ALSO INSIDE: The role of multiphysics simulation in next-gen electric motors

ALSO INSIDE: The role of multiphysics simulation in next-gen electric motors

WHERE IMDS, RCMS, AND RCDS FIT INTO EV SYSTEMS

JEFF SHEPARD • CONTRIBUTOR

Insulation monitoring devices (IMDs) are used in ungrounded high-voltage applications to ensure electrical safety, prevent accidents, and ensure reliable operation by continuously monitoring insulation resistance for early fault prediction.

A residual current monitor (RCM) is the corresponding device used in grounded systems. In contrast, residual current devices (RCDs) protect against hazards such as fires or electrocution in AC-powered applications, such as electric vehicle (EV) chargers.

In EVs, IMDs ensure safety by continuously measuring the insulation resistance between the high-voltage (HV) system and the vehicle chassis. The foundational IEC standard for IMDs is IEC 61557-8, which addresses electrical safety in low-voltage distribution systems with voltages up to 1 and 1.5 kVDC.

While the standard was developed for information technology (IT) equipment in applications like data centers, the voltage limits also apply to other applications, including EV drivetrains.

The drivetrain encompasses not only the EV’s motor but also the entire high-voltage architecture that delivers and controls power from the battery to the wheels (Figure 1).

This includes:

• The HV battery pack (typically 400 or 800-V systems)

• Inverter(s) that convert DC battery power to AC for the motor

• The electric motor(s)

• Associated power electronics and cables

Since this system carries high-voltage electricity (up to 1,000 to 1,500 Vdc), insulation integrity is critical for safety and performance. A breakdown in insulation between the high-voltage (HV) system and the vehicle chassis could lead to electrical faults, shock hazards, or thermal events.

EV chargers, especially DC fast charging systems, operate at similar voltage levels and are tightly integrated with the

Coilcraft offers a wide range of voltage-rated power inductors that assure the safe, reliable operation of your designs.

Coilcraft voltage-rated inductors support applications such as high-voltage DC-DC and AC-DC power supplies, industrial and home automation controls, appliances, and automotive, including electric vehicles (EVs).

Our XEL and XGL Families of molded power inductors offer operating voltage ratings from 60 V to 120 V, and many of our

LPS and MSS Family inductors are suitable for 400-volt operation or higher.

Our new MSS1514V Series offers an 800 V rating in a 15.5 x 15.5 mm footprint, with excellent current handling and low DCR.

Learn more about operating voltage ratings for inductors and see our full line-up at www.coilcraft.com/ HighVoltage.

drivetrain’s HV system. Proper insulation and continuous monitoring across the charger and vehicle-side systems are essential for end-to-end safety and compliance with international standards.

For example, standards UL 2232 for EV chargers and IEC 61851 for EV DC fast chargers explicitly refer to IEC 61557. IEC 60204-1, which deals with the safety of electrical equipment in machines, also refers to IEC 61557.

Working principle

IMDs apply a low-voltage signal to the HV system and measure the resulting current flow through the insulation to the ground. In addition to ensuring safety, IMDs enhance system reliability.

For example, excessive voltage can damage the winding insulation and reduce the lifespan of motors. An IMD alerts operators to potentially harmful conditions, allowing the system to be shut down before a critical value is reached (Figure 2).

In EVs, this protection is vital to the safe operation of traction motors and inverters, which are core elements of the high-voltage drivetrain. IMDs help prevent propulsion loss or thermal failure under dynamic load conditions by continuously

Aktif Elektroteknik

monitoring insulation integrity in these components.

It’s worth noting that insulation monitoring is also vital to the safe and reliable operation of marine and aerospace systems, renewable energy installations, battery energy storage systems, low-voltage industrial motors, and more.

Monitoring current

RCMs are designed to protect against excessive leakage currents in grounded electrical systems. They continuously monitor the difference between the current flowing in and out of a circuit to identify leakage current.

They provide data for system monitoring, potentially triggering alarms or other actions without immediately shutting down the power. If the leakage current reaches a critical level, the RCM will trip and disconnect the circuit (Figure 3). RCMs can be designed to monitor AC or DC flows.

