Italian machine builders lead the way in machine and process innovation

Italian machine builders lead the way in machine and process innovation

Bedrock industries like manufacturing, agriculture, and construction – key sectors served by Italian machine builders – are experiencing numerous growing pains as North American end users seek ways to adjust to challenging business environments and the rapid progression of paradigm-shifting technologies like automation. Navigating these treacherous waters remains a challenge for North American end users, with common problems like operating costs and difficulties incorporating new technology continually bubbling up to the surface.

Fortunately for North American customers, Italian machine builders are dedicated experts in helping end users find workable and efficient solutions to ongoing industry challenges. In this issue of Machines Italia , we take a closer look at how Italian machine builders are using innovation, technology, and collaborative problem solving to tackle the pressing concerns of their end users. By innovating together with their end user customers, Italian machine builders are leveraging their cutting-edge equipment designs to address common industry challenges. By providing technology-focused solutions that incorporate the latest in machine design and functionality, Italian machine builders make meaningful contributions to key end user goals like driving down operating costs.

These core competencies are not only defining characteristics of Italian machine builders, they are also readily acknowledged and deeply appreciated by North American end users. Consider the collaborative, innovative spirit that underpins the culture of Italian machine builders, for instance. When asked about their

In this issue of Machines Italia, we explore in more detail how Italian machine builders are working together with North American end users, seeking innovative and technology-focused solutions to persistent industry challenges, such as managing operating costs. Articles focus specifically on how Italian machine builders present technology-focused solutions; how Italian machine builders are addressing industry-wide challenges; how Italian machinery is helping end users drive down operating costs; and how Italian machine builders are working with their end user customers to innovate machines and processes to succeed together.

perceptions, 94% of North American end users agreed or somewhat agreed that Italian machinery incorporates innovative and unique design features. In addition to recognizing the ubiquity of Italian design innovation, 93% North American end users also agreed or somewhat agreed that Italian machine builders are trusted industry collaborators. There is no doubt that North American end users recognize the powerful, innovative solutions being dreamed up by Italian machine builders.

The near-unanimous recognition and acclaim for Italian excellence translates all the way down through the topics explored in this issue of Machines Italia. From recognizing Italian machine builders’ skill and creativity at incorporating the latest design features to provide technology-focused solutions (87% of end users) – to providing transformative solutions to address common industry challenges (92% of end users) and specifically helping customers drive down operating costs (93% of end users) – North American end users overwhelmingly acknowledge the foundational strengths of Italian engineering.

2025 has already proven to be a challenging year for North American end users, with significant uncertainty likely remaining for the immediate future. Fortunately, North American end users do not have to embark on this rocky road alone – they can count on the dedicated support of their Italian machine builder partners. To all of our North American end user partners, both current and future, we say: Italian machine builders are here to support your success –through thick and thin – to reach new heights of excellence together.

Avanti insieme!

Sincerely,

Marco Verna Trade Commissioner—Chicago

2 Cornerstones to Success: Collaboration and Cooperation

Italian machine builders lead the way in machine and process innovation.

4 Robots in the Field

Robots are popping up everywhere these days, helping companies carry out essential functions and freeing up employees to apply their skill and expertise to other critical tasks.

5 Inside the Surge of Trust: Why North American Manufacturers Choose Italian Machine Builders

North American manufacturers looking for a trusted machine builder often don’t look at home. They head to Italy.

8 Beyond the Build: How Italy’s Machine Makers Are Powering Smart Manufacturing

From predictive maintenance to robotics and digital twins, Italian OEMs are fusing tradition with technology to deliver intelligent, adaptable, and futureready solutions for North American industry leaders.

12 Engineered to Solve: Italian Ingenuity in Action

From digital integration to sustainability, discover how Italy’s OEMs are transforming North American manufacturing challenges into competitive advantages.

18 Efficiency Is the New Luxury — and Italy Is Delivering

With economic pressure mounting, North American manufacturers are turning to Italian machines that promise performance and savings.

22 Innovating Together: How Italian Machine Builders Drive Industry Forward Through Collaboration

By blending deep expertise with close client collaboration, Italian OEMs are transforming North American industry challenges into cutting-edge, customized solutions across molding, extrusion, and digital retrofitting.

25 Machines Italia News

News briefs from a selection of our 10,000 machinery manufacturers.

30 Italian Technology Award Programs

Connecting international students and faculty members with Italian companies and associations.

31 Italian Innovation in the Spotlight

From Chicago and Las Vegas to Mexico City and Ontario, Machines Italia is on the road to innovation.

32 Upcoming Trade Shows in Italy

Experience some of the industry’s best and brightest at these upcoming events.

34 Innovation at Work in Global Markets

A look at Machines Italia’s 15 partner associations and industries.

For a detailed interactive digital map on Italian Solution Providers in North America, please visit tinyurl.com/ItalyNAProviders.

401 N. Michigan Avenue, Suite 1720 | Chicago, Illinois 60611 1-888.ITALTRADE/482.5872 (U.S. and Canadian Callers) 312.670.4360 (Outside the U.S. and Canada) chicago@ice.it www.machinesitalia.org ADDRESS TOLL-FREE TELEPHONE E-MAIL WEBSITE

The Italian Trade Agency’s USMCA offices in Chicago, Houston, Los Angeles, Toronto, and Mexico City are principally responsible for the machinery and technology sectors covered in this publication.

Robots are popping up everywhere these days, helping companies carry out essential functions and freeing up employees to apply their skill and expertise to other critical tasks. More than just a flashy piece of technology, robots are invaluable tools helping to advance industries, like agriculture, and strengthen bottom lines.

Italy has rapidly become an epicenter of robot innovation and advancement, with urban centers like Pisa and Milan hosting a number of established robotics manufacturer headquarters and nurturing a thriving ecosystem of ambitious startups. With nearly 700 robotics companies, Italy now outpaces even the most prestigious industry-leading robotics countries like France and Germany. Thanks to this diversity of robotics manufacturers, Italian robots are now some of the most innovative and diverse options available on the market. As Italian robot manufacturers continue to expand the depth and breadth of their offerings, they are looking abroad to North America, in search of fertile fields to apply their cutting-edge solutions.

One of the emerging markets for robotics in North America in particular is the agriculture industry. With labor-intensive, repetitive processes like planting and picking, and high employee turnover rates, agricultural operations are always on the lookout for strategies to trim costs and increase efficiency. Italian robot manufacturers have a number of solutions to help address these sticky industry challenges, from fully autonomous mobile field robots, to robotic components that can help automate specific machine functions like precision seed planting. Many of these robotics-based solutions are already being incorporated on Italianmade farm equipment, thanks to partnerships between Italian machine builders and Italian robotics experts.

There are so many more functionalities and tools that agricultural robots can open the door to beyond automating physical tasks like planting and harvesting. Consider the power of real-time monitoring, for instance. In industries like manufacturing,

real-time dashboards can be effective tools to monitor production environments. In the agricultural industry, robots can also power real-time monitoring directly in the field to help farmers guard against devastating threats like pests and disease. Farm machinery equipped with additional robotic visual inspection systems can help operations search for signs of disease or pest infestation as the equipment passes through the field. This task can be automated even further by mounting these powerful robotic vision detection systems on mobile robot bases able to traverse rows of crops all on their own. Gathering data on pest and disease instances in this way enables the creation of real-time dashboards, empowering farmers to carefully monitor their crops and guard against potentially disastrous consequences. No longer do farmers have to rely on spot checks and gut feelings: with robot-powered real-time data, they can confidently make decisions and nip developing disease and pest problems in the bud.

The partnerships between Italian machine builders and Italian robot experts are yielding tangible benefits for the agriculture industry. As these robotic features become more common on Italian machinery, and as Italian robot makers expand their reach further into the North American market, end users are primed to “reap” the benefits of Italian engineering.

Tom Ryden

Executive Director MassRobotics

Largest independent robotics hub massrobotics.org

North American manufacturers looking for a trusted machine builder often don’t look at home. They head to Italy.

That’s according to results from a new survey conducted on behalf of the Italian Trade Agency’s Machines Italia project by WTWH Media and Reach Solutions, which found that 92% of respondents either agree or somewhat agree that Italian OEMs/suppliers are trusted collaborators. The survey, via WTWH Media and Reach Solutions, also found that 26% of respondents identify the collaborative nature of Italian machine builders as a key factor in their decision to buy Italian.

Beyond the numerous technical advantages of choosing Italian machinery, end users across industries confidently view Italian machine builders as true partners, mutually invested in their success.

Q1: Italian OEMs/suppliers are trusted collaborators

Q2: Italian machinery incorporates the latest technology features like AI and machine learning

Q3: Italian OEMs/suppliers offer solutions that save our operations money

Q4: Italian machinery includes innovative or unique design features

Q5: Italian OEMs/suppliers are turn-key providers, offering solutions at all steps of a project

Q6: Italian machinery reduces our reliance on skilled human labor

Q7: Italian OEMs/suppliers offer solutions that save our operations time and capacity

Q8: Italian machinery helps us meet our sustainability goals and improve operational sustainability

Q9: Italian OEMs/suppliers provide transformative solutions that improve our entire operations

Q10: Italian machinery is customized to fit our unique operations and needs

This sentiment is neatly summed up by Antonio Nencini, CEO of Ramatex, as he explains how Italian machine builders believe their own success is closely tied to that of their clients. “If you are following along with the same roadmap, you will both wind up at the same place,” he says. Italian machine builders are here to support their customers throughout their journey, a reality that is acknowledged and greatly appreciated by the industries and end users they serve. Buying Italian means more than purchasing a piece of equipment – end users are acquiring a collaborative partner dedicated to their success.

