Excellent –Ultra low to zero BPS/BPF syntans

TANIGAN® MBO Liq, TANIGAN® OSO Liq, TANIGAN® FAO Liq and TANIGAN® VRO Liq. These TFL pioneering syntans address the latest regulatory challenges ahead of time with a BPS content below detection limit and are completely free of BPF. These ultra-low bisphenol syntans remain an essential part of wet-end processing to ensure the required leather tightness, fullness, softness and fastness are attained. You can expect further product launches adding onto these essential “building blocks” shortly.

TFL – Great chemicals. Excellent advice. www.tfl.com

News

2 News map News highlights from around the global leather industry.

4 Industry & Innovation New technology, new ideas from leather industry suppliers and service providers.

6 Leatherscene People from around the industry and famous lovers of leather who have made the headlines in recent weeks.

8 Backtrack Headlines from www.leatherbiz.com, the industry’s best and most complete news website.

Leather Leaders

11 China looks upwards Vice-president of the China Leather Industry Association, Chen Zhanguang, says demand for new-energy vehicles is helping increase optimism in the leather sector in China.

Technology

14 Show of resilience The Simac TanningTech 2024 exhibition in Milan celebrated the resilience that leather- and footwear-focused technology providers have demonstrated in recent years.

18 Stamping ground As the race to trace hides heats up, well established stamping technology from Gibson Bass is providing valuable insight.

20 Gains in stain resistance Colour options for car interiors are expanding, which means, according to Dow, an increased interest in durable anti-soiling additives for leather finishing applications.

25 Better business Lifecycle analysis (LCA) gives organisations the data they need to take informed decisions, Trumpler argues, making the exercise worthwhile from a business as well as an environmental perspective.

31 IULTCS update The specialist commissions that the International Union of Leather Technologists and Chemists Societies runs for fastness and physical test methods have had a busy 2024.

Leather and the Circular Economy

32 Thought Leadership: Startling figures on hide waste New analysis shows that the carbon footprint of wasted hides is much greater than previously thought and that tanners do the world a huge service.

36 Thought Leadership: Added time on EUDR Postponed deadlines for the European Union Deforestation Regulation give leather manufacturers extra time to prepare, but a major traceability task remains.

40 Circular Stories: Careful path Accessories and footwear group Tapestry will increase its investment in leather, but will make its choices carefully, with circular principles at the core of its decisions.

42 Circular Stories: A valuable connection New ties to the China Leather Industry Association are making industry leaders in Pakistan optimistic about a massive increase in export revenues.

Beast to Beauty

44 Green machine Italian carmaker Automobili Pininfarina has unveiled the identity of the buyer of its first one-off, coach-built model, the Battista Targamerica, sparking great excitement at the supplier of leather for the vehicle’s interior.

The World Leather team has been publishing a series of original, dynamic podcasts since 2019. The whole series is available on Anchor, Spotify, Apple Podcasts, Google Podcasts, Pocket Casts, Overcast and other podcasting platforms. Just search for the World Leather Podcast on the platform you prefer.

The world’s best leather industry magazine is now available to download on iPad from www.leatherbiz.com

@WTPworldleather

@WTPworldleather

linkedin.com/showcase/wtpworldleather

@WTPworldleather

World Trades Publishing Ltd 2024. Contributions: The editor welcomes news items, articles and photographs for consideration and possible publication but no responsibility can be accepted for the loss or non-publication of such material. Opinions expressed by individual contributors do not necessarily reflect the view of the editor or publisher.

• Whilst every effort is made to ensure accuracy in reproduction, no responsibility can be accepted for the technical content or for claims made by manufacturers for product performance that are published. Publication in World Leather cannot be construed as an endorsement for a claim or product by the publisher.

• World Leather is published 6 times per year by World Trades Publishing, The Old Stone House, Teeton, Northampton NN6 8LH UK. Price UK £90, ROW: £150 per year (six issues).

Graphic origination by WTP. Print by Bishops Printers, Walton Road, Portsmouth, Hampshire PO6 1TR, England. All rights reserved. ISSN 0894-3087

World Trades Publishing 2024: All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means mechanical, electronic, recording, photocopying or otherwise, without the written permission of the publisher. World Leather®, Tannery of the Year® and Nothing to Hide® are registered trademarks

Cover image: The buyer of the Battista Targamerica from Italian carmaker Automobili Pininfarina, remained a secret until this October. See our Beast To Beauty feature to find out about the mystery owner and the special leather in the car’s interior.

CREDIT: PININFARINA

The World of News

FRANCE Production has begun at the new workshop that luxury leathergoods group Hermès has set up in Riom in central France. The new workshop is in a renovated tobacco factory in the town; 250 specially trained leathergoods artisans will work there. This takes the total number of company-owned leathergoods factories that Hermès operates to 23, which are spread across nine different regions of France.

SPAIN Spanish leather manufacturer

Tenerías Omega has announced that it is to close down. At its tannery, 40 kilometres south-west of Pamplona, the company developed a specialism for producing leather for transportation applications, particularly automotive. It was also one of the pioneers of the Olivenleder process, which uses residues from the olive oil industry in tanning, having carried out its first tests of the technology in 2016. Tenerías Omega had been in operation since 1991.

TUNISIA Tunisia hosted an event called ‘Italian technology, key to creativity’ in October. Italy’s export promotions agency ICE co-organised the event with leather industry bodies Assomac and UNIC. The agenda included a technical seminar and B2B meetings involving 13 Italian companies and 160 local operators. A delegation also visited local companies and the Centre National du Cuir et de la Chaussure (CNCC) laboratories.

DENMARK Travel retail group Heinemann has opened its first dedicated, duty-free, second-hand luxury goods airport boutique. It opened the new store, Pre-Loved Luxury, at Copenhagen airport in September. Products in stock at the boutique include certified, preowned handbags and other leathergoods from Hermès, Chanel, Louis Vuitton and other prominent brands. Heinemann said it had “tested the concept” by offering second-hand luxury handbags and other items on board cruise ships this summer of 2024.

ITALY Two leather-sector companies were amont the winners at Italy’s 2024 Sustainability Awards. This year’s edition was the fourth for these national awards. Leather manufacturer Gruppo Dani was named as one of the winners for environmental management for its commitment to facing climate change and promoting responsible use of natural resources. In parallel, footwear and accessories group Tod’s won in a category called institutional framework compliance.

GERMANY Carmaker Volkswagen is planning to shut at least three factories in Germany and cut pay by 10%, according to union leaders. Europe’s biggest carmaker has been negotiating with unions over plans to cut costs. The group said it faces pressure from high energy and labour costs, Asian competition, weakening demand in Europe and China, and a slower-than-expected electric transition. In the first nine months of this year, Volkswagen delivered 6.52 million vehicles, down 2.8% on the previous year.

RWANDA Rwandan dealers in hides and skins are seeking access to the African Continental Free Trade Area (AfCFTA) to expand their market, as the East African Community (EAC) market is insufficient. Jean D’Amour Kamayirese, representing the Kigali Leather Cluster, has said that over 100 tonnes of hides and skins are currently unsold due to limited demand within the EAC. Current regulations restrict trade of hides and skins outside the EAC, with an 80% tax on exports beyond the region.

KENYA The Kenyan government is seeking new international markets for locally produced hides and skins. This follows complaints from dealers about limited market access locally and abroad. The government is working with 16 training institutions to create a curriculum for leather technicians. One programme has trained more than 2,000 new abattoir technicians in the past year. The government said it wants to train people to turn the raw material into finished leather, and to make finished products with the leather.

UZBEKISTAN Uzbek leather and footwear association Uzcharmsanoat has celebrated its companies’ success at the September edition of Lineapelle, where they signed several large contracts. In a report, it noted that Peng Sheng factory showed shoe samples to suppliers from Portugal, Turkey, India, and Indonesia; tanner Hamkor Nur Savdo agreed to sell wet blue and crust materials to Portuguese and Spanish companies, while Ulkan Laziz agreed to supply special footwear to a Hungarian group.