The primary standard for residual current monitors (RCMs) is IEC 62020, which applies to applications up to 440 VAC and rated currents not exceeding 125 A. The standard details the requirements for two types of RCMs. Type A RCMs detect AC and pulsating DC residual currents in general-purpose applications. Type B RCMs are designed for applications with electronic loads, variable-speed drives, and other systems where smooth DC currents must be monitored. They can also monitor AC and pulsating DC currents.

Electric vehicle drivetrains operate at elevated voltages (typically between 400 and 1,500 VDC), making insulation integrity critical. Any part of the drivetrain losing insulation to the vehicle chassis could pose a severe electrical hazard or lead to vehicle malfunction.

Insulation monitoring devices (IMDs) ensure safety by constantly monitoring the resistance between HV components and the chassis ground.

IMDs are used in EVs to:

■ Continuously check that the insulation between the HV components and the vehicle chassis remains within safe resistance limits.

■ Detect early signs of degradation or fault conditions before they become dangerous.

■ Trigger alerts or system shutdowns in the event of a fault.

■ Support compliance standards, aligning with IEC 61557-8, which sets safety requirements for ungrounded low-voltage DC systems (up to 1.5 kV) — applicable to most modern EV architectures.

In summary, the HV system in an EV drivetrain is the electrical backbone that drives the vehicle, and IMDs monitor its safety in real time. Without IMDs, an undetected insulation fault in the HV drivetrain could result in serious safety risks or system failures.

In the EV charging environment — particularly AC-powered residential or workplace chargers — RCMs provide an essential layer of fault detection between the power source and the vehicle's onboard systems, enhancing overall charging safety.

An RCD, also known as a ground fault circuit interrupter (GFCI), quickly shuts off power in case of an earth fault or leakage current. It doesn’t provide any monitoring. It simply detects imbalances in the current flowing through the circuit and trips if a predetermined number of current leaks to the ground, preventing electric shock and protecting from fires.

In residential settings, RCDs are often used as standalone protection devices. In industrial and commercial applications, they can be used with RCMs to provide more reliable system operation.

IEC 60755 covers general safety requirements for RCDs, including those intended for AC systems (IEC 60755:2017) and DC systems (IEC 60755-1:2022).

RCDs are classified by their sensitivity to different types of residual currents, including:

• AC is for general-purpose use and detects sinusoidal AC residual currents.

• A for equipment with electronic components detects sinusoidal AC and pulsating DC residual currents.

• F is used with frequency-controlled speed drives and detects sinusoidal AC residual currents, pulsating DC residual currents, and smooth DC residual currents.

• B is used for specific three-phase applications, including EV chargers and solar photovoltaic systems. It detects smooth DC residual currents in addition to AC and pulsating DC.

• S has a time delay to ensure selectivity between devices and cannot be used for life protection.

Summary

IMD, RCM, and RCD support electrical safety and system reliability across many high and low-voltage applications, each governed by separate IEC standards.

In electric vehicles, IMDs are essential for monitoring insulation integrity in high-voltage drivetrains, while RCDs and RCMs enhance safety in AC-powered or grounded charging systems. These devices help prevent faults, support reliable performance, and ensure compliance with global safety requirements. EV

