Your guide to air conditioning and refrigeration products, services and solutions.

Packed with thousands of products, the Climate Guide has everything you need for your projects. From refrigeration equipment, tools, service products and installation materials, this guide has you covered.

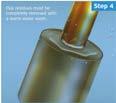

The Climate Guide is also easy to use and products are easy to find. The contents and each section has been colour coded, every page has related products, and there is a simple to use product index at the back. Not only that, throughout the guide, you’ll also find useful facts, tips and information relating to refrigeration.

The contents and each section has been uniquely colour coded to help you easily identify the products you need quickly. Using the contents page, simply look for the products you need, and you’ll quickly be able to flick open to the section you need. This is especially useful when you are on site.

At the bottom of each page, we have created an associated products key, to help remind you of key items that relate to the products you’re looking. For example, if you are looking at the page covering copper tube, you may need fittings, tube cutter, pipe clamps or insulation. The icons across the bottom of the page will show the page number and this relates to the section containing related items.

At the back of the guide, you’ll find a useful index to help find the specific products and brands you need.

One of the UK’s leading specialists in air conditioning and HVAC, with the largest network of specialist cooling branches across the country.

Aberdeen

Hareness Road, Altens, Aberdeen, AB12 3QA

Telephone: 01224 335420

Email: zo.aberdeen@wolseley.co.uk

Exeter

Units 2&3 Grace Units, Grace Road

Central, Marsh Barton Trading Estate, Exeter, EX2 8QA

Telephone: 01392 427552

Range and availability

We stock a full range of air conditioning and refrigeration equipment, accessories and spares from the world’s leading brands. Our national scale and supply quantity ensures that we always have stock available - when you need it, where you need it.

Service and expertise

Whatever size your project, our Climate Centre experts are on hand to support you with everything you need to get the job done. Whether that’s product advice or bespoke delivery requirements, we’re here to please.

Help and advice

Technical experts are always on hand to offer support and advice, with dedicated teams available for refrigeration or air conditioning products. Support includes everything from product selection, parts identification and duty calculations, to after sales service and troubleshooting. Our engineers may even visit your site if required.

Basildon

Paycocke Road, Basildon, Essex, SS14 3JS

Telephone: 01268 246990

Email: zd.basildon@wolseley.co.uk

Belfast

Unit 1 M2 Business Park, 132 Duncrue Street, Belfast, BT3 9AR

Telephone: 02890 751851

Email: g24.belfast@wolseley.co.uk

Birmingham

Units C and D Dartmouth Industrial Estate, 4-6 Bracebridge Street, Birmingham, B6 4NE Telephone: 01213 597091

Email: pl.birmingham@wolseley.co.uk

Brentford

Unit 7 Great West Trading Estate, 985 Great West Road, Brentford, TW8 9DN Telephone: 02085 683663

Email: g52.brentford@wolseley.co.uk

Bristol

Unit A, St Vincents Industrial Estate, Feeder Road, Bristol, BS2 0UY Telephone: 01179 165690

Email: nba.bristol@wolseley.co.uk

Cambridge

Unit D Beadle Trading Estate, Ditton Walk, Cambridge, CB5 8PD Telephone: 01223 275200

Email: zc.cambridge@wolseley.co.uk

Canning Town

Unit G, Project Park, London, E16 4TG Telephone: 02075 111395

Email: g51.canningtown@wolseley. co.uk

Cardiff

Unit 3, Dominion Way Industrial Estate, Cardiff, CF24 1RF Telephone: 02920 480046

Email: k38.cardiff@wolseley.co.uk

Carlisle

Unit 2, Currock Road, Carlisle, CA2 5AE Telephone: 01228 529345

Email: RB.Carlisle@wolseley.co.uk

Email: pk.exeter@wolseley.co.uk

Glasgow

Unit 6 31 Orton Place, Moorpark Industrial Estate, Glasgow, G51 2HF Telephone: 01414 252730

Email: gt.glasgow@wolseley.co.uk

Gloucester

Unit 8 Central Trading Estate, Cole Avenue, Gloucester, GL2 5HA Telephone: 01452 393870

Email: pg.gloucester@wolseley.co.uk

Greenford

Unit 23 Derby Road, Metropolitan Business Park, Greenford, UB6 8UJ Telephone: 02085 782300

Email: k83.greenford@wolseley.co.uk

Hull

Leads Road, Hull, HU7 0BY Telephone: 01482 838880

Email: k77.hull@wolseley.co.uk

Hutton

Units 2 & 3 Kestrel Park, Tallon Road, Brentwood, CM13 1TN Telephone: 01277 228060

Email: g61.hutton@wolseley.co.uk

Ipswich

Unit 22 Ransomes Park, Foxtail Road, Ipswich, IP3 9RT Telephone: 01473 270072

Email: bn.ipswich@wolseley.co.uk

Kings Cross

Unit 30 Cedar Way, Elm Village Industrial Estate, Camden, N1C 4PD Telephone: 02073 804230

Email: k94.kingscross@wolseley.co.uk

Leeds

Unit 3 Jack Lane Industrial Estate, Jack Lane, Leeds, LS11 9NP Telephone: 01132 431339

Email: gr.leeds@wolseley.co.uk

Leicester

92 Freemans Common Road, Leicester, LE2 7SQ Telephone: 01162 553199

Email: g9.leicester@wolseley.co.uk

Newbury

Unit C Hambridge Road Industrial Estate, Hambridge Road, Newbury, RG14 5SS Telephone: 01635 568256

Email: g69.newbury@wolseley.co.uk

Newcastle

Unit 31 New York Way, New York Industrial Estate, Newcastle upon Tyne, NE27 0QF Telephone: 01912 961200

Email: k85.newcastle@wolseley.co.uk

Northampton

Unit 2 Crow Lane Industrial Estate, Hartburn Close, Northampton, NN3 9UE Telephone: 01604 410888 Email: bv.northampton@wolseley. co.uk

Norwich

To find out more, scan the QR code

Crawley

Unit 12 And 13 Crawley Industrial Estate, Royce Road, Crawley, RH10 9NX Telephone: 01293 536534

Email: g55.crawley@wolseley.co.uk

Crayford

Unit 23 Bourne Road Industrial Estate, Bourne Road, Crayford, DA1 4BZ Telephone: 01322 559696

Email: g56.crayford@wolseley.co.uk

Derby

Dunstall Park Road, Ascot Drive, Derby, DE24 8HJ Telephone: 01332 297222

Email: rv.derby@wolseley.co.uk

Eastleigh

Unit 1 Boyatt Wood Industrial Estate, Goodwood Road, Eastleigh, SO50 4NT Telephone: 02380 611555

Email: G49.eastleighwbs@wolseley. co.uk

Edinburgh

Unit A Hailes Park, 9 Dumbryden Drive, Edinburgh, EH14 2QR Telephone: 01314 441570

Email: gw.edinburgh@wolseley.co.uk

Liverpool

Unit 1 Spindus Road, Speke Hall Industrial Estate, Liverpool, L24 1YA Telephone: 01514 860848

Email: g64.liverpool@wolseley.co.uk

Luton

Unit 8B, Cosgrove Way Industrial Estate, Luton, LU1 1XL Telephone: 01582 404162

Email: k13.luton@wolseley.co.uk

Maidstone

Unit 16/17 Lake Road, Quarry Wood Industrial Estate, Aylesford, ME20 7TQ Telephone: 01622 790010

Email: g65.maidstone@wolseley.co.uk

Manchester

Textilose Road, Trafford Park, Manchester, M17 1WA Telephone: 01618 728431

Email: pb.trafford@wolseley.co.uk

Minworth

Unit 10 Stockton Close, Minworth, Sutton Coldfield, B76 1DH Telephone: 01213 517777

Email: g68.minworth@wolseley.co.uk

189-191 Aylsham Road, Norwich, NR3 2AD Telephone: 01603 258080 Email: zn.norwich@wolseley.co.uk

Nottingham

Unit 5 Riverside Industrial Estate, Centurian Way, Nottingham, NG2 1RW Telephone: 01159 578200

Email: k86.nottingham@wolseley. co.uk

Peterborough

Unit 5 Peterborough Trade Centre, Newton Way, Peterborough, PE1 5PJ Telephone: 01733 566731 Email: g26.peterborough@wolseley. co.uk

Portsmouth

Units 5 and 6, Admirals Business Park, Portsmouth, PO3 5RQ Telephone: 02392 699714

Email: g5.portsmouth@wolseley.co.uk

Potters Bar

Opposite The Enterprise Centre, Cranbourne Avenue, Cranborne Industrial Estate, Potters Bar, EN6 3DQ Telephone: 01707 655413

Email: g74.pottersbar@wolseley.co.uk

Preston

428 Oakshott Place, Walton Summit Centre, Preston, PR5 8AT Telephone: 01772 628608

Email: gl.preston@wolseley.co.uk

Sheffield

Unit 2 Greenland Industrial & Trade Park, Greenland Road, Sheffield, S9 5HG Telephone: 01143 082668

Email: sh2.sheffield@wolseley.co.uk

Slough

838-840 Yeovil Road, Slough Trading Estate, Slough, SL1 4JG Telephone: 01753 843550

Email: Email: bs.slough@wolseley. co.uk

Stockton

20/25 Pennine Avenue, North Tees Industrial Estate, Stockton-On-Tees, TS18 2RJ

Telephone: 01642 671904

Email: zs.stockton@wolseley.co.uk

Stoke

Unit 3, Tunstall Arrow, James Brindley Way, Stoke on Trent, ST6 5GF Telephone: 01782 576311

Email: K19.Stoke@wolseley.co.uk

Swansea

16A Mannesmann Close, Enterprise Park, Swansea, SA7 9AH Telephone: 01792 797079

Email: ph.swansea@wolseley.co.uk

West Bromwich

Unit B Doranda Way Industrial Park, Doranda Way, West Bromwich, B71 4LE Telephone: 01215 003700

Email: K68.birmingham@wolseley. co.uk

Wrexham

Rivulet Road, Wrexham, LL13 8DT Telephone: 01978 312330

Email: KE.Wrexham@wolseley.co.uk

comfort without compromising energy efficiency

› Blends in easily with any interior décor

› Air is distributed efficiently and evenly, thanks to auto-swing louvres

› Heat up or cools down the room rapidly with turbo mode

› Quiet operation down to of 20 d(BA)

At Climate Centre We have a comprehensive range From Splits, Multi Splits to VRV & VRF from leading brands such as Daikin and Fujitsu; and Chillers and commercial heat pumps to suit every application.