CHINA The China Leather Industry Association (CLIA) has said it will launch a new event for finished product manufacturers in 2025. The new exhibition, Moda China International Shoes, Bags and Apparel Fashion Fair, will run concurrently with next year’s edition of the All China Leather Exhibition (ACLE) in Shanghai, with September 3-5 as the dates. The vicechairman of CLIA, Chen Zhanguang, said: “This marks a significant milestone in the development of China’s leather industry.”

The World of News

US Tanners, traders and packers in the US exported 17.6 million hides in the first eight months of this year, a decline of 8.4% year on year. In terms of value, hide exports brought in more than $715 million between January and August this year, down by 4.8% year on year, but wet blue exports continued to grow. Between January and August 2024, exports of wet blue increased by 15% in volume and 17% in value year on year.

TURKEY The Istanbul Leather and Leather Products Exporters’ Association (IDMIB) is set to host its annual design competition, ‘Detail’, aiming to foster emerging talent in Turkey’s $1.5 billion leather sector. IDMIB members contribute approximately 70% of the nation’s leather exports, making this competition a strategic platform to drive innovation and growth within the industry. This year’s competition will feature two categories, apparel and bag design, building on last year’s focus on footwear.

INDONESIA Footwear group Stella International has reported revenues of more than $1.1 billion for the first nine months of 2024, an increase of 4.9% year on year. Over the nine-month period, Stella shipped 39.4 million pairs, a rise in volume of 10.1%. But its average selling price per pair was down by 4.7% to reach $28.60. The group’s plan is to use a new factory in Indonesia to make sports shoes, freeing up more of Stella’s existing manufacturing capacity “to produce higher-margin products”.g.

VIETNAM Vietnam’s footwear industry is on track to reach its export target of $27 billion in 2024 after a recovery in orders. Exports between January and September are estimated at $20 billion. LEFASO, the Vietnam Leather, Footwear and Handbag Association, said many manufacturers have orders until the end of this year and into the first quarter of 2025.

BRAZIL Brazil’s competition regulator, CADE, has approved Minerva’s acquisition of meat processing assets from Marfrig, valued at $1.3 billion. The deal requires Minerva to sell a plant in Pirenópolis, Goiás, to address competition concerns. The transaction includes 11 of Marfrig's cattle slaughter and deboning units in Brazil, as well as facilities in Argentina and Chile. Plans to include Uruguayan assets were blocked earlier by that country’s antitrust authority.

GUATEMALA Leather belt manufacturer Tata Accesorios Globales has been named as a finalist in Guatemala’s Exporter of the Year competition. Tata Accesorios claims to be the largest producer of belts in the world. Chief executive, Rodrigo Toledo, said that to have achieved what Tata Accesorios has done was remarkable, especially because Guatemala does not have the raw materials required for the volume or quality of product the company is making.

Industry & Innovation

Portugal plan

Leather manufacturer Gruppo Mastrotto has acquired a majority stake in Coindu as part of a strategic move to support the relaunch and growth of the Portuguese automotive interiors materials manufacturer.

Founded in 1988, Coindu specialises in the design and production of high-quality leather and textile automotive interiors, particularly seat covers and decorative interior parts.

Group president, Chiara Mastrotto, stated that the deal would reinforce the business through downstream integration. “It unlocks potential synergies in both revenue and cost structures,” she said. Both companies aim to enhance production capabilities and expand their presence in the automotive market.

Durability, the elephant in the room

Work by the United Nations Industrial Development Organisation (UNIDO) to compile a guide for assessing the environmental footprint of leather reached a new milestone at Lineapelle in September.

A technical advisory group that UNIDO has set up reported its initial findings at the event and will now take the project into a new phase.

Its development officer for the leather industry, Ivan Král, said at the Sustainable Leather Forum in Paris earlier in September that the outcome he hopes to achieve is to walk a steady and sure path towards a platform for calculating accurately and explaining leather’s impact.

Mr Kral went on to say that an important part of the technical advisory group’s work was finding an effective way to reflect the contribution of durability to leather’s sustainability.

“Durability is the elephant in the room,” he said, “because making products with a long lifetime is much more beneficial environmentally than any other measure. But measuring durability is not so simple.”

IULTCS launches new scientific newsletter

The International Union of Leather Technologists and Chemists Societies (IULTCS) released its inaugural scientific newsletter at the end of October.

This new publication aims to provide the latest advancements in leather research, regulatory updates, technological innovations, and standardised methods specific to the leather industry.

The newsletter is designed to keep industry professionals, researchers, and stakeholders informed of the rapidly evolving field of leather science. By offering

At last, the Higg twigs

Environmental impact assessment tool the Higg Materials Sustainability Index (MSI) has updated its score for leather, attributing much lower impacts to the material.

The leather industry has been campaigning since 2020 to have the Higg MSI reflect more fairly the environmental impact of leather. Now, in an October 2024 update, it gives new average values for bovine leather showing environmental impacts that are lower by between 55% and 67% than previous scores.

As a result, the Higg MSI scale, which previously gave bovine leather a global warming potential score of 36.8 points, has been amended to attribute 14.6 points to the material. This is a reduction of more than 60%.

Using lifecycle assessment (LCA) information from the Leather Working Group and Leather Naturally, specialist leather industry-focused environmental consultancy Spin 360 submitted detailed data for leather’s impact to the Higg Index.

In its submission, Spin 360 used data collected from 45 manufacturing facilities across 18 countries for leather destined for use in footwear, automotive, leathergoods and upholstery.

The October update shows that the Higg has now adopted these more accurate figures as a new average for bovine leather. The leather industry bodies involved in this effort have reacted by saying this significant shift advances real change, promoting “a more nuanced understanding of bovine leather as a sustainable material choice”.

up-to-date insights, IULTCS hopes to foster greater collaboration and awareness within the global leather community.

This initiative reflects the organisation’s commitment to advancing leather technology and addressing emerging industry challenges through scientific knowledge and innovation.

Grants available

IULTCS and the IUR Commission, led by Dr. Volker Rabe, have also launched the 2025 IULTCS Young Scientist Grant Programme. The initiative aims to support young researchers under 35 working in leather science and technology, with grants recognising outstanding achievement. Winners will receive grants ranging from €1,000 to €1,500, sponsored by industry leaders such as Tyson Leather, Leather Naturally, and Italprogetti. The application deadline is November 30, 2024.

International leather industry calls for a fair COP

Organisations that lead the global leather industry have joined forces to raise awareness of the benefits of leather ahead of COP29.

The twenty-ninth United Nations Climate Change Conference will take place this year, with Baku, Azerbaijan, hosting the event from November 11-22.

In advance of the event, the International Council of Tanners, the Leather and Hide Council of America and Leather Naturally have united to reissue a manifesto calling on delegates to recognise the positive role that long-lasting leather products can have in reducing consumption and the environmental impact of fashion industry.

A first leather industry manifesto appeared three years ago in the build-up to COP26. In total, more than 20 leather industry organisations around the world put

Bovine leather processing at Scottish Leather Group.

their names to it and have done so again for COP29.

Expanding on previous messages, this latest edition of the Leather Manifesto aims to highlight to delegates the capacity for leather “to be part of the solution to climate change”, but it also calls for “informed, holistic measures of the impact of materials”.

It asks COP29 delegates to support the promotion of durable products, items that can be used many times, repaired and refurbished. Next year’s COP conference will take place at Belém in Brazil.

French parliament approves tax boost

Anational organisation representing shoe repair service providers across France, the Fédération Française de la Cordonnerie Multiservice (FFCM), has welcomed a tax change.

On October 26, France’s lower house of parliament, the Assemblée Nationale, voted in favour of lowering the rate of value added tax (VAT) for repairs to shoes and leathergoods from 20% to 5.5%.

