Nowadays, as we move across various cities and rural areas, there are signs of infrastructure development all over. Construction of buildings, flyovers, roads, metro development is a norm as the country moves towards faster economic development. While the sprawling commercial complexes, 90-floor buildings and skyscrapers amaze us all the time, it is important to note that there is a material that is helping these structures stick together and be strong over the years.

Although they remain as an invisible element in the objects they are used in, adhesives and sealants play a major role in the strength and tenacity of some of the fastest cars and tallest buildings ever designed.

The technologies in automotive adhesives has undergone a sea change in recent years. From use of solvent-based adhesives, the solutions have moved to solvent free adhesives. Also there is rising use of methyl methacrylate adhesives, eco-friendly automotive adhesives and water-based adhesives in vehicles.

Further the use of adhesives is increasing due to the demand of lightweight materials in vehicle manufacturing and replacement of mechanical fasteners with adhesives to make vehicles lighter and to meet higher fuel economy requirements.

Other than automotive and construction industry, use of adhesives is even becoming more prominent in the biomedical industry. Considering the internal wound applications, the demand will be a soaring market in the near future where bio-adhesives can play a major role in chronic organ leak repairs to limit bleeding complications.

Separately, looking at the paints & coatings industry, the industrial and decorative color tones have seen a paradigm shift. People are now looking at nature, comfort and balance to match their moods with the hues on their walls or their cars. New age colors are following the tones of harvested crops, creating a strong, long lasting connection among people and nature.

In Asia Pacific too people are looking for automotive colors that bring them happiness and spice, reflecting human individuality, which is gaining importance. These describe to people how to live gently and vividly with their own narratives.

The rise of e-commerce and access to new technologies has accelerated counterfeiting and other forms of illicit trade. That makes fighting counterfeit medical products an ever-more urgent priority for pharma companies both in terms of patient safety and brand reputation.

Yann Ischi

Director, New Channels and Partnerships, SICPA

Within the Volkswagen Group, we have a clear strategy for how we want to put battery-electric vehicles into series production across our brands and in many different market segments. However, a major qualification for success in the volume market is more powerful battery concepts. In Volkswagen Group R&D we are focusing on close cooperation, not only with industrial partners but also with the smart minds of the scientific community.

Dr Ulrich Eichhorn

Head, Group R&D, Volkswagen AG.

India is a very important market for polyurethanes and has a wonderful potential for growth. When leaders of the industry from all over the world get together under one roof, it leads to better production and faster growth of the industry

R C Bhargava

Former CEO and current Chairman, Maruti Suzuki.

Indian Solar Manufacturers Association (ISMA) members have expressed positive sentiments as manufacturing and Make in India initiative gathered momentum. The phenomenal growth opportunity of Renewal Energy is unparalleled in the world today, looking at current and future energy consumption in India over the next 2-3 decades. All stakeholders have immense opportunities especially those who make and develop products in India.

K N SubramaniamCEO, Moserbear Solar Ltd and Treasurer, Indian Solar Manufacturers Association (ISMA)

FREMONT, US/BANGALORE, INDIA: Ohmium International, a green hydrogen company that designs, manufactures, and deploys PEM Electrolyzers, said it is collaborating with Shell India Markets Pvt Ltd, to evaluate hydrogen applications, markets and project opportunities in India and globally.

As part of signing an MoU, the companies launched joint working groups to assess opportunities from the technical, commercial, and safety perspectives. The collaboration would elevate Shell’s ambition to help build a global hydrogen economy by developing opportunities in the production, storage, transport and delivery of hydrogen to endcustomers.

“We have set an ambitious goal of becoming a net-zero emissions business by 2050 with a target to reduce absolute emissions by 50 percent by 2030. Green hydrogen has a critical role in helping the

world reach zero emissions. We plan to develop integrated hydrogen hubs to serve the industry and heavy-duty transport to be a leading player in this space,” said Nitin Prasad, chairman, Shell group of companies in India.

“We would like to work with Ohmium to make this a productive collaboration which would help us make our Hydrogen projects most competitive. We are keen to explore all opportunities to work with all our contract partners to continuously drive competitiveness in our projects,” said Prasad.

“We’re thrilled to collaborate with Shell to explore green hydrogen opportunities and solutions worldwide. Shell has demonstrated tremendous ambition to become a net zero carbon business by 2050– we believe that green hydrogen is a critical component of that transition,” said Arne Ballantine, CEO of Ohmium International.

“I am pleased to share that over the next 5 years, we will invest Rs 750 billion and expand capacities in existing and new value chains. In the polyester value chain, vinyl value chain and new materials,” said Mukesh Ambani, chairman & MD, Reliance Industries Limited, during the company’s 45th AGM.

Reliance manufactures polyester fibers and yarns under the Recron brand name, with a capacity of 2.5 million tonnes annually. Recron Partially Oriented Yarn (POY) products are produced using multiple process technologies like Barmag, Dupont, Toray, Inventa, and Zimmer to suit various customer requirements.

The Reliance Group chairman also unveiled aim to turn net carbon zero by 2035 as part of its commitment to support climate change by focusing on new and affordable climate friendly energy and materials.

MUMBAI, INDIA: Reliance Industries Ltd (RIL) said it will invest $9.4 billion (Rs 750 billion) in its petrochemicals and textile business over the next five years. The investment will be setting up a Purified Terephthalic Acid (PTA) plant, expanding polyester capacity and tripling the capacity of vinyl chain and a chemical unit in UAE

“In the polyester value chain, we will build one of the worlds’ largest single-train PTA plant of 3 million metric tonne per annum (MMTPA) capacity at Dahej. We will also invest in a 1 MMTPAPET plant at Dahej. Both PTA and Polyethylene terephthalate (PET) will be targeted for completion by 2026. We will also reinvest in Polyester Filament Yarn (PFY) and Polyester Staple Fibre (PSF). Polyester expansion with capacity of over 1 MMTPA will be completed in phases by 2026,” added Ambari.

MUMBAI, INDIA: Indian Oil Corporation Limited (IOCL) has awarded $75 million EPC contract to Thyssenkrupp Industrial Solutions India Pvt Ltd (tkIS India) to construct a 270 KTPA Catalytic Dewaxing Unit (CDWU) for Baroda Refinery, Gujarat.

The scope of EPC of this project includes Management, Procurement, & Supply, Inspection & Expediting, Fabrication, Erection & Construction, Mechanical Completion & Pre-commissioning of Plant, Commissioning, Start up, PGTR & Hand over of plant.

The CDWU is an important unit in the production of lube base oils and finds its applications in the manufacture of lubricants.

“This contract is a significant milestone in our refinery journey and of our association with IOCL. With this very important contract award, that serves as a strong motivation to all in the organisation, we are sure we are driven towards its successful implementation. The engineering of the unit will be based on the package received from Chevron Lummus Global. The scope of EPC work of this project includes detail engineering project,” said Rajesh Kamath, CEO and managing director, thyssenkrupp’s chemical plant business, India.

In the past, tkIS India has executed multiple refineries and petrochemical projects for IOCL. Currently, it is also implementing IOCL’s n-Butanol project on an EPC basis.

“The R&D Excellence Centre at Merck enables employees with an innovation-friendly environment, encouraging their curiosity. The Centre in Bangalore aims to establish a one-team culture, delivering critical responsibilities in the drug development journey as well as develop a valuable talent pool. The R&D Excellence Centre strives to bring the best of global practices and local talent to enable the vison of enhanced patient outcomes,” said Thatte.

The six different functions which the center constitutes from its inception in 2021 are:

• Global Regulatory Affairs (GRA) harmonizes and centralizes regulatory execution, driving deliverables in strong collaboration with the global R&D functions and other R&D hubs in healthcare.

• Global Patient Safety (GPS) monitors safety of Merck’s medicines throughout their use in healthcare practice. The team collaborates with the global R&D functions and plays a significant role in integrating deep knowledge of safety into early decision-making.

INDIA: Merck India inaugurated Healthcare Research and Development Centre facility in Bangalore, offering facilities and technical expertise to support the Indian life science community. Since 2020 the Excellence centre has onboarded around 300 employees and will continue its expansion over the next 2 years.

In July, Merck announced their first microbiology application and training (MAT) lab in Jigani with an investment of €200,000 in the infrastructure.

“India has a wealth of talent and expertise in Science and Technology. At Merck, we believe that curiosity is the key to driving innovations to address current and future challenges in the society. Through the Centre, we will strengthen our presence in healthcare R&D in India, while supporting Merck Group’s global efforts in drug discovery,” said Suneela Thatte, VP and head R&D Excellence Centre, Merck.