A common theme from survey respondents is the ability of Italian equipment to unlock new opportunities in their business. The superior design and build quality of Italian machinery, combined with unique Italian innovation for new machines and new processes, can fundamentally overhaul end user operations.

At a base level, end users are keenly aware of the Italian capability for transformative innovation, with 50% of respondents noting the innovative design of Italian machinery as the most influential factor in their decision to purchase Italian. End users also specifically acknowledged the disruptive power of Italian machinery, with 18% of respondents indicating they purchased Italian based on the operation-wide transformative capability of Italian equipment.

End users had even more to say about Italian machinery expanding their capabilities. An astounding 91% of respondents at least somewhat agreed that Italian machine builders deliver transformative solutions that improve their entire operations, while 35% noted that Italian machinery allowed them to expand their capabilities to new products and services previously out of reach. In this way, Italian machine builders are helping end users open entirely new avenues of business that were previously inaccessible.

Beyond operation-wide, deeply transformative capabilities, Italian machine builders are helping end users achieve specific, incremental goals and unlock new levels of efficiency. An excellent example of this is sustainability. Consider these responses:

• 91% of respondents at least somewhat agreed that Italian machinery explicitly helped them meet their sustainability goals and improve their overall operational sustainability

• 93% of end users at least somewhat agreed that Italian machine

builders offer solutions that save their operations time and capacity

• 42% of end users noted Italian machinery has expanded their overall throughput and/or work efficiency, the number one benefit identified in the survey

• 92% of respondents agreed or somewhat agreed that Italian OEMs are turn-key providers, offering solutions at all steps of a project

For manufacturers attempting to fix these common challenges — managing production schedules, expanding throughput, increasing operation-wide efficiency — Italian machine builders are at the forefront of innovation, delivering solutions that help end users fundamentally transform their operations for the better. Through superior machine design and creative applications of technology, Italian machine builders are empowering end users to pursue new business opportunities.

While it is commendable how universally acclaimed Italian machine builders are for their machine innovation and the transformative power of their products and services, how they go about achieving those accolades is even more impressive.

Specifically, Italian machine builders are experts in creatively applying new technology to their machines and the processes they carry out. This leveraging of technology-focused solutions is a key component of the success Italian machine builders have found in helping clients unlock new capabilities with their machinery.

End users are keenly aware of the technological advantages delivered by Italian machine builders. Eightyfive percent of respondents agreed or somewhat agreed that Italian machinery incorporates the latest technology features. This use of technology begins all the way in the conceptualization stage, with Italian machine builders using cutting-edge software to ensure efficient designs.

Additionally, 26% of end users identified the advanced line design, mapping, and modeling capabilities of Italian machine builders as one of the top three reasons that most influenced their decision to buy Italian, while 14% indicated that Italian use of technology-focused features was a defining reason for their purchase of Italian equipment. Much like the transformative power of Italian innovation mentioned above, 34% of end users explained that their use of Italian machinery allowed them to access new technology not previously present in their operations.

For specific technology applications, end users identified a host of high-tech features already incorporated into their Italian equipment. From integrated HMI/PLC displays (31%), to predictive/preventive maintenance (42%), real-time data monitoring (48%), robotics (29%), and AI-supported processes (30%), end users report numerous technology-centric features on the equipment they purchase from Italian machine builders.

Through the creative use of innovative, technology-focused features on equipment, Italian machine builders are supporting their customers in driving new operational efficiencies. End users can be confident that when they buy Italian, they are selecting the latest in process and technology innovation.

Are you using any of the following hightech features with your Italian machinery?

What technology-focused Italian machine features are most important to you?

Now more than ever, the values and quality that Italian machine builders represent are the same essential qualities that end users seek. With older industry challenges like sustainability, digital integration, automation, and labor constraints still common, the experience, expertise, and creativity of Italian OEMs continue to drive end users to purchase Italian machinery.

Yes, these existing challenges are compounded in 2025 with newer challenges like deep economic uncertainty and ongoing supply chain woes, pinching end users between competing needs that must be addressed within tightening budget constraints. Fortunately for North American end users, Italian machine builders are already rising to meet these challenges. Through technology-focused solutions and collaborative innovation designed to directly address industry-wide challenges and drive down operating costs, Italian machine builders are well-positioned to help North American end users confront their greatest challenges.

With collaboration and cooperation baked into their DNA, Italian machine builders stand ready to man the helm and steer end users through the rough seas of 2025 and beyond.

In an industry where performance, adaptability, and partnership are paramount, Italian machine builders continue to distinguish themselves as trusted allies to North American manufacturers. The survey results reinforce that Italian OEMs are more than suppliers, they are collaborative partners who bring innovation, quality, reliability, and transformative technology to the table. Whether it’s unlocking new product capabilities, advancing sustainability goals, or boosting operational efficiency, Italian machine builders are consistently delivering value where it counts most.

What sets Italian suppliers apart is a distinctive combination of strengths: a deeply collaborative approach, a commitment to high quality manufacturing, and technological innovation - integrating advancements like AI, machine learning, and digital twinning. Their responsiveness to emerging challenges - operational or technological - further strengthens their position as essential partners for long-term success.

While local suppliers may offer speed and convenience, Italian OEMs bring global competitiveness and a proven track record in international trade. As end users face increasingly complex demands, the commitment and ingenuity of Italian OEMs offer both stability and a path forward in a rapidly evolving global landscape. The message is clear: when manufacturers choose Italian, they’re not just buying machines, they’re investing in shared progress.

The survey was conducted using WTWH Media’s and ITA’s respective databases and targeted a mix of Italian machine users and nonItalian machine users to better understand North American end-user perceptions of Italian machinery in the wider market. The survey reached 184 respondents, with 52% representing current or past end users of Italian machinery, 29% comprising end users who have not used Italian machinery, and an additional 19% who were unsure if they are currently using or have used Italian machinery in the past. Survey takers represented all of North America, with 84% from the United States, 11% from Canada, 5% from Mexico.

This pool of participants was also asked for their top considerations when making a machine purchase, data that is included throughout the body of this issue. Current and past confirmed users of Italian machinery were targeted to solicit their insights into how Italian machinery improved their operations, as well as what features and functionalities of Italian machinery influenced their decision to purchase. This data is also included throughout this issue.

36% of end users indicated increases in the number of automated processes in their operation that were enabled by Italian machinery.

Ahallmark of Italian machine builders is a dedication to detail and uncompromising build quality. A key component of these two qualities is the use of technology-focused features and solutions being deployed by Italian machine builders. These features are meaningful considerations for end users, directly influencing their purchasing decisions. From the survey, respondents identified real-time data monitoring (48%), predictive/preventive maintenance (42%), AI-supported capabilities such as vision and inspection systems (38%) and data and process analysis (31%) as their most desired machinery features. End users report that, to some extent, all of these features are already being offered on Italian machinery. This is excellent news for both Italian machine builders and their customers, reflecting the Italian commitment to building cutting-edge machinery equipped with the high-tech features end users want.

Thanks to the precision application of new technologies, end users of Italian machinery report significant advancements in their automation goals. When asked how Italian machinery has improved their business, 36% of end users indicated increases in the number of automated processes in their operation that were enabled by Italian machinery, with 33% able to reduce their overall reliance on human labor.

“The production methods and – above all – the know-how of Italian manufacturers to integrate technology into their machinery greatly influenced our decision to buy Italian,” says Khaled Lajili, Head of Industrial IoT at Alstom and user of Italian machinery. The thoughtful design of technology into Italian machinery is a key advantage for end users. Italian machine builders’ use of high-tech features are not just gimmicks chasing trends, they are innovative applications that advance concrete end user goals.

A key challenge for OEMs across industries is designing machinery versatile enough to be used by operations of different sizes and different technical capabilities. This is especially true for the metal forming industry, where operations can require a wide range of machine speeds and tolerances to accommodate different tasks. Italian machine builders have devised innovative designs anchored by high-tech solutions to support the metal forming needs of their customers. Zani SpA (zani.net), a third-generation, family-owned builder of metal forming machines and a member of UCIMUSISTEMI PER PRODURRE (ucimu.it), the Italian Machine Tools, Robots and Automation Manufacturers’ Association, has adopted this technology-centered mindset of innovation across its line of metal presses and lathes.

Johnson, Principle Electrical Instrumentation and Controls Engineer at Chevron and user of Italian machinery, has been vocal in his acknowledgement of how Italian machine builders improved digital twin processes, thus “easing the task of inputting digital information for the development of digital twins,” he says. “These easier-to-construct digital twins from Italian machine builders made it easy for our engineers to work either onsite directly at a project, or more remotely from regional offices.”

This kind of technology-focused solution that increases the capability and flexibility of an operation has become a facet of Italian machine builders.

For those customers pursuing deeper levels of digital integration in their operations, Zani has developed a suite of new technologies centered around their machine software. Zani’s Spin Master lathe incorporates this high-tech software suite, unlocking advanced functionality such as pre-programmed and easily changeable production settings, continuous improvement through machine self-learning, and easily refinable code that includes image-based systems for lower skilled operators. One end user of Italian equipment, Muhammad Ali, an electrical engineer at Key Engineering Group, emphasizes how Italian equipment is thoughtfully designed to maximize machine capability.