VIGNESH GURUSAMY • SENIOR APPLICATION ENGINEER • COMSOL, INC

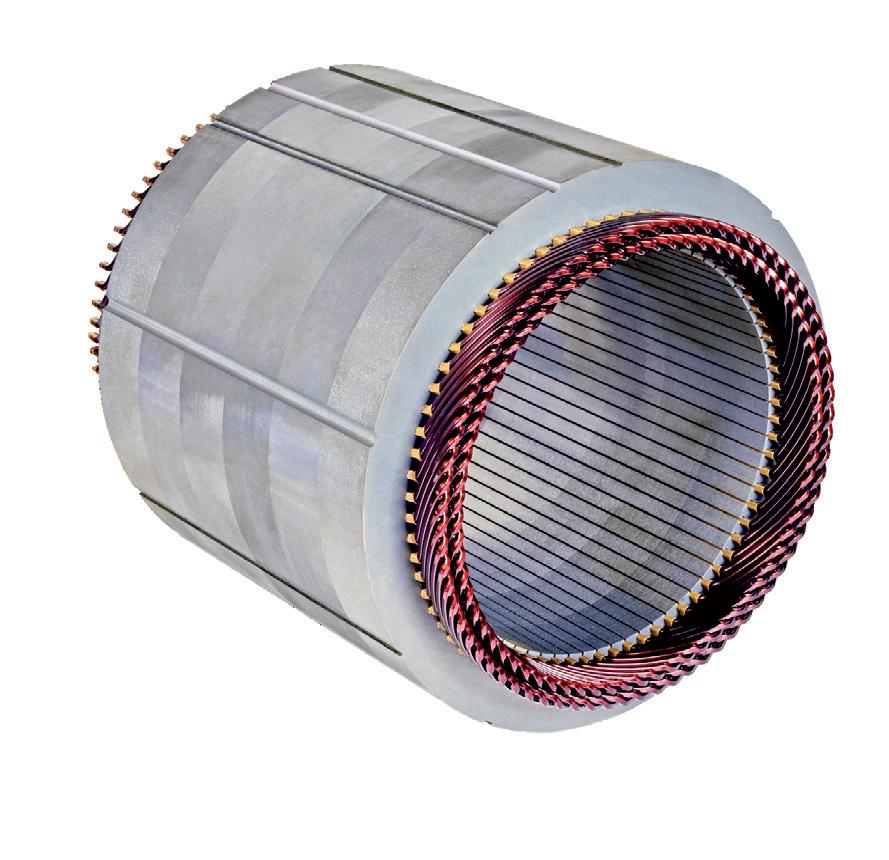

Electric motors play a vital role in electrifying transportation systems. They enable vehicle operation and work as generators during regenerative braking. E-motors with high power density and efficiency enable the maximum distance to be traveled on a single charge.

Achieving high power density and efficiency in e-motors is a standard design goal. Modeling and simulation can be used to ensure that these requirements, among others, are met. Here, we’ll first briefly cover different motor types and the approaches for modeling them.

Modeling various motor types

Several types of electric motors are used in automotive applications. Radial flux motors are the most commonly used type. However, axial motors are becoming

increasingly popular since they’re compact and well-suited for in-wheel applications.

Another popular type of motor is the linear motor, which is used in transportation systems that employ magnetic levitation techniques. These three motor types can be modeled with fully coupled multiphysics modeling capabilities.

Linear motors can be effectively modeled in 2D, while 3D is more suitable when end-winding effects are of interest. Due to their geometric structure, axial motors are typically modeled in 3D. An equivalent 2D design can be modeled by rolling out the cross-section parallel to the axis of rotation. Radial flux motors can also be modeled in 2D and 3D, with the 2D model being the most common.

Some effects, such as rotor skew,

cannot be accurately reproduced in plain 2D, but 2.5D provides a good approximation. In 2.5D modeling, multiple 2D cross-sections corresponding to various skewing angles can be modeled together to achieve results similar to those of 3D modeling with only a small fraction of the computational effort.

Typically, 3D modeling is only used to capture multiphysics effects that are extremely hard to capture in 2D and to verify the accuracy of existing 2D models.

Multiphysics modeling of e-motors Electric motors operate through electromagnetic fields, mechanical forces, heat transfer, and other physical phenomena. To fully understand them, a multiphysics simulation is required.

By building finite element models incorporating multiphysics effects, performance is more closely aligned with real-world applications, and designs can be optimized early in product development.

One of the primary steps in modeling an e-motor is computing the electromagnetic fields. This computation must examine the machine’s electromagnetic torque for electrical excitation. Additionally, electromagnetic losses obtained from this type of simulation can be used with a heat transfer model to calculate the rise in temperature.

The primary effect of temperature on the electromagnetic analysis can be considered by including temperature-dependent material properties, such as linearized resistivity. This will result in a two-way coupled multiphysics model. Similarly, different multiphysics

phenomena can be modeled by coupling a wide range of relevant physics phenomena, as shown in Figure 1.

Electrothermal modeling

Modeling electromagnetic motors involves modeling the stator and rotor geometry, which includes laminated electrical steel, permanent magnets, and multiphase windings. The primary results from the electromagnetics analysis are torque, electromagnetic losses, and efficiency, which can be obtained as a function of torque and speed.

Some of the losses of interest are the eddy current losses in the permanent magnets and the iron losses in the laminated steel, a soft magnetic material with nonlinear B-H characteristics.

The eddy current losses can be computed based on the electrical conductivity of the magnets. The iron losses in steel can be computed using standard loss models, such as Steinmetz

or Bertotti, or obtained from a loss data curve that provides losses as a function of magnetic flux density and frequency.