• Global Development Operations (GDO) in alignment with the global R&D functions delivers clinical study portfolio leveraging technology and digital innovations.

• Strategy, Portfolio & Innovation (SP&I) team is responsible for interfacing cross-functional management of the Development portfolio, along with R&D digital and data transformation.

• Global Scientific Exchange and Communication (GSEC) manages scientific exchange to enhance patient care by improving efficiency and ensuring quality and consistency.

• Global Biostatistics Epidemiology and Medical Writing (GBEM) team of medical writers focuses on bringing data to life in core decision making, consistently delivering on improving medicine.

KOCHI, INDIA: Bharat Petroleum Corporation Ltd (BPCL) has started work to set up an 8.40 MW solar power plant on its Kochi refinery campus in Irumpanam.

Once completed, the plant will spread across 25 acres and will generate 123 lakh units of electricity. The project is in tune with BPCL’s goal of building a strong renewable energy portfolio of 1 gigawatt of renewable energy by 2025.

“This is another step towards enhancing the green energy capabilities of Kochi Refinery. We are continuing efforts to generate green energy through roof-mounted and ground-mounted solar power projects. In 2018 we commissioned a roof-mounted 120 kwp solar power plant,” said Ajith Kumar, executive director, BPCL.

“An MoU was signed with Solar Energy Corporation of India for leveraging their expertise in developing solar power projects,” said Shelly Abraham, renewable energy wing head, BPCL.

NEW DELHI, INDIA: Cairn Oil & Gas, a unit of Vedanta Group, celebrated the 13th anniversary of successful operations from Mangala Oil field located in Barmer, Rajasthan.

Discovered in 2004, the field which was the largest discovery that year, still considered to be India’s largest onshore discovery. According to the Cairn Oil & Gas company, the first oil discovery of oil on 29 August 2009. Mangala oil field has produced 497 mmbbls till date.

“We are happy to announce that Mangala oil field has completed its 13th year of production. The field has been instrumental in supporting India’s domestic crude production and we are confident that the field will remain relevant in the coming years as India charts its path towards energy aatmanirbharta. The field has been home to some of the finest global partnerships that have propelled innovation in technologies of oil and gas exploration and production. At Cairn, we have announced our goal to double production capacities and contribute 50% to India’s domestic crude basket and in this mission, the Mangala field will continue to play a driving role,” said Prachur Sah, Deputy CEO, Cairn Oil & Gas.

Cairn Oil & Gas contributes 25 percent of India’s domestic crude oil production. Most of the crude oil will be extracted from Mangala, and its sister fields Bhagyam and Aishwariya. Collectively, they have contributed $21 billion to the national and state exchequer as on FY’22. The cumulative production from the block has crossed 660 mmboe. Now, Cairn Oil & Gas aims to double production capacities and contribute 50percent to domestic crude production. Here too, the Mangala field and Rajasthan block will play a driving role.

The Mangala field has also witnessed crucial innovation in Enhanced Oil Recovery (EOR), use of Alkaline Surfactant Polymer (ASP) technology and the Mangala pipeline which is the world’s longest continuously heated and insulated pipeline that traverses ~705 km carrying crude from the fields of Rajasthan to refineries in Gujarat. As per the company, the pipeline will be powered by solar energy in the future. Since Cairn commenced operations, the district of Barmer has registered a 650 percent increase in per capita income.

DELHI, INDIA: Avaada Group has entered into a memorandum of understanding (MoU) with the Department of Industries and Commerce, Government of Rajasthan, to set up a green ammonia facility and a renewable energy power plant in Kota, Rajasthan. The company plans to reach 11 GW by 2025 and 30 GW by 2030.

The MoU signed is part of the Investment promotion strategy for the Investment Rajasthan Summit. It proposes an investment of Rs 40,000 crore while providing direct employment opportunities to about 3,500 people and indirect jobs to over 10,500 people

“Green energy transition is vital to the country’s Atmanirbharta and will pave the way towards net-zero goals. Aligning with the nation’s vision of self-reliance, at Avaada, we aim to make India energy independent by focusing on green energy security,” said Vineet Mittal, chair, Avaada Group.

“At Avaada, we believe that business and sustainability go handin-hand. We are grateful to the Government of Rajasthan for this partnership. It will help strengthen India’s green energy revolution, led by prime minister Narendra Modi, as we make significant investment in innovative clean energy solutions to support the country’s exponential growth in the renewable energy (RE) sector,” he added

“For industries that require high-temperature heat, such as foundries and glass and steelmakers, this could be ground-breaking as it will not only replace fossil fuels with renewable sources but also produce green ammonia and a substitute for gas,” stated Mittal.

Elaborating on clean energy technology, Mittal further explained that the biggest advantage of green hydrogen is that it burns clean, leaving only water vapor behind.

PARIS, FRANCE/ COURBEVOIE, FRANCE: TotalEnergies

announced that it has sold remaining 49 percent stake in the Russian company Terneftegaz, joint venture between TotalEnergies and Russian Company Novatek which operates the natural gas field Termokarstovoye, located in Siberia.

With this, Novatek will now own 100 percent stake in Terneftegas. This sale comes as a consequence of criticism on TotalEnergies’ in Russian business. The transfer of the share is expected to close in September 2022.

TotalEnergies will contribute their duty towards securing Europe’s gas supply from Yamal LNG plant as per the long-term contracts as long as Europe’s government do not take sanctions on Russian gas. In addition to divesting stake in Termokarstovoye gas, Total Energy unveiled their

plans to gradually suspends activities in Russia, which do not contribute to the Europe’s security of energy. This included assets producing oil (Kharyaga field) and gas for the local Russian market (Termokarstovoye field) as well as other local businesses (lubricants, batteries) which were mothballed in the first half of the year.

In July this year, TotalEnergies sold its 20 percent interest in the Kharyaga oil project to Zarubezhneft and the transfer was finalized made in August. Pursuant to Russian regulations, a request to authorize this transaction was addressed to the Russian authorities on August 8, 2022. On August 25, 2022, Russian authorities issued their agreement to the proposed sale. As a result, on August 26, 2022, TotalEnergies and Novatek signed the final sale and purchase agreement of TotalEnergies’ 49 percent interest in Terneftegaz.

concepts- direct and indirect heating- in parallel processing around 4 tons of hydrocarbon per hour and consumption of 6 megawatts of 6 megawatts of renewable energy. The demonstration plant aims to show that continuous olefin production is possible using electricity as a heat source.

“BASF’s mission is to achieve climate neutrality, and electrification of the hugely energy-intense steam cracker is a significant milestone in our transformation journey towards net zero,” said Dr. Martin Brudermuller, chairman of the board of executive directors of BASF SE. “We are proud that BASF has been granted project funding by the German Federal Ministry for Economic Affairs and Climate Action, as it is a testament to the support of our approach also by policymakers,” said Brudermuller.

commenced the construction of world’s first demonstration plant for large-scale electrically heated steam cracker furnaces at BASF’s Verbund site in Ludwigshafen, Germany. The start-up of the demonstration plant is targeted for 2023.

The project will use electricity from renewable sources instead of natural gas and reduce CO2 emissions of one of the most energyintensive production processes in the chemical industry by at least 90% compared to technologies commonly used today.

BASF will operate and invest alongside SABIC in the project and Linde will be engineering, procuring, and constructing, according to the company statement. The project also received €14.8 million ($14.8 million) in grants from German Federal Ministry for Economic Affairs and Climate Action under “Decarbonisation in Industry” funding programme. The demonstration plant will test two different heating

“Our vision is to transform our business and to help address urgent global challenges through efficient carbon management. This project holds huge potential for all of the petrochemical industry around the world in our drive for low carbon emitting processes. With the milestone we are jointly announcing today on the start of construction, we hope that our three-party collaboration can inspire many more collaborations that ultimately bring the world to net-zero greenhousegas emissions through a circular carbon economy, said Yousef AlBenyan, vice-chairman and CEO of SABIC.

“This project demonstrates how global companies can successfully collaborate by combining their expertise in technology development, engineering, procurement and construction execution and operation. The timely delivery of the demonstration plant will be a major milestone on the path to making sustainable solutions available to the petrochemical industry. We are proud to be part of this breakthrough project,” said Jurgen Nowicki, executive vice president Linde plc and CEO of Linde Engineering.

LUDWIGSHAFEN,GERMANY: BASF, SABIC and Linde Yousef Al-Benyan, Vice-Chairman and CEO of SABIC, Dr. Martin Brudermüller, Chairman of the Board of Executive Directors of BASF SE and Jürgen Nowicki, Executive Vice President Linde plc and CEO of Linde Engineering on the construction site of the world’s first demonstration plant for large-scale

GERMANY: Covestro announced it will receive two mass-balanced raw materials by INEOS Capital to produce polycarbonate plastics. Phenol and acetone, the two mass-balanced raw materials will be delivered from INEOS’ INVIRIDIS™ product range. These raw materials also support customers to achieve carbon emissions sustainability goals.

Polycarbonate plastics are used in headlights and other automotive parts and also in housings for electronic devices, light guides and lenses, medical devices, and many other high-value applications.

“As part of our sustainability strategy, we have developed these more sustainable phenol and acetone products, which we have named INVIRIDIS™. This new product range provides our customers with drop-in product options that meet their stringent quality and performance requirements. At the same time, we’re moving the industry toward a more climate-friendly economy for phenol and acetone without compromising its unique product attributes,” said Gordon Adams, business director, INEOS phenol.

INVIRIDIS™ brand phenol and acetone are produced from bioattributes cumene at INEOS Gladbeck and Antwerp sites. These both sides are certified and recognized by the International Sustainability

& Caron Certified (ISCC Plus) and Roundtable on Sustainability Biomaterials (RSB) standard. The raw materials have a lower-carbon footprint than petroleum-based products.

“By switching to mass-balanced renewable raw materials, we aim to significantly reduce our indirect emissions in the supply chain and offer products with a reduced carbon footprint,” said Sucheta Govil, chief commercial officer of Covestro. “In doing so, we’re helping our customers to meet their climate goals and advance the transition to a circular economy.”

Launched in June, these mass-balanced raw materials are the first of its kind range of bio-attributes products line for phenol, acetone alphamethylstyene(AMS). These materials are made without using fossil fuels as feedstock and they are sold under the Inviridis brand and helps in creating a lower-carbon product, noted INEOS.

“We offer them a drop-in solution that they can quickly and easily integrate into existing production processes without requiring any technical changes. The products show the same good quality as their fossil-based counterparts,” said Lily Wang, global head of the Engineering Plastics segment.

TOKYO, JAPAN: Toray Industries announced it has developed the world’s first 100 percent bio-based adipic acid, a raw material for nylon 66, from sugars derived from inedible biomass plant and crop residues.

The achievement came from using a proprietary synthesis technique combining the firm’s microbial fermentation technology and chemical purification technology that harnesses separation membranes.

It will test the polymerization of nylon 66, develop production technology, conduct market research, and take steps to commercialize applications

for this bio-based adipic acid by 2030. The firm highlighted that nylon 66 has been used for many years in fibers, resins and other applications due to its exceptionally durable, strong and rigid properties.

The company confirmed that they are the first in the world to discover microorganisms that produce adipic acid intermediate from sugars. The process led bioinformatics technologies to design optimal microbial fermentation for synthesis. Quantity of the intermediate synthesized by microorganisms has increased more than 1,000-fold since the initial discovery and the efficiency of synthesis has improved dramatically, it said.

CANADA: HUDSON Resources and Neo Performance Materials have signed a binding agreement under which NEO will acquire an exploration license for the Sarfartoq Carbonatite rare earth (RE) complex in Southwest Greenland.

The project hosts a mineral deposit that is enriched in neodymium and praseodymium, key elements for rare earth permanent magnets. These two essential elements are used in electric vehicles, wind turbines and high-efficiency electric motors and pumps that help reduce greenhouse gas emissions, the company said.

Located 60 kilometers from the international airport in Kangerlussuaq, the project is close to tidewater and a major port facility and is directly adjacent to some of the best hydroelectric potential in Greenland. The Sarfartoq carbonatite complex used to host two Hudson’s project- ST1 REE and the Nukittooq Niobium-Tantalum project in Greenland. The REEs on the property have a high ratio of neodymium and praseodymium at 25-40 percent of total rare earth oxides.

It has completed a Preliminary Economic Assessment on the ST1 project in November 2011 that outlined a National Instrument 43-101 complaint resource containing 27 million kilograms of neodymium oxide and 8 million kilograms of praseodymium oxide. Three kilometres east of the ST1 Zone is another high-grade zone (ST40) that contains highest-known ratios of neodymium oxide for rare earth oxide, Hudson said.

Through a special purpose entity (SPE), Neo stated it plans to develop the Sarfartoq project and expand the rare earth supply chains at their rare earth separation facility in Estonia. The Sarfartoq project also is a key element of Neo’s “Magnets-to-Mine” vertical integration strategy.

“We are very pleased to have signed this agreement with a global leader in the production of advanced materials. As the world faces critical shortages of rare earth elements outside of China, we are pleased to help bring the Sarfartoq project a step closer to commercial reality. This deal

provides a significant cash injection to the company and importantly, also gives Hudson shareholders potential significant upside in the future value of the Sarfartoq projects through equity or additional consideration,” commented Jim Cambon, Hudson’s president.

The key terms of the agreement are as follows:

- Hudson receives a non-refundable initial cash payment of $250,000 upon signing of the agreement.

- Upon receipt of approval from the Greenland government, Hudson will transfer the license to Neo or the SPE.

- Hudson will receive an additional $3,250,000 upon closing of the transaction.

“Neo continuously pursues supply chain optionality in order to ensure that our customers have a dependable supply of engineered rare earth products. Once in production, this project will significantly increase the diversity of global rare earth supply for our processing facilities around the world. It also is another step in our Magnets-to-Mine vertical integration strategy,” said Constantine Karayannopoulos, Neo’s president and chief executive officer.

“Based on our significant experience in assessing strategic mineral resources around the world, we believe the Sarfartoq resource in Greenland is a strategic asset that uniquely complements Neo’s European rare earth magnet growth strategy. This resource would supplement our current supply of rare earth concentrate from Energy Fuels in the US,” said Karayannopoulos.

Neo and the SPE to conduct additional exploratory drilling and other work to move the project forward to eventual commercial operation. Neo also intends to enter into an offtake agreement with the SPE with rights to purchase 60 percent of the ore or mineral concentrate produced from the project.

specialist Grupo Antolin and BASF subsidiary TrinamiX GmbH collaborated to develop biometric solution by integrating face authentication into new product lines.

The two companies will present automotive OEMs the solution to enhance future driving experiences.

Antolin will take advantage of its experience and knowledge in smart surface to offer exterior human machine interface (HMI) systems. On the other hand, trinamiX Face Authentication operates on claimed unique patent protected algorithms, which verify a person’s liveness based on skin detection.

The combination of software and hardware has the potential to authenticate drivers based on their biometrics as soon as they get close to their car. While allowing for a stronger data protection and premium

performance, the solution comes with low hardware requirements for a seamless and easy integration.

“By incorporating biometric solutions into our components, we can offer our clients added value systems that combine lighting, electronics, and smart surfaces with face authentication,” highlighted Marta Cuevas, Grupo Antolin Lighting & HMI business unit director. “trinamiX Face Authentication has proven to reliably keep up its high performance even under particularly challenging conditions. This trusted performance is what makes the solution the perfect addition to our growing, innovative portfolio.”

“Grupo Antolin and trinamiX share a common goal. Providing consumers around the world with higher comfort and security. We are happy that we can contribute with extensive knowledge and a strong network on this exciting path,” said Wilfried Hermes, director business development at trinamiX.

LUDWIGSHAFEN, GERMAN/BURGOS, SPAIN: Interiors

INDONESIA: Lenzing Group, leading provider of wood-based specialty fibers, said it is expanding its global clean electricity portfolio and reducing carbon emission at its production site in Purwakarta.

The Indonesian subsidiary PT. South Pacific Viscose (SPV) has been using electricity generated solely from renewable sources since July this year, which will reduce its specific carbon emissions by 75,000 tonnes annually.

Not just carbon emissions, Lenzing is aiming to reduce the air and water emissions by 2030 and become climate neutral by 2050. The company will invest 100 million Euros in Purwakarta area and gradually transition its existing capacities to LENZING™ ECOVERO™ and VEOCEL™ branded specialty viscose.

“Demand for our wood-based, biodegradable specialty fibers is constantly rising. We see enormous growth potential, especially in Asia.

The switch to green, renewable electricity marks a huge step forward in converting our Indonesian site into a specialty fiber supplier. This makes us better positioned to meet the growing demand for sustainably produced fibers,” said Robert van de Kerkhof, chief commercial officer for fiber.

Specialty fibers are Lenzing’s key strength. The company aims to generate more than 75 percent of its fiber revenue from the woodbased, biodegradable specialty fibers business under the TENCEL™, LENZING™ ECOVERO™ and VEOCEL™ brands by 2024.

With the launch of the lyocell plant in March, in Thailand and the investments in existing production sites in Indonesia and China, the share of specialty fibers in Lenzing’s fiber revenue is set to exceed the 75 percent target by a significant margin as early as 2023.

will replace professor Fei Fei Li, who stepped down from the board at the end of August due to personal medical reasons.

Since 2022, Mathisen has been a non-executive member of the board of directors of Aker Biomarine ASA in Norway. In 2021, she was CEO of HUB Ocean, an independent non-profit foundation, a joint initiative of Aker Group and World Economic Forum with a global ocean mandate. In 2016, Mathisen joined Microsoft Corporation as General Manager with responsibility for the company’s entire business in Norway.

In 2013, she was appointed CEO of the home & personal care division of the Norwegian branded consumer goods company Orkla. Before that, she joined the pharmaceutical company Eli Lilly and held a variety of positions with growing responsibility in the UK, Norway and Germany. She has also worked for Procter & Gamble in the US.

“We are delighted that we will be joined by Kimberly Mathisen. She is an outstanding personality who has more than 20 years of international experience in digitalization, technology, branded consumer goods and the pharmaceuticals business,” explained professor Norbert Winkeljohann, chairman, supervisory board of Bayer AG.

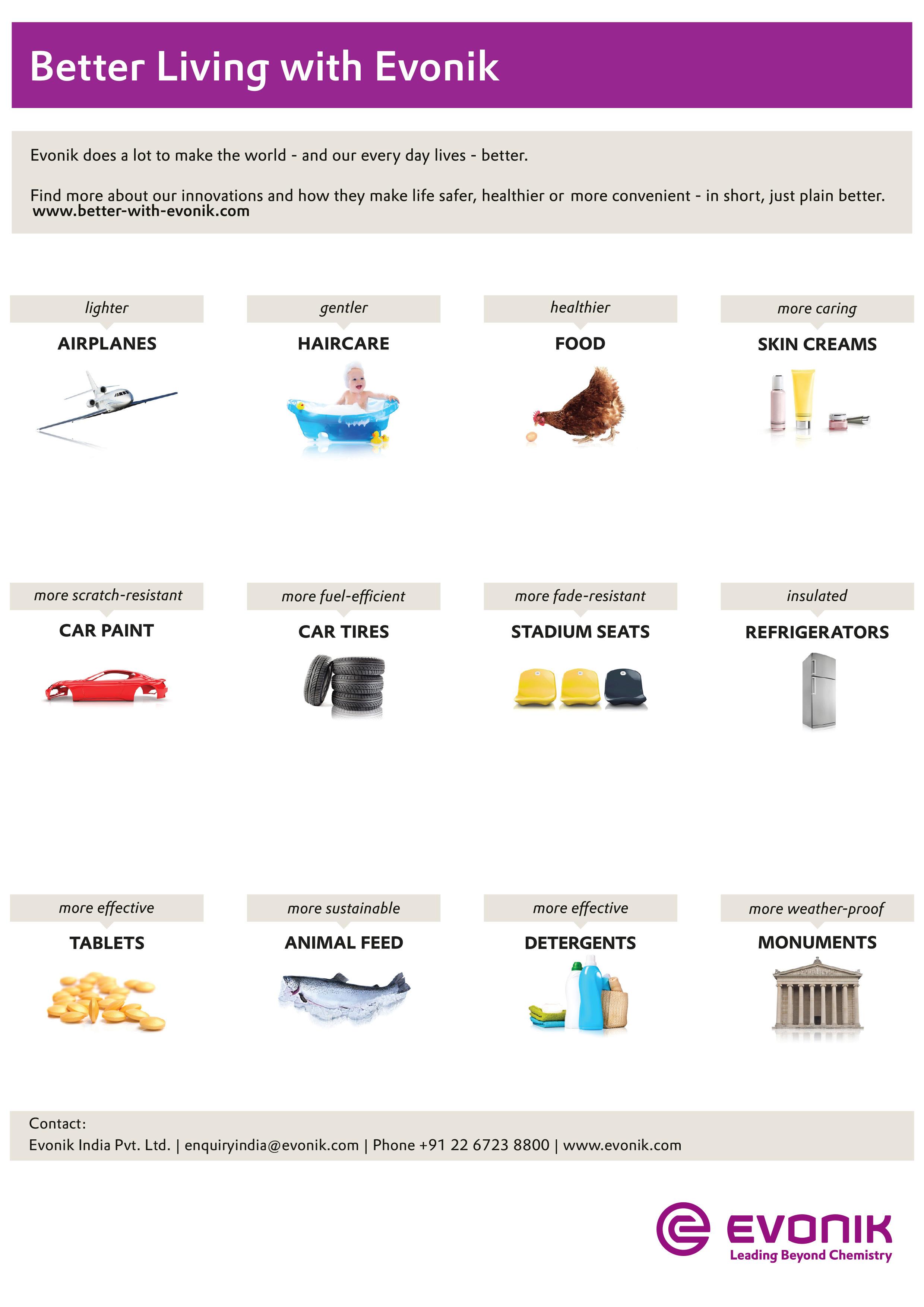

UAE: Evonik said it has appointed Joerg Syrzisko as the new president of Middle East & Africa (MEA), succeeding Hendrik Schoenfelder, who has taken the position of regional president for Evonik in Central and South America.

Prior to joining Evonik in 2017, Syrzisko held several international management positions in the healthcare and chemical industries since 1989.

Evonik opened its first offices in Egypt, marking the start of the company’s presence in the Middle East and Africa (MEA). As a cluster with over 150 employees covering the United Arab Emirates (UAE), Saudi Arabia, Iran, Egypt, Jordan, South Africa, Ghana and Kenya.

With a hydrogen peroxide plant in South Africa and a superabsorbent manufacturing facility in Saudi Arabia, Evonik also has animal nutrition activities in South Africa and Kenya, as well as silica activities which is also in South Africa.

AMSTERDAM, NERTHERLANDS: AkzoNobel announced that Gregoire Poux-Guillaume will become the company’s new chief executive officer, effective on 1 November. Poux-Guillaume will succeed Thierry Vanlancker, who has been CEO and management board member since 2017, as his office term is coming to an end.

Poux-Guillaume’s previous roles include CEO of Sulzer, CEO of GE Grid Solutions (previously Alstom Grid) and senior managing director of CVC Capital Partners.

“I would like to welcome Gregoire Poux-Guillaume, who is an experienced business leader with an impressive track record of delivering results, growth and building strong teams. His experience will play a key role in helping the company to further improve its operational excellence and performance,” commented Nils Smedegaard Andersen, chair of AkzoNobel’s supervisory board.

After becoming the president of ELANTIS, Kumar will also become a member of ALTANA’s executive management team, as of 1 January. Jan Behnke will fill in the position of Kumar in ELANTAS PDG as the managing director for sales and technology in the US company.

Kumar has been managing director of ELANTAS PDG in St. Louis, since August 2019. He has worked in the chemical industry for 26 years. In the first 15 years of his career, the chemical engineer held various sales and marketing positions at Asian Paints, BASF and Huntsman in India.

“Ravindra Kumar is distinguished not only by his excellent professional competence and international management experience; he is also a true team player who understands how to achieve top performances with good cooperation – in keeping with ALTANA’s corporate culture,” said Martin Babilas, CEO, ALTANA AG.

WESEL, GERMANY: ALTANA has announced a change in their composition of its presidentship at ELANTAS, division specializing in innovative insulating and protective coatings. By the end of the year, Dr. Guido Forstbach will retire and will hand over the worldwide leadership of ELANTAS to Ravindra Kumar, who is currently the managing director of ELANTAS PDG in St. Louis.

Forstback joined ATLANA group in 2000 as MD of ACTEGA Rhenania. He became president of the ACTEGA division in 2001. As part of the rotation of all four of ALTANA’s division presidents, Forstbach became head of ELANTAS in November 2012.

“Guido Forstbach has successfully managed two divisions over a period of more than 20 years and has thus played an essential role in helping to shape ALTANA’s sustained success,” said Babilas.

join the Nutrien board of directors. He brings more than 25 years of global management experience working across 60 countries and more in agriculture and mining sector.

Previously, Nutrien Ltd board of directors announced that Mayo Schmidt had left his position as president and CEO of Nutrien and had named Ken Seitz, EVP and CEO of Potash, as the company’s interim CEO effective January.

“Nutrien’s record performance and disciplined execution of strategy during some of the most turbulent times we have seen globally underscore the strength of Ken Seitz’s leadership. As the company’s president and CEO, Seitz will continue to drive positive outcomes for all our stakeholders as we strive to safely and sustainably feed the world,” said Russ Girling, chair, Nutrien board of directors.

SASKATOON, CANADA: Nutrien Ltd said it has appointed Ken Seitz as president and CEO, effective 8 August. Seitz will also

“Growing up on a dairy farm in Saskatchewan, I am honored to work alongside growers during these challenging times today and going forward. Nutrien is extremely well positioned to help meet the global goals of food security and climate action, partnering across the food system. Our purpose is to feed the future, and I am invigorated by the noble pursuit to help solve these critical world needs,” said Seitz.

KOLKATA, INDIA: Linde India Ltd said it has appointed Neeraj Kumar Jumrani as the chief financial officer (CFO) effective 9 August, as the earlier CFO has resigned from his position. He last worked in PT. Linde Indonesia as head of finance for Linde Plc’s gases business in Indonesia, Philippines and Vietnam.

Jumrani had joined Linde India Ltd in 2006 and brought in 18 years of experience in different sectors within Linde Plc Group of companies. He worked for 16 years in various finance department such as tax management, internal controls, financial planning & controlling with Linde India Ltd.

The board of directors of the company had on recommendation of the nomination & remuneration committee and audit committee of the board respectively approved Jumrani as the CFO of the company.

DOMO Chemicals is a key polyamide player equipped with one of the world’s most modern polymerization lines for staple fiber. The company is committed to achieving performance breakthroughs in polyamide 66 fibers. This is clearly shown by its new NYLEO® line of polyamide 66 value-added solutions. These include innovative products for flame retardancy, biodegradability and inhibiting bacteria.

The new brand name for DOMO’s Performance Fibers product line, NYLEO® represents the strong synergy of our rich heritage in the polyamide 66-based fiber market and an intense focus on innovation. Thanks to its unique properties, this pioneering fiber can be used in numerous applications in the textile, flooring, automotive and industrial markets. These offer consumers state-of-the-art solutions to meet their demanding requirements when it comes to health, safety and sustainability.

NYLEO® PROTECT fibers offer improved flame retardancy, NYLEO® 4EARTH® fibers provide enhanced biodegradability, and NYLEO® SAFE fibers feature bacteriostatic properties. The NYLEO® value proposition represents a new milestone in DOMO’s enhanced offering of sustainable solutions.

Based at our Valence site in France, our DOMO Performance Fibers teams work passionately to create unique fibers designed to meet key market needs. We have been producing world-class polyamide 66 fibers since 1955 for such industries as nonwovens for polishing, surface treatment, tennis balls and aerospace, worsted and semiworsted for flooring, flocked fabric for upholstery, automotive interiors, packaging, and many other consumer products.

The NYLEO® brand now represents the full range of polyamide 66 products, including staple fibers, crimped tow and tow for flock. These are well known for their superior resilience, outstanding abrasion resistance, higher tenacity, good dyeability and color fastness, consistent quality, and soft touch. NYLEO® now also means

cutting-edge innovation with our new line of polyamide 66 fibers. NYLEO® PROTECT for flame retardancy

With the aim to contribute to higher levels of safety in the clothing, furniture and transportation sectors, DOMO has developed a new flame retardant polyamide 66 fiber.

NYLEO® PROTECT combines all the advantages of polyamide 66, such as mechanical properties, comfort, low specific weight and outstanding abrasion resistance, with better flame retardancy. The limiting oxygen index (LOI) of NYLEO® PROTECT has been improved up to 28 percent, which is the level of typical flame retardant fibers.

Thanks to its unique properties, NYLEO® PROTECT offers a wide range of qualities to enhance product performance, including the workwear segment. Our global customers rely on DOMO’s performance fibers because they are particularly resistant and resilient, including for under and outer garments for firefighters, military, construction and trades functions.

Our fiber is antimony-, halogen- and bromide-free and is OEKOTEX® certified. NYLEO® PROTECT is available in a broad range of solutions, including staple fibers (from 1 to 30 Dtex; cut length from 38 to 155 mm), tow for flock or short cut fibers (from 1 to 30 Dtex) and crimped tow (from 2.2 to 6.7 Dtex). NYLEO® PROTECT has an outstanding density of 1.14 g/cm3.

In comparison to polyester FR, Modacrylic, Viscose FR, Metaaramid, cotton FR or wool, NYLEO® PROTECT polyamide 66 displays a higher tenacity, enhanced mechanical properties and excellent abrasion resistance.

More and more manufacturers are concerned about sustainability and the circular economy, and seek to reduce their impact on the environment through better waste management, among other actions.

This applies to the textile industry as well, since the pollution it generates has a significant impact on the planet and the textile value chain is a major contributor to landfills, where most clothing ends its life.

To be more sustainable, manufacturers will need to redesign production to make it easier to manage the end-of-life of products and waste. For this reason, DOMO has developed this new fiber, which demonstrates enhanced biodegradation when landfilled.

While a traditional polyamide 66 fiber decomposes in about 50100 years, NYLEO® 4EARTH® with enhanced biodegradability decomposes within only five years. Its unique composition allows bacteria to gain access to and digest the waste materials, thus accelerating the biodegradation process.

Like other biodegradable products, once landfilled, NYLEO® 4EARTH® polyamide 66 fiber with enhanced biodegradability breaks down into organic matter (biomass) and biogas (methane).

Within five years, more than 90 percent of the fiber is converted into biogas, with the remainder as biomass residues. Moreover, in well controlled landfills, methane is not released directly into the atmosphere, but burned or reused for power generation.

By offering enhanced biodegradability to safeguard the environment while maintaining all the standard characteristics of polyamide 66, including durability, long life, high tenacity, soft touch, and abrasion resistance, NYLEO® 4EARTH is the optimal solution for sustainable fiber applications.

With bacteria propagation becoming a health concern of increasing urgency, DOMO has developed NYLEO® SAFE fiber to fight this problem. A bacteriostatic agent is introduced into the polymeric matrix, creating a long-lasting effect to protect the fibers and

inhibit the growth of bacteria, while maintaining all the standard characteristics of polyamide 66 fibers like comfort, mechanical resistance and durability.

NYLEO® SAFE features a powerful and compliant solution of silverbased ions. Silver is widely used for human contact applications and is known to be effective against a broad spectrum of microorganisms that cause odor, discoloration, biofouling and other aesthetic problems.

Thanks to this technology, we can better control the level of bioactivity and the bacteriostatic properties, which are resistant to washing as the agent cannot wash out. NYLEO® SAFE provides a proven, longlasting effect even after 100 washing cycles, and a significant effect with a 20 percent blend of NYLEO® SAFE fiber with other nontreated fibers.

According to laboratory tests under the best standards, over 99.99 percent of bacteria are inhibited on pure polyamide 66 fabrics with bacteriostatic fiber after 24 hours of contact with bacteria like staphylococcus aureus or klebsiella pneumoniae.

DOMO Chemicals is a leading engineering materials company and highly integrated solution provider committed to the sustainable future of polyamides. Caring is our formula to create value – for our customers and consumers, for our teams and our people, for our shareholders as well as for the wider society and communities in which we operate.

The NYLEO® brand represents an important step in our quest to strengthen DOMO’s polyamide-based performance fibers business. It’s also a key milestone in our sustainability journey, as we endeavor to support our customers through our enhanced offering of sustainable solutions.

Author: Olivier Huang is Sales Director, Performance Fiber, Nyleo at DOMO Chemicals.

Every industry is looking for sustainability wins these days, so the latest innovation from DSM Engineering Materials should come as muchneeded good news for the markets we serve. The company has recently developed a 100 percent bio-based polyamide, one that performs just as well as its fossil-based equivalents whilst carrying a 50 percent lower carbon footprint.

For those in the automotive, electronics, and consumer goods industries, Stanyl Bio-Based Mass Balanced (B-MB) is a clear stepping stone on the path to net-zero, while for chemists in any sector, this new approach reminds us that a greener world is within reach.

This product is the latest – and most sustainable – addition to our Stanyl PA46 range. All solutions within the Stanyl PA46 portfolio offer three core properties: high-temperature mechanical performance, superior flow and processing, and distinguished wear and friction resistance.

What is unique about Stanyl B-MB, however, is a substantial reduction in planetary impact. This sends a message to the rest of the value chain: we have a solution, and it works. We hope this resonates with organizations trying to meet ambitious climate targets of their own. All our connected industries are under similar pressure to make business operations more sustainable, so adopting a 100 percent bio-based polyamide can make a significant contribution to meeting these goals.

Since the 2015 Paris Accords, the world has agreed on a clearly defined climate target – net-zero by 2050 – and many governments have subsequently enshrined this into law. Product and operational innovation are essential to meeting these targets. To make the world habitable for generations to come, we need everyone in the value chain to play their part in radically transforming industrial production.

In over three decades at DSM, I’ve seen the company become a true sustainability frontrunner. Since closing our last coal mine in 1973, the company has evolved dramatically by placing ever-greater focus on planetfriendly solutions and technologies.

In 2018, we defined our official purpose as “creating brighter lives for all”, directly aligning our executive pay and strategy with the UN’s Sustainable Development Goals and how much progress we make toward them. We at DSM Engineering Materials have also made a binding commitment to providing bio-based and recycled-based alternatives for our entire product portfolio by the year 2030.

As part of this endeavor, DSM Engineering Materials has been tackling the challenge of de-fossilizing polyamides – an issue with ramifications all along the value chain. Our latest product, Stanyl B-MB, is a major step forward in the field of sustainable high-performance polyamides.

Like most innovations, this one did not happen overnight. Stanyl PA46 has a product history stretching back more than 30 years. Ever since its launch, it has been the world’s most widely used high-temperature polyamide, and today, it can be found in multiple applications across the automotive, electronics, electrical and consumer goods industries.

Creating a bio-based Stanyl alternative that retains the aforementioned core qualities of PA46 has involved years of sustained effort. We had a breakthrough in 2019, when we first developed a 40 percent bio-based mass balanced Stanyl B-MB. This was a big step toward sustainability: of the two monomers used in our process, we had successfully made one of them available via the bio-based mass balancing route.

Soon after that, we discovered how to derive the other monomer from natural sources via the mass balancing route. But even with the chemistry figured out, there was still a way to go before launch. We needed to offer decisive proof that our method is, indeed, 100 percent bio-based.

And so, the amount of bio-based materials in Stanyl B-MB is verified based on the International Sustainability and Carbon Certification (ISCC plus)-certified mass balance approach. The extensive ISCC certification process was at least as challenging as the product research – if not more! But it was a crucial step. Resolving this issue has given us a firm foundation to make our case to our customers and partners across the value chain.

Same high performance, enhanced sustainability

In using this renewable feedstock for Stanyl B-MB, the performance, quality, and durability of the final product are unaffected: the monomers function the same as if they were derived from hydrocarbons. Stanyl B-MB offers the same high levels of crystallinity that have made previous editions of the product so valuable.

Switching to 100 percent bio-based feedstocks has cut the product’s carbon footprint in half. For every ton of Stanyl B-MB produced, we have achieved a 3.3-ton reduction in CO2 emissions. That is the equivalent of charging 420,000 smartphones or powering a home for half a year!

Inspiring the value chain to make a difference Stanyl is an essential component in the electronics and automotive industries. Our product is used in almost every smartphone device, and in nearly 40 million gears in 100 million automotive actuation systems each year. Both industries are acutely aware of the need to move toward netzero, and this pressure is especially intense for the automotive value chain.

In December 2020, the European Commission presented its Strategy for Sustainable and Smart Mobility, stating that “we must shift the existing paradigm of incremental change to fundamental transformation” – in other words, that the automotive industry needs to move faster on sustainability.

For this to be successful, the Commission maintains, manufacturers need to do more to internalize external costs. Other industries have already taken this step, accepting that sustainable solutions carry a slightly higher price (at least for now). Within the broader context of the European Green Deal and stronger climate legislation around the world, we hope that forward-thinking members of the auto industry will embrace Stanyl B-MB, incorporate it into their designs, and enjoy the same high performance whilst contributing to a greener world.

The average car has 30,000 parts, often from dozens of different countries. Stanyl B-MB is just one of these many parts, and therefore offers only part of the answer when it comes to environmental compliance. But its development shows the automotive industry, and other sectors too, that biobased products can take the place of traditional fossil-based solutions without sacrificing performance.

Beyond that, it can inspire other component manufacturers to redouble their efforts and achieve similar innovations. We hope that, before long, every component in a car will be produced as sustainably as Stanyl B-MB.

Further innovations on the horizon Achieving net-zero emissions and creating a circular economy are two enormous challenges, and our work is far from over. The manufacturing process for Stanyl B-MB still emits some carbon, so our next goal is to reduce this as much as possible. Furthermore, DSM Engineering Materials is making good progress on other problems, such as implementing recyclingbased solutions. Like many in the industry today, I am fascinated by the development of pyrolysis oil as derived from advanced recycling of mixed plastic waste – another crucial piece of the sustainability puzzle.

In the medium term, I also expect other chemical recycling methods to continue working their way up the agenda. With so many developments and innovations occurring, it is an exciting time to work in this field. Let’s hope we can report a new breakthrough within the next five to ten years!

Author: Bert Havenith is Sustainability Director and Strategic & Market Intelligence Director at DSM Engineering Materials.

Lean and efficient kitchen designs are making a comeback to reflect the current trend for practicality and healthy living. Thus, convenience and safety are prioritized in modern yet functional kitchen designs.

Here the global TPE manufacturer of a diverse range of thermoplastic elastomer products and custom solutions for a variety of industries KRAIBURG TPE, offers the THERMOLAST® K FC/AD1 and FC/AD/ PP series of TPE compounds for kitchenware applications.

Based on this, ergonomic kitchenware is designed to help make food preparation less of a chore and more of a joyful experience. For this reason, advanced materials such as thermoplastic elastomers (TPEs) are becoming more popular as kitchen utensils. The company offers highquality and custom-engineered TPE compounds that allow kitchenware manufacturers to benefit from the food-safe, flexible and soft-touch feel of TPEs.

THERMOLAST® K compounds, offerings from the company have exceptional durability and mechanical qualities. It gives products a

unique smooth touch and silky surface, anti-slip qualities, with varied color options.

Additionally, its high elasticity; heat resistance and good abrasion, as well as flexibility makes it ideal for a wide range of utensils, such as spatulas, spoons, colanders and many more.

Similarly, the TPE material’s tactile nature and anti-slip properties improves the grip of implements such as kitchen knives and kitchenware handles.

With outstanding adhesion qualities to polar thermoplastics such as ABS, PC, and PC/ABS, the THERMOLAST® K compound is able to adhere to a variety of materials, allowing for flexibility in designing kitchenware products.

KRAIBURG TPE’s FC/AD1 series of compounds’ feature a dry haptic advantage, allowing a silky surface and comfortable grip for kitchenware such as the handles of knives and food-cutting scissors; grips for bottles, spatula grips, and other utensils.

The food-approved series complies with a wide range of regulations including EN71-3, Regulation (EU) No 10/2011, US FDA CFR 21 (raw material conformity), and UL 94 HB. The FC/AD1 series also adheres well to PC, ABS, PC/ABS, ASA, SAN, PET, and PETG, and offers a wide hardness range of 30-90 Shore A, making it excellent for use in a number of kitchenware applications.

Meanwhile, KRAIBURG TPE’s FC/AD/PP series of compounds conforms to known food contact regulation such as China GB48062016, US FDA CFR 21 and Regulation (EU) No 10/2011, as well as the regulatory norms of the Asia Pacific market.

Other features include the good mechanical properties and a silky, nonsticky surface, which is especially useful in food preparation applications such as chopping boards. With a hardness of 30-90 Shore A, this series is the choice material for most everyday applications.

In addition to ensuring product quality and safety, KRAIBURG TPE’s compounds are highly colorable, adding an aesthetic dimension to the overall product design.

The company’s in-house coloring team can provide the correct shade of colors and promptly distribute color samples with excellent delivery times with guaranteed color quality consistency all over the world.

Besides the materials for kitchenware, KRAIBURG TPE’s recent sustainability innovations include a specially developed material solution for automotive, medical, and industry applications comprising post-consumer recycled (PCR) and post-industrial recycled (PIR) content.

Digital technology for chemical distribution, supply chain in Asia Pacific and India.

Digitalization and data driven insights are key drivers of growth for the industry, and are ways of ensuring the ability to meet customer demands and business needs. At Azelis, our digital strategy has allowed us to keep a closer, real-time connection with customers and principals.

We have rolled out customer-facing digital platforms such as the Customer Portal and e-Lab, which provide customers with insights into trends, product information, and 24/7 access to our innovation capabilities and technical expertise. All this is supported by a cloudenabled technology backbone comprised of a centralized data lake, product information management solution, and customer relationship management tool.

Utilizing our master data management team based in India, Azelis leverages data to assist in pinpointing where our innovation efforts should focus to support the sustainable growth of our business. Data gives us a clear understanding of the needs of our customers, and allows us to better understand where we can improve our systems and increase global efficiency.

Company’s future strategies and roadmaps for growth.

Our mergers and acquisitions (M&A) are part of our group strategy to accelerate growth in the region and complete the lateral value chain

(LVC) in each of our strategic markets through strategic acquisitions. We actively search for the right acquisition candidates in target geographics and industries. This allows us to offer a larger coverage for our principals and enhance the portfolio offered to our customers.

We look for companies with a strong focus on specialties, technical expertise, formulation, and application development. What is essential is not only commercial strategic fit, but also the company must share our values and ambitions.

To support our M&A strategy from sourcing to integration, we have created new positions in our regional headquarters in Singapore and hired employees to ensure a successful end-to-end M&A plan. This also allows us to focus on integrating companies successfully into Azelis, finding synergies and creating a stronger combined company together.

R&D and innovation in chemicals distribution and supply chain.

Azelis’ ambition is to develop a globally connected network of innovation through our labs, that allows us to leverage insights and trends and enhance our formulations and technical expertise for all the markets we serve in the chemicals industry.

In Asia Pacific, we have over 20 dedicated application laboratories across market segments including Personal Care, Food & Nutrition, CASE and more. We recently inaugurated our Regional Innovation Center for Food & Nutrition in Singapore, that will articulate and orchestrate innovation across Asia Pacific for that market segment, collaborating closely with our local application labs to work as one team with one goal: to develop innovative formulations.

Thanks to our combined technical knowledge across the region, we are able to deliver ground-breaking formulations matching the unmet needs of the consumer market, and with our network of laboratories, we will be able to pro-actively develop conceptual formulations that allow manufacturers to tap into new markets and opportunities, while also providing localization of trends for specific countries. Our vision is to be a driver for positive and sustainable change within the chemicals industry through innovation.

Sustainability strategies for chemicals distribution and supply chain.

We are honoured to be awarded the EcoVadis Platinum rating, which puts us in the top 1 percent of companies assessed, and is a strong reflection of our commitment to sustainability. In tandem, we have developed our sustainability strategy, Action 2025, which is an integral part of our identity and business model.

As part of our Action 2025 plan, we have four pillars (People, Products & innovation, Governance and Environment), and we actively work across all four towards goals such as increasing our gender diversity ratio for senior management, increasing the percentage of our revenue that is covered with ESG assessed suppliers, reducing our carbon intensity, and ensuring zero material breaches in laws and regulations.

We also partner with Together for Sustainability (TfS) to assess the sustainability protocols of our suppliers, and help them develop their own sustainability practices and improve standards across the value chain. Being part of TfS and assessing our suppliers allows us to take action to influence sustainability within the chemicals and supply chain industry. Our sustainability goals are also linked to our innovation capabilities.

We aim to advance the sustainability agendas of our stakeholders, by leveraging our LVC and technical expertise to develop new or alternative sustainable formulations, cascading sustainable materials into the supply chain and innovating for a better tomorrow.

Opportunity for sourcing of renewable, recyclable, biobased chemicals for distribution and supply chain.

Sustainability is engrained in everything we do, which is why

we are actively reviewing our portfolio to identify sustainable products, which can then be used to develop sustainable formulations, and also allow us to suggest sustainable alternatives to our customers. This is especially important as consumers are increasingly more conscious about climate change and desire a more sustainable lifestyle.

Consumer demand focuses on products that support or minimize their own impact on the environment, especially eco-friendly products. We partner with blue-chip principals to ensure our portfolio contains a range of sustainable products to meet this requirement from consumers. We see strong demand for sustainable formulations, especially in Asia Pacific and India, from the Personal Care, Agri and Food & Nutrition market segments especially.

Our team of experts have already been working on plantbased alternative concepts, for example we recently assisted a customer with developing and launching a new oat milk for the Indian market. We plan to continue on this path, exploring further options to provide plant-based alternatives, which is also in line with our sustainability ambitions.

Challenges faced in chemicals distribution and supply chain in Asia Pacific and India.

Markets have been impacted by raw material shortages, supply chain disruptions, inflation, and price increases of raw materials. This has led to more instances of shortages of certain ingredients, increasing demand across the industry. Many other elements are also influencing these shortages, including geopolitical situations, which is affecting access to raw materials.

For Azelis, this presents an opportunity to focus even more on providing innovative and sustainable solutions to support customers with their challenges in this area. By combining our extensive portfolio of products and deep technical expertise, we are able to offer complementary products for formulations or sustainable alternatives to ensure customer requirements for certain products are met, assisting with business continuity.

Our team proactively proposes alternative products or formulations to address these issues, while working in close collaboration with our principals and suppliers to ensure their requirements are met. Innovation through formulation is our tagline and our mindset, where we demonstrate the value we bring by providing innovative solutions.

BY SHIVANI MODY

BY SHIVANI MODY

Macro economic trends, future dynamics in pulp & paper industry.

Global economy is passing through a challenging phase with threats of inflation looming large and rising interest rates. Russia-Ukraine conflict has queered the pitch putting paid to the post pandemic recovery. There is all round uncertainty in the global economic environment. Supply chain disruptions following the pandemic were already a drag on the economic recovery.

With threat to energy security and soaring commodity prices following the Russia-Ukraine conflict, the challenge for all the economies have gone up multifold, India being no exception. Though based on economic parameters, the Indian economy appears to be better cushioned against the uncertainties as compared to other large economies.

As a leading manufacturing sector, pulp & paper industry in India is also facing the onslaught especially since the sector is energy intensive and also import dependent for several raw materials and inputs. Major impact has been on the availability of pulp and wastepaper, and also coal.

However, the domestic demand seems to have revived after two years of disruptions. After the opening of schools and colleges, there has been a positive impact on demand for writing & printing paper. Office paper consumption is also witnessing recovery. A major shot in the arm has been the continuing demand for packaging paper and paperboard following the e-commerce revolution sweeping the country.

On a long-term basis, India’s paper industry is in a sweet spot. The consumption is projected to go up with the growth of the economy. The per capita consumption of paper in India is a low 15 kgs as compared to the global average of 57 kgs and 200+ kgs in developed

Rohit Pandit, Secretary General, Indian Paper Manufacturers Association (IPMA) delves into the journey of the pulp & paper industry and the opportunities that the tides of economic disruption can bring for this industry to sail through.

countries. Therefore, growth is bound to take place as the Indian economy grows.

The sustainability of paper is also being recognised. The ban on single use plastic has led to increased demand for paper for several applications. On its part, the industry is innovating to produce paper for all different requirements. With Government’s sustainability drive gathering momentum and consciousness to use sustainable products growing, paper as a biodegradable and recyclable product will benefit in the times to come.

Opportunities for the pulp & paper industry in India.

Paper industry is one of the traditional manufacturing sectors in the country having played a key role in India’s independence as paper was the medium through which our freedom fighters reached out to people at large and mobilised opinions. In independent India, the industry has continued to play a distinct role in meeting national objectives of education for all (Sarv Shiksha Abhiyan) and rural employment notwithstanding the challenges. As India completes 75 years of independence, it is important to recognise the unique contribution of the paper industry.

Agro / farm forestry is the principal source of wood for the paper industry in India, whereby over 1.2 million hectares of largely degraded land of the farmers has been brought under pulpwood cultivation. Over 5 lakh farmers are involved in the paper industry led agro-forestry programme. The paper industry is intensely involved in R&D. Pioneering work has been carried out by the industry over the last three decades in producing tree saplings which are disease and drought resistant and can be grown in a variety of agro climatic conditions.

Improving international trade with Asia Pacific and global markets.

For widening its export footprint, paper industry in India needs a level playing field available to its counterparts in other major paper producing countries. These include adequate availability of raw materials at competitive prices, export incentives to increase international trade, and also a level playing field domestically to compete with duty-free imports coming into India under the different free trade agreements.