“One point worth highlighting is the exceptional craftsmanship and design sensibility that often comes with Italian machinery,” Ali says. “Beyond just functionality, many Italian manufacturers bring a strong emphasis on ergonomics, aesthetics, and intuitive user interfaces, which not only enhance operator experience but also contribute to safer, more efficient workflows.”

“One point worth highlighting is the exceptional craftsmanship and design sensibility that often comes with Italian machinery. Beyond just functionality, many Italian manufacturers bring a strong emphasis on ergonomics, aesthetics, and intuitive user interfaces, which not only enhance operator experience but also contribute to safer, more efficient workflows.”

— Muhammad Ali, electrical engineer at Key Engineering Group

Through its core company values, pillars, flexibility and innovation, Zani has committed itself to pursuing customer solutions through innovative deployments of technology designed to bolster operational nimbleness. In an industry that retains a high level of legacy manual processes, Zani is forging a new path by embracing high-tech, digital solutions that support greater physical machine functionality.

Zani’s commitment to technology-forward machine designs begins in the initial drafting stage, where the company utilizes a suite of cutting-edge 2D and 3D digital modeling programs to refine machine designs. This same technology is further applied to customer installation models, empowering Zani’s clients to see exactly how their line of presses and stamps can improve their production cycles.

One leader at Chevron has complimented Italian machine builders for their use of digital models and digital twins. Dale

End users recognize the superior quality of Italian equipment manufacturers like Zani. Reflecting on the Italian machine building industry as a whole, one end user emphasizes how buying Italian is truly different than purchasing from other OEMs.

“The machinery KDR purchased is an excellent machine – so much better than the domestic clone,” says Donovan Vulk, Owner of KDR Farms and Trucking. By embodying the precision and quality Italian machine builders have built their renown on, and applying it to technology-forward digital solutions in an industry that has been slower to adopt them, Zani is breaking new ground in Italian machine innovation.

Camozzi Group

When talking about technology in manufacturing and production, many manufacturers conceptualize cutting-edge components

with complex electrical applications such as semiconductors, or advanced finished products used in modern technology such as microchips. While these operators and the products they produce rely on a high degree of technology-focused strategies, high-tech applications in manufacturing have many uses beyond high-end electronics production.

For Italian machine builders, technology-focused manufacturing solutions are not just for the sterile rooms of semiconductor producers. These cutting-edge applications can be utilized across industries, including heavy industrial manufacturing. Through innovative applications of technology-centered expertise, Italian machine builders are helping customers in traditionally lowertechnology manufacturing sectors realize tangible benefits.

An excellent example of this technology-first approach is the Camozzi Group SpA (en.camozzigroup.com) , experts in the production of components and systems for high-tech industrial automation in the manufacturing, life science, robotics and mechatronics sectors. Recently, the Camozzi Group division Innse-Berardi, a member of

(ucimu.it), the Italian Machine Tools, Robots and Automation Manufacturers’ Association, was challenged by one of their longstanding customers, Rete Ferroviaria Italiana (RFI) – a company of the Ferrovie dello Stato Italiane Group responsible for the overall management of the national railway network – to help modernize their manufacturing operations. RFI asked Innse-Berardi to design a machine capable of milling “frogs” (large metal components essential to railway track management) from solid blocks of cast steel.

The extra caveat: RFI wanted the process to be as automated as possible, while maintaining a high degree of precision and technical accuracy on the final product.

“The needs to be met were to obtain high production volumes with minimum manpower commitment and maximum machining accuracy,” said Sergio Leoni, Product Development Manager of Innse-Berardi.

Always up for a challenge, the Camozzi Group was able to draw on their extensive company network and internal expertise to design numerous technology-focused features into a customized milling machine. To address one of RFI’s biggest problems – managing vibration – Camozzi Group division Innse-Berardi equipped the polar axes of the machine with a multiple pinion system on a toothed wheel. This crafty design guaranteed constant preload of the system without the need for periodic adjustments and with minimal maintenance requirements, contributing to RFI’s most important goal of increasing automation and reducing reliance on human intervention during production.

In addition to this creative application of machine automation, the experts at the Camozzi Group fitted the milling machine for RFI with a robotic tool magazine with 30 total seats, double the number of tooling components required for the machine, creating fail-safe redundancy. Taking the use of high-tech robotics even further, Camozzi integrated ergonomic tool changing stations directly into the robot-managed tool seats, enabling the replacement of worn tools without stopping machining, all while maintaining total operator safety.

Camozzi’s use of robots dovetails smoothly with end user requests: the survey revealed 29% of end users would like to see more robotics integrated into machinery.

Camozzi’s use of robots dovetails smoothly with end user requests: the survey revealed 29% of end users would like to see more robotics integrated into machinery.

The end result of this technology-forward design is a superior milling machine that improves upon a difficult manufacturing process. “Ultimately, we believe we have created a particularly advanced solution,” Leoni said. “Its modular and suitably customized concept has allowed the customer to optimize the machining of difficult materials and productivity.”

Machine building is a demanding endeavor, requiring not only intellectual rigor but also reliable and robust high-speed motion combined with precise command and control. From initial design through to final assembly, the development process demands thoughtful engineering, close collaboration, and meticulous execution. In Italy — a country renowned for its mechanical engineering heritage — machine builders have long excelled at mastering these complexities. Yet, the responsibilities of original equipment manufacturers (OEMs) go far beyond production: they must also ensure strict compliance with evolving regulations and meet a wide array of certification standards.

To address these complex needs, a specialized sector of testing and verification services has emerged to support machine builders with reliable, accurate evaluation processes. Among the key players in this space is AC&E SRL (acenorthamerica.com), a company that has provided laboratory services and validation expertise to machine builders for over two decades. What sets AC&E apart is its ability to combine advanced technology with deep sector knowledge — helping manufacturers implement innovation across both individual machines and full production lines.

As recognized experts in machine manufacturing technology, AC&E frequently collaborates with multinational corporations to deliver educational seminars focused on new production methodologies and technological advancements. These sessions are designed for practical application, aligning technical advancement with marketspecific regulatory frameworks and international compliance protocols.

From the earliest stages of machine design, AC&E works alongside manufacturers — either directly or through third-party engagements—to ensure that advanced technological features are integrated in accordance with regulatory standards. The company employs a multidisciplinary team of engineers, IT professionals, and cybersecurity specialists to support the integration of software and digital tools in machinery while maintaining compliance with relevant guidelines.

This holistic, technology-centric approach enhances the value of AC&E’s service portfolio. According to company founder and president Gino Zampieri, “Our processes are completely computerized. AC&E is fully equipped with all the necessary remote inspection systems, including smart glass technology, to manage quality and safety inspections through a digital interface and dedicated servers.”

AC&E’s capabilities span the full spectrum of machine validation needs. The company offers expertise and recommendations to support compliance and optimization, reinforced by sophisticated in-lab testing infrastructure. Their facilities include a wide array of advanced equipment used for certification, validation, and safety assessments, covering parameters such as electrical performance, dust resistance, mechanical stoppage, noise, and thermal behavior.

“Our processes are completely computerized. AC&E is fully equipped with all the necessary remote inspection systems, including smart glass technology, to manage quality and safety inspections through a digital interface and dedicated servers.”

— Gino Zampieri, AC&E company founder and president

Digital tools also play a central role in AC&E’s offerings. The company uses virtual modeling software to create digital replicas of machinery, enabling clients to visualize design modifications and test functionality in a simulated environment before implementing physical changes.

Through a combination of technical knowledge, state-of-the-art facilities, and commitment to innovation, AC&E continues to support machine builders in improving performance and ensuring regulatory compliance. By bridging cutting-edge technology with hands-on expertise, the company remains a key partner in advancing the capabilities of Italy’s machine manufacturing sector.

From our survey, 11% of respondents indicated that by simply using Italian machinery and the digital features designed into it, they were able to immediately advance their digitalization/digitization goals.

The creative use of technology is a defining aspect of Italian machine builders, and while highly desired by customers, these features are ultimately a tool for end users to address their own needs and challenges. With this goal in mind, Italian machine builders strive to provide equipment and services that speak to entire industries, helping to address the most pressing challenges encountered by whole market segments of end users. The transformative solutions offered by Italian machine builders can help entire industries overcome common challenges encountered frequently by end users. Take digital transformation in manufacturing, for instance. The quest for digitally integrated operations able to realize full Industry 4.0 advantages is an ongoing challenge across manufacturing, with operations all over the spectrum on achieving full connectivity. From our survey, 11% of respondents indicated that by simply using Italian machinery and the digital features designed into it, they were able to immediately advance their digitalization/digitization goals.

Or consider sustainability, an ever-present concern for manufacturers, especially as consumer scrutiny of sustainable practices has steadily increased over the years. There are innumerable solutions end users can pursue to improve the sustainability of their operations, and the use of Italian machinery is one of them. From the survey, end users reported numerous sustainability improvements from installing Italian machinery in the operations, including reduced runtimes for production (48%), reductions in material waste and scrap (42%), and the ability to use more sustainable materials (23%).

By designing more sustainable machinery using a number of different strategies, Italian machine builders are helping to directly address a persistent industry challenge. With their deep industry knowledge and an open-door policy to end user requests, Italian machine builders are among the best OEMs in the world at collaborating with end users to solve the most complex industry-wide challenges.