FFCM said this lower rate of VAT represented “true recognition of the key role that our artisans play in the preservation of our savoir-faire and in the transition towards a more sustainable economic model”.

UITIC announces congress dates

The International Union of Shoe Industry Technicians (UITIC) has announced that its 22nd Congress will take place in Shanghai from August 31 to September 3, 2025. The event will focus on the theme of ‘Footwear Industry Competitiveness and Sustainability in the Era of Artificial Intelligence’.

The first two days of the congress will involve visits to local shoe factories, research centres, and educational institutions. A formal banquet, hosted by the China Leather Industry Association (CLIA), will be held on the evening of August 31. The following two days will feature indoor conferences with presentations and panel discussions on technologies for the footwear industry. Attendees will have opportunities to explore advances in AI and sustainability.

Encouraging result for Stahl

Chemicals group Stahl achieved sales revenues of € 687.9 million in the first nine months of this year, an increase of 1.6% compared to the same period last year.

Parent group Wendel said Stahl had achieved an encouraging result “in a

Industry & Innovation

context of tougher markets in automotive and luxury goods”. It pointed out that Stahl had suffered a fall of sales revenues of 4.7% in the third quarter.

Wendel said August had been “a particularly quiet month this year” owing to reduced activity in tanneries.

Bag designers are the target audience for software launch

Software provider Strategies has launched a new digital leathergoods design module as part of its Romans CAD suite.

Two versions of the software, RCS 3D Bag and RCS 3D Bag Expert, are available as part of the launch.

According to the technology provider, the software allows designers to choose whether to work in 2D or 3D, speeding up the process for developing new products and collections. The tool delivers “the seamless creation” of volumes for bag construction and real-time generation of 2D parts that are ready for cutting.

Net-zero goals are near

Scottish Leather Group (SLG) has published its 2024 ESG (environmental, social and governance) report, detailing the company’s progress towards its goal of net-zero-impact leather manufacturing.

Its 21st ESG Report reveals the group is now 90% of the way to achieving net zero greenhouse gas emissions for its scope 1 and 2 impacts, with 89% of waste recycled or recovered through its own processes. It aims to recycle 100% by next year.

The group offers 100% traceability of hides, ensuring zero deforestation. Around 98% of Scottish Leather Group’s hides come from the UK and Ireland.

Boost for renewable gas

JBS

USA has partnered with GreenGasUSA to expand renewable natural gas (RNG) production at its beef and chicken processing facilities in the US.

With an investment of $9.6 million in bioenergy projects, this initiative reinforces JBS’s commitment to sustainability and reducing carbon emissions. The project will begin with installations at sites in Grand Island, Nebraska, Hyrum, Utah, and the Pilgrim’s facility in Sumter, South Carolina.

By capturing methane from animal waste, purifying it into RNG, and distributing it through existing pipelines, the partnership aims to offset greenhouse gas emissions equivalent to 96 million kilometres of car travel annually. The first facilities are expected to be operational in 2025.

Common ground on traceability

Industry representative body COTANCE has said the preparatory work for launching a new Leather Traceability Cluster is almost complete. It explained that a number of organisations that focus on standards for leather production had been working together on traceability. COTANCE said they had been working to agree on “the essential requirements and means of verification” for tracing leather back to its origin.

Organisations that have formed the Leather Traceability Cluster are the Quality Certification Institute for the Leather Sector (ICEC), the Leather Working Group (LWG), Oeko-Tex and the Sustainable Leather Foundation (SLF).

Shavings prove valuable for fertiliser makers

Automotive leather group Pangea has announced its zero-waste initiative in leather shaving at its León, Mexico, facility will be realised by the end of this year.

In 2023, the site diverted nearly 2,000 tonnes of leather shavings from landfill, sending it instead to be made into fertilisers.

Italian branch

Supplier of shaving and fleshing blades to the tanning industry, Hardy UK, has announced a new Italian branch of the business. Its Italian facility, located in Santa Croce, will aim to enhance service levels for tanneries in the region.

With the opening of Hardy Italy, the company also plans to increase efficiency and better serve its growing customer base across Europe and beyond.

Ten years of LVMH’s Métiers d’Excellence

Luxury group LVMH has marked the tenth anniversary of its launch of its Métiers d’Excellence Institute with an event at a cinema in central Paris.

LVMH calls Métiers d’Excellence a pioneering skills training programme through which it aims to preserve and pass on “exceptional know-how” in areas such as leathergoods production.

It said at the Paris event that the programme has now become “the world’s leading private-sector training ecosystem for uniquely skilled professions”. It said that making its products requires 280 different professions, each of them demanding “exceptional savoir-faire”.

More than 800 people attended the event, representing learners, creatives, recruitment teams, partners and business leaders from across the LVMH group.

Leather scene

Assomac will fight a lone battle if it has to

The director general of Assomac, the industry body for Italian leather and footwear manufacturers, Agostino Apolito, has called on luxury goods brands to support the organisation’s member companies.

At the end of the 2024 Simac Tanning Tech exhibition in Milan, Mr Apolito said it was one problem for rivals in Asia to reproduce machinery from Italy, but a more serious one for luxury product manufacturers to be won over by these rivals’ lower costs.

“It seriously harms Assomac member companies for rivals in Asia to reproduce, to use a more elegant word than ‘copy’, our machines,” Mr Apolito said. “But it is even more serious for luxury brands to turn their backs on Italian machinery because of the lower costs of non-European products.”

He said Assomac hoped to work with other industry organisations, with the Italian government and with the European Union authorities to stand up against this, but insisted that Assomac was prepared to fight the battle on its own if it has to.

New chief executive to take over at Gucci in 2025

Luxury leathergoods group Kering has named Stefano Cantino as the new chief executive of Gucci, its biggest brand. Mr Cantino joined Gucci as deputy chief executive in May after five years at rival luxury leathergoods brand Louis Vuitton. He will take over the top role at Gucci on January 1, replacing Jean-François Palus Mr Palus, previously Kering’s group managing director, took up the Gucci role in July 2023 following the departure of Marco Bizzarri. Kering said Marco Bizzarri had “masterminded the execution of Gucci’s outstanding growth strategy since 2015”, but the brand had gone through a more turbulent time towards the end of his tenure.

The group said its main intention in appointing Jean-François Palus to the role last year was to “set up the foundations of Gucci’s next chapter and hire key talents, including his successor”.

Prominent industry figure to retire

Head of business development and industry relations at leather chemicals group TFL, Dr Dietrich Tegtmeyer, has announced his retirement. A past president of the International Union of Leather Technologists’ and Chemists’ Societies (IULTCS), Dr Tegtmeyer worked at Lanxess for many years.

He held sales and marketing roles in the leather business unit before becoming

head of product development there in 2005, following the retirement of Dr Wolfgang Wenzel . This role developed into a business development and industry relations brief in the course of the 2010s.

In this capacity, he was frequently on the speaker list at industry events in all parts of the world and used this experience to launch Lanxess’s own series of leather industry seminars in Cologne in 2016 with the aim of spelling out to finished product brands the value and qualities of leather.

When TFL finalised its acquisition of Lanxess’s organic leather chemicals business in 2021, Dr Tegtmeyer continued in the same business development and industry relations role there.

Former chairman of Tata Group dies

The business leader who steered the Tata Group towards becoming the international conglomerate it is today, Ratan Tata, has died. The group announced that Mr Tata, its emeritus chairman, had died in Mumbai on October 9. He was 86.

Ratan Tata took up managerial positions in his family’s company in the 1970s and became chairman in 1991, staying in the position until his retirement in 2012. During his time as chairman, the group’s focus shifted from producing and exporting commodities to developing global brands.

Brands that the group acquired during this period include automotive group Jaguar Land Rover, tea group Tetley and steel manufacturer Corus.

