8 minute read

Product World

igus igus.com

The TX2 bearing has an improved iglide material, which o ers self-lubricating and maintenance-free properties for heavy-duty applications. The TX2 increases wear resistance by a factor of 3.5 in load ranges with more than 100 MPa surface pressure. The material is suitable for components in machines that serve construction and agriculture, requiring more than 50 liters of lubricant annually. These tribo plain bearings made of high-strength fi lament fabric are used where very high loads occur. The robust fi lament, in its specially interwoven design, ensures maximum resistance and enables a maximum permissible compressive strength of 400 MPa. The newly developed material was extensively tested on the indoor and outdoor test rigs in the 3,800 square-meter igus test laboratory. Pivot tests on hard-chrome shafts showed that iglide TX2 is around 3.5 times more wear-resistant than the standard heavy-duty material TX1. Like all iglide plain bearings, iglide TX2 is self-lubricating and operates dry.

Thermoplastic polyurethane parabolic pitch belts

Gates gates.com/TPU

Gates has added two new thermoplastic polyurethane (TPU) belts — the Gates Parabolic Pitch (GPP) in 8 mm and 14 mm profi les. The new GPP belts are stronger, more durable, quieter, safer to operate, and require less maintenance than other alternatives, including alternative rubber belts, roller chains, and steel cables. The high-strength, reinforced steel (RSL) GPP 14-RSL has the highest break strength of any 14 mm pitch TPU belt on the market, and the standard product versions are compatible with Timken’s RPP sprockets, making them suitable drop-in replacements across a range of applications. All Gates GPP belts are equipped with nylon fabric on the tooth sides for high abrasion resistance and quieter operation, and the optional low-temperature construction provides an operating range from minus 30 up to 50° Celsius.

Expanded range of universal joints

Ruland ruland.com

Ruland Manufacturing has expanded its line of Belden Universal single and double friction bearing universal joints to o er over 3,500 standard items. Customers will have the widest selection of universal joints to choose from, including straight, step, and inch to metric bore sizes with or without keyways in sizes ranging from ¼ to 1-1/2-in. (6 to 35 mm). The expanded range of universal joints will be available through Ruland’s eCommerce platform and traditional distribution channels, o ering customers various ways to purchase. When using ruland.com, customers have access to 2D and 3D cad fi les, full product specifi cations, live chat with technical specialists, pricing, and lead times.