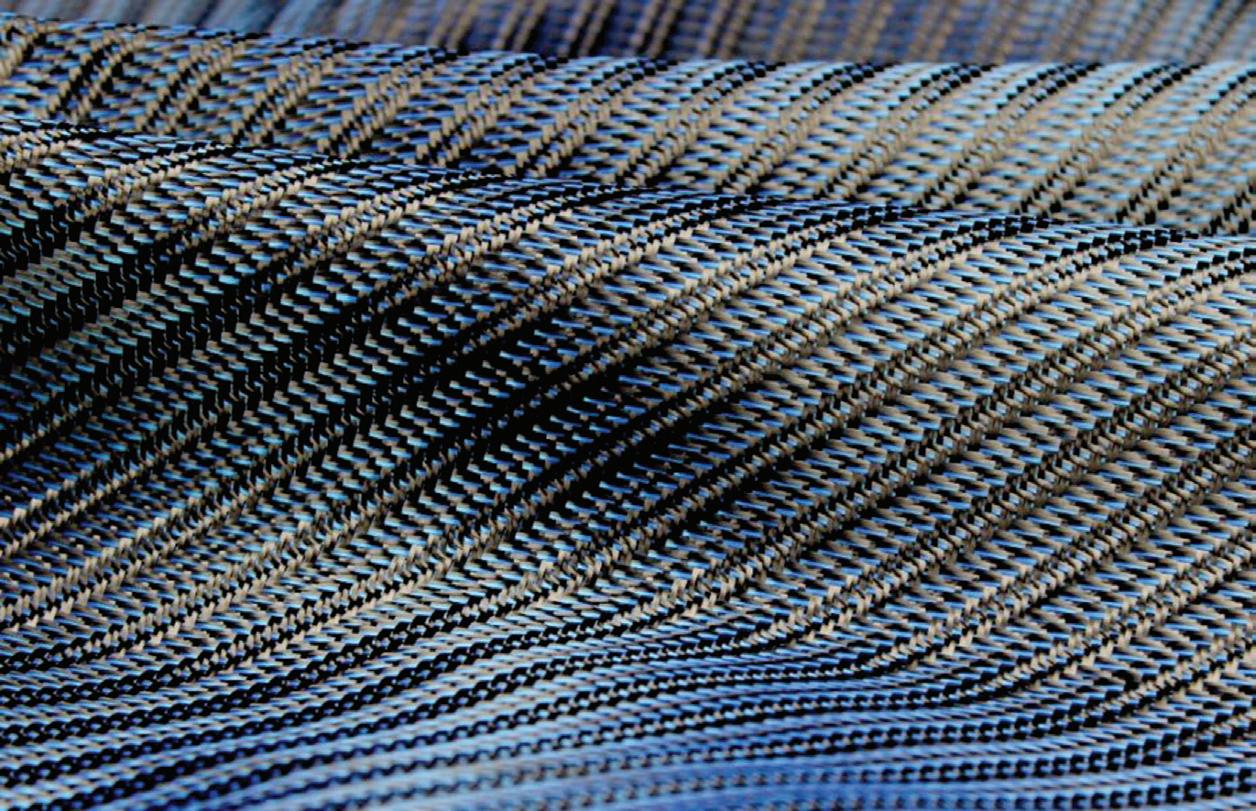

Textile manufacturing is an expansive industry, with networks of suppliers and manufacturers spanning the globe. With complex supply chains and often diverse origins, textile manufacturing requires a focus on planning and logistics to execute effectively. Managing this complicated array of logistical considerations is a recurring challenge for textile manufacturers.

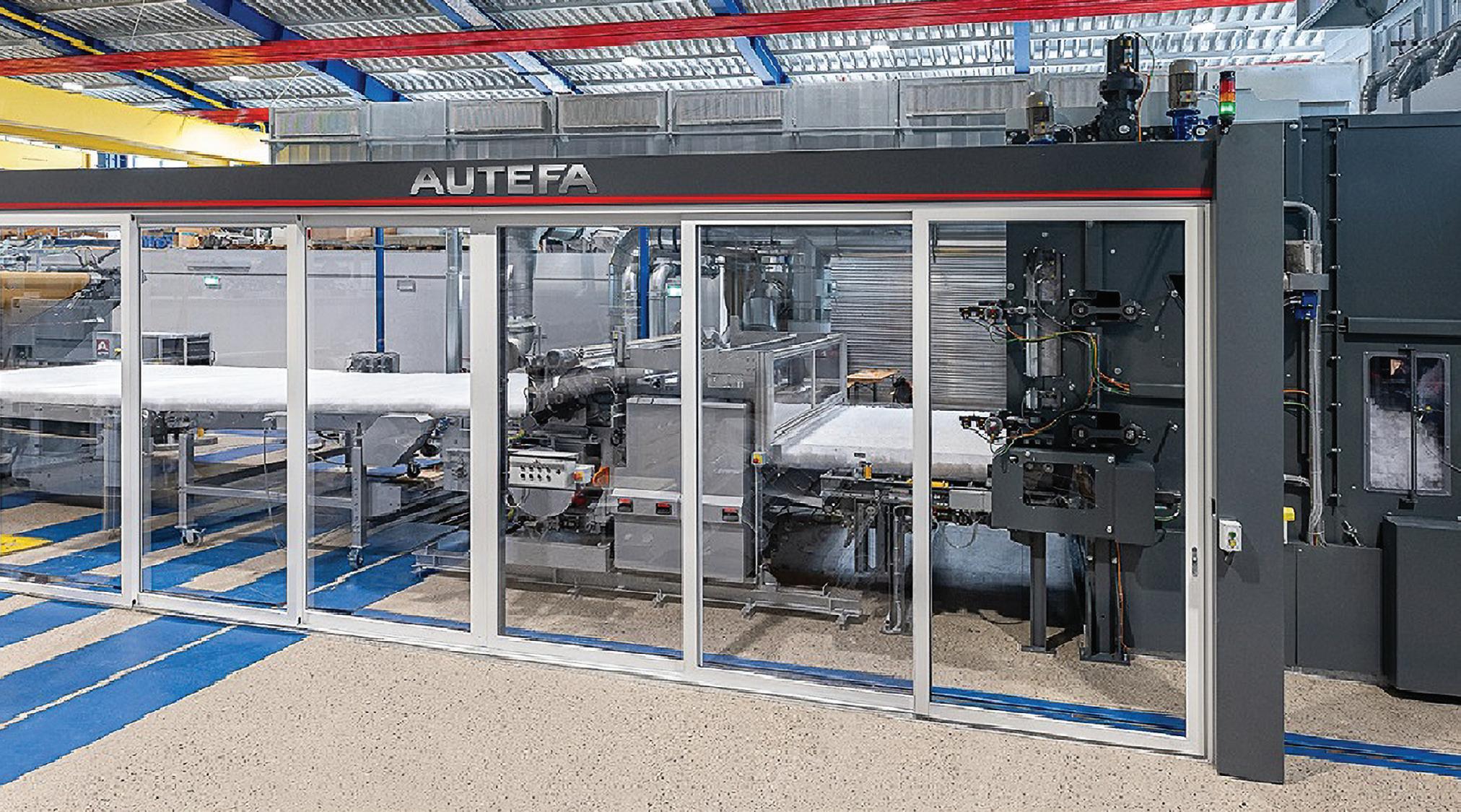

Fortunately for the textile industry, Italian machine builders are keenly aware of the logistical challenges in sourcing materials and producing textiles. To help end users directly address this perennial headache, Italian machine builders like AUTEFA Solutions Italy Srl (autefa.com/autefa-solutions-group) , a member of ACIMIT (acimit.it) , the Association of Italian Textile Machinery Manufacturers, are designing machinery that speaks directly to textile manufacturers’ needs.

Coordinating a global supply chain of materials is a complicated task for any manufacturer, but the textile industry must also balance globally diffuse production locations, warehousing, and distribution networks. The end result is a complex, highly fragmented network of internal facilities and external partners that must be monitored to ensure the seamless flow of materials and finished goods. To orchestrate all of these disparate but vital aspects of textile manufacturing, textile producers must pursue more digitally integrated operations unified under a comprehensive management software umbrella.

AUTEFA is tackling this challenge head on by maximizing the connectivity and integration capability of their machinery. Through deep knowledge and extensive experience in designing and working with Industry 4.0-capable operations, AUTEFA has baked nimble networking capabilities into the very foundation of their machinery platforms. AUTEFA machinery is integration-ready right out of the box, with equipment explicitly designed to easily connect

to operation-wide management systems like an enterprise resource program (ERP) or specific logistics-focused programs like material requirement planning (MRP) systems.

This connectivity is essential for textile manufacturers looking to better manage their supply chains. By connecting machinery to ERP and MRP systems, manufacturers can better plan out production schedules, obtain a deeper understanding of their material needs, time orders to ensure minimal backstock while maintaining always-up production, and track products throughout the supply chain once shipped. Unlocking these logistics tools is vital to maximizing production efficiency, which is why AUTEFA has ensured all of their machinery contributes integration solutions that directly address this ongoing industry challenge.

“Our research and development department is continuously working on new technologies, new improvements, and new details for increasing efficiency,” says Roberto Degrandi, Regional Sales Director of Woolen and Nonwovens Technology at AUTEFA Solutions Italy.