The group’s leather division still operates under the name Tata International. It runs tanneries at Dewas and Chennai in India and in Tanzania. It also has offices in Singapore and Vietnam.

SLF 2024: time to listen

The sixth Sustainable Leather Forum took place in Paris in September.

Sessions at the event covered developments in raising livestock, the perspectives of leather manufacturers in France, the environmental footprint of leather and current initiatives in corporate social responsibility.

Welcoming delegates at the start of the day, the president of leather industry association Alliance France Cuir, Christophe Dehard, said his hope was that the discussions at the Sustainable Leather Forum would “vulcanise exchanges between supply chain partners”.

He explained that what he envisaged were more in-depth conversations involving raw material suppliers, tanners and finished product manufacturers and brands, and for them “not just to hear, but to listen carefully to one another”.

Silvateam marks 170 years in Milan

Leather chemicals group Silvateam celebrated its 170th anniversary with an evening reception after the second day of the Simac Tanning Tech exhibition in September. The event took place at a restaurant overlooking Milan Cathedral.

In comments at the event, the director of Silvateam’s leather business unit, Antonio Battaglia, mentioned that the business started with a small chestnut extract factory in Corsaglia, near San Michele Mondovì in Piedmont, where the company still has its headquarters. Initially, the extract was produced for dyeing silk, and later expanded to leather applications. Now the company is involved in a wide range of applications that promote sustainable chemistry.

Calfskin warning for brands

Past-president

of ICHSLTA, Nick Winters, has said a decrease in the availability of calf skins is likely to affect the leathergoods sector.

Speaking at the Sustainable Leather Forum in September, Mr Winters said the annual volume of calfskins coming onto the market in France has fallen by around 600,000 in the last ten years.

He said that, in France, the availability of calfskins fell by around 7% in 2022 and by the same percentage again in 2023. In 2024, to date, he said there had been a further decline, which he put at 5% year on year.

“What this means,” he said, “is that the luxury industry is going to have to look for alternative materials.” He said brands might look at young bull hides instead.

Leather scene

Addition to TFL’s executive board

Leather chemicals group TFL has appointed Marc Schebben to its executive board, joining existing members Henrik Pedersen and David Blatch

Mr Schebben has been part of TFL’s C-suite team since August 2023 and will now take on a more prominent leadership role within the company.

In his new capacity as head of human resources, he will be responsible for shaping the corporate structure, guiding transformation processes, and overseeing human capital development.

Ali’s iconic leather glove set for auction

Aboxing glove worn by Muhammad Ali during his 1963 fight against Henry Cooper was expected to fetch between £4 million ($5.3 million) and £6 million ($8 million) at an online auction at the end of October.

Stuart Bull Auctions in Somerset uncovered the glove’s history, tracing it to leather from cape hair sheep dyed at Pittards Tannery in Yeovil before being crafted by Baily’s of Glastonbury for the British Boxing Board of Control. The glove, now stored in a secure vault, has a matching counterpart believed to be owned by the Qatari Royal Family.

‘Visionary advocate’ for leather dies

The Leather and Hide Council of America (LHCA) has announced the death of Shep Hermann, chief executive of the Hermann Oak Leather Company in St Louis, Missouri.

Mr Hermann was the fourth-generation leader of the company, which makes veg- and chrome-tanned finished leather. LHCA described him as “a persistent and visionary advocate for the leather and hide industry”.

Real Leather, Stay Different names winner

Astudent from California College of Art, Josslyn Shi, has been named as the overall winner of the Real Leather, Stay Different international student design competition for 2024.

She emerged as the judges’ stand-out choice for the overall prize from four category winners at the competition’s grand final. The US Embassy in London hosted the event on September 23.

Developed by Leather & Hide Council of America (L&HCA), the competition celebrates talented young designers who use leather as a natural alternative to fast fashion. Participants are encouraged to create a bespoke item using 50% or more bovine leather. Entries can be in the apparel, footwear or accessory categories.

Ms Shi’s design project is a jacket called Ephemeral Eclosion, inspired by the lifecycle of butterflies, impressed the judging panel with its combination of craftsmanship, innovation and commitment to sustainability.

Senior appointment at Scottish Leather Group

Leather manufacturer Scottish Leather Group (SLG) has appointed James Muirhead as its chief commercial officer.

Mr Muirhead represents the eighth generation of the group’s founding family; Andrew Muirhead, who launched the business in 1840, was his great-great-grandfather.

James Muirhead began working in 2006. The group said he had built up a deep understanding of SLG’s products and its customers. “This will make him a great addition to the board and invaluable to the group’s continued success,” it said.

Backtrack

World Leather’s publishing cycle and limitations on space make it impossible for us to run more than a carefully selected sample of news from across the industry. However, we publish hundreds more stories on leatherbiz.com. The site is updated every day with news from every continent and every part of the industry, making leatherbiz.com one of the most comprehensive archives of news anywhere on the web for the global leather industry.

We list below just a few of the headlines that have appeared on the site in recent weeks and can still be accessed.

30 October 2024

Leather garment downturn leads to closures in Turkey

Top spot in supply chain ranking for Pasubio

Timeless leather redefines the Air Force 1

29 October 2024

Porsche asserts it remains highly profitable

Surplus Leather Project provides students sustainable leather access

28 October 2024

Tapestry to appeal after Capri court set-back

TFL launches spring-summer 2026 leather colour trends

25 October 2024

New partnership boosts sustainability in Brazilian leather

‘Control over know-how’ pays off for unstoppable Hermès

SLF and ALLPI partner for sustainable leather

24 October 2024

No further Mulberry moves for now, Frasers says

Leather looks like the way forward for struggling Kering

Design-A-Bag competition 2025 now open

23 October 2024

China: not all bad news for luxury brands

22 October 2024

MILE Museum showcases leather’s sustainable evolution

21 October 2024

Adidas announces leadership change in global sales

Exports to Hong Kong boost UK beef

18 October 2024

‘Luxurious and rugged’ look in new Jitrois collection

Elmo returns to Design Post

China’s economic growth slows amid stimulus

17 October 2024

January-September figures show growth for Brazilian leather exports

Gruppo Mastrotto acquires majority stake in Coindu Ferragamo captures new European customers but Asia falters

16 October 2024

Codyeco launches spring-summer 26 leather trends

Nine-month fall of 2%, but LVMH remains confident

Stahl opens polyurethane dispersions facility in Singapore

15 October 2024

Higg’s ‘dysfunctional’ durability criteria draw formal complaint

14 October 2024

Competition in China keeps Volkswagen sales muted

SLF listed on ITC global standards map

11 October 2024

Yue Yuen manufacturing leads recovery

10 October 2024

Turkish leather industry groups hold joint meeting

Violence erupts amid Prato protests

09 October 2024

Hangover for leathergoods brands as China hits back

Isa Next-Gen partners with Apex footwear

08 October 2024

Cambridge Satchel announces ‘most exciting partnership’

Puma and PETA: Exploring leather’s sustainable fashion role

07 October 2024

Tuscan tanners seek government support

EU member states approve move to impose duties on Chinese BEVs

Sustainable fashion event wins Assomac support

Adidas unveils premium Italian Samba

03 October 2024

Inspiring venue for Phi 1.618

Nike revenues drop

Mulberry says no to Frasers Group offer Italy: strength in numbers for tanners’ association

02 October 2024

LVMH and Ruffini set stake limit Hide exports could be hit by US ports strike

01 October 2024

First winners of the Only Natural Student Design Competition announced

30 September 2024

ISA TanTec hosts US students in Vietnam

Bid from Frasers Group to take full ownership of Mulberry

27 September 2024

Veja and Asphaltgold launch sun-reactive sneakers

SCRD Plants 1.5 million trees

26 September 2024

Elche prepares for new edition of Futurmoda

Influencers boost global visibility at Lineapelle

Leather companies celebrated at Sustainable Fashion Awards

25 September 2024

Vegan brand ventures into leather

Leather sector companies sign Circular Fashion Manifesto

MLA report highlights red meat industry resilience

24 September 2024

Leather Naturally board appointments

23 September 2024

Mulberry earns B Corp certification

Leather Leaders: Chen Zhanguang

Increasing demand for new-energy vehicles and for high-end shoes, bags and apparel is helping increase optimism in the leather industry in China.

