Withoutourteam,noneofthis wouldbepossible!

FounderEllen Zawada; OwnerofWoolandFiberArtsLLC

Wool and Fiber Arts Show Program Editor in Chief

Graphic Design

Ellen Zawada

Vendor Team - Heather Campbell, Lorna Violet (Mentor Program), Jean Story, Danielle Lefor Wallace, Candice Smith

Customer Team -(anything that happens publicly in WAFA) - Erika Lindgren, Heather Campbell, Molly Richter (craft-along), MAry Dillon, Katelyn Dunn, Candice Smith, Jessica Holt Pack, Amy Olshewski Bowling

Marketing Team - Raven Reynolds (social Media) Ellen Zawada, Tedi Jansen

Inclusivity Team - Liza Q Wirtz, Alaura Pittman, TeDi Jansen, Vidya Gopalakrishna Travis, Maddy McLendon

Education TeamTeDi Jansen, Alanna Wilcox

Tedi Jansen

Celebrate TDF 2023

Pages 4-5

From Fleece to Fiber

Pages 6-9

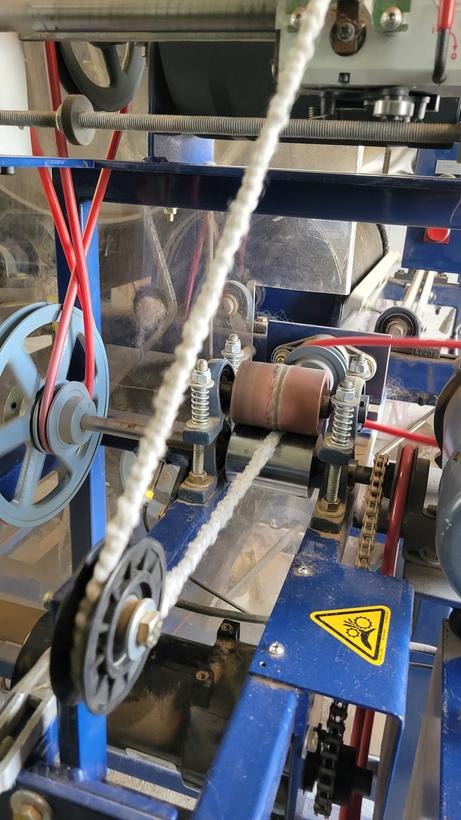

Mill Equipment

Pages 10-11

10 Dirty Things about Running a Mill Pages 12-13

DnD Fiber Arts

Photo by Erika Lindgren

Macedos Mini Acres

Photo by Erika Lindgren

Macedos Mini Acres

by Sandra Wilson Morris

by Sandra Wilson Morris

Our interest in wool started about 25 years ago, when we bought our first sheep, four Romney ewes. Our flock grew quickly, as we added additional breeds, with our focus being largely on wool. I knew nothing about fiber arts, but my interest was peaked as I attended sheep and wool shows. My first purchase of fiber processing equipment was a table picker and drum carder. I then purchasedmyfirstwheel,andwashooked!

I started selling raw fleeces online, when we still had dial up internet and yahoo wool groups were a thing. I read “Turning Wool into a Cottage Industry” by Paula Simmons and that was the inspiration I needed to look further intoaddingmorevaluetoourwool.

It was exciting and overwhelming at the same time. If we had purchased new equipment, that would have at least come with some training, modern controls, along with some other advantages. But Mikes interest in the historyandloveforoldmachines,wonout.He had to make some modifications, as most of the old cards were set up for production, and we were working with various types of wool, and different staple lengths. This would have been difficult if Mike had not had a background in machine building/engineering. A lot of wool went through that carder before we felt we had a grasp on what we were doing.

Mikesinterestgrewwhenheseenawool card demonstration, at Sauder Village.

Being a machinest, and having an appreciation of old things, he started studying the history of the machines, behind the wool mills that once existed in the United States. He threw the idea around, of us processing our own wool, but I didn’t take him seriously, until he found a Davis and Furber carding machine, and sold his Harley Davidson to buyit.BeforeIknewit,wewereownersof ourveryownwoolcard.

Just when we had things all figured out, we added a spinning frame to our mill. Again, no training, but at least it came with a manilla folder with some notes, from previous owners. It took Mike about a year to go through the machine, find and replace parts, and get the spinning frame, in good working order. It has definitely been the most challenging of all the machines to learn, but being able to take our wool from sheep to yarn,hasbeenveryrewarding.

We added a Davis and Furber picker, that was found on the East coast. With the picker and carder, we were able to turn ourrawwoolintoroving.

Davis and Furber Wool Picker (manufacturedinNorthHanover,MAcirca 1940

The picker opens up the wool and prepares itforcarding.Thepickerbox(whichwebuilt) collectsthewoolasitleavesthepicker.

DavisandFurber

24inchWoolCard circa1950s

After the wool is picked, it is placed on conveyer of the carding machine. The wool works its way through 4 sets of workersandstrippers.Itcomesoffthecard,inathinsheet,whichcanbemadeintoabattform,orputthroughroving attachment.

www.mittenstatewool.com

SacoLowell

manufacturedinSouthCarolina circa1960

circa1962

manufacturedinClevelandOhio

The carded wool roving is pindrafted to prepare it for the spinningframe.Thepindrafter,straightensanddraftsthefiber.It is fed through pindrafter 2-4 times to prepare it for spinning. It makesasemiworstedyarn.

Thepindrafterisalsousedtoblenddifferentfibersandcolors

The spinning frame produces yarn. This machine has had some modifications, it spins on one side and plies on the other.Itusestheoldschoolgears,fortwistanddraftsettings.Wewouldliketoeventuallyupdateit,toservocontrols.

I'm going to make so much money I won't know what to do with it… as I enjoy my gourmet dinner of Mac & Cheese

by Vicki Glenn-Donley

by Vicki Glenn-Donley

My children...who are grown adults and one teen will be more than happy to help in the mill...this will be a family effort... husband naps in his chair, one daughter moves to Alaska, the other travels and is a nurse, oldest son is a welder and races cars...youngest...well he is a teen.

I'm going to have so much extra time to complete old fiber art projects...as I dust off my loom...monthly

I have a few friends that want to help out in the mill part time….don't have friends "work" for you….too many wine and coffee breaks.

Cats are a must in the mill! The mill cats will keep the critters at bay... Found them napping and a mouse scampering by them!

Receiving a call of a client in need of just a few more fleeces that need to be processed asap, then the shipment arrives, a few huge boxes!

Receiving "donations" of fibery goodies at the mill. Then play the game between myself and Farmer Bob as to who will open the bag/box (outside) to see if critters are also part of the "donation " .

Playing the game of...Guess this Wool Breed

Skirting a fleece and finding unmentionables

...yup it happened!

Going out for a quick bite to eat, having other patrons stare due to fiber clung on clothing!

All In all I truly am blessed I get to enjoy clients fiber and create amazing fibery goodness! It's a LOT of very dirty work, some days are very very trying, tears have fallen. But for some crazy reason I keep on keeping on! -Vicki

GREAT PLACE

Weareafamilyownedmillandfarm.Stopbyand checkoutouryarn/giftshop.Wecarryroving,yarn, feltedsheetsandmoreprocessedatourmill.Itemsin thegiftshoparemadeatthemillorarecarefully chosen.Wehavebeautifulitemsthatarefairtrade products Openhousesareofferedthroughoutthe yearandparticipateduringNationalAlpacaDays. Checkoursiteforevents FollowusonFacebook, Twitterandinstagram.

Larry and Maureen Macedo have owned alpacas for over 18 years. We now have Belfast mill equipment to create rug yarn or dryer balls from alpaca fiber. Suri or Huacaya fiber makes beautiful rug yarn. Our mill uses alpaca fiber around a cotton core. We also make dryer balls from huacaya alpaca fiber.

Wearethrilledtoannouncethedebut ofourlatestadditiontothewebsite-a comprehensivedirectoryofUSwool andfibermillsdedicatedtoservicing thevibrantandcreativefiberarts industry.Weareexcitedtopresent thispreliminaryversion,whichaimsto connectfiberenthusiasts,artists,and businesseswiththefinestdomestic millsintheUnitedStates.Whether youareseekinghigh-qualityraw materials,artisanalyarns,or specializedfiberprocessingservices, ourdirectoryoffersacuratedselection oftop-notchestablishments.Aswe continuetoexpandandimprovethis resource,weencourageyouto exploreoursiteandstaytunedfor moreupdatesinthefuture.Joinuson thisjourneyaswefosterathriving communityforallfiberenthusiasts

Summer greetings from TeDi and Toot, the Timber and Twine gals! We've been busy planning, weaving, spinning, dyeing, building and teaching here on the farm In northern Colora during these off months and can't wait to see you again in the fall!