Beyond the physical functions of machines themselves, Italian machine builders like AUTEFA are drawing on their holistic manufacturing expertise to ensure the digital components of their machinery are directly addressing industry-wide challenges.

One of the biggest challenges faced by the textile manufacturing industry is quality assurance. With a range of raw materials and a complex production process that often involves the weaving and combination of numerous different fibers and stitch points, textile manufacturers face significant challenges in ensuring this process occurs seamlessly. To directly address this industry snag, BTSR International SpA (btsr. com), a member of ACIMIT (acimit.it), the Association of Italian Textile Machinery Manufacturers, has worked diligently with clients to develop their IRIDIUM 3D optical sensor for fiber inspection.

By drawing on their extensive industry experience and leveraging the knowledge gained from a wide range of customers, BTSR’s IRIDIUM 3D sensor is designed explicitly to help textile customers untangle the complexity of raw material quality verification.

To achieve this, BTSR has developed several innovative design features for its sensors, such as a proprietary algorithm that enables the automatic detection of any defects in yarn. The IRIDIUM 3D sensor uses this algorithm to detect six key yarn defects that can slow down production and compromise product quality. Combined with 3D visual inspection, the sensor can identify these defects in all yarn types, regardless of thickness and shape.

Not only does the IRIDIUM 3D help customers with the complexity of fiber quality assurance, it does so in an innovative way that addresses several potential pain points simultaneously. While yarn quality inspection is essential, traditional methods that require sensors to physically contact the yarn have significant drawbacks. From compromising fiber tension needed to maintain production to physically damaging the yarn itself, sensors that require physical contact are often imperfect solutions to a pressing problem. BTSR has sidestepped these drawbacks by removing the need for physical contact, creating a sensor capable of quality assurance through purely visual inspection.

“Innovation is in our DNA,” says Paolo Caviggioli, the BTSR North and South American Sales Manager “We will continue to invest in increasingly advanced technologies to provide our customers with reliable and efficient tools.”

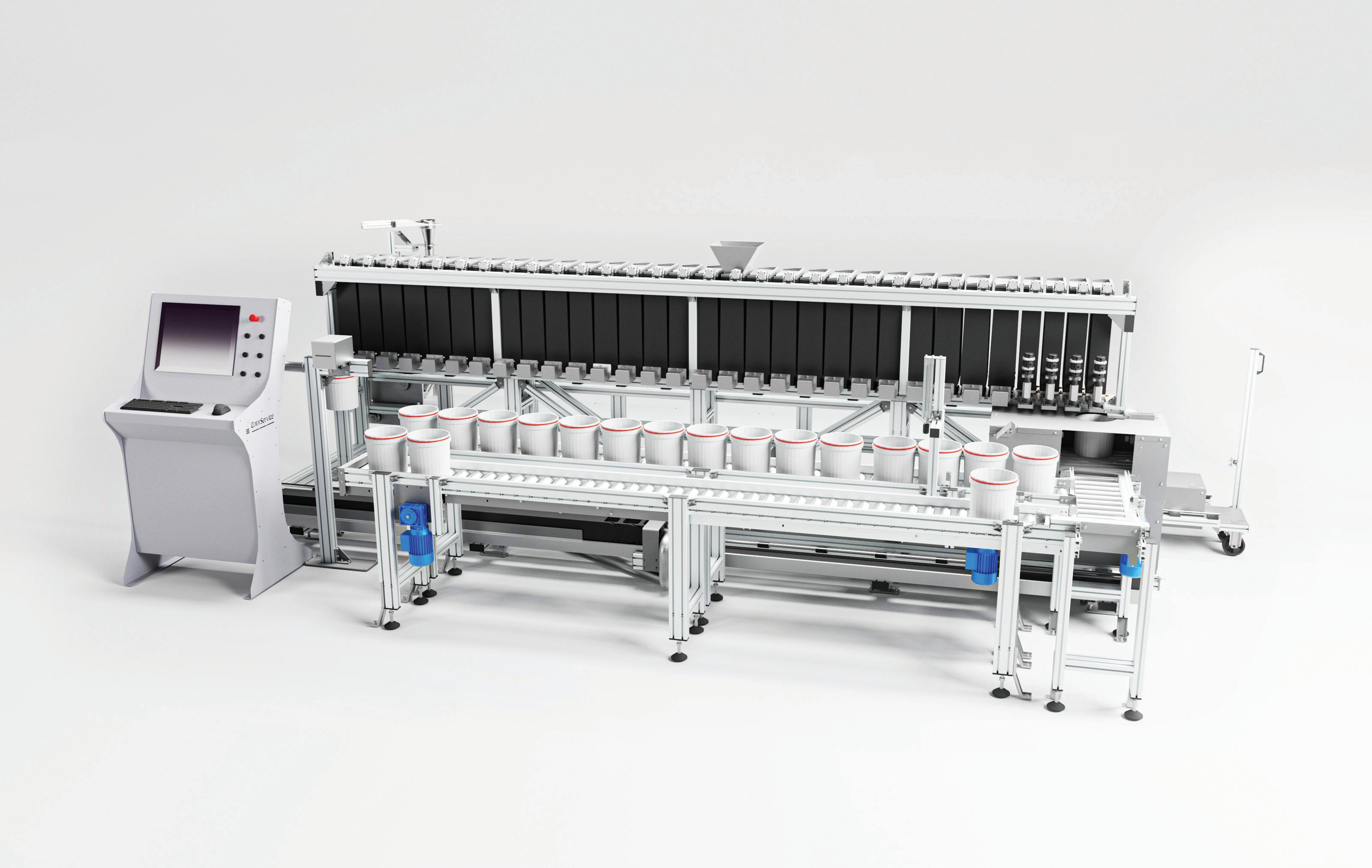

Dositech Srl , formerly Colorservice (colorservice.eu) serves as an excellent example of this industry-spanning approach. A member of ACIMIT (acimit.it) , the Association of Italian Textile Machinery Manufacturers, Dositech is a manufacturer of ingredient dosing machines with applications in a wide range of industries, including the textile, rubber, tire, cosmetics, plastics, and food industries. Thanks to innovative machine designs and creative use applications, Dositech is constantly iterating on their capabilities to open their machines to new industries and new applications, such as liquid and powder dosing in the electric battery market, a brand-new use of their machinery that Dositech has successfully deployed.

This creativity perfectly encapsulates one of the greatest strengths of Italian machine builders: thinking outside-the-box to help customers find new solutions and new applications in entirely new industries. Through Italian ingenuity comes industry success.

“We rely on an R&D Department focused on the constant upgrading of existing products as well as on the creation of new ones,” says Stefano Bortoli, Global Sales Director at Dositech. “Our main objective is to introduce our technological innovation to new customers.”

Dositech

While some Italian machine builders specialize in one specific industry, like textiles, others opt to focus on one process that is used across a number of different industries, such as ingredient dosing. While the angle is slightly different, the approach is ultimately the same: Italian machine builders are experts in directly addressing industry-wide challenges within an industry, or application-wide challenges across numerous industries. By directly addressing challenges through innovation, Italian OEMs deliver industry-leading solutions to complex problems.

Beyond expanding to new applications and new industries, Dositech also diligently works to ensure their machines assist in addressing challenges that span the entirety of manufacturing, delivering value to their customers regardless of industry. Through features such as adaptive dosing, multi-ingredient dosing, and high-accuracy micro-dosing, Dositech is directly addressing the ubiquitous request for machinery that is more flexible, versatile, and reliable. Dositech is even striving to alleviate labor struggles reported by their clients by designing more machinery with cobot capabilities, remote diagnostics, and smart automation that requires fewer employees and fewer specialized skills to operate.

“Our main objective is to introduce our technological innovation to new customers, in order to allow them to take advantage of all the benefits that our systems can offer and improve production.”

— Stefano Bortoli, Global Sales Director at Dositech

“Our main objective is to introduce our technological innovation to new customers, in order to allow them to take advantage of all the benefits that our systems can offer and improve production,” Bortoli says.

With extensive experience, deep knowledge, and a creative approach to problem-solving, Italian machine builders are helping customers across industries tackle their most pressing challenges. Whether those challenges are industry-specific or industry-spanning, companies like Dositech are leveraging their unique expertise to elevate clients to new heights of efficiency.

Salmoiraghi

A common challenge that many manufacturing industries face is finding ways to upgrade legacy equipment to be compatible with more integrated, automated production. This is particularly true for the textile industry’s use of bobbin carts, an essential part of largescale fabric manufacturing that is often older and entirely manual, but also cannot be easily swapped out for a new system.

This was a challenge that Salmoiraghi SpA (salgroup.it), a member of ACIMIT (acimit.it), the Association of Italian Textile Machinery Manufacturers, encountered often enough that they developed an entirely new system specifically to overcome this recurring obstacle. To add automation too difficult to accommodate legacy bobbin carts, Salmoiraghi SpA brainstormed a new system and new process that includes robotic handling of bobbins to add or remove them from the cart, an advanced vision system to ensure proper cart placement, and an adaptive, rotating floor table capable of automatically adjusting to different cart dimensions.

Born out of a common industry problem, Salmoiraghi SpA’s bobbin automation system is an excellent example of how Italian machine builders proactively identify frequent customer challenges and swiftly move to address them.

“Our creative engineering approach is the key to our success,” says Sandro Salmoiraghi, President of Salmoiraghi SpA. “We dive deep into data, evaluate safety, and explore every angle where automation can create value.”