No doubt, the paper industry is energy and water intensive. However, the industry, especially the organised players, have been working on reducing the environmental footprint. The industry has worked hard on reducing specific energy consumption. Under the PAT (Perform Achieve Trade) scheme of the Government, under the National Mission for Enhanced Energy Efficiency (NMEEE), the Paper Industry has been one of the top performing sectors, and has over-achieved the mandated stiff targets.

In fact, the industry has managed to bring down its energy consumption by about 20 percent in the last five years. Integrated paper mills in India generate over 40 percent of the power they use by utilising the biomass from the pulping process. Till a few years ago, the industry used to consume 200 cubic metres of water to produce a tonne of paper. Now, the integrated mills have reduced that to under 50 cubic metres.

A rising tide lifts all the boats. As the industry grows in size and scale, all the associated sectors, including chemicals used by the paper industry will find new avenues for growth. Indian manufacturing has received a fillip with the Government putting some checks on indiscriminate imports for realising the vision of AatmaNirbhar Bharat. The rules of origin have been tightened under the free trade agreements.

Directorate General of Foreign Trade (DGFT) has introduced a Paper Import Monitoring System (PIMS) by amending the import policy of major paper products from ‘Free’ to ‘Free subject to compulsory registration under PIMS’. Steps are being taken to curb dumping of paper and paper products in the domestic market by way of unfair means such as under-invoicing, mis-declaration, rerouting goods through other countries in lieu of trade agreements etc, while imparting a push to domestic manufacturing. Challenges faced by pulp & paper industry in India.

Yes, the industry has its share of challenges too. India is a fibre deficient country. Inadequate raw material availability domestically is a major constraint for the paper industry. Unlike its peers in other countries, paper industry in India doesn’t have access to industrial plantations around the mills making the cost of accessing pulpwood higher.

Secondly, the wastepaper collection / recovery mechanism (another source of fibre) is also not very strong in the country. Indiscriminate import and dumping of paper from low-cost producing nations is a continuous concern.

IPMA to support members, enhance effectiveness on a global level.

As a national industry body, Indian Paper Manufacturers Association (IPMA) represents the resurgent and organised face of the paper industry in India. IPMA provides an effective platform for interface with government, media, opinion leaders, NGOs, etc. so as to present the perspective of the paper industry and thereby participate in the policymaking process.

IPMA also provides opportunities for networking with international paper industry / forestry organisations. Industry’s collaboration with research institutes is a must for shaping future growth. IPMA provides a platform for industry-research collaboration besides offering avenues to sponsor and participate in events, workshops, seminars, exhibitions, delegations and promotional activities related to the paper industry.

BASF and footwear design house Maddy Plant have collaborated to explore the possibilities of BASF’s innovative material solutions and use industry-leading technologies that enable energy-efficient production, for its concept athleisure shoe ‘MADGAMMA - Intertekk Saturn’.

“The concept shoe features our winning ideas to make footwear sustainable and at the same time high performing. Our ambition is to bring these advanced technologies into mainstream footwear production,” said Minli Zhao, vice president, Consumer Industry, Asia Pacific, BASF Performance Materials.

Key features of the MADGAMMA - Intertekk Saturn are:

Upper of the shoe made with the 100 percent recyclable monofilament fiber Freeflex™ thermoplastic polyurethane (TPU): Freeflex conforms to the foot using minimal seams and stitch lines to provide superior comfort and maximum performance. It is also lightweight. Additionally, its transparency enables design flexibility.

Tongue of the shoe made of polyethylene terephthalate (PET) fiber knitted with Freeflex TPU elastic fiber: Freeflex TPU elastic

fiber is used as an alternative to dry spandex for its soft stretch performance. It is eco-friendly as it is made without organic solvents and uses cost-efficient manufacturing processes.

Replaceable midsole made with the lightweight, high-rebound, and bio-based Elastopan® N polyurethane (PU) series: Compared to conventional midsoles, the PU is made with bio-circular material, providing superior cushioning and durability while being more sustainable. Another replaceable midsole option is made with TPU foaming, which has a lower density, high energy return, and is recyclable. With the replaceable midsoles, users can choose a midsole for different occasions – the lightweight and high-rebound Elastopan midsole for sports performance or the TPU foaming midsole for casual wear.

Shank of the shoe made with bio-based Elastollan® N TPU series comprising 35 percent bio-content: Elastollan provides great stiffness and complements high-performance sport shoe components such as the torsion system for improved stability.

Outsole and cage made with bio-based Elastopan PU: The outsole made with Elastopan incorporates a high-grip tread pattern to optimize traction and provide maximum surface contact. The high-performance material also consists of 30 percent bio-content.

Two of The Coca-Cola Company’s biggest brands in North America are taking major steps to support a circular economy for plastic packaging. DASANI is rolling out bottles made from 100 percent recycled PET plastic (excluding caps and labels), and Sprite is transitioning from green to clear plastic to increase the material’s likelihood of being remade into new beverage bottles.

A majority of DASANI bottles in the United States—from 20oz. and 1.5-liter singles to 10-oz. and 12-oz. multipacks—will be offered in 100 percent recycled plastic rolling out this summer. In Canada, this innovation spans all DASANI bottles. The shift supports both DASANI’s pledge to remove the equivalent of 2 billion virgin plastic bottles from production by 2027 compared to 2021 levels and the company’s World Without Waste goal to use at least 50 percent recycled material in its bottles and cans by 2030.

The DASANI announcement follows a successful launch of 100 percent recycled plastic bottles in New York, California and Texas, which also included Coca-Cola Trademark 20-oz. bottles. The launch helped the Coca-Cola system identify the bestquality sources of recycled PET (rPET) and fine-tune production processes needed to make 100 percent recycled plastic bottles.

The initial launch helped drive consumer awareness through the bold, on-pack “100 percent Recycled Bottle” and “Recycle Me Again” calls-to-action also used on retail signage and other communications. DASANI bottles will continue to feature this messaging.

“Demand for rPET currently exceeds supply, so the first step to scaling up use of 100 percent rPET across our portfolio is building a sustainable pipeline of high-quality material,” said Chris Vallette, senior vice president of Technical Innovation and Stewardship, Coca-Cola North America. “We do this by working with communities to boost PET recycling and collection;

collaborating with recycling partners; and, finally, securing rPET to help ensure the material for our bottles is used again and again.”

“We saw how much the 100 percent recycled PET message truly resonates with our customers and consumers, particularly DASANI fans whose sustainability expectations are especially high,” Vallette added.

New Bottle, Same Sprite Sprite, meanwhile, is shifting all of plastic PET packaging from its signature green color to clear, beginning Aug. 1. Although green PET is recyclable, the recycled material is more often converted into single-use items like clothing and carpeting that cannot be recycled into new PET bottles. During the sorting process, green and other colored PET is separated from clear material to avoid discoloring recycled food-grade packaging required to make new PET bottles.

“Taking colors out of bottles improves the quality of the recycled material,” said Julian Ochoa, CEO, R3CYCLE, which is working with Coca-Cola Consolidated to enable bottle-to-bottle recycling across the largest US bottler’s 14 state-territory. “This transition will help increase availability of food-grade rPET. When recycled, clear PET Sprite bottles can be remade into bottles, helping drive a circular economy for plastic.”

In addition to transitioning to clear bottles, Sprite is introducing a new visual identity system featuring a revamped logo and packaging design to provide a consistent look and voice around the world. Sprite’s packaging graphics will retain the brand’s recognizable green hue and include prominent “Recycle Me” messaging.

Coca-Cola North America’s entire green plastic portfolio— including packaging for Fresca, Seagram’s and Mello Yello—will transition to clear PET in the coming months.

The BMW Group has implemented several projects in its packaging logistics to further save resources. With these projects, the Group aims to work closely with suppliers to reduce carbon emissions and realize the principles of the circular economy as best it can. As part of this initiative, the European plants will use more recycled material in their packaging.

This will mean that, for newly awarded contracts, the proportion of recycled material in reusable packaging for logistics purposes will almost double this year from around 20 percent to over 35 percent. However, using alternative sustainable materials, reducing singleuse packaging, introducing lightweight packaging in certain areas and reducing transport volumes will also help cut carbon emissions.

The BMW Group is monitoring the impact of individual measures via a CO2 calculator for packaging. The group’s overall aim is to reduce CO2 emissions in the supply chain by 20 percent per vehicle (compared to 2019).