experts are now more extensively engaged in a spectrum of activities,

ranging from conceptual work to machine design and system architecture projects. By leveraging this high level of support, customers not only ensure the integration of the right technology for their specific applications but also gain the assurance of support from the extensive Festo Global Network

What trends do you see in the packaging industry?

Korkowski: The current trend is to go fast, go green, and go electric. LinMot is part of many large, medium, and small OEMs in their packaging solutions. Case packers, fillers, diverters, stackers, pick and place robots are some of the solutions we offer our customers.

|

|

|

|

packaging 25 DESIGN WORLD — MOTION 03 • 2024

Solutions for Automation and Robotics Learn more today. 847-215-0591 smw-electronics.com

Pneumatic Grippers

Change Systems

Robotic Quick

Inductive Coupling Systems

Mechatronic Grippers

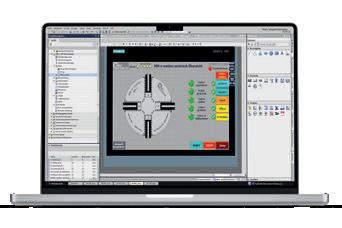

With the free PC-based Festo Automation Suite software, OEMs and integrators only need to use one application and always have all the information and tools they need at hand. The Festo automation suite simplifies setting up the drive package, from the mechanical system to the controller.

YOUR CUSTOM SOLUTIONS ARE CGI STANDARD PRODUCTS

Advanced Products for Robotics and Automation

CGI Motion standard products are designed with customization in mind. Our team of experts will work with you on selecting the optimal base product and craft a unique solution to help di erentiate your product or application. So when you think customization, think standard CGI assemblies.

Connect with us today to explore what CGI Motion can do for you.

copyright©2021 cgi inc. all rights reserved.

800.568.GEAR (4327) • www.cgimotion.com

Giunta: Automation has helped reduce the number of accidents in a packaging environment. The human body is not designed well to stack or de-stack bags and boxes over 50 lb in a repetitive and continuous fashion. Due to the reduction in available workforce, companies can focus on using the tactile strengths of a human at the right locations in a product-manufacturing process. The next jump in the industry is to be able to offer a lower cost, higher value, and competitive packaging solution.

B. Burke: Packaging equipment continues to be a critical industry for increasing productive throughput for market leading brands as they scale to meet the needs of an expanding population. Packaging machines keep getting faster to provide more capacity per hour. A major shift in packaging machine design is happening with the adoption of linear motors as the driving mechanism where magnetic movers can be positioned independently from each other around an oval or rectangular motion system. The movers offer a greater degree of flexibility in motion and at much higher speeds than belt-driven motion system designs.

Varley: With respect to robotic automation, there are numerous areas of opportunity. Many of our robots are deployed in packing applications with both producers and co-packers in the food and beverage sector. As with traditional manufacturing, the availability and cost of labor has presented many challenges for this industry. For fresh produce handling, any delays in processing and packing the produce results in a shorter shelf life and missed deliveries. Robotic automation allows users to accurately predict both output

MEET THE EXPERTS

Brian Burke | Product manager III Bishop-Wisecarver Corp.

Thomas Burke | Global strategic advisor CC Link Partner Association (CLPA)

Chris Caldwell | Product manager — material handling Yaskawa Motoman

Brian Dengel | General manager KHK USA Inc.

Michael Giunta | VP of sales and marketing Macron Dynamics Inc.

Mike Korkowski | Operations manager • LinMot USA

Troy Manley | Sales Director — Food and Packaging North America Festo

Alex Marques | Product manager • Bishop-Wisecarver Corp.

Gian Sachdev | Marketing head — Americas demand generation Cognex

Patrick Varley | Product marketing manager — robotics Mitsubishi Electric Automation Inc.

Ori Yudilevich | CTO MaterialsZone

–

| Digitized Workholding Hybrid / Electric | Sensor Systems | Inductive Coupling Systems Energy + Signals | PLC Safety + Hardware Components Solutions for Automation and Robotics Learn more today. 847-215-0591 smw-electronics.com Our innovative automation systems will help you maximize productivity, reliability and profitability.

Process automation

Mechatronic drives

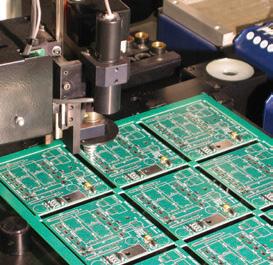

COGNEX products enable robotic pick and place functions for packaging tasks.

–

–

Reduced CO2 footprint

Reduced energy consumption packaging 27 DESIGN WORLD — MOTION 03 • 2024

–

and cost.

We anticipate quite a bit of activity in this sector, especially as the capabilities of necessary third-party devices, such as grippers, 2D vision and 3D vision, increases while their cost decreases.

Yudilevich: As eco-friendly practices become a growing trend, with regulations and consumer awareness putting pressure on the packaging industry to develop and utilize more sustainable packaging solutions, MaterialsZone actively contributes by offering an innovative, data-driven, and target-oriented approach to biodegradable material development for packaging. Our involvement in the packaging industry centers on supporting sustainability, focusing on biodegradability and eco-friendly materials.

Varley: Mitsubishi Electric Automation recently worked with industry leaders SICK, Inc. and Realtime Robotics to put together a 3D bin-picking application with multiple robots operating in a collisionfree environment. This resulted in a high throughput-per-square-foot ratio and we see cooperative efforts such as this becoming more common.

Yudilevich: Traditionally, the design and development of packaging materials involve constraints on the supply chain, processing techniques, and cost, often addressed through trial-and-error methods. We have developed an efficient workflow that minimizes the reliance on trial-anderror methodologies. This streamlined approach accelerates R&D efforts by reducing the number of experiments and iterations required to achieve the desired biodegradable material.

By embracing data-driven methodology, we align with the growing trend in the packaging industry toward sustainable and eco-friendly solutions.

Marques: Our DualVee Motion Technology has been a staple in the packaging industry for decades; manual guides for adjusting settings, bearings, and actuators for high-speed motion, and multi-axis systems for palletizing. One trend we’ve noticed in the packaging industry among so many others is a renewed emphasis on durability and long life. That’s part of the reason why we developed the LEAP award-winning DualVee solid lubricant

guide wheels. It allows our customers to have a solution that lasts for 2.5 times as many cycles as our technology, which already leads the market.

Caldwell: Robotic packaging is a wellestablished application with decades of installs. There are a variety of specific tasks, from case-erection to secondary case packing, with primary packaging typically requiring the highest speed manipulators. Trends in this area are largely driven by an increase in 3D vision and AI solutions allowing for robotic packaging of kits or mixed items within

a single secondary case. E-commerce fulfillment and other 3PL or distribution centers can greatly enhance their scalability by deploying these intelligent robotic solutions.

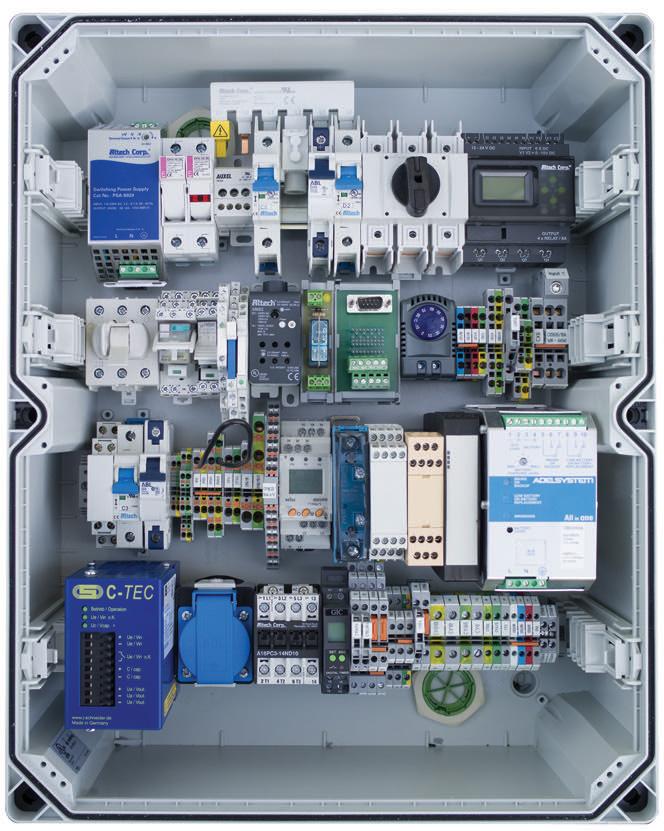

T. Burke: As a leader in discrete manufacturing, we’re also a leader in delivering technology and components for packaging. That means the delivery of excellent PLCs and motion controls (in the form of amplifiers and servo drives, and inverters) as well as robotics. Advantages come in the form of quality of products (measured in failure parts per million); faster

28 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com industry trends

In the dynamic area of packaging, trends shape the industry. Currently, the most prevalent trend is the electrification of equipment.