Salmoiraghi SpA has also applied their creative approach to another tricky aspect of bobbin management: removing bobbins from machines on the line. A time intensive process that traditionally requires manual handling by an employee to achieve, bobbin removal is a common bottleneck for textile manufacturers. To address this frequent production choke point, Salmoiraghi SpA designed their Doffing Robot, a robotic solution to bobbin removal.

Combining the robot unit, which Salmoiraghi designed themselves, as well as overhead tracking, automated vision systems, and robotic loading systems, the full Doffing Robot configuration represents the kind of holistic solution to a common challenge Italian machine builders have become known for.

“Our research and innovation constantly project us into the future with new ideas, production capabilities, and continuous innovation,” Salmoiraghi says. End users choosing Italian machinery can be confident that their Italian partners are dedicated to both their individual company success and to addressing industry-wide challenges.

Ramatex

Italian machine builders have two great strengths that stand out from the rest of their value proposition: a relentless attention to detail in their machinery, as well as a dedication to cooperatively addressing industry challenges. By combining these two core competencies, Italian machine builders are helping advance industries by innovating new and creative equipment to address common hurdles. This twopronged approach not only yields new machine designs with new capabilities but also directly addresses customer needs and ensures end users’ voices are heard and acknowledged.

Italian machine builders don’t just see a client and a capital gain — they see a partner whom they are invested in helping succeed.

Ramatex Srl (ramatexitalia. it) has taken this mantra to heart. Builders of non-woven textile machinery and a member of ACIMIT (acimit.it), the Association of Italian Textile Machinery Manufacturers, Ramatex approaches every project not as a contracted supplier but as a trusted partner, ready to collaborate with customers to deliver uniquely tailored solutions. For Ramatex, this process begins all the way back at the conceptualization stage, as customers first realize they need something else from their machinery, even when they cannot clearly define what that something is.

out between Ramatex and the client, achieved these superior results for a lower cost.

This kind of creative, innovative approach to machine design has come to define not just Ramatex, but Italian machine builders in general. Italian machine builders are truly helping to address some of the most pressing industry-wide challenges their customers face.

In another instance of tackling industry challenges head-on, Ramatex was presented with a complex project to completely reimagine a key process in automotive manufacturing. After a comprehensive exchange of information, Ramatex worked closely with the client to compile a list of needs and goals that guided a second exchange of Ramatex’s past projects and innovations.

“The core of the new machine idea already existed in the company; when Ramatex shared some of their other unique applications, the company saw the potential,” Nencini said “We worked together to mix and match applications to collaboratively arrive at a new solution.”

This collaboration was deeply informative for both companies, resulting in Ramatex designing an entirely new machine, informed by key insights from the client themselves into how they envisioned using Ramatex expertise to achieve their goals. In this sense, Ramatex did not build this machine alone; they built this machine with their client, creating a bespoke solution that revolutionized the client’s production methods.

“We are very small compared to multinational companies, but we have excellent people that are able to fully develop solutions from a dream to an actual machine,” he says. “This attention to detail and full dedication to customers is the great strength of Italian machine builders.”

— Antonio Nencini, Ramatex CEO

“Sometimes it’s just a question of modifying the dimensions of a machine, but more often, the customer wants to do new things with machinery and expand the products they can make,” says Antonio Nencini, Ramatex CEO.

To turn customer visions into functional machinery, Ramatex looks to innovative machine design and creative use of new technologies to push their equipment to new heights of productivity. For instance, Ramatex modified their machine designs for a client to move needle changeovers from a manual process to an automated one through innovative deployment of automation and digital machine features, allowing the customer to reduce downtime and redeploy valuable manpower elsewhere in the operation. This new process was more efficient than the limited existing automated changeover options and, thanks to unique innovations hammered

This solution was so transformative and innovative that the client was able to patent the new manufacturing process being carried out on the new machine, a development that stands to completely upend the industry, all thanks to Ramatex’s unwavering dedication to solving industry-wide challenges. By listening carefully to their customer, Ramatex has helped redefine an industry, addressing not just one common challenge but revolutionizing the entire production process.

Ramatex’s collaborative approach to innovation has elevated the capabilities of their customers and helped to carve out new processes and new technology applications in the industries they work with. This tenacity to cooperatively find solutions and innovate new processes together with clients is a hallmark of Italian machine builders. Nencini neatly sums up Ramatex’s own philosophy on cooperative innovation, and also emphasizes the strengths of Italian machine builders in general.

“We are very small compared to multinational companies, but we have excellent people that are able to fully develop solutions from a dream to an actual machine,” he says. “This attention to detail and full dedication to customers is the great strength of Italian machine builders.”

Italian machine builders are not just vendors and service providers, they are true partners dedicated to achieving results for their customers and advancing entire industries by addressing common challenges.

Monti Antonio

Achieving seamless connectivity and integration remains a persistent challenge in manufacturing. Whether it’s digitally aligning operations, linking disparate facilities, or enabling secure remote access, manufacturers often face a complex web of technical and operational obstacles. These challenges are only intensifying as automation and data-driven technologies become increasingly embedded across the industry.

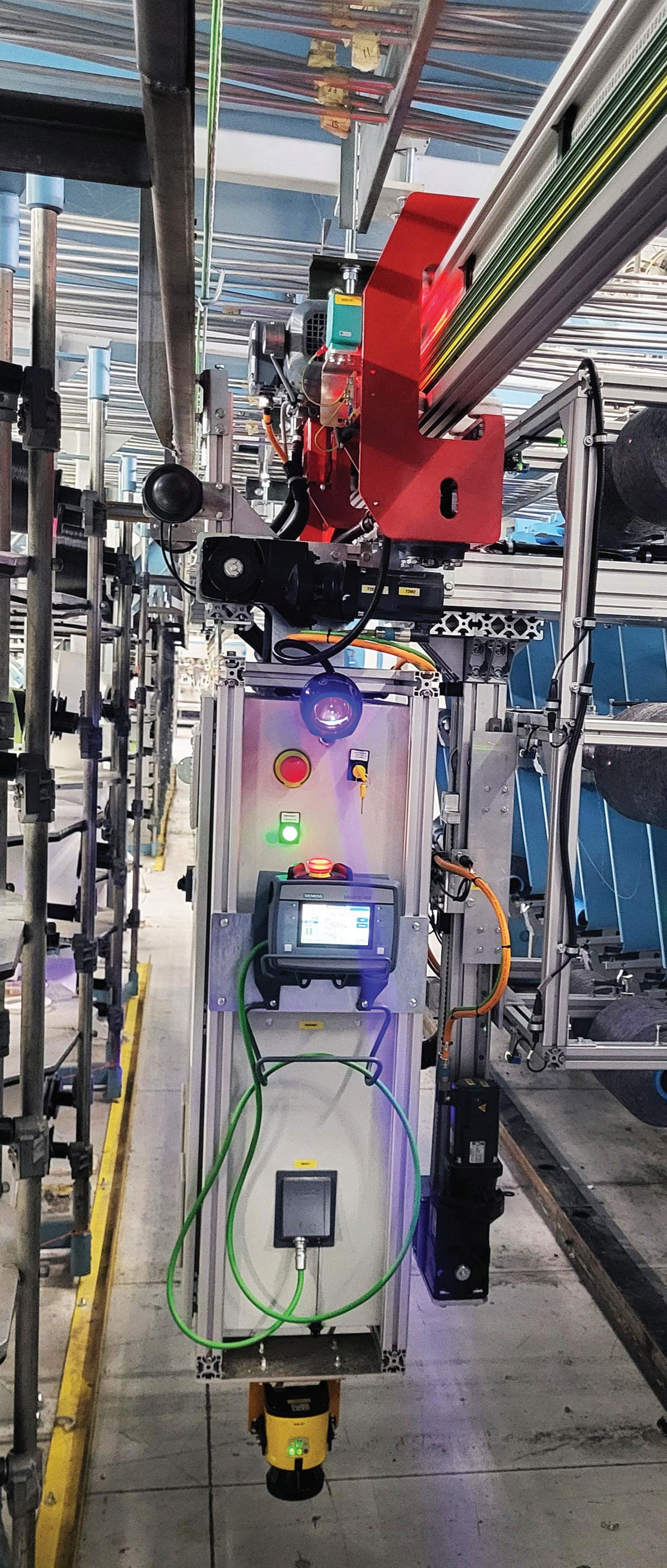

When it comes to individual facilities, one of the greatest hurdles to increasing the number of interconnected processes is the variance in programming languages used. This is particularly true for machines that vary in age, country of origin, and OEM. Fortunately for manufacturers struggling with digital integration, Monti Antonio SpA (montiantonio.com), a member of ACIMIT (acimit.it), the Association of Italian Textile Machinery Manufacturers, has devised a number of solutions that support end user connectivity needs, regardless of industry or product. For instance, all Monti Antonio machines can be outfitted with devices and features designed to ease the integration process, enabling machines to connect to a wide variety of different programming languages and machine types, regardless of who manufactured the equipment. By leveraging the power of open protocol programming, Monti Antonio empowers their machines with the versatility needed to network numerous disparate pieces of equipment into one harmonized system, enabling machines to communicate seamlessly with one another, as well as management software like an enterprise resource management system. If an existing solution from Monti Antonio does not meet a customer’s specific needs, the company is adept at customizing integration solutions tailored to individual operations, without sacrificing turnaround time. As Monti Antonio themselves explain: “Thanks to our skill and experience in the creation of highly customized solutions, we are able to offer custom machines with delivery guaranteed in record time.”