All equipment is fully supported by our dedicated air conditioning technical team, and available via our extensive branch network that consists of over 40 branch locations nationwide.

The air conditioning technical team have 100 years of industry experience providing customers with pre and after sales support. Our Experts offer a range of services which include:

Design, selection and application –including, technical documentation, schematics, selection reports and run cost estimates to provide an accurate proposal.

Site visits – for more complicated projects, a site visit is one of the best ways to ensure the most appropriate solution is proposed.

Commissioning – we help customers complete the installation with commissioning support.

Telephone support – when engineers are trying to diagnose a faulty system, telephone support is available to guide customers with their technical queries.

Fault finding – assisting our customers on site to help diagnose a system error, where a spare part is required, the team will also inform a branch local to the customer to order the part for collection or delivery.

If you would like to speak to the team today about your next project email acsupport@wolseley.co.uk

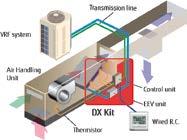

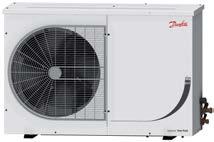

• Energy efficient solution for retrofit or de-carbonisation projects

• DX on coil temperature -7°C in heating mode

• Cooling capacity range of 5kW to 50kW per DX circuit

• Heating capacity range of 6kW to 56kW per DX circuit

• Combine multiple circuits into 1 system up to 150kW

• Various control options available to suit the application

Giving you 2% back on qualifying product purchases, which can be redeemed for vouchers or other great items on the Fujitsu Shop website.

Get vouchers from: Amazon, M&S, John Lewis, Love2Shop or B&Q Register Here:

New Wall Mounts for 2024

&

Offering a full range of innovative Air Conditioning equipment:

We’re national but think local

•

•

•

•

•

The amendments to the F-Gas regulations came into force on 1 January 2015 with the aim of encouraging users to switch to lower GWP refrigerants: On leaving the EU F-Gas II regulations were fully adopted into UK law and enforced by DEFRA.

The UK is still bound by F-Gas II but as of April 2024 a review is underway to accelerate the phase-down in line with F-Gas III which was enacted by the EU in January 2024. It is likely that UK changes will be similar and adhere to the same timelines as the EU and could come into effect in 2026.

The phase down will be controlled in two ways:

Cap

F-Gas II (UK Current): This is measured by the amount of HFC’s placed on the market from 1st January 2015. The total market use will be stepped down from 100% (based on the average level between 2009 and 2012) to 21% in 2030, a 79% reduction of available GWP on 2015. This will require the introduction and use of low GWP, low flammable and natural refrigerants.

F-Gas III (EU Current): This is measured by the amount of HFC’s placed on the market from 1st January 2025. The total market use will be stepped down from 100% to 5% by 2030. This equates to 95% reduction in GWP allowed on the market compared to 2015. This will require the rapid take up of low GWP, low flammable and natural refrigerants. A major step in the reduction occurs in 2027 when 2025 available GWP is reduced by 50.5%.

(Note: DEFRA is likely to implement new legislation with similar F-Gas phase down targets).

F-Gas II vs F-Gas III

Use F-Gas II (Current UK regs)

2020 Ban on using new refrigerants with GWP of 2500 or greater for servicing existing commercial refrigeration

Service & Maintenance Bans

Date of Prohibition: January 1st 2020

> Refrigerators and freezers for commercial use (hermetically sealed systems) containing HFCs with GWPs of 2500 and over

Date of Prohibition: January 1st 2020

> Stationary refrigeration equipment that contains, or that relies upon for its functioning, HFCs with GWPs of 2500 or greater (except equipment for temperatures below -50°C)

Date of Prohibition: January 1st 2020

> Movable room air-conditioning appliances (hermetically sealed equipment which is movable between rooms by the end user) that contain HFCs with GWP of 150 or greater

Date of Prohibition: January 1st 2022

> Refrigerators and freezers for commercial use (hermetically sealed systems) containing HFCs with GWPs of 150 or greater

Date of Prohibition: January 1st 2022

> Multipack centralised refrigeration systems for commercial use with a capacity of 40kW or greater that contain, or that rely upon for their functioning, fluorinated greenhouse gases with GWP of 150 or greater (except in the primary refrigerant circuit of cascade systems, where fluorinated greenhouse gases with a GWP of less than 1500 may be used)

Date of Prohibition: January 1st 2025

> Single split air-conditioning systems containing less than 3kg of fluorinated greenhouse gases, that contain, or that rely upon for their functioning, fluorinated greenhouse gases with GWP of 750 or greater

Date of Prohibition: January 1st 2020

> The use of all VIRGIN Refrigerants with a GWP of 2500 or greater to service existing equipment with a charge size of 40MT CO2e or greater

Date of Prohibition: January 1st 2030

> The use of all RECLAIMED Refrigerants with a GWP of 2500 or greater to service existing equipment with a charge size of 40MT CO2e or greater

Features

> Under the F-Gas phase down the refrigeration and air conditioning industry is required to move away from high GWP refrigerants and adopt the use of low flammable refrigerants.

> Low flammable refrigerants have been designed to have similar properties to existing refrigerants and can offer more energy efficiency and higher capacity. For example, refrigerants R454C, R455A have a GWP below 150 are designed to replace higher GWP R448A and R449A in the market. R32 has already replaced R407C in AC applications and R1234YF in now a popular choice in the car industry.

> All low flammable refrigerants are designated as A2L’s and can be safely and effectively used in both MT and LT applications however additional safety features may be required to comply with best practice and regulatory constraints. More information on the application of low flammable refrigerants can be found in EN378-2016, DSEAR and the BRA Guide to Flammable Refrigerants.

Features

> Service and installation engineers must hold a current F-Gas certification to work on any equipment containing F gases. It is also highly recommended that a flammable gas safe handling course is undertaken using a reputable training provider such as Cool Concerns.

> A2L equipment must be specifically designed and approved for flammables, retrofitting low flammable refrigerants to non-compliant legacy equipment is not safe.

> Working on A2L refrigerants requires approved tools such as recovery machines, gauges, leak detectors and charging lines. Engineers must adopt safe working practices and be aware of potential ignition sources. For example, a safe working exclusion zone must be set up to prevent third parties for entering the work area when charging or recovering refrigerant. Purging of pipework with OFN must be carried out to ensure no flammable gas is in the system prior to brazing works. Climate Centre stock a full range of compliant service tools, consult your local climate branch or visit our web site for more information.

Best in Class, Tandem Scroll Low GWP Multi Refrigerant Condensing Unit

FRIGA-BOHN DUO

Features

> Developed specifically for the retail sector the Friga-Bohn Duo unit offers unrivalled flexibility.

> Using the latest Copeland YB and YF Scroll compressors the DUO is approved for both A1 and A2L refrigerants. Duties range from 7kW to 38kW MT and 6kW to 15kW LT.

> Highly efficient scroll compressors with a lead digital and EC condenser fans the DUO give smooth quiet and reliable operation matching your refrigeration demands though peak and low demand to maximise energy savings.

> Incorporating Carel control technologies that allow remote communication and ease of setting the DUO can be installed and commissioned with ease.

> Approved for use with A2L sub 150 GWP refrigerants R455A and R454C and utilising a microchannel condenser to minimise system charge the DUO is best in class

Our refrigerant service is backed up by an efficient rental and recovery service – saving you time and hassle, ensuring all the correct environmental and disposal procedures are correctly followed.

> Pipework is generally the same as for HFC refrigerants however in some instances pipe sizing will increase the PED rating to Cat II which will require the Brazer to have a CAT II brazing certification and line fittings must be rated for Group 1 gas. Climate Centre stock a full range of A2L compliant Danfoss products and can provide the part selection and documentation for your category assessment and for your notified body compliance proof. Climate Centre can advise on or design your pipework, please contact our technical team for assistance

Ensure you have a well-ventilated work area, which is free of source of ingition and use appropriate leak detection.

Use measures such as forced ventilation, automatic valve shut-off and pressure switch regimes.

DO NOT Retrofit to an A2l

These mildly flammable products must only be used with new, purpose-built equipment.

Attend suitable training courses for the safe use of A2L refrigerants.

• Consult safety data sheets and take all necessary safety measures.

• Follow the Manufacturer’s insallation and Operating Instructions.

• Use the correct tools and equipment.

• Ensure compliance with Refrigeration Standard EN378.

• Seek further advice where required. agas.com | info.uk@agas.com

CO2 equivalent becomes the norm; refrigerant use and records are to contain the CO2 equivalent and not only the kilogram quantity.

The CO2 equivalent can be calculated by taking the GWP of the refrigerant in use and multiplying it by the kilogram quantity used.

For example, R404A has a GWP of 3922. A 10kg system would contain 39T CO2 equivalent (10kg x 3922 ÷ 1000 = 39 tonnes CO2 equivalent).

Leak Testing

The regular leak testing requirements are now as follows based on the CO2 equivalent of the system charge:

From 2020 until 2030 it will be possible to use

Refrigerant for servicing systems which contain refrigerants with a GWP of 2500 or more. This will mainly affect R404A systems.

Labelling Requirements Equipment

At wolseley.co.uk you can set appropriate limits and user permissions to meet your business needs in real time. Scan the QR code and register online today.

F-Gas II is designed to promote the use of low GWP synthetic and natural refrigerants.

The phase down of high GWP gases will accelerate markedly in 2027 under both road maps. To have enough available quota high GWP A1 HFC use must transition to A2L low flammable and natural refrigerants resulting in significant challenges to the market. A2L refrigerants cannot be retrofitted or used as a drop in to replace gas in existing A1 equipment. A2L gases can only be charged to appropriately designed and approved equipment. PE(S)R categories for A2L gases are higher than A1 meaning most systems will be placed in category II or above necessitating that a notified body must be involved in the sign off of contractor’s installations.

(Note: this is a legal requirement).

Since 2019 R448A and R449A have been promoted as an alternative to R404A but these are interim refrigerants. A2L refrigerants with similar thermal and temperature/ pressure properties such as R454C, R455A and R454A are intended to replace R449A and R448A.

A2L system maximum charges sizes are limited by location and access category, charge size guidance can be found in EN378-1(2016) Annex C table C.2.