China moves upscale

What is the view of the China Leather Industry Association (CLIA) and of the leaders of CLIA member companies of the general state of the economy in China right now?

In terms of the overall direction, the situation is fine, but it is true that 2024 has been a difficult year; the economic recovery has been a little slower than we would have liked. The covid-19 pandemic had a negative effect on consumption here and consumer confidence is still weak; the recovery needs more time. There are lots of factors; it is not only about the pandemic. For example, 2022 was a good year for us, 2023 was so-so and 2024 has not been as good. But without the pandemic, consumption here would certainly have kept going up. Now people are being more careful and are keen to save money. This situation will reverse, but it will take some time.

What is CLIA’s opinion of the situation in the leather industry in China at this moment?

The domestic market was down in the first half of 2024. Since then, it has recovered little by little and we hope that will continue into next year. We are confident of a recovery in 2025, at least in the domestic market. For the reasons mentioned, many Chinese consumers, are being careful about what they spend. And because leather shoes are relatively expensive, the shoes that some people are choosing to buy these days are athletic shoes. In footwear in general, though, the growth of imports into China is greater than the growth of domestic production. This shows the significant potential that the Chinese market offers to exporters of high-end footwear. CLIA has calculated that the average price per pair of imported shoes in China in 2022 was $30.91. This is the highest among the top 20 shoe-importing countries in the world.

On that subject, important athletic footwear brands are now making a lot of shoes from suede because the styles of the 1970s and 1980s are popular again. Is this trend taking place in China too?

Yes, that is happening here too, which is good news for the tanners that specialise in split leather. In the last year, the prices they are able to charge have increased and demand has been very good. This is a good thing. But demand for grain leather is not so good at the moment and, of course, if you have the split you have to be able to do something with the grain side too.

CREDIT: ACLE

Many observers in North America and Europe are surprised by how quickly the Chinese automotive industry is driving the change to electric vehicles. What does this change mean for manufacturers of automotive leather in China?

Last year, automotive manufacturers in China produced a record 30 million vehicles and 9.5 million of these were newenergy vehicles (NEVs). That figure, 9.5 million, represents an increase of 35% year on year. This growth continued in the first half of 2024. NEVs’ share of the total, already more than 30%, will keep increasing. This is good news for the leather industry because traditional vehicles were using less and less leather, even though Chinese people in general think leather is good. Total leather production in China was down by 7% last year, but production of automotive leather increased by about 5%. NEV customers certainly like leather. Young people like these vehicles and they want them to be very comfortable and very smart inside. NEV manufacturers are using more leather to give users a good experience. I bought an NEV six years ago and it has been a very good experience, not least because it is around one-sixth of the cost to run compared to a traditional vehicle. NEVs have a good future in China.

Vice-president of the China Leather Industry Association, Chen Zhanguang, at the 2024 All China Leather Exhibition.

What is C LIA’s observation of the current global situation in the supply of hides and skins?

The price of raw hides is cheap; China is the biggest buyer of hides in the world and we have a high volume of raw material coming in. The US is our biggest market for wet-salted hides and Brazil is the biggest for wet blue and crust. Argentina is another important source. Meat production is stable in China and the consumption of meat is growing higher and higher. But the style of farming is a bit different from that in Europe and North America and there are limitations in the number of hides from domestic sources. Chinese tanners need to bring in many more hides and semifinished leather from other countries. These hides offer a large area, too, so they are good for making upholstery leather.

On the subject of upholstery leather, furniture manufacturers have had some very positive results in recent years, but 2024 seems to have been more difficult. What signs have you seen of a positive turnaround for furniture companies and for the leather manufacturers that supply them?

In the first half of 2024, furniture leather had a poor performance and the domestic market was particularly difficult. This segment, too, is recovering in the second half of the year. The situation in the international market is harder to predict. Tanners here have considered the possible effects of the US presidential election in November because the US is one of the biggest export markets for the furniture that Chinese manufacturers produce. While China remains the biggest market for US hides, any trade conflict will also be harmful to the US hide industry. If there is to be any disruption because of the election, our counterparts in the US should speak up about it.

What is your observation of the intense increase in regulations and legislation that manufacturers of leather in Europe are having to prepare for and comply with? Do Chinese tanners think this added complexity could be good news for them?

What the authorities in the European Union are asking for does seem to create a lot of hard work upstream, especially considering the lack of operational methods for carrying this work out, but I don’t think it will have any evident influence on the leather industry in China in the short term. We will pay close attention to the progress of these regulations and legislation.

You said that, in general, Chinese consumers have a positive opinion of leather, even though many are being careful not to spend too much money at the moment. What can CLIA and its members do to make sure consumers continue to have a high regard for leather?

We intend to launch a new event for finished product manufacturers in 2025. The new exhibition, Moda China International Shoes, Bags and Apparel Fashion Fair, will run concurrently with next year’s edition of the All China Leather Exhibition (ACLE) in Shanghai, with September 3-5 as the dates. This marks a significant milestone in the development of China’s leather industry. It is the right thing for us to do and the right time to do it. People are being careful about spending right now, but in general consumption in China is becoming more upscale, diversified and personalised and there is going to be increased demand among consumers in China for products from high-end brands. There has been a shift from consuming for basic survival to consuming for enjoyment. Moda China will help meet consumer demand for high-end leather shoes, bags and apparel and offer a platform for international and Chinese brands, designers and industry associations to bring products and brands to this market

The interior of a BYD Dolphin. Overall, leather production fell in China in 2023, but there was an increase in automotive leather. CLIA thinks the rise of new-energy vehicles is the main reason for this.

CREDIT: BYD AUTO

Resilience and innovation in the leather industry

Highlights from Simac TanningTech 2024

Celebrating its 50th edition since its launch in 1973, SIMAC TanningTech welcomed over 9,000 attendees to its 15,000 square metres of exhibition space. The event attracted a strong international presence, with 44% of visitors and 26% of exhibitors from more than 20 countries, highlighting the global recognition of the "Made in Italy" brand. The overlap with MICAM and MIPEL events further boosted attendance, emphasising the continued importance of industry events for sparking business initiatives. In the leather sector, face-toface interactions remain essential, as tactile and olfactory experiences play a critical role in transactions — elements that digital solutions have yet to fully replicate.

Now seen as crucial indicators of the leather and footwear industry's health, the autumn Lineapelle and Simac TanningTech events provide invaluable insights into market trends and strategic adjustments necessary for businesses looking to navigate the complexities of the current economic landscape. Despite concerns about a "fight or flight" mentality among companies, the reality has proven more nuanced.

In a recent reflection of 2023, the Italian footwear, leather goods, and tannery machinery sectors demonstrated notable

resilience despite global economic uncertainties. Data from ASSOMAC, the national association representing Italian manufacturers, revealed a 3.66% increase in overall exports, showcasing the sector's adaptability under challenging conditions. The tannery machinery segment stood out, experiencing impressive growth of 12.76%, driven largely by robust sales in Europe, America, and Africa. Conversely, the footwear and leather goods machinery sectors faced challenges, contracting by 4.61%. This decline can be attributed to the ongoing impacts of international conflicts

CREDIT: SIMAC TANNING TECH

and a weakened global economic outlook. Similarly, exports of spare parts saw a decrease of 4.02%.

Looking ahead, ASSOMAC President Maria Vittoria Brustia emphasised the critical role of institutional support in maintaining international competitiveness. “While 2023 demonstrated our resilience, it’s crucial that we relaunch investments,” Mrs Brustia stated. She highlighted the necessity of implementing Industry 5.0 policies and adopting long-term strategies to foster growth. The sector faces risks of diminished productivity and competitiveness without adequate incentives for digital innovations and energy transition initiatives.