Since many of these loss models are frequency-dependent (meaning different harmonics contribute to the loss differently), simulation data in the time domain is converted to the frequency domain using the Fast Fourier Transform (FFT).

Based on the computed loss, an electrothermal model can determine the motor’s temperature rise. The increase in temperature affects the material properties of copper windings and permanent magnets, which can be modeled as a function of temperature. This results in a fully coupled electrothermal model.

Figure 2 shows an efficiency map obtained from a fully coupled electrothermal model. It shows a reduction in peak torque with an increase in speed due to the rise in temperature of the permanent magnets. Modifying the

design to improve the efficiency at critical operating points increases the vehicle’s driving range.

Coupling electromagnetics with structural analysis

Electromagnetic forces in the air gap between the stator and the rotor can cause the stator and motor housing to vibrate, resulting in acoustic noise.

To better understand a motor’s structural and acoustic behavior, the electromagnetic stator forces can be used as an excitation in a structural mechanics model, resulting in stress and strain. The mechanical vibrations can then be coupled with pressure acoustics to determine the noise.

Figure 3 shows the von Mises stress on a stator due to electromagnetic forces and the resulting acoustic noise levels. This type of multiphysics analysis is essential for understanding an electric vehicle’s (EV’s) noise, vibration, and harshness behavior.

Partial discharge measurements for the electric motors’ long life. NOW YOU CAN FIND IT!

The standard electrical tests are not enough to identify all types of failure. Marposs’ E.D.C. partial discharge measurements allow the detection of all latent defects that could generate failures in e-motors. For your electric vehicles’ safety choose Marposs E.D.C. testing system.

The traditional transient method can be used for electromagnetic analysis when modeling highly inductive devices such as electric motors. However, using this method to compute steady-state results requires solving for multiple electrical cycles.

To simplify the computation of a steady state, the time-periodic formulation can be used instead, which solves the steadystate results directly. In this approach, the electromagnetic field is solved for all times at once, and periodicity is imposed in time. The time-periodic formulation is particularly well-suited for periodic systems with anharmonic properties. This can be because of a non-harmonic excitation or a nonlinear material property.

Apart from directly finding steady-state conditions, the time-periodic method simplifies the coupling of electromagnetics with other physics. Since the time constant of an electromagnetic model is extremely small compared to heat transfer, the traditional transient approach would need to continue the electromagnetic simulation until nominal thermal conditions have been reached. This may require many electrical cycles.

With the time-periodic approach, the fully coupled physics phenomena can be solved in one go, with the electromagnetics model solving for the time-periodic conditions and the thermal model solving for the thermal steady-state conditions. This results in a significant reduction in computation time.

To summarize, the time-periodic approach is well-suited for multiphysics problems.

E-motor

An electric motor is typically designed to meet specific performance requirements. Obtaining the design parameters that result in higher power density and efficiency is crucial for EVs, making the optimization study essential in the design process.

Different optimization methods can be used, including parameter optimization, shape optimization, and topology optimization. Each method requires defining an objective function and a set of constraints. The objectives and constraints can be defined based on a single physics or multiphysics phenomenon.

For example, you could define an objective as maximizing the average torque the motor develops while constraining the volume of permanent magnets and stress on the rotor bridge in an interior permanent magnet motor.

In parameter optimization, optimal dimensions can be determined for various motor geometry parameters (such as magnet thickness and width, back iron thickness, etc.), given a specific set of objective functions and constraints. Shape optimization finds the optimal shape of a surface or a part. Figure 4 shows how the surface of an interior magnet rotor can be optimized to minimize the torque ripple.

Ultimately, topology optimization optimizes the material distribution, enabling the reduction of weight without compromising performance.

These methods can easily incorporate objectives based on multiple physics to find an optimal design for multiphysics machines.

Designing efficient, cost-effective motors is key to improving EV range and lowering costs. Multiphysics simulation helps engineers model real-world behavior and optimize designs faster, supporting quicker, more competitive product development. EV

High Voltage

Coilcraft’s MSS1514V high-voltage power inductors are rated at 800 V, doubling the voltage capacity of comparable parts.

Scan the QR code for more information

inductors/ferrite-drum/mss-mos/mss1514v/