Product World

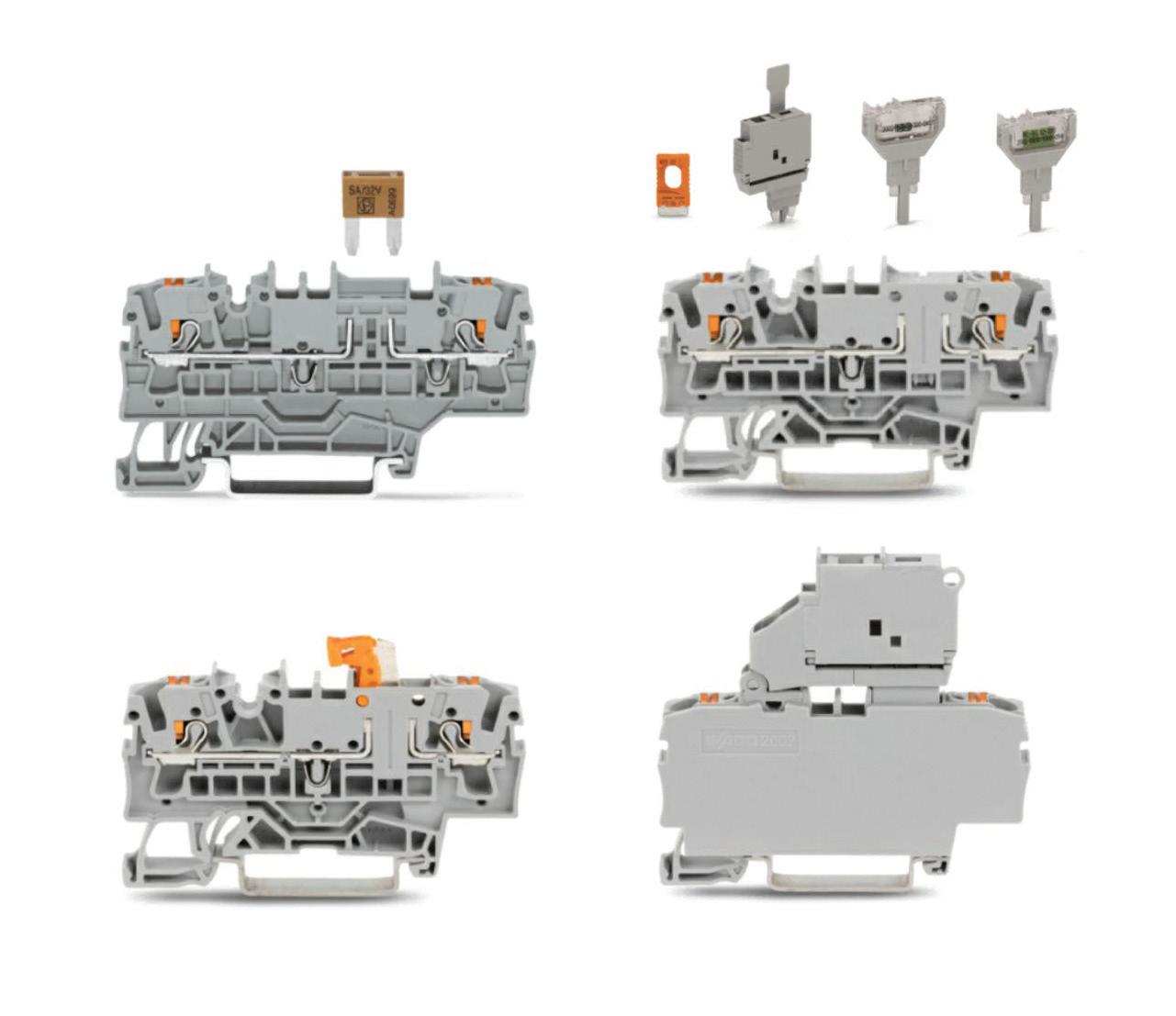

Terminal block series expansion

WAGO wago.us

A complete line of function terminal blocks has been added to WAGO’s TOPJOB S push-button terminal block family. This expansion includes automotive and pivoting fuse holders, blade disconnects, and base carrier terminal blocks for pluggable modules. All variants have industry-proven Push-In CAGE CLAMP connection technology and the intuitive, easy-to-identify, orange push-button, which can be actuated using a standard tool. Using the same profi le as other terminal blocks in the TOPJOB S family, accessories such as jumpers and universal marking strips may be interchanged throughout the entire line.

These new Function Terminal Blocks come in four basic styles and in 2, 3, and 4 conductor variants: 1. Mini automotive blade fuses or mini-circuit breakers (multiple LED blown fuse indication options). 2. Pivot-style glass fuse holder (5 x 20 mm mini metric fuses) 3. Blade disconnect. 4. Base carrier style for pluggable glass fuse holders, orange disconnect plugs, or electronic component modules (o ering various plugs, including custom and empty, allowing users to design their own).

Miniature photoelectric sensor

SICK sick.com

The W4F is SICK’s latest generation of miniature photoelectric sensors. A new ASIC platform delivers numerous performance advantages to this product family; these sensors can detect jet black, highly refl ective, fl at, or transparent objects with the utmost reliability. The W4F can also provide distance information, such as the height of objects and, as a result, identify process errors. The Blue Pilot operating concept combined with the monitoring options make confi guring and monitoring the sensors easier than ever, which saves time during commissioning. IO-Link and new smart functions for sensor monitoring and diagnostics create the link to the digitalized machine and application world. The W4F provides maximum performance in the smallest installation space, reliable switching behavior, and a guaranteed process setup, even in the new applications that open up for the W4F.

Digital differential measuring systems

Kaman Precision Products kamansensors.com

The KD-5600 family of digital eddy current measurement systems is suitable for COTS applications for fast steering mirrors, magnetic bearing active control, shaft vibration, image stabilization, and adaptive optics. Customers in the small satellite, semi-conductors, military/aerospace, high precision metal-working, and UAV/drone sectors benefi t from the KD-5600 system’s host of features. Designed for non-contact linear position displacement sensing applications, Kaman released two confi gurations for tailored use. The KD- 5656 (Full System) and KD-5690 FE (Front-End) are equipped with custom sensors, signal processing, analog to digital converter, and a custom calibration system to ensure precision and accuracy. For optimum operation for each channel, the KD-5600 system has two matched sensors. Input signals are fi ltered, and SWaP-C scaled to provide optimum operation, remove common mode noise, and deliver a drive signal. They also o er digital fi ltering as part of the signal conditioning to reduce signal noise.

Hybrid bearings for tough industrial applications

NKE nke.at

These hybrid bearings consist of ultrapure steel bearing rings and ceramic rolling elements made of bearing grade silicon nitride Si3N4. “At fi rst glance, this material pairing is highly unusual, but it o ers many advantages in an enormous range of applications, which signifi cantly increases the reliability of the overall system,” says Michael Rössl, Application Engineer at NKE in Steyr, Austria. The silicon nitride rolling elements are 60% lighter than those made from steel and are suitable for high rotating speeds. These hybrid bearings can reach limit speeds that are over 20% higher than conventional standard bearings. Even at these high and demanding speeds, NKE hybrid bearings demonstrate strong performance characteristics and minimal running noise. They are particularly well-suited for high-speed electric motors. The ceramic rolling elements have high wear resistance and can achieve better results under demanding conditions, such as poor lubrication, extending service life signifi cantly.

Product World

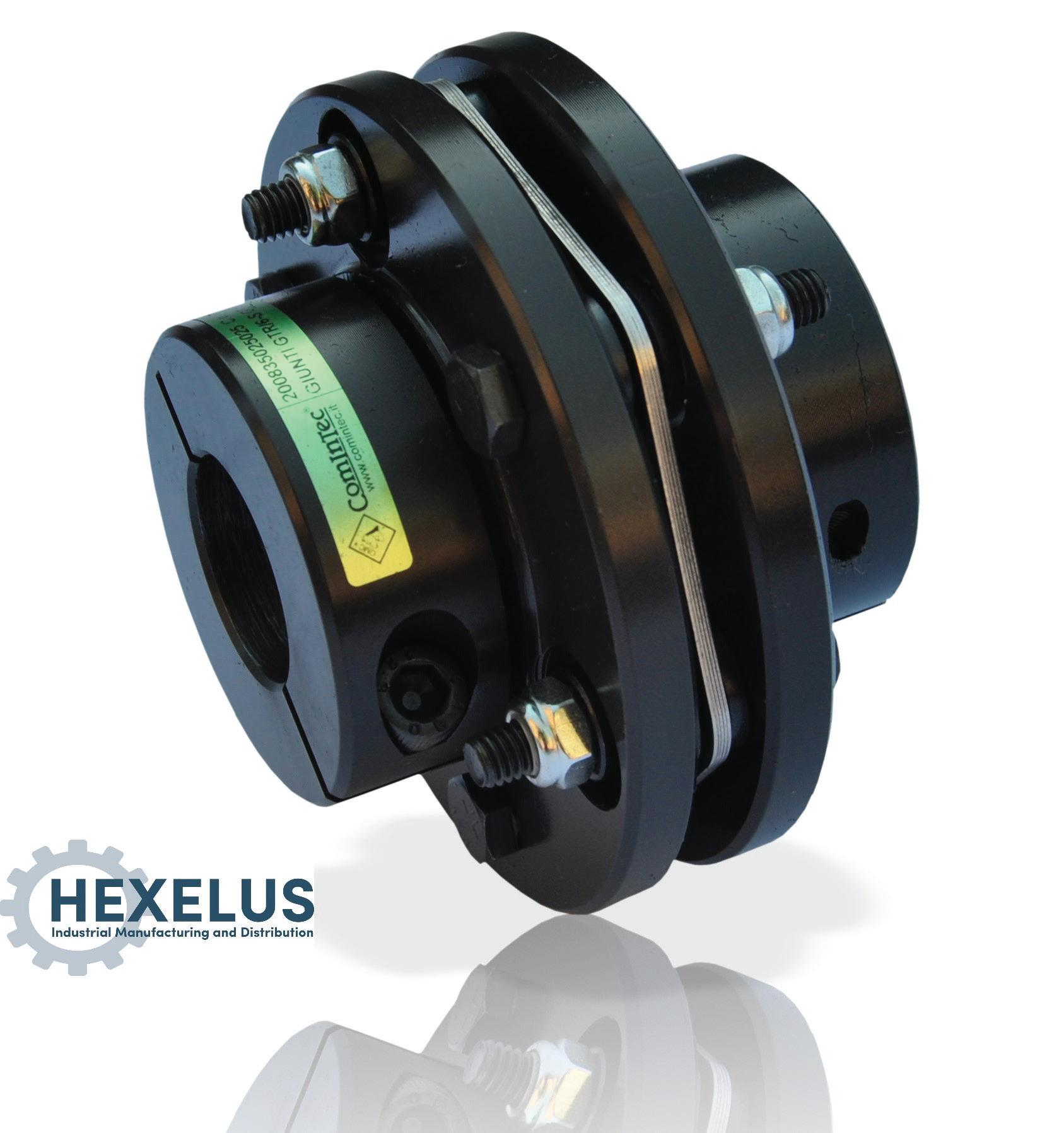

Heavy-duty, torsionally rigid disk couplings

Hexelus hexelus.com

Designed to suit applications where high reliability, precision, and an optimum weight/power ratio are required, these couplings are well-suited for applications with high speeds and power. This coupling is composed of three main items: the two fully-turned steel hubs and a single or double disc pack in 304 stainless steel. • Larger and more rigid than “typical” disk couplings • Made in fully turned steel with standard phosphating treatment • Disc pack in stainless steel. • Extremely high torsional rigidity. • Maintenance and wear-free. • Version with double disc pack: GTR/D. • High torque – up to 130,000 Nm (1,150,000 in-lbs) • Maximum Bore Diameter: 205 mm (8-in.)

Instrumentation and compensating cables for sophisticated applications

HELUKABEL helukabel.com/us/home.html

Helukabel now has four new in-stock instrumentation and compensating cable product groups for applications in the oil and gas sector, and use in the chemical, pharmaceutical, and food and beverage industries. Reliable data transmission is a must, even under the most extreme conditions. As a result, these robust instrumentation cables (HELUDATA) and compensating cables (HELUTHERM) have been designed for sophisticated applications to ensure the continuous transmission of sensitive measurement data even under harsh conditions. These new cable products come in various designs and insulation materials and guarantee minimum losses, even over long distances. Confi guration options include conductors wrapped in a single or double shield, cables with an overall shield, and with or without wire armor. This ensures that the correct cable version can be found for each application. Both cable series have a robust PVC jacket, and are certifi ed according to European, US, and Canadian (UL and cUL) standards along with their halogen-free, fl ame-retardant (LS0H) variants. The LS0H versions can be used in areas where corrosive or toxic combustible gases are not permitted. HELUTHERM compensating cables for thermocouple connection are available in a diverse variety of metal combinations. All cables are resistant to UV rays, sunlight, and oil.

Servo-coupling for hollow shaft connections

Ringfeder ringfeder.com

The GWE 5117 series of elastomer jaw servo-couplings have a new hub design. With its partially slit hub located directly under the jaws and two screw clamps, this model eliminates radial loads on the shaft and achieves uniform power transmission. This hub design also prevents premature wear and system failure. Designed for hollow shaft connections, the GWE 5117 servo-coupling is equipped with an expanding mandrel for friction-locked torque transmission. It has a spider element that is available in solid standard form, minimizing movement and achieving longer life, or drilled through the center. For convenience, the coupling comes with a slightly shorter design for compact use cases. It also provides easy accessibility with its interactive hub QR code that links to instructions.

Drive couplings

AutomationDirect automationdirect.com

AutomationDirect has added SIM drive couplings to its line of mechanical power transmission products. SIM drive couplings are power transmission components used to couple the shafts of various mechanical devices, often of di erent sizes, and compensate for shaft misalignment. Four di erent styles of couplings are available. Jaw/Spider couplings provide a range of fi tment and higher torque. Oldham couplings o er a higher speed rating and allow for a higher misalignment of mated shafts. Servo beam style couplings add a signifi cant increase to speed rating and have zero backlash, while high-gain couplings o er the highest speed ratings, excellent vibration absorption, as well as zero backlash.