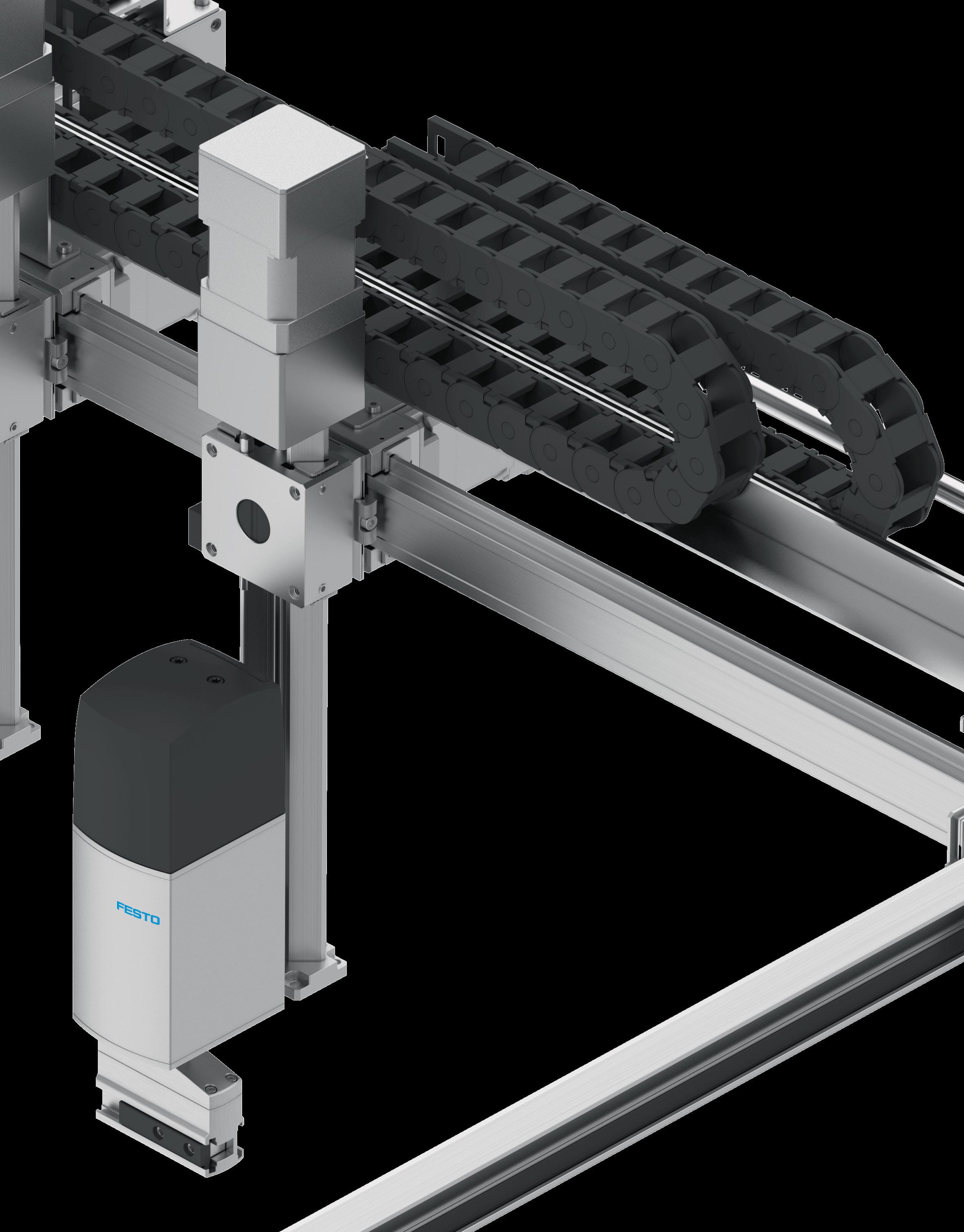

This Festo two-axis, servo-controlled linear actuator provides an energy efficient and small footprint case packing solution.

packaging

and more precise performance; and compatibility — delivering the highest performance network communications, but also supporting other industry standards.

Sachdev: We see four trends in the packaging industry; operational efficiency, digitalization, personalized manufacturing, and sustainability — all areas where machine vision can play a key role. We also see increased reliance on robotic automation. Food and beverage and pharmaceutical industries, for example, use pick-and-place robots to boost efficiency and quality while minimizing contamination risks.

Yet another trend is manufacturers increasing production of personalized items to target consumers more precisely. While effective, personalization presents major challenges; shorter production runs, more batches, and more frequent changeovers, for instance. To address that challenge, manufacturers are turning to vision systems that use edge learning technology, as they can be trained on new images in a matter of minutes, keeping downtime to a minimum.

What about packaging in the food and beverage industry?

B. Burke: We introduced a linear guide bearing with a food grade H1 rated solid polymer lubricant that eliminates foreign material ingress. The solid polymer fills the entire internal cavity and ensures that the lubricating oil stays contained inside the bearing where it is most needed. This innovation can extend the usable service life of linear guide bearings in harsh food grade applications with frequent washdown cleaning requirements.

An additional use of this innovation is that the solid polymer guide wheel bearing is well suited for extremely dirty or contaminated environments because foreign materials have no space to occupy on the inside of the bearing.

Non-contact

–

–

–

29 DESIGN WORLD — MOTION 03 • 2024

Inductive Coupling Systems (Energy + Signals)

Linear Positioning Systems

PLC Safety + Hardware Components

USP-Ultrasonic Positioning Measuring System Solutions for Automation and Robotics Learn more today. 847-215-0591 smw-electronics.com

|

|

|

|

transmission of

power and data offers

both

Safe and fast data communication via Ethernet Signals (Profinet, Ethernet IP, etc.)

High energy transmission (up to 400 Watts)

Coupler

Totally wear and maintenance free F180 Inductive

High Efficiency

Up to 95% Efficiency

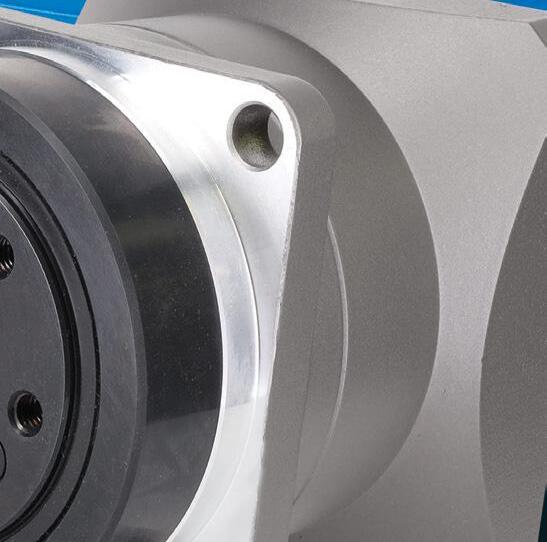

Low Backlash for Life

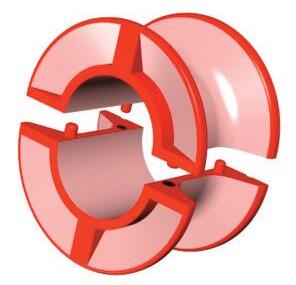

Innovative ring gear inherently compensates for interference between meshing parts, ensuring consistent, low backlash for the life of the gearhead.

High Load Capacity Output Bearing

A Cross-Roller bearing is integrated with the output flange to provide high moment stiffness, high load capacity and precise positioning accuracy.

The Harmonic Gearhead® gearbox design allows for backdrivability while ensuring highefficiency performance, maximizing elapsed operational time before recharging is necessary. High-capacity cross roller bearing supports heavy payloads.

Easy Mounting to a Wide Variety of Servomotors

Quick Connect ® motor adaptation system includes a clamshell style servo coupling and piloted adapter flange.

Flange Output Standard

Flanged output is standard for convenient, stable wheel mounting.

Harmonic Drive®, Harmonic Planetary®, Harmonic Gearhead® and Quick Connect® are registered trademarks of Harmonic Drive LLC. Harmonic Drive LLC | 42 Dunham Ridge | Beverly, MA 01915 | 800.921.3332 | www.HarmonicDrive.net Servo Gearheads for AMR/AGV Propulsion

HPG Gearheads

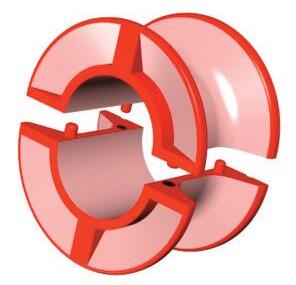

LARGE BORE DISC COUPLINGS

• Bore sizes up to 1-3/4” and 45mm

• Torque up to 1150 in-lbs (130 Nm)

• Reduced vibration due to a balanced design

LARGE BORE BELLOWS COUPLINGS

• Bore sizes up to 1-3/4” and 45mm

• Torque up to 1300 in-lbs (152 Nm)

• Reduced vibration due to a balanced design

• Highest torsional stiffness

SHAFT COLLARS WITH FACE HOLES

• Maximum mounting flexibility with drilled holes

• Most secure mounting connection with thread- ed holes

• Bore sizes from 3/8”-2” and 10-50mm

• Carefully made by Ruland in aluminum, steel, and stainless steel

• Double disc for increased misalignment www.ruland.com

INCH-METRIC RIGID COUPLINGS

• Widest selection of standard inch-tometric bores with or without keyways

• Supplied with proprietary Nypatch® anti-vibration hardware

• One-piece style for easy installation

• Two-piece style with a balanced design

products are available directly on RULAND.COM

WHAT’S NEW FROM RULAND All

| sales@ruland.com

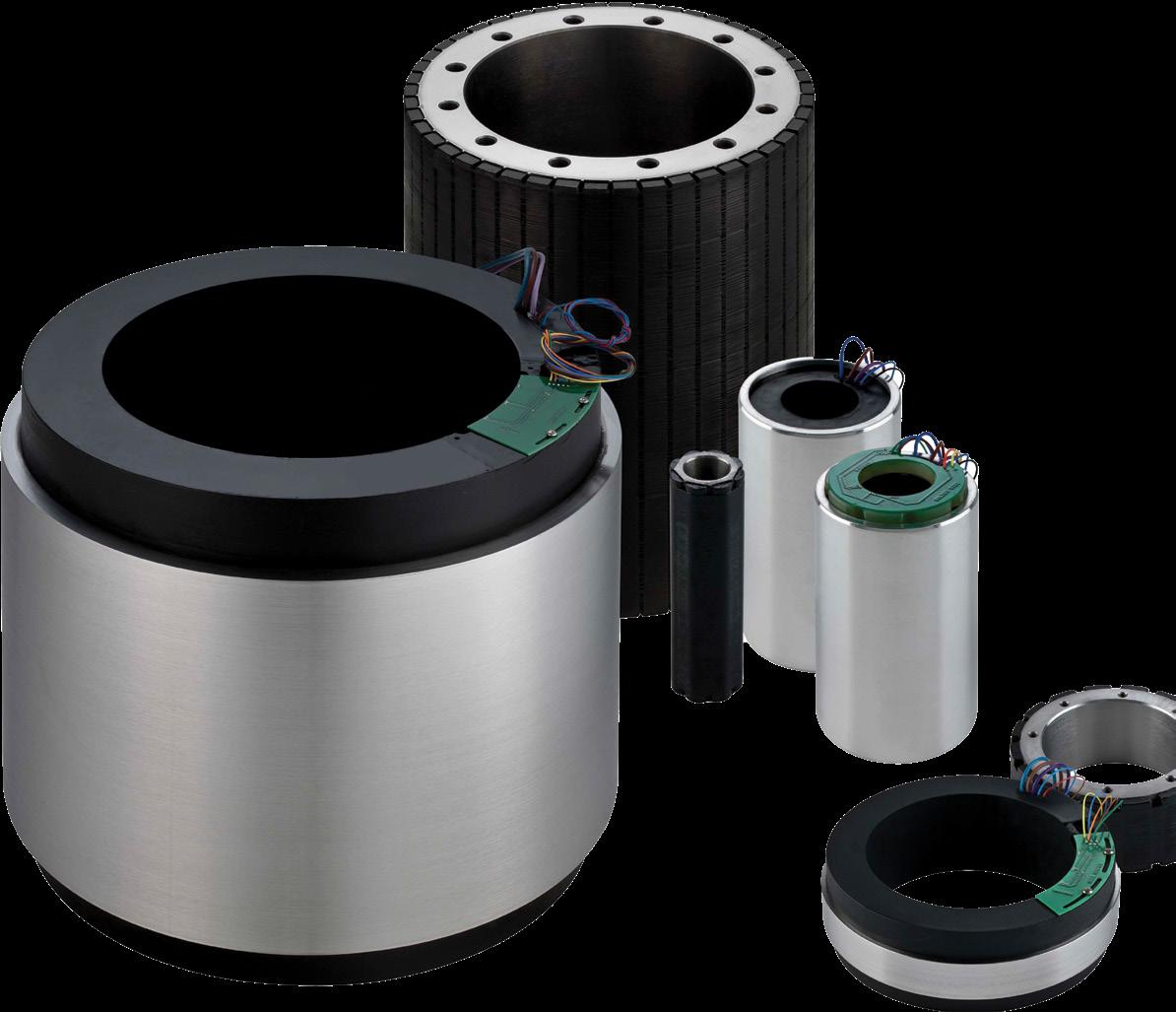

NEW MOTOR DESIGNS REDEFINE CAPABILITIES

Electric motors are at the core of industrial motion control. From servo and stepper motors to various linear motor designs, demand for these motors across a wide range of applications is only expected to increase. The rise in automation and ongoing electrification calls for more efficient electric motors and more diversified and specialized designs to meet changing design requirements.