EN378 2016 parts 1,2,3 and 4 standard can be purchased from a reputable standards library such as BSRIA.

(Note: EN378 is currently under review).

The use of flammable gas is covered in DSEAR regulations and dictate the installing contractor’s legal responsibility for risk assessment and system design features of flammable gas use to ensure systems are compliant and safe for the applicable zone.

Lower GWP Alternatives (to products affected by F-Gas regulations)

* A1: Non-Flammable and Lower Toxicity; A2: Lower Flammability and Lower Toxicity; A2L:

and Lower Toxicity; B2L Lower Flammability and Higher Toxicity

** POE=Polyolester oil, MO=Mineral oil, AB=Alkylbenzene, PAG=Polyalkylene oil

† Not a direct retrofit replacement in existing equipment. New equipment required. Information for guidance only. For system specific advice please contact us.

At wolseley.co.uk you can manage your online workforce efficiently; upload multiple new users, set roles and reset their passwords at a time that suits you. Scan the QR code and register online today.

Oxygen Free Nitrogen (OFN)

For use when strength and pressure testing, cleaning condenser coils and for use alongside Braze-A-Gas® to reduce oxidation and scale build up when brazing.

Oxygen (Part of the BRAZE-A-Gas Range)

Oxy-acetylene is the professional engineer’s choice for applications such as brazing copper pipes together in refrigeration and air conditioning systems or brazing dissimilar metals, such as steel to copper.

A 5% Hydrogen and 95% Nitrogen mixture which is non-flammable, nontoxic and safe for the environment. When used with a suitable leak detector it is capable of identifying much smaller leaks than OFN and leak detector spray.

Acetylene (Part of the BRAZE-A-Gas Range)

Oxy-acetylene is the professional engineer’s choice for applications such as brazing copper pipes together in refrigeration and air conditioning systems or brazing dissimilar metals, such as steel to copper.

Recovery cylinders are used for the sole purpose of returning used or reclaimed refrigerant to Climate Centre.

Receiver Cylinders are used as a temporary storage vessel for refrigerant that the engineer wishes to re-introduce into a system. Receiver cylinders are internally clean and evacuated prior to dispatch and come complete with a yellow and black banded valve guard and a dual port valve to enable push-pull recovery of gas.

Hydrocarbon refrigerants must be returned in the Flammable Receiver Cylinder and not mixed with conventional refrigerants.

HP Recovery Cylinders must be used for higher pressure refrigerants such as R23.

The below costs include Environmental charges in England, Wales and Scotland. Quarterly returns are submitted to the Environment Agency and also to customers for England and Wales.

Additional Charges will be made for the following:

> Cylinders which have been overfilled above the Maximum Fill weight

> Cylinders containing mixed hydrocarbon and standard refrigerants

> Cylinders containing CFC’s and R123.

Do you recover oil from refrigeration systems during service or decommission work?

If yes, Climate Centre’s oil disposal service will help you dispose of this refrigeration oil responsibly. Our oil disposal service provides you with an empty 10ltr container. Simply fill it with recovered refrigerant oil and return it with your hazardous waste note to your local Climate Centre Cooling branch.

The main application of heat transfer fluids is their role as secondary refrigerants.

Both MEG and MPG have been specifically designed to deliver high resistance to degradation, scale, bacterial growth and corrosion. Available in both concentrate and diluted form, MEG is a Monoethylene based Glycol and MPG is a Monopropylene based Glycol.

Instructions for a Refrigerant Analysis Sample:

This analysis cylinder is rated to 47bar and is only for low pressure refrigerants. It is not suitable for Carbon Dioxide (CO2/R744). If a Carbon Dioxide analysis is required ensure you use high pressure sample cylinder rated to 250bar or higher (Code 624746).

1) Ensure the system can sustain the reduction in charge needed to take the sample.

2) Fill a 1kg analysis cylinder with a minimum of 500 grams Don’t exceed the maximum fill of 1kg

3) Fill a 5kg analysis cylinder with a minimum of 2kg Don’t exceed the maximum fill of 3kg.

4) After sampling make sure the cylinder valve is closed.

5) Return sample cylinder and completed form to A-Gas via your nearest Climate Centre branch.

6) Please advise labservicesuk@agas.com prior to returning used analysis cylinders to avoid any delays.

Instructions for a Carbon Dioxide (CO2/R744) Sample:

Ensure a high-pressure sample cylinder rated to 250bar or higher is used for your Carbon Dioxide (CO2/R744) sample. Do not use a standard 47bar refrigerant analysis cylinder.

1) Ensure the system can sustain the reduction in charge needed to take the sample.

We provide a range of analysis kits that enable end users to identify the purity and moisture levels of the product in the system.

Carrying out routine testing can provide early warning of potential problems by identifying contaminants in the system.

2) Ensure the fitting and cylinder inlet is dry before taking a sample.

3) Fill the sample cylinder with a minimum of 2kg Don’t exceed the maximum fill of 5Kg

4) Work under a pressure range of max 200bar.

5) Sample from the liquid phase

6) After sampling make sure the cylinder valve is closed.

7) Return sample cylinder and completed form to A-Gas via your nearest Climate Centre branch.

8) Please advise labservicesuk@agas.com prior to returning used analysis cylinders to avoid any delays.

Instructions for Oil Analysis Kits:

1) Take the sample into the glass sample bottle provided.

2) Ensure the sample bottle is at least half full. Amounts below this will not be sufficient for an analysis to be conducted.

3) Fill in the sample details on the form provided.

4) Please make sure the sample bottle is clean and sealed securely and unable to leak in transit.

5) Return the sample bottle and completed form to A-Gas (Banyard Road, Portbury West, Bristol, BS20 7XH) using the shipping box and pre-paid label provided.

6) Please advise labservicesuk@agas.com prior to returning used analysis kits to avoid any delays.

Paperless billing and online documents.

Create your personal job lists. Branch real-time stock check available online.

Access to over 300,000 products.

Specification

> Tube is manufactured according to BS EN 12735-1

Material Analysis

> Material grade phosphorus de-oxidised copper, Cu-DHP or CW024A as defined in BS EN 1976

> Minimum copper content 99.90% (including silver)

> Phosphorus 0.015-0.040%

> Total impurity maxima 0.060% (excluding phosphorues and silver)

> The melting point of copper is 1083° and it has a density of 8.9 gm/cc

Pre-Insulated Coil

A fast and easy solution that meets the needs of UK Building regulations.

> Meets UK Building and Fire Safety Regulations

> Class O tested and passed in the UK for complete peace of mind

> Suitable for Air Conditioning and Refrigeration application

> Available in 20mtr coils, in both 9 and 13mm thicknesses

> Easy installation, no glue, tape or messy powder

> Using pre-insulated coil achieves pipework installation in less than half the time of conventional methods

1.3/8" 12 85

1.3/8" 14 64

1.3/8" 16 51

1.3/8" 18 38

1.5/8" 12 71

1.5/8" 14 54

1.5/8" 16 43

Reduced Couplings (Copper to Copper)

644090 3/8 x 1/4" 644091 1/2 x 1/4"

90° Long Radius Elbow (Copper to Copper)

644301 3/8 x 3/8 x 1/4”

644302 1/2 x 1/2 x 1/4”

644303 1/2 x 1/2 x 3/8”

644304 5/8 x 5/8 x 1/4”

644305 5/8 x 5/8 x 3/8” 644306

3/4 x 3/4 x 5/8”

7/8 x 7/8 x 3/8” 644311 7/8 x 7/8 x 1/2”

644312 7/8 x 7/8 x 5/8”

End Tee

x 1.5/8 x 1.3/8”

x 2.1/8 x 5/8”

2.1/8 x 2.1/8 x 7/8”

644326 2.1/8 x 2.1/8 x 1.1/8” 644327 2.1/8 x 2.1/8 x 1.3/8” 644328 2.1/8 x 2.1/8 x 1.5/8”

644329 2.5/8 x 2.5/8 x 5/8”

644330 2.5/8 x 2.5/8 x 7/8”

644331 2.5/8 x 2.5/8 x 1.1/8”

644332 2.5/8 x 2.5/8 x 1.3/8” 644333 2.5/8 x 2.5/8 x 1.5/8”

644334 2.5/8 x 2.5/8 x 2.1/8”

644335 3.1/8 x 3.1/8 x 1.5/8”

644336 3.1/8 x 3.1/8 x 2.1/8”

644337 4.1/8 x 4.1/8 x 2.1/8”

644338 4.1/8 x 4.1/8 x 2.5/8”

644339 4.1/8 x 4.1/8 x 3.1/8”

Reduced End and Branch Tee Code

644360 3/8 x 1/4 x 1/4” 644361 1/2 x 1/4 x 1/4” 644362 1/2 x 3/8 x 3/8”

644363 5/8 x 3/8 x 3/8”

644364 5/8 x 3/8 x 1/2”

644365 5/8 x 1/2 x 3/8”

644366 5/8 x 1/2 x 1/2”

644367 3/4 x 1/2 x 1/2”

644368 3/4 x 5/8 x 5/8”

644369 7/8 x 5/8 x 1/2”

644370 7/8 x 5/8 x 5/8”

644371 7/8 x 3/4 x 3/4”

644372 1.1/8 x 5/8 x 7/8”

644373 1.1/8 x 7/8 x 5/8”

644374 1.1/8 x 7/8 x 7/8”

644375 1.3/8 x 7/8 x 7/8”

644376 1.3/8 x 7/8 x 1.1/8”

644377 1.3/8 x 1.1/8 x 5/8”

644378 1.3/8 x 1.1/8 x 7/8”

644379 1.3/8 x 1.1/8 x 1.1/8”

644380 1.5/8 x 1.1/8 x 7/8”

Both Ends Reduced Tee

K65 Tube is made of the high-strength copper alloy K65 and is available in two ranges with pressure ratings of either 80 bar or 120 bar.

It is intended for use with CO2 sub critical or transcritical applications depending on system pressure requirements.