In addition to utilizing open protocol programming languages to create a web of interconnected machinery, Monti Antonio is also addressing industry challenges by opening the door to more remote monitoring and remote connectivity. By leveraging the same technology features on their machines used to power open protocol connectivity, Monti Antonio can connect equipment securely to the internet, allowing for remote access and monitoring. Through this remote strategy, Monti Antonio is able to configure and optimize machinery anywhere in the world from their centralized Italian location, eliminating the need for time-consuming and costly on-site visits for standard machine calibration. This is a particularly powerful tool for companies with a number of locations spread across the globe, allowing them to consolidate service needs and organize machine calibrations without the need to juggle complicated on-site schedules.

By designing machinery with digital integration in mind and leveraging those features to open the door to remote connectivity, Monti Antonio is helping their customers address a major industry challenge in manufacturing. With machines harmonized and communicating, and calibration able to take place nearly instantly at any point on the globe, Monti Antonio is a standard-bearer in Italian ingenuity and technological capability. End users can rest assured that when purchasing Italian machinery, Italian machine builders and the equipment they produce will help them solve persistent industry challenges like integration and connectivity.

“Thanks to our skill and experience in the creation of highly customized solutions, we are able to offer custom machines with delivery guaranteed in record time.”

— Monti antonio

Efficiency Is the New Luxury — and Italy Is Delivering

From the survey of North American end users, 61% of respondents selected cost and overall ROI as a top three consideration when evaluating machinery purchases.

Every operation, from manufacturing to construction, has its own careful balancing act to play with budgeting and costs. With significant global economic uncertainty persisting in 2025, cost has consistently risen to the top of concerns for end users of Italian machinery. From the survey of North American end users, 61% of respondents selected cost and overall ROI as a top three consideration when evaluating machinery purchases. Cost is likely to remain a top concern for the near future as factors like trade uncertainty and ongoing supply chain woes continue to challenge operations to work within constrained budgets. Thankfully, Italian machine builders are experts at delivering top-quality machinery while simultaneously managing overall costs. End users have recognized these efforts, with 35% of survey respondents noting the cost savings associated with Italian machinery as a primary motivator in their decision to purchase. From

a different perspective, 92% agreed or somewhat agreed that Italian machine builders offer solutions that save their operations money.

It is clear from these findings that end users are not only aware of the cost savings they can derive from using Italian machinery, but are making key purchasing decisions based on those potential savings.

The cost and budgeting benefits are also immediately tangible for many end users. When asked about how Italian machinery has improved their business, 42% of respondents indicated that incorporating Italian equipment into their business reduced their overall operating costs. This is an enormous boon that cannot be overestimated for end users, especially as many face ongoing uncertainty and trepidation over future budgets and costs. Italian machine builders’ ability to produce cuttingedge equipment while mitigating overall costs, with an eye toward helping end users manage their own long-term budgets, helps Italian machinery stand out on the world stage.

Managing operating costs is an ongoing challenge for manufacturers, especially those dealing with high volumes of product and packaging. In a bottling plant, for instance, where manufacturers have fast-moving, high-volume products with multiple components to the packaging, even small deviations or errors can pile up into meaningful capital loss. Having machinery that is reliable and efficient is essential to maximizing uptime and profit in these complex environments. End users emphasized this need, with 60% of survey respondents stating machine durability and reliability as a crucial consideration when evaluating machinery.

Arol (arol.com), a member of UCIMA (ucima.it), the Italian Packaging Machinery Manufacturers’ Association, and a manufacturer of capping, feeding, and orientation systems, is intimately familiar with the challenges of managing cost during manufacturing. As experts in all things capping, Arol has helped numerous clients across several industries improve the efficiency of their bottling operations, with an eye toward responsible budget management.

problem through superior customer service, ensuring customer needs are addressed immediately and remedies implemented as quickly as possible to ensure machines are back up and running.

As one Arol customer, Garrett Yanta, the Operations Director at Adams Extract and Spices explains: “We had a line go down, and AROL had a custom part manufactured and shipped via overnight air within 24 hours. No other supplier moves that fast.”

By hitting this lightning-fast turnaround time, Arol was able to minimize machine downtime at Adams and get them back on track for their production schedule. This strategy again speaks directly to end user needs, with 30% of survey respondents choosing availability and lead times as top considerations when evaluating machinery purchases.

Placing a heavy emphasis on addressing machine service needs in the field is a workable strategy for Arol because their machinery is already some of the best-in-class options available in the market. Arol machinery enables customers to realize cost savings immediately – from gains in productivity and machine reliability, to mitigating material and product waste. Arol machines are designed with budget efficiency at the forefront. Prospective customers do not have to take Arol’s word on the quality of their machinery — they can hear it directly from satisfied Arol clients.

“That first machine was a game-changer,” Yanta says. “Since then, we’ve purchased seven more AROL cappers, and the service and performance have only improved.”

One way manufacturers look to manage their operating costs is through versatile machinery setups. Machines able to handle a wide variety of tasks or machines that can be easily moved around an operation can give end users the flexibility and nimbleness they need to gain a competitive advantage. This is particularly true for small and mid-sized filling companies, as their growth often requires tricky scaling to grow volumes and manage machine capacities.

“That first machine was a game-changer. Since then, we’ve purchased seven more AROL cappers, and the service and performance have only improved.” — Garrett Yanta, Operations Director at Adams Extract and Spices, and Arol customer

While the actual equipment produced by Italian machine builders has rightfully earned a stellar reputation around the globe, Arol has taken that Italian ethos of excellence one step further and applied it to service requests. This application speaks directly to end user needs as well, with 31% of survey respondents stating aftermarket support services are a top consideration when evaluating machinery, and 21% indicating aftermarket services were a highly influential factor in their decision to purchase Italian machinery.

One way Arol is helping customers drive down their operating costs is by ensuring quick turnaround for service. Despite manufacturers’ best efforts, unexpected downtime and machine failures do still occur and remain challenging for operators to handle without significant losses. Arol has sought to address this

To better assist filling operations looking to grow and scale, AXTRA Srl (axtra.com/en), a member of UCIMA (ucima.it), the Italian Packaging Machinery Manufacturers’ Association, has designed machinery with operating cost optimization at the forefront. As manufacturers of bottling and packaging machinery for the filling industry, AXTRA uses machines based on modular design, allowing equipment to be easily redeployed throughout an operation with minimal downtime and extra recommissioning cost.

On top of this, AXTRA’s modular designs emphasize compact components and small footprints, ensuring machine additions take up as little valuable floor space as possible. With the addition of standardized components to manage service and maintenance costs, driving down operating costs is a key advantage of AXTRA machinery.

“One of the most direct benefits our clients report is a measurable reduction in operating costs,” says David Nolli, Founder and CEO of AXTRA. “Flexibility and modularity allow our customers to adapt quickly, without costly downtime or retraining. By also minimizing the number of components and standardizing across platforms, we help clients cut down on spare parts and maintenance requirements while improving uptime.”

AXTRA’s focus on modular design is in line with end user requests, with the survey revealing 14% of end users view modularity and machine flexibility as essential factors in their machine purchase decision making process.

While AXTRA’s dedication to thoughtful, cost-saving machine design is a hallmark of Italian machine builder excellence, they have also adopted a more holistic approach to conceptualizing operating costs by focusing on empowering machine operators. Utilizing a creative software architecture anchored around operator accessibility, AXTRA is empowering employees on the line to directly address potentially costly machine issues on the spot. Utilizing crosscompatible machine interfaces to maximize flexibility, operators are guided through step-by-step maintenance and troubleshooting routines, allowing machine operators to intervene immediately as a problem is identified to minimize machine stoppages and avoid costly downtime. Even with these impressive features, AXTRA is always on the lookout for strategies to improve their design.

“We continuously optimize not only the machine software, but also the maintenance processes themselves,” Davide says. “With a task- and knowledge-based access system, clients can safely reassign operators across different machines, enhancing flexibility while fully complying with both general and client-specific safety regulations.”

In addition to this on-the-spot capability, the machine-agnostic design for AXTRA’s interfaces means operators can be easily moved between machines with little to no retraining, creating a much nimbler and more capable workforce. With labor remaining a top issue for North American manufacturers, this is a particularly attractive area of cost savings that AXTRA machines support.

By marrying top-notch build quality with thoughtful design, Italian machine builders are helping their customers drive down operating costs on a number of different fronts. When it comes to managing cost and balancing budgets, North American end users can trust Italian machine builders to consider all the angles and exhaust all the strategies to deliver savings.

There are many approaches that Italian machine builders take to help end users drive down operating costs. While some builders focus on physical solutions through machine additions and alterations, others seek to manage costs through digital tools like software integration and digital monitoring.

And some, like Technowrapp Srl (technowrapp.com) a manufacturer of advanced stretch-film pallet wrapping equipment, and a member of UCIMA (ucima.it), the Italian Packaging Machinery Manufacturers’ Association, take a dual-pronged approach by developing both physical and digital tools to help customers balance their budgets.

On the physical side, Technowrapp has developed the tangible properties of their wrapping machinery to help address one of the packaging industry’s perennial and expensive challenges: sustainability. An endless challenge for manufacturers and an ever-growing demand from consumers, sustainability is a trend that continues to define the heart of the packaging industry. Technowrapp thoroughly understands the importance of this goal, and has made it a central part of their identity.