Design World editors recently asked a number of leading motor manufacturers about trends they’re seeing in the electric motor industry.

Here’s what they told us.

What’s changing about motor and gearmotor technologies?

Reed: One of the main disadvantages of gearmotors is the inefficiency of the gears; the only reason they’re needed is to fit the application’s torque and speed requirements with the motors that are available in the current market. Consequently, motor users add belts, pulleys, and gearboxes — paying an efficiency penalty to get the motor they want. Electrostatic motors such as C-Motive’s technology can meet torque and speed requirements with direct-drive capabilities. This eliminates the gearboxes, inefficiencies, and added energy costs for motor users.

Dengel: As motor manufacturers move away from cylindrical output shafts with keys to D-shaped output shafts, end users are no longer able to use standard gears as the drive pinion. This change is forcing users to have custom gears made to match the D shape of the output shaft.

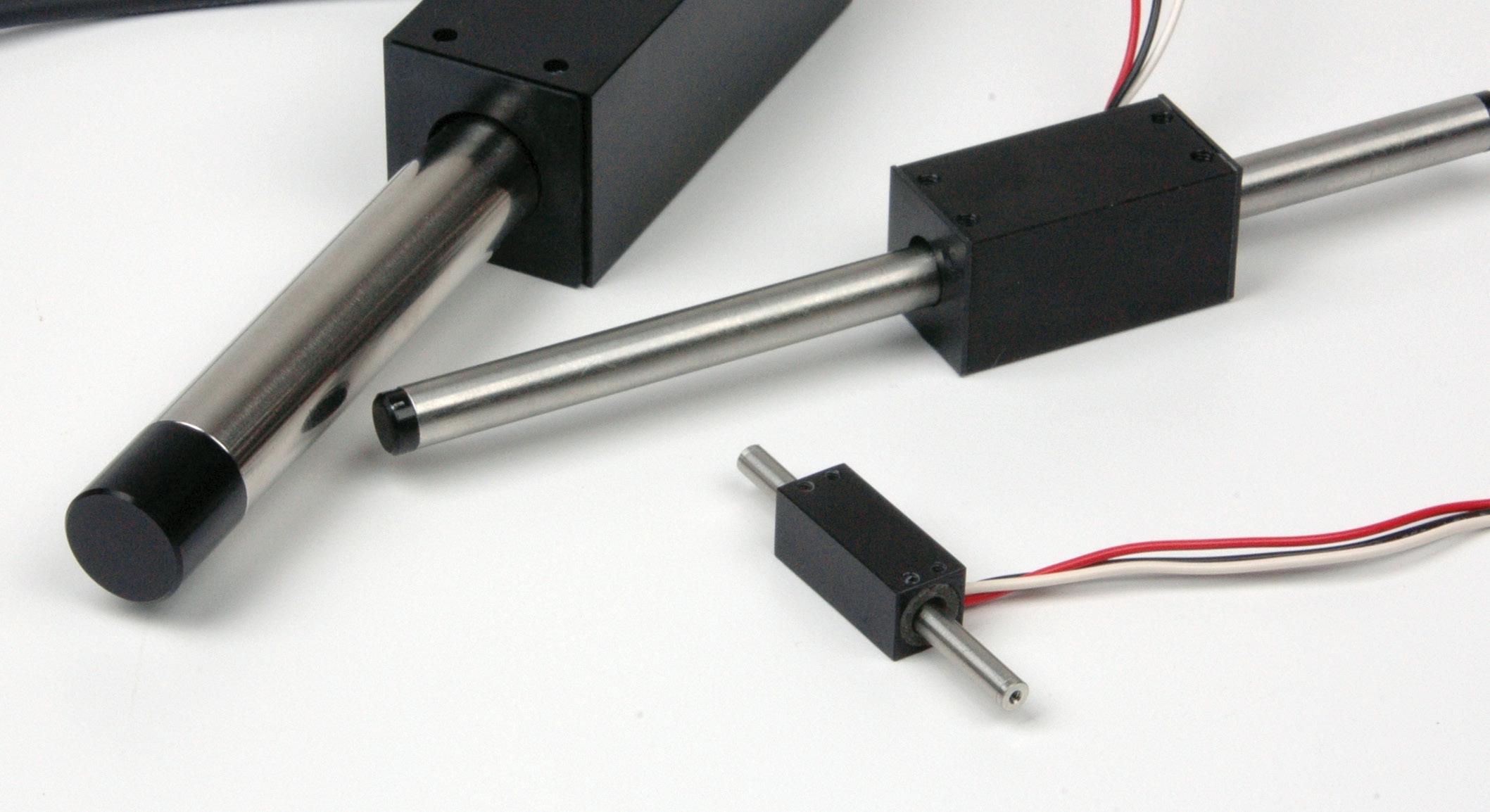

The miniaturization of motor technology is being driven by advancements in the machinery that produces motor components. Assembly equipment is also being automated, and that’s imparting the precision required to assemble motors having incredibly small diameters. In fact, the equipment producing and assembling small-size motors is utilizing motors that may have been considered quite small just a decade ago.

What must electric motors have to satisfy the rising tide of electric mobility?

Denman: Such motors must deliver programmable and precise profile moves, all controlled digitally — and must have minimal wear, so no contacting surfaces. Where rotary brushless dc motors are chosen, they need high resolution (often absolute) encoders with high torque-to-weight ratios for end effector and sample control. In many cases, they must have IP65 washdown capabilities.

32 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

industry trends

KBM frameless motors from Kollmorgen are direct-drive long-life components. Optional latching digital Hall-effect sensors can be factory installed. Choice of insulation allows operation over a wide range of line input voltage.

MEET THE EXPERTS

Dave Beckstoffer | Industry manager • Portescap

Jeff Coffed | Industry manager — aerospace and defense • Kollmorgen

Brian Dengel | General manager • KHK USA Inc.

Paul Denman | Applications engineer Nippon Pulse

Ramon Guitart | VP of engineering — electric motors Infinitum

Richard Halstead | President • Empire Magnetics Inc.

Mike Korkowski | Operations manager LinMot USA

Robert Luchars | Executive VP ECM PCB Stator Technology

Justin Reed | CTO C-Motive Technologies

Artem Rogachev | Systems manager for motor drivers Texas Instruments

Jonathan Spensieri | Product line manager Kollmorgen

trends in electric motors

33 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

Image: Kollmorgen

Custom Synchronous Drives Precise. Reliable. Trusted. American Engineering | American Made © 2017 Custom Machine & Tool Co., Inc. Manufacturer of Power Transmission and Motion Control Components You’ve created a unique design. Now relax. We’ll take it from here. Custom precision manufacturing.

required of electric motors to meet the evolving demands of electric mobility.

Most notably, electric motors for e-mobility systems must offer higher power density in a smaller package, greater durability, lighter weight, reduced noise, and provide design flexibility to optimize form factor. ECM PCB Stator Tech uses patented PCB Stator innovation and advanced Motor CAD to create next-generation electric motors that incorporate these benefits for e-mobility systems. ECM’s PCB Stator electric motors are used as the central component for converting electrical energy to torque, horsepower, mechanical output, and forward motion in e-mobility applications.

In fact, our coupling of printed circuit board, axial flux motor topology to a SaaS platform represents a new technology tool for electric mobility. ECM’s PCB Stator electric motors are lighter, faster, quieter, and achieve much higher efficiencies than conventional machines. We connect that to our CAD software, PrintStator, which offers unprecedented flexibility to optimize electric motors for e-mobility systems.

PrintStator Motor CAD takes discreet inputs — how much torque, dimensional specs, desired rotation speed — and converts those into a design for a custom PCB Stator that’s used in axial flux machines. ECM’s motor designs in axial-flux air-core machines have maximum torque and superior power in a much smaller footprint.

These attributes are highly beneficial to product designers in the electric vehicle and e-mobility space. The superior power density and high efficiency of ECM solutions enable extended battery life for integrated systems. Less mass means EV platforms have capacity for additional

range. An ultra-thin form factor and compact envelope allow these machines to integrate seamlessly as mid-drive, axial flux motors with little to no obstruction to other mechanical components.

Furthermore, ECM’s durable design contributes to increased system safety for e-mobility systems. Fully encapsulated motor windings prevent insulation failure, and the totally enclosed case makes ECM’s machines durable under extreme conditions. ECM’s motors are also acoustically quiet, meaning they generate less noise externally wherever an electric vehicle may operate.

What applications are ripe for automation with custom motors?

Guitart: Sustainable air-core motors that integrate variable frequency drives (VFDs) are bringing innovation and efficiency to conveyor applications. They can reduce energy usage by running the motor at lower speeds when possible. Advanced air-core motors replace the traditional motor’s stator, which is an iron core wrapped in copper wire, with etched copper wiring on a printed circuit board. In addition to improving the efficiency, the approach delivers better noise, reliability, and Internet of Things (IoT) connectivity. When a large-scale warehouse could have hundreds if not thousands of motors, the potential savings are significant.

In addition to cutting power bills, sustainable air-core motor systems offer improved reliability and can also help warehouse operators reduce the labor needed to maintain industrial equipment.

In a traditional iron-core stator, the operating heat produced by the load current through the copper wires expands and contracts the wire at a different rate than the steel core that holds it. Over time, the different expansion rates break the insulation, and the motor has failures to

ground or coil to coil short circuits.

The components in Infinitum’s design have very similar coefficients of expansion. This makes Infinitum systems much more reliable, which is important for missioncritical facilities such as logistics and food handling, which can’t afford to have downtime.

Reed: Conveyors are much more prevalent in industrial facilities than people realize. Even for those aware of widespread conveyor use, the sheer quantity of motors driving conveyors within an industrial setting is astonishing. These conveyors contribute significantly to the overall energy consumption in industrial facilities. However, when the motor systems powering them operate at only 50 to 60% efficiency (primarily due to gearboxes reducing energy efficiency), it results in motor users paying higher-than-necessary energy costs. Additionally, the emitted heat necessitates improvements in HVAC systems to manage the increased heat being emitted by motors and gearboxes.

What recent motor innovations have benefitted aerospace and defense?

Coffed: We’ve been supplying motion systems optimized for aerospace and defense applications for more than seven decades. Our motors, drives, and other motion products have always been of the highest quality, and that hasn’t changed. What’s new is that we achieved AS9100D certification in 2023. This certification provides documented assurance that the company’s quality-management systems comply with the high standards expected in the aerospace and defense industry. That is something end users can appreciate as they seek to identify the best motion partner for their mission-critical aerospace and defense projects – including rapid development in low-earth-orbit (LEO) satellites, space

35 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

trends in electric motors

These direct-drive motors from Nippon Pulse are compact rotary servos with an integrated incremental or absolute feedback device for accuracy and precision in positioning applications. Standard or hollowshaft options are available in a variety of sizes and stack lengths.

Motion Components to Automate any Industry 800-652-5095 diequa.com/dw Precision Rotary Flange Servo Worm Gearheads

exploration, unmanned aerial vehicles (UAV), electric vertical takeoff and landing vehicles (eVTOL), and more.

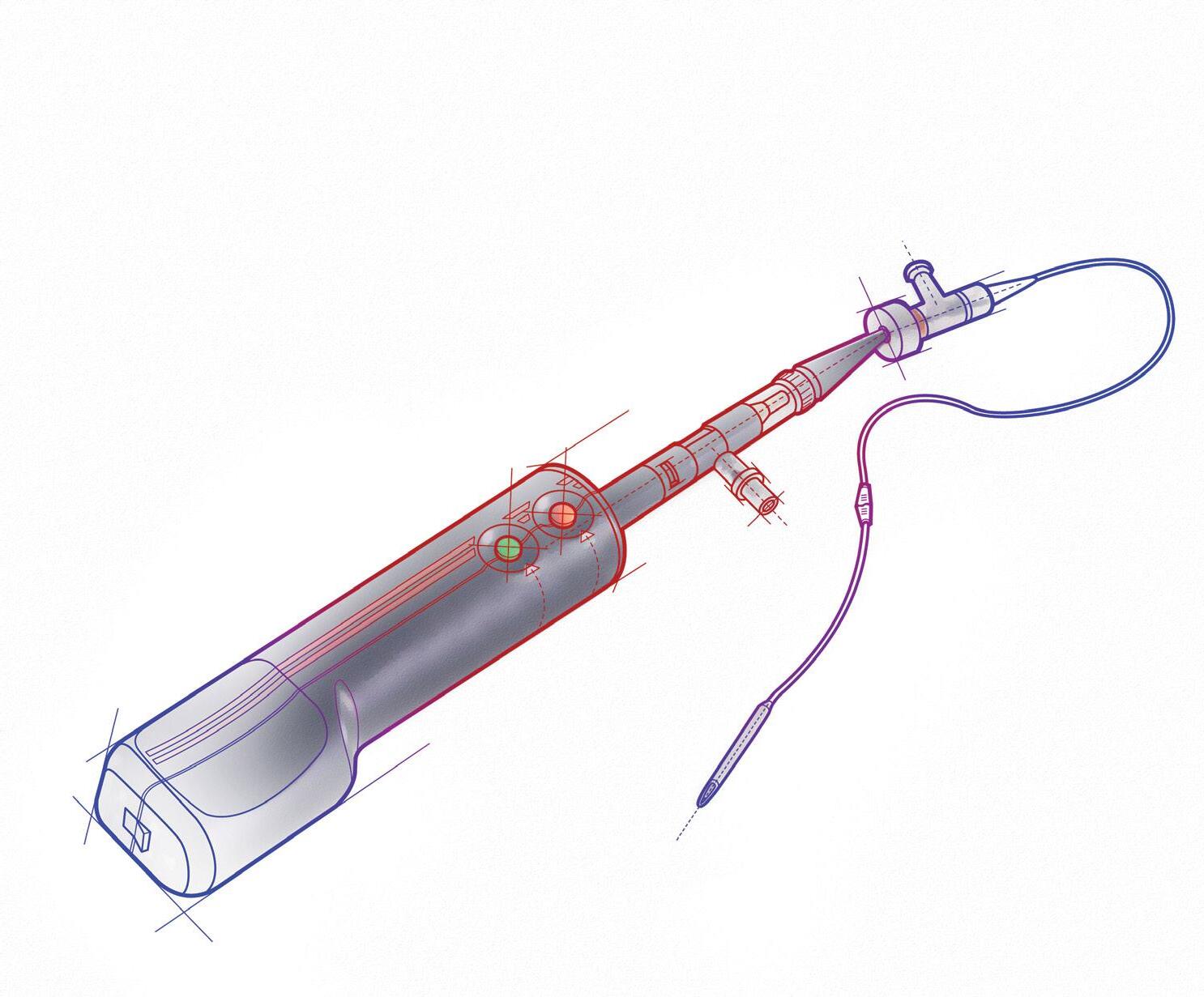

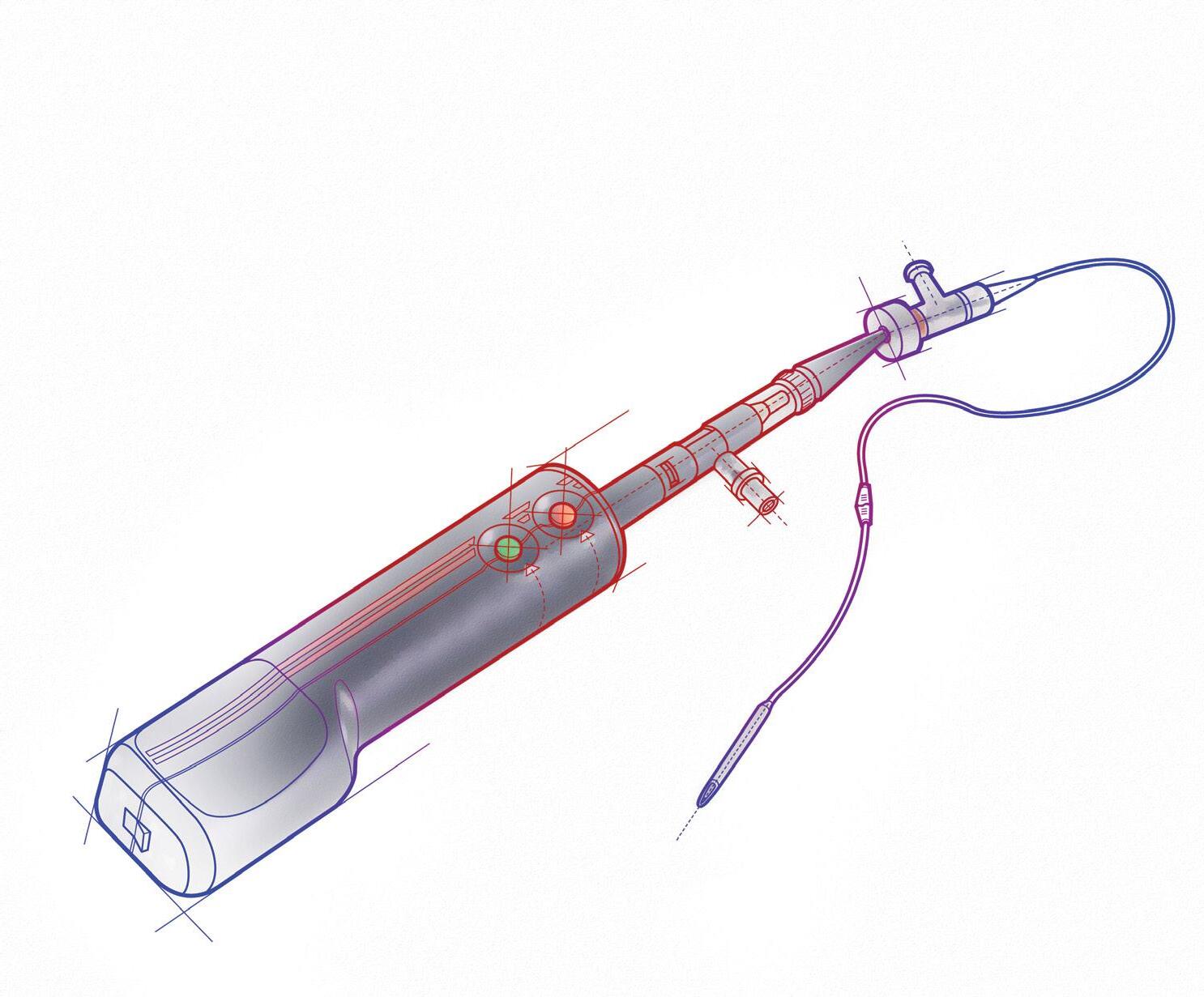

Luchars: ECM has prototyped custom electric motors for electric motorcycles, bicycles, and scooters. In the marine and defense space, ECM collaborated with aerospace and defense company L3 Harris to design an electric motor for their IVER4 900 autonomous underwater vehicle.

Any new washdown-grade, explosionproof, or specially certified motors?

Spensieri: Our newest product offering for the hygienic and washdown market is the AKMA servomotor. This IP69K-rated motor features a hardened anodized aluminum surface to offer machine designers a more cost-effective option when compared to stainless steel.

The lightweight design of the AKMA motor makes it easy to install and maintain, and its high torque density offers machine builders more performance in a smaller footprint. The motor is ideally suited for precision motion applications in food and beverage processing, pharmaceutical, and medical packaging operations..

Korkowski: We offer explosion proof motors (ATEX) suitable in 1/2 gas zones and 21/22 dust zones. These are completely encapsulated with an IP67 rating. We have stainless steel guide modules with IP69 /IP67S ratings. These can be easily assembled as fully washdown pick-andplace units. If you add a washdown gripper module, which is rated at IP67, this becomes a full washdown pick and place unit with gripper.

Spensieri: We recently expanded our offering of ATEX and IECEx/cETLus certified explosion-proof motors to cover high-voltage applications up to 480 Vac. These new explosion-proof approvals for the

high-voltage Goldline EBH servomotor exemplify our commitment to advancing the state of the art in motion control and meeting the most demanding application requirements.

Explosion-proof motors are required in hazardous locations where flammable gases, mists, or vapors may exist in explosive or ignitable concentrations. Such environments are often found in mines, oil and gas refineries, textile mills, and industrial paint booths. Goldline EBH servomotors in frame sizes 1 to 6 join other explosionproof motors in the Goldline EB family to meet ATEX/IECEx standards, and more specifically CE 0081 Ex II 2 G Ex d IIB T3 Gb –40ºC ≤ Ta ≤ 40ºC.

Any trends in the use of brushed and brushless motors?

Spensieri: There continue to be notable trends of various industries moving away from brushed motor technology to brushless designs. Brushless motors offer several advantages including higher efficiency, longer lifespan, and reduced maintenance requirements compared to brushed motors. Robotics is one of the most favorable industries for brushless designs because of their lightweight design, power efficiency, and improved reliability.

Beckstoffer: Brushed motors, specifically coreless motors, are being used more frequently in battery-powered applications based on their high

The

designed for harsh environments such as food and beverage processing.

efficiency, power density and lower weight. Combining high performance magnets with flux focusing housings is leading to an increase in output power in the same package. For brushless motors, new applications in the cardiovascular space are utilizing their high speed and reliability for surgical procedures to circulatory support.

Denman: New trends are in optical controls with high-resolution absolute encoders. Motors with high-resolution absolute encoders are replacing strain-wave gearing drives. We’re also seeing stages that are in HEPA biohazard chambers for highperformance liquid chromatography (HPLC) and drug-discovery spectrum analyzers.

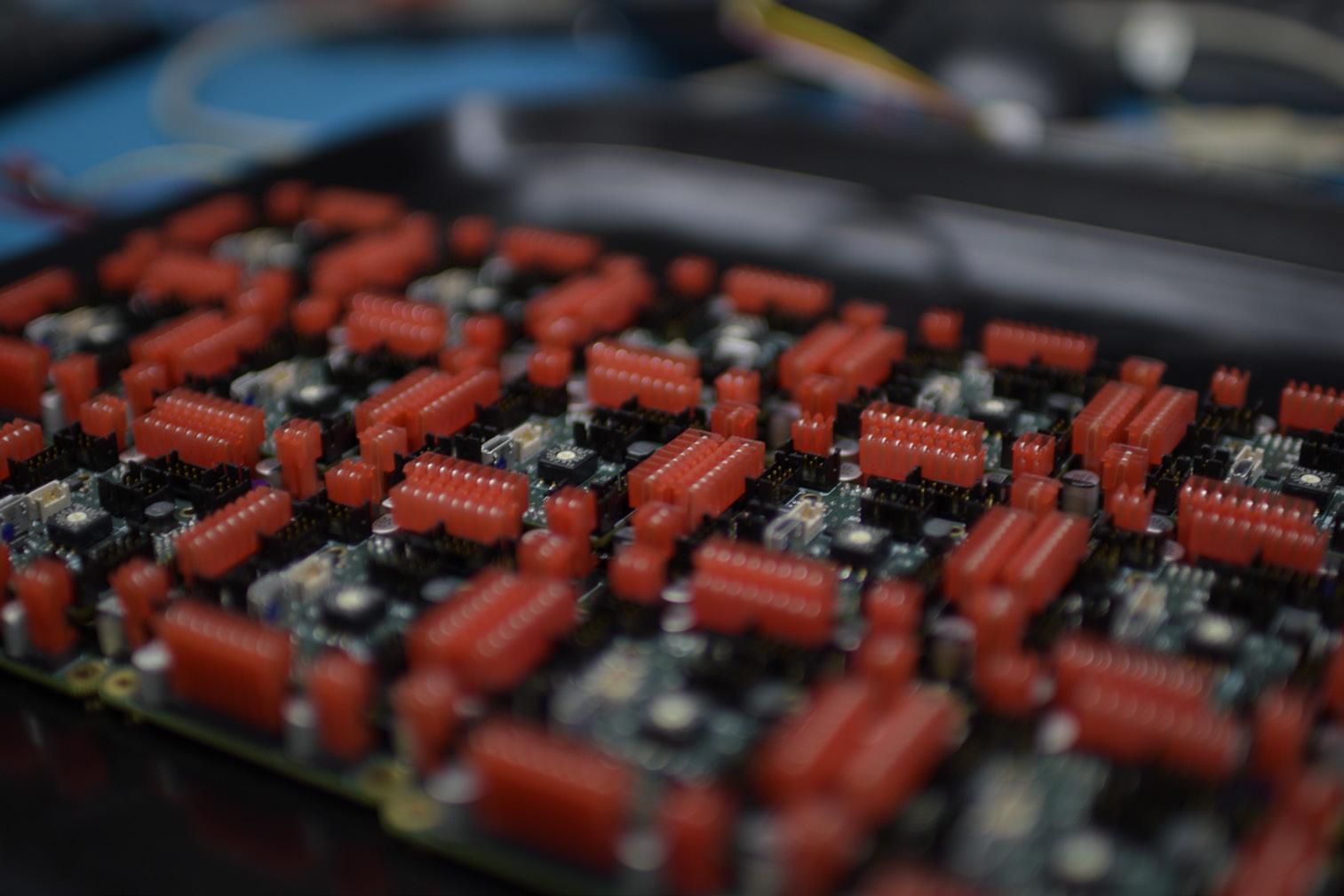

Rogachev: Next-generation motor drivers are increasingly integrating more advanced functions for motor control, fault management, and sensing. These functions can significantly offload traditionally software-based functions, enabling a reduction in R&D software development efforts and more optimized MCU selections. Of course, functional safety is an increasingly vital requirement for modern systems as smart motors and motor drives continue to proliferate into applications that closely interact with humans. Beyond factory settings, passenger vehicles and other automotive designs persist in delivering advanced functions for intelligent actuator controls in windows, doors, liftgates, seats, steering, and various other areas of the car where safety is a core priority.

37 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

in electric motors

trends

lightweight AKMA servomotor is

This artery disease treatment device incorporates a brushed motor. Image: Portescap

SETTING IDEAS INTO MOTION Engineering Development & Manufacturers of Small Mechanical Components Manufacturing Precision Gears, Mechanical Components, and Custom Solutions 100,000 Mechanical and Electromechanical Components • Shop 24/7 • Competitive pricing • 3D CAD models • Customizable 1 (516) 328-3300 Call our Engineers Today! Place a RFQ Online! www.sdp-si.com • In-house engineering and manufacturing in the USA • World-class quality • Assembly • ISO 7 Class 10000 Clean Room • AS9100:D + ISO 9001:2015 Registered • ITAR Compliant / DDTC Registered

ADVANCES BEGET ADVANCES IN LABORATORY AUTOMATION

According to Global Market Insights, laboratory automation’s market size was 6.7 billion (USD) in 2023.

The site also reported an expected CAGR of over 6.7% between 2024 and 2032. What’s expected to account for this growth? What specific trends will act as the catalyst for bringing the laboratory automation sector into the double-digit billions? We asked top industry experts about the components, innovations, and trends we might see in 2024 and beyond.

We begin by drilling down to the component level to see what technologies the major players are using to influence lab automation from the ground up.

What components are used in laboratory automation?

Tomar: Various sensing and driving technologies have advanced lab automation designs. Machine learning and AI are crucial in intelligent decision-making, predictive analysis, and optimizing experimental workflows. Robotics and automation handle tasks such as sample handling, pipetting, and plate manipulation. IoT connectivity enables real-time lab equipment monitoring and control, allowing remote access and data sharing. Multi-sensor modules for high throughput facilitate rapid data collection and analysis.

Graham: Our components provide feedback on the speed and positioning of various lab automation applications, from fluid handling and test equipment to larger robotic and equipment parts. What we have seen in this space is the further development of automation efficiency and the integration of AI control systems perhaps on the horizon to handle some of the most challenging analysis and identification applications in the space.

40 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

industry trends

MEET THE EXPERTS

Ankur Tomar | Manager — Technical marketing Newark (an Avnet Company)

Sam Stoney | LifeTech Industry Segment manager Festo

Dave Beckstoffer | Industry manager • Portescap

Patrick Varley | Product marketing manager — robotics • Mitsubishi Electric Automation

Brian Dengel | General manager KHK USA Inc.

Paul Denman | Applications engineer • Nippon Pulse

Yoshi Umeno | Industry manager — global medical and robotics • Kollmorgen

Richard Halstead | President Empire Magnetics Inc.

Yugi Ikeuchi | GM — engineering and app development • IKO International

Karl Wickenheisser | VP of sales and marketing IKO International

Stuart Graham | Business development specialist Heidenhain

laboratory automation

41 DESIGN WORLD — MOTION 03 • 2024 motioncontroltips.com | designworldonline.com

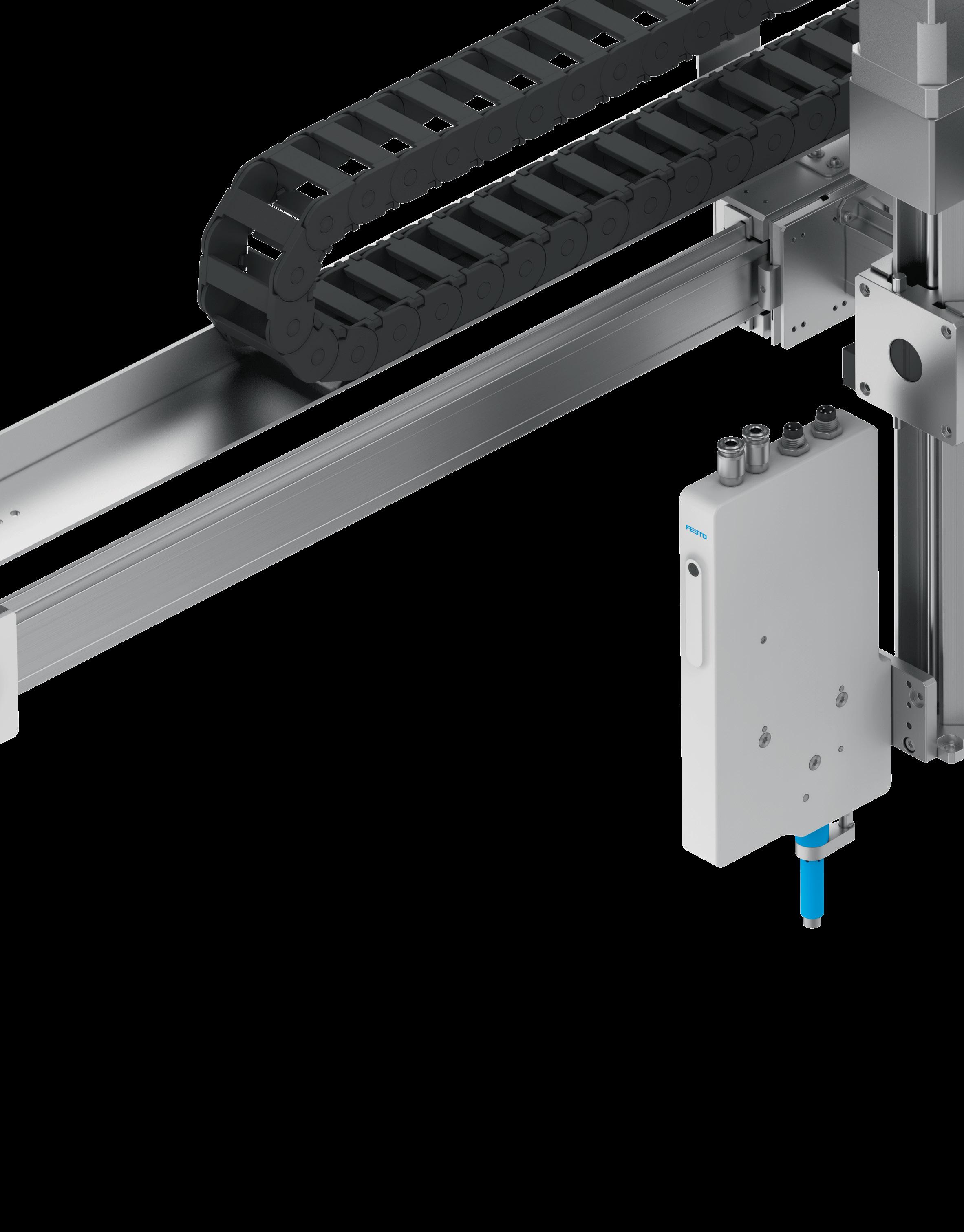

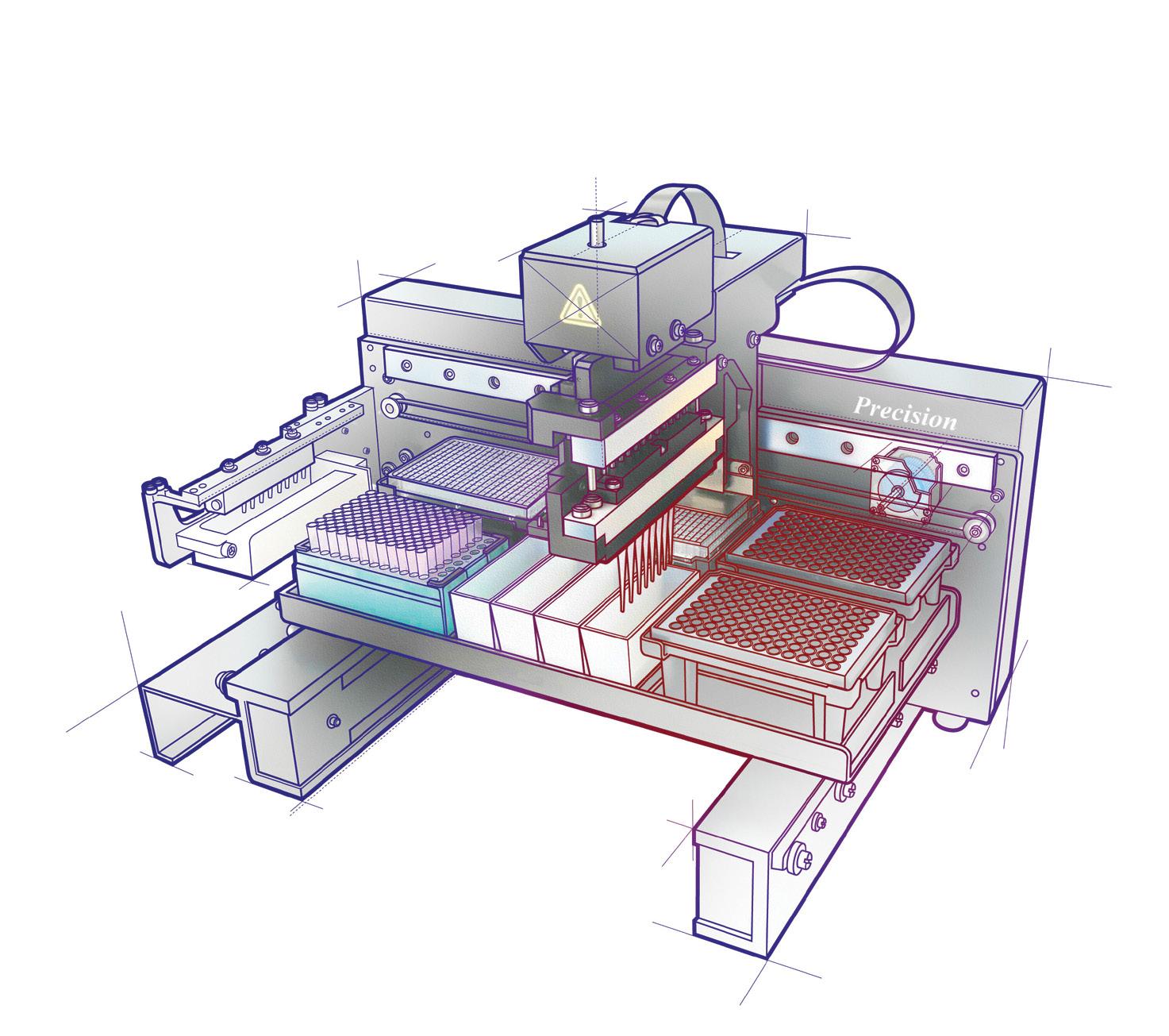

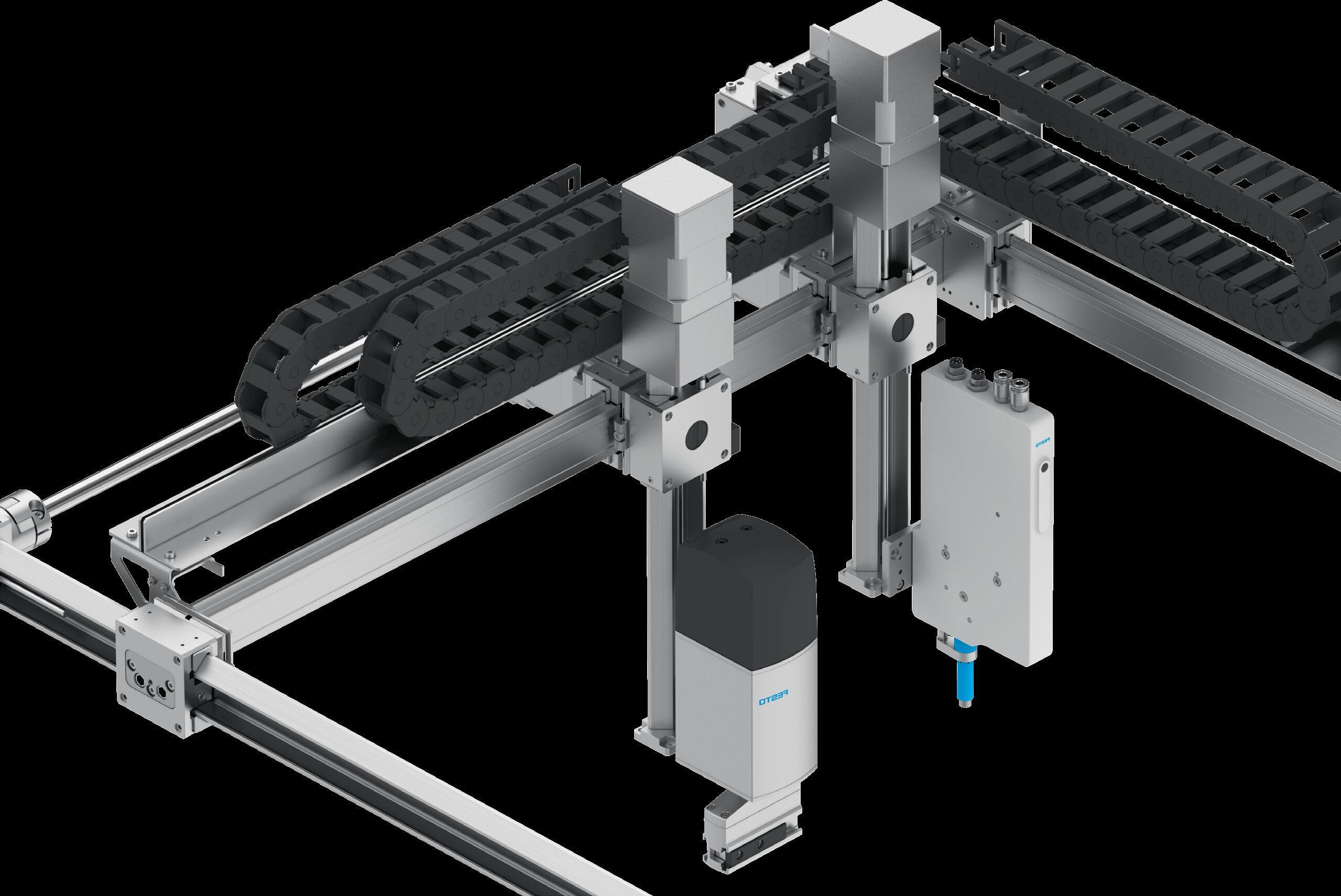

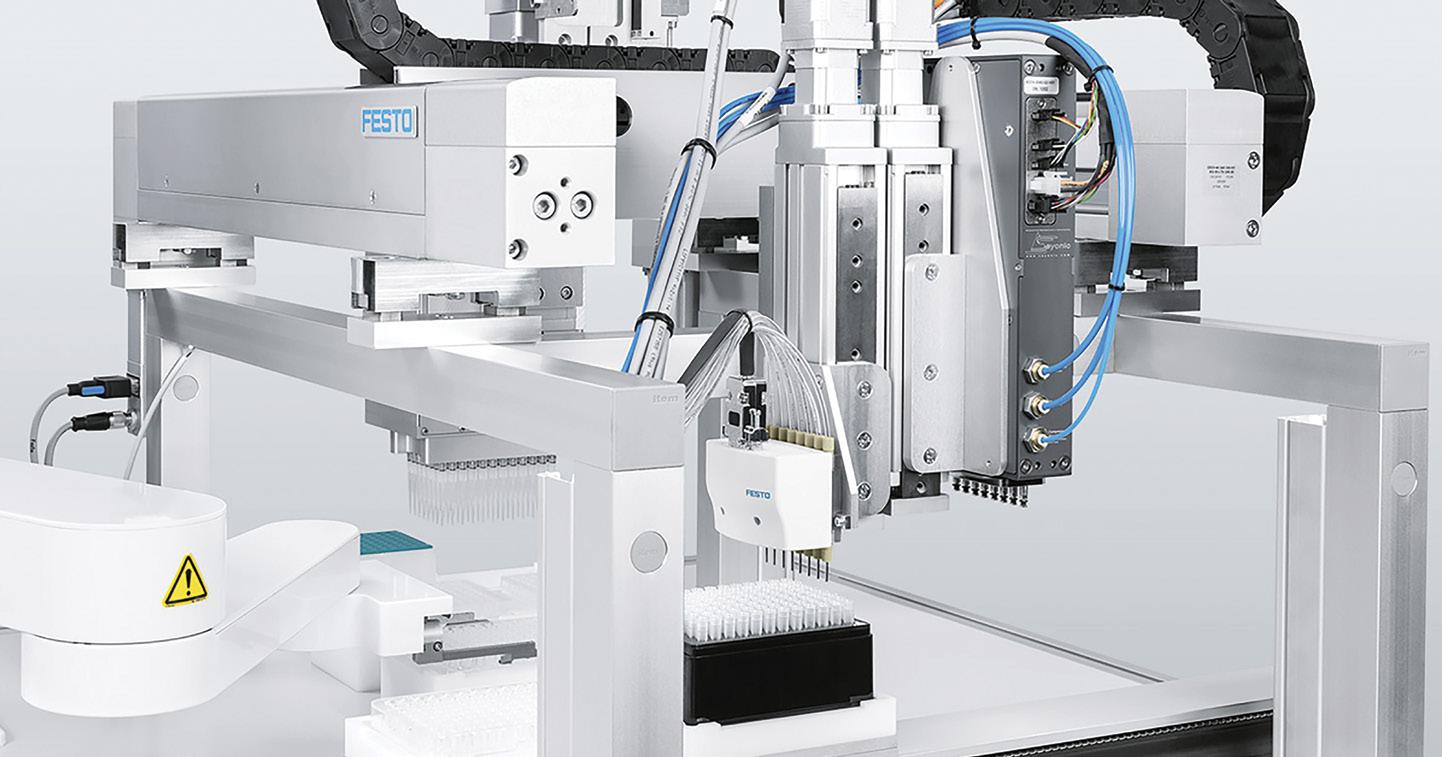

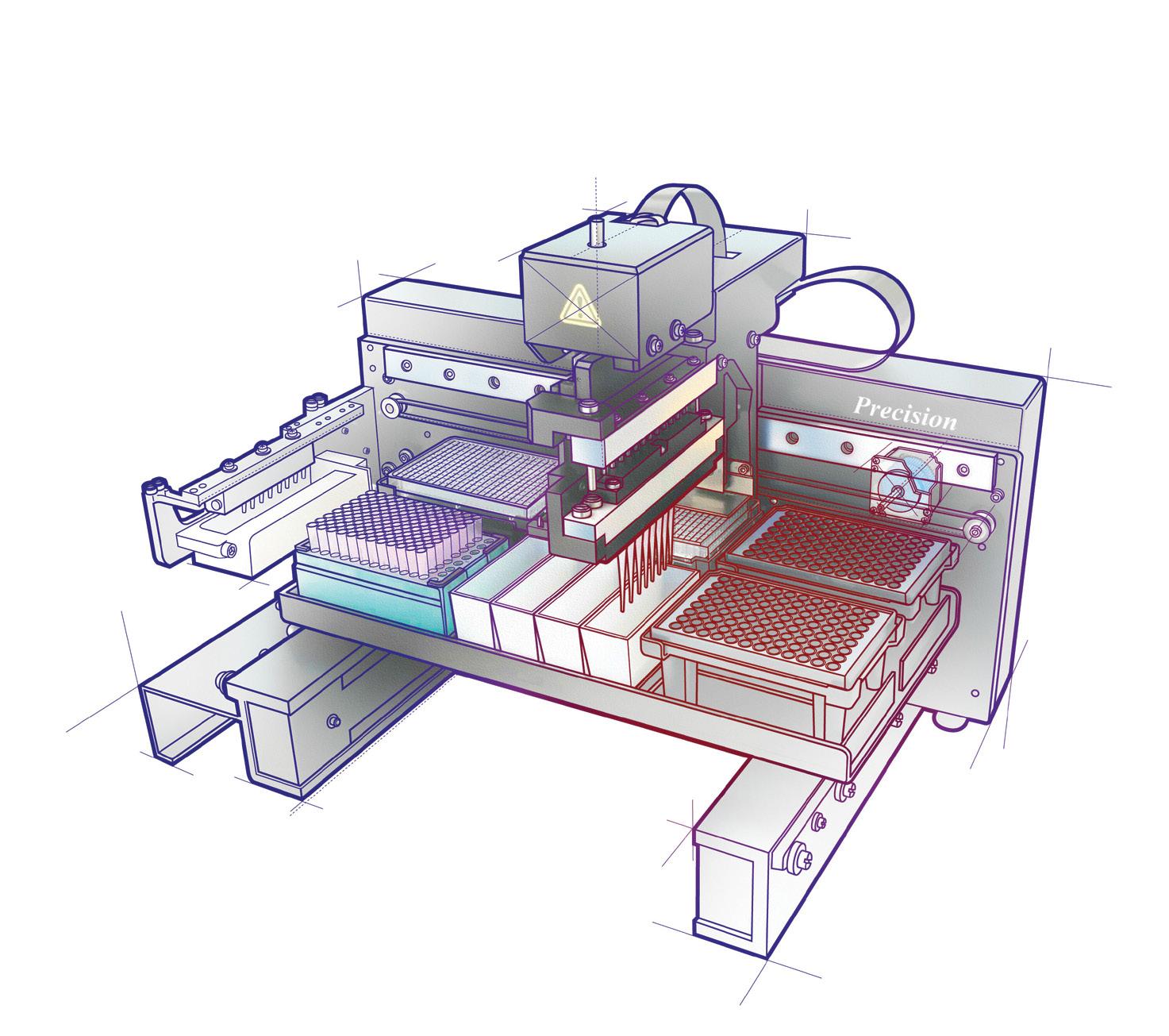

This configuration of a Festo EXCL gantry includes two independent Z axes. Left, a pipette system aspirates and dispenses. Right, the EHMD rotary gripper decaps and grips.