K65 Tube 5m Lengths Code

Reduced Couplings (Copper to Copper)

Straight Couplers

K65 Tube 6m Lengths

Reduced End and Branch Tee

(Copper

605156 3/8 x 1/4” MPA5243 0030201

605157 1/2 x 3/8” MPA5243 0040301

605158 5/8 x 3/8” MPA5243 0050301

605159 5/8 x 1/2” MPA5243 0050401

605160 3/4 x 1/2” MPA5243 0060401

605161 3/4 x 5/8” MPA5243 0060501

605162 7/8 x 1/2” MPA5243 0070401

605163 7/8 x 5/8” MPA5243 0070501

605164 7/8 x 3/4” MPA5243 0070601

605165 1.1/8 x 1/2” MPA5243 0090401

605166 1.1/8 x 5/8” MPA5243 0090501

605167 1.1/8 x 3/4” MPA5243 0090601

605168 1.1/8 x 7/8” MPA5270 0090701

605121 1/4” MPA5002 0020001

605122 3/8” MPA5002 0030001

605123 1/2” MPA5002 0040001

605124 5/8” MPA5002 0050001

605125 3/4” MPA5002 0060001

605126 7/8” MPA5002 0070001

605128 1.1/8” MPA5002 0090001 606228 1.5/8 MPA5002L0130001

605169 1/4” MPA5041 0020001

605170 3/8” MPA5041 0030001

605171 1/2” MPA5041 0040001

605172 5/8” MPA5041 0050001

605173 3/4” MPA5041 0060001

605174 7/8” MPA5041 0070001

605176 1.1/8” MPA5041 0090001

606230 1.5/8 MPA5041 0130001

605136 1/4” MPA5T 002020201

605137 3/8” MPA5T 003030301

605138 1/2” MPA5T 004040401

605139 5/8” MPA5T 005050501

605140 3/4” MPA5T 006060601

605141 7/8” MPA5T 007070701

605143 1.1/8” MPA5T 009090901

606229 1.5/8 MPA5T 013131301

605177 1/4” MPA5301 0020001

605178 3/8” MPA5301 0030001

605179 1/2” MPA5301 0040001

605180 5/8” MPA5301 0050001

605181 3/4” MPA5301 0060001

1.1/8” MPA5001 0090001

605182 7/8” MPA5301 0070001

605184 1.1/8” MPA5301 0090001 606231 1.5/8 MPA5301 0130001

Cylinder Adaptor Male Flare to Female Flare BSP Furnished with Fibre Gasket

Female Flare to Male Flare Reducer

3/4”

Suitable for insulating pipework for energy conservation and controlling condensation.

> It can be used on hot and cold water services, chilled lines, heating systems, air conditioning duct-work and refrigerated pipework

> Temperature range -50°C to +110°C. Supplied in 2m lengths

> ArmaFlex has built in anti-microbial protection to reduce mould and bacteria growth

> It is free from Formaldehyde, dust and CFCs with an ODP of zero.

Code

621324 1/4” 6 2m AF-CO-06X006

House Line Tap Valve with Gauge Port

621325 3/8” 10 2m AF-CO-06X010

621326 1/2” 12 2m AF-CO-06X012

Code

621327 1/4” 6 2m AF-CO-09X006

621328 3/8” 10 2m AF-CO-09X010

621329 1/2” 12 2m AF-CO-09X012

621330 5/8” 15 2m AF-CO-09X015

621331 3/4” 20 2m AF-CO-09X020

621332 7/8” 22 2m AF-CO-09X022

621333 1.1/8” 28 2m AF-CO-09X028

621334 1.3/8” 35 2m AF-CO-09X035

621335 1.5/8” 42 2m AF-CO-09X042

621336 2.1/8” 54 2m AF-CO-09X054

Code

Tube ID Length Supplier Code Inches mm M

621337 1/4” 54 2m AF-CO-13X006

621338 3/8” 10 2m AF-CO-13X010

621339 1/2” 12 2m AF-CO-13X012

621340 5/8” 15 2m AF-CO-13X015

621341 3/4” 20 2m AF-CO-13X020

621342 7/8” 22 2m AF-CO-13X022

621343 1.1/8” 28 2m AF-CO-13X028

621344 1.3/8” 35 2m AF-CO-13X035

621345 1.5/8” 42 2m AF-CO-13X042

621346 2.1/8” 54 2m AF-CO-13X054

621347 2.5/8” 67 2m AF-CO-13X067

621348 3.1/8” 80 2m AF-CO-13X080

3/4” Wall Thickness

Wall Thickness

AF/ArmaFlex

Perfect for conditioned areas

needing thermal and microbial protection.

// Microban© antimicrobial protection, only

- available with Armacell

// LEED® and BREEAM® certified

// Extended system warranty of 10 years*

// Fire safety B-s3,d0

// Guaranteed condensation control and- protection against corrosion under insulation

AF/ArmaFlex EVO

Combining excellent condensation control, energy efficiency and fire safety.

// Microban antimicrobial protection, only- available with Armacell

// LEED and BREEAM certified

// Extended system warranty of 10 years*

// Fire safety B/B ����-s2,d0

> ArmaFlex 15m coils are supplied individually bagged

> ArmaFlex AC continous coils are supplied in a box for easy dispense

> The AC coils length varies from 20m to 75m depending on the tube diameter.

Continuous

ArmaFix Ecolight

Insulation pipe support with enhanced safety capabilities.

// Self-sealing, fast and easy to install

// Extended system warranty of 10 years*

// 100% recycled PET insulation

// Prevent thermal bridging

ArmaFlex Protect

Through the wall firestop solutions for cable, pipe and mixed penetrations.

TO FIRE

// Comprehensive range for almost all applications

// Qualified to 2 hour fire resistance

// Fire stop solution can be paired with- AF/ArmaFlex EVO product for optimised safety - and insulation as a complete solution

621377

1/2” Wall Thickness

> The ideal choice when insulating tanks, ductwork, large pipes or irregular shapes

> Standard sheets supplied in 2m x 0.5m sizes

> Continuous rolls are 1 metre wide.

0.9mm 28mm TX0283

V18307 28mm 6 m 0.6468 kg 0.9mm 28mm TX0286

508863 35mm 3 m 1.0817 kg 1.2mm 35mm EN 1057 R250

508843 35mm 6 m 1.07667 kg 1.2mm 35mm TX0356

508864 42mm 3 m 1.3057 kg 1.2mm 42mm TX0423

508844 42mm 6 m 1.3057 kg 1.2mm 42mm TX0426

508865 54mm 3 m 1.6897 kg 1.2mm 54mm TX0543

508845 54mm 6 m 1.6897 kg 1.2mm 54mm TX0546

508866 67mm 3 m 2.04445 kg 1.5mm 67mm TX0673

508846 67mm 6 m 2.04444 kg 1.5mm 67mm TX0676

508867 76mm 3 m 2.9701 kg 1.5mm 76mm TX0763

508847 76mm 6 m 2.90864 kg 1.5mm 76mm TX0766

508868 108m

At wolseley.co.uk you can set appropriate limits and user permissions to meet your business needs in real time. Scan the

Coupling

543581 8mm 14mm

543582 10mm 10mm

543583 15mm 15mm

543585

543531

Female Iron Connectors

CB902.15

543533 22mm x 1” 32.25mm FF CB902.22

543534 28mm x 1” 32mm FF CB902.23

543535 35mm x 1.1/4” 36.75mm FF CB902DR.24

CB902DR.26

MUNBRCC054

Ring (M10) Single – Brass

637074 15mm 25 mm 100 0.0198 kg 15mm MUN015-M10

637075 22mm 37 mm 50 0.024 kg 22mm MUN022-M10

637076 28mm 47 mm 50 0.034 kg 28mm MUN028-M10

637077 35mm 58 mm 50 0.043 kg 35mm MUN035-M10

637078 42mm 69 mm 25 0.05 kg 42mm MUN042-M10

637079 54mm 85 mm 25 0.074 kg 54mm MUN054-M10

Board

– Cast Brass

637080 67mm 93 mm 10 0.103 kg 67mm MUN067-M10

637081 76mm 103 mm 10 0.13 kg 76mm MUN076-M10

637082 108mm 127 mm 5 0.229 kg 108mm MUN108-M10

637083 133mm 161 mm 5 0.489 kg 133mm MUN133-M10

637084 159mm 190 mm 3 0.571 kg 159mm MUN159-M10

Munsen Ring (1/8”) Single – Brass

Munsen Ring (M10) Single – Chrome

637085 15mm 25 mm 100 0.0198 kg 15mm MUNC015-M10

637086 22mm 37 mm 50 0.024 kg 22mm MUNC022-M10

637088 35mm 58 mm 50 0.043 kg 35mm MUNC035-M10

637089 42mm 69 mm 25

Munsen Ring (1/4”) Single – Brass

Munsen Ring (M10) Rapid Fix Single

Ring

Double – Brass

Code Size Length Pack Qty KG/M Outside Diameter Part Number

637103 15mm 33 mm 100 0.022 kg 15mm MUND015-M10

637104 22mm 41 mm 50 0.027 kg 22mm MUND022-M10

637105 28mm 52 mm 50 0.045 kg 28mm MUND028-M10

637106 35mm 61 mm 25 0.052 kg 35mm MUND035-M10

637107 42mm 70 mm 25 0.054 kg 42mm MUND042-M10

637108 54mm 87 mm 25 0.08 kg 54mm MUND054-M10

637109 67mm 104 mm 10 0.117 kg 67mm MUND067-M10

637110 76mm 116 mm 5 0.152 kg 76mm MUND076-M10

637111 108mm 152 mm 5 0.252 kg 108mm MUND108-M10

Munsen Ring (1/4”) Double – Brass

637114

Male Backplate (M10) – Brass

White Overflow Pipe and Fittings

Male Backplate (M10) – Chrome

Male Backplate (1/8”) – Brass

Male Backplate (1/4”) – Brass

All our Channel and Channel Components are galvanised to ensure that they stand up to the elements and maintain their appearance, ensuring that they do not rust.

Also both the channel and accessories conform to the BS 6946 1988 standards to give you all the confidence you need in your installation.

Our Medium Duty Cable tray and components are produced using mild steel and is pre-galvanised to ensure reliability and a longer life span.

All of our Medium Duty Cable tray conforms to BS 61537:2007 to provide you with confidence in your installation.

Code Description Unit

M92999 Cable Tray Light Duty - Galvanised 50mm x 3m Length Each

M93000 Cable Tray Light Duty - Galvanised 75mm x 3m Length Each

M93001 Cable Tray Light Duty - Galvanised 100mm x 3m Length Each

M93002 Cable Tray Light Duty - Galvanised 150mm x 3m Length Each

M93003 Cable Tray Medium Duty - Galvanised 50mm x 3m Length Each

M93008 Cable Tray Medium Duty - Galvanised 75mm x 3m Length Each

M93015 Cable Tray Medium Duty - Galvanised 100mm x 3m Length Each

M93023 Cable Tray Medium Duty - Galvanised 150mm x 3m Length Each

M93032 Cable Tray Medium Duty - Galvanised 225mm x 3m Length Each

M93042 Cable Tray Medium Duty - Galvanised 300mm x 3m Length Each

M93053 Cable Tray Medium Duty - Galvanised 450mm x 3m Length Each

M93004 Flat Bend Medium Duty - Galvanised 90° / 50mm Each

Channel Nuts, Threaded Rod and Fixings

M93009 Flat Bend Medium Duty - Galvanised 90° / 75mm Each

M93016 Flat Bend Medium Duty - Galvanised 90° / 100mm Each

M93024 Flat Bend Medium Duty - Galvanised 90° / 150mm Each

M93033 Flat Bend Medium Duty - Galvanised 90° / 225mm Each

M93043 Flat Bend Medium Duty - Galvanised 90° / 300mm Each

M93054 Flat Bend Medium Duty - Galvanised 90° / 450mm Each

Did you know …

At wolseley.co.uk you can manage your online workforce efficiently; upload multiple new users, set roles and reset their passwords at a time that suits you. Scan the QR code and register online today.

eDocuments – View

At wolseley.co.uk access all your invoices, credit notes and statements from the last 7 years. Scan the QR code and register online today.

691586 Nut full for nylon rod M12

691579 Nut domed for nylon rod M10

691580 Nut domed for nylon rod M12

691591 Washer faced nut for nylon rod M10

691592 Washer faced nut for nylon rod M12

Plastic Hanger

Code Description

697041 P2 plastic hanger (pack

At wolseley.co.uk you can manage your account preferences to save you searching for paperwork. Scan the QR code and register online today.

Metal Connector

Code Description

Nylon Rod

Stud Clips

Code Description

671570 Stud clip M8 x 5/8” 16mm (pack of 10)

671571 Stud clip M8 x 3/4” 19mm (pack of 10)

671572 Stud clip M8 x 7/8” 22mm (pack of 10)

671574 Stud clip M8 x 1.1/8” 28mm (pack of 10)

671575 Stud clip M8 x 1.1/4” 32mm (pack of 10)

671576 Stud clip M8 x 1.3/8” 35mm (pack of 10)

671578 Stud clip M8 x 1.5/8” 41mm (pack of 10)

671584 Stud clip M10 x 5/8” 16mm (pack of 10)

671585 Stud clip M10 x 3/4” 19mm (pack of 10)

671586 Stud clip M10 x 7/8” 22mm (pack of 10)

671588 Stud clip M10 x 1.1/8” 28mm (pack of 10)

671589 Stud clip M10 x 1.1/4” 32mm (pack of 10)

671590 Stud clip M10 x 1.3/8” 35mm (pack of 10)

671592 Stud clip M10 x 1.5/8” 41mm (pack of 10)

T83727

Description

IS5494 10mm x 1.1/2” zinc plated countersunk pozi woodscrew (pack of 200)

IS5498 10mm x 2.1/2” zinc plated countersunk pozi woodscrew (pack of 100)

IS5485 8mm x 1.1/2” zinc plated countersunk pozi woodscrew (pack of 200)

IS5496 10mm x 2” zinc plated countersunk pozi woodscrew (pack of 200)

IS5499 10mm x 3” zinc plated countersunk pozi woodscrew (pack of 100)

IS5483 8mm x 1” zinc plated countersunk pozi woodscrew (pack of 200)

IS5487 8mm x 2” zinc plated countersunk pozi woodscrew (pack of 200)

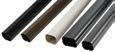

The range of internal and external trunking will ensure that the air conditioning refrigeration pipes are protected with a professional finish.

The colours- black, white, brown and anthracite will match most brands of condensing units available, UV resistant, fire proof and can be painted to suit many indoor and outdoor applications.

90° Vertical Elbow

Code

631683 ID-SC-100-W Slimduct - 100mm Elbow Bend - White

697263 ID-SC-100-K Slimduct - 100mm Elbow Bend - Black

631708 ID-SC-100-B Slimduct - 100mm Elbow Bend - Brown

691440 ID-SC-100-A Slimduct - 100mm Elbow Bend - Anthracite

631684 ID-SC-75-W Slimduct - 75mm Elbow Bend - White

697251 ID-SC-75-K Slimduct - 75mm Elbow Bend - Black

693437 ID-SC-75-B Slimduct - 75mm Elbow Bend - Brown 691430 ID-SC-75-A Slimduct - 75mm Elbow Bend - Anthracite

45° Vertical Elbow

697264

ID-SCF-100-K Slimduct - 100mm 45 Degree Elbow Bend - Black

631685 ID-SCF-100-W Slimduct - 100mm 45 Degree Elbow Bend - White 631709 ID-SCF-100-B Slimduct - 100mm 45 Degree Elbow Bend - Brown 631686 ID-SCF-75-W Slimduct - 75mm 45 Degree Elbow Bend - White 697252 ID-SCF-75-K Slimduct - 75mm 45 Degree Elbow Bend - Black 693438 ID-SCF-75-B Slimduct - 75mm 45 Degree Elbow Bend - Brown

Reducer

631687 ID-SDR-100-75-W Slimduct - 100-75mm Reducer Joint - White 697265 ID-SDR-100-75-K Slimduct - 100-75mm Reducer Joint - Black

631710 ID-SD-100-B Slimduct - 100mm - 2000mm -

-

45° Flat Elbow

631705

ID-SKF-100-W Slimduct - 100mm 45 Degree Flat Bend - White

697270 ID-SKF-100-K Slimduct - 100mm 45 Degree Flat Bend - Black

631696

Slimduct - 100mm

631716

691444

ID-SKF-100-B Slimduct - 100mm 45 Degree Flat Bend - Brown

ID-SKF-100-A Slimduct - 100mm 45 Deg Flat Bend - Anthracite

631706 ID-SKF-75-W Slimduct - 75mm 45 Degree Flat Bend - White

697257 ID-SKF-75-K Slimduct - 75mm 45 Degree Flat Bend - Black

693444 ID-SKF-75-B Slimduct - 75mm 45 Degree Flat Bend - Brown

691434 ID-SKF-75-A Slimduct - 75mm 45 Deg Flat Bend - Anthracite

697271 ID-SP-100-K Slimduct - 100mm Flat Rosette Black

688633 ID-SP-100-W Slimduct - 100mm Flat Rosette White

631717 ID-SP-100-B

ID-SP-75-B Slimduct - 75mm Flat Rosette Brown

T Joint - Brown

SpeediChannel™ is an innovative channel system used to cover air conditioning line sets. The two-part system has a base and a cover. The base is fastened to a wall or ceiling, then a clever little plastic clip (SpeediClip™) snaps into a channel already molded into the base. SpeediClip™ is the fastest, most convenient way to complete a line set cover installation.

Manufactured from rigid PVC, the SpeediChannel™ system is a natural colour that is a very close match to the typical mini split condensing unit case. However, the SpeediChannel™ system can be painted as desired to match any wall colour. The PVC used in the SpeediChannel™ system is resistant to UV light, and is UL rated.

SpeediChannel – 105mm Ivory

613560 EB-105 Inside Elbow 90° 105mm 90° Bend

613564 EIN-105 Outside Elbow 90° 105mm 90° External Elbow

613568 FB-105 Flat Bend 90° 105mm 90° Flat Bend

613571 FB-105-45 Flat Bend 45° 105mm 45° Flat Bend

613544 CP-105 Connection Piece 105mm Connector

613580 FR-105 Flat Rosette 105mm Rosette

613596 WR-105 Wall Rosette 105mm Rosette Wall

613556 DE-105 Duct End 105mm Duct End

613592 WC-105 Wall Cover 105mm Wall Cover

668005 DC-105 105mm End Cap Duct Cap

613588 TJ-105 T-joint 105mm Tee

613576 FJ-105 Flexi Hose Kit 105mm Ivory Flex Joint

667965 RJ-70-105 70/105mm T-joint Reducer Reducer Joint

1,000s

Speak to a member of our team to find out more.

of essential products stocked in

every

branch. Ready for you when you need them.

At wolseley.co.uk our refrigeration selector makes choosing the correct refrigeration system simple. Scan the QR code and register online today.

Ring Mounted Electronic (EC) Fans

3 Way Dual Shut-Off Valve For PRV’s

Steel Connection For 925 3 Way Valve Code

672559 SDK2-24.8BAR-CE

674277 SDK2-27.6BAR-CE

674278

SDK2-31.0BAR-CE

Danfoss High Pressure Ball Valves (120bar MWP)

Danfoss Ball Valves with Schraeder & Sight Glass (48bar MWP)

Danfoss Ball Valves (48bar MWP)

Danfoss Hand Wheel Shut-Off Valves

Hand Wheel Shut-Off Valves

Henry Packed Shut-Off Valves (Angled Connections)

Danfoss Ball Valves with Schraeder (48bar MWP)

Danfoss

(Extended Ends)

Danfoss Check

116003 3/8"

116004 1/2" 672671

11/8"

NRV35S 1.3/8"

NRV355 1.5/8"

Did you know …

are

Sieve

(Heat Pump) Driers

693757 023Z1467 DCB163S 3/8" S

693752 023Z1405 DCB163 3/8" Flare

693754 023Z1409 DCB303 3/8" Flare

693756 023Z1466 DCB164S 1/2" S

693751 023Z1404 DCB164 1/2" Flare

693987 023Z1408 DCB304 1/2" Flare

693755 023Z1465 DCB165S 5/8" S

693750 023Z1403 DCB165 5/8" Flare

693758 023Z1469 DCB305S 5/8" S 693753 023Z1407 DCB305 5/8" Flare

DCL (80% Molecular Sieve, 20% Activated Alumina)

Best used as a service replacement on existing systems Code Supplier Code Model Size

693959 023Z4501 DCL032S 1/4" S

693968 023Z5000 DCL032 1/4" Flare

693960 023Z4506 DCL052S 1/4" S

693970 023Z5002 DCL052 1/4" Flare

694034 023Z4511 DCL082S 1/4" S

693972 023Z5004 DCL082 1/4" Flare

694036 023Z5028 DCL162 1/4" S

694035 023Z5007 DCL162 1/4" Flare

694033 023Z5015 DCL033S 3/8" S

693969 023Z5001 DCL033 3/8" Flare

693961 023Z4509 DCL053S 3/8" S

693971 023Z5003 DCL053 3/8" Flare

693962 023Z4514 DCL083S 3/8" S

693973 023Z5005 DCL083 3/8" Flare

693964 023Z4521 DCL163S 3/8" S

693975 023Z5008 DCL163 3/8" Flare

693966 02324528 DCL303S 3/8" S

693955 023Z0012 DCL303 3/8" Flare

693963 023Z4516 DCL084S 1/2" S

693974 023Z5006 DCL084 1/2" Flare

694037 023Z4523 DCL164S 1/2" S

693976 023Z5009 DCL164 1/2" Flare

693956 02320013 DCL304 1/2" Flare

693965 023Z4524 DCL165S 5/8" S

693977 023Z5010 DCL165 5/8" Flare

693957 02320014 DCL305 5/8" Flare

693958 023Z0156 DCL306 3/4" Flare

694038 02325034 DCL167S 7/8" S 693967 023Z4534 DCL307S 7/8" S

Burnout Driers

AC&R

AC&R Helical Oil Separators (Flanged Type)

AC&R Oil Reservoirs

AC&R Suction Line Accumulators (Vertical)

Valve Bodies – Externally Equalised

068Z3209 TEX 2 Range N R22

068Z3229 TEX 2 Range B MOP R22

068Z3211 TEX 2 Range N MOP R22

/ A

068Z3404 TES 2 Range B R404A

068Z3411 TES 2 Range B MOP R404A 675086 068Z3348 TEN 2 Range N R134a 693556 068Z3349 TEN 2 Range N MOP R134a 675132

TE2 Range N R1234yf

Valve Bodies – Internally Equalised

Code Supplier Code Description Refrigerant

623131 068Z3714 T2 Range N R407F / A

693554 068Z3228 TX 2 Range B MOP R22

675081 068Z3206 TX 2 Range N R22

693557 068Z3401 TS 2 Range B R404A

675087 068Z3400 TS 2 Range N R404A

693558 068Z3402 TS 2 Range N MOP R404A

693563 068Z3408 TS 2 Range NL MOP R404A

693561 068Z3406 TS 2 Range NM R404A

675085 068Z3346 TN 2 Range N R134a

693555 068Z3347 TN 2 Range N MOP R134a

675131 068Z3496 TZ 2 Range N R407C

623361 068Z3727 T 2 Range N R448A / R449A

622158 068Z7483 T 2 Range N R454C

622160 068Z7496 T 2 Range N R455A

622162 068Z7487 T 2 Range N R1234yf

Orifice Assembly With Filter - GREEN CAP - Requires Solder Adaptor For Inlet

Valve Bodies – Externally Equalised Code

693509 068Z3713 TE2 Range N R407F / A

675092 068Z3284 TEX 2 Range N R22

675096 068Z3415 TES 2 Range N R404A

693568 068Z3417 TES 2 Range N MOP R404A

693574 068Z3430 TES 2 Range NL MOP R404A

693570 068Z3419 TES 2 Range B R404A

693572 068Z3421 TES 2 Range B MOP R404A

675094 068Z3385 TEN 2 Range N R134a

693575 068Z3446 TEZ 2 Range N R407C

693576 068Z3447 TEZ 2 Range N MOP R407C

623364 068Z3730 TE2 Range N R448A / R449A

624497 068Z3807 TE2 Range N R452A

622165 068Z7492 TE2 Range N R454C

622167 068Z7501 TE2 Range N R455A

622169 068Z7493 TE2 Range N R1234yf

tba 068Z2900 TE2 Range N CO2

Valve Bodies – Internally Equalised

Code Supplier

623133 068Z3716 T2 Range N R407F / A

068Z3281 TX 2 Range N R22

068Z3418 TS 2 Range B R404A 693565 068Z3410 TS 2 Range

068Z3429

Thermostatic Elements

Code

693468 067B3501 TE 5 Element Range N R407F/A

693469 067B3502 TE 5 Element Range NM MOP R407F/A

693470 067B3503 TE 5 Element Range NL MOP R407F/A

693536 067B3250 TEX 5 Element Range N R22

693538 067B3267 TEX 5 Element Range N MOP R22

693537 067B3251 TEX 5 Element Range B MOP R22

675125 067B3342 TES 5 Element Range N R404A

693543 067B3343 TES 5 Element Range B MOP R404A

693545 067B3358 TES 5 Element Range NL MOP R404A

693544 067B3357 TES 5 Element Range NM MOP R404A

693541 067B3297 TEN 5 Element Range N R134A

693542 067B3298 TEN 5 Element Range N MOP R134A

693540 067B3278 TEZ 5 Element Range N R407C

693539 067B3277 TEZ 5 Element Range N MOP R407C

693045 067B3252 TE5 Element Range N R448A / R449A

My Most Ordered

At wolseley.co.uk you can access all the products you order regularly, for easy re-ordering. Scan the QR code and register online today.

Orifice Assembly

Thermostatic Elements

693477 067G3500 TE 55 Element Range N R407F/A

693610 067G3205 TEX 55 Element Range N R22

693611 067G3220 TEX 55 Element Range N MOP R22

693614 067G3302 TES 55 Element Range N R404A

693612 067G3222 TEN 55 Element Range N R134A

693613 067G3240 TEZ 55 Element Range N R407C

067B3366 TEZ 12 Element Range N R407C

693046 067B2512 TE 12 Element Range N R448A / R449A

693474 067B3560 TE 20 Element Range NM MOP R407F/A

693475 067B3561 TE 20 Element Range N R407F/A

Order At wolseley.co.uk you can add items to your basket quickly and easily using Wolseley product codes. Scan the QR code and register online today.

Cross Reference Chart - Old To New Danfoss TE5 To TE55 Orifices

The chart below compares the duty of the latest TE valve range with the original. In general the new and old parts can be mixed however it is important to realise that the duty is based on the orifice size. Please see notes below the table.

2

2

4

1

Notes:

1 The rated capacity is given for the N Range orifice temperature range -40°C to 10°C

2 If an orifice needs replacing for TE12 with orifice 1,2 or 3 the complete valve will need replacing with the TE5 version.

3 Orifices marked * are new additions to the range.

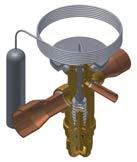

TUA Expansion Valve (R410A) - Interchangeable Orifice

TUA stainless steel thermostatic expansion valves are used for liquid injection into evaporators on both refrigeration and air conditioning systems using fluorinated refrigerants.

TUA valves are compact in design, light weight and have steel/copper bi-metal connections for fast soldering. TUA have an interchangeable orifice and adjustable superheat.

623331 068U2414 TUA

623333 068U1031 TUA Orifice No. 1 1.3 - -

623334 068U1032 TUA Orifice No. 2 2.1 - -

623335 068U1033 TUA Orifice No. 3 2.9 - -

623336 068U1034 TUA Orifice No. 4 4.5 - -

623337 068U1035 TUA Orifice No. 5 5.9 - -

623338 068U1036 TUA Orifice No. 6 9 - -

623339 068U1037 TUA Orifice No. 7 12 - -

623340 068U1038 TUA Orifice No. 8 18 - -

623341 068U1039 TUA Orifice No. 9 26 - -

TGEL Expansion Valve (R410A) - Fixed Orifice

> TGE is an innovatively designed series of thermostatic expansion valves for fluorinated refrigerants.

> TGE has copper connections upgraded to high-pressure applications for hermetically tight soldering, and is available with a wide variety of connection types such as solder, flare, MIO, and ORFS, and a wide variety of connection sizes.

> Head pressure independent.

> Version with MOP (Max. Operating Pressure).

> Rated capacity from 3.5 to 52 TR (12 to 182 kW) - R410A.

> Straightway flow.

> Bi-flow balanced port design for TGE 20/TGE 40, TGE 10 is balanced port design in normal flow direction. Low hysteresis/reduced friction.

> Opening superheat (OSH) max. 4°K

> Max. working pressure 46 bar/667 psi.

> Increased lifetime for heat pump application (also with R 410A ).

> New cylindrical bulb design made of stainless steel.

> Easy adjustment of static superheat setting (0K/ 0°F8K/14.4°F).

> Stainless steel capillary tube for superior strength and ductility.

> Laser welded stainless steel power element for unsurpassed joint strength and operational lifetime. Solder copper or flare connection (flare, MIO, ORFS) available.

Danfoss Evaporator Pressure Regulating Valves

Designed to maintain a pre-determined minimum evaporator pressure or temperature.

The valves can be used on either single or multi-evaporator systems and only respond to variations in inlet pressure.

Danfoss Crankcase Pressure Regulating Valves

Crankcase Pressure Regulating Valves are designed to prevent overloading of the compressor motor by limiting the crankcase pressure to a predetermined maximum value during and after a defrost cycle or a normal shutdown period.

Danfoss Condenser Pressure Regulating Valves

These valves respond to changes in inlet pressure, opening on a pressure rise.

KP1

674968 KP2 060-112066

693690 RT1 017-524566 LP -0.8 to 5.0 0.5 to 1.6 Auto 25 Flare

693663 KP7B 060-119166 HP 8.0 to 32 4.0 Fixed Manual 35 Flare

674987 KP5 060-117166 HP 8.0 to 32 1.8 to 6.0 Auto 35 Flare

693661 KP5 060-117966 HP 8.0 to 32 1.8 to 6.0 Auto 35 Solder

693662 KP7W 060-119066 HP 8.0 to 32 4.0 to 10 Auto 35 Flare

693682 RT1A 017-500166 LP -0.8 to 5.0 0.5 to 1.6 Auto 25 3/8" BSP

693683 RT6B 017-503466 HP 10 to 28 1.0 Fixed Manual 38 Flare

693693 RT5AL 017L004066 HP 4.0 to 17 0.35 Fixed Auto 25 3/8" BSP

693686 RT5A 017-504766 HP 4.0 to 17 1.3 Fixed Manual 25 3/8" BSP

693685 RT5A 017-504666 HP 4.0 to 17 1.2 to 4.0 Auto 25 3/8" BSP

Oil Pressure Differential Switches

MP55 060B017366 0.3 to 4.5 120

Ranco Dual Pressure Switches

Ranco Single Pressure Switches

Controls Dual Pressure Switches

Controls Single Pressure Switches

Danfoss Mini (Cartridge) Pressure Switches

Ranco Mini (Cartridge) Pressure Switches

Mini (Cartridge) Pressure Switches (Beer Master)

Danfoss Thermostats

Ranco ‘Varifix’ Service Replacement Thermostats

Code

674050 VL1 Refrigerator

674051 VL2 Electric Absorbtion Refrigerator

674052 VL3 Freezer & Ice Cream Cabinet

674053 VL4 Refrigeratore With Push Button Defrost

674054 VL5 Freezer With Standard Signal

674055 VL6 Freezer With Reverse Signal

674056 VL7 Bottle Cooler

674058 VL9 Two Temp Refrigerator

Johnson Controls Thermostats

674060 CTD9 Two Temp Refrigerator Did

AKV 10P and AKV 10PS are electronic operated expansion valves designed for refrigerating plants.

The AKV 10P and AKV 10PS valves are normally controlled by a controller from Danfoss range of ADAP- KOOL® controllers, that ensures a precise liquid injection into evaporators. AKV 10P and AKV 10PS valves are fully serviceable valves and are supplied as a parts programme with separate valve body and coil (with terminal box, cable or DIN plug).

Direct operated valve for AKV 10P

Valve type:

> AKV 10P0 to AKV 10P7

Working principle:

> PWM (Pulse-width modulation)

Recommended period of cycle time:

> 6 seconds

Regulation range (Capacity range):

> 10 - 100%

Connection type:

> Solder

Evaporating temperature

> -60 – 60°C / -76 – 140°F

Ambient temperature:

> -50 – 50°C / -58 – 122°F

MOPD, AKV 10P0 to AKV 10P6:

> 35 bar / 508 psig

MOPD, AKV 10P7:

> 18 bar / 261 psi

Minimum OPD, AKV 10P0 to AKV 10P7:

> 0 bar / 0 psi

Filter, replaceable:

> Internal 100 µm

Maximum working pressure:

> 90 barg / 1305 psig

MAP (Maximum Abnormal Pressure):

> 1305 psig

COT (Continuous Operation Temperature):

> 140°F

Applications:

> Traditional refrigeration

> Cold rooms

> Water chillers

> Applicable to R744, R22, R23, R134a, R404A, R407A, R407C, R407F, R410A, R422B, R422D, R448A, R449A, R449B, R450A, R452A, R507, R513A

For a fully updated list of approved refrigerants, visit www.products.danfoss.com and search for individual code numbers, where refrigerants are listed as part of product specifications

> Precise control of liquid injection

> The AKV 10P/10PS valves cover a capacity range from 0.2 – 12.5 kW / 0.06 – 3.55 TR (404A / R507) and are divided into 8 capacity ranges

> Supports variety of refrigerants

> Solenoid tight shut-off

> Fully serviceable valve

> Superior valve technology that provides soft pulse operation

> Approvals: REACH, UL, LLC CDC EURO TYSK, EAC

> The AKV 10P/10PS valves are supplied as a parts programme, as follows: separate valve incl. exchangeable orifice - separate coil

> The valve requires no adjustment

> Manufactured according to ISO/TS16949

Servo operated valve for AKV 10PS

Valve type:

> AKV 10PS4 to AKV 10PS7

Working principle:

> PWM (Pulse-width modulation)

Recommended period of cycle time:

> 6 seconds

Regulation range (Capacity range):

> 10 - 100%

Connection type:

> Solder

Evaporating temperature

> -60 – 60°C / -76 – 140°F

Ambient temperature:

> -50 – 50°C / -58 – 122°F

MOPD

> 35 bar / 508 psig

Minimum OPD, AKV 10PS4 to AKV 10PS7:

> 0.1 bar / 1.45 psi

Filter, replaceable:

> Internal 53 µm

Maximum working pressure:

> 90 barg / 1305 psig

MAP (Maximum Abnormal Pressure):

> 1305 psig

COT (Continuous Operation Temperature):

> 140°F

Recommended Danfoss Drier:

> ELIMINATOR® Hermetic filter drier, type DML / DMSC

AKV are electric expansion valves designed for refrigeration plants.

The AKV valves are supplied as a component programme, as follows:

> Separate valve

> Separate coil with terminal box or cable

> Spare parts in the form of upper part, orifice and filter

> The valve requires no adjustment

> Wide regulation range

> Replaceable orifice assembly

> Both expansion valve and solenoid valve

Did you know …

The cold room was originally invented in 1820 by Michael Faraday.

ETS is a series of electric expansion valves for precise liquid injection in evaporators for air conditioning and refrigeration applications. The valve piston and linear positioning design is fully balanced, providing bi-flow feature as well as solenoid tight shut-off function in both flow directions. The valve design uses bipolar drive providing very precise flow regulation. ETS valves are compatible with electronic control solutions from Danfoss and other manufacturers.

To replace the EKD316 use the EKE1A and change the temp sensors. To replace the EKC316a use the EKE1C

Did you know …

Wolseley UK was founded in 1887 by Fredrick Wolseley in New South Wales Australia. Fredrick, invented and developed the first commercially successful sheep shearing machinery which revolutionised the wool industry.

E2V is a series of electric expansion valves for precise liquid injection in evaporators for air conditioning and refrigeration applications. The valve piston and linear positioning design is fully balanced, providing bi-flow feature as well as solenoid tight shut-off function in both flow directions. The valve design uses bipolar drive providing very precise flow regulation. E2V valves are compatible with electronic control solutions from` and other manufacturers.

669490 E2VCABS3I0 Bipolar 3m Extension cable - superseal

669491 E2VCABS6I0 Bipolar 6m Extension cable - superseal

669492 E2VCABS9I0 Bipolar 9m Extension cable - superseal

669474 EVD0000E00 EVD Universal Superheat Controller

669475 EVD0000T00 EVD Universal Twin Superheat Controller

669476 EVDIS00EN0 EVD display module - English

669477 EVD0000UC0 Ultracap Back-up power supply

669478 EVDCNV00E0 EVD USB/tLan converter module

Sensors & Transducers

Code Part No. Description

669494 SPKT0013P0 -1 to 9.3bar transducer SPKT0013P0

669495 SPKT00E3P0 -1 - 12.8bar transducer SPKT00E3P0

669496 SPKT0033P0 0 - 34.5bar transducer SPKT0033P0

669497 SPKT00G1S0 0 - 60bar transducer SPKT00G1S0

669498 SPKT00L1S0 0 - 90bar transducer SPKT00L1S0

669493 SPKC005313 5m cable for SPKT transducers

668676 NTC060WH01 NTC Temperature Sensor - 6m

E2VSTAS230 Bipolar starter with 0.3m cable

>

>

>

>

669516 IJWPSA2N01S0724 115/230Vac 10 Amps - 8 Amps 2 NFC TTL-Modbus

669517 IJWPSA2B02S0519 115/230Vac 10 Amps - 8 Amps 2 NFC, RTC & Bluetooth RS485-Modbus

669518 IJWPSA4N01S0527 115/230Vac 10 Amps 5 Amps 8 Amps 2 NFC TTL-Modbus

669519 IJWPSA4R02S0518 115/230Vac 10 Amps 5 Amps 8 Amps 2 NFC & RTC RS485-Carel

669520 IJWPSA4B02S0523 115/230Vac 10 Amps 5 Amps 8 Amps 2 NFC, RTC & Bluetooth RS485-Modbus

669521 IJWPSA4B07S0517 115/230Vac 10 Amps 5 Amps 8 Amps 3 NFC, RTC, Bluetooth & Humidity RS485-Modbus

669522 IJWPLA6N01S0723 115/230Vac 16 Amps 8 Amps 12 Amps 2 NFC TTL-Modbus

669523 IJWPLA6B07S0516 115/230Vac 16 Amps 8 Amps 12 Amps 3 NFC, RTC, Bluetooth & Humidity RS485-Modbus

Code Model No.

668347 CM00005953

Temperature Sensors

Transformer

Code Model No. 668372 TRA0030000

RDM

Did you know …

Danfoss DGS Leak Detectors

Code Supplier Part No. Description Refrigerants

761370

761371

761372

761373

080Z2803 DGS Group 1 R1234ze, R454C, R1234yf*, R452A, R454A, R455A, R454B, R513A

080Z2804 DGS Group 2 R407F, R416A, R417A, R407A, R422A, R427A, R449A, R437A, R134A*, R438A, R422D

080Z2805 DGS Group 3 R448A, R125, R404A, R32, R507A, R434A, R410A, R452B, R407C*, R143B

080Z2806 DGS Propane Sensor R290

761374 080Z2800 DGS CO2 Sensor R744

761375 080Z2801 5m DGS CO2 Sensor R744

761376 080Z2802 2x 5m DGS CO2 Sensor R744

761377 080Z2809 DGS Group 1 + Buzzer & Light R1234ze, R454C, R1234yf*, R452A, R454A, R455A, R454B, R513A

761378 080Z2810 DGS Group 2 + Buzzer & Light R407F, R416A, R417A, R407A, R422A, R427A, R449A, R437A, R134A*, R438A, R422D

761379 080Z2811 DGS Group 3 + Buzzer & Light R448A, R125, R404A, R32, R507A, R434A, R410A, R452B, R407C*, R143B

761380 080Z2812 DGS Propane Sensor + Buzzer & Light R290

761381 080Z2807 DGS CO2 Sensor + Buzzer & Light R744

761382 080Z2808 5m DGS CO2 Sensor + Buzzer & Light R744

DGS Spares & Accessories Code Supplier

R1234ze, R454C, R1234yf*, R452A, R454A, R455A, R454B, R513A

R407F, R416A, R417A, R407A, R422A, R427A, R449A, R437A, R134A*, R438A, R422D

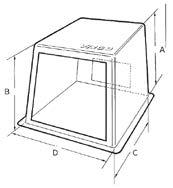

Eliwell Coldface Control Panel

> Standard model with 5 relays

> Easy to wall or panel mount

> Powerful and flexible enough to manage all functions in both conventional and ventilated cold rooms

Eliwell Coldface Temperature Probes

MasterCella Control Panel - 1ph

> SIP65 rated panel for demanding environments

> Complete cold room control

> Manage the end defrost completely and independently

Carel MasterCella Temperature Probes

Danfoss Optyma Panels

> Panels are supplied with 2off NTC sensors

Our network of over 40 branches nationwide with highly trained experts is here to support you with nationwide delivery and next day collection.

Probe For Optyma Control Panels

Evaporator Panels (1ph Fans)

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Evaporator control via Eliwell EWNext 961 controller or EWNext 974

> 1ph evaporator fans via common MCB protected output

> 3ph evaporator fans via individual MCBs with connections for fan klixons

> Coldroom door switch connections to stop fans

> MCB for coldroom lights

> MCB for door/drain heater

> LED lamps for Panel Live, defrost on

> NTC probe included

Twin Evaporator Panels

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Twin evaporator control via EliwellEW Next 961 or EWNext 978

> 1ph evaporator fans via common MCB protected output

> Coldroom door switch connections to stop fans

> MCB protected electric defrost output

> MCB for coldroom lights

> MCB for door/drain heater

> LED lamps for Panel Live, Defrost On

> NTC probes included

Universal Evaporator Control Panel

> Technopolymer enclosure / RAL7035 (Grey) / Top entry / IP55

> Door interlocked isolator

> Evaporator control via EliwellEW Next 974 controller

> Indications via controller display only

> Coldroom door switch connections to stop fans

> MCB & illuminated switch for coldroom lights

> MCB for drain heater

> MCB for door heater

> NTC probes included

4.5A 3ph (x3) 12.4kW

4.5A 3ph (x3) 15.5kW 3ph

4.5A 3ph (x3)

4.5A 3ph (x3)

4.5A

Universal Twin Evaporator Control Panel

> Technopolymer enclosure / RAL7035 (Grey) / Top entry / IP55

> Door interlocked isolator

> Twin evaporator control via EliwellEW Next 978 controller

> Indications via controller display only

> Coldroom door switch connections to stop fans

> MCB & illuminated switch for coldroom lights

> MCB for drain heater

> MCB for door heater

> NTC probes included

Standard Full System Coldroom Control Panels (Electric Defrost)

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Common MMS overload & contactor for 1ph compressor & condenser fans

> Adjustable anti short-cycle timer

> MCB for crankcase/oil separator heater

> Connections for oil return solenoid valve

> Evaporator control via Eliwell EWNext 961 or EWNext 974 controller

> 1ph evaporator fans via common MCB protected output

> Coldroom door switch connections to stop fans

> MCB protected electric defrost output

> MCB for coldroom lights

Standard Full System Coldroom Control Panels (Off Cycle Defrost)

GBSC-P614-1P1-EEN-03E 12 - 14A

GBSC-P626-1P1-EEN-03E 19 - 26A

696075 GBSC-D131-1P0-EEN-02A 24

GBSC-D139-1P0-EEN-02A

GBSC-D304-1P1-EEN-01A

GBSC-D306-1P1-EEN-01A

696088 GBSC-D309-1P1-EEN-01A 6 - 9A - 3ph 4.5A

GBSC-D313-1P1-EEN-01A

696090 GBSC-D317-1P1-EEN-01A 13

GBSC-D322-1P1-EEN-01A

GBSC-D324-1P1-EEN-01A 20

GBSC-D331-1PC-EEN-01A

696095 GBSC-D313-1P1-EEN-02A

GBSC-D339-1PC-EEN-02A

GBSC-P618-1P1-EEN-02A

Universal (1ph or 3ph Units) Full System Control Panels

> Technopolymer enclosure/RAL7035 (Grey)/Top entry/IP55

> Door interlocked isolator

> MMS overload & contactor for 1ph/3ph DOL compressor (selectable)

> Evaporator control via Eliwell EWNext 974 controller

> Indications via controller display only

> Coldroom door switch connections to stop fans

> Pump-down or non pump-down (selectable)

> Suitable for air defrost applications

> MCB & illuminated switch for coldroom lights

> MCB for drain heater

> NTC probes included

Standard Coldroom Auto Change-Over Control Panels

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> MMS overloads & contactors for 2x condensing units

> Adjustable anti short-cycle timers

> MCBs for crankcase heaters

> Connections for oil return solenoid valves

> Auto-changeover operation by time, temperature alarm or condensing unit fault

> Evaporator control via 2x Eliwell EWNext 978 controllers

> 1ph evaporator fans via 2x common MCB protected outputs

> Coldroom door switch connections to stop fans

> MCB for coldroom lights

> Manual change-over switch & LED lamps for Panel Live, individual Unit Run, Unit Fault, System Fault

> NTC probes included

Standard Evaporator Auto Change-Over Control Panels

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Auto-changeover operation by time, temperature alarm or condensing unit fault

> Evaporator control via 2x Eliwell EWNext 978 controllers

> 1ph evaporator fans via 2x common MCB protected outputs

> Coldroom door switch connections to stop fans

> MCB for coldroom lights

> Manual change-over switch & LED lamps for Panel Live, individual System Fault

> NTC probes included

Carel MPX Pro Stepper

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Evaporator control via Carel MPX Stepper controller with Ultracap

> 1ph evaporator fans via common MCB protected output

> Coldroom door switch connections to stop fans

> MCB protected electric defrost output

> MCB for coldroom lights

> MCB for door/drain heater

> LED lamps for Panel Live, Defrost On

> Volt-free alarm contact wired to terminals

> Complete with: 3 x Air probes (NTC060HP00), 1 x Fast pipe probe (NTC030HF01)

> Suitable for valves: Carel E²V / E³V

RDM Mercury MK3 PR0740-SD-IP-STEP

> Mild steel enclosure / RAL9010 (White) / Top Entry / IP65

> Door interlocked isolator

> Evaporator control via RDM Mercury MK3 Stepper controller

> RDM PR0627 Power store to close stepper valve on mains failure on -PS version only

> 1ph evaporator fans via common MCB protected output

> Coldroom door switch connections to stop fans

> Liquid Line Solenoid Valve (LLSV) output

> MCB protected electric defrost output

> MCB for coldroom lights

> MCB for door/drain heater

> LED lamps for Panel Live, Defrost On

> Volt-free alarm contact wired to terminals

> Complete with: 3 x PT1000 Air probes (PR0170), 2 x PT1000 Pipe probes (PR0180)

EWN961P7D30B003 Eliwell EWNext 961P Controller

EWN974PED30B003 Eliwell EWNext 974P Controller

EWN978P4D50B003 Eliwell EWNext 978P Controller

692401 GBBT-961/974 Eliwell Bluetooth Dongle - IDNext 961/974

692402 GBBT-978 Eliwell Bluetooth Dongle - IDNext 978

679231 LC1D09U7 LC1D09 - 9A/AC3 (230V

(230V Coil) Contactor

679236 LRD12 Overload Relay (5.5 to 8A)

679237 LRD14 Overload Relay (7 to 10A)

679238 LRD16 Overload Relay (9 to 13A)

679239 LRD21 Overload Relay (12 to 18A)

679240 LRD22 Overload Relay (16 to 24A)

679241 LRD32 Overload Relay (23 to 32A)

Note: For both RDM & Carel options - Pressure Transducers / Cables / Stepper Valves not

Account Preferences At wolseley.co.uk you can manage your account preferences to save you searching for paperwork. Scan the QR code and register online today. Did you know … Evaporative

Cable

The galvanised steel wire braid makes this cable ultra-strong and is stronger than CY and YY. It also offers reliable mechanical protection. CY Cable

Is used in environments where interference-free transmission is needed. CY Cables are multi-core, tinned copper wire braided cable with a PET (Polyethlene Terephthalate) separator which will protect it from electromagnetic interference.

LSOH = Low Smoke Zero Halogen cable rating

This cable works well with light mechanical stress and is suited to most environments. It is a very versatile cable and can be used outside when protected and also works well in dry and moist conditions.

LSOH = Low Smoke Zero Halogen cable rating

Heat Resistant Cable

Schneider Overloads for LC1 Contactors

Did you know …

The first ever ‘cable’ was developed by Thomas Edison in 1882. It wasn’t even a proper cable, it was made of copper tubes wrapped in jute.

Pump House General Purpose Lubricant

hard surfaces and deposits the acid into the filter drier leaving no harmful residue.

Rectorseal Acid Detector Kit

> Designed to detect acid in air conditioning and refrigeration oils

> Quickly detects the smallest trace of acids

Spectroline HVAC Fluorescent Leak Detection System pinpoints the exact source of every refrigeration and air conditioning leak.

Spectroline works with all CFC, HCFC and HFC refrigerants. By introducing a fluorescent additive to the refrigerant/oil system leaks can be identified upon scanning with an ultraviolet inspection lamp. The leaks will appear as a bright yellow green glow. Even intermittent leaks will be clearly identified.

Advantages

> Proven safe and effective. Compatible with all refrigerants, mineral, Alkyl Benzene and POE lubricants

> Remains in system even if refrigerant is lost

> Pinpoints leaks smaller than 3g/yr

Additives

Sporlan Acid Test Kits

Rectorseal Acid-Away 118ml

> Neutralises acid normally left behind in the system after a compressor burnout

> Suitable for preventative maintenance

> Eliminates the need for flushing systems

> Can be used to treat recovery, recycling and reclaiming units

Spectroline Oil Spillage Kits

Spectroline Acid Buster works by capturing acid which prevents it causing damage to the compressor. Compatible with all refrigerants and oils. Leaves no residue or contamination.

BEZ-2ECS

> Single POE/UNIVERSAL Cartridge

> Small to medium systems

> A cartridge treats up to 23 litres of lubricant or 70Kg of refrigerant

> 1 graduation treats 720ml of oil or 2.1Kg of refrigerant

BEZ-4/ECS

> Single POE/UNIVERSAL Cartridge

> Medium to largesystems

> A cartridge treats up to 61 litres of lubricant or 180Kg of refrigerant

> 1 graduation treats 1.9 litres of oil or 5.6Kg of refrigerant

Complete Leak Detection Kit

Kit includes:

> Violet light LED leak detection lamp

> (2) 0.5 oz (15 ml) universal/POE dye cartridges

> EZ-Ject™ dye injector assembly

> 8 in (20 cm) EZ-Ject™ hose assembly

> Fluorescence-enhancing glasses

> 2 oz (60 ml) GLO-AWAY™ Plus dye cleaner

> R-410a adapter/purge fitting

> Drip Plugs - Absorbent foam plug for end of hose assembly after use with dye