Despite the challenges, marked by an overall export contraction of 11.55% in the first half of 2024, the tannery machinery sector recorded a positive increase of 6.77%. This growth stemmed primarily from foreign orders placed in 2023, demonstrating the sector’s adaptability and innovation. However, over 75% of sales during this period were concentrated in just ten countries, suggesting that many areas within the tannery machinery sector continue to experience challenges similar to other industry segments. The spare parts sector saw a smaller decline in exports, falling by 5.52%.

Mrs Brustia highlighted the optimistic outlook for the leather processing machinery segment, noting the growing recognition of Italian technologies in global markets. She stressed the crucial role of government support in promoting and safeguarding the “Made in Italy” label, especially in light of increasing international competition and the need for Italian companies to expand globally. The collaboration between SIMAC Tanning Tech and Lineapelle has proven beneficial, resulting in enhanced visitor exchanges between the two exhibitions.

Agostino Apolito, General Manager of ASSOMAC, underscored the event's importance as a global hub for the industry and the central role of innovation within it. He expressed optimism that recent discussions and engagements would lead to new opportunities, as evidenced by a rise in visitor numbers, and taken as a positive sign of potential future investments.

The Lineapelle and SIMAC Tanning Tech shows serve as vital platforms for industry stakeholders to gain insights, forge connections, and explore new growth opportunities in an evolving market.

Collaboration and innovation

In recent years, it has become increasingly evident that collaborations between technology providers are gaining momentum. At this year's event, these partnerships were more prominent than in the past, operating on several levels. The most immediate impact was seen with shared exhibition space among some, somewhat more understandable or justified in today’s climate of uncertainty, but these collaborations also offer something fresh to purchasers. Many industry experts noted that investing in upgrades to existing machinery has become less of a priority, with a stronger focus on exploring cutting-edge technology that promises a higher return on investment. As capital investment becomes more critical, pursuing innovation is seen as a smarter, more justifiable approach.

These collaborations can take various forms, whether through direct business partnerships between individual companies or by integrating complementary technologies for

Mindhive's advanced grading systems harness machine vision and neural networks to inspect leather with precision, identifying and classifying defects at a level often exceeding human accuracy. Designed to boost efficiency, especially in large-scale operations, this technology standardises grading and eliminates the need for repetitive manual sorting.

CREDIT: WTP

mutual benefit. An example of technological integration is the collaboration between Bauce and Hidexe, which involved combining Bauce’s samming machines with the Hidexe NHQ scanning system. This merger aimed to enhance functionality and deliver added value for both companies, resulting in improved efficiency and precision in the production process. The synergistic approach optimises the performance of the individual systems and facilitates advancements in industrial automation and quality control.

Another notable case is the Italtannery project, which brings together seven technology providers — Erretre, Fratelli Carlessi, Bergi, Ger, I-Tech, Bertech, and Huni. These companies are collaborating to develop a comprehensive data collection and analysis framework across the leather supply chain. The initiative hopes to enhance production efficiency by integrating real-time data into decision-making processes, thereby reducing downtime and improving overall quality. Additionally, the project aims to promote sustainable practices by minimising resource consumption and reducing the environmental impact of leather production, reflecting the industry's commitment to eco-friendly solutions.

Advanced finishing

A collaboration among another three companies has led to the introduction of a new approach to the leather finishing process. The Ascender machine, featuring a release foil system, provides tanneries with a compact and modular setup that can be used for standalone or in-line production. Available in three working widths, this system is said to streamline the finishing process, reducing the number of steps from half a dozen, down to just a few and significantly decreasing the finishing time from approximately five hours

with traditional systems to a maximum of one and a half hours. Additionally, the drying process is conducted at gentler, lower temperatures.

Developed by Barnini, IM Innovating, and Stahl, this technology aims to enhance leather processing by enabling the transformation of lower-quality hides into valuable finished products, thus promoting sustainability. The chemical solutions used in the Ascender machine are designed to improve leather quality, allowing for the upgrading of low-grade materials without the need for buffing or stucco application. These solutions are solvent-free, amine-free, low in volatile organic compounds (VOCs), and compliant with the latest ZDHC MRSL. The chemical compounds not only enhance the aesthetic properties but also improve the durability of high-quality leather goods, including footwear and automotive applications. Although the Ascender machine can operate independently of these chemical solutions, their combined use is recommended to ensure optimal results and meet quality standards.

Drum innovation

Italprogetti, a tanning machinery developer based in Pisa, unveiled its new Injection Drum along with a new company logo. The drum features a dual-layer structure with an inner stainless-steel core and an outer PPH layer, creating enhanced insulation. The drum includes heated plates for efficient warming, three folded shelves, and six staggered shelves to optimise skin processing. It also incorporates an advanced injection system and a 21-inch touch panel for user-friendly operation. Functioning as a vaporisation chamber for oils, greases, reagents, and resins, the drum supports various processes such as wetting back, retanning, fatliquoring, and fixation, and the manufacturers claim that the drum reduces water consumption by up to 85% by using steam instead of water, thus preventing imperfections in the leather. With its updated design and advanced software, the Injection Drum aims to improve efficiency and quality in leather processing.

Augmented reality

Swiss machinery group Zünd introduced a compact cutting system tailored to the leather-processing industry. The Zünd G3 cutter offers enhanced production efficiency by allowing nesting, cutting, and parts removal to occur simultaneously. The design is said to minimise downtime and aid the processing of medium-sized hides while enabling the easy removal of smaller cut parts. Key to the system was the Mind production software, which supported an interactive nesting function using augmented reality (AR) glasses. This patented feature allows operators to manipulate parts on leather, optimising the nesting process according to specific criteria. Zünd showcased live demonstrations of this mixed-reality technology, highlighting its effectiveness, especially on treated, shiny surfaces. In keeping with the collaboration theme, Zünd has formed an exclusive partnership with Mindhive Global to develop automated solutions for finished leather grading, further advancing technological innovation within the leather industry.

On the Mindhive Global stand, they showcased the automated leather grading system for high-volume manufacturing environments. The system, powered by AI and machine vision, integrates with existing samming machines, operating at full line speed. It provides precise inspection and

the 50th anniversary of the Tanning Tech exhibition, Italprogetti showcased its new visual identity and introduced the Injection drum. This system is designed to reduce water usage by up to 85% with its steam-based technology and includes automatic dosing tanks for precise chemical mixing, aiming to set a new standard in leather treatment.

CREDIT: WTP

classification within four seconds, grading up to 360 hides per hour and claiming a classification accuracy of up to 91%.

The system identifies defects using high-resolution imaging and rule-based grading, offering detailed reports and realtime data through a centralised dashboard. Integrated with ERP, enterprise resource planning systems, it enhances workflow efficiency. Early adopters report significant improvements in product quality and operational speed, making it a trusted solution for wet-blue tanneries.

These examples illustrate how strategic partnerships and technological integration can enhance operational efficiency and environmental responsibility in manufacturing.

However, it should be noted that the amount of technology and machinery on display has been greatly reduced from previous years. There is no longer the overarching rhythmic sound of drums turning, staking machines vibrating, or compressors firing up to provide much-needed air for spray machine demonstrations. Yes, the stands were smaller, and the space was optimised by moving the stands further away from the external walls. If the organisers want to conceal the visible signs of maximising space, they might consider sourcing a wider carpet to avoid the noticeable 18-inch strip of bare concrete on either side. Nonetheless, it should also be noted that by the end of the event, most participants left with a positive impression.

While foot traffic has significantly decreased compared to previous years, the quality of attendees has improved. Those who came had valid reasons to be there, with meaningful business opportunities and budgets to spend or invest in discussions about future projects. The industry is undoubtedly facing challenging times, but the resilience of the leather sector has always been a stronghold.

