Working With Waste

Redefining the UK wastewater treatment works to better their role in river health and employ true waste circularity in the creation and exhibition of the compressed sludge brick.

William Pelling - MArch 2 Thesis - 2024

“My optimism lies precisely in the alliance of scarcity and agency, because design agency in the broadest sense is well placed to address the relational, contextual, and contingent senses of scarcity, and with this, in turn, new roles and opportunities for architectural thinking and action emerge.”

Jeremy

Till in Scarcity And Agency (2014)

Chapter 1: Nature-based wastewater treatment.

04 A new (foot)path.

05 Proposal site plan.

06 The importance of a transitional riparian zone.

Existing site sectional critique.

08 Proposed site sectional integration.

09 Reimagining waste infrastructure.

10 Superterranean pipes / Constructed wetland filtration tanks.

Sed-tank alley.

12 Not all wastewater is liquid.

Chapter 2: The compressed sludge brick (CSB).

13 Our big sludge problem.

14 Human pipeline advertisement.

15 > 2 billion bricks.

16 > 52 million tonnes.

17 > Why go with CSB?

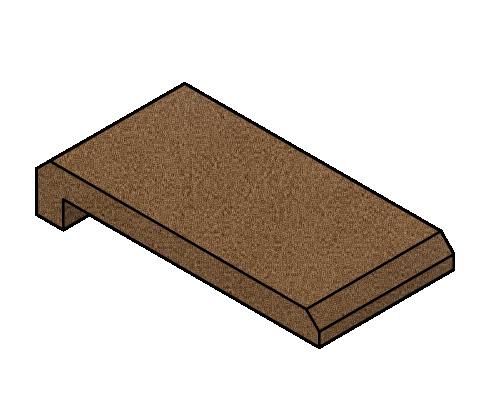

18 > How are they made?

19 > All products.

20 > Any colour (as long as its sludge).

21 We are running out of choices.

22-25 1:1 brick models.

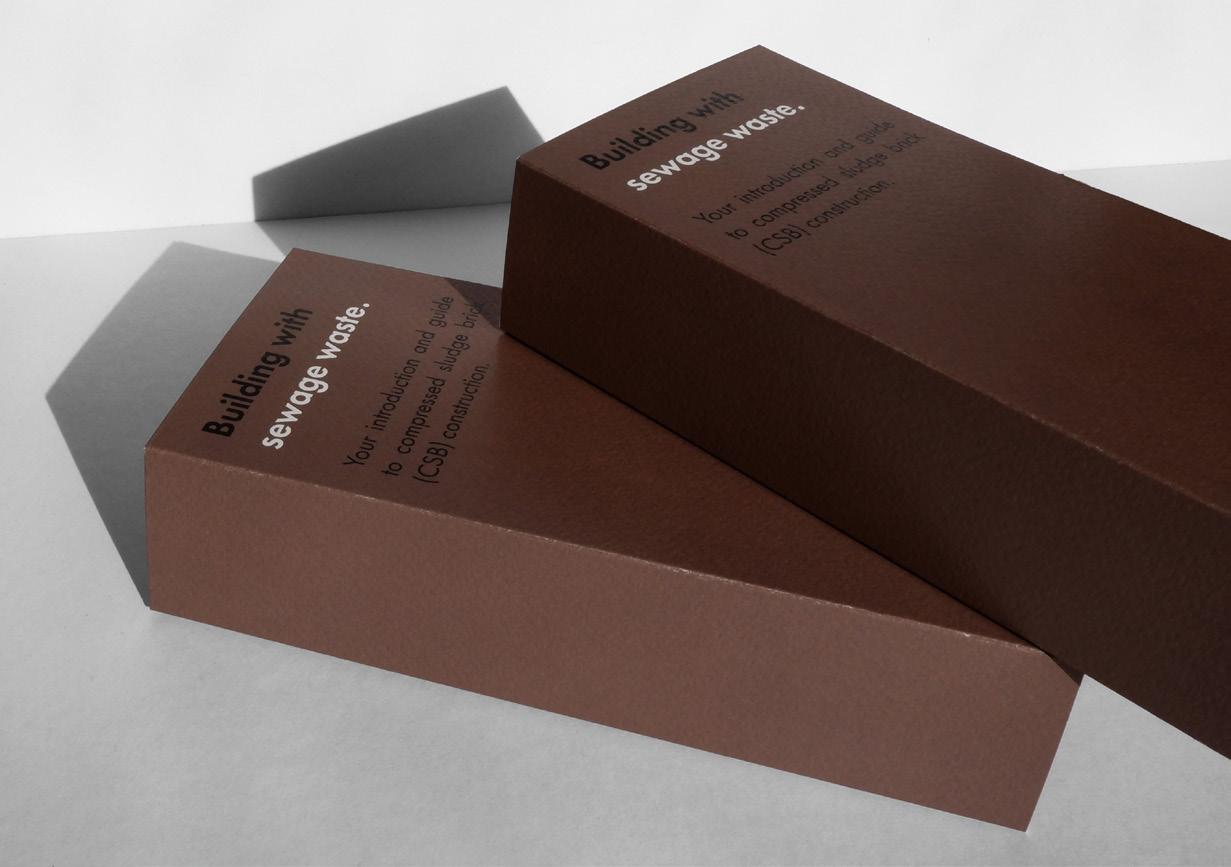

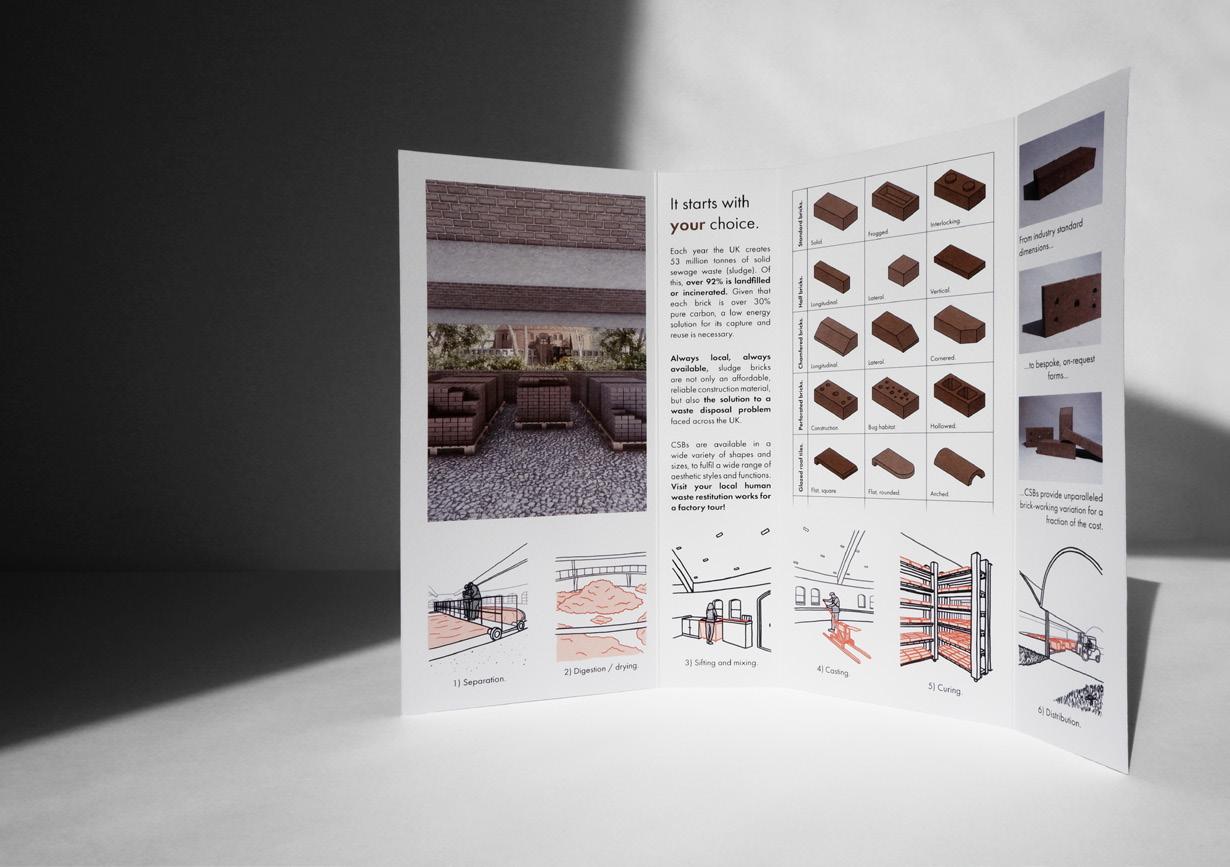

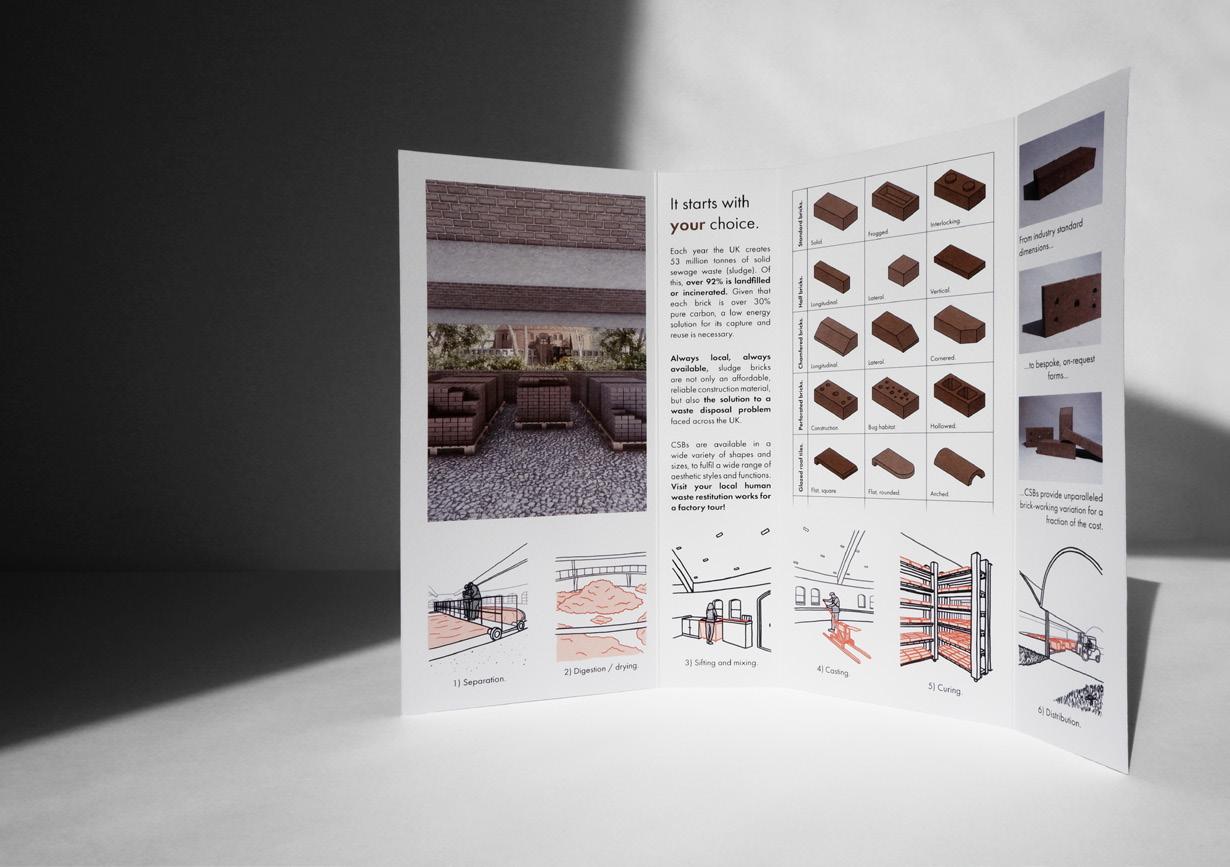

26-27 Bathroom reading.

28 Open source manufacture - model/render composite.

Chapter 3: The Sludge Brick Factory.

Contents:

07

11

29 From store and factory in 30 meters. 30 How it works. 31 The aesthetic of scarcity. 32 Ground floor circulation. 33 First floor circulation. 34 Three-dimensional manufacture. 35 Environmental strategy. 36 The brick-making room. 37 Natural dome lighting. 38 Brick delivery system. 39 Construction strategy. 40 Structural strategy. 41 The

bugs. 42

breakdown. 43

factory. Chapter

True

44 A self-sustaining system. 45 Sewage-sourced heat. 46 Surplus renewable power. 47 Minimising waste with superuse. 48 Visitor education. 49

redundancy. 50

bats and the

1:5 eave

A public

4:

circularity.

Accounting for

In 10, 20, 30 years time...

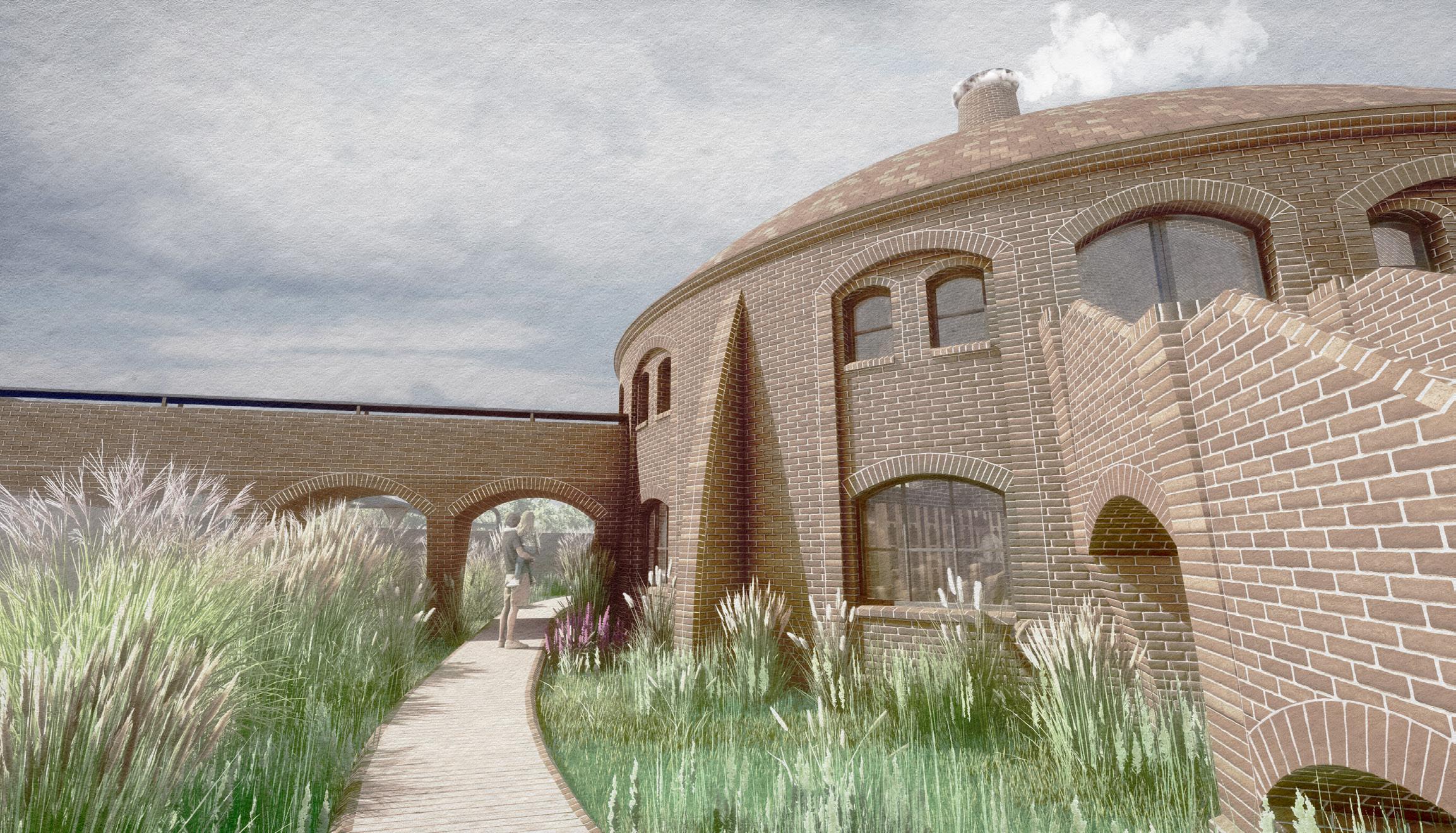

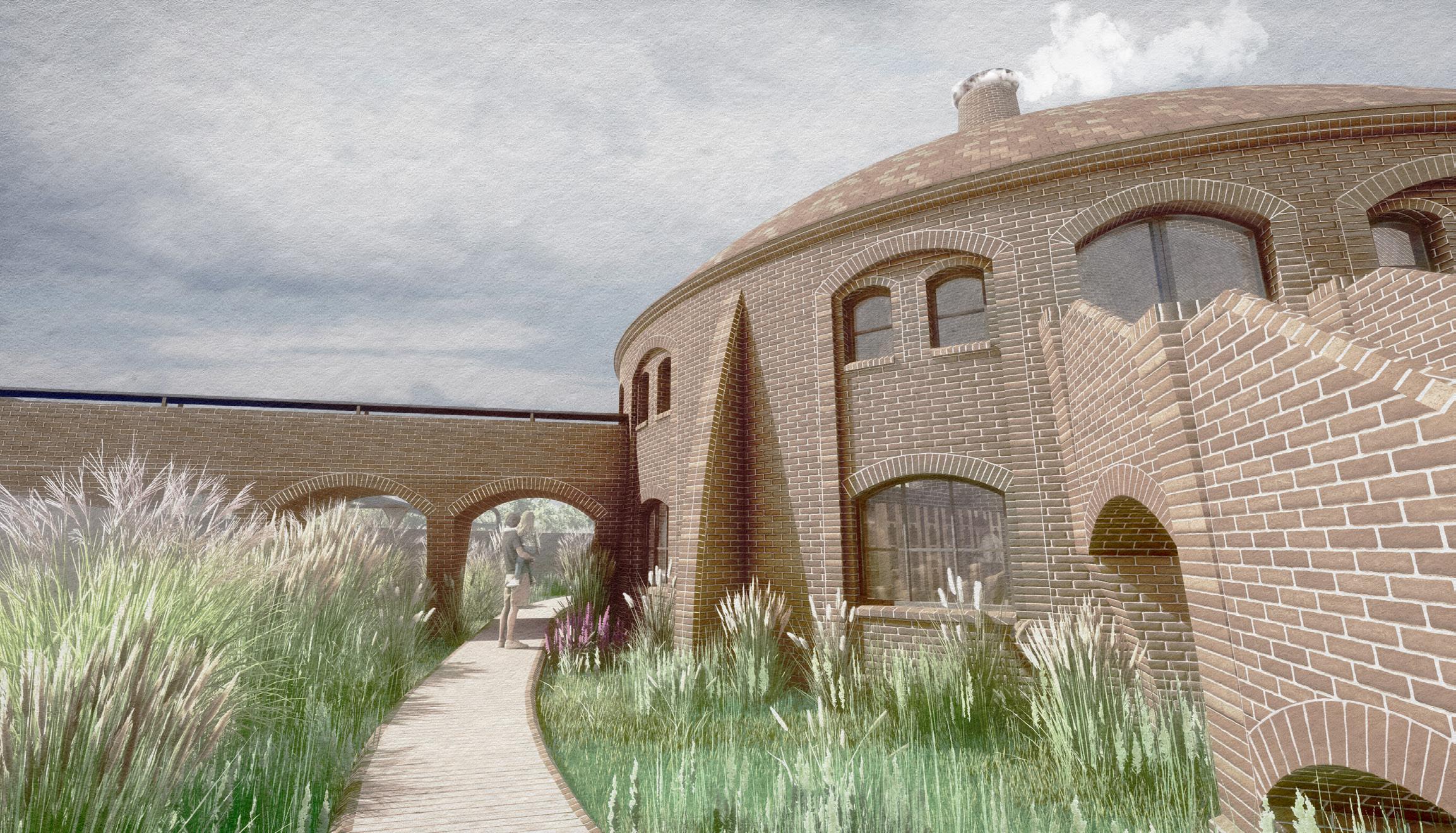

A new (foot)path.

The River Mersey is a popular walking route in the South of Manchester. Exploiting the fact that wastewater treatment works are located adjacently to their host rivers, these sites can be opened to the public, and their riverside walking routes diverted to encourage the public to interact with the site and their own waste.

01 04

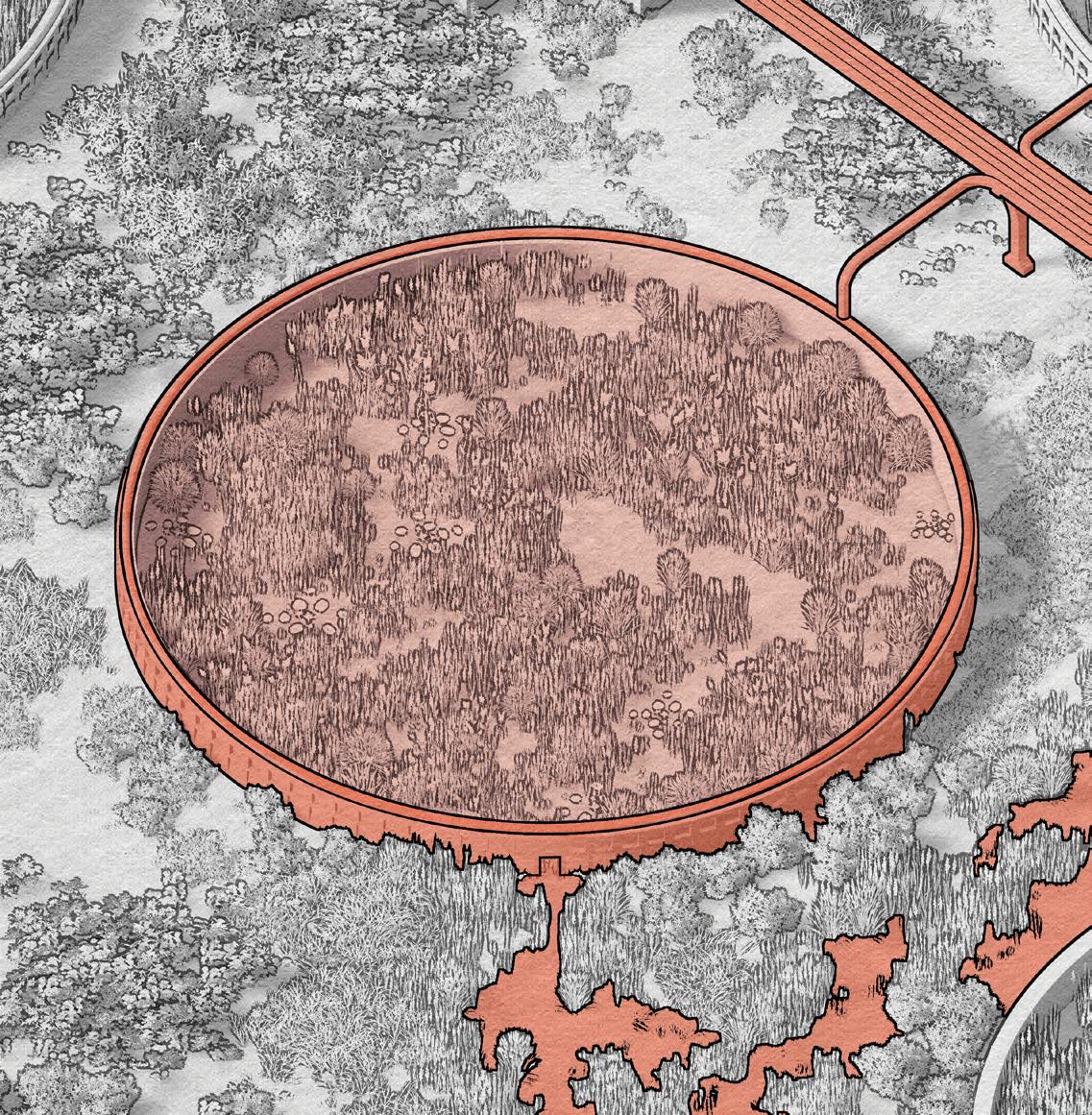

Grid size: 50m Proposal Site Plan 1.

2.

3.

4.

5.

14.

16.

17.

18.

1 2 3 4 5 6 7 8 9 10 12 13 14 15 16 17 18 11 01 05

Conveyor filter screen.

Brick store.

Vehicle access routes.

Pedestrian access routes.

Visitor’s centre / cafe.

6.

Pump room. 7. Digestion/de-watering tanks. 8. Storm overflow basin. 9. Brick factory. 10. Sludge store. 11. Admin building. 12. Sedimentation tank covers. 13. Constructed wetland tanks.

Filtration channels.

15.

Static wetland tanks.

Mersey footpath diversion.

Liberated Mersey river.

Low wetland habitats.

The importance of a transitional riparian zone.

The existing. Highly artificial. Low biodiversity. Human-centric. The proposed. Wild, diverse spread. High biodiversity. River-centric.

Barren upland, harsh drop. Separation from the riparian zone due to human footpaths restricts ecosystem size and depth. A harsh drop to maximise land development causes this bank area to remain dry and the soil to remain infertile.

Reinforced bank. Large rocks and aggregate are added to bank soil to inhibit crucial river meander, stunting root growth vegetation density.

Steep riverside. A harsh riverbank transition makes migration for large animals difficult, giving them no transitory habitat.

Wide, spacious river.

A wider river not only provides more habitat for aquatic life, but can hold and spread more flood water than a restricted river width.

Shallow wetland. By allowing rivers to meander, concave areas flatten to create thick reed beds, giving aquatic life a safe habitat and breeding ground for both animals and insects.

Shrubs/graminoids. At the extent of the flood plain, low shrubs and grasses provide safe transitory routes for animals.

Loose earthy ground promotes healthy root and vegetation growth.

Structural woodland. Above the flood plain, trees take root. These roots stabilise the riverbank and naturally prevent further erosion. A much higher canopy attracts avian species, further increasing riparian biodiversity.

Protection from humans. A gradual but dense vegetative area creates a protective buffer between the diverse riparian zone and human development. Any human development here will ideally further contribute to a smooth transition to forest.

Same

bank height.

01 06

Woodland habitat.

Access road.

Filtration tank field, cleared of vegetation for surveillance.

Woodland habitat.

Access road.

Filtration tank field, cleared of vegetation for surveillance.

Woodland habitat.

Conveyor filter screen, pump house mechanisms, open sedimentation tanks. All cleared of vegetation for surveillance.

Access road.

Human-designated land.

Non-human land habitat.

Non-human aquatic habitat.

Riverbanks cleared for river restriction and footpath views.

Riverbanks cleared for river restriction and footpath views.

Restricted river.

Riverbanks cleared for river restriction and footpath views.

Restricted river.

The existing. Harsh barriers, human segregation.

By erecting fences and clearing vegetation for purely human purposes, there is no gradual transition between the dense upper woodland habitat and the river. This not only prevents the land from supporting non-human, but also restricts migration from woodland to river.

The riparian zone has been blocked by and for human development.

Thin tree line barrier.

Thin tree line barrier.

Thin tree line barrier.

Footpath. Footpath. Footpath.

Restricted river.

Thin, sludgeseparating tree line.

Thin, sludgeseparating tree line.

Sludge store.

Sludge store.

01 07

Deeper woodland habitat. Constructed wetlands. Wild, non-human, intermediate areas.

Deeper woodland habitat.

Human factory/sludge store buildings. Surrounding wetland basins.

Wild, non-human, intermediate areas.

Main development area.

Human-designated land.

Non-human land habitat.

Non-human aquatic habitat.

Riparian protective zone. Riparian protective zone. Footpath.

Footpath. Footpath. Riparian protective zone.

The proposed. Human/non-human integration.

By integrating non-human habitats into human development, as well as giving large amount of land back to nature, transitory zones are established. This opens the river up to migration from upper woodland areas, all the while allowing perfectly operational human development.

Human development is are now incorporated into a healthy riparian zone.

Widened river with wetland riverbanks. Opposing wild riverbank.

Deeper woodland habitat. Sheltered brick store.

Sheltered conveyor filter screen.

Opposing wild riverbank.

Widened river with wetland riverbanks.

Widened river with wetland riverbanks.

01 08

Reimagining waste infrastructure.

At its core, the wastewater treatment works is the ‘end’ of a large infrastructure network for waste removal. The pipes that carry wastewater are buried, and contribute no biodiversity gain to the area. Infrastructure does not need to be purely subterranean pipe. In some places it needn’t be pipe at all.

01 09

Super-terranean pipes.

Burying pipes is done for two main reasons. One is to better allow heat retention in hot fluid pipes, but the other is to conceal them from view. This makes maintenance extremely difficult.

Using Berlin’s temporary pink construction pipes as precedent, all pipes on site that transport wastewater and sludge are elevated above ground, increasing their potential locations and reducing the need for destructive groundwork when maintaining.

We should not conceal our infrastructure if it may cause harm to micro or even macro ecosystems. If construction is required, it should be acknowledged and beautified.

Constructed wetland filtration tanks.

By converting the existing tanks into contained micro-ecosystems of wetland plants, not only can the water be filtered, but other life can benefit from the habitat created, for example small amphibious creatures and river flies, both essential for the greater river ecosystem it connects to.

The wastewater passes into the tanks through super-terranean pipes and is spread evenly around the ring. It passes slowly through the wetland where it is purified by reeds, eventually spilling into more wildly dug channels which trickle into the River Mersey as pure, naturally filtered water.

Not only does the process support additional life, but it also allows for much more filtration time to ensure far safer water for the river.

01 10

Sed-tank alley.

By containing the hazardous facilities within buildings, the site and land can be given back to the public for a much more human connection to the process. As well as this, wildlife that would previously use these unknowingly hostile environments as habitats are kept out, ensuring both a healthy ecosystem and an educated public.

01 11

Not all wastewater is liquid...

What happens to it?

...the sheer volume processed means that a huge volume of solid waste is produced.

While over 99% of wastewater is liquid...

This cant (legally) be discharged into rivers, so...

01 12

This is sludge.

It is the solid material filtered from sewage wastewater, and can contain anything from human excrement to pathogens, pesticides or antibiotics.

It is something that, as humans, we will always produce.

It is used to grow the food we eat and form the land we stand on, but the reality is that so much of it is unusable. It is simply considered a waste product.

(Sludge Processing, 2021:online). 02 13

Every year, the UK produces Of this, a staggering A solution could store

53m tonnes 15.9m tonnes 92.2%

That equates to 1680kg of sludge incinerated or landfilled every second. of pure carbon, every year. is either landfilled or incinerated. of raw, untreated sludge.

02 14

02 15

About. > The bricks. > 2 billion bricks.

“In 2022, over 1.9 billion bricks for construction were delivered in Great Britain. Deliveries peaked in 2018 with over two billion bricks, an increase of approximately 28 percent compared to 2010.”

(Stein, 2022).

“The industry is also struggling to acquire roof tiles, with... The price of clay tiles is being pushed up due to soaring energy prices.”

(Querol Cumbrera, 2023).

“Industrial-scale clay mining leaves landscapes scarred and barren once clay deposits have been exhausted...”

“...Firings are a significant problem, thanks to the carbon impact of heating a kiln to temperatures as high as 1,300°C.”

(Crafts Council, 2020).

UK clay brick

usage is currently not sustainable.

The solution may lie in our waste...

02 16

About. > The bricks. > Why go with CSB?

Carbon capture.

By dry weight, sludge is 30% carbon. One year of UK brick construction could store 1.72 billion kg of carbon.

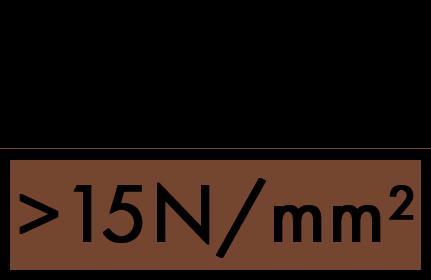

Strength.

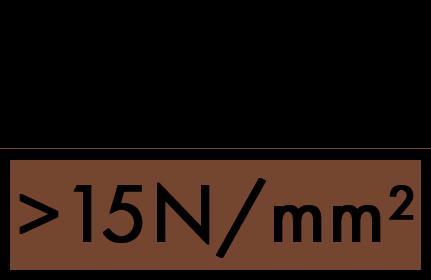

Despite their simple creation process, the addition of only 10% lime allows the bricks to exceed minimal structural standards.

Low embodied energy.

Not only are the bricks already a waste solution, but the energy cost to make each brick without firing is extremely low.

One brick, undeniable benefits.

Our human connection with our sludge is fractured, and understandably so. Can we overcome this social barrier for such a favourable building material?

Abundance. Humans will always produce solid sewage waste. This brick offers a permanent solution with long-term availability assurance.

Reusability. Compressed sludge can be pulverised to return to its material form for reuse, essentially allowing for complete circularity.

High thermal mass.

Being compressed and so dense, the bricks offer very high thermal mass properties for excellent temperature retention.

Flexibility.

By changing the brick mould used, the bricks can be easily shaped with minimal change to the creation process.

Workability.

Dried sludge requires minimal preparation before casting, making it extremely easy to work with by hand alone.

02 17

About. > The bricks. > How are they made?

1) Separation.

Raw sewage is less than 1% solid, therefore large-scale sedimentation is required to extract the usable waste material. Large tanks allow the solids to sink and separate while the liquid floats above.

4) Casting.

Using a manual block press, sludge is compressed with a force of 150KN. This compacts the mixture and creates a dense brick of sludge. Different moulds allow for different brick shapes.

2) Digestion.

The sludge is left to aerobically digest and further dry in the highly ventilated sludge store. Here, bacteria digest harmful organic compounds to make the sludge safe to handle.

5) Curing.

The bricks are taken to a warm, ventilated curing room for a minimum of one month. Here, the water evaporates to leave a cured, dried brick capable of withstanding a minimum of 15N/mm2 of load.

3) Mixing.

Large particles such as aggregate weaken the bricks, therefore need to be removed with a fine mesh before casting. As the sludge falls into the mixing tub below, additives such as lime or straw can be mixed in.

6) Distribution.

Once cured and tested, the bricks are loaded into a brick store and organised by shape, colour and function. They are then sold locally to minimise final product transport distance.

02 18

About. > The bricks. > All products.

Standard bricks.

Your basket:

The standard brick for all construction purposes. Like all CSBs, this lime-fortified basic brick shape is pressed to a standard 215x102.5x65mm dimension to integrate seamlessly within clay... read more.

The chamfered brick gives a gradual 50mm chamfered edge to use in stepped soldier bond construction. Created with a negative mould, the chamfer is no less structural than the full height... read more.

Bricks are not only for stacking. The perforated engineering brick features core holes for integrating tensile cables to create lofted brick arches, otherwise unattainable with conventional brick and mortar... read more.

Human construction should not only be for humans. The bug brick has smaller cored holes to allow small nooks for bugs to reside. Whether your project is within a built-up cityscape or deep into nature, the... read more.

Compressed sludge can also be formed into tiles! With a glazed finish, the flat tile provides an excellent roof finish for optimal, long-term water repulsion. These tiles are overlapped to create a... read more.

Add a brick.

You are sequestering 2812.2kg of carbon!

Proceed to colour selection...

x2000 x200 x50 x20 x1000

Solid.

Vertical. Lateral. Lateral. Lateral. Two sided. Engineering. Fluted. Flat, squared.

Glazed!

Glazed!

Glazed!

Wood. Flat, rounded.

Geometric. Arched.

Frogged. Longitudinal. Longitudinal. Longitudinal. Longitudinal. Three sided. Bug.

Interlocking. Lateral. Cornered. Cornered. Cornered. Four sided. Hollowed.

Half bricks. Chamfered bricks. Filleted bricks. Multi-filleted bricks. Rounded bricks. Perforated bricks. Textured bricks. Roof tiles.

02 19

About. > The bricks. > Any colour (as long as its sludge).

Week 35

Red haze. Pantone 7566 C. #AD6433

Higher content of red mud, used as industrial an oxygen carrier.

Week 34

Banana brick. Pantone 7562 C. #BD9B60

Sudden surge in concentrations of iron and manganese.

Re-imagining Zeitgeist.

Historically, bricks have represented space. Limited logistical reach meant that an areas material character was represented by its material locality.

Week 33

Sludge brown. Pantone 875 C. #87674F

Darker mix of sludge from higher organic compound presence.

Week 32

Pale white. Pantone 480 C. #C6A992

Lighter mix of sludge from lower organic compound presence.

Now, the UK imports 2 billion bricks a year, crushing local brickmasons and perpetuating a carbonintensive overseas transport process.

The CSB is always as local to you as your sewage. With hundreds of wastewater centres across the UK, local construction brick procurement is now shaped by its geography once again.

Check your local centre for their current stock of colours. Differing sludge make-ups will alter the brick colour week on week, allowing a wide range of natural brick colours.

02 20

We are running out of choices.

‘A brick made of sewage’ might not initially sound all that desirable, but the reality is that it must be. Sludge is a massive waste issue that the UK needs a solution to, and clay bricks are not an infinite resource. This project aims to solve both issues with one elegant solution. To give sludge the new perspective it is so desperately calling for, with an architecture that is both functionally innovative and visually comfortable.

02 21

1:1 brick models.

After testing some compressed earth bricks in S2 to assess their feasibility, I concluded that I should revisit the process and push it further.

The primary aim of this was to explore the result of stabilising the bricks with 10% lime and straw to add further strength and water/temperature resistance.

Lime is a naturally occurring, mined mineral. It’s procurement scars landscapes and it is not renewable, however it allows these bricks to be structural feasibly without the need for firing or cement.

02 22

The standard 215x102.5x65mm brick is sized to integrate into existing construction standards. A solid, all-purpose brick.

The half brick demonstrates the ability to compress less material while retaining the same structural capabilities at only 27.5mm thick.

The chamfered brick was formed using a negative triangular shape when compressed in a standard mould.

A flexible mould press with allowance for negative dowels allows for a perforated brick, used for bird/bug habitats or for construction purposes.

02 23

The bricks adhere to standard bricklaying principles, and can be lain using a mortar slurry made of the same very fine material.

02 24

Compressed material bricks are nothing new, and are currently a standard practise in may places globally. Given that sludge has the adequate physical properties to be compressed, why shouldn’t it?

The compressed sludge brick is entirely possible. All it requires is public acceptance.

02 25

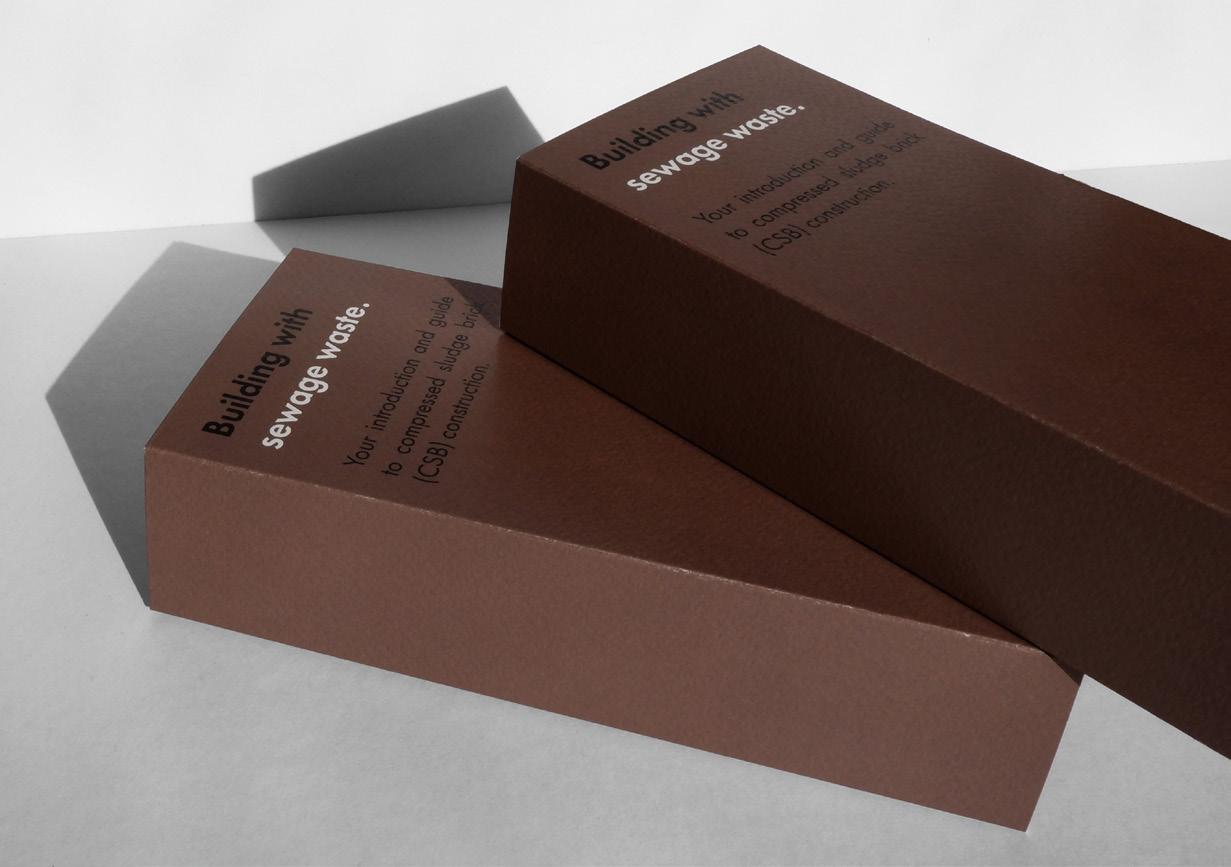

Light bathroom reading.

For such a topic, a brochure is the most convenient way for someone to engage with the concept. The deeper the interest, the further the brochure can be explored.

The rear of the brochure contains some of the most frequently asked questions I have personally received from inquisitive peers, while the inner leaf contains a more detailed overview for scales of interest.

02 26

While formatting the brochure, I noticed that the dimensions of an A4 page are very close to that of a standard UK brick.

Using a thicker paper gives the brochure rigidity, allowing it to be folded to represent the very product it is advertising.

02 27

Open source manufacture - model/render composite.

The CSB represents consequence for action. We must take blame for our waste, and therefore its manufacture should be accessible to us.

This perspective is a composite, combining the brick representation of humanscale observation and its (not so) distant place of manufacture...

02 28

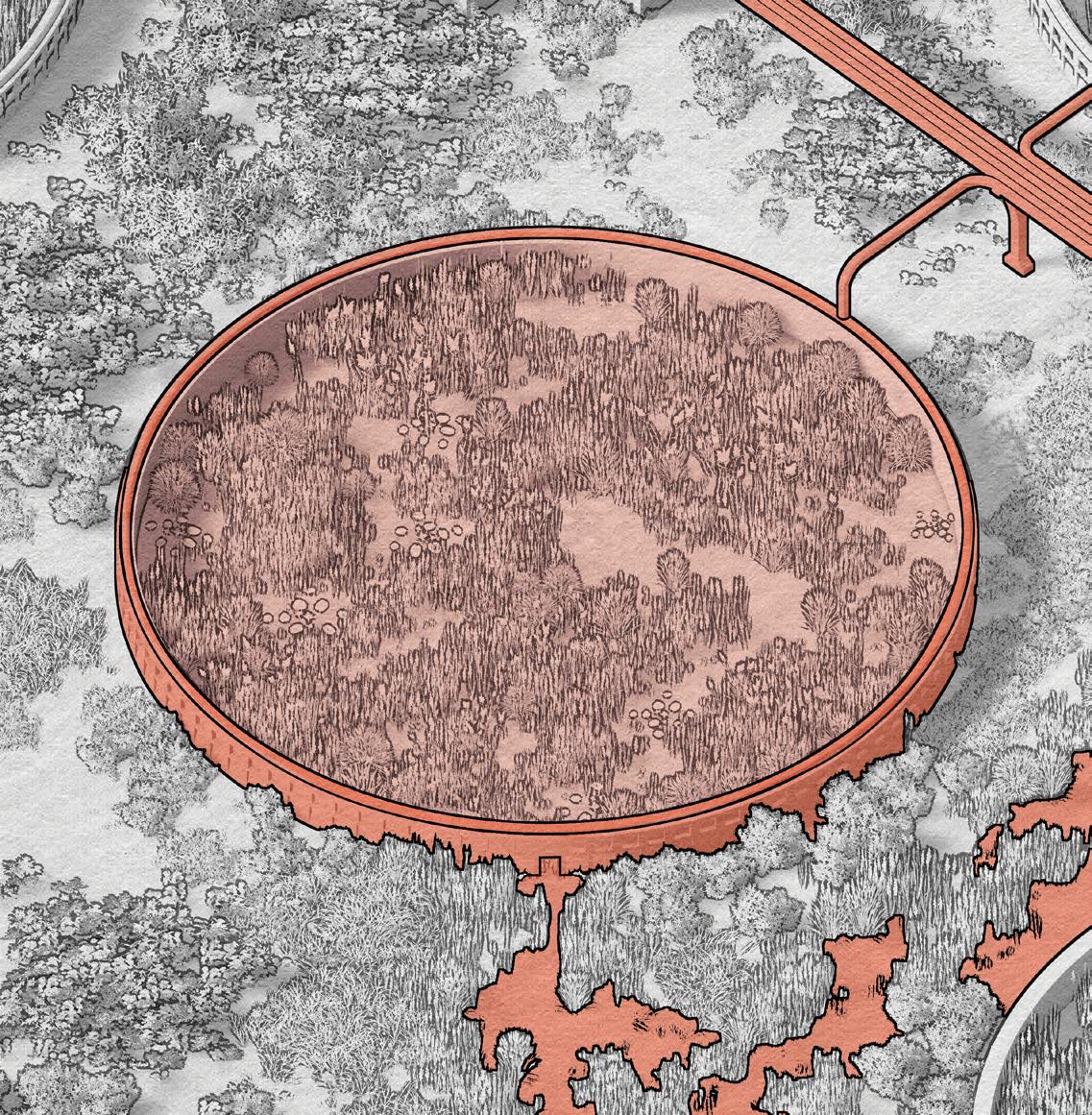

From store to factory in 30 meters.

Both the sludge store building and compressed earth brick factor are located within the closest converted filtration tanks. They are connected by a bridge, allowing the separation of odorous sludge and comfortable human work. A cut in the factory tank creates an inviting, brick-accented entrance point.

03 29

How does the factory work?

1) The digestion/dewatering tanks remove harmful organic material and any remaining water from the sludge. It is pumped to the sludge store through a raised dewatering conveyor.

2) The sludge store keeps the sludge long enough for odour to dissipate and for any final water to evaporate off. It is then loaded onto the bridge conveyor and sent towards the factory.

3) The factory working first floor receives the sludge, mixes and presses it into a brick. A workshop provides in-house mould creation, while a visitor’s foyer allows the public to engage with the process.

4) The factory ground floor curing rooms store the bricks long enough to cure, where they are then transported back up to the first floor to be collected by forklift, ready to be distributed.

5) The upper mezzanine floor compartmentalises the rooms that require specialist ventilation and houses all mechanical systems. A central, inner dome supports a radial oculus to provide the majority of natural light.

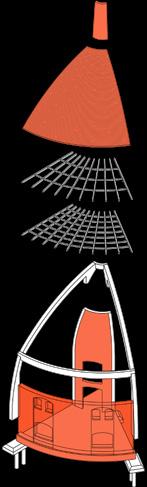

6) The domed roof structure houses the facilities below, made possible by using traditional brick-dome construction. It’s structure is shared by the sludge store for ease of construction.

1 2 3 5 6 4 03 30

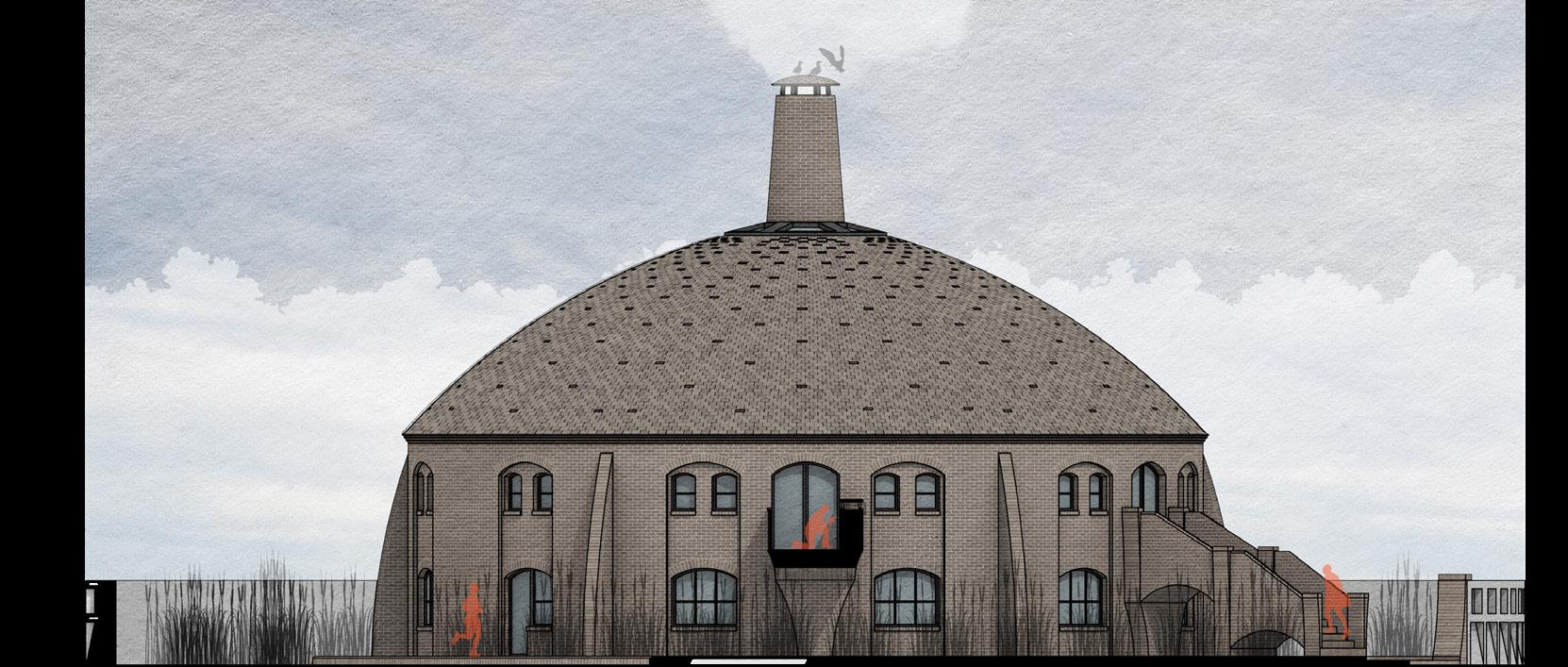

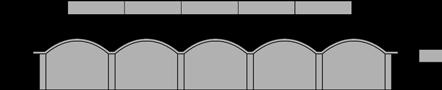

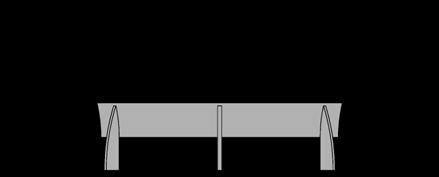

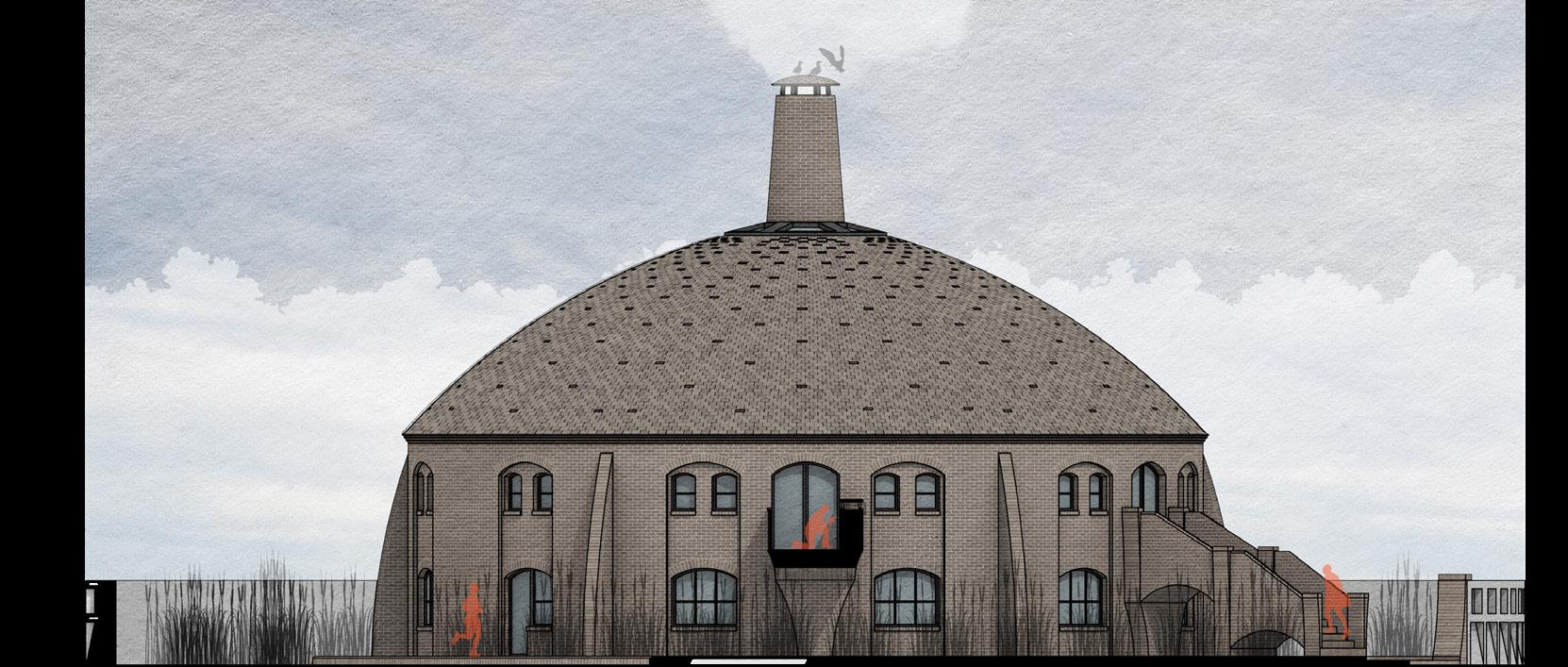

Exploiting arches.

The primary strength of a brick is compression. To exploit this, the design has utilised arches wherever a span is required.

The window recesses used arched bricks to create lintels, which direct load into stacked bricks below. By using smaller windows in the upper floor and larger windows for the ground floor, load is gradually directed away towards the thicker brick walls.

The roof tiles are also supported on arching roof bricks, which direct load into structural arched ribs and buttresses.

South-eastern factory elevation showing the main entrance procession.

Southern factory elevation cutting through the bridge.

South-eastern factory elevation showing the main entrance procession.

Southern factory elevation cutting through the bridge.

03 31

Site reference plan + section showing relation to other buildings.

Factory proposal ground floor plan.

1. Forklift brick loading area.

2. Filter tank constructed reed wetland.

3. Outer reed walkway.

4. Brick conveyor vertical exit.

5. Fire-rated staircase.

6. Central dome intersection.

7. Brick storage rack bays.

8. Brick conveyor.

9. Fire exit point.

10. Main entrance stairs.

1 2 3 4 5 6 7 8 9 10 11 03 32

11. Entrance cut in existing sedimentation tank wall.

Site reference plan + section showing relation to other buildings.

Factory proposal first floor plan.

1.

2.

3.

4.

5.

12.

15.

16.

Forklift loading area bridge collection point.

Brick loading conveyor point.

Pallet storage.

Workshop bench w/ wood storage underneath.

Workshop island.

6. Bandsaw.

7. Press mould storage racks.

8. Staircase to lower floor.

9. Mixture tub storage.

10. Brick presses.

11. Brick conveyor.

Sludge store access bridge.

13. Sludge conveyor entry point.

14. Sludge mixing area/storage.

Sample brick display.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 21 20 03 33

Retired exhibition brick press. 17. Main entrance. 18. Reception desk. 19. W.Cs

20.

Access corridor.

21.

Staff break room.

Three-dimensional manufacture.

As sludge arrives from the south bridge conveyor, it is mixed and pressed above. It then travels on the outer spiralling conveyor to the store below, where it is heated and ventilated to cure the bricks. Once dry, the bricks return to the upper floor where they are loaded onto forklift, ready to be stored externally.

03 34

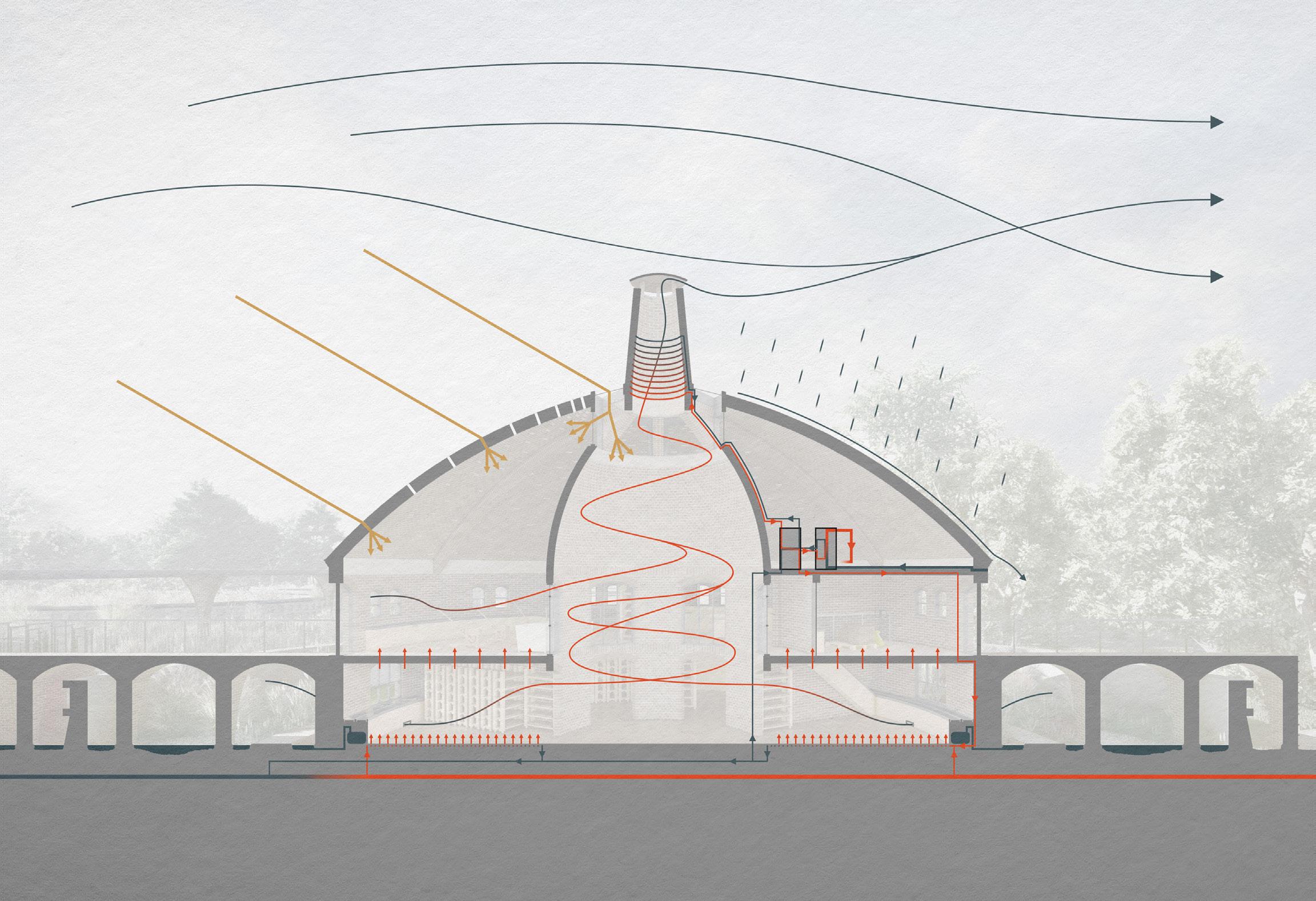

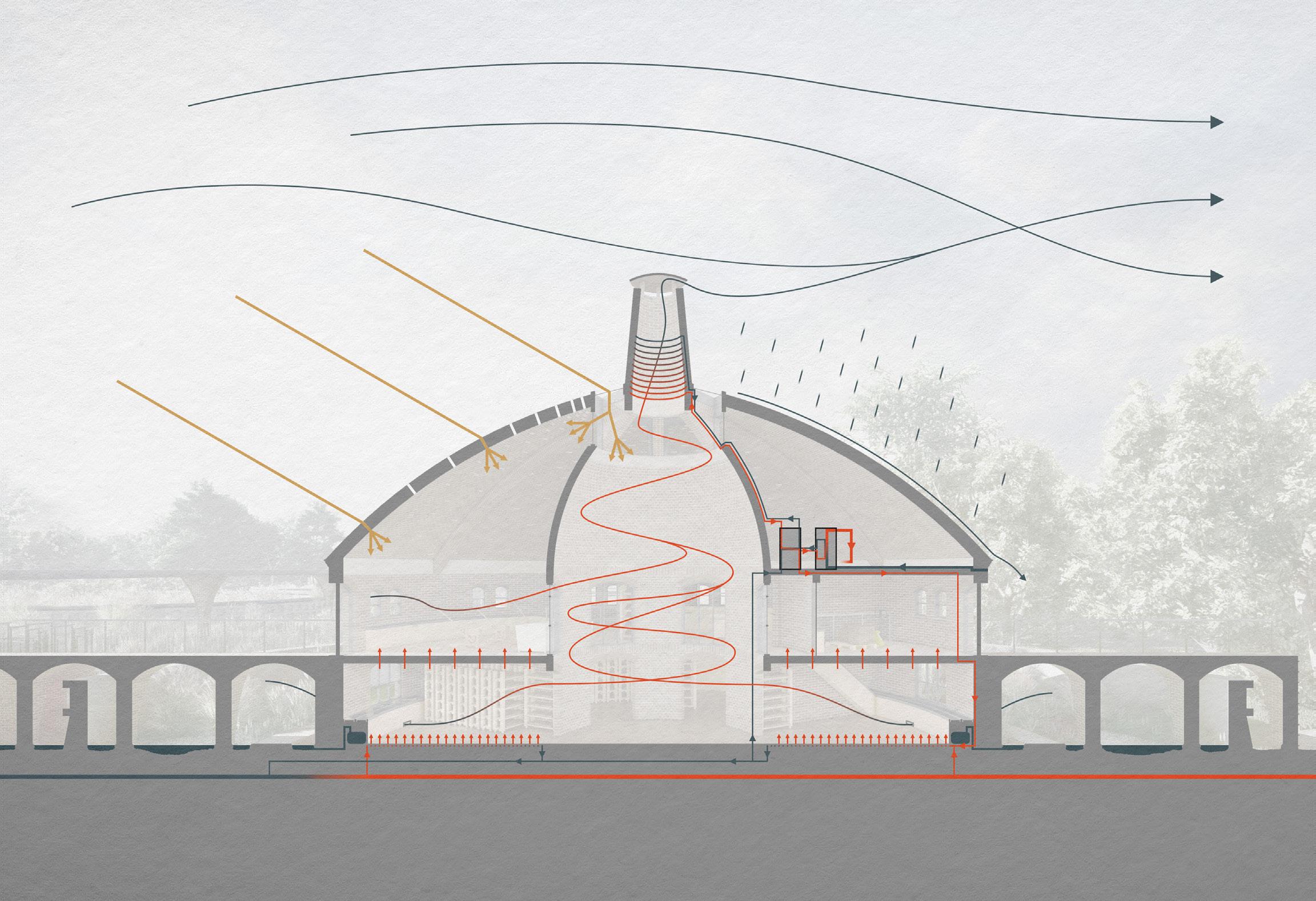

1) Natural light. Both the main oculus and gradual glazed brick openings concentrated natural in both upper dome layers, diffusing it to the spaces below.

2) Grey rainwater. As rainwater trickles off the roof, a lipped eave ramps it into the reed bed below. Here it is purified and collected in concealed tanks as grey water.

3) Chimney heat recovery. A heat exchanger within the chimney recaptures escaping heat, recirculating it into the hot water loop to assist with HVAC heating and ventilation.

4) HVAC. Air taken in from outside is heated and pumped into rooms like the workshop that require mechanical ventilation. Water is also similarly heated here.

5) Efficiency heating. As underfloor heating warms the brick curing rooms, this heat rises and ambiently warms the rooms above. This heat is all passively sourced.

6) Room ventilation. Embedded vents intake and filter air from outside, passing into the rooms to ventilate. Openable windows can assist and allow a night purge.

7) Oast house funnel effect. To ensure thorough ventilation, the curing rooms are open to a central stack dome. Using differential pressure, the heat pushes the air upwards and out.

1 2 3 4 5 6 7

03 35

The brick-making room.

The radial design of the building allows for an array of linear brick pressing motion. The sludge moves outwards from the recycled plastic tubs (made in-house), through the press and onto the outer conveyor, where it is taken downstairs to the store.

03 36

Natural dome lighting.

The centre of the dome is a concentrated source of diffused natural light from the main oculus and glazed bricks. The direct light punctures the steam from below, casting beams onto the inner dome’s surface.

03 37

Brick delivery system.

To minimise human circulation, the bricks are delivered to their storage rack by a manually operated conveyor belt. The lower floors have capacity for 108 pallet wood racks, for a total of 7,776 bricks.

03 38

Construction sequence.

1) Existing tank disassembly.

Before groundwork, all filter aggregate, pipework and cabling is carefully removed to be reused elsewhere on-site. The entrance portal is cut from the tank wall.

4) Wall bricklaying.

Once the groundwork is ready, the external walls between the buttresses can be lain, as well as the internal ground floor walls. The ground floor can be fitted out with M&E, and the first floor can be installed above.

2) Groundwork.

Necessary soil is excavated and stored to be converted into earth bricks. Foundation-grade concrete is poured on-site to create a strong, level surface to build from above the weak riverside soil.

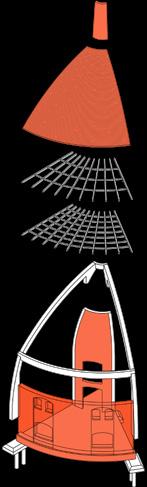

5) Roof dome brickwork.

Using the now-assembled external walls, the brick dome can be lain using steam-shaped plywood formwork hung from the ribs. This formwork can be disassembled and reassembled for each roof segment.

3) Main structure prefabrication.

The brick ribs and reinforced hempcrete tension/compression rings are assembled on-site, then lifted into position. The central tension ring is temporarily supported by scaffolding until all ribs are in place.

6) Final assembly.

Once the roof system is in place, the final brick elements such as the bridges and stairs can be lain. The railings can now also be cut from fencing and fitted, as well as all other fittings (windows, furniture etc).

03 39

Structural strategy.

Primary structure.

An upper steel box section compression ring (5) radially supports the 6 pre-tensile brick arched ribs (6), which also use the inner brick dome structure load points (7) for direct vertical load support.

These ribs push laterally against a continuous steel-pipe-reinforced hempcrete tension ring (8), which then spreads the majority of this load at its connection points to brick buttresses (9)

These buttresses divert this load into twin-pile concrete foundation pads (12) which pierce the weak riparian soil to bedrock below.

Secondary structure.

The weight of the brickwork chimney (1) is transferred directly into the steel tension ring system.

The arched brick dome (2) infill section is stacked to splay outwards, diverting the roof load laterally into the brick ribs.

The main brick facade (10) is partially load-bearing, receiving tension ring weight both vertically and laterally. This load, as well as live internal loads and the inner dome brickwork (7) is dispersed across a concrete foundation slab (11) into the foundations.

Tertiary structure.

The live loads of the upper floors are spread across timber floor beam lattices (3,4) that splay radially from the dome centre.

The upper floor carries far less load, and is therefore value engineered to contain less structural beams than the floor below.

These floor beams connected to the inner and outer dome walls, eventually being directed into the foundation system.

1 2 4 5 6 6 7 8 9 9 10 11 12 12 3

03 40

The bats and the bugs.

Like many avian species, bats rely heavily on waterways such as rivers for hydration, migration routes and food (Bat Conservation Trust, 2024). Given its proximity to the river and its immersion within constructed wetlands, the proposed factory is an ideal location for bats to roost and bugs to breed.

Bat-boxes incorporated into the warm chimney’s structure provide the habitats for bats, and a concealed ring of bug bricks below attract a habitat for their food. Despite being incorporated into human development, both habitats are excluded and safe from human contact.

Wall construction.

102.5-215mm compressed sludge brick.

10mm cavity.

Breather membrane.

140mm cellulose insulation. Vapour control layer.

102.5mm compressed sludge brick.

U-value: 0.15-0.14.

Roof construction.

Single lap glazed compressed sludge tiles on 25mm timber battens. 25mm vertical timber battens.

Breathable membrane.

9mm plywood.

180mm cellulose roof insulation. Vapour control layer.

102.5mm pre-tensile compressed sludge brick.

U-value: 0.15.

Intermediate floor construction. Glazed compressed sludge floor tile. 25mm Cork sound-absorbing layer. 160mm cellulose insulation between timber beams.

12mm soundproof plasterboard. Water-resistant plaster skim finish.

U-value: 0.18.

Ground floor construction. Heated floor system within 65mm rammed sludge floor finish. Separation layer.

150mm cellulose floor insulation.

250mm concrete floor slab. Damp-proof membrane.

U-value: 0.09.

03 41

Compressed sludge glazed roof tiles. To redirect rainwater and snow away from the building.

Timber roof batten system. To elevate and receive roof tiles, creating a breathable cavity for insulation below.

Recycled cellulose roof insulation. To prevent cold-bridging through the roof system. Superused from newspaper discarded at a local waste centre.

Single-leaf compressed sludge brick dome. Spreads roof tile compressive load and provides internal finish.

Compressed sludge brick cavity wall. Spreads compressive load and provides interior/exterior finish.

Cavity closer.

To prevent damp from entering the wall cavity.

Material

preservation through design.

By giving the roof tiles a slight upward lip towards the eave, rainwater is directed away from the wall below, thus reducing the extent of weathering.

Recycled cellulose wall insulation.

This is further executed by using two brick courses of stepping chamfered bricks, further extending the roof tiles from the wall.

No gutter system is required, as rainwater simply falls into the large reed bed below, where it is naturally filtered and drained as necessary.,

To prevent coldbridging through the brick wall system. Superused from newspaper discarded at a local waste centre.

The assembled eave section.

Hempcrete tension ring. To encase and contain the tensile steel pipes and take compressive dome load.

Thermal break pad. To prevent coldbridging through the tension ring.

Steel tension ring pipes. To take the splaying load of the roof arches. Superused water pipe from the dismantled filtration tanks.

03 42

A public factory.

By incorporating a walkway though the reed bed around the factory, any member of the public is able to see what happens to their waste, while also learning about reed-based filtration.

03 43

Biogas electricity.

Heat from biogas burning.

Digesting/de-watering tanks.

A self-sustaining system.

This project has, thus far, promoted true circularity and absolute waste avoidance. It is only right that the site itself should follow these principles.

Both heat and energy are required to make the human-centric aspects of this project work. Heat is captured and recaptured to maximise efficiency, while energy is created through passive means with sustainable back-ups. Both of which are distributed around the site to ensure a completely selfsupporting energy grid. Any excess can be provided to the local grid.

Captured heat from digestion.

Brick factory.

Pump house /visitors centre.

Sedementation tank covers.

Sludge store.

Captured heat from curing.

Ground sourced heat from sewage.

Photovoltaic electrcity. Solar heat.

04 44

Sewage-sourced heat.

1) Hot wastewater is discharged.

Much of the waste discharged from domestic and industrial sources is warm, ranging from boiling water to human-temperature waste. This waste travels towards the nearest restitution works at roughly 2km/h.

2) Subterranean insulation.

As the wastewater travels underground, the earth around it remains a constant and stable temperature (roughly 15°C average), despite the temperature above ground. Therefore, the sewage in these pipes also remains roughly this temperature.

3) Heat exchange and use.

Before being treated, a heat exchanger wraps around the inlet pipe and circulates cold water. This water extracts heat from the warm sewage pipe and pumps it to on-site buildings that require heat regulation to assist in HVAC.

4) Continued restitution.

Now cooler, the wastewater is pumped through the system to be purified. Heat energy has been extracted as zero cost to the original process.

15°C

04 45

Surplus renewable power.

Highest (27,331kWh).

All excess power generated is returned to local grid.

Lowest (6193 kWh).

Average required (3,692 kWh).

Biogas overproduction power to counter solar unreliability.

Existing photovoltaic panels.

As part of a renewable energy incentive, many UK WWTWs have been fitted with large PV arrays. These have been relocated to the roof of the sedimentation tank, and easily provide more than enough solar power to run the existing site, let alone the now-reduced facilities.

Use of an immersion diverter. Use of combined heat and power generator

Back-up biogas generator.

In the colder months of the year when solar power is less reliable, the site can switch from aerobic sludge digestion to anaerobic. This process produces methane, which can be used as fuel to power an on-site generator.

(kWh/month) Feb Mar May Jun Jul Aug Sep Oct Nov Dec Apr Jan

Power

Additional heat generated 04 46

Minimising waste with superuse.

Steel cable (1,250m).

Used as smaller tensile member in brickwork.

Steel pipe (500m).

Used as larger tensile member in tension rings.

Filter tank aggregate (10,000m³).

Used to create permeable footpaths + roads.

Paving rubble (9150m²).

Lain, filled + polished to create industrial terrazzo floor.

Chain link fence (3500m²).

Cut and used as handrail infill.

Fence post rebar (690m).

Polished and coated to create railing balustrades.

Route from local recycling centre to site: 1.25km

retaining wall structures.

Timber/metal waste.

be used in the workshop for brick moulds/site maintenance.

paving and flooring.

Rubble. Can be used in site

Can

Tyres. Can be used in

Textile waste. Can be recycled to use as insulation.

04 47

Furniture waste. Can be refurbished in the factory workshop and used on-site.

Visitor education.

To give the public a reason beyond curiosity to explore the site, a visitor’s centre and cafe is located within view of the factory. Using refurbished furniture, anyone can learn about and experience waste circularity.

04 48

Accounting for redundancy.

As architects, it is short-sighted to believe that our buildings will last forever. Especially with technology-oriented construction, there will most likely be a time when the building is not required, or is in need of upgrading to meet new standards.

This has been the case with the large, expansive wastewater treatment works, where very little account for their future has been made.

Before construction, a detailed list of materials and prefabricated components is created. In doing so, exact numbers, volumes and configurations of materials can be logged so that near to when the building’s disassembly is demanded, the materials can be listed for use in other buildings, as opposed to being discarded.

This is designing for deconstruction. Any materials, bricks or tiles able to be salvaged will be done so carefully. With the CSB, and that are damaged beyond reuse can simply be pulverised and reincorporated into CSB production as raw material.

True circularity, with no net loss of material value.

04 49

In 10 years time...

...Stretford wastewater restitution centre is thriving. The sludge brick has taken off as an affordable construction material and the site’s filtration systems continue to process wastewater.

Nature-based water treatment has established roots in the UK.

In 20 years time...

...the government takes note of the benefits after United Utilities adopts the scheme company-wide. At this point, almost every wastewater treatment works in the North-West is adopting the project’s principles.

Rivers are finally beginning to show long-term recovery, but is it too late?

In 30 years time...

...nature-based becomes a necessity in the face of failed carbon targets. Overwhelming pressure from constructionsector climate activists pushes policy to adopt the system.

The CSB is no longer a choice. They are a necessity.

04 50