“Sustainability is a core value at Technowrapp,” Technowrapp says. “Our systems are designed to minimize environmental impact.”

To tackle this universal packaging goal, Technowrapp machinery incorporates the latest technology to improve overall energy consumption and reduce utility usage during production, precision cutting technology to minimize plastic waste during wrapping, and comprehensive idle modes to manage utility consumption during line downtime like changeovers.

All of this translates into machinery that is not only sustainable, but also significantly less expensive to operate day-to-day.

Tehcnowrapp keeps a finger on the pulse of the industry, listening to customer needs and tirelessly seeking solutions that forward their customers’ budgeting goals. As leaders at Tehcnowrapp note,“Every system is developed by listening to the customer’s requirements.”

Technowrapp uses these physical machine properties as key tools to both enhance the sustainability of operations and, crucially, save their customers money. End users have taken note of Italian machine builders’ skill at addressing sustainability, with many reporting meaningful sustainability improvements that translate into reduced operating costs from using Italian machinery.

From the survey, 21% were able to lower their utility usage on machines during operation, 25% reported more efficient idle and sleep modes for downtime, and 15% indicated a reduction in carbon emissions, all from simply using Italian machinery.

In addition, 20% of end users noted sustainability is a top consideration when purchasing equipment.

In this sense, Technowrapp is helping their end users minimize their production costs while supporting their sustainability initiatives.

On the digital side, Technowrapp collaborates with their internal sister division, Intralogika, to assist customers in the tricky process of digital integration and data gathering. An essential step in overall process improvement, digitally integrating manufacturing processes and gathering digital operational data from those processes is one of the greatest challenges faced by manufacturers and packagers across industries. To ease clients along this path, Technowrapp and Intralogika have developed the Twiko system. Twiko collects and analyzes machine data to optimize predictive maintenance, reduce failure risks, and ensure uninterrupted operations.

These capabilities are not only essential to more digitally integrated operations, but are also some of the powerful tools end users can access to drive down their operating costs. The Twiko system’s intuitive dashboard enables monitoring of crucial KPIs such as asset availability, production rates, and energy efficiency, ensuring continuous performance improvement and enabling realtime monitoring of OOE and operating costs.

The value of this analysis and the cost savings that can be derived from it are significant. By combining physical machine improvements with powerful digital tools, Italian machine builders like Technowrapp are helping their customers improve operational efficiency and drive down operating costs. With their innovative use of physical solutions and creative deployment of technology, Italian machine builders are leading manufacturers to new frontiers of sustainability and efficiency, all while keeping a watchful eye on end users budgets.

94% at least somewhat agreed that Italian machinery includes innovative or unique design features, while 91% agreed or somewhat agreed that Italian machinery is customized to fit their unique operations and needs.

Italian machine builders are masters of collaboration, fostering close relationships with end users, often with a personal touch and dedicated employee contact points. This hands-on, collaborative spirit contributes greatly to a culture of innovation that has come to define Italian machine builders and the equipment they produce.

End users are keenly aware of this spirit of innovation, which has become a defining reason why they choose Italian machine builders as partners. When asked about innovation and customization, end users overwhelmingly indicated the skill of Italian machine builders in these fields: 94% at least somewhat agreed that Italian machinery includes innovative or unique

design features, while 91% agreed or somewhat agreed that Italian machinery is customized to fit their unique operations and needs.

End users’ overwhelming praise for Italian machine builders’ ability to innovate creative solutions is a highly positive perception that has become a motivating force behind selecting Italian equipment. Italian machine builders are mutually invested in the success of their clients – when they innovate a new solution to help clients succeed, they too succeed. In this way, Italian machine builders have established themselves as trusted partners in numerous industries, demonstrating a commitment to succeeding together through innovation.

“Italian equipment manufacturers have advised us on what technologies to use and have helped us obtain a competitive advantage.”

— Jeff Cupples, President and Owner of Cupples J&J Company

The plastics blow molding industry is a diverse market representing innumerable different products, from simple plastic packaging to essential assembly components like automotive parts. By nature, blow molded plastics are highly customizable, able to be formed into nearly any shape and thickness a project may require. An essential part of this customization ability is the molds themselves, which must be carefully designed to withstand repeated use, while also producing blow molded products with reliable accuracy and repeatable quality.

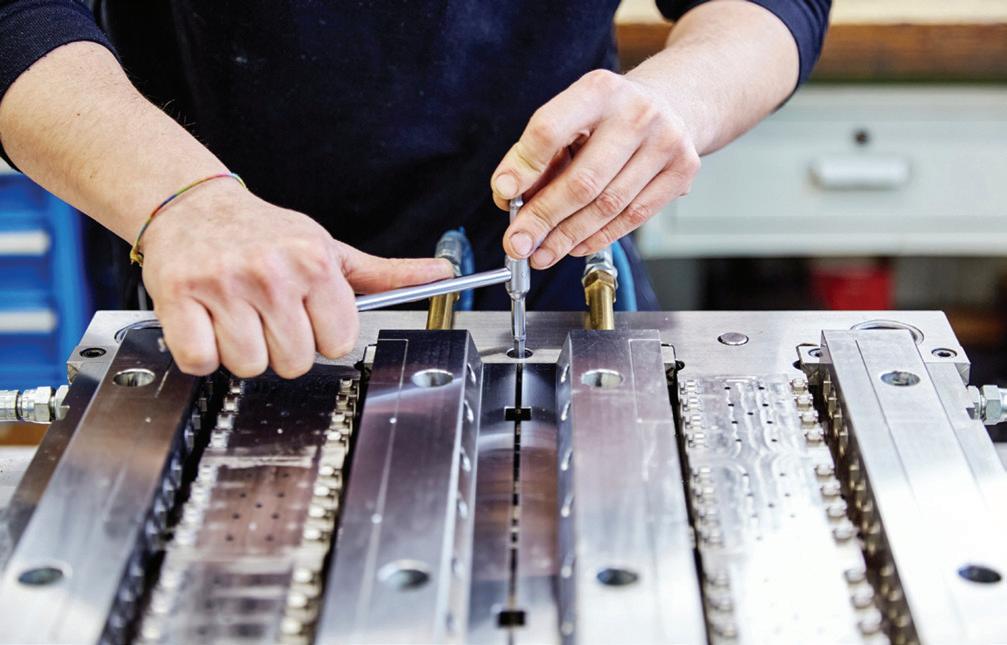

Designing the molds used in plastic blow molding is a complex process that requires the consideration of numerous different variables. Oftentimes, mold producers and their customers must collaborate closely to understand the needs, goals, and requirements of a new mold. FESP Mold Srl (fespmold.com/en), an Italian mold producer with over 25 years of experience and a member of AMAPLAST (amaplast. org), the Italian Plastics and Rubber Processing Machinery and Molds Manufacturers Association, are masters of this collaborative innovation process for injection mold production and design

FESP’s approach to collaborative innovation begins in the early consultancy and fact-finding stage. First and foremost, FESP will verify the feasibility of a mold application. Using state-of-the-art modeling software, FESP will ensure that a mold can be correctly designed for a requested application. This capability is fast becoming essential for machine builders, with 18% of end users from the survey requesting more digital twinning and digital modeling capabilities for future projects.

Once proof of concept is obtained, FESP works closely with clients to tease out their overall needs and goals, collaborating to refine a new, often innovative mold design. They are experts at listening to clients and working closely with them to collaboratively reach innovative solutions. As FESP themselves explain, “No idea is a bad idea: you just need to develop it in the right way.”

Beyond overall design, FESP offers innovative testing and implementation options. To ensure molds perform as required, FESP works closely with clients to devise innovative polymer blends and combinations, rigorously trialing them to find the perfect combination for each customer. FESP will even test different formulations and shapes side-by-side to tease out a truly superior design. They also leverage 3D printing technology when feasible, allowing for the rapid production and testing of prototypes.

Through this design-test-refine process, FESP and their customers work together to arrive at truly innovative injection mold designs. One end user of Italian equipment, Jeff Cupples, President and Owner of Cupples J&J Company, notes how collaborative innovation is deeply ingrained in Italian machine building culture. Cupples states.

“Italian equipment manufacturers have advised us on what technologies to use and have helped us obtain a competitive advantage,” he says. By working closely with customers to arrive at shared solutions, FESP embodies this spirit of cooperative Italian innovation, putting them at the top of the mold manufacturing mountain.

Much like plastic blow molding, pipe extrusion is an industry with wide-ranging applications, from standard components to vital pieces of infrastructure. With so many options – from inner diameter and wall thickness to material type, length, and numerous other considerations – manufacturers of pipe extruding machinery and their end users must work together to innovate new solutions and strategies for pipe production.

To stand out in this field, manufacturers of piping need to stay ahead of new materials and applications for their products, while also pursuing the latest in production technology for their extrusion equipment. Fortunately for pipe producers, Tecnomatic Srl (tecnomaticsrl.net), a member of AMAPLAST (amaplast.org), the Italian Plastics and Rubber Processing Machinery and Molds Manufacturers Association, has a long history of manufacturing innovative pipe extrusion machinery.

Tecnomatic has been producing pipe extrusion equipment from its location in Italy for over 40 years. Evidence of their innovative design process and thoughtful quality of life features can be found throughout their portfolio of extrusion equipment.