At

Multiple blades give an almost infinite number of marking combinations.

ALL CREDITS: GIBSON BASS

Traceability –the stamp of approval

The Gibson Bass Stamper is considered to be an important innovation in the leather industry, providing solutions for traceability, inventory management, and sustainability. Its customisation options, integration with digital systems, and strong construction make it a useful tool for tanneries and abattoirs seeking to enhance operational efficiency and uphold high standards of quality and transparency.

The Gibson Bass Stamper is a precision-engineered machine designed for marking hides in abattoirs and tanneries. Its efficiency is primarily attributed to an advanced hydraulic system capable of delivering 2,000 psi of pressure, enabling the machine to stamp through full substance hides in approximately one second. Each stamping head utilises up to 40 kg of force per cutter to produce clear, permanent marks, which is essential for maintaining traceability throughout the production chain. This feature is increasingly relevant as the leather industry responds to rising consumer demand for ethical and transparent supply chains.

Offering customisable stamping configurations, ranging from 3 to 9 digits, it can accommodate various identifiers, including serial numbers, barcodes, and hexadecimal

codes. This flexibility allows the machine to generate over 16 million unique identifiers, meeting the diverse requirements of the industry. It is equipped with an Allen Bradley Compact Logix PLC, ensuring seamless automation and network integration, which facilitates remote adjustments and real-time data collection on stamping rates, hide types, and other operational metrics. A significant advantage of the stamper is its role in traceability systems within the leather industry. By permanently marking hides with serial numbers, lot numbers, and date stamps, the stamper aids in tracking hides through various production stages, ensuring that the provenance of the leather can be verified from the slaughterhouse and along the leather processing chain. The machine’s touchscreen interface simplifies control over

stamping settings, such as stamp orientation and timing adjustments. Its connectivity to local area networks (LAN) further supports remote monitoring and data management, allowing operators to access critical information, including production rates and stamping performance.

It is made from high-grade stainless steel and brass, designed to withstand the demanding conditions of abattoirs and tanneries, ensuring longevity in harsh environments. The precision-engineered components, such as hydraulic valves and solenoids, have been optimised for durability, with reports indicating virtually zero valve failures in over 15 years of operation. This reliability underscores the machine’s effectiveness in delivering consistent performance.

The Gibson Bass Stamper features a compact footprint of 650mm x 500mm, aiding easy integration into existing production lines. The hydraulic power pack and control box can be positioned up to four metres away from the stamping head, promoting a flexible and uncluttered work environment. Installation is straightforward, with a plugand-play setup and minimal maintenance requirements.

In terms of inventory management, the stamper provides a consistent method for marking hides with individual identifiers. This capability is particularly valuable in toll tanning operations, where accurate tracking is critical for efficient processing. In operational assessments, the machine has demonstrated a 99.9% accuracy rate on batches of hides, highlighting its effectiveness in ensuring traceability and optimising production.

The integration of modern data systems is another advantage of the stamper. Its Ethernet connectivity enables real-time data integration with existing software systems, allowing for seamless data transfer, remote monitoring, and operational control from various locations. The touchscreen interface presents key operational data, such as stamping rates, hide counts, and species identification, providing valuable insights into production performance

COLOURS BY LANGRO

Cutting through the full thickness, traceability can be assured for splits as well as grain leathers.

Advances in anti-soiling technology

Dr. Lucia Bivona, Bertrand Lenoble, Dhanya Puthenmadom

Dow Europe

In addition to traditional black and deep brown, the automotive industry is expanding the range of coloured leather interiors. Dow has created a siliconebased, waterborne emulsion that acts as a durable anti-soiling additive for leather finishing applications. This technology offers effective soil repellency while maintaining the natural feel of leather. The silicone emulsion prevents soil penetration, improving the longevity and cleanliness of leather surfaces. It represents a significant advancement in leather finishing technology.

The widespread use of blue jeans presents indigo dye as a common source of staining on leather seats, due to its tendency to transfer easily to surrounding surfaces, particularly leather. This study focuses on understanding and mitigating the penetration of indigo dye through enhanced topcoat additive technology.

Investigating analytical techniques for soiling characterisation

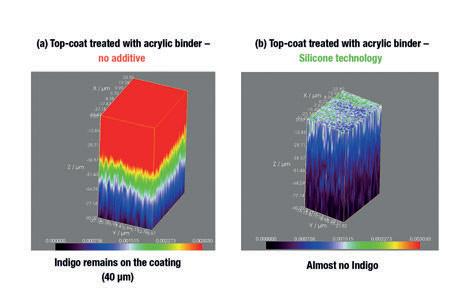

The first step involved examining the distribution of indigo within the topcoat using cross-sectional optical analysis on a treated leather sample (Figure 1, white leather treated with polyurethane dispersion (PUD) but without additives). This analysis confirmed the presence of indigo on the leather surface. A second step complemented the initial optical observations, employing confocal Raman microscopy to characterise the depth of indigo penetration within the leather crust. This advanced technique facilitates the analysis of chemical composition to a depth of up to 100 microns, confirming the distribution of indigo both on the surface and within the bulk of the leather. The chemical imaging intensity scale used in this study correlates red and blue extremes to high and low concentrations of indigo dye, respectively.

Based on the analysis, it was demonstrated that indigo dye penetrates through the topcoat and into the basecoat if left on the leather for

Cross-section optical microscopy and confocal Raman microscopy images of white leather treated with PUD and no additive after soiling using the VDA 230-212 test method (EMPA 128 soiled jeans). The red colour corresponds to high levels of the indigo dye.

one day before cleaning. Due to this deep penetration beyond the surface, the dye remains even after cleaning with a detergent solution, in the absence of an anti-soiling additive, as illustrated in Figure 1

Martindale soiling and cleaning rub method

To address the requirements of automotive applications, Dow selected a standard testing method to assess soil repellency. The Martindale test method, VDA 230-212, evaluates the soiling and cleaning behaviour of leather used in automotive interior trim. The test involves rubbing a soiling cloth made from denim on a treated leather surface coated with an aliphatic polyurethane dispersion (PUD) and/or acrylic binders. Dow selected two soiled denim fabrics for the test: EMPA 128 and DENIM 2550-Y. EMPA 128 was soiled

Figure 1

with indigo dye, carbon black, and olive oil, while DENIM 2550-Y contained only indigo dye impregnated on a thick cotton fabric. To increase the test’s difficulty, the DENIM 2550-Y fabric was further impregnated with an artificial perspiration solution. All tests were performed on the surface of a white leather substrate, chosen to enhance the visibility of soil. For analysis, Dow focused specifically on the indigo component from both test fabrics, using calibrated Raman microscopy.

After soiling, the lower half of the leather sample was cleaned using a cotton cloth soaked in a detergent solution. An optical measurement of colour change, denoted as ΔE (delta E), was then conducted to compare the initial colour of the leather before soiling with its colour after both soiling and cleaning (Figure 2). The goal is to achieve the lowest level of colour change, or the lowest ΔE value.

Silicone

emulsion as anti-soiling technology

Silicones are widely used in various leather applications, including footwear, the automotive industry, and garments. One of the most prominent silicone polymers is polydimethylsiloxane (PDMS), which consists of an inorganic backbone of repeating silicon-oxygen units, with two organic methyl groups attached to each silicon atom. The basic PDMS structure can be modified to produce silicones with a wide range of molecular weights, classified as fluid, gum, elastomer, or resin. Additionally, PDMS can be functionalised with reactive groups, such as organic moieties introduced onto the PDMS backbone (Figure 3)

lower flexibility and a negative impact on tactile properties. By carefully choosing functional groups, it is possible to fine-tune silicone properties such as surface tension, solubility, compatibility, and reactivity with other chemicals in the formulation. When silicone is incorporated into the topcoat and applied to leather, it can form a protective barrier that prevents indigo dye penetration while maintaining the appearance of the finished leather.