Precision Linear Motion when you need it NOW! Order Today! 800.245.5013 • deltron.com ISO 9001:2015/AS9100D CERTIFIED MADE IN USA Linear Motion Specialists deltron.com 800-245-5013 Solid Models Available for all Del-Tron Model Numbers Standard And Custom Engineered Linear Motion Components Designed to Serve A Wide Variety of Markets

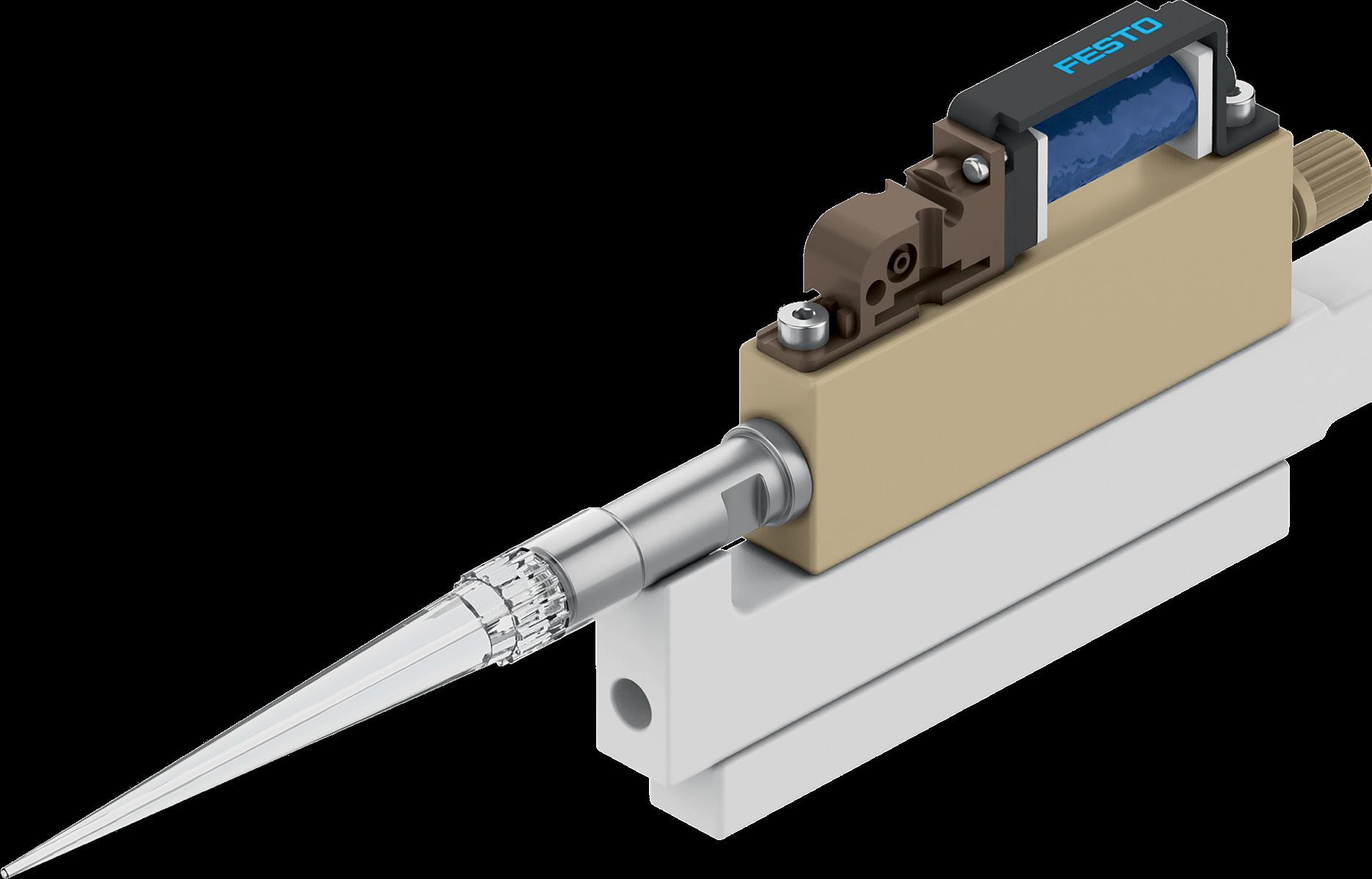

Stoney: Festo industrial pneumatic and electric actuators are common in high-volume automated labs where a single installation may process 100,000 test-tube-based samples each night.

Less visible are the standard miniature fluid valves and specialized manifolds Festo designs for use inside clinical and analytical instruments. At the end of the day, though, most Festo lab automation applications involve a combination of mechanical handling and liquid transfer from test tubes to microplates or other formats more suitable for automation.

Beckstoffer: Portescap motion solutions address several needs in laboratory automation equipment including X-Y-Z movement, pipette dispensing, and aspiration. Brushless DC, DC coreless, and stepper technologies are all used within lab automation on varying axes, depending on the specific requirements. For pipetting, linear stepper technology has seen upgrades and improvements in design and efficiency. In addition, DC

coreless motors with gearboxes and even leadscrew output shafts provide higher performance in a small package. Varley: The robotics group at Mitsubishi Electric Automation has been involved with many lab automation projects. This involvement is with manufacturers and OEMs of lab automation equipment all the way down to startups trying to establish and refine their offerings. As with many other industries, the availability and cost of labor factors in, but the traceability and efficiency that laboratories gain by deploying automation are very important in this time-critical industry.

Dengel: KHK was selected as a supplier to a large laboratory device manufacturer. They require samples to rotate from one position to another for proper analysis. We were able to supply the pinion needed for this operation which allows millions of Covid-19 test to be analyzed annually.

Stoney: Most of the new sensing and drive technology we see in lab automation is related to software development — making sensors and cameras smart using machine learning and other AI tools so they’re selfdiagnosing, robust, and easy to use. Our research team in Boston is deeply involved in this area, and we see a lot of new ideas reaching the lab in the coming years.

Slim. Thru-bore. Absolute. NEW Model A36R absolute thru-bore encoder Ø36 mm x 1.0” depth (actual size) EPC is leveraging new technology to bring you smaller, more accurate, and higher resolution encoders, manufactured in and delivered fast from Idaho, USA. Contact us to learn more. 1-800-366-5412 · encoder.com

automation

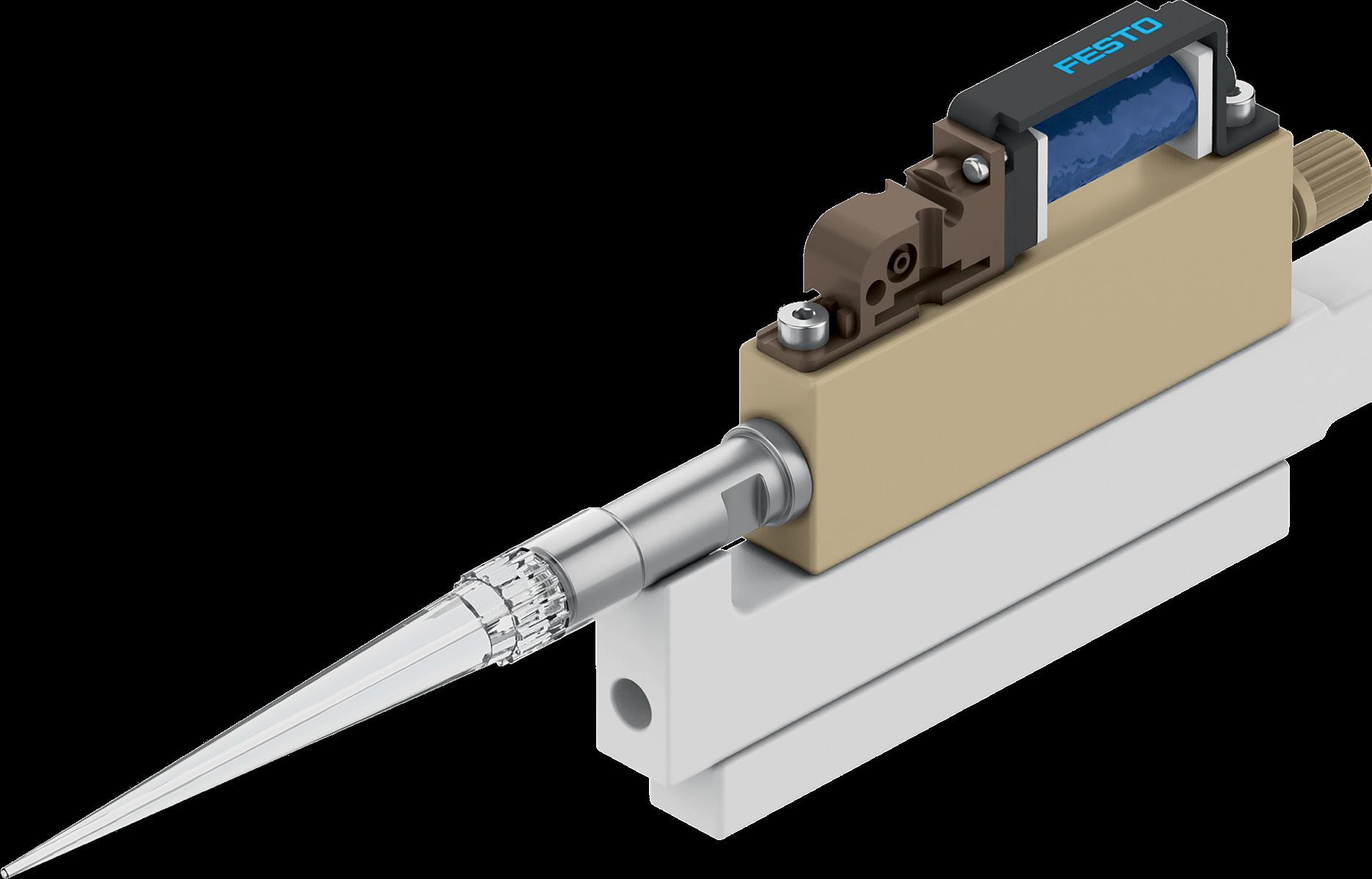

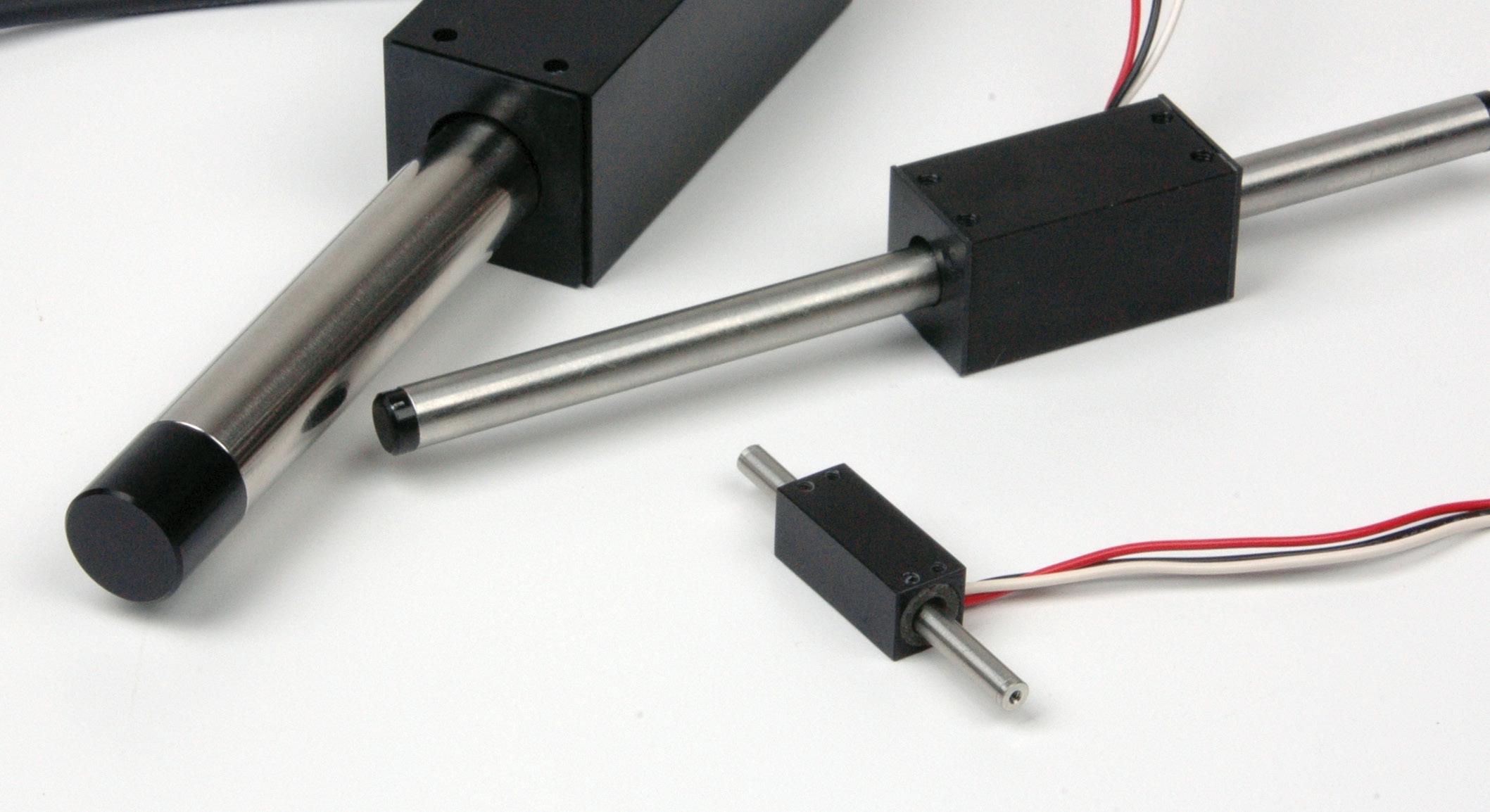

Portescap’s 35DBM-K digital linear actuator is suitable for pipette applications.

laboratory

Denman: Nippon Pulse motion-control components are being used in three critical areas in laboratory automation. First is moving dispensing heads and microplates into position. The second is in liquid handling and dispensing applications. Our motion controllers and motor drivers enable highprecision liquid dispensing, and our Linear Shaft Motor technology can pick up pipette tips for single- or multi-axis dispensing.

Finally, our magnetic counter-balance technology is being used in vertical (Z-axis) motion to provide sample safety and prevent contamination of sample reagents.

Tomar: High-resolution imaging technologies provide real-time monitoring of cell cultures and microscopy. Continually improved are automated sample-preparation techniques — including nucleic acid extraction, purification, and library preparation. Lab informatics and LIMS platforms are used for efficient data management, workflow optimization, and regulatory compliance. 3D printing is employed for the rapid prototyping of custom lab equipment.

Moreover, cobots and mobile robots handle repeated complex tasks and transport samples, minimizing manual handling. Augmented reality and virtual reality enhance visualization, training, and guidance in lab procedures.

Any technologies allowing the laboratory-on-a-chip and animaltesting substitute technologies?

Stoney: A significant challenge in lab-on-achip technology can be getting media into and out of the chip and controlling fluid flow through the devices. Here, Festo has a broad range of dispense valves (VTOE/I), pipettes (DHOE/P), and disposable tips (DHAP) designed especially for high-speed and highthroughput automation.