A Design of Experiments (DoE) approach was employed, varying parameters such as the functionality of the siloxane polymer, pH, and particle size of the emulsion. Each variation was evaluated using the Martindale rub method, and the colour change ( Δ E) was measured across all experiments. A specific set of emulsion parameters was identified, offering optimal soil repellency in both PUD and acrylic binders. The use of silicones with amino functionality,

combined with high molecular weight PDMS, enhances durability, protection, and lubrication of the leather.

The performance of this nextgeneration silicone anti-soiling additive technology is illustrated in Figure 4(b), in comparison to leather treated without additives, shown in Figure 4(a) The corresponding colour change values for the PUD and acrylic topcoat samples are plotted in Figure 5

Fine-tuning the emulsion of the siloxane polymer

Once the polymer architecture was defined, a crucial criterion for success was the ability to offer the silicone additive in a water-based coating without generating defects.

Formulating the specific silicone into a water-based emulsion provides an enhanced solution to the compatibility challenges posed by siloxane polymers when incorporated into PUD or acrylic emulsions commonly used in topcoat formulations.

The selection and optimisation of silicone functionality and molecular weight

The selection of specific functionalities and molecular weights allows the use of silicones in applications where other anti-soiling technologies may be limited due to

Figure 2

VDA 230-212 test method (EMPA 128 soiled jeans), picture of the white leather treated with PUD (left), and level of discolouration, ΔE (right).

Func – (Si-O)x

Figure 3: Chemical structure of organic functional PDMS backbone.

Figure 4

White leather treated with PUD water-based topcoat, without anti-soiling additive (a) and with the silicone anti-soiling additive technology (b).

Durability

To further assess the performance of this enhanced anti-soiling additive technology, a durability test was conducted, simulating repeated cleaning cycles as would occur with regular consumer use. The test involved repeating the soiling procedure on the same leather sample. Notably, even after four cycles of soiling and cleaning, the indigo dye repellency remained excellent (Figure 6)

Evidence of anti-soiling benefit

Confocal Raman microscopy was once again employed to analyse the indigo dye soiling. Leather treated with the new generation silicone antisoiling additive technology exhibited no penetration of indigo dye into the coating ( Figure 7b , compared to Figure 7a ). This indicates that the silicone anti-soiling additive effectively prevents the dye from seeping into the coating, thereby significantly enhancing the leather's anti-soiling properties. These findings also demonstrate the potential for silicone technology in other applications requiring soil repellency.

New generation silicone antisoiling additive technology

In addition to its anti-soiling performance, the newly developed silicone anti-soiling additive emulsion technology is produced without the use of catalysts. It has a shelf life of 18 months at room temperature and remains stable in formulations containing waterborne acrylics and PUD for up to one month. Importantly, this technology does not alter the natural colour of the leather (as summarised in Table 1)

Conclusion: silicone emulsion as an excellent anti-soiling additive technology for natural leather

Dow has developed a silicone antisoiling additive emulsion technology specifically designed for water-based binders in leather finishing applications. Using confocal Raman microscopy, visual evidence of dye penetration in both the top-and basecoats of leather was obtained, enabling a thorough characterisation of the performance of this new generation technology. The emulsion demonstrated effective and durable soil repellency while exhibiting

Measurements of optical discoloration of white leather with PUD (left) and acrylic (right) water-based binder topcoat, comparing without anti-soiling additive and with silicone anti-soiling additive technology.1

Durability of anti-soiling in leather topcoat (thickness: 34 µm wet). The silicone anti-soiling technology was dosed at 20% in acrylic water-based binders.1

Raman microscopy images of white leather treated with acrylic water-based topcoat, with silicone anti-soiling additive technology

without (a).2

Figure 5: Anti-soiling performances

Figure 6: Durable anti-soiling performances

Figure 7: Indigo distribution (after cleaning)

(b) and

excellent compatibility with the most common water-based binders. This technology has potential applications beyond the automotive industry, including furniture, fashion, and footwear (Figure 8)

References

1. Typical values, not to be construed as specifications. Users should confirm results by their own tests.

2. The graphic representations should not be construed as product specifications.

Acknowledgements

The authors thank Corentin Mars: emulsion preparation, Nancy Delys: application testing, Nathalie Wautier: optical images and Brett Zimmerman.

Credit

All images Dow, except Figure 3, World Leather (Feb-March 2004).

Figure 8

Need of the automotive industry (left) and Dow solutions for leather finishing (right).

We also own the largest wetblue tannery in France. CET can process up to 500 tonnes of raw hides per week.

● SALTED CROUPONS ● SHOULDERS & BELLIES

Nick Winters Hides & Skins division is a leading supplier of quality European Hides & Skins with a rigorous selection process since 1992.

With operations in France, Ireland, Italy and the UK, we service the most demanding tanneries worldwide.

We are part of the Bigard group, one of the largest meat companies in Europe, processing 26,000 cattle, 120,000 pigs, 20,000 lambs and 4,500 veals weekly.

WETBLUE AND WETWHITE HIDES

LCA is more than an abbreviation: it’s transparency, efficiency, and better business

Dr Jordi Escabrós, Dr Benjamin Autenrieth Trumpler, Spain/Germany

Life Cycle Assessment (LCA) is a method used to evaluate the environmental impacts of products and services throughout their entire life cycle, from raw material extraction to final disposal. It helps improve resource efficiency, reduce emissions, and support waste management practices. Trumpler, the German chemical company headquartered in Worms, Germany, applies LCA methodologies to assess the environmental performance of its chemical products, contributing to greater transparency and data-driven decision-making. By implementing LCA, opportunities for reducing environmental impacts and enhancing sustainability across the supply chain can be identified and addressed. It also should be noted that more brands and businesses are requiring such information

Life Cycle Assessment (LCA) involves analysing the environmental impacts of a product or service at every stage of its life cycle, from the extraction of raw materials to its final disposal1,2. This entails considering every step of the process, from the extraction of raw materials to the ultimate disposal of waste, including the stages of manufacture, transportation, usage, and recycling. Both ISO 140403 and 1404444 serve as standards for it.

LCA is essentially the balance of materials and energy of the examined product system plus an evaluation of the possible environmental effects of the inputs (material and energy consumption) and outputs (air, soil, and water emissions) of the same system. Altogether, it provides a comprehensive and holistic view of the environmental loads of products and services under study, covering a wide set of environmental performance indicators such as global warming potential (GWP), acidification potential (AC), eutrophication potential (EP), ozone layer depletion potential (OLDP), human toxicity potential (HTP) or ecotoxicity potential (ETP).

LCA consists of the following crucial steps (Figure 1):

1. Definition of goals and scope5: The goals of the analysis are established, and the elements and stages of the life cycle that will be covered are decided.

2. Life cycle inventory: Data on the inputs and outputs of every step of the life cycle is gathered.

3. Life cycle impact assessment: This involves evaluating any possible environmental effects linked to the selected inputs and outputs.

4. Results interpretation: Interpreting the data to pinpoint areas that need improvement and offering solutions that will have the least negative effects on the environment is the most crucial step.

Direct applications:

• Product development and improvement

• Strategic planning

• Public policy making

• Marketing

• Process improvement

Trumpler values the importance of life cycle assessment (LCA) methodology in making data-driven decisions related to sustainability. This approach helps in identifying opportunities for enhancing resource efficiency, reducing emissions, and improving waste management practices.

The role of LCA in the leather industry LCA in the leather industry is essential to assess the environmental impacts at each stage of the production process, from raw material extraction to manufacturing and final disposal6,7,8 Chemical manufacturers in the supply chain support such analysis. The

Figure 1: Steps towards Life Cycle Assessment

LCA is more than an abbreviation: it’s transparency, efficiency, and better business

implementation of LCA in the leather industry presents several challenges and opportunities.